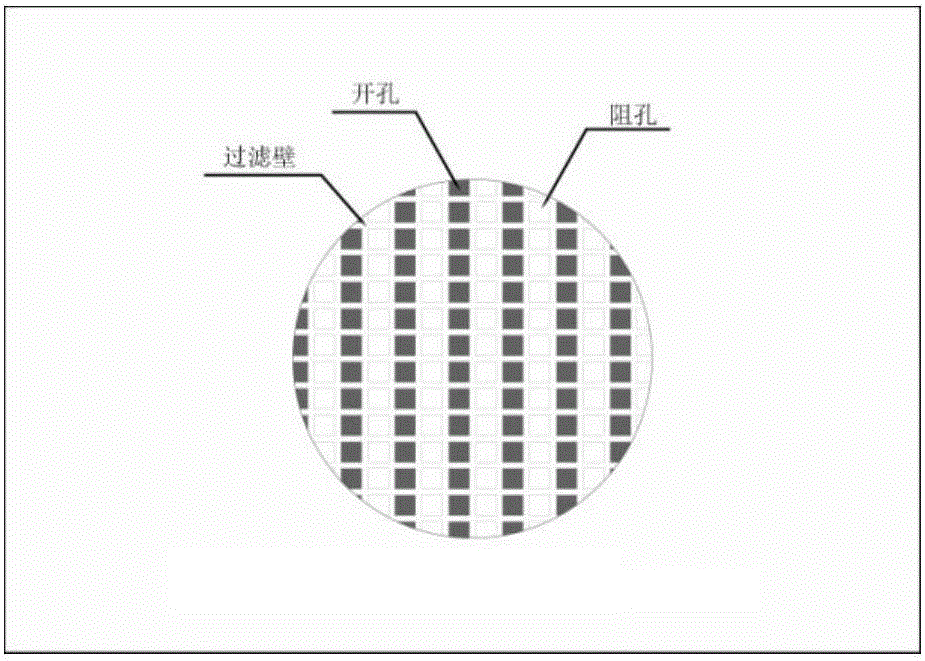

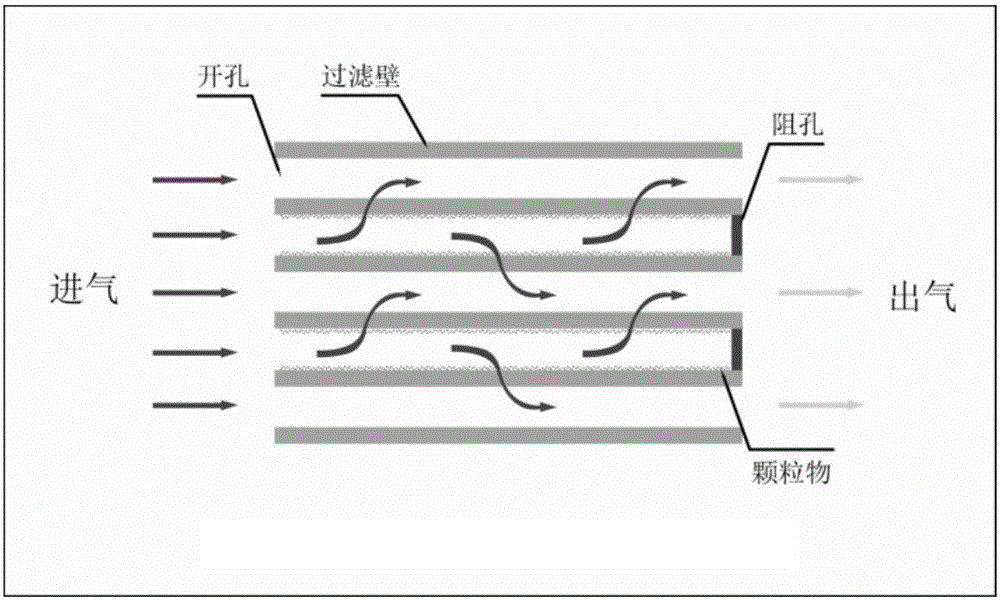

Semi-passing honeycomb ceramic grain filter and preparation method thereof

A particulate filter and honeycomb ceramic technology, applied in the field of material science, can solve the problems such as the semi-pass type honeycomb ceramic particulate filter that has not been reported, and achieve the effect of large removal rate, uniform distribution of micropores, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First prepare 27 parts of kaolin with an average particle size of 3 μm (parts by mass, the same below), 39 parts of flake talc with an average particle size of 13 μm, 16 parts of alumina with an average particle size of 4 μm, and 8 parts of fused silica powder with an average particle size of 8 μm , 12 parts of methyl methacrylate pore-forming agent particles with an average particle size of 35 μm, the water-soluble binder used is 6 parts of hydroxypropyl methylcellulose, 32 parts of water and other raw materials.

[0025] Then fully mechanically mix and knead the prepared raw materials to make them uniform, then degas and refine them three times under a vacuum degree of 95KPa, and stale for 24 hours to obtain plastic clay.

[0026] The plastic mud is formed into a cylindrical wet body through a mold mechanical extrusion machine. The cross section of the mold is circular, the outer diameter is 267mm, and the hole density is 300 holes / square inch; the length of the wet bo...

Embodiment 2

[0032] The addition of pore-forming agent particle methyl methacrylate in embodiment 1 is reduced to 6 parts from 12 parts, and other raw material addition and preparation process are all identical with embodiment 1, to the sample detection result that makes is:

[0033] The appearance size, wall thickness, etc. are the same as the sample in Example 1, but the porosity is 45%, the average pore diameter of micropores is 9 μm, the wall thickness is 0.3 mm, the compressive strength is greater than 19 MPa, and the thermal expansion coefficient is 1.0×10 -6 / ℃, thermal shock resistance 550 ℃, removal rate of particulate matter in flue gas 50%. It shows that reducing the amount of methyl methacrylate added has a certain decrease in the porosity of the sample, the average pore size of micropores and other indicators, and also caused a reduction in the filtration rate of particulate matter.

Embodiment 3

[0035] The pore-forming agent in embodiment 1 is replaced methyl methacrylate with starch, and its addition, other raw materials and addition, and preparation process are all identical with embodiment 1, to the sample detection result that makes is:

[0036] The appearance size, wall thickness, etc. are the same as the sample in Example 1, but the porosity is 50%, the average pore diameter of micropores is 11 μm, the wall thickness is 0.3 mm, the compressive strength is 19 MPa, and the thermal expansion coefficient is 1.0×10 -6 / ℃, thermal shock resistance 560 ℃, the removal rate of particulate matter in flue gas is 55%. Compared with the measurement results of the sample in Example 1, it is shown that the effect of using starch as a pore-forming agent is not as good as that of methyl methacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Micropore average pore size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com