Patents

Literature

30results about How to "Microporous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antifouling antibacterial high-molecular furniture decorative film and preparation method thereof

ActiveCN103738035AImprove fire resistanceHigh strengthLamination ancillary operationsLaminationFire resistanceProduction quality

The invention relates to an antifouling antibacterial high-molecular furniture decorative film and a preparation method thereof. The antifouling antibacterial high-molecular furniture decorative film is characterized by comprising a base material, an antibacterial film and a printed surface film. The antifouling antibacterial high-molecular furniture decorative film is formed by hot-pressing lamination of the base material, the antibacterial film and the printed surface film. The preparation method of the antifouling antibacterial high-molecular furniture decorative film comprises the following steps: step one, preparing the base material; step two, preparing the antibacterial film; step three, preparing the printed surface film; step four, printing the surface film; and step five, carrying out hot-pressing lamination. The antifouling antibacterial high-molecular furniture decorative film has the advantages of fire resistance and high strength, and the preparation method has the advantages of low production cost and high product production quality.

Owner:ECONESS ENERGY

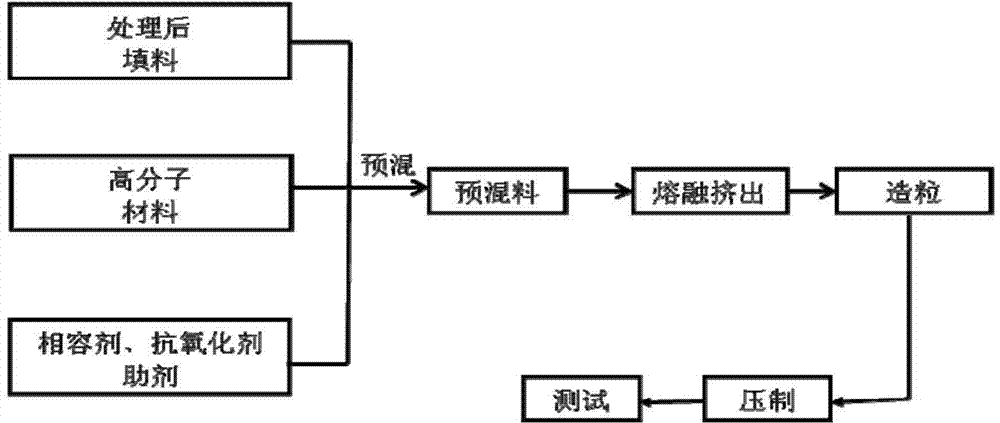

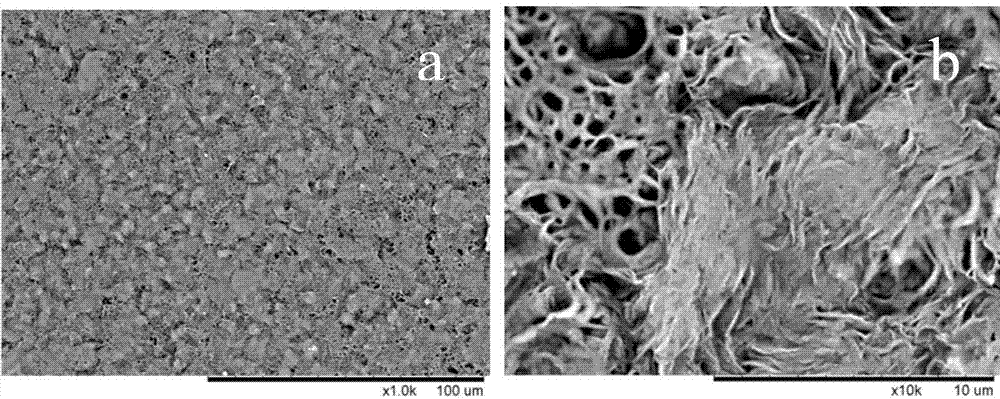

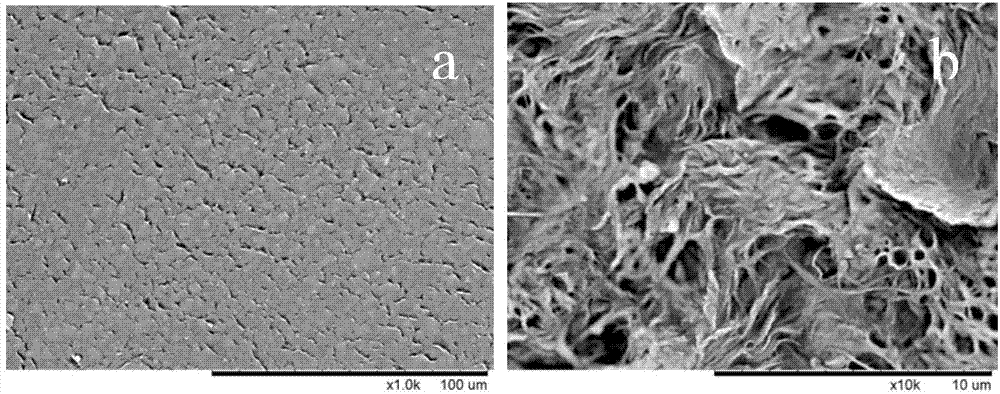

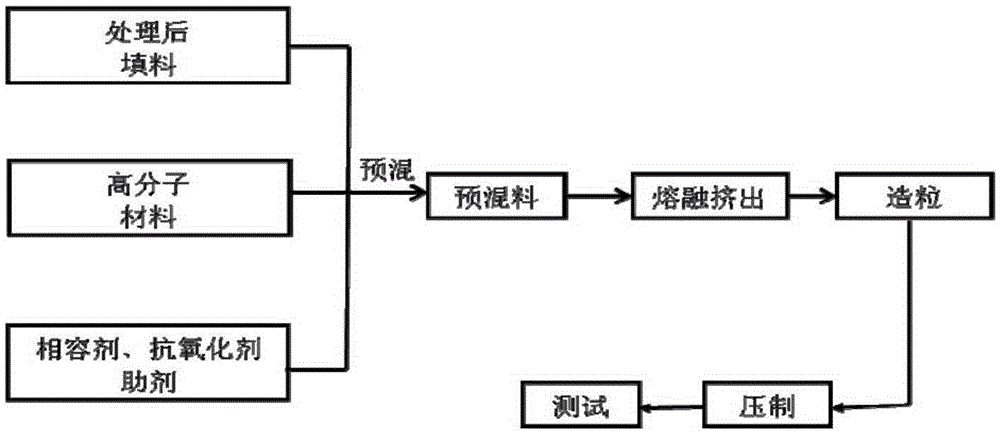

Method for preparing synthetic paper based on ultrahigh-molecular weight polyethylene

The invention relates to a method for preparing synthetic paper based on ultrahigh-molecular weight polyethylene. The method comprises the following steps: modifying an inorganic filler to obtain a modified filler, then uniformly premixing the modified filler with the ultrahigh-molecular weight polyethylene, a compatilizer, an antioxidant and an additive, performing melt-extrusion, and pelleting to obtain master batches; flatly laying the master batches on a hollow mold, melting and hot-pressing the master batches in the shape of a membrane, cold-rolling, and extracting to obtain the synthetic paper. The synthetic paper prepared by the method disclosed by the invention has excellent performances of good mechanical properties, light weight, solvent resistance, micro-porosity and the like.

Owner:DONGHUA UNIV +1

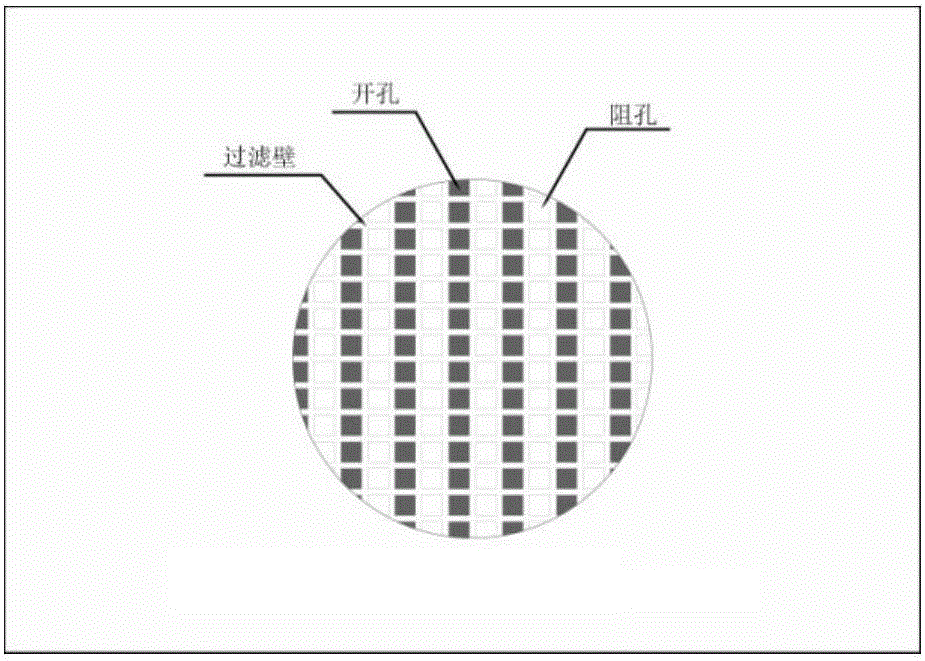

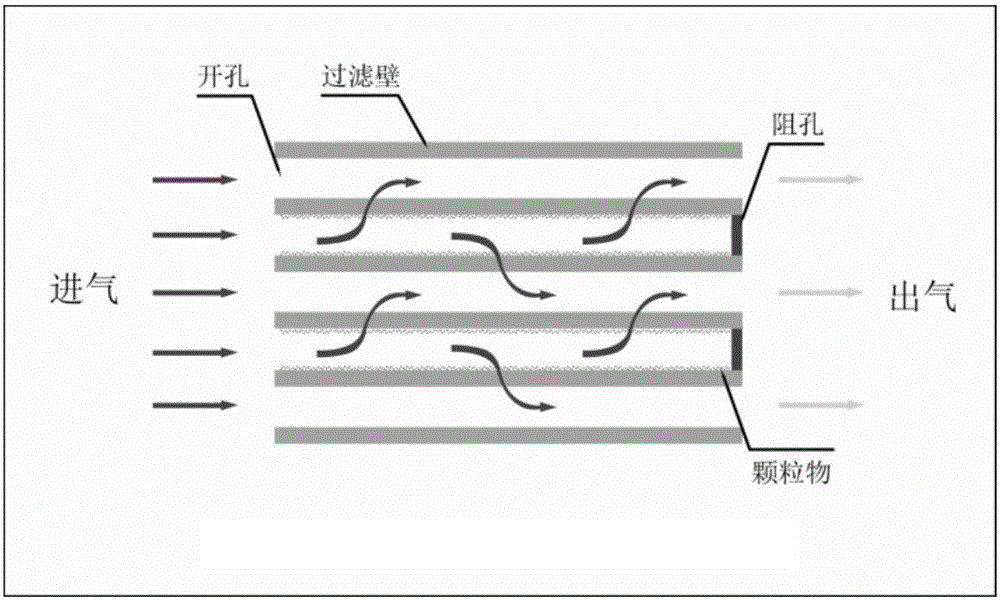

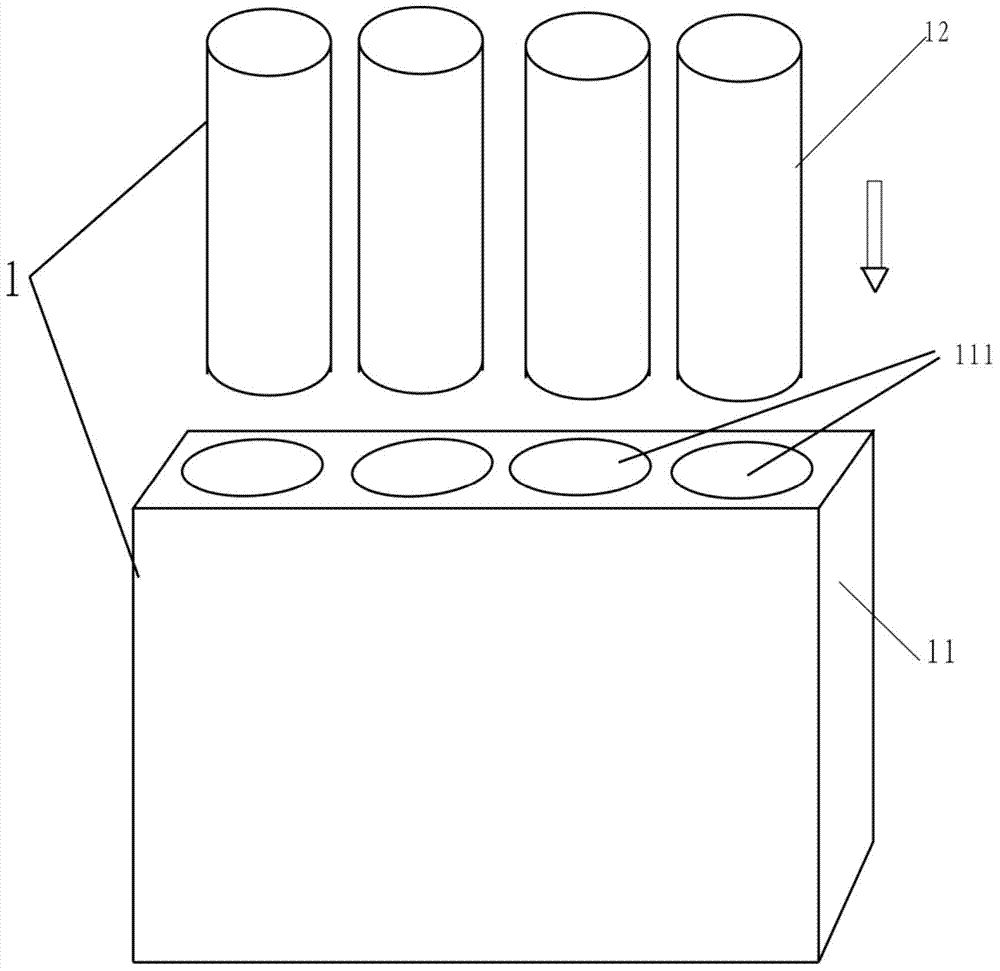

Semi-passing honeycomb ceramic grain filter and preparation method thereof

InactiveCN105833620AGuaranteed roundnessReduce energy consumptionDispersed particle filtrationTransportation and packagingWater solubleSkin grafting

The invention provides a semi-passing honeycomb ceramic grain filter and a preparation method thereof. A filter is made of honeycomb ceramic with blocking holes alternately crossed at one end and no block hole at the other end. The raw material comprises the following components in parts by weight: 25-30 parts of flake kaolin, 15-20 parts of alumina powder, 37-40 parts of flake talcum, 6-10 parts of fused quartz powder, 8-20 parts of pore forming materials, 3-10 parts of water-solubility binder and a defined amount of water. The preparation method comprises the following steps: mechanically mixing and uniformly kneading the raw materials; performing vacuum processing on the mixture for 2-3 times at the vacuum degree of 90-95KPa and then ageing for 20-40h, thereby acquiring plastic slurry; extruding a honeycomb ceramic wet green body in a certain size through a mold; performing microwave drying for 2h at 8-12Kw, cutting and trimming, thereby acquiring a dry green body; increasing the temperature according to the procedure and sintering into a semi-finished product at high temperature; and mechanically stripping the irregular outer wall of the green body, performing skin-grafting again, performing microwave drying, crossing the blocking holes at single end at intervals and then performing microwave drying, thereby acquiring a finished product.

