Manufacturing process of coke-reducing molding paper of net groove

A technology for making craft and forming paper, which is applied in papermaking, paper machine, textile and papermaking, etc. It can solve problems such as difficulty in shaping, softening, and large expansion and contraction of corrugated paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

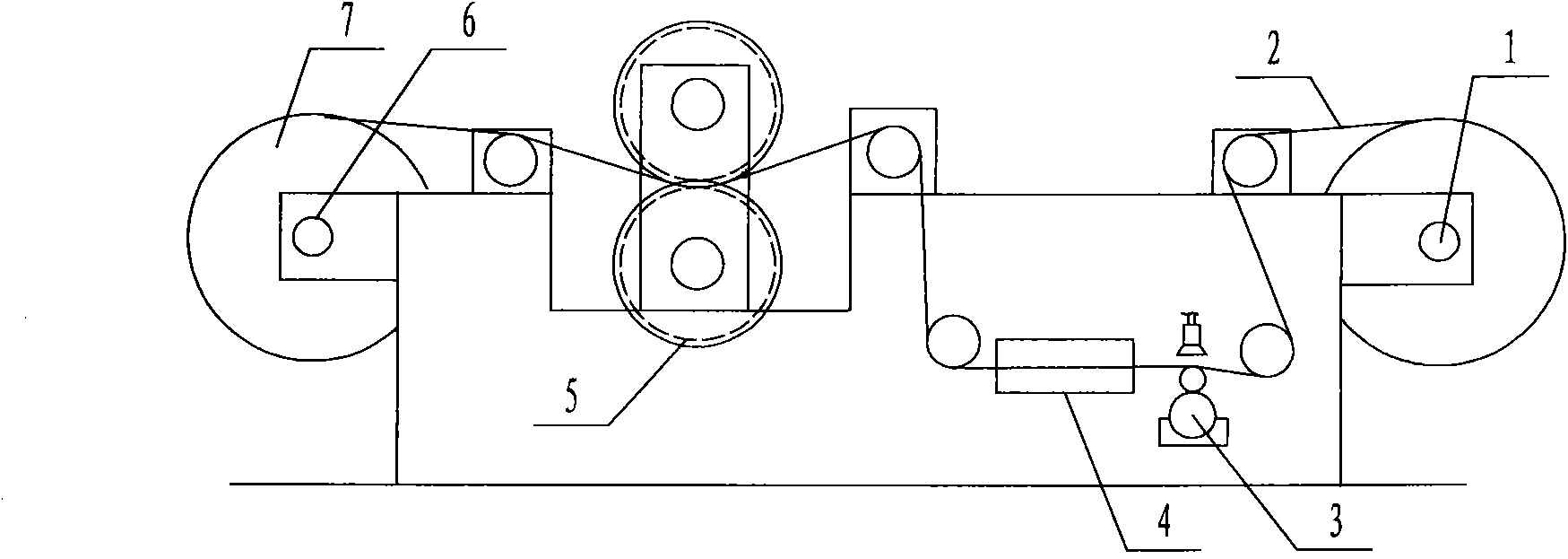

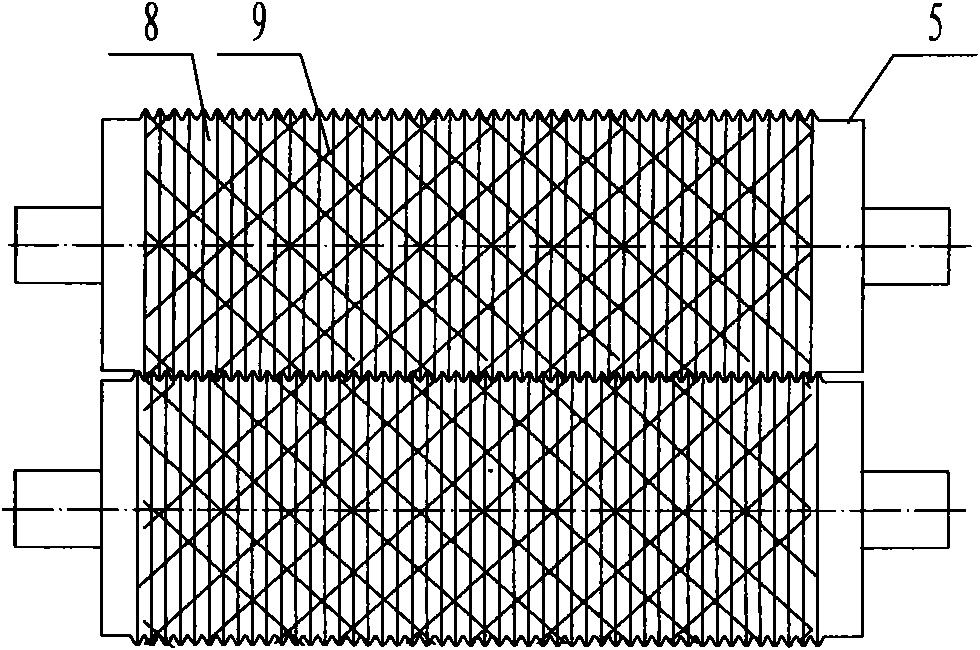

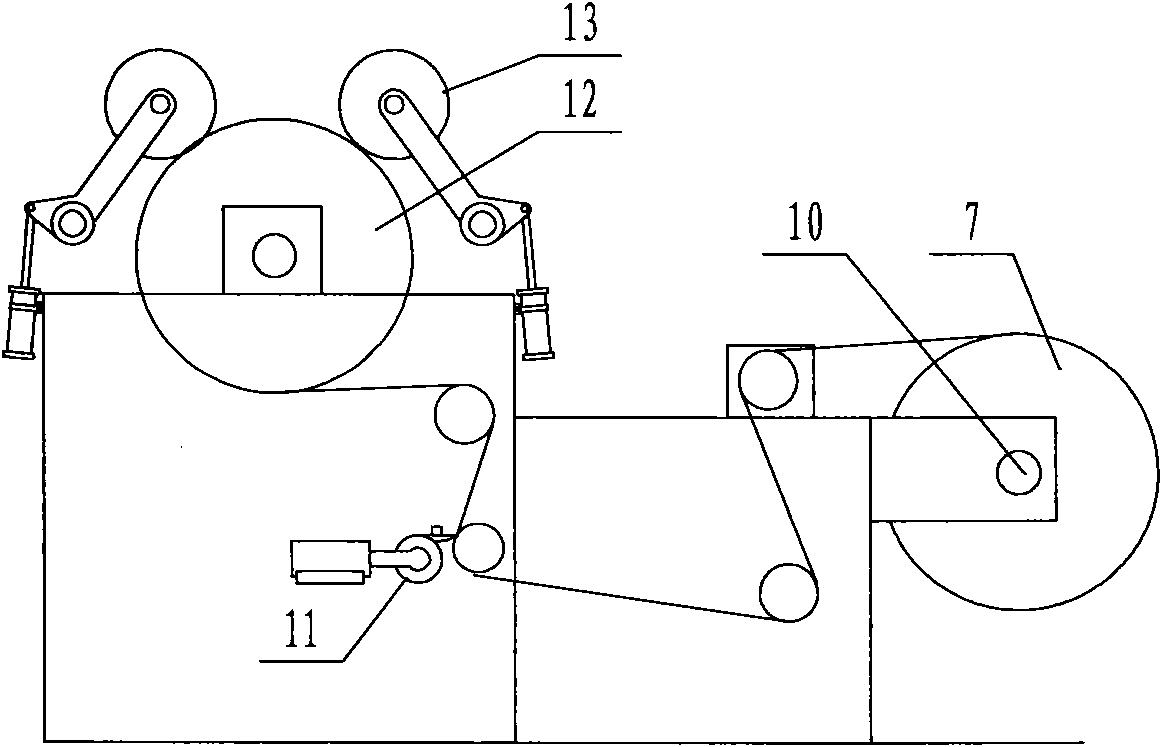

[0030] Example: such as figure 1 , figure 2 and image 3 Shown is a manufacturing process for mesh-grooved coke-reducing forming paper. The forming paper produced by the production process is used to wrap the outer surface of the tow of the cigarette filter rod. The production process mainly includes forming paper corrugated pressing and forming paper corrugated There are two major processes of slitting and cutting, among which in the forming paper corrugated pressing process, the specific steps are:

[0031] A. Release the wide reel forming paper 2 from the unwinding reel 1 in the unwinding mechanism of the reel paper corrugating machine;

[0032] B, on the strip channel of the forming paper 2 released, a coating device 3 is arranged, and the glue solution is coated on the surface of the forming paper 2 with the coating device 3;

[0033] C. An oven 4 is set on the reel paper corrugating machine, and the forming paper 2 with glue on the surface is introduced into the oven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com