Patents

Literature

41results about How to "Good tensile mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing tungsten-copper composite material with fine grain

The invention relates to the field of powder metallurgy technology characterized in that, forming the powder with 200 MPa-500 MPa and feeding into sintering furnace, elevating the temperature to 400-700 deg. C. at the speed of 5-20 deg. C per minutes, heat preserving for 15-120 mins, elevating the temperature to sintering temperature of 1150-1350 deg. C. at the speed of 20-60 deg. C per minutes, heat preserving for 30-120 mins.

Owner:CENT SOUTH UNIV

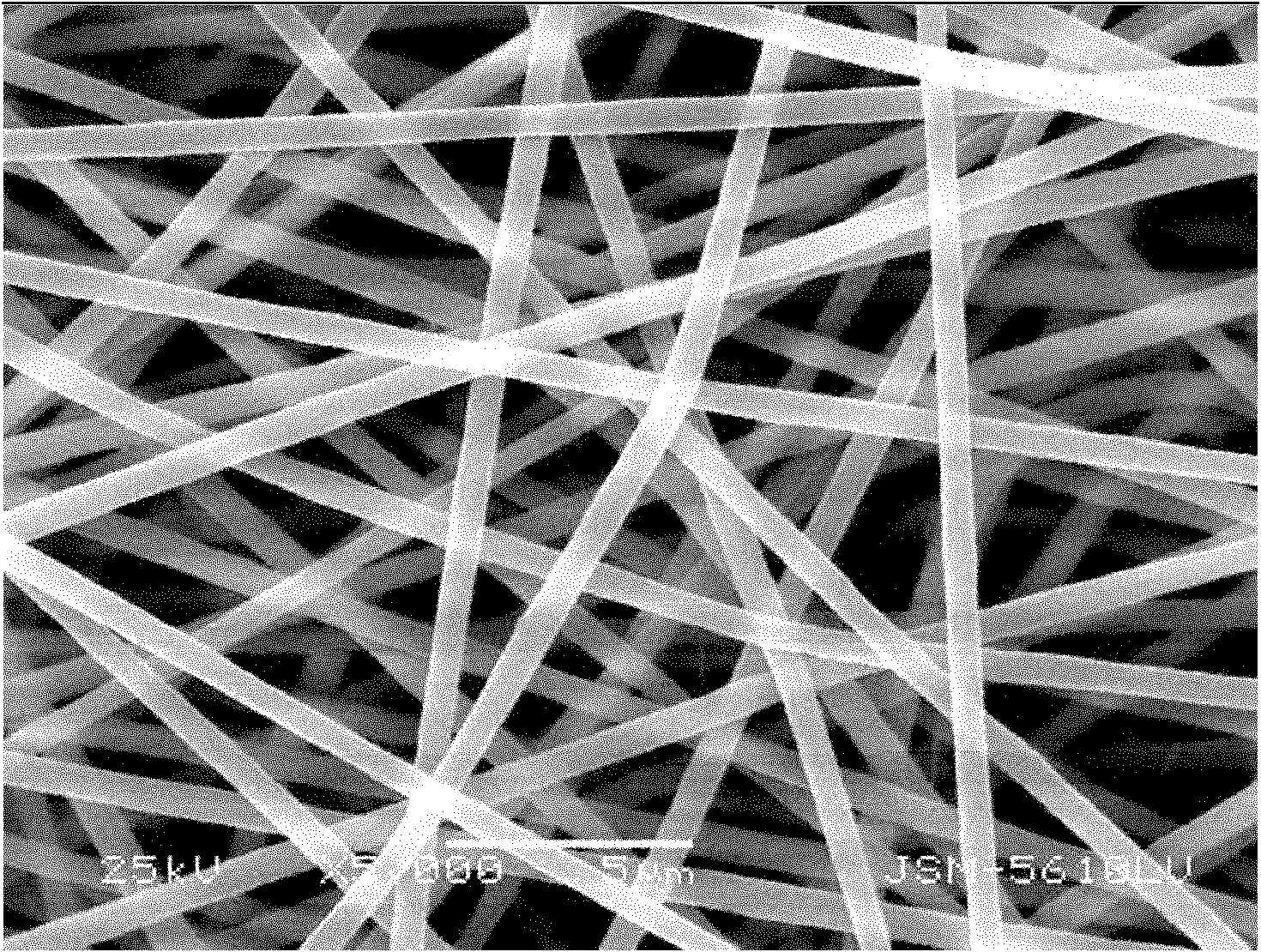

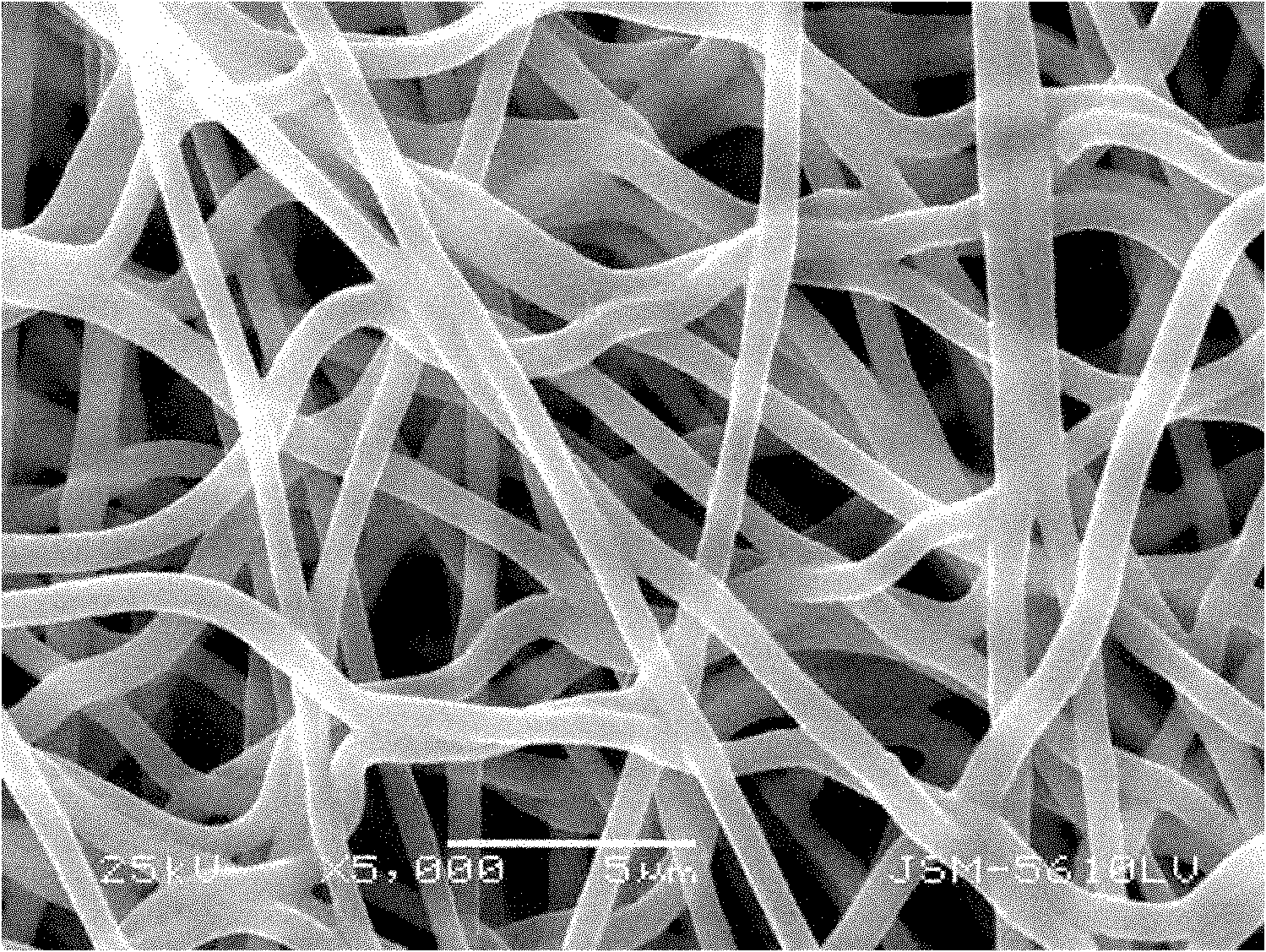

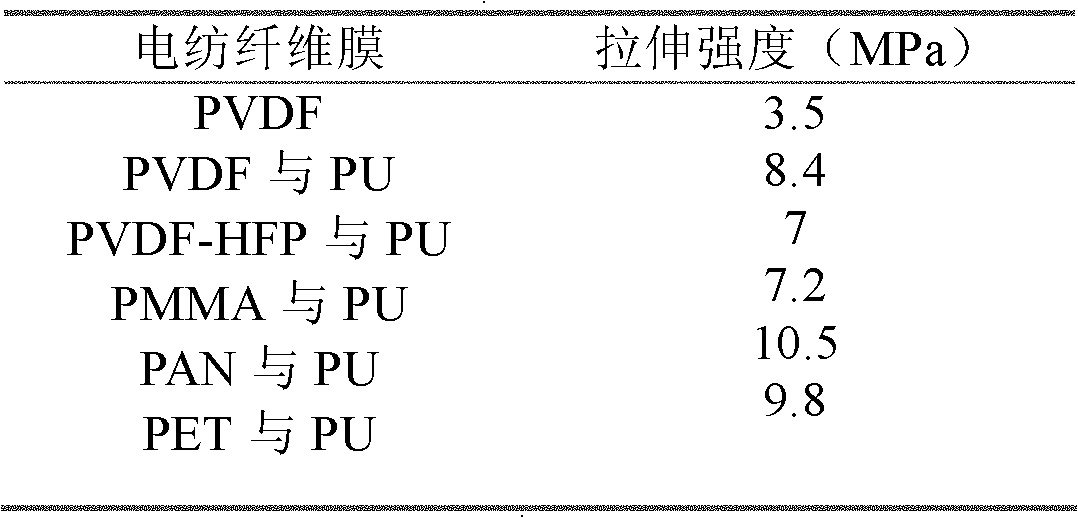

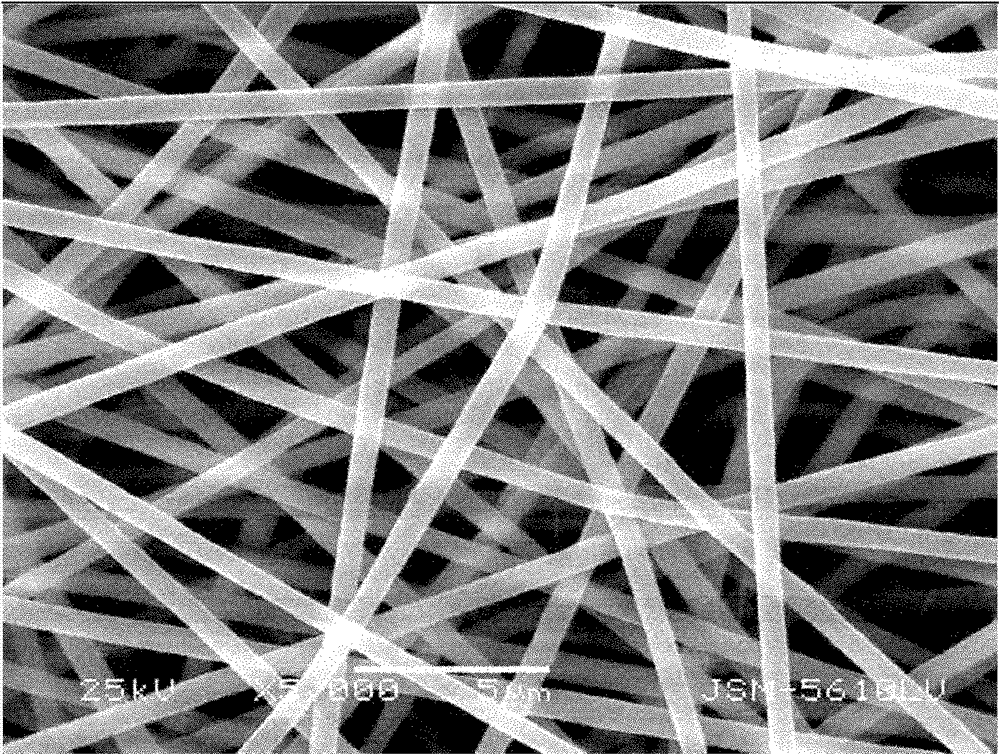

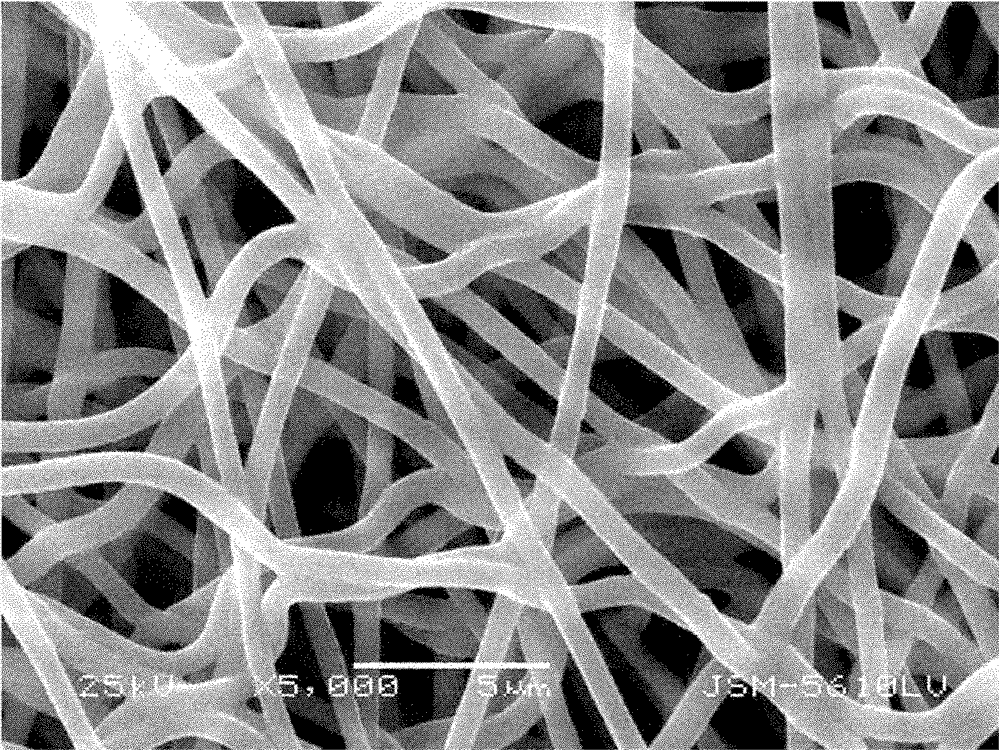

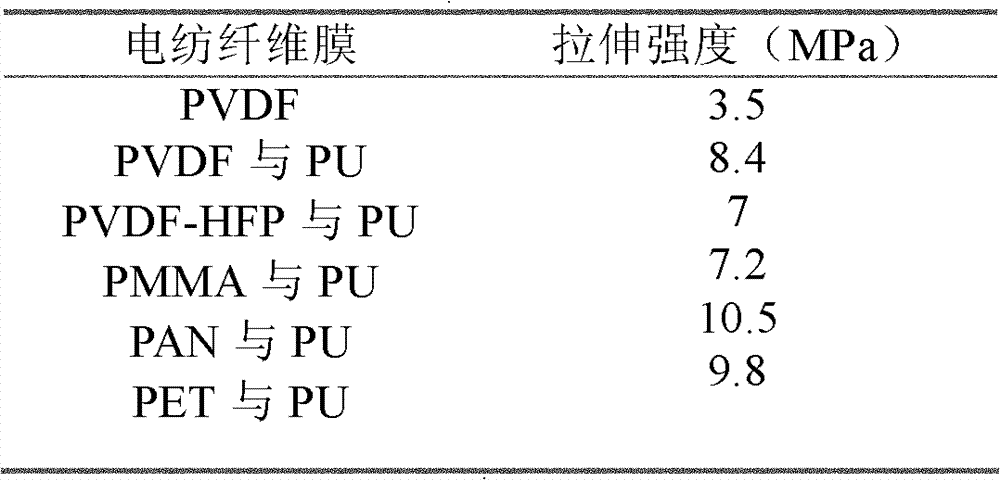

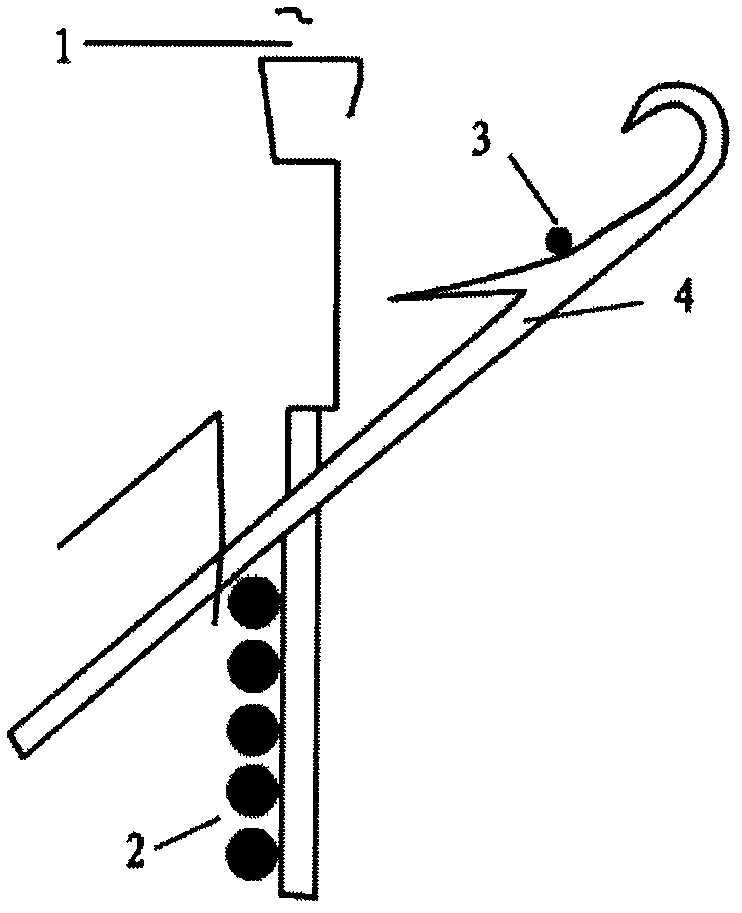

Enhanced bi-component nanofiber porous membrane and preparation method thereof

InactiveCN102140734AHigh porosityImprove wettabilityFilament/thread formingCell component detailsPolymer scienceVoid ratio

The invention relates to an enhanced bi-component nanofiber porous membrane and a preparation method thereof. The porous membrane is a lithium ion battery membrane with two components of polymer resin and polyurethane. The membrane is in a semi-interpenetrating network structure which has a void ratio of 60-80%, and the mechanical property is 2-3 times higher than a single-component porous membrane of polymer resin. The preparation method comprises the steps of: dissolving a polymer resin and polyurethane prepolymer bi-component composition in a solvent, and preparing a nonwoven membrane through an electrospinning technology; and putting the nonwoven membrane at room temperature to make -NCO in the polyurethane prepolymer react with the -OH bond of water in the air to produce polyurethanethrough crosslinking and autopolymerization. In the invention, the nanofiber in the nonwoven membrane binds to form the polymer resin and polyurethane bi-component compound membrane, and the mechanical strength of the fibrous membrane is improved greatly. The method is easy, and the prepared nonwoven membrane maintains the advantages of high void ratio, and good thermal stability of polymer resinof the membrane prepared by using the electrospinning technology, and the membrane has good ion permeability and electrolyte affinity.

Owner:WUHAN UNIV OF TECH

Method for improving tensile mechanical property of fibers

