Patents

Literature

77results about How to "Good mechanical properties at room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard alloy using iron-aluminum intermetallic compound as bonding phase and preparation method thereof

ActiveCN101985718AUniform tissue structureGood mechanical properties at room temperatureIron powderAlloy

The invention discloses a hard alloy using an iron-aluminum intermetallic compound as a bonding phase and a preparation method thereof. The hard phase is carbide, and the bonding phase is 10 to 40 volume percent of FeAl or Fe3Al. The preparation method comprises the following steps of: ball-milling and mixing 1.69 to 19.09 mass percent or 1.31 to 13.75 mass percent of pre-alloying powder of Fe2Al5, 2.10 to 23.78 mass percent or 3.23 to 33.81 mass percent of iron powder and the balance of carbide powder based on the component of FeAl or Fe3Al for 18 to 36 hours, preparing the obtained ball-milling mixture into uniform mixture powder by spray drying, pressing the mixture powder to form a blank, preserving the heat for 1 to 2 hours at the temperature of 1,200 + / - 20 DEG C under the vacuum condition during sintering the pressed blank, and then performing low-pressure liquid phase sintering at the temperature of between 1,250 and 1,550 DEG C to obtain the hard alloy using the FeAl or the Fe3Al as the bonding phase, wherein the FeAl or the Fe3Al is 10 to 40 volume percent. The preparation method has simple process and is low in manufacturing cost; holes are difficult to form in the liquid phase sintering process or are small; and the obtained hard alloy has high strength, good abrasion resistance and excellent high-temperature oxidation resistance and sulfur corrosion resistance.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

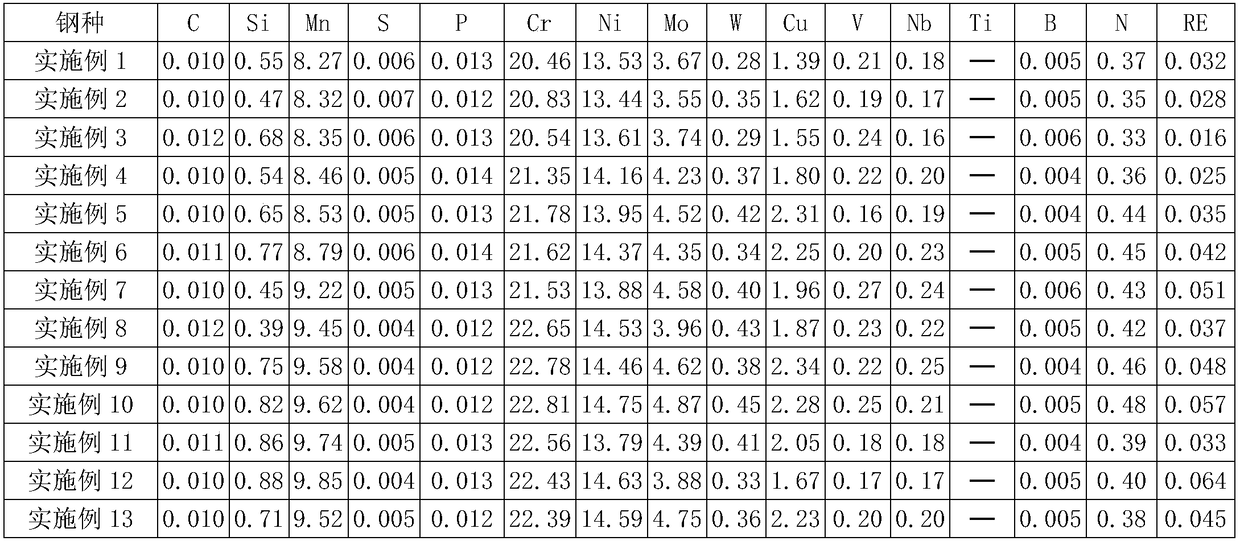

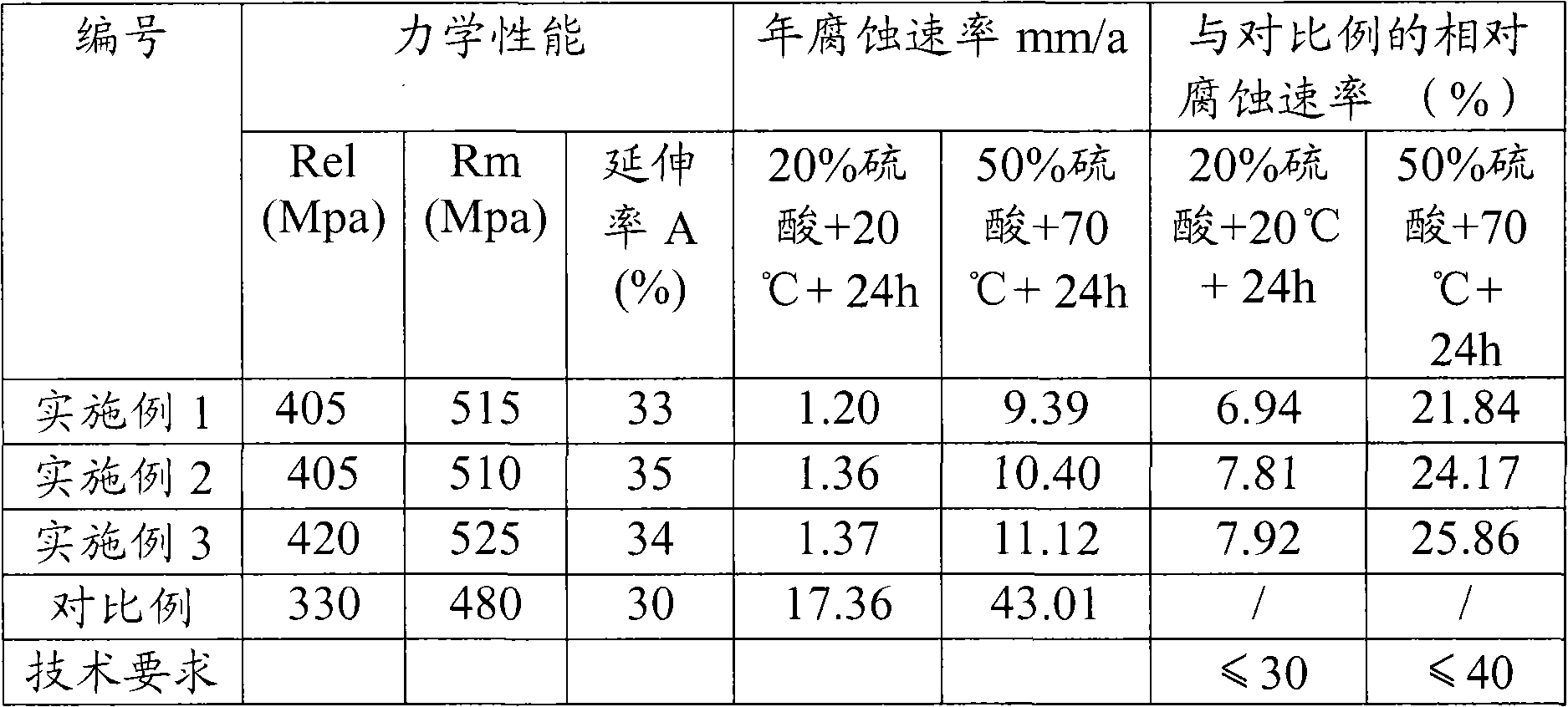

Corrosion-resistant super austenitic stainless steel and manufacturing technique thereof

InactiveCN108642409AImprove corrosion resistanceGood mechanical properties at room temperatureRare earthAustenite

The invention particularly relates to corrosion-resistant super austenitic stainless steel and a manufacturing technique thereof. The stainless steel comprises the following components of, by weight percentage, less than or equal to 0.03% of C, less than or equal to 0.02% of S, less than or equal to 0.03% of P, less than or equal to 1.0% of Si, 8.0-10.0% of Mn, 19.0-23.0% of Cr, 13.0-15.0% of Ni,3.0-5.0% of Mo, 1.0-2.5% of Cu, less than or equal to 0.5% of W, less than or equal to 0.3% of V, less than or equal to 0.3% of Nb, less than or equal to 0.1% of B, 0.3-0.5% of N, 0.001-0.1% of rare earth, and the balance Fe. The super austenitic stainless steel is low in cost and excellent in corrosion resistance, and can better adapt to equipment development under the harsh condition of the high-corrosion environment such as sulfuric acid and seawater.

Owner:JIANGSU UNIV OF TECH

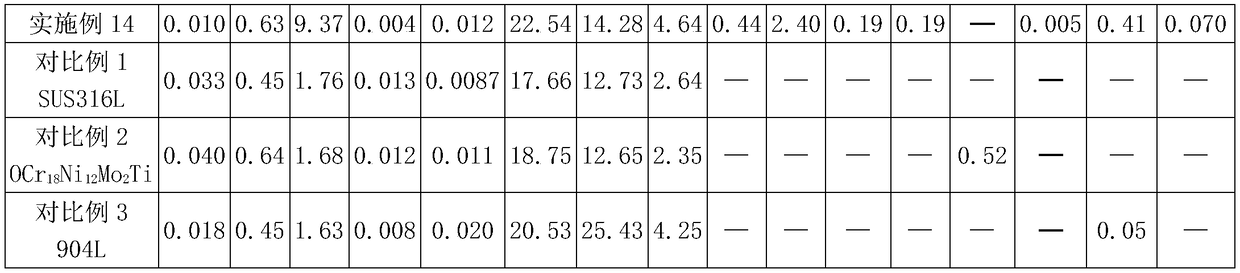

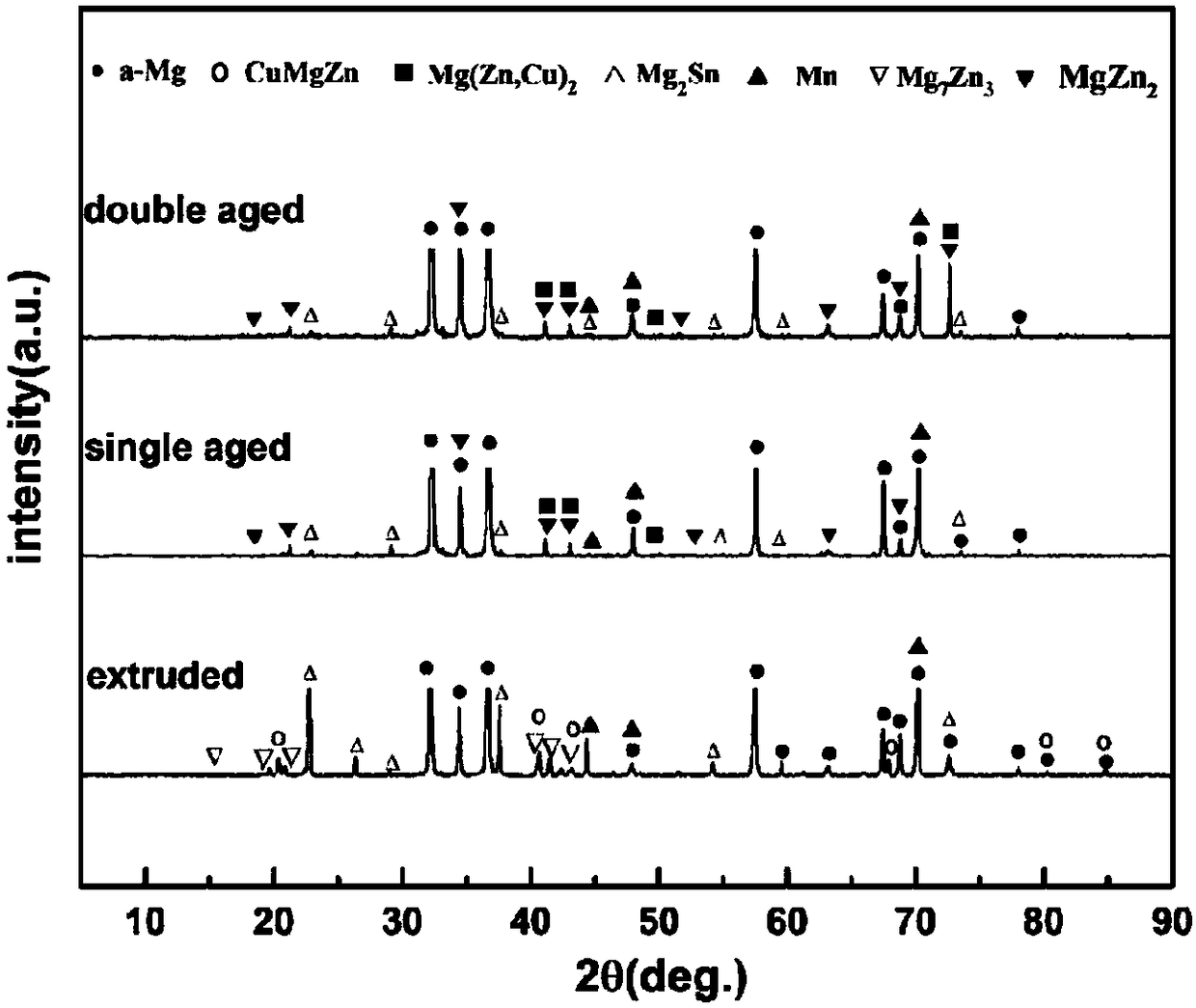

Wrought magnesium alloy material with low cost, high performance and heat resistance, and preparation method thereof

InactiveCN108385007AHigh strengthImprove mechanical propertiesRare-earth elementChemical composition

The invention provides a wrought magnesium alloy material with low cost, a high performance and heat resistance, and a preparation method thereof. The wrought magnesium alloy material is prepared fromthe chemical components in percentage by weight: 4.0 to 9.0 percent of Zn, 0.5 to 8 percent of Sn, 0.1 to 5 percent of Cu, 0.5 to 2 percent of Mn, and the balance magnesium and inevitable impurities.According to the wrought magnesium alloy material with the low cost, the high performance and the heat resistance, and the preparation method thereof provided by the invention, the problems that an existing high-strength heat-resistant wrought magnesium alloy material uses a rare earth element and a high-price alloy material, so that complicated processes such as large plastic deformation (rapidsolidification, powder metallurgy and the like) are higher in cost and the like are solved; and the element components of the alloy are reasonably blended, a conventional smelting and casting processis adopted, and reasonable heat treatment process conditions are selected after conventional plastic deformation and forming, so that the wrought magnesium alloy material with an excellent mechanicalproperty and a performance being remarkably superior to a high-strength ZK60 wrought magnesium alloy can be obtained. The wrought magnesium alloy material provided by the invention has the characteristics of low cost, high performance, no rare earth, and excellent high temperature and room temperature properties, and has a great application prospect.

Owner:XIANGTAN UNIV

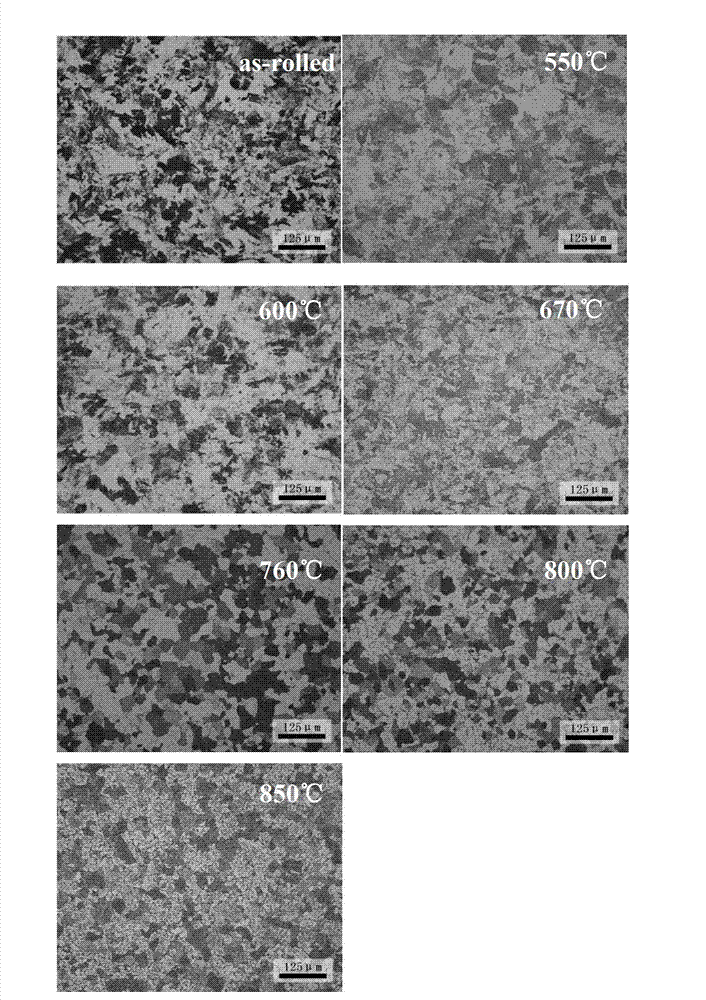

Production method of sulfuric acid dew-point corrosion resistance hot rolled sheet

InactiveCN101921966AGood value for moneyReduce the effect of acid resistanceMaterials scienceHot rolled

The invention provides a production method of a sulfuric acid dew-point corrosion resistance hot rolled sheet, which comprises the following steps: smelting blast furnace molten iron and smelting furnace material in a converter, alloying and deoxidizing to obtain molten steel; carrying out LF refining on the molten steel, feeding Ca-Si wire to carry out sulphide inclusion modification, and carrying out electric heating; carrying out continuous casting on molten steel, and cooling to form a hot rolled slab; carrying out hot rolling on the hot rolled slab, and controlling the discharge rolling temperature of the slab at 1200-1240 DEG C; and cooling, coiling and finishing to obtain the sulfuric acid dew-point corrosion resistance hot rolled sheet. The invention has the advantages of low production cost, simple hot rolling technique, no need of additional equipment investment and excellent sulfuric acid dew-point corrosion resistance.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