Owner:NANJING KERUI SPECIAL CERAMICS

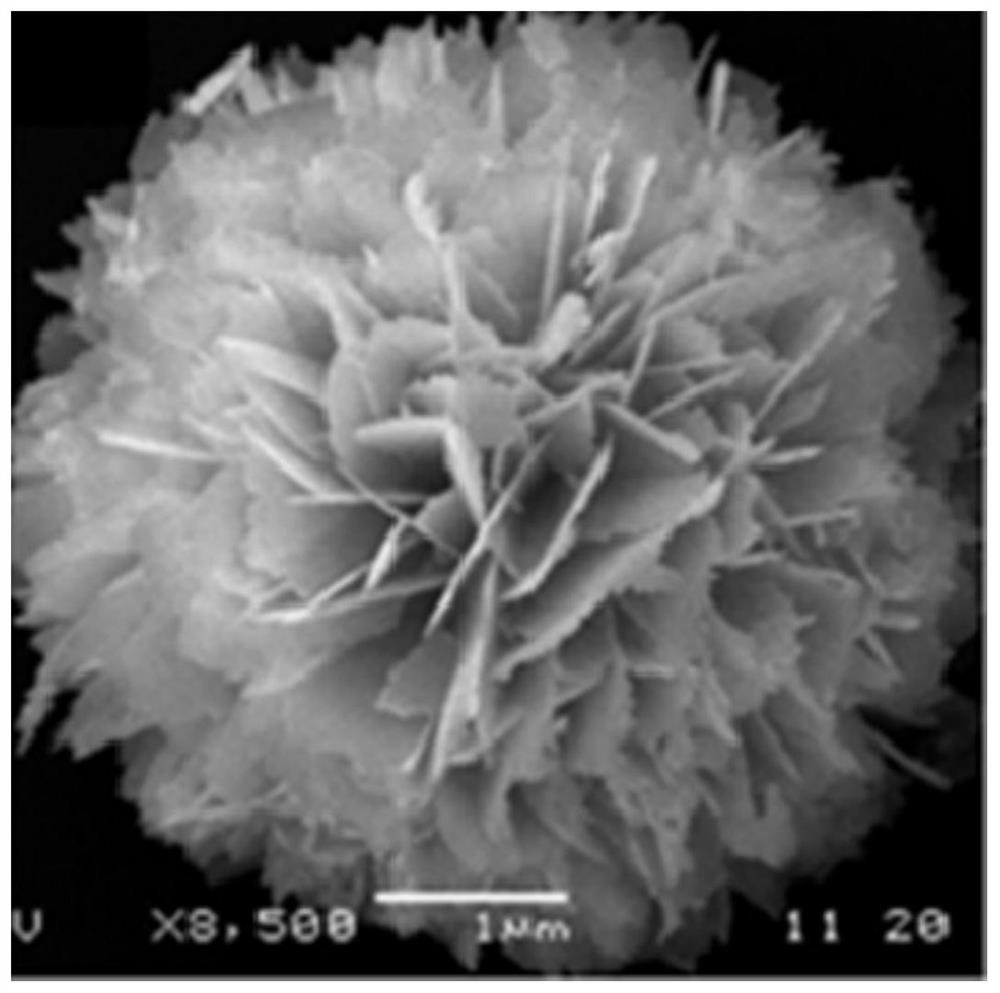

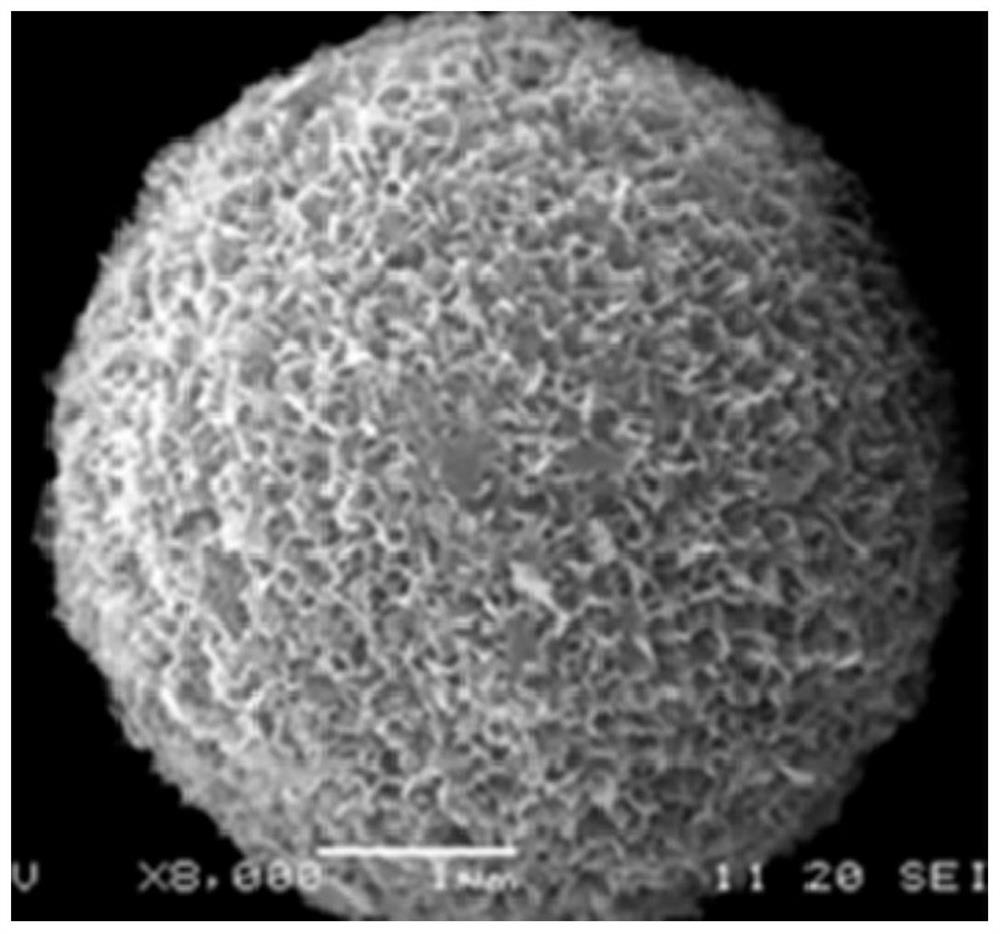

Method for synthesizing kilogram-stage nano molecular screen MCM-56 and template agent removing method

InactiveCN101164885APromote mass formationGrow fastCrystalline aluminosilicate zeolitesMolecular sieveHorizontal axis

This invention discloses a method for synthesizing kilogram grade nanometer molecular sieve MCM-56, and method for removing metrix agent. The procedures are: mixing silicon source, aluminium source, alkali, metrix agent and water in proper ratio, heating at 80-200deg.C, crystallizing for 5-240hrs; taking the product out and proceeding water-washing, drying to obtain the inventive product MCM-56 molecular sieve. Said crystallization is in a 30L reaction tank and being rotating round a central horizontal axis at speed of 5-40 rpm. Hydrogen peroxide is used for removing metrix agent. In this invention, due to the use of less water and metrix agent to form athick raw material mud, it is beneficial to formation of molecular sieve kernels in great amount. The even heating in the reaction tank makes the final product being of crystalline phase homogeneous. No use of high temperature calcinations makes the skeleton keep its original structure. This inventive method is suitable for commercial production.

Owner:JILIN UNIV

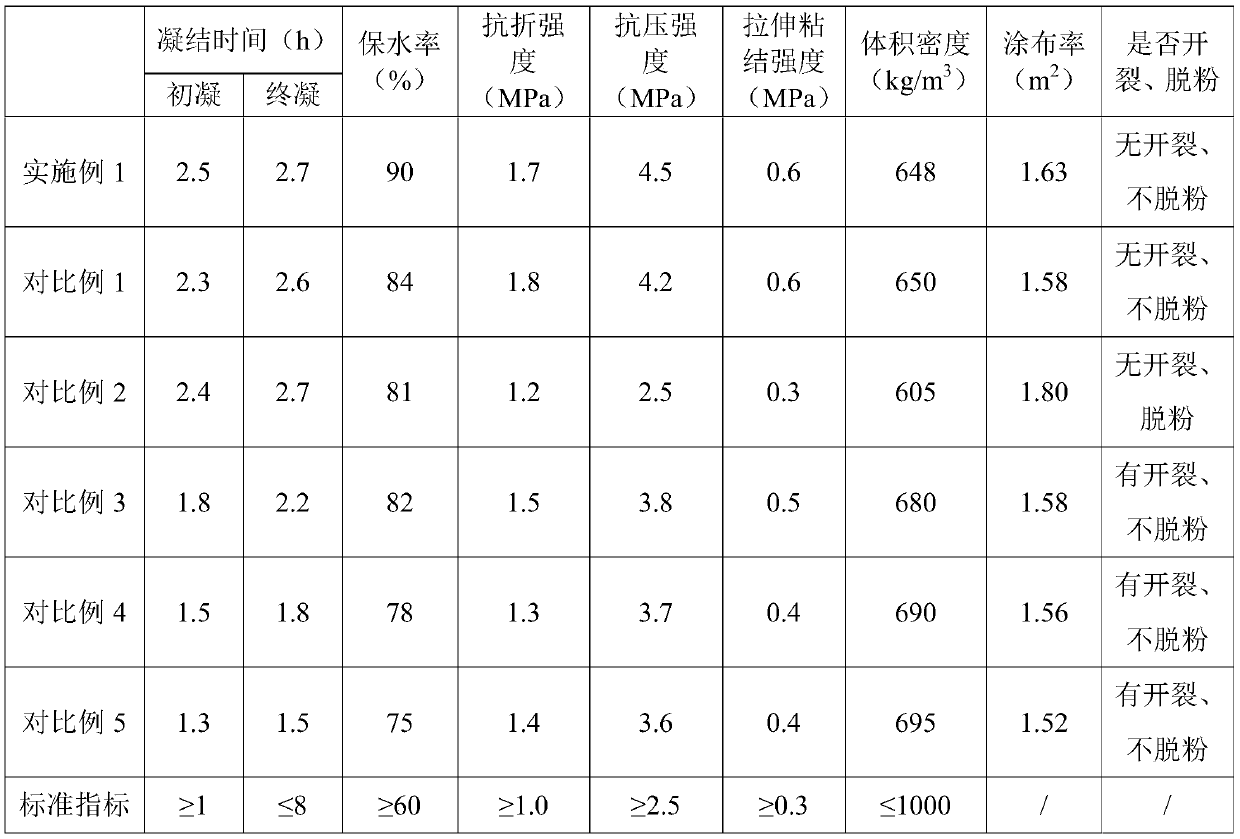

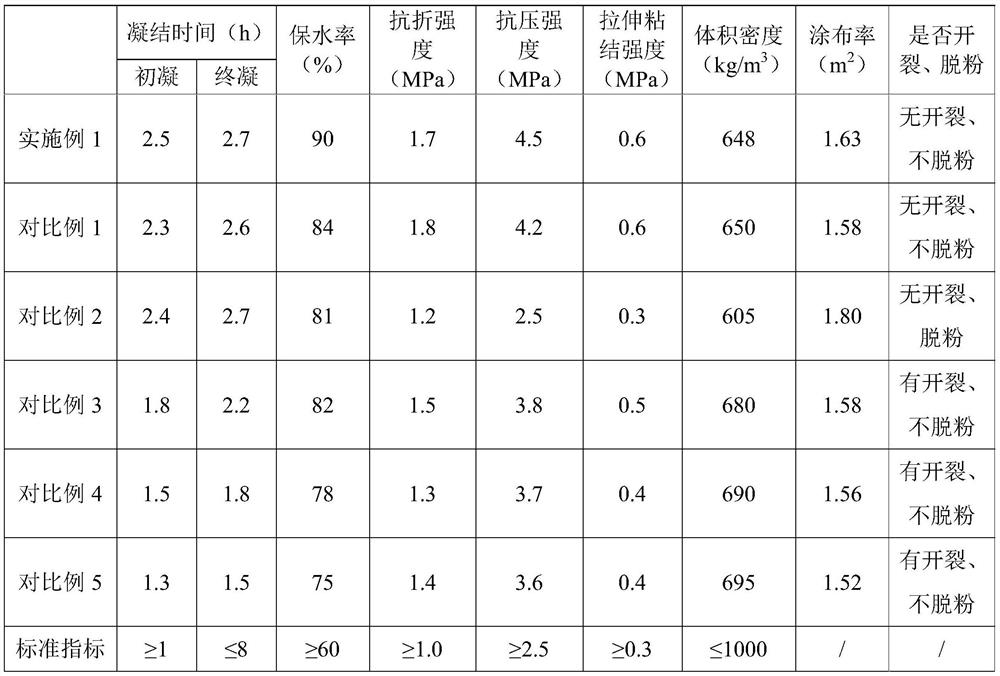

Gypsum-based light plastering material and preparation method thereof

The invention relates to the technical field of buildings, and particularly provides a gypsum-based light plastering material and a preparation method thereof. The first aspect of the invention provides a gypsum-based light plastering material which at least comprises the preparation raw materials in parts by weight: 80-95 parts of gypsum powder, 0.5-2 parts of an alkaline agent, 0.1-0.2 part of awater-retaining agent, 0.1-0.3 part of a mixture, 0.05-0.2 part of a retarder and 0-20 parts of glass microbeads.