InactiveCN106367947AGood tensile mechanical propertiesUniversalUltrasonic/sonic fibre treatmentChemical vapor deposition coatingFiberEcological environment

The invention in particular relates to a method for improving tensile mechanical property of fibers and belongs to fiber modification technologies. The method comprises the following steps: taking papa-phenylene diisocyanate and ethidene diamine as precursors, and depositing a polyurethane film on the fiber surface by adopting an atomic layer deposition technique. Due to excellent shape preservation of the atomic layer deposition technique, the defects of the original fibers can be effectively reduced, and due to high elasticity of polyurethane, the original fibers can effectively buffer instantaneous mechanical changes in the tensile process, so that the tensile mechanical properties of fibers can be effectively reduced. The preparation method is simple, the deposition process is easy to control, the cost and energy consumption are low, and the method is pollution-free to the ecological environment and suitable for industrial production.

Owner:WUHAN TEXTILE UNIV

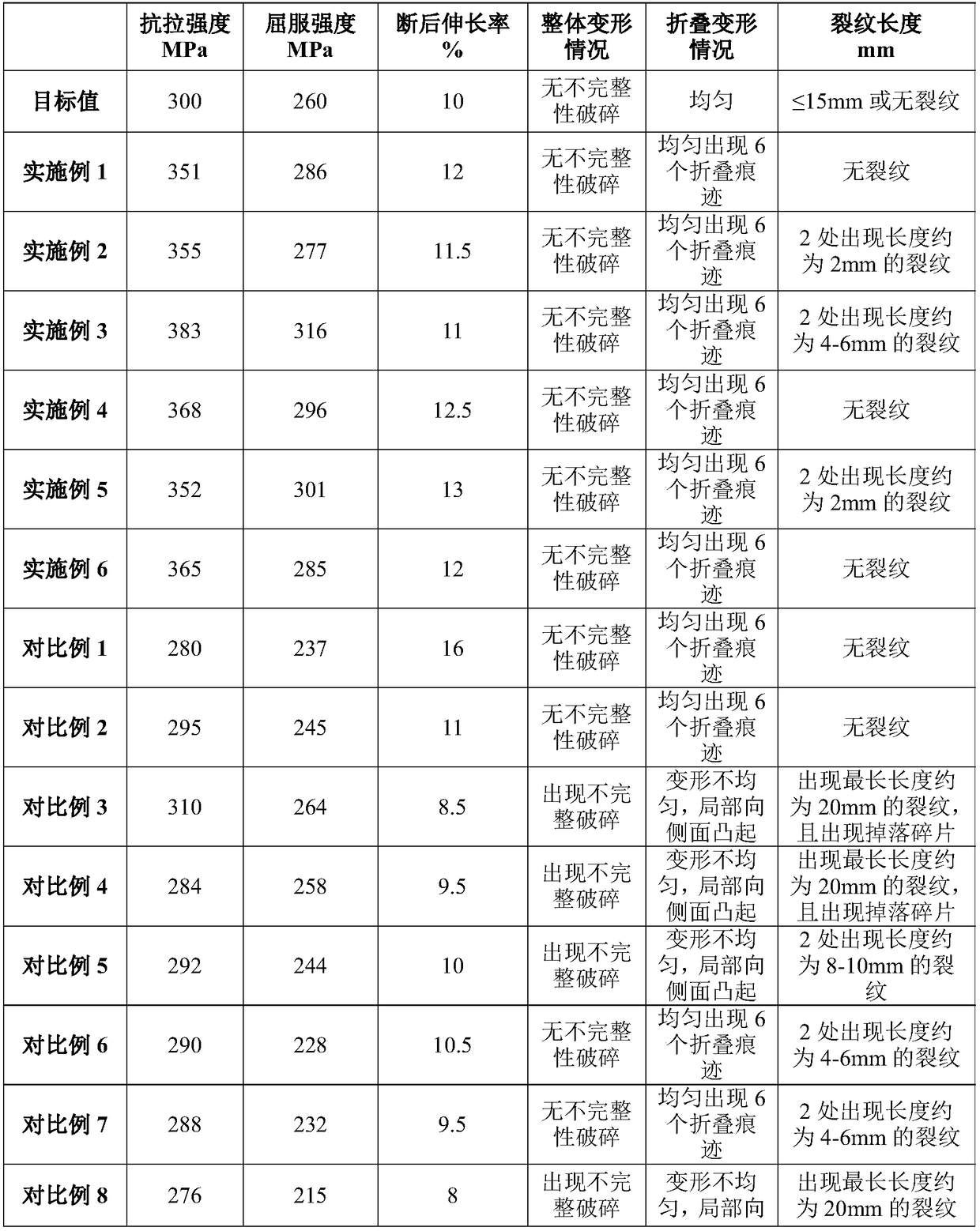

Production process of aluminum profile for automobile impact energy absorbing components and produced aluminum profile

The invention discloses a production process of an aluminum profile for automobile impact energy absorbing components and a produced aluminum profile, relates to the technical field of aluminum and aluminum alloy extrusion machining and heat treatment. The production process comprises the following steps that an aluminum alloy ingot is subjected to uniform annealing treatment, extrusion and quenching treatment, tensile treatment and aging treatment in sequence; then, the aluminum alloy ingot is cooled to 490-525 DEG C after the uniform annealing treatment, and extrusion is carried out again; and the aging treatment includes first, natural aging treatment and then secondary artificial aging treatment, the natural aging treatment time is carried out for 30-60 h, the heat preservation temperature of a first artificial aging stage is 100-120 DEG C, the heat preservation time is 2-3.5 h, the heat preservation temperature of a second artificial aging stage is 150-170 DEG C, and the heat preservation time is 8-12 h. By reasonably designing parameters of extrusion process and heat treatment process, the production process can improve tensile mechanical properties simultaneously without reducing the plasticity, so that the aluminum profile has better compression performance.