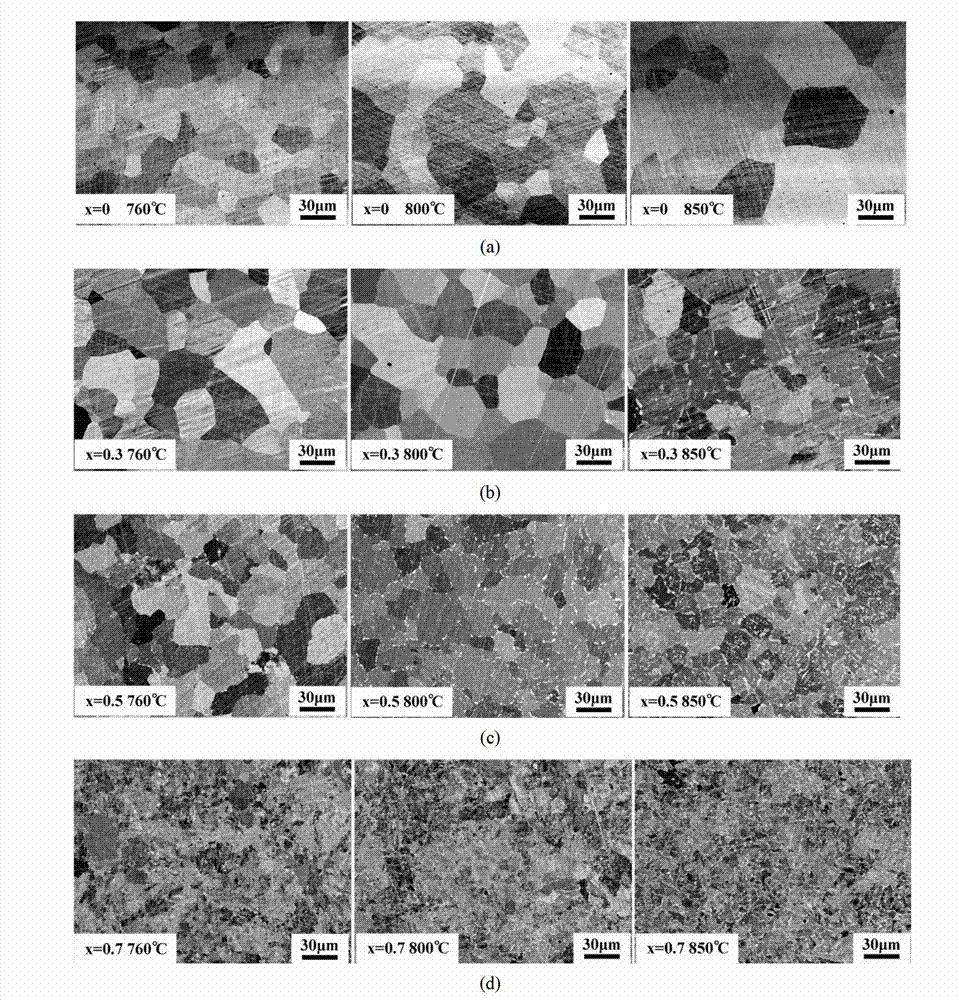

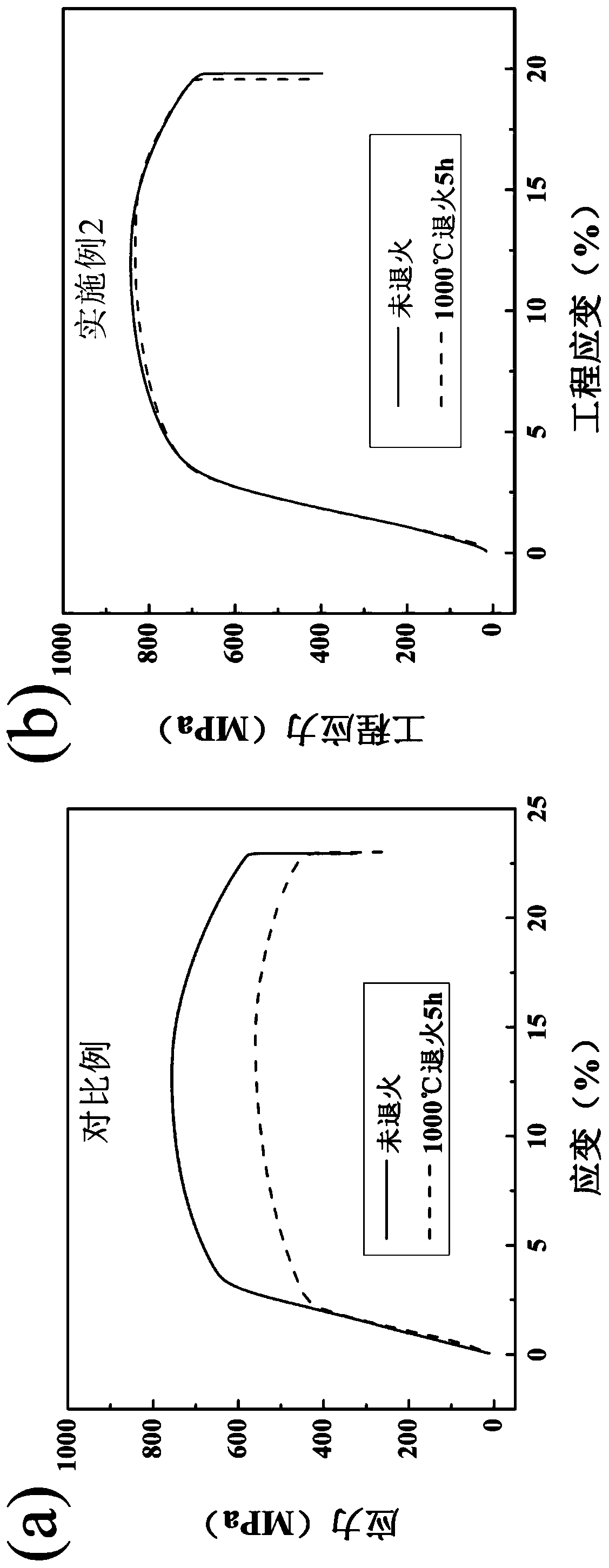

Alloy with excellent room-temperature soft magnetic property and mechanical property, and preparation method thereof

InactiveCN103114234AGood mechanical properties at room temperatureBoth soft magnetic propertiesMagnetic materialsCoercivitySmelting

The invention discloses alloy with excellent room-temperature soft magnetic property and mechanical property, and a preparation method thereof, and belongs to the technical field of soft magnetic alloy, wherein the alloy is Fe-49Co-2V-xCr, wherein x is smaller than or equal to 1.0 and greater than 0, and is atomic percent; preferably x is smaller than 0.5 and greater than 0; the preparation method comprises the steps of smelting, vacuum diffusing and annealing, high-temperature forging, hot rolling, cold rolling and final heat treatment. The FeCoVCr alloy provided by the invention is excellent in room-temperature mechanical property; the tensile strength can be up to 912MPa; the elongation can be up to 10.9%; the alloy has soft magnetic property; and the coercivity does not exceed 3.58Oe. The alloy is simple in preparation technology, and a large-sized alloy material can be prepared conveniently.

Owner:BEIHANG UNIV

High-strength corrosion-resistant wrought magnesium alloy and preparing method thereof

ActiveCN107236884AImprove mechanical propertiesImprove corrosion resistanceSolid solution strengtheningCa element

The invention relates to a high-strength corrosion-resistant wrought magnesium alloy and a preparing method thereof. The magnesium alloy comprises, by mass percentage, 6.0%-9.0% of Sn, 1.5%-4.0% of Zn, 0.1%-1.0% of Mn, 0%-1.0% of Ca, 0.01%-0.1% of Na, less than 0.03% of inevitable impurities in total and the balance Mg. The Sn element serves as a main alloy element, and therefore the solution strengthening effect and the second phase strengthening effect are guaranteed, SnO2 can be formed in the corrosion process, and the protection performance of a Mg(OH)2 film is improved; the Zn element is added into a solution strengthening magnesium base; through adding of the Mn element, the content of impurity elements in the magnesium base can be reduced, the grain size of the extrusion state alloy is reduced, and the mechanical property and the decay resistance of the alloy are improved; through adding of the Ca element, a CaMgSn phase can be formed to participate in formation of an oxidation film, and the density of the oxidation film is increased; and through adding of the Na element, the size of a second phase can be refined. In cooperation with joint effects of several aspects, the alloy has the excellent mechanical property and decay resistance.

