Patents

Literature

241results about How to "With flame retardant function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramicized silicon rubber, preparation method and application

ActiveCN102964836AEasy to processReduce manufacturing costRubber insulatorsPlastic/resin/waxes insulatorsCouplingOrganic group

The invention relates to a ceramicized silicon rubber, which comprises 1)60-100 parts of silicon rubber, wherein a general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 2)20-100 parts of silicon dioxide; 3)1-20 parts of silicone oil, wherein the general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 4)0.1-10 parts of coupling agent and 5)20-120 parts of ceramicized powder. The above raw materials are mixed in a kneader and then vacuumized, the ceramicized powder and the coupling agent are added in the kneader and then uniformly mixed to form the bulk ceramicized rubber, and the ceramicized rubber is performed roll mixing and filtered to obtain the ceramicized silicon rubber. The ceramicized silicon rubber has the advantages that the processing is easy, the production cost is low, the ceramicized silicon rubber can be performed ablation to a ceramic shell, and can protect the burned objects from damaging.

Owner:常州市沃科科技有限公司

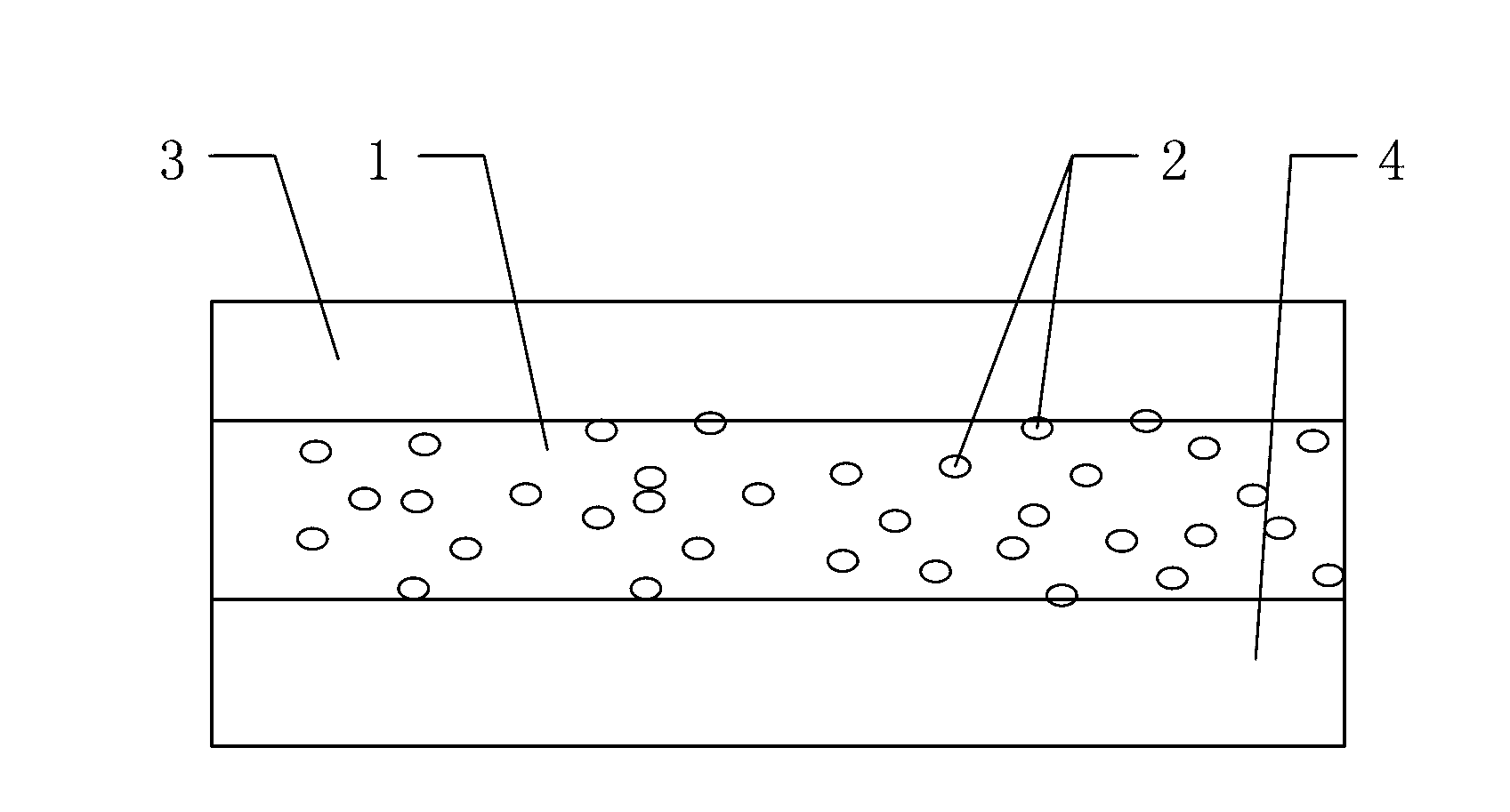

Flame-retardant ceramic composite material and preparation method thereof

ActiveCN103601954AEasy to processReduce manufacturing costRubber insulatorsInsulated cablesCeramic compositePolyolefin

The invention discloses a flame-retardant ceramic composite material which comprises the following components in parts by weight: 100 parts of polyolefin, 0-100 parts of silicone rubber, 1-100 parts of silica, 0-30 parts of silicone oil, 0.00001-10 parts of platinum complex or platinum compound calculated based on platinum, 0-10 parts of coupling agent, 0-100 parts of flame retardant, 1-250 parts of porcelain powder, 0-10 parts of antioxidant, and 0.01-10 parts of vulcanizing agent. The materials are mixed in a kneading machine, the materials are added into the kneading machine through vacuumizing and then uniformly mixed so as to obtain bulk ceramic rubber, and after being cooled, the cooled rubber is subjected to open milling by adding the vulcanizing agent so as to obtain the flame-retardant ceramic composite material. The flame-retardant ceramic composite material disclosed by the invention is easy to process and low in production cost, and can be ablated into a ceramic shell so as to protect a burnt object from being damaged. Because a platinum complex or a platinum compound is added in the flame-retardant ceramic composite material disclosed by the invention, the sintering temperature of the flame-retardant ceramic composite material can be reduced, the reaction speed of preparation can be increased, the production efficiency is improved, and the production cost is lowered.

