Patents

Literature

407 results about "Liquid nitrogen cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid nitrogen cooling systems (LN2) The cooling system consists of liquid nitrogen to cool the CPU with liquid nitrogen which has an evaporation temperature of -196 ° C. The operating principle is the same cooling system dry ice, but in this case, the Copper Pot is filled with liquid nitrogen, and then be positioned as a heat sink above the CPU.

Multimode autofluorescence tomography molecule image instrument and rebuilding method

ActiveCN101301192AImprove signal-to-noise ratioIncrease the amount of information availableImage enhancementSurgeryDiagnostic Radiology ModalityLiquid nitrogen cooling

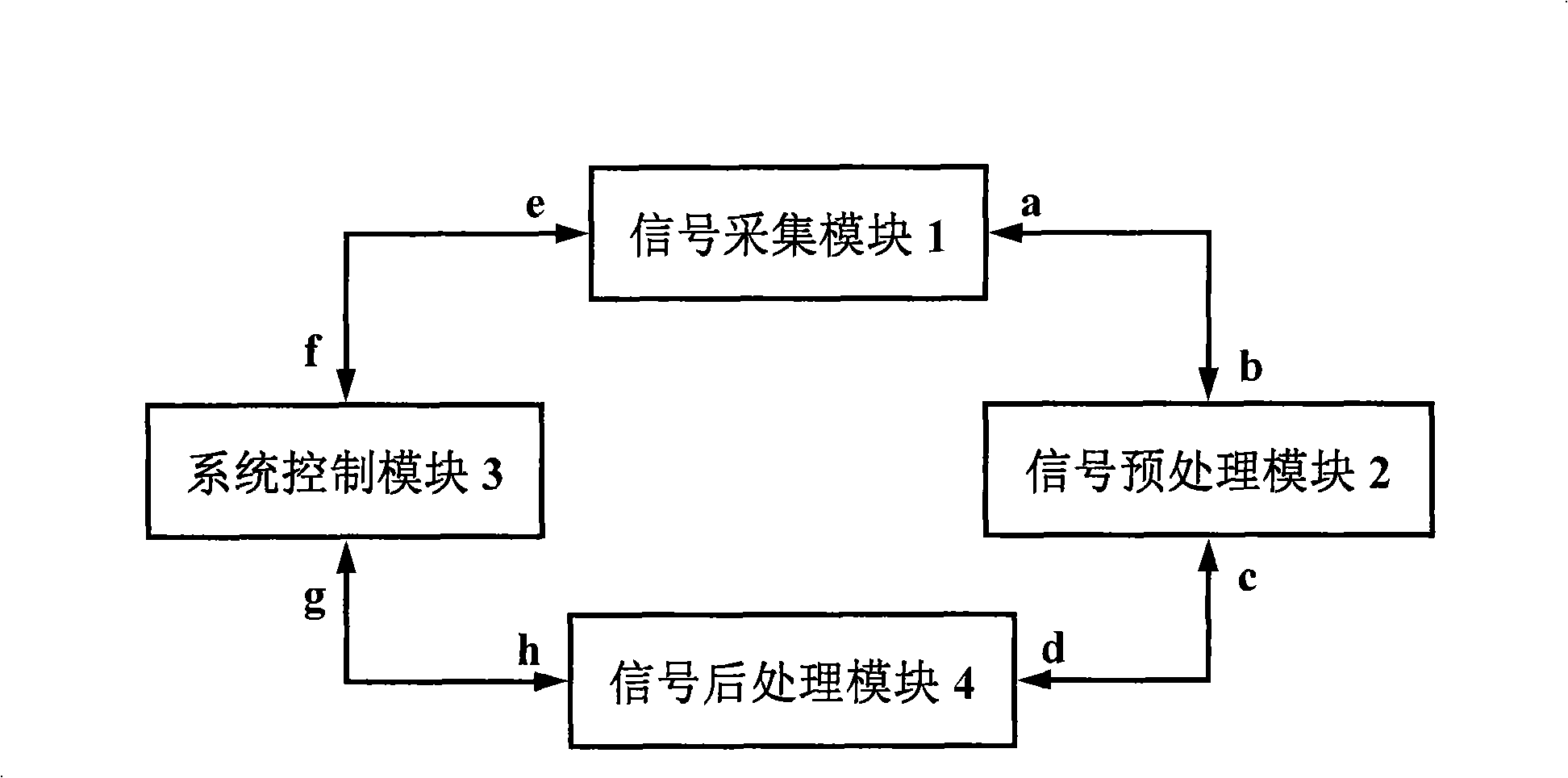

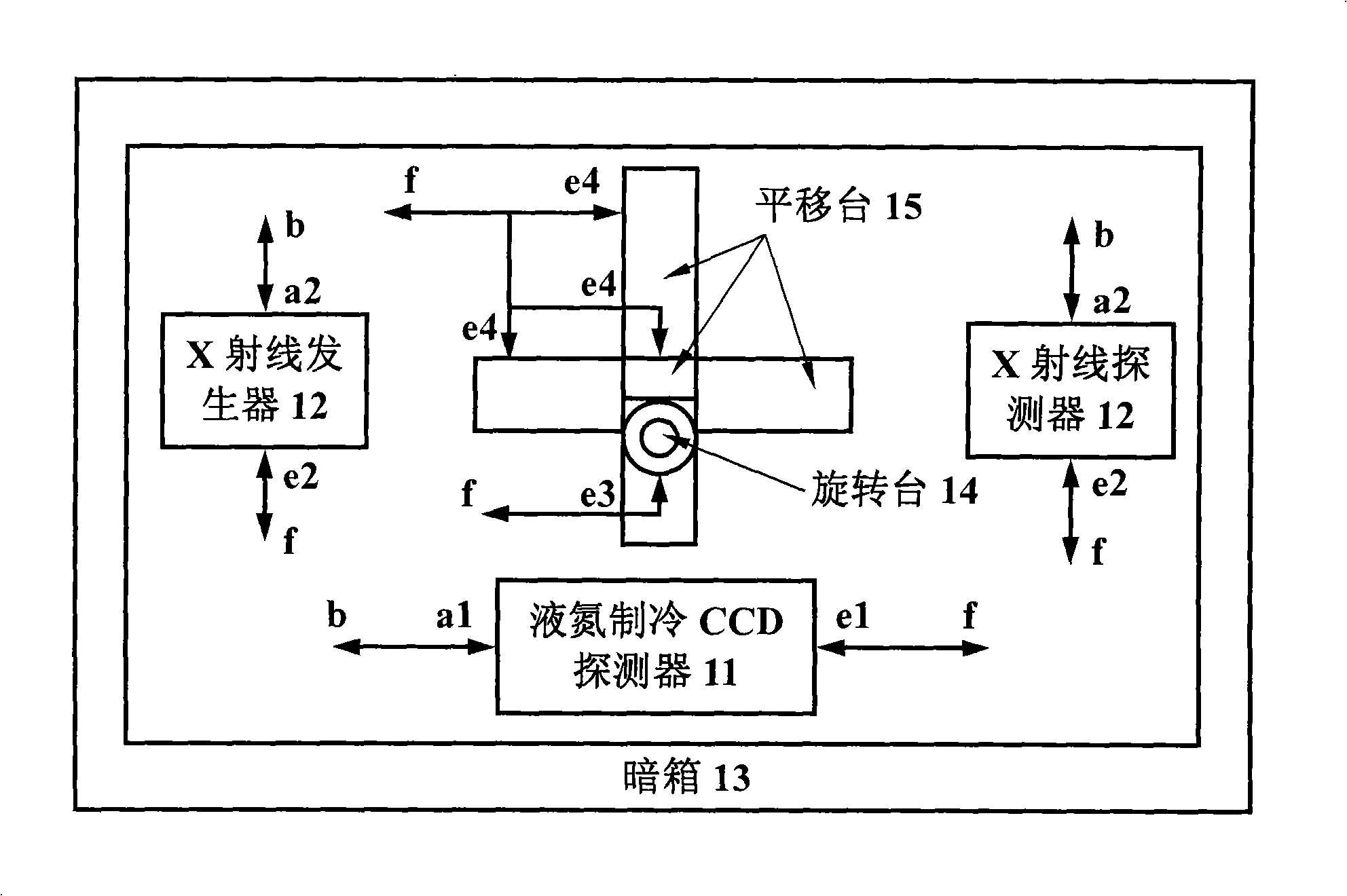

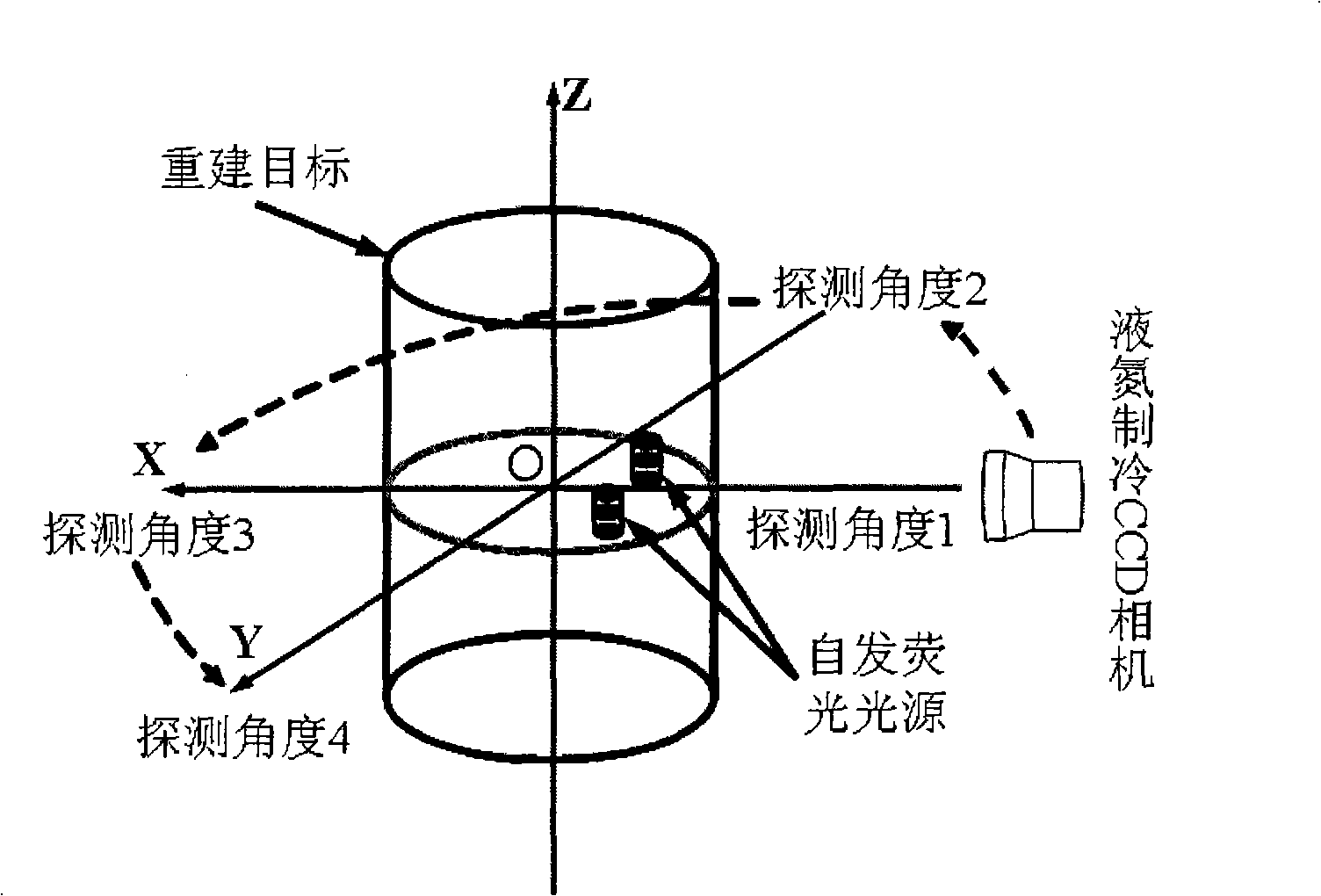

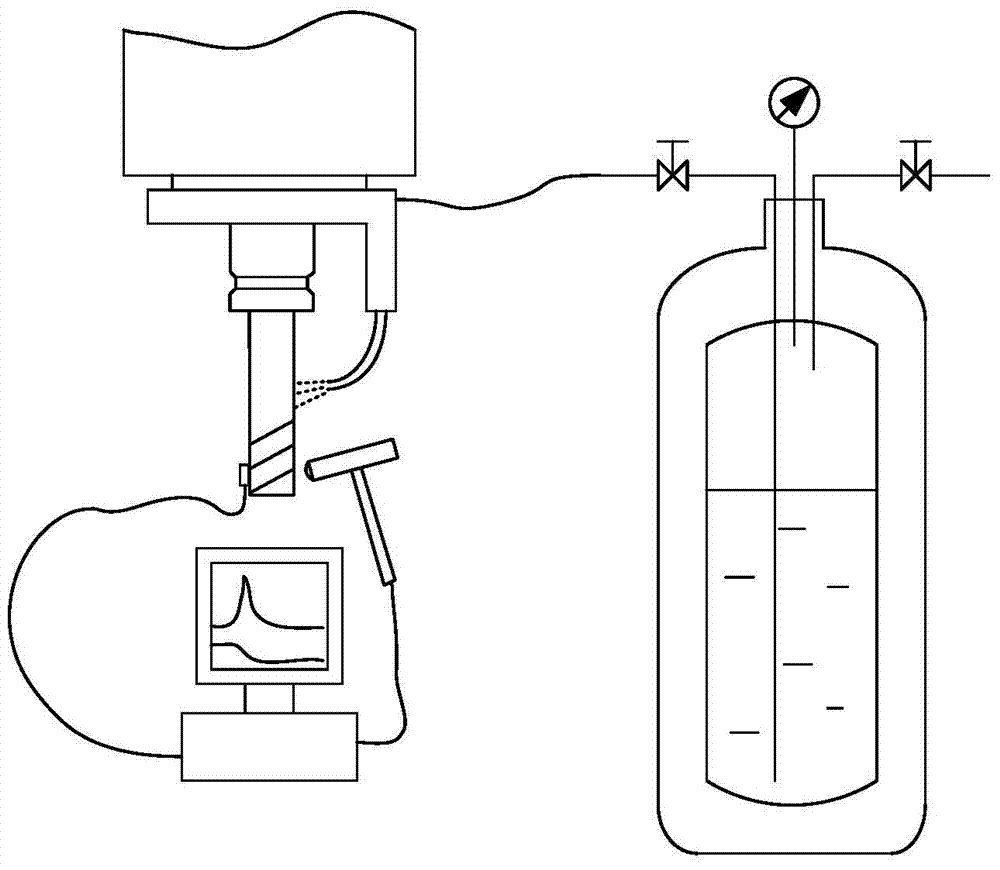

The invention discloses a multi-modality autofluorescence molecular tomographic imaging instrument, comprising a signal gathering module, a signal preprocessing module, a system control module, and a signal post-processing module. The method of the invention comprises determining the feasible region of light source through X-ray imaging and autofluorescence tomographic imaging based on multi-stage adaptive finite element combined with digital mouse, reconstruction target area optical characteristic parameter, and modality fusion, and adaptive optimized factorization for partial texture according to the posterior error estimation to obtain the fluorescence light source in reconstruction target area. The morbidity problem of autofluorescence molecular tomographic image can be efficiently solved, and the precise reconstruction of the autofluorescence light source can be carried out in the complicated reconstruction target area by the multi-modality fusion imaging mode of the autofluorescence molecular tomographic imaging. The precise reconstruction of the autofluorescence light source can be finished by the liquid nitrogen cooling CCD probe, multi-angle fluorescence probe technology, and multi-modality fusion technology, and the autofluorescence molecular tomographic imaging algorithm based on multi-stage adaptive finite element with the non-uniformity characteristics of the reconstruction target area.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

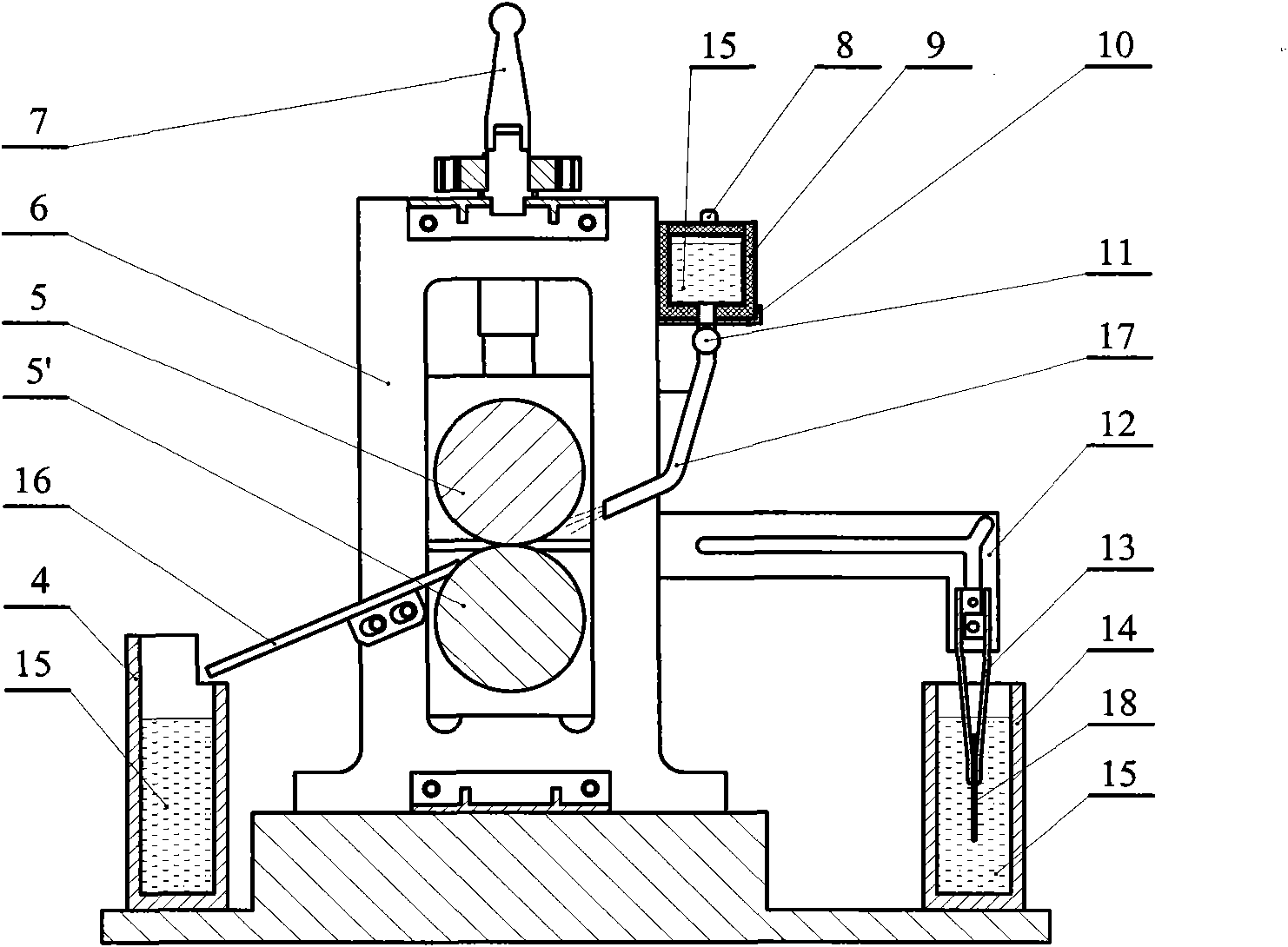

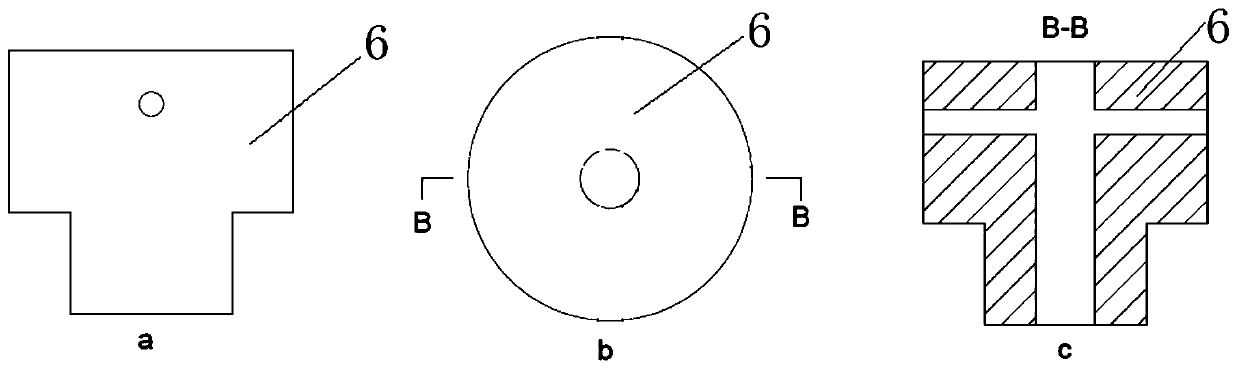

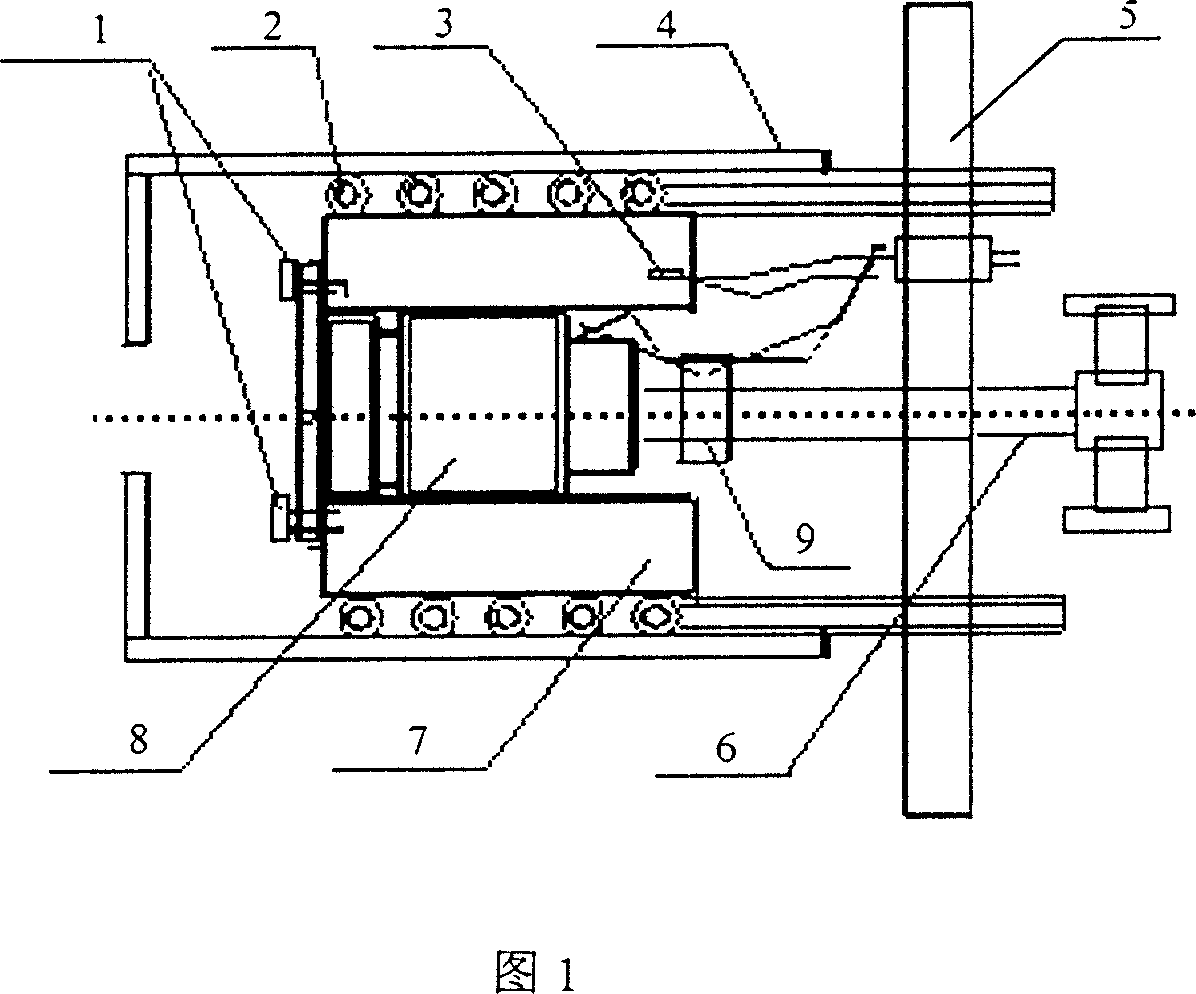

Electro-plastic two-roll mill of low-temperature liquid nitrogen cooling medium

InactiveCN102059250AReduce deformation resistanceImprove plastic deformation abilityMetal rolling stand detailsWork treatment devicesLiquid nitrogen containerStrip mill

