Patents

Literature

448results about How to "Improve service performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

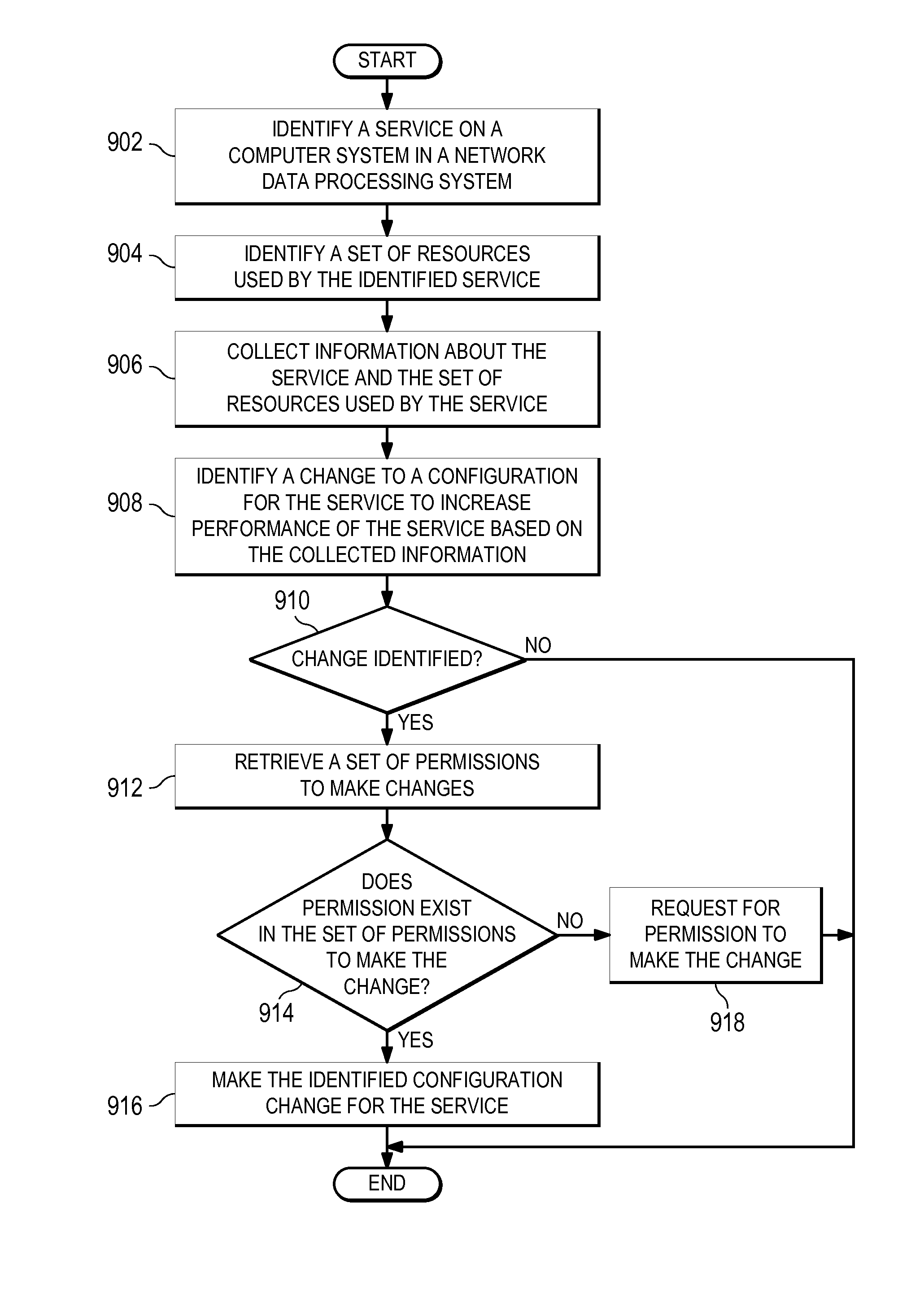

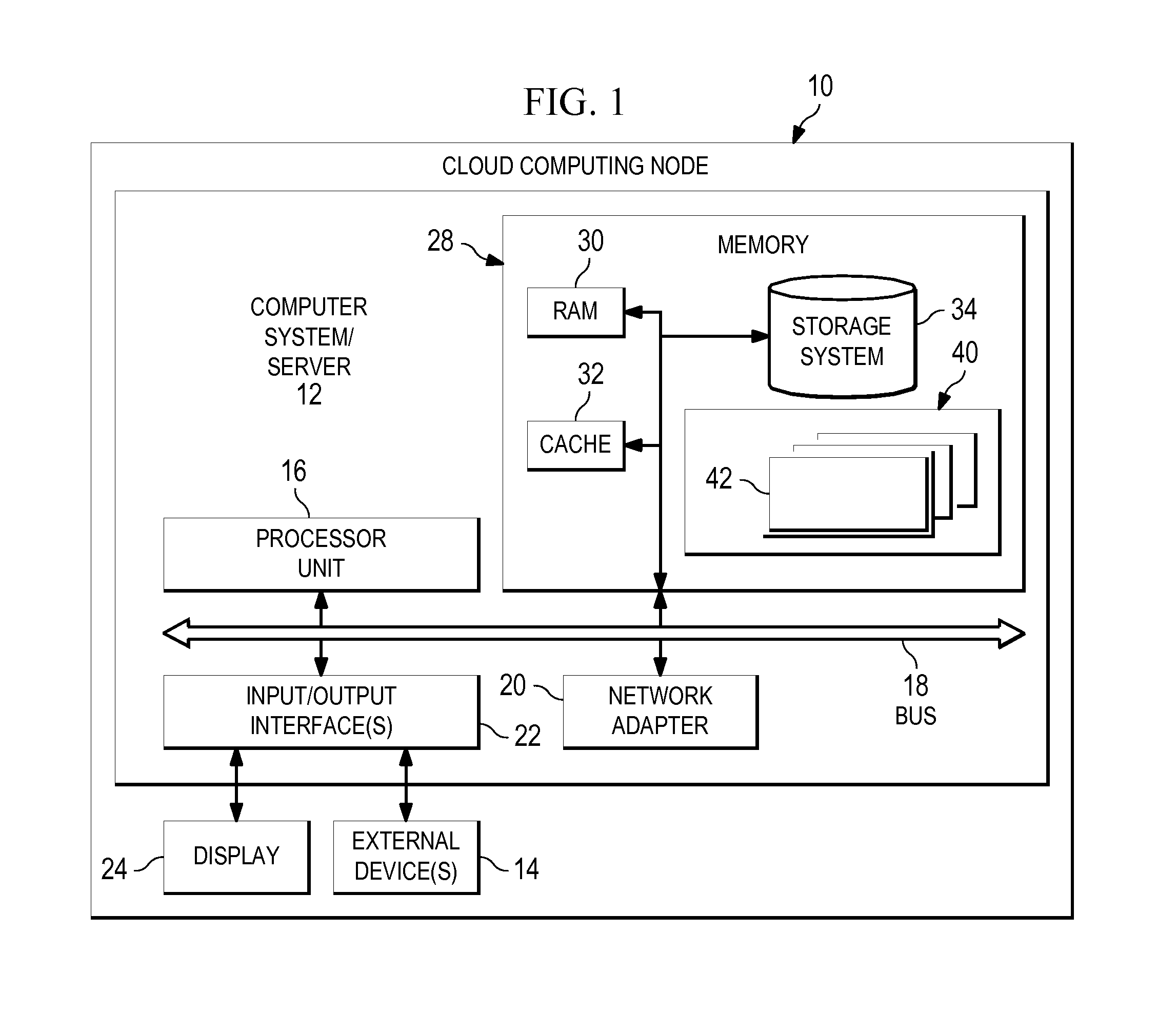

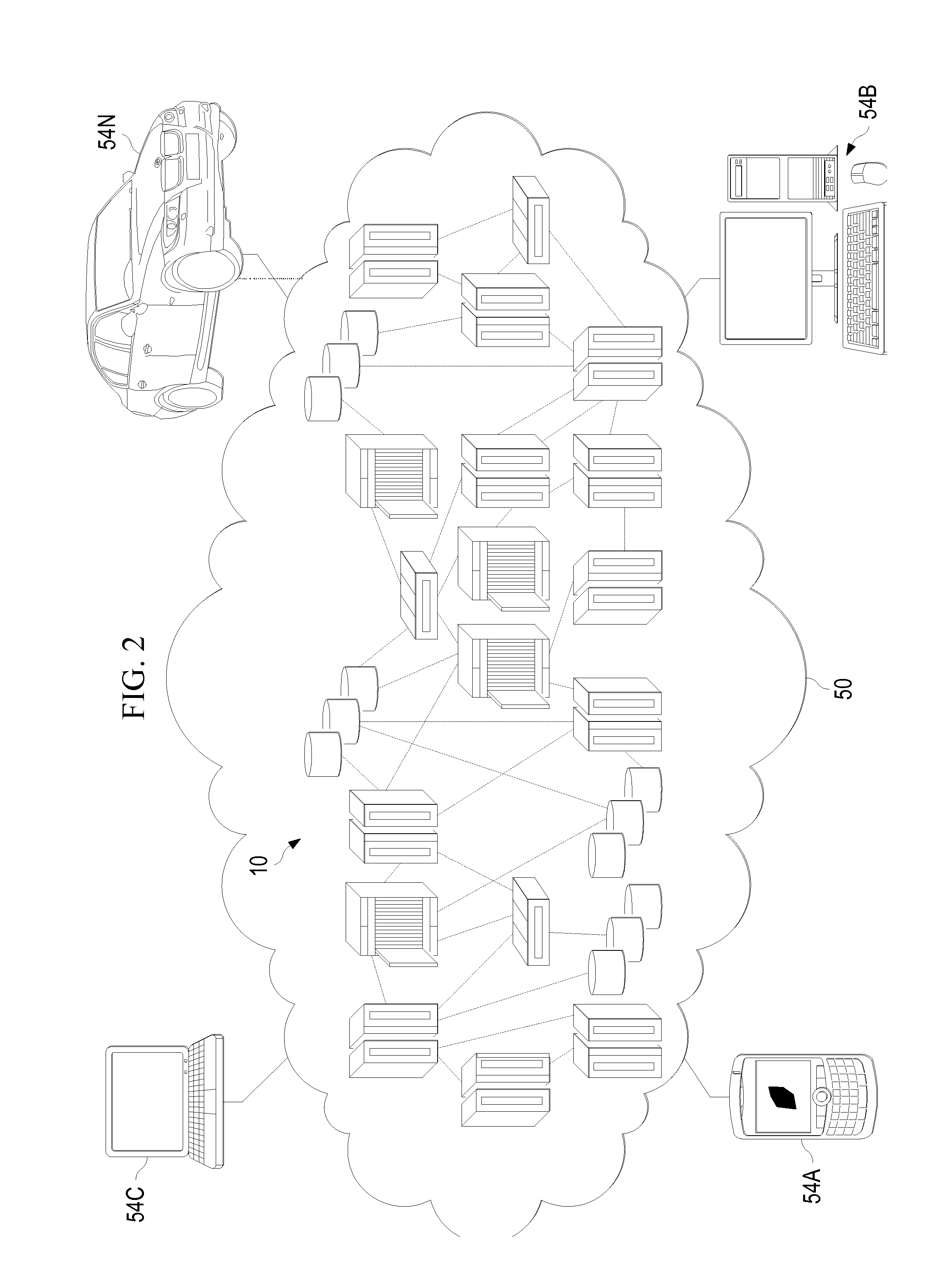

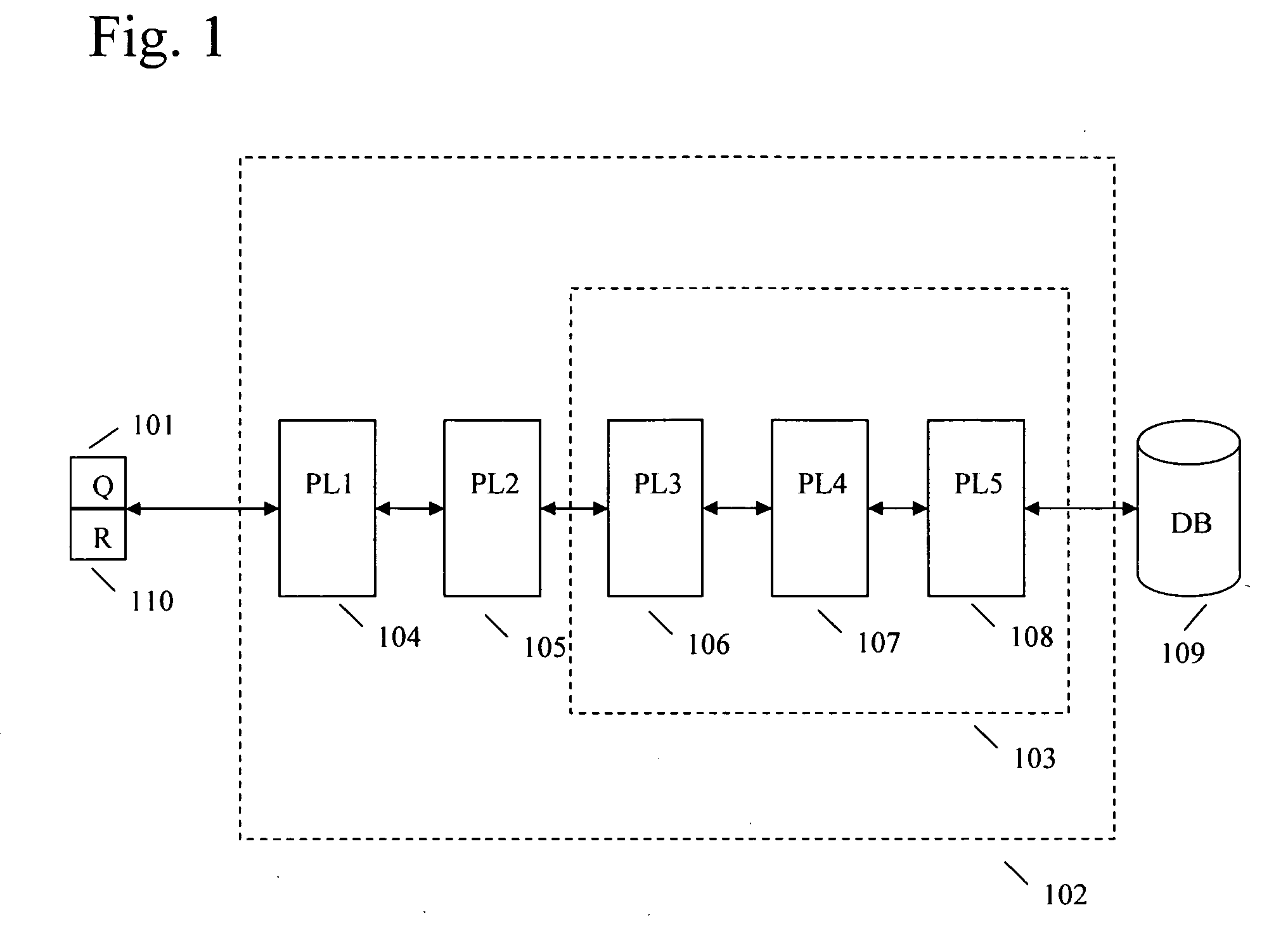

Resource configuration for a network data processing system

ActiveUS20130326032A1Improve service performanceDigital computer detailsProgram controlData processing systemComputerized system

A method for managing a service is disclosed. A program system running on a computer system in a network data processing system identifies the service on the computer system and a set of resources used by the service. The program system collects information about the service and the set of resources used by the service. The program system uses the information collected to identify a change to a configuration for the service which will increase performance of the service. The program system then makes the identified change to the configuration for the service.