Owner:SHANGHAI KETER POLYMER MATERIAL

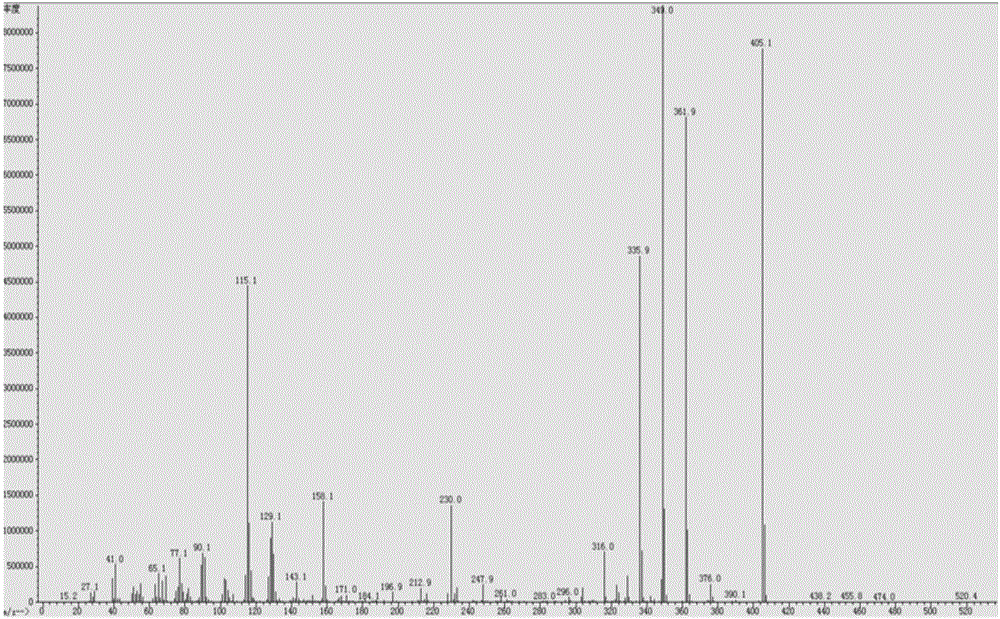

Lithium ion secondary battery and electrolyte thereof

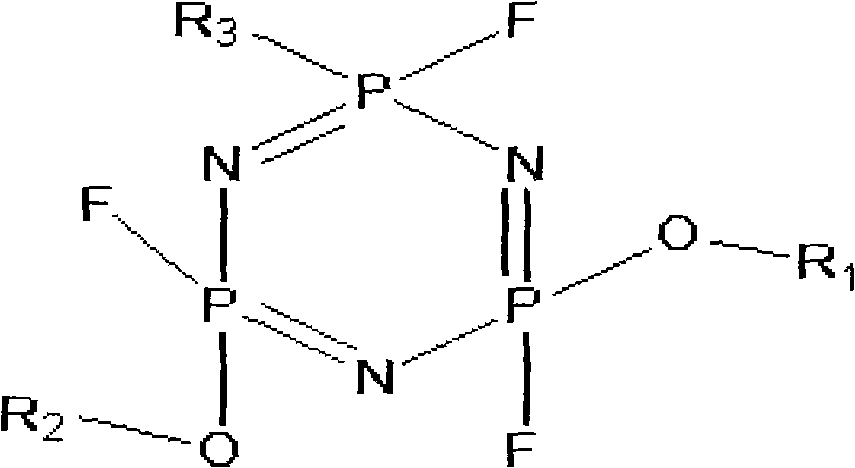

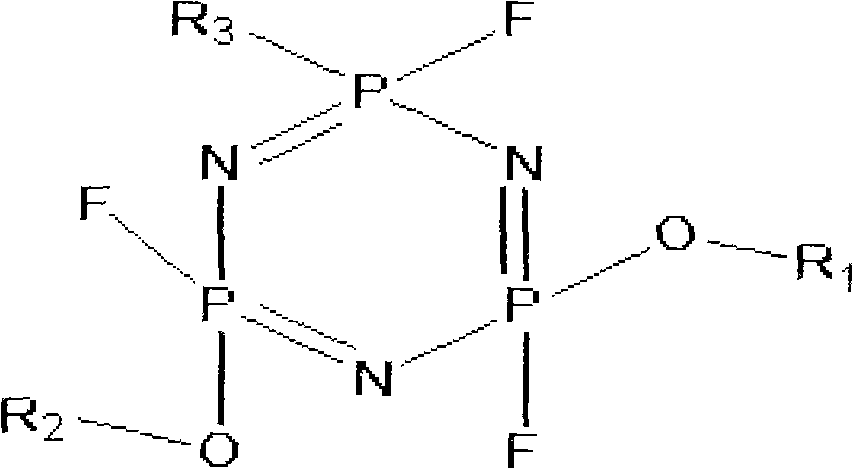

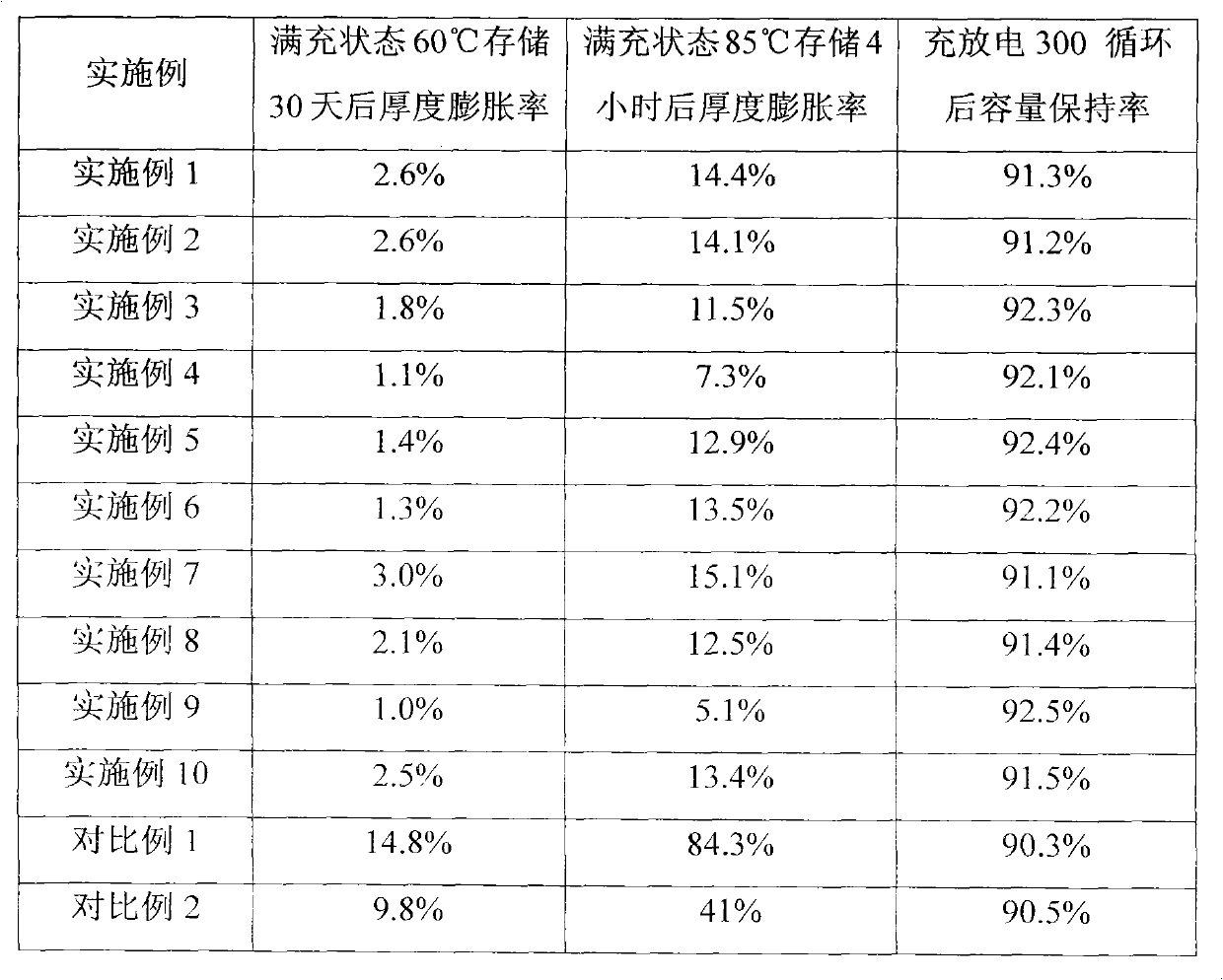

The invention, belonging to the technical field of lithium ion secondary battery, particularly relates to an electrolyte for a lithium ion secondary battery, comprising a non-aqueous solvent, lithium salts and additives, wherein the additives comprise a fluorinated cyclotriphosphazene derivative of formula (I), R1 represents aromatic group or aromatic group containing halogen substituent group, R2 represents alkyl, alkylene or halogen substituted alkyl, alkylene, R3 represents hydrogen, halogen, alkyl or alkyloxy, halogenated alkyl groups or halogenated alkyloxy, and the fluorinated cyclotriphosphazene derivative accounts for 0.1-20 wt% of the total weight of the electrolyte. Compared with the prior art, by using the fire resistance function of fluorinated cyclotriphosphazene derivative, the decomposition of the electrolyte on the anode surface can be effectively prevented, the decomposition and gas generation of the electrolyte are reduced, and the high temperature storage thickness expansion ratio of the battery is greatly reduced. In addition, the invention further discloses a lithium ion secondary battery containing the electrolyte.

Owner:DONGGUAN AMPEREX TECH

Flame-retardant synthetic paper

Owner:CHANGZHOU JINKA CARD BASE SHEET

Manufacture method of conductive fire-retardant acrylic fiber

InactiveCN104805684AMake up for the shortcomings of flammabilityPrevent static electricityFibre typesPolymer scienceFire retardant

The invention discloses a manufacture method of conductive fire-retardant acrylic fiber. The manufacture method comprises the following steps: (1) preparing a spinning solution; (2) performing spinning formation; (3) performing copper salt treatment; (4) adding acrylic fiber containing copper ions obtained in the step (3) into a mixed aqueous solution, and reacting in an airtight high-temperature reaction kettle at 120-140 DEG C for 4-5 hours to prepare the fire-retardant acrylic fiber; (5) taking out and cleaning the acrylic fiber obtained in the step (4), and putting the acrylic fiber at 70-90 DEG C for 2-3 hours in a constant-temperature manner. Through the manner and with the adoption of the manufacture method of conductive fire-retardant acrylic fiber, the acrylic fiber subjected to the antistatic treatment can prevent static electricity during application, ensures normal application of a user, has a fire-retardant function, and overcomes the flammable defect of cloth.

Owner:CHANGSHU XIANGYING SPECIAL FIBER

Method for producing damping porous denoise tunnel asphalt covering material

ActiveCN101173104AExcellent structural performanceImprove skid resistanceBuilding insulationsFiberSurface layer

The invention relates to a preparation method of a tunnel asphalt surface layer material. A preparation method for damping porous noise-reducing tunnel asphalt pavement material is characterized in that it comprises the following steps: 1) preparation of high-viscosity and high-elasticity modified asphalt: base asphalt according to the mass ratio of each component: modifier SBS : Activated rubber powder: Viscosifying compatibilizer: Antioxidant: Stabilizer=100: 6.0~18.3: 20.2~45.7: 1.2~3.7: 0.2~1.4: 0.4~1.9, select; obtain high viscosity and high elasticity modification Asphalt; 2) Add flame retardant to high-viscosity and high-elasticity modified asphalt, heat and melt high-viscosity and high-elasticity modified asphalt to add flame retardant, stir for 3-9 minutes, and stand at 150-170°C for 15-30 minutes to obtain Flame-retardant high-viscosity high-elasticity modified asphalt; 3) according to the mass ratio, mineral material: flame-retardant high-viscosity high-elasticity modified asphalt: fiber stabilizer = 100: 3.6~5.2: 0.1~0.4, choose; noise tunnel asphalt surface material. The invention has the functions of noise reduction, flame retardancy and anti-skid.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Preparation method of coated halogen-free flame-retardant foamable polystyrene

InactiveCN102977402AAvoid fireWith flame retardant functionNon-macromolecular adhesive additivesMacromolecular adhesive additivesBenzoyl peroxideThermal insulation

The invention belongs to the field of expandable polystyrene heat insulating materials, and particularly relates to a preparation method of coated halogen-free flame-retardant foamable polystyrene. The method comprises the following steps: adding polyvinyl alcohol and tricalcium phosphate into deionized water, and evenly mixing to obtain a mixed solution A; adding ammonium polyphosphate, melamine polyphosphate or PNP intumescent flame retardant into styrene, and adding benzoyl peroxide to obtain a mixed solution B; adding the mixed solution B into the mixed solution A to react, and adding a foaming agent to react to obtain halogen-free flame-retardant foamable polystyrene granules; and adding the prepared granules into a phenol formaldehyde resin or melamine resin binding agent containing small amounts of alkali silicate water solution and smoke inhibitor to carry out coating, thereby finally obtaining the coated halogen-free flame-retardant foamable polystyrene granules. The coated halogen-free flame-retardant foamable polystyrene has the advantages of excellent thermal insulation and heat shielding properties, and outstanding flame retardancy and smoke inhibition property, and can be used a flame-retardant architectural thermal insulation material.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for preparing carved wood grain-simulated PVC decorative film

ActiveCN101531081AWith flame retardant functionSolve the disadvantage of being easy to burnFlexible coversWrappersColor printingSlurry

The invention relates to a method for preparing a carved wood grain-simulated PVC decorative film. The method comprises the following technological steps: preparing a PVC face film; preparing a PVC substrate; carrying out two to six sets of color printing on the surface of the PVC face film according to the pattern demands; adopting each set of color slurry, and entering the next set of color printing after printing each set of colors and drying the PVC face film at a temperature of 140 to 160 DEG C; preparing the colorful PVC face film; coiling the printed colorful PVC face film into a large coil; heating, pressing and jointing the printed colorful PVC face film and the PVC substrate on a dual-roller jointing embossing machine, making pressing rollers used for pressing the colorful PVC face film surface be wood thorn embossing rubber rollers, and adjusting the temperature of both rollers to between 100 and 200 DEG C; directly loading the jointed and embossed PVC decorative film into a drying box to carry out secondary heating to 200 to 220 DEG C, and foaming the PVC face film; and cooling the PVC face film. The carved wood grain-simulated PVC decorative film prepared by the method has the advantages of flame retardant function, lifelike sculpture, hollow three-dimensional view and flash discoloration functions.

