Patents

Literature

246results about How to "Uniform tissue structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

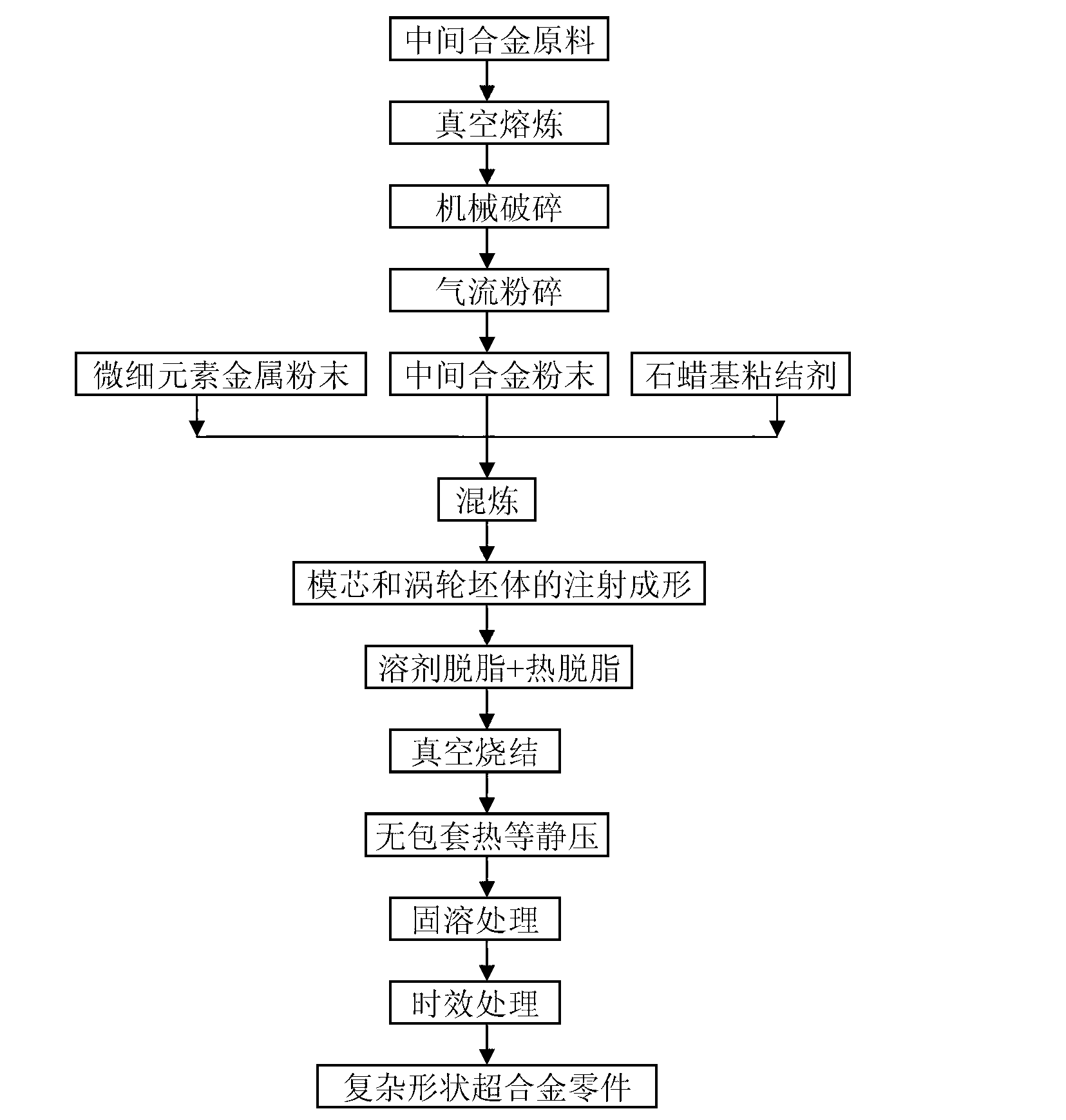

Method for preparing powder super-alloy by near net shape

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

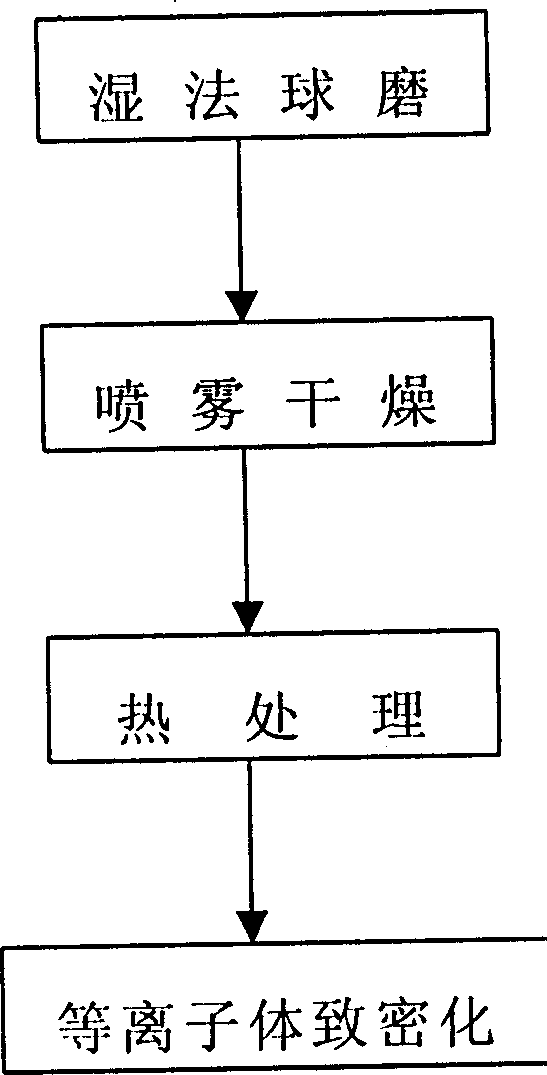

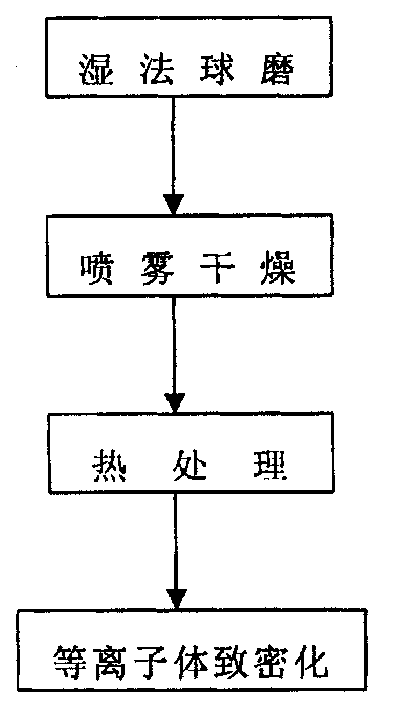

Method for producing and using large particle ball nano ceramic powder

InactiveCN1377857AUniform tissue structureImprove performanceCeramic layered productsThermal sprayingHigh density

The production process of nano ceramic powder includes the steps of: wet ball milling to obtain water-thinned nano colloid; spray drying to obtain large particle spheircal nano ceramic powder; heat treatment; and plasma densifying the large particle spherical nano ceramic powder after being heat treated. The nano ceramic powder thus produced has good flowability and high density and may be used through hot spray painting and sintering to form. The present invention reduce fragility of ceramic and raise the performance of hot spray painted and sintered ceramic products.

Owner:BAIFURUI MATERIAL HUNAN

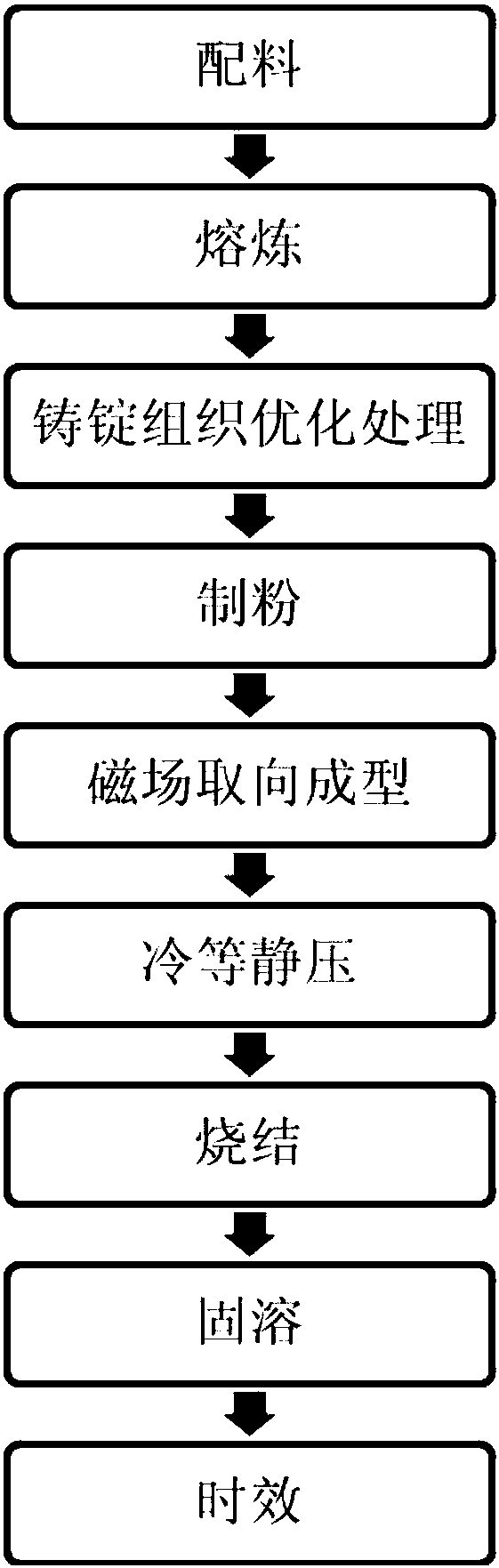

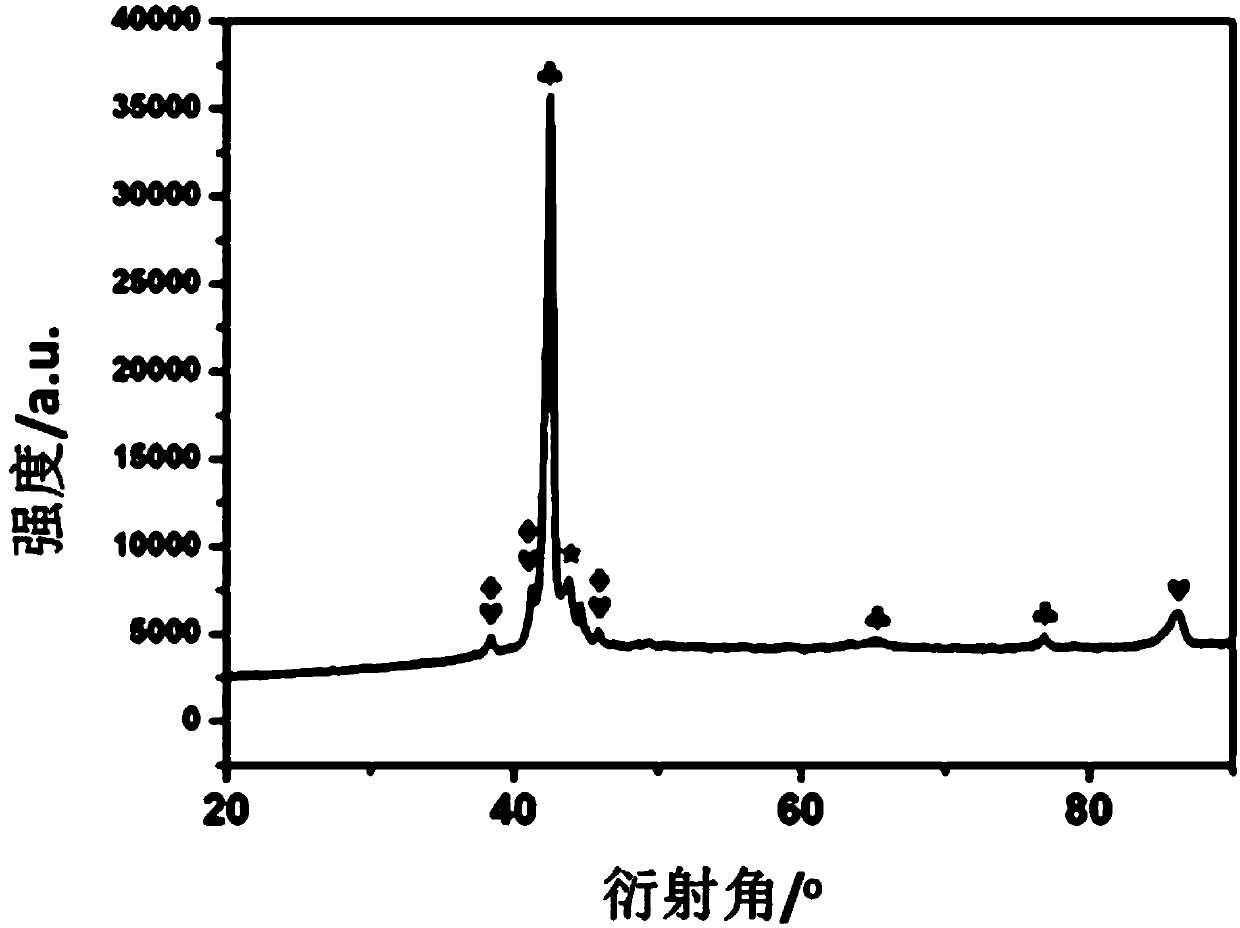

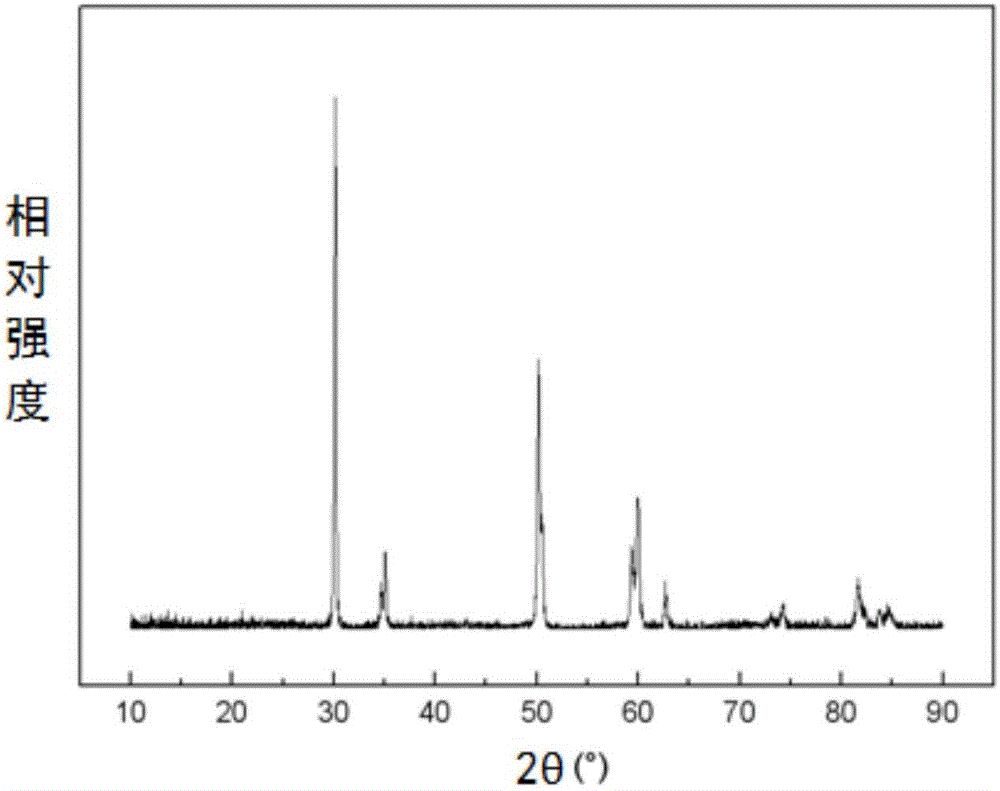

High-temperature high-coercivity samarium-cobalt permanent magnet material and preparation method thereof

ActiveCN108039258ALarge-scale industrial productionPromote growthInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementIngot

The invention provides a high-temperature high-coercivity samarium-cobalt permanent magnet material and a preparation method thereof. The permanent magnet material is Sm(Co1-u-v-wFeuCuvZrw)z, whereinu ranges from 0.09-0.18, v ranges from 0.05-0.10, w ranges from 0.02-0.04 and z ranges from 6.9-7.8. The preparation method includes the steps that the rare earth element Sm with the purity of 99.95%,Co with the purity of 99.98%, Cu with the purity of 99.99%, Fe with the purity of 99.9% and Zr with the purity of 99.9% are evenly mixed and smelted into an alloy ingot, and the ingot is subjected tostructure optimization treatment; micron-sized alloy powder is prepared by using the powder metallurgy technology, then orientation forming, high-temperature sintering, solid solution and aging treatment are conducted, and the samarium-cobalt permanent magnetic alloy is prepared. According to the method, the proportion of a TbCu7 structure is effectively improved, and a samarium-cobalt permanentmagnet free of a Zr6(FeCo)23 phase and uniform in structure is prepared, has high coercivity, high magnetic energy and other excellent properties at ultra-high temperature and can be suitable for ultra-high-temperature environments with the temperature of 550 DEG C or above.