Owner:SHANDONG NANSHAN ALUMINUM +3

Flexible self-healing conductive hydrogel sensor and preparation method thereof

InactiveCN110698693AGood tensile mechanical propertiesImprove fatigue resistanceFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsPolyvinyl alcoholMaterials science

The invention relates to a flexible self-healing conductive hydrogel sensor and a preparation method thereof. According to the preparation method, the flexible self-healing conductive hydrogel sensoris prepared through following steps: blending an acrylamide solution and an acetoacetated polyvinyl alcohol solution, initiating polymerization to obtain a flexible precursor hydrogel, and then soaking the flexible precursor hydrogel in a ferric trichloride solution to obtain a finished product. The prepared hydrogel has excellent sensing performance and can be successfully used for monitoring human motion or physiological signals, meanwhile, the hydrogel device has good fatigue durability and self-healing performance, and therefore the requirements of sensing devices on the service life and signal stability can be met.

Owner:DONGHUA UNIV

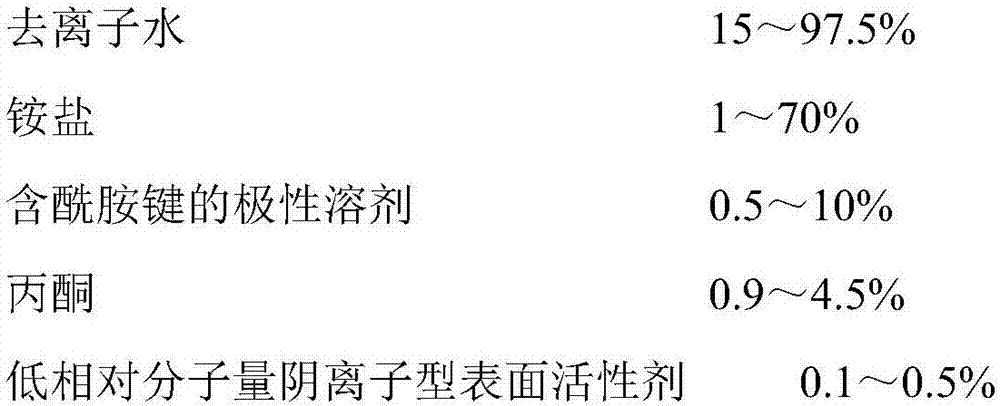

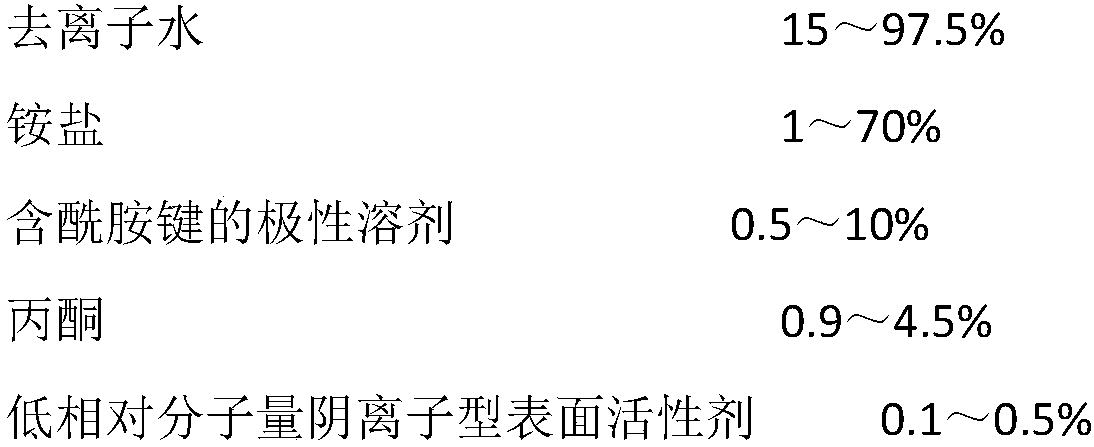

High-strength, high-modulus, high-elastic polyurethane film preparation method

The present invention relates to a high-strength, high-modulus, high-elastic polyurethane film preparation method, and belongs to the technical field of film material. The preparation method for the high-strength, high-modulus, high-elastic polyurethane film provided by the invention comprises: putting a polytetrafluoroethylene plate blade coating with a polyurethane solution into coagulating bath mixed by deionized water, ammonium salt, amide linkage-containing organic solvent, acetone, and anionic surfactant with a low relative molecular weight, mechanically stirring the coagulating bath, and carrying out wet forming and drying to obtain the high-strength, high-modulus, high-elastic polyurethane film. The preparation method provided by the invention can enhance breaking strength, Young's modulus and elongation at break of the polyurethane film simultaneously. The breaking strength of the polyurethane film is enhanced by 270-560%, elongation at break is enhanced by 80-280%, and the Young's modulus is enhanced by 50-270%. The preparation method provided by the invention is simple in processing equipment, low in cost, and pollution-free to ecological environment, high in controllability, and has a great application prospect.

Owner:WUHAN TEXTILE UNIV

Method for enhancing stretching mechanical property of polyurethane fiber

ActiveCN105063993AGood tensile mechanical propertiesHigh breaking strengthPhysical treatmentFibre typesFiberEcological environment

The invention relates to a method for enhancing stretching mechanical property of polyurethane fiber, which belongs to the technical field of fibrous material. The method is characterized in that the polyurethane fiber is obtained through polyurethane fiber pretreatment, polyurethane fiber low temperature corona irradiation modification, preparation of a modification solution, embedding of ammonium salt molecules in polyurethane fiber, cleaning of ammonium salt molecules-imbedded polyurethane fiber, micro drawing and heat fixing. The polyurethane fiber is modified after moulding, polyurethane fiber breaking tenacity is realized, young modulus and fracture elongation are simultaneously enhanced, the breaking tenacity of the prepared polyurethane fiber is increased by 60-150%, fracture elongation is increased by 70-120%, and the young modulus is increased by 30-80%. The preparation method has the simple equipment, low cost, no pollution on ecological environment, high controllability and large application prospect.

Owner:WUHAN TEXTILE UNIV

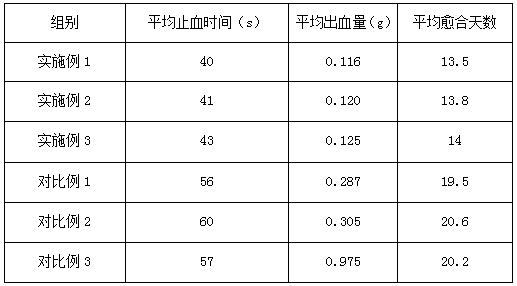

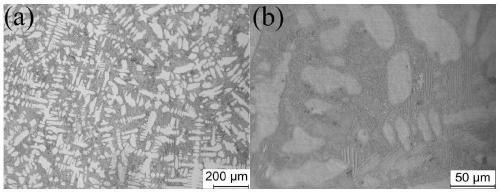

Antibacterial medical hemostasis absorbent cotton gauze and preparation method thereof

InactiveCN108478848APrevent agglutinationAntiarrhythmicAbsorbent padsBandagesEscherichia coliDeep wounds

The invention provides antibacterial medical hemostasis absorbent cotton gauze, which consists of medicine dressing and a tissue material carrying the medicine dressing, wherein the medicine dressingis prepared from traditional Chinese medicine and western medicine; the tissue material carrying the medicine dressing is blended by scleroprotein fiber and cotton fiber. The hemostasis and the antibacterial effects are integrated; the obvious effects are achieved on abnormal bleeding in operations of lung, liver, pancreas, adrenal gland and the like, the bleeding except for obstetrics departmentand postpartum hemorrhage, urinary tract bleeding and the like; in addition, the antibacterial medical hemostasis absorbent cotton gauze can be used under the conditions of great and deep wound and great bleeding quantity; the hemostasis is fast; the wound surface wound recovery is facilitated; meanwhile, the antibacterial spectrum is wide; the sterilization power is strong; the action is fast; the effectiveness can also be achieved on pseudomonas aeruginosa, klebsiella, escherichia coli, enterobacter, staphylococcus, mycoplasma and chlamydia; in addition, good effects are achieved on trimethoprim drug resistant bacteria, penicillin drug resistant staphylococcus aureus andtylosin or tiamulin drug resistant mycoplasma.