Owner:ECONESS ENERGY

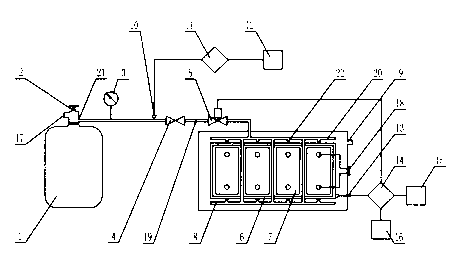

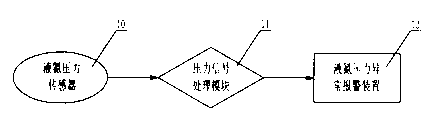

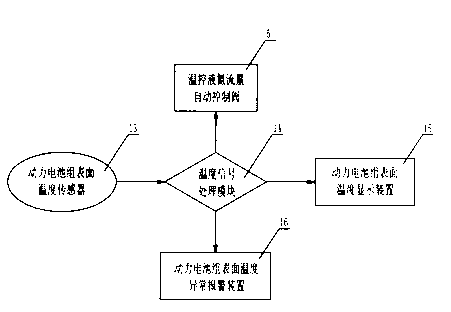

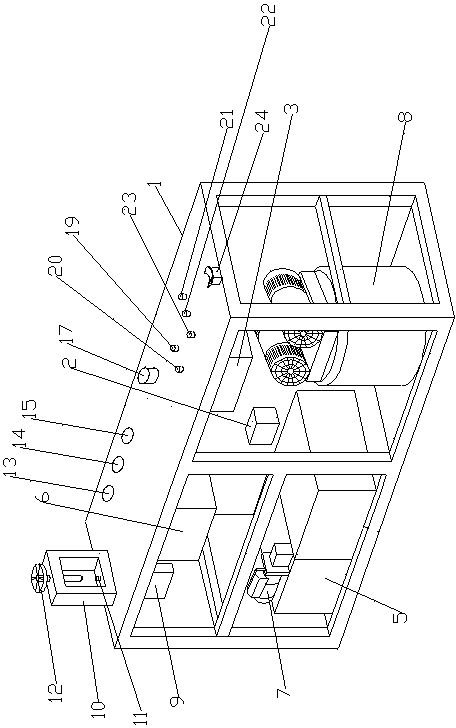

Liquid-nitrogen cooling method and device for automotive power battery pack

ActiveCN102760920AImprove performanceGuaranteed powerSecondary cellsPropulsion coolingPower batteryLiquid nitrogen cooling

The invention relates to a battery cooling method and a battery cooling device, in particular to liquid-nitrogen cooling method and device for an automotive power battery pack. The liquid-nitrogen cooling method for the automotive power battery pack includes directly releasing liquid nitrogen to the surface of the power battery pack and a casing of each battery cell to convert the liquid nitrogen into gas nitrogen, and cooling the surface of the power battery pack and the casing of each battery cell by absorbing a substantial amount of heat in process of converting the liquid nitrogen from liquid into gas. The liquid-nitrogen cooling device for the automotive power battery pack comprises a liquid nitrogen tank (1), a cooling container (8), a connecting pipeline (19), a cooling passage (20), a nitrogen exhaust port (9) and the like. The liquid nitrogen tank (1) is communicated with the cooling passage (20) arranged in the cooling container (8) through the connecting pipeline (19). The liquid-nitrogen cooling method and device for the automotive power battery pack are good in cooling effect, free of consumption of electric energy of the power battery pack, environment-friendly and energy-saving. The cooling method is simple and easy to implement. The cooling device is small in size, the structure is simple and stable, noise and vibration can be avoided, cooling stability is good, and safety is high.

Owner:上海奇可网络科技有限公司

Flame-retardant shrinkable anticorrosive packaging film and manufacturing method thereof

InactiveCN102029755ARealize batchImprove packaging efficiencyFlexible coversWrappersBlow moldingEngineering

The invention provides a flame-retardant shrinkable anticorrosive packaging film which is composed of a two-layer or three-layer structure, wherein, the inner layer contains an anti-rusting agent with an anticorrosive protection function on metal; the middle layer and the outer layer contain flame retardants with a flame retardance function; and the layers contain plastic particles with heating contractibility. The packaging film is formed by mixing raw materials according to a certain type and proportion, heating and then performing coextrusion blow molding on double-layer or three-layer coextrusion film blowing equipment according to a certain temperature condition and at thickness ratio, and the obtained packaging film is a novel multifunctional metal anticorrosive protective packaging material. The flame-retardant shrinkable anticorrosive packaging film has the characteristics of heating contractibility, excellent anti-rust property, skin packaging, good tightness, good fastness, flame retardance, being convenient in automated operation, and being economical and practical; and the packaging film can be widely applied to anticorrosive protective package of products such as auto parts, mechanical equipment, hardware tools, metallurgic products, aerospace products, electronic equipment, weapon equipment and the like during the storage and transportation period, thus being a novel material applicable to the current metal protective packaging field.

Owner:沈阳防锈包装材料有限责任公司

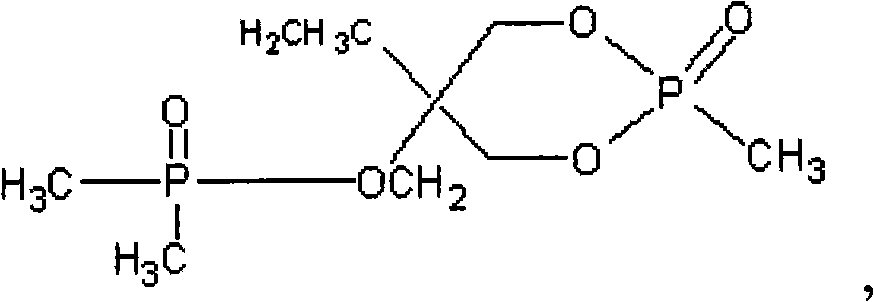

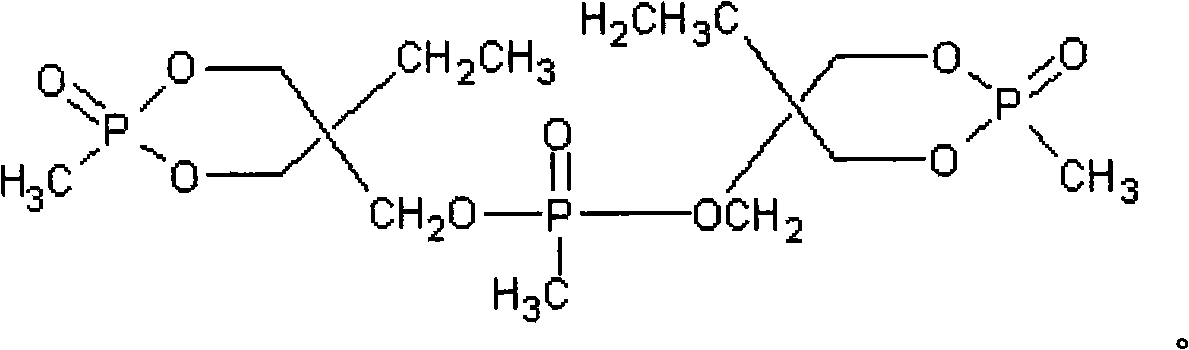

Lithium ion battery electrolyte and lithium ion battery

InactiveCN106532117AAnti-overchargeWith flame retardant functionGroup 5/15 element organic compoundsSecondary cellsHydrogenPhysical chemistry

The invention relates to a lithium ion battery electrolyte. The lithium ion battery electrolyte comprises a lithium salt, a solvent and additives, wherein the additives are selected from one or combination of the structures: FORMULA which is as shown in the specification, wherein R1, R2, R3, R4 and R5 are independently selected from any one kind of hydrogen group, alkyl group, alkoxy, alkylene, alkyl halide group, alkyl halide oxygen group, alkenyl halide group, hydroxyl, carboxyl, ether oxygen group or halogen, wherein the halogen is F, Cl or Br; A is group constituted by O, S, N or P; and R6, R7, R8, R9 and R10 are independently selected from any one kind of hydrogen group, alkyl group, naphthenic group, alkoxy, phenyl group, fluoroalkane group, fluoro-naphthene group, fluoroalkoxy group, fluorophenyl, fluoro-phenoxyl and a fluoro group which is constituted by O, S, N and P, wherein the halogenating or fluorination is wholly substituted or partially substituted. The lithium ion battery electrolyte provided by the invention has anti-overcharge and flame-retardant functions, and has relatively low adverse influence on the performance of the battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Polyurethane sponge and processing method thereof

InactiveCN106957408AWith flame retardant functionGood flame retardant functionDiethyl phosphateHalogen

The invention discloses polyurethane sponge and a processing method thereof. Polyether polyol with a flame retardant function is directly added to a material A, and a diethyl ethylphosphonate fire retardant is selectively added to a material B, so that the polyurethane sponge does not contain halogen, is low in viscosity and very stable in a two-component system of the material A and the material B, and a product is endowed with good fireproof and flame-retardant properties while the process is simple. The product is endowed with good mildew-proof and antibacterial effects through an antibacterial agent and a mildew preventive added to the material B; and through addition of nanoscale inorganic material tourmaline powder, the product has the function of lastingly emitting anions. The production technology and the formula are relatively simple on the premise that all performance indexes reach the expected requirements; the production process and the formula are relatively simple; the processes such as heating or refrigerating do not need to be specifically carried out in the production process and foaming and curing in a natural state can be carried out; the production success rate of sample post-detection is very high; the produced polyurethane sponge has obvious fireproof and flame-retardant functions, antibacterial and anti-mildew functions and continuous anion release function, and is beneficial to improvement of the competitiveness of the product.