Owner:BEIHANG UNIV

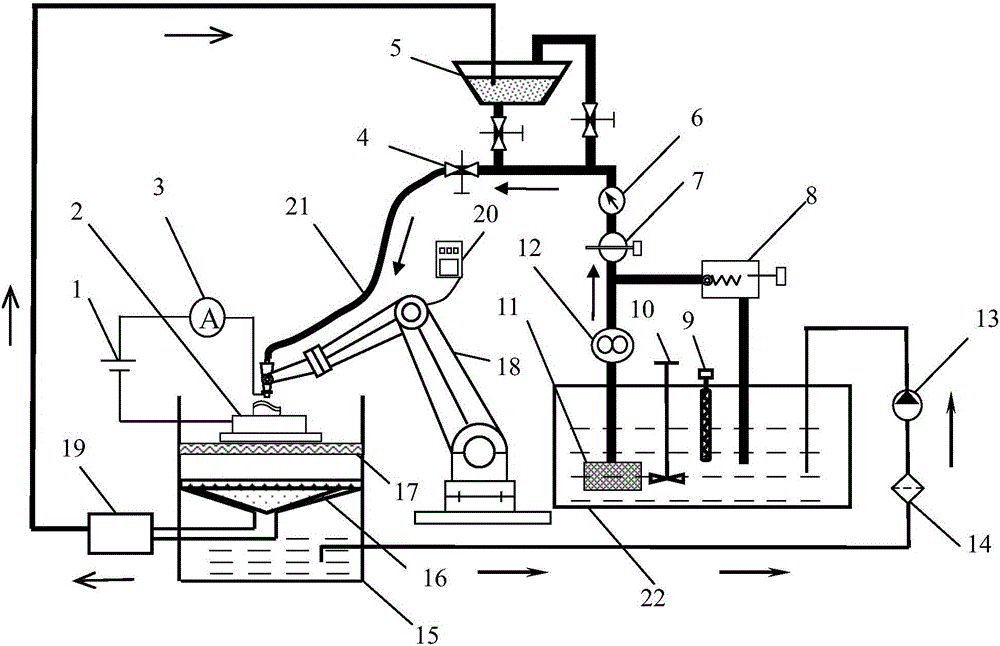

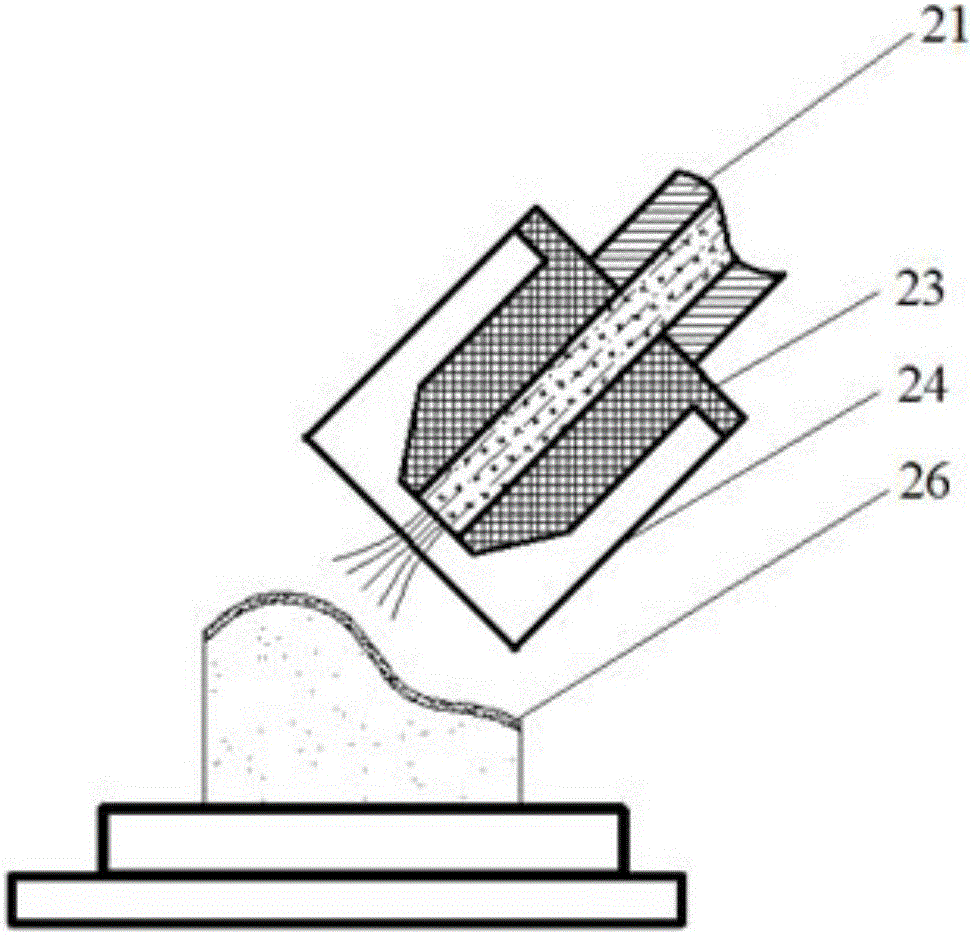

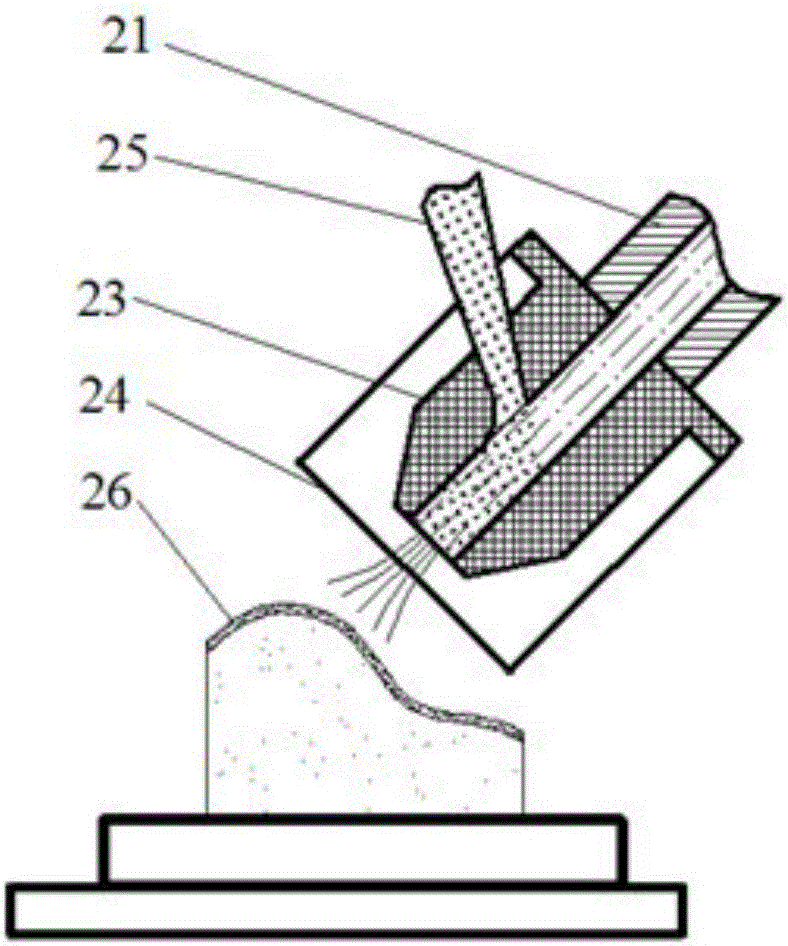

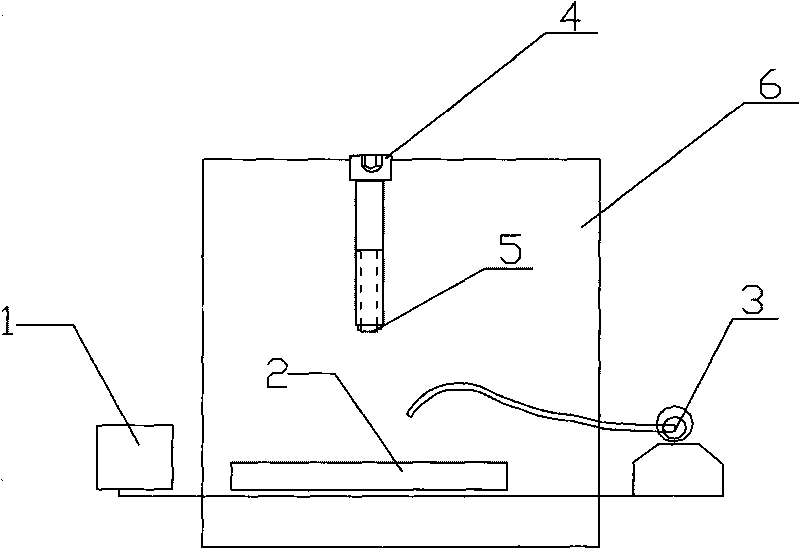

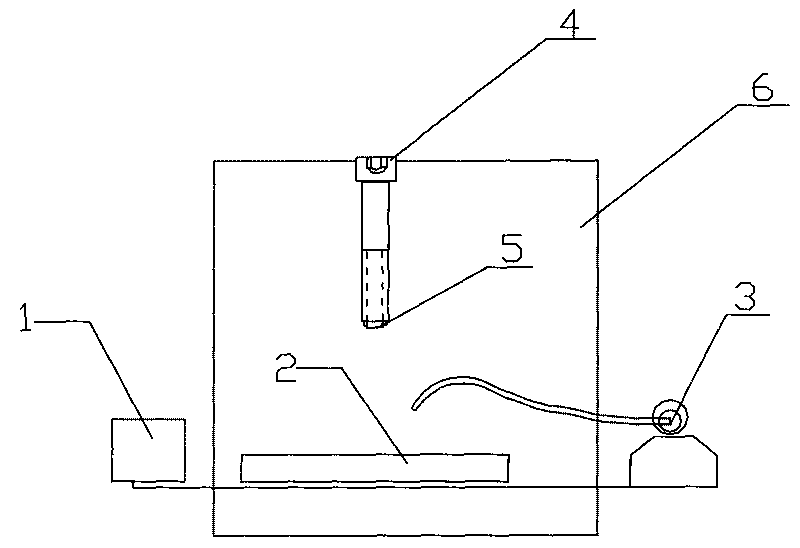

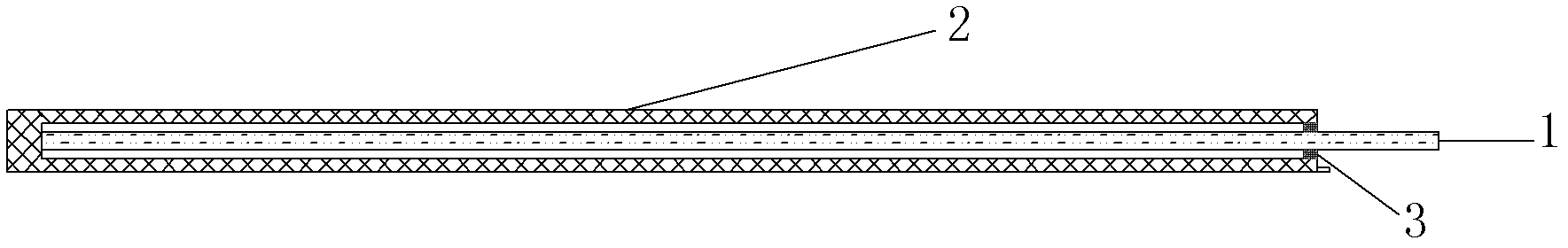

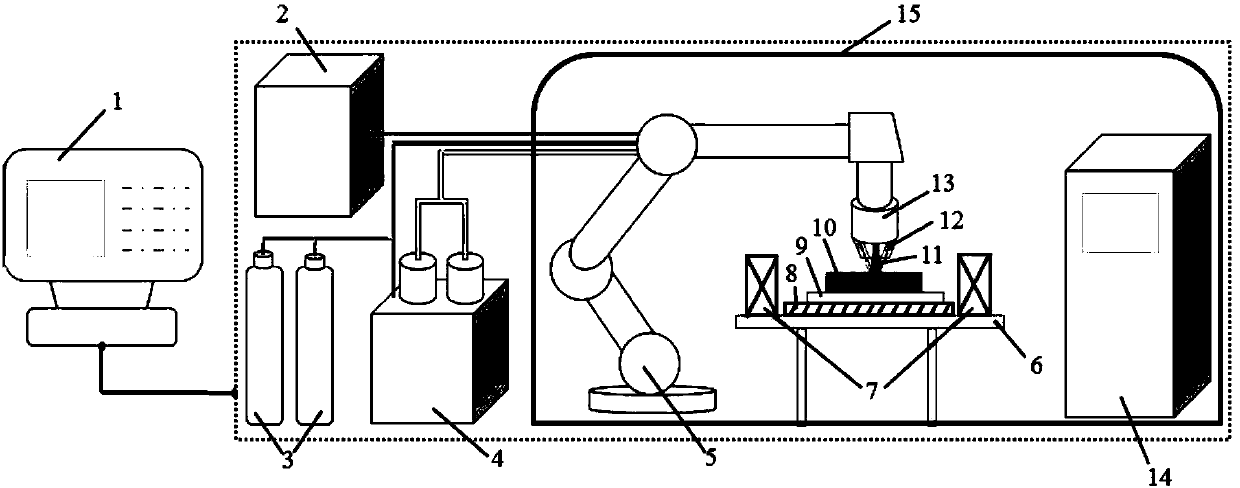

Three-dimensional surface shot peening jet electrodeposition manufacturing method and device

InactiveCN105951141ARemove in timeInhibit nodulationElectrolysis componentsElectrolytic coatingsNumerical controlImpurity

The invention provides a three-dimensional surface shot peening jet electrodeposition manufacturing method and device. According to the manufacturing method and device, a deposition solution and hard particles are mixed and deposit on a conductive substrate in a spraying manner, so that the rapid manufacturing technology of electrodeposition is realized, the growth rate of grains in the electrodeposition process is slowed down, the purpose of refining the grains is reached, and the quality of a deposition layer is dramatically improved; with combination of the shot peening strengthening technology and the electrodeposition technology, the defects of loose texture, pockmarks, pits and the like of the deposition layer caused by single electrodeposited cathode hydrogen evolution and impurity adhesion can be effectively overcome, and the hardness and the compactness of the deposition layer are improved; meanwhile, by introducing a five-axis linkage numerical control machining system, processing formation of a three-dimensional space can be realized, and the uniformity and the shape accuracy of the deposition layer are improved; and the technology can be widely applied to production of noble metal devices and parts in complex shapes and can also be used for surface rapid coat-plating, a strengthening technology and the like.