Owner:DONGHAO MECHANICAL & ELECTRONICS

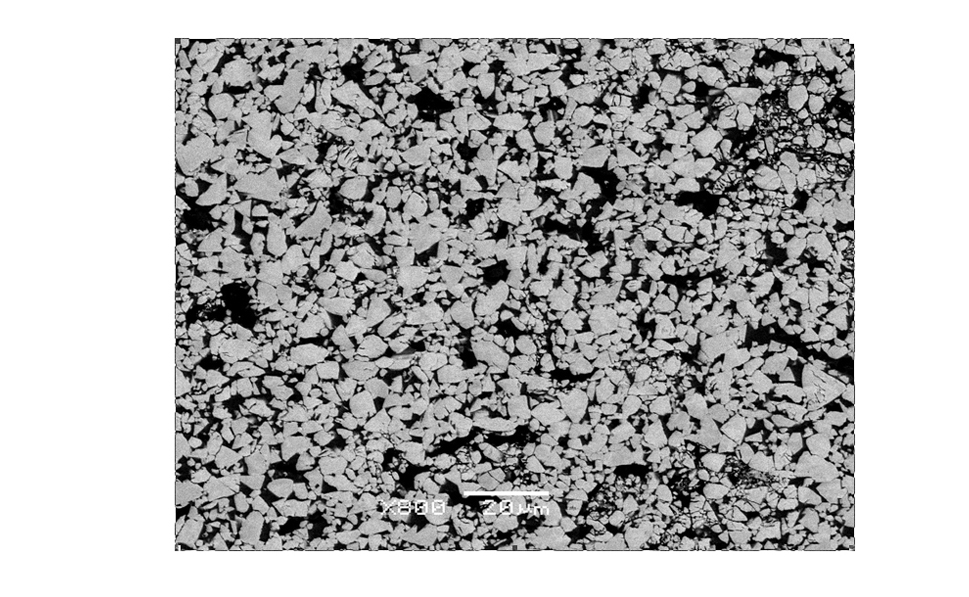

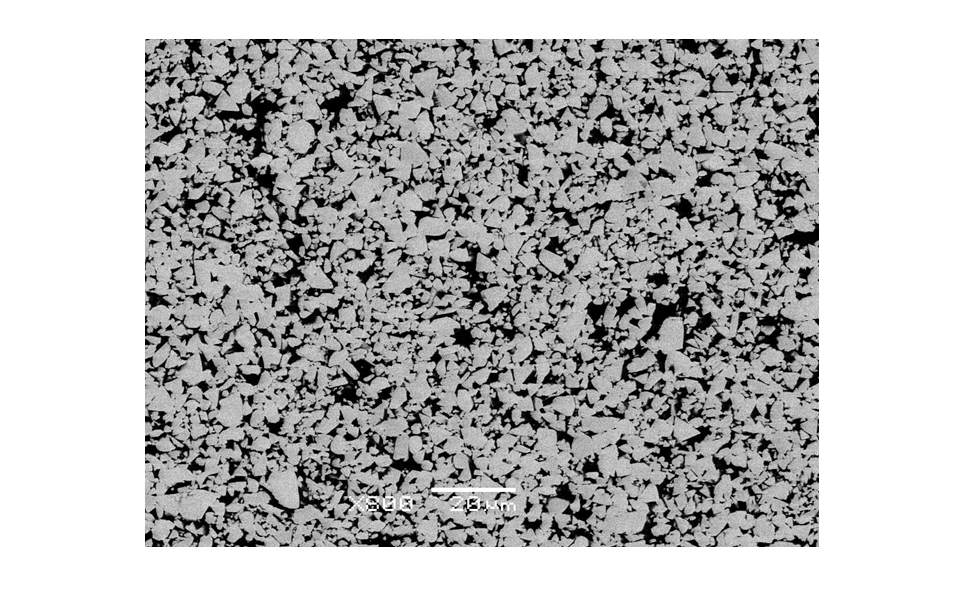

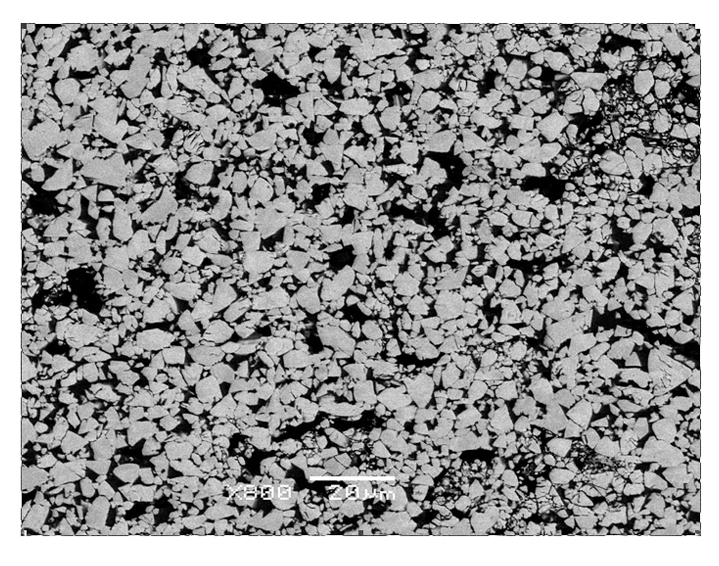

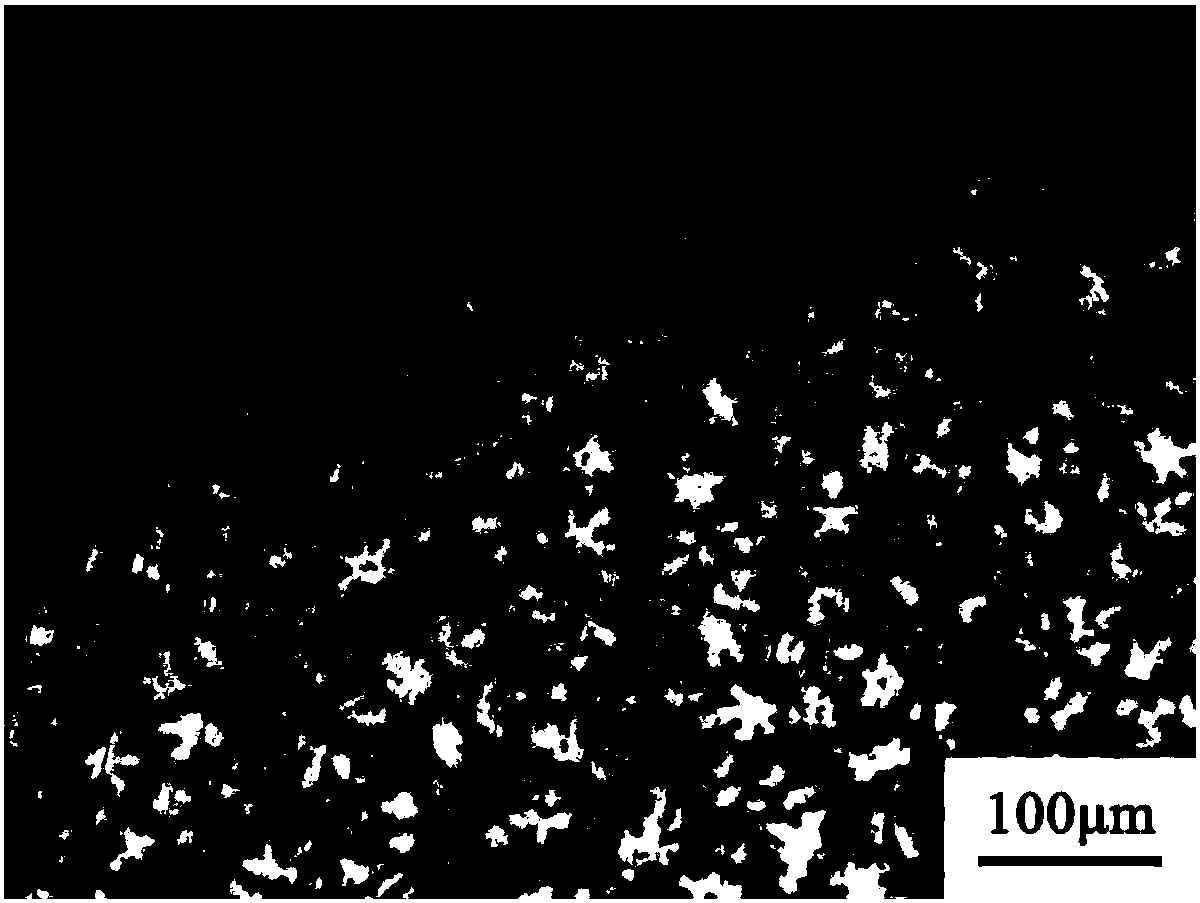

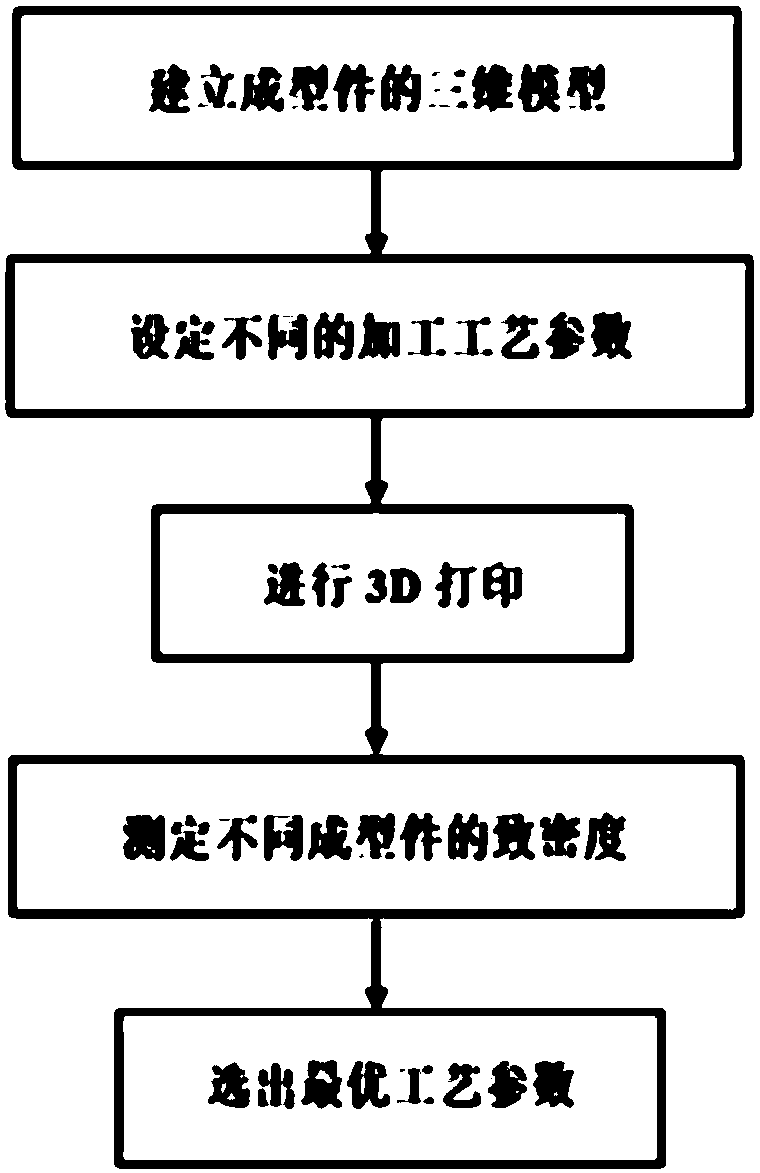

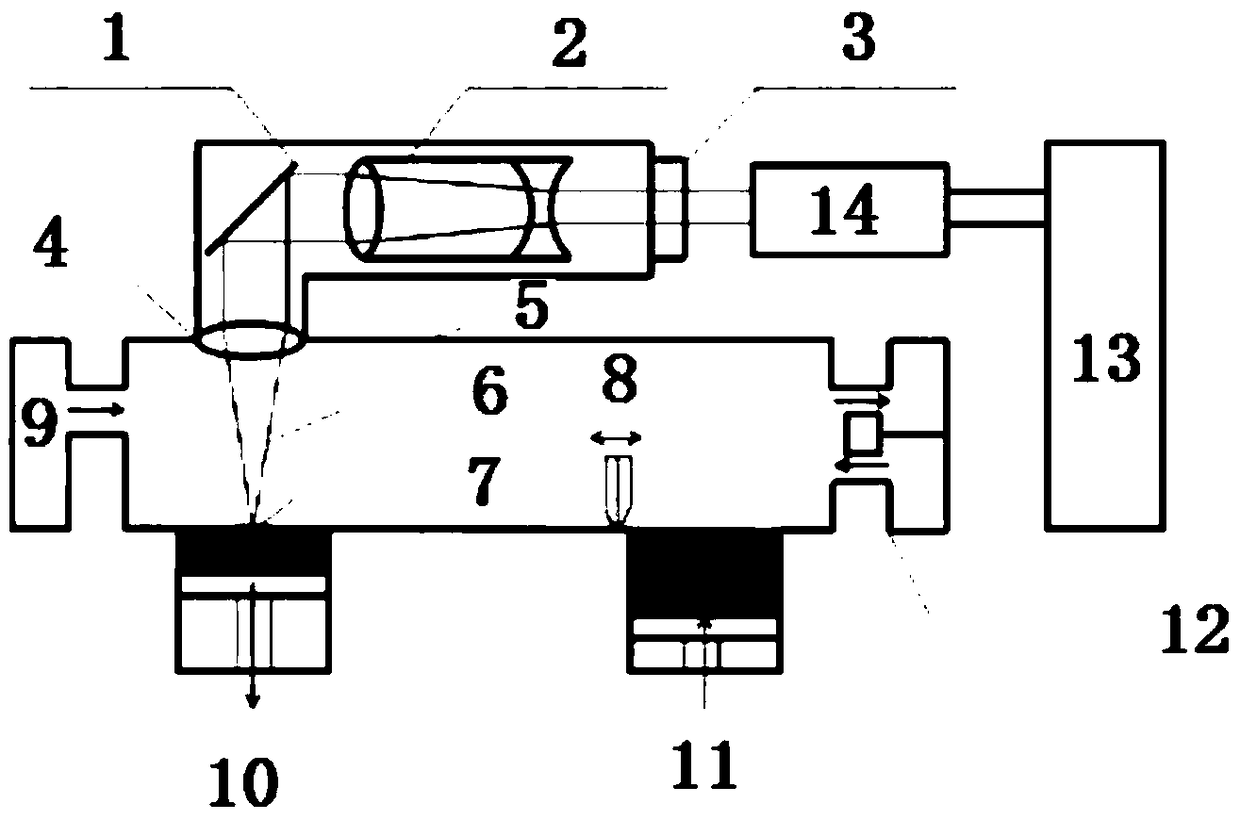

High-density pure molybdenum selective laser melting producing method

InactiveCN109317675APrevent oxidationImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh density

The invention provides a high-density pure molybdenum selective laser melting producing method. The high-density pure molybdenum selective laser melting producing method comprises the following stepsof establishing a molybdenum plate three-dimensional solid numerical model on a computer; setting the power, scanning speed, scanning spacing and scanning mode of a laser beam; performing 3D printing;determining the density of different formed parts; and selecting the optimal process parameters. By optimizing the process parameters of SLM technology, the pure molybdenum formed parts with high density and high surface quality can be obtained, traditional machining and post-processing are avoided, manpower and material resources are saved, and the machining period is shortened. Pure molybdenumworkpieces produced according to the machining process have good mechanical properties at room temperature and technically have certain theoretical research value and practical application value.

Owner:HARBIN ENG UNIV

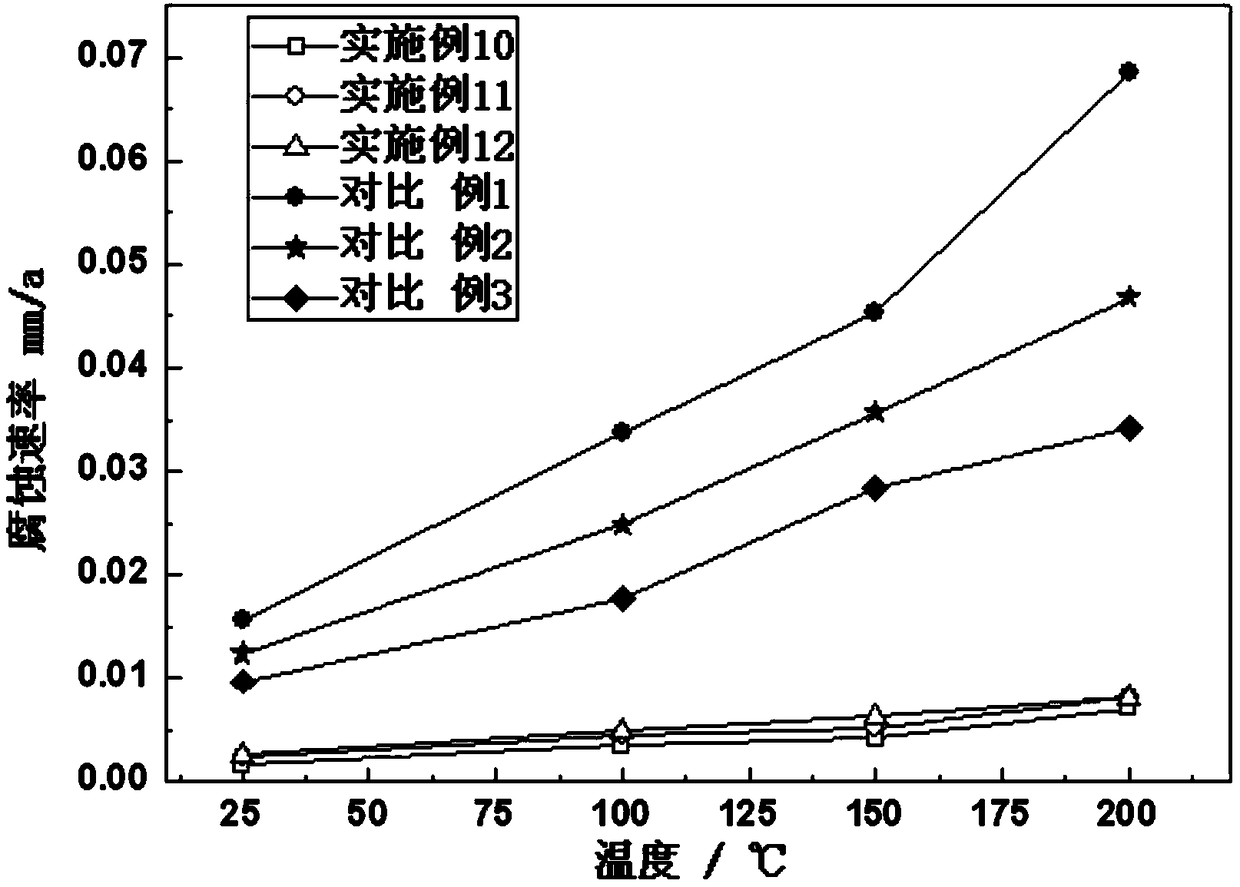

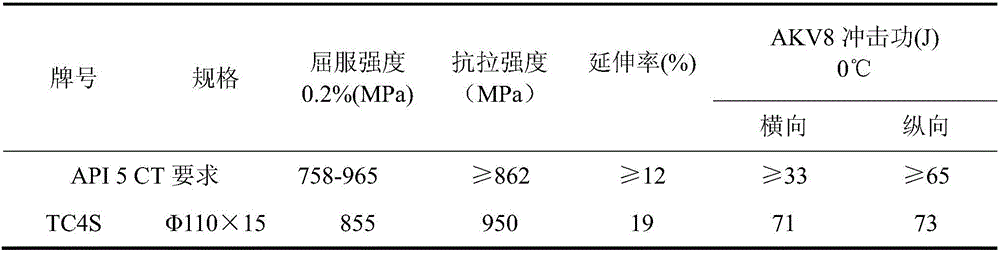

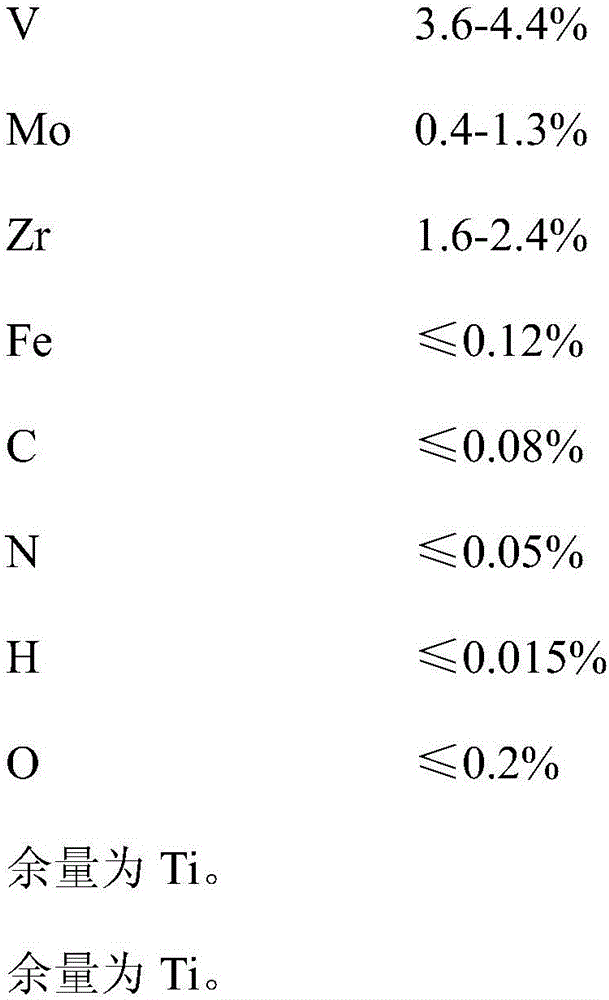

ZSA-3 titanium alloy pipe, and preparation method and application thereof

ActiveCN106636742AExtended service lifeGood mechanical properties at room temperatureHigh resistanceRoom temperature

The invention discloses a ZSA-3 titanium alloy pipe, and a preparation method and application thereof. The ZSA-3 titanium alloy pipe is composed of the following components in percentage by mass: 4.6-5.4% of Al, 3.6-4.4% of V, 0.4-1.3% of Mo, 1.6-2.4% of Zr, at most 0.12% of Fe, at most 0.08% of C, at most 0.05% of N, at most 0.015% of H, at most 0.2% of O and the balance of Ti. The preparation method comprises the following steps: smelting a cast ingot according to the proportion, perforating the forged bar, rolling to obtain the finished pipe, and carrying out heat treatment, thereby obtaining the ZSA-3 titanium alloy pipe. The titanium alloy pipe has the characteristic of corrosion resistance at high temperature, and especially has very high resistance to corrosion of H2S and CO2 at 150-260 DEG C under petroleum working conditions; and the corrosion rate is lowered to 0.0006 mm / a or below. The ZSA-3 titanium alloy pipe has excellent room-temperature mechanical properties: the tensile strength is 830-1200 MPa, the yield strength is 750-1120 MPa, and the elongation percentage is 10-20%; and thus, the ZSA-3 titanium alloy pipe is a high-strength material capable of resisting corrosion of H2S and CO2 at high temperature. The ZSA-3 titanium alloy pipe has long service life, fills up the blank in China, and thus, has wide application prospects.

Owner:中世钛业有限公司

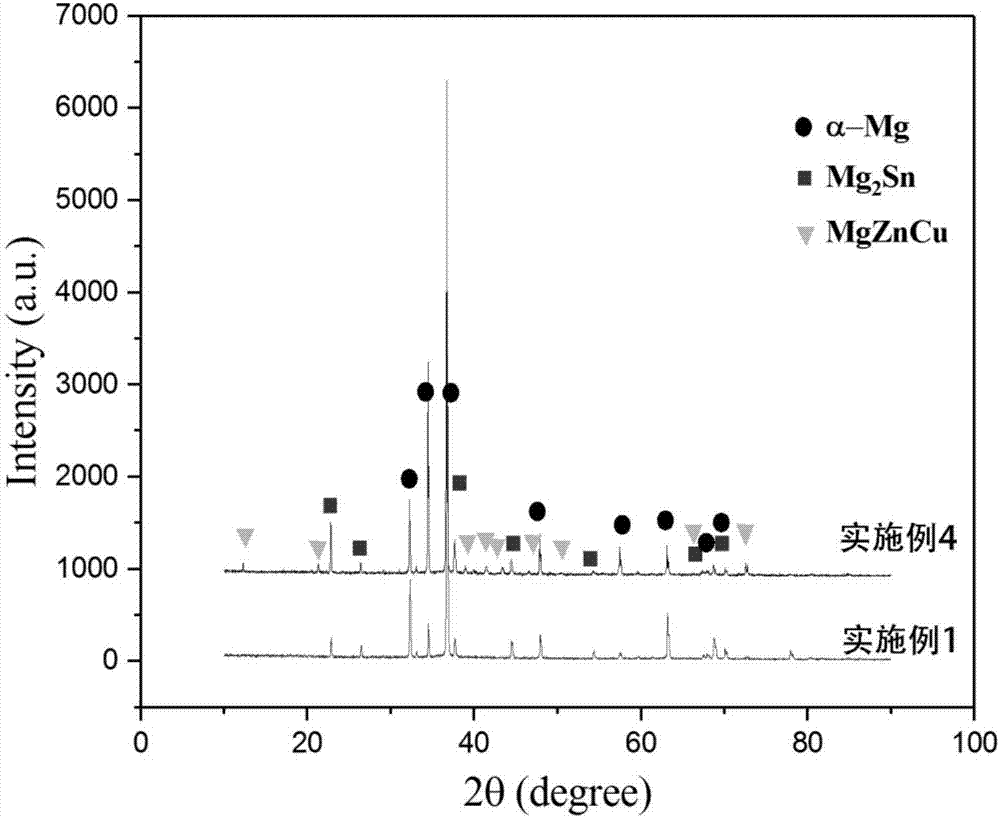

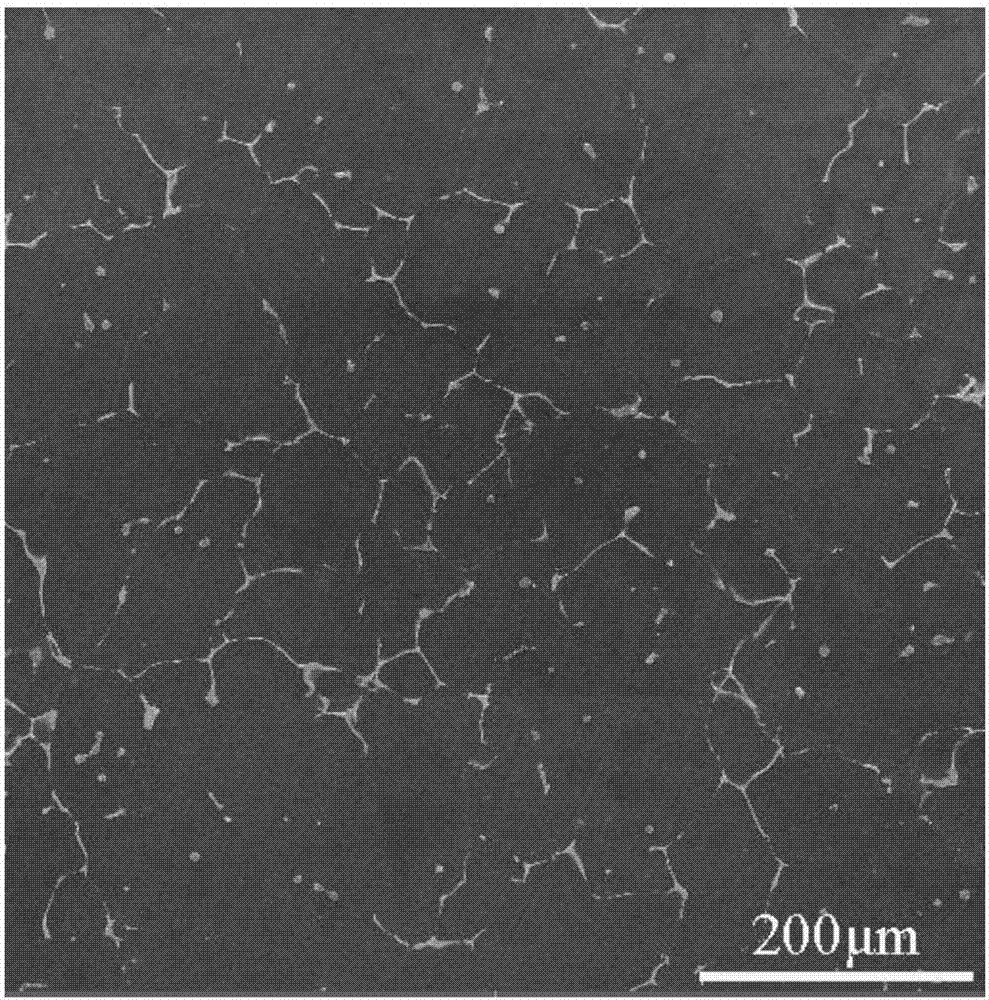

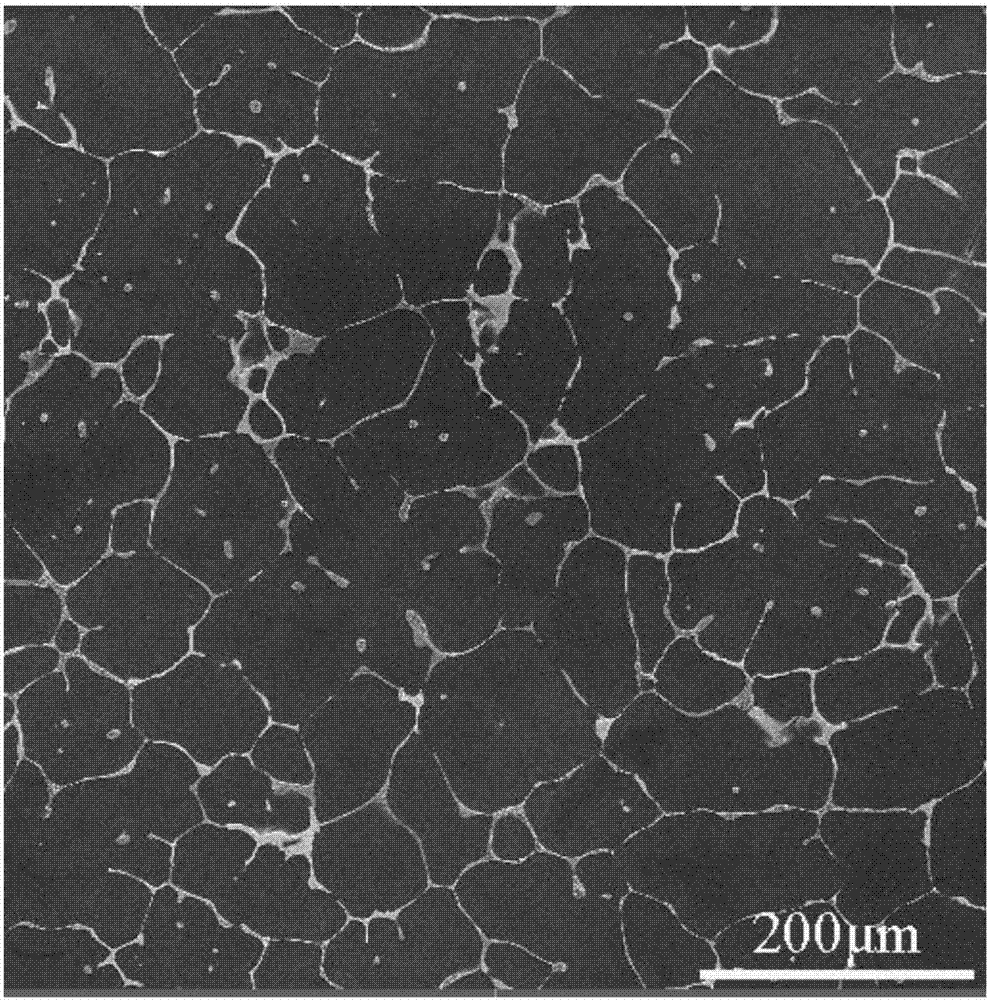

Non-rare-earth high-strength wrought magnesium alloy and preparing method thereof