Owner:东莞恒生高分子科技有限公司

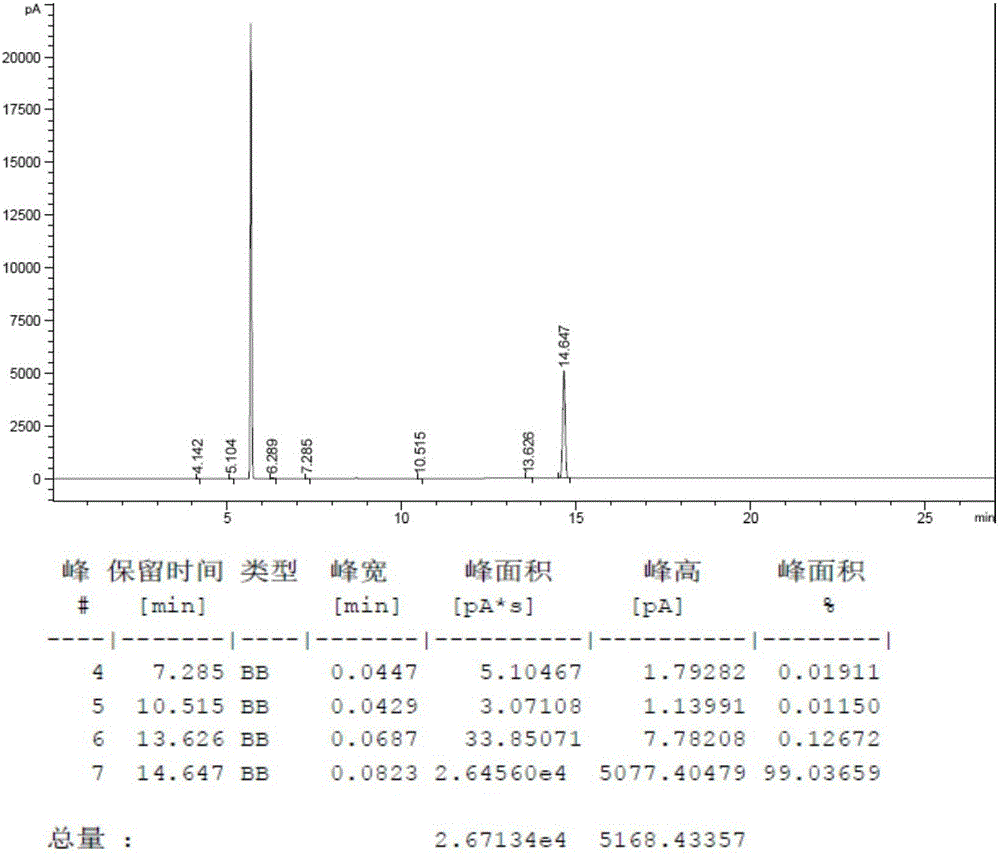

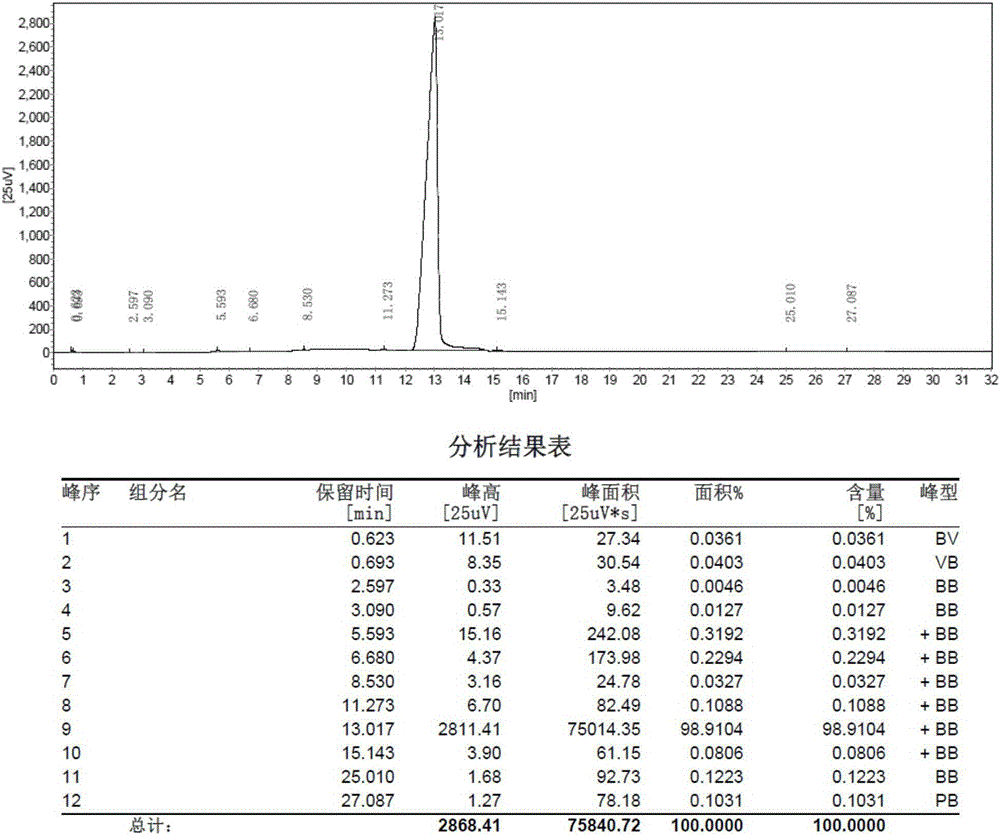

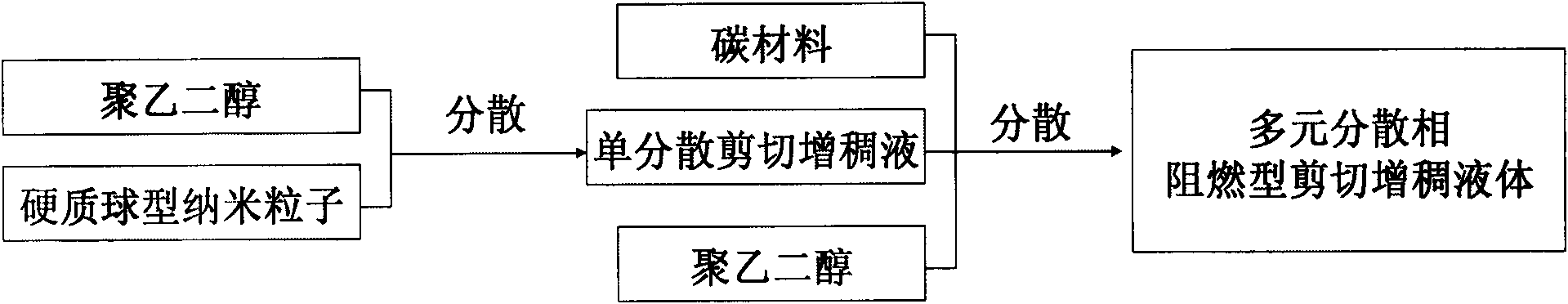

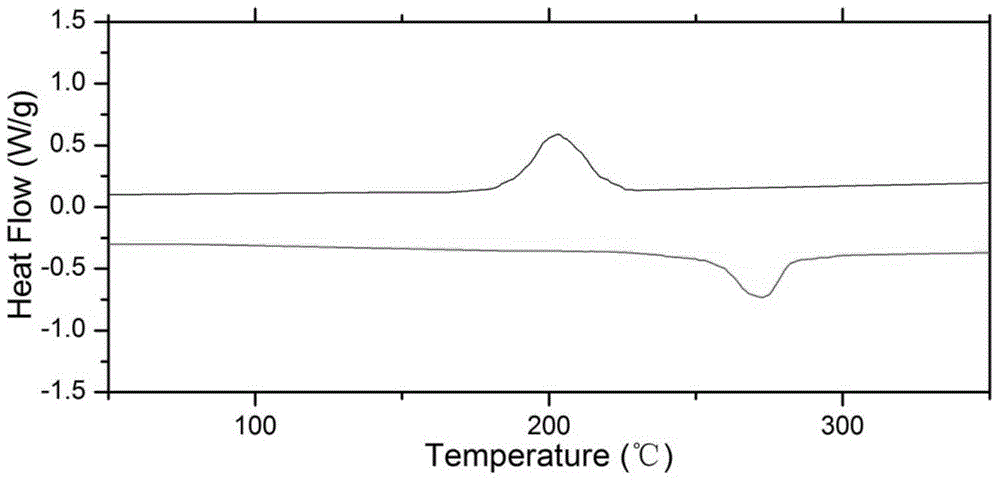

Multiple dispersed phase flame retardant shear thickening fluid, its preparation method and application thereof

ActiveCN102733175ARaw materials are cheap and easy to getReduce manufacturing costFibre treatmentFiberDispersed media

The invention relates to a multiple dispersed phase flame retardant shear thickening fluid, its preparation method and an application thereof, and belongs to the technical field of nano materials. The preparation method of the multiple dispersed phase flame retardant shear thickening fluid comprises the following steps of: firstly, respectively fusing 100 parts by weight of a disperse medium at the temperature of 30-60 DEG C, adding 40-70 parts by weight of hard spherical nanoparticles, dispersing at the temperature of 30-60 DEG C for 40-70 minutes, adding 1-10 parts by weight of a carbon material and simultaneously adding 10-20 parts by weight of a disperse medium, and continuously dispersing at normal pressure for 1-4 hours, so as to obtain a multiple dispersed phase fluid with a substantial shear thickening characteristic. The viscosity is 100-100000 Pa.S / 25 DEG C and the flame retardancy reaches UL-94V-0 level. By reasonable design and application of the nanometer effect of the hard spherical nanoparticles and characteristics of the carbon material, the multiple dispersed phase flame retardant fluid with the substantial shear thickening characteristic is prepared. Through an ultrasonic technology, a spraying technology, a sizing technology, loading and thermal sewing technologies, the multiple dispersed phase flame retardant shear thickening fluid can be used for impregnation composition, coating composition or embedding composition of fabrics, so as to prepare a light-duty flexible soft protection material with a flame retardant function.

Owner:JIANGNAN UNIV

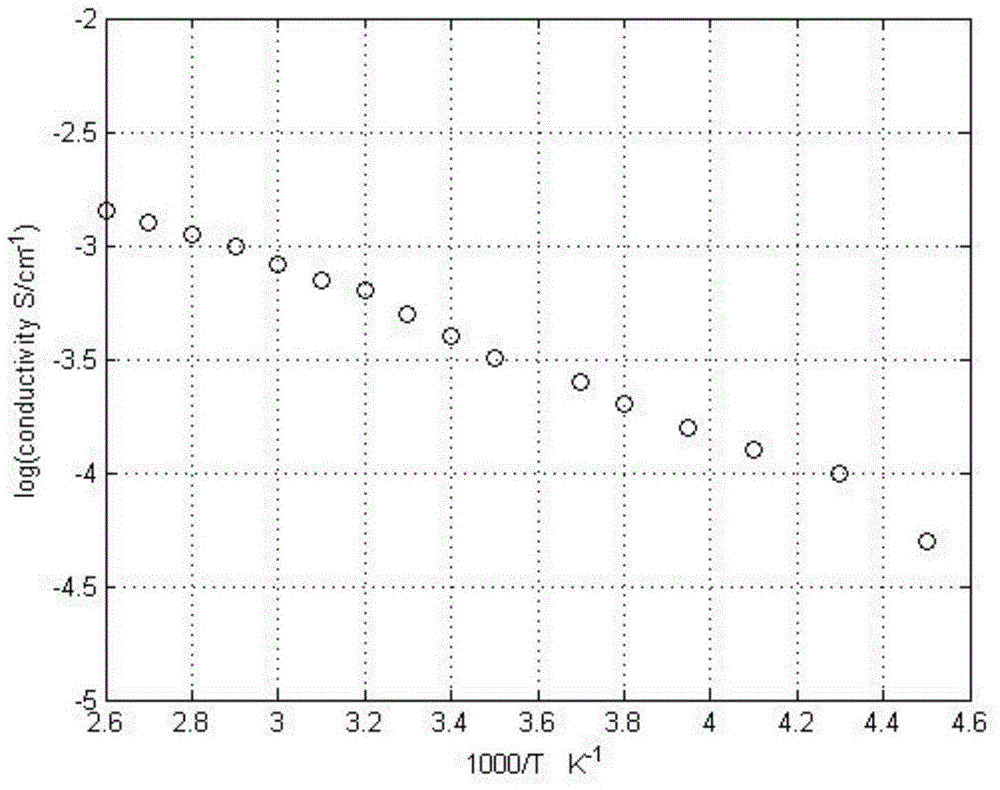

Solid electrolyte, preparation method and application thereof, and lithium battery using solid electrolyte

ActiveCN104009253AWork lessImprove conductivitySolid electrolytesLi-accumulatorsSolid state electrolyteElectro conductivity

The invention discloses a solid electrolyte and a preparation method thereof. The solid electrolyte is prepared by uniformly mixing 30-97mass% of a polyphenylene high-molecular organic polymer, 3-70mass% of a lithium salt and 0-20mass% of a surfactant. The conductive performance and the mechanical performances of the solid electrolyte are comprehensively improved, so the solid electrolyte has a very high conductivity in a large temperature range. The solid electrolyte provided by the invention can substitute original isolation films and liquid electrolytes in original lithium batteries, or original gel electrolytes.