Owner:JIANGSU UNIV

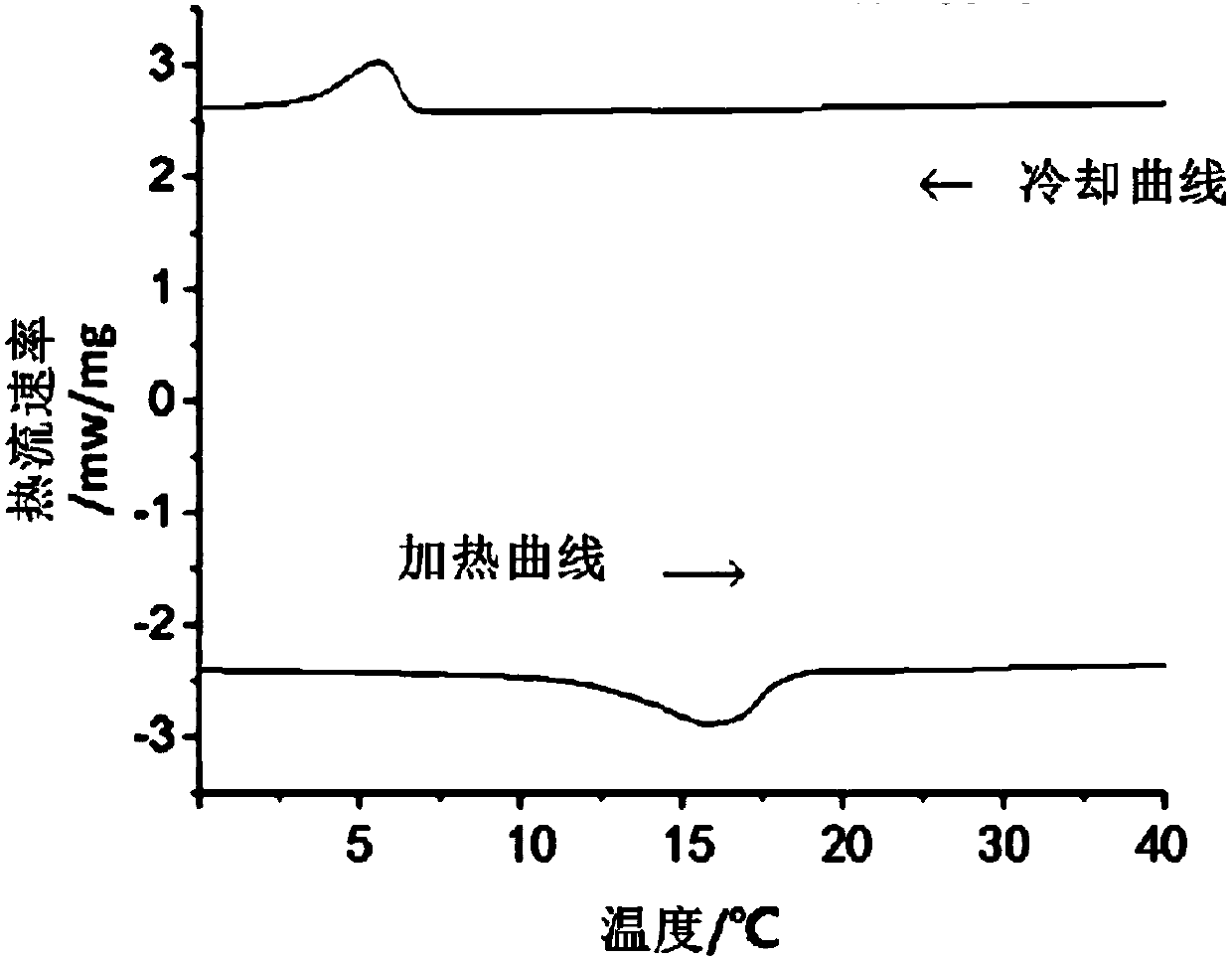

Preparation method of nanometer iron-based soft magnetic block

InactiveCN101752074ALow costSimple processInductances/transformers/magnets manufactureAutomatic controlLaser scanning

The invention discloses a preparation method of a nanometer iron-based soft magnetic block. Nanometer iron-based soft magnetic powder is served as the main raw material. The shape of a nanometer iron-based soft magnetic block to be prepared is designed by professional 3D graphics software on a computer; then, computer graphics processing software decomposes the designed 3D graphics into a series of processing signals controlling laser scanning speed, output power, sintering paths, feeder feeding amount, feeding position and the like by an automatic control device; the feeder and the laser feed and sinter by layers under the control of the signals until the shape of the nanometer iron-based soft magnetic block to be prepared is sintered. The novel nanometer iron-based soft magnetic block is different from the block produced by nanometer ligatures, forms a unified entity, does not have gaps and has favourable permeability; with respect to the known production process of other nanometer soft magnetic blocks, the preparation method has low requirements of environment and technology and does not need to manufacture the corresponding mould in advance.

Owner:WUHAN FUHAN TECH

Hot-dip zinc aluminum magnesium silicon rare earth coated steel strips taking air as air source of air knife during production

InactiveCN101812653AEvenly distributedUniform tissue structureHot-dipping/immersion processesCeriumAir knife

The invention relates to hot-dip zinc aluminum magnesium silicon rare earth coated steel strips taking air as an air source of an air knife during production. The coating material on the surface of the steel strips comprises the following components in percentage by weight: 9.9 to 12.1 percent of Al, 1.0 to 1.8 percent of Mg, 0.18 to 0.22 percent of Si, 0.01 to 0.3 percent of rare earth (RE), and the balance of Zn. Based on a quaternary component Zn-Al-Mg-Si in Nippon Steel, the rare earth (RE) comprising lanthanum and cerium is added into the coating material so as to become a quintuple component Zn-Al-Mg-Si-RE, and the content of the magnesium is reduced. Because of the addition of the trace RE, the component distribution of the coating can become more uniform, the organizational structure is more uniform, and the corrosion resistance is further improved based on the original corrosion resistance; and because the content of the magnesium is reduced properly, the coating can bear the blowing of the air knife and cannot be oxidized and discolored on the premise of ensuring high corrosion resistance, and meets the requirements of the corrosion resistance and apparent mass.

Owner:梁士臣

Method for preparing recrystallized SIC high temperature gas filter element

InactiveCN1821180AAchieve functional optimizationAvoid erosionFiltration separationCeramicwareFiberPore distribution

The present invention relates to preparation process of porous ceramic filter element for high temperature corrosive condition use. The preparation process features the pore creating with organic pore creating agent, spray pelletizing and isostatic pressing formation, high temperature Ar protected sintering to prepare high strength and low filtering resistance recrystallized SiC filter element support, multiple spraying of ceramic slurry with pore creating agent of different granularity to the surface of the support, and sintering to form filtering mullite coating with gradient pore distribution, adding alumina fiber into the filtering layer to raise the strength of the filtering layer and the combination between the coating and the support. The filtering element of the present invention has high mechanical strength, high heat shock resistance, high corrosion resistance, high wear resistance, high filter precision, low pressure drop and high stability.

Owner:GUIZHOU NEW MATERIAL MINING DEV

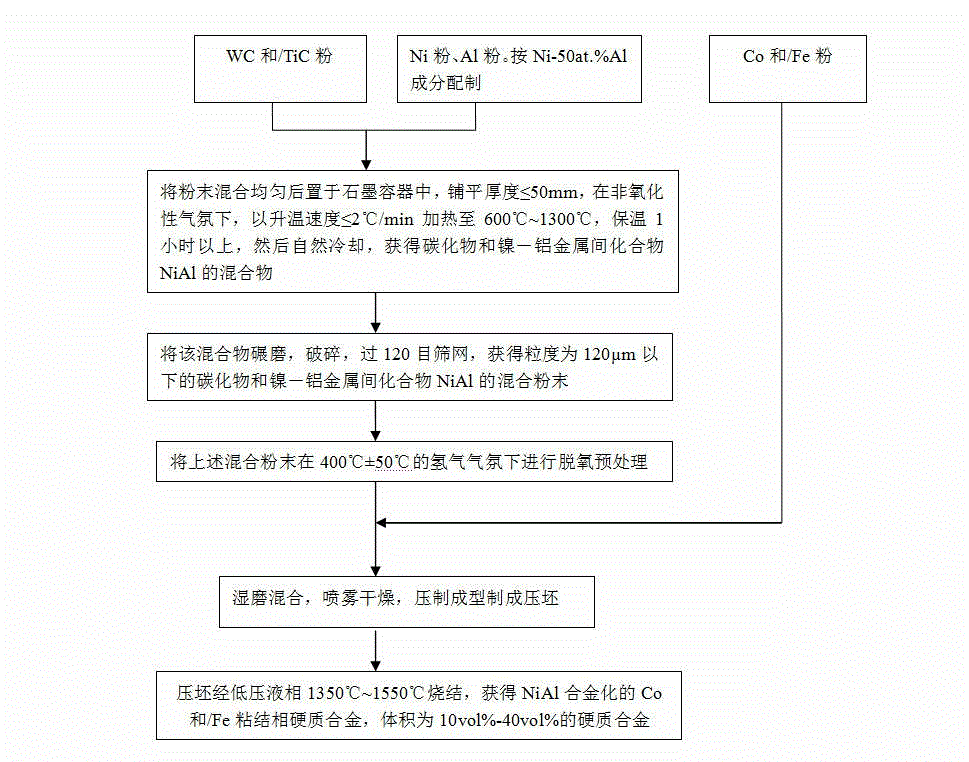

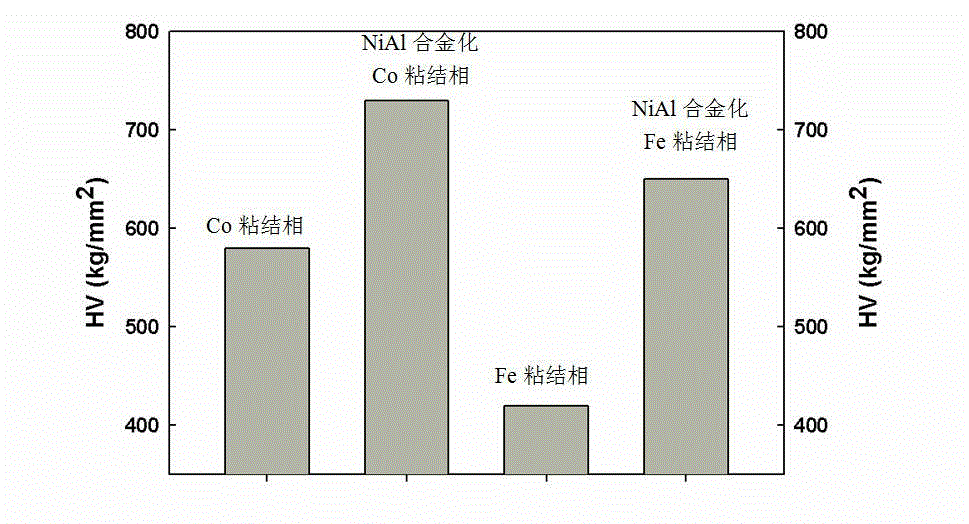

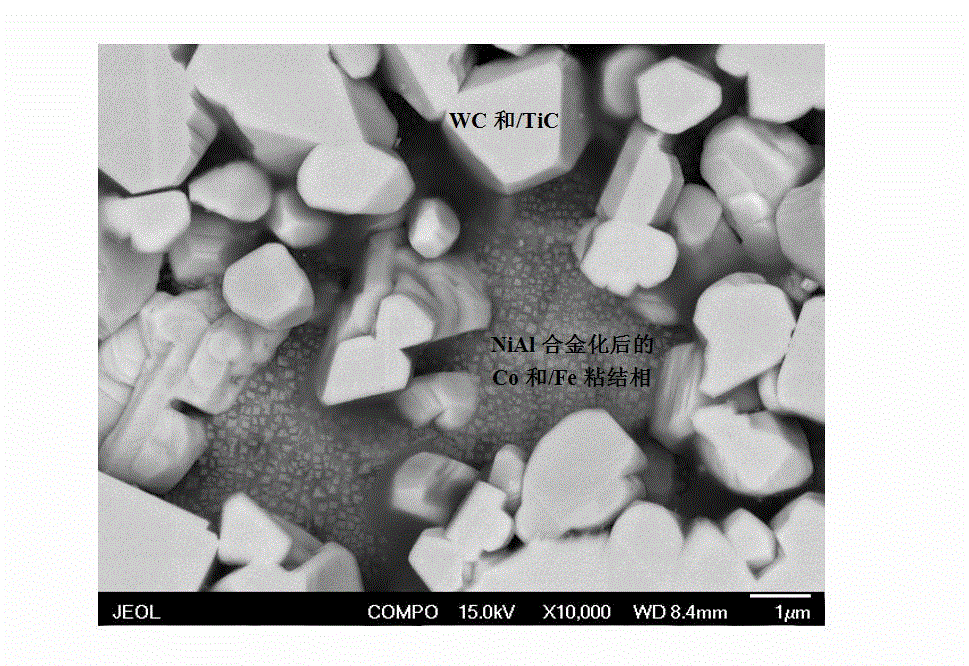

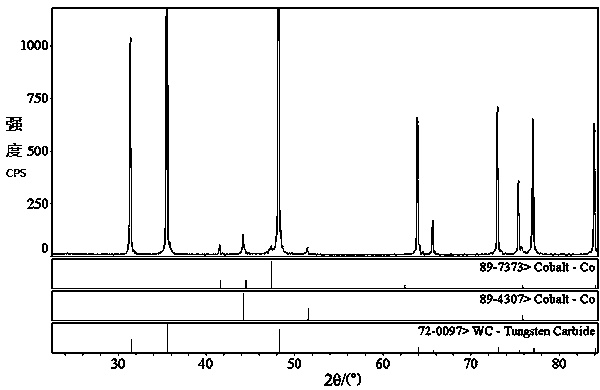

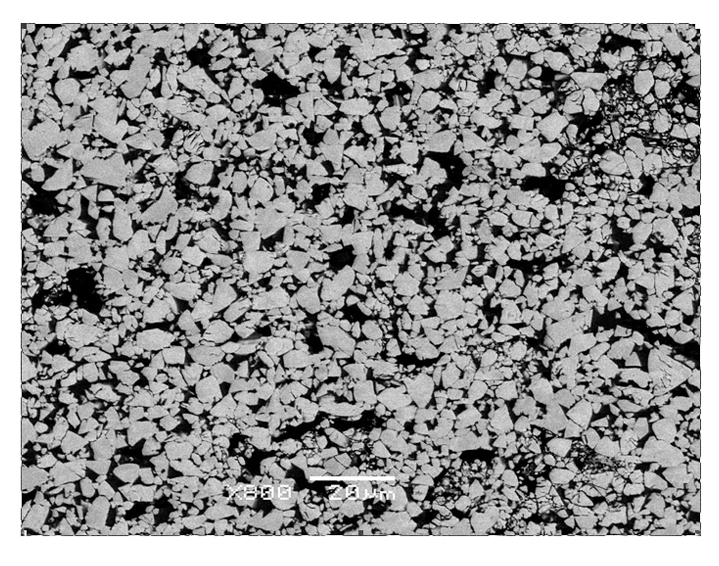

High-temperature-resistant and wear-resistant hard alloy and preparation method thereof