The invention relates to a non-rare-earth high-strength wrought magnesium alloy and a preparing method thereof, and belongs to the technical field of metal materials. The non-rare-earth high-strength wrought magnesium alloy comprises, by weight percentage, 6.0%-10.0% of Sn, 1.5%-6.0% of Zn, 0.15%-1.0% of Mn, 0.1%-2.0% of Cu, 0.01%-0.2% of Na, less than 0.03% of inevitable impurities including Fe, Ni and Si and the balance Mg. The Sn element and the Zn element are added, and therefore alloy solution strengthening and second phase strengthening can be carried out; through adding of the Mn element, the content of impurity elements in the magnesium base can be reduced, the grain size of the extrusion state alloy is effectively reduced, and the mechanical property of the alloy is improved; through adding of the Cu element, a MgZnCu phase strengthening alloy can be formed; through adding of the Na element, the size of a second phase can be refined obviously, and the dispersion strengthening effect is strengthened; and in addition, three-level solution treatment and low temperature extrusion treatment are adopted, it can be promoted that the elements in the alloy are separated out in the manner of a wee second phase, and the non-rare-earth high-strength wrought magnesium alloy has the excellent mechanical property in cooperation with the effects of the several aspects.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Wear-resistant aluminum alloy

The invention discloses a wear-resistant aluminum alloy which is a novel aluminum-silicon alloy and comprises the following raw material components in percentage by mass: 15-18% of silicon powder, 0.1-0.4% of copper powder, 1.5-4% of magnesium powder, 0.5-1% of titanium powder, 0.2-0.6% of manganese powder, 0.05-0.1% of carbon powder, 0.3-0.7% of chromium powder, 0.8-1.2% of iron powder, and the balance of aluminum powder and inevitable impurities. The novel aluminum-silicon alloy is prepared by mixing the elements, pressing into an ingot and performing high-temperature sintering. By virtue of the manner, the wear-resistant aluminum alloy disclosed by the invention has better wear resistance and corrosion resistance compared with a eutectic aluminum-silicon alloy, has good normal-temperature mechanical properties at the same time, and can be widely used in the machining industry.