Owner:NANJING BOCHI NEW ENERGY CO LTD

Preparing method for carving simulating UV scratch resisting wood grain decoration film

InactiveCN107877892ANot easily stainedImprove scratch resistanceFlat articlesWood splinterEngineering

The invention relates to a preparing method for a carving simulating UV scratch resisting wood grain decoration film. The preparing method comprises the technology steps that a PVC face film is prepared; a PVC base material is prepared; two to six polychrome printing is conducted on the surface of the PVC face film according to pattern requirements; color pulp of one color in each set is adopted,a colorful PVC face film is prepared, and finally the printed colorful PVC face film is rolled into a big roll; the printed colorful PVC face film and the PVC base material are heated, pressurized andattached on a double-roller attaching embossing machine, press rollers pressing and attaching the face of the PVC face film are wood splinter embossing rubber rollers, and the temperature of the tworollers can be adjusted to range from 100 DEG C to 200 DEG C; and the attached and embossed PVC decoration film is fed to a printing machine and coated with UV to be conveyed into an oven, secondary temperature increasing is conducted to range from 200 DEG C to 220 DEG C, and PVC face film foaming and cooling are conducted. The carving simulating UV scratch resisting wood grain decoration film prepared through the method has the functions of being capable of achieving the three-dimensional hand feeling, scratch resistance, inflaming retarding, rich colors, carving hollow-out three-dimension and flickering color changing.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

High-efficiency phosphorus flame retardant panlite, preparation method and film thereof

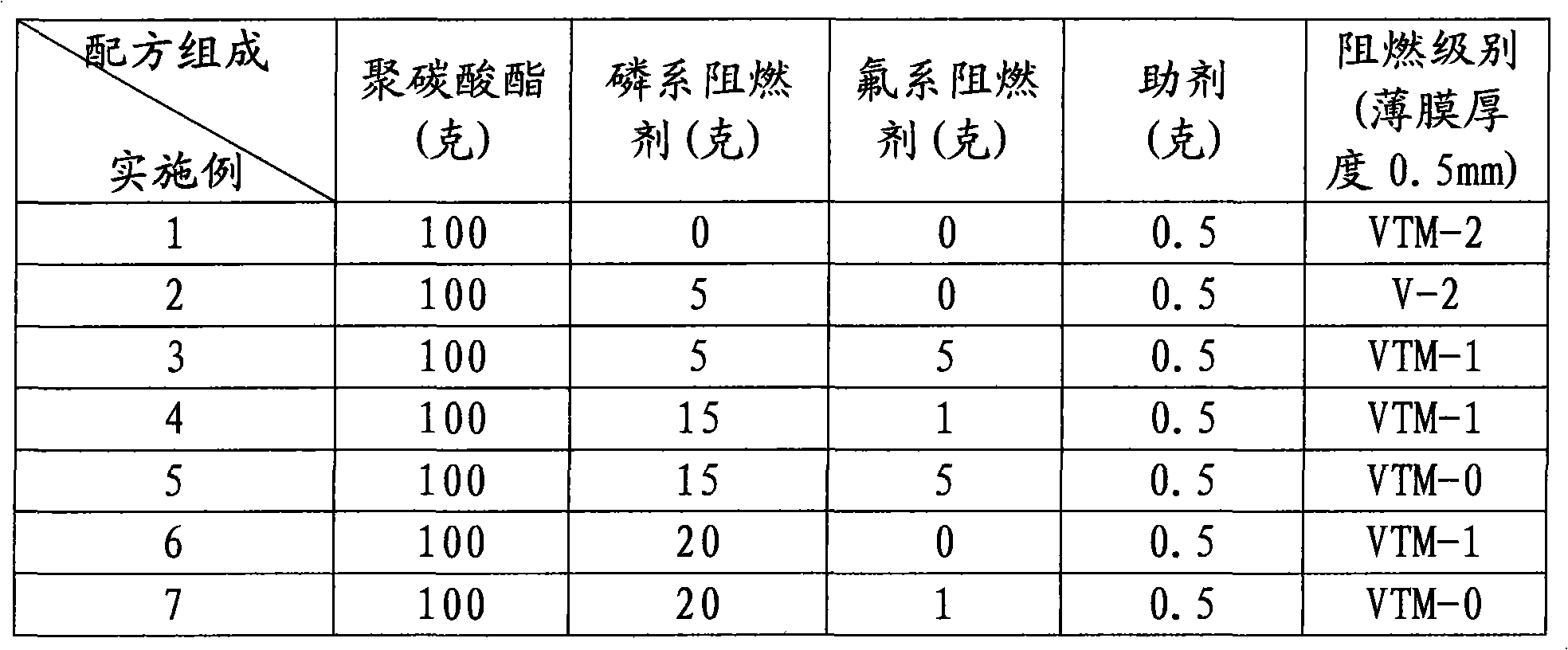

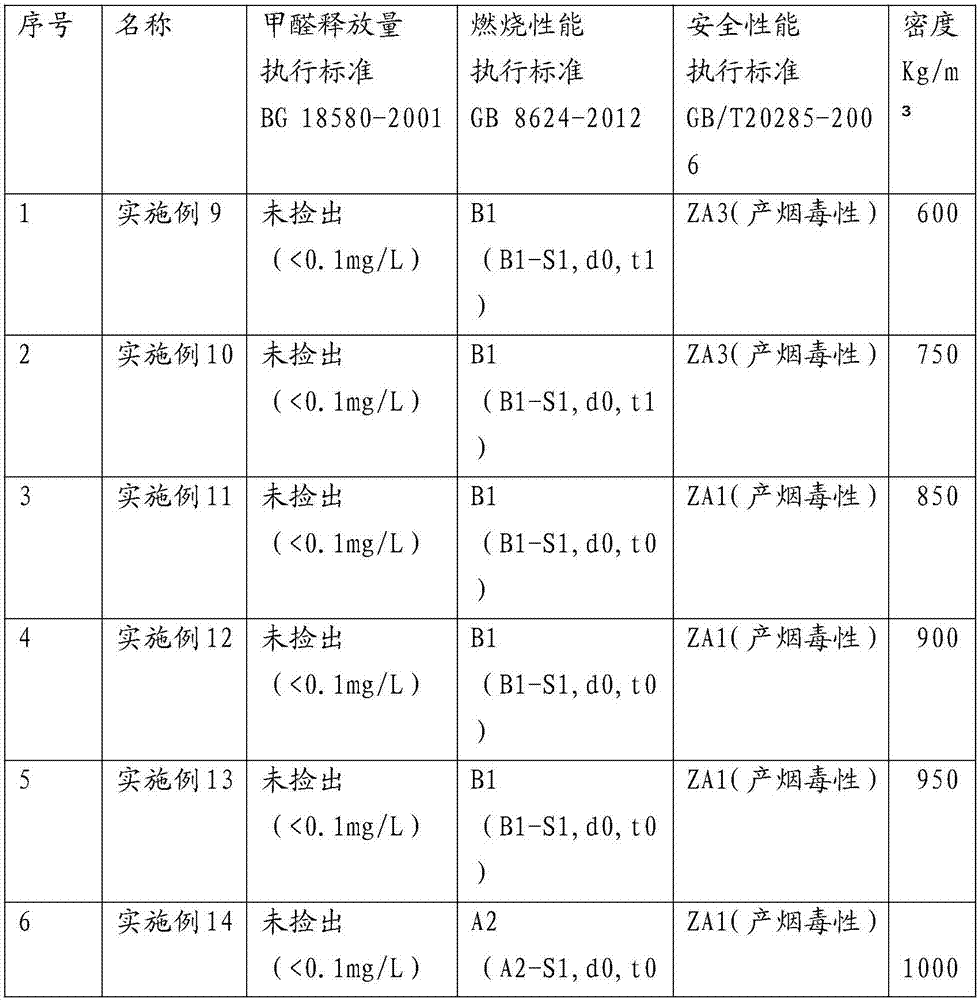

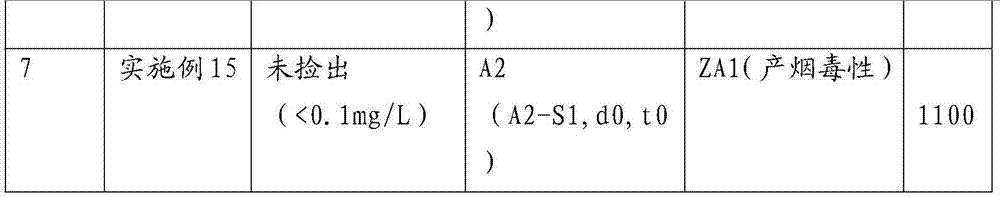

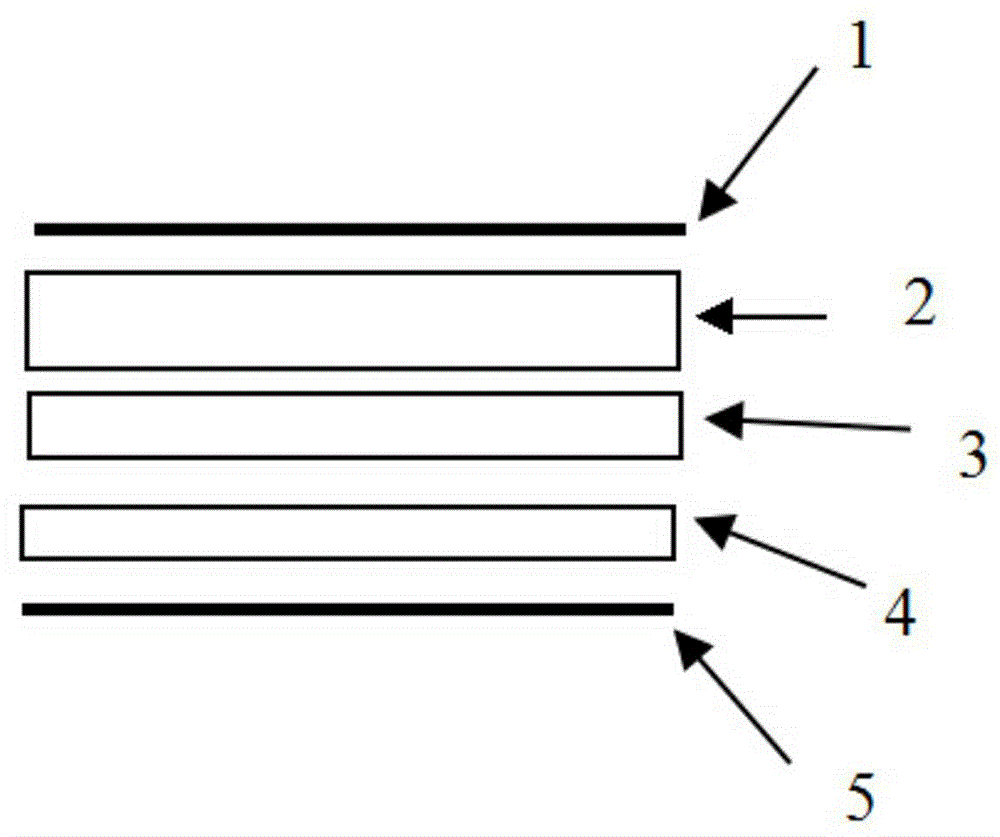

The invention relates to high-efficiency phosphorus flame retardant panlite, a preparation method and a film thereof. The panlite comprises the following components: makrolon, a phosphorus flame retardant, a fluorine flame retardant and an auxiliary agent, wherein the content of the phosphorus flame retardant accounts for 5-30 percent of the weight of the makrolon, the content of the fluorine flame retardan accounts for 0.1-10 percent of the weight of the makrolon, and the content of the auxiliary agent accounts for 0.1-10 percent of the weight of the makrolon. The film prepared from the high-efficiency phosphorus flame retardant panlite has good flame retardance and good shock resistance and also reduces the toxicity compared with an ordinary halogen flame retardant makrolon material whenexposed at high temperature; meanwhile, an addition agent containing chlorine or bromine is not used by the film. When the contents of the added phosphorus flame retardant and the fluorine flame retardant reach a certain quantity, the flame retardance of the film confirms to the standard of a UL94-VTM0 grade.