ActiveCN102978499AGuaranteed temperatureEnsure that the temperature of the powder does not exceed the temperatureHydrogen atmosphereWear resistant

The invention discloses a high-temperature-resistant and wear-resistant hard alloy with a NiAl alloying bonding phase. WC and / TiC is used as a hard phase, NiAl alloying Co and / Fe is used as a bonding phase, and the volume ratio of the hard phase to the bonding phase is equal to 10-40%. The preparation method comprises the following steps of: uniformly mixing 0.03-21.04wt% of nickel powder and aluminum powder with carbide powder based on the component proportion of Ni-50at.%Al; placing the mixture in a graphite container to spread out, heating the mixture to 660-1300 DEG C at a non-oxidative atmosphere, preserving heat, and then naturally cooling to obtain a mixture of a carbide and NiAl; grinding, crushing and screening to obtain mixed powder; carrying out deoxidation pretreatment at a hydrogen atmosphere of 400+ / -50 DEG C; carrying out wet grinding on 45.77-96.34wt% of mixed powder and the balance of Co and / Fe powder; carrying out spray-drying on the mixed material subjected to wet grinding and pressing; and sintering a compaction in a liquid phase at low pressure at the temperature of 1350-1550 DEG C to obtain the high-temperature-resistant and wear-resistant hard alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Production method for copper-nickel-tin alloy strip

The invention relates to a production method for a copper-nickel-tin alloy strip. The production method includes the following steps of smelting, double-roller continuous casting, on-line solution treatment, cleaning, cold rolling, aging treatment and the like. The production method has the beneficial effects that (1) the high-speed double-roller continuous casting process is adopted, in this way, molten metal can be solidified rapidly, segregation of tin is restrained effectively, and the structure of a product is more uniform; and (2) a copper-nickel-tin thin strip subjected to double-roller continuous casting and surface cleaning is formed through cold rolling, and thus good surface quality and a fine-grained internal structure can be obtained.

Owner:YANTAI WANLONG VACUUM METALLURGY

Extra-coarse hard alloy parcel powder and preparation method thereof

The invention discloses extra-coarse hard alloy parcel powder and a preparation method thereof. The preparation method comprises the steps of adding tungsten carbide powder of which the average Fisher particle size is 3-8 microns and other hard phase carbide powder of which the average Fisher particle size is 0.5-1.5 microns into a soluble cobalt salt solution, wherein the tungsten carbide powder and the hard phase carbide powder are used as a nucleating agent; performing chemical coprecipitation wrapping reaction on ammonium oxalate serving as a precipitator to enable the produced cobalt oxalate to be precipitated to the surfaces of the tungsten carbide powder and the hard phase carbide powder, and performing filtration, washing, drying and hydrogen reduction to obtain hard alloy parcel powder. The extra-coarse hard alloy parcel powder comprises the following components in percentage by weight: 6-12 percent of cobalt, 0-2 percent of crystalline grain inhibitor and the balance being tungsten carbide, wherein the average Fisher particle size of the tungsten carbide is 3-8 microns.

Owner:CENT SOUTH UNIV

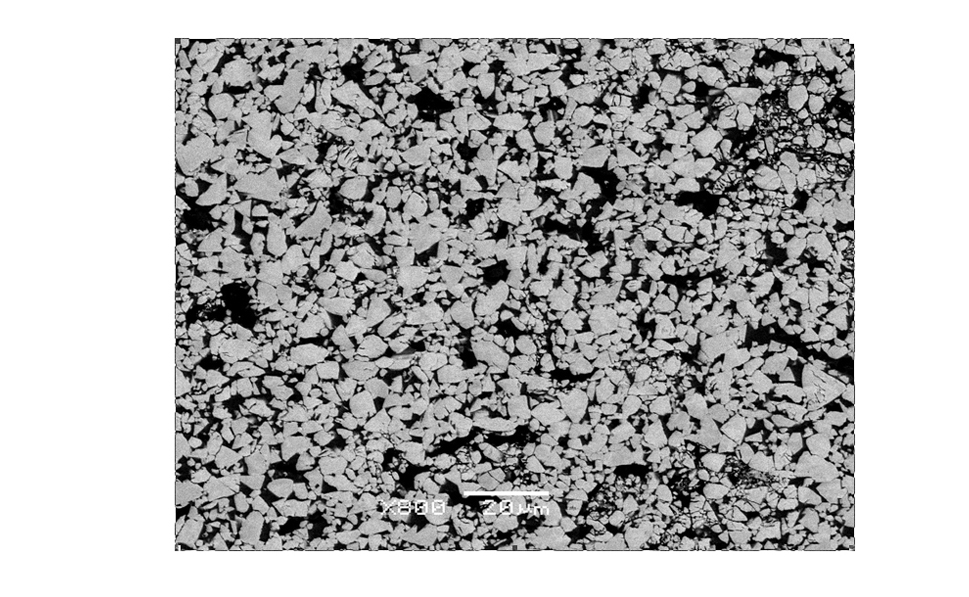

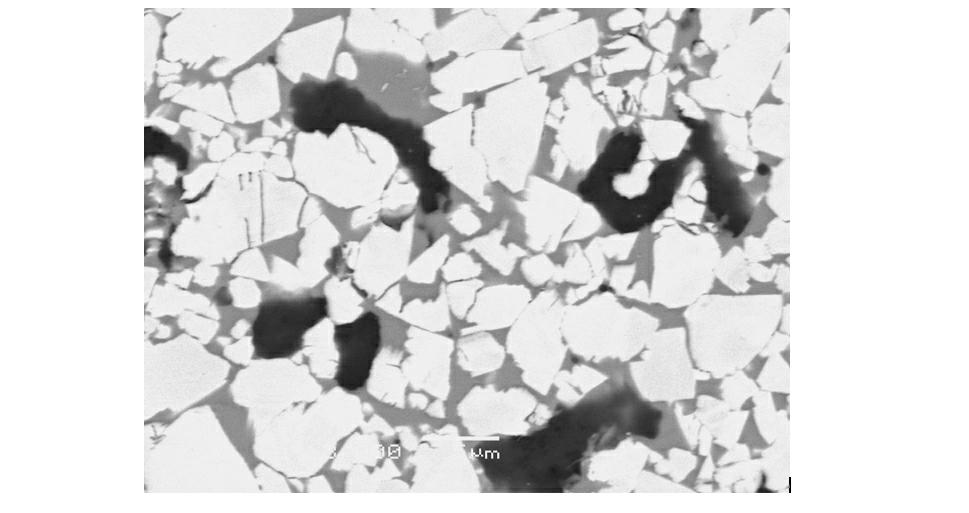

Hard alloy using iron-aluminum intermetallic compound as bonding phase and preparation method thereof

ActiveCN101985718AUniform tissue structureGood mechanical properties at room temperatureIron powderAlloy

The invention discloses a hard alloy using an iron-aluminum intermetallic compound as a bonding phase and a preparation method thereof. The hard phase is carbide, and the bonding phase is 10 to 40 volume percent of FeAl or Fe3Al. The preparation method comprises the following steps of: ball-milling and mixing 1.69 to 19.09 mass percent or 1.31 to 13.75 mass percent of pre-alloying powder of Fe2Al5, 2.10 to 23.78 mass percent or 3.23 to 33.81 mass percent of iron powder and the balance of carbide powder based on the component of FeAl or Fe3Al for 18 to 36 hours, preparing the obtained ball-milling mixture into uniform mixture powder by spray drying, pressing the mixture powder to form a blank, preserving the heat for 1 to 2 hours at the temperature of 1,200 + / - 20 DEG C under the vacuum condition during sintering the pressed blank, and then performing low-pressure liquid phase sintering at the temperature of between 1,250 and 1,550 DEG C to obtain the hard alloy using the FeAl or the Fe3Al as the bonding phase, wherein the FeAl or the Fe3Al is 10 to 40 volume percent. The preparation method has simple process and is low in manufacturing cost; holes are difficult to form in the liquid phase sintering process or are small; and the obtained hard alloy has high strength, good abrasion resistance and excellent high-temperature oxidation resistance and sulfur corrosion resistance.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

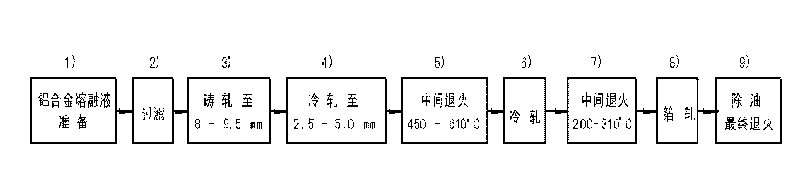

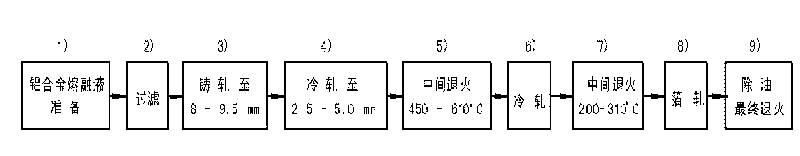

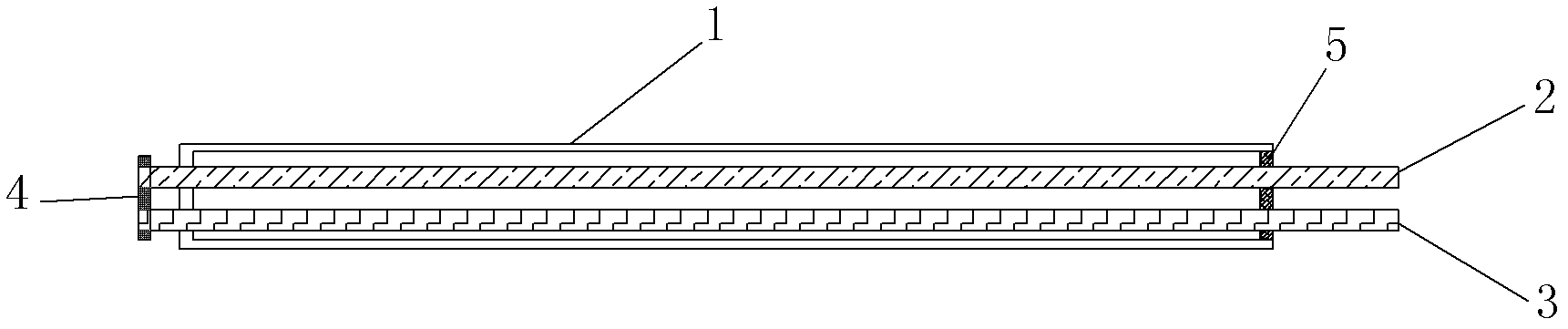

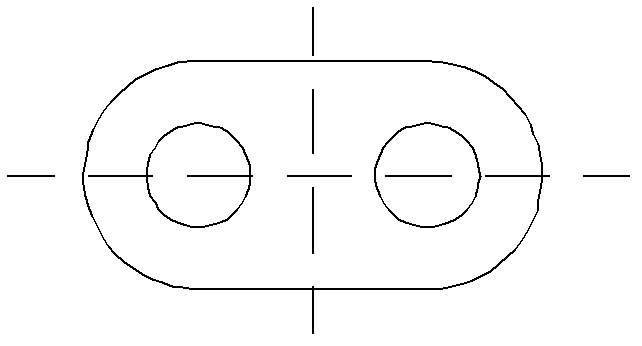

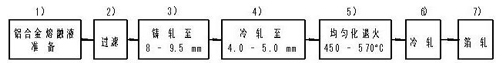

Production method of aluminium foil for electrode of electrolytic capacitor

InactiveCN101733275AUniform compositionUniform tissue structureMetal rolling arrangementsElectrolysisElectrolytic capacitor

The invention relates to a production method of an aluminium foil for an electrode of an electrolytic capacitor, specifically comprising the steps of the smelting and the casting of an aluminium plate, an aluminium tape and the aluminium foil, pressure processing and heat treatment. The production method of the aluminium foil for the electrode of the electrolytic capacitor comprises the following steps of: preparing an aluminium alloy melting solution, and filtering the prepared aluminium alloy melting solution; directly inputting the filtered aluminium alloy melting solution to a casting machine, and casting into a coiled sheet with certain thickness; carrying out cold rolling on the casting coiled sheet; carrying out intermediate annealing; continuously carrying out the cold rolling to rolling to a preset thickness; carrying out the intermediate annealing; rolling the aluminium foil to a preset product thickness; and removing oil and the like. The invention directly provides cold rolling plates with uniform components and organization structures and saves the step of the component uniformization and uniformization treatment which is needed before a conventional hot rolling method is carried out, thereby shortening the production process, lowering the energy consumption and enhancing the plate yield; and in addition, the manufactured aluminium foil can not only meet the property requirement of an anode of a medium-voltage electrolytic capacitor, but also save the energy for subsequent corrosion processing.

Owner:内蒙古中拓铝业股份有限公司

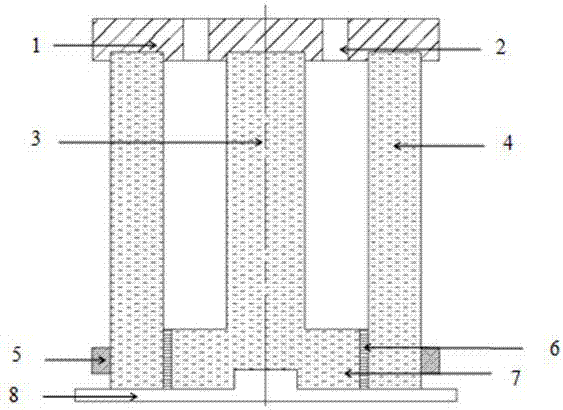

Zirconium boride based composite ceramic material thermocouple and preparation method thereof

The invention discloses a zirconium boride based composite ceramic material thermocouple and a preparation method thereof, and relates to a ceramic material thermocouple and a preparation method thereof. The invention solves the problem that the existing thermocouple is difficult to apply in a high-temperature oxidative environment and other severe environments. The zirconium boride based composite ceramic material thermocouple consists of a positive electrode and a negative electrode. The preparation method comprises the following steps of: 1, weighing ZrB2, SiC and an additive, and preparing the positive electrode by hot pressing sintering; 2, weighing ZrB2, SiC and the additive, and preparing the negative electrode by hot pressing sintering; and 3, assembling the positive electrode and the negative electrode into the thermocouple. The thermocouple has high sensitivity, and the sensitivity of the thermocouple is in a range from 1 to 100mu V / DEG C; the thermocouple can be measured at the temperature of between 500 and 2,000 DEG C; and use of scarce resources is reduced, and the cost is reduced. The zirconium boride based composite ceramic material thermocouple is applied to the field of high-temperature measurement.

