Pure polyfluortetraethylene gradient overlay film filter material with high intensity

A polytetrafluoroethylene and polytetrafluoroethylene cloth technology is applied in the field of high-strength pure polytetrafluoroethylene gradient membrane filter materials, which can solve the problem of high and low temperature resistance, poor corrosion resistance and oxidation resistance, and shorten the filter material. service life, accelerated wear of filter materials, etc., to achieve the effect of good peelability, stable size, and reduced energy consumption for ash cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

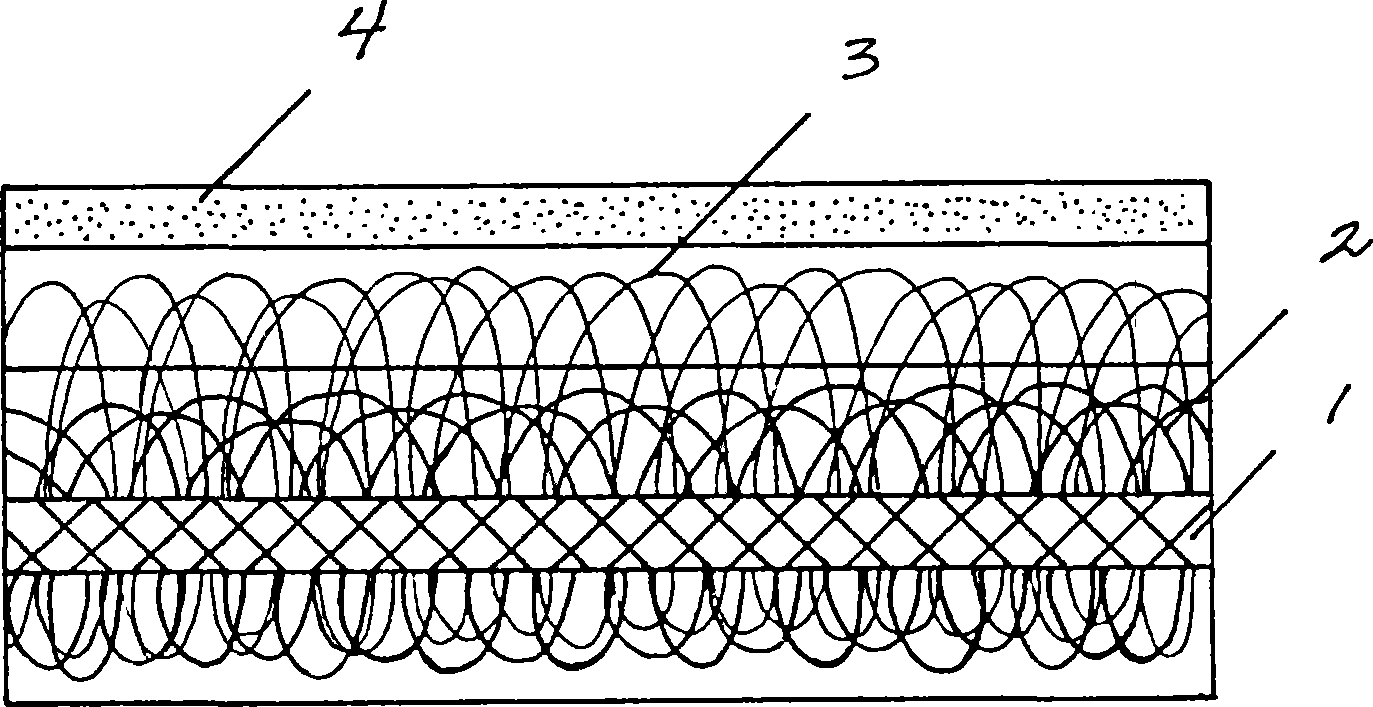

[0008] The high-strength pure polytetrafluoroethylene gradient film-coated filter material of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0009] refer to figure 1 , the high-strength pure polytetrafluoroethylene gradient membrane filter material of the invention consists of the described polytetrafluoroethylene film 4, the described polytetrafluoroethylene superfine fiber layer 3, the described polytetrafluoroethylene thick fiber Layer 2 and the base cloth 1 are formed.

[0010] The base cloth 1 is a polytetrafluoroethylene base cloth, and the polytetrafluoroethylene thick fiber layer 2 and the polytetrafluoroethylene superfine fiber layer 3 are sequentially needle-punched on the polytetrafluoroethylene base cloth. On the cloth 1, the polytetrafluoroethylene film 4 is coated on the upper surface of the polytetrafluoroethylene superfine fiber layer 3, and the micropore diameter of the polytetrafluoroethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com