Owner:IBM CORP

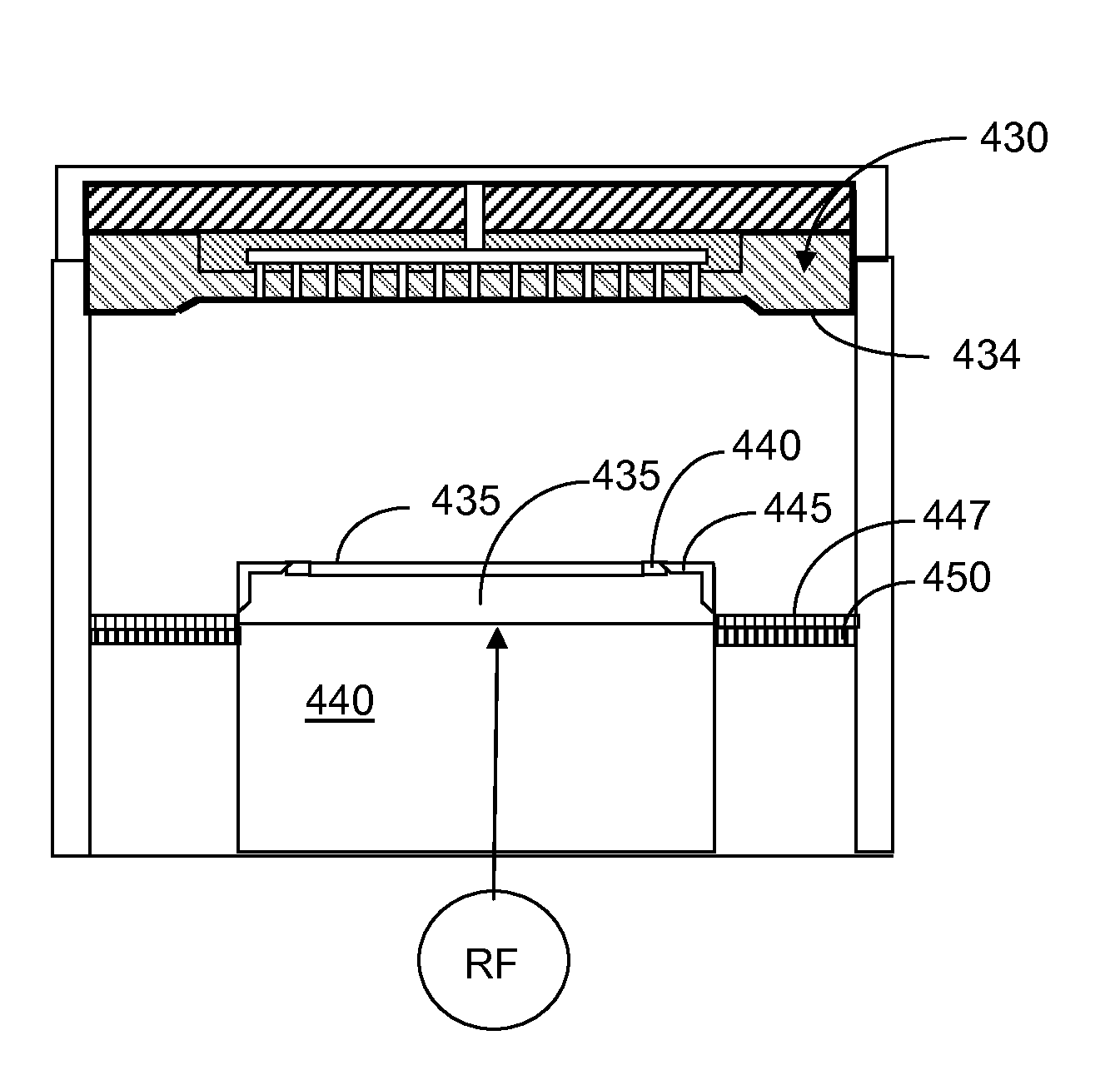

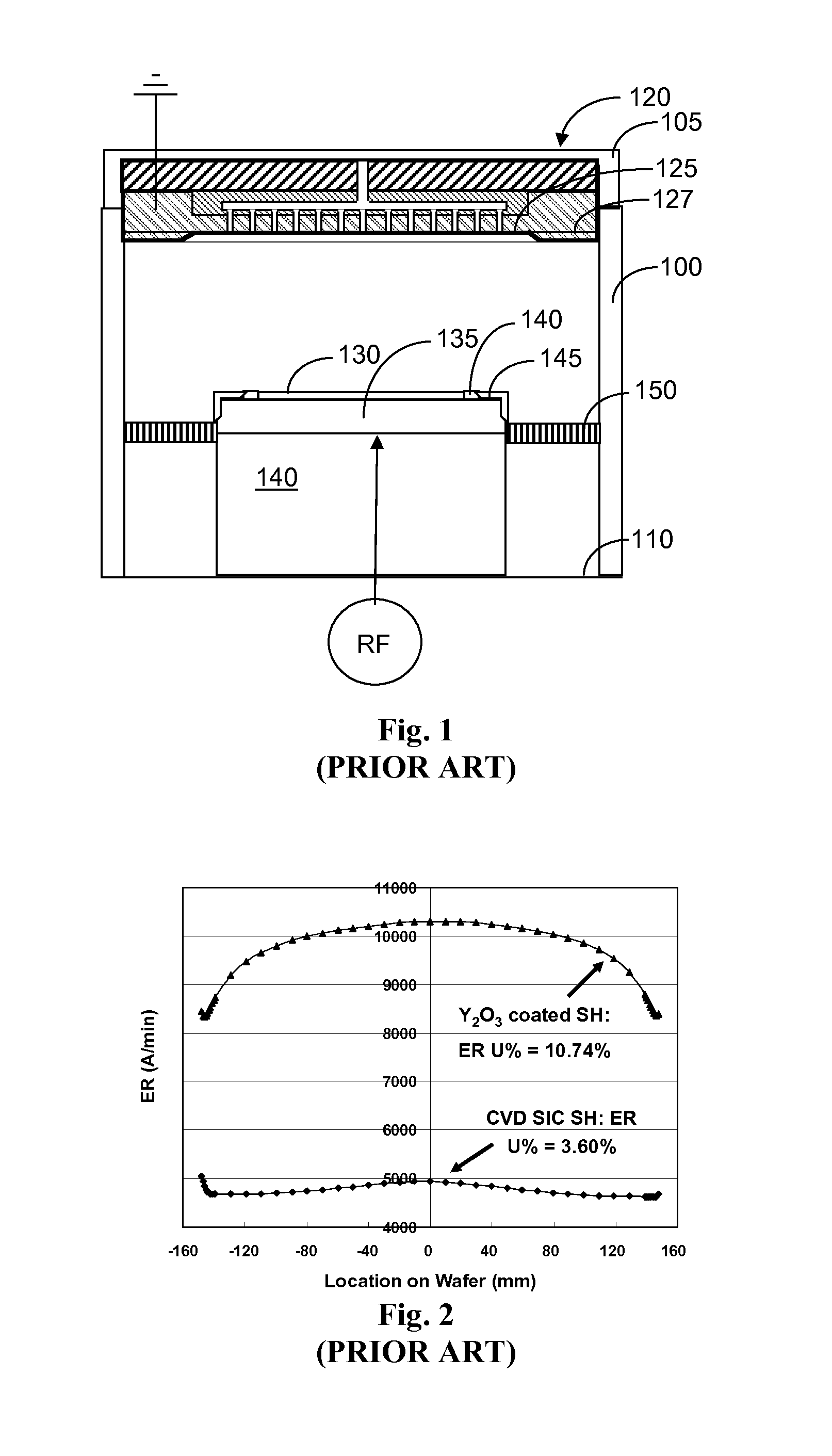

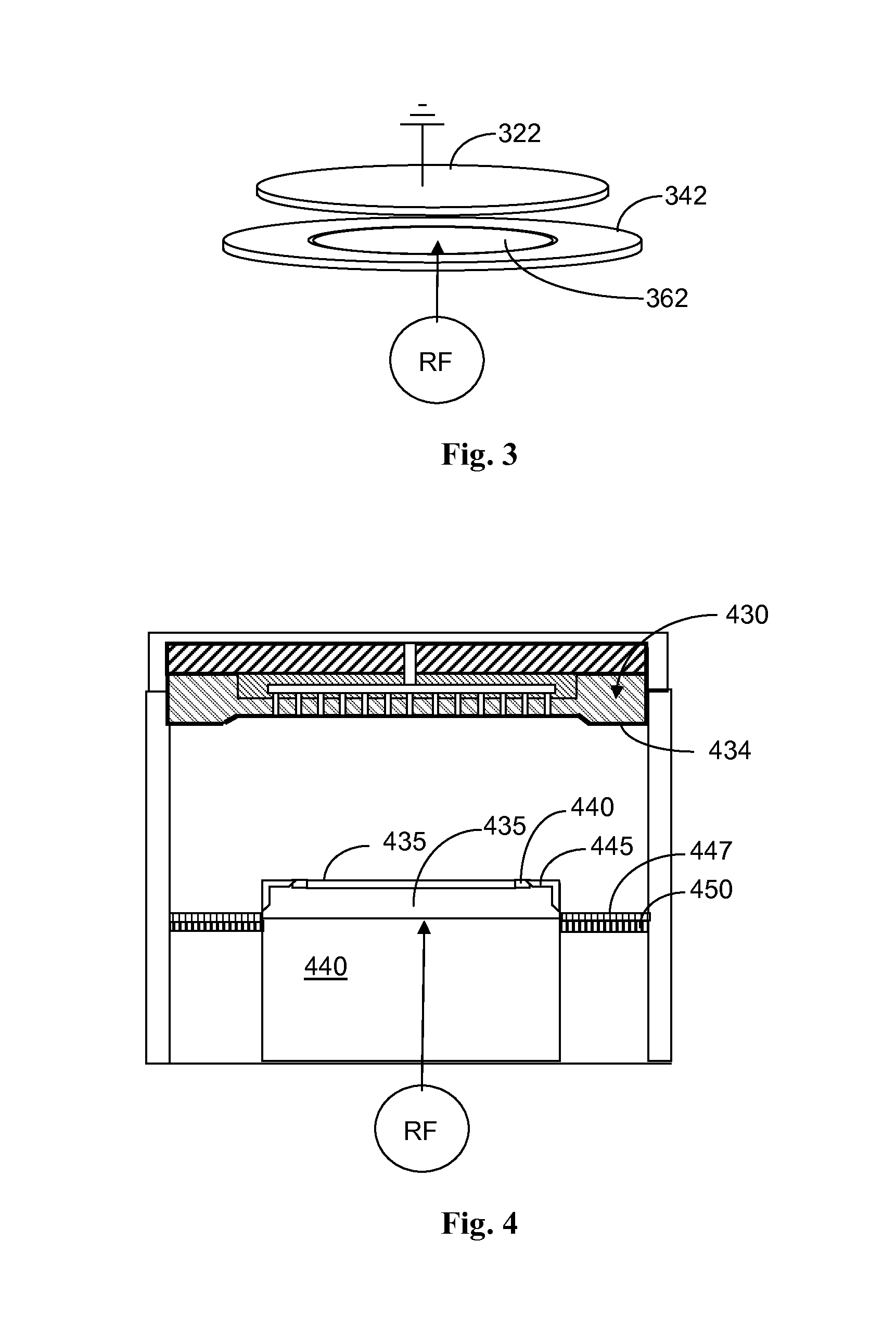

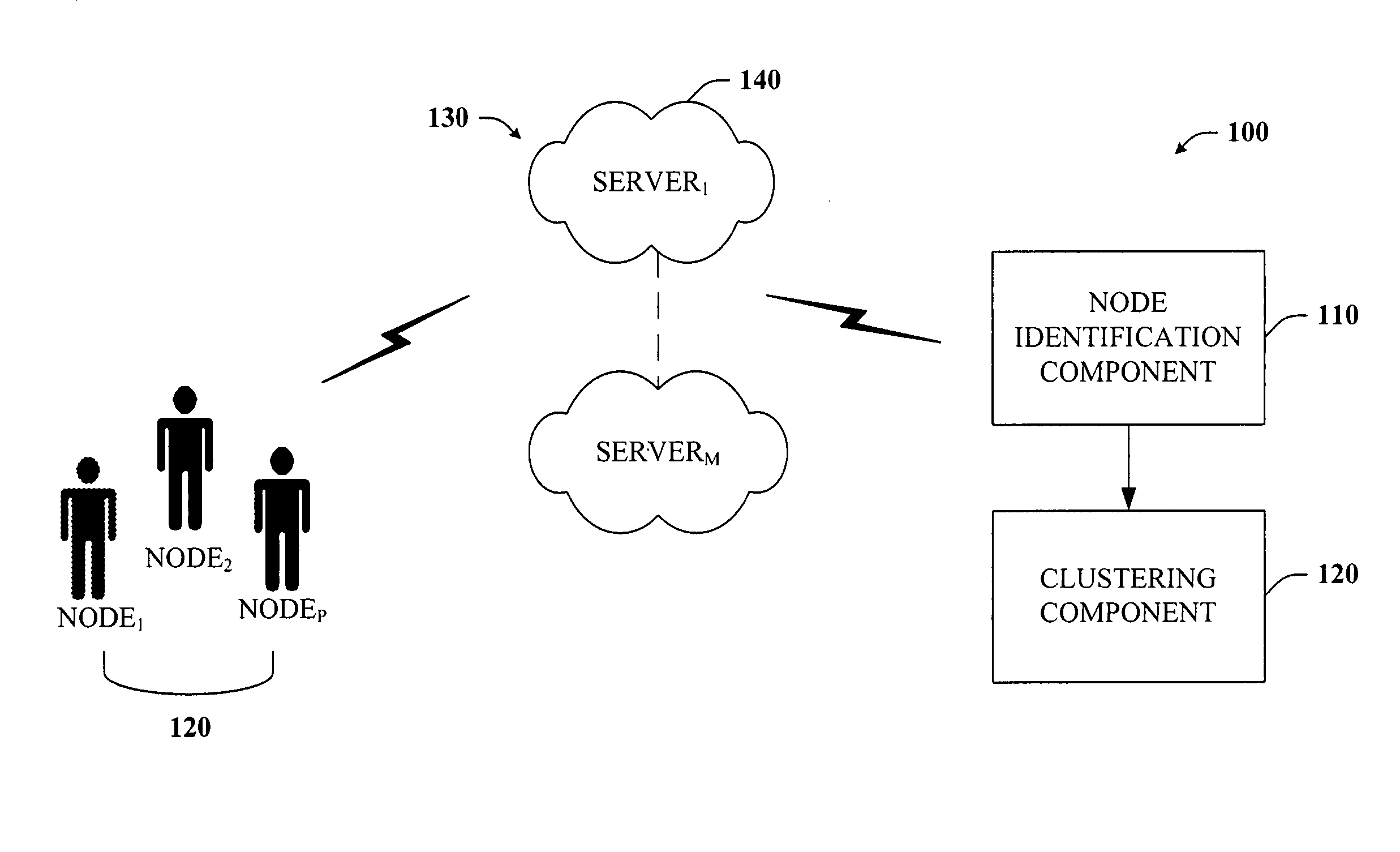

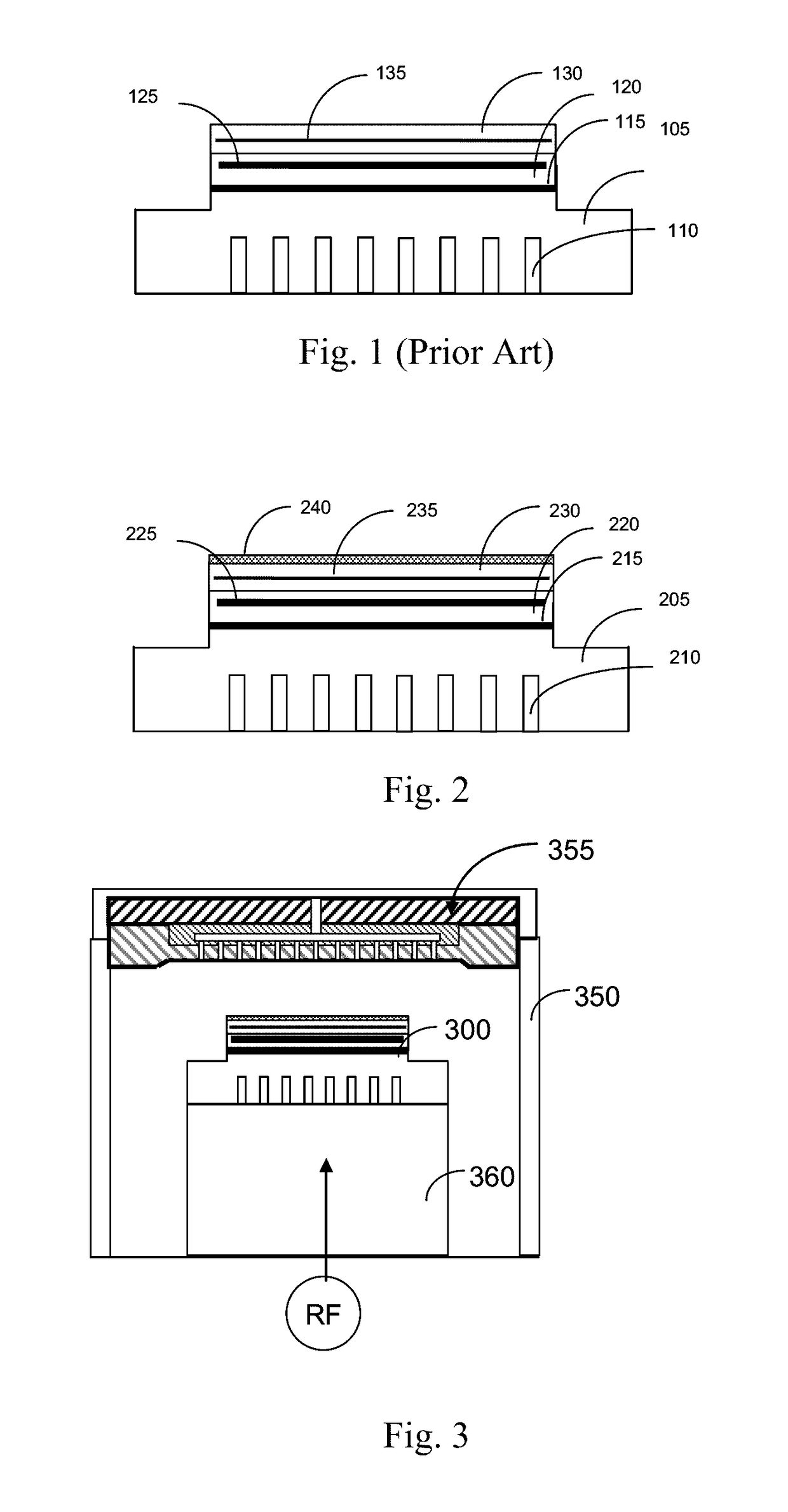

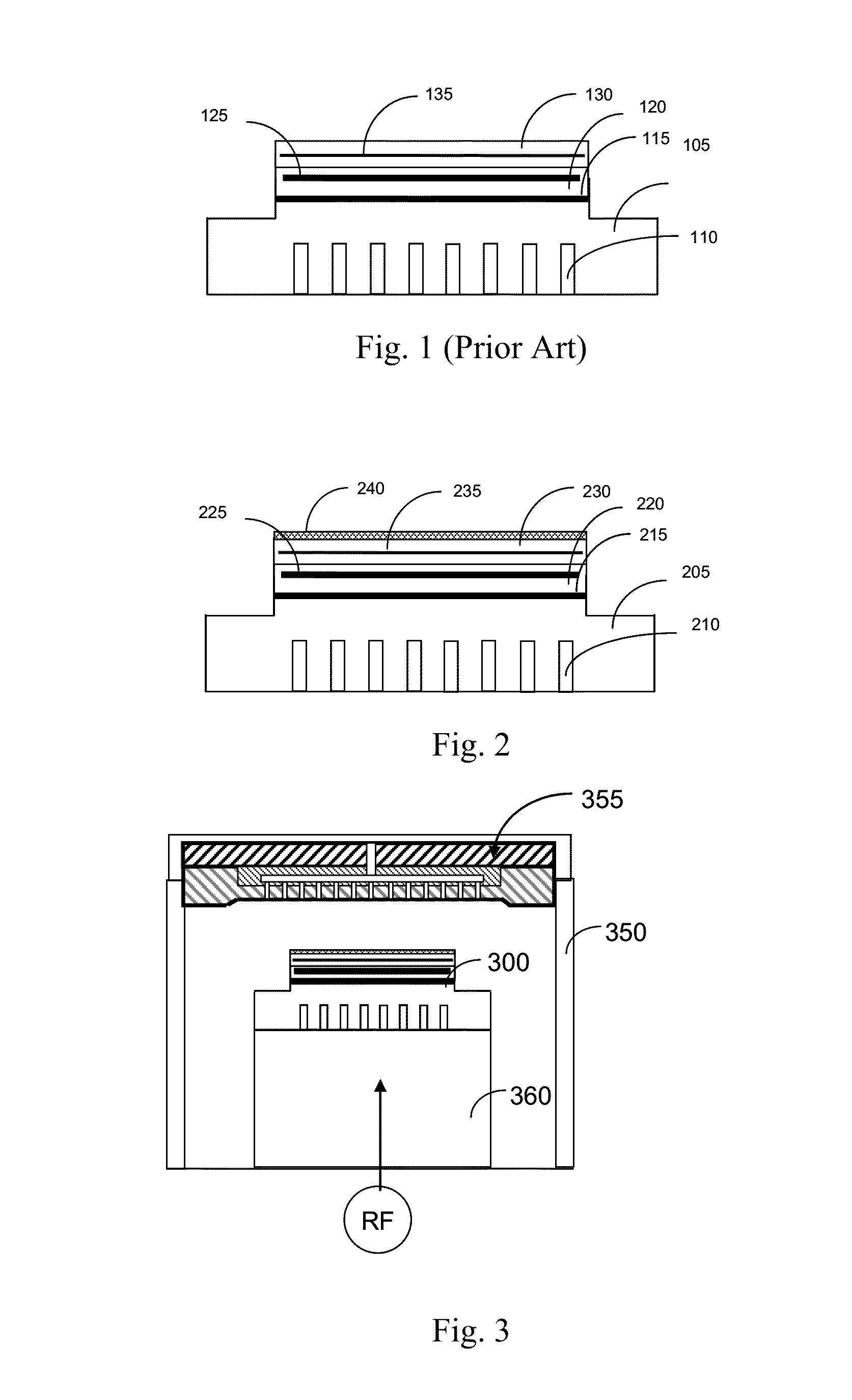

Coating for performance enhancement of semiconductor apparatus

InactiveUS20140116338A1Improve performanceImprove stabilityElectric discharge tubesVacuum evaporation coatingPerformance enhancementPlasma coating

A plasma processing chamber having advanced coating for the showerhead and for an extended bottom electrode. The extended bottom electrode can be formed by one or more of the focus ring, cover ring, and plasma confinement ring. The extended electrode can be formed using a one-piece composite cover ring. The composite cover ring may be made of Al2O3 and include a Y2O3 plasma resistant coating. The plasma confinement ring may include a flow equalization ion shield that may also be provided with the plasma resistant coating. The plasma resistant coating of the extended electrode may have elements matching that of the showerhead.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

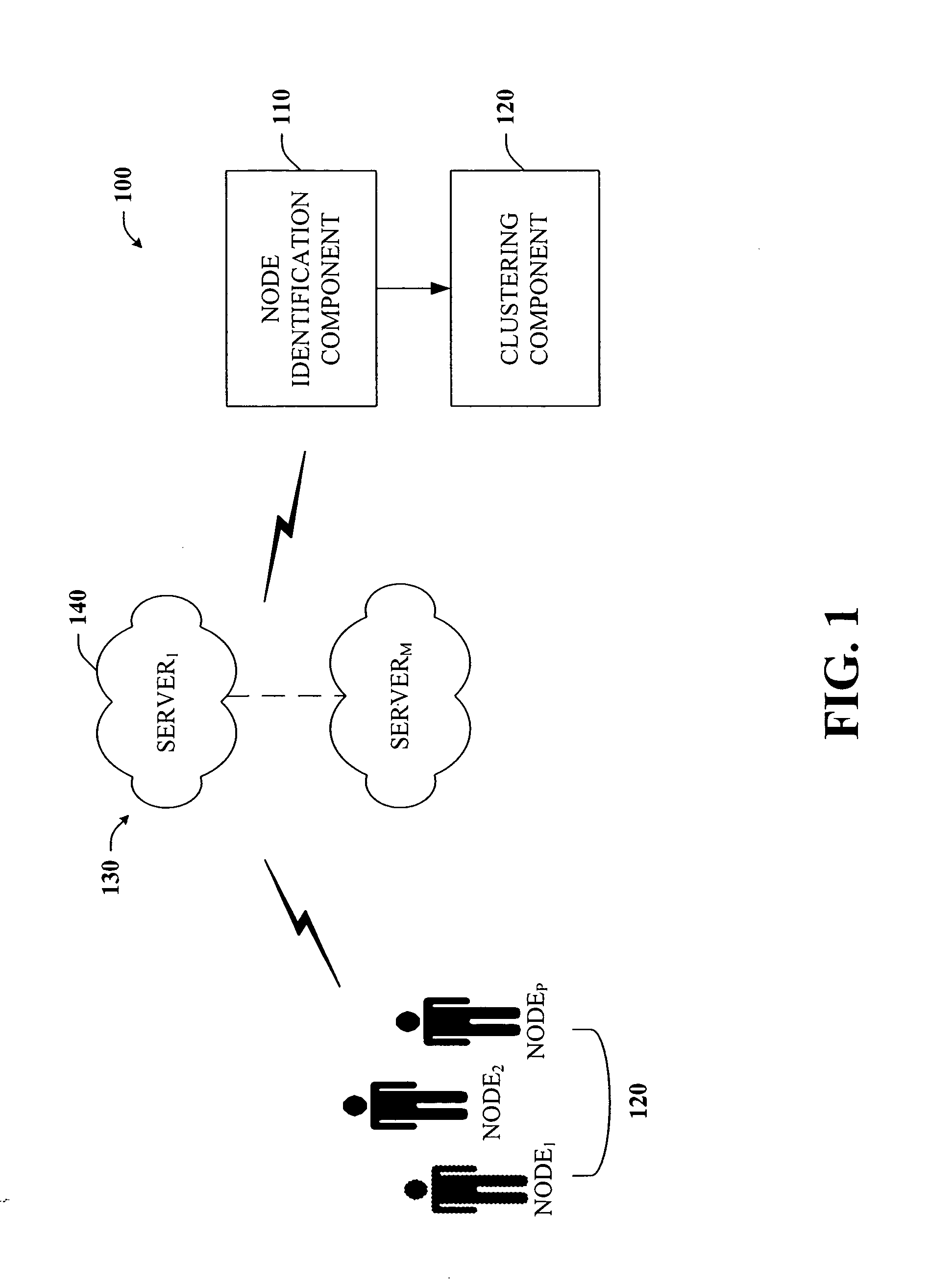

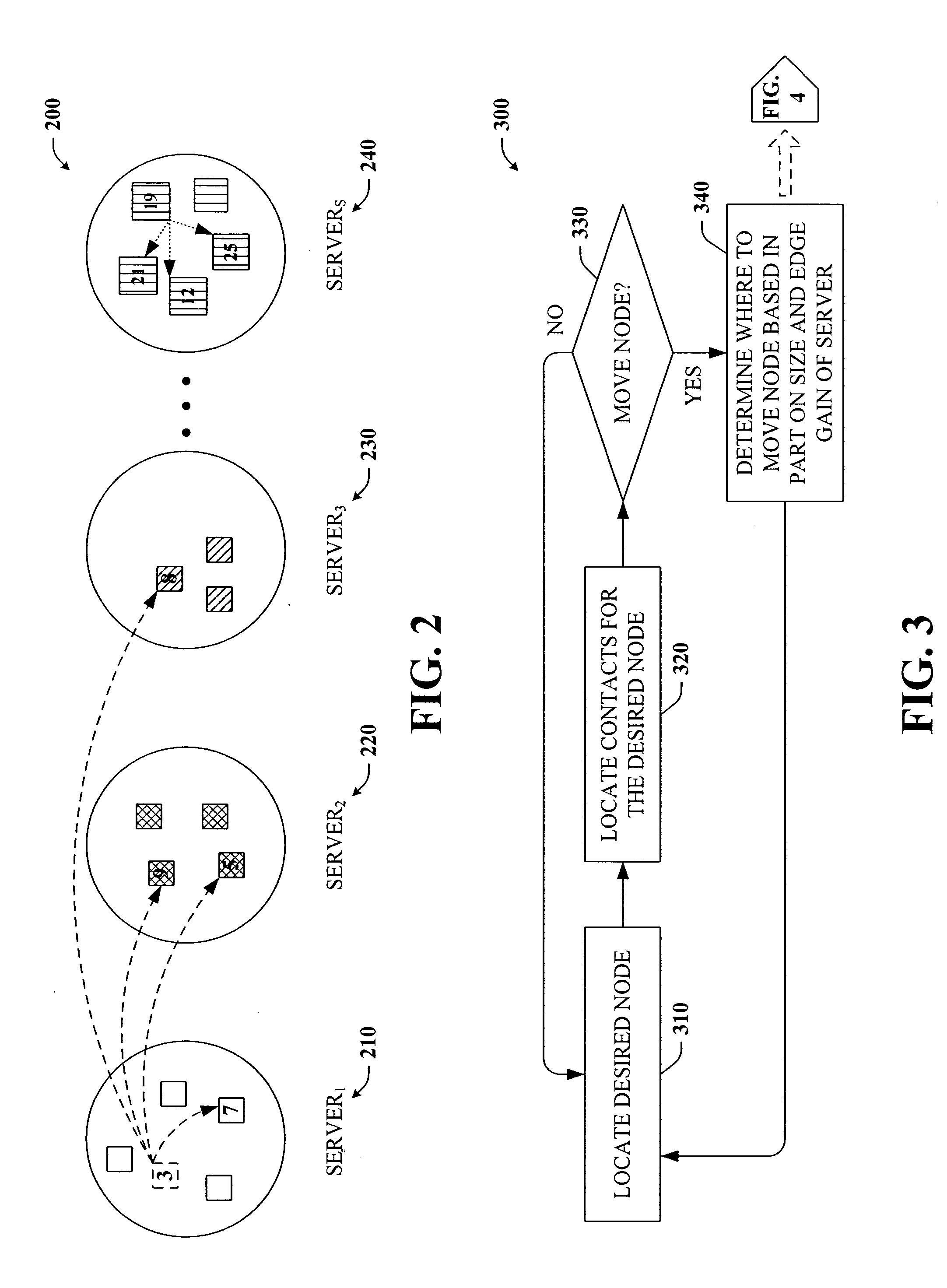

Partitioning social networks

ActiveUS20060015588A1Communication be reduceEasy to placeDigital computer detailsMarketingTraffic volumeTraffic capacity

The present invention provides a unique system and method that facilitates reducing network traffic between a plurality of servers located on a social-based network. The system and method involve identifying a plurality of vertices or service users on the network with respect to their server or network locations. The vertices' contacts or connections can be located or determined as well. In order to minimize communication traffic, the vertices and their connections with respect to their respective server locations can be analyzed to determine whether at least a subset of nodes should be moved or relocated to another server to facilitate mitigating network traffic while balancing user load among the various servers or parts of the network. Thus, an underlying social network can be effectively partitioned. In addition, the network can be parsed into a collection of nested layers, whereby each successively less dense layer can be partitioned with respect to the previous (partitioned) more dense layer.

Owner:MICROSOFT TECH LICENSING LLC

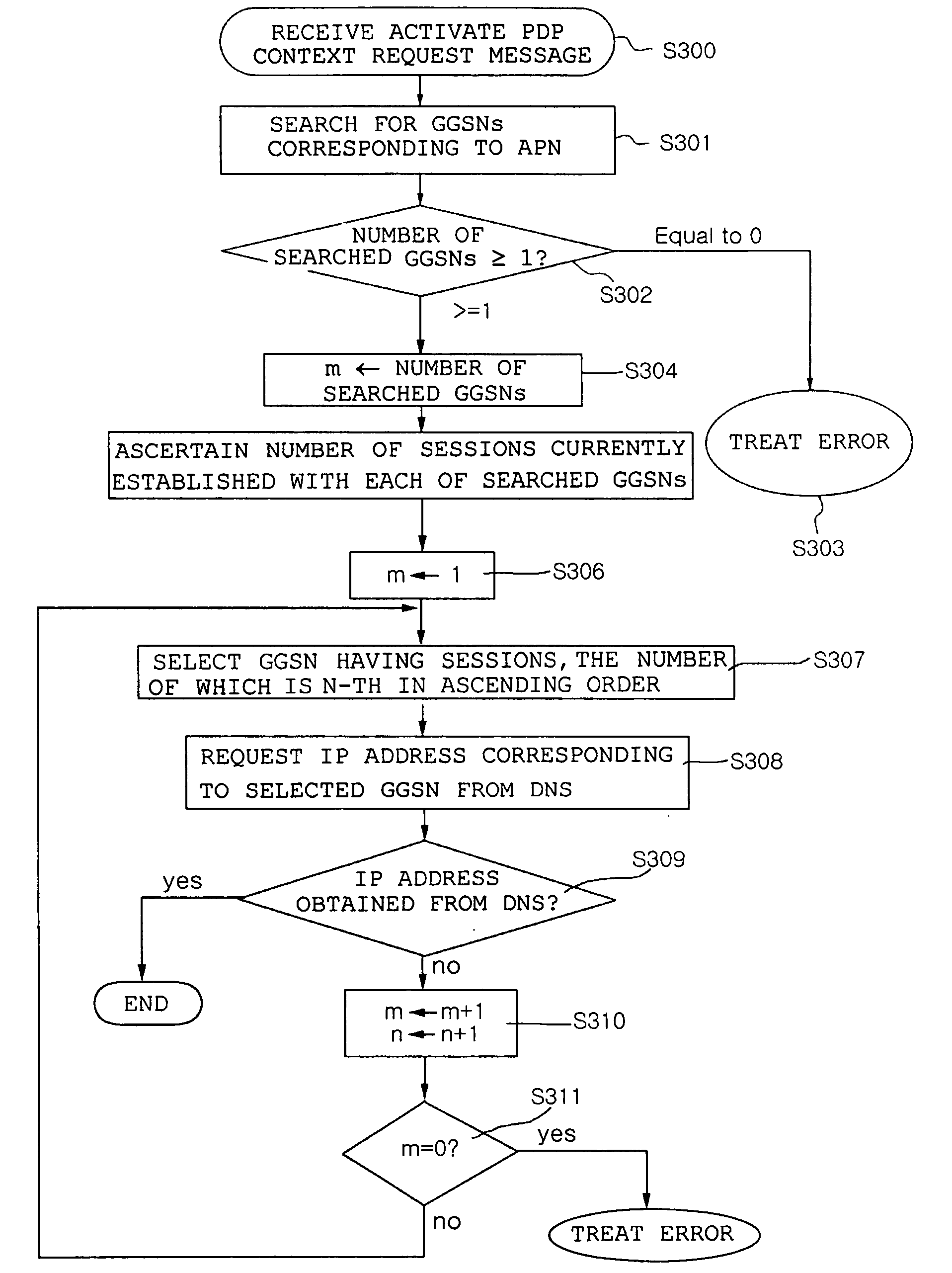

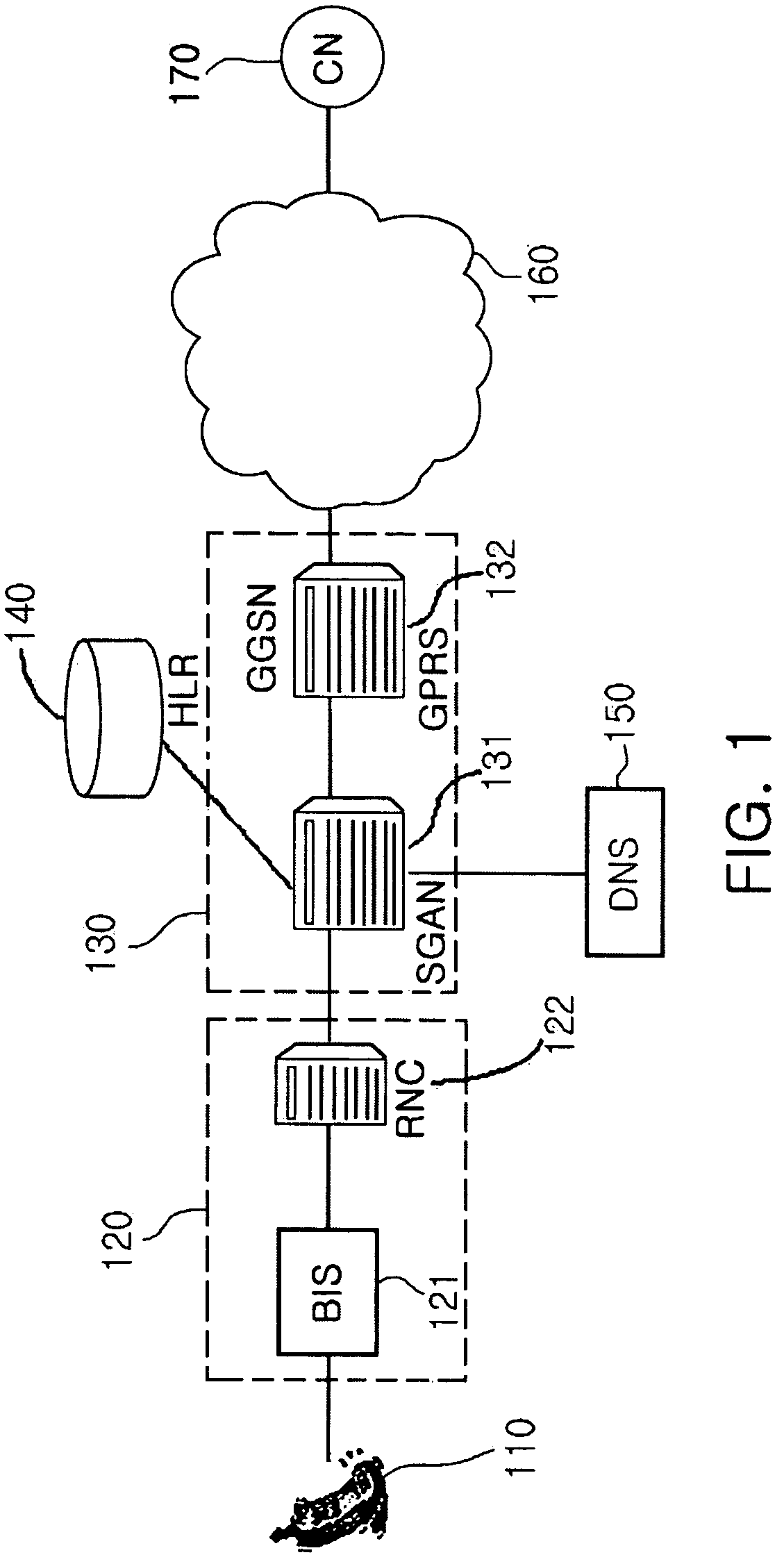

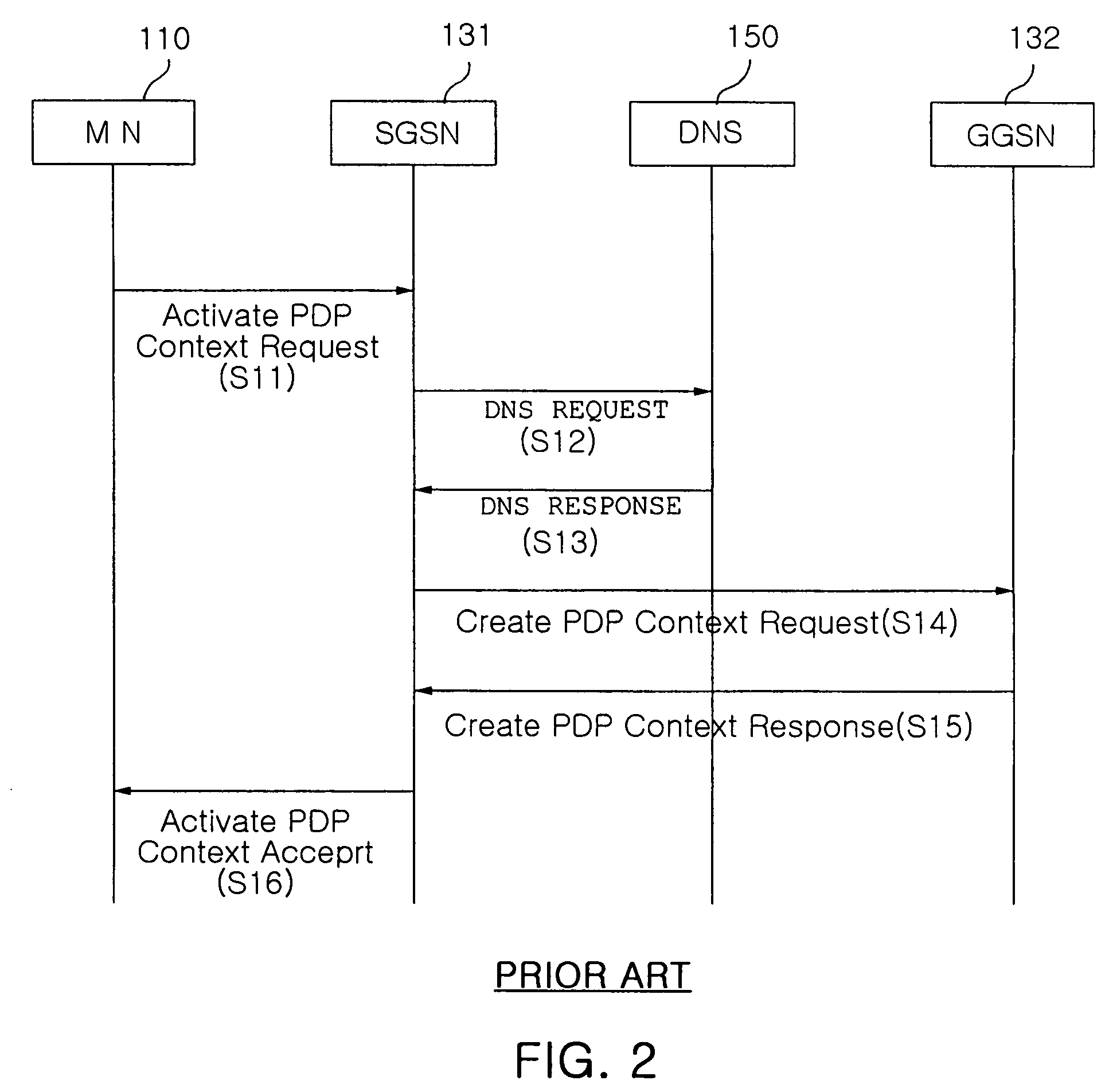

Method of balancing load and method of setting up call using the same in general packet radio service network

InactiveUS20050122942A1Reduce failure rateImprove service performanceNetwork traffic/resource managementNetwork topologiesLoad SheddingTelecommunications

The present invention relates to a method of balancing a load and method of setting up a call using the load balancing method in a General Packet Radio Service (GPRS) network, which prevents a load from concentrating on a specific Gateway GPRS Supporting Node (GGSN) in the GPRS network, thus reducing a probability of failure in session establishment due to increased traffic. In the load balancing method, when a Service GPRS Supporting Node (SGSN) connected to a mobile node establishes a session, it selects a GGSN having a smallest number of established sessions among a plurality of GGSNs corresponding to an Access Point Name (APN) included in an Activate PDP Context Request message received from the mobile node and requests the selected GGSN to establish a session, thus solving a problem in which a load concentrates on a specific GGSN.

Owner:KT CORP

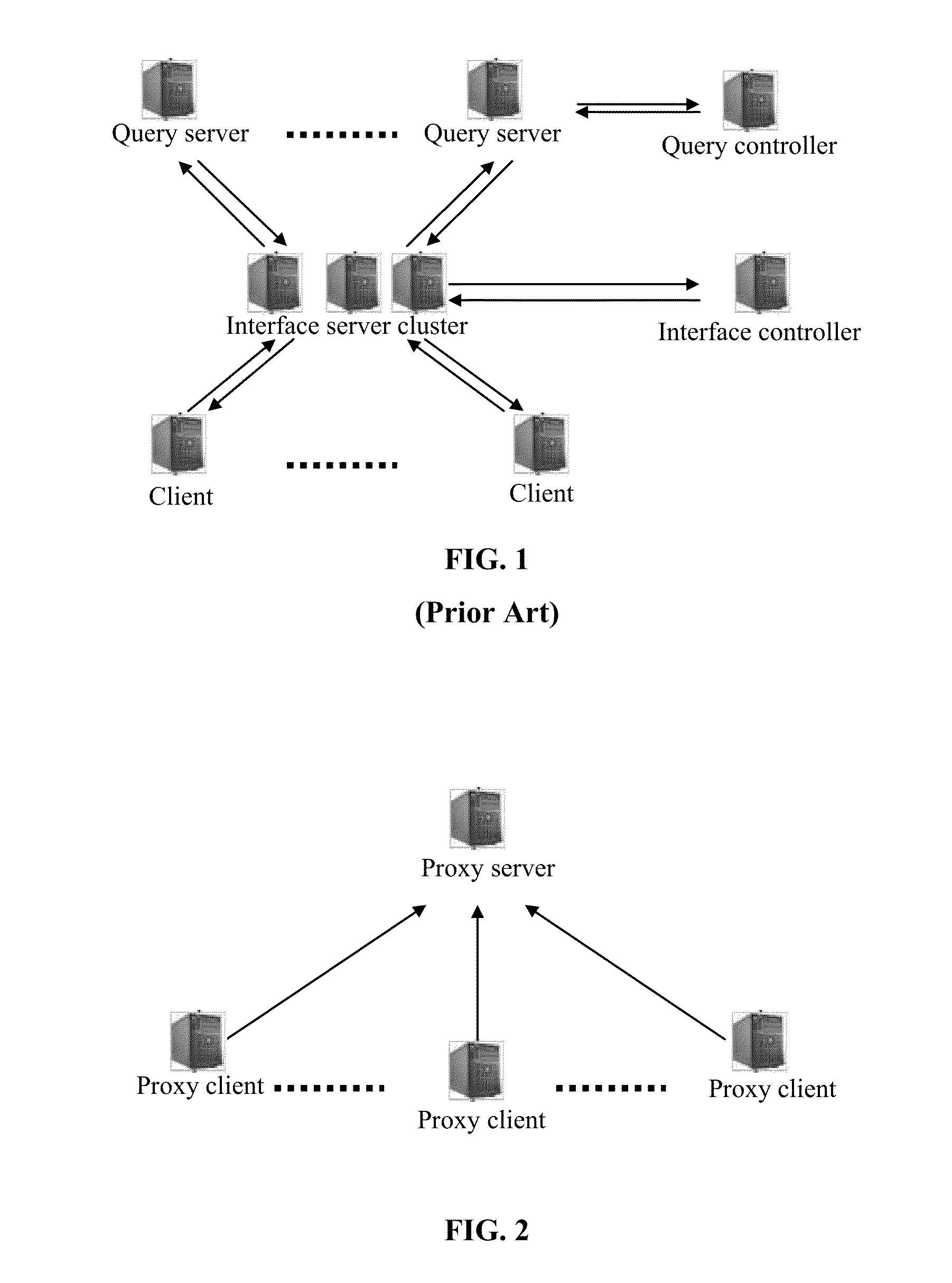

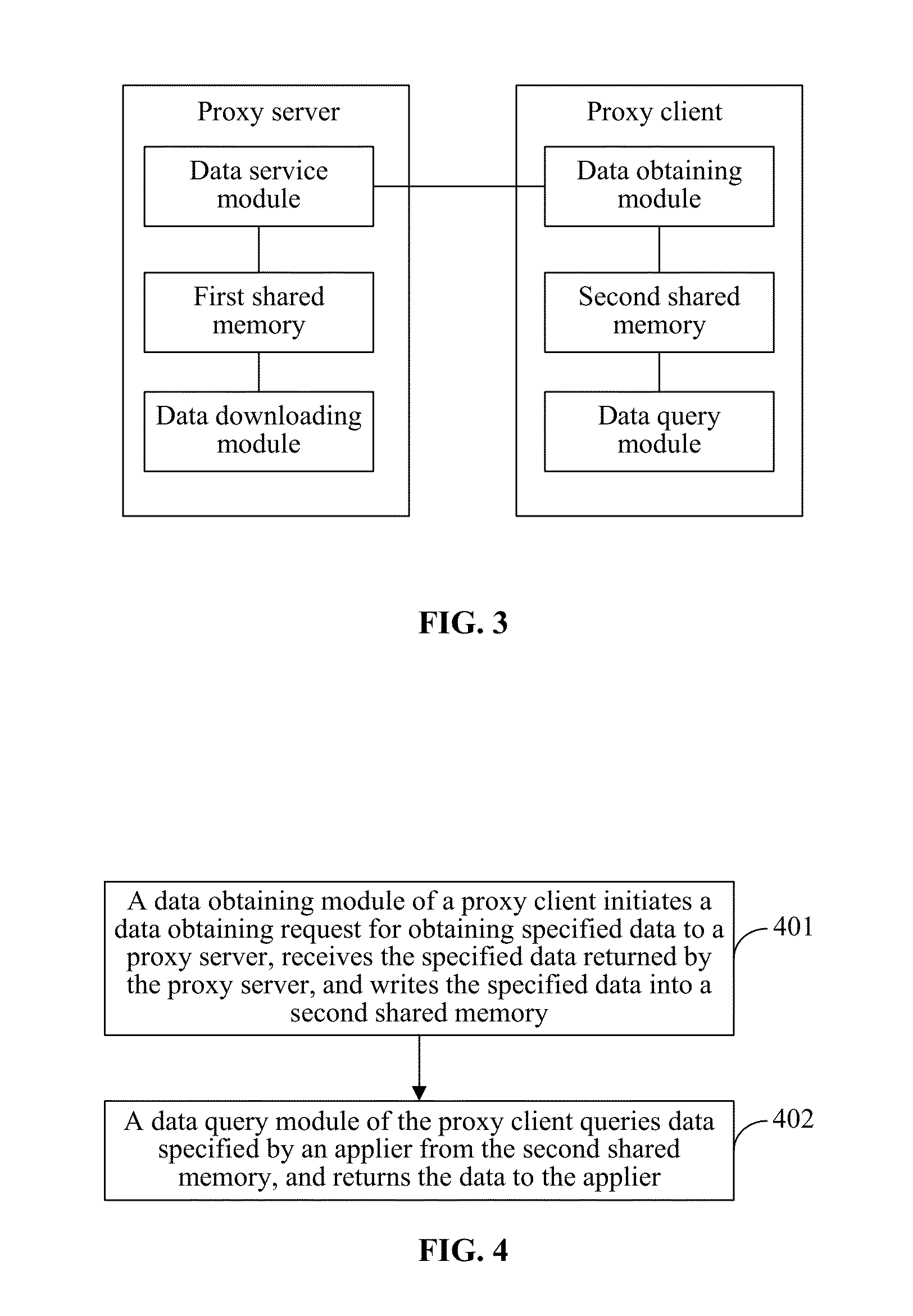

Data query method and system and storage medium

InactiveUS20150213134A1High cost of deploymentPoor service performanceWeb data indexingDigital data processing detailsData providerClient-side

The present disclosure discloses a data query system, method, and storage medium. The data query system includes a proxy server and at least one proxy client. The proxy server is disposed on a server that serves as a data provider, and is configured to provide the proxy client with a data delivery service. The proxy client is disposed on a client that serves as a data user, and is configured to obtain data from the proxy server and save the data and provide a data query service. The proxy client thus includes a data obtaining module, a data query module, and a second shared memory. Accordingly, the present disclosure further discloses a data query method. The present disclosure has a simple structure, achieves fast data update, requires a low deployment cost, saves bandwidth resources, and achieves excellent service performance.