Owner:HARBIN INST OF TECH

Method for producing ultra-coarse grain cemented carbide through utilizing high energy stirring and ball-milling technology

The invention relates to a method for producing ultra-coarse grain cemented carbide through utilizing a high energy stirring and ball-milling technology. Preparation raw materials comprise WC, Co and a small amount of NbC or / and TaC which is served as an additive, wherein the particle granularity of the WC is not less than 15 micrometers, and the WC accounts for 82.0-95.5wt%, the Co accounts for 4.5-18wt%, and the additive accounts for 0.0-0.5wt%. The preparation method comprises the following steps: (1) a high energy stirring and ball milling process, namely, filling all the preparation raw materials, i.e. the WC, cobalt powder and the additive into a high energy stirring ball mill, and adding a plasticizer and a ball-milling addition agent for ball milling; (2) a vacuum drying and granulating process; and (3) conventionally pressing a mixture for forming, and carrying out vacuum sintering or pressure sintering within a scope of 1400 DEG C-1480 DEG C. By utilizing the technology, the milling effect of the powder can be greatly improved, the ball milling time is obviously shortened, the production efficiency is improved, the energy consumption is reduced, and alloy crystal grains are uniformly distributed.

Owner:ZIGONG JINDUN CEMENTED CARBIDE

Preparation method of ITO tubular target material

ActiveCN107244911AIncrease profitMeet application requirementsDischarging arrangementVacuum evaporation coatingHigh densitySlurry

The invention discloses a preparation method of an ITO tubular target material. The preparation method comprises: using ITO nanometer powder as a raw material, dewatering and molding a prepared ITO slurry by using a rotation mold and an ultrasonic wave vibration device to obtain an ITO target material billet, carrying out degreasing treatment on the billet at a low temperature, and sintering the degreased billet under a certain sintering condition to obtain the ITO tubular target material. According to the present invention, with the preparation method, the automated production is easily performed so as to reduce the labor intensity and the labor cost; and the prepared ITO rotating target material product has characteristics of uniform and stable structure, high density and good market prospect, and can meet the application requirements of downstream enterprises.

Owner:KUNMING UNIV OF SCI & TECH

Quick forming method for complex structure of shape memory alloy based on multi-field auxiliary adjusting control

ActiveCN108296484AIncrease profitUniform tissue structureAdditive manufacturing apparatusIncreasing energy efficiencyMulti fieldShape-memory alloy

The invention discloses a quick forming method for the complex structure of shape memory alloy based on multi-field auxiliary adjusting control, and belongs to the field of shape memory alloy. The problems that existing smelting, casting and other traditional shape memory alloy structure preparation methods are complex in technology and low in material increasing efficiency are solved. The quick forming method comprises the steps that 1, a shape memory alloy powder material is prepared; 2, a structure piece model is built through three-dimensional drawing software and then guided into materialincreasing path planning software, and the material increasing path of the whole structure piece model is planned; 3, a base plate, an ultrasonic generator and a magnetic field generator are put intoa protection bin, additive forming of a structure piece is conducted by a plasma arc gun head according to the material increasing planning path, and a magnetic field and / or an ultrasonic field are / is applied in the material increasing process to assist in forming; and 4, heat treatment is conducted on the structure piece subjected to material increasing. According to the quick forming method, through multi-field assistance and plasma arc additive manufacturing, the function and structure integrated quick forming of the shape memory alloy and the structure piece of the shape memory alloy is achieved.

Owner:HARBIN ENG UNIV

Zirconia base ceramic target material for electron beam physical vapor deposition and preparing method of zirconia base ceramic target material

ActiveCN106518065AUniform compositionAvoid stabilityCeramic shaping apparatusElectron beam physical vapor depositionPolyvinyl alcohol

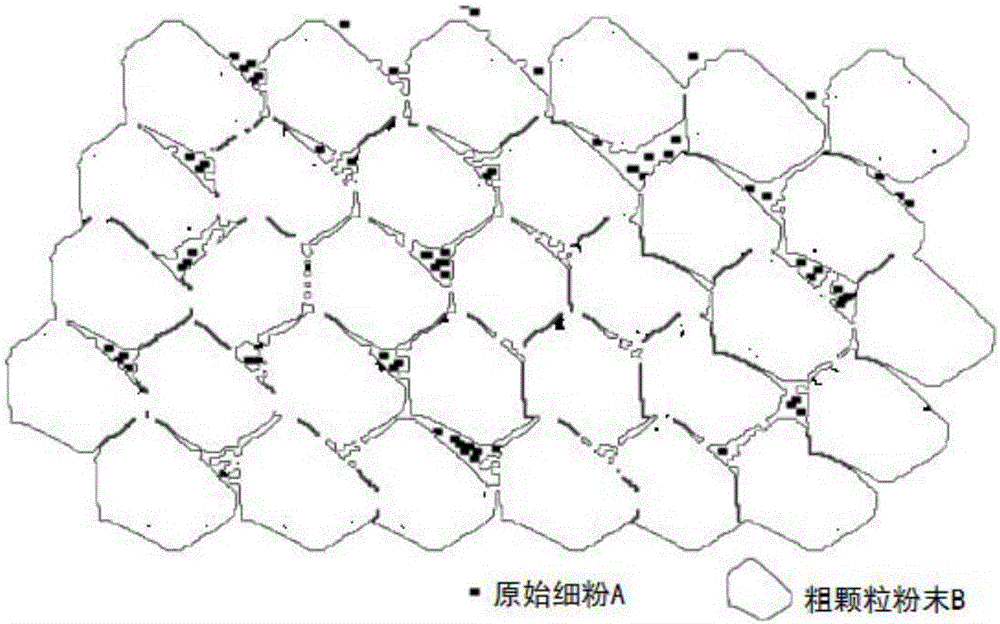

A zirconia base ceramic target material for electron beam physical vapor deposition comprises Y2O3 and ZrO2. On the basis that the weight of the target material accounts for 100%, the content of Y2O3 is 6 wt%-9 wt%. A preparing method of the target material comprises the steps that raw material powder is weighed; part of the weighed raw material powder is dried for 10-12 h at the temperature ranging from 500 DEG C to 700 DEG C, original fine powder A is obtained, and the average grain size ranges from 10 nm to 30 nm; part of the weighed raw material powder is dried for 1-2 h at the temperature ranging from 1,400 DEG C to 1,500 DEG C, the coarse particle powder B is obtained, and the average grain size ranges from 400 nm to 1,500 nm; the coarse particle powder B and the original fine powder A are mixed according to the mass proportion of 9:1-1:1, polyvinyl alcohol accounting for 1-5% of the total mass of the coarse particle powder B and the original fine powder A is added, centrifugal spray drying granulating treatment is conducted, and spherical aggregated powder C is obtained; the spherical aggregated powder C is dried for 60-120 min under the condition that the temperature ranges from 80 DEG C to 100 DEG C and placed in a chloroprene rubber sleeve to be compacted by vibration; under the condition of 100-150 MPa and 10-40 min or under the condition of 150-200 MPa and 5-10 min, pressing forming is conducted, and a ceramic pressed blank is obtained; and the ceramic pressed blank is sintered for 5-15 h at the temperature ranging from 1,100 DEG C to 1,300 DEG C, and the target material is manufactured.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

Precision titanium part manufacturing method

The invention provides a precision titanium part manufacturing method. The method includes the following steps that titanium powder with the average particle size being 46.82 micrometers, titanium powder with the average particle size being 34.48 micrometers, and titanium powder with the average particle size being 24.36 micrometers are evenly mixed; the titanium powder is added to binder particles to be mixed for 1 hour at the temperature of 175 DEG C to 180 DEG C, and feed is obtained after the mixture is cooled; the feed is injected into forming titanium part green bodies under the conditions that the injection temperature ranges from 175 DEG C to 180 DEG C, the injection pressure ranges from 70 MPa to 80 MPa, the dwell pressure ranges from 80 MPa to 85 MPa, the injection speed ranges from 60 mm / S to 65 mm / S and the cooling time is 10 S; the titanium part green bodies are degreased under the conditions that the temperature ranges from 110 DEG C to 130 DEG C, the nitric acid flow rate is 1.5 ml / min, and the nitrogen flow rate is 120 ml / min; and the degreased titanium part green bodies are sintered to form titanium parts under the conditions that the temperature rising speed is 4 DEG C / min, the temperature ranges from 1200 DEG C to 1280 DEG C, the time is 90 min and the vacuum degree is 1*10<-3> Pa. By means of the precision titanium part manufacturing method, the titanium parts in the final shape with high size precision can be manufactured directly with the low production cost.

Owner:GUANGDONG INST OF NEW MATERIALS

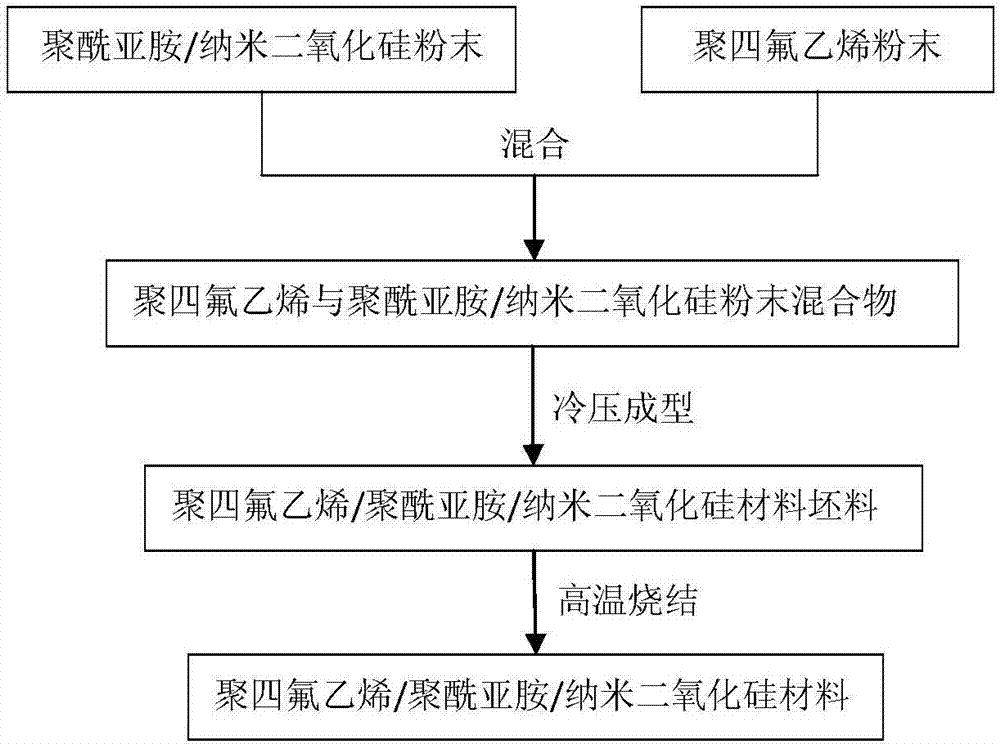

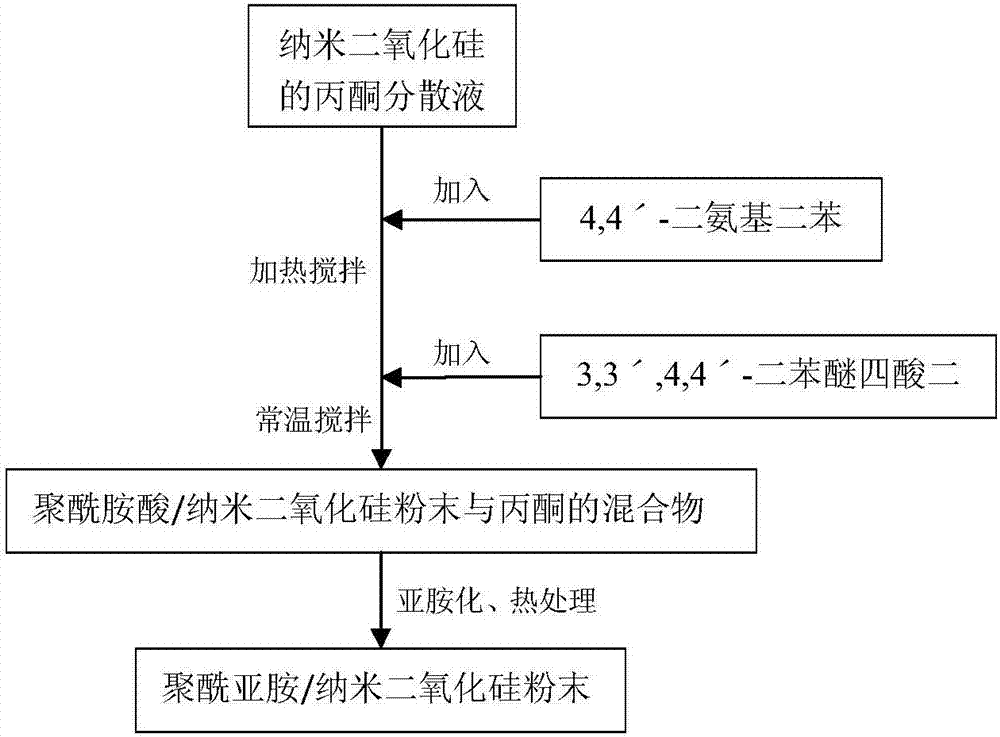

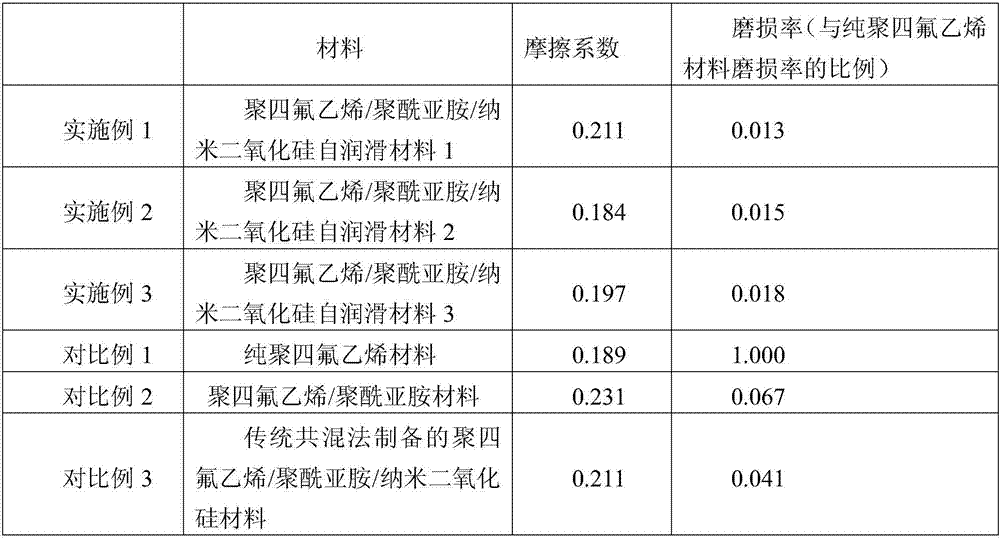

Polytetrafluoroethylene/polyimide/nano silicon dioxide self-lubricating material and preparation method thereof