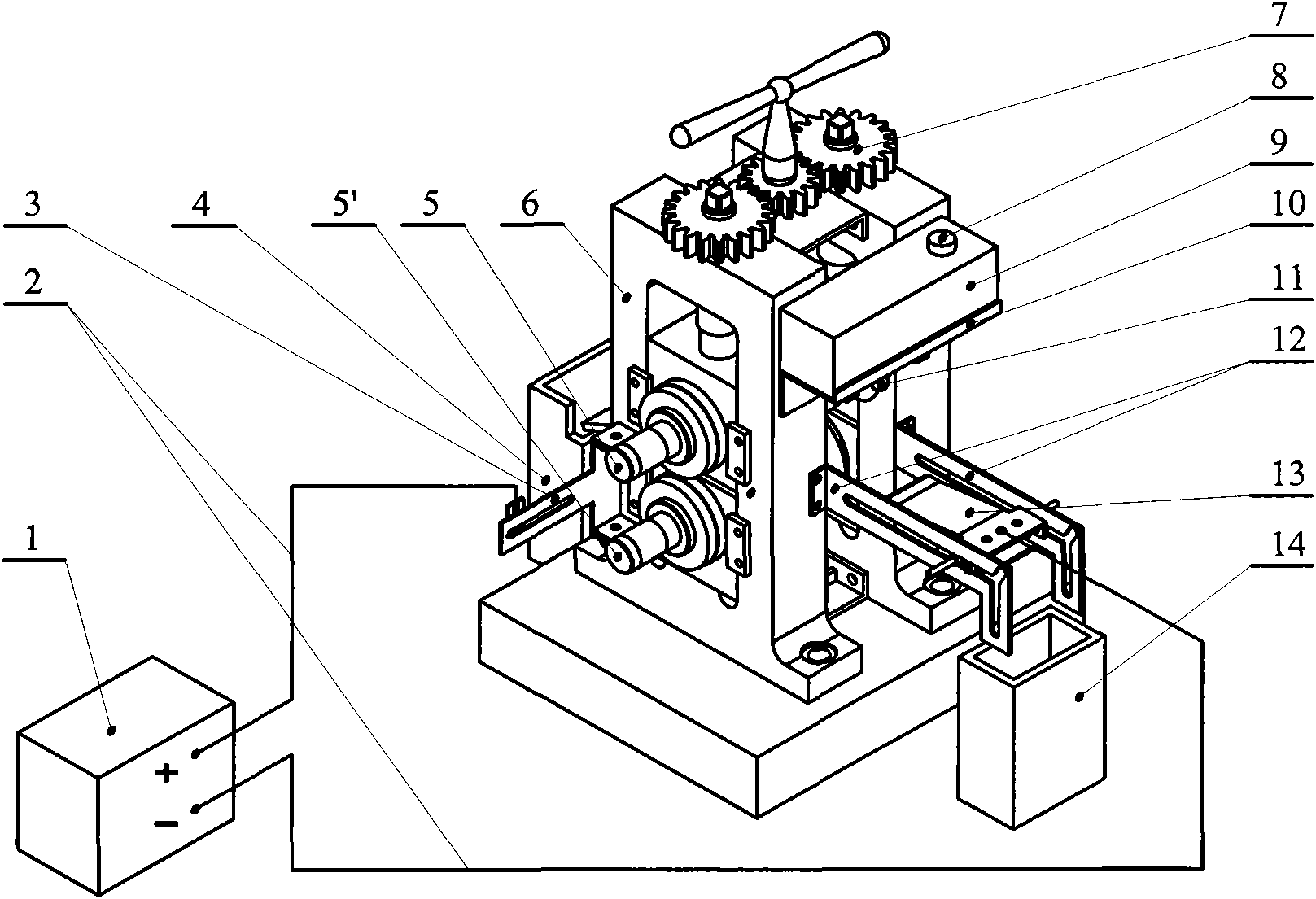

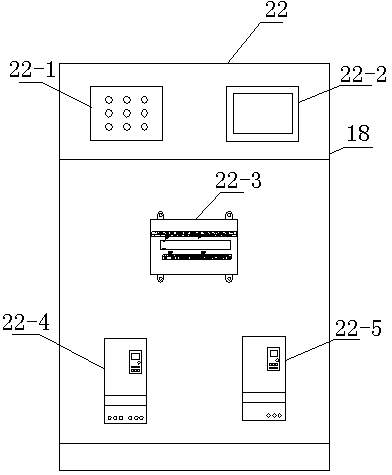

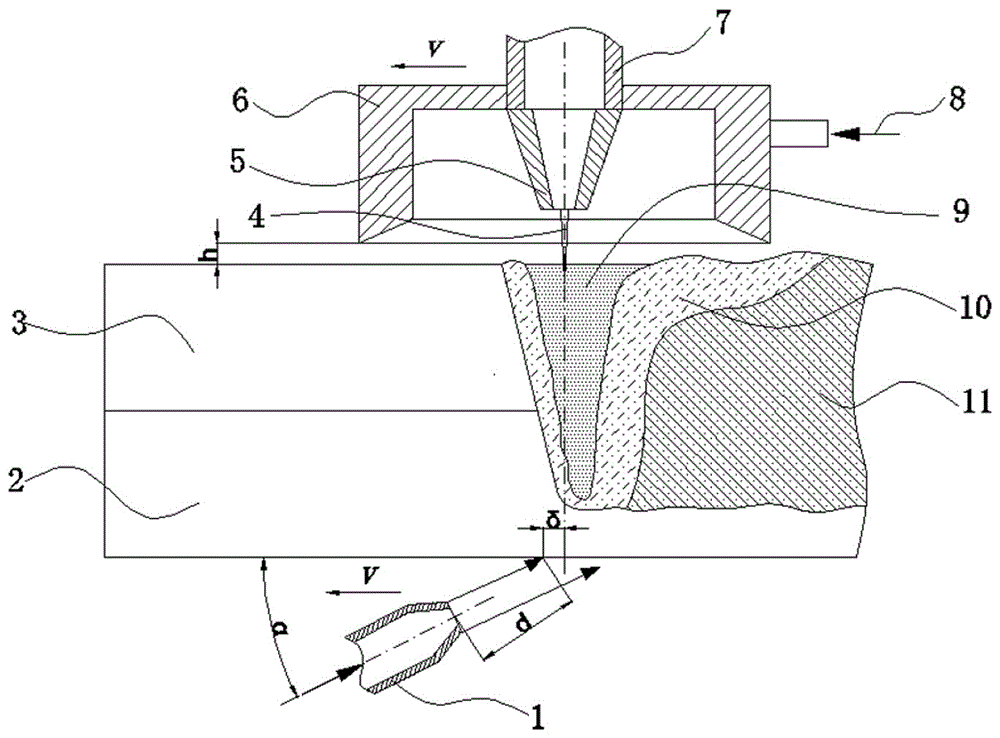

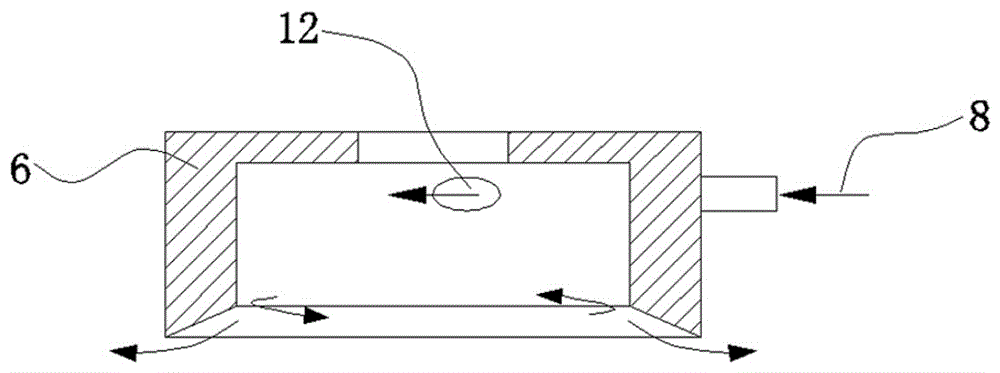

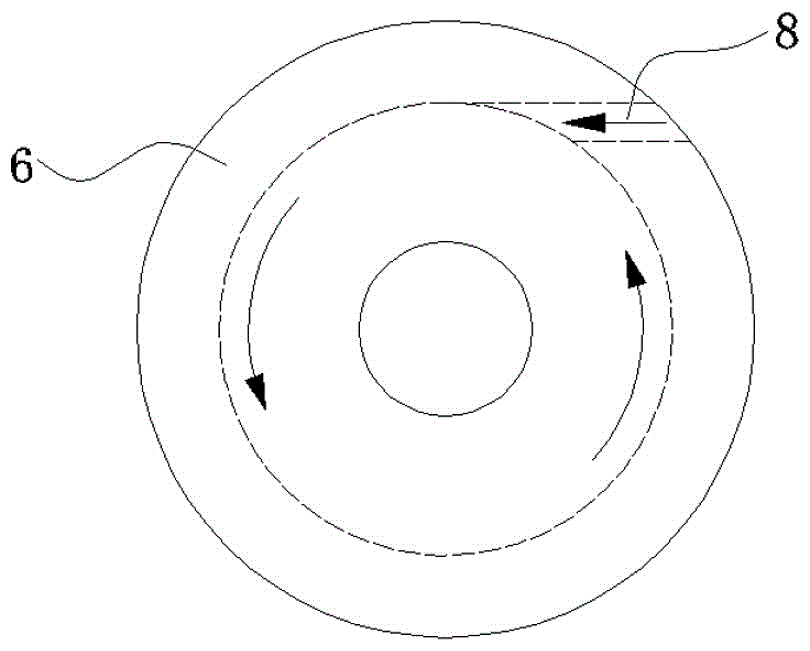

The invention discloses an electro-plastic two-roll mill of a low-temperature liquid nitrogen cooling medium. A rack (6) at the entrance of the two-roll mill is provided with two dragging tracks (12 and 12'); a track groove between the two dragging tracks (12 and 12') is internally provided with a feeding clamp (13); a cooling tank (14) is arranged below the rear ends of the two dragging tracks (12 and 12'); the rack (6) at the entrance of the two-roll mill is provided with a delivery guide (16); a collecting tank (4) is arranged below the delivery guide (16); a liquid nitrogen container (9) is arranged on a bracket (10) for fixing the rack (6); the negative electrode of an impulse power source (1) is connected with the upper plywood of the feeding clamp (13) by a cable (2), and the positive electrode of the impulse power source (1) is connected with a roll electrode (3) by the cable (2). In the rolling process by using the electro-plastic two-roll mill, the low-temperature liquid nitrogen is automatically sprayed on a rolled piece deformation zone; and the rolled piece is in the low temperature environment of minus 160 to minus 70 DEG C before the process of rolling processing, in the process of rolling plastic deformation, and after the process of rolling processing. Hard pulse current vertical to the deformation direction is imported into the rolled piece deformation zone between an upper roller and a lower roller, and the electro-plastic effect is used to reduce the deformation resistance of the rolled piece and improve plastic deformation capacity of the rolled piece, thus obtaining the rolled piece product with serious plastic deformation.

Owner:YANSHAN UNIV

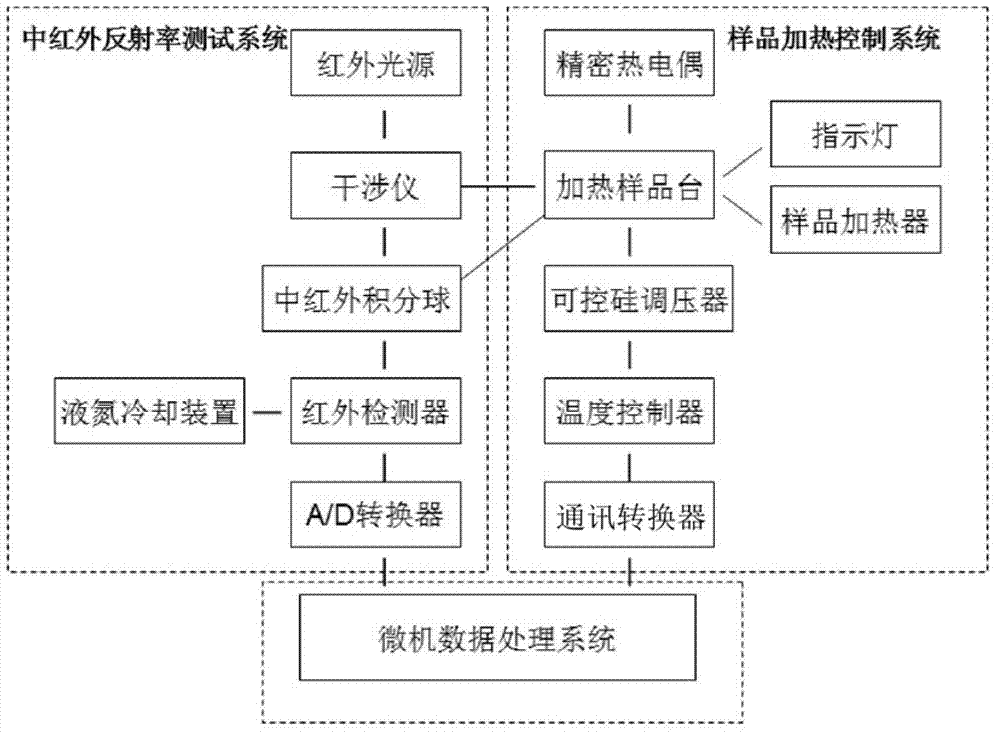

Middle/high-temperature infrared emissivity testing device

ActiveCN102830064AEasy to operateRelaxed test conditionsMaterial analysis by optical meansMaterial thermal analysisLiquid nitrogen coolingData treatment

The invention discloses a middle / high-temperature infrared emissivity testing device. The middle / high-temperature infrared emissivity testing device comprises an infrared reflectivity testing system, a sample heating control system and a microcomputer data processing system. The infrared reflectivity testing system comprises an infrared source, an interferometer, an intermediate infrared integrating sphere, an infrared detector, an A / D convertor and a liquid nitrogen cooling device. The sample heating control system comprises a sample heating table, a communication convertor, a temperature controller, a silicon-controlled voltage regulator, a sample heater and an indicator light, wherein the communication convertor, the temperature controller, the silicon-controlled voltage regulator, the sample heater and the indicator light are orderly connected. The temperature controller is connected to a precision thermocouple. The microcomputer data processing system is used for inputting preset parameters and acquiring and treating data. The middle / high-temperature infrared emissivity testing device is simple, can be used conveniently, can realize fast and accurate measurement of infrared emissivity of a material in a middle / high-temperature range of 20 to 600 DEG C, and can be used for the field of key development of middle / high-temperature solar photo-thermal coatings.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