Owner:TENCENT TECH (SHENZHEN) CO LTD

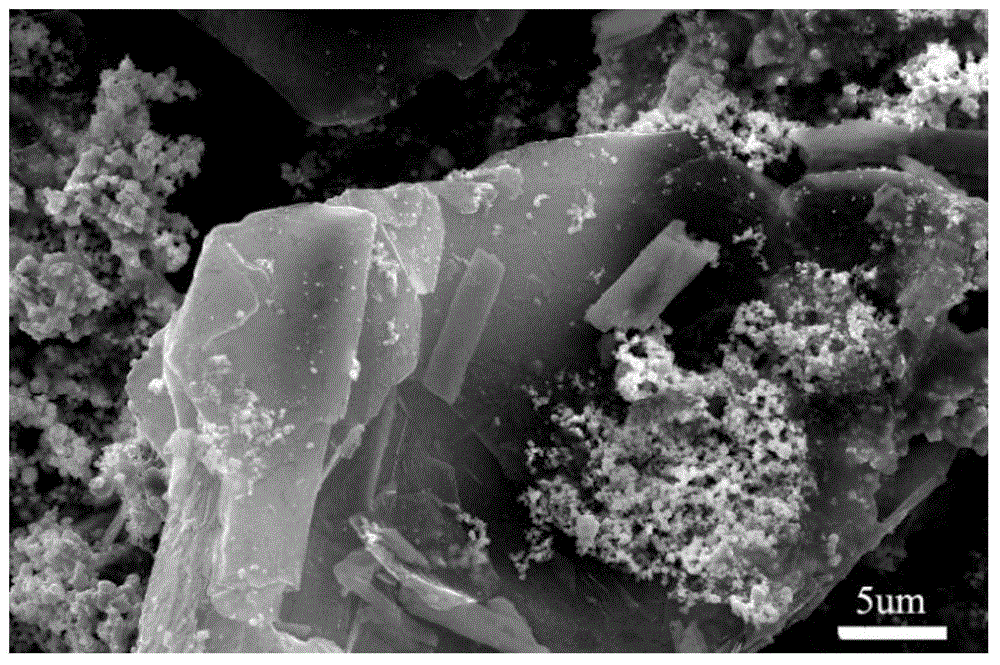

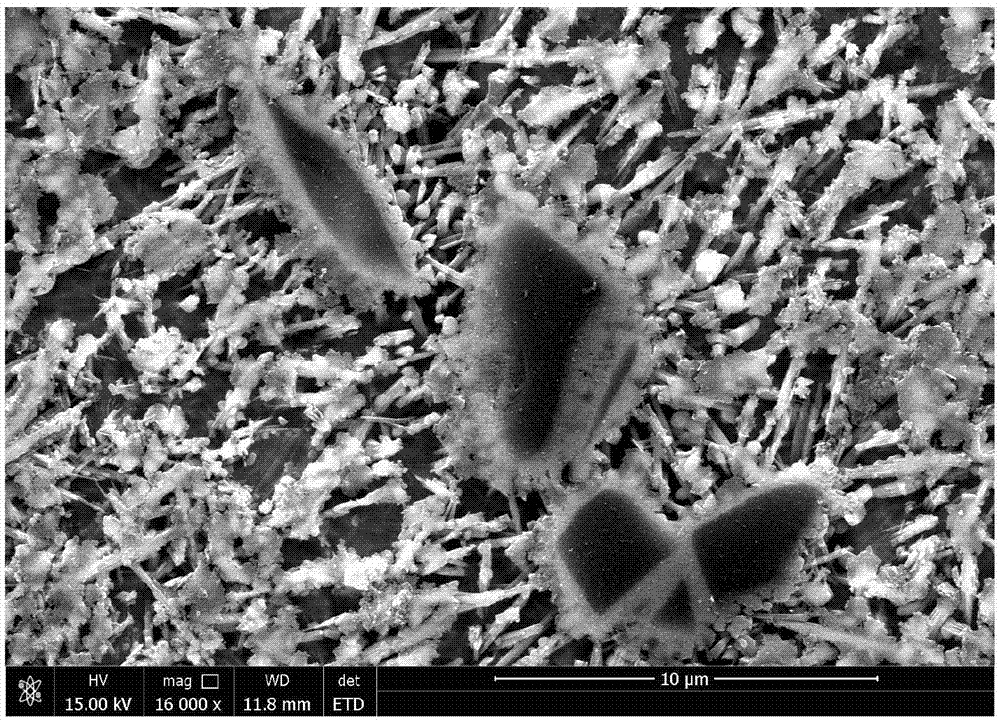

Preparation method of high-thermal conductivity graphene-Sn-Ag composite brazing filler metal

ActiveCN104400247AImprove performanceSolve reunionWelding/cutting media/materialsSoldering mediaDensity differenceCvd graphene

The invention discloses a preparation method of a high-thermal conductivity graphene-Sn-Ag composite brazing filler metal, ad relates to a preparation method of a high-thermal conductivity composite brazing filler metal. The preparation method has the following purposes: the problem of graphene floating and agglomeration in the preparation and application process of the composite brazing filler metal is solved by reducing a greater density difference between graphene and an Sn-Ag brazing filler metal matrix through plating a metal on the graphene; meanwhile, the graphene is dispersed more uniformly in the brazing filler metal matrix; and the reliability of sealing and brazing is improved by improving the heat conductivity of the composite brazing filler metal through adding the graphene. The method comprises the following steps: (1) the metal is plated on the graphene; and (2) the ball milling, the mixing and the medium-temperature smelting are performed for the metal-plated graphene and the Sn-Ag brazing filler metal to obtain the high-thermal conductivity composite brazing filler metal. The prepared composite brazing filler metal is high in thermal conductivity, has a higher wettability compared with a traditional Sn-Ag brazing filler metal, and is a composite brazing filler metal accordant with the present development tendency of an electronic industry as a connecting material of traditional large-scale integrated circuits.

Owner:HARBIN INST OF TECH

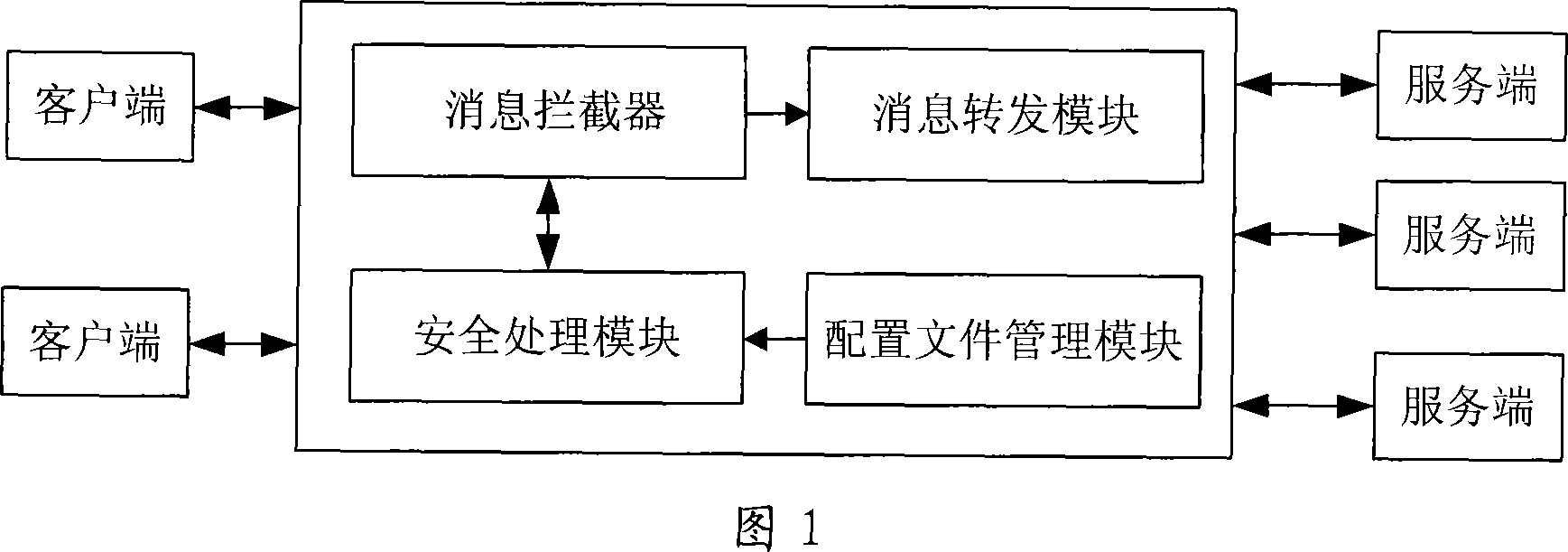

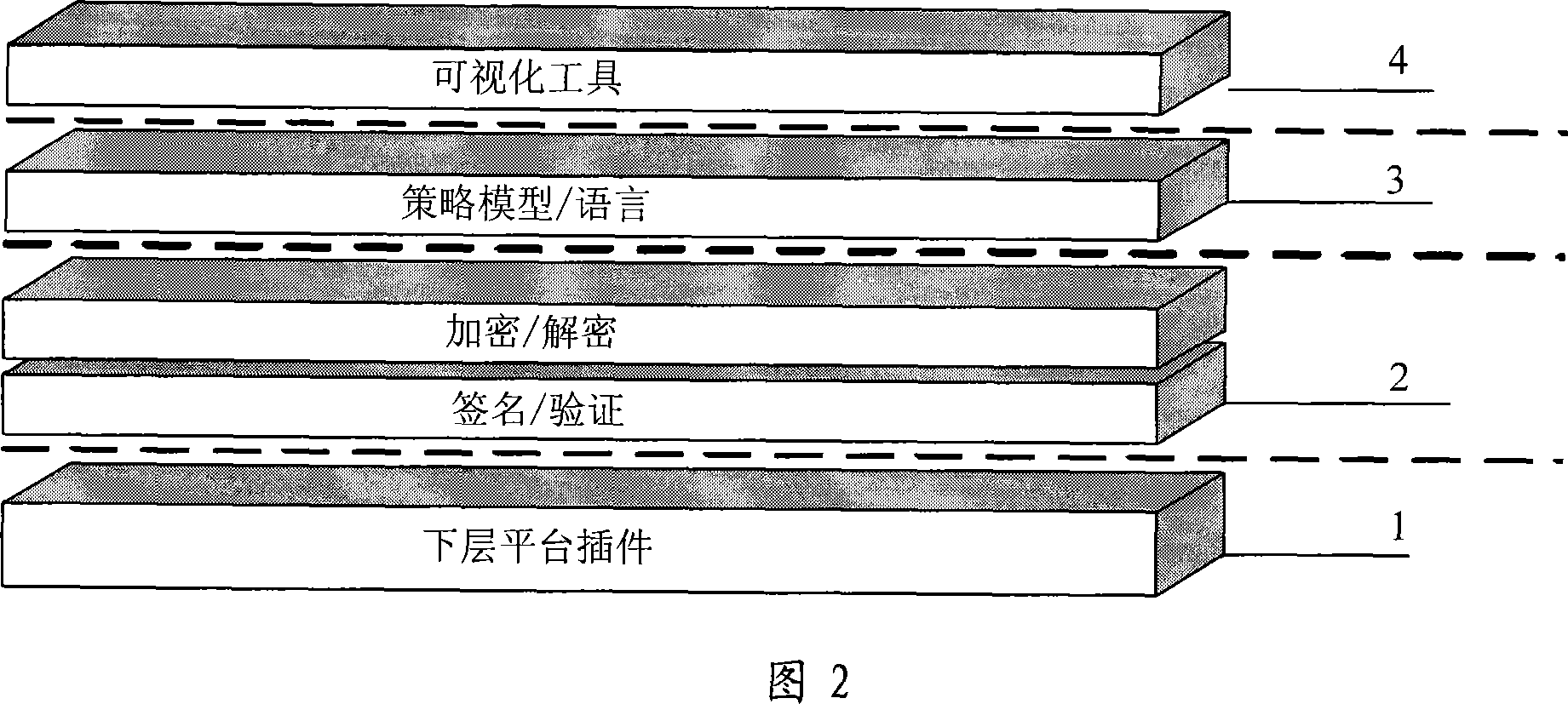

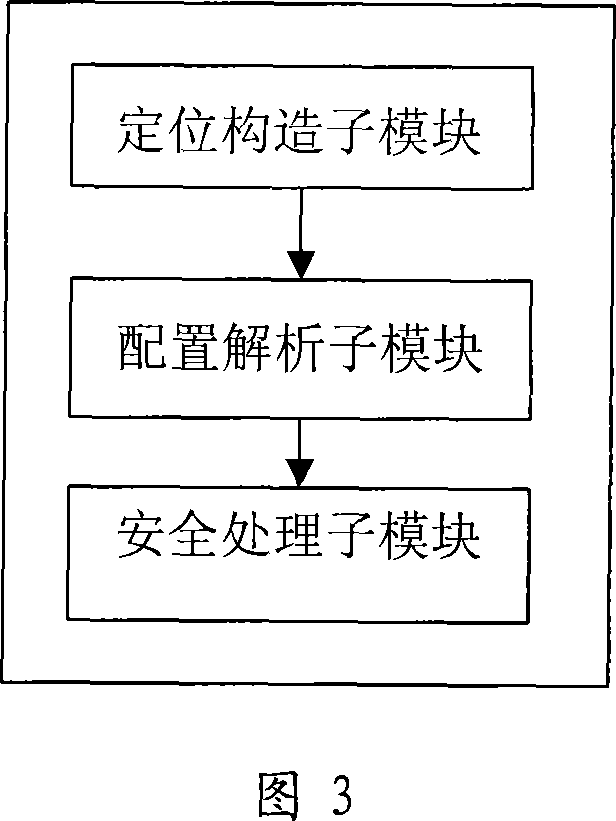

Service gateway and method for realizing message safe process

InactiveCN101043478AImprove service performanceLower average response timeData switching by path configurationNetwork connectionsService gatewayService resource

The related service gateway comprises: a message interceptor to transmit the intercepted user request and / or service response message to the next module and sends message from the next module to a message transmission module; a safe processing module to safe process message from last module and return result; and a message transmission module to transmit the processed message to a grid server. It also relates the corresponding processing method. This invention P2P transmits message safely, and realizes seamless visiting for service resource to mobile terminal.

Owner:BEIHANG UNIV

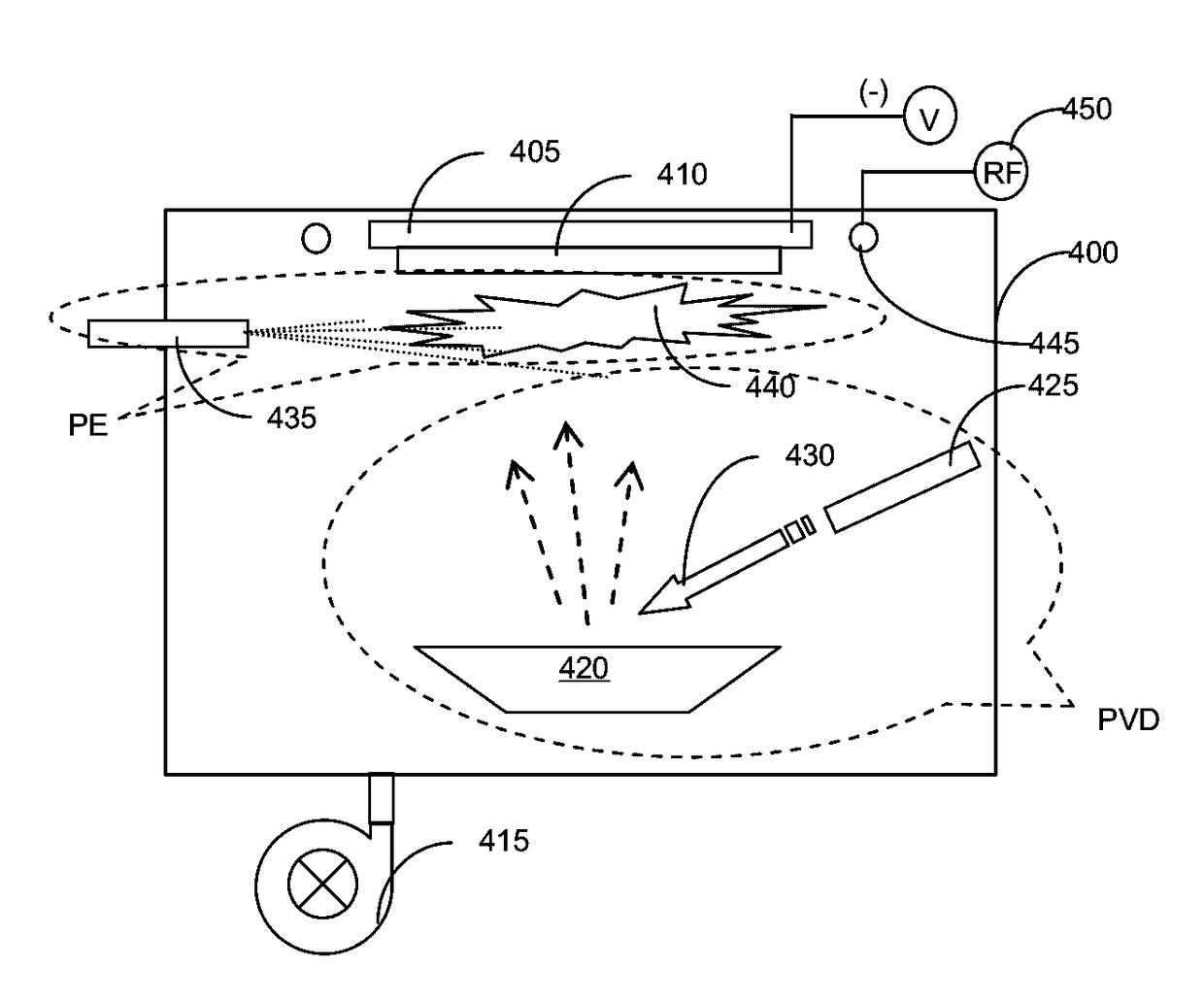

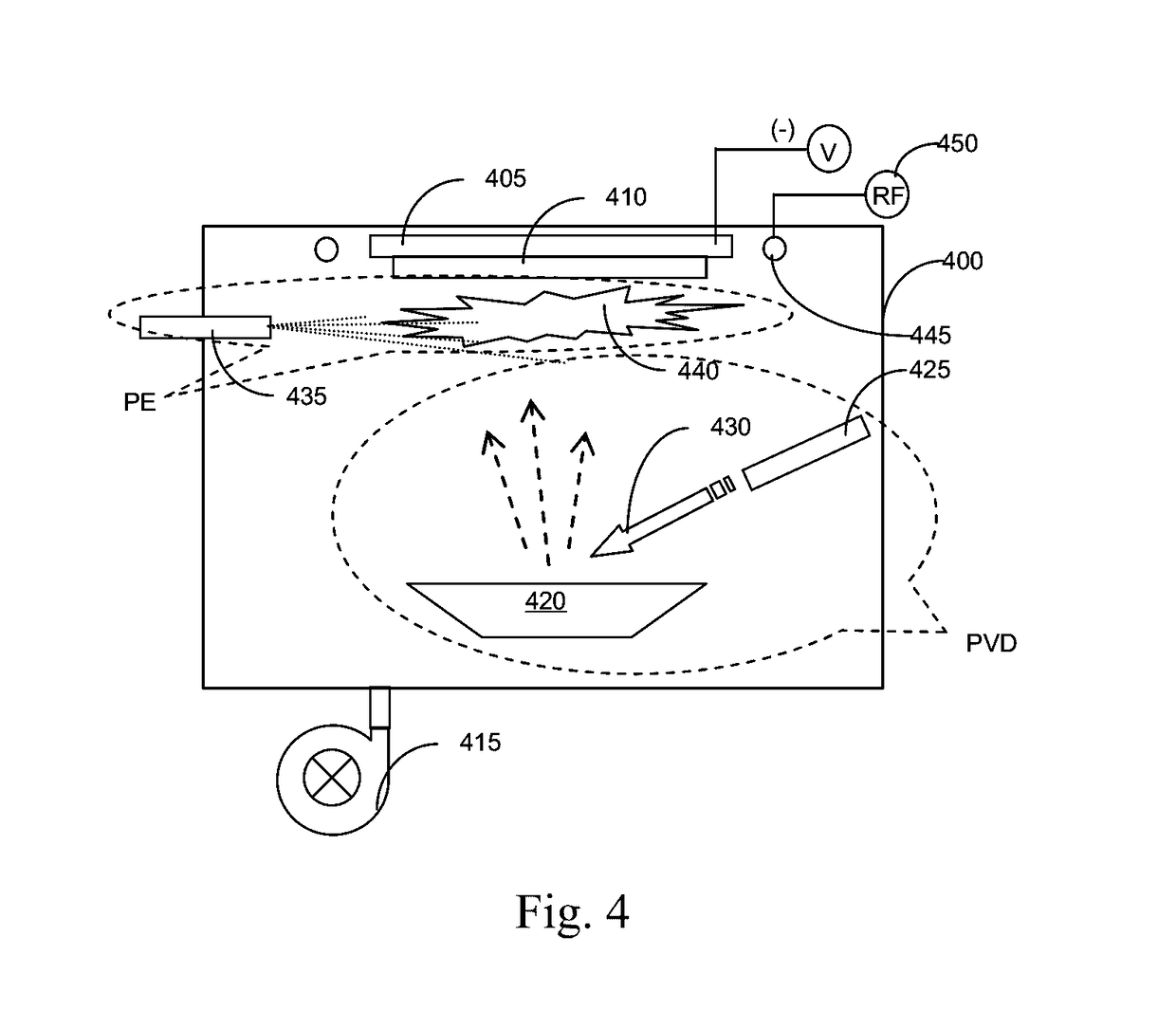

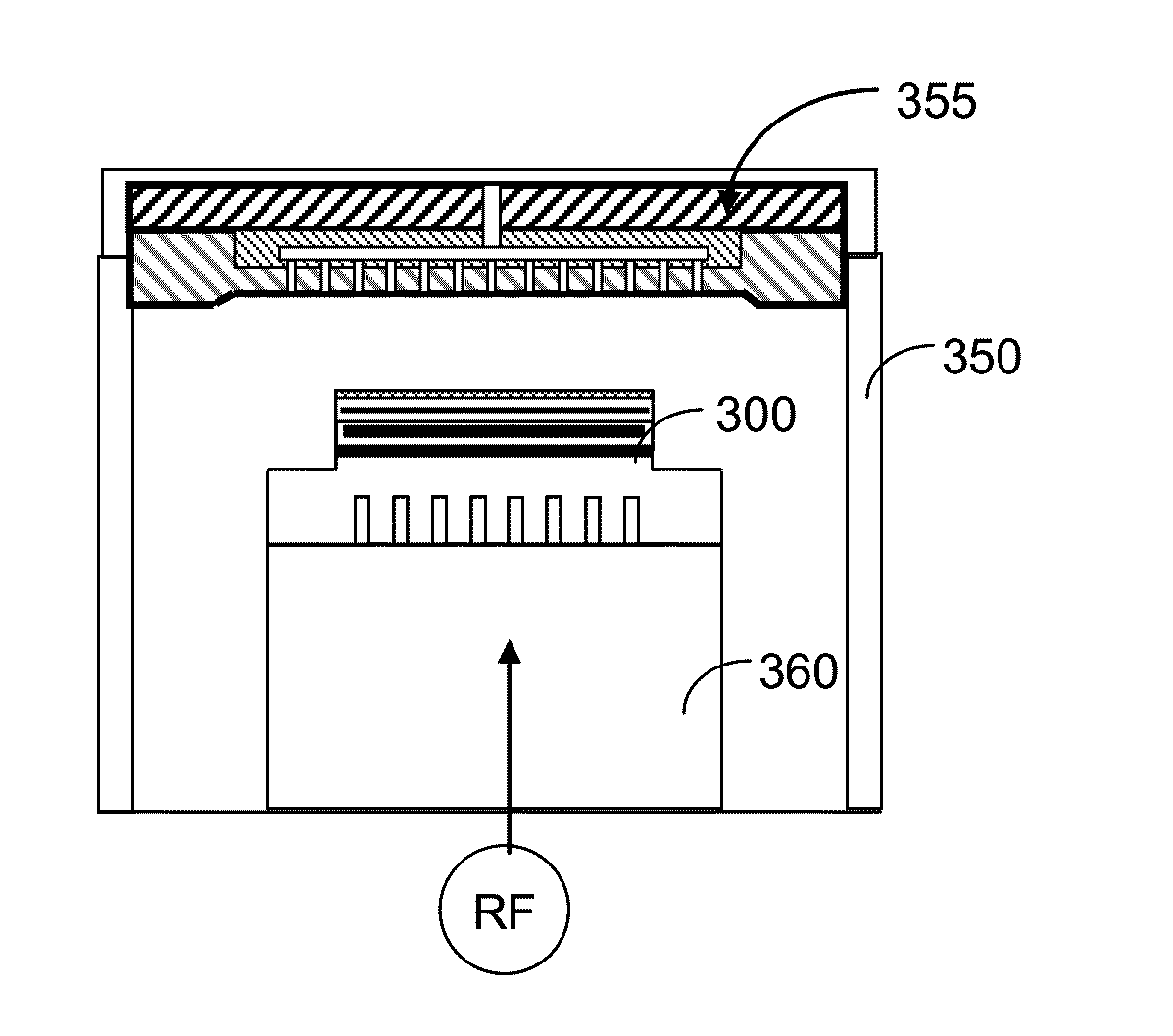

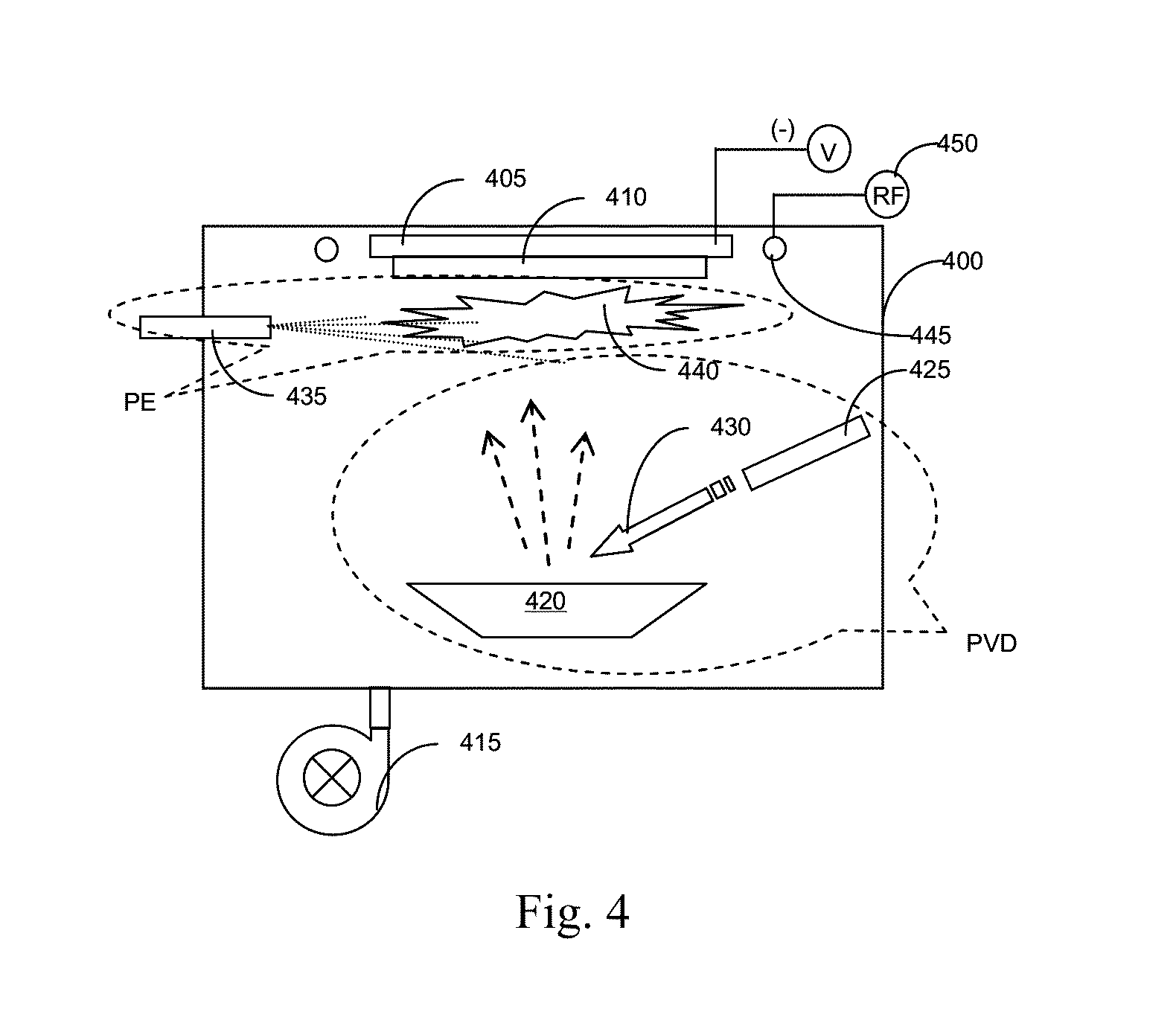

Performance enhancement of coating packaged ESC for semiconductor apparatus

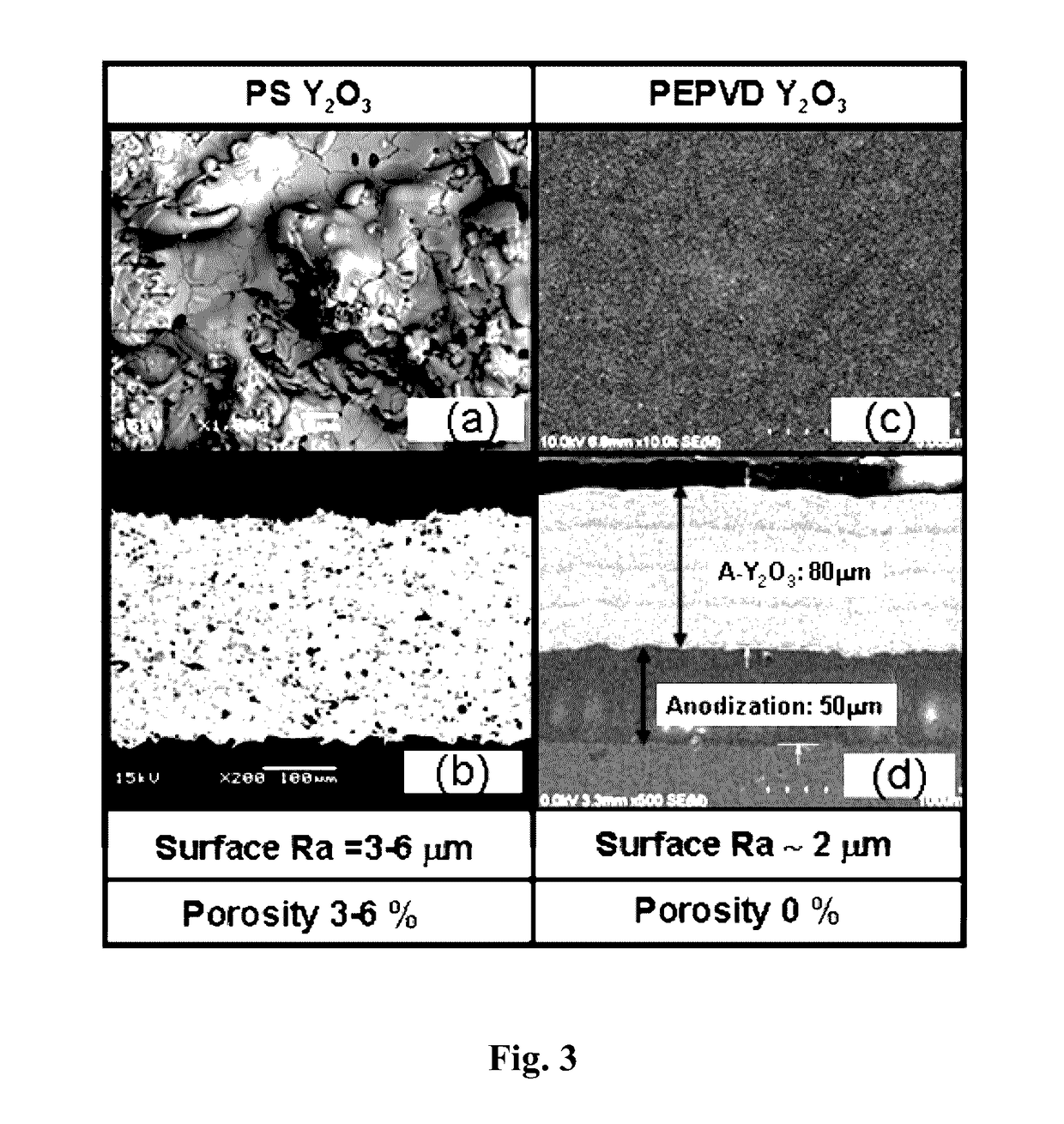

ActiveUS9633884B2Improve service performanceImprove processing qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingPerformance enhancementGas phase