Owner:CHANGSHU JINGCHENG ALUMINUM

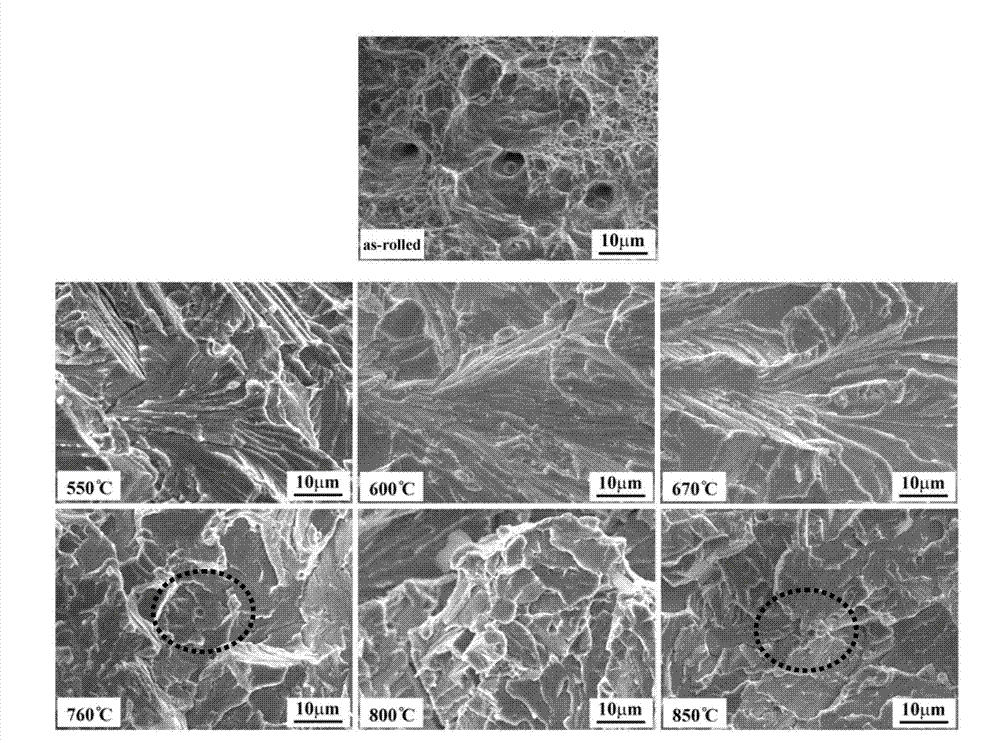

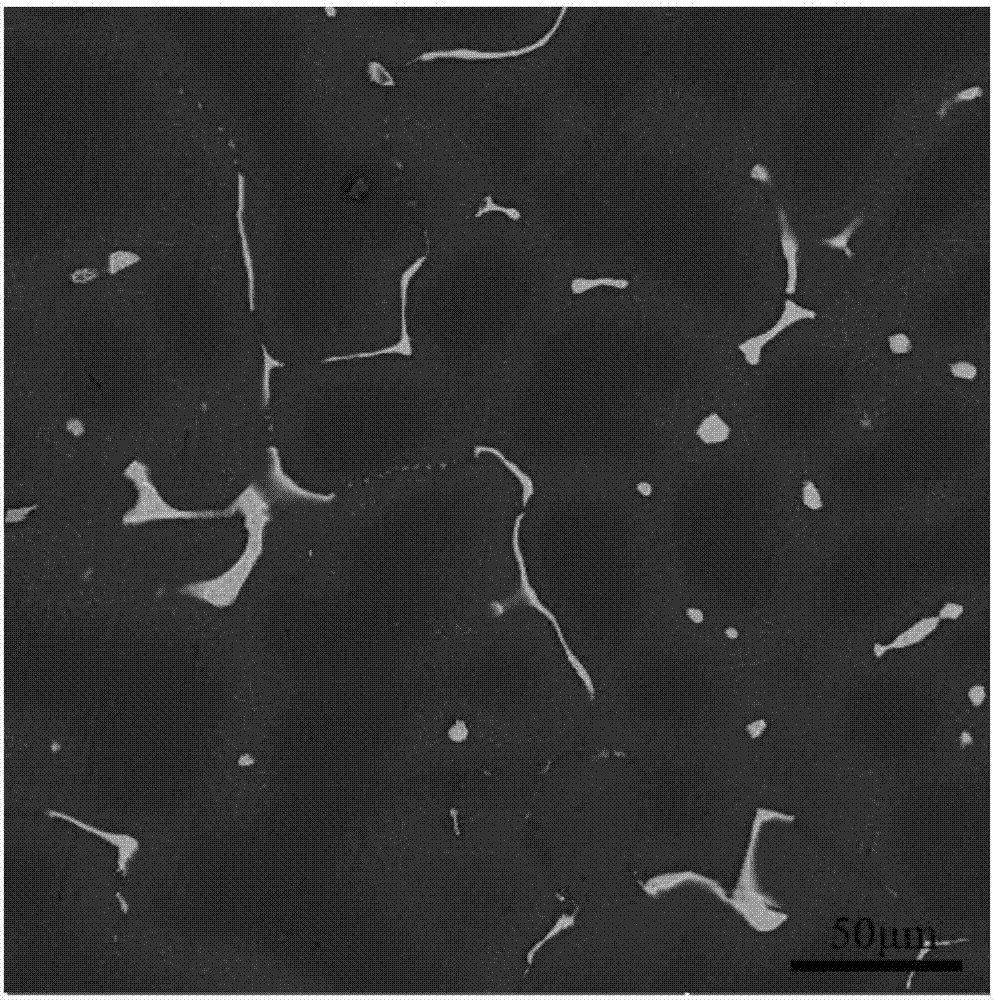

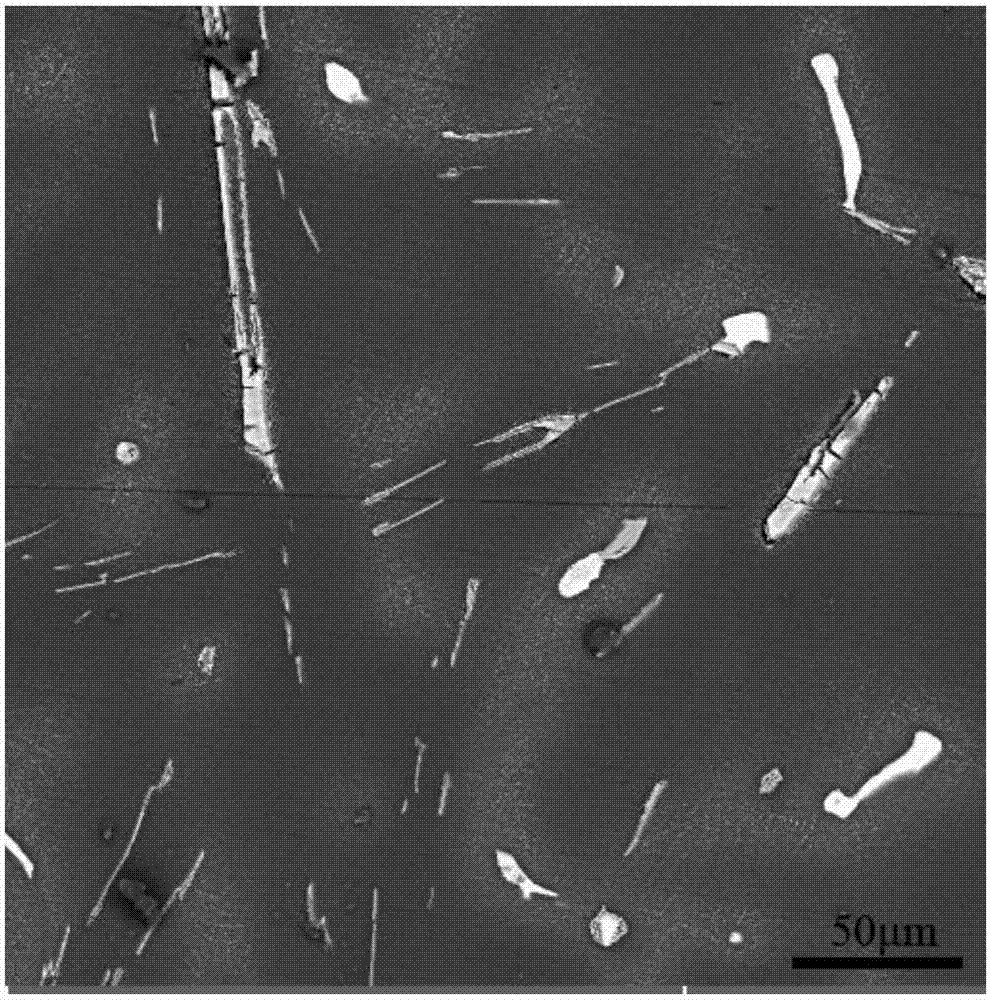

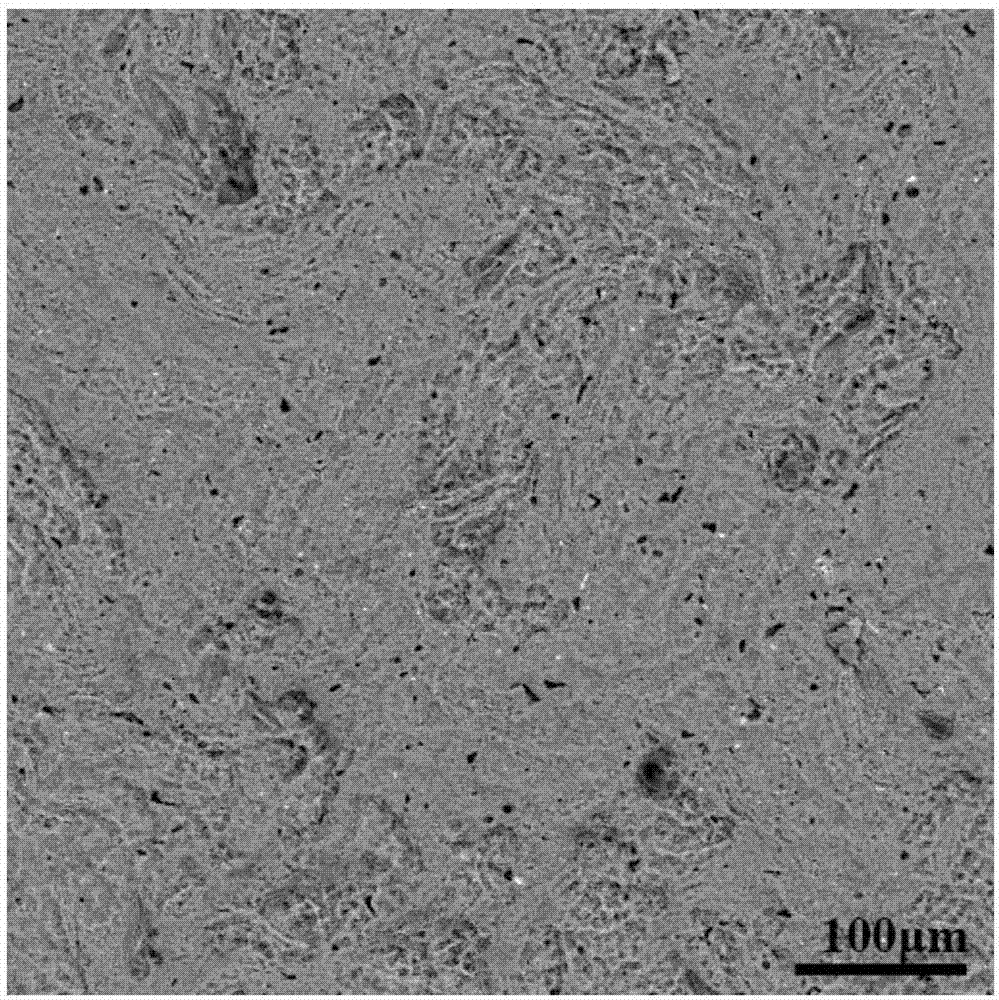

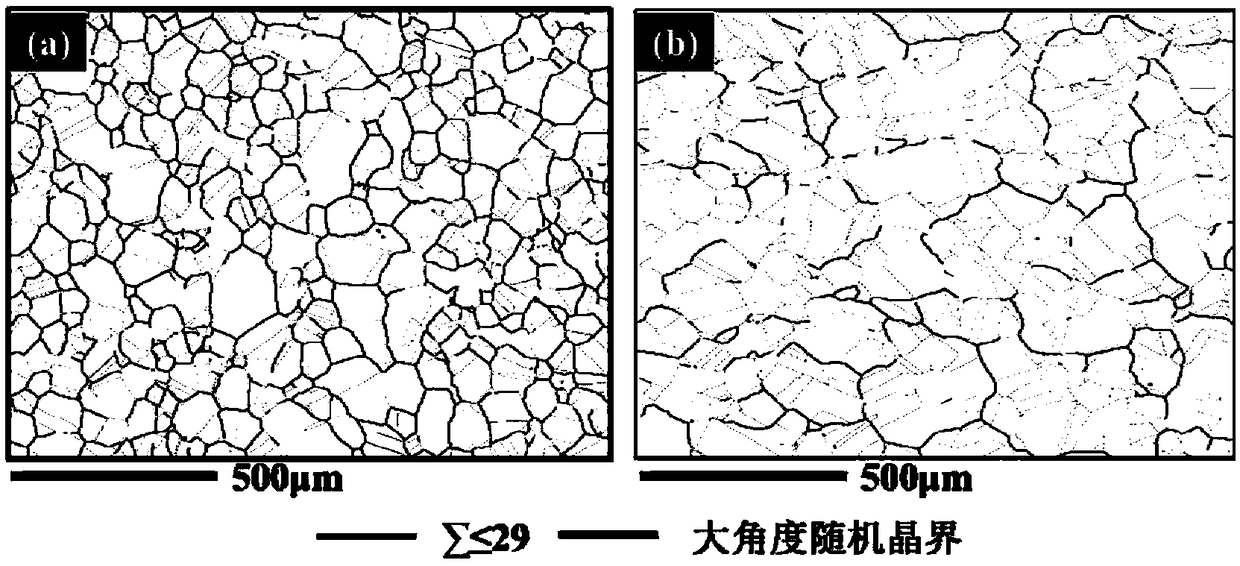

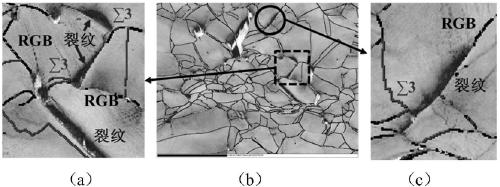

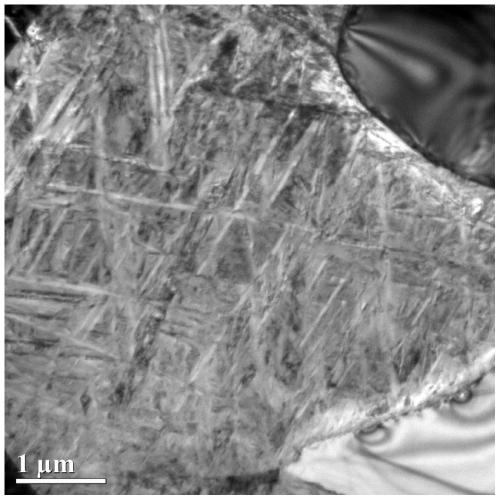

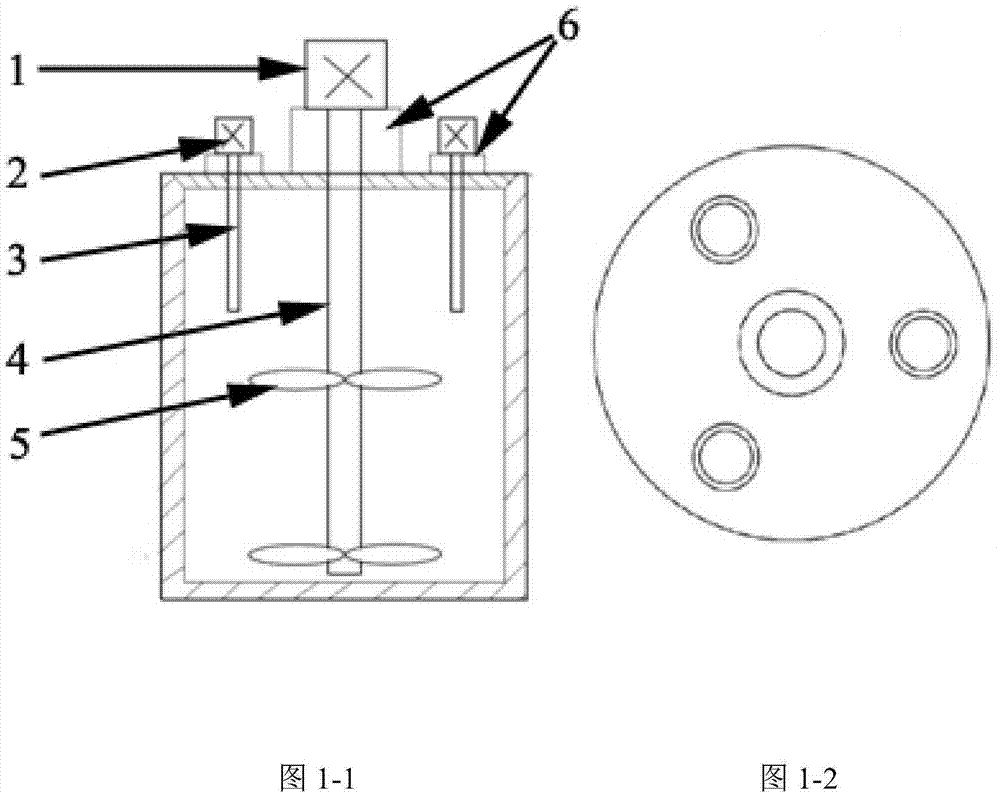

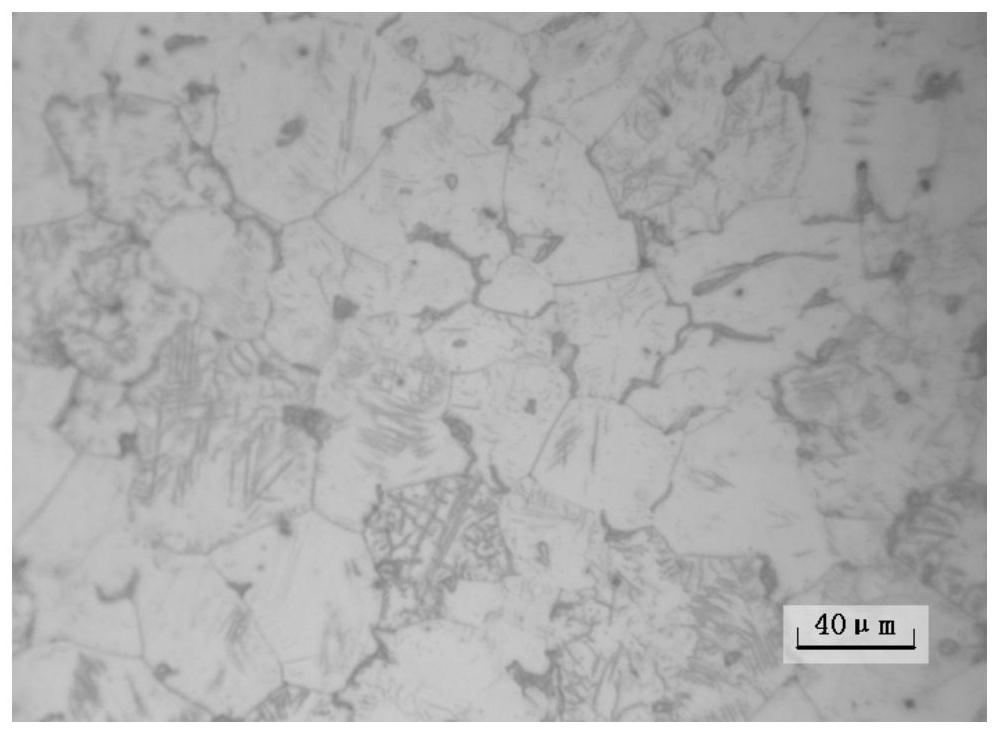

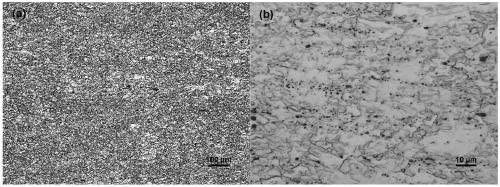

Method for improving hydrogen resistance of iron-nickel-based alloy by increasing special grain boundary ratio

ActiveCN108998649AIncrease resistanceImproved resistance to hydrogen damageGrain boundaryHeat treated

The invention relates to the field of iron-nickel-based alloy, in particular to a method for improving the hydrogen resistance of iron-nickel-based precipitation-strengthened austenite alloy by increasing the special grain boundary ratio, and solves the problems that after saturated hydrogenation of the existing iron-nickel-based alloy, hydrogen-induced grain boundary cracks are easily formed andhydrogen embrittlement sensitivity increase and elongation decrease are caused thereby. By a thermal mechanical treatment (single-step deformation heat treatment) method, the special grain boundary ratio of the alloy is increased, the initiation and expansion resistance of the hydrogen-induced cracks in the alloy is increased, and the hydrogen damage resistance of the alloy is improved; the methodcomprises the following specific technological route: performing solution treatment, predeforming, preserving heat, performing water cooling, performing aging treatment and performing air cooling. The iron-nickel-based alloy treated by the method provided by the invention has the special grain boundary ratio of 65-80% and has the room-temperature tensile elongation of 33% or above; after saturated thermal hydrogenation, the room-temperature elongation of the alloy can still keep 30% or above, and the hydrogen-induced elongation loss is reduced within 10%.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ti-Al-Zr-Cr-series martensitic titanium alloy and preparation method thereof

ActiveCN111394616AHigh strengthGood mechanical properties at room temperatureTitanium alloyCr element

Owner:XI AN JIAOTONG UNIV

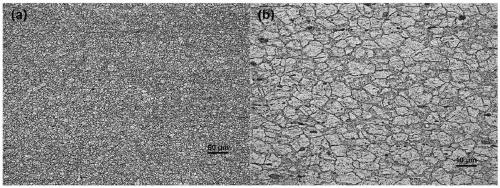

Low-alloyed high-performance superplastic magnesium alloy and preparation method thereof

The invention provides a low-alloyed high-performance superplastic magnesium alloy and a preparation method thereof. The chemical components of the low-alloyed high-performance superplastic magnesiumalloy comprises, by mass, 0.5-2.5% of zinc, 0.05-1.0% of argentum, 0.05-1.0% of calcium, 0.05-1.0% of zirconium and the balance magnesium. The gross of mass percent of the chemical components of alloyelements except magnesium is less than 3%. The preparation method for the low-alloyed high-performance superplastic magnesium alloy comprises four steps of gradient-temperature smelting, accurate andrapid solidifying, rolling technology and recrystallization treatment. According to the low-alloyed high-performance superplastic magnesium alloy and the preparation method thereof, a traditional superplastic magnesium alloy design principle is broken through; through combination of a multi-element small-amount alloy component design principle, an accurate and rapid solidifying method and the rolling technology, the superplastic magnesium alloy which is characterized by having low-alloyed high performance and being short in process and low in cost and the preparation method thereof are acquired; the tensile strength of larger than 300 MPa can be acquired by the alloy with components optimized; the elongation rate is larger than 15%; room-temperature performance is outstanding; and in addition, the alloy with components optimized has superplasticity, the elongation rate at the temperature of 300 DEG C is 300%, and the elongation rate at the temperature of 250 DEG C is 250%.

Owner:JILIN UNIV

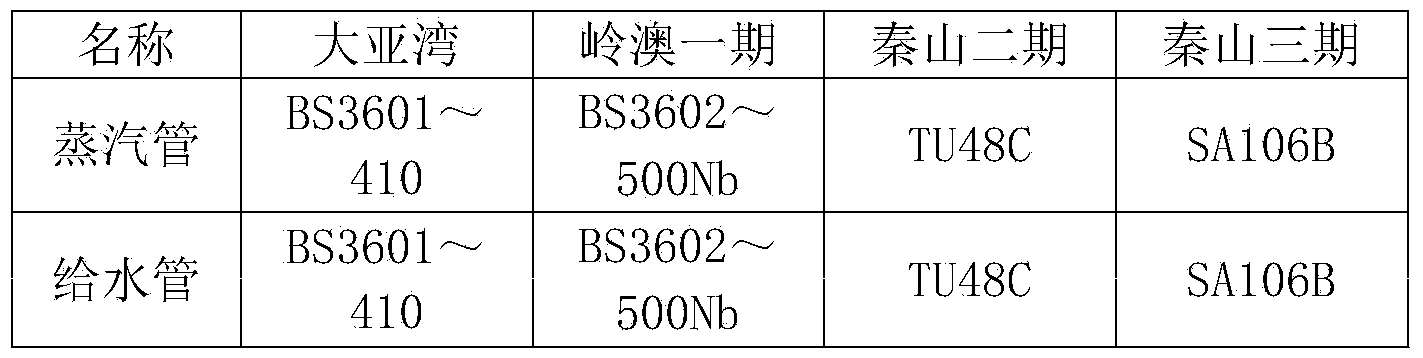

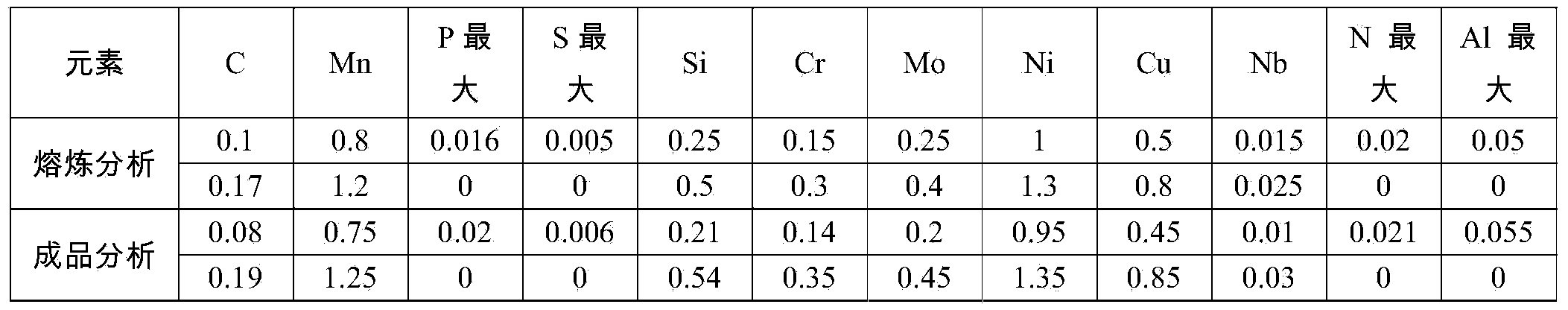

Main steam and main water supply pipeline in a conventional island of nuclear power plants and preparation method thereof

The present invention discloses a main steam and main water supply pipeline in a conventional island of nuclear power plants and a preparation method thereof. The main water supply pipeline comprises the following components in percentage by weight: 0.06-0.20% of C, 0.70-1.30% of Mn, 0-0.020% of P, 0-0.006% of S, 0.20-0.60% of Si, 0.15-0.35% of Cr, 0.15-0.50% of Mo, 0.90-1.40% of Ni, 0.40-0.90% of Cu, 0.008-0.035% of Nb, 0-0.021% of N, 0-0.055% of Al and the balance of Fe and unavoidable impurities. The preparation method comprises the following two methods, namely, directly rolling pipes on a periodic mill and carrying out pipe cross-rolling piercing on a forging blank. The main steam and main water supply pipeline disclosed by the invention has the advantages of good FAC (Flow Accelerated Corrosion) resistance, good mechanical properties at room temperature and tensile properties at high temperature and impact toughness at low temperature.

Owner:中广核工程有限公司 +1

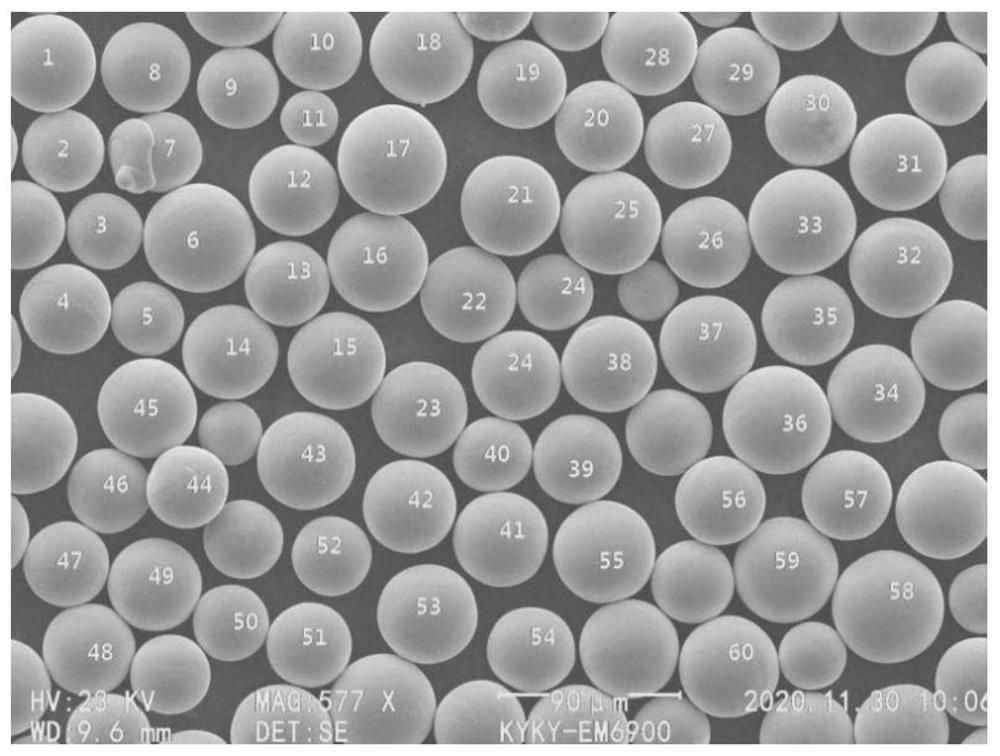

High-purity nickel-based high-temperature alloy and preparation method of spherical powder of high-purity nickel-based high-temperature alloy

PendingCN113817935AHigh purityHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyIngotSuperalloy

The invention discloses a high-purity nickel-based high-temperature alloy and a preparation method of spherical powder of the high-purity nickel-based high-temperature alloy. The alloy comprises the following steps of selecting high-purity metal ingredients, smelting in a vacuum induction suspension smelting furnace, realizing pure smelting by controlling parameters such as smelting vacuum degree, refining temperature, time and the like, then pouring to obtain a steel ingot, and preparing the steel ingot into a bar; carrying out smelting, atomizing and powdering on the bar through EIGA and PREP technologies to obtain spherical metal powder; adopting vibrating screening and airflow classification, and classifying spherical powder under the protection of inert gas. According to the method, the content of nonmetal impurities is effectively controlled through raw material smelting control, atomization process control and post-treatment control, so that chemical elements of the powder have extremely high purity, and the high-purity high-temperature alloy spherical powder is not prone to generating cracks and other defects in the subsequent laser additive printing and laser cladding process and is good in binding force, high in strength, good in toughness and good in mechanical property, and the powder can be used for repairing high-end parts.