Owner:代清燕

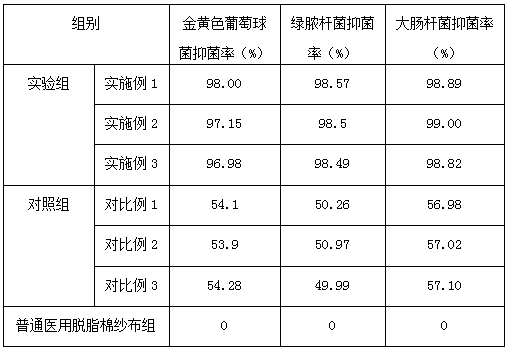

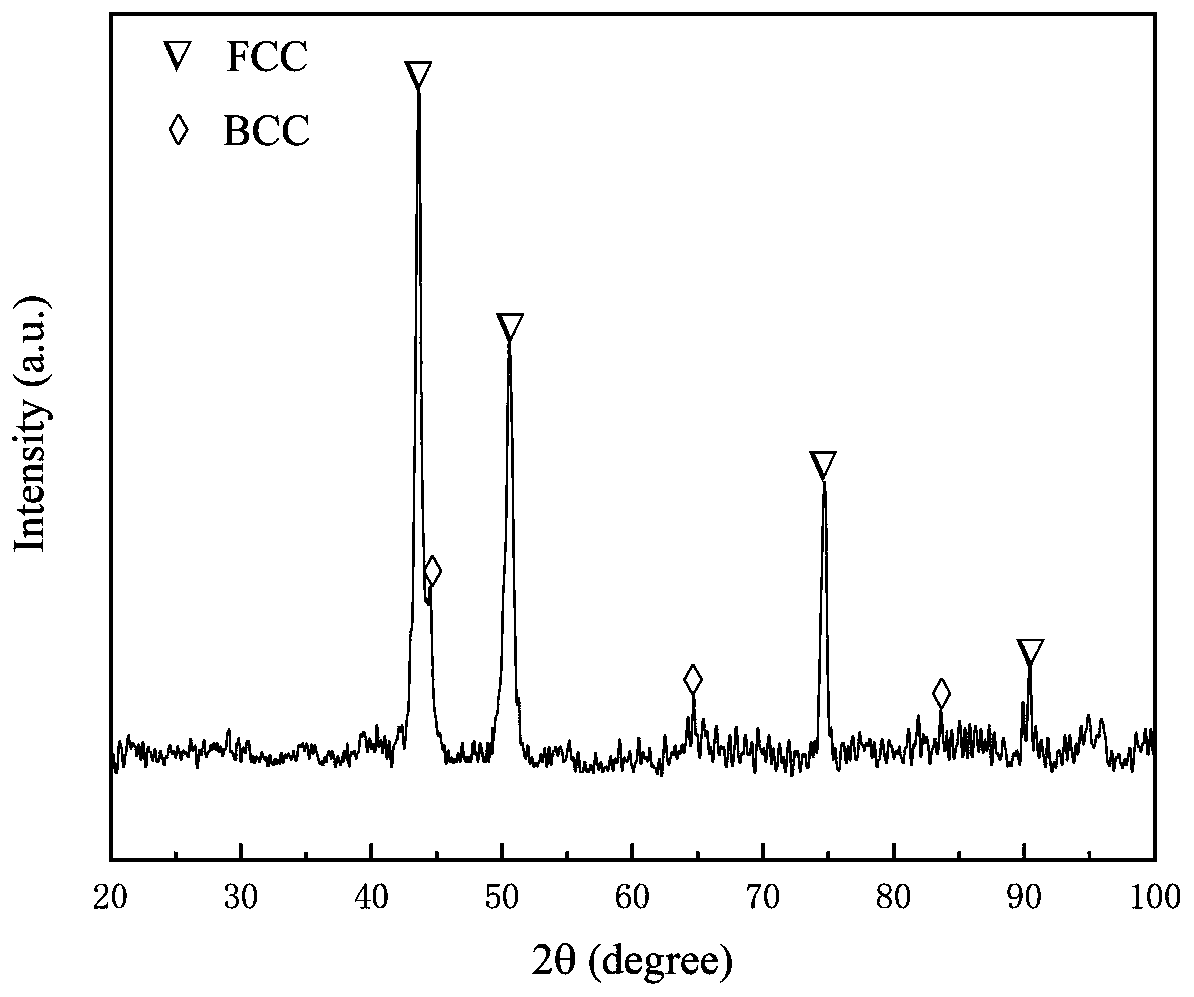

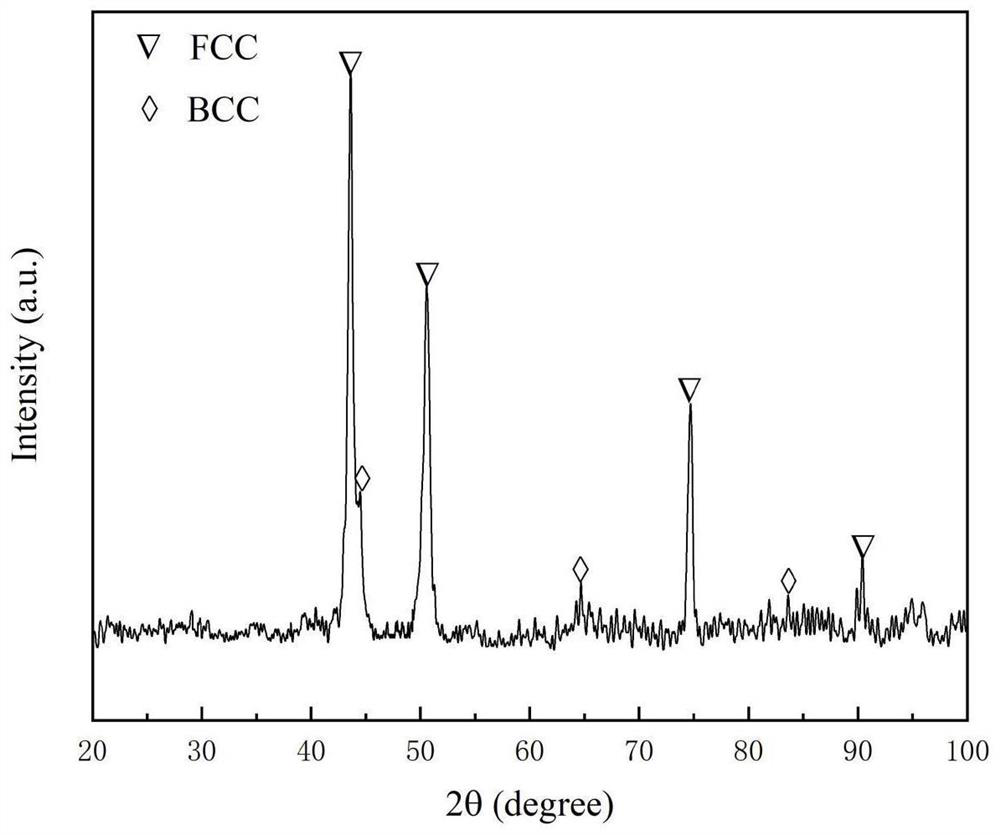

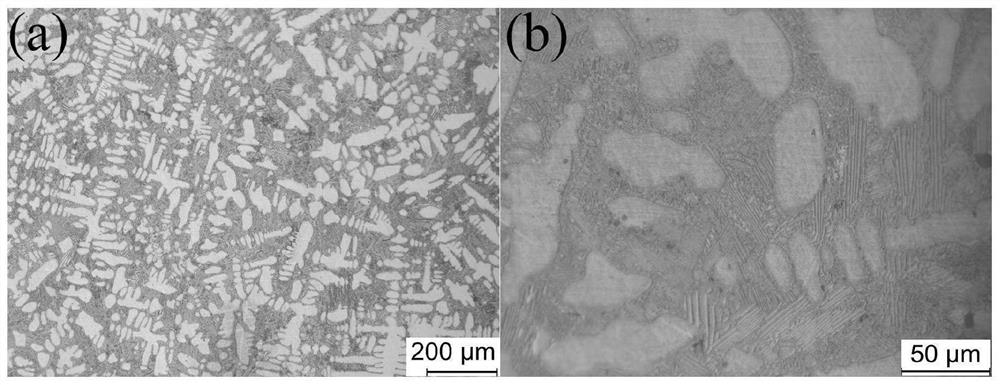

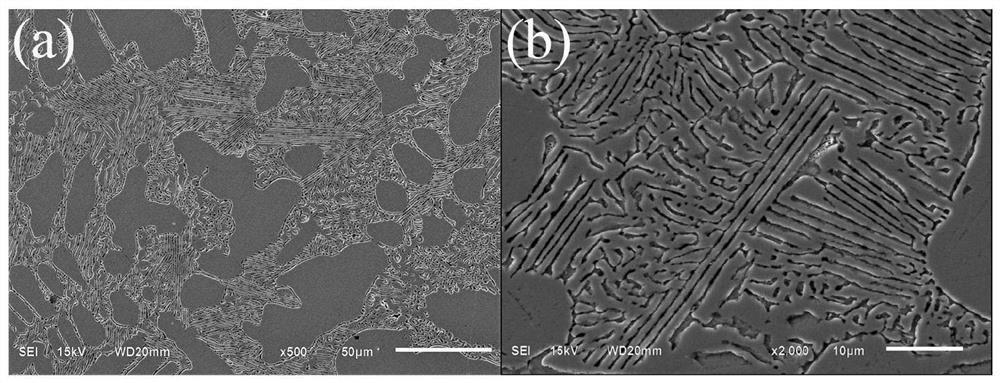

Quaternary hypoeutectic high-entropy alloy excellent in strength and plasticity match and preparation method thereof

The invention discloses a quaternary hypoeutectic high-entropy alloy excellent in strength and plasticity match. The quaternary hypoeutectic high-entropy alloy consists of a component of AlxCoyCrzNiw,wherein x, y, z and w respectively are molar ratios of corresponding elements, the molar ratios meet the relationships: 16>=x>=12, 30>=y>=26, 30>=z>=26, and 32>=w>=28. The quaternary hypoeutectic high-entropy alloy is of hypoeutectic structure, and excellent in strength and plasticity match. Simultaneously, the invention further provides a preparation method of the quaternary hypoeutectic high-entropy alloy. The preparation method includes: first, removing oxide skin from the elementary metals, weighing and mixing the elementary metals according to the molar ratios to obtain a mixture, placing the mixture in a high vacuum non-self-consuming arc melting furnace, performing electric arc melting in vacuum under argon protection, obtaining an alloy solution, stirring and cooling the alloy solution, obtaining an alloy ingot, repeating smelting for four times to obtain a high-entropy alloy, removing oxide skin from the obtained high-entropy alloy, performing ultrasonic cleaning twice by using ethyl alcohol, placing a clean alloy ingot in a high vacuum arc smelting rollover casting and centrifugation casting system, pouring molten alloy obtained after remelting into a copper mold, and then obtaining a high-entropy alloy test sample Al14Co28Cr28Ni30. The preparation method is simple, safe and stable.

Owner:QINGHAI UNIVERSITY

Preparation method for bacteria-resistant medical gauze

ActiveCN105133130AEfficient cross-linking processGood tensile mechanical propertiesWoven fabricsYarnCotton fibreBlood circulation

The invention relates to a preparation method for a bacteria-resistant medical gauze. The raw material of the medical gauze is formed by chitosan fibers and cotton fibers; and the weight ratio of the chitosan fibers and the cotton fibers is 55 to 65 to 35 to 45. The bacteria-resistant medical gauze prepared by the method has traditional functions of bacteria elimination and prevention and cleaning and can further improve blood circulation, promote metabolism, remove fatigue and inducting resuscitation and caring brain; the gauze has smooth hand feeling and gentleness as well as comfort; the medical gauze is moisture-absorptive and ventilating and has comfortable feeling; and the gauze is a novel bacteria-resistant and mite-removal medical gauze.

Owner:JIANGSU PROVINCE JIANERKANG MEDICAL DRESSING CO LTD

Method for producing fibers used for twisted threads

InactiveCN104862793AImprove spinnabilityHigh breaking strengthArtificial thread manufacturing machinesSpinning head liquid feederFiberYarn

The invention discloses a method for producing fibers used for twisted threads. According to the method, MMWPE resin, HDPE resin, nanometer SiO2, an auxiliary agent, an agitator, a yarn separating machine, a yarn withdrawal machine, a single screw extruder and a twice-drafting electrical heating drafting machine are adopted, and the method is characterized in that the MMWPE resin, the HDPE resin, the nanometer SiO2 and the auxiliary agent are stirred to be uniform with the agitator, nano-modified compound granules are obtained, the nano-modified compound granules are melt and extruded through the single screw extruder, newly-generated yarn obtained through the extrusion is subjected to cooling and pre-drafting through a cooling water tank and a first drafting roller, pre-drafted yarn is subjected to hot drafting for twice through a high temperature first drafting water bath and a second drafting roller as well as a high temperature second drafting water bath and a third drafting roller, and after the drafting, fiber tows are reeled through the yarn withdrawal machine which uses a moment electric motor; the fiber tows are separated into the fibers used for the twisted threads through the yarn separating machine under the yarn separation tensile force, and the yarn separation tensile force is controlled to be 12%-21% of the fiber breaking force.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

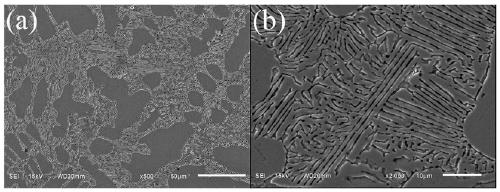

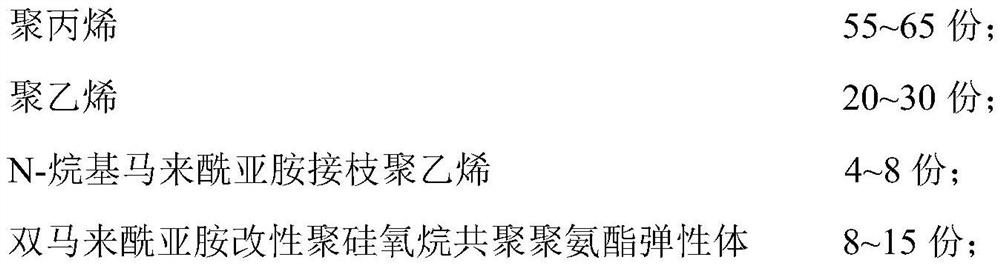

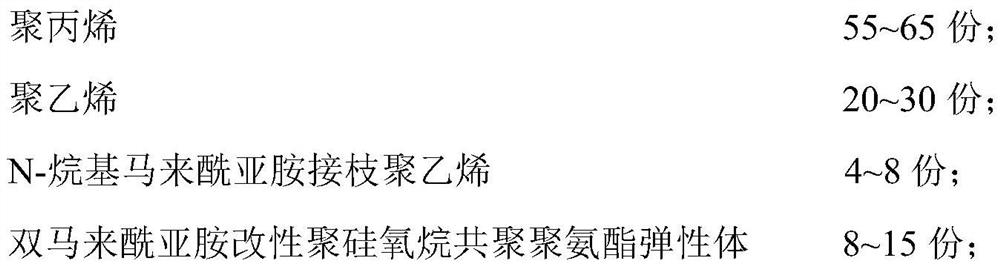

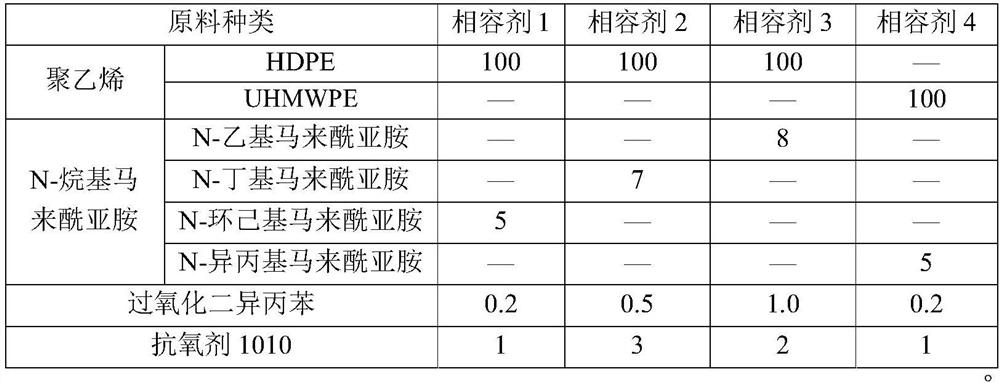

High-temperature-boiling-resistant low-temperature-toughness polyolefin plastic as well as preparation method and application thereof

The invention provides a high-temperature-boiling-resistant low-temperature-toughness polyolefin plastic as well as a preparation method and application thereof. The high-temperature-boiling-resistantlow-temperature-toughness polyolefin plastic is prepared from polypropylene and polyethylene, and Nalkyl maleimide grafted polyethylene is added as a compatilizer, so that not only is the compatibility of the polypropylene and the polyethylene improved, but also the heat resistance of the material can be improved by the Nalkyl maleimide; and in addition, a bismaleimide-modified polysiloxane copolymerized polyurethane elastomer and polyethylene are added to synergistically toughen the polypropylene, and meanwhile, the heat resistance of the material can be improved. According to the high-temperature-boiling-resistant low-temperature-toughness polyolefin plastic provided by the invention, the polypropylene is used as a continuous phase, the polyethylene is used as a dispersion phase, and asystem penetrated by a polysiloxane copolymerized polyurethane network does not deform after being boiled at the high temperature of 121 DEG C for 30 minutes, does not fall off and is not damaged at the low temperature of -30 DEG C and has excellent tensile and bending properties.