Owner:JASON PLASTERBOARD JIAXING

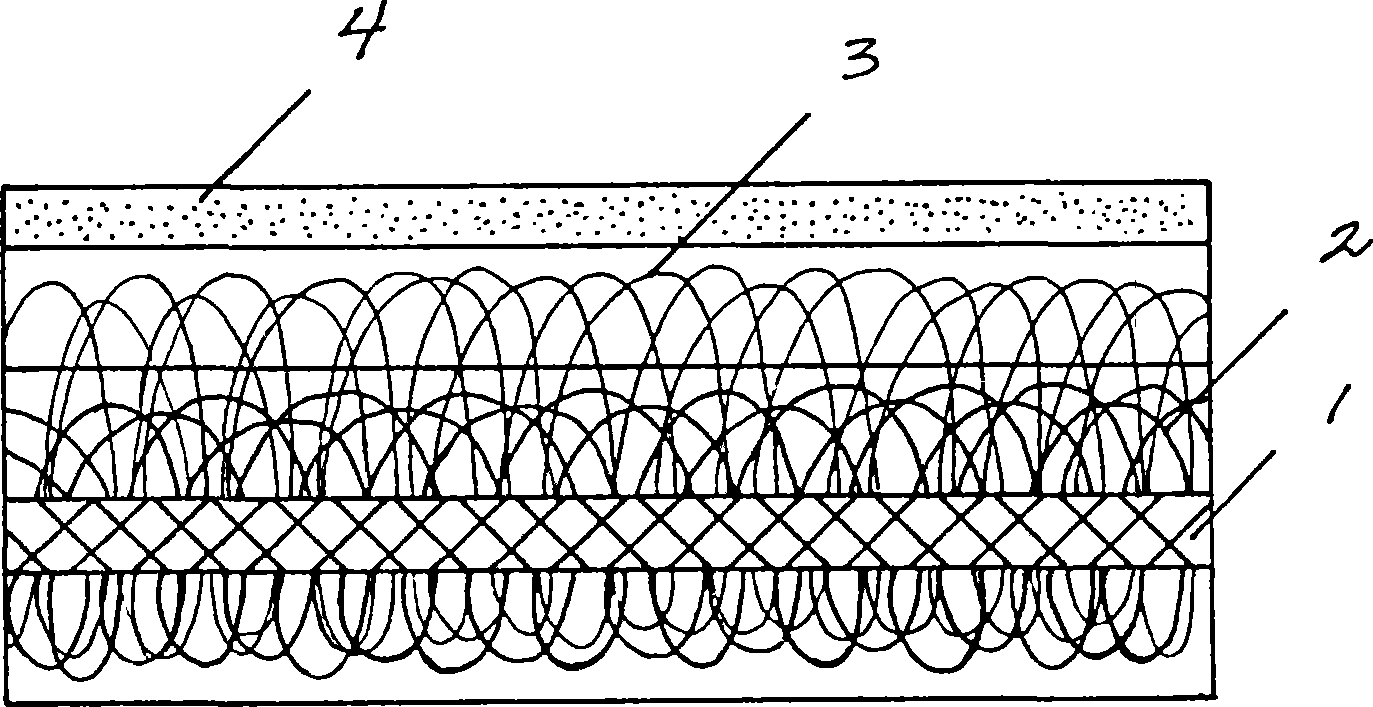

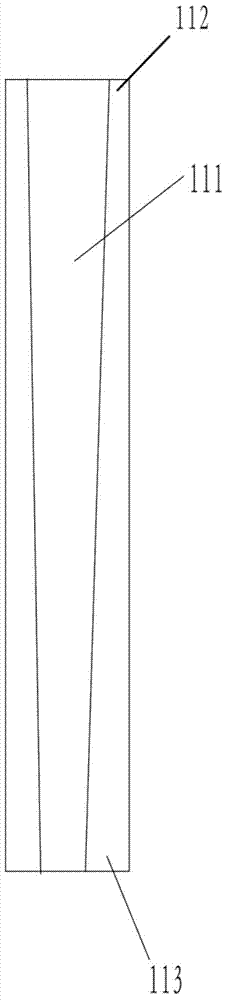

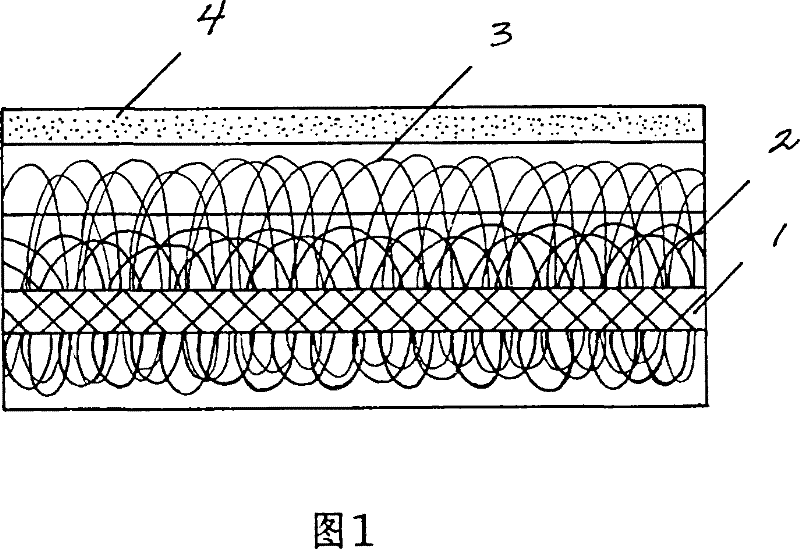

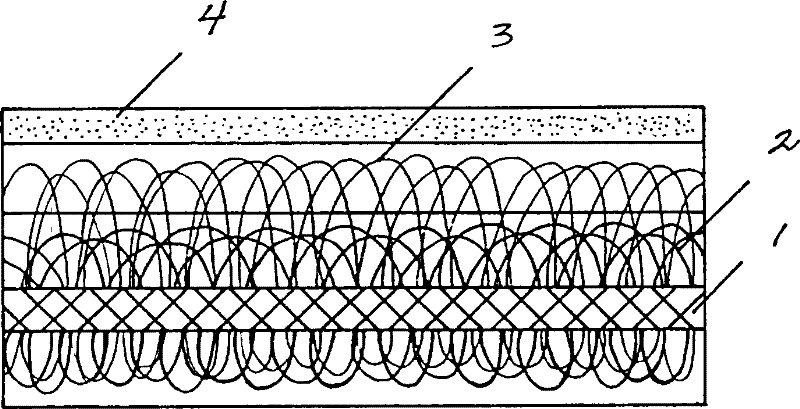

Pure polyfluortetraethylene gradient overlay film filter material with high intensity

The invention relates to a high-strength pure polytetrafluoroethylene gradient coating filter material, which comprises base cloth, and is characterized in that the base cloth is a polytetrafluoroethylene base cloth; a polytetrafluoroethylene coarse fiber layer and a polytetrafluoroethylene superfine fiber layer are pricked on the polytetrafluoroethylene base cloth; and a polytetrafluoroethylene film is coated on the polytetrafluoroethylene superfine fiber layer. The high-strength pure polytetrafluoroethylene gradient coating filter material has the characteristics of high and low temperature resistance, high acid and alkaline resistance, high humidity resistance, good chemical stability, high filtration efficiency, quick filtration speed, long service life and the like, can be used in various bag-type dusters for flue gas purification, dust removal, dust treatment and material recovery, and has wide application scope.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

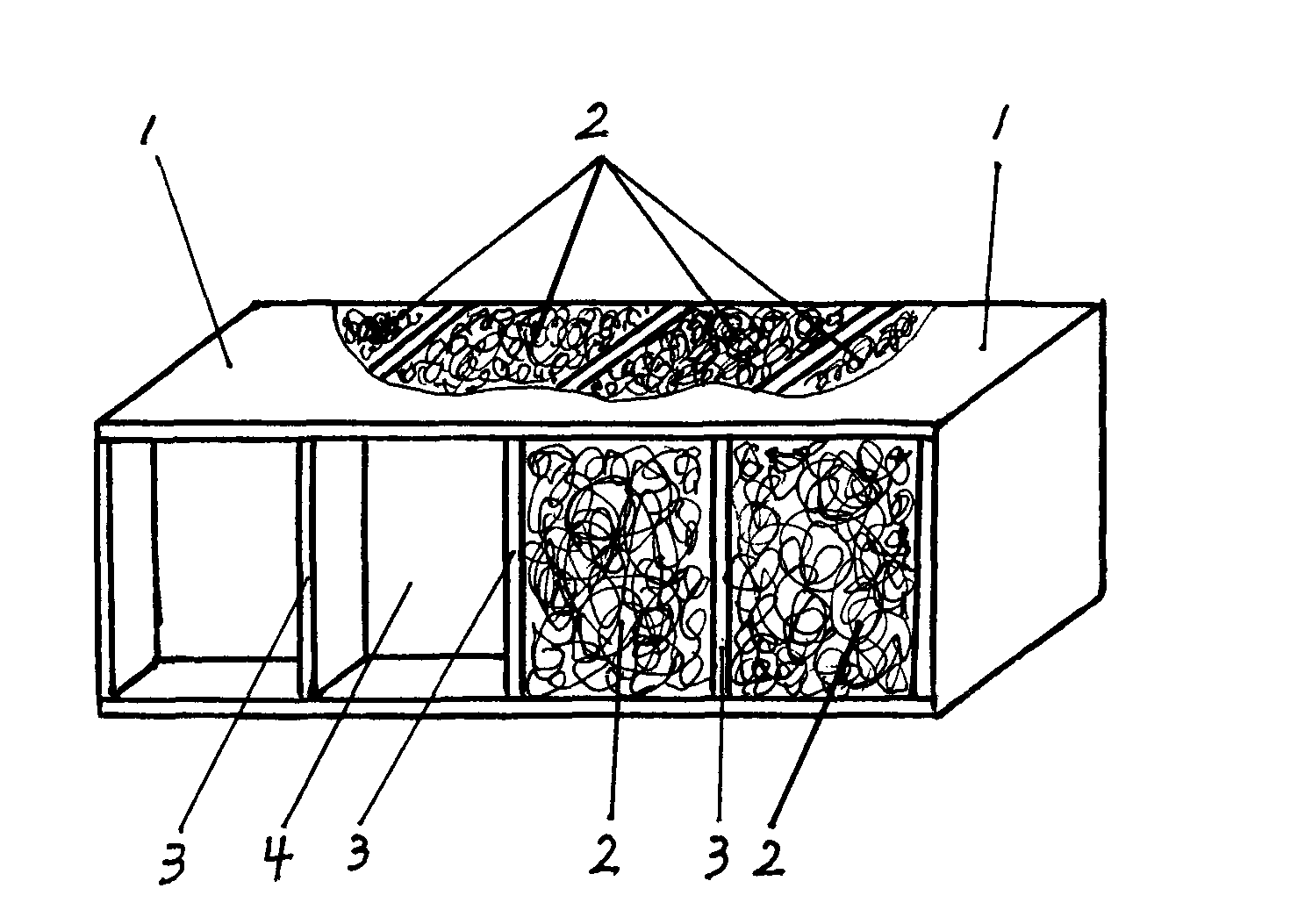

Surface growth type photosynthetic microorganism culture plate having core-shell structure, culture unit, system and culture method

InactiveCN104328029APromote absorptionGood water absorption/permeabilityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismNutrient solution

The invention discloses a surface growth type photosynthetic microorganism culture plate having a core-shell structure, which comprises a shell plate arranged outside and a core part arranged in the shell plate, wherein the shell plate is of a porous plate-shaped structure made from a rigid water seepage material; the filling core is made from a water retention and water seepage material; and the filling core is arranged in the shell plate. According to the core-shell type composite culture plate disclosed by the invention, photosynthetic microorganisms are attached to the surface, a nutrient solution for supporting growth of the photosynthetic microorganisms is retained in the filling core, and the nutrient solution gradually permeates to the surface of the shell plate from the filling core and then is supplied for sustainable reproduction of the photosynthetic microorganisms. In addition, the invention further discloses a culture unit comprising the core-shell type composite culture plate, a culture system, a culture method and application thereof.

Owner:STATE DEV & INVESTMENT +1

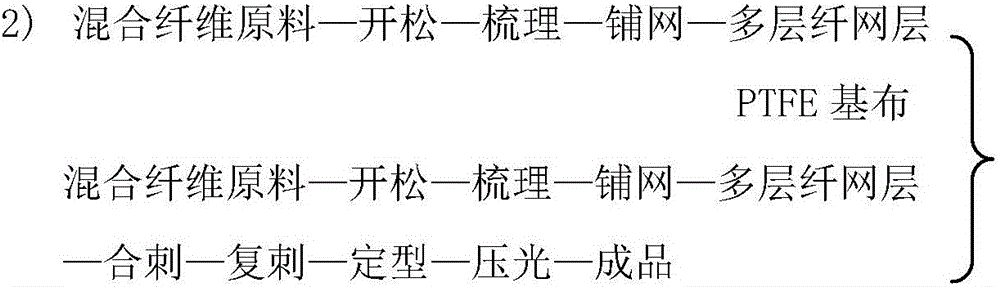

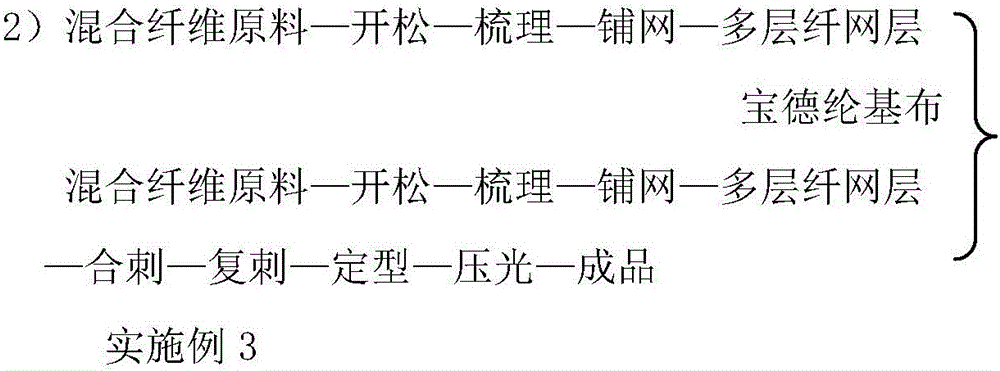

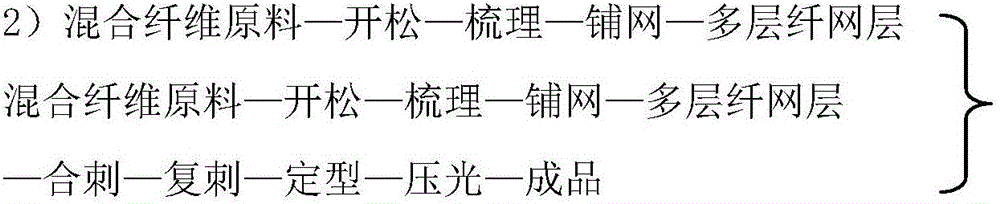

High-temperature filter material and preparation method and application thereof

InactiveCN106268027AHigh strengthHigh densityDispersed particle filtrationMembrane filtersCardingPolymer science

The invention provides a high-temperature filter material and a preparation method and application thereof. The high-temperature filter material is composite filter cloth with a single layer structure or composite filter cloth with a multi-layer structure, and the composite filter cloth is prepared from, by mass, 10%-90% of Podlon fibers and 10%-90% of polytetrafluoroethylene fibers. The preparation method of the composite filter cloth with the single layer structure in the high-temperature filter material comprises the steps of raw material mixing, opening, carding, web lapping, multi-layer fiber web layer forming, needle-punching, shaping, calendering and finished product obtaining; The preparation method of the composite filter cloth with the multi-layer structure in the high-temperature filter material comprises the steps of raw material mixing, opening, carding, web lapping, multi-layer fiber web layer forming, combined needle-punching, compound needle-punching, shaping, calendering and finished product obtaining. According to the application of the high-temperature material, the composite filter cloth with the single layer structure or the composite filter cloth with the multi-layer structure is used for high-temperature flue gas dust removal equipment. The high-temperature filter material has the advantages of being high in strength and having certain density and elasticity and is of an astatic three-dimensional structure which can be a single-layer structure or a multi-layer structure.