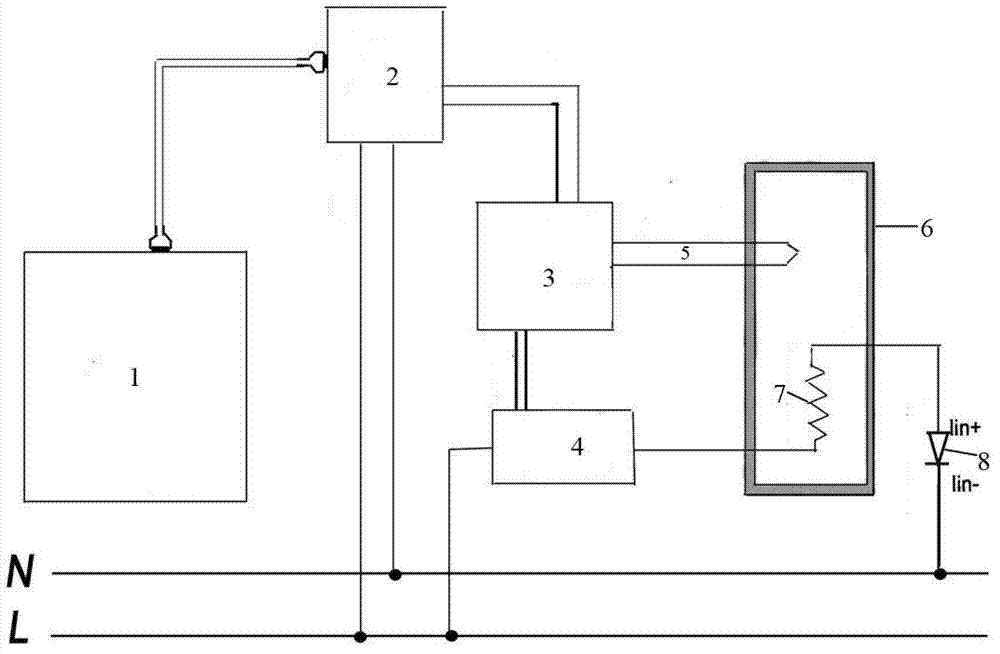

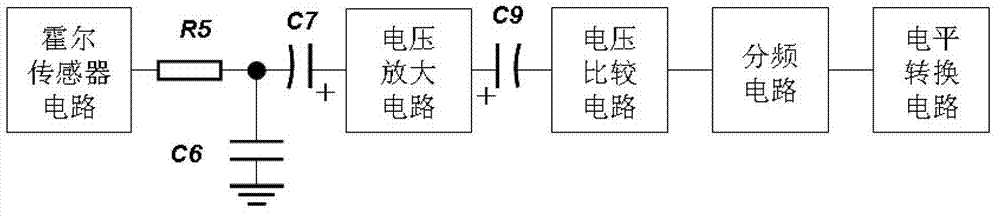

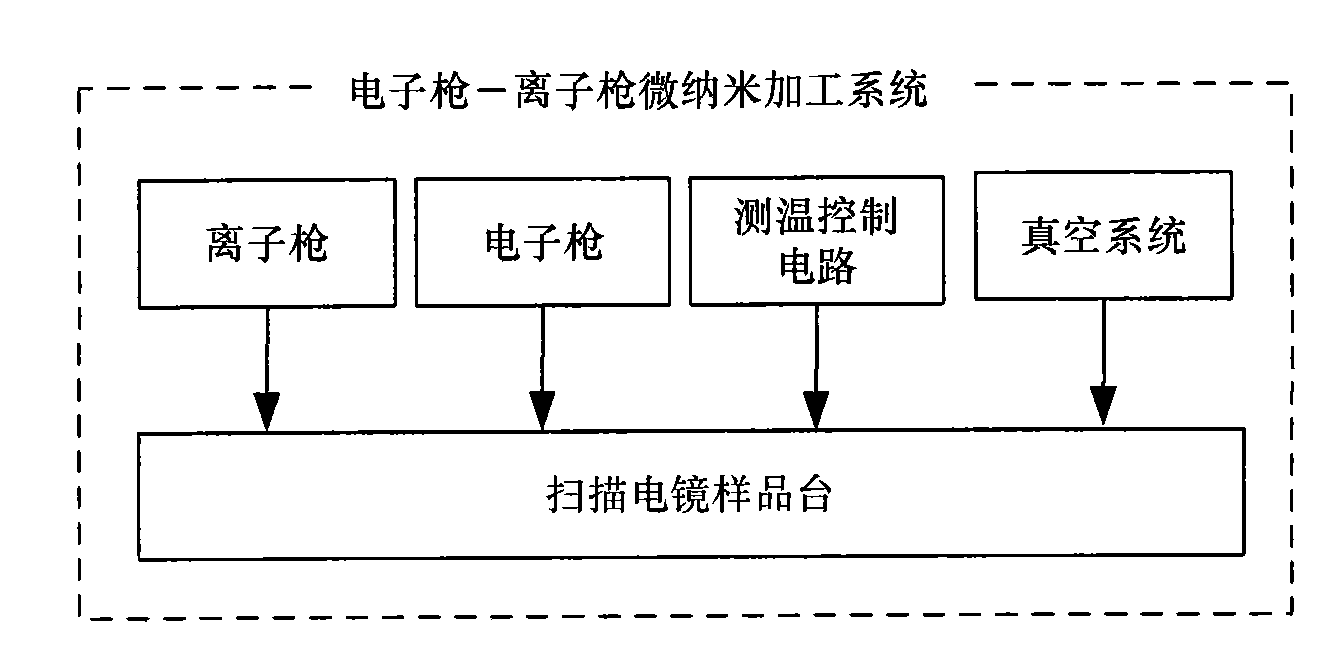

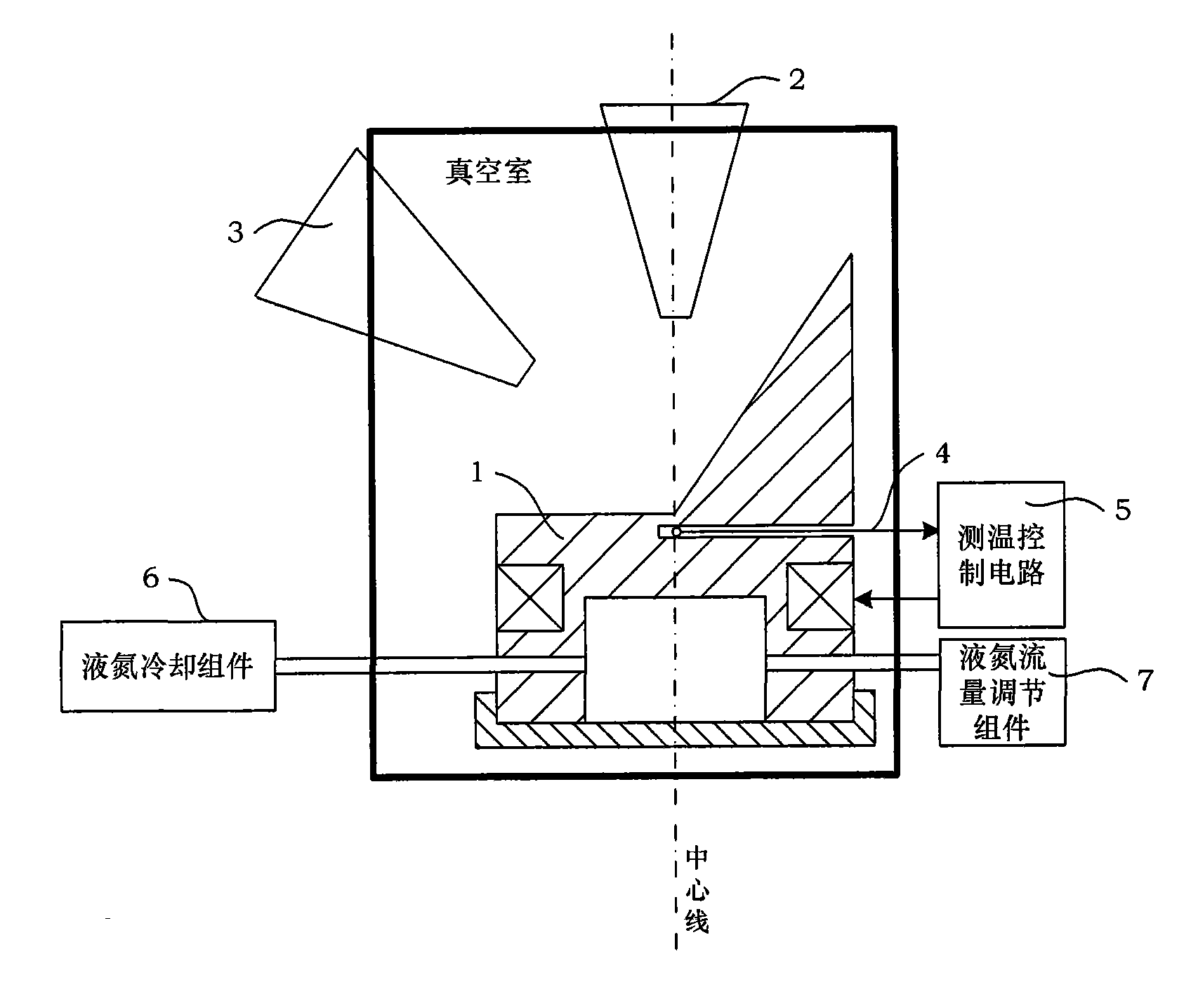

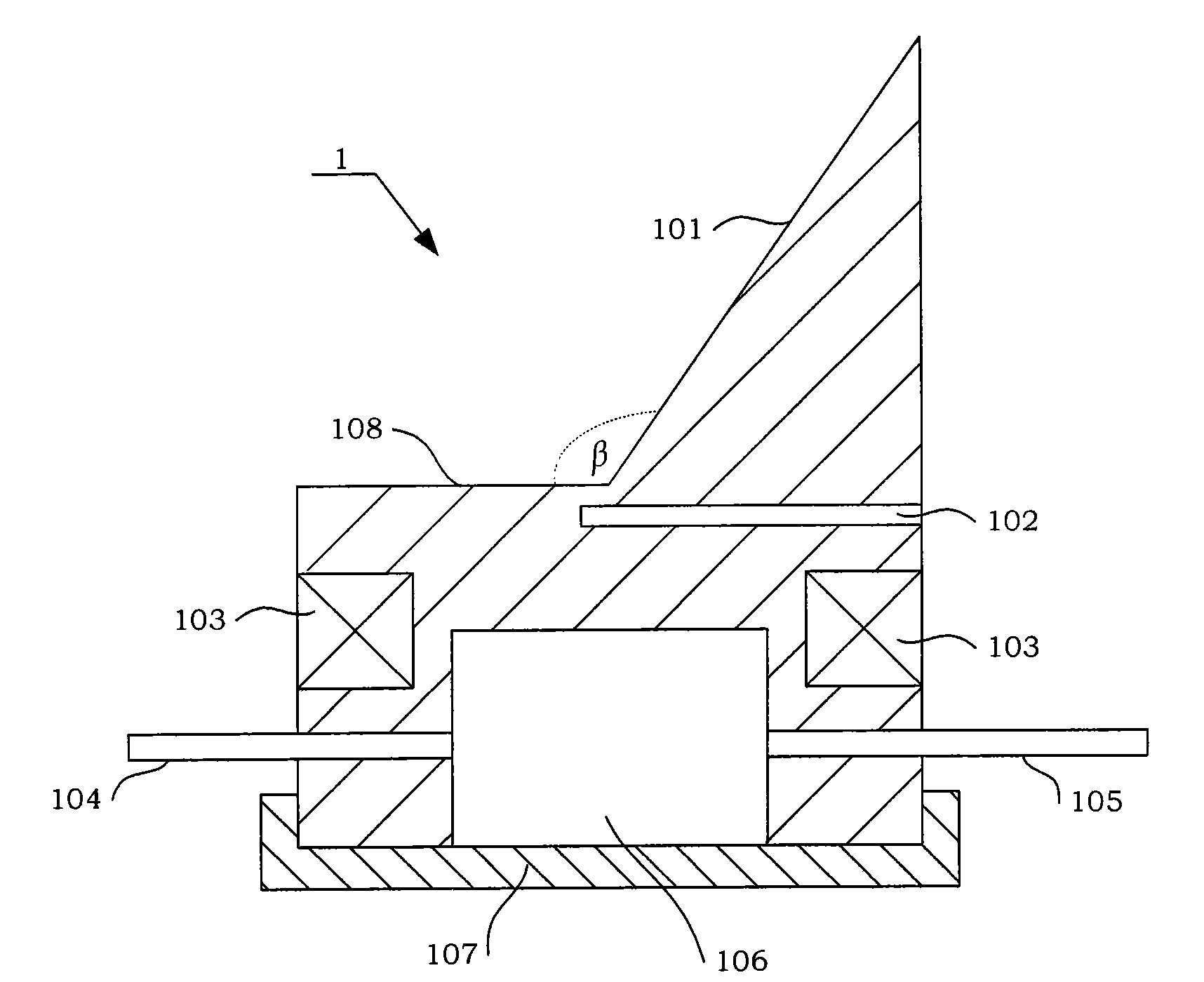

Controllable temperature sample table with controllable temperature range of 77K to 400K

InactiveCN101665236AClear imagingNo need to adjust the angleNanostructure manufactureTemperatue controlMicro nanoTemperature control

The invention discloses a controllable temperature sample table with the controllable temperature range of 77K to 400K, comprising a temperature control sample table and a liquid nitrogen cooling assembly, wherein the liquid nitrogen cooling assembly is used for providing a cooling medium to the temperature control sample table which is installed on a scanning electron microscope sample table; theliquid nitrogen cooling assembly is arranged outside a vacuum chamber; and in a processing course, the scanning electron microscope sample table is not tilted or rotated in a large range, thereby simplifying the operation step in processing micro nano materials. The temperature control sample table is used for continuously controlling the temperature of a sample to be measured by the common action of liquid nitrogen and coil heating. The controllable temperature range is from 77K to 400K and the temperature control precision is 0.1K.

Owner:BEIHANG UNIV

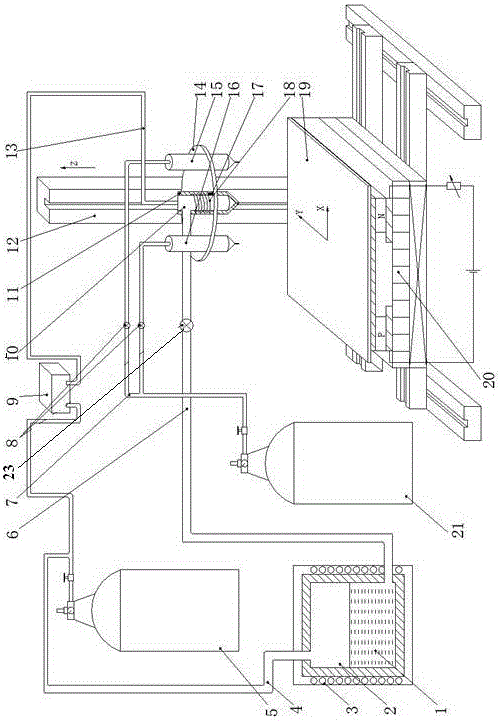

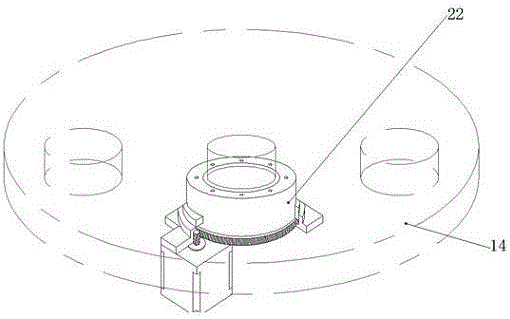

Preparation and forming integrated three-dimensional printing method and preparation and forming integrated three-dimensional printing device for amorphous alloy materials

ActiveCN105728728AGuaranteed amorphous propertiesAchieve preparationAdditive manufacturing apparatusSelective laser meltingManufacturing technology

The invention relates to a preparation and forming integrated three-dimensional printing method and a preparation and forming integrated three-dimensional printing device for amorphous alloy materials, belonging to the technical field of micro-droplet jetting material increase manufacturing and amorphous alloy preparation. Crystalline molten metal is directly jetted by using a metal droplet jetting material increase manufacturing technology; environmental cooling of a substrate before metal droplet jetting and deposition droplet cooling after the metal droplet jetting are realized by adopting a method of combining a rotatable double-jetting liquid nitrogen cooling device with a cold substrate; and by using a point-to-point cooling method for two times, the molten metal can be quenched and amorphized, and further the integration of preparation of the amorphous alloy materials and three-dimensional forming of a large-size complex structure are realized. According to the preparation and forming integrated three-dimensional printing method and the preparation and forming integrated three-dimensional printing device disclosed by the invention, the limit of a traditional preparation method of an amorphous alloy in a forming critical dimension of a bulk amorphous alloy is overcome; the defects of crystallization behavior and buckling deformation generated in the selective laser melting three-dimensional printing process of amorphous alloy powder are avoided; and the problem that the amorphous alloy materials are difficult to machine is solved, and the preparation and structure forming integrated three-dimensional printing of the amorphous alloy materials is realized.