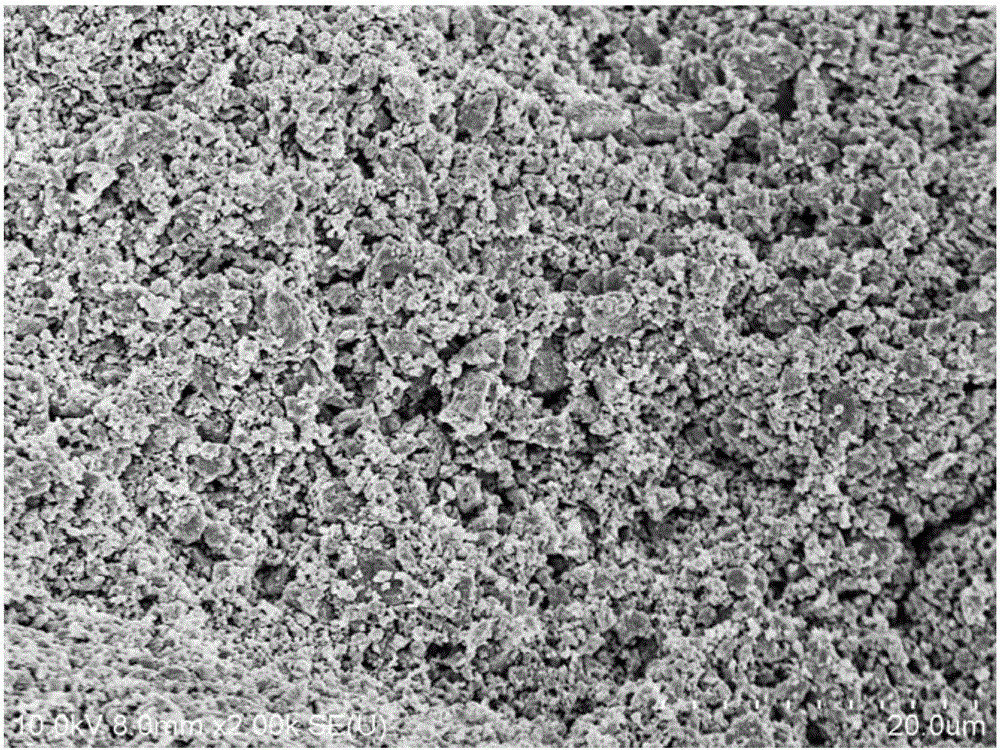

The invention provides a polytetrafluoroethylene / polyimide / nano silicon dioxide self-lubricating material and a preparation method thereof. The polytetrafluoroethylene / polyimide / nano silicon dioxide self-lubricating material comprises 19-20% of polytetrafluoroethylene, 0.01-3% of polyimide and the balance of nano silicon dioxide. The polyimide is uniformly distributed in a polytetrafluoroethylene matrix while the nano silicon dioxide is fully and uniformly distributed in polyimide. The preparation method comprises the following steps: (1) preparing a self-lubricating material mixture; (2) forming the self-lubricating material; and (3) sintering the self-lubricating material. The polytetrafluoroethylene / polyimide / nano silicon dioxide self-lubricating material provided by the invention has the characteristics of being low in coefficient of friction, high in wear resistance, relatively good in tissue uniformity and the like, can be applied to occasions of an inner ball of a self-lubricating spherical plain bearing, a self-lubricating sleeve, a self-lubricating guide rail and a retaining rack of the self-lubricating spherical plain bearing and etc, and has very high application value.

Owner:YANSHAN UNIV

Silicon carbide brick and preparation method thereof

The invention relates to a silicon carbide brick and a preparation method thereof. According to the silicon carbide brick, silica is used as a main raw material, and is divided into silica powder, silica coarse powder and silica fine powder according to grain diameters. The graphene silicon carbide brick is prepared from silica powder, silica coarse powder, silica fine powder, graphene, composite mineralizer and binding agents including nano-sized chromic oxide and nano-sized titanium oxide. The silicon carbide brick is a graphene silicon carbide brick with excellent thermal shock resistance, strong slag and alkaline metal corrosion resistance, excellent washing resistance, excellent heat-isolation and insulation performance and good high-temperature volume stability; the contact inside the silicon carbide brick is closer due to the graphene, so that the stress generated by expansion when the brick is burnt can be reduced, and the brick is prevented from loosening or cracking; and due to the high strength of the graphene, the excellent mechanical performance of the silicon carbide brick is guaranteed, and the acid and alkali corrosion resistance of the silicon carbide brick can be improved.

Owner:浙江长兴银兴窑业有限公司

Material capable of preventing large grains from being produced in aluminium alloy and preparation method thereof

The invention relates to a material capable of preventing large grains from being produced in aluminium alloy and a preparation method thereof. The material provided by the invention comprises the following ingredients in percentage by weight: 0.58-0.61% of Mg, 0.03-0.035% of C, 0.75-0.78% of Si, 0.30-0.35% of Mn, 0.1-0.15% of Cr, 0.2-0.24% of Cu, 0.2-0.4% of Fe, 0.03-0.05% of Ti, 0.001-0.0015% of V, 0.05-0.1% of Mo and the balance of Al. The material provided by the invention better realizes that grains in the structure of the aluminium alloy are fine and the growth of the grains is inhibited; and a uniform structure is guaranteed by virtue of a preparation process.

Owner:姚富云

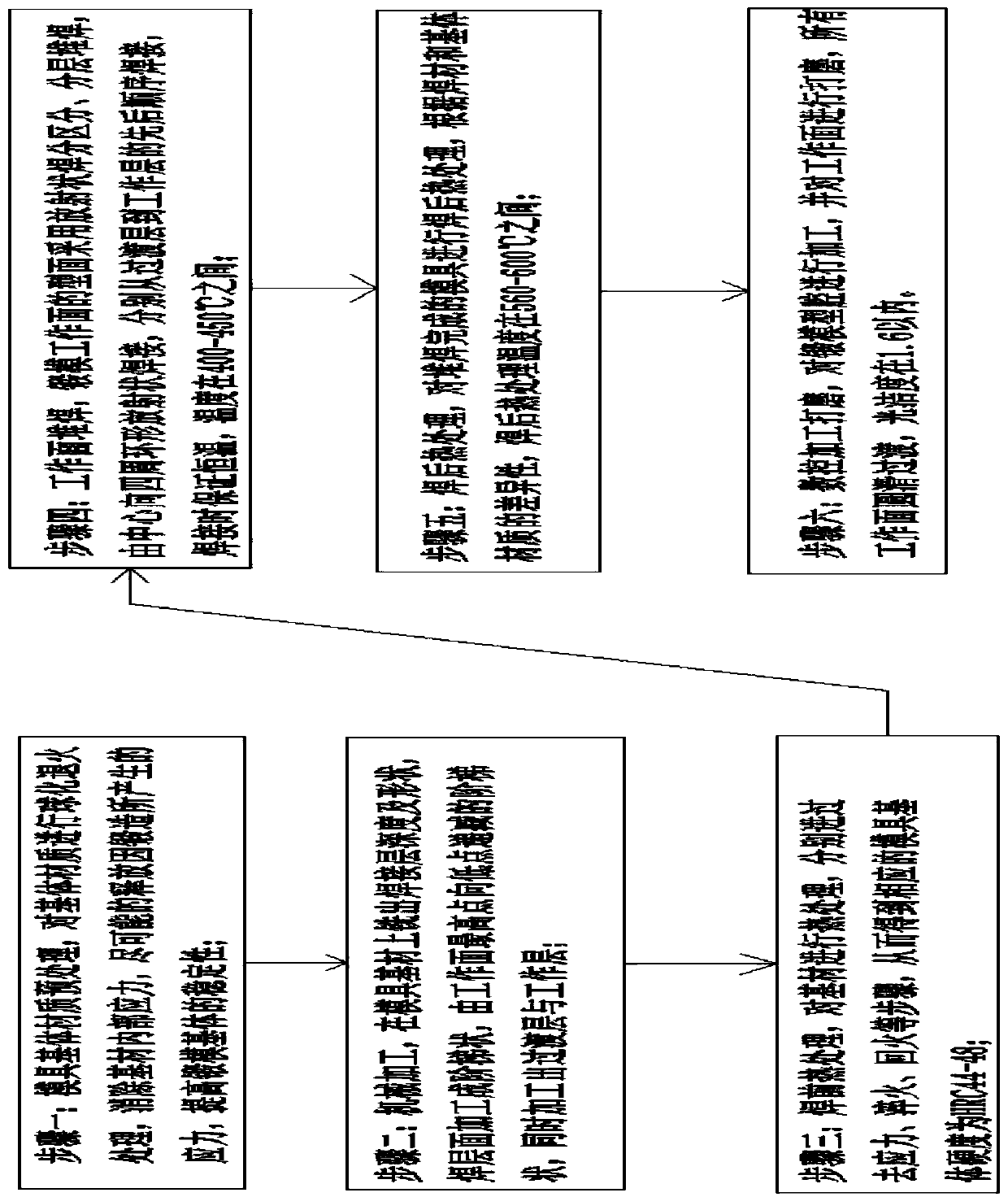

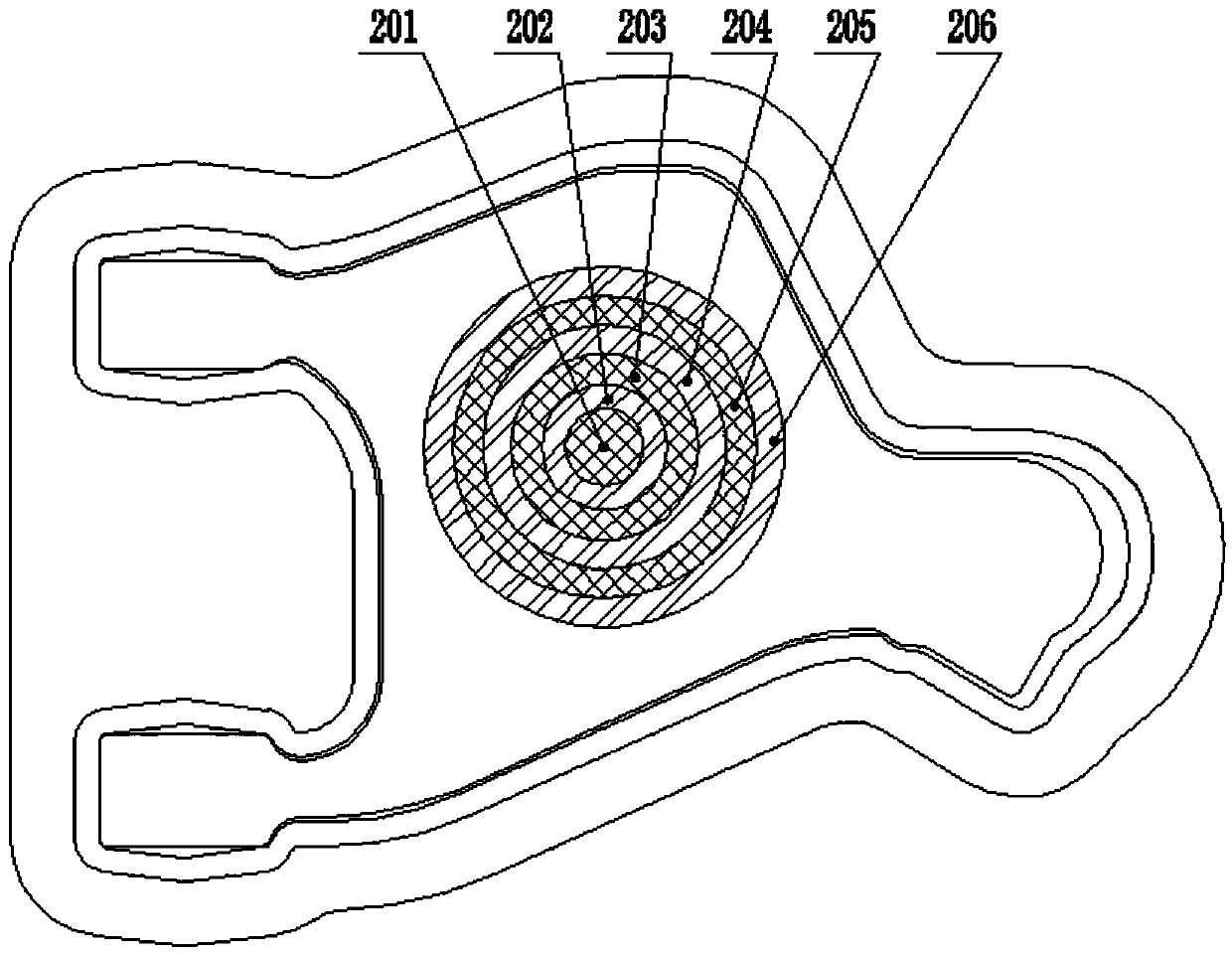

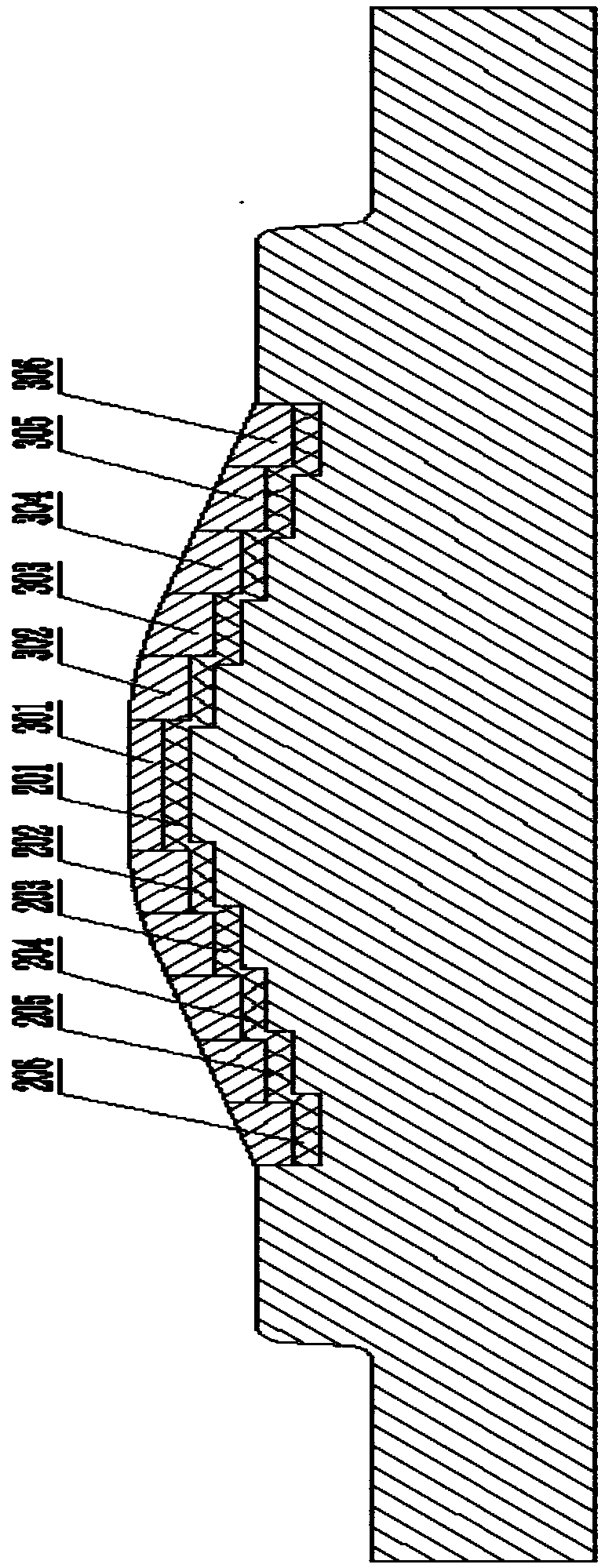

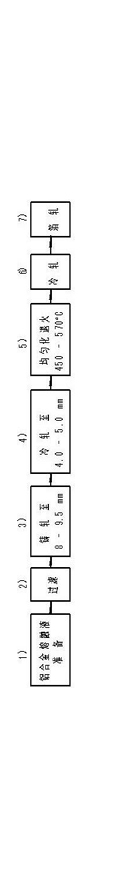

Processing technology of molded surface of high-strength wear-resistant titanium alloy forging mold

The invention discloses a processing technology of a molded surface of a high-strength wear-resistant titanium alloy forging mold, and belongs to the field of high alloy material forging mold processing. The processing technology comprises the following step of: step 1. pretreating a mold base material; step 2. machining, to be specific, milling the depth and shape of a welding layer on the mold base material, and processing a welding layer surface into a stepped shape decreasing from the highest point of a working face to a low point; step 3. carrying out pre-weld heat treatment, to be specific, carrying out heat treatment on the base material; step 4. carrying out build-up welding on the working face, carrying out subdivision build-up welding on the molded surface of the forging mold working face by adopting a radial welding unit, annularly and radially welding from the center to the periphery; step 5. carrying out post-weld heat treatment, to be specific, carrying out post-weld heattreatment on the mold subjected to build-up welding; and step 6. carrying out numerical control machining and polishing, machining a cavity of the forging mold, and grinding the working face. The processing technology improves the performance of the forging mold, and prolongs the service life of the forging mold. According to the particularity of a forged product, the radial welding process is adopted to improve the stability of the working face and reduce the abrasion of the forging mold.