An advanced coating for electrostatic chuck used in plasma processing chamber is provided. The advanced coating is formed using plasma enhanced physical vapor deposition. The coating is generally of Y2O3 / Al2O3, although other material combinations can be used. Also, a multi-layered coating can be formed, such that an intermediate coating layer can be formed using standard plasma spray, and a top coating can be formed using PEPVD. The entire ESC assembly can be “packaged” by the coating.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

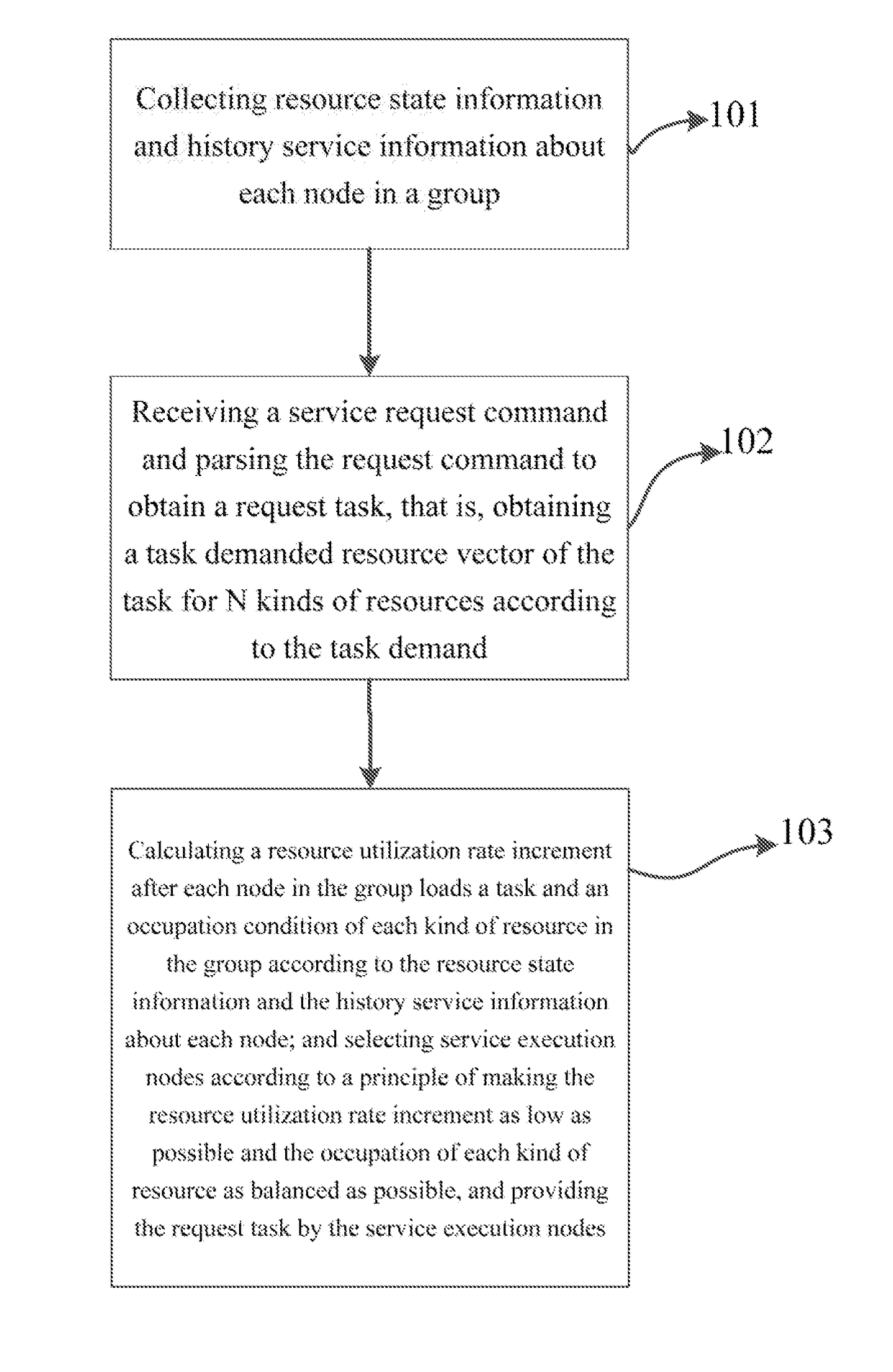

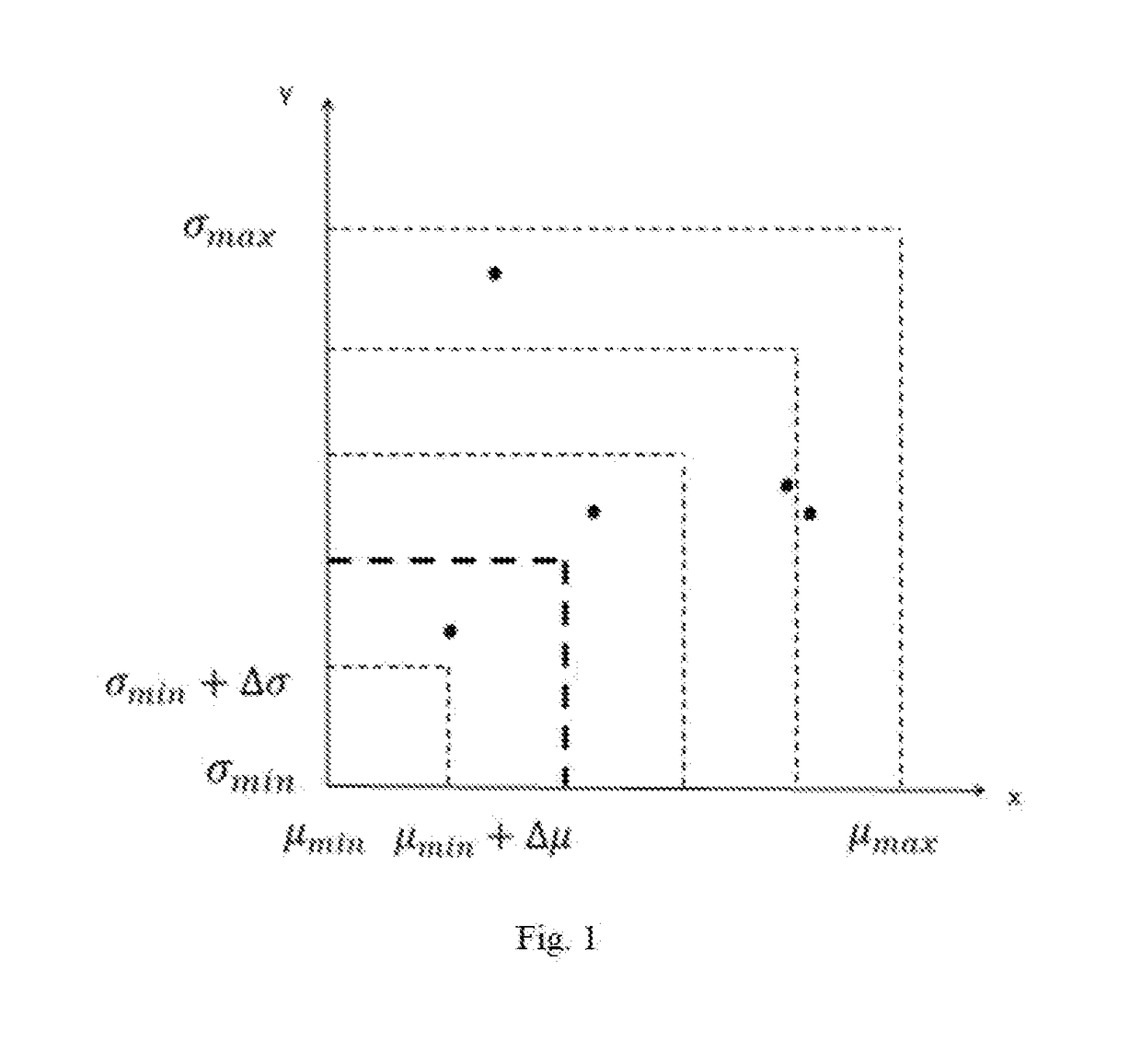

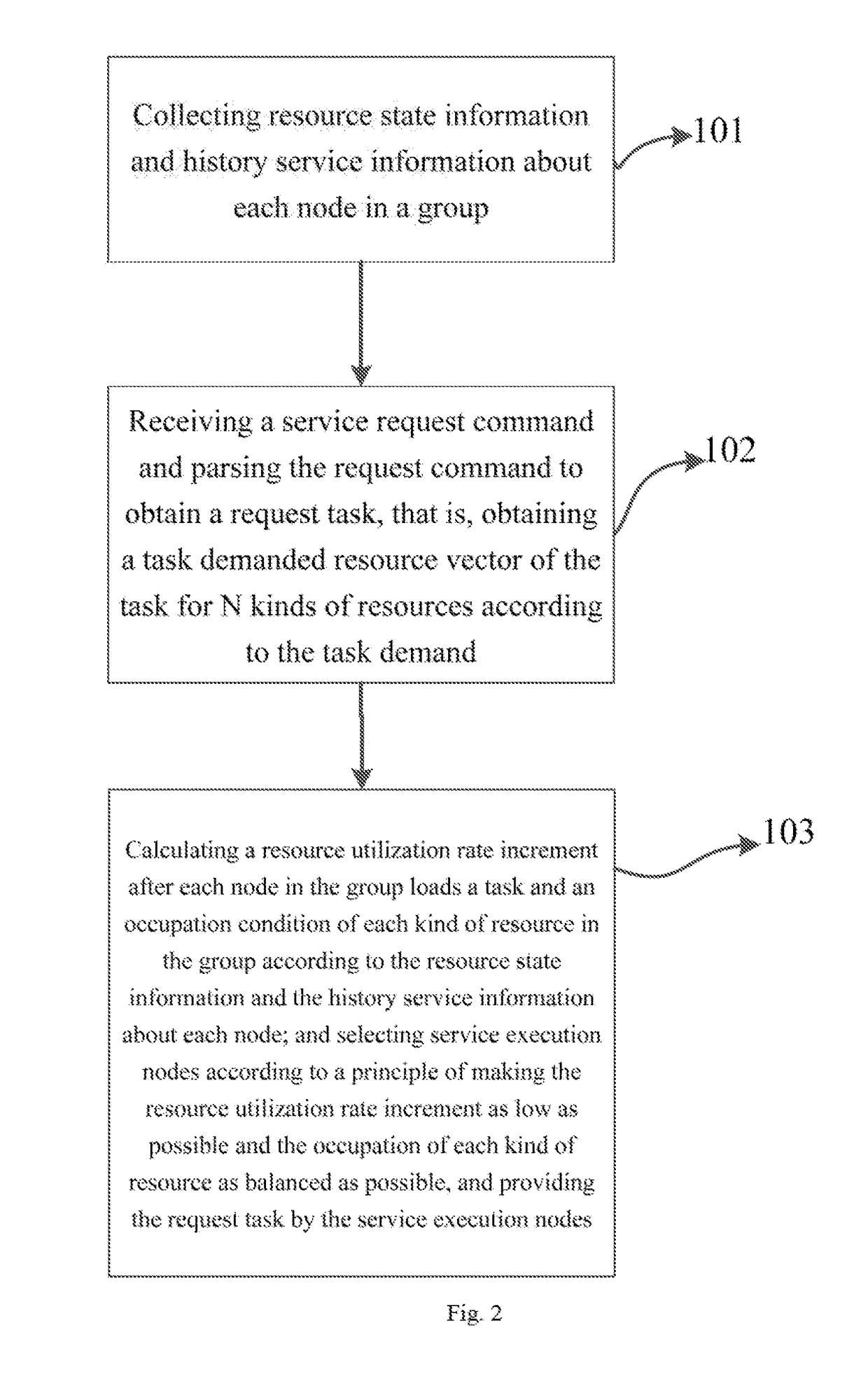

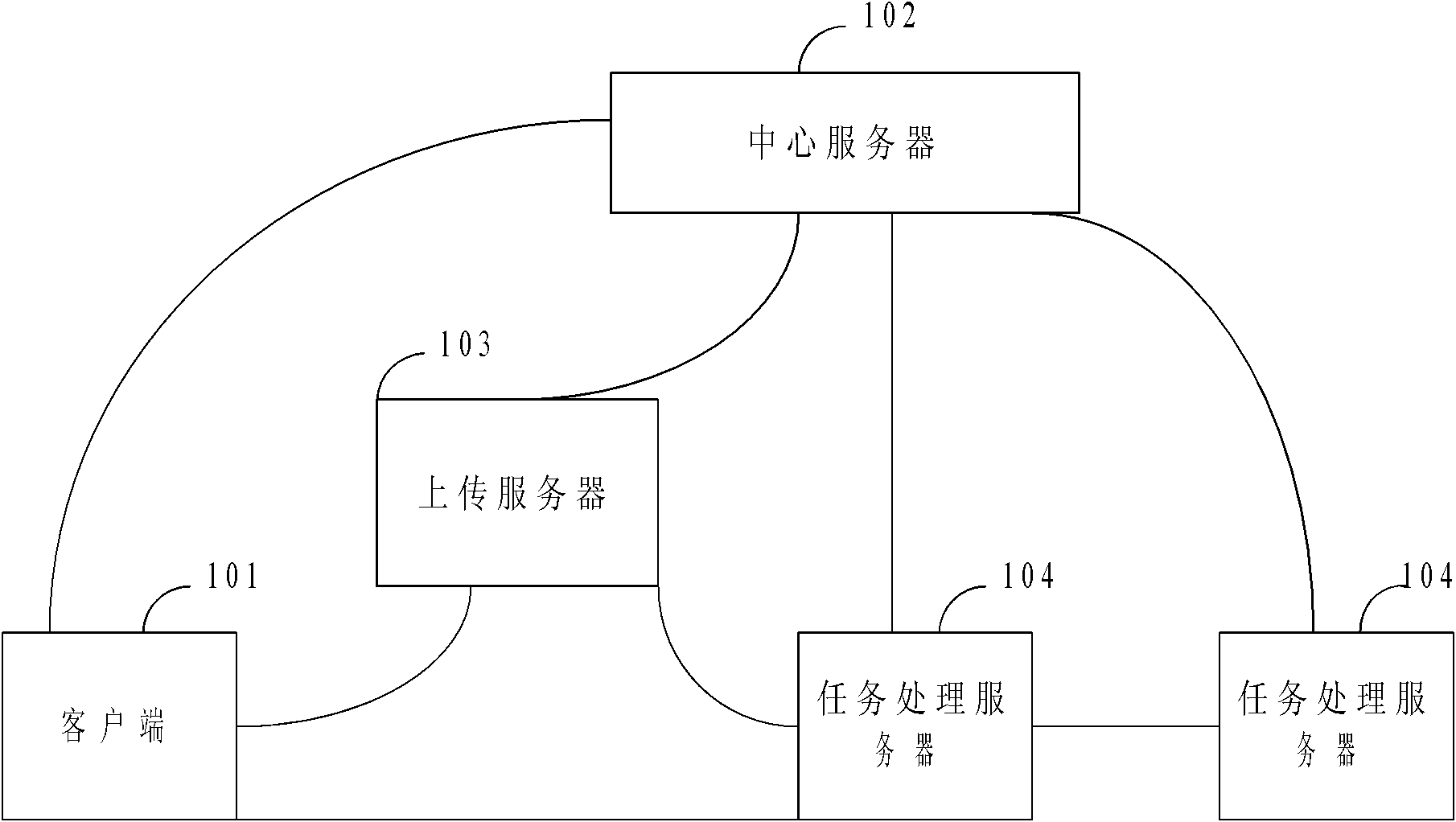

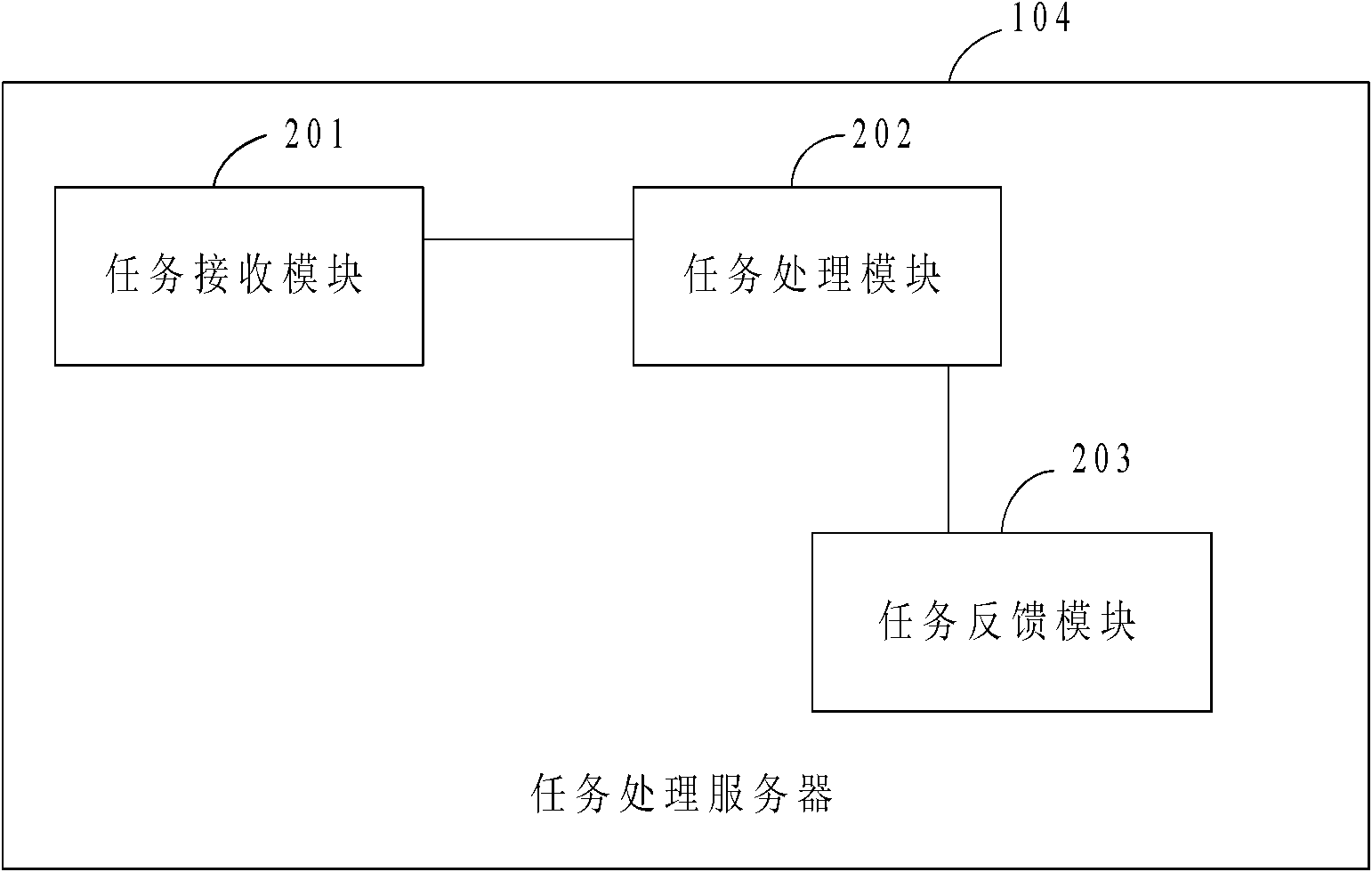

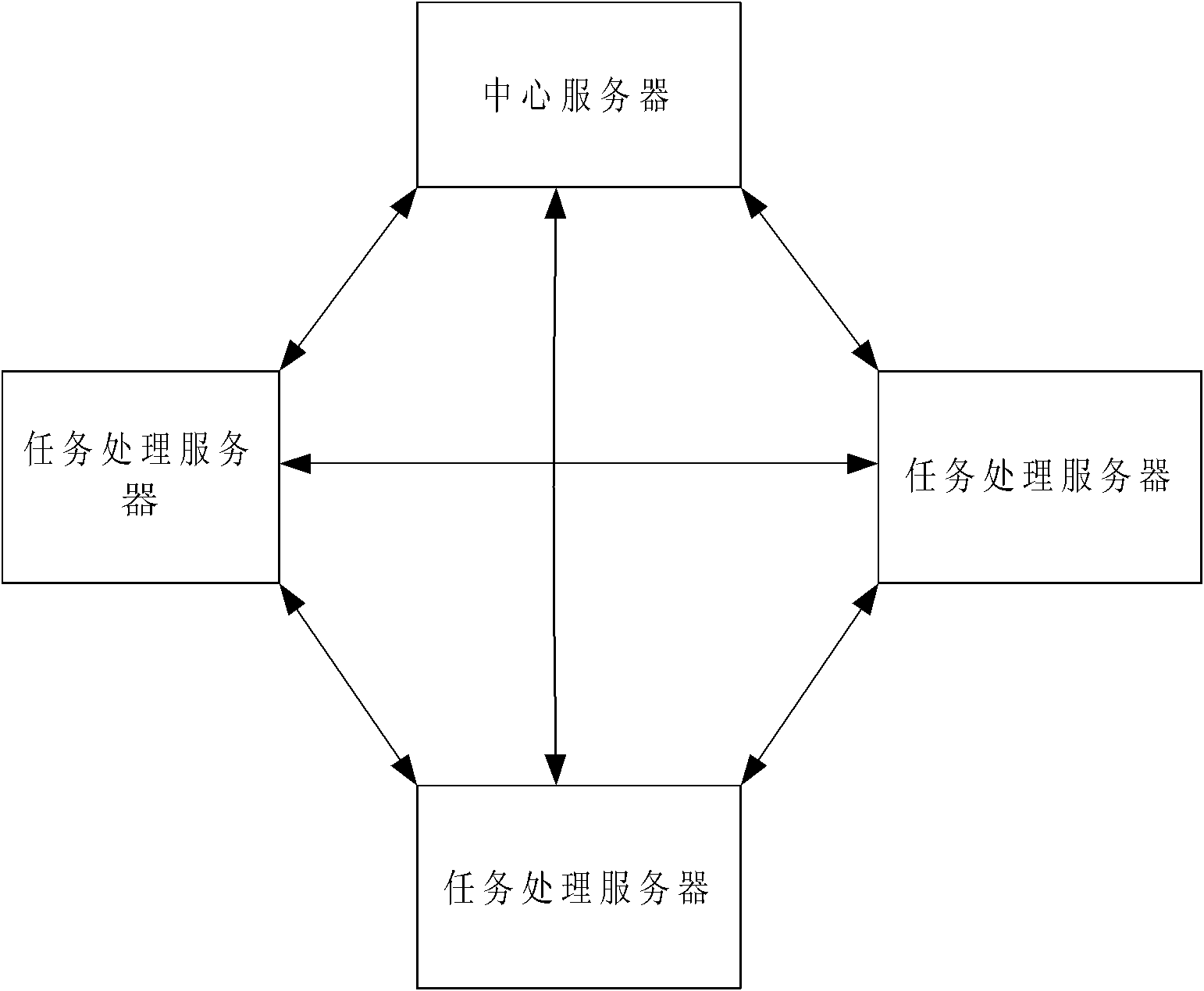

Distributed node intra-group task scheduling method and system

ActiveUS20170329643A1Guarantee efficiencyService performance be improveResource allocationSecuring communicationData packDistributed computing

An SSH protocol-based session parsing method and system. The method includes: step 101) receiving an SSH protocol-based session data packet and respectively preprocessing the received data packet as follows: when one data packet contains several complete messages, extracting each complete message from the data packet; when the data packet contains an incomplete message, firstly caching the incomplete message contained in the current data packet, then receiving the subsequent data packet, and finally splicing the message contained in the subsequent data packet with content of the cached message until a complete message is spliced; and step 102) extracting a content associated with log generation from each obtained complete message, packaging the content associated with the log according to a set format, and then obtaining a parsed log and finishing the session parsing.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI +2

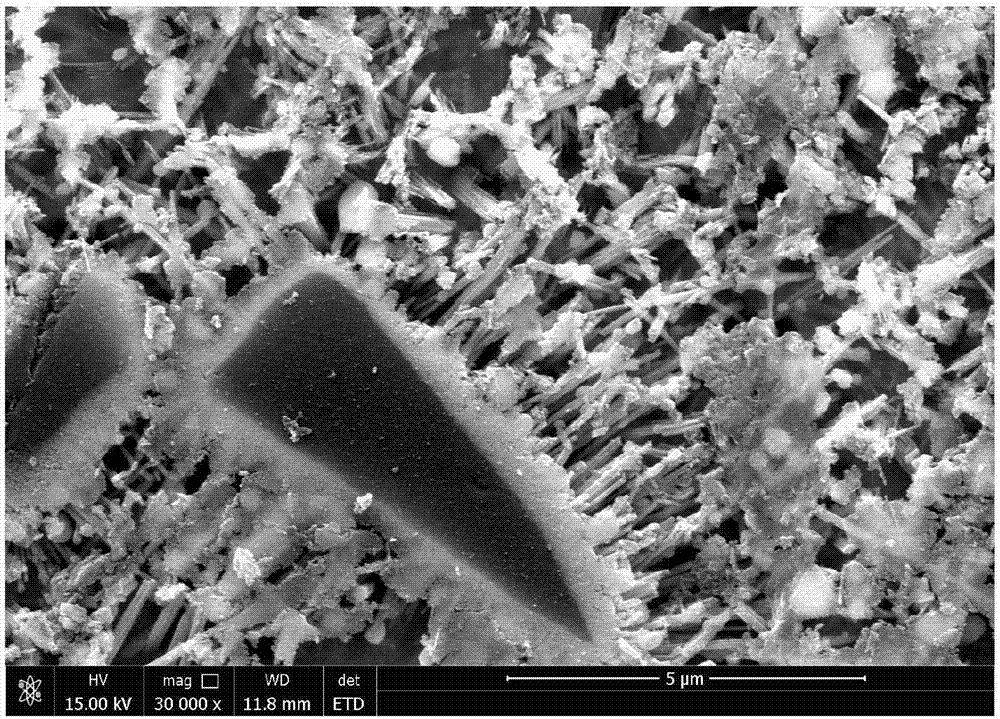

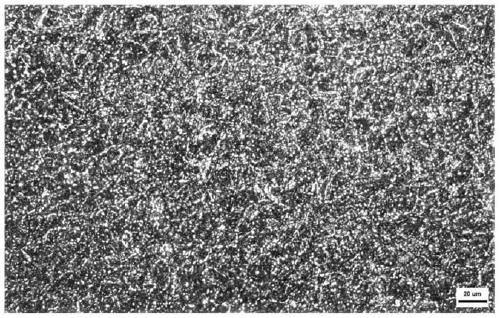

Medical high abrasion resistance titanium alloy composite and gradient in-situ nano multiphase abrasion reduction medical titanium alloy 3D printing method

ActiveCN107130138AFast formingHigh diffusion activityAdditive manufacturing apparatusIncreasing energy efficiencyHigh energyBoron carbide

The invention discloses a medical high abrasion resistance titanium alloy composite and a gradient in-situ nano multiphase abrasion reduction medical titanium alloy 3D printing method. The physical characteristics of boron carbide ceramic and a titanium alloy are combined, a laser selective melting forming process is adopted, and under the effect of high energy lasers, active elements of carbon and boron can be conveniently diffused outwards in a radial gradient mode along boron carbide ceramic particles, and nano ceramic reinforced phases such as Ti-B, TiB2 and TiC can be easily synthesized through the carbon, the boron and the medical titanium alloy. On one hand, forming of a gradient ceramic particle / titanium alloy interface is promoted, and wettability of the gradient ceramic particle / titanium alloy interface is remarkably enhanced; and on the other hand, based on good physical properties and the uniform dispersion strengthening effect of the in-situ synthesis multiphase nano ceramic particles, the friction and abrasion characteristics of the medical titanium alloy can be effectively improved, manufacturing of the high performance medical titanium alloy is achieved, and the medical high abrasion resistance titanium alloy has good clinical application prospects and economic value.

Owner:洋紫荆牙科器材(深圳)有限公司

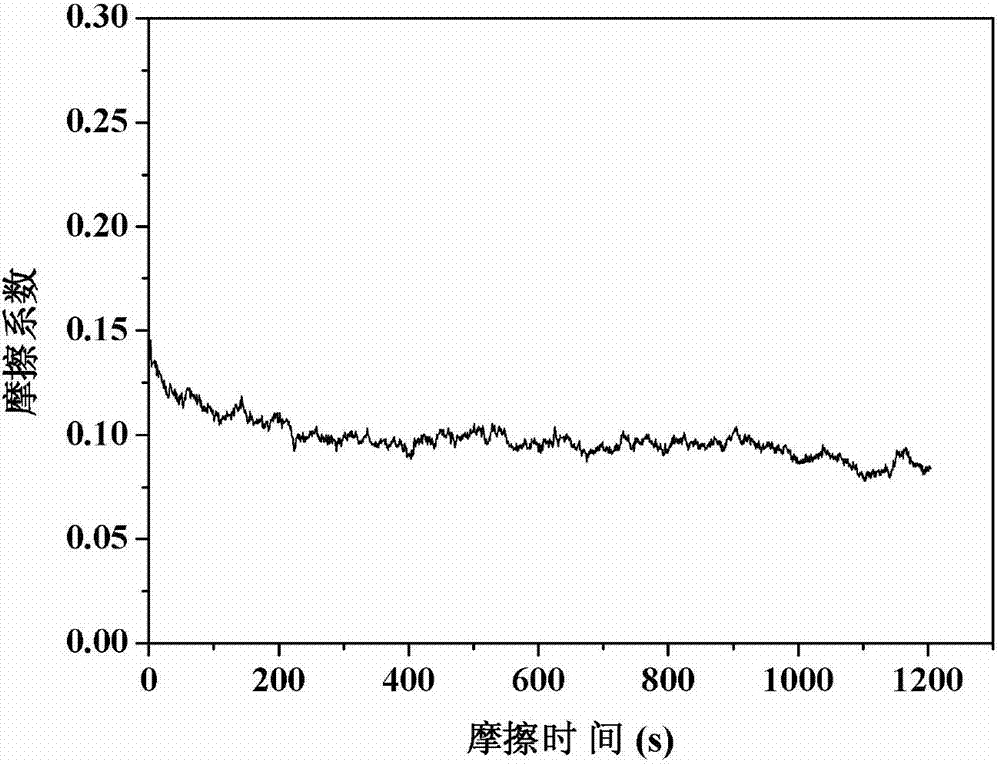

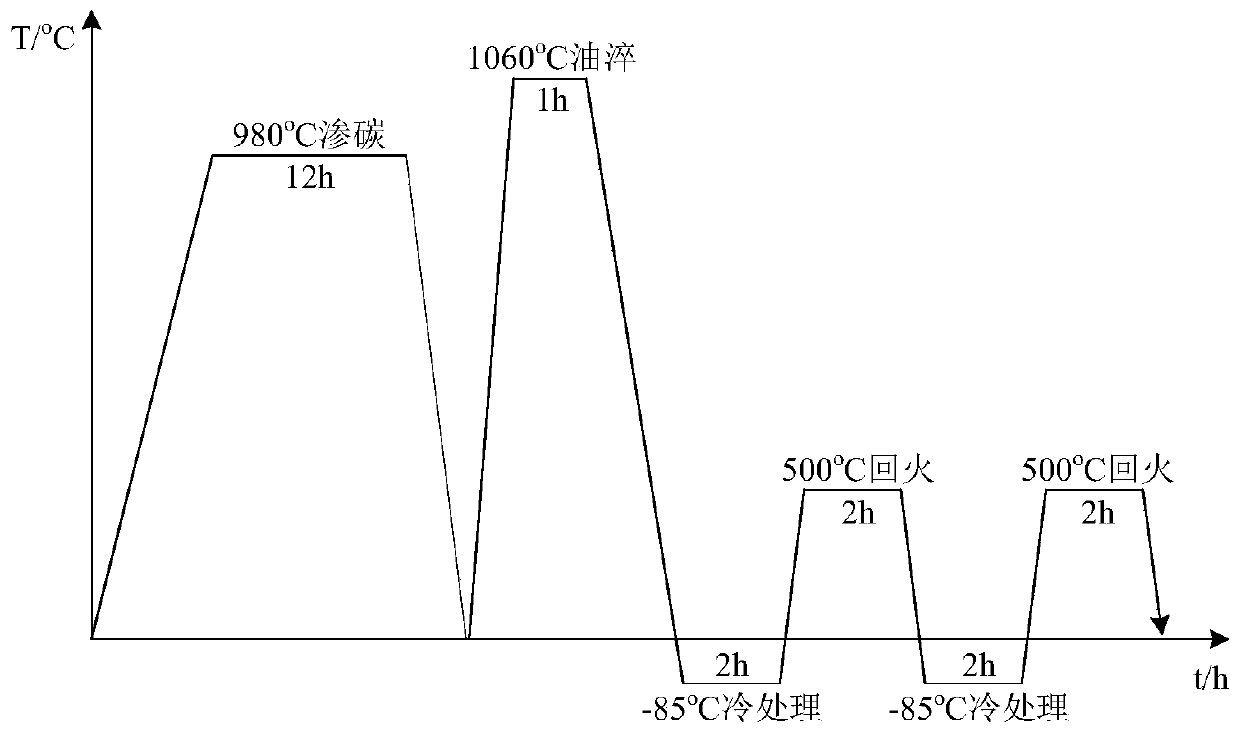

Low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel

ActiveCN109735794ASolve pollutionHigh fatigueSolid state diffusion coatingQuenchingPrepared Material

The invention relates to a low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel. The method comprises the treatment steps of low-pressure vacuum carbonizing, quenching, deep cooling and high-temperature tempering; and the steps can be repeatedly performed. The low-pressure vacuum carbonizing process uses a saturated value adjusting method for multi-section pulse carbonizing; a carbonizing agent adopts acetylene gas; the carbonizing temperature is 850-1050 DEG C; the carbonizing pressure is 100-2000 Pa; and the powerful seepage and dispersion circulating period is 20-70 times. The treatment method is safe, energy-saved and environment-friendly, can eliminate intergranular oxidation, realizes precise control of the seepage layer depth, and canguarantee excellent service performances of prepared materials above 400 DEG C.

