Multiple dispersed phase flame retardant shear thickening fluid, its preparation method and application thereof

A disperse phase, flame retardant technology, applied in the field of nanomaterials, can solve the problems of limited application range of shear thickening liquid, single function of monodisperse phase shear thickening liquid, unsuitable for ultra-high shear stress range, etc. Achieve the effect of light weight, low production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

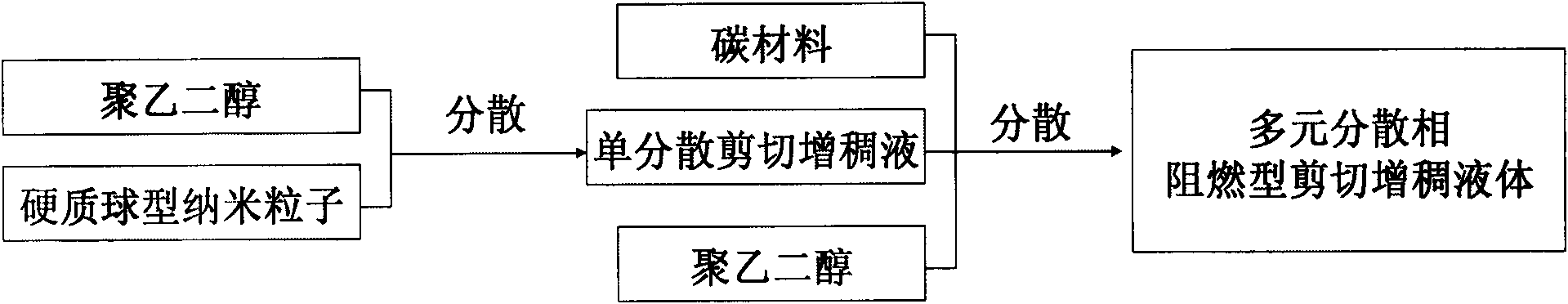

Method used

Image

Examples

Embodiment 1

[0023] Pour 100 parts by weight of polyethylene glycol with a molecular weight of 200 into the reaction vessel, raise the temperature to 30°C, and then add 50 parts by weight of hard nano-spherical silica particles, disperse at 30°C for 50 minutes, and then add 2 parts by weight of carbon black, while adding 10 parts by weight of polyethylene glycol with a molecular weight of 400, continued to disperse for 1 hour under normal pressure to obtain a multi-component dispersed phase flame-retardant liquid with significant shear thickening properties, and the initial viscosity was 178Pa·S / 25℃, the flame retardant level has reached UL-94V-0 level.

[0024] Dilute the volume ratio of the shear thickening liquid to the fiber fabric at a ratio of 1:3 to prepare a shear thickening impregnation liquid, and use ultrasonic technology to make the fiber fabric fully absorb the shear thickening impregnation liquid, and dry and evaporate the solvent ethanol after impregnation. That is to say, i...

Embodiment 2

[0026] Pour 100 parts by weight of polyethylene glycol with a molecular weight of 400 into the reaction vessel, raise the temperature to 35°C, and then add 60 parts by weight of hard nano-spherical silica particles, disperse at 35°C for 50 minutes, and then add 5 parts by weight of carbon nanotubes, while adding 15 parts by weight of polyethylene glycol with a molecular weight of 200, continue to disperse for 2 hours under normal pressure, and obtain a liquid with significant shear thickening properties of a multi-component dispersed phase, with an initial viscosity of 1510Pa ·S / 25℃, the flame retardant level has reached UL-94V-0 level.

[0027] The prepared liquid with shear thickening properties is slowly filled in batches into the prepared bag-shaped fiber sealing fabric according to the proportion, and the light-duty flexible soft protection with flame-retardant function is prepared by filling hot sewing technology Material.

Embodiment 3

[0029] 95 parts by weight of polyethylene glycol with a molecular weight of 200 and 5 parts by weight of a molecular weight of 10,000 are poured into the reaction vessel, the temperature is raised to 45°C, and then 55 parts by weight of hard nano-spherical silica particles are added, and at a temperature of 45°C After dispersing for 50 minutes, add 5 parts by weight of graphene, and simultaneously add 20 parts by weight of polyethylene glycol with a molecular weight of 200, and continue to disperse for 4 hours under normal pressure to obtain a multi-component dispersed phase liquid with significant shear thickening properties , the initial viscosity is 15400Pa·S / 25℃, and the flame retardant level reaches UL-94V-0 level.

[0030] Dilute the volume ratio of the shear thickening solution to the fiber fabric at a ratio of 1:7 to prepare a shear thickening impregnation solution, and make the fiber fabric fully absorb the shear thickening impregnation solution through spraying techno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com