Condensable particle sampling device

A sampling device and particulate matter technology, applied in the field of sampling devices and condensable particulate matter sampling devices, can solve the problems of not representing a fixed source, negative effects, etc., and achieve the effects of reducing residual loss, fast cooling speed, and reducing blocking loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

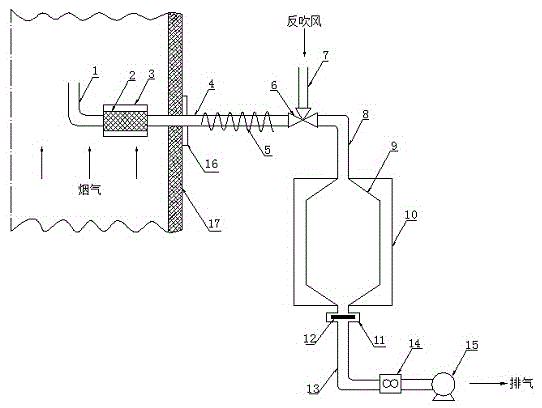

[0022] Such as Figure 1-3 The condensable particulate matter sampling device shown includes a sampling head 1, a filter 2, a heater 3, a sampling pipe 4, a heating cable 5, a three-way ball valve 6, a blowback pipe 7, an air inlet pipe 8, a condenser 9, and a refrigerator 10 , filter clip 11, filter membrane 12, exhaust pipe 13, flow meter 14, vacuum pump 15.

[0023] Sampling head 1, filter 2, sampling pipe 4, three-way ball valve 6, inlet pipe 8, condenser 9, filter membrane clamp 11, exhaust pipe 13, flow meter 14, and vacuum pump 15 are connected in sequence. The sampling head 1 and the filter 2 are located in the flue 17 . Sampling head 1 is an upwardly bent stainless steel tube for reverse sampling. The filter 2 is a ceramic filter or a sintered metal filter, which is used to filter filterable particles in the flue gas. The filter 2 is provided with a heater 3 for heating the flue gas and preventing the flue gas from condensing in the filter 2 . The sampling pipe 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com