Low cost beta titanium alloy and its preparing method

A titanium alloy and alloy technology, applied in the field of β-type titanium alloy and its preparation, can solve the problems of hindering sintering densification, high cost, low production efficiency, etc., and achieve the effect of promoting the densification process and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

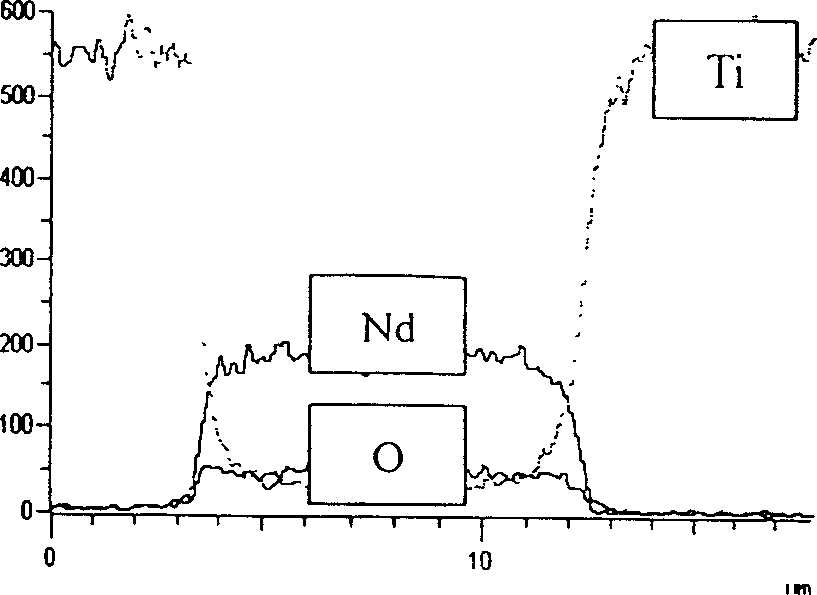

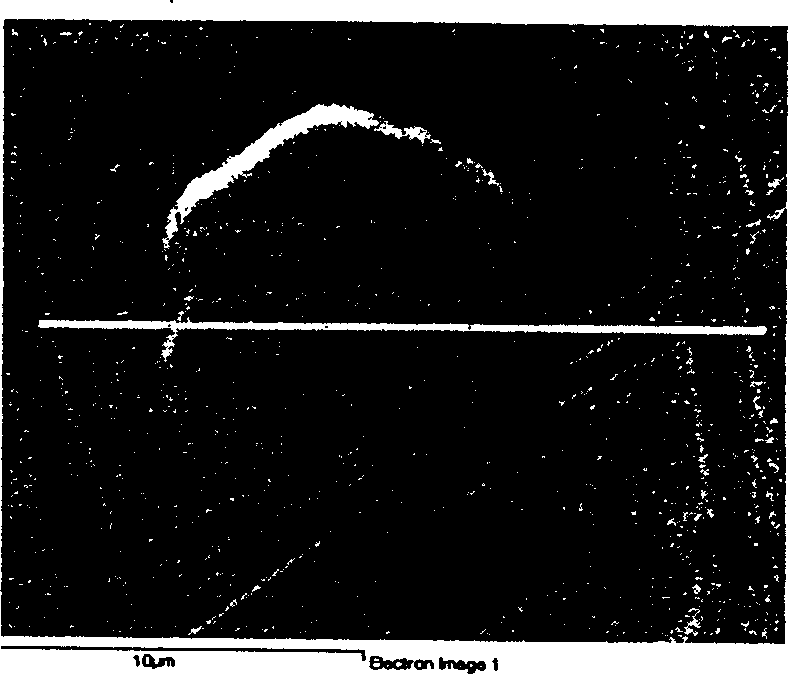

[0015] Use hydrogenated dehydrogenation titanium powder with an oxygen content of 0.3wt%, Fe-Mo alloy powder with an oxygen content of 0.68% and Nd-containing master alloy powder with an oxygen content of 0.51wt%, and mix them uniformly according to the nominal alloy ratio. After 200MPa The pressure isostatic pressing into a powder metallurgy cylindrical standard tensile specimen (GB / T7963-1987), in a vacuum of 1 × 10 -3 Pa, sintered at 1250°C to get 1 # Sample, the test results are shown in Table 1 # sample data.

Embodiment 2

[0017] Use hydrogenated dehydrogenation titanium powder with an oxygen content of 0.3wt%, FeMo alloy powder with an oxygen content of 0.68%, and Nd-containing master alloy powder with an oxygen content of 0.51wt%, and mix them evenly according to the nominal alloy ratio. Isostatic pressing into powder metallurgy cylindrical standard tensile specimen (GB / T7963-1987), in a vacuum of 1 × 10 -3 Pa, sintered at 1200℃ to get 2 # Sample, the test results are shown in Table 2 # sample data.

Embodiment 3

[0019] Use hydrogenated dehydrogenation titanium powder with an oxygen content of 0.3wt%, FeMo alloy powder with an oxygen content of 0.68%, and Nd-containing master alloy powder with an oxygen content of 0.51wt%, and mix them evenly according to the nominal alloy ratio. Isostatic pressing into powder metallurgy cylindrical standard tensile specimen (GB / T7963-1987), in a vacuum of 1 × 10 -3 Pa, sintered at 1350°C to get 3 # Sample, the test results are shown in Table 3 # sample data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com