Owner:JILIN UNIV

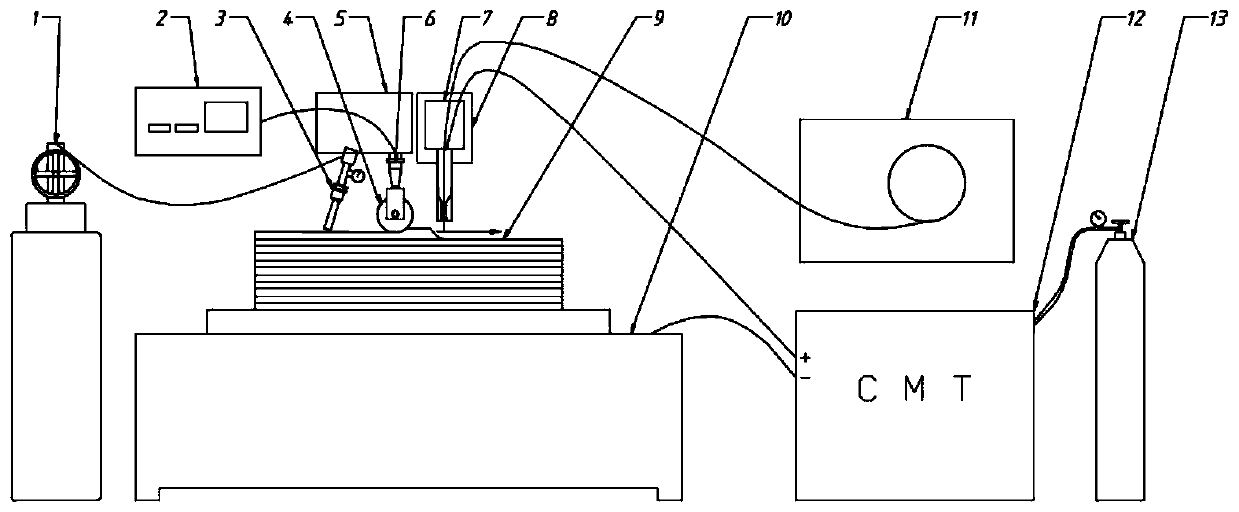

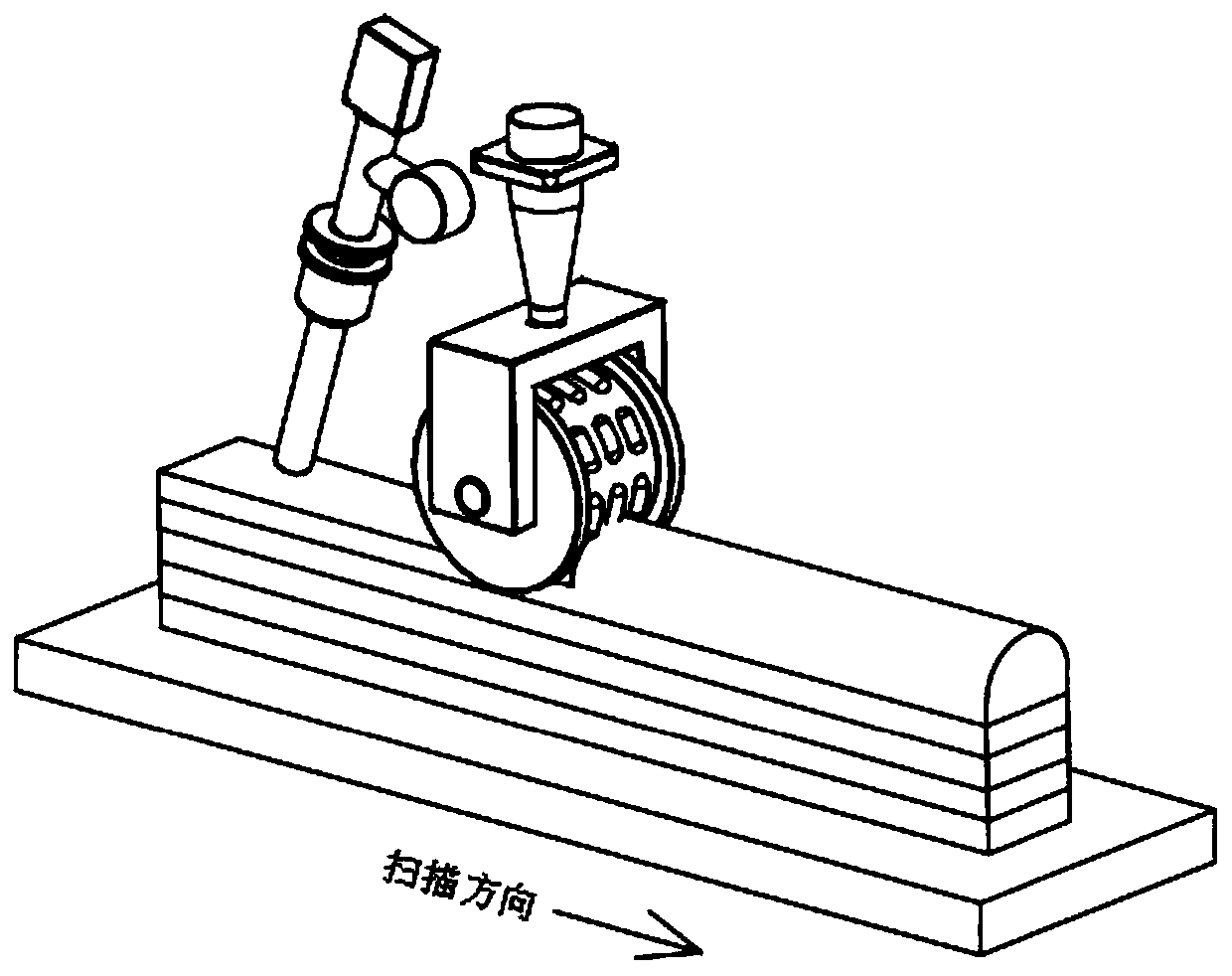

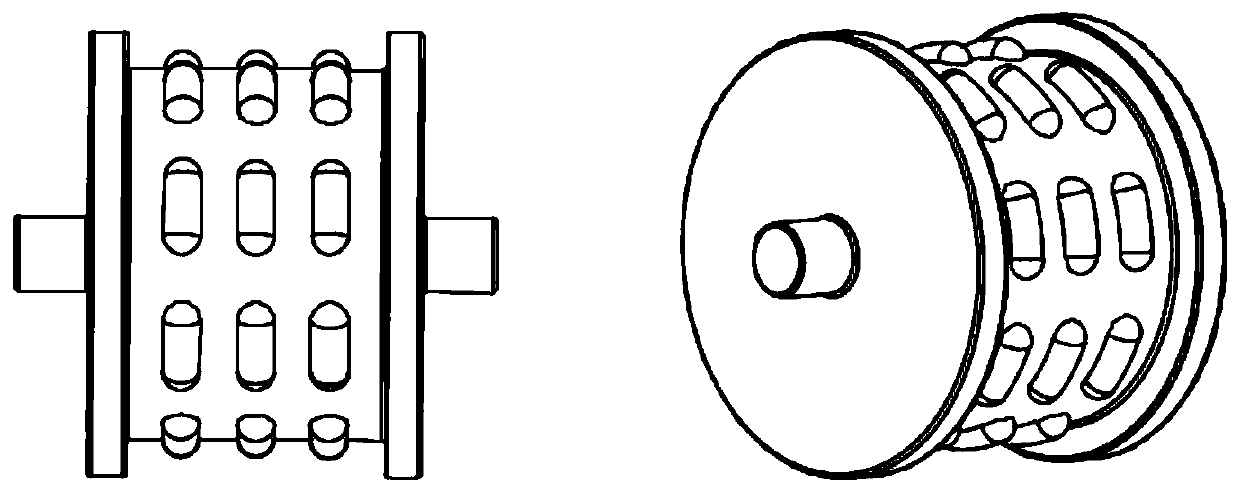

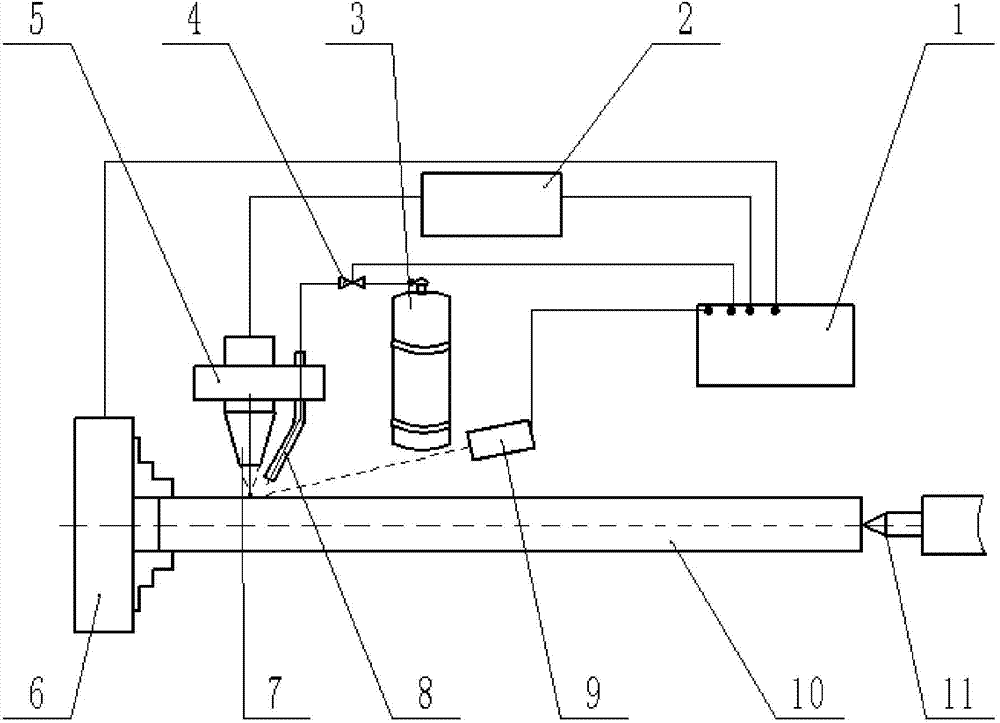

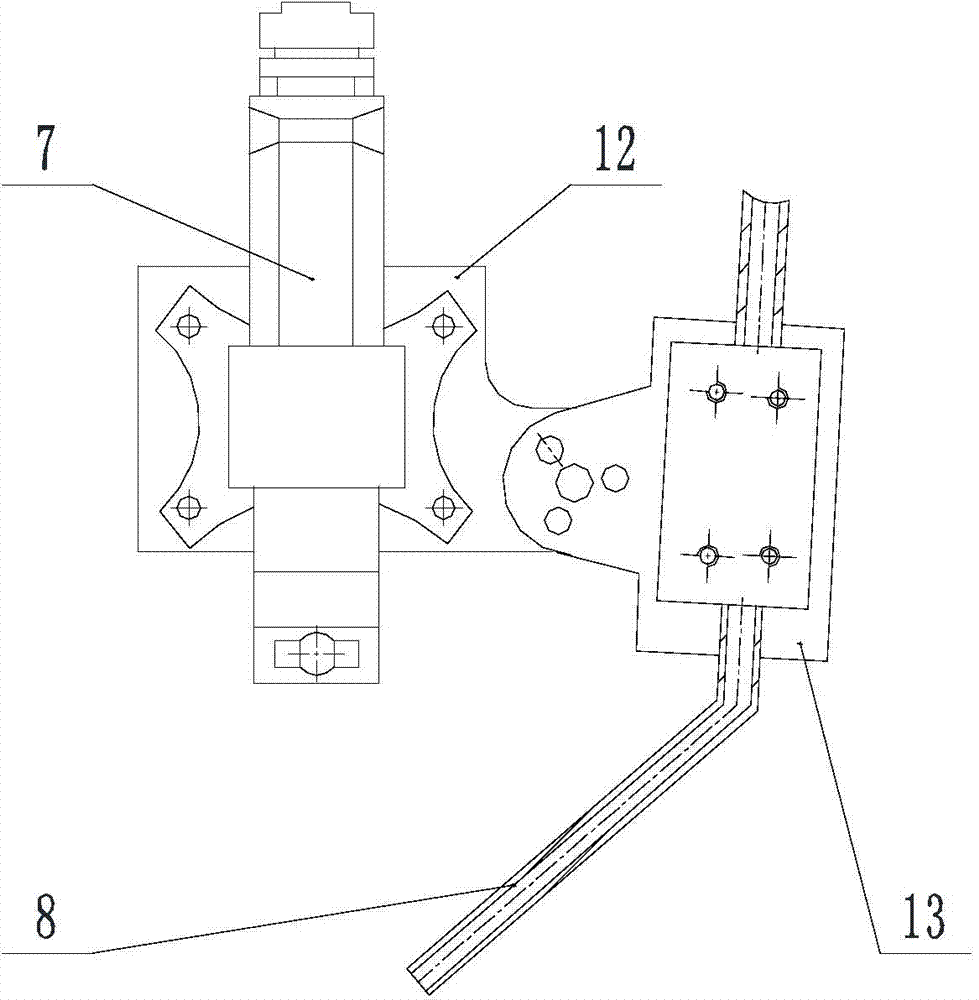

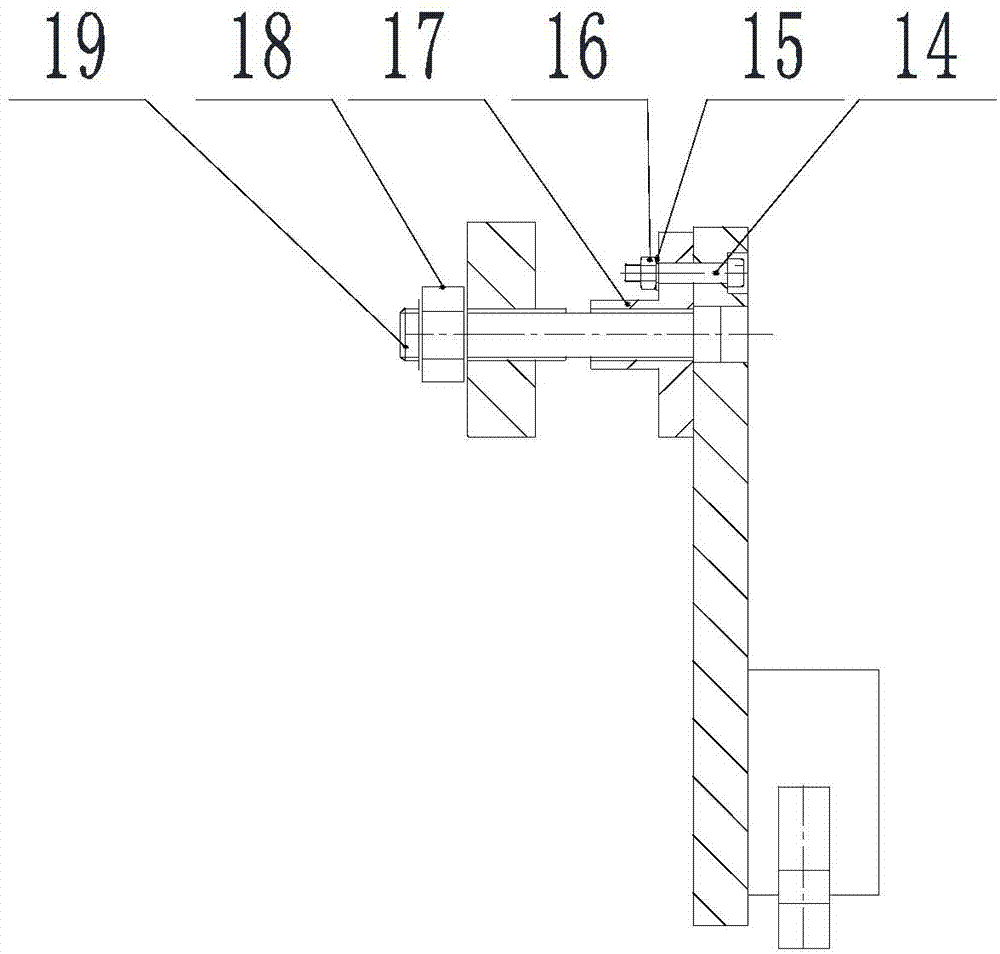

Wire arc additive manufacture (WAAM) synchronous ultrasonic hot rolling and quick cooling combined processing device and method

ActiveCN111215898ASolve the problem of rapid coolingImprove performanceAdditive manufacturing apparatusOther manufacturing equipments/toolsLiquid nitrogen coolingEngineering

The invention discloses a wire arc additive manufacture (WAAM) synchronous ultrasonic hot rolling and quick cooling combined processing device and method and belongs to the technical field of 3D printing. The combined processing device mainly comprises an additive manufacturing device, an ultrasonic vibration hot rolling device and a liquid nitrogen cooling device. During the WAAM process, an ultrasonic vibration profile roller is added; according to the forming characteristics of WAAM, the roller is designed into three different forms of profile rollers, namely, the dot-matrix profile roller,the screw type profile roller and the bevel gear type profile roller. The combined processing device adopts ultrasonic impact to impact the profile roller and the liquid nitrogen cooling device. Through the processing method of the combined processing device, the internal porosity of a WAAM formed part is reduced, the influence of heat accumulation is reduced, grains are refined, and accordingly,the mechanical performance is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

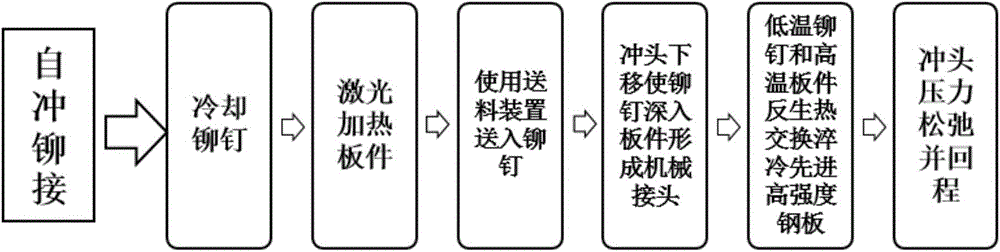

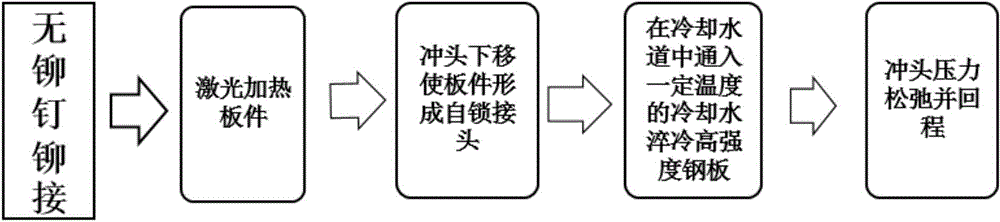

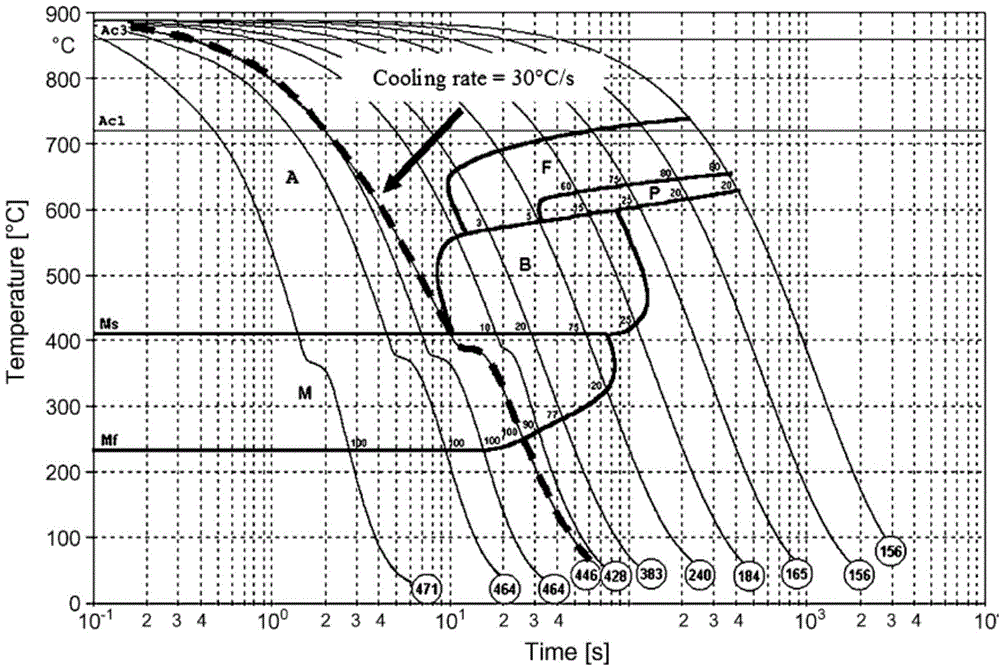

Riveting method of ultrahigh strength steel plates or aluminum alloy plates

The invention discloses a riveting method of ultrahigh strength steel plates or aluminum alloy plates and aims to solve the problems that ultrahigh strength steel plates cannot be riveted and joints are difficult to effectively weld since rigid and crispy metallic compounds occur to welding spots when the ultrahigh strength steel plates and the aluminum alloy plates are under spot welding. The riveting method includes the steps of 1, performing liquid nitrogen cooling on rivets in a cooling chamber before riveting so as to cool the rivets to below 0 DEG C; 2, placing an upper plate and a lower plate on a first compound female die, and holding down the upper and lower plates with a first compound binder ring; 3, heating riveting areas of the upper plate with a first fiber-optic heater to a threshold; 4, heating riveting areas of the lower plate with a second fiber-optic heater to a threshold; 5, feeding the low-temperature rivets to a central light through hole of the first compound binder ring, and pressing the rivets for riveting with a first compound punch; 6, co-pressing the rivets with the first compound punch and the first compound female die to turn out ring feet of the rivets to obtain rivet fasteners; 7, releasing the first compound punch to allow it to move up and return.

Owner:JILIN UNIV

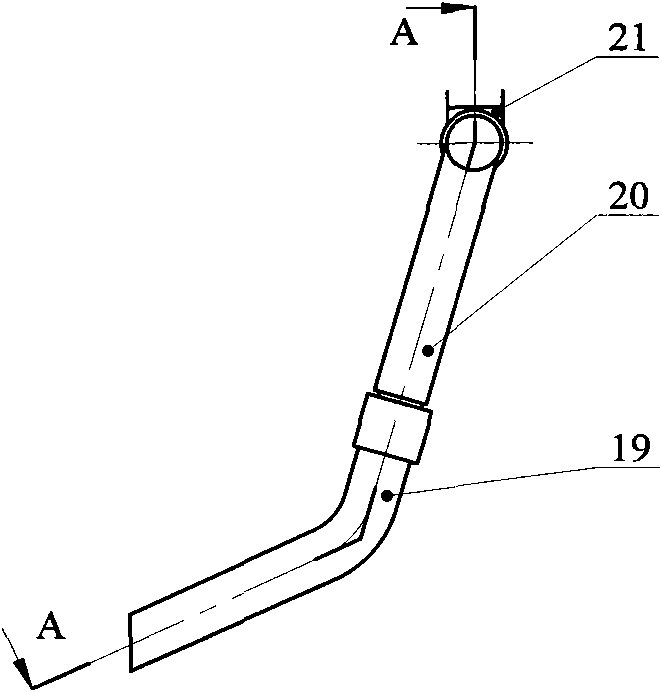

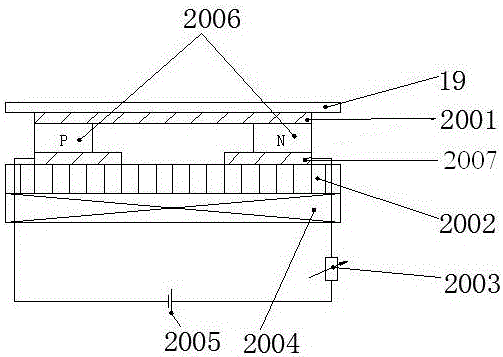

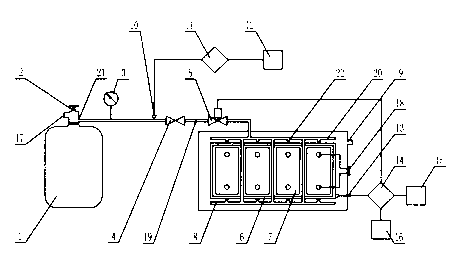

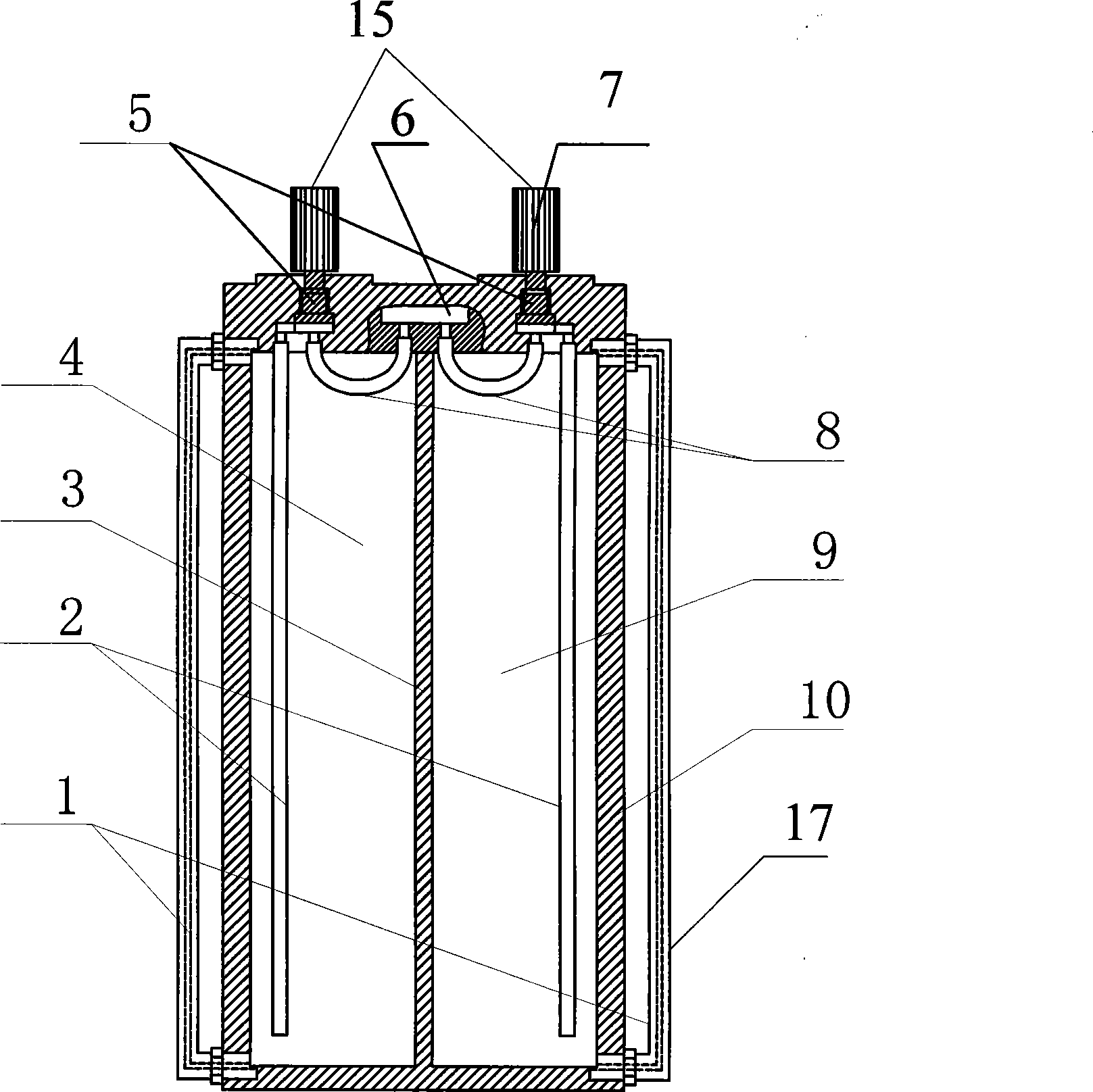

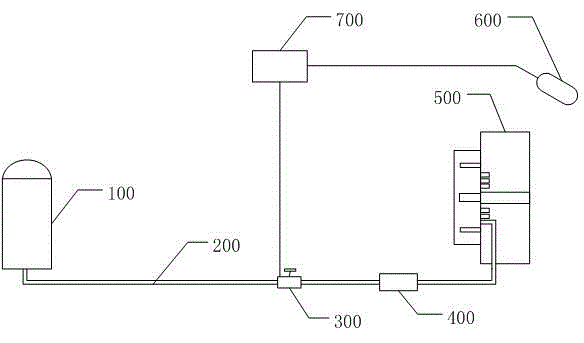

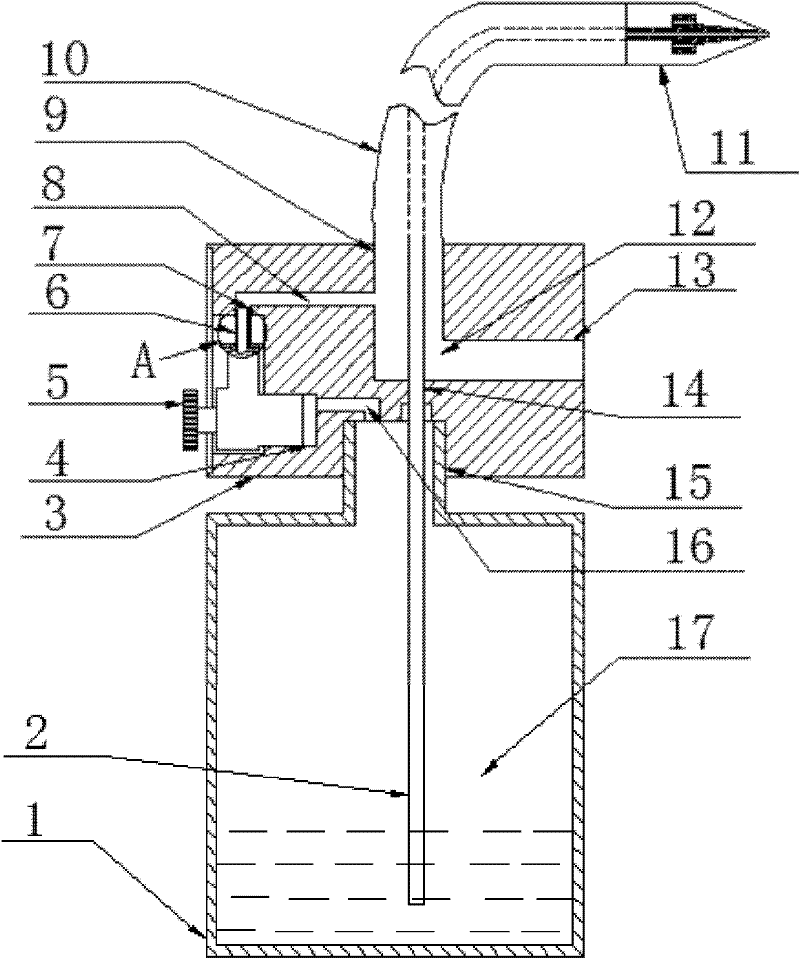

Liquid-nitrogen cooling method and device for automotive power battery pack

ActiveCN102760920AImprove performanceGuaranteed powerSecondary cellsPropulsion coolingPower batteryLiquid nitrogen cooling

The invention relates to a battery cooling method and a battery cooling device, in particular to liquid-nitrogen cooling method and device for an automotive power battery pack. The liquid-nitrogen cooling method for the automotive power battery pack includes directly releasing liquid nitrogen to the surface of the power battery pack and a casing of each battery cell to convert the liquid nitrogen into gas nitrogen, and cooling the surface of the power battery pack and the casing of each battery cell by absorbing a substantial amount of heat in process of converting the liquid nitrogen from liquid into gas. The liquid-nitrogen cooling device for the automotive power battery pack comprises a liquid nitrogen tank (1), a cooling container (8), a connecting pipeline (19), a cooling passage (20), a nitrogen exhaust port (9) and the like. The liquid nitrogen tank (1) is communicated with the cooling passage (20) arranged in the cooling container (8) through the connecting pipeline (19). The liquid-nitrogen cooling method and device for the automotive power battery pack are good in cooling effect, free of consumption of electric energy of the power battery pack, environment-friendly and energy-saving. The cooling method is simple and easy to implement. The cooling device is small in size, the structure is simple and stable, noise and vibration can be avoided, cooling stability is good, and safety is high.