Owner:FOSHAN SOUTHERN PACKAGING

Stable manufacturing method of high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for pressure vessel

PendingCN112775204AHigh strengthHigh strength and high toughnessFurnace typesHeat treatment furnacesThick plateHeat treated

The invention relates to a stable manufacturing method of an aluminum alloy thick plate, in particular to a stable manufacturing method of a high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for a pressure vessel. The invention aims to solve the problem that the aluminum alloy plate with high strength, high toughness, high allowable stress and high corrosion resistance at the same time is difficult to prepare in the prior art. The manufacturing method comprises the following steps of 1, weighing and smelting; 2, casting; 3, homogenizing annealing treatment; 4, heating; 5, primary hot rolling; 6, secondary hot rolling; 7, solid solution; 8, high-temperature annealing; 9, primary aging; 10, secondary aging; 11, stabilizing heat treatment; 12, stretching; and 13, tertiary aging. The stable manufacturing method is mainly used for stably manufacturing the high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for the pressure vessel.

Owner:NORTHEAST LIGHT ALLOY CO LTD

A kind of preparation method of antibacterial and mite-removing medical towel

ActiveCN104958023BLow costFeel smoothTextile storage in superimposed formDry-cleaning apparatus for textilesWheat glutenResuscitation

The invention relates to a method for preparing an antibacterial anti-acarid towel. The medical towel is prepared by blending wheat gluten protein fibers and cotton fibers, and the weight ratio of the wheat gluten protein fibers to the cotton fibers is (10-15):(85-90). The towel has traditional sterilizing and bacteriostatic functions and a cleaning function, and also has the functions of improving blood circulation, promoting metabolism, eliminating fatigue, inducing resuscitation and strengthening brain; the prepared towel is smooth in hand feeling, soft, comfortable, capable of absorbing moisture, breathable and more comfortable, and is a brand new antibacterial anti-acarid medical towel.

Owner:保定金浩阳纺织品有限公司

A kind of preparation method of high-strength, high-modulus and high-elasticity polyurethane fiber

ActiveCN105155003BHigh breaking strengthHigh elongation at breakMonocomponent polyurethanes artificial filamentSpinnerette packsFiberPolymer science

The invention relates to a preparation method of high-strength, high-modulus and high-elasticity polyurethane fiber, belonging to the technical field of fiber materials. The preparation method of a high-strength, high-modulus and high-elasticity polyurethane fiber of the present invention is that after the polyurethane spinning solution is extruded through the spinneret holes, the polyurethane spinning solution is passed through deionized water, ammonium salt, organic solvent containing amide bonds, acetone with a long solidification distance. In a coagulation bath mixed with a low relative molecular weight anionic surfactant, wet drawing molding and heat treatment are carried out to obtain high-strength, high-modulus and high-elastic polyurethane fibers. The preparation method of the present invention realizes simultaneous enhancement of the breaking strength, Young's modulus and elongation at break of the polyurethane fiber, and the breaking strength of the polyurethane fiber prepared by the present invention increases by 150-280%, and the elongation at break increases by 60-120% , Young's modulus increased by 50‑160%. The preparation method of the invention has simple process equipment, low cost, no pollution to the ecological environment, high controllability and great application prospects.

Owner:WUHAN TEXTILE UNIV

Method of preventing corrosion by marine microorganisms by using artificial supper-smooth surfaces

InactiveCN104805532AImprove rigidityImprove toughnessFilament forming substance formingArtificial filament heat treatmentAntioxidantTorque motor

The invention discloses a method of preventing corrosion by marine microorganisms by using artificial supper-smooth surfaces. The method comprises the following steps: weighing and taking polycarbonate, acrylonitrile and styrene copolymer, a compatilizer, a flexibilizer, an antioxidant, a lubricating agent, a flame-retardant synergist, a brominated flame retardant, nanoscale dried titanium dioxide, a turpentine assistant for spinning, an acrylic acid type additive with perfluoroalkyl group, a heat-resistant agent and inorganic nanoparticles according to parts by weight; blending the raw materials, mixing and pelletizing the blended materials through a double-screw extruder to obtain mixed material aggregates; preparing the mixed material aggregates into nascent composite filaments through a single screw extruder; cooling the nascent composite filaments and carrying out hot stretching two times; degreasing the stretched composite filaments with high pressure draft and quickly cooling the degreased composite filaments, and using the filament-collecting machine of a torgue motor to collect and roll filament tows of composite filaments to obtain finished products. According to the invention, special proportion and special spinning technology are adopted, so as to improve the surface smoothness, capacity of microbiological corrosion resistance, breaking strength, knot strength, knot use ratio, durability and suitability of rope nets.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

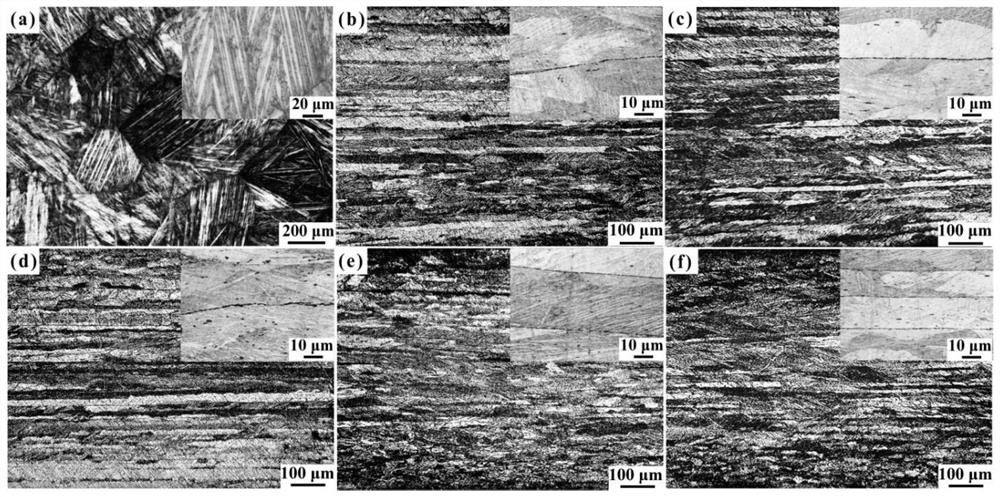

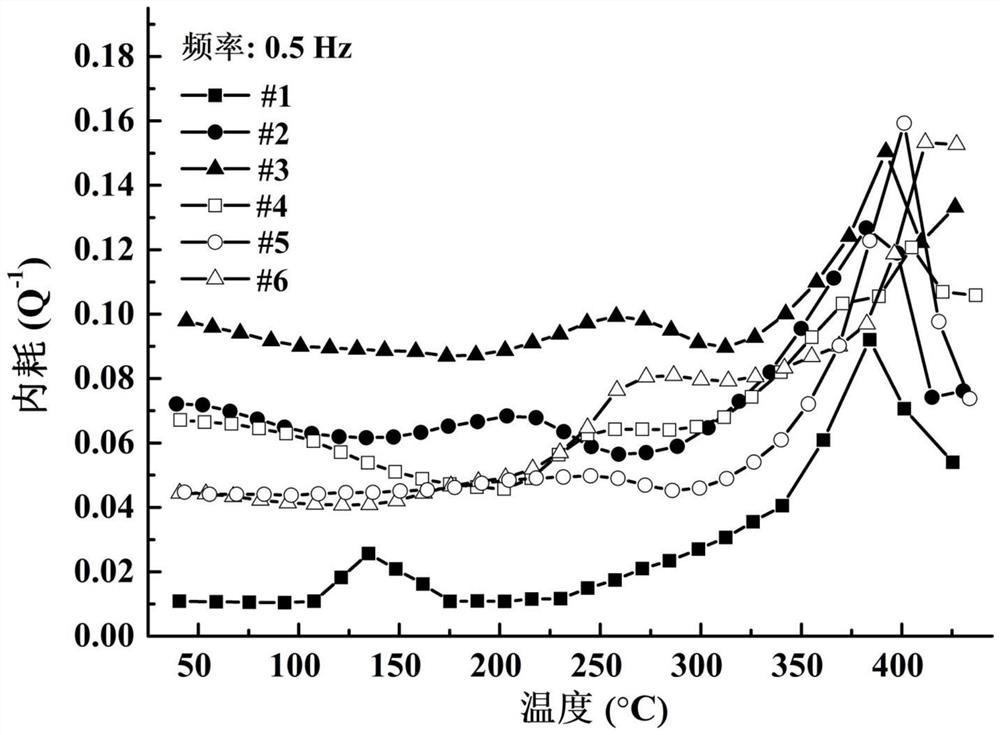

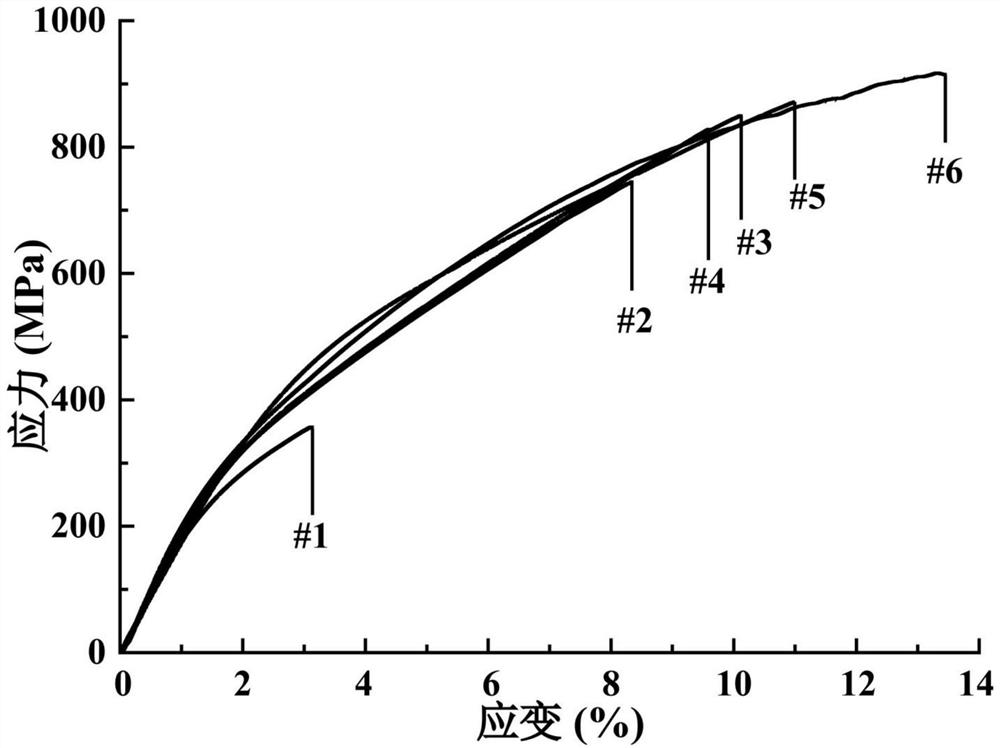

Ultrahigh-damping and high-strength metal-based composite material and preparation method thereof

