Vapour chamber evaporation imbibition core of fractal groove-hole structure and manufacturing method

A manufacturing method and technology for a soaking plate, applied in the field of heat transfer, can solve the problems of complicated execution steps, expensive equipment, small capillary radius, etc., and achieve the advantages of simple and easy technical means, low equipment cost investment, and increased specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

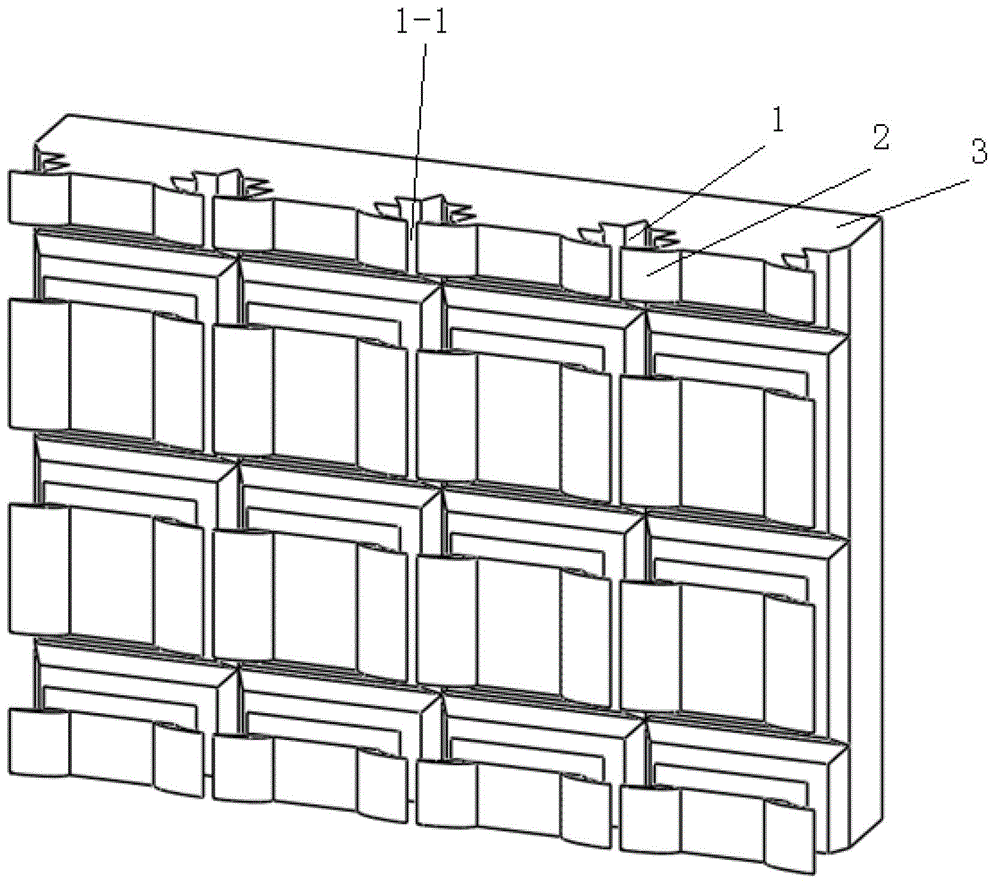

[0031] Such as figure 1 shown. The vapor chamber evaporating liquid-absorbing wick with a fractal groove-hole structure of the present invention includes an evaporation plate 3, fractal grooves 1 are distributed along the longitudinal and transverse arrays of the evaporation surface of the evaporation plate, and fins 2 are arranged on the groove top of the fractal groove, Rectangular slits 1-1 with semi-closed rectangular openings are formed between the fins, and the fractal groove 1 is composed of multiple V-shaped grooves. The distance between the fractal grooves 1 is 2.96mm-4mm; the depth of the V-shaped grooves on both sides of the fractal grooves 1 is 0.26mm-0.49mm, and the depth of the V-shaped grooves at the bottom of the fractal grooves 1 is 0.5mm~1.3mm.