Owner:上海奇可网络科技有限公司

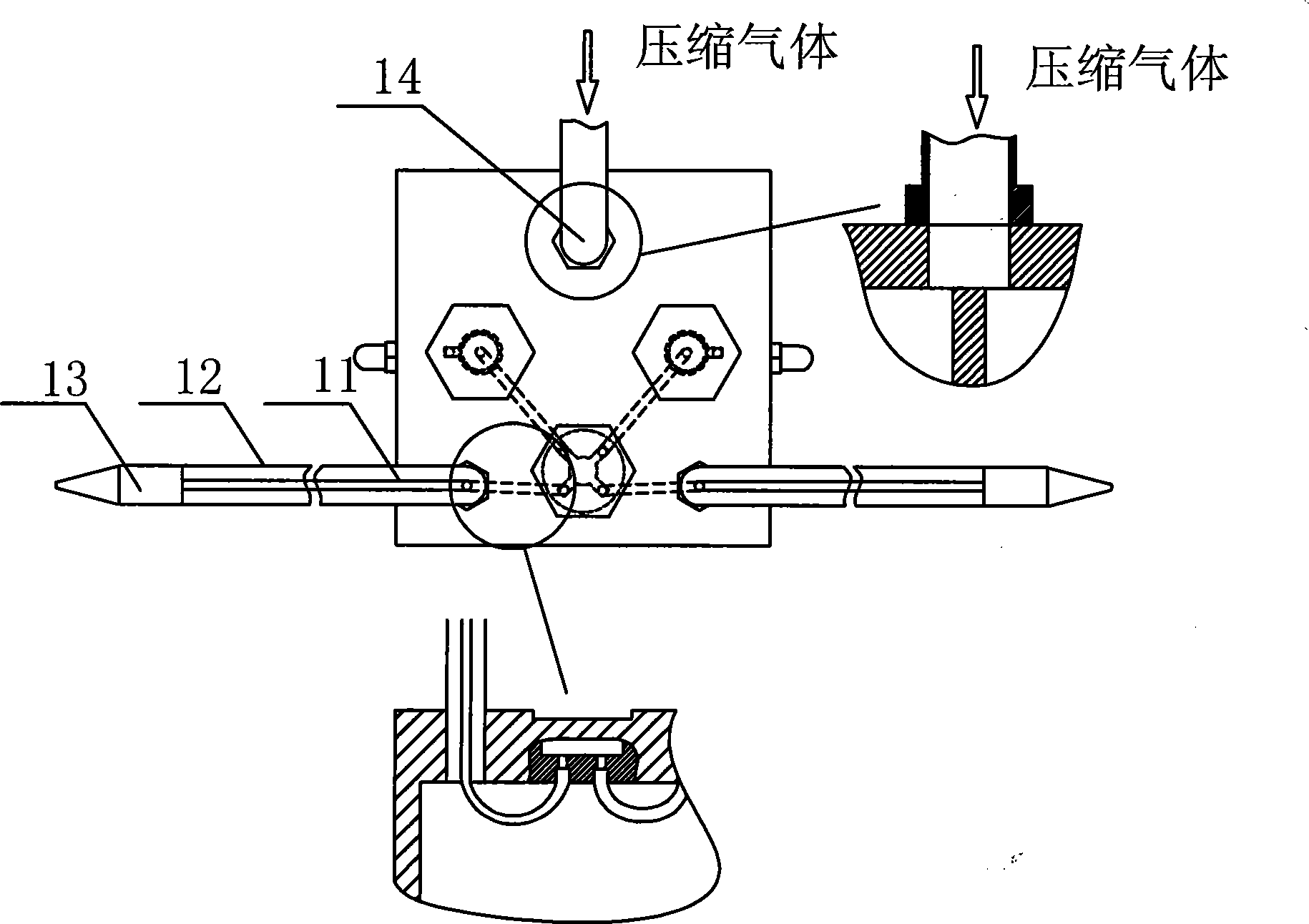

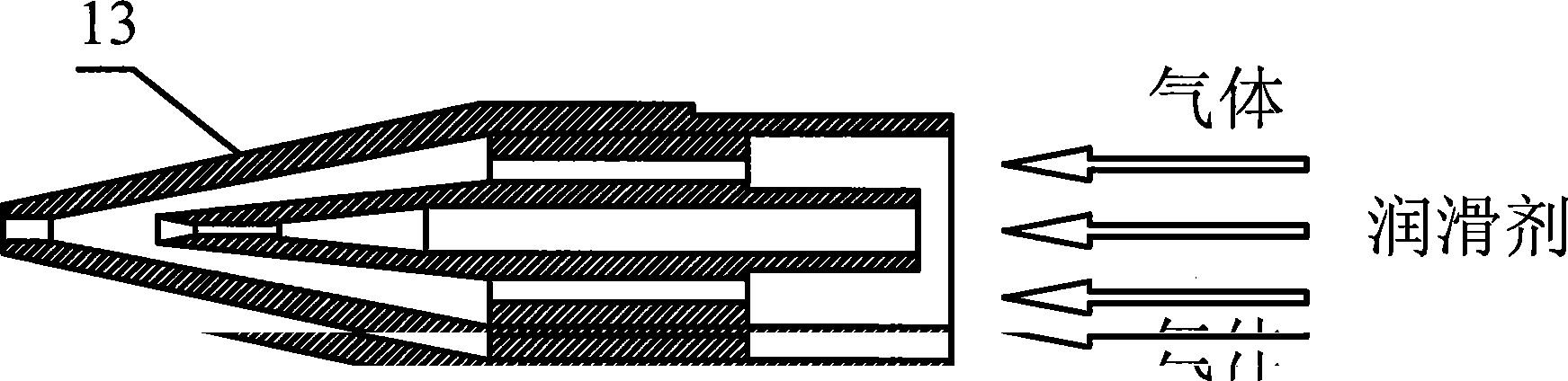

Near dry cutting liquid supply apparatus

InactiveCN101244520ARealize the effect of dust removalLubricating effect is sufficientMaintainance and safety accessoriesResource consumptionLiquid nitrogen cooling

The invention relates to a quasi-dry cutting liquid supply device, which comprises a plurality of chamber walls, a chamber, a partition, an adjusting valve, a hybrid chamber, a drain pipe, a liquid guide pipe, an inner pipe, an outer pipe, an inlet for compressed gas, and a nozzle; wherein, the partition divides the chamber into two sub-chambers for respectively holding different lubricants, which enter the pipeline under the action of the compressed gas, and the quantity of the lubricants can be selected by means of the adjusting valve; the inner pipe and the outer pipe form a double-layer tubular structure, and the nozzle also adopts a double-layer structure. The device can be used as a liquid supply device for oil-less lubrication, low temperature cutting, and liquid nitrogen cooling and process, and can regulate the usage quantity of the lubricants in a reasonable manner. The liquid supply device in the invention has the advantages of simple structure, low costs, less resource consumption, and suitability for mass production. Moreover, by using the nuisance and pollution-free green lubricants, the liquid supply device effectively solves the problems in the prior liquid supply systems, such as large usage of cutting liquid, difficulty in controlling, and severe environmental pollutions.

Owner:BEIHANG UNIV

Method and device for liquid nitrogen cooling of aluminum profile extrusion die

The invention discloses a method and a device for liquid nitrogen cooling of an aluminum profile extrusion die. According to the method and the device, a channel is opened on an extrusion die cushion according to the shape of the cross section of the die cushion, liquid nitrogen is input into the channel during the extrusion process of profiles, the liquid nitrogen cooling process is controlled by a closed ring control system, and the temperature of an extrusion die is controlled at 440-480 DEG C. With the method and the device for liquid nitrogen cooling of an aluminum profile extrusion die, the problems that the product quality is lowered and the extrusion efficiency is low caused by overhigh temperature during extrusion of aluminum alloy profiles are avoided, the extrusion speed of the die is improved by 10-50 percent, the service life of the die is prolonged, and meanwhile, the product quality is improved, the dimension precision of aluminum profiles machined is higher, the surface smoothness is better, and the rejection rate is reduced.

Owner:佛山市三水凤铝铝业有限公司 +1

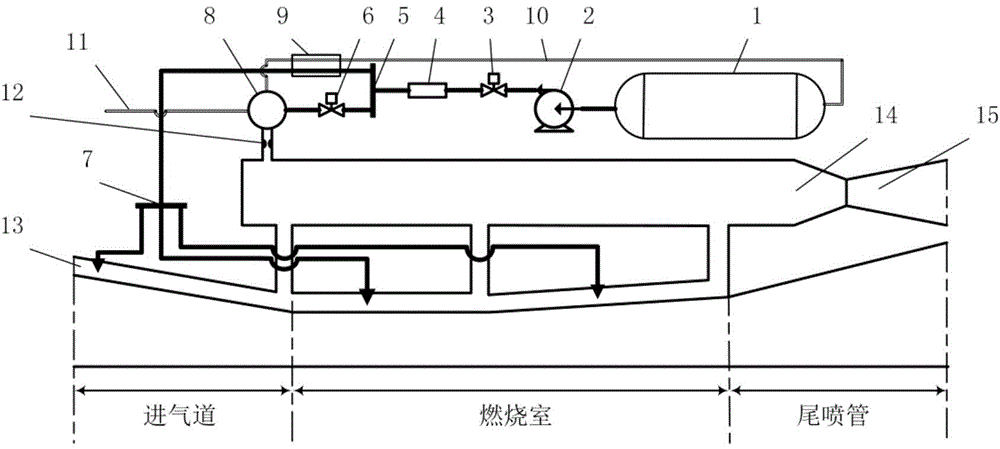

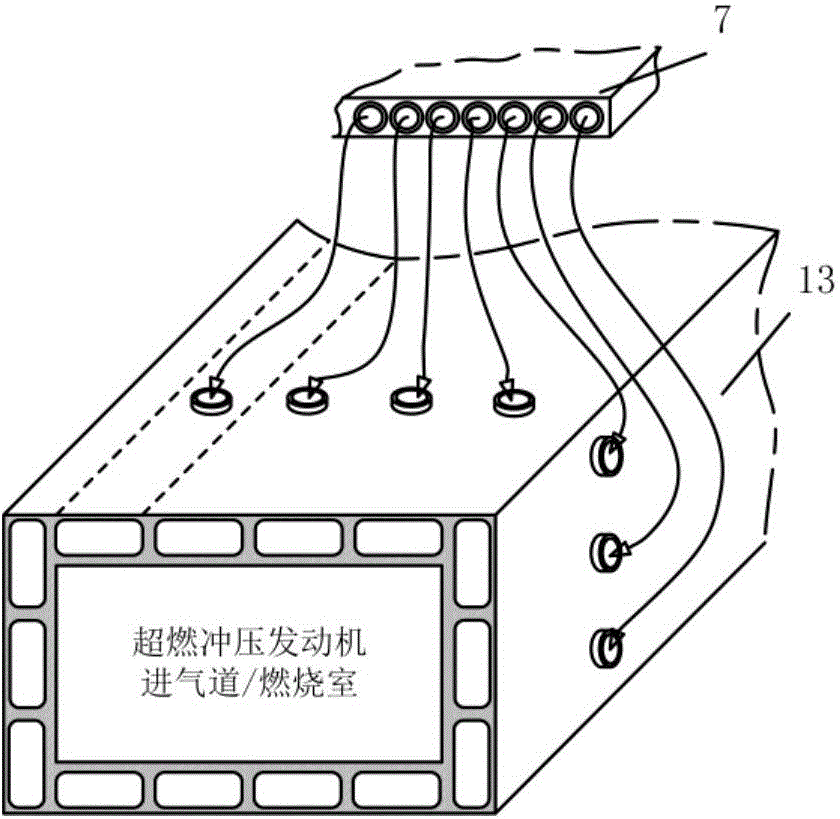

Liquid-nitrogen cooling system of scramjet engine

InactiveCN104989550ASolve the cooling problemImprove securityRam jet enginesLiquid nitrogen coolingAttitude control

The invention discloses a liquid-nitrogen cooling system of a novel scramjet engine. The liquid-nitrogen cooling system is combined with the scramjet engine through a heat structure, and the system mainly comprises a liquid nitrogen supply device, a high-pressure air source generation device, an engine casing pipe type heat exchange panel, a high-pressure gas collection chamber and a movable spraying pipe. The liquid-nitrogen system mainly executes three masks including (1) solving the problems in heat dissipation of the scramjet engine; (2) serving as a secondary power device so as to assist a hypersonic vehicle in acceleration and attitude control; and (3) providing low-temperature high-pressure nitrogen for subsystems of cabin environment control, fire prevention and the like. The liquid nitrogen serves as a low-temperature refrigerant so as to have the higher heat sink capacity, the wall face of the engine can be fully cooled, and in the cooling process of the liquid nitrogen, chemical cleavage does not exist; compared with a traditional system, refrigeration cooling is easily achieved; and the reliability and safety of the system are higher. The ultrahigh heat flow of the wall face of the scramjet engine will make the liquid nitrogen to achieve phase changes and expansion sufficiently, and the efficient auxiliary power is provided for an aircraft.

Owner:BEIHANG UNIV

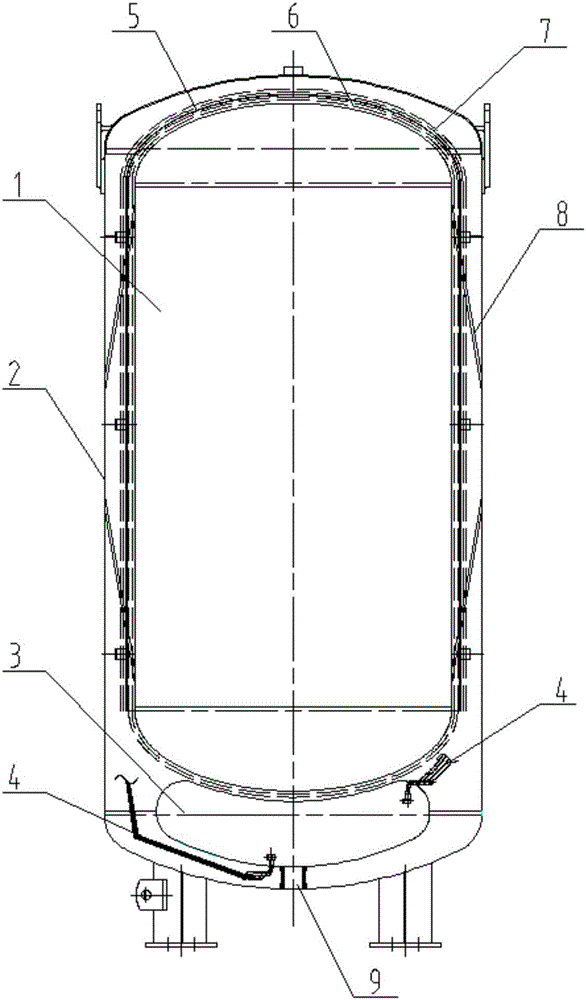

Vertical container used for storing low-temperature liquid

ActiveCN106015921AIncrease the lengthReduce lossVessel geometry/arrangement/sizeVessel wallsLiquid nitrogen containerHeat flow

The invention discloses a vertical container used for storing low-temperature liquid. The vertical container comprises a shell provided with a seal cavity, an inner container mounted in the cavity and used for storing the low-temperature liquid and a cold source container used for storing liquid nitrogen; the outer side of the inner container is coated with a liquid nitrogen cold shield, a liquid nitrogen cooling pipe is arranged on the liquid nitrogen cold shield, and the liquid nitrogen cooling pipe and the cold source container are communicated to form a liquid nitrogen circulation loop; and the vertical container mainly adopts a heat insulation manner combining vacuum multi-layer heat insulation with the liquid nitrogen cold shield to reflect the excellent heat insulation performance. An inner container used for storing liquid nitrogen media is arranged in the vertical container, the independent liquid nitrogen cold source container and the independent liquid nitrogen cold shield are arranged, through dissipation of liquid nitrogen in the cold source container, the heat wall temperature of the liquid nitrogen container is reduced to 77 K from 300 K, the radiant heat flux is reduced to 1 / 150 to 1 / 200 of the original flux, and therefore the aim of greatly reducing the daily evaporation rate loss of the container is achieved.

Owner:ZHANGJIAGANG FURUI HYDROGEN ENERGY EQUIP CO LTD

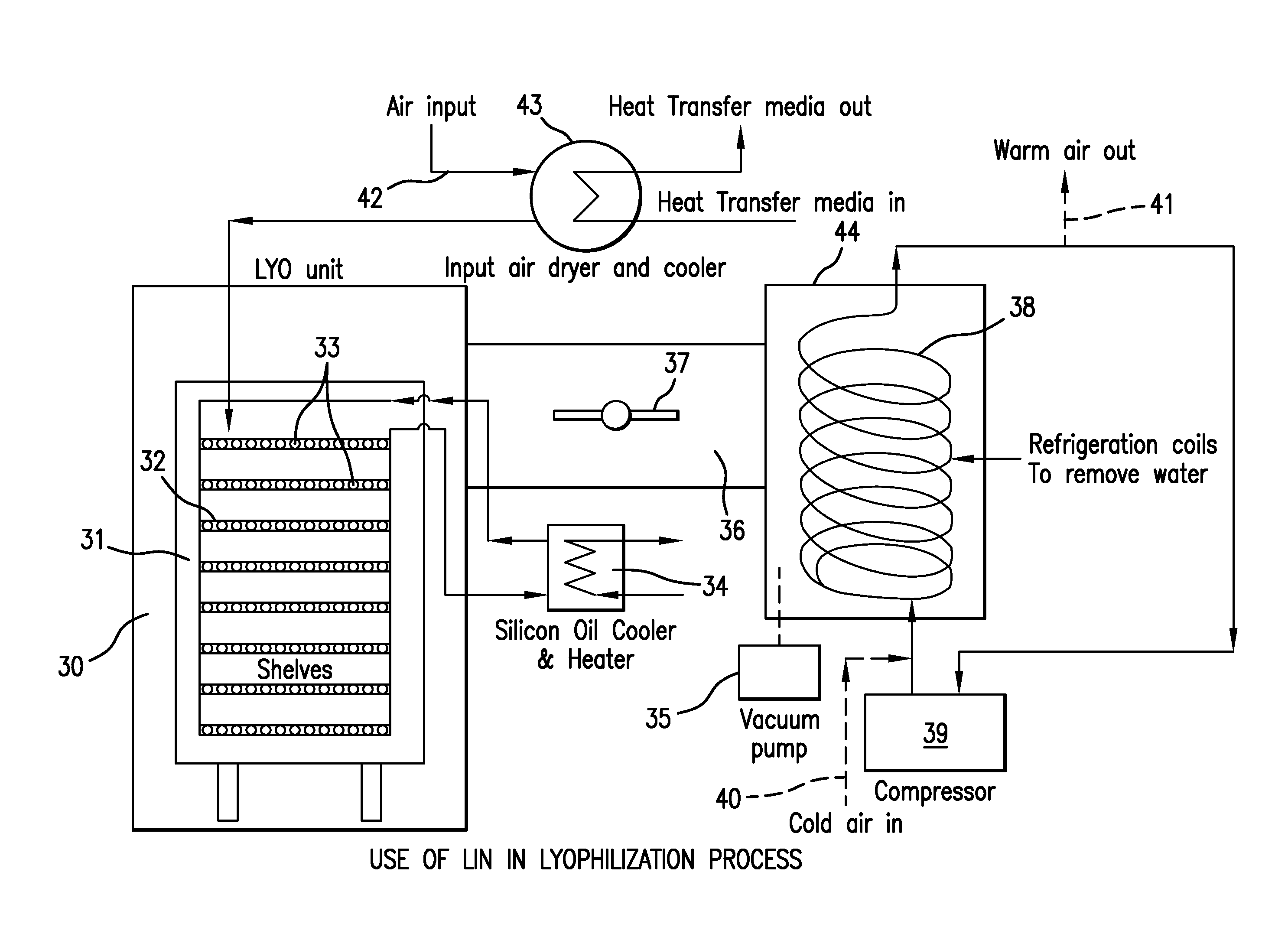

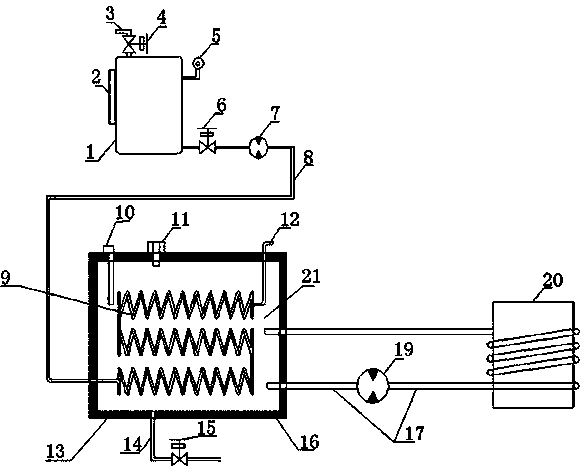

Lyophilization unit with liquid nitrogen cooling

InactiveUS20060277926A1Reduce needImprove productivityMilk preservationWort preparationCold airLiquid nitrogen cooling