Owner:厦门美达斯环保工业有限公司

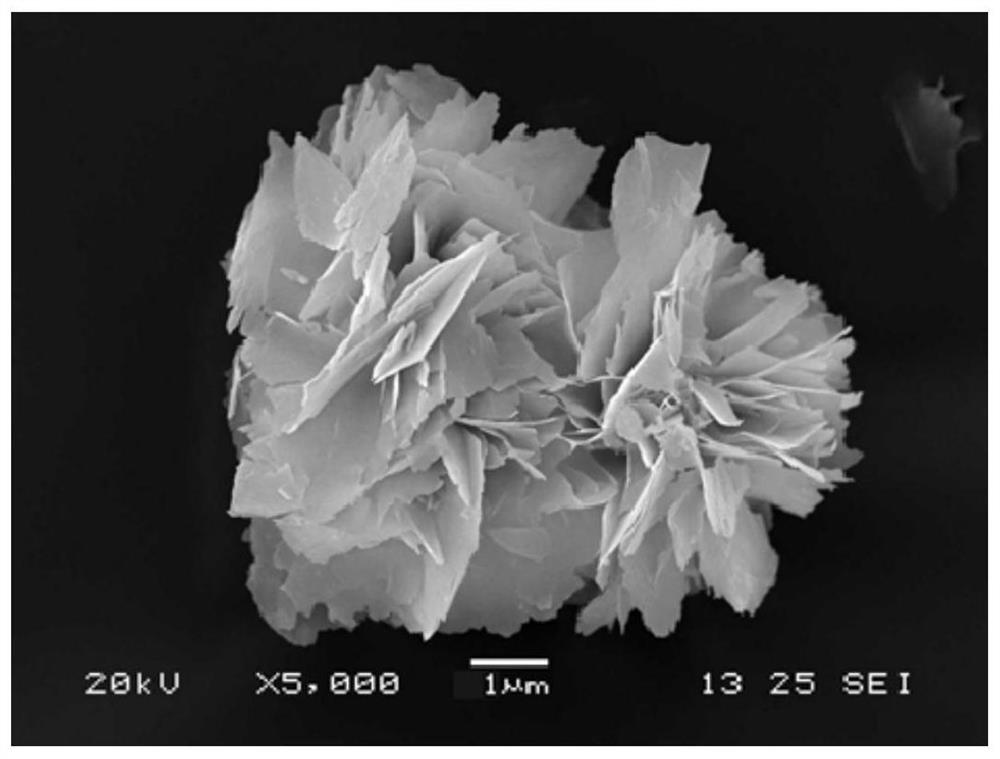

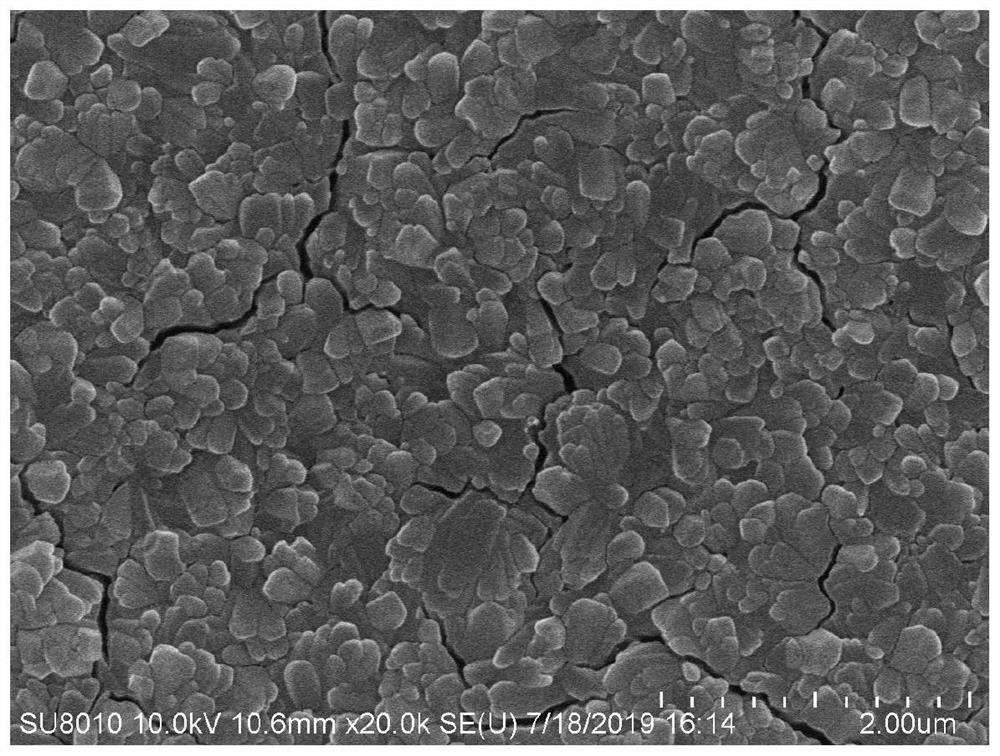

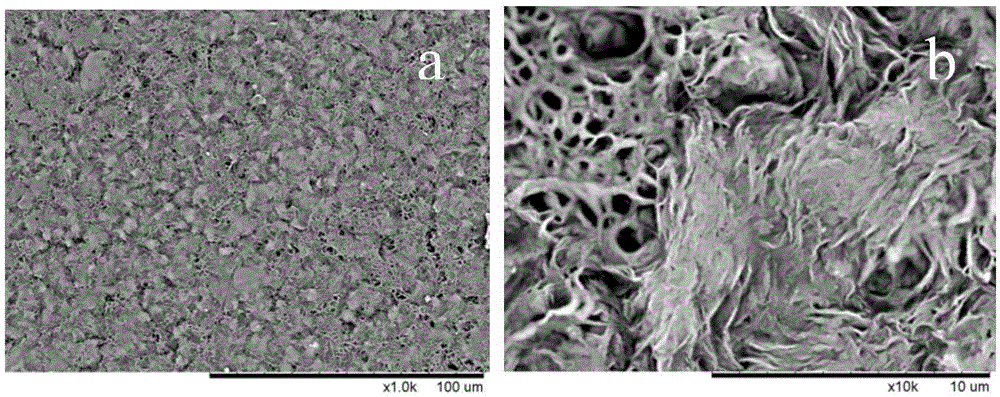

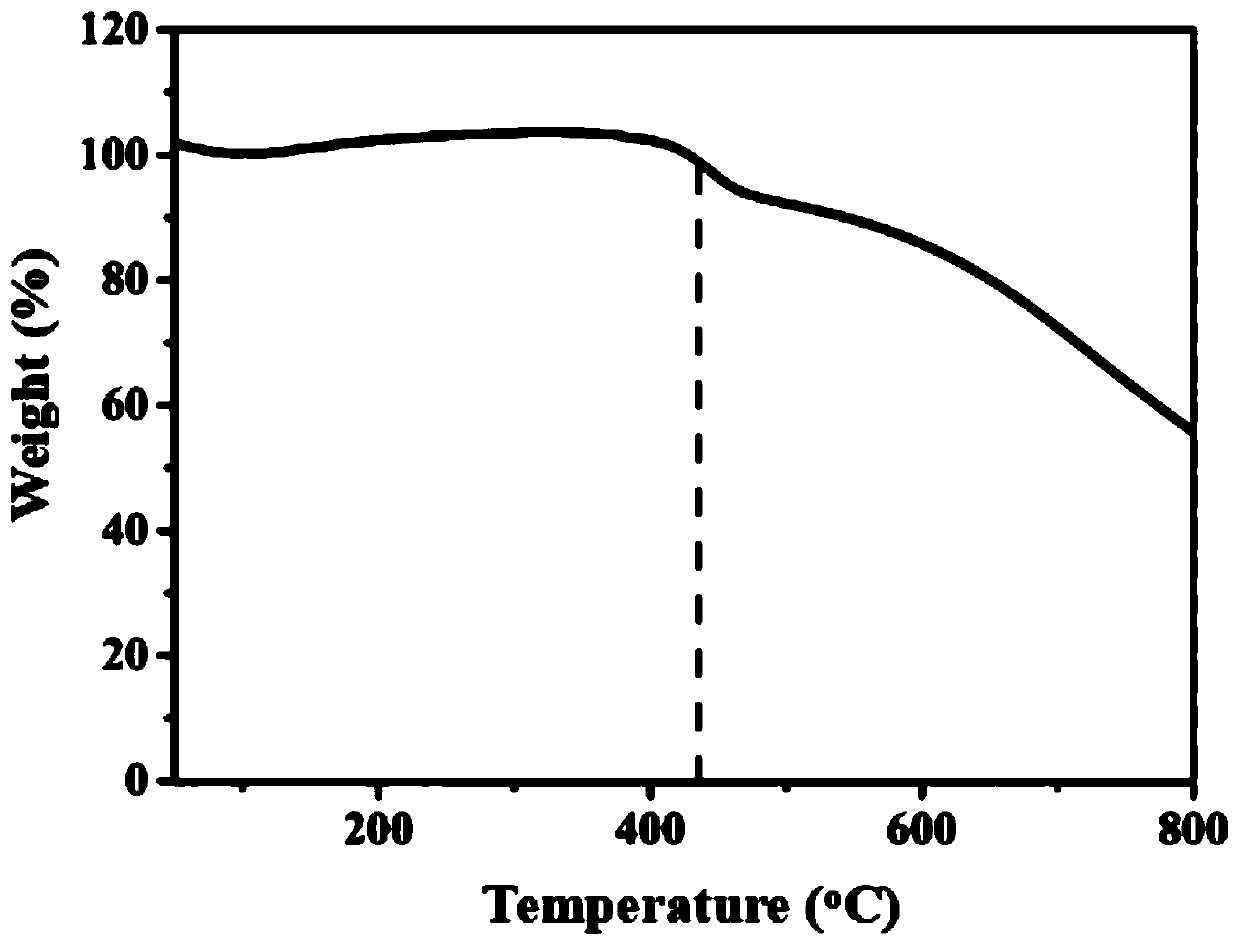

Lithium iron phosphate material, and preparation method and application thereof

ActiveCN111646449AMany defectsMicroporousCell electrodesSecondary cellsLithium iron phosphatePhysical chemistry

The invention relates to a lithium iron phosphate material, and a preparation method and application thereof. The preparation method comprises the following steps: (1) dispersing a lithium source, aniron source, a phosphorus source, a template and a chelating agent in water to prepare a raw material mixed solution, wherein the template can generate bubbles in the water; and (2) carrying out a hydrothermal reaction on the raw material mixed solution under a preset pressure to obtain a pre-product. The template and the chelating agent are added into the raw material mixed solution, the templatecan generate bubbles in water to form vacuole films, further, lithium iron phosphate crystals in the raw material mixed solution are promoted to directionally grow along gaps among the vacuole films,the chelating agent can make the vacuole films stably exist in the reaction system under the predetermined pressure, and the size of the vacuole films is controlled by adjusting the pressure of the system so as to stably control the pore size and the morphology of the lithium iron phosphate.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

Method for preparing modified activated carbon from phenol through fast ultralow-temperature freezing

ActiveCN106744944AWith abrasion resistanceMicroporousCarbon compoundsActivated carbonPhosphoric acid

The invention discloses a method for preparing modified activated carbon from phenol through fast ultralow-temperature freezing. The method comprises the steps of weighing crushed nutshell as a raw material, dipping in a phosphoric acid solution, mixing with phenol and drying; carrying out activation in an oxygen-free environment at a high temperature of 300-1100 DEG C for 0.5-24h; after activation is completed, quickly soaking the activated material into liquid nitrogen or brine ice below -20 DEG C at the high temperature, carrying out sealed oscillation for 2h and then taking out the activated material; oscillating and cleaning the activated material by using deionized water until neutral and drying to obtain the modified activated carbon. According to the method for preparing the activated carbon, the specific surface area of the obtained activated carbon is obviously increased in comparison with that of a phenolic hydroxyl group of the activated carbon obtained through same-concentration phosphoric acid activation and natural cooling, and the energy-saving effect is obvious.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

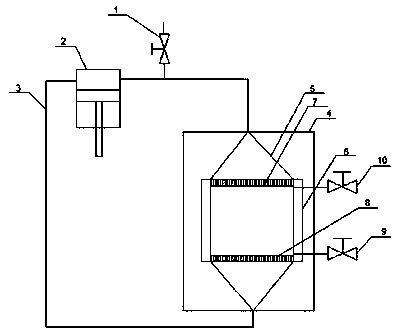

Method for preparing thermoplastic polymer foamed beads by clean waterless process

The invention provides a method for preparing thermoplastic polymer foamed beads by a clean waterless process, the method comprises the following preparation steps: a feed inlet valve of a vulcanization kettle is opened, an appropriate amount of polymer particles are poured into the vulcanization kettle, the feed inlet valve is then closed, and circulation is formed in the vulcanization kettle; agas replenishing valve of a reciprocating booster pump is opened, foaming agent gas is injected into the vulcanization kettle, foaming pressure is regulated to 5MPa to 30MPa, and the gas replenishingvalve is closed; when the polymer particles are completely in a fluidized state, the temperature of the vulcanization kettle is increased to foaming temperature; temperature and pressure are kept for10 to 30 minutes, a discharge outlet valve is opened, the pressure release rate is 1MPa / s to 1000MPa / s, the gas carries beads to get out of a fluidized bed, and thereby foamed polymer beads are obtained. The method utilizes the high-pressure fluidized bed to carry out preparation and directly utilizes a supercritical fluid foaming technique, the demand on heat quantity is low, the cost is low, thecontrollability is high, moreover, the efficiency of production is high, the micropores of the prepared foamed beads are fine and dense, the diameter uniformity of the cells is good, and overall safety and cleanliness in the process of production are high.

