Thermal fabric for plant

A technology of fabrics and plants, which is applied to plant protection covers, etc., can solve problems such as difficulty in achieving ideal heat preservation effects, waste of resources, and poor moisture-proof performance, and achieve the effects of reducing heat dissipation performance, increasing heat dissipation performance, and temperature balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

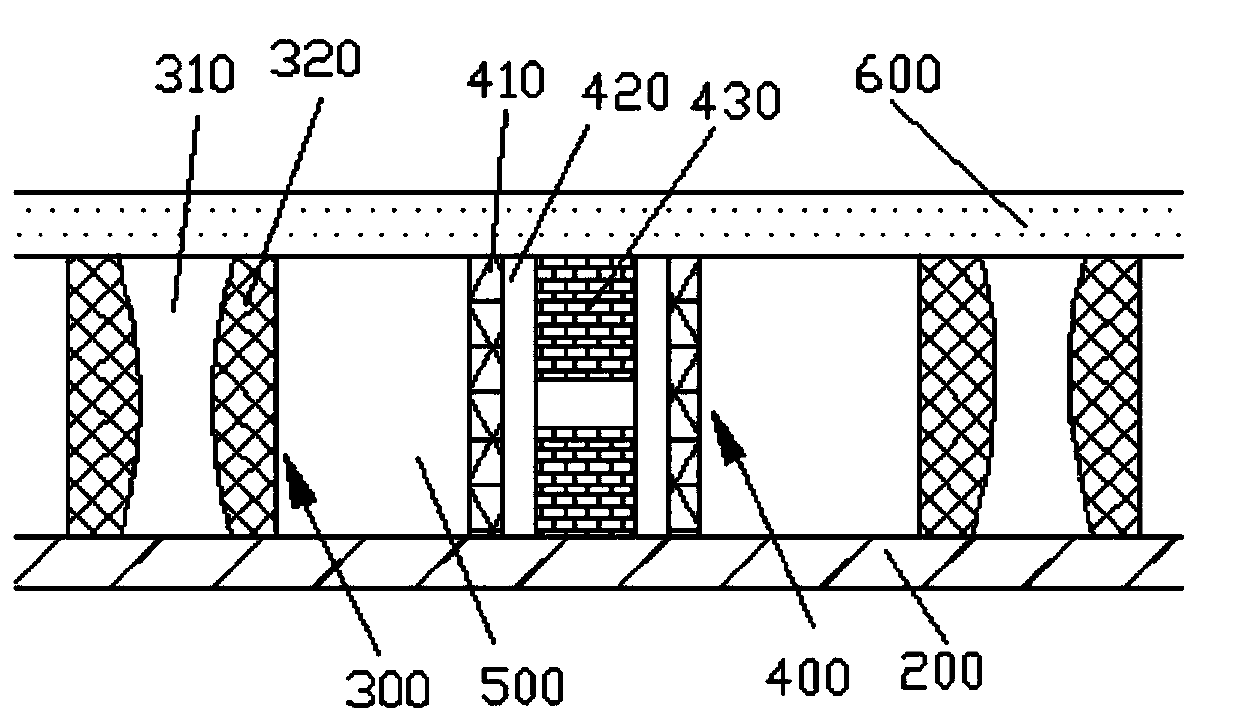

[0014] In this example, see figure 1 , the plant thermal fabric includes a waterproof layer 600 from the outside to the inside, a heat-preserving and air-permeable layer and a sealing layer 200, the waterproof layer 600 is made of chemical fiber blended polymer water-absorbing resin material, and the heat-preserving and air-permeable layer includes air-permeable layers arranged at equal intervals. The gas-permeable part 300 and the heat-conducting part 400 are composed of a heat-insulating cavity 500, the gas-permeable part 300 is made of a flexible column 320 with a through hole 310, and the heat-conducting part 400 is made of a solid ring 410 , the airbag 420 embedded in the solid ring 410 and the flexible heat-conducting material 430 wrapped by the airbag 420, the flexible heat-conducting material 430 has a gap in the middle of the non-heated state, and the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com