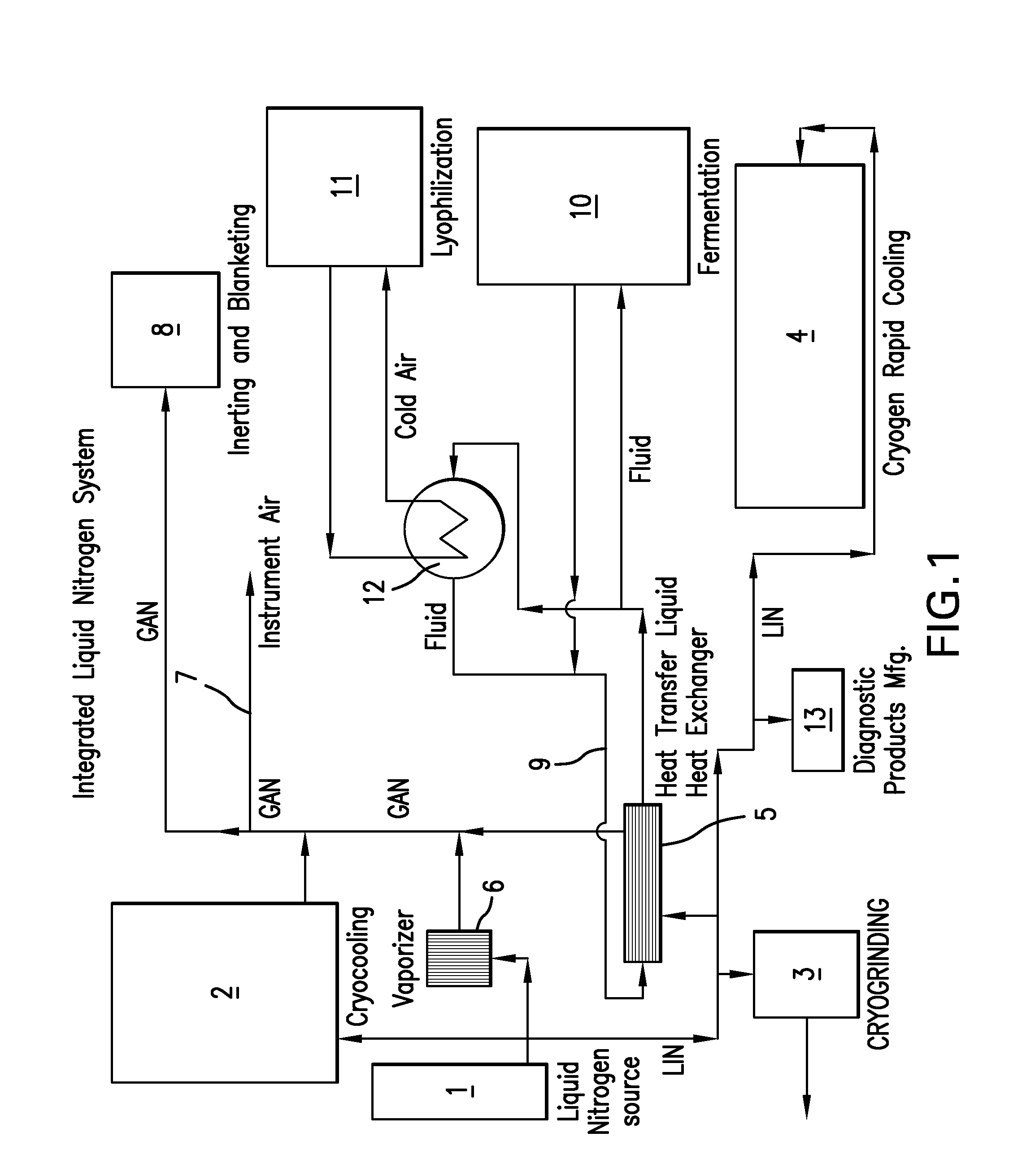

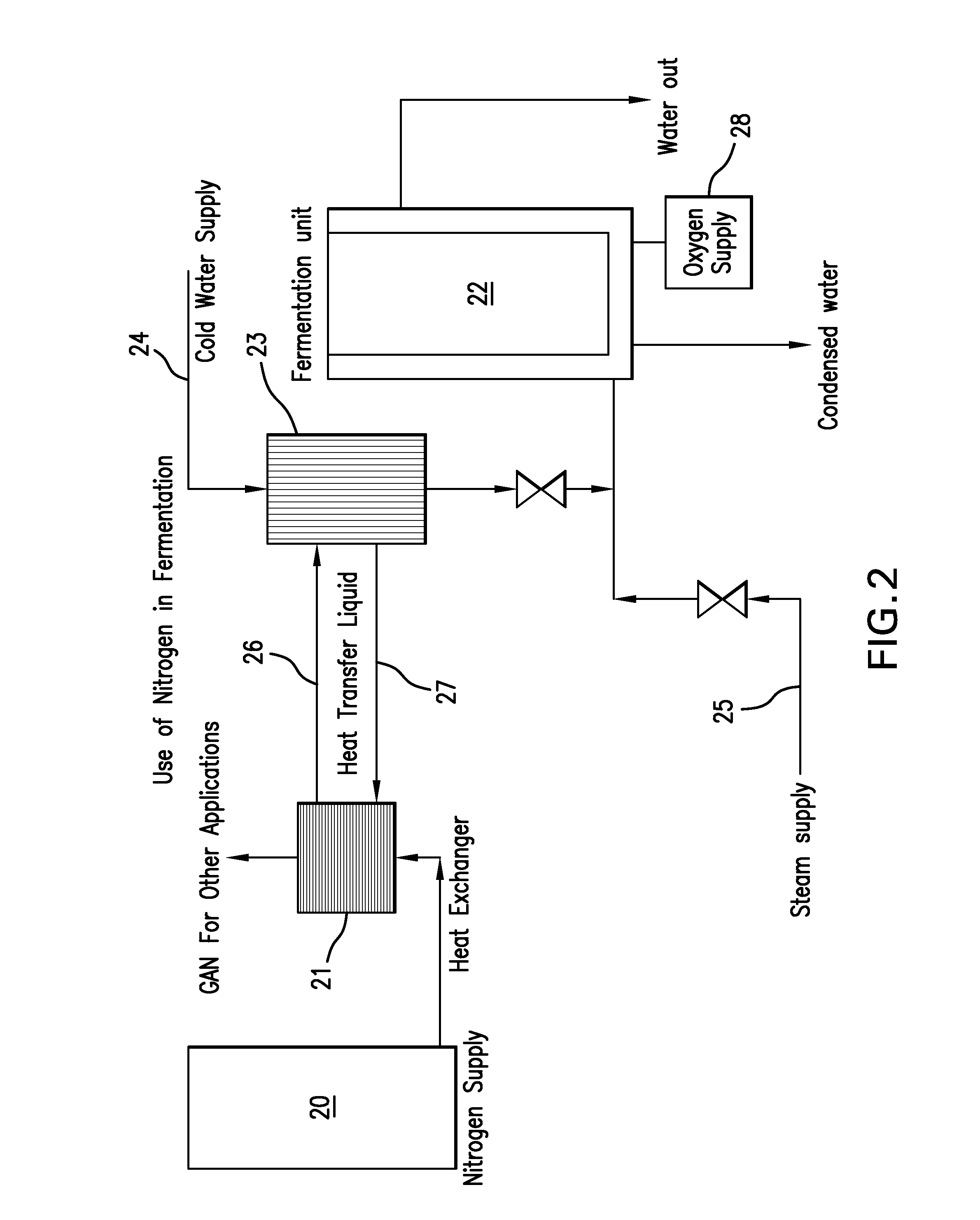

An integrated industrial plant includes various systems, all of which use a cryogenic liquid obtained from a common source. One system includes a fermentation unit, in which cold air, chilled by heat exchange with the cryogenic liquid, absorbs excess heat generated by the fermentation. Another system is a lyophilization unit, in which a refrigeration step is performed through the use of air that has been chilled by heat exchange with the cryogenic liquid. Another system is a device for freezing discrete samples of biological products, the samples being frozen by partial immersion in the cryogenic liquid. The invention substantially reduces the use of electric power, and provides systems which operate economically and reliably.

Owner:AIR LIQUIDE AMERICA INC

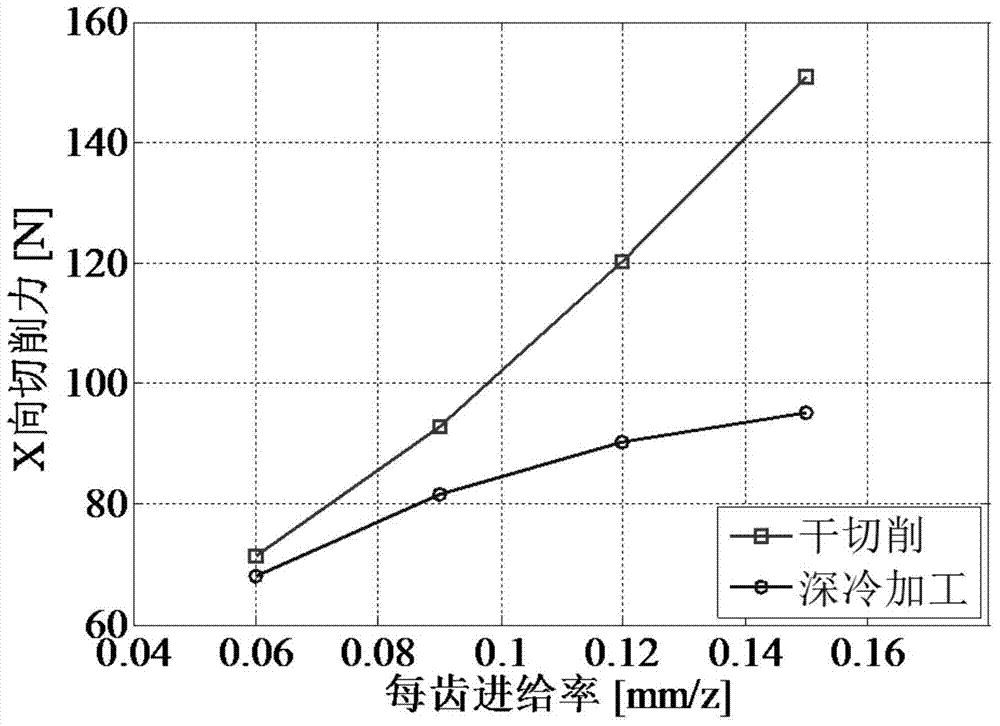

Metallic cryogenic tempering method for improving milling stability

ActiveCN104493636AHigh removal rateImprove damping effectMeasurement/indication equipmentsAdverse effect compensationProcess systemsMaterial removal

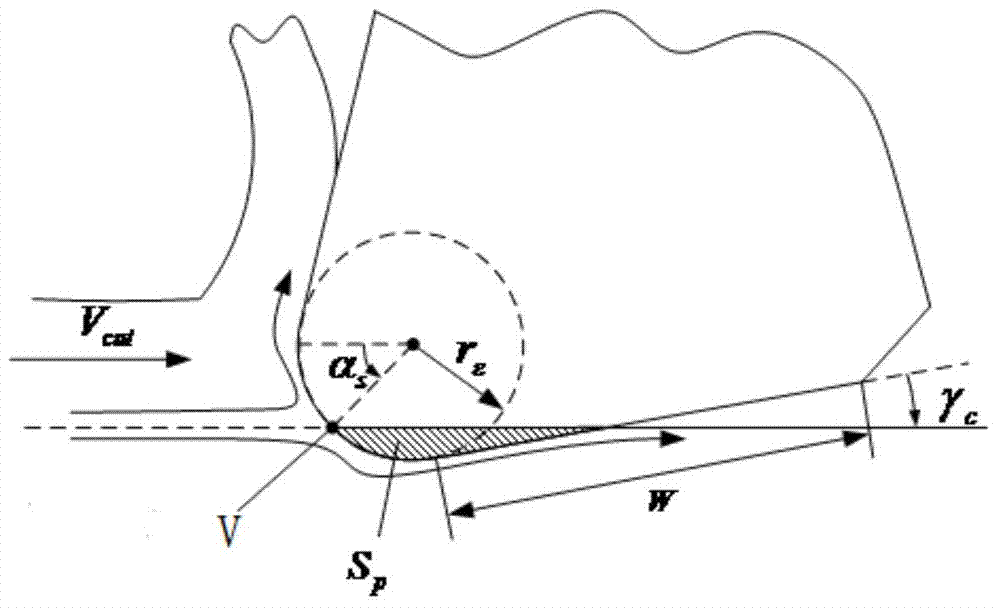

The invention discloses a metallic cryogenic tempering method for improving milling stability. The method includes: (a), assembling a liquid nitrogen cooling nozzle, synchronously moving with a milling machine spindle and an end mill, to the milling machine spindle and the arranged end mill; (b), executing climb milling under the condition of cryogenic cooling, and performing experiment calculation to obtain cutting force coefficients of tangential milling force coefficients, tangential cutting edge force coefficients, radial milling force coefficients, radial cutting edge force coefficients and the like; (c), executing hammer test on a point of a milling cutter, acquiring a corresponding displacement frequency response function based on test result fitting, and extracting modal parameters such as modal mass, modal damping and modal stiffness; (d), constructing a two-degree-of-freedom milling dynamics equation, then predicating stability boundaries in the metal milling process based on the dynamics equation, and correspondingly adjusting the milling parameters. By the method, the problems of cutting heat and cutting process system unstability can be solved comprehensively, and the maximum chatter-free material removal rate of cryogenic tempering is significantly increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Equipment for puffing garden stuff with air current and microwave

InactiveCN101480245AImprove low temperature air puffingImprove microwave puffingFood shapingFood preparationThermal energyMicrowave

The invention relates to an airflow microwave fruit and vegetable puffing device which can rapidly and uniformly puff, rapidly cool and shape fruits and vegetables by a liquid nitrogen cooling device and a rotating cylinder connected with a microwave generating device and provided with a dispersion plate and can keep the favors and the colors of the fruits and the vegetables. The invention has the working theory that high-temperature and high-pressure nitrogen and microwaves act to rapidly increase the temperature and the pressure of the fruits and the vegetables to set values; a ball valve is opened, and a puffing tank is connected with a pre-vacuumized vacuum tank so as to rapidly reduce the pressure, realize the flash evaporation of water and then puff the fruits and the vegetables and fill liquid nitrogen to cool and shape materials. The invention has the advantages of rapid heat exchange, uniform material heating, rapid shaping process and little heat energy loss.

Owner:SHAANXI UNIV OF SCI & TECH

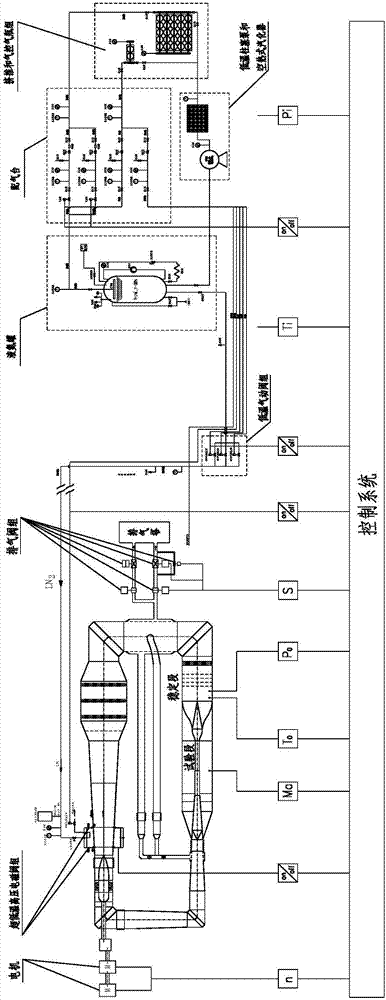

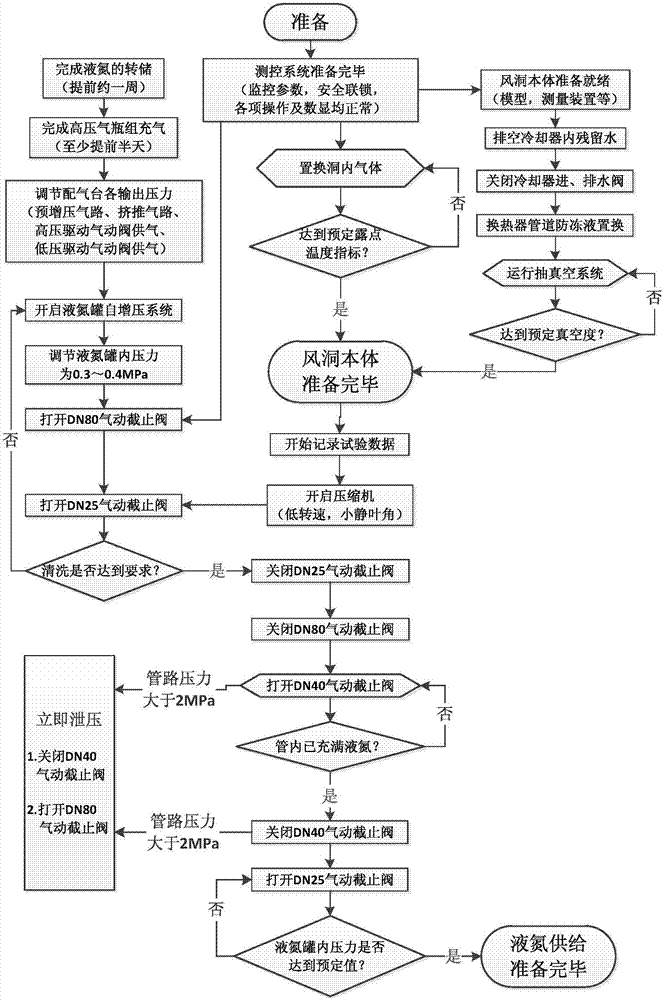

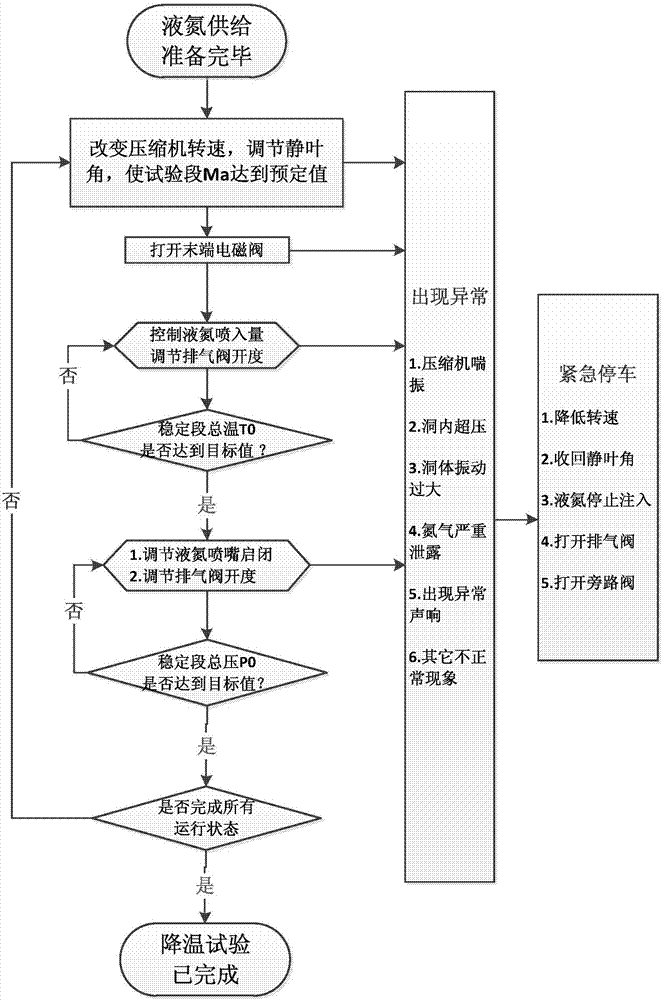

Continuous transonic speed wind tunnel spray liquid nitrogen cooling test operation method

InactiveCN107192531ASafe and effective liquid nitrogen spray cooling testAerodynamic testingEnd stagesLiquid nitrogen cooling

The invention provides a continuous transonic speed wind tunnel spray liquid nitrogen cooling test operation method. The method comprises three stages of work which includes preparation, operation and end. Preparation work comprises liquid nitrogen preparation, push and shove gas preparation, gas distribution bench preparation, wind tunnel preparation, measurement and control system preparation, liquid nitrogen conveying pipeline preparation, storage tank pre-pressurization and gas replacement in a wind tunnel. Operation stage work comprises wind tunnel cleaning, gas flow cooling, parameter transition and stable parameter testing. An end stage comprises steps that data recording is stopped; liquid nitrogen is stopped to be injected into the wind tunnel; through an exhaust system, wind tunnel decompression is performed; and a compressor continuously runs under a set work condition and heat released by the compressor is used to heat a gas flow and a wind tunnel body to a set temperature or to a normal temperature, and then the compressor stops running. By using the method of the invention, operation of a spray liquid nitrogen cooling system and operation of the wind tunnel are integrated into one body so that spray liquid nitrogen cooling testing can be safely and effectively performed in a continuous transonic speed wind tunnel.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