Owner:苏州奥美材料科技有限公司

Method for preparing clinquant high molecular decorative film

ActiveCN101850689AAchieve the same effectLow costLamination ancillary operationsSynthetic resin layered productsCompound aSurface layer

The invention relates to a method for preparing a clinquant high molecular decorative film. The decorative film is formed by tightly compounding a base material and a printed surface film, wherein the printed surface film is formed by tightly compounding three layers of materials, namely a printed film, a primitive color layer of golden yellow and a film surface layer of golden yellow, and the film surface layer of golden yellow is arranged on the inner layer of the decorative film and is directly and firmly stuck to the base material. The method comprises the following processing steps of: firstly, calendaring the base material; secondly, preparing the printed film; thirdly, printing the surface film; and fourthly, laminating. The method is characterized in that titanium white powder and fire retardant are added to the formula of the base material so as to achieve the opacity and the fire-retardant function of the base material, and simultaneously, the firmness of lamination is enhanced through the corona treatment. Besides, a great amount of valuable gold dust is saved by adopting the technology of secondary printing so that a little gold dust can be arranged on the surface of a printed layer without being laminated and covered by a thick ink layer. In addition, the fire retardant is added to the printed film so that both the interior and the exterior of the decorative film can achieve the fire-retarding function. As the color of golden yellow and the gold dust are sequentially printed, the decorative film has the same appearance effect with gold foil.

Owner:ECONESS ENERGY

Flame-retardant nanometer bamboo charcoal antibiosis filler fiber and manufacturing method thereof

InactiveCN102485981AWith flame retardant functionHas antibacterial functionHollow filament manufactureMelt spinning methodsSpinningBamboo charcoal

The invention provides a flame-retardant nanometer bamboo charcoal antibiosis filler fiber. The fiber comprises the following components, by mass, 1-20% of a nanometer bamboo charcoal antibiosis master batch and 80-99% of a sliced carrier. A manufacturing method of the fiber comprises the following steps: mixing the nanometer bamboo charcoal antibiosis master batch and the needed sliced carrier according to a certain ratio, uniformly stirring them, selecting a spinneret plate according to the fiber processing fineness and the section shape of the fiber, fusion-spinning, cooling, reeling, filament bunding, drafting, and spirally and curly cutting into short fibers to prepare the flame-retardant nanometer bamboo charcoal antibiosis filler fiber. The fiber of the invention has the advantages of substantial flame retardation and antibiosis, peculiar smell adsorption function possessing, soft handle, good elasticity, and wide application.

Owner:SHANGHAI JAROS NEW MATERIAL

Flame-retardance formaldehyde-free industrial hemp straw fiberboard and manufacturing method thereof

InactiveCN107322745AWith flame retardant functionClear componentsDomestic articlesFlat articlesSolventFiberboard

The invention provides a flame-retardance formaldehyde-free industrial hemp straw fiberboard. The fiberboard comprises raw materials of industrial hemp straw all-straw core fragments and flame-retardance adhesive being 18-48 weight% of the fragments; and the fiberboard is prepared by such steps as cold pressing and curing. Aiming at a hot pressing process and a method for applying solvent adhesive in traditional fiberboard manufacturing, the flame-retardance formaldehyde-free industrial hemp straw fiberboard is prepared by using a cold pressing process and special flame-retardance formaldehyde-free adhesive. Compared with a traditional fiberboard preparation method, the method has the advantages of simple process, low energy consumption and no environmental pollution; and compared a wood fiberboard, the obtained product has such characteristics as flame retardance, low smoke, no irritation, no poison, no formaldehyde, bacteria resistance, insect resistance, water resistance, high strength and possession of both medium density and high density.

Owner:洪家敏

Wear-resisting waterproof flame-retardant wooden floor and manufacturing method thereof

ActiveCN104790635AReduce usageBoth waterproofNon-macromolecular adhesive additivesLamination ancillary operationsFiberSolid wood

The invention discloses a wear-resisting waterproof flame-retardant wooden floor. Fast growing wood plain cut veneer, high-quality broad-leaved wood sliced veneer and an inorganic flame-retardant layer are adopted as main raw materials of the wear-resisting waterproof flame-retardant wooden floor, and the wear-resisting waterproof flame-retardant wooden floor is formed by modified inorganic flame-retardant adhesives in a cold pressing and gluing mode. A manufacturing method comprises the steps that the inorganic adhesives and plant fibers are adopted to manufacture the inorganic flame-retardant layer; the inorganic adhesives are adopted to manufacture a veneer reinforcement layer; the modified inorganic adhesives are adopted to assemble the inorganic flame-retardant layer, the veneer reinforcement layer, the high-quality sliced veneer and balanced veneer, a floor blank is formed through cold pressing, then maintenance, longitudinal and transverse edge cutting, two-sided polishing, double-sided milling and UV paint treatment are carried out, and the wear-resisting waterproof flame-retardant wooden floor is obtained. The wear-resisting waterproof flame-retardant wooden floor completely has the decorative effect the same as that of a natural solid wood floor, is free of formaldehyde release harm, and has the functions of resisting wear, preventing water and retarding flames, the amount of adopted natural wood is quite small, and good ecological and environmental benefits are achieved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for preparation of flame-proof chinlon gluing buckle

ActiveCN101116566AImprove flame retardant performanceImprove securityBucklesPulp and paper industryFire retardant

The invention relates to a manufacturing method of a flame retardant Velcro, including procedures as follows: the Velcro is put into a tincture machine to be cleaned at first, then the Velcro is bleached; and then the bleached Velcro is dehydrated and is friezed by a friezing machine; the processed Velcro is dried by baking, the dried Velcro is sunk into fireproof agent in a tincture machine, after soaking, the Velcro is dehydrated; then the dehydrated Velcro undergoes fire retardant treatment and gum on a gum machine, finally the Velcro is dried by baking. The Velcro manufactured by the method of the invention is not easy to burn with flame retardant invention, thereby being applied to vehicles such as the airplanes and the automobiles to improve the safety in use.

Owner:WUXI PAIHO TEXTILES CO LTD

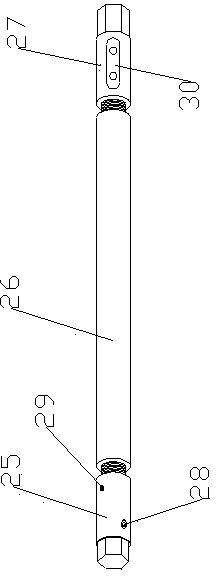

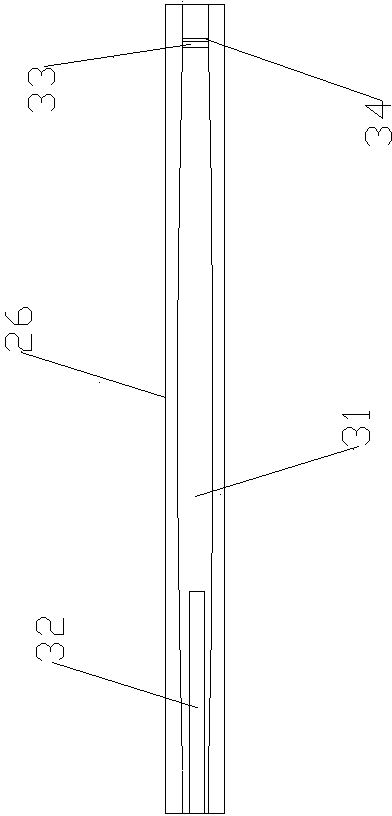

Low-frequency shock source in supercritical CO2 phase change energy-gathered explosion and shock source collection method

ActiveCN104297778ANot easy to integrateNo pollution in the processSeismic signal recordingFrequency changerEngineering

The invention relates to a low-frequency shock source in supercritical CO2 phase change energy-gathered explosion and a shock source collection method. A shell is internally provided with a booster station connected with a Dewar bottle. The booster station is connected with an air compressor. One side of the air compressor is provided with a frequency changer. A vacuum pump is arranged on the frequency changer. The vacuum pump is connected with a high-pressure valve. The high-pressure valve is connected with a liquid conveying opening. An inflatable bolt is movably arranged above the liquid conveying opening. The inflatable bolt is connected with an explosion cylinder in a threaded mode. The explosion cylinder is connected with a pressure relief bolt in a threaded mode. The explosion cylinder is internally provided with an inner cavity. The inner cavity is internally provided with a safety heater. The position, at the tail end of the safety heater, in the inner cavity is movably provided with an explosion piece. A liquid filling opening is formed in the inflatable bolt. One side of the liquid filling opening is provided with a heater connection line opening. A pressure relief opening is formed in the pressure relief bolt. By means of the low-frequency shock source in the supercritical CO2 phase change energy-gathered explosion and the shock source collection method, an effective special tool is provided for the land and marine geological exploration and development in China.

Owner:河南国科特种装备有限公司

Flame-retardant heat preservation type shading curtain fabric

InactiveCN103317797AInsulation hasWith flame retardant functionSynthetic resin layered productsCurtainsEngineeringWeft yarn

The invention provides a flame-retardant heat preservation type shading curtain fabric. The fabric comprises a fabric body, wherein the fabric body is prepared from outer warps, inner warps and weft yarns according to a double-tissue structure; the outer warps, the inner warps and the weft yarns are flame-retardant polyester filament yarns; and a heat-storage heat-preservation microcapsule is arranged on the fabric body. The flame-retardant heat preservation type shading curtain fabric has functions of flame retardance, heat preservation, heat storage and heat insulation.

Owner:ZHEJIANG XINTAO TEXTILE TECH

Production technology of auxiliary-modified flame-retardant velvet fabric with high color fastness

InactiveCN104178873AOvercoming poor color fastnessOvercome the long processWoven fabricsLiquid/gas/vapor textile treatmentBurning outColour fastness

The invention discloses a production technology of auxiliary-modified flame-retardant velvet fabric with high color fastness. The production technology comprises steps as follows: 1), weaving; 2), pretreatment; 3), burnt-out process; 4), dyeing and flame retardant finishing; 5), post-treatment; and 6), shaping of a finished product. According to the production technology of the flame-retardant fabric, the produced fabric has a flame retardant function, upright piles, good brightness and soft and smooth hand feeling.