Owner:MAANSHAN CITY ZHONGYE MACHINERY

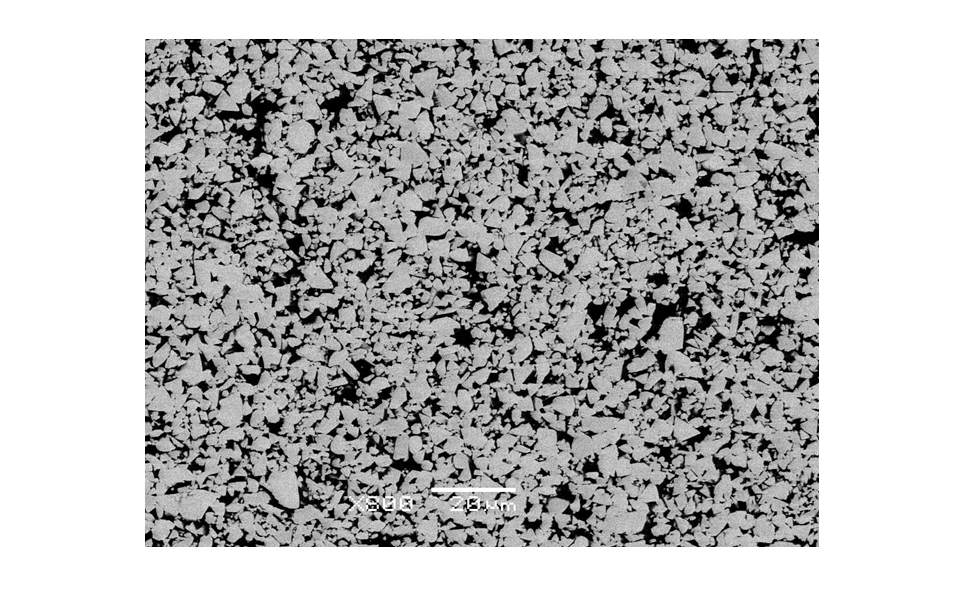

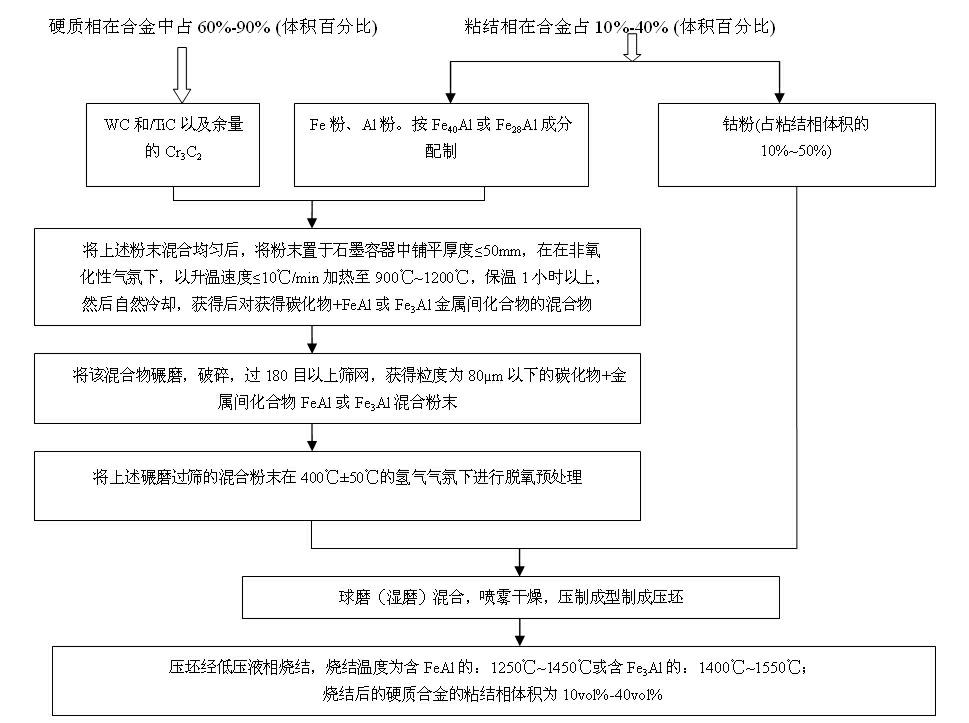

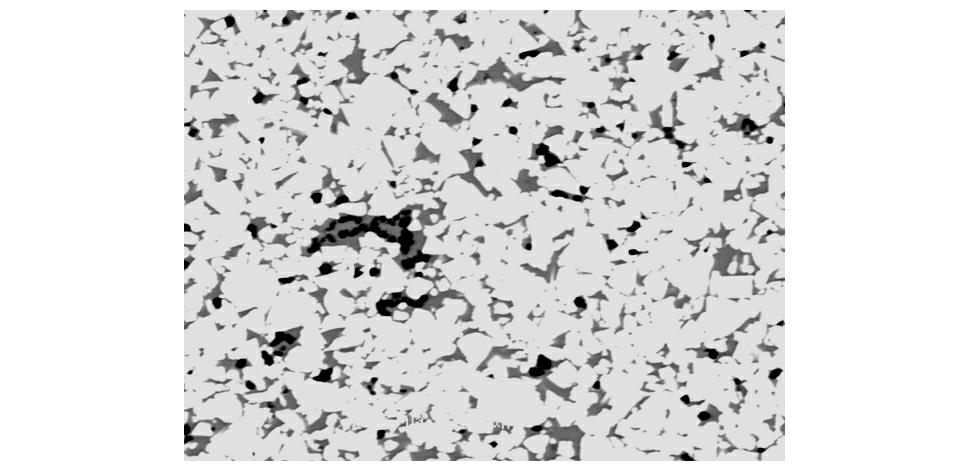

Hard alloy with iron-aluminum intermetallic compound as main binding phase and preparation method of hard alloy

The invention discloses a hard alloy with an iron-aluminum intermetallic compound FeAl or Fe3Al as a main binding phase, cobalt as a secondary binding phase, and tungsten carbide and / or titanium carbide and Cr3C2 as a hard phase, and the preparation method of the hard alloy comprises the steps in sequence of: uniformly mixing iron powder and aluminum powder with WC and / or TiC powder based on the component ratio of Fe40Al or Fe28Al; under a non-oxidative atmosphere, heating, preserving heat and cooling to obtain a mixture of WC and / or TiC and FeAl or Fe3Al; grinding and crushing the mixture to obtain the mixed powder of WC and / or TiC and FeAl or Fe3Al with the grain size below 120 microns; carrying out deoxygenization pretreatment; wetly grinding and mixing cobalt powder and Cr3C2 powder having certain mass ratio with the balance of the mixture powder of WC and / or TiC and FeAl or Fe3Al; spray drying and compacting to obtain a green compact; and subjecting the green compact to liquid phase sintering at a low pressure to obtain the hard alloy with FeAl or Fe3Al as the main binding phase. The hard alloy disclosed by the invention has the advantages of uniform organizational structure, high densification, high intensity, good abrasive resistance, excellent high temperature oxidation resistance and sulfidation corrosion resistance, simple preparation process and low manufacturing cost.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Powder metallurgy flange and preparation method thereof

InactiveCN103014507AImprove air tightnessUniform tissue structureTurbinesOther manufacturing equipments/toolsPowder metallurgyChromium

The invention relates to a powder metallurgy flange and a preparation method thereof. The powder metallurgy flange comprises the following components in percentage by weight: 0.5-1.5% of copper, 0.3-0.5% of chromium, 0.3-0.5% of silicon, 0.5-0.8% of graphite, 0.3-0.8% of manganese, 0.8-1.0% of zinc stearate, 0.5-1.0% of ferrophosphorus powder, and the balance of iron. According to different needs, the components of the material are adjusted, so that the produced flange has high tensile strength, high gas tightness and a uniform organization structure, and can be extensively adaptive to various environments.

Owner:NINGBO QUNXING POWDER METALLURGY

Edible foaming agent produced from rice starch, rice protein and emulsifier and production method thereof

InactiveCN102177935AReduce interfacial tensionIncrease contact areaDough treatmentSODIUM ISOSTEAROYL LACTYLATESodium bicarbonate

The invention discloses an edible foaming agent produced from rice starch, rice protein and an emulsifier and a production method thereof. The edible foaming agent is prepared from the rice starch, the rice protein, glycerin monostearate (GSM), sodium stearoyl lactylate, tripolyglycerol monostearates, sodium bicarbonate and sodium chloride. The edible foaming agent has the advantage of available raw materials and convenience in production.

Owner:凯爱瑞食品(南通)有限公司

Magnesium-aluminum refractory material and preparation method therefor

The present invention relates to a magnesium-aluminum refractory material. The magnesium-aluminum refractory material is prepared by using magnesium aluminate spinel of different particle sizes as a raw material, and adding an auxiliary additive, nanometer magnesia, boron carbide, a binder and nanometer aluminium oxide. According to the product provided by the present invention, the organization structure is more uniform, and therefore strength and thermal shock resistance of the product are improved; the particle size of nano-zinc oxide is small, and therefore micro pores can be filled with the nano-zinc oxide, porosity of the product is reduced, and volume density is increased; and refractoriness is high, corrosion resistance is excellent, thermal shock resistance is good, and the sintering temperature range is wide.