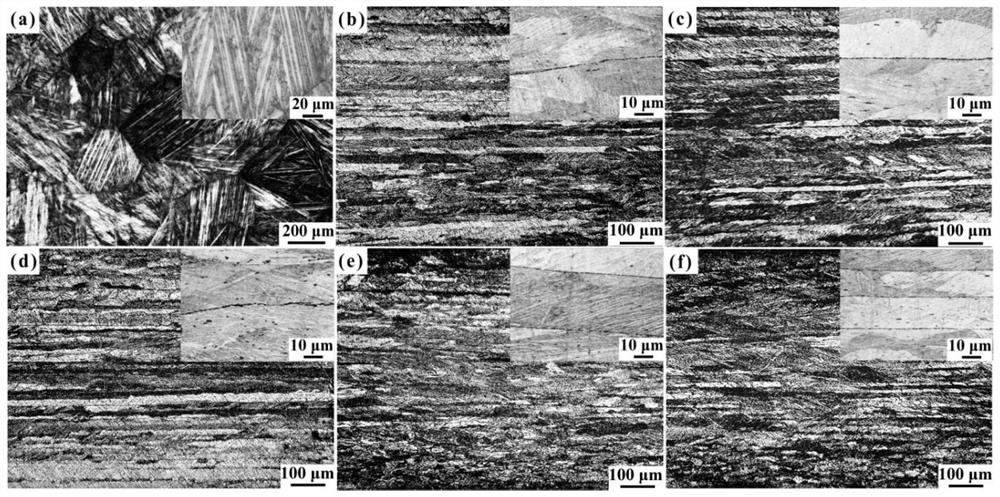

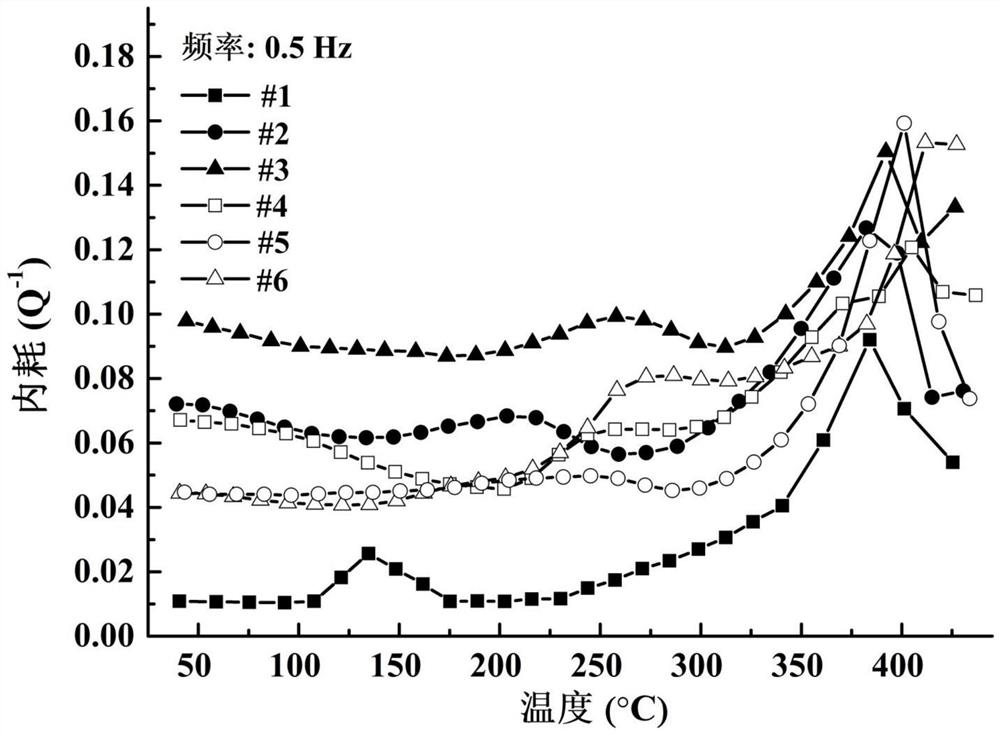

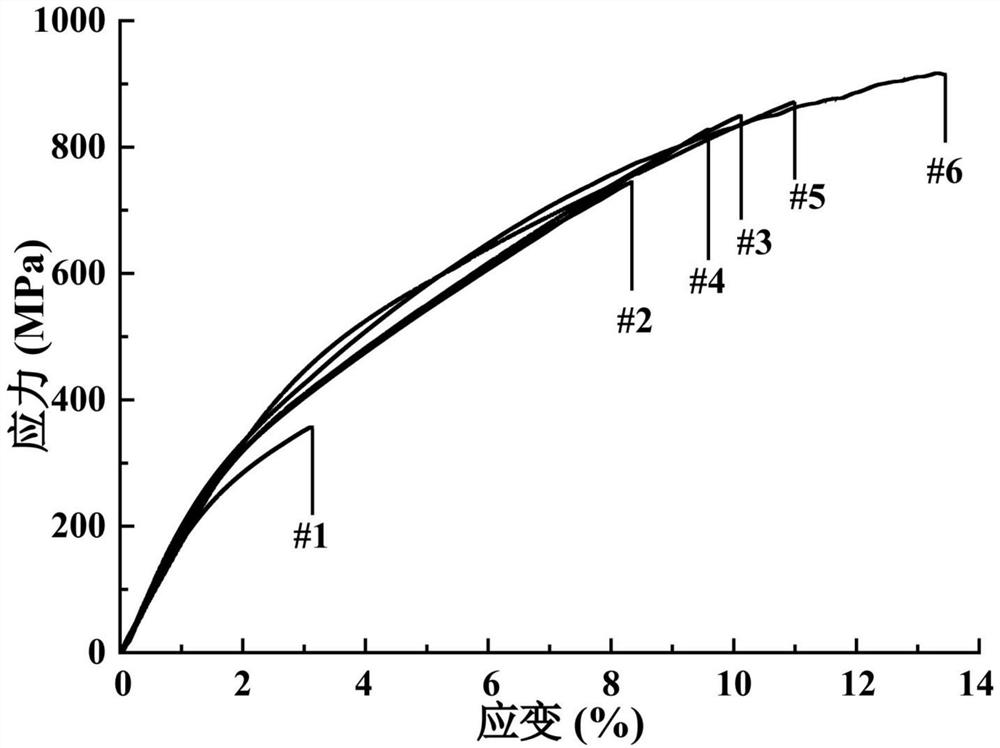

ActiveCN113119545AHigh mechanical dampingImprove energy consumptionLamination ancillary operationsLaminationLamellar structureGraphene

The invention discloses an ultrahigh-damping and high-strength metal-based composite material and a preparation method thereof, and relates to the technical field of composite materials. The composite material is composed of Cu-11.9Al-2.5Mn, 1.0 wt.% of a Cu51Zr14 nucleating agent and 0.05 wt.%-0.15 wt.% of multi-layer graphene, the room temperature damping of the composite material is 0.0444-0.0979, the tensile strength is 750.36 MPa-913.37 MPa, and the percentage elongation after fracture is 8.34%-13.48%. The composite material can better meet application requirements in the technical field of damping, and noise reduction. According to the preparation method of the material, the intrinsic high-damping reinforced-phase multi-layer graphene of a lamellar structure is added into a CuAlMn shape memory alloy by using a vacuum hot rolling technology for the first time, overcoming the defects that in the prior art, the damping improvement degree is limited, the process is complicated; the production period is long, and the like.

Owner:HEBEI UNIV OF TECH

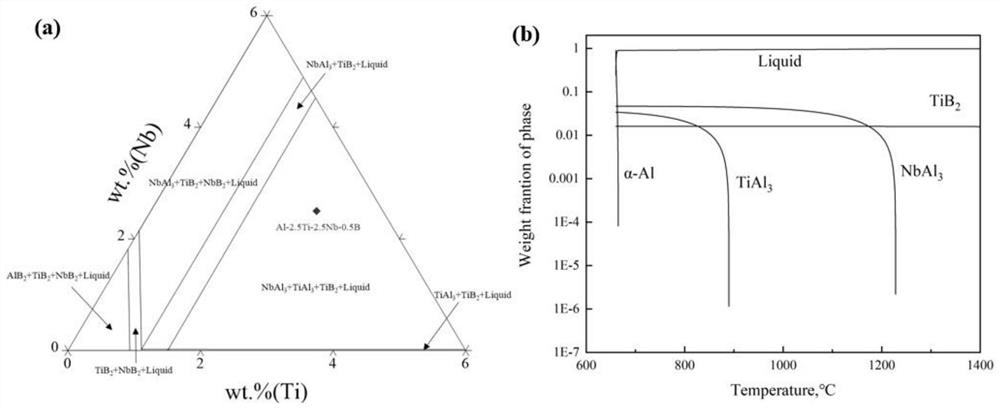

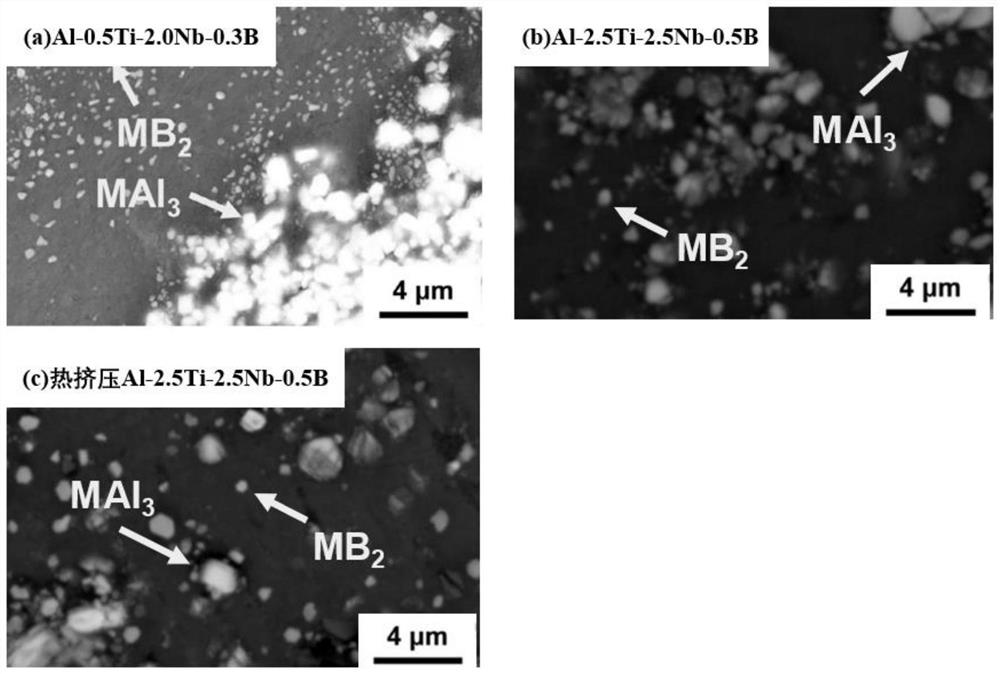

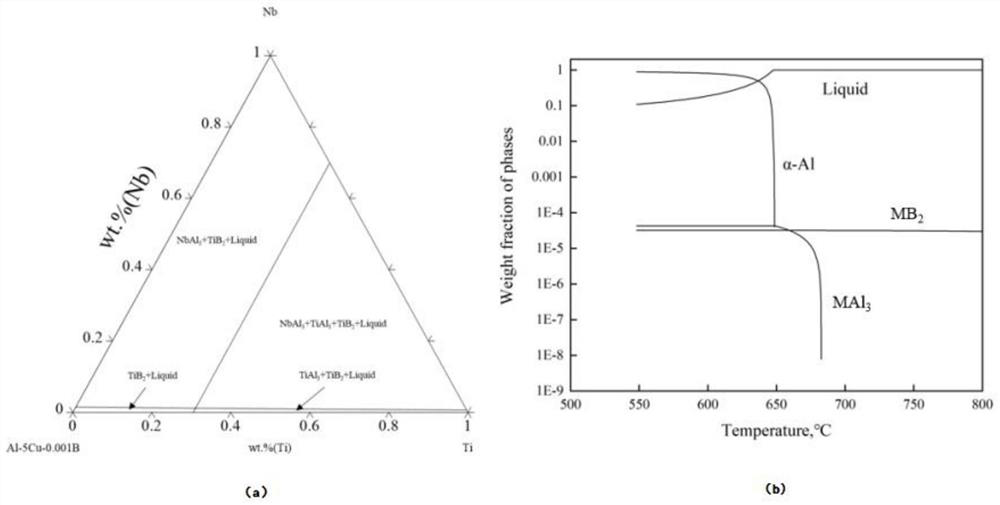

High-strength and high-toughness Al-Cu-(Al-Ti-Nb-B) alloy and preparation method thereof

ActiveCN113943879AHighlight substantiveGood tensile mechanical propertiesAlloyUltimate tensile strength

The invention discloses a high-strength and high-toughness Al-Cu-(Al-Ti-Nb-B) alloy and a preparation method thereof. The ratio of Ti to Nb of an Al-Ti-Nb-B intermediate alloy is determined to be 1: 1 according to thermodynamic calculation, the Al-Ti-Nb-B intermediate alloy is prepared by adopting a villiaumite reaction method, and the Al-Ti-Nb-B intermediate alloy is reprocessed by adopting a hot extrusion method. The Al-Cu-(Al-Ti-Nb-B) alloy disclosed by the invention is prepared from the following components in percentage by mass: 5% of Cu, 0.005-0.0125% of Ti, 0.005-0.0125% of Nb, 0.001-0.0025% of B and the balance of Al; and the phase of the alloy comprises one or more of NbAl3, TiAl3, TiB2 and NbB2 refining and strengthening phases, and the balance of Al2Cu and alpha-Al phase. The preparation method comprises the following steps: preparing an Al-Ti-Nb-B intermediate alloy, and carrying out hot extrusion and reprocessing; carrying out smelting and grain refining process of Al-Cu alloy melt; and preparing an as-cast alloy and carrying out T6 heat treatment. The grain size of the alpha-Al phase of the obtained alloy is smaller than 90 microns; and the maximum room temperature yield strength is 190.4 MPa, the tensile strength reaches 360.0 MPa, and the maximum ductility is 25.2%. The production cost is reduced, and the application range is expanded.

Owner:SHANGHAI UNIV

Preparation method of mite-removing and antibacterial medical towel

InactiveCN107338647ALow costFeel smoothBiochemical treatment with enzymes/microorganismsAbsorbent padsFiberPediatrics

The invention relates to a preparation method of mite-removing and antibacterial medical towel. The medical towel is prepared from raw materials including gluten fiber and cotton fiber through blending, and the weight ratio of the gluten fiber to the cotton fiber is (10-15):(85-90). The towel has traditional sterilization, antibacterial and cleaning functions and has the effects of improving blood circulation, promoting metabolism, relieving fatigue , inducing resuscitation and strengthening the brain, and the prepared towel touches smooth, soft, comfortable, moisture-absorbent and breathable, is comfortable and is novel mite-removing and antibacterial medical towel.