Owner:MF

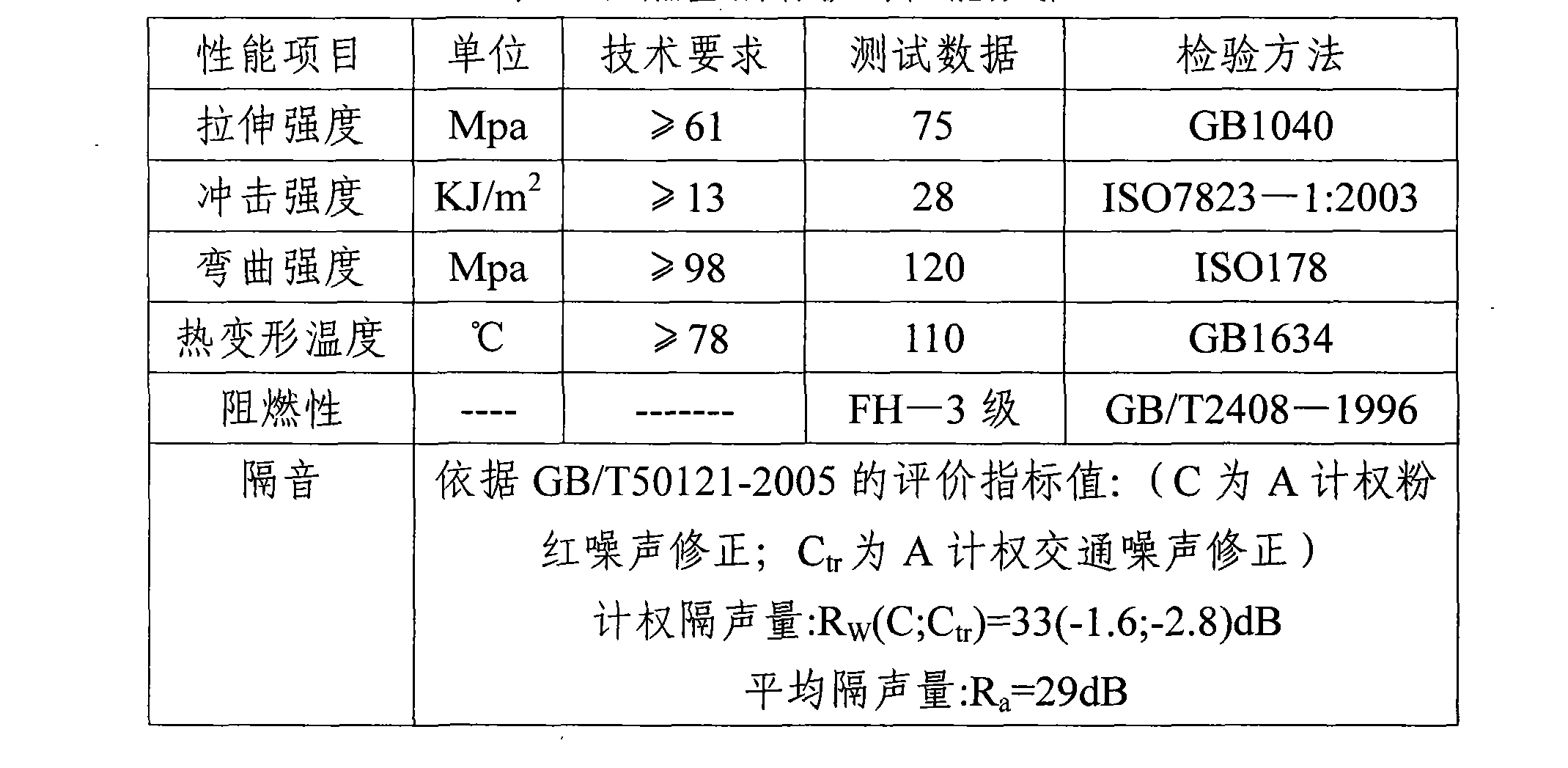

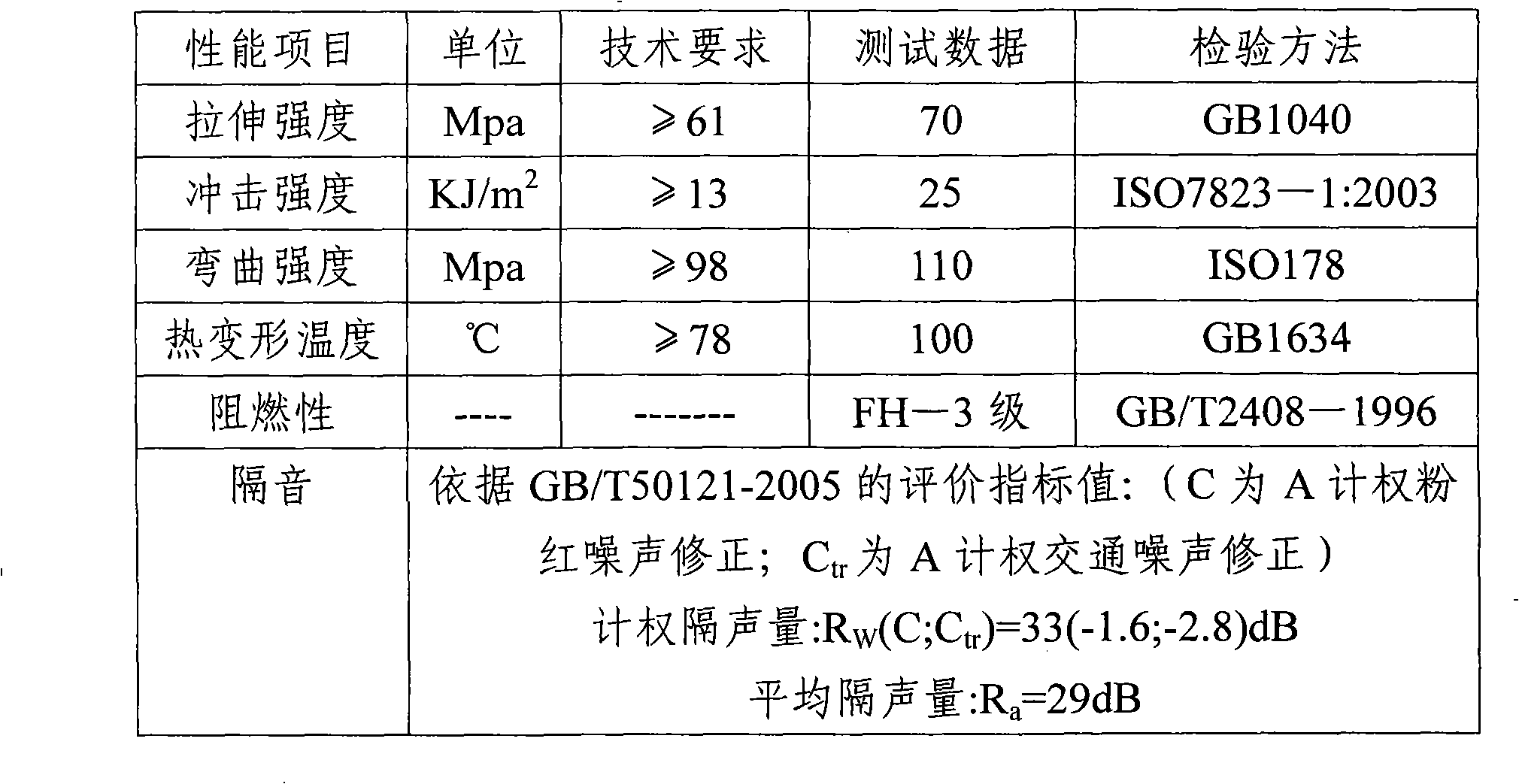

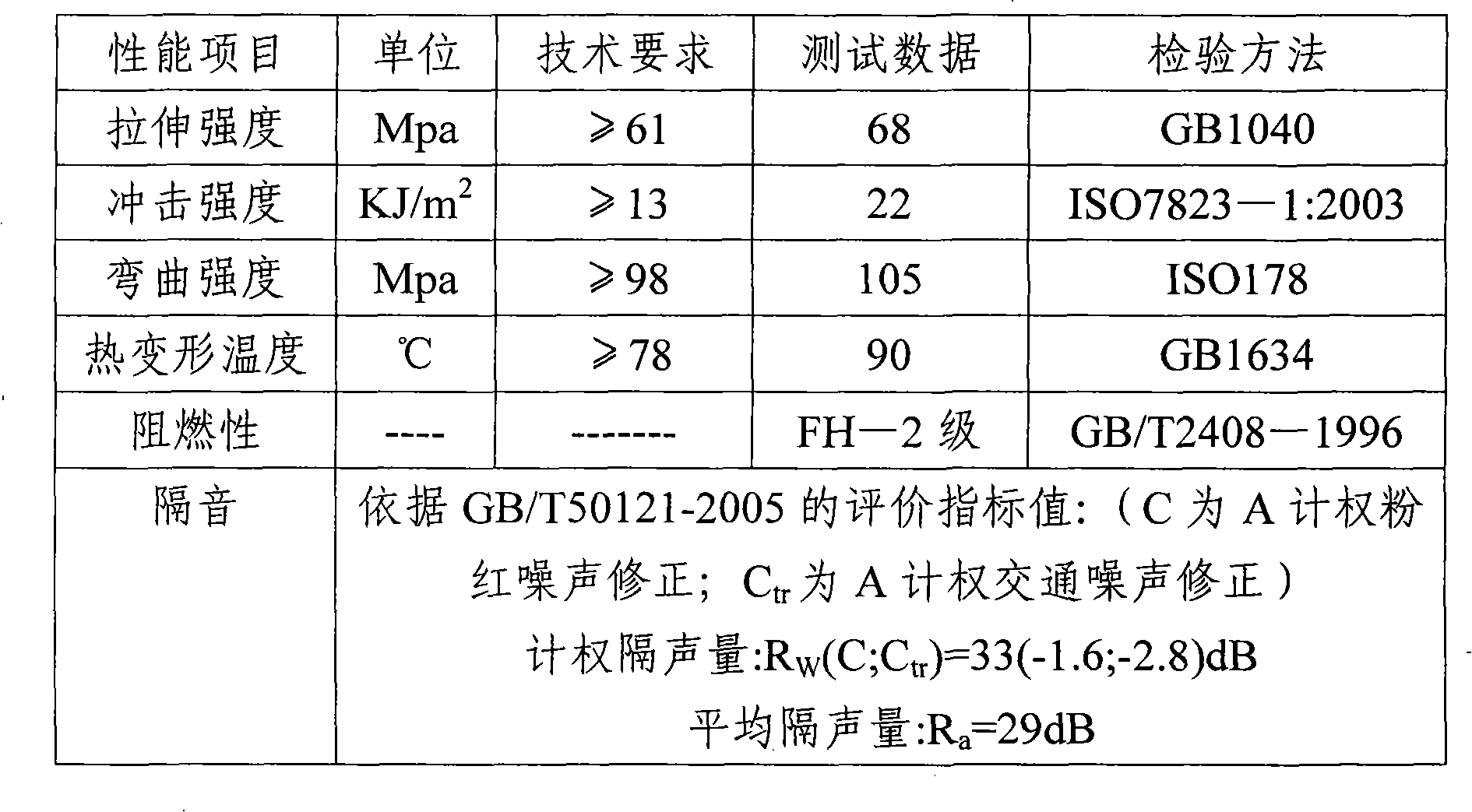

Flame-proof sound-proof board and preparation thereof

ActiveCN101274971ASatisfy the use effectSolve potential safety hazardsNoise reduction constructionAbrasion apparatusHindered amine light stabilizersUltraviolet

The invention aims at solving the defect of being incendive in the existing acoustic board and discloses a flame retarding acoustic board, which comprises a board material body and plastic supporting structure that is inserted into the board material body; wherein, the board material body is prepared by a flame retarding polymer material which comprises the following components by weight percentage: 69.953 to 95.97 percent of methyl methacrylate monomer, 3 to 30 percent of fire retarding agents, 0.007 to 0.03 percent of evocating agents, 0.02 to 0.5 percent of ultraviolet radiation absorbent and 0.02 to 0.5 percent of hindered amine light stabilizer. The preparation method of the flame retardant acoustic board comprises the steps of preparing the flame retardant polymer material, surface treatment of the plastic supporting structure, mold preparation and casting molding process. The flame retardant acoustic board of the invention can not only meet the requirements of the acoustic board, but also have the function of being flame retardant; in addition, the preparation method of the invention not only has simple operation and is easy for industrial application, but also has low cost and environmental friendliness.