Owner:长兴泓矿炉料有限公司

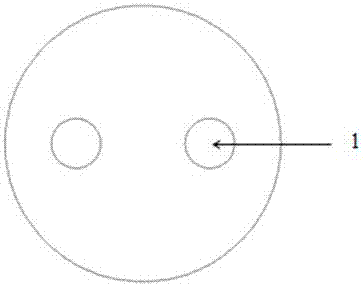

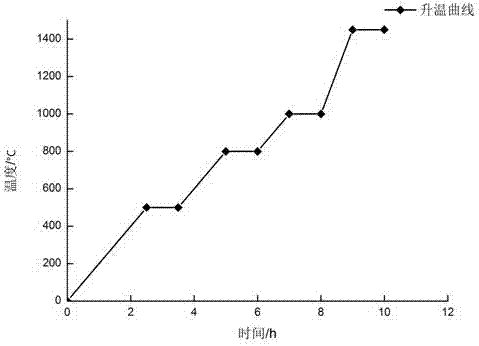

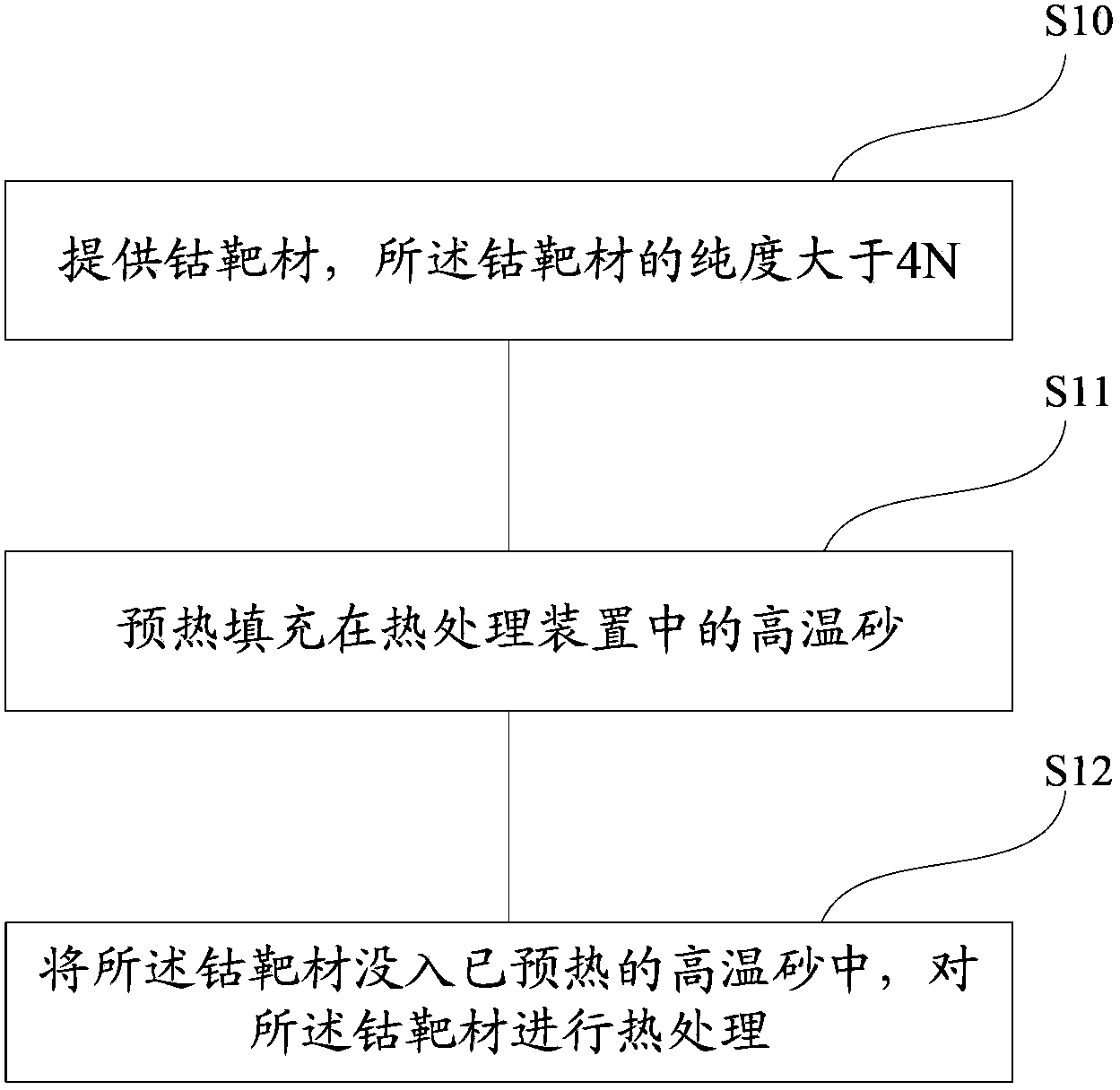

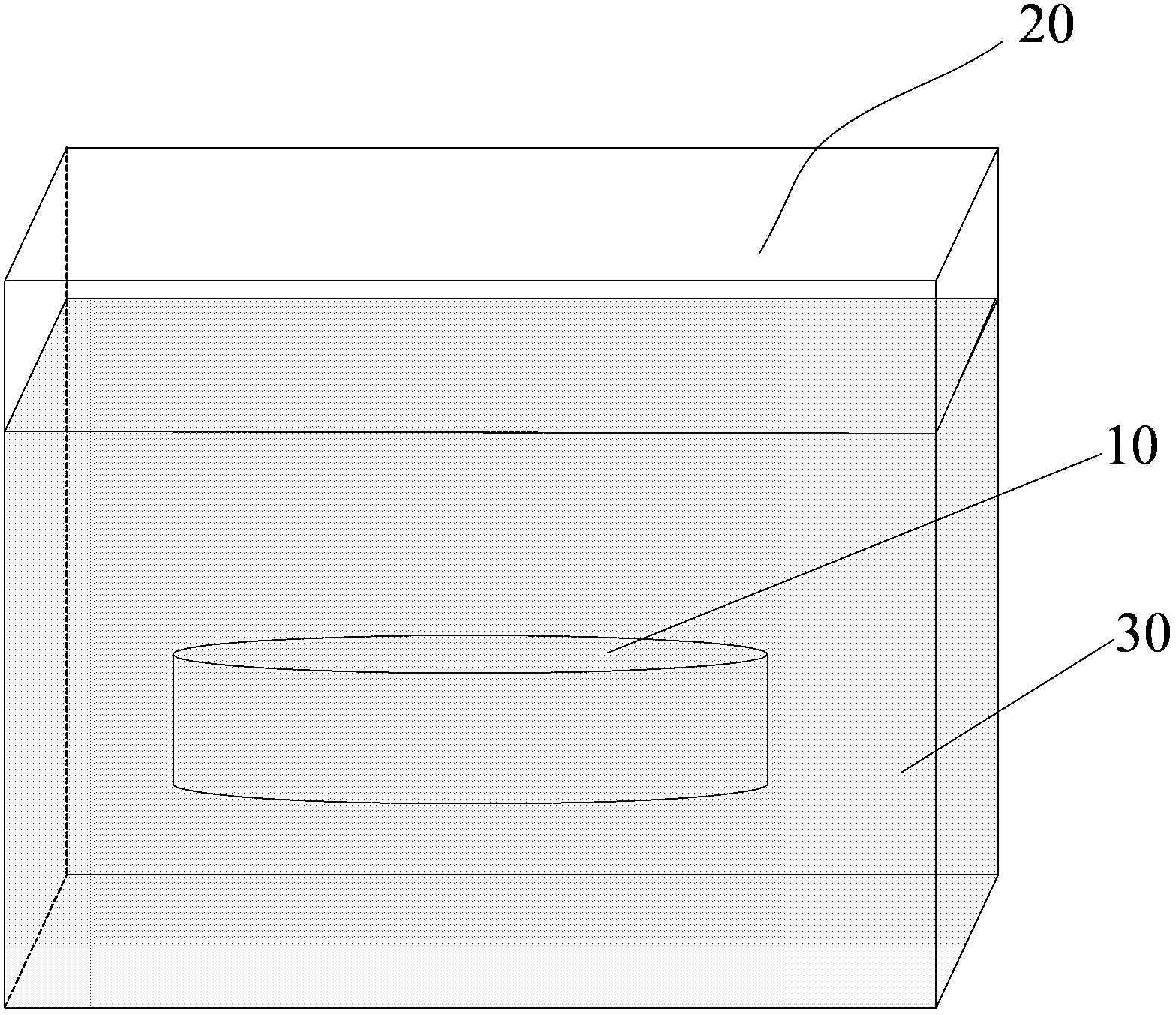

Heat treatment method of cobalt target

The invention provides a heat treatment method of a cobalt target. The heat treatment method comprises the following steps of providing the cobalt target having the purity greater than 4 N; preheating sand; covering the cobalt target with the preheated sand; and performing heat treatment on the cobalt target. Compared with the prior art, the heat treatment method provided by the invention avoids the problems that the cobalt target obtained after the heat treatment process in the prior art does not have the desired magnetic conductivity and the crystalline grains of the cobalt target do not meet the requirements of sputtering in the prior art in the heating way of preheating sand bath.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Aluminum foil for capacitor anode and production method

ActiveCN101770871AUniform compositionUniform tissue structureElectrolytic capacitorsElectrolysisHigh density

The invention discloses an aluminum foil for a capacitor anode and a production method, relating to a metallurgical technology and belonging to the production technical category of aluminum plates, aluminum strips and aluminum foils. The invention particularly relates to manufacture of the aluminum foil, in particular to manufacture of the aluminum foil for a low voltage electrolytic capacitor anode by using a cast-rolling method. In the invention, excessive dissolution can not be generated, corrosion pits are uniformly generated with high density and the face expansion ratio is increased in the process of electrochemical corrosion by controlling the purity of Al and the content of each element i.e. Cu, Fe, Si, Mg, B, Ti, Ni, Zn, Cr and V, thereby increasing the electrostatic capacity after corrosion; and cold rolling plates with uniform components and uniform tissue structures can be directly provided by adopting the cast-rolling method, thereby saving the necessary component uniformization and soaking treatment before a conventional hot rolling method, shortening a production procedure, lowering the energy consumption and enhancing the finished product rate, therefore, the prepared aluminum foil can satisfy the performance requirement of the low voltage electrolytic capacitor anode and can also save the energy for subsequent corrosion processing.

Owner:BEIJING CHN TOP MACHINERY

Steel-based surface chrome-contained abrasion-resistant ceramic coating and preparing method of steel-based surface chrome-contained abrasion-resistant ceramic coating

The invention relates to a steel-based surface chrome-contained abrasion-resistant ceramic coating layer and a preparing method of the steel-based surface chrome-contained abrasion-resistant ceramic coating, and belongs to the technical field of methods for preparing steel-based protective coatings. The steel-based surface chrome-contained abrasion-resistant ceramic coating and the preparing method are characterized in that the steel-based surface chrome-contained abrasion-resistant ceramic coating is composed of silicon carbide ceramic abrasion-resistant powder, silicon dioxide, water glass, ferrochromium powder and the like; structure defects are overcome through the ferrochromium powder, the compactness of the coating structure is improved, and the metallurgical bonding strength between the coating and a steel base is greatly improved. By means of the preparing method, as a two-time curing technology is adopted, the curing time can be shortened, the coating quality can be improved, and a ceramic phase between the steel base and the coating can be easily generated; meanwhile, the coating has the abrasion resistance several times higher than that of the steel base, and the overall performance such as the surface rigidity and the corrosion resistance of the coating is improved. The preparing method is simple, construction is convenient, the production efficiency is high, and the economical effect and the practical effect are achieved. The problem that as a ceramic coating prepared in the prior art is poor in structure compactness, the overall performance of the ceramic coating can not be guaranteed through one-time curing is solved.

Owner:YANGTZE UNIVERSITY

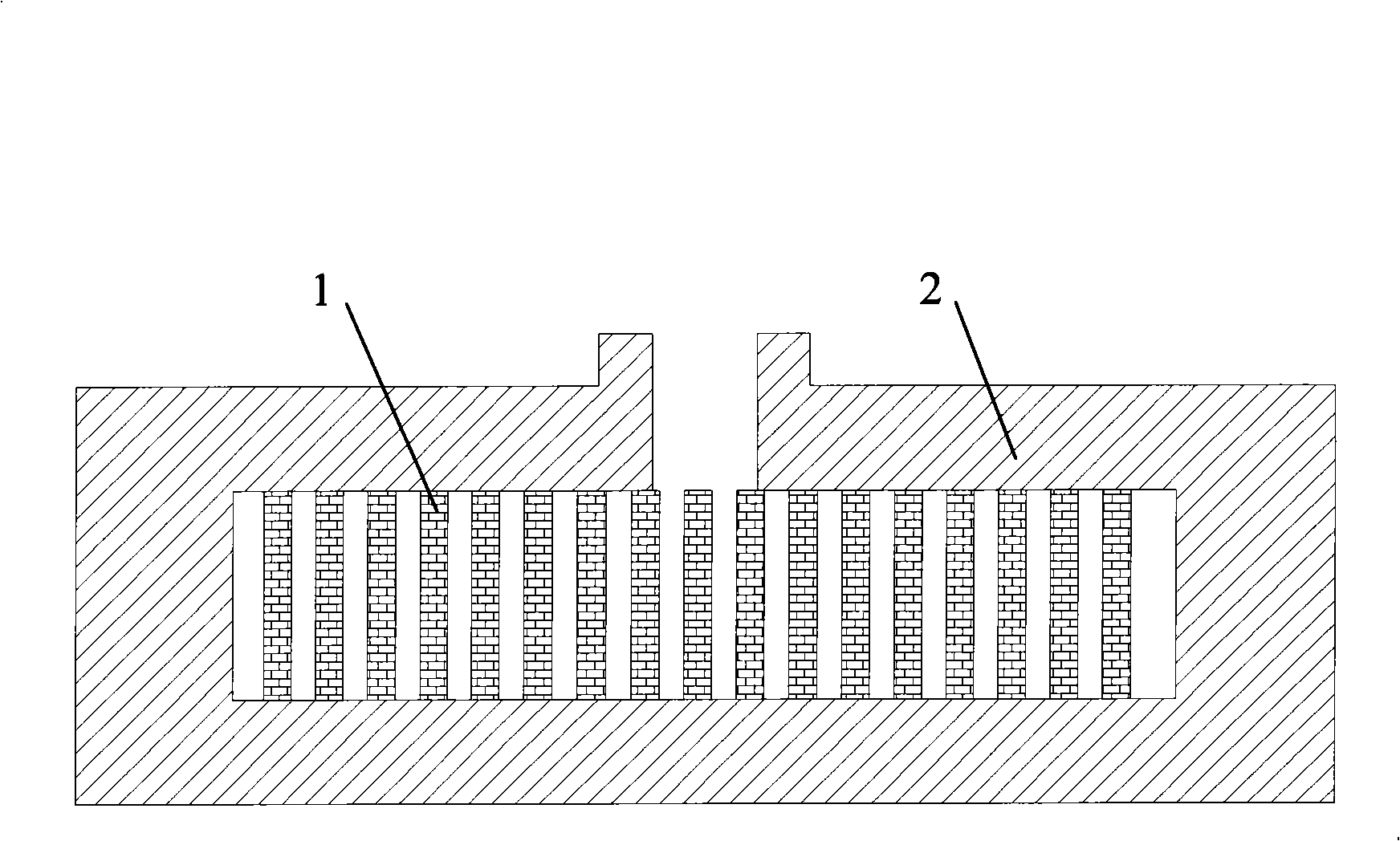

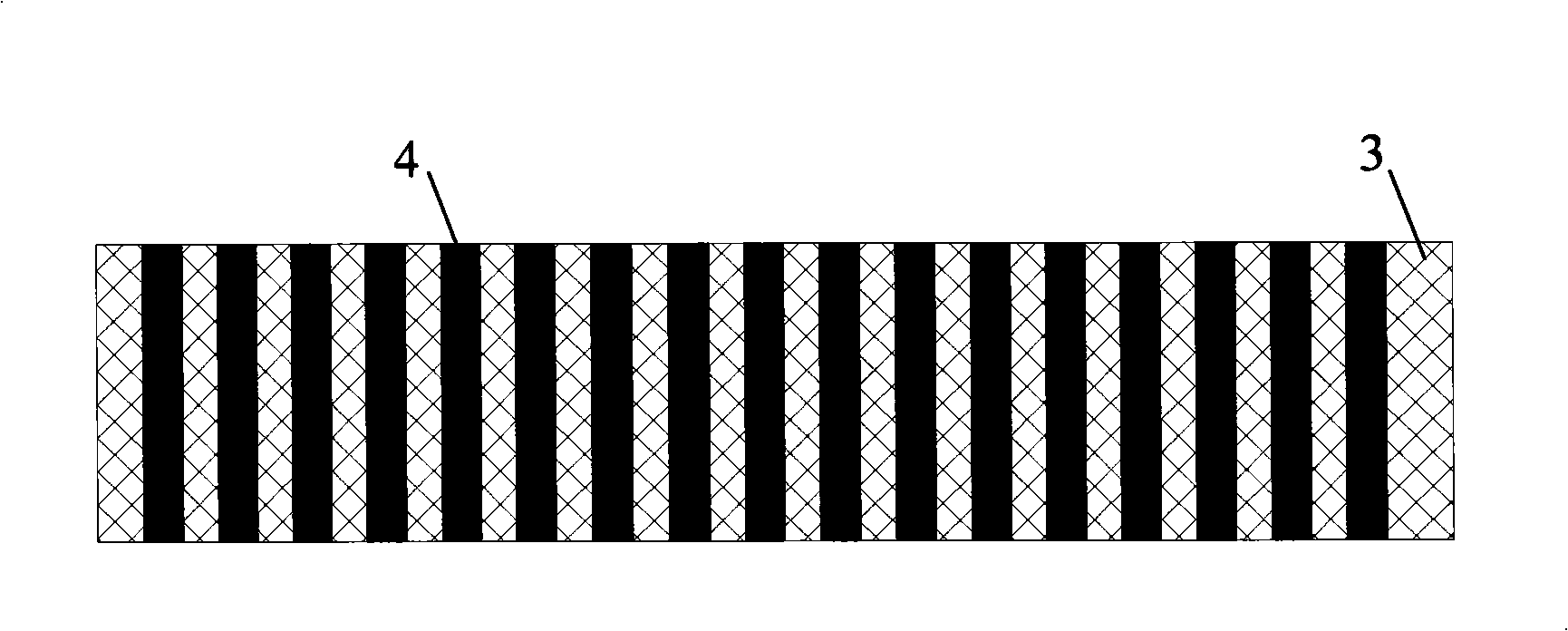

Method for preparing composite abrasion-proof lining board

The invention discloses a method for preparing a composite wear resistant lining plate. The method comprises the following steps: adopting alloy powder core bar materials of which the volume percentage is between 20 and 60 percent of the total volume of the lining plate, filling alloy powder in the core part of the alloy powder core bar materials, preset the alloy powder core bar materials in a lining plate casting mould, selecting base metal to be melted and poured in the lining plate casting mould, and cooling and demoulding the lining plate to obtain the composite wear resistant lining plate consisting of the alloy powder core bar materials and the base metal. The cylindrical hard phase of the composite wear resistant lining plate prepared by the method is generated by compounding in situ in a matrix, thus the composite wear resistant lining plate has the characteristics that segregation is not generated, the organization structure is even, the hard phase is difficult to fall off, the lining plate not only has the intensity and the toughness of the base metal but also has the high hardness and the high wear resistance of the hard phase, the service life is improved by an order of magnitude compared with the prior lining plate, the lining plate can bearing high impact force and strong wear at the same time, the technological parameter controllability of the preparation process is strong, and the price is low. The composite wear resistant lining plate can satisfy the applications under complex working conditions such as various wears, high impact and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com