Owner:ZHEJIANG TWIN LANTERN HOME TEXTILE

Method for preparing akund fiber blended yarn fabric

InactiveCN106521785AGood tensile mechanical propertiesGood antibacterial propertiesWeft knittingBiochemical fibre treatmentCotton fibrePolyvinyl alcohol

The invention relates to a method for preparing akund fiber blended yarn fiber, and belongs to the technical field of textile fabrics. The method includes: using chitosan as a raw material, allowing the chitosan to react with succinic anhydride, and performing surface grafting modification on the chitosan to acquired N-succinyl modified chitosan; dissolving the N-succinyl modified chitosan in polyvinyl alcohol to acquire a processing solution; soaking akund fibers in the processing solution; allowing films to be attached to surfaces of the akund fibers so as to improve the antibacterial performance and the mechanical property of the akund fibers; blending the akund fibers with films on the surfaces thereof, cotton fibers and polyester staple fibers into yarns to improve the mechanical property; and interweaving the yarns according to a weft plain stitch structure into the akund fiber blended yarn fabric. The prepared akund fiber blended yarn fabric is excellent in fabric tensile mechanical property, abrasive resistance, air permeability and thermal insulation property, is good in antibacterial effect, and can greatly expand the application range of the akund fiber blended yarn fabric in spinning.

Owner:陈建峰

Gluten fiber preparation method

ActiveCN103484962ALow costSimple production processMonocomponent protein artificial filamentCellulose/protein filament chemical after-treatmentFiberThermal treatment

The invention relates to a gluten fiber preparation method which comprises steps as follows: (1), preparation of a spinning solution; (2), spinning with a wet method; (3) solidification; (4) crosslinking treatment of citric acid; (5), secondary drafting; and (6), thermal treatment for sizing. The gluten fiber preparation method has the advantages of low production cost and simple and efficient production process of gluten fiber.

Owner:JIANGSU SUNSHINE

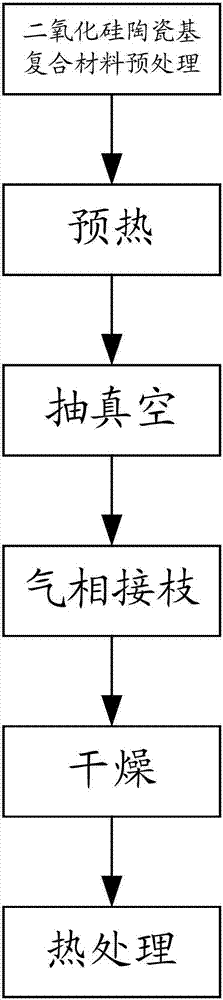

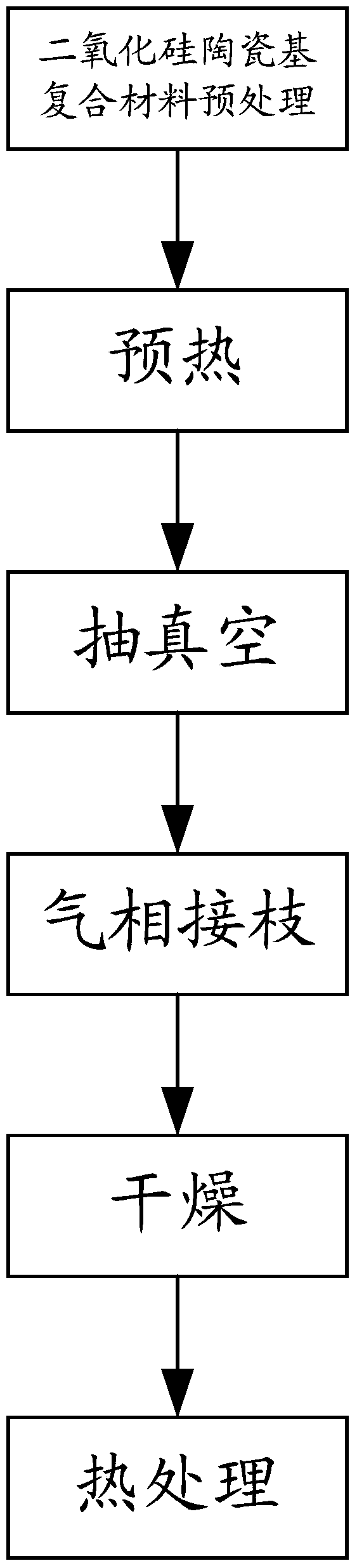

Method for improving tensile strength of silica ceramic based composite material

The invention provides a method for improving tensile strength of a silica ceramic based composite material. Gas phase grafting treatment is carried out for the silica ceramic based composite material by using methoxytrimethylsilane, drying pretreatment, preheating, vacuum-pumping, gas phase grafting, drying and heat treatment and other processes are used, in order to carry out enhancement for the silica ceramic based composite material, and the tensile strength of the material is increased by 15% or above. The technology is controllable, the technical bottleneck that tensile strength of the material in the prior moulding technology is improved, and the method is especially suitable for enhancing silica ceramic radome, antenna window, and other wave-transparent components.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of preparation method of high-strength, high-modulus, high-elasticity polyurethane film

The invention relates to a preparation method of a high-strength, high-modulus and high-elasticity polyurethane film, and belongs to the technical field of film materials. In the method for preparing a high-strength, high-modulus, and high-elasticity polyurethane film of the present invention, a polytetrafluoroethylene plate coated with a polyurethane solution is put into a mixture of deionized water, ammonium salt, an organic solvent containing an amide bond, acetone and a low relative molecular weight. The anionic surfactant is mixed into the coagulation bath obtained by mixing the coagulation bath, and the coagulation bath is mechanically stirred, and then wet-formed and dried to obtain a high-strength, high-modulus, and high-elasticity polyurethane film. The preparation method of the invention realizes simultaneous enhancement of the breaking strength, Young's modulus and elongation at break of the polyurethane film, the breaking strength of the polyurethane film prepared by the invention increases by 270-560%, and the elongation at break increases by 80-280% , the Young's modulus increases by 50‑270%. The preparation method of the invention has simple process equipment, low cost, no pollution to the ecological environment, high controllability and great application prospect.

Owner:WUHAN TEXTILE UNIV

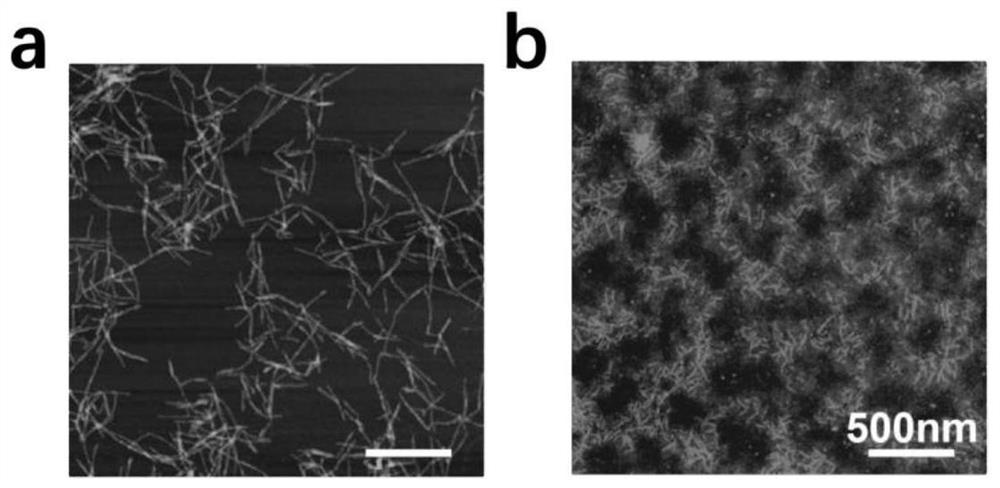

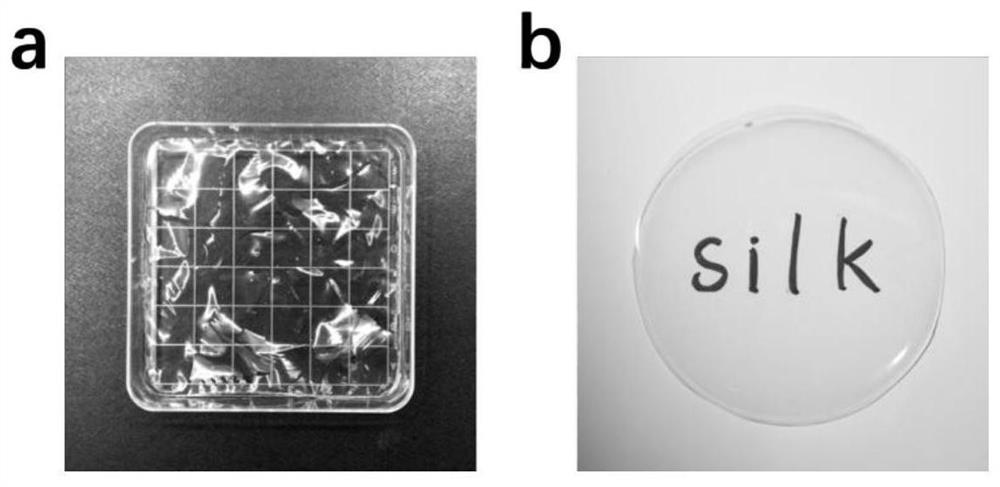

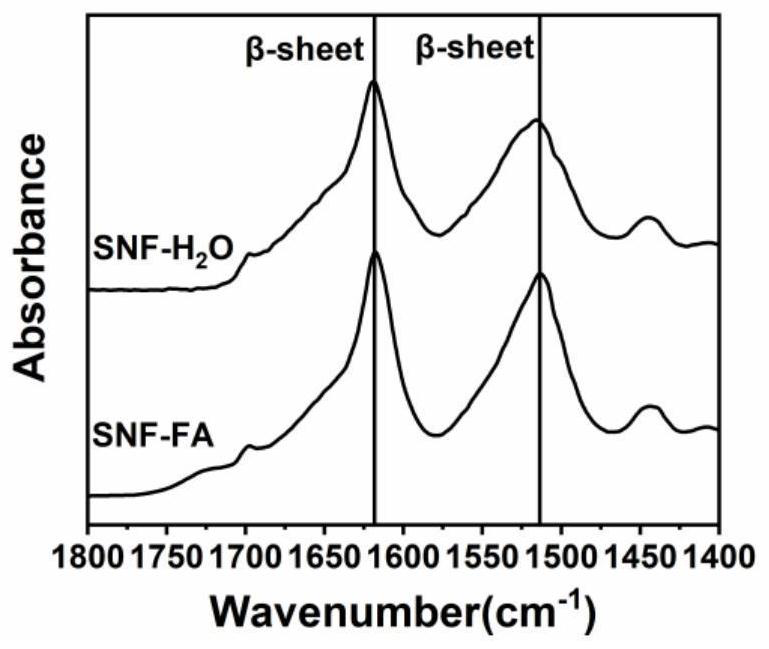

A kind of high-strength silk protein nanofiber membrane and its preparation method

ActiveCN112876711BImprove stabilityGood tensile mechanical propertiesPolymer sciencePolymer chemistry

The invention provides a high-strength silk egg nanofiber film and a preparation method thereof. The aqueous solution of high-crystalline silk protein nanofibers is freeze-dried to obtain silk protein nanofiber freeze-dried powder; dissolved in formic acid solution to obtain silk protein nanofiber formic acid The solution is volatilized to form a film to obtain a silk protein nanofiber film. The high-crystalline fibroin nanofibers used in this method have a beta-sheet crystal structure and good stability, and can still maintain their original secondary structure and nanofiber morphology when dissolved in formic acid, and due to the optimization of non-covalent interactions The tensile mechanical properties of the prepared membrane material are greatly improved. The invention realizes the transition of mechanical properties from fragile to strong and tough through simple solvent conversion, and shows high tensile mechanical strength in dry state and wet state, reaching 69.2-76.9MPa and 13.5-14.6MPa respectively, and in It is carried out under normal temperature and pressure, and the preparation method is simple and feasible.

Owner:SUZHOU UNIV

An ultra-high damping and high-strength metal matrix composite material and its preparation method

ActiveCN113119545BEfficient consumptionImprove energy consumptionLamination ancillary operationsLaminationShape-memory alloyPhysical chemistry

The invention relates to an ultra-high damping and high-strength metal matrix composite material and a preparation method thereof, and relates to the technical field of composite materials. The composition of the composite material is Cu‑11.9Al‑2.5Mn+1.0wt.% Cu 51 Zr 14 Adding 0.05wt.%-0.15wt.% multilayer graphene to the inoculant, the room temperature damping of the composite material is 0.0444-0.0979, the tensile strength is 750.36MPa-913.37MPa, and the elongation after fracture is 8.34%-13.48%, which can It satisfies the needs of applications in high-tech fields of vibration and noise reduction. This material preparation method uses vacuum hot rolling technology for the first time to add multilayer graphene with a lamellar structure to the CuAlMn shape memory alloy, which overcomes the The prior art has the disadvantages of limited damping improvement, complex process, long production cycle and the like.