Owner:TAIXING TOMSON ACRYLIC CO LTD

Flame-retardance-type multi-layer wrapping anticorrosion system and construction method thereof

ActiveCN107955531AGood construction toleranceImprove adaptabilityAntifouling/underwater paintsHeat resistant fibresWeather resistanceAdhesive

The invention discloses a flame-retardance-type multi-layer wrapping anticorrosion system. The system comprises anticorrosion paste, a flame-retardance-type anticorrosion band, an oil separation basecoating, a flame-retardance-type nonmetal protection cover and a dirt-adhesive-resistance surface coating along the metal structure surface towards outside in sequence. The flame-retardance-type multi-layer wrapping anticorrosion system has excellent construction tolerance and adaptability, a long-acting and lasting anticorrosion effect, flame retardance, excellent dirt-adhesive-resistance and weather resistance and is attractive in appearance, wide in application field and particularly suitable for steel structure connection parts, local severe-corrosion parts, facilities of splash areas in ocean and the like, the anticorrosion effect can last for above 20 years, maintenance is not needed within the anticorrosion validity period, and the system has remarkable economic benefits and wide popularization prospects.

Owner:青岛海弗莱安全科技有限公司

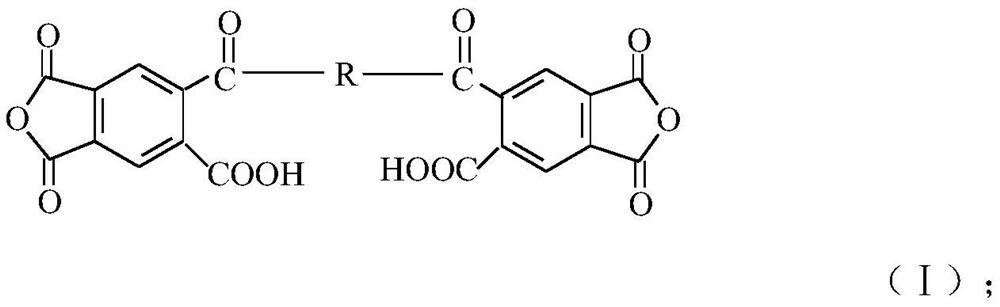

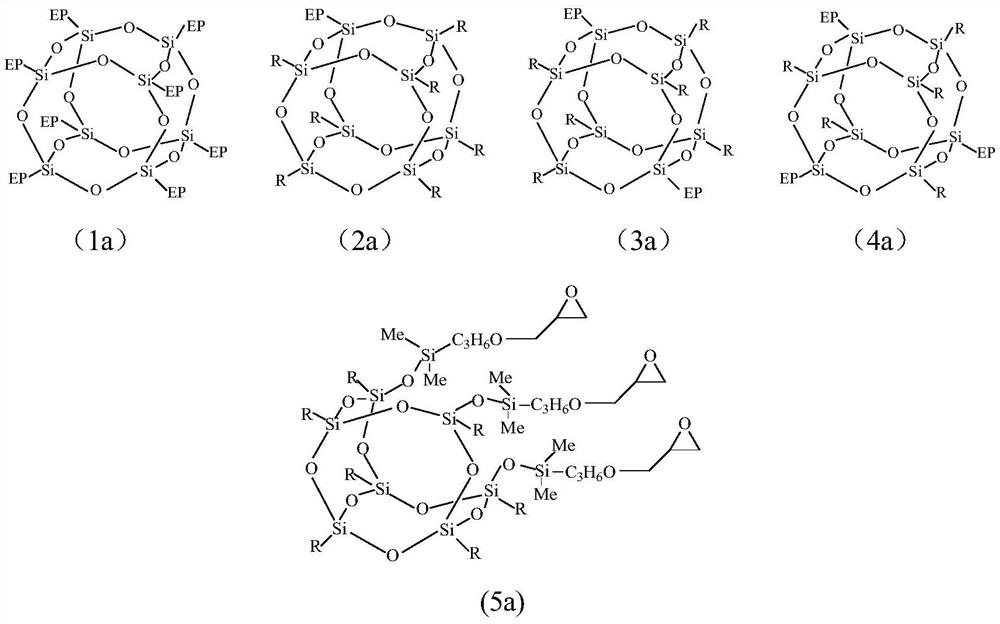

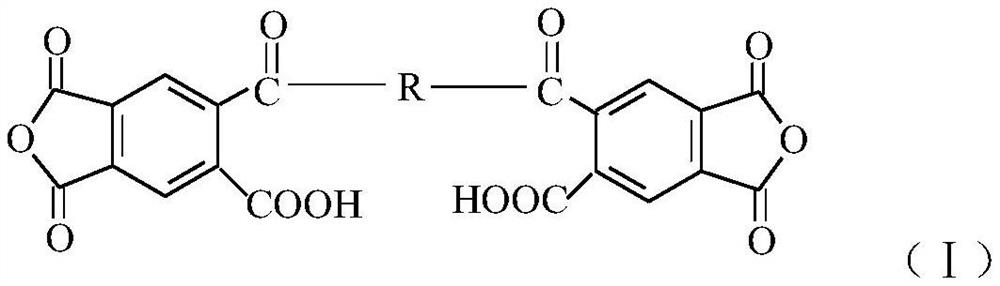

Paint and coating based on bridged dianhydride and POSS hybrid epoxy resin

ActiveCN112708325AEasy to useHeat resistantFireproof paintsPretreated surfacesPolymer scienceFirming agent

The invention relates to a preparation method of a paint and a coating constructed based on a bridged dianhydride curing agent and POSS hybrid epoxy resin. The coating disclosed by the invention is prepared from 100 parts of epoxy resin, 3-25 parts of epoxy POSS, 10-20 parts of an active epoxy diluent ED, 0.5-2 parts of a dispersing agent, 25-50 parts of a nano pigment filler and a latent bridged dicarboxylic anhydride CBA curing agent. The dosage of the latent bridged dicarboxylic anhydride CBA curing agent is controlled such that the ratio of the mole number of epoxy groups contained in the system to the mole number of anhydride groups and carboxyl groups contained in the bridged dicarboxylic anhydride curing agent is 1: (1-0.8). According to the invention, solid anhydride which is insoluble in epoxy resin at room temperature is converted into liquid bridged dianhydride which is convenient to use through reaction, and the anhydride is used in the epoxy POSS hybridized epoxy resin coating system, so that the thermal curing of the epoxy resin coating can be realized, and a coating with good hardness, flexibility, heat resistance and flame retardance is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

Manufacturing method for crop straw building external wall heat insulation plate

ActiveCN105382911AEfficient use ofReduce energy consumptionFlat articlesDomestic articlesMildewEngineering

The invention provides a manufacturing method for a crop straw building external wall heat insulation plate. The method includes the steps that wheat straw, rice straw, cotton stalks and other agricultural leftovers are used as the raw materials; the technological processes of chopping smashing, mixing opening, airflow laying, acupuncturing felt forming, gluing sizing and curing, inflaming retarding, corrosion and mildew preventing treating, dicing molding and the like are conducted; and finally the light and durable building external wall heat insulation plate with the inflaming retarding and sound insulating functions is manufactured. Development of green buildings of our country is facilitated, energy consumption of buildings is greatly lowered, and efficient and high-additive value recycling of crop straw is achieved.

Owner:NINGBO ZHONGJIA LOW CARBON NEW TECH RES INST

Clean production and processing technology of ecological multifunctional digital-printing real-silk adornment silk fabric

InactiveCN103603179AWith flame retardant functionWith antibacterial functionDyeing processAnimal fibresNitrogenEngineering

The invention discloses a clean production and processing technology of an ecological multifunctional digital-printing real-silk adornment silk fabric, and relates to the technical field of production of real-silk adornment silk fabrics. The clean production and processing technology has following steps: pretreatment of a real-silk fabric; cationization or non cationization of the real-silk fabric; use of phosphorus and nitrogen containing components in the real-silk fabric for flame-retardant modification by use of an electrostatic layer by layer self-assembly technology; digital ink-jet printing; water repellent function processing; and inspection and packing to obtain a finished product. Due to use of a digital paint ink-jet printing technology, paper tracing, sheet producing, screen producing, color blending and pulp mixing, scrapping printing and other processes need in a traditional printing technology are omitted, a screen producer, a photosensitive machine, a drying room and other facilities are omitted, a silk screen, a roller and other consumable items are omitted, the digital printing is not limited by color process flower backing, and incomparable, personalized and highly fine art textiles which cannot be produced by traditional printing can be produced. Due to the use of digital paint ink-jet printing, a final water washing process is omitted, and the clean production and processing technology is energy saving and emission reducing, and has important social significances.

Owner:XINYUAN COCOON SILK GROUP

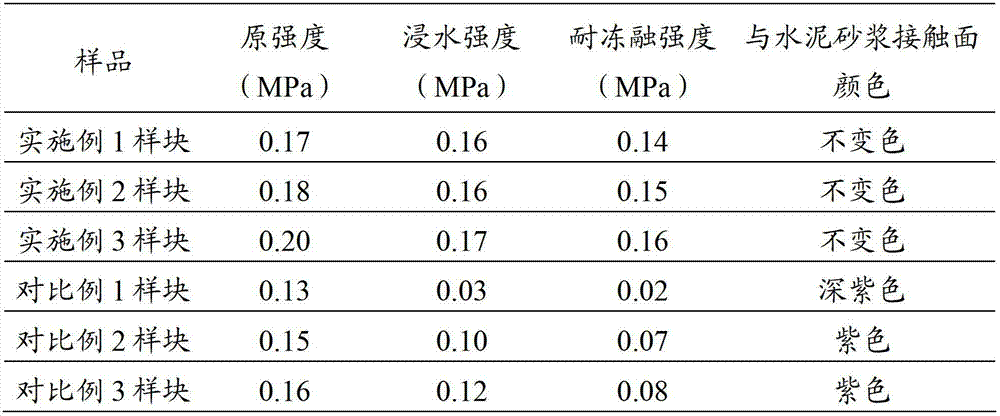

Interfacial agent for foam insulation board

ActiveCN102816479AIncreased durabilityHigh bond strengthConjugated diene hydrocarbon coatingsChloropene polymer coatingsEmulsionPolymer chemistry

The invention provides an interface agent for a foam insulation board. The interfacial agent comprises, by weight, 100 parts of macromolecule emulsions, 1-30 parts of acid curable adhesives, 10-50 parts of flame retardants, 0.1-2 parts of water repellents, 20-60 parts of self-crosslinking type adhesives, 0.1-5 parts of thickener and 0-5 parts of pH modifiers. The acid curable adhesives perform curing by the aid of acidity of the foam board and provide chemical crosslinking for the interfacial agent and the board, and durability of the interfacial agent is improved; the macromolecule emulsions and the acrylic acid polymer self-crosslinking type adhesives are mixed for using, so that film formation of the interfacial agent is good, water permeating is stopped, water resistance of the interfacial agent is improved, and the acid-base reaction between the foam insulation board and cement mortar is prevented; and the interfacial agent is provided with a flame retardant function through the addition of the flame retardants into the interfacial agent.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com