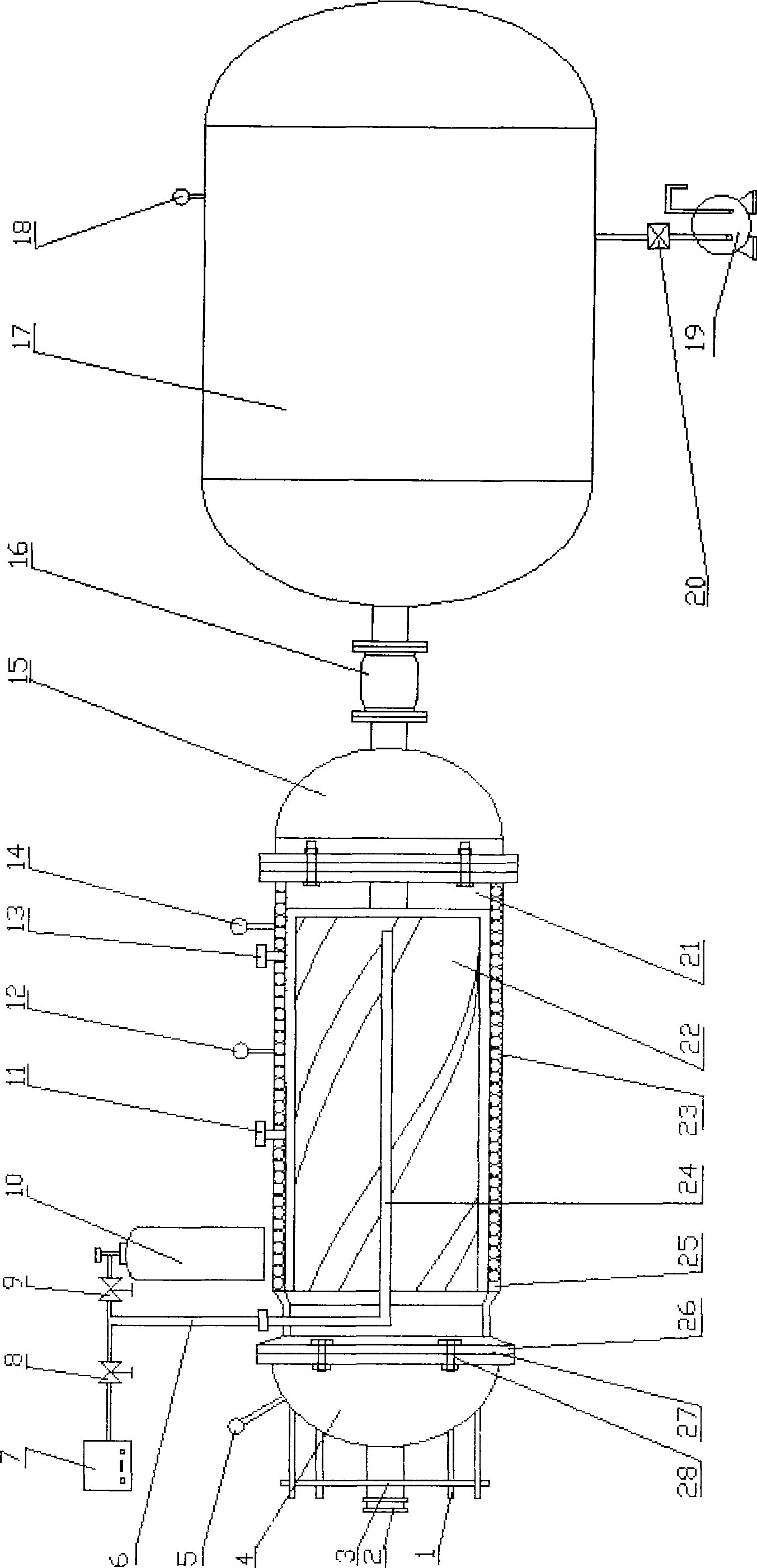

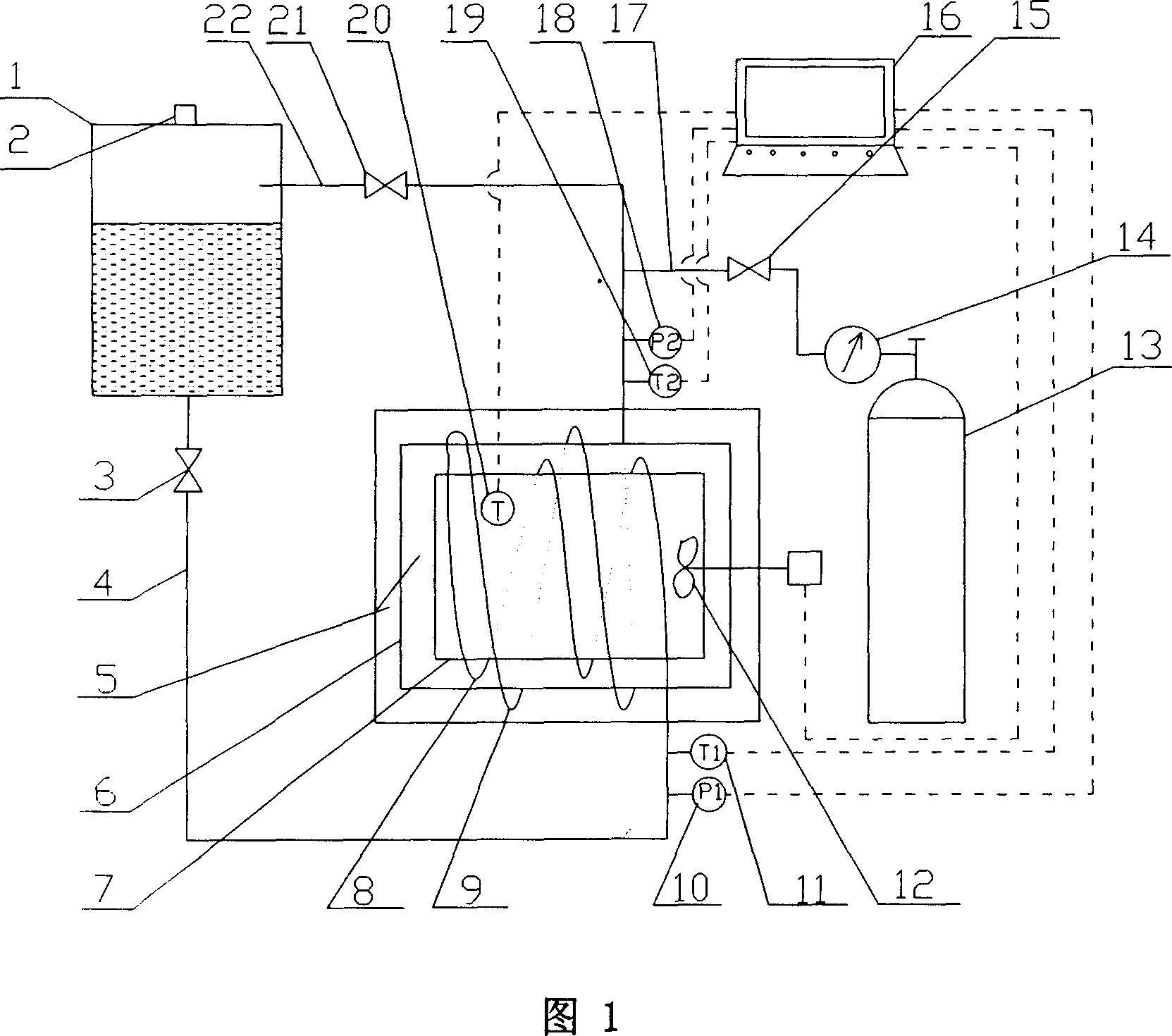

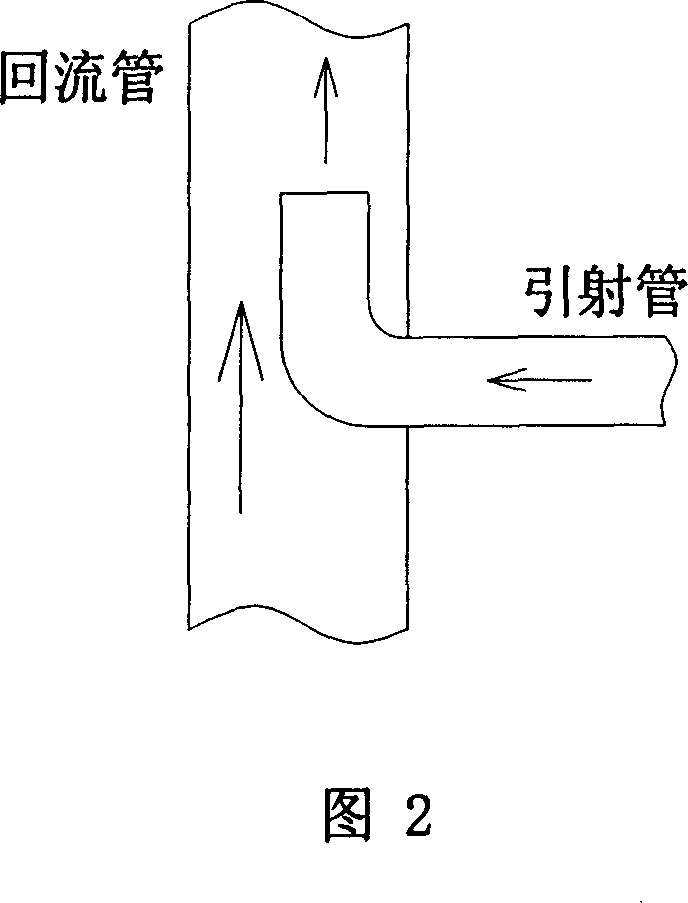

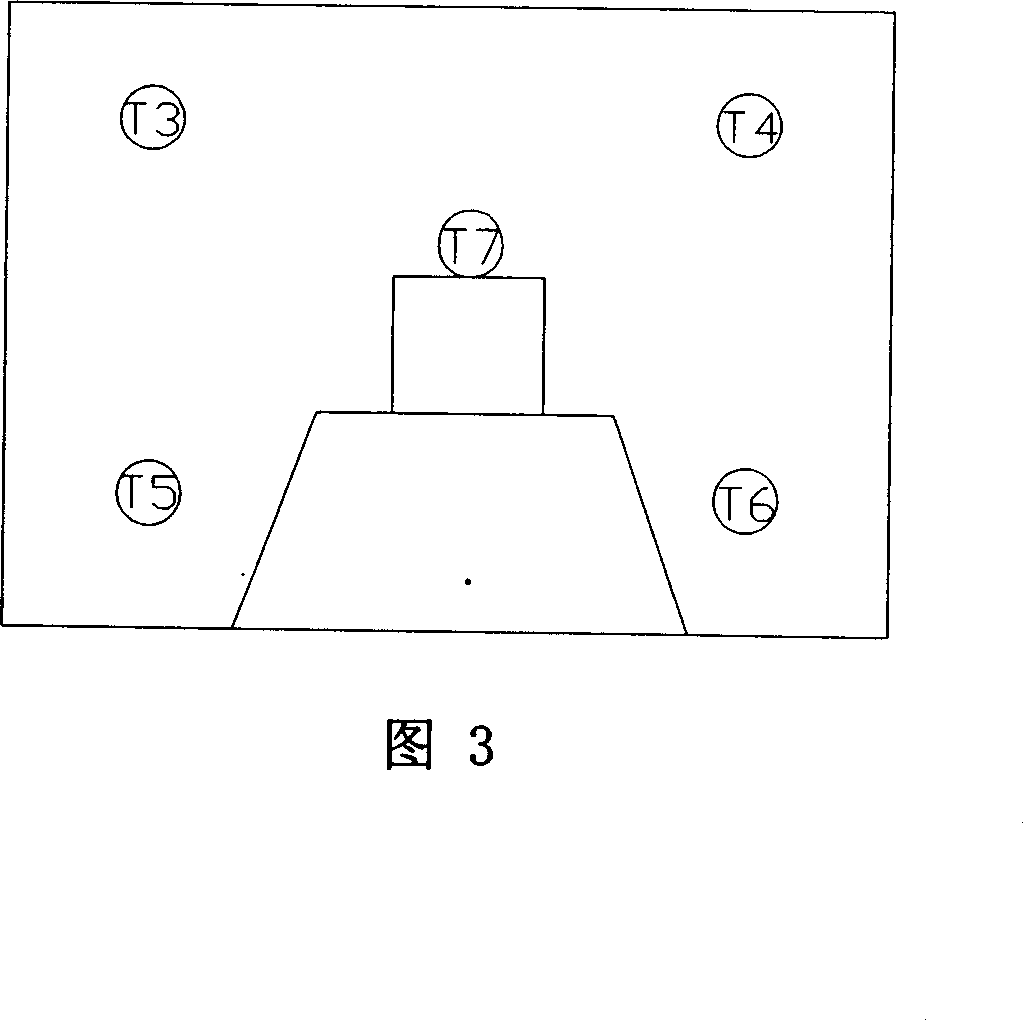

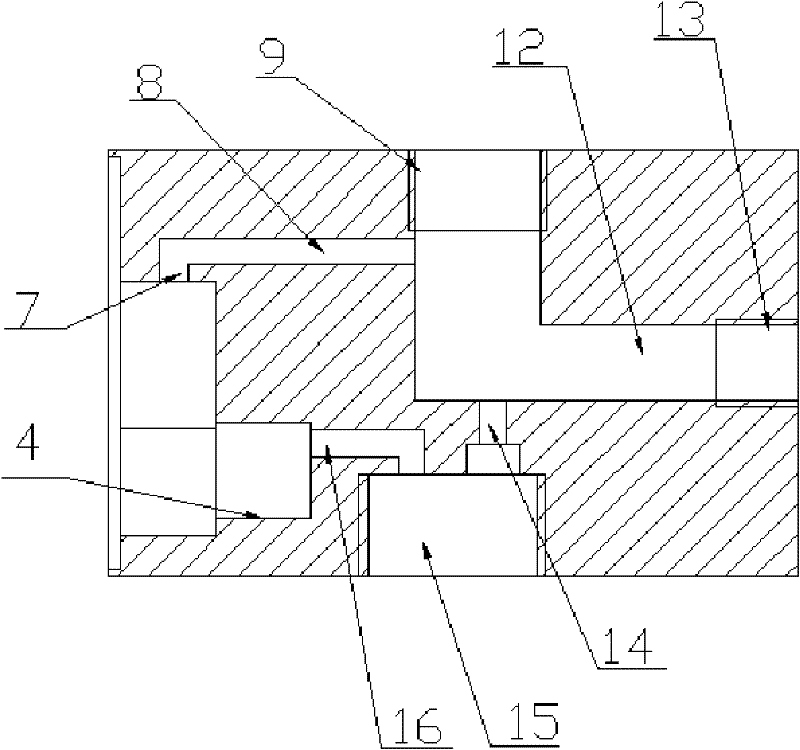

Temperature controllable deep cooling treatment system bases on natural circulation

InactiveCN1948516ASave cycle powerSave liquid nitrogen consumptionLiquid nitrogen coolingData acquisition

The invention discloses a system of treatment by deep cooling with temperature controlling based on natural circulation. The system is composed of liquid nitrogen tank, filling port, perfusion valve, perfusion tube, heat insulating layer, cold shield, treatment room for deep cooling, internal coil, external coil, pressure transducer of internal-coil entry, temperature transducer of internal-coil entry, fan, nitrogen cylinder, reducing valve, injection control valve, injection tube, pressure transducer of external-coil entry, temperature transducer of external-coil entry, temperature transducer in treatment room for deep cooling, reflux control valve, reflux tube, data acquisition of computer and control system. The system depends on pressure-difference resulting from different consistency of liquid nitrogen and gas nitrogen to impel coolant of liquid nitrogen for circular flowing. Adjusting of coefficient of heat transfer on the surface of work is realized conveniently by controlling flux of circulate liquid nitrogen and rotate speed of fan. The system has much strongpoint including saving circulate power and consumption of liquid nitrogen, easy to control cooling speed of treatment by deep cooling and treatment temperature etc.

Owner:ZHEJIANG UNIV

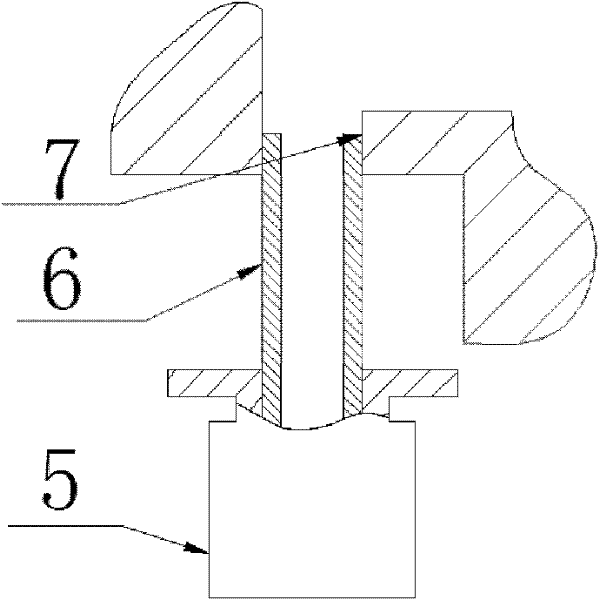

Micro-lubricating system

ActiveCN102229062ARealize the atomization effectReasonable adjustment of usageMaintainance and safety accessoriesEngine lubricationLiquid nitrogen coolingEngineering

The invention relates to a micro-lubricating system which comprises an oil tank, a liquid guide pipe, an upper cover, a flow adjusting valve port, a flow adjusting valve, a gas guide tubule, a gas guide tubule port, a second chamber, a gas outlet port, a gas outlet, a nozzle, a first chamber, a compressed air inlet, a liquid guide through hole, an oil tank port, a third chamber and an oil tank chamber and is characterized in that the oil tank is filled with lubricating agent; the lubricating agent enters a pipeline under the action of compressed gas, and the using amount of the lubricating agent can be adjusted by the adjusting valve; the pipelines are of an internal and external double-layered pipe structure; and the nozzle is of a double-layered spraying structure. The micro-lubricatingsystem can be used as a lubricating agent supply device in micro-lubricating, low-temperature cutting and liquid nitrogen cooling and processing and can be used for reasonably adjusting the using amount of the lubricating agent. The micro-lubricating system has the advantages of simpleness in manufacture, low cost and less consumed resources and can be suitable for batch production. The micro-lubricating system disclosed by the invention solves the problems of large using amount of cutting liquid, control difficulty, serious environment pollution, and the like in the traditional liquid supplysystem by using the non-polluted environment-friendly lubricating agent.

Owner:BEIHANG UNIV

Ultrafine grinder liquid nitrogen cooling device

InactiveCN103913027AReduce the temperatureImprove the crushing finenessDomestic cooling apparatusLighting and heating apparatusLiquid nitrogen coolingNitrogen

The invention belongs to the technical field of cooling equipment structures, and relates to an ultrafine grinder liquid nitrogen cooling device comprising a liquid nitrogen tank carrying liquid nitrogen and a vaporizer communicated with the liquid nitrogen tank. The vaporizer is arranged in a cooling liquid tank and is provided with a nitrogen outlet communicated with outside of the cooling liquid tank, and the cooling liquid tank is filled with cooling liquid and is provided with a temperature sensor; the output end of the cooling liquid tank is communicated with a cooling liquid circulating outlet pipeline, part of the cooling liquid circulating pipeline wraps an ultrafine grinder cooling disc, and the output end of the cooling liquid circulating pipeline is communicated to the inside of the cooling liquid tank; a liquid nitrogen pump is mounted between the liquid nitrogen tank and the vaporizer; the cooling liquid circulating outlet pipeline is provided with a cooling liquid pump, and the liquid nitrogen pump, the cooling liquid pump and the temperature sensor are controlled by an electric control system. The ultrafine grinder liquid nitrogen cooling device is reasonable in structural design, high in safety and reliability, small in occupation, and capable of decreasing the temperature of the material smashed by an ultrafine grinder greatly.

Owner:LAIYANG GUIHE MACHINERY

Non-penetration laser welding method

InactiveCN106077954AReduce aggregationReduce heat buildupLaser beam welding apparatusLiquid nitrogen coolingThermal deformation

The invention relates to a non-penetration laser welding method. The non-penetration laser welding method is characterized by comprising the steps that first, impurities on the upper surface and lower surface of first parent metal (2) and the upper surface and lower surface of second parent metal (3) are removed, and then the first parent metal and the second parent metal are accurately overlapped and clamped with a welding jig; second, a vacuum cover (6) is connected to a laser welding head (7) and can rotate on the laser welding head; third, the laser welding head is moved to the position above a workpiece so that the vacuum cover can keep a certain distance away from the workpiece surface; fourth, compressed air of certain pressure is supplied to an air inlet (8) of the vacuum cover; fifth, industrial liquid nitrogen is injected to the lower surface of the workpiece through a spray gun (1) of a special device; and sixth, a laser welding system is started, a laser beam (4) is vertically radiated to the upper surface of the workpiece, and the laser beam and the spray gun (1) move synchronously to complete the welding process. According to the non-penetration laser welding method, the local vacuum environment and liquid nitrogen cooling act synchronously, so that thermal deformation and oxidizing discoloration on the back face of a welding seam during non-penetration laser welding are avoided, and practicability is high.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of extracted high-purity molybdenum trioxide

InactiveCN103449523AReduce labor intensityImprove thermal efficiencyChemical industryMolybdenum oxides/hydroxidesLiquid nitrogen coolingMetal membrane

The invention relates to the field of molybdenum trioxide, and specifically relates to a preparation method of extracted high-purity molybdenum trioxide. The preparation method is characterized by comprising the following steps: treating industrial molybdic acid to remove moisture, oil and various trace impurities with a volatilization point lower than 750 DEG C in materials; metering according to sublimation speed for feeding the materials into a subliming furnace, and controlling the temperature of the subliming furnace to 1100 DEG C-1160 DEG C; selectively adopting clean air coiling or liquid nitrogen cooling according to the requirements of the grain size, and controlling the temperature to 250 DEG C or 50 DEG C; collecting the dust by a primary metal membrane for recycling with a yield of 99%, and collecting the dust by a secondary cloth bag with the yield of 1% to recycle high-purity molybdenum trioxide. The technical scheme is adopted, and the subliming furnace is used as a carbon rod for directly heating up, and therefore, the heating efficiency is high, the temperature is controlled by using a computer, and a temperature fluctuation range is + / -1 DEG C. Residues at the furnace bottom are calculated according to material balance and exhausted regularly, and waste of the residues is used as steel-making ferro-molybdenum after being cooled or used as the material for producing sodium molybdate after being crushed. The preparation method disclosed by the invention is safe and reliable in process, high in recovery rate and high in quality, thereby improving production efficiency and relieving labor intensity of operation personnel.

Owner:HUBEI ZHONGAO NANO MATERIAL TECH CO LTD

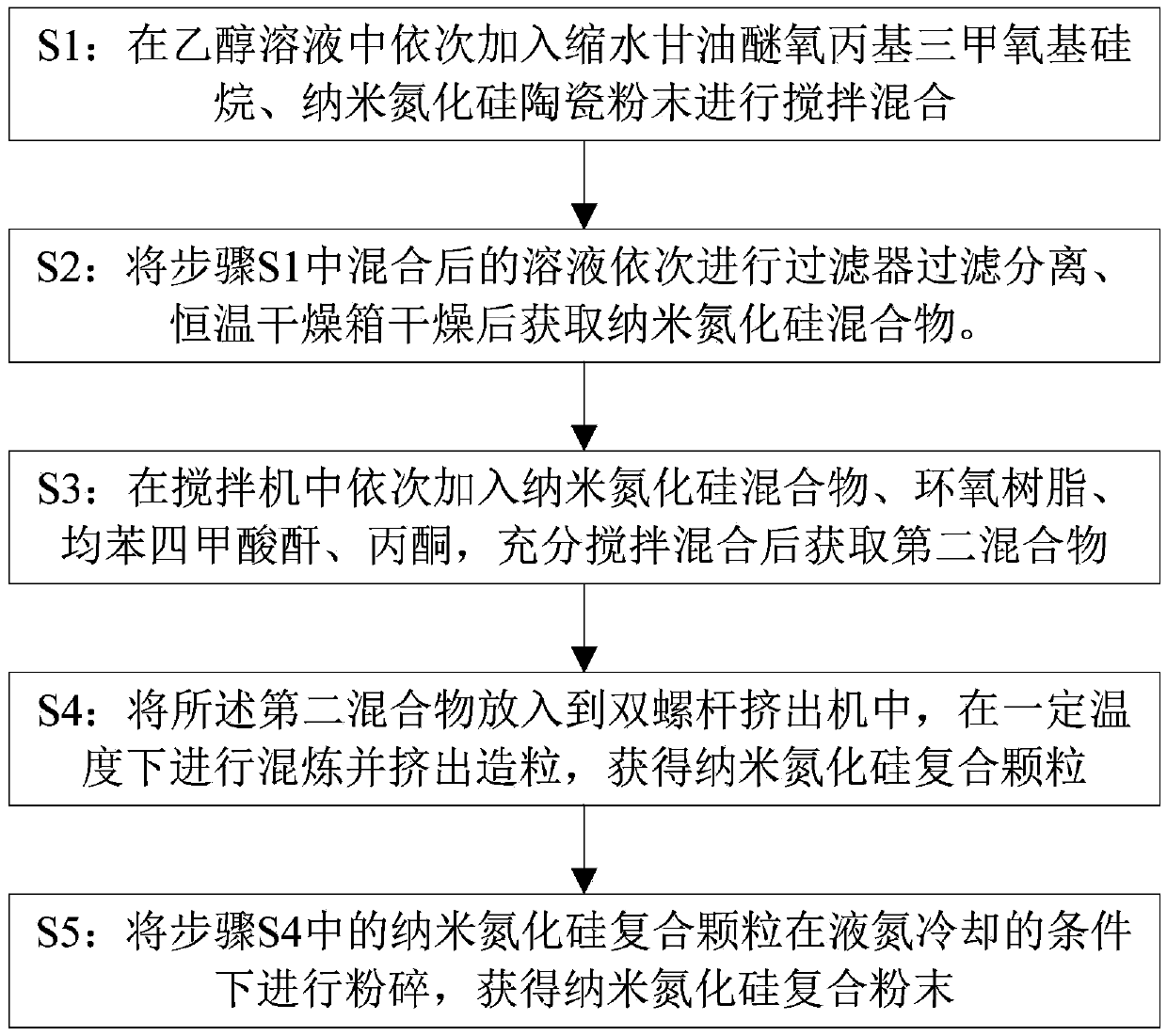

Preparation method of 3D printing material

InactiveCN105367998AIncreased durabilityHigh precisionAdditive manufacturing apparatusEpoxyLiquid nitrogen cooling