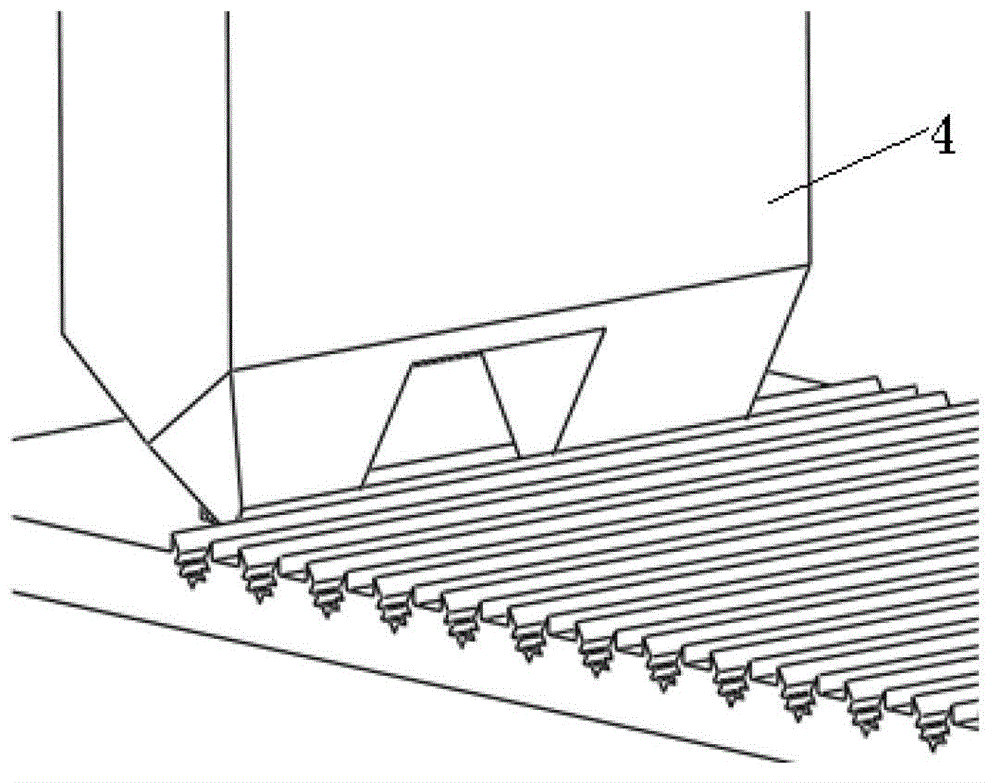

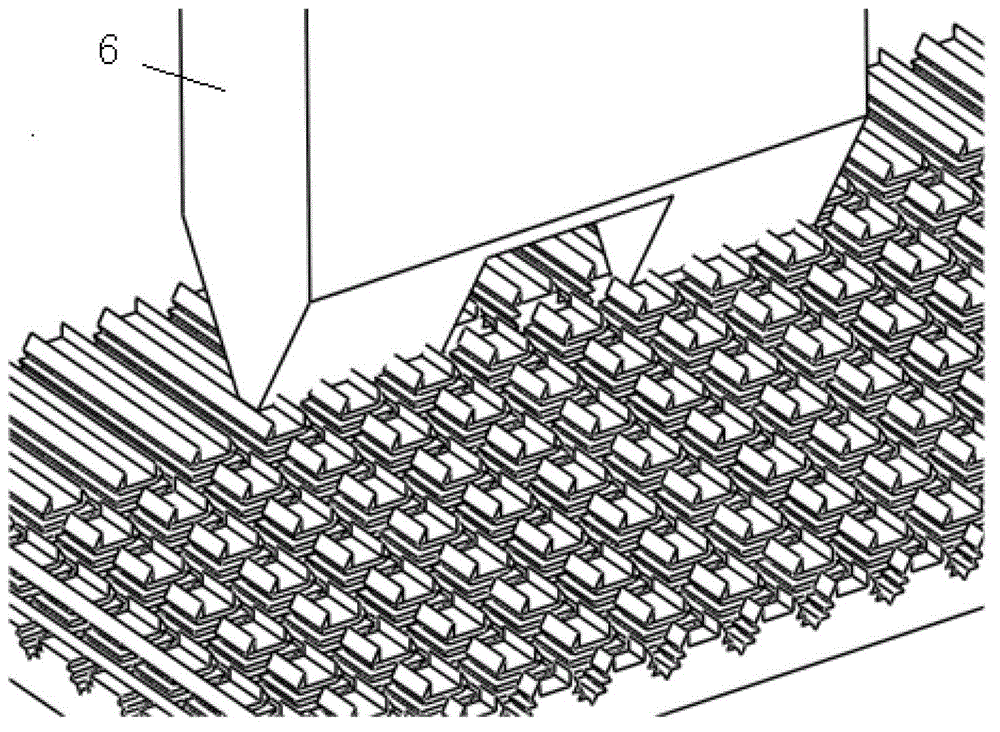

[0032] Such as Figure 2 ~ Figure 6 shown. The above-mentioned manufacturing method of vapor chamber evaporative liquid-absorbing core with fractal groove-hole structure can be realized through the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com