Owner:盘星新型合金材料(常州)有限公司

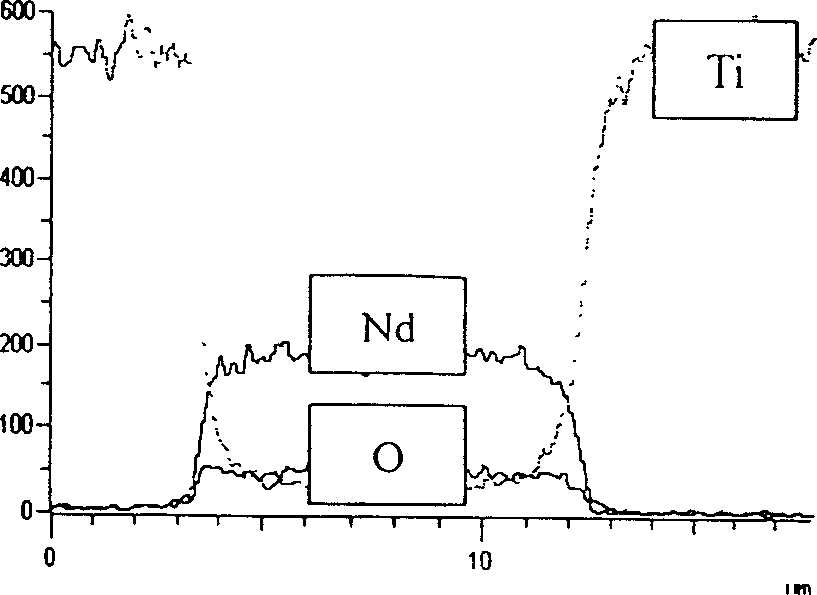

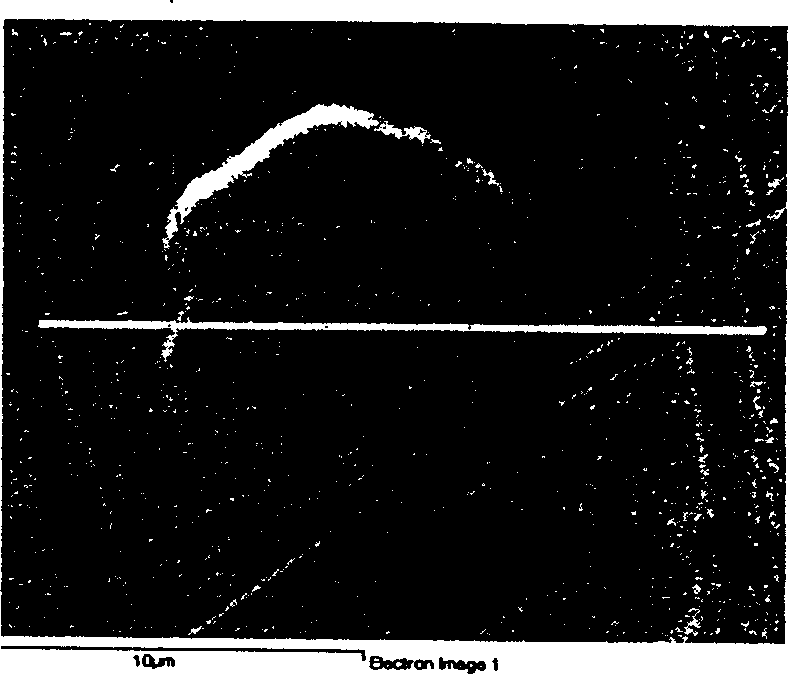

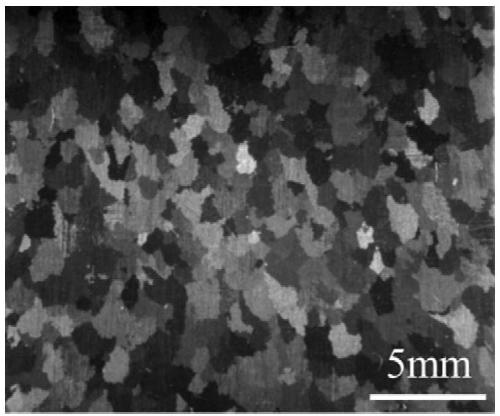

Low cost beta titanium alloy and its preparing method

The present invention relates to low cost beta-type titanium alloy prepared with cheap elements and its preparation process. The alloy consists of Fe 1-1.5 wt%, Mo 1-2.25 wt%, Al 0.3-6 wt%, Nd 1.2-2 wt% except Ti and inevitable impurity. The preparation process includes compounding Nd containing mother alloy powder, Fe powder, Mo powder or intermediate alloy powder and Ti powder in nominal alloy components; cold equipressure forming the mixture powder, and sintering at 1250-1400 deg.c for 1-6 hr. The tested mechanical performance includes the room temperature stretching parameters of: sigma-b of 750-940 MPa, sigma-0.2 of 660-860 MPa and sigma-5 of 14-25 %.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

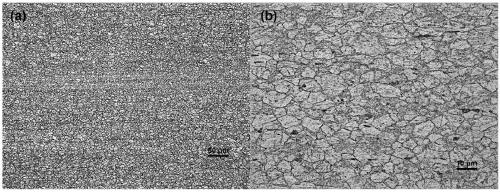

Wrought magnesium alloy with nanostructure characteristics and preparation method thereof

The invention provides a wrought magnesium alloy with nanostructure characteristics and a preparation method thereof. The alloy is prepared from, by mass, 0.8-1.5% of aluminum, 1.5-2.5% of zinc, 0.15-0.4% of calcium, 0.2-0.4% of manganese, 0.15-0.3% of gadolinium, and balance magnesium, wherein the content of impurity iron is controlled at 0.003% or less. The preparation method comprises the stepsthat 1, raw materials of an Mg ingot, an Al ingot, a Zn ingot, Mg-Ca and Mg-Gd intermediate alloy are smelted; 2, MnCl2 is added at lower temperature to remove iron; 3, secondary refining time afterMg-Ca is added is shortened, and the actual yield of Ca reaches 50-60%; 4, electromagnetic semi-continuous casting is carried out; 5, uniform treatment is carried out; 6, extrusion treatment is carried out to obtain a wrought magnesium alloy extruded bar. The wrought magnesium alloy with the nanostructure characteristics and the preparation method thereof have the advantages that a wrought magnesium alloy ingot blank is prepared by adopting a low-frequency electromagnetic semi-continuous casting technology, low-temperature extrusion can be achieved, the extruded material is in a nanometer complete recrystallized structure, and the mechanical properties at room temperature are excellent.

Owner:NORTHEASTERN UNIV

Low-cost high-strength magnesium alloy and preparation method thereof

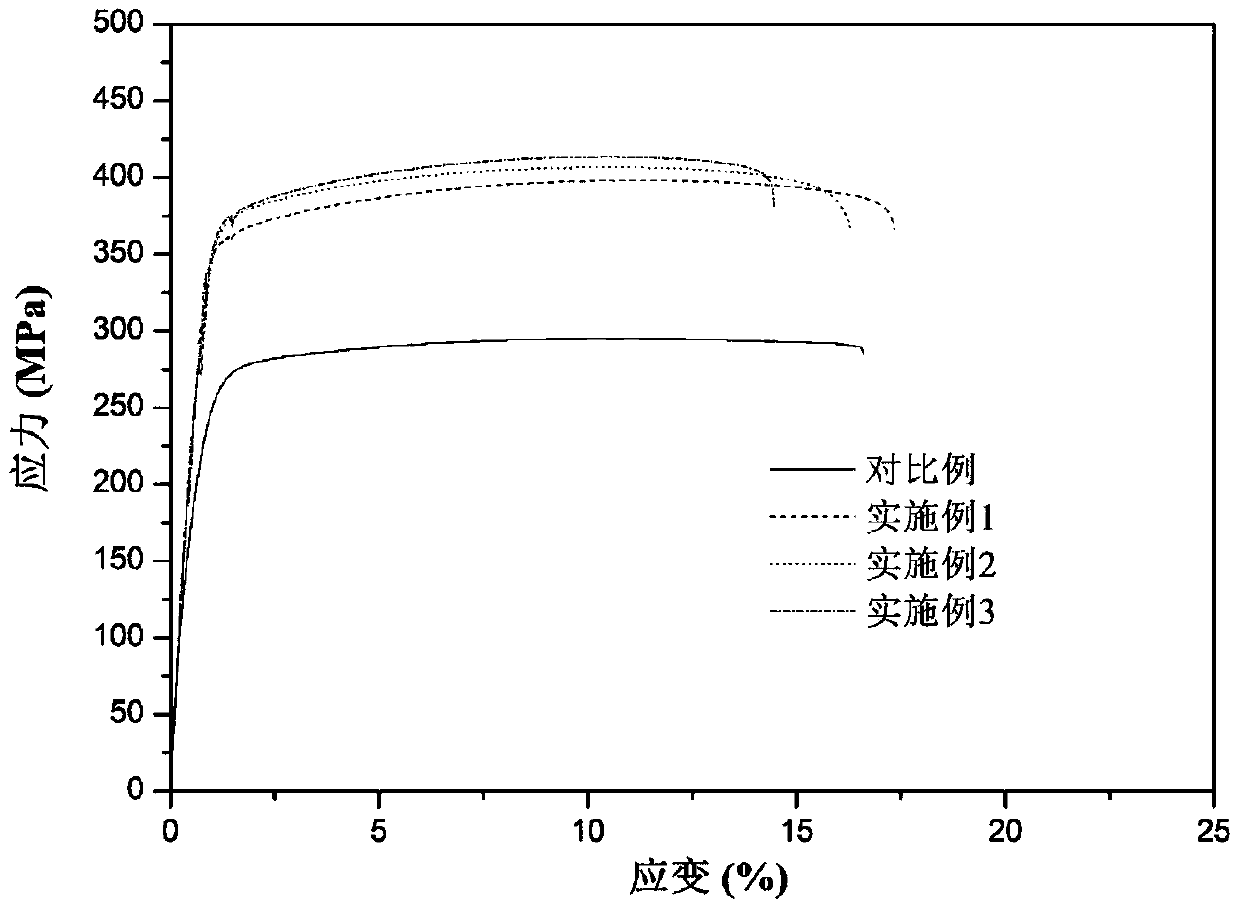

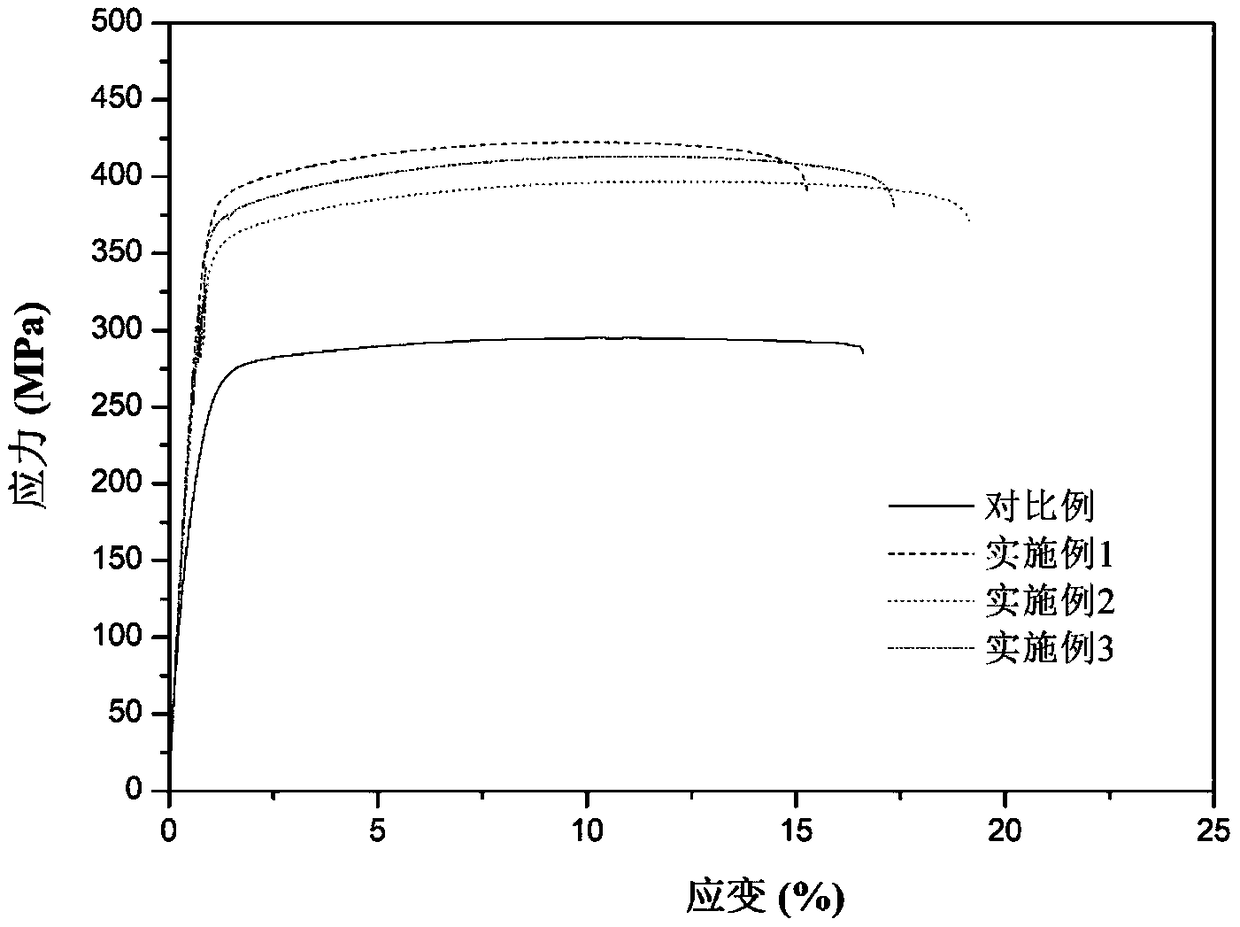

The invention relates to low-cost high-strength magnesium alloy and a preparation method thereof. The alloy is Mg-Bi-Sn-Al-Zn-Ca-Y magnesium alloy, and is prepared from the chemical components in percentage by mass: 2.0-4.5wt% of Bi, 2.0-4.5wt% of Sn, 1.0-3.0wt% of Al, 0.8-1.2wt% of Zn, 0.02-0.1wt% of Ca, 0.02-0.1wt% of Y and the balance magnesium and inevitable impurities; moreover, a mass ratioof the Bi to the Sn is (0.7 to 1.5) to 1. According to an obtained high-strength magnesium alloy material, the yield strength is 350-367 MPa, the tensile strength is 398-413 MPa, the ductility is higher than 14%, and the high-strength magnesium alloy material presents a good inflaming retarding effect, has a high strengthening phase melting point, and has application prospects as a potential heat-resistant magnesium alloy material.

Owner:HEBEI UNIV OF TECH

Low-cost, high-strength and high-toughness wrought magnesium alloy and preparation method thereof

ActiveCN109182809AImprove toughnessImprove flame retardant performanceUltimate tensile strengthMaterials science

The invention discloses a low-cost, high-strength and high-toughness wrought magnesium alloy and a preparation method thereof. The alloy is a Mg-Al-Bi-Ca-Y magnesium alloy and comprises the chemical components of 6.0-8.5 wt% of Al, 1.5-4 wt% Bi, 0.02-0.1 wt% of Ca, 0.02-0.1 wt% of Y, and the balance being magnesium and unavoidable impurities, wherein the sum of the mass of the Al and Bi is less than or equal to 10% of the total mass of the alloy. The alloy has a yield strength of about 360 MPa, a tensile strength of about 410 MPa, and an elongation of 15% or above; and the alloy exhibits a good flame retardant effect.

