Zirconia base ceramic target material for electron beam physical vapor deposition and preparing method of zirconia base ceramic target material

A physical vapor deposition, zirconia-based technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of electron beam physical vapor deposition technology research starting late, stabilizer composition segregation, low purity, etc., and achieve segregation-free coating The effect of preparation, improvement of density uniformity, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In order to achieve the above purpose, the present invention also provides a preparation method of a zirconia-based ceramic target for electron beam physical vapor deposition, comprising the following steps:

[0036] Step 1: Weigh the above-mentioned raw material powders respectively;

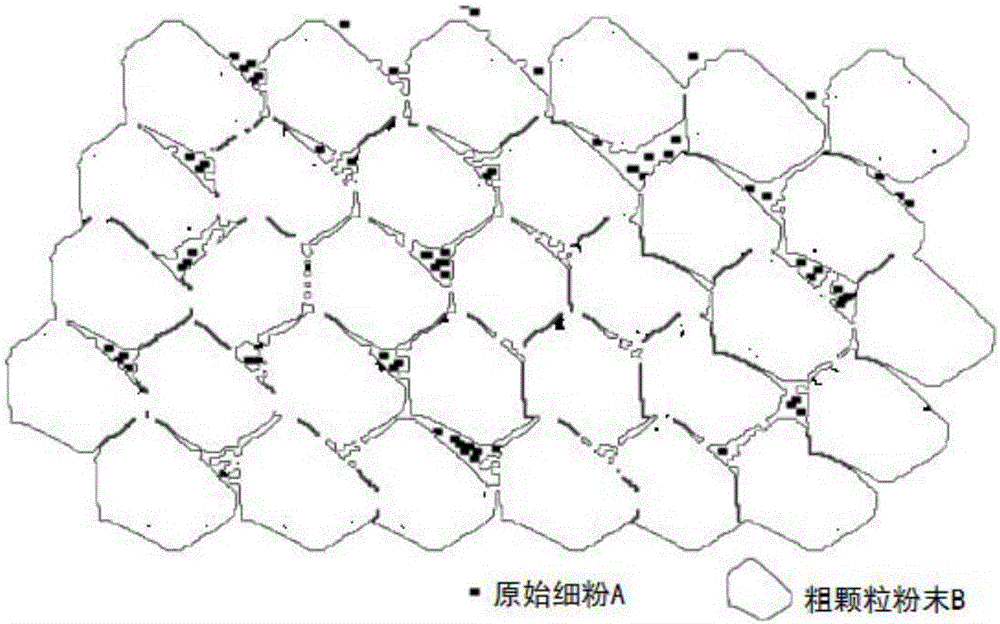

[0037] Step 2: Dry the portion of each raw material powder weighed in step 1 at 500-700 ° C for 10-12 hours to obtain original fine powder A, and the average particle size of original fine powder A is 10-30 nm; Part of each raw material powder taken is dried at 1400-1500° C. for 1-2 hours to obtain coarse-grained powder B, and the average particle size of coarse-grained powder B is 400-1500 nm;

[0038] Step 3: Mix the coarse-grained powder B and the original fine powder A according to a mass ratio of 9:1 to 1:1, and add 1-5% polyethylene of the total mass of the coarse-grained powder B and the original fine powder A Using alcohol as a binder, centrifugal spray drying is carried out to ...

