Liquid-nitrogen cooling method and device for automotive power battery pack

A power battery pack and liquid nitrogen cooling technology, which is applied in the direction of the power unit, the arrangement of the cooling combination of the power unit, and the secondary battery, etc., can solve the problems of battery safety that affects the cooling effect, difficult control of the cooling process, and power consumption of the power battery. , easy to control the cooling temperature, excellent cooling effect, and good cooling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

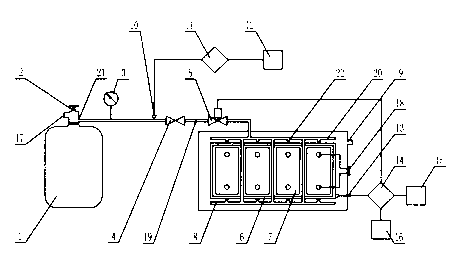

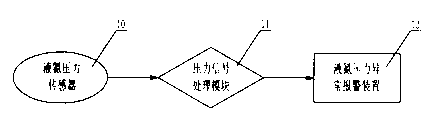

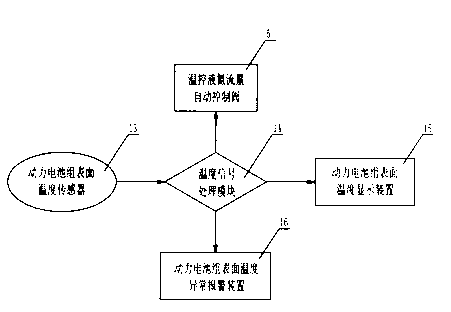

[0027] like figure 1 As shown, a liquid nitrogen cooling method for a vehicle power battery pack, the method is: the power battery pack 6 is arranged in the cooling container 8, through the cooling channel outlet 22 on the cooling channel 20 arranged in the cooling container 8, The liquid nitrogen is vaporized and released directly to the surface of the power battery pack and each battery cell shell, and the surface of the power battery pack and each battery cell shell are cooled by absorbing a large amount of heat in the process of converting liquid nitrogen into a gas. .

[0028] like Figures 1 to 3 As shown in the figure, a device for realizing the above-mentioned liquid nitrogen cooling method for a vehicle power battery pack includes a liquid nitrogen tank 1 for storing liquid nitrogen, a cooling container 8 with a power battery pack 6 inside, a connecting pipe 19, and a liquid nitrogen inlet switch valve. 2. Liquid nitrogen outlet switch valve 4 , cooling channel 20 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com