Owner:GUANGDONG BENDI NEW MATERIAL TECH

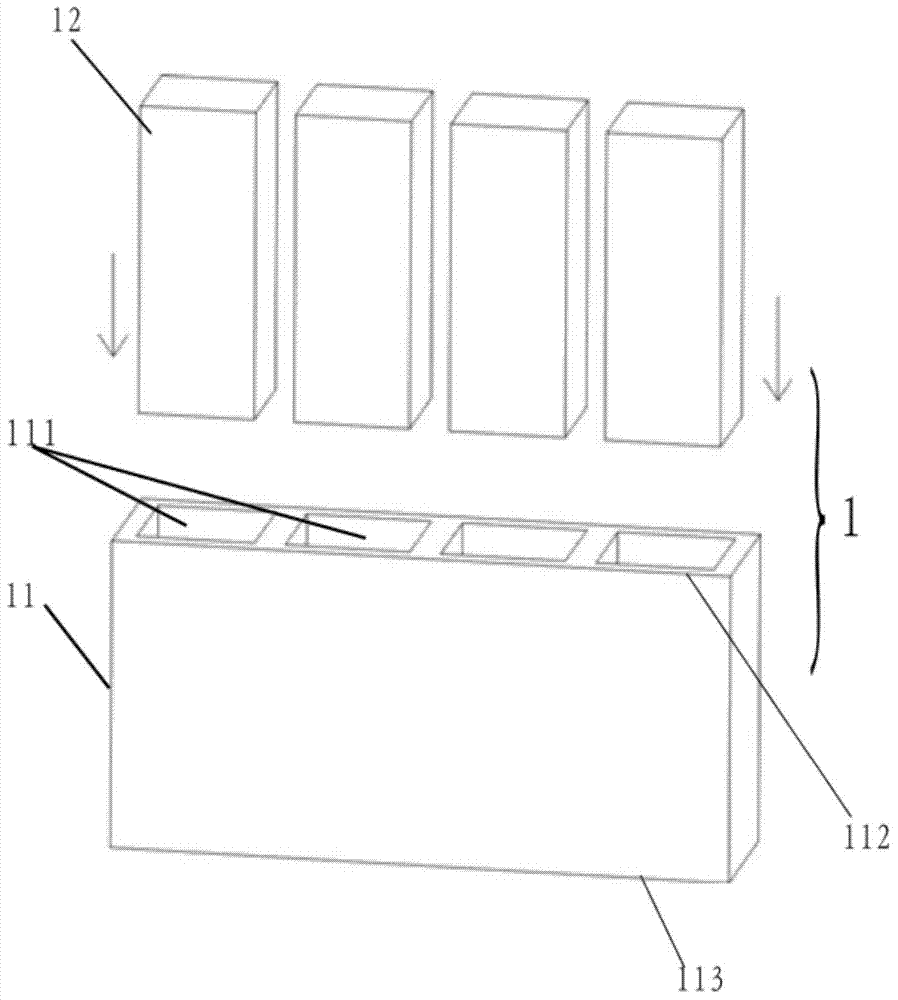

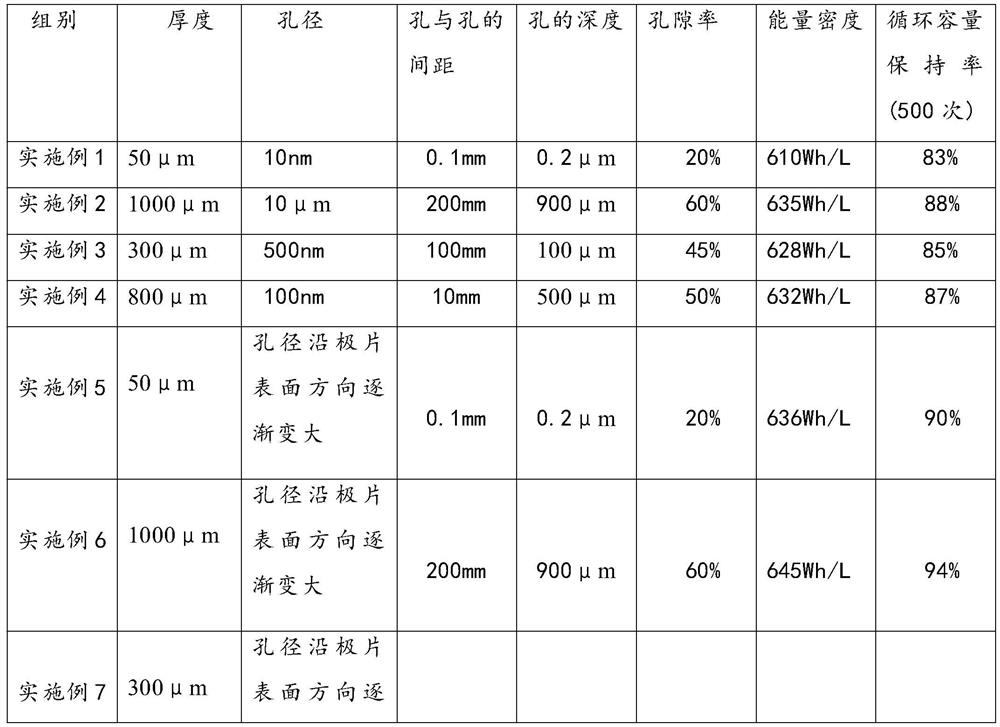

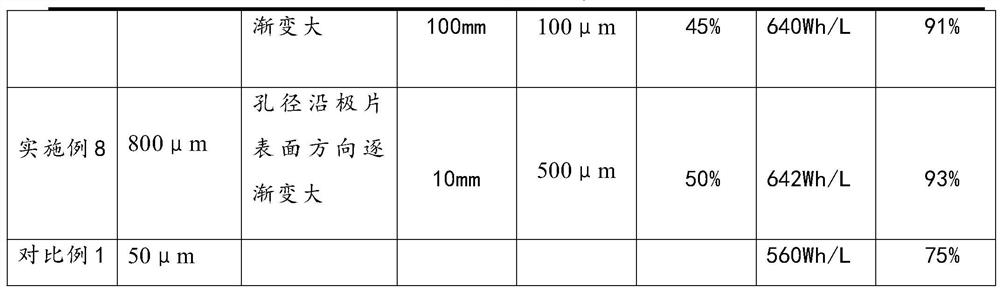

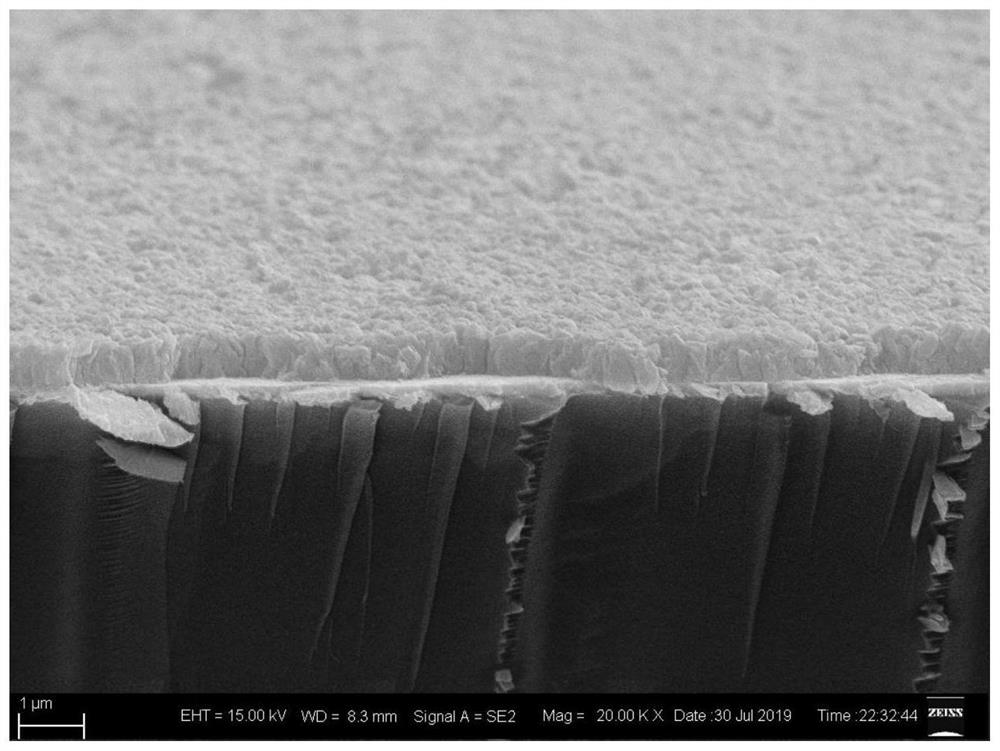

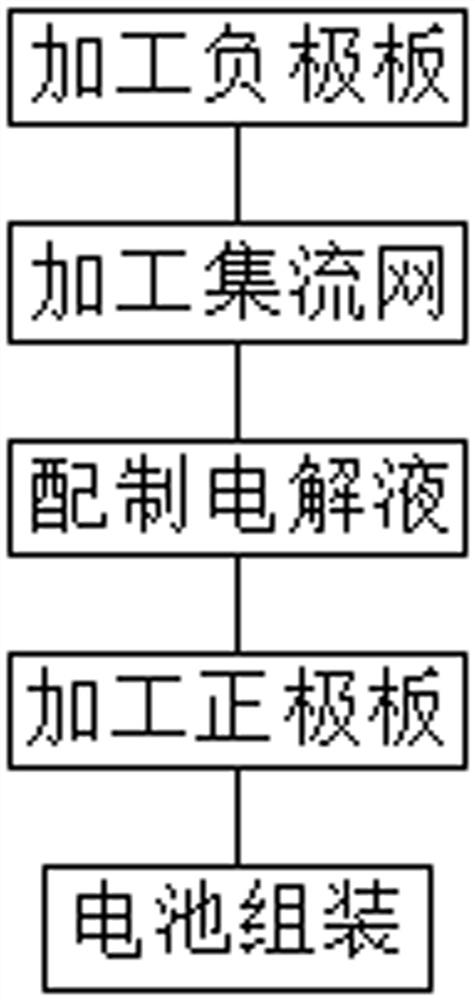

Thick electrode structure and manufacturing method thereof

PendingCN113991064AMicroporousIncrease the number ofNon-aqueous electrolyte accumulator electrodesMetallurgyEngineering

The invention discloses a thick electrode structure and a manufacturing method thereof. The manufacturing method comprises the following steps: step 1), coating an electrode plate with a preset thickness and rolling the electrode plate; step 2) after rolling is completed, performing micro-pore forming on the surface of the electrode plate; step 3) removing particles on the surface of the electrode plate; and step 4) forming a thick electrode plate with a porous structure. Compared with the prior art, the thick electrode structure and the manufacturing method thereof have the advantages that pore forming on the surface of the thick electrode is realized, the quantity of battery cell electrolyte can be increased, the cycle performance can be improved, more ion shuttle channels can be provided, and polarization on an interface is avoided.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

Baking-free ceramic prepared by using industrial wastes and preparation method thereof

The invention provides a baking-free ceramic prepared by using industrial wastes. The ceramic is characterized in that the ceramic is prepared by the following components in parts by weight: 20-30 parts of magnesium oxide, 15-25 parts of magnesite slags, 12-20 parts of magnesium chloride, 10-20 parts of coal ash, 10-16 parts of diatomite, 6-12 parts of flue gas desulfurization gypsum, 4-8 parts of plant fiber, 3-6 parts of silica sol, and 15-25 parts of water. Magnesite slags, coal ash, flue gas desulfurization gypsum and other industrial wastes are selected, synergistic effect between different solid wastes is fully performed, the baking-free ceramic material obtained by production meets the national standard, comprehensive utilization of industrial solid wastes is realized, pollution of environment due to solid waste discharge is reduced, and economic benefits are improved; and unique raw materials are prepared scientifically, the production process is simple, the production cost is low, and the obtained baking-free ceramic product does not have micro-area cracking and bending phenomenon.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Method for preparing medical collagen sponge from East sea dark gensing

ActiveCN103409488AImprove securityMicroporousPeptide preparation methodsAbsorbent padsChemistryChemical residue

The invention discloses a method for preparing medical collagen sponge from East sea dark gensing, which comprises the following steps: adding pepsase into East sea dark gensing defibrination going through dirt removing process; adding solid edible salt after the enzymolysis; salting, separating and collecting pulpy sediment, precipitating liquid, salting again, and separating; dissolving pulpy sediment by L- lactic acid, carrying out desalination process to the dissolved sea cucumber collagen liquid, adding food grade glutamine transaminase, spraying nepheloid sea cucumber collagen liquid into a mould, quick-freezing and forming the collagen liquid into collagen sponge instantly; freezing, alternating temperature and drying, and drying the material until the content of water is 1 to 3 %; withdrawing the collagen sponge, packing, irradiating, and entering the medical collagen sponge library. The method has the beneficial effects that East sea dark gensing is used as raw material to prepare the medical collagen sponge, the rich marine resource is enabled to be highly utilized, the sponge can also be used for crowd rejecting the mammal collagen, the problem of chemical residue in the product is solved, and the safety of the product is higher.