Owner:HEBEI UNIV OF TECH

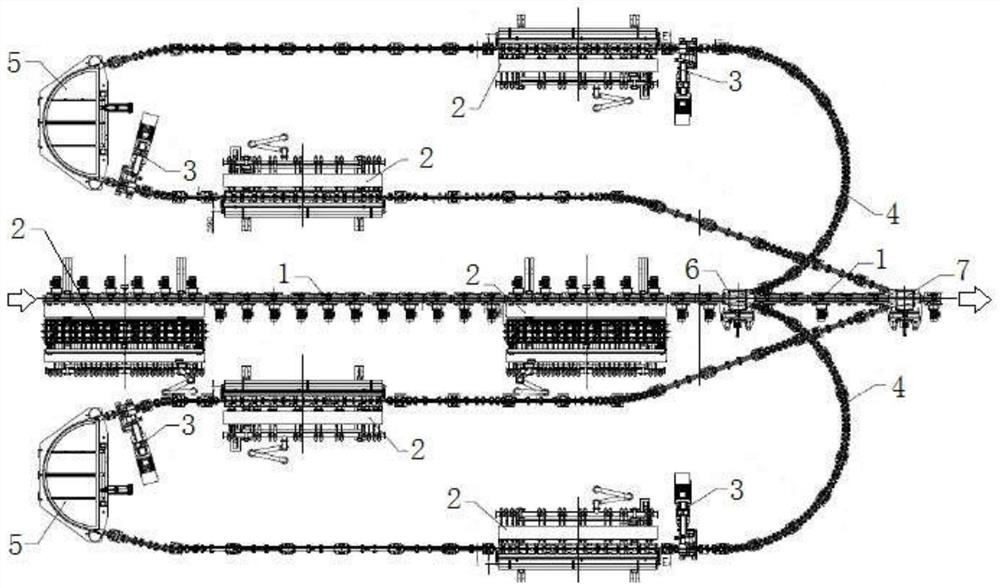

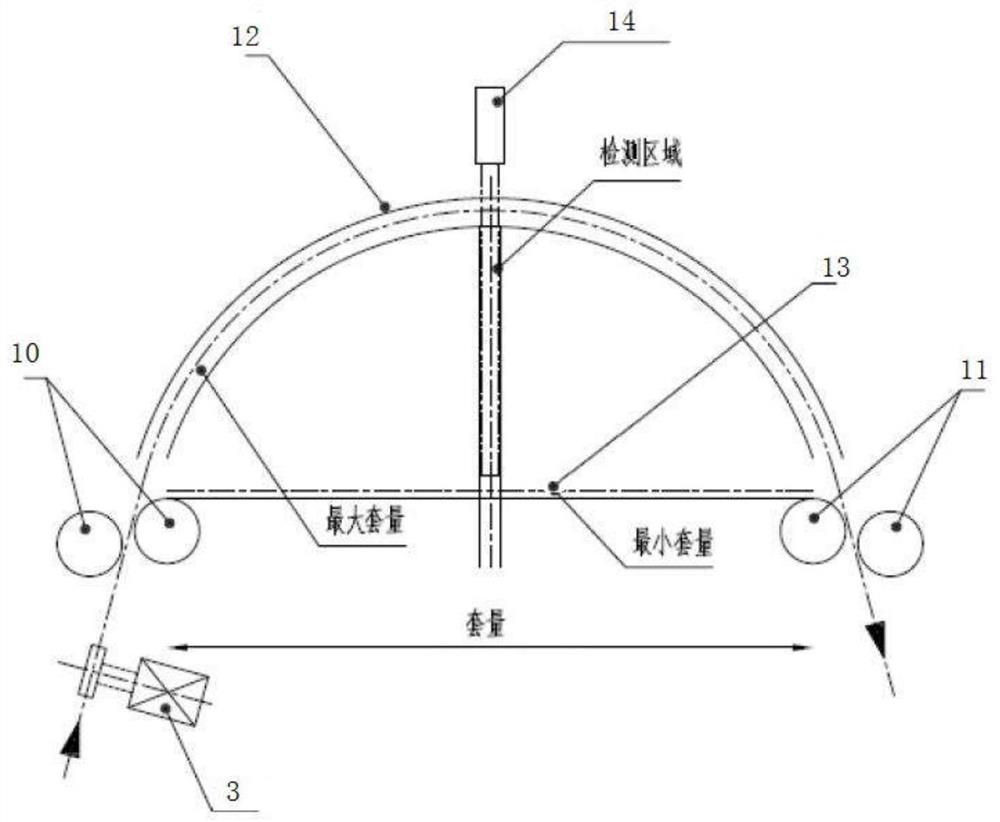

A real thermomechanical rolling 180-degree uniform temperature large looper production line or bar equipment

ActiveCN111229830BUniform temperatureGood tensile mechanical propertiesWork treatment devicesFlexible work arrangmentsSteelmakingWire rod

The present invention provides a real thermomechanical rolling 180-degree uniform temperature large looper production line or bar equipment, including a middle rolling mill, a temperature uniform device assembly, and a finishing mill; the temperature uniform device assembly is fixedly installed between the middle rolling mill and the finishing mill During the real thermomechanical rolling, the wire rod or bar is rolled at 750-800°C as a rolled piece, and the section along the entire rolled piece direction is in an ultra-fine grain state, and the temperature in the uniform temperature device assembly is controlled at 650-1100°C . This equipment utilizes the existing limited distance between the intermediate rolling mill and the finishing mill, and adds a section of side-mounted uniform temperature equipment assembly, which can effectively increase the cooling distance and cooling time, ensure sufficient cooling capacity, and make the distance between the intermediate rolling mill and the finishing mill The rolled piece continues to be kept at a low temperature without causing the grain fusion to become larger, effectively achieving the purpose of temperature control, so that the material can maintain a good tensile mechanical capacity, and at the same time relatively reduce the need to add manganese, etc. to the material in the steelmaking process. Percentage of precious metals to achieve cost savings.

Owner:无锡瑞进智能工程有限公司

A kind of method for improving the tensile strength of silica ceramic matrix composites

The invention provides a method for improving tensile strength of a silica ceramic based composite material. Gas phase grafting treatment is carried out for the silica ceramic based composite material by using methoxytrimethylsilane, drying pretreatment, preheating, vacuum-pumping, gas phase grafting, drying and heat treatment and other processes are used, in order to carry out enhancement for the silica ceramic based composite material, and the tensile strength of the material is increased by 15% or above. The technology is controllable, the technical bottleneck that tensile strength of the material in the prior moulding technology is improved, and the method is especially suitable for enhancing silica ceramic radome, antenna window, and other wave-transparent components.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Enhanced bi-component nanofiber porous membrane and preparation method thereof

InactiveCN102140734BHigh porosityImprove wettabilityFilament/thread formingCell component detailsPolymer scienceVoid ratio

The invention relates to an enhanced bi-component nanofiber porous membrane and a preparation method thereof. The porous membrane is a lithium ion battery membrane with two components of polymer resin and polyurethane. The membrane is in a semi-interpenetrating network structure which has a void ratio of 60-80%, and the mechanical property is 2-3 times higher than a single-component porous membrane of polymer resin. The preparation method comprises the steps of: dissolving a polymer resin and polyurethane prepolymer bi-component composition in a solvent, and preparing a nonwoven membrane through an electrospinning technology; and putting the nonwoven membrane at room temperature to make -NCO in the polyurethane prepolymer react with the -OH bond of water in the air to produce polyurethanethrough crosslinking and autopolymerization. In the invention, the nanofiber in the nonwoven membrane binds to form the polymer resin and polyurethane bi-component compound membrane, and the mechanical strength of the fibrous membrane is improved greatly. The method is easy, and the prepared nonwoven membrane maintains the advantages of high void ratio, and good thermal stability of polymer resinof the membrane prepared by using the electrospinning technology, and the membrane has good ion permeability and electrolyte affinity.

Owner:WUHAN UNIV OF TECH

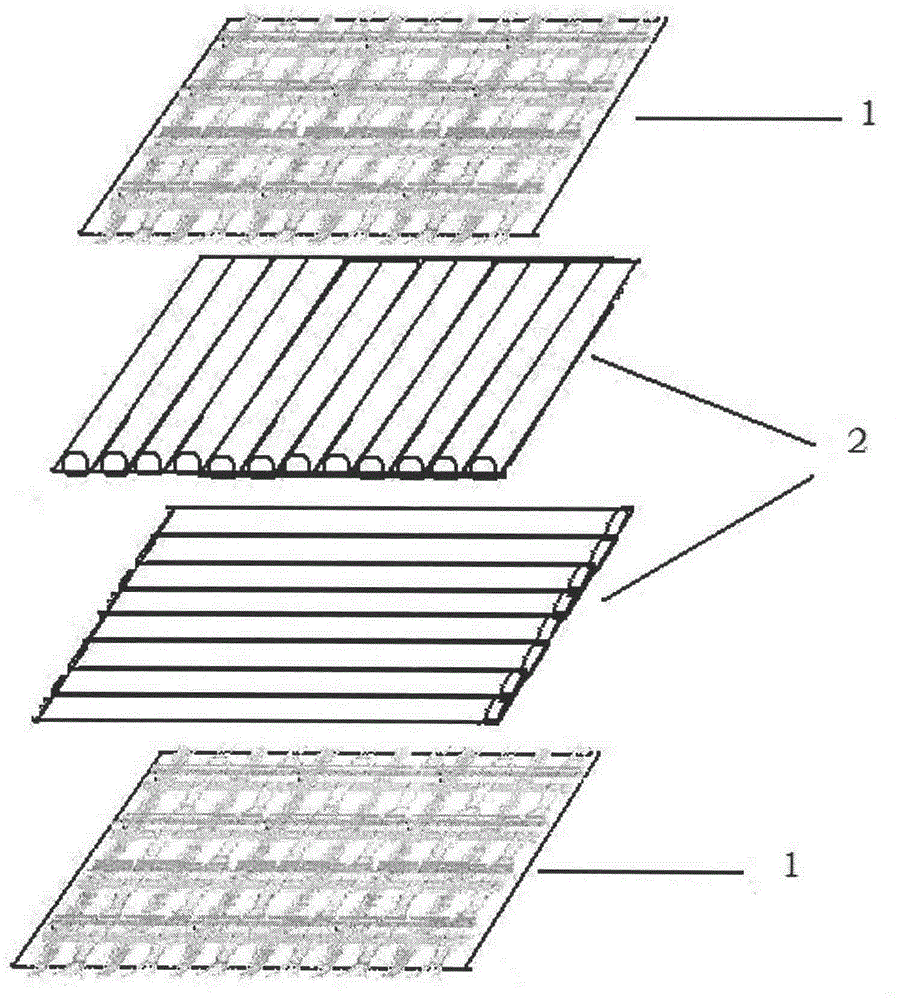

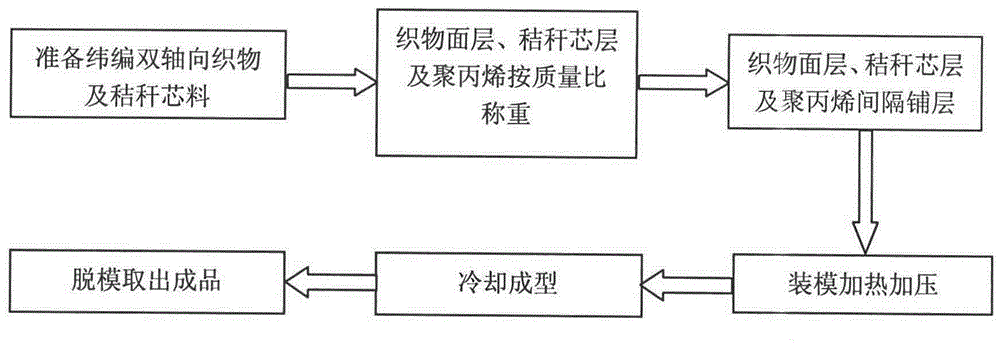

Light sandwich-structure composite material and preparation method thereof

ActiveCN102615870BImprove protectionEasy thickness changeSynthetic resin layered productsLaminationYarnSurface layer

The invention discloses a light sandwich-structure composite material and a preparation method of the light sandwich-structure composite material, belonging to the field of materials and relating to a weft knitting duel-axial fabric. The light sandwich-structure composite material takes a jute weft knitting duel-axial fabric as a surface layer and a straw core material as an intermediate layer and is prepared by performing hot pressing on the fabric and the core material and polypropylene chopped fibers. The weight of the light sandwich-structure composite material is lighter than a jute fabric reinforced polypropylene layer composite layer with the same thickness by 10-25%, the tensile strength is 23.5-50.2Mpa, and the flexural strength is 32.6-75.2Mpa. The surface layer fabric of the composite material can bring the characteristics of high strength and high modulus of yarns into full play, and simultaneously has unique excellent forming property. The sources of raw materials of a straw core layer are rich, and the straw core layer has the characteristics of low density, easiness in compression, good heat insulation, etc. The light sandwich-structure composite material can replace wood or synthetic fibers such as glass. The composite material can meet the general requirements of mechanical property; in addition, on the aspect of civil use, the light sandwich-structure composite material can be used as a non-load-carrying structure or a partial load carrying part and has vast potential for future development.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com