Embodiment 1

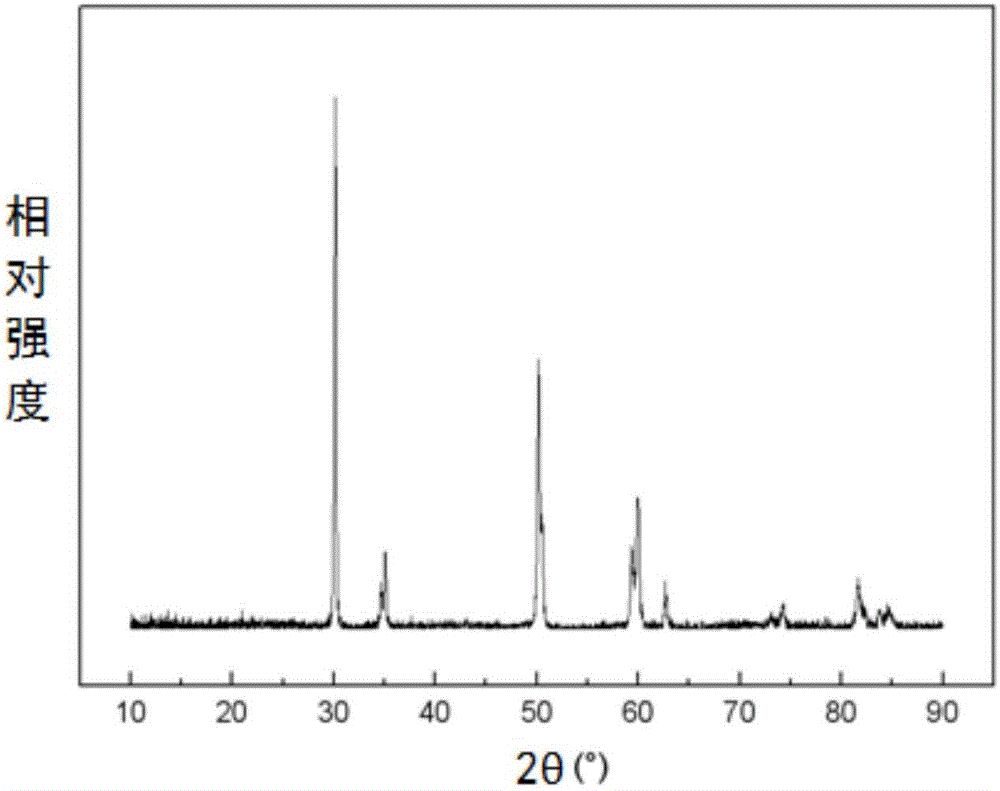

[0049] The first step: use chemically synthesized raw materials (the raw materials are subjected to spray drying treatment after synthesis), and Y in the raw materials 2 O 3 The content is 8.23wt%, ZrO 2 The content is 91.75wt%, the remaining impurities are less than 0.1wt%, the average particle size of the raw materials is 18nm, and the purity is greater than 99.9%;

[0050] The second step: heat treatment of the raw material powder at 500° C. for 11 hours to obtain original fine powder A, and heat treatment at 1450° C. for 1.5 hours to obtain coarse particle powder B. The average particle size of the original fine powder A is 19nm, and the average particle size of the coarse powder B is 1000nm;

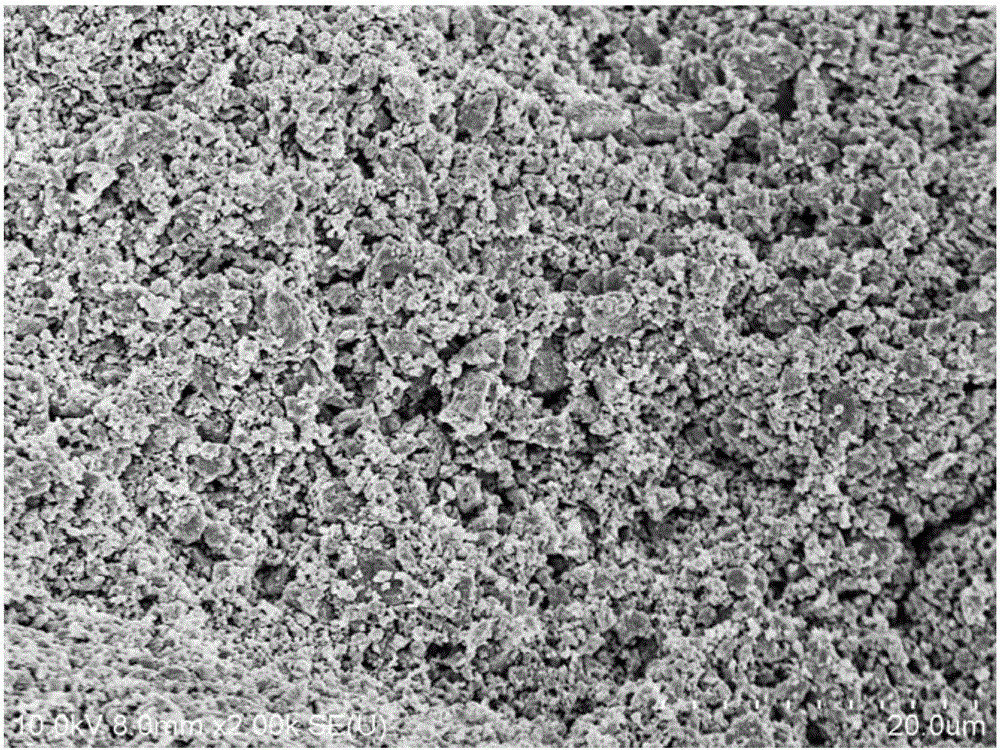

[0051] The third step: The coarse particle powder B and the original fine powder A are mixed and ball-milled according to the mass ratio of 1:1, added with 3% polyvinyl alcohol (PVA) binder, and then subjected to centrifugal spray drying and granulation to obtain spherical Agglom...

Embodiment 2

[0057] The first step: use chemically synthesized raw materials (the raw materials are subjected to spray drying treatment after synthesis), and Y in the raw materials 2 O 3 The content is 6.05wt%, ZrO 2 The content is 93.9wt%, and the remaining impurities are less than 0.1wt%, wherein the average particle size of the raw materials is 18nm, and the purity is greater than 99.9%;

[0058] The second step: heat treatment of the raw material powder at 500° C. for 10 hours to obtain original fine powder A, and heat treatment at 1400° C. for 1 hour to obtain coarse particle powder B. The average particle size of the original fine powder A is 10nm, and the average particle size of the coarse powder B is 415nm;

[0059] The third step: the coarse particle powder B and the original fine powder A are mixed and ball-milled according to the mass ratio of 1:1, added with 1% PVA binder, and then subjected to centrifugal spray drying and granulation to obtain spherical agglomerated powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com