Owner:宁波超星海洋生物制品有限公司

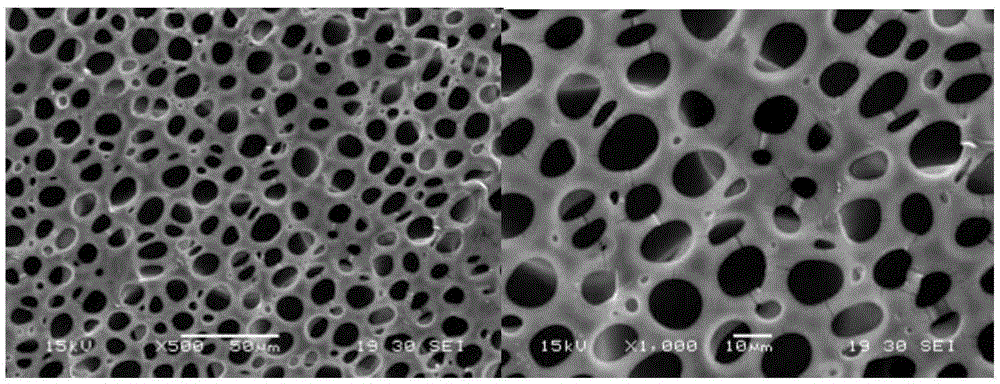

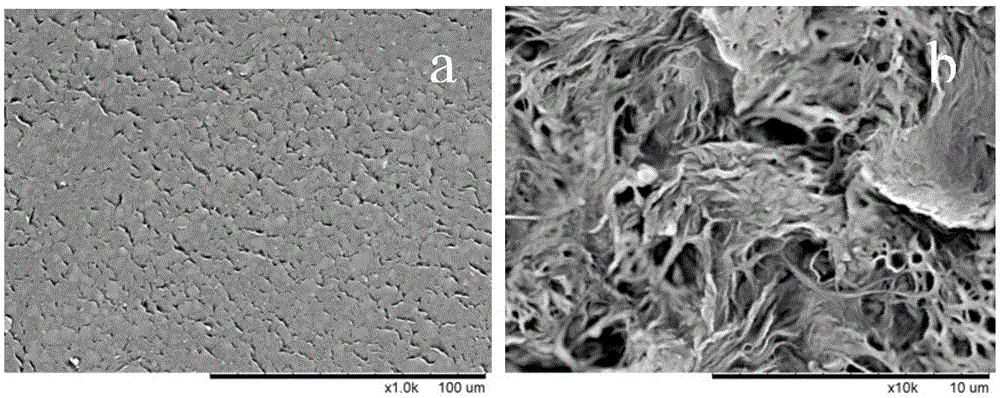

Degradable aliphatic polycarbonate film and preparation method thereof

The invention discloses a degradable aliphatic polycarbonate film and a preparation method thereof. The film has a bore diameter of 3 mu m-20 mu m, an aperture ratio of 5%-80% and a thickness of 1 mu m-100 mu m. The preparation method of the film comprises the following steps of dissolving aliphatic polycarbonate in a solvent to obtain film casting liquor; and pouring the film casting liquor on a film casting plate and spreading, and stewing and drying to constant weight in sequence to obtain a product. The degradable aliphatic polycarbonate film provided by the invention has porosity characteristic and wide application prospect in the fields of biology, medicine, chemicals, environment and the like. The preparation method of the degradable aliphatic polycarbonate film is simple in process, simple and convenient to operate, easy to realize, low in device dependency and fewer in materials.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A kind of degradable aliphatic polycarbonate film and preparation method thereof

The invention discloses a degradable aliphatic polycarbonate film and a preparation method thereof. The film has a bore diameter of 3 mu m-20 mu m, an aperture ratio of 5%-80% and a thickness of 1 mu m-100 mu m. The preparation method of the film comprises the following steps of dissolving aliphatic polycarbonate in a solvent to obtain film casting liquor; and pouring the film casting liquor on a film casting plate and spreading, and stewing and drying to constant weight in sequence to obtain a product. The degradable aliphatic polycarbonate film provided by the invention has porosity characteristic and wide application prospect in the fields of biology, medicine, chemicals, environment and the like. The preparation method of the degradable aliphatic polycarbonate film is simple in process, simple and convenient to operate, easy to realize, low in device dependency and fewer in materials.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A method of producing high-quality filter material by using discarded walnut shells

Owner:DANFENG FENGLIN BIOTECH DEV

Low-noise traveling crane

The invention relates to hoisting mechanical devices, and particularly relates to the improvement of traveling cranes. The low-noise traveling crane comprises a box-type beam, wherein two ends of the box-type beam are provided with wheel groups; the outer surface of the box-type beam is provided with rib plates and trolley tracks; the trolley tracks are provided with a movable trolley; the trolley is provided with an electric hoist; the internal spaces of the box-type beam and concave clearances in two sides of the rib plates are internally filled with polyester foaming materials. The low-noise traveling crane has the advantages of low running noise, environment protection and slight interference to workers.

Owner:JIANGSU HUAYANG HEAVY IND

Pure polyfluortetraethylene gradient overlay film filter material with high intensity

The invention relates to a high-strength pure polytetrafluoroethylene gradient coating filter material, which comprises base cloth, and is characterized in that the base cloth is a polytetrafluoroethylene base cloth; a polytetrafluoroethylene coarse fiber layer and a polytetrafluoroethylene superfine fiber layer are pricked on the polytetrafluoroethylene base cloth; and a polytetrafluoroethylene film is coated on the polytetrafluoroethylene superfine fiber layer. The high-strength pure polytetrafluoroethylene gradient coating filter material has the characteristics of high and low temperatureresistance, high acid and alkaline resistance, high humidity resistance, good chemical stability, high filtration efficiency, quick filtration speed, long service life and the like, can be used in various bag-type dusters for flue gas purification, dust removal, dust treatment and material recovery, and has wide application scope.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

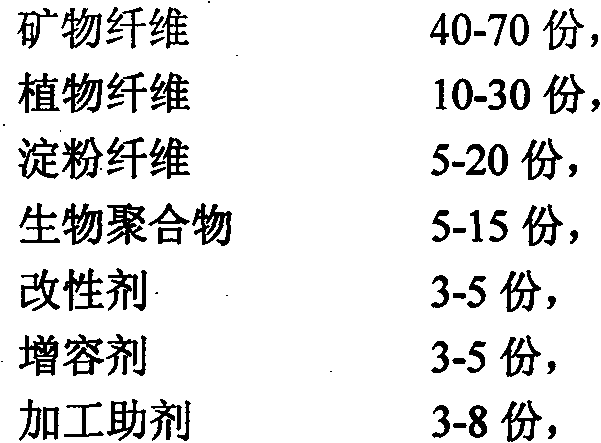

Paper-imitating biodegradable resin and preparation method

ActiveCN101914294BAvoid pollutionImprove rigidityInorganic fibres/flakesPaper/cardboardBiopolymerVegetable fibers

The invention discloses a paper-imitating biodegradable resin and a preparation method. For improving the degradability and natural recoverability of paper-imitating materials and making the paper-imitating materials have similar lightness, foldability and printing and writing performance as the conventional paper. The paper-imitating biodegradable resin uses mineral fibers, vegetable fibers and starch fibers as main components, and concretely comprises the following components in part by weight: 40 to 70 parts of mineral fibers, 10 to 30 parts of vegetable fibers, 5 to 20 parts of starch fibers, 5 to 15 parts of biopolymer, 3 to 5 parts of modifier, 3 to 5 parts of compatibilizer and 3 to 8 parts of processing assistant. The mineral fibers, vegetable fibers and starch fibers are interweaved through thermoplastic processing, and the preparation process is clear and pollution-free. The paper-imitating biodegradable resin can be processed into various paper-imitating products by hot plasticizing equipment, and the products, when discarded, can be swallowed and decomposed by microbes without polluting the environment.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

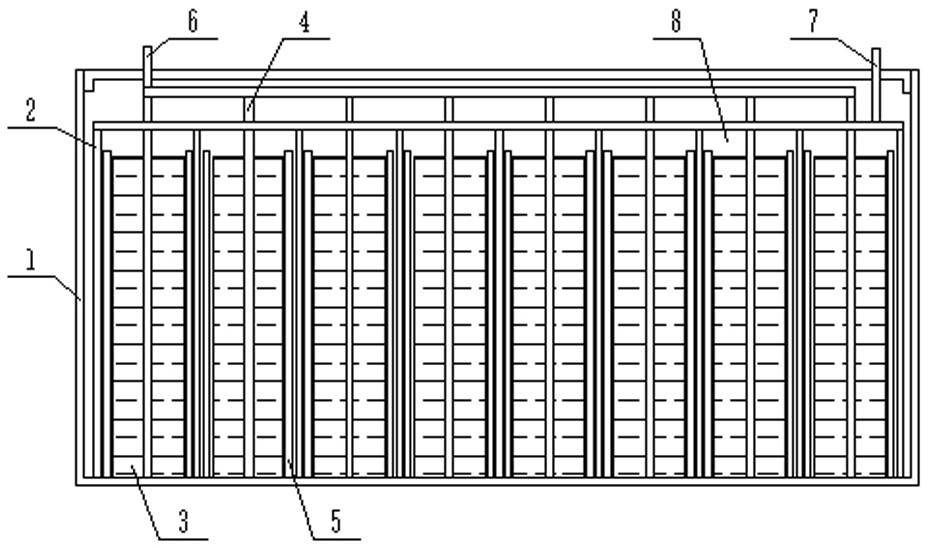

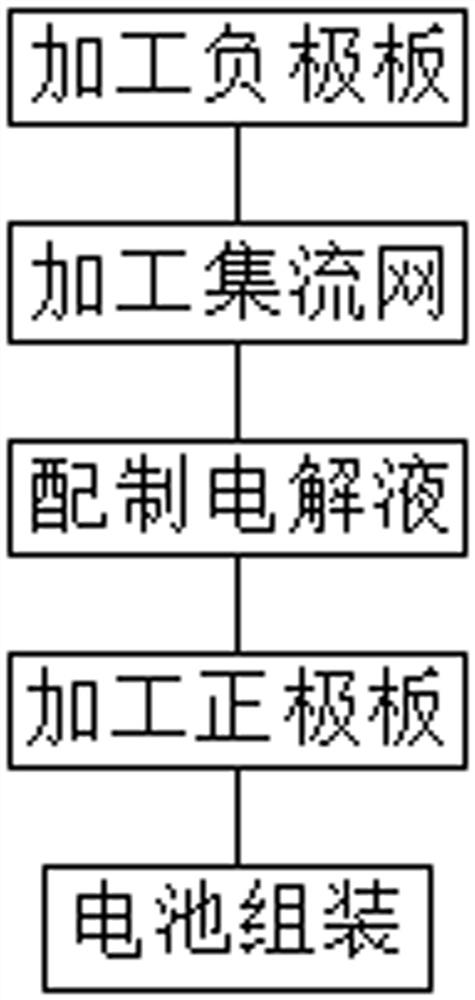

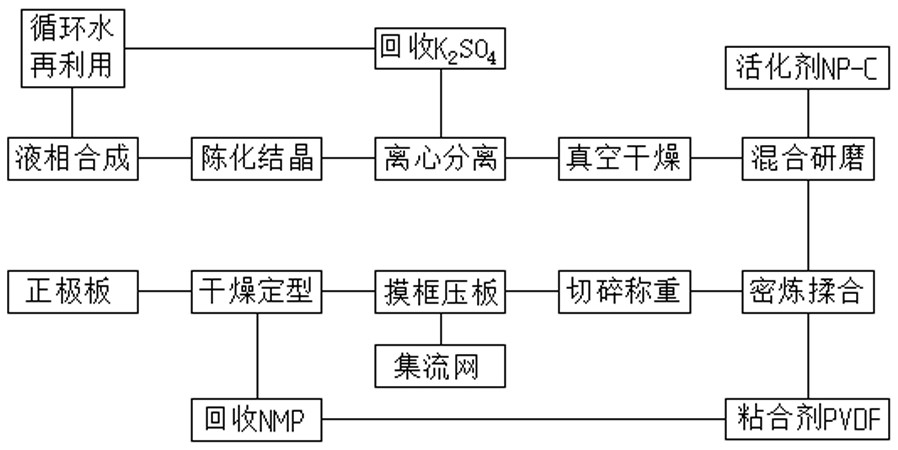

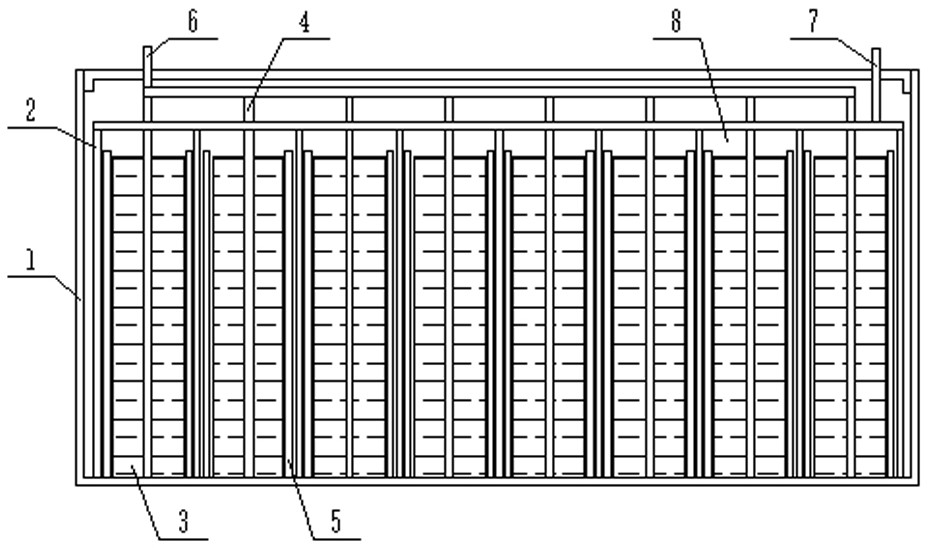

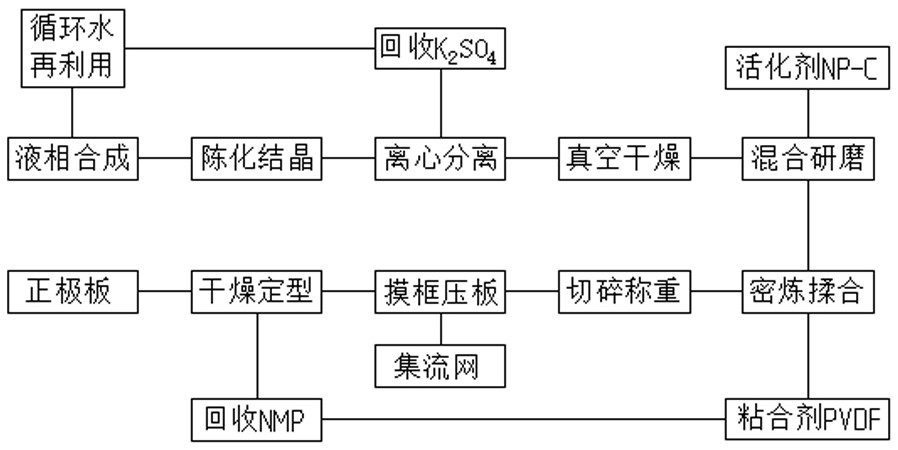

Copper energy storage battery and production process thereof

ActiveCN112952213AImprove stabilityIncrease oxidation rateFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention discloses a copper energy storage battery and a production process thereof. The copper energy storage battery comprises a box body, wherein the surface of the box body is provided with a positive terminal and a negative terminal, the box body is filled with electrolyte, copper negative plates and copper hexacyanoferrate positive plates are arranged in the box body in a staggered manner, the number of the copper negative plates is one more than that of the copper hexacyanoferrate positive plates, the adjacent copper negative plates are connected with each other and are connected with the negative binding post; and the current collecting grids in the adjacent copper hexacyanoferrate positive plates are connected with each other and are connected with the positive binding post. The copper energy storage battery has the advantages of low manufacturing cost, no pollution, high charging and discharging speed, better comprehensive performance than the existing energy storage battery, and low investment and operation cost; copper ferricyanide is adopted as the positive electrode material of the copper energy storage battery, synthesis is simple, and raw materials are easy to obtain; and in order to give full play to the advantage of super-long stability of a copper ferricyanide positive electrode material in strong acid and the properties of rapid intercalation and de-intercalation of copper ions, functionalized porous carbon is adopted as an activating agent of copper ferricyanide, so that a copper ion transmission channel is optimized and adjusted, the oxidation corrosion resistance of a carbon material is enhanced, and the service life of a battery is prolonged. The production process has the technical effect that the copper energy storage battery with high stability, long cycle life, high discharge rate and low price is obtained.

