Machining method of capillary wick and assembly method of capillary wick and pipe casing

A processing method and assembly method technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complex processing, blockage, high cost, etc., and achieve the goal of increasing capillary suction, increasing heat exchange area, and improving heat exchange effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

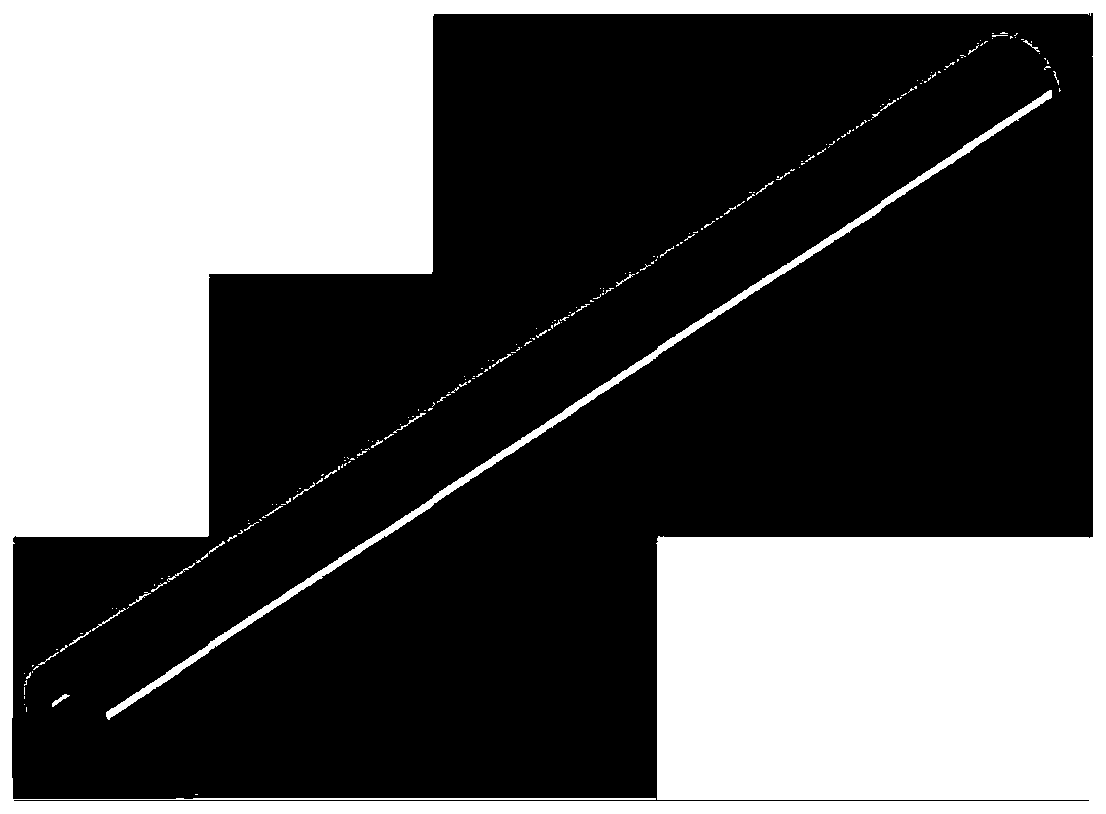

[0055] Such as figure 2 The schematic diagram of the product structure of the capillary core, the capillary core prepared in this embodiment is a 316L stainless steel capillary core with a length of 150 mm, an outer diameter of 10 mm, and an inner hole diameter of 5 mm.

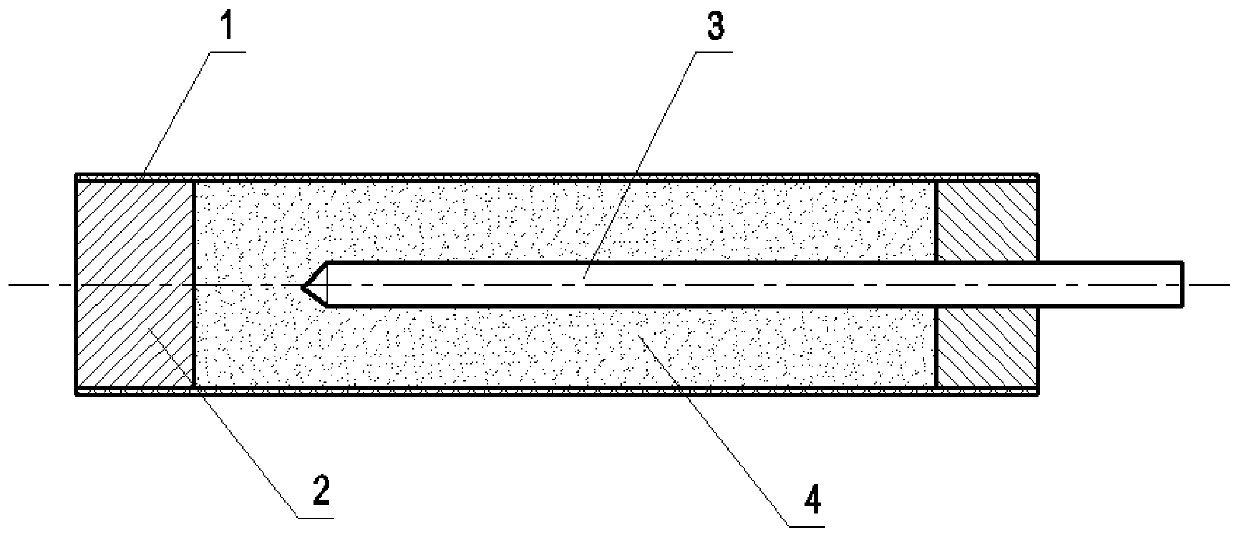

[0056] The structure of the isostatic die used in the processing of the capillary core in this embodiment is as follows: figure 1 As shown, the material forming the capillary core is placed in the outer rubber sleeve 1 of the mold, and a hollow structure is formed at the position of the core rod 3. After the material is added, the rubber plug 2 is sealed tightly. The capillary core 4 can be obtained by pressing and molding.