Owner:HEBEI UNIV OF TECH

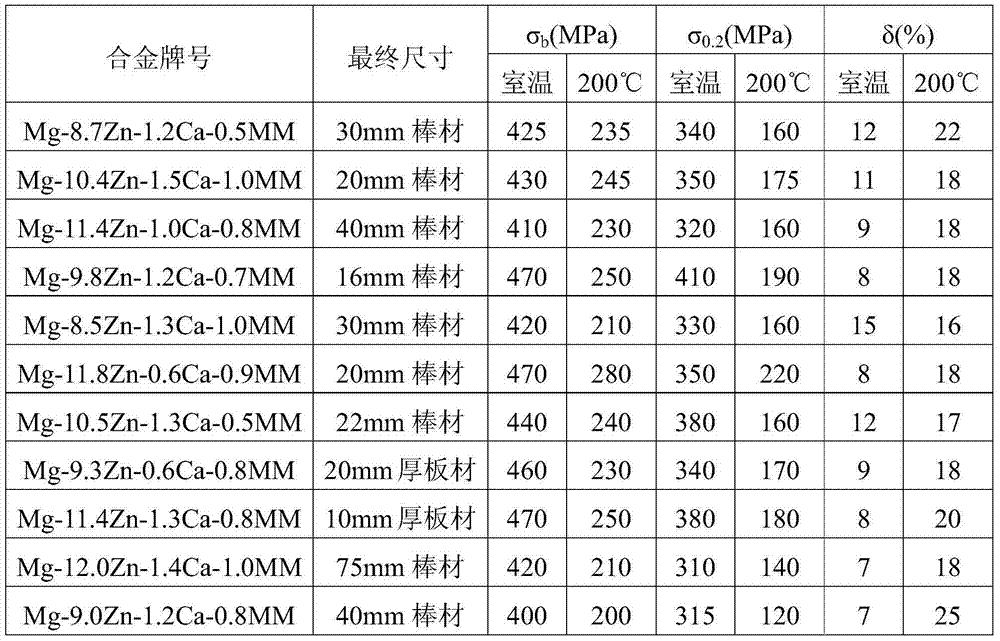

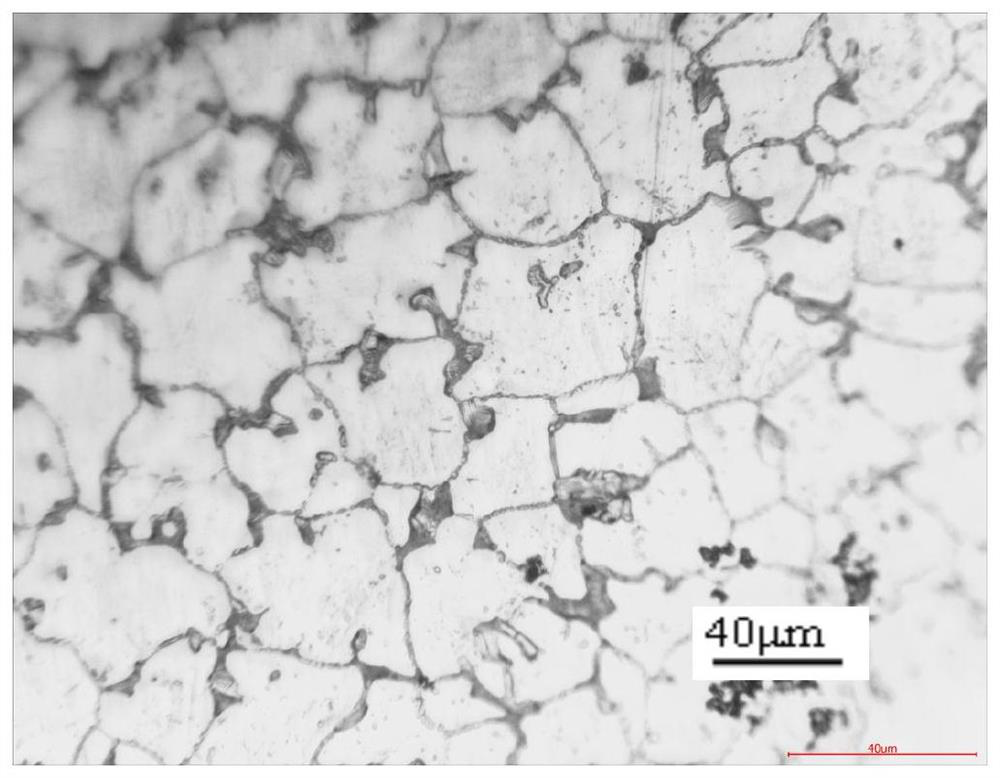

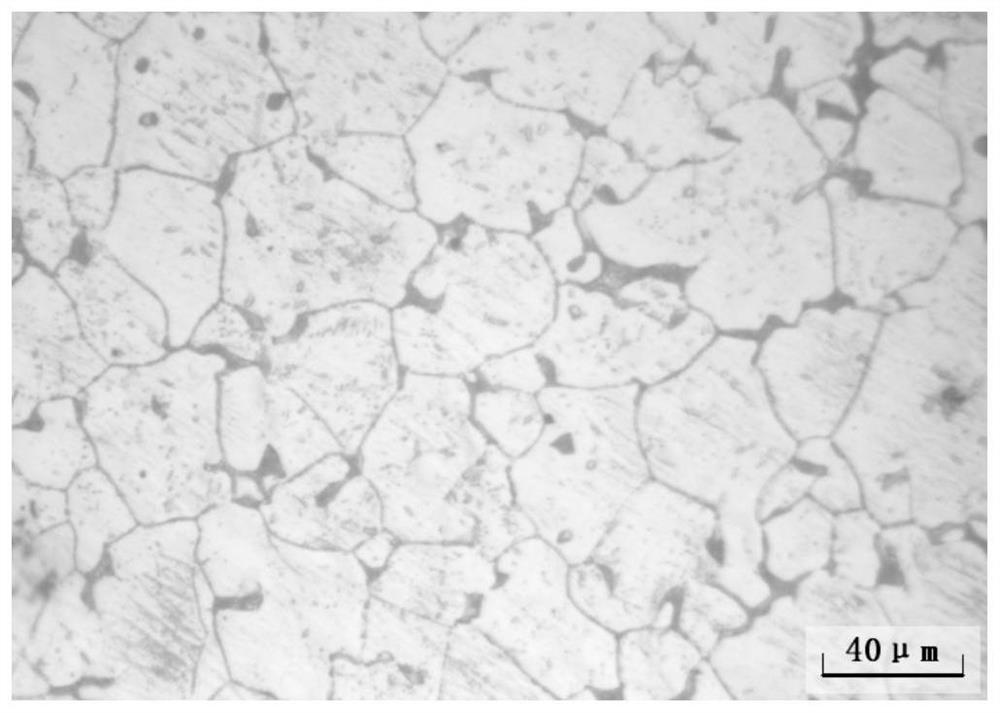

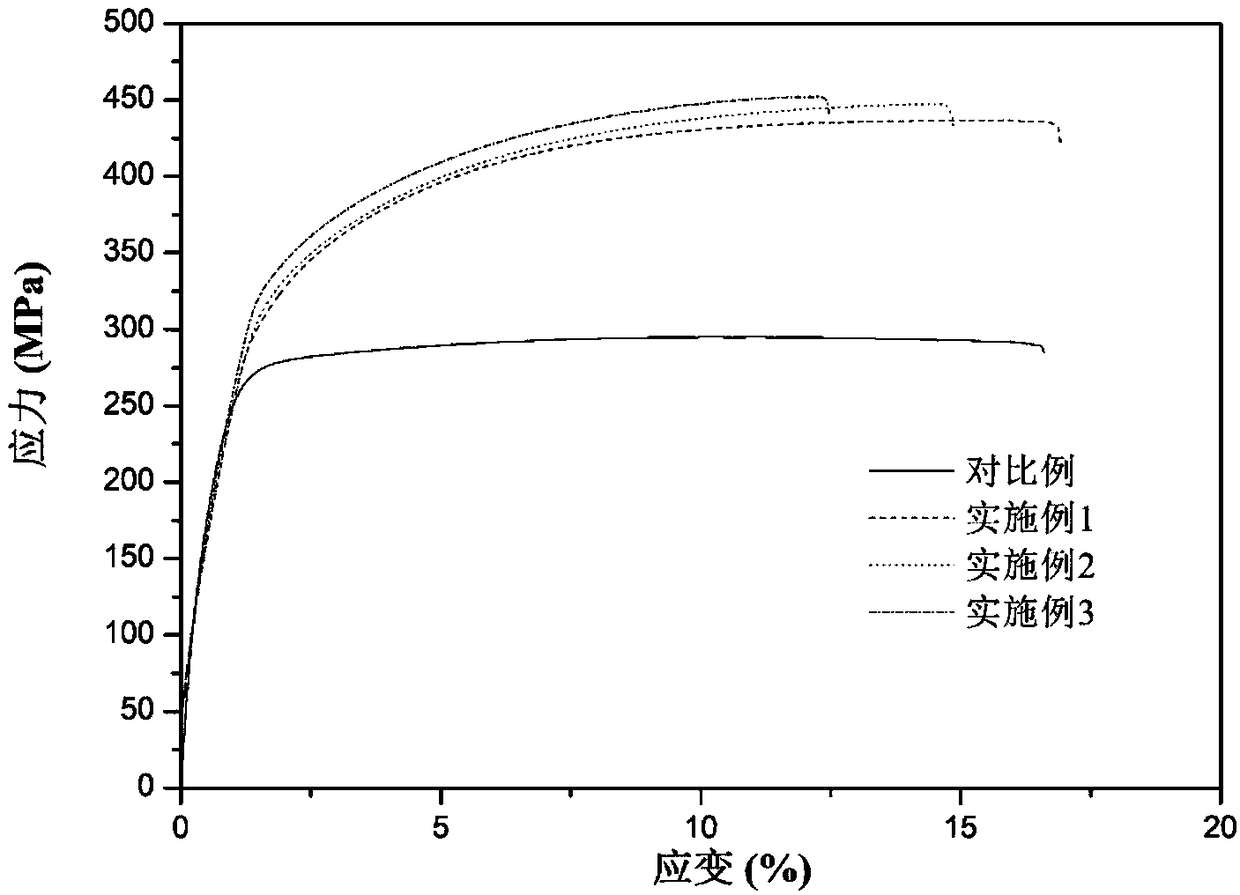

High-zinc deformation magnesium alloy and preparation and processing method thereof

ActiveCN104726755AGood mechanical properties at room temperatureHigh temperature resistanceBreaking strengthRare earth

The invention relates to a high-zinc deformation magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components in percentage by mass: 8-12% of Zn, 0.5-1.5% of Ca, 0.5-1.0% of MM and the balance of Mg, wherein MM represents Ce-rich mixed rare earth and comprises the following components in parts by mass: 48 parts of Ce, 30 parts of La, 18 parts of Nd, 3 parts of Pr and about 1% of impurities which are Fe and Mn mainly. The preparation method of the magnesium alloy comprises the steps of smelting of the alloy, semi-solid extraction, homogenization treatment, re-deformation and aging deformation heat treatment. The Mg-Zn-Ca-MM alloy provided by the invention has better room-temperature mechanical property, and the mechanical property of the alloy after solid solution and aging can achieve 400-460MPa; meanwhile, the elongation rate of the alloy can achieve 7%-10%; and in addition, the alloy has certain high temperature resistance, and the breaking strength can be above 200MPa when breaking at 200 DEG C.

Owner:GRIMAT ENG INST CO LTD

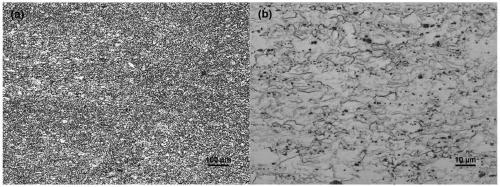

High-strength and heat-resisting rare earth aluminum alloy and preparing method thereof

InactiveCN111763861APoor high temperature performanceGood mechanical properties at room temperatureMaterials sciencePlastic property

The invention relates to a high-strength and heat-resisting rare earth aluminum alloy containing rare earth samarium and a preparing method of the high-strength and heat-resisting rare earth aluminumalloy and belongs to the technical field of alloys. The aluminum alloy comprises the following components including, by mass percent, 5%-6% of Zn, 2%-3% of Mg, 1%-2% of Cu, 0.1%-0.2% of Sm and the balance Al and inevitable impurities. Various second phases, uniform and fine microstructures and weak base plane textures are evenly distributed in the alloy, and therefore the alloy can have high strength and high plasticity. The invention further discloses a preparing method of the high-strength and heat-resisting rare earth aluminum alloy material, nano-order and micron-order second phases and grains with the size being relatively fine are evenly distributed in the tissue of the prepared aluminum alloy, and the mechanical performance of the aluminum alloy is obviously improved.

Owner:YANTAI NANSHAN UNIV

Method for preparing carbon-fiber-toughened alumina ceramic material

The invention belongs to the ceramic material field, and in particular relates to a method for preparing a high strength alumina-based ceramic material. The ceramic material is prepared from alumina and 2.5D woven carbon fiber as raw materials. The method is characterized in that in accordance with the ratio of 85-92% of the alumina and 8-15% by volume of the 2.5D woven carbon fiber, preparing theraw materials; pretreating the surface of the 2.5D woven carbon fiber, filling the 2.5D woven carbon fiber inn a die, and performing hot-pressing sintering in vacuum; wherein the sintering temperature is 1450-1550 DEG C, sintering pressure is 28-35 MPa, and heat preservation time is 30-35 min. The alumina / 2.5 D woven carbon fiber ceramic material prepared by the method has good room temperaturemechanical properties and high densification degree, and the strength and the toughness of the material are increased significantly compared with that of pure alumina prepared by a same process. Theceramic material has a good application prospect in the preparation of ceramic moulds, sand blasting nozzles, tools and other parts with high abrasion resistance requirements.

Owner:LUDONG UNIVERSITY

Low-temperature rolling high-toughness wrought magnesium alloy and preparation method thereof

The invention discloses a low-temperature rolling high-toughness wrought magnesium alloy and a preparation method thereof. The alloy is Mg-Bi-Y-Zn-Mn magnesium alloy which is prepared from the following chemical components in percentage by weight: 3.0-6.0% of Bi, 2.0-3.5% of Y, 0.3-0.5% of Zn, 0.01-0.08% of Mn and the balance of magnesium and unavoidable impurities, wherein the mass ratio of Bi toY is (0.9 to 3) to 1. The high-toughness magnesium alloy material prepared in the invention has the advantages of excellent mechanical properties and relatively good flame-retardant effect.

Owner:北京中安璟润新材料技术有限公司

6000 series aluminum alloy with high long-term thermal stability and preparation method thereof

The invention provides a 6000 series aluminum alloy with high long-term thermal stability. The alloy comprises the following components of, in percentage by mass, 0.5%-0.8% of Si, less than or equal to 0.3% of Fe, less than or equal to 0.3% of Cu, 0.05%-0.3% of Mn, 0.6%-0.9% of Mg, less than or equal to 0.15% of Zr, less than or equal to 0.15% of Ti, less than or equal to 0.05% of a single impurity, less than or equal to 0.15% of impurities in total, and the balance Al, wherein the range of Si / Mg is controlled at 0.7-0.9. The invention also comprises a preparation method of the aluminum alloy.According to the method, through the alloy design, a long-term thermally stable phase can be generated in the 6000 series alloy, the roughening of an Mg<2>Si phase is effectively inhibited, and the reduction in yield strength is no more than 10 MPa when the alloy is subjected to heat preservation at 150 DEG C for 1000 h. The 6000 series aluminum alloy material not only has the very good long-termthermal stability, but also has the good room temperature mechanical performance, good bending forming performance, crushing performance and the like, and thus the industrial batch production of automobile part profiles can be realized.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

Preparation method of Al-Zn-Mg alloy

ActiveCN111455197ASmall mechanical propertiesLow natural aging strengthening abilityUltimate tensile strengthCorrosion resistant

The invention relates to a preparation method of an Al-Zn-Mg alloy. The preparation method of the Al-Zn-Mg alloy comprises the following components of, in percentage by weight, 0.12%-0.18% of Si, 0.12%-0.18% of Fe, 0.15%-0.25% of Cu, 0.03%-0.1% of Mn, 0.7%-1.5% of Mg, 5.5%-6.0% of Zn, 0.15%-0.25% of Zr, 0.08%-0.2% of Ti, and the balance Al and inevitable impurities; and the preparation method comprises the specific preparation steps of smelting, casting, homogenizing annealing, extrusion, cooling, pretreatment and subsequent treatment. The Al-Zn-Mg alloy material prepared through the method has a smaller recrystallization structure, higher strength, better corrosion resistance, better room-temperature mechanical performance, better bending forming performance, better welding performance and the like, and industrial batch production of Al-Zn-Mg alloy bumper profiles can be achieved.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

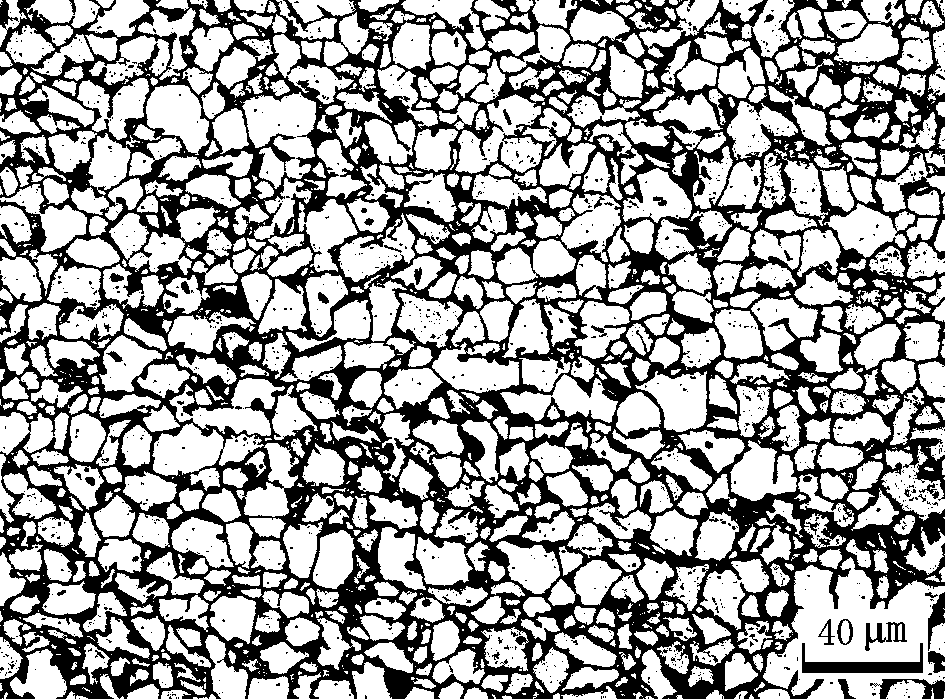

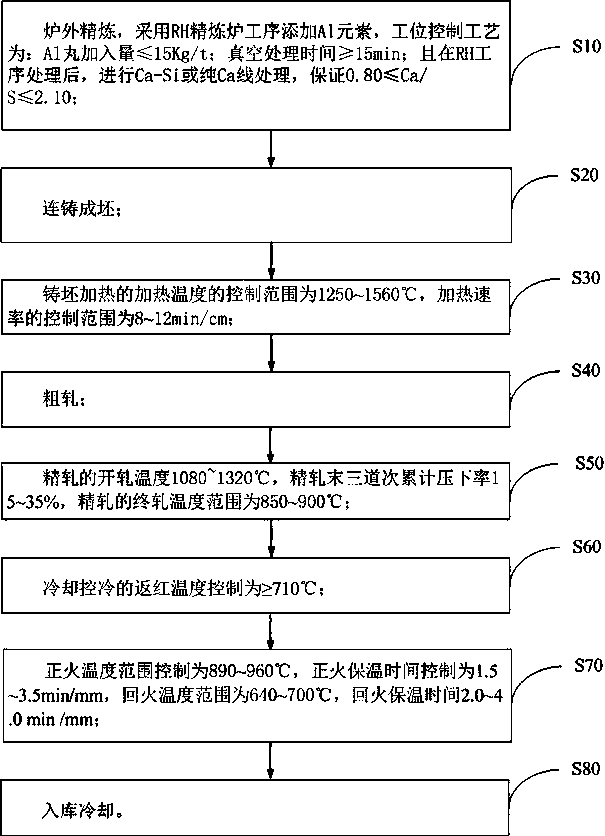

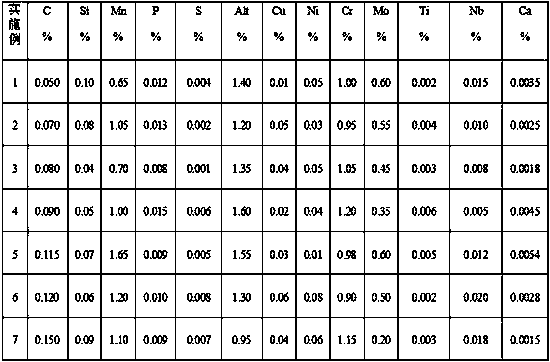

Steel plate for mid-temperature hydrogen-containing pressure container and manufacturing method of steel plate

InactiveCN108914016AImprove mechanical propertiesNo reduction in fracture toughnessSheet steelHydrogen

The invention discloses a steel plate for a mid-temperature hydrogen-containing pressure container and a manufacturing method of the steel plate. The steel plate for the mid-temperature hydrogen-containing pressure container comprises the following components in percentage by weight: 0.050-0.150% of C, no more than 0.10% of Si, 0.60-1.65% of Mn, no more than 0.015% of P, no more than 0.008% of S,0.90-1.60% of Alt, 0.01-0.06% of Cu, 0.01-0.08% of Ni, 0.90-1.20% of Cr, 0.20-0.60 % of Mo, no more than 0.006% of Ti, no more than 0.020% of Nb, no more than 0.0055% of Ca, and the balance Fe and inevitable impurities, wherein the contents the above elements have to meet the following relations: the quotient of the sum of Cr and Mo divided by C is greater than or equal to 8 and less than or equalto 25; and the sum of 54Al, 156 divided by Cr, and 96Mo is greater than or equal to 208 and less than or equal to 331.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

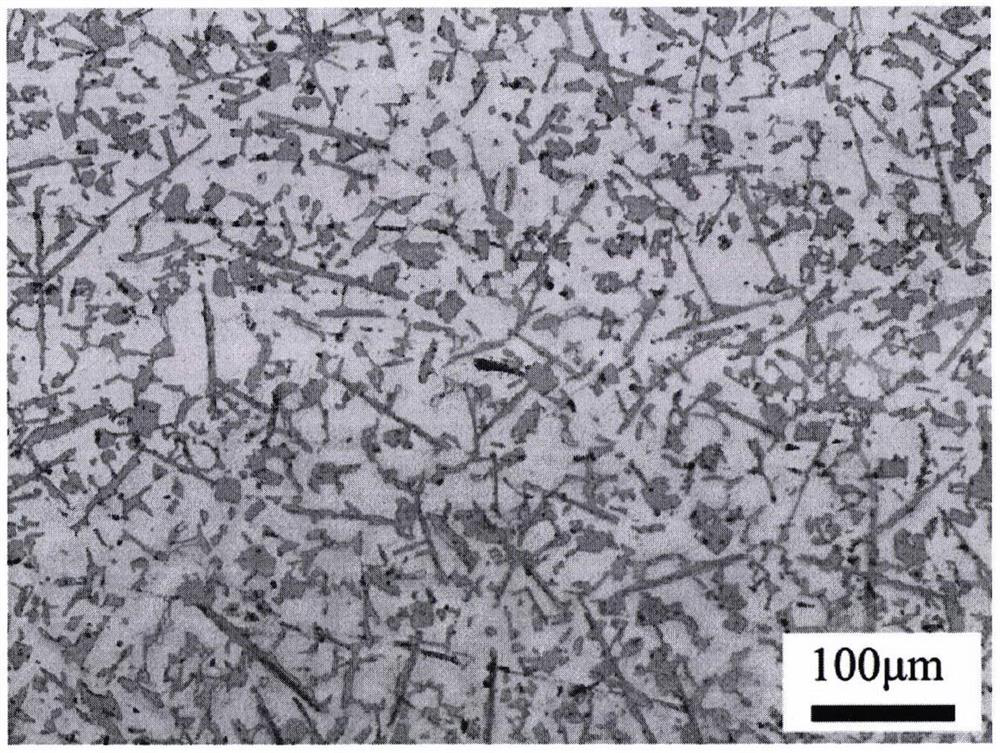

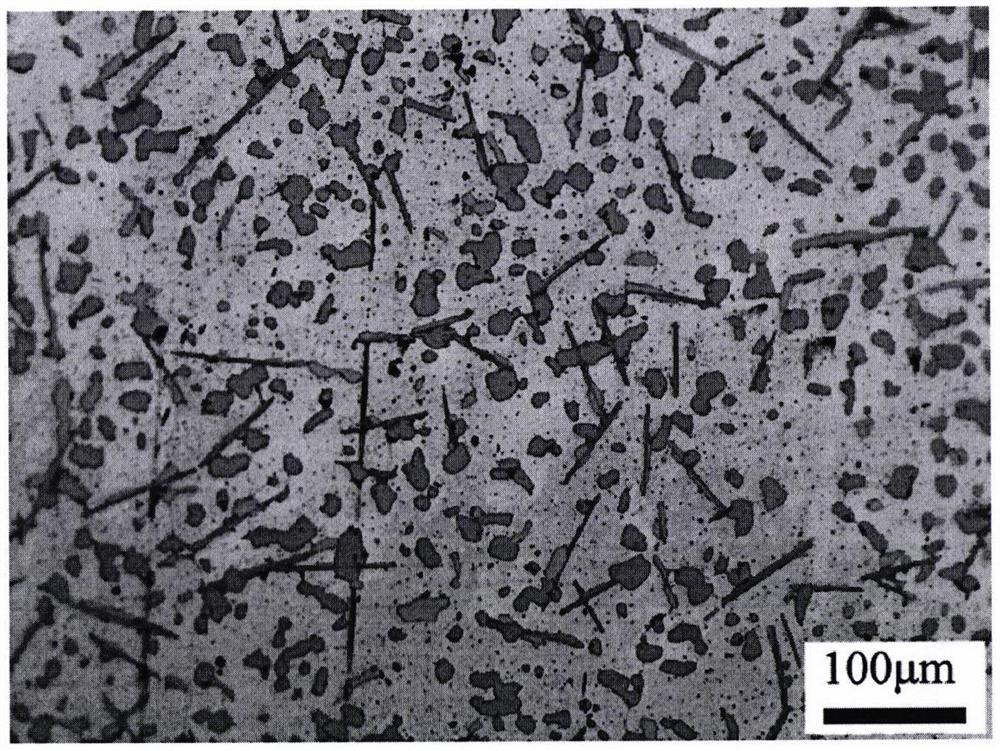

High Nb-TiAl alloy added with nano yttrium oxide and preparation method of high Nb-TiAl alloy

