A real thermomechanical rolling 180-degree uniform temperature large looper production line or bar equipment

A looper, thermo-mechanical technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of increasing cost and the inability to guarantee the mechanical properties of materials, and achieve cost saving and good tensile mechanical ability. , the effect of uniform organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

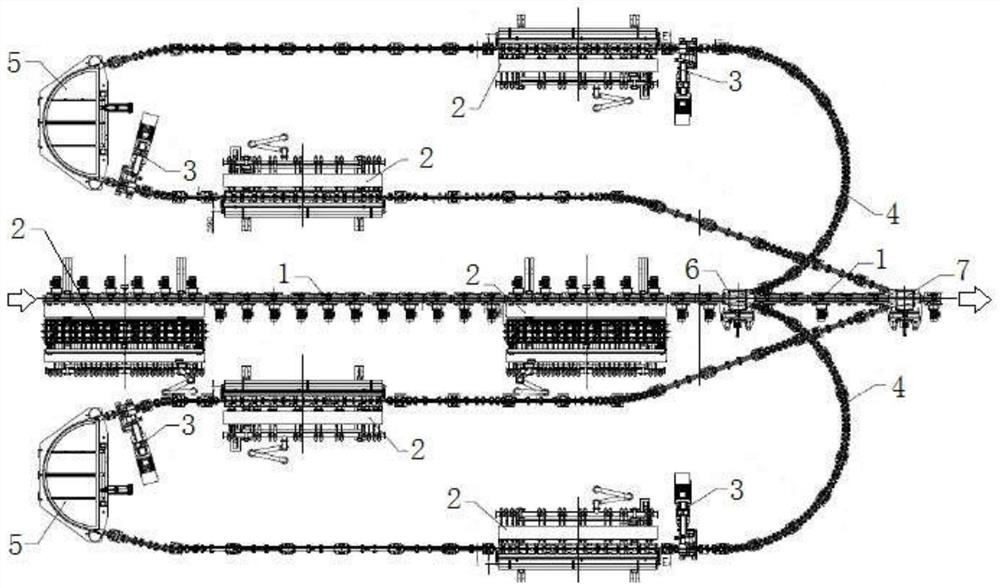

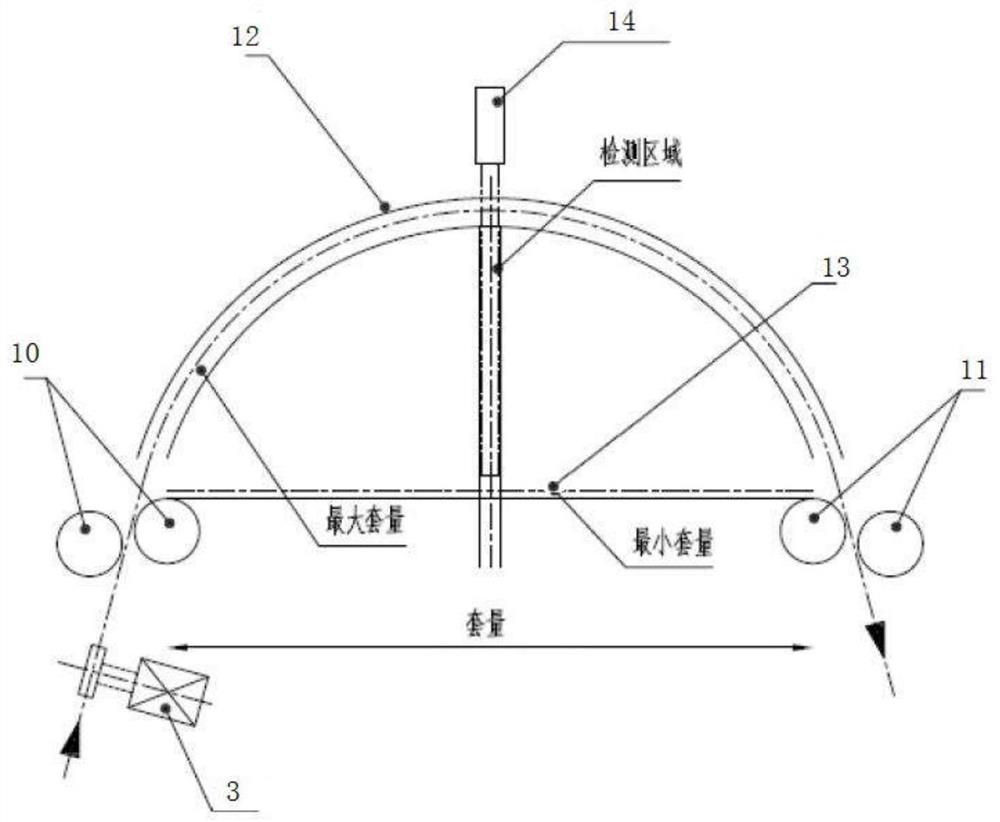

[0035]The diameter of the hot-rolled material is 30mm, and it passes through the 18V intermediate rolling mill, the No. 1 cooling water tank, the cooling water tank No. 1 and No. The group of forks are respectively arranged symmetrically in a circular shape, with the same structure, all of which are extended ring structures. The third group of forks is passed through a set of uniform temperature rails 1 and directly enters Hegang turnout 7 for rolling and transported out, and then passes through the 19H finishing mill to obtain the final product .

[0036] Taking the first fork as an example, the hot-rolled material transported from the sub-steel switch 6 sequentially passes through the uniform temperature guide groove 4, the No. 1 pinch roller, the No. 3 cooling water tank, the uniform temperature guide groove 4, and the uniform temperature large looper 5 , No. 2 pinch roller, No. 4 cooling water tank, and uniform temperature guide groove 4 enter Hegang turnout 7 for rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com