Owner:NORTHEASTERN UNIV

Friction stir welding-braze welding composite welding method for dissimilar metal bonding structure

InactiveCN104923927AAvoid problems with brittle intermetallic compoundsIncrease widthWelding/soldering/cutting articlesWelding apparatusStress concentrationHardness

A friction stir welding-braze welding composite welding method for a dissimilar metal bonding structure is provided. The operation process of the method is as follows: before welding, a material with low hardness is placed on the upper layer, a material with high hardness is placed on the lower layer, and a soft solder with a low melting point, such as pure Zn or a Zn-matrix solder, is placed between two plates; a stirring head which rotates at a high speed is inserted into the metal in the upper layer, a stirring pin enters the metal in the lower layer, and the solder which is clamped between two types of metal is melted by stirring friction heat; and finally excess melted solder is extruded under the pressure action of a shaft shoulder, the purification of the interface is realized, diffusion bonding is formed, and the purpose of welding is achieved. According to the method, composite welding seams can be obtained; the effective bonding width of the bonding structure can be increased; stress concentration and the interface effect of the bonding interface are reduced; and the service performance of joints is improved.

Owner:NANCHANG HANGKONG UNIVERSITY

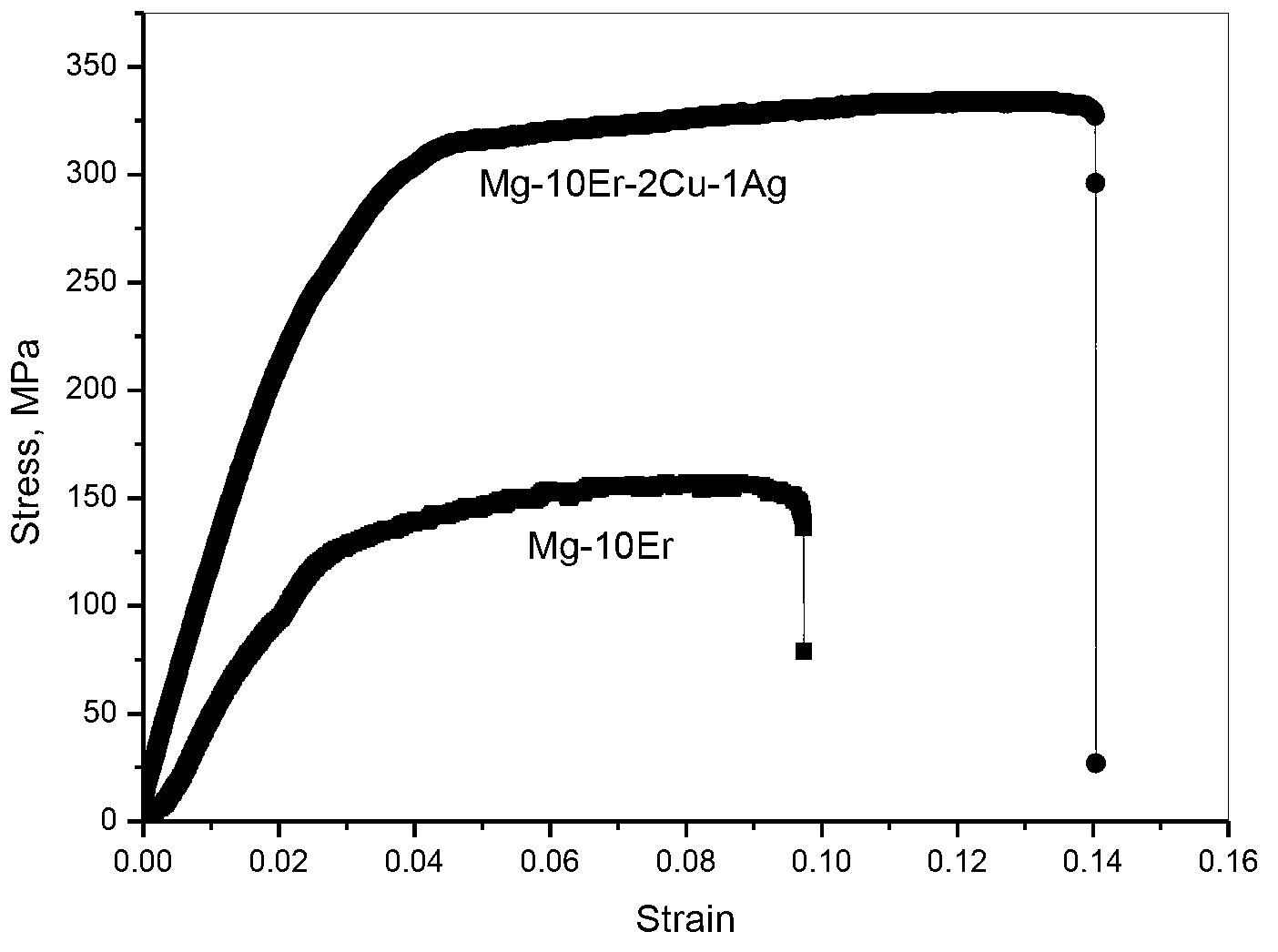

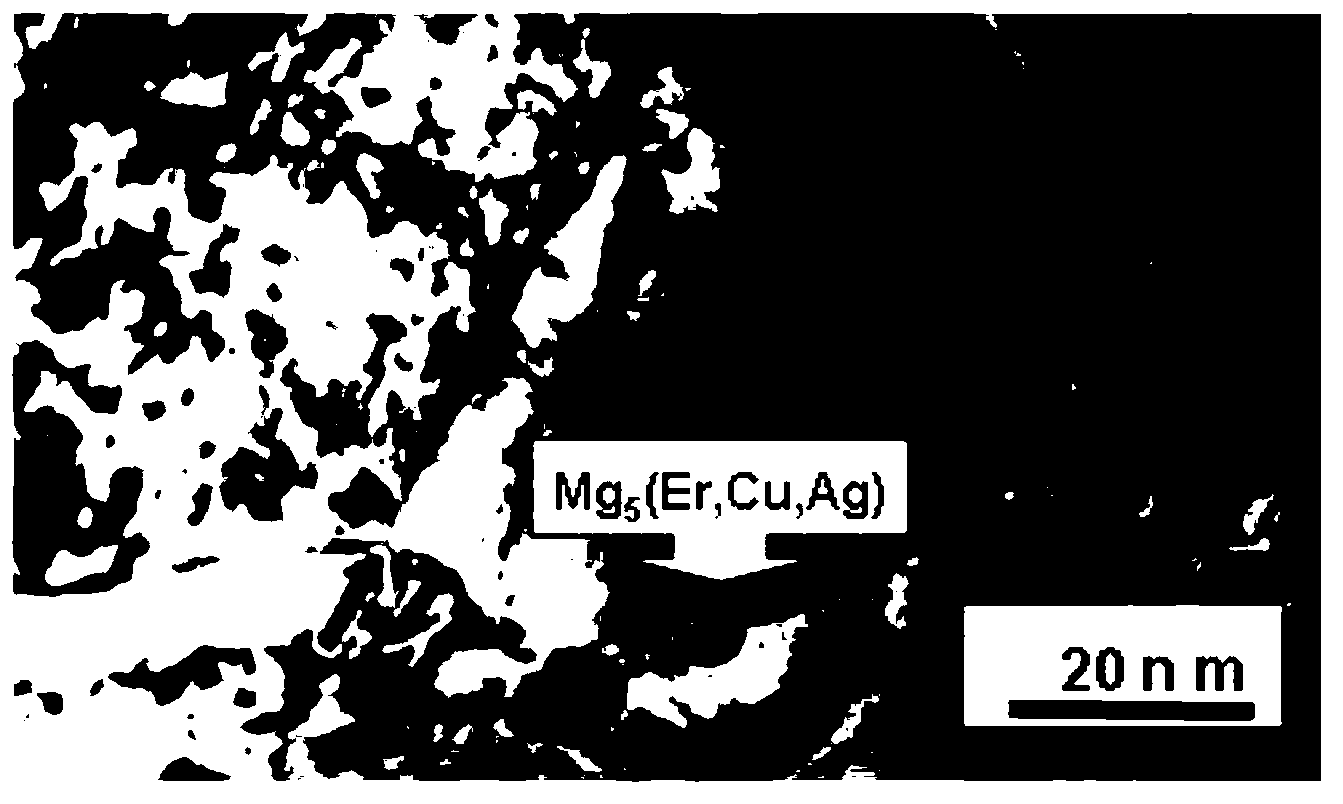

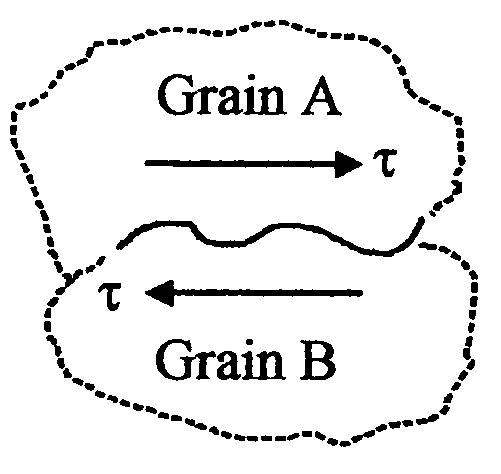

High-performance magnesium base alloy material and method for preparing same

InactiveCN102796928AGood tensile mechanical propertiesImprove thermal stabilityRoom temperatureThermal stability

The invention discloses a high-performance magnesium base alloy material and a method for preparing the high-performance magnesium base alloy material, which are designed for achieving the purpose that a great quantity of small reinforcements which have good thermal stability and are generated when the form of magnesium base alloy is varied and small recrystallization macrostructures which are produced through the small reinforcements are obtained for improving the shear strength of the magnesium base alloy. Mg alloy is taken as a basic material, Er, Cu and Ag which improve the non-crystallizing forming capability of the Mg alloy are selected as alloying elements, and common casting and hot extrusion methods are selected for preparing the alloy material. Because negative formation heat is generated among the elements and the atomic radiuses are more different from each other, a great quantity of interatomic solute clusters are firstly formed during the extrusion process, and furthermore, small intermetallic compound particles with stable mechanical property at high temperature can be separated out on the basis. Moreover, the macrostructure of the alloy is also thinned. The alloy can have very high strength and good plasticity within the range of room temperature to 300 DEG C.

Owner:SHENYANG AEROSPACE UNIVERSITY

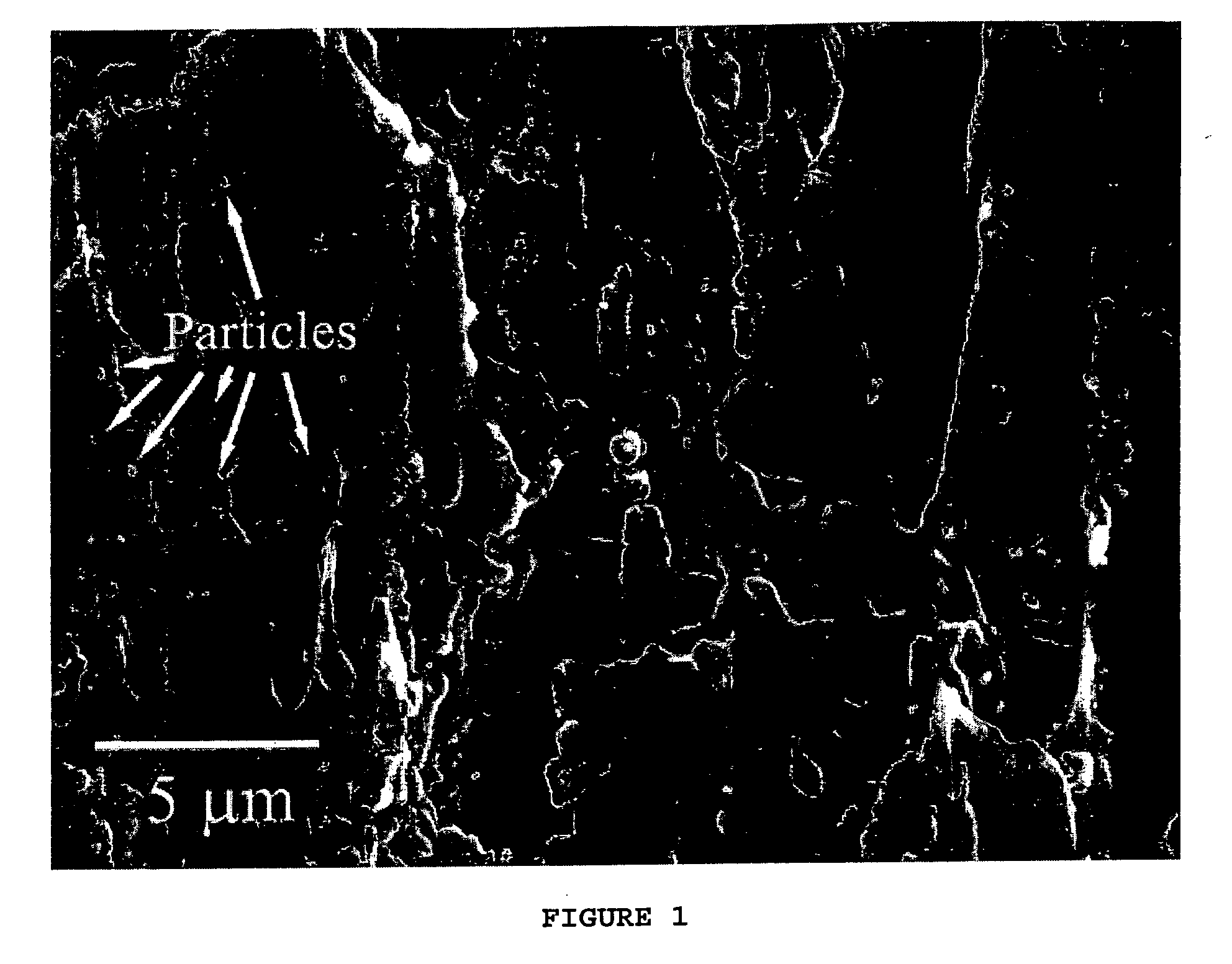

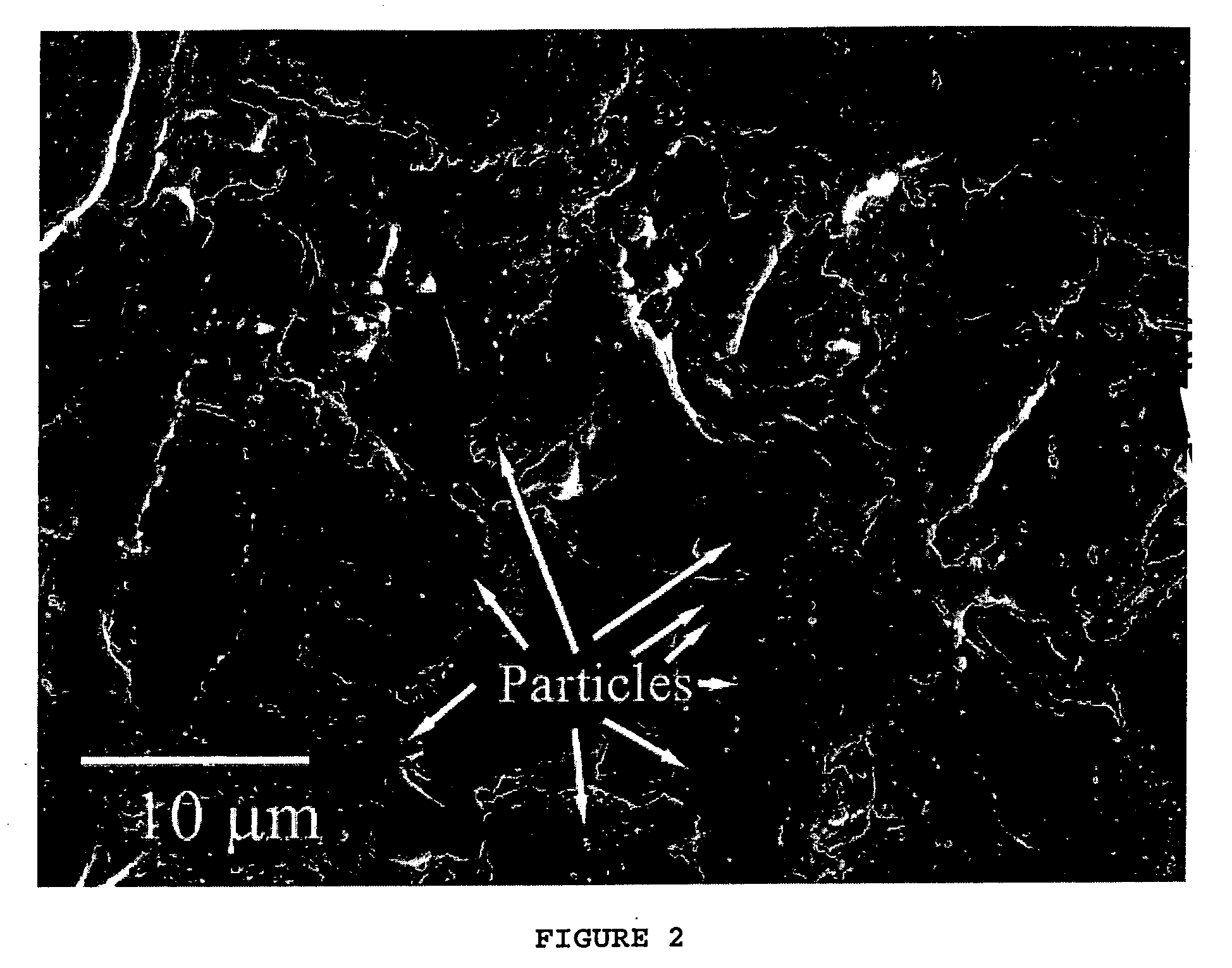

Composite metal matrix castings and solder compositions, and methods

InactiveUS20050034791A1Improve service performancePrinted circuit assemblingPrinted circuit aspectsComposite solderMaterials science

A composite composition and methods for making the composition, providing a metal matrix and dispersed inorganic oxide particles with a bound organofunctional group on a surface of the particles are described. A composite solder composition and methods for making and using the composition, providing a metal matrix and dispersed inorganic oxide particles with a bound organofunctional group on a surface of the particles are described. An apparatus comprising this composite solder composition is also described. In particular, organofunctional POSS, and POS, particles are described. The compositions provide cast metals and solders.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Large-file multipoint distribution system

ActiveCN101977236ARelieve work stressImprove service performanceTransmissionDistribution systemClient-side

Owner:BEIJING 21VIANET DATA CENT

Coating packaged chamber parts for semiconductor plasma apparatus

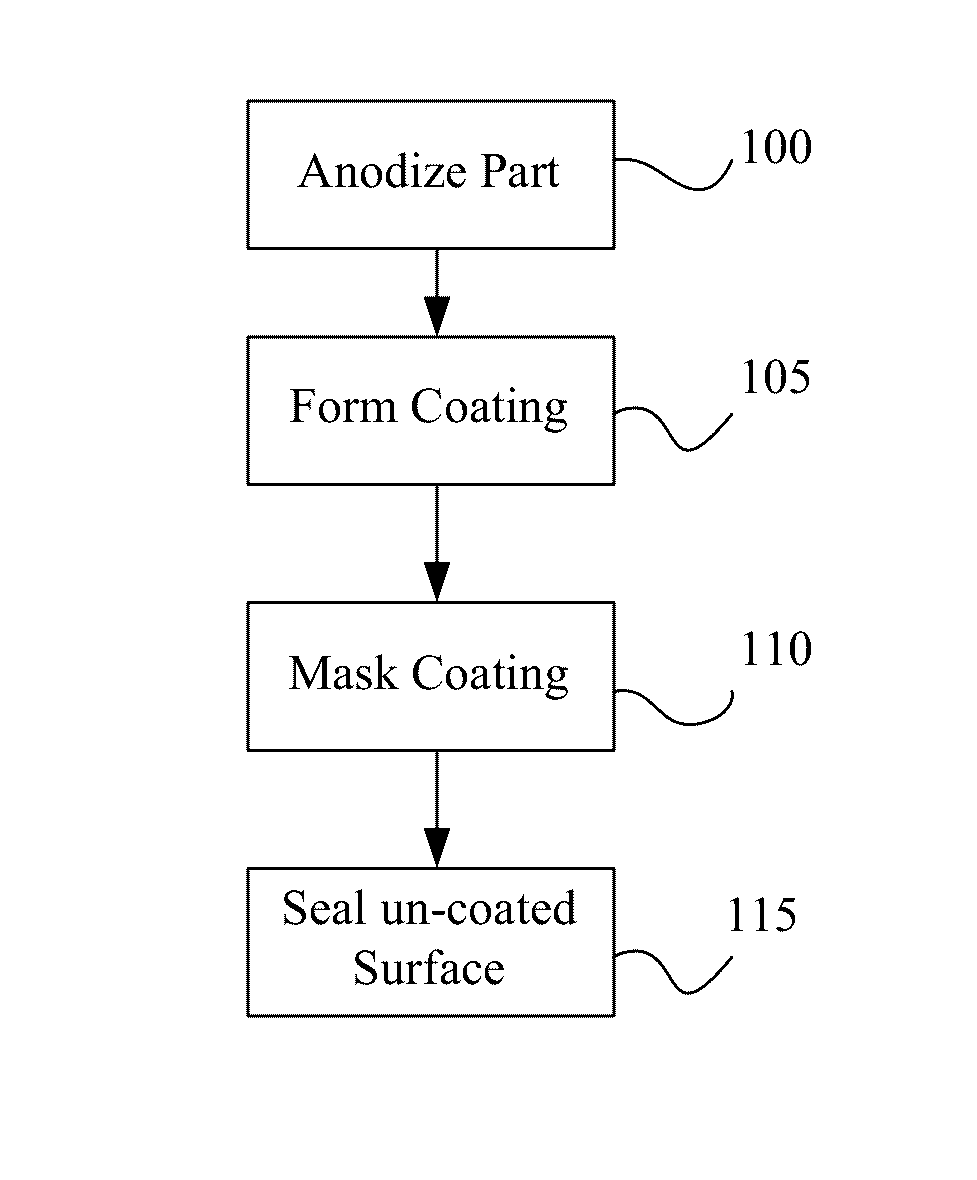

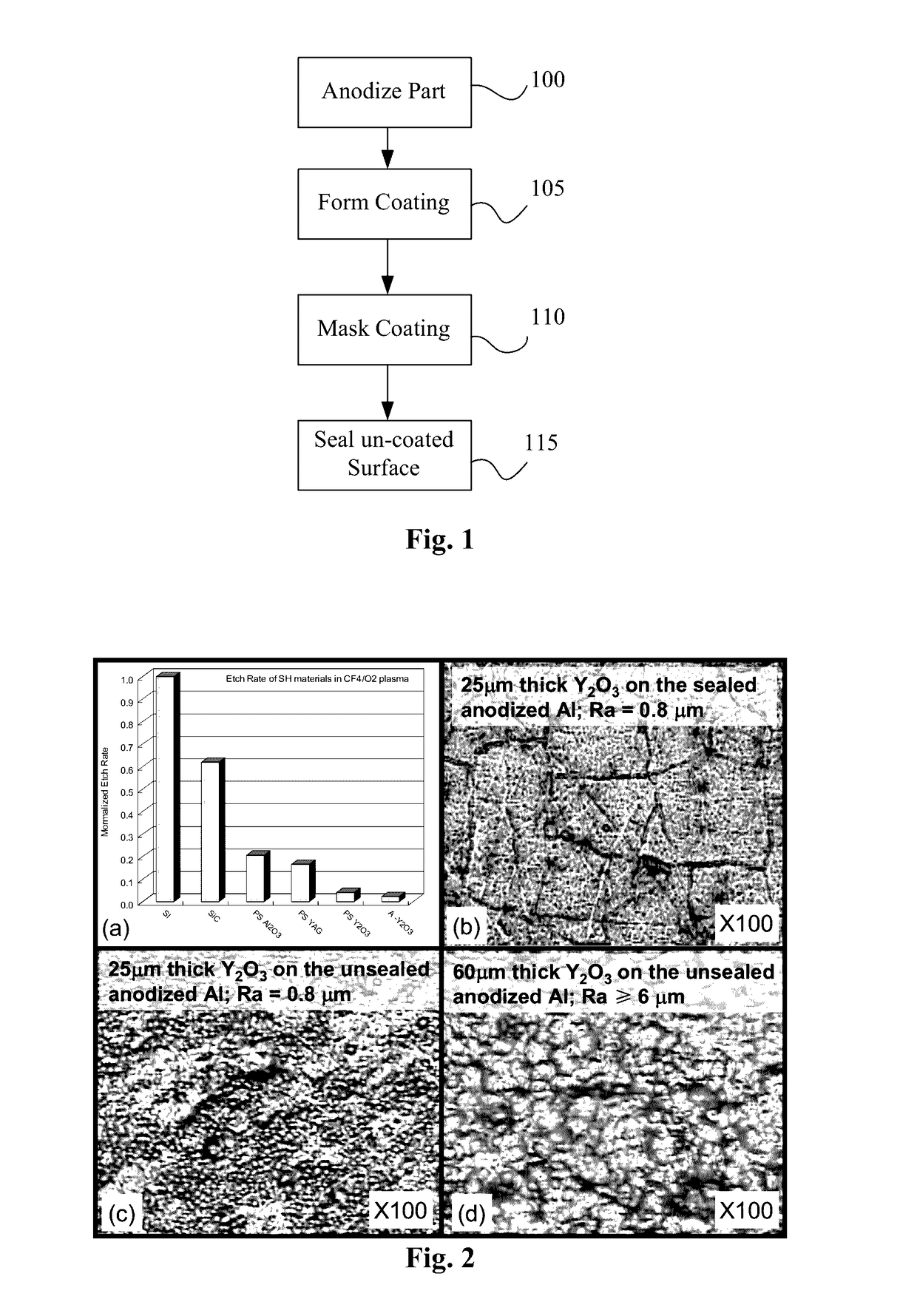

ActiveUS9617633B2Improve service performanceImprove processing qualityAnodisationVacuum evaporation coatingSemiconductor plasmaParticle generation

An advanced coating for parts used in plasma processing chamber. The advanced coating is formed over an anodized surface that has not been sealed. After the coating is formed, the coated area is masked, and the remaining anodized surface is sealed. The porous and rough structure of the anodized but un-sealed aluminum enhances adhesion of the coating. However, to prevent particle generation, the exposed anodized surface is sealed after formation of the coating. The coating can be of yttria, formed by plasma enhanced atomic deposition techniques which results in a dense and smooth coating.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