The invention discloses a high Nb-TiAl alloy added with nano yttrium oxide and a preparation method of the high Nb-TiAl alloy, relates to the field of intermetallic compounds and preparation processesthereof, and aims to solve the technical problems of poor high-temperature mechanical property and weak creep resistance of an existing TiAl alloy. The alloy comprises, by mole: Al: 45-48%, Nb: 6-10%, V: 2.5-3.5%, nano yttrium oxide: 0.05-3%, and the balance Ti. The preparation method comprises the steps of briquetting and shaping raw materials; melting alloy block materials, and adding an yttrium oxide prefabricated block for smelting to obtain an alloy ingot; and then carrying out homogenization annealing treatment to finish the preparation. According to the high Nb-TiAl alloy added with the nano yttrium oxide and the preparation method of the high Nb-TiAl alloy, the high-temperature mechanical property and high-temperature creep resistance of the high Nb-TiAl alloy are improved; and the high Nb-TiAl alloy added with the nano yttrium oxide is applied to the field of high-temperature structural materials.

Owner:HARBIN INST OF TECH

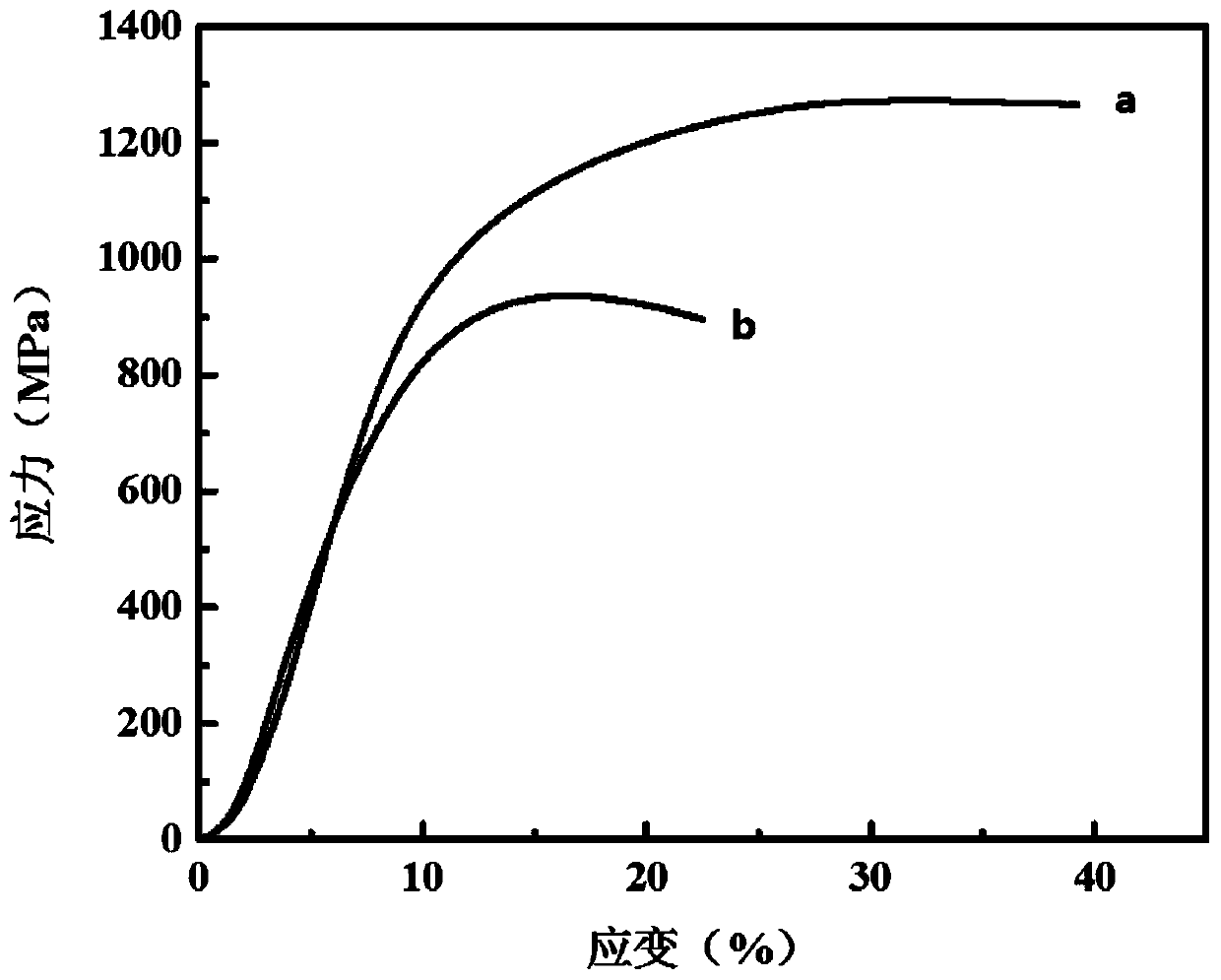

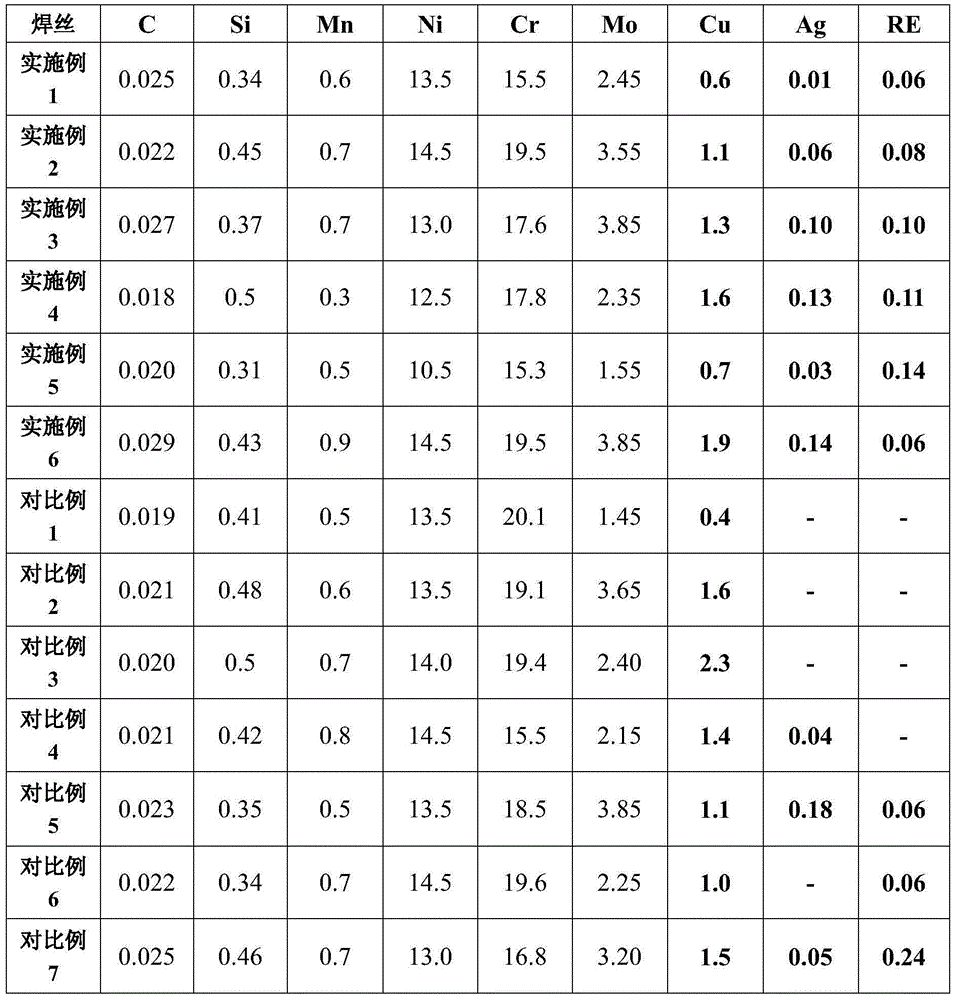

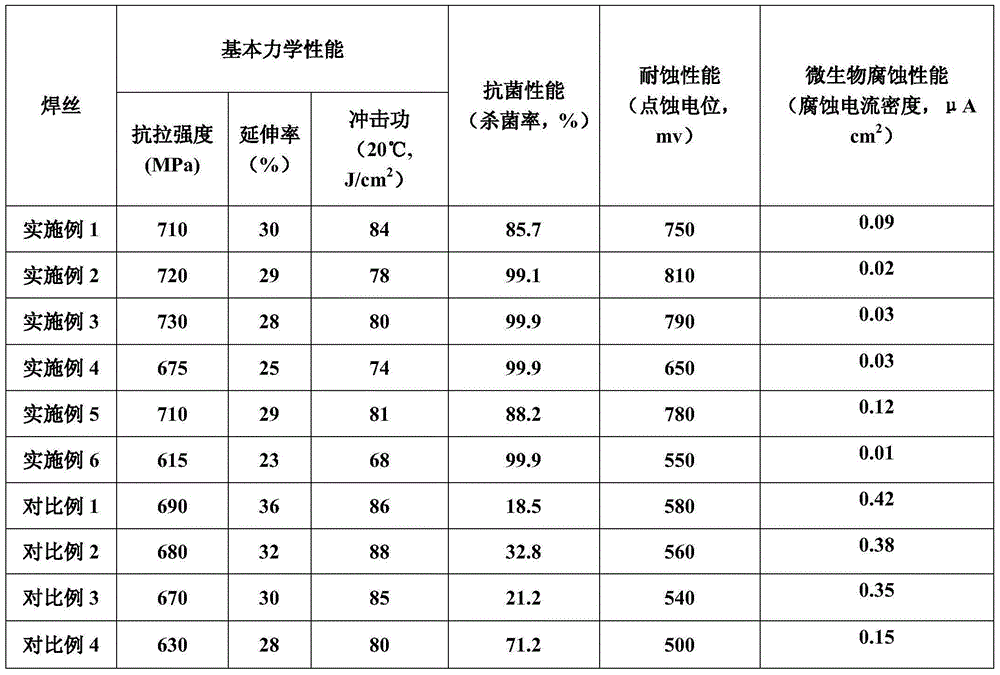

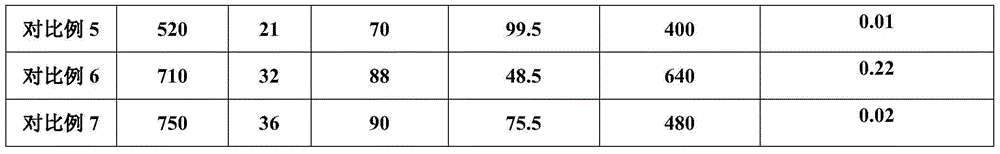

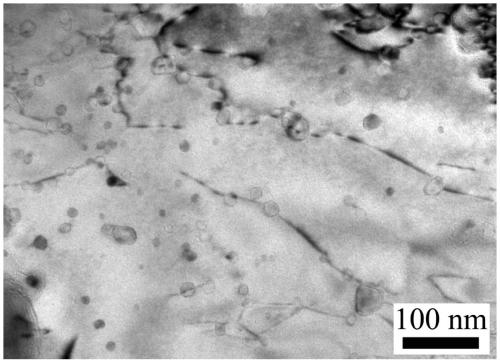

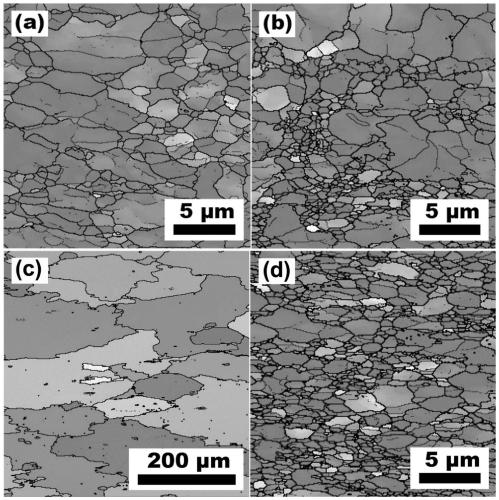

Austenitic stainless steel welding wire having antibacterial function

InactiveCN105057917AGood antibacterial functionGood mechanical properties at room temperatureWelding/cutting media/materialsSoldering mediaChemical compositionMicrobial corrosion

The invention aims to provide an austenitic stainless steel welding wire having an antibacterial function. The welding wire has the following chemical components in percentage by weight: C not more than 0.03, 0.3-0.5 of Si, 0.3-1.0% of Mn, S not more than 0.01, P not more than 0.01, 10.5-15 of Ni, 15-20 of Cr, 0.5-2.0% of Cu, 1.5-4.0 of Mo, 0.01-0.15 of Ag, 0.06-0.15 of RE, and the balance of Fe. On the basis of satisfying the basic requirements of room-temperature mechanical performance and corrosion resistance, the welding wire can enable a welding line connecting place to have excellent antibacterial performance without needing the after-welding heat treatment, and can prominently reduce the microbiological corrosion in the welding line place.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of nano ZrC reinforced FeCrAl alloy

PendingCN109794613AImproved neutron economyImprove radiation resistanceFuel elementsNuclear energy generationAlloyMaterials science

The invention discloses a preparation method of nano ZrC reinforced FeCrAl alloy. The preparation method of the nano ZrC reinforced FeCrAl alloy comprises a window frame and a window sash, wherein thewindow sash comprises a first window sash body and a second window sash body; the first window sash body is fixed to the window frame; a hollow area of the window frame is covered with the first window sash body; the second window sash body is rotatably connected to the window frame or a wall used for installing a squint window through a hinge piece; and the second window sash body can rotate around the hinge piece to overlap with the first window sash body. The squint window is convenient to install and maintain and has high safety in the maintenance process.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

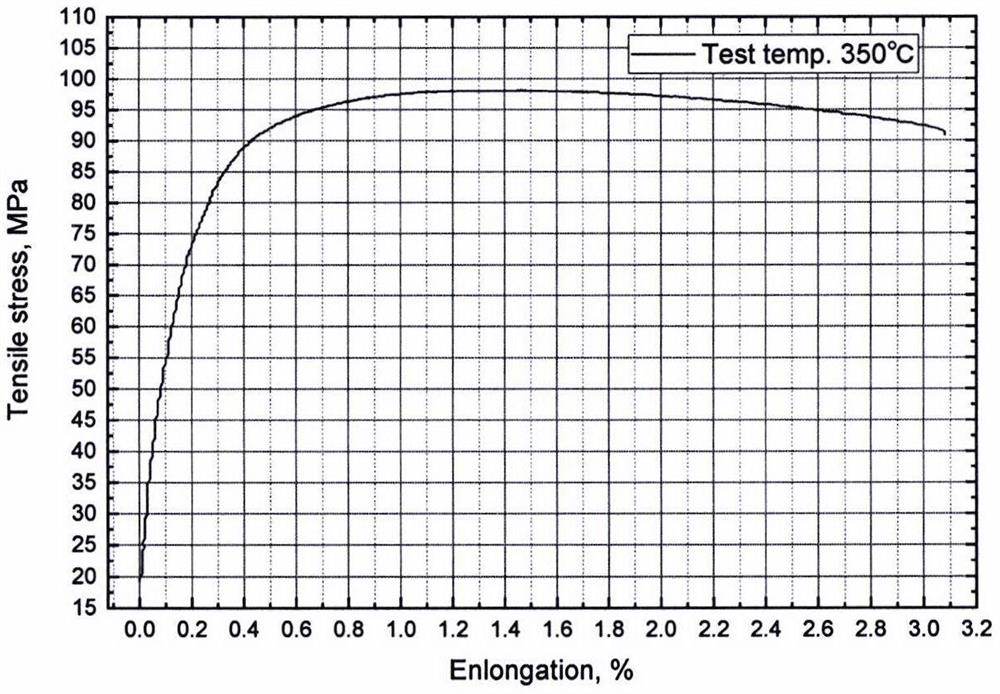

High-strength heat-resistant casting aluminum-silicon alloy for engine piston

InactiveCN113897520AHigh temperature strengthImprove organizational stabilityMachines/enginesPistonsSilicon alloyUltimate tensile strength

The invention discloses an aluminum-silicon alloy material for an engine piston. The aluminum-silicon alloy material comprises the following elements in percentage by mass, 12.0%-15.0% of Si, 2.0%-4.5% of Cu, 0.5%-1.5% of Mg, 0.2%-0.5% of Mn, 2.2%-4.5% of Ni, 0.1%-0.6% of Zr, Al, incidental elements and impurities. The microalloying incidental elements are one or more of Er, Hf, Nb, Nd, Sc and Ti, and the total adding amount of the microalloying incidental elements meets the condition that (Er + Hf + Nb + Nd + Sc + Ti) wt% is larger than or equal to 0.1% and smaller than or equal to 0.9%. The content of each inevitable impurity element in the aluminum-silicon alloy is less than or equal to 0.05 wt%, and the total content is less than or equal to 0.15 wt%; and the high-temperature performance of the alloy exceeds that of the existing ZL109 alloy, and particularly, the high-temperature strength at 350 DEG C reaches up to 98 MPa.

Owner:济南科为达新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com