Owner:湖南清源储能科技有限公司

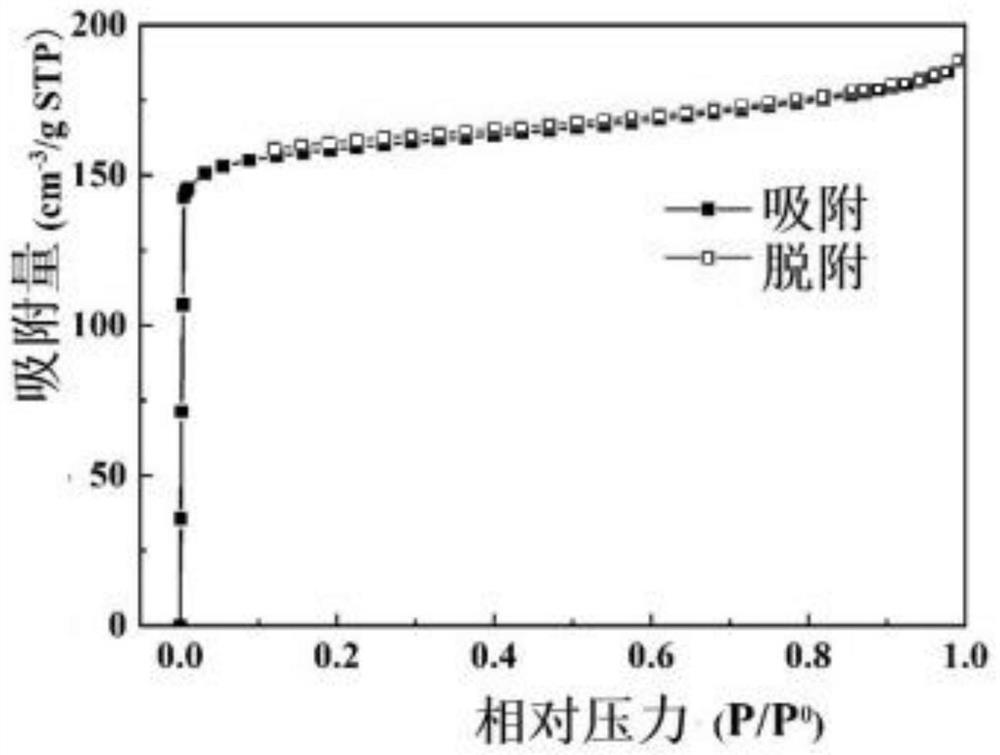

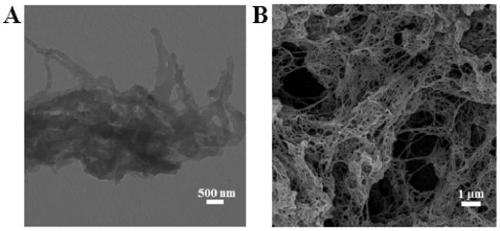

Preparation and application of metal organic framework material Ni-based MOF-74

ActiveCN114716686AMicroporousLarge specific surface areaScattering properties measurementsColor/spectral properties measurementsGas detectorMetal-organic framework

The invention relates to preparation and application of a metal organic framework material Ni-based MOF-74, and aims to solve the problems that an existing CO2 sensor is small in detection range, tedious in preparation process and complex in test. The preparation method comprises the following steps: 1, pretreating ITO glass; 2, preparing a Ni (NO3) 2.6 H2O and 2, 5-dihydroxy terephthalic acid solution by taking DMF (Dimethyl Formamide) as a solvent; and 3, preparing a mixed solution, putting the mixed solution into ITO glass, and reacting in a reaction kettle to obtain the Ni-based MOF-74. The method is applied to preparation of a CO2 gas detector so as to carry out full-concentration detection of CO2. The microporous structure and the high specific surface area of the Ni-based MOF-74 provide guarantee for CO2 adsorption. The prepared CO2 gas detector has the advantage of wide CO2 detection range, can be used for full-concentration detection of CO2, and is simple in detection process, easy to operate, low in cost, simple in process and suitable for industrial production. The Ni-based MOF-74 prepared by the preparation method disclosed by the invention is applied to a CO2 gas detector.

Owner:HARBIN BOILER +1

A kind of copper energy storage battery production process

ActiveCN112952213BImprove stabilityVery high stability in strong acid electrolytesCell electrodesFinal product manufactureElectrolytic agentElectrical battery

The invention discloses a production process of a copper energy storage battery, comprising a box body, a positive terminal post and a negative terminal post are arranged on the surface of the box body, the inside of the box body is filled with an electrolyte, and the inside of the box body is staggered with A copper negative plate and a copper ferricyanide positive plate, and the copper negative plate is one more than the copper ferricyanide positive plate, and the adjacent copper negative plates are connected and connected with the negative terminal posts. The current collecting nets inside the adjacent copper ferricyanide positive plates are connected and connected with the positive terminal. The beneficial effects are: low production cost and no pollution, fast and stable discharge and charging, better performance than existing energy storage batteries, no electrolyte consumption during charging and discharging, and low operating cost; copper ferricyanide precursor is used as the original positive electrode of the copper battery The material is simple to synthesize, and the raw materials are readily available; the use of functionalized porous carbon as an activator can optimize the adjustment of the pore structure and enhance the oxidation resistance of the carbon material to prolong the life of the electrode.

Owner:湖南清源储能科技有限公司

A method for preparing synthetic paper based on ultra-high molecular weight polyethylene

The invention relates to a method for preparing synthetic paper based on ultrahigh-molecular weight polyethylene. The method comprises the following steps: modifying an inorganic filler to obtain a modified filler, then uniformly premixing the modified filler with the ultrahigh-molecular weight polyethylene, a compatilizer, an antioxidant and an additive, performing melt-extrusion, and pelleting to obtain master batches; flatly laying the master batches on a hollow mold, melting and hot-pressing the master batches in the shape of a membrane, cold-rolling, and extracting to obtain the synthetic paper. The synthetic paper prepared by the method disclosed by the invention has excellent performances of good mechanical properties, light weight, solvent resistance, micro-porosity and the like.

Owner:DONGHUA UNIV +1

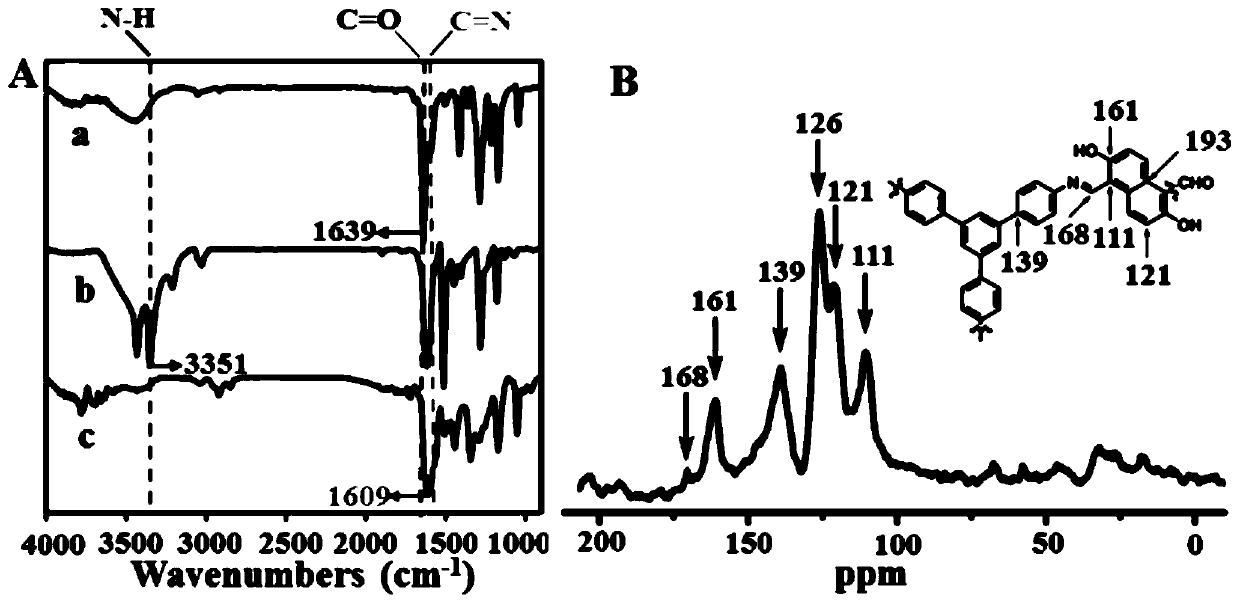

A kind of covalent organic framework material and its preparation method and application in fluorescent sensor

ActiveCN110240683BHigh fluorescence intensityGood repeatabilityFluorescence/phosphorescenceLuminescent compositionsCrystallinityPhenyl group

The invention belongs to the technical field of environmental detection, and particularly relates to a covalent organic framework material, a preparation method thereof and application thereof in a fluorescent sensor. The covalent organic framework material (COFS-DT) is obtained by reacting monomers 2,6-dihydroxynaphthalene-1,5-dialdehyde (DHNDA) and 1,3,5-tris (4-aminophenyl) benzene (TAPB) through Schiff base reaction by a solvothermal method. The crystallinity, porosity and chemical stability of the COFS-DT are improved through O-H..N = C hydrogen bond interaction, and the COFS-DT is connected with many bidentate coordination sites interacting with target ions. Compared with the monomers, the COFS-DT shows stronger fluorescence when dispersed in isopropanol. The strong fluorescence and the bidentate coordination sites enable the COFS-DT to be used to construct a high-performance fluorescence sensor with high sensitivity, high selectivity and high stability for detecting Cu<2+>.

Owner:SHANDONG UNIV

Multi-nozzle ointment shell

InactiveCN101830311AEasy envelopeWrinkledFlexible containersPliable tubular containersWrinkle skinToothpaste

The invention provides a multi-nozzle ointment shell, in particular to a multi-nozzle toothpaste shell which comprises a soft shell with an inside cavity and a circular discharging hole communicated with the cavity of the soft shell. The multi-nozzle toothpaste shell is characterized in that an end port of the discharging hole is provided with a baffle, the baffle divides the discharging hole into a plurality of nozzle holes, soft toothpaste extruded from the nozzle holes is in a plurality of strips, therefore, the surface area is increased, wrinkles and micropores are more, bubbles are easy to wrap, and the soft toothpaste is more loose. Paste skin care products and paste medicines are filled by using the soft ointment shell, which is more convenient for operation and used more comfortably. Toothpaste is filled by using the soft ointment shell, the extrusion amount is easy to control, the extrusion and the distribution of the toothpaste are more uniform and stable, and the brushing and the use are more clean and time-saving. The multi-nozzle soft ointment shell has reasonable structure, simple process, convenient use and easy popularization and application; and the additional value of products can be improved.