The invention discloses a preparation method of a 3D printing material. The method includes: adding glycidyloxypropyl trimethoxysilane and nano silicon nitride ceramic powder into an ethanol solution to conduct stirring mixing, performing filtering by a filter, and conducting drying by a drying oven to obtain a nano silicon nitride mixture, adding the nano silicon nitride mixture, epoxy resin, pyromellitic dianhydride and acetone into the stirrer in order, fully stirring and mixing the substances, then putting the mixture into a double-screw extruder to perform mixing and extrusion granulation, and conducting crushing under the liquid nitrogen cooling condition to obtain nano silicon nitride composite powder. As a 3D printing material particle, the nano silicon nitride composite powder can reach nanoscale, has small particle size and good dispersion uniformity, can shape rapidly and directly under laser sintering equipment without spraying an adhesive, and the shaped product has high precision and strength and good durability. The method provided by the invention has the advantages of simple making process and low equipment requirement, and is in favor of industrial promotion of 3D printing technology.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

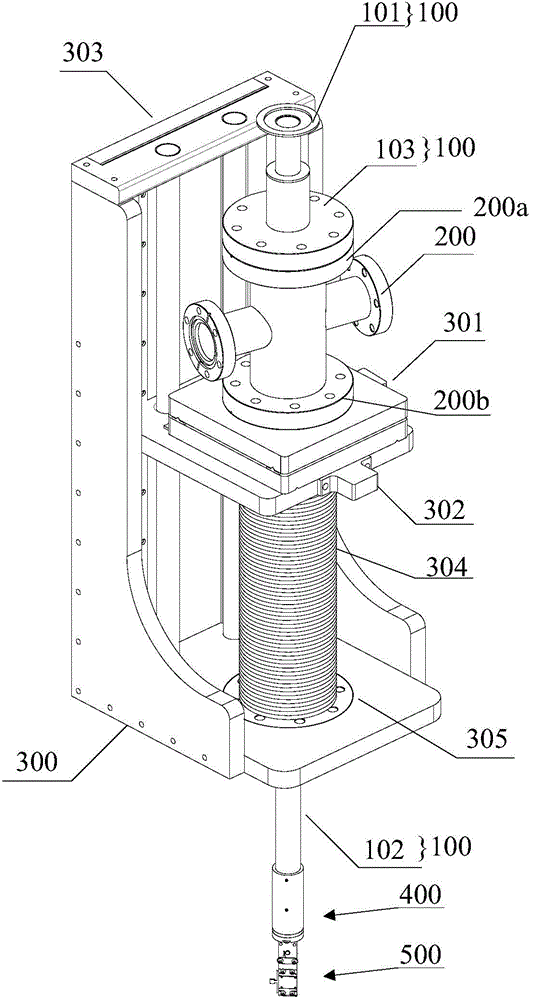

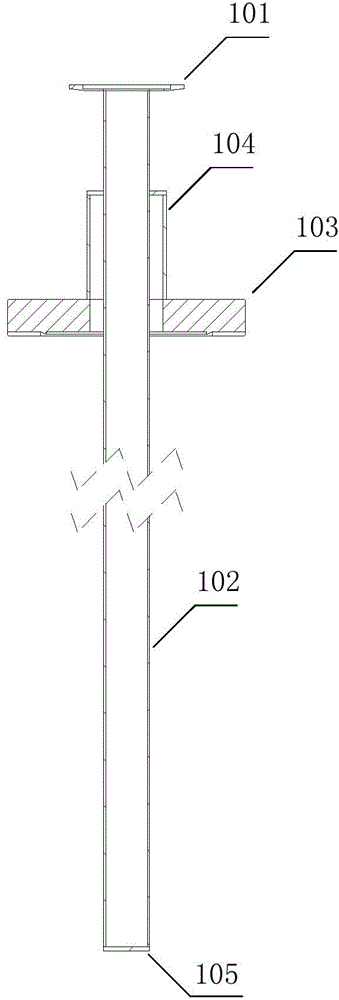

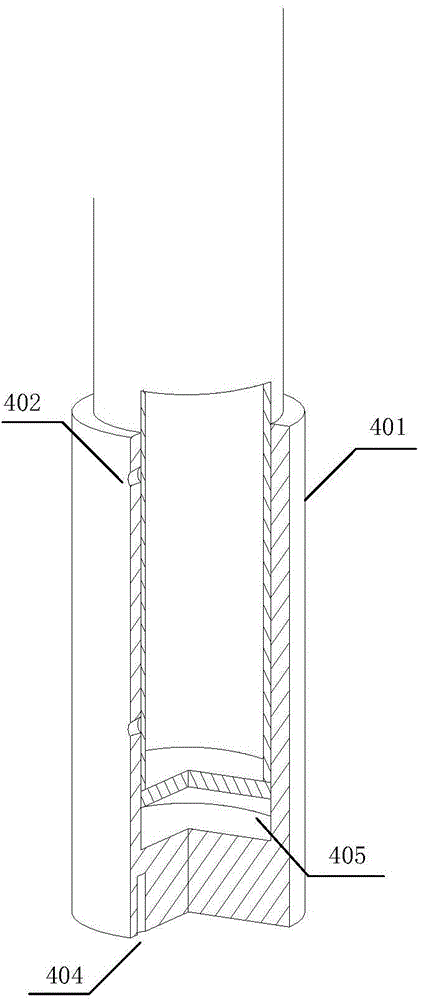

Low-temperature sample operation bench used for soft X-ray magnetic circular dichroism (MCD)

InactiveCN105987923AAchieve low temperature refrigerationMeet the use requirementsMaterial analysis by measuring secondary emissionSoft x rayLiquid nitrogen cooling

The present invention proposes a low-temperature sample manipulator for soft X-ray magnetic circular dichroism (XMCD), comprising: a wiring cavity with an upper end and a lower end; an XYZ three-dimensional mobile stage installed on the XMCD ultra-high vacuum cavity, and the The lower end of the wiring cavity is installed on the XYZ three-dimensional mobile platform; the liquid nitrogen cooling device is connected to the upper end of the wiring cavity and passes through the XYZ three-dimensional mobile platform; the copper cold head is fixed on the liquid nitrogen The lower end of the cooling device; the sample rack is installed at the lower end of the copper cold head and is insulated from the copper cold head; wherein, the liquid nitrogen cooling device is injected with liquid nitrogen to cool the samples on the sample rack. The low-temperature sample manipulation table suitable for soft X-ray magnetic circular dichroism absorption spectrum proposed by the embodiment of the present invention realizes cryogenic refrigeration of liquid nitrogen to the greatest extent on the premise of insulation, non-magnetism and high vacuum.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Experimental simulation device for relieving near-wellbore plugging of gas-condensate well and simulation method

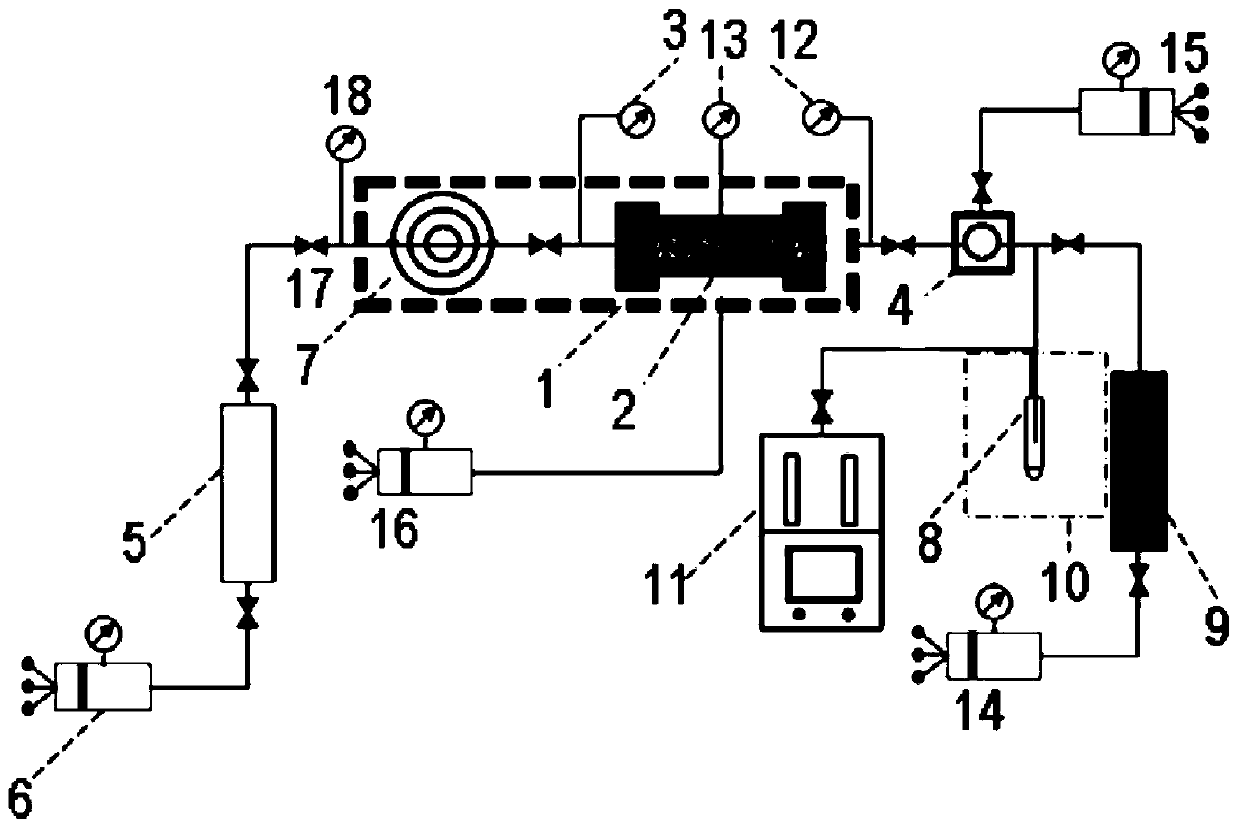

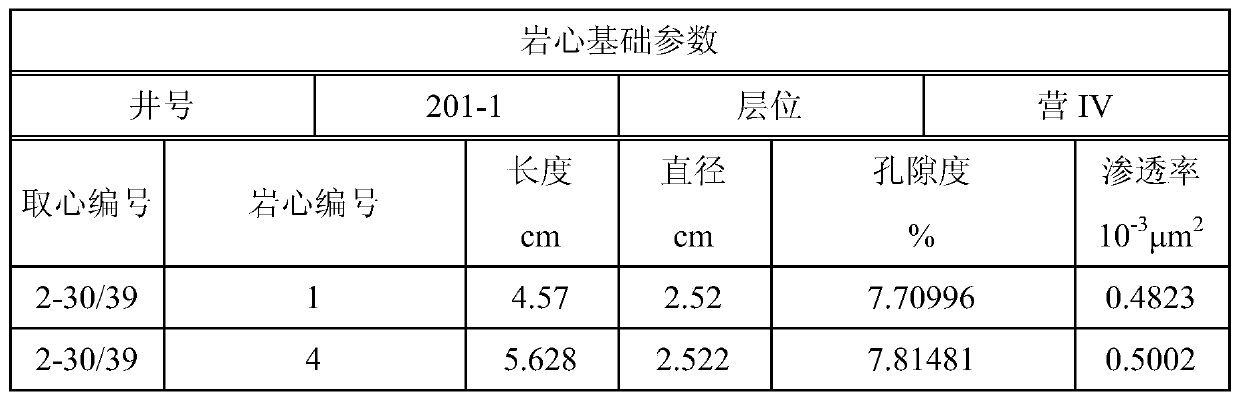

ActiveCN110530768AReduce holdupImprove test accuracyOther gas emission reduction technologiesEarth material testingLiquid nitrogen coolingEngineering

The invention provides an experimental simulation device for relieving near-wellbore plugging of a gas-condensate well, and a simulation method. The device comprises an adjustable constant temperatureoven, a long-core clamper, a sand-filling tubule, a gas-condensate sample storage tank, an ethanol sample storage tank, an oil-condensate collecting tube, a liquid-nitrogen cooling system and a full-automatic gasometer; the long-core clamper is used for placing a target long-core for simulating immediate vicinity of wellbore; the gas-condensate sample storage tank is connected with the sand-filling tubule; the sand-filling tubule is connected with an inlet end of the long-core clamper through a first high-precision pressure monitoring gauge, and an outlet end of the long-core clamper is connected with the ethanol sample storage tank through the second high-precision pressure monitoring gauge and a back-pressure valve and connected with the oil-condensate collecting tube through a capillary tube and the oil-condensate collecting tube; the long-core clamper and the sand-filling tubule are located in the adjustable constant temperature oven; the oil-condensate collecting tube is locatedin the liquid nitrogen cooling system; and the middle of the long-core clamper is further connected with a confining pressure gauge.

Owner:PETROCHINA CO LTD

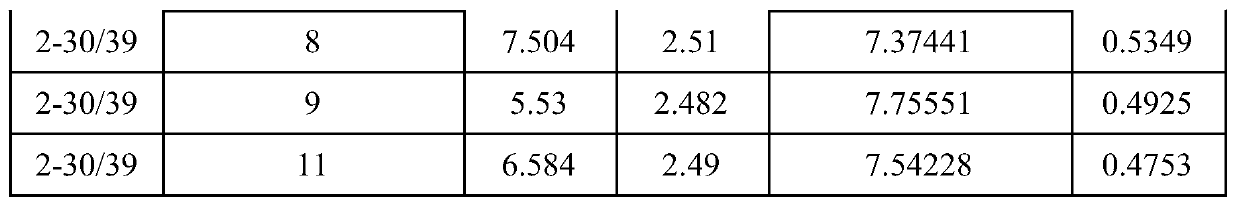

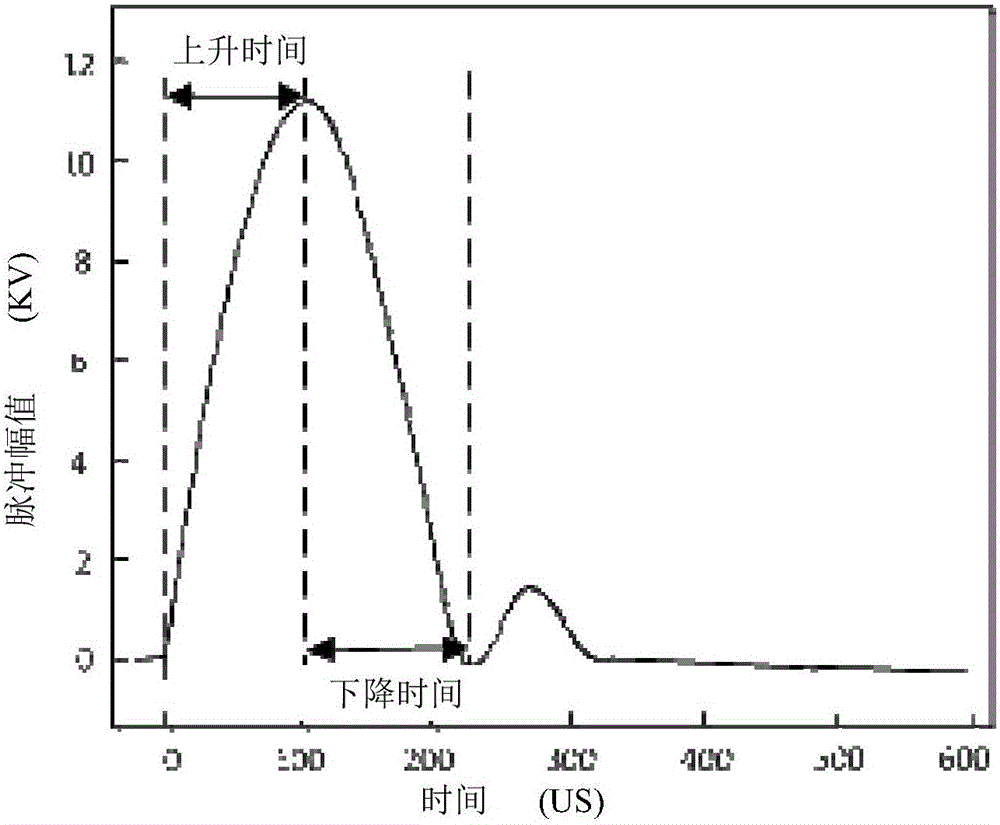

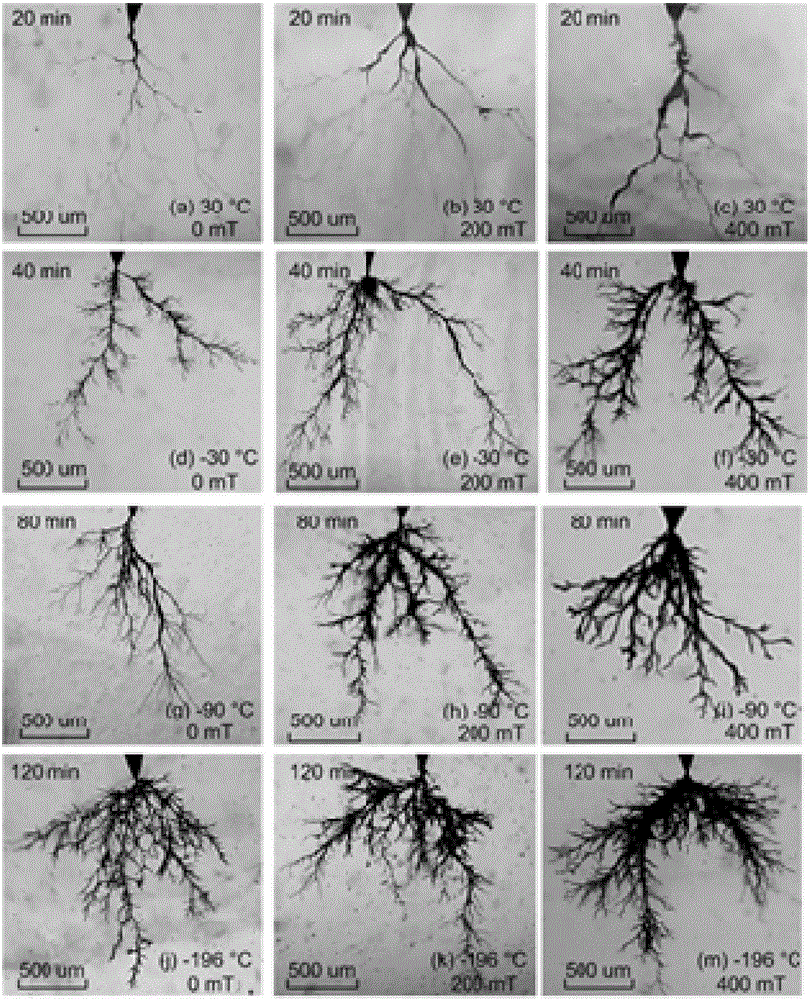

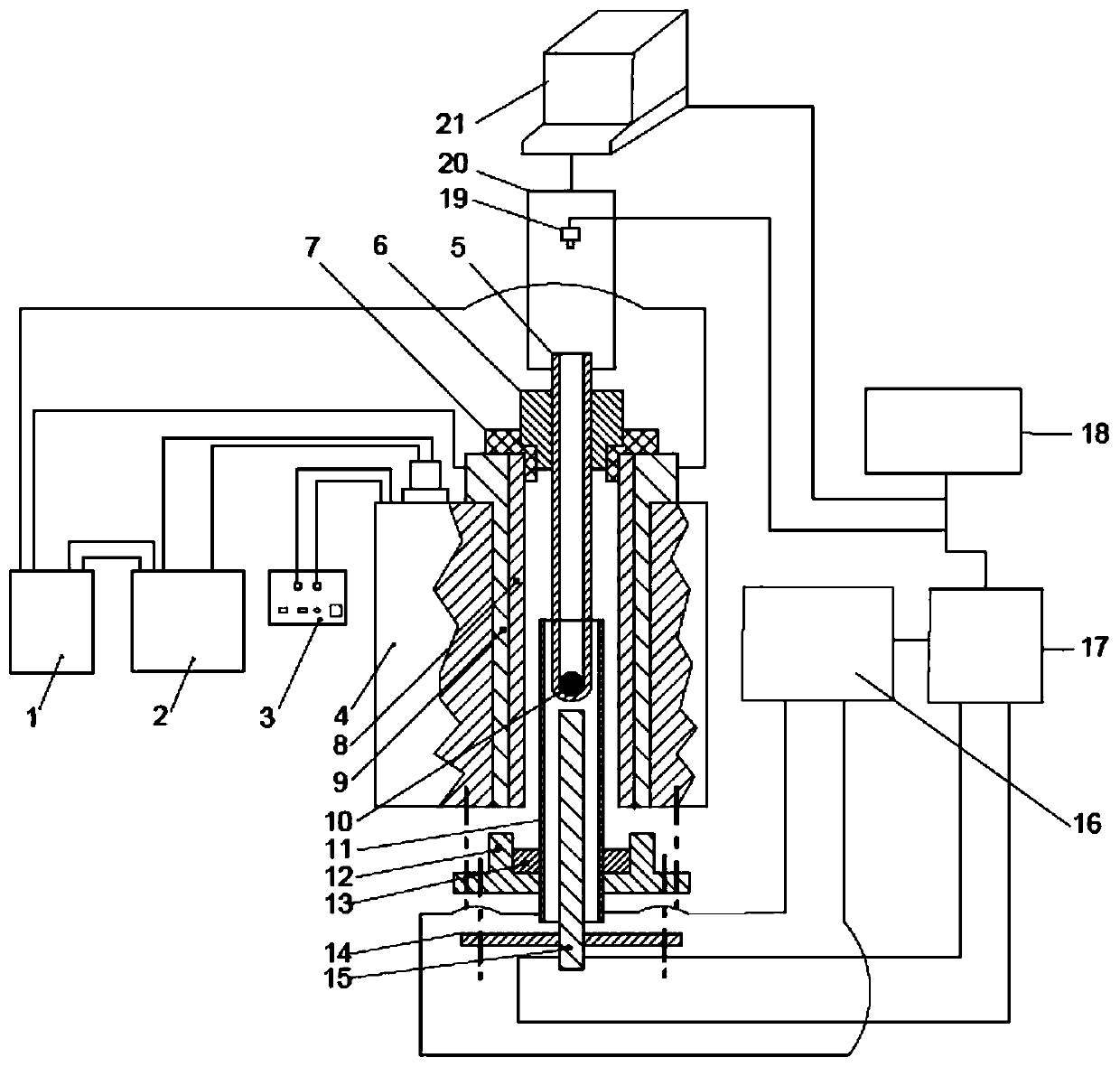

