Austenitic stainless steel welding wire having antibacterial function

A technology of austenitic stainless steel and stainless steel, applied in welding medium, manufacturing tools, welding equipment, etc., can solve the problems of antibacterial properties of lost material weld joints, reduced practical value, etc., and achieve good room temperature mechanical properties and good welding quality , the effect of inhibiting microbial corrosion of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

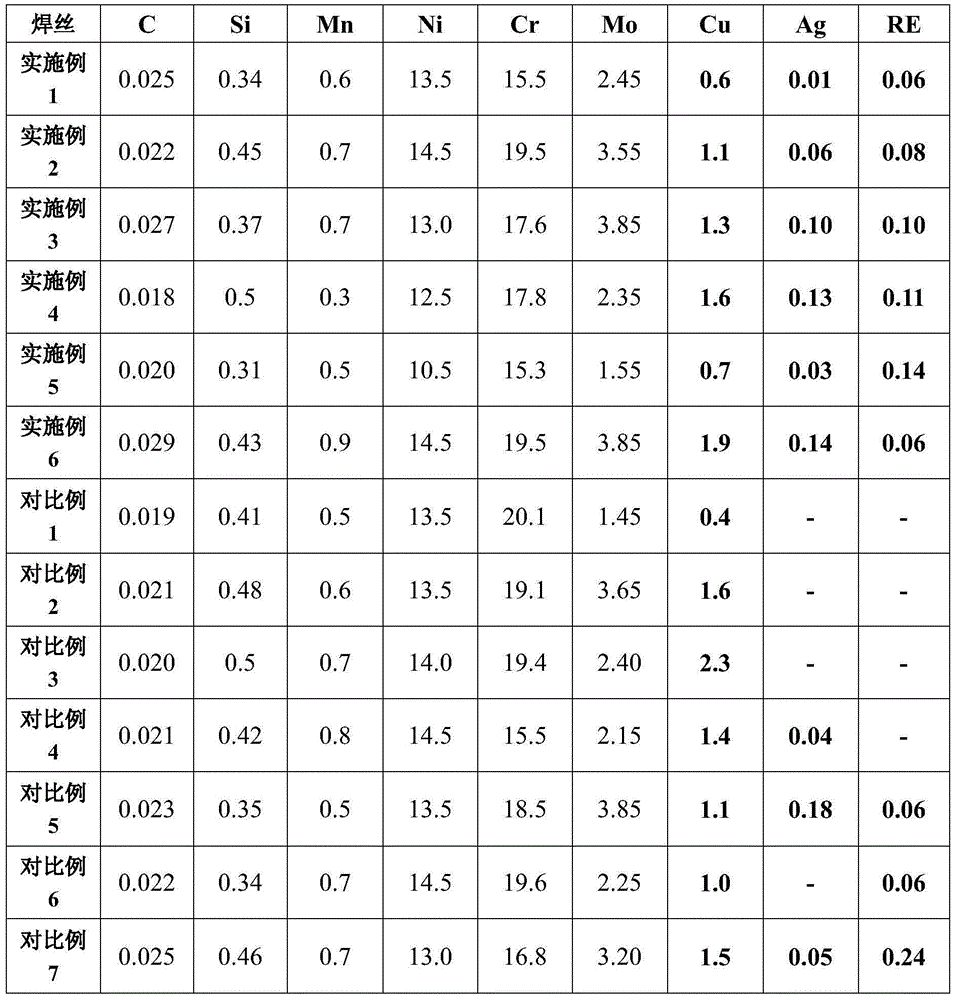

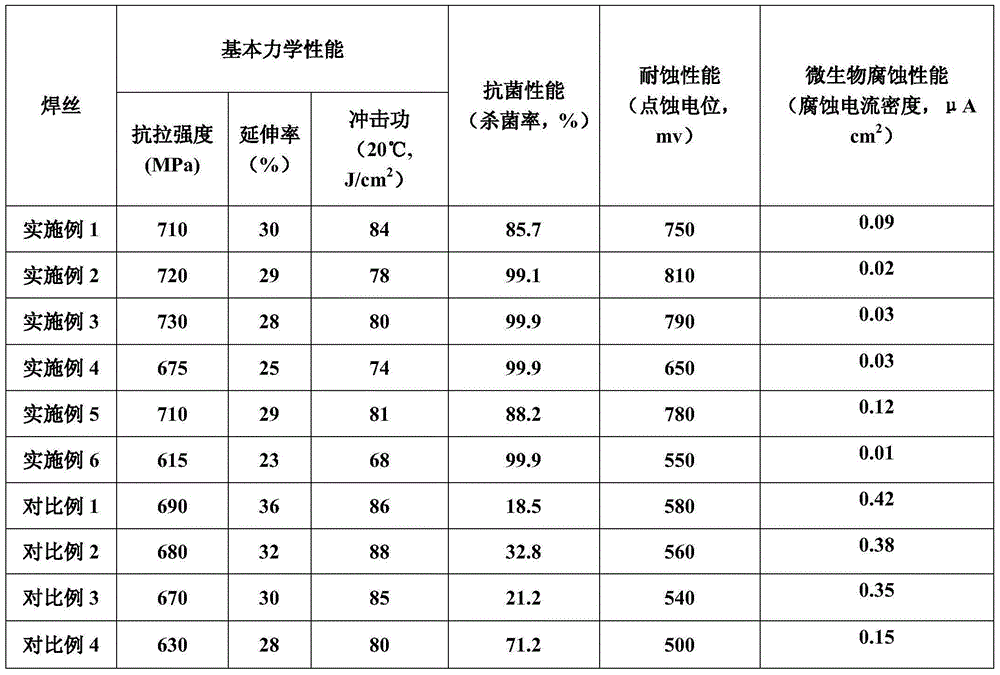

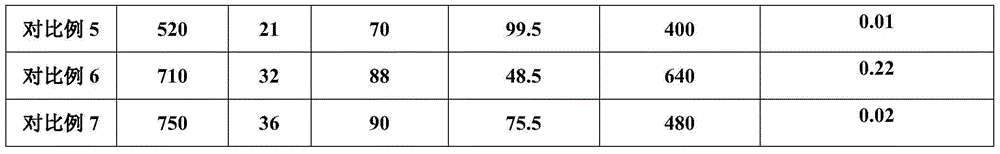

[0020] The chemical compositions of the austenitic stainless steel welding wires with antibacterial properties of Examples 1-6 are shown in Table 1. Controlled smelting is carried out according to the chemical composition range of the welding wire of the present invention. The smelted steel ingots are rolled into wire rods, and then heat treated, drawn, and finally obtained. diameter of the wire. Manual arc welding was carried out on the test plate with welding wires of three components. The test plate was a 20mm thick 316L stainless steel plate, the welding voltage was 13V, the welding current was 180A, the welding speed was 100mm / min, the shielding gas was high-purity argon, and the interlayer temperature was less than 100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com