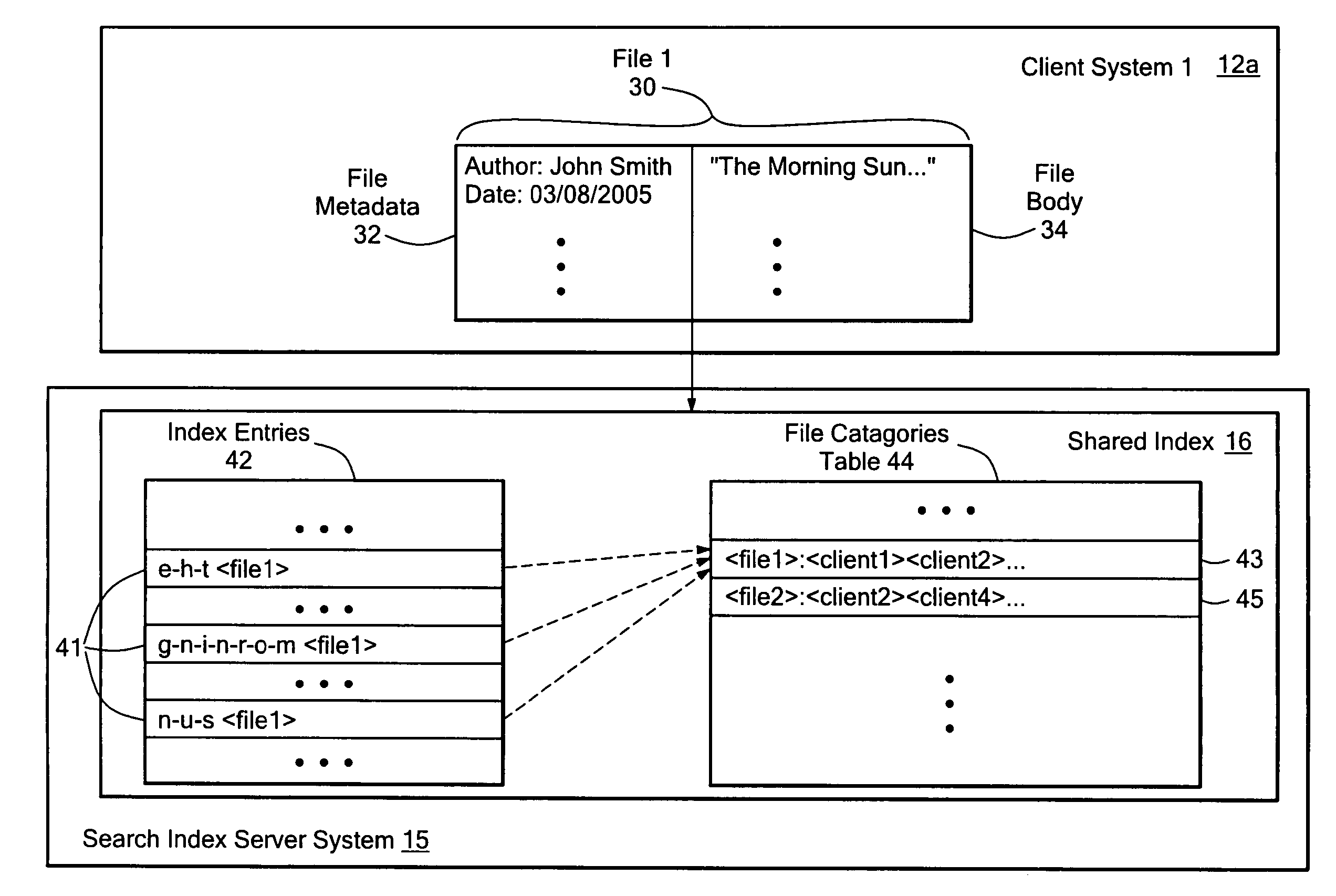

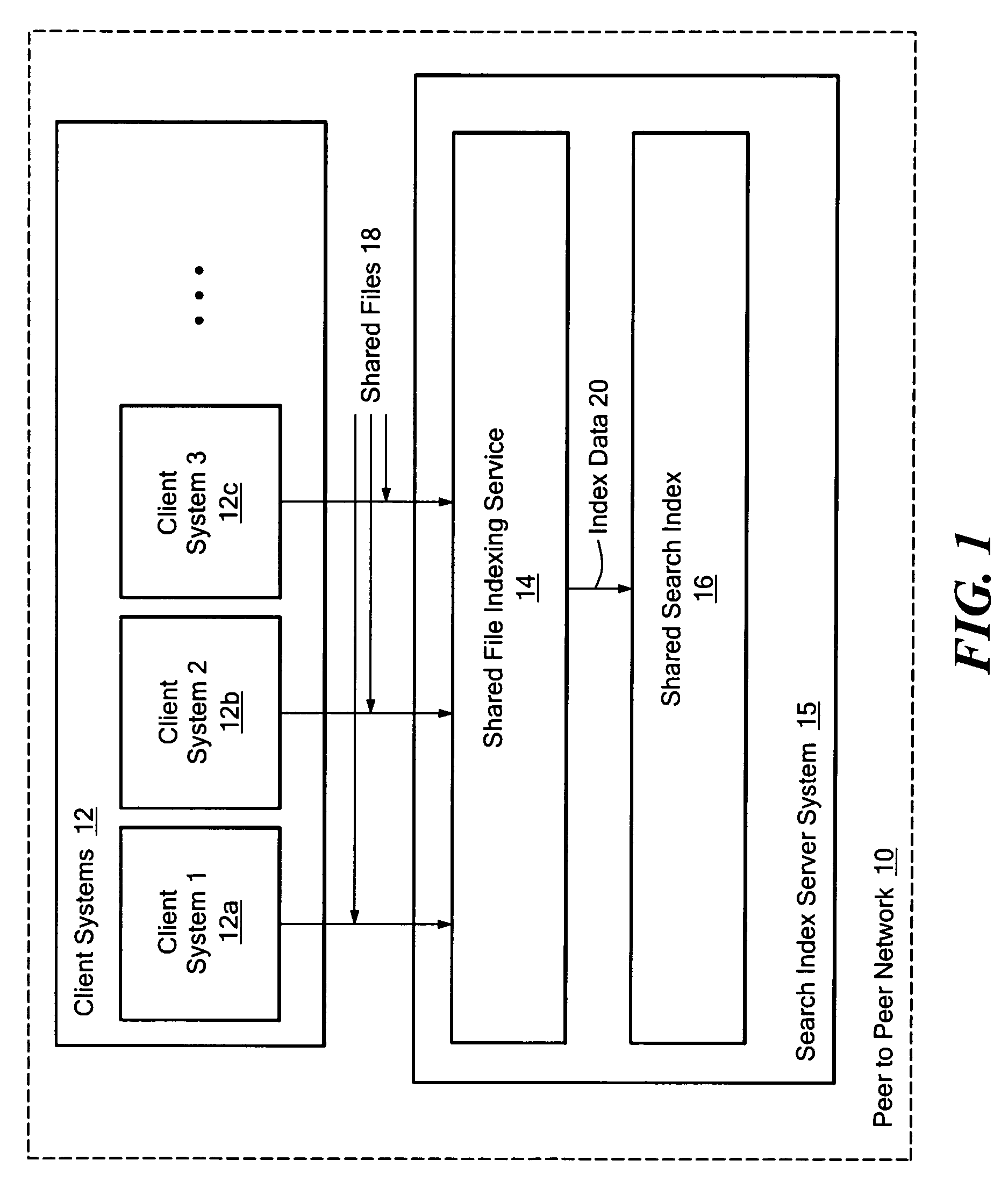

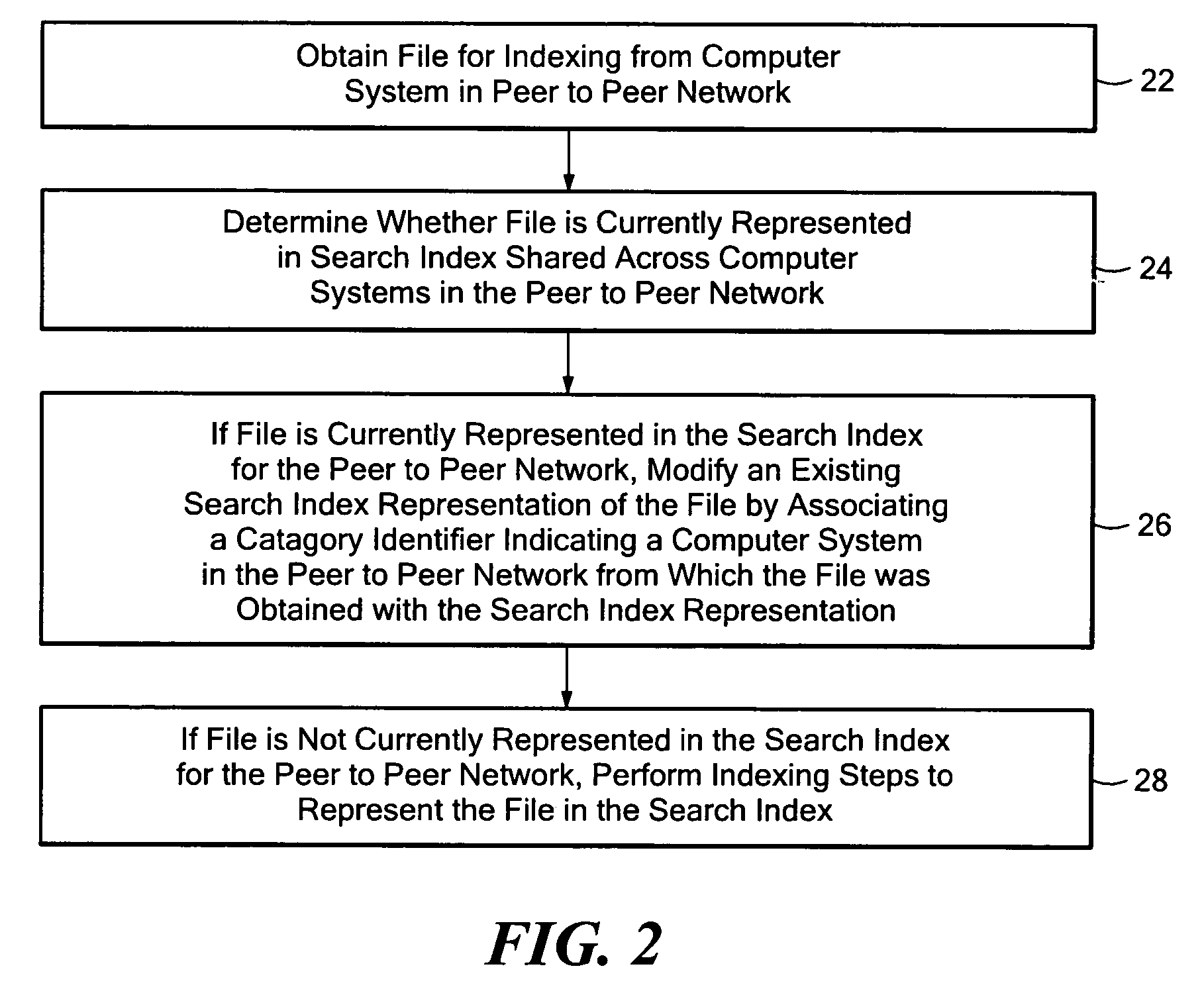

Method and system for providing a shared search index in a peer to peer network

InactiveUS20060248067A1Eliminate needImprove service performanceDigital data processing detailsFile access structuresIndexing ServiceMultiple category

A method and system for sharing search index entries across multiple computer systems organized in a peer to peer network, in which unique content is indexed only once, even though the content may be physically duplicated in multiple computer systems in the peer to peer network. When files are obtained by a shared indexing service, and a determination is made as to whether the received files are duplicates with regard to previously indexed files. If a file is determined to be a duplicate, the index representation of the previously indexed copy of the file is modified to indicate that the file is also associated with another computer system in the peer to peer network. If a file is not a duplicate of a previously indexed file, the file is indexed to support future searches. The index representation of a file includes category identifiers associating one or more computer systems with the file. When a file is indexed, one or more category identifiers are generated and stored in association with that file. The category identifiers for an indexed file may represent host computer systems on which copies of the file are stored. The category identifiers enable location specific searching by computer systems in a peer to peer network sharing a common search index. A software category filter may be provided to process search results from the shared search index, so that only files associated with certain categories are returned.

Owner:IBM CORP

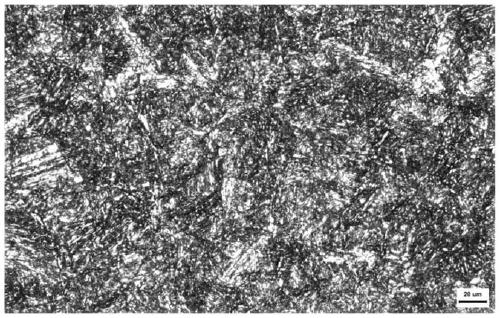

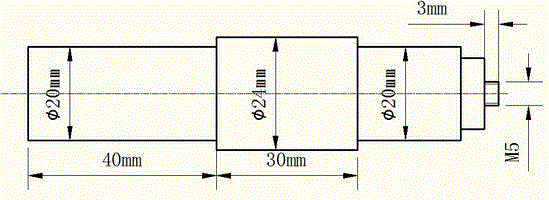

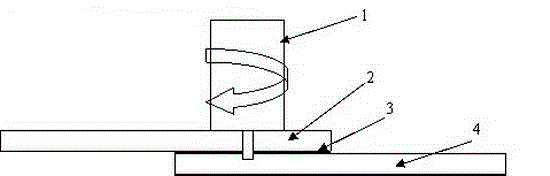

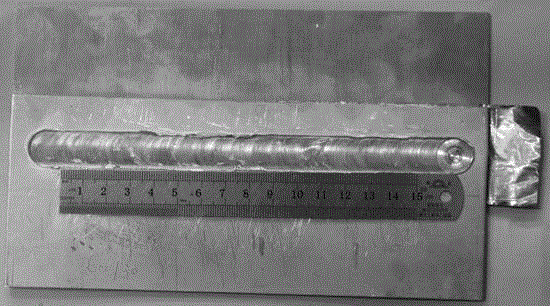

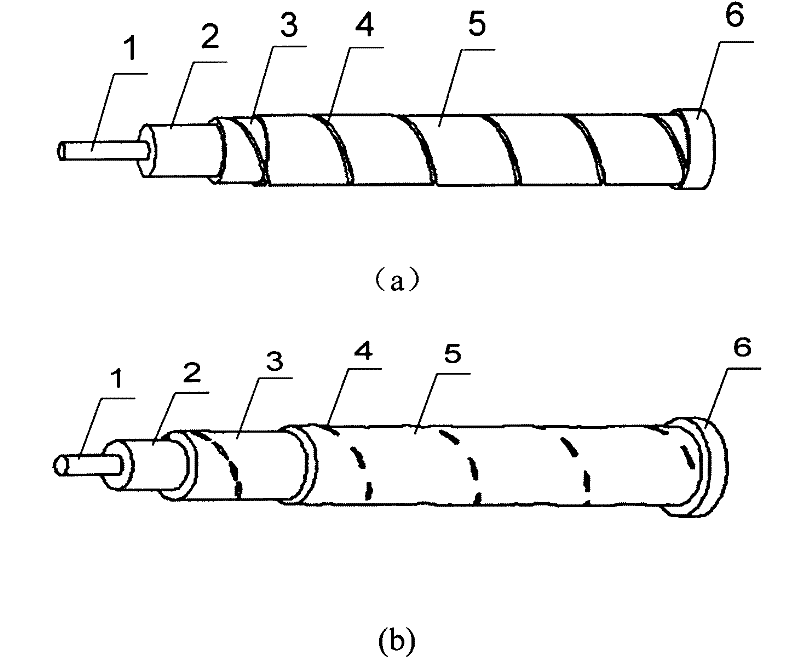

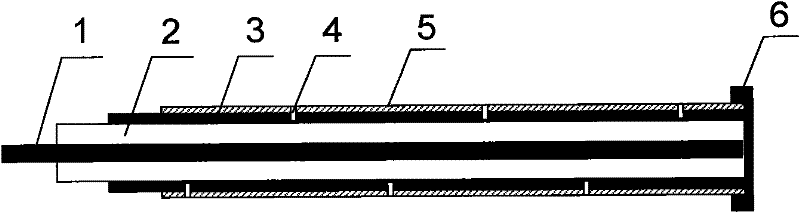

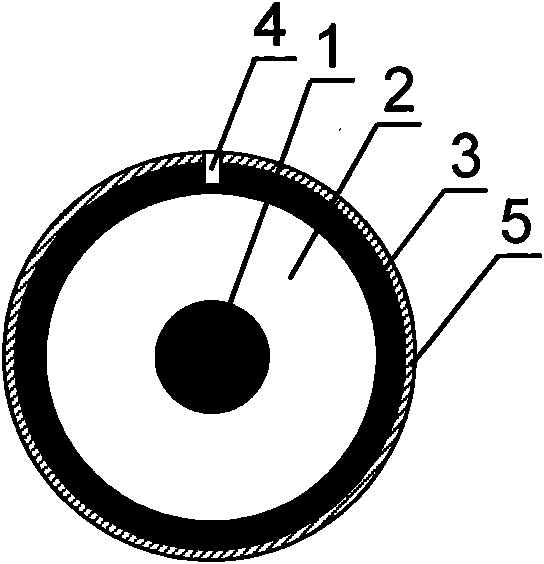

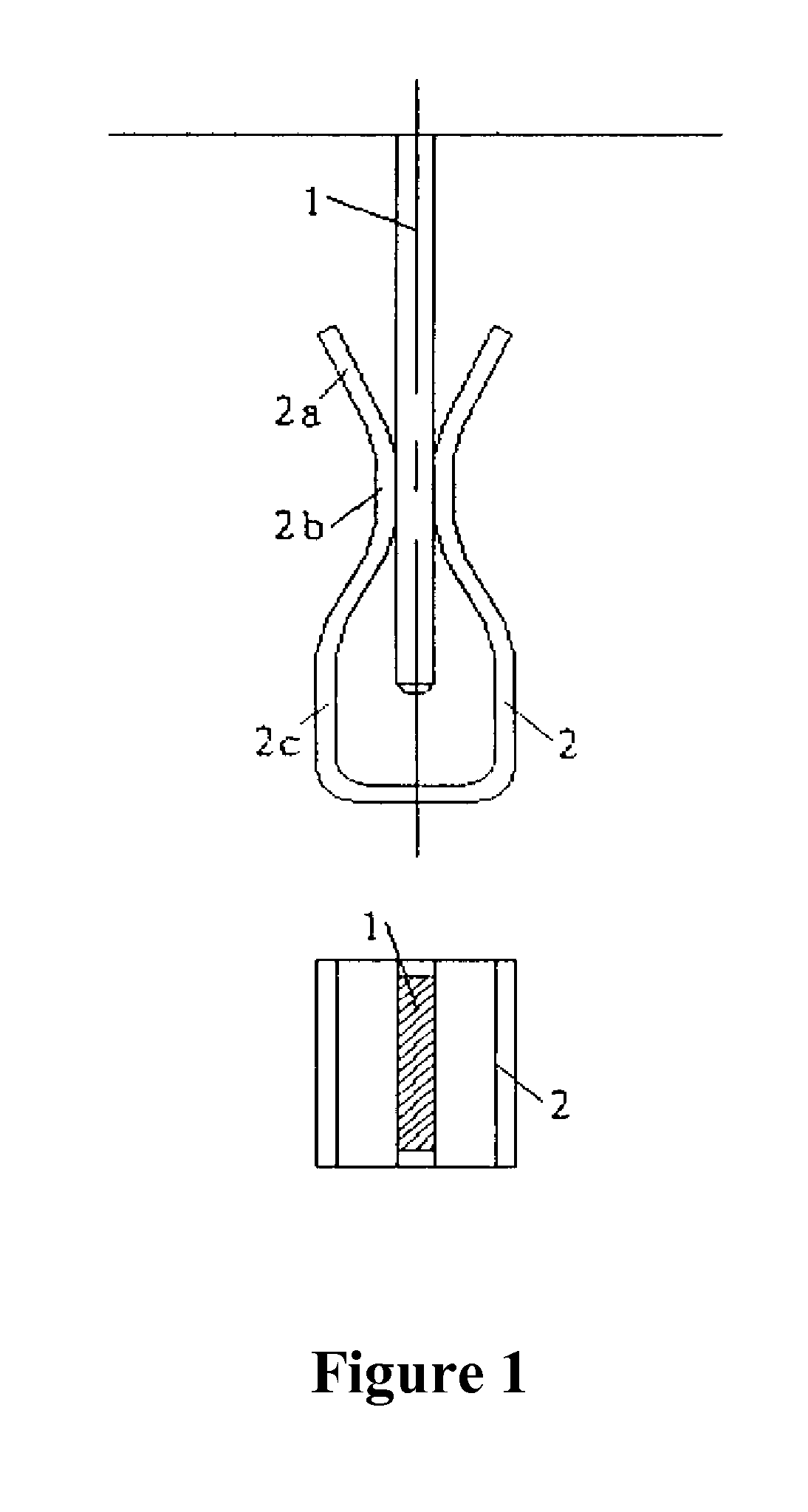

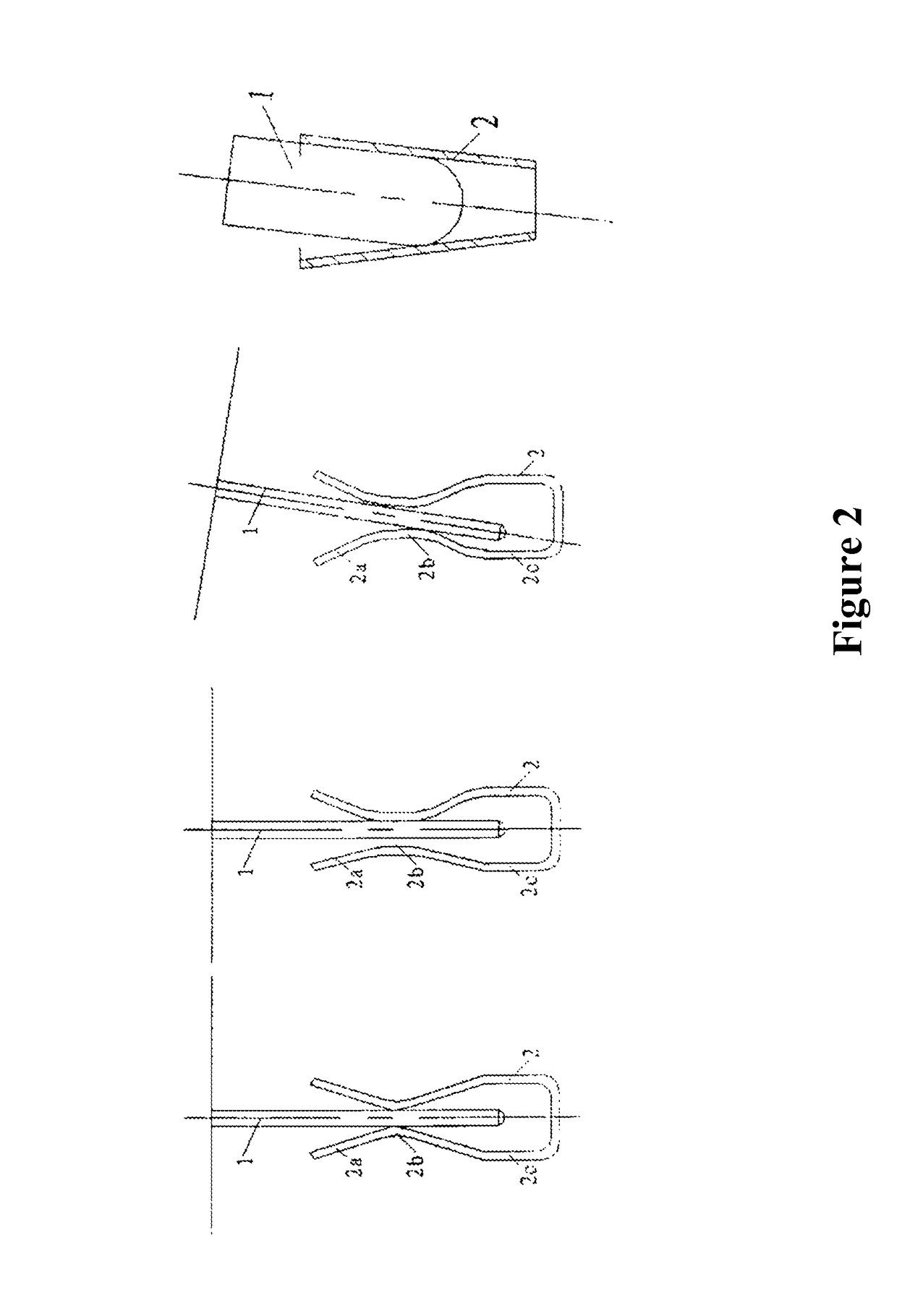

Distributed crack sensor based on coaxial cable

InactiveCN102175723AEliminate winding bad contactsImprove service performanceMaterial impedanceElasticity measurementTime-domain reflectometerTest sensitivity

The invention relates to a distributed crack sensor based on a coaxial cable, belonging to the technical field of an engineering structure safety monitoring. The distributed crack sensor provided by the invention is characterized in that a metal conductor core on the inner layer, an insulating layer in the middle, the metal conductor layer provided with a weak link (such as sunk weak threads, dot mode weak threads and the like) and a surface anticorrosive material are sequentially arranged from inside to outside; the weak threads are machined by applying the rotation advancing traction to the coaxial cable and simultaneously utilizing a drill to carve grooves on an outer conductor layer or utilizing a puncher to continuously punch on the outer conductor layer; the depth and pitch of the weak threads select different numerical values according to the requirements of the structure on the test sensitivity and the space resolution; and when cracks are monitored, the attenuation signals which are generated because of the crack modulation of the coaxial cable are obtained through an electric time domain reflectometer to determine the occurrence position and expansion degree of the cracks. The sensor provided by the invention has the beneficial effects that the sensor is a coaxial cable distributed crack sensor provided with weak threads, the structure is simple, the durability is good, the crack monitoring scale is large, and a structural damage memory function is achieved.

Owner:DALIAN UNIV OF TECH

Performance enhancement of coating packaged esc for semiconductor apparatus

ActiveUS20140118880A1Improve service functionsEasily damagedWave amplification devicesSemiconductor/solid-state device manufacturingPerformance enhancementGas phase

An advanced coating for electrostatic chuck used in plasma processing chamber is provided. The advanced coating is formed using plasma enhanced physical vapor deposition. The coating is generally of Y2O3 / Al2O3, although other material combinations can be used. Also, a multi-layered coating can be formed, such that an intermediate coating layer can be formed using standard plasma spray, and a top coating can be formed using PEPVD. The entire ESC assembly can be “packaged” by the coating.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Heat treatment method for increasing the depth of hardening layer in a steel rail and steel rail obtained with the method

ActiveUS20160010188A1Enhance layeringImprove service performanceFurnace typesHeat treatment furnacesSurface layerFree cooling

The present invention relates to a heat treatment method for increasing the depth of hardening layer in a steel rail, and belongs to the field of steel rail production process. The technical problem to be solved in the present invention is to provide a heat treatment method for increasing the depth of hardening layer in a steel rail and a steel rail obtained with the method. The method comprises the following steps: cooling a finished rolling steel rail by natural cooling, till the temperature at the center of rail head surface is 660˜730° C.; cooling the steel rail by accelerated cooling at 1.5˜3.5° C. / s cooling rate, till the temperature at the center of rail head surface is 500˜550° C.; increasing the cooling rate by 1.0˜2.0° C. / s and further cooling down the steel rail, till the temperature at the center of rail head surface is 450° C. or lower; then, stopping the accelerated cooling, and cooling down the steel rail by air cooling to room temperature. With the heat treatment method disclosed in the present invention, a deep-hardening layer thicker than 25 mm can be obtained in the rail head part, the portion within 25 mm depth below the surface layer of rail head has hardness equivalent to the hardness of the surface layer of rail head, and the rail head is in a pearlite structure across its cross section. Thus, the service performance of the steel rail against the wearing incurred by the contact between the train wheels and the steel rails can be improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

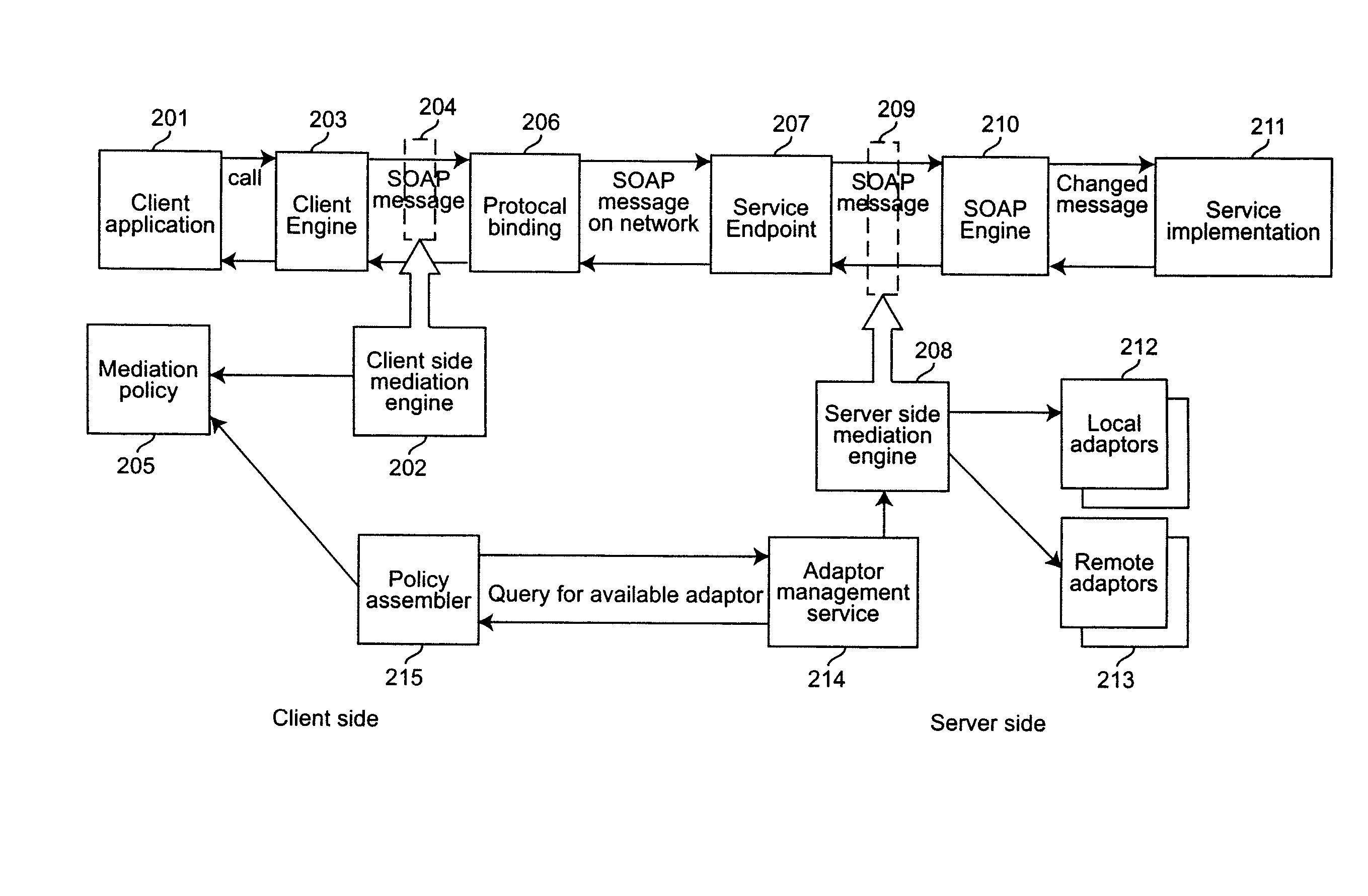

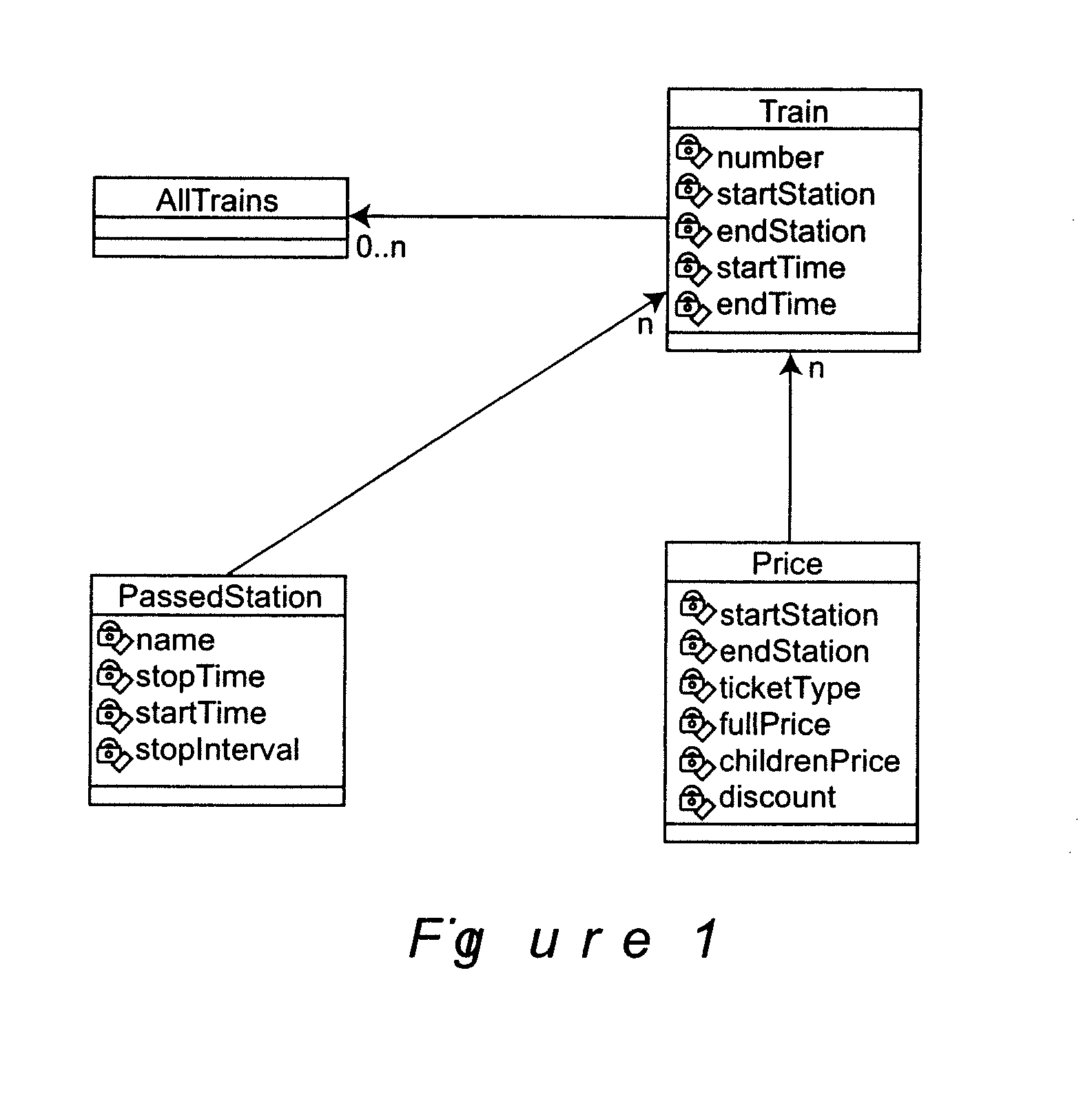

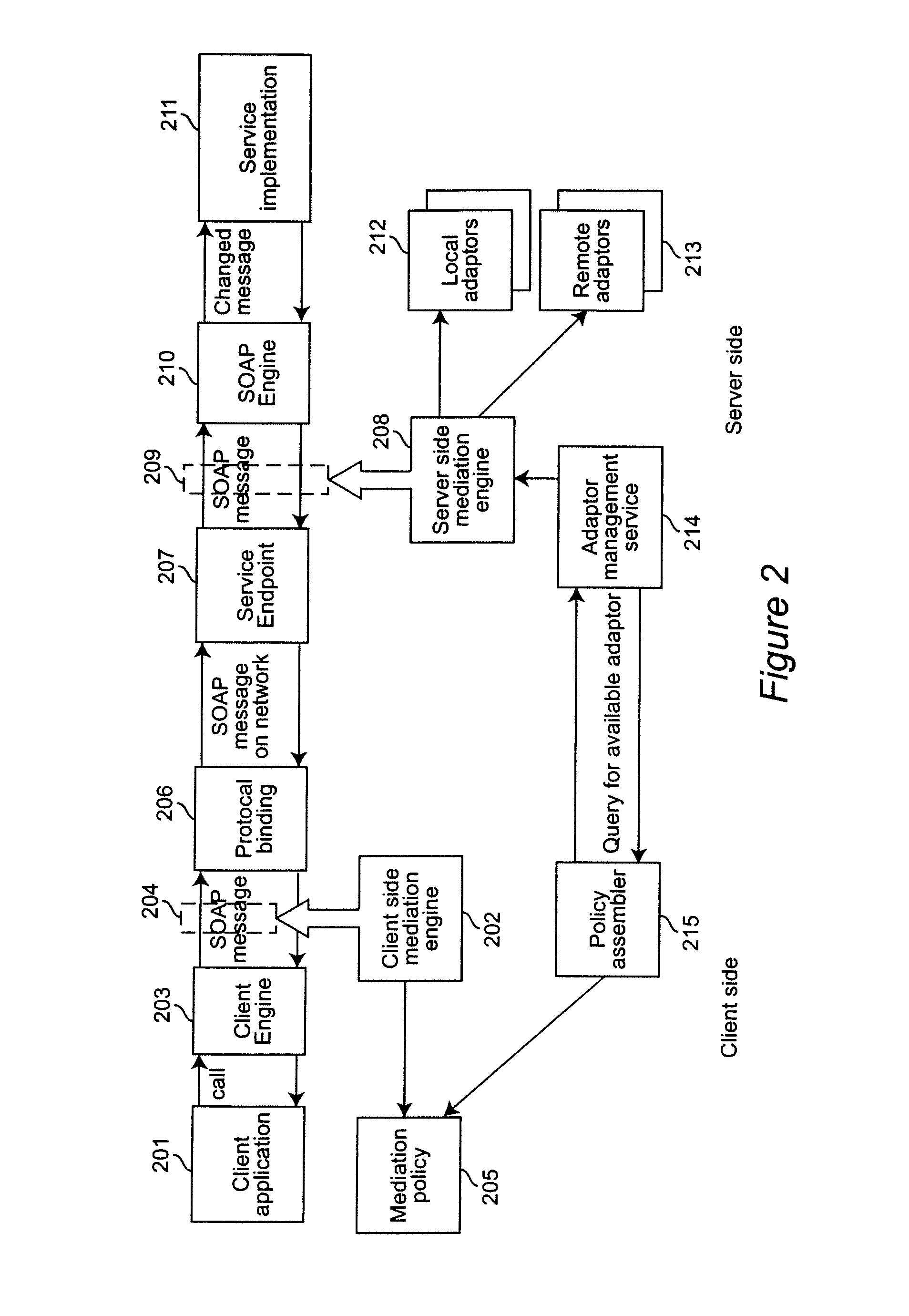

Method and apparatus for metadata driven web service mediation

InactiveUS20080168150A1Improve performanceReduce processing timeMultiple digital computer combinationsResourcesClient-sideSimple object

A mechanism lets a service consumer add mediation metadata in a Simple Object Access Protocol (SOAP) message and lets a service provider perform server side mediation based on the pre-defined mediation metadata. A client side mediation engine is plugged into a client SOAP engine. When the client side mediation engine receives a request message from the client SOAP engine metadata is attached to a message header of a SOAP message and returned to the client SOAP engine. A server side mediation engine is plugged the server side mediation engine receives a SOAP message from the server SOAP engine, metadata is mapped with an appropriate adaptor and returned to the server SOAP engine.