Owner:戴永锋

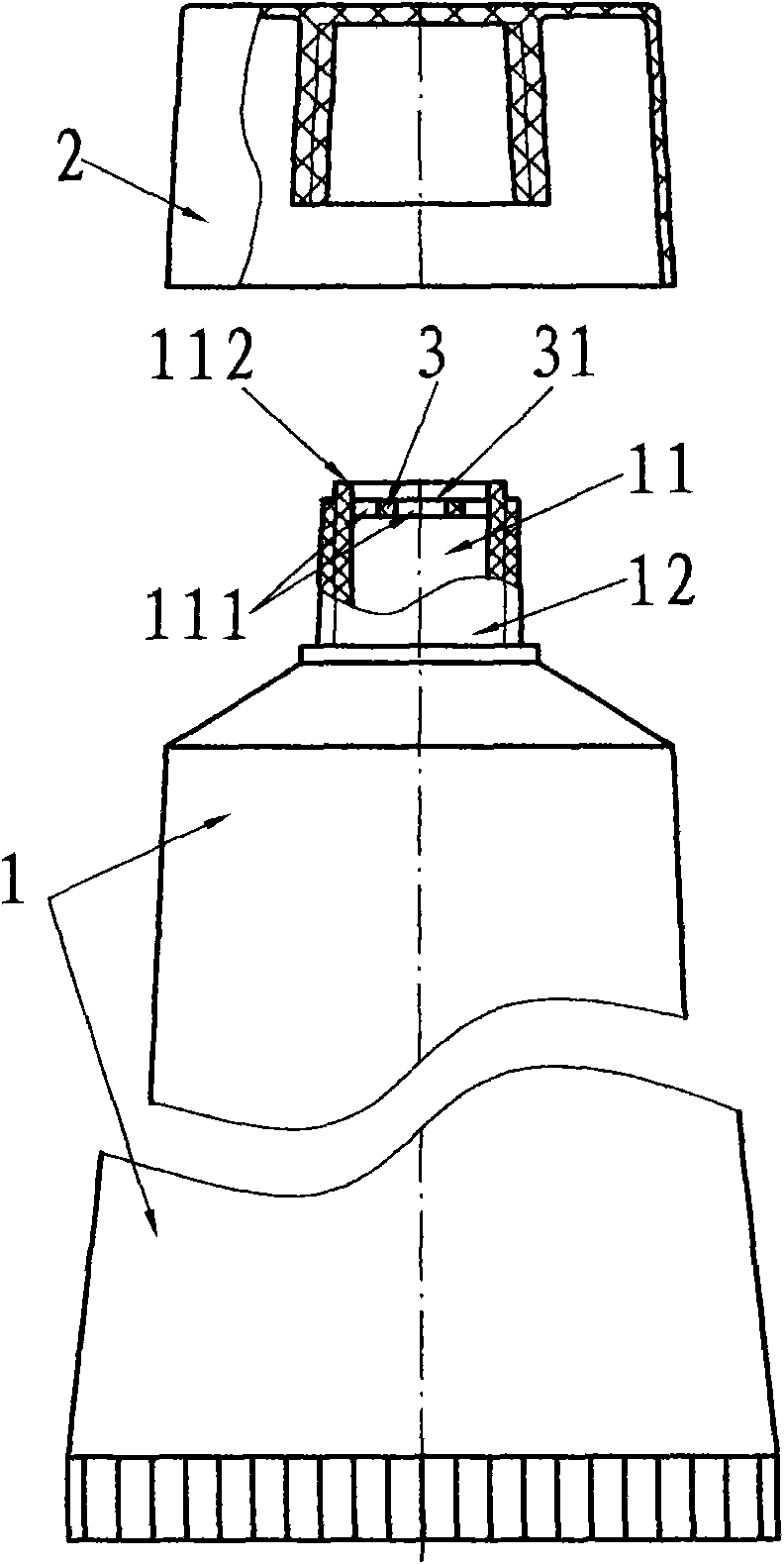

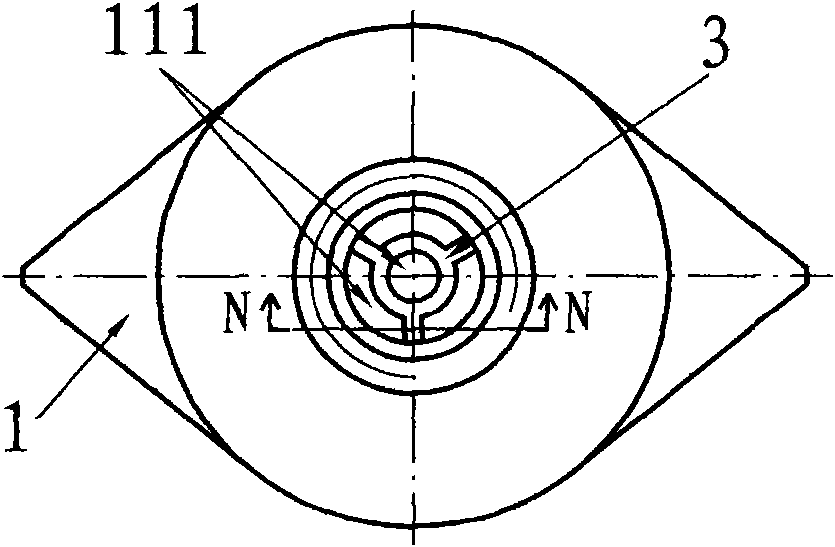

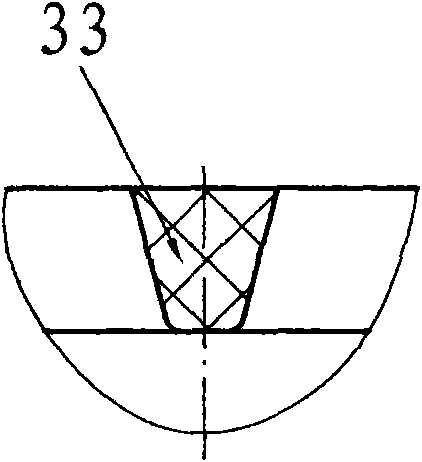

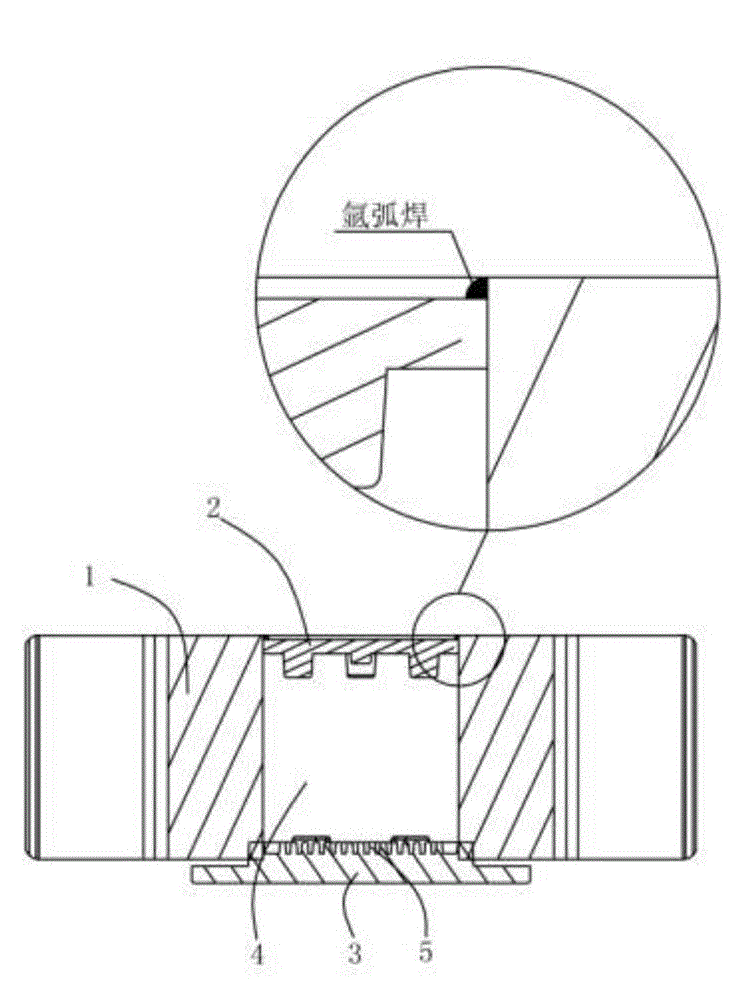

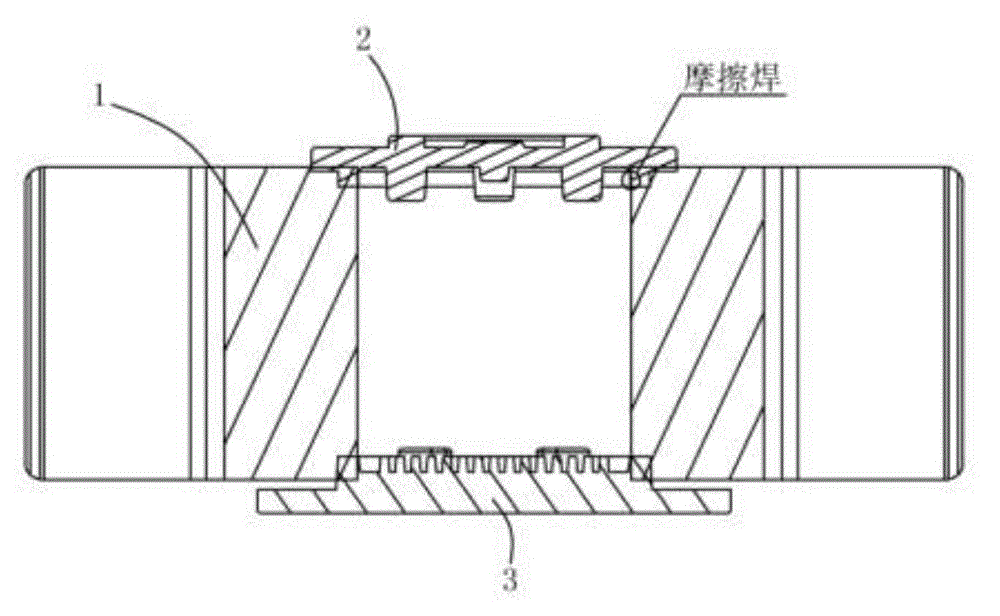

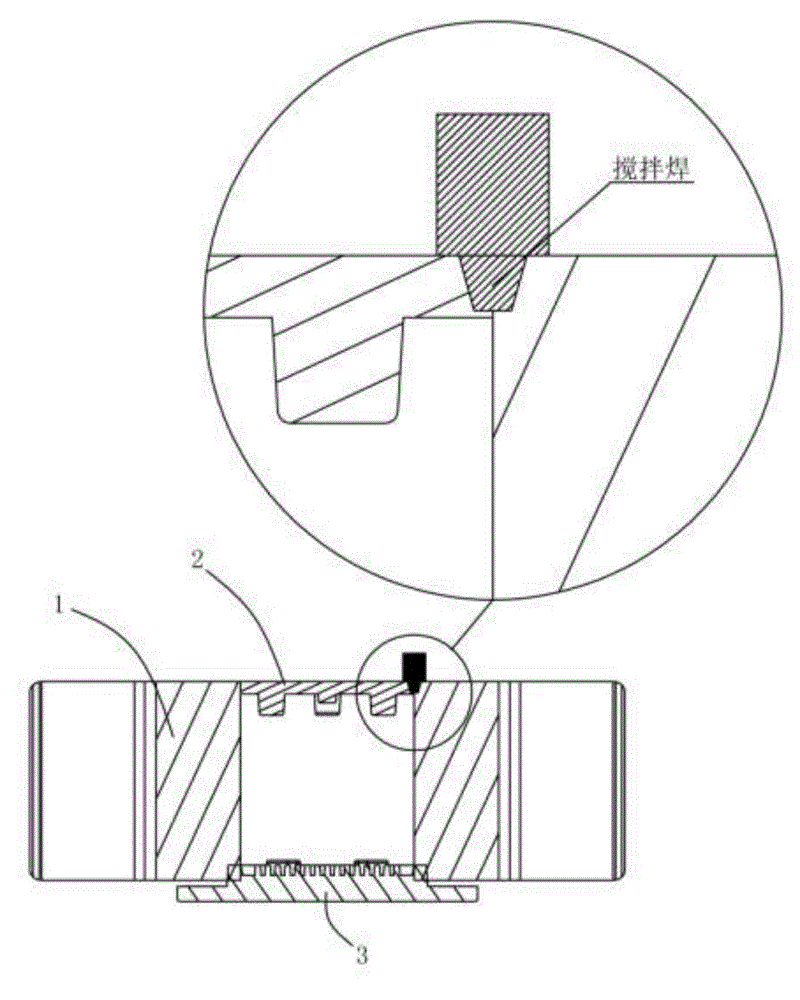

Manufacturing method of vacuum phase-change radiator

InactiveCN104668922AImprove compactnessSolve MicroporesNon-electric welding apparatusFriction weldingEngineering

The invention discloses a manufacturing method of a vacuum phase-change radiator. The vacuum phase-change radiator comprises a radiator body, an upper end cover and a lower end cover, wherein the radiator body has a hollow pipe; a phase-change working medium is loaded in the hollow pipe; the upper end cover and the lower end cover are welded at the two ends of the hollow pipe respectively; the upper end cover and / or the lower end cover are / is subjected to machine-shaping by using a hot extrusion process. The hot extrusion process comprises the following steps of material cutting, heating, shaping, preheating, reshaping and cooling. According to the manufacturing method of the vacuum phase-change radiator, the upper end cover and the lower end cover are molded by using the hot extrusion process; the cost is reduced; the problem that an end cover subjected to the machine-shaping in a conventional manner has micropores or finedraws is solved; the upper end cover and the lower end cover are welded on the radiator body by using a stirring welding or friction welding process; the connection at a welding spot is firm; the vacuum tightness is enhanced; the service life is longer.

Owner:NINGBO LIPINGE VACUUM PHASE TRANSITION LIGHTING CO LTD

A kind of gypsum-based lightweight plastering material and preparation method thereof

The invention relates to the technical field of construction, and more specifically, the invention provides a gypsum-based lightweight plastering material and a preparation method thereof. The first aspect of the present invention provides a gypsum-based lightweight plastering material. In parts by weight, the preparation raw materials at least include: 80-95 parts of gypsum powder, 0.5-2 parts of alkaline agent, 0.1-0.2 parts of water-retaining agent, 0.1- 0.3 parts of mixture, 0.05-0.2 parts of retarder, 0-20 parts of vitrified microbeads.

Owner:JASON PLASTERBOARD JIAXING

Method for preparing medical collagen sponge from East sea dark gensing

ActiveCN103409488BSolve chemical residue problemsGood for sublimation evaporationPeptide preparation methodsAbsorbent padsDesalinationCollagen sponge

The invention discloses a method for preparing medical collagen sponge from East sea dark gensing, which comprises the following steps: adding pepsase into East sea dark gensing defibrination going through dirt removing process; adding solid edible salt after the enzymolysis; salting, separating and collecting pulpy sediment, precipitating liquid, salting again, and separating; dissolving pulpy sediment by L- lactic acid, carrying out desalination process to the dissolved sea cucumber collagen liquid, adding food grade glutamine transaminase, spraying nepheloid sea cucumber collagen liquid into a mould, quick-freezing and forming the collagen liquid into collagen sponge instantly; freezing, alternating temperature and drying, and drying the material until the content of water is 1 to 3 %; withdrawing the collagen sponge, packing, irradiating, and entering the medical collagen sponge library. The method has the beneficial effects that East sea dark gensing is used as raw material to prepare the medical collagen sponge, the rich marine resource is enabled to be highly utilized, the sponge can also be used for crowd rejecting the mammal collagen, the problem of chemical residue in the product is solved, and the safety of the product is higher.

Owner:宁波超星海洋生物制品有限公司

Antifouling antibacterial high-molecular furniture decorative film and preparation method thereof

ActiveCN103738035BImprove fire resistanceHigh strengthLamination ancillary operationsLaminationPolymer scienceAnti bacterial

The invention relates to an antifouling antibacterial high-molecular furniture decorative film and a preparation method thereof. The antifouling antibacterial high-molecular furniture decorative film is characterized by comprising a base material, an antibacterial film and a printed surface film. The antifouling antibacterial high-molecular furniture decorative film is formed by hot-pressing lamination of the base material, the antibacterial film and the printed surface film. The preparation method of the antifouling antibacterial high-molecular furniture decorative film comprises the following steps: step one, preparing the base material; step two, preparing the antibacterial film; step three, preparing the printed surface film; step four, printing the surface film; and step five, carrying out hot-pressing lamination. The antifouling antibacterial high-molecular furniture decorative film has the advantages of fire resistance and high strength, and the preparation method has the advantages of low production cost and high product production quality.

Owner:ECONESS ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com