[0057] The specific processing technology of capillary core described in the present embodiment comprises the following steps:

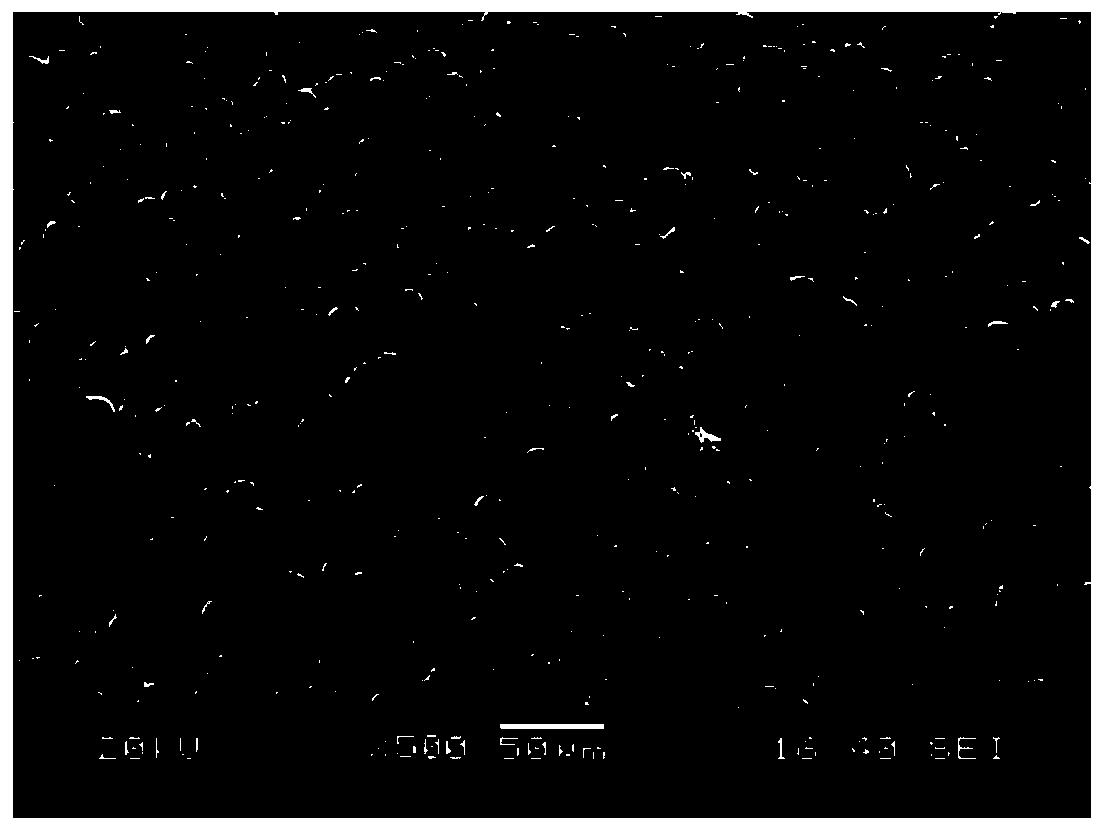

[0058] (1) According to the proportion of paraffin wax 2wt%, polyethylene glycol 2wt%, 316L powder (particle size: 25-30μm) 96wt%, take the binder and heat ...

Embodiment 2

[0068] Such as Figure 5 The schematic diagram of the product structure of the capillary core, the capillary core prepared in this embodiment is length × width × height: 100mm × 60mm × 5mm capillary core with a channel, which is assembled with a copper tube shell, and the specific processing steps are as follows:

[0069] (1) According to the ratio of 4wt% of polyvinyl alcohol and 96wt% of copper powder (particle size 50-60 μm), take the binder and heat it at 60-120° C. to melt and mix it with the metal powder. After mixing evenly, use 60 The mesh sieve separates the agglomerated powder and removes the agglomerated large particles;

[0070] (2) Weigh about 110g of mixed copper powder material, pour it evenly into the corresponding mold, seal it with a rubber stopper after shaking for 2 minutes, then put the mold into a cold isostatic press, control the pressure at 100MPa and carry out pressure holding treatment for 120s, The green body of the capillary core can be prepared, b...

Embodiment 3

[0079] Such as figure 2 The schematic diagram of the product structure of the capillary core. The capillary core prepared in this embodiment is a 304L stainless steel capillary core with a length of 150 mm, an outer diameter of 10 mm, and an inner hole diameter of 5 mm. The structure of the isostatic die used for processing the capillary core in this embodiment is as follows figure 1 shown.

[0080]The specific processing technology of capillary core described in the present embodiment comprises the following steps:

[0081] (1) According to the proportion of glycerol 1wt%, 304L powder (particle size 25-30μm) 99wt%, take the binder and heat it at 60-120°C until it melts, and mix it with the metal powder, and use it after mixing evenly A 60-mesh sieve separates the agglomerated powder and removes the agglomerated large particles;

[0082] (2) Weigh 80g of mixed metal powder material and pour it evenly into figure 1 In the mold shown, after vibrating for 6 minutes, seal it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com