Polytetrafluoroethylene (PTFE) membrane material capable of realizing catalytic degradation function by grafting photocatalyst and application of PTFE membrane material

A catalytic degradation and photocatalyst technology, which is applied in applications, household appliances, chemical instruments and methods, etc., to achieve the effect of low surface energy, large air permeability, and increased catalytic degradation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

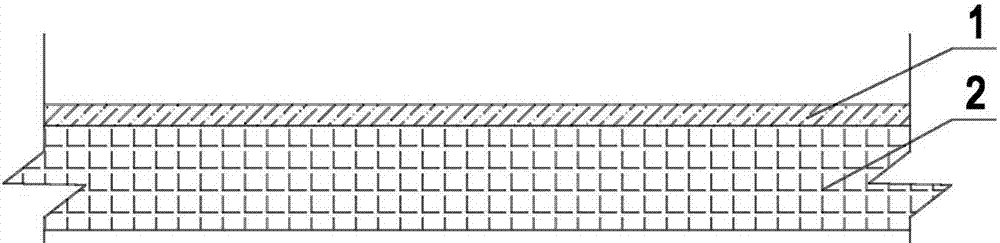

[0025] Such as figure 1 As shown, the photocatalyst PTFE membrane 1 is grafted on the PET base material 2 by a special process, and the thickness of the filter material after lamination is 1.8mm, and a filter bag is made. Manufacture of photocatalyst PTFE fiber gap membrane 1: First, nano-sized TiO 2 Blend and mix with 18-alkane solvent until it is transparent, and complete the first step of combining photocatalyst with polytetrafluoroethylene; Next, the UV254 light synthesis process is used to form a resin after polymerization, so that the photocatalyst nanoparticles are evenly distributed in the PTFE resin; finally, the photocatalyst PTFE film with a cracked pore structure is formed by calendering, extrusion, biaxial stretching and other processes. , At the same time realize the uniform grafting of nano-TiO2 in the spatial structure of the PTFE fiber gap membrane.

[0026] Application 1. The above-mentioned membrane material is laminated with PP to make a filter net, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com