Owner:SERVICENOW INC +1

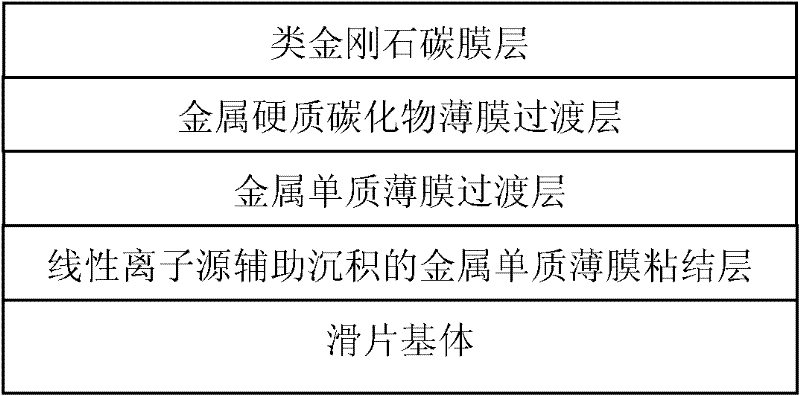

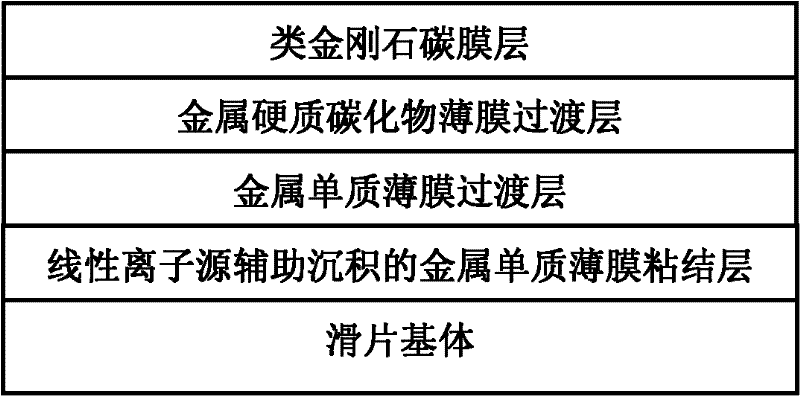

Film for raising abrasion resistance of compressor slide plate and preparation method thereof

ActiveCN102225640AHigh hardnessGood compatibilityVacuum evaporation coatingSputtering coatingCarbon layerDiamond-like carbon

The invention discloses a film for raising the abrasion resistance of a compressor slide plate and a preparation method thereof. The film provided by the invention is positioned on the surface of the slide plate matrix and has a multilayer structure, wherein the first layer, close to the surface of the slide plate matrix, is a linear ion source auxiliary depositional metal simple substance adhesive layer; the second layer is a metal simple substance transition layer; the third layer is a metal hard carbide transition layer; and the fourth layer is a diamond-like carbon layer. In comparison with the prior art, by the optimization design of the film structure on the surface of the slide plate matrix and the optimization of the preparation technology, the produced film provided by the invention has advantages of high hardness, low friction coefficient, high wear resistance and corrosion resistance, smooth surface, uniform thickness and high adhesion strength, and can be used to raise the abrasion resistance of the compressor slide plate so as to enable the slide plate matrix to be used in the environments of R410A or a higher-level novel refrigerant and a lubricant and prolong the service life of the slide plate matrix.

Owner:NINGBO YONGWEI GROUP

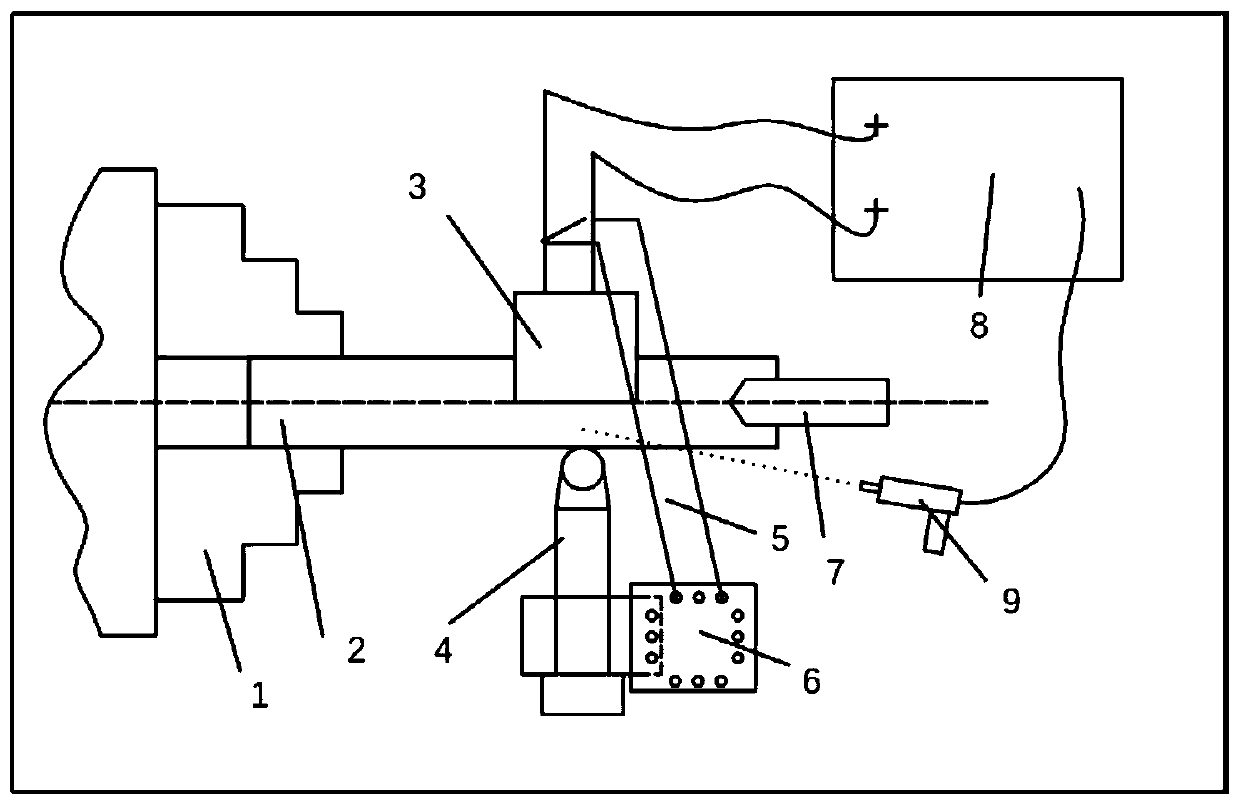

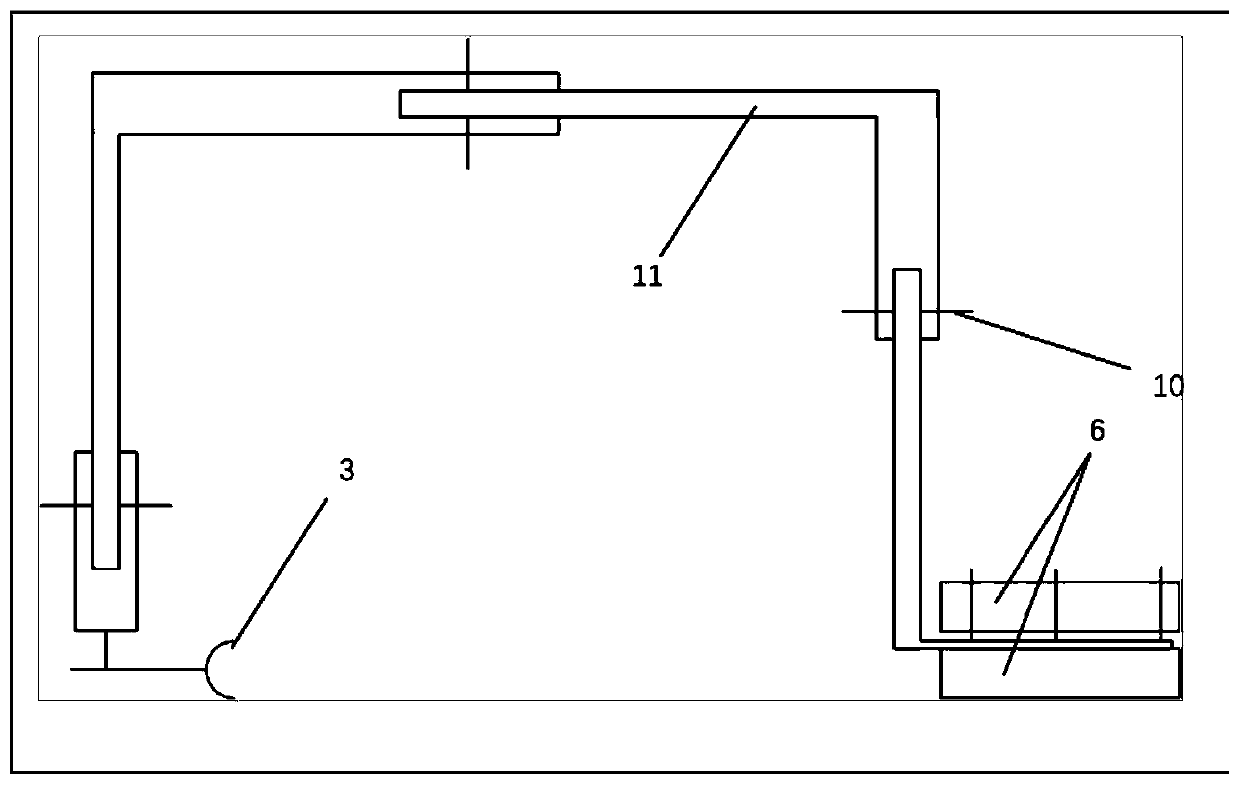

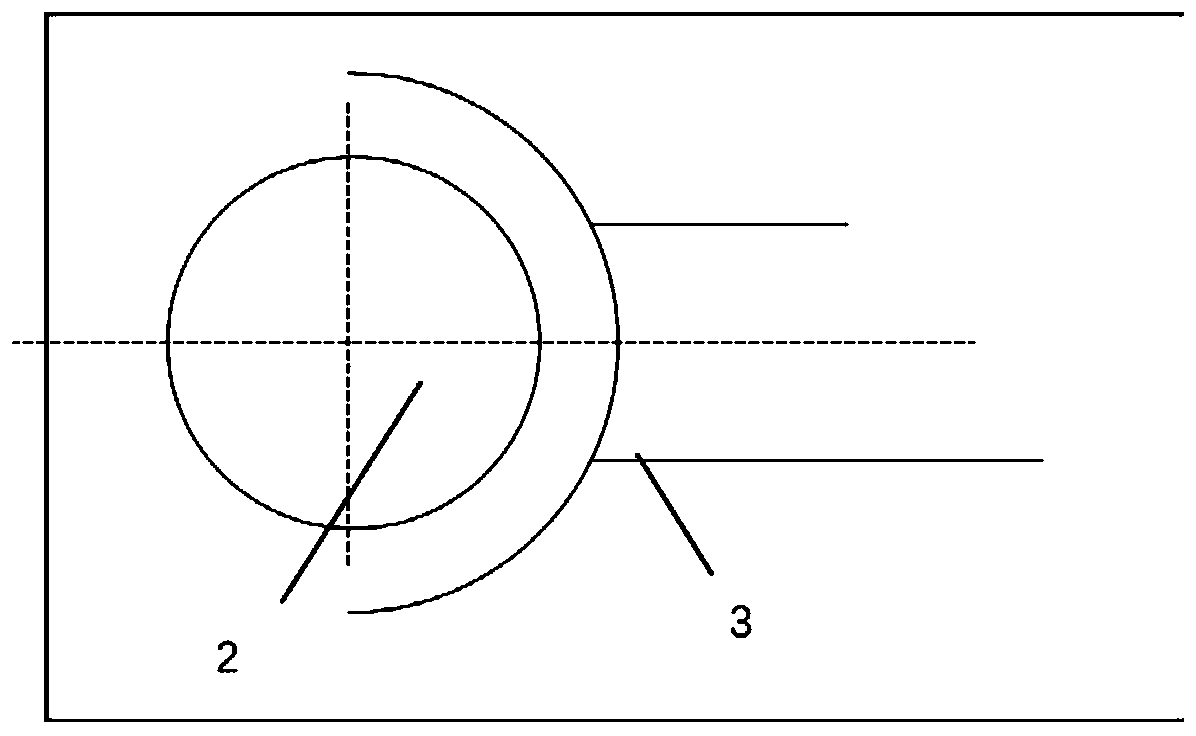

Induction heating auxiliary surface ultrasonic rolling device and method

InactiveCN111531322AImprove versatilitySimple structureMetal working apparatusEngineeringInfrared temperature measurement

The invention discloses an induction heating auxiliary surface ultrasonic rolling device and method. The device comprises a lathe chuck, a running center and a lathe cutter holder, the surface ultrasonic rolling device further comprises an induction coil, a movable arm, an induction power source and an infrared temperature measuring gun, one end of the movable arm is used for mounting of the induction coil, the other end of the movable arm is fixed to the lathe cutter holder, the surface ultrasonic rolling device is fixed to the lathe cutter holder, the induction heating power source is turnedon, meanwhile, a lathe is started, a part rotates, a part in the induction coil work area is heated to the high temperature, in the whole process, the temperature is measured through the infrared temperature measuring gun, when a sample is heated to the needed temperature, the part is subjected to surface ultrasonic rolling machining, through induction heating, the part deforming resistance is reduced, the surface ultrasonic rolling machining effect is better, the device is simple in structure, convenient to use, economic and environment-friendly, and the device can be used for machining shaft parts with high machining hardness and poor surface quality.

Owner:SOUTH CHINA UNIV OF TECH +1

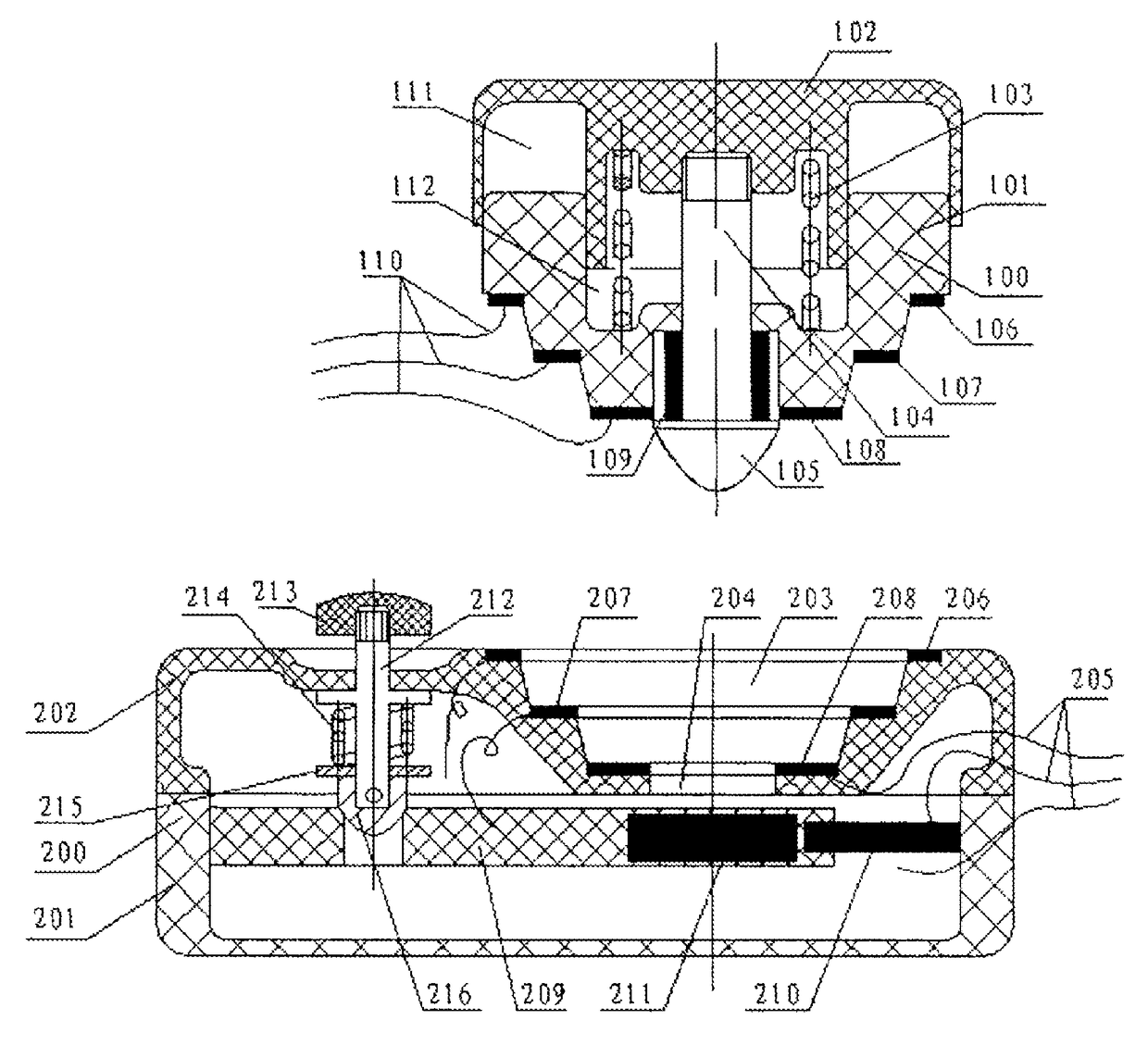

Surface contact plug and socket

ActiveUS9685742B2Low costImprove conductivityEngagement/disengagement of coupling partsCoupling contact membersContact electrificationEngineering

The present invention relates to the technical field of plugs and sockets for electrical appliances. Disclosed are a surface contact plug and socket, comprising a matching plug and socket; a plug contact piece connected with a plug electric wire is arranged on the lower surface of the plug; and a socket contact piece connected with a socket electric wire is arranged on the upper surface of the socket; when the plug is inserted into the socket, the plug contact piece vertically or obliquely meets the socket contact piece to cause surface contact electrification. The surface contact plug and socket of the present invention employ surface contact between contact pieces, enlarge the contact area and improve current transmission capacity since the plug and socket are of the same size, and therefore the contact is always reliable, and the more the plug and the socket are used, the more reliable the contact is.

Owner:FIRST ELECTRIC ING CHONGQING

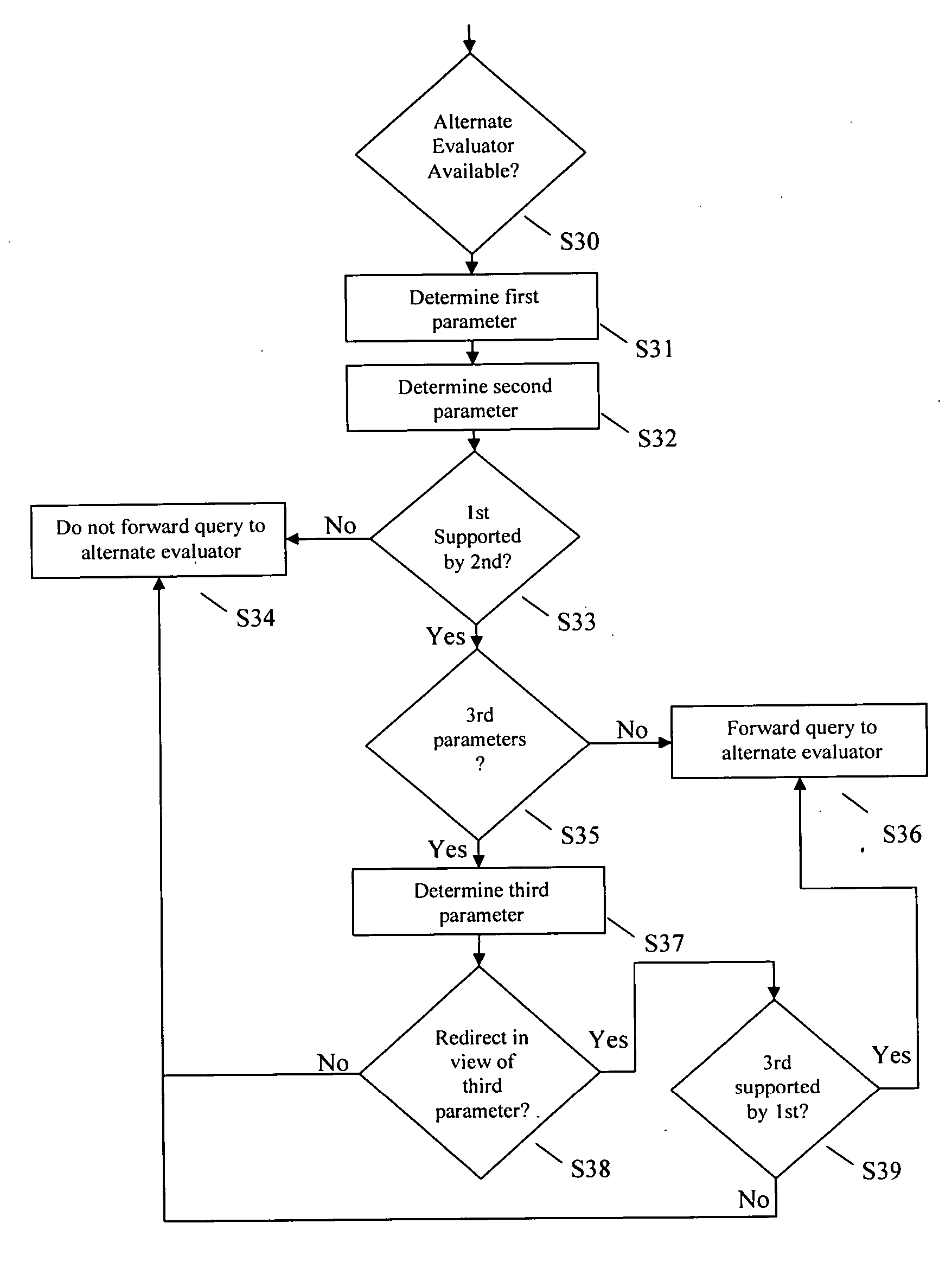

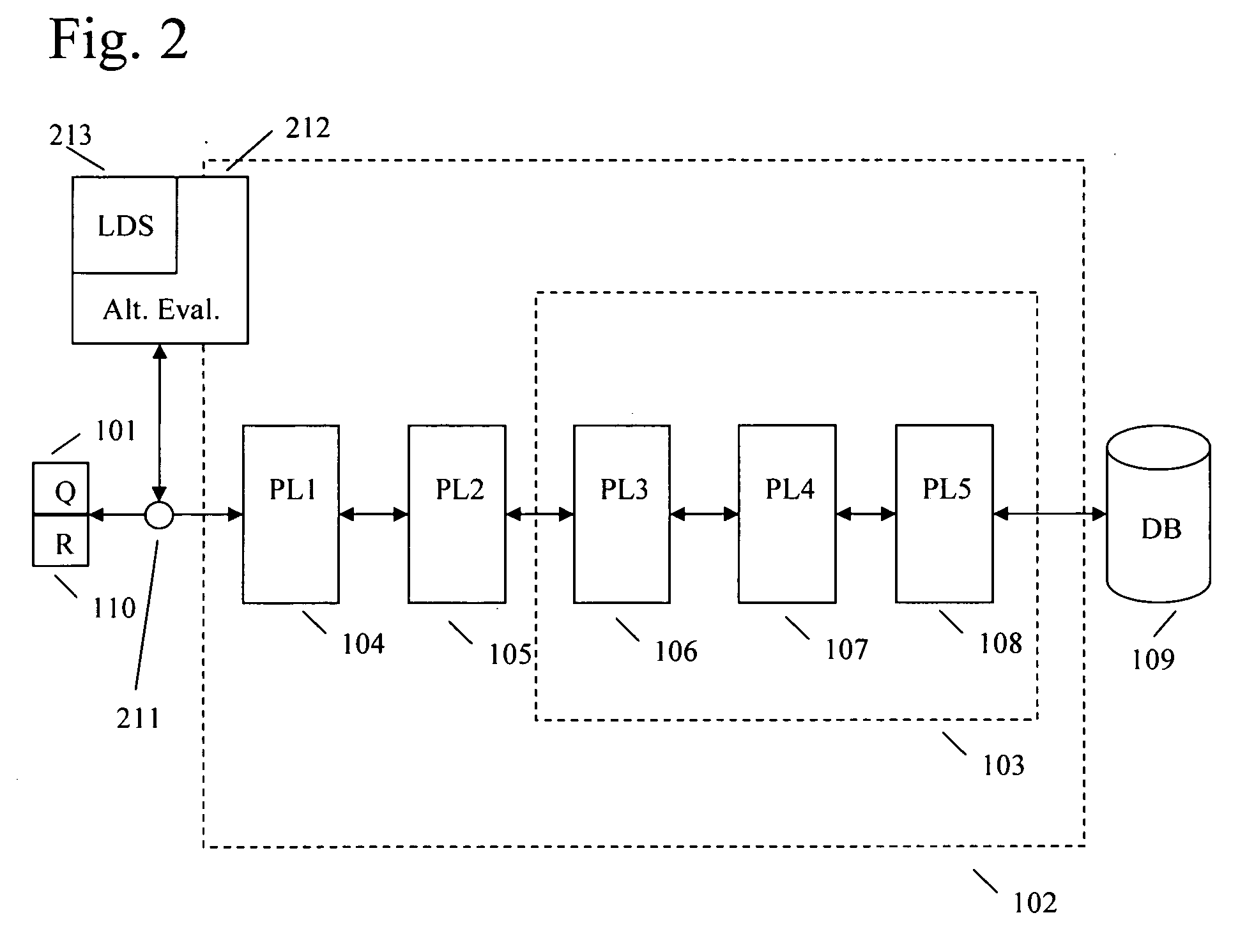

Method and apparatus for enhancing directory performance

ActiveUS20050267857A1Enhancing directory service performanceImprove service performanceDigital data information retrievalDigital data processing detailsData typeDatabase

A method for enhancing directory service performance includes determining one or more data types to be loaded. Retrieving data objects that includes the determined data types from storage. Preloading object name and determined data type data into a directory service alternate evaluator for each data object retrieved from storage.

Owner:COMP ASSOC THINK INC

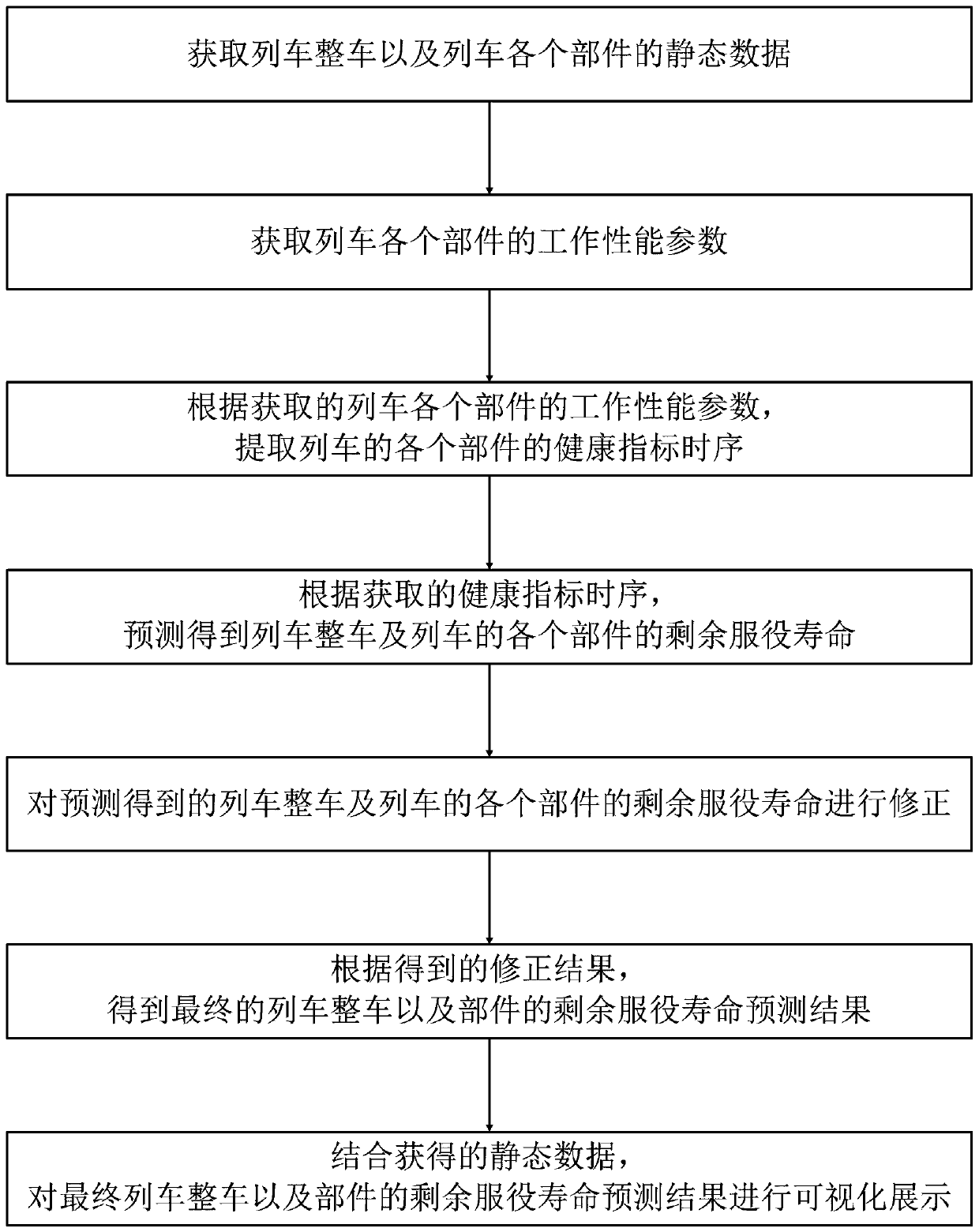

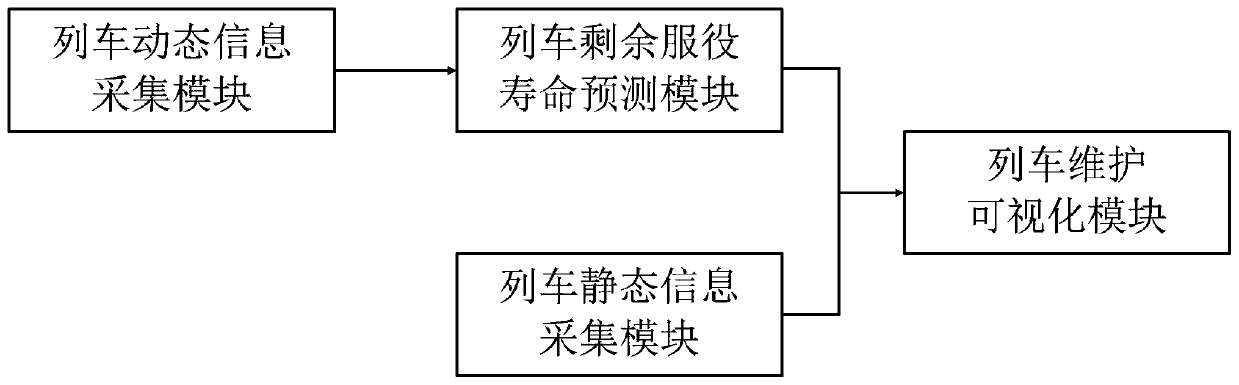

BIM-based intelligent train whole-vehicle service life prediction method and system thereof

ActiveCN110376003AImprove service performanceComprehensive visualization of informationRailway vehicle testingComputer scienceReliability engineering

The invention discloses a BIM-based intelligent train whole-vehicle service life prediction method, which comprises the steps of: acquiring static data and operating performance parameters of a wholetrain and components of the train; extracting a health indicator timing sequence of the components of the train; predicting to obtain remaining service life of the whole train and the components of the train, and correcting the remaining service life; and acquiring a final remaining service life prediction result of the whole train and the components. The invention further discloses a system for implementing the BIM-based intelligent train whole-vehicle service life prediction method. The BIM-based intelligent train whole-vehicle service life prediction method and the system can realize the monitoring of the train service state and external influencing factors, complete the modeling of uncertainty influence of the external factors on the remaining service life, provide comprehensive visualinformation, can realize the prediction of the remaining life of the train, effectively improve the service performance of the train, and have the advantages of high reliability, high applicability and comprehensive and precise evaluation.

Owner:CENT SOUTH UNIV

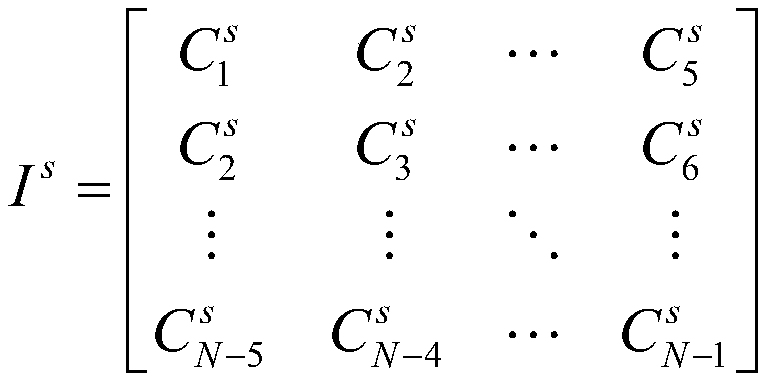

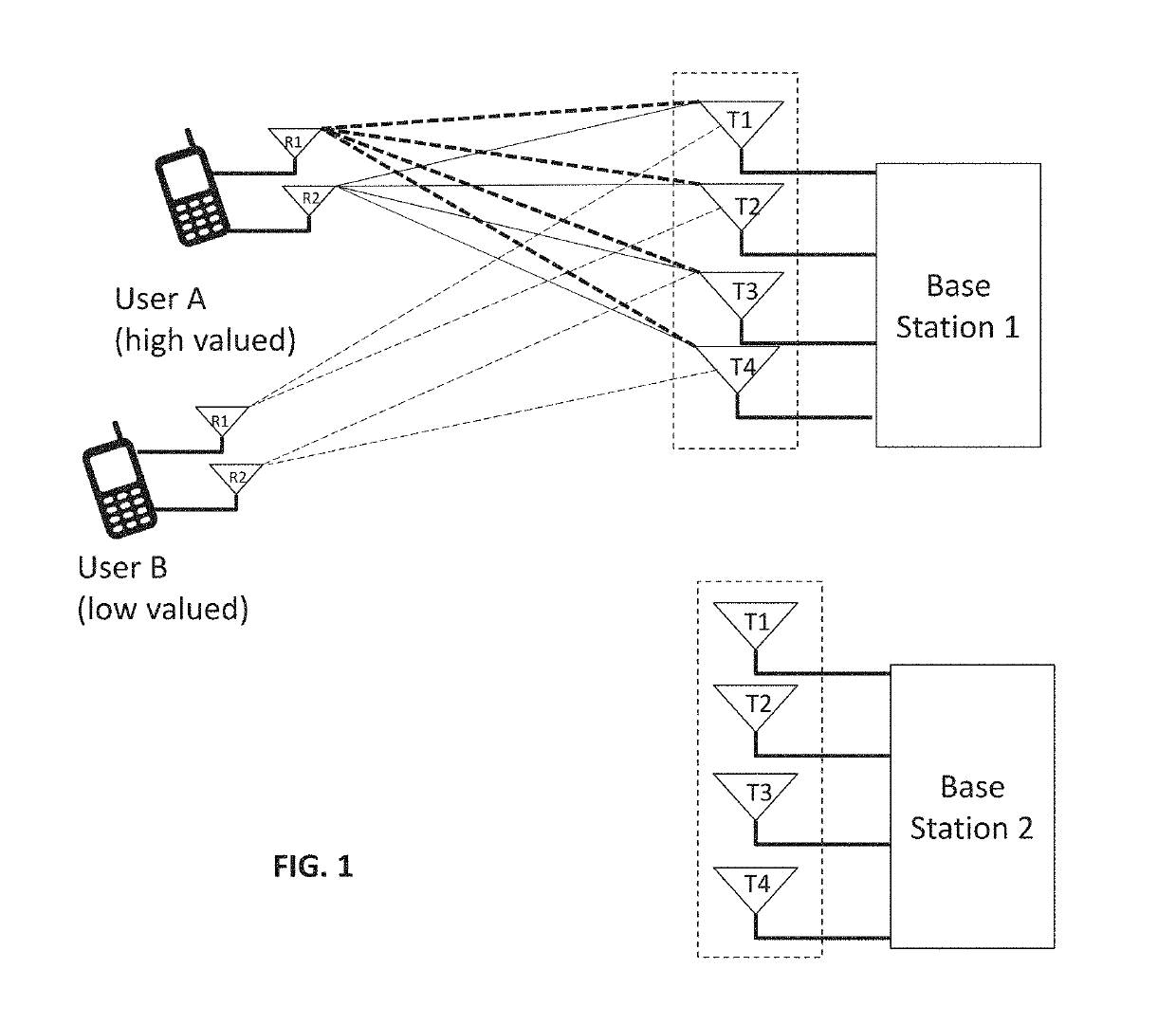

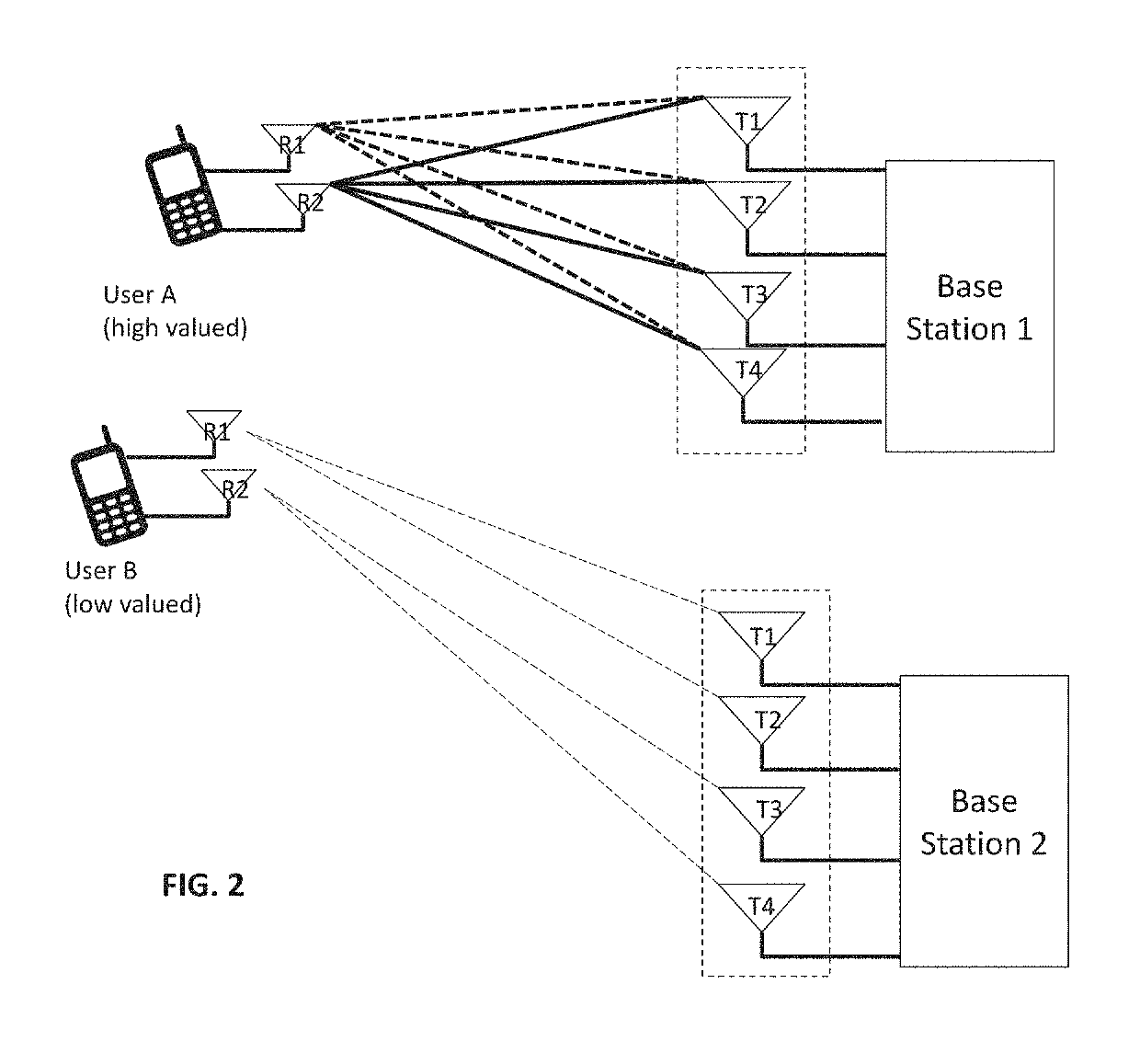

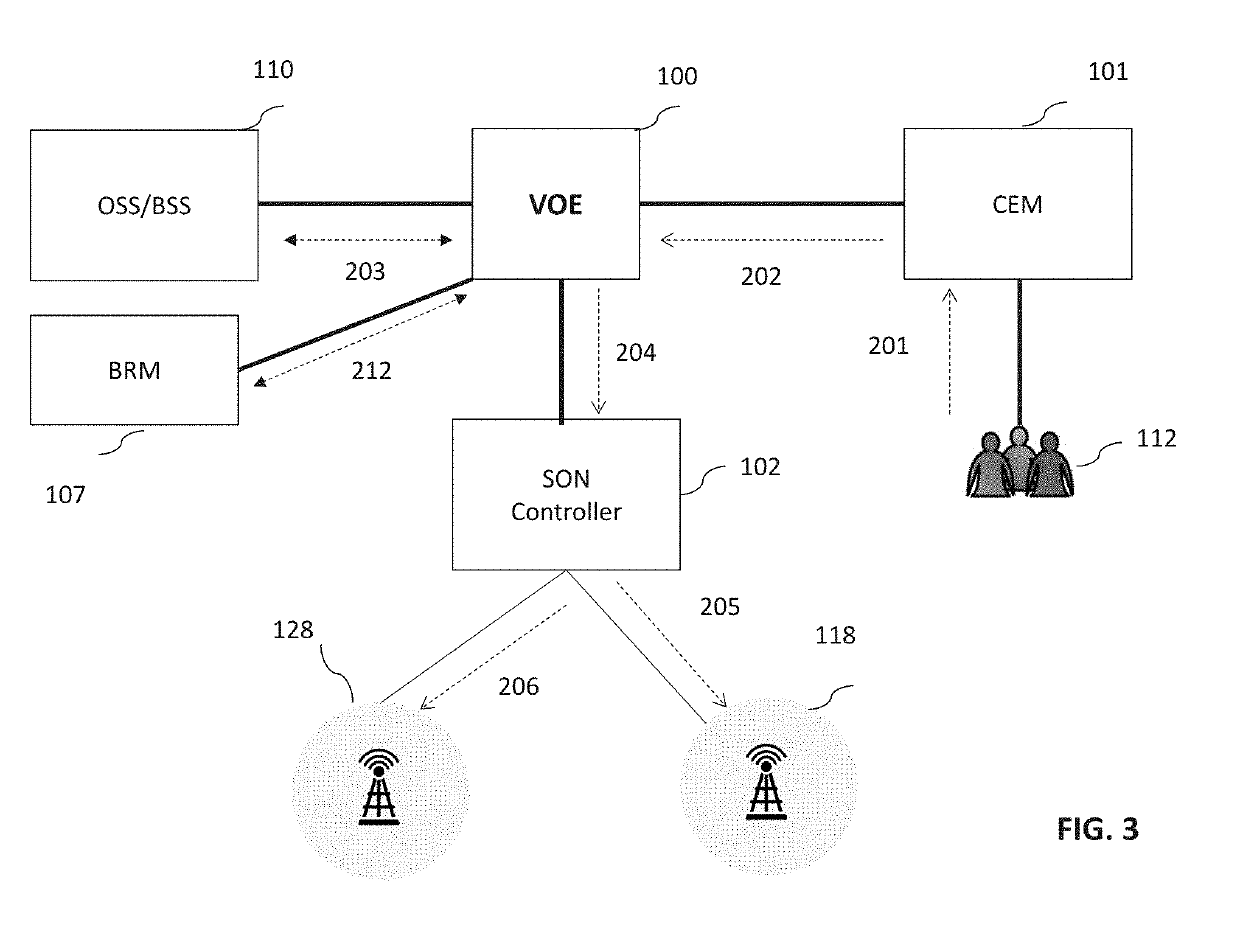

System and method for value optimized mobile networks

ActiveUS20190141580A1Improve service performanceImprove communication serviceNetwork traffic/resource managementNetwork planningWeb of ThingsMobile Web

Self-Organizing Network (SON) technology has been developed to make the planning, configuration, management, and self-healing of mobile networks easier and faster, where such planning, configuration and management of the mobile networks are targeted to optimize the value offered to a group of subscribers using criteria such as (a) subscriber type (consumer, corporate, IOT, etc.), (b) service type (mission critical, public safety, VoIP, etc.), (b) subscriber usage volume (high, medium, low), (c) subscriber's requested / subscribed QoS, and (d) subscriber's paying value (i.e., revenue). The same teachings can be extended to also optimize a single subscriber's service or a service type.

Owner:NETSIA INC

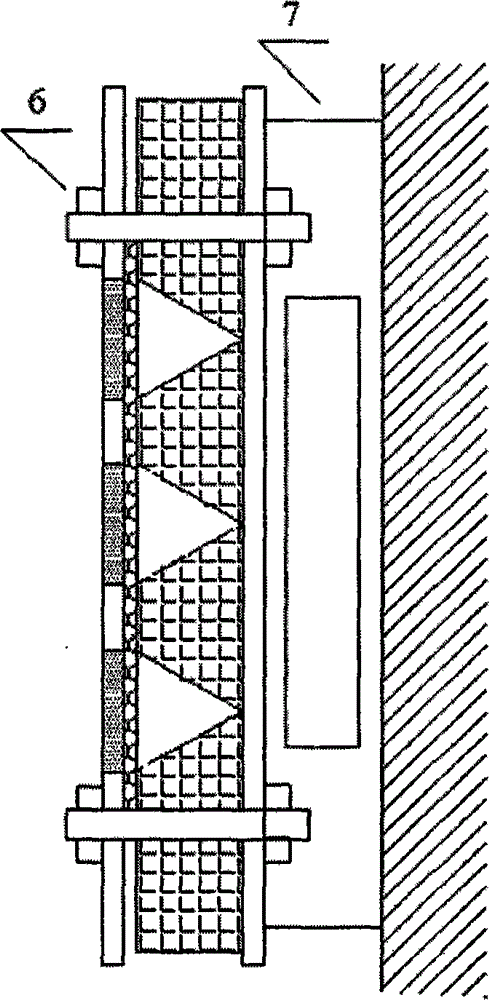

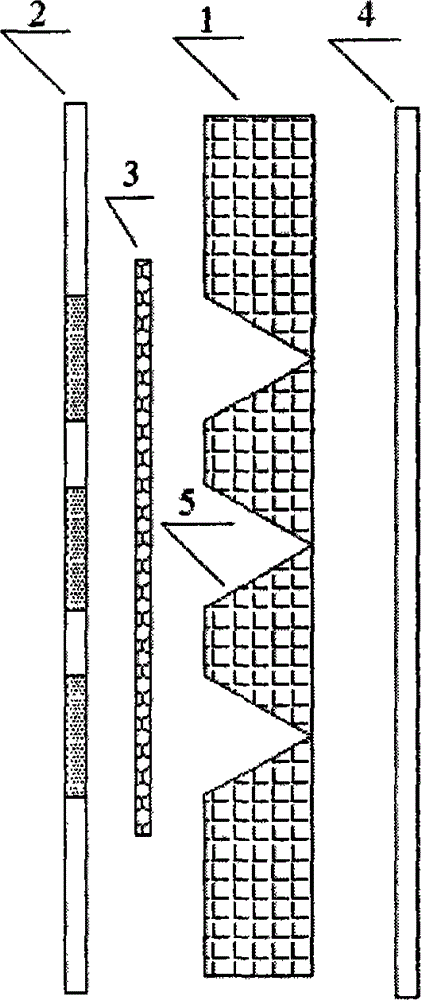

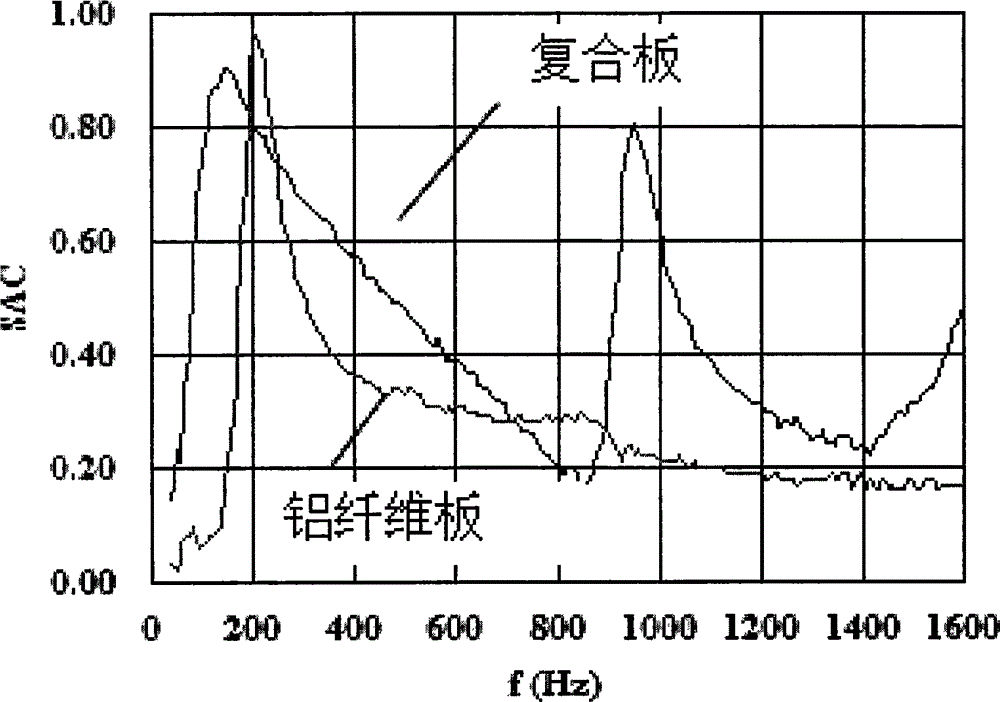

Noise reduction sound absorption layer

ActiveCN104485096AIncrease the barrier to spreadAchieve resistive sound absorption effectSound producing devicesFiberResonance

The invention provides a noise reduction sound absorption layer. The sound absorption layer comprises a keel and a sound absorption component, wherein the component comprises a micro-perforated panel 2, non-woven fabrics 3, a bi-component fiber mat 1 and a back plate 4, which are sequentially arranged along the direction from a noise source to a wall. The sound absorption principle of the noise reduction sound absorption layer couples the effects of bi-component resistive sound absorption and dual-layer resonance sound absorption; low-frequency noise of a substation transformer and a high-voltage reactor is effectively absorbed, and thus the target of reducing sensitive points on the boundary of a transformer substation and sensitive points out of the transformer substation is achieved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

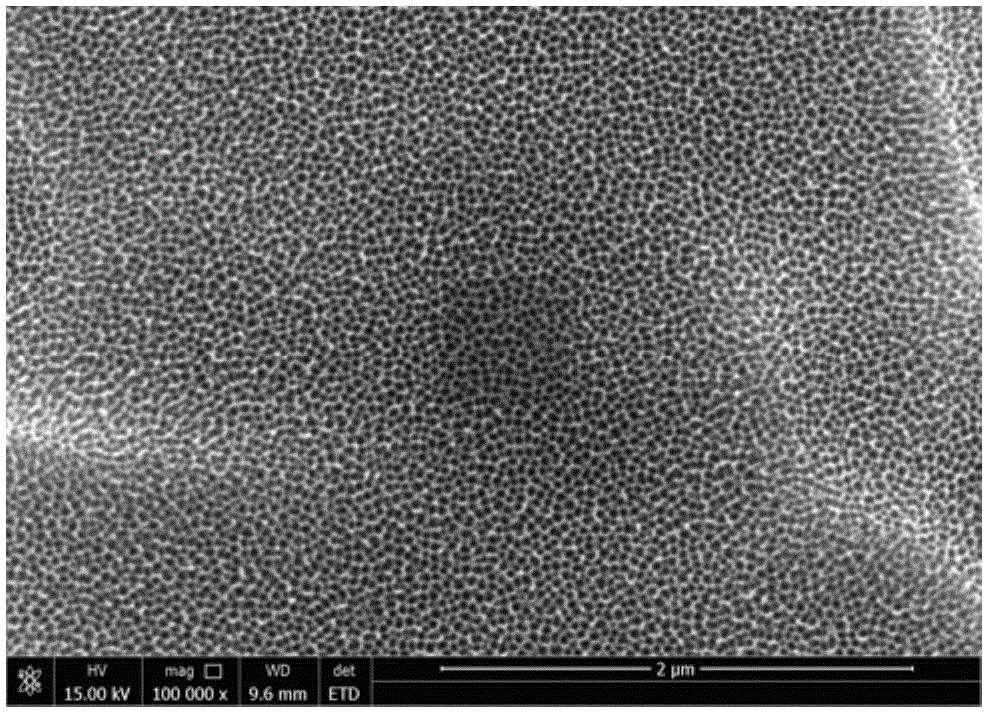

Method for forming high-anti-bacterial-performance titanium-alloy artificial hip joint

ActiveCN106420119AMeeting the Hip Performance Needs Needed for ReplacementRealize integrated formingAdditive manufacturing apparatusSurface reaction electrolytic coatingMicro nanoTitanium alloy

The invention discloses a method for forming a high-anti-bacterial-performance titanium-alloy artificial hip joint. The method includes the following technological steps that (1) CT scanning and layered slicing processing of a patient hip joint data model are carried out; (2) titanium-copper alloy powder is designed and prepared; (3) laser 3D printing forming of a titanium-alloy artificial hip joint is carried out; (4), a titanium-alloy artificial hip joint with micro-nano-size porous structure surface is constructed in situ with the anodic oxidation technology; (5) the anti-bacterial performance of the titanium-alloy artificial hip joint is further improved with the plasma high-temperature nitridation technology; (6) cleaning, sterilizing and drying are carried out, and then packaging is carried out. According to the method, the complex structure and the high anti-bacterial function of the artificial hip joint are integrally manufactured in sufficient cooperation with the laser 3D printing technology, the surface modification technology and the excellent anti-bacterial performance of copper elements. The forming method is simple, outstanding in performance, suitable for personalized customization of the high-anti-bacterial-performance titanium-alloy artificial hip joint, and has good social benefits and economic benefits.

Owner:金湖县综合检验检测中心

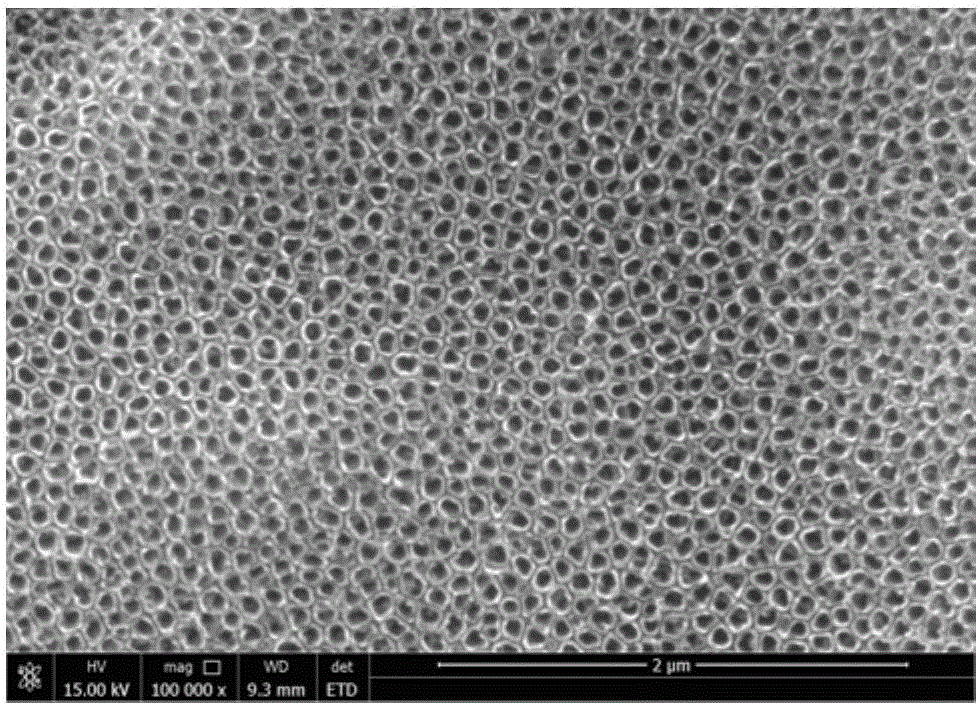

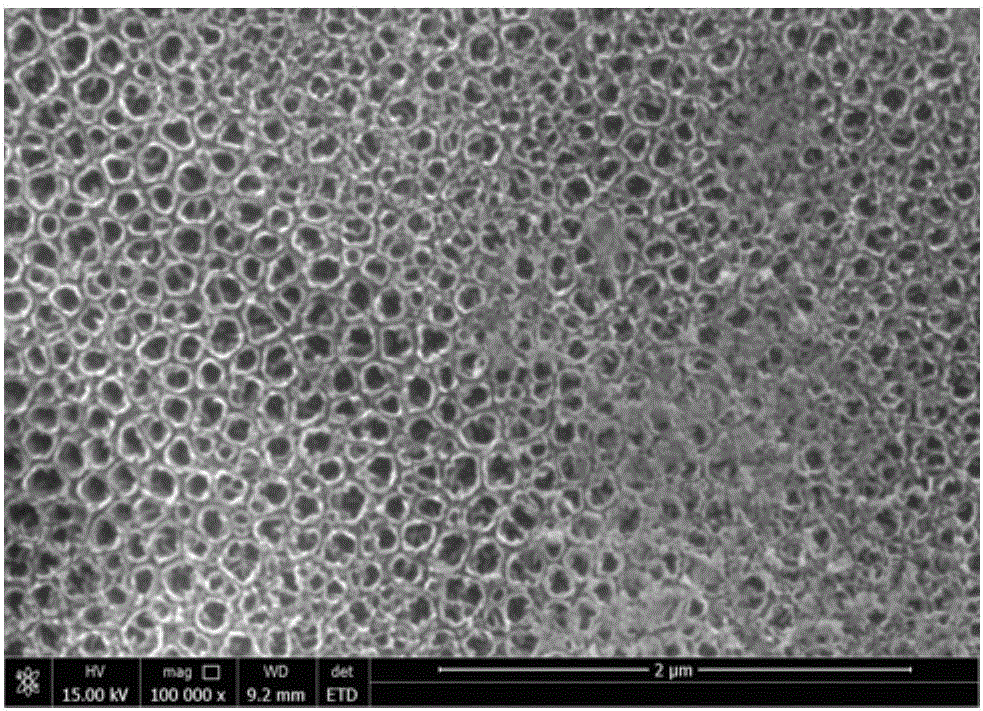

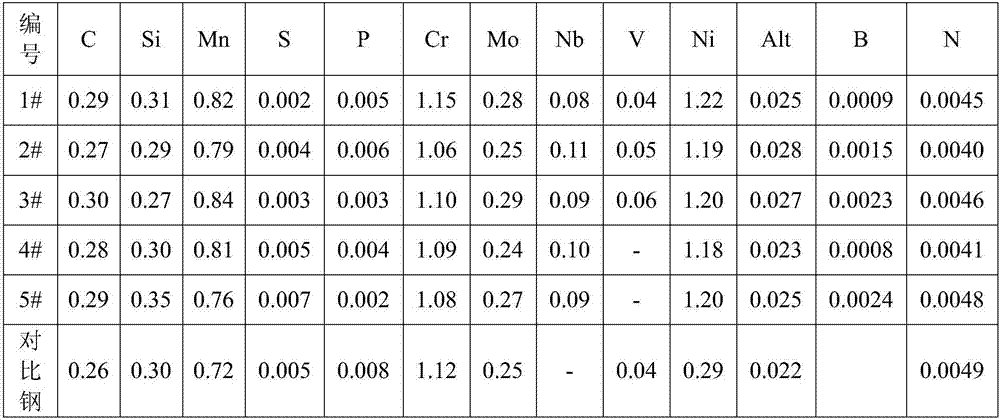

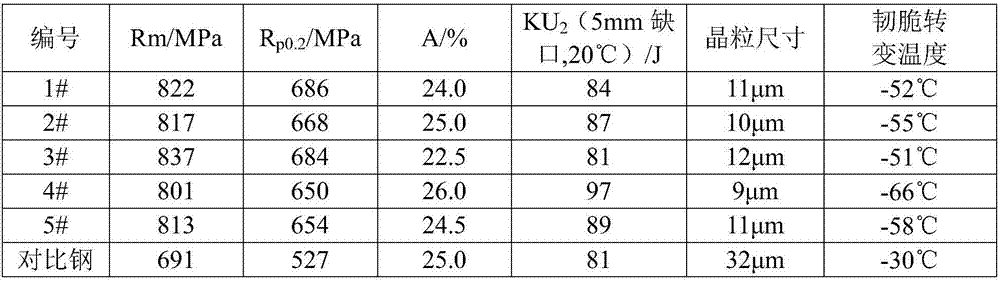

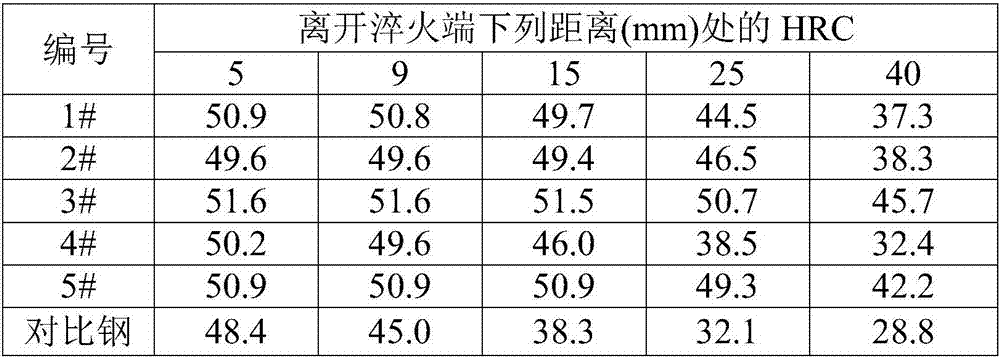

High-strength high-toughness high-hardenability high-speed axle steel and heat treatment method thereof

The invention relates to high-strength high-toughness high-hardenability high-speed axle steel. The yield strength Rp0.2 of the axle steel is larger than or equal to 630 MPa, the strength of extensionRm is larger than or equal to 800 MPa, the ductility A is larger than or equal to 20%, the 5 mm notch indoor temperature longitudinal impact absorbing energy KU2 is larger than or equal to 80 J, andthe ductile-brittle transition temperature is lower than -40 DEG C; and a chemical component of the steel comprises B, and the weight percentage of the B is 0.0008%-0.0025%. Meanwhile, a preparing method of the steel is further provided. By means of the high-strength high-toughness high-hardenability high-speed axle steel and the preparing method have the beneficial effects that full play can be given to the effects of all elements in the axle steel sufficiently, and microscopic structures with wee crystalline grains and with martensite as a main are obtained. Through two times of quenching and high temperature tempering heat treatment are adopted, and therefore even fine grain austenite grains and Nb microalloy second-phase strengthened martensitic structures can be obtained, excellent matching of high strength, high toughness and high hardenability is achieved, and finally the high-speed axle steel has the good anti-shock, anti-fatigue service performance and the like, excellent strength and toughness matching and good hardenability.

Owner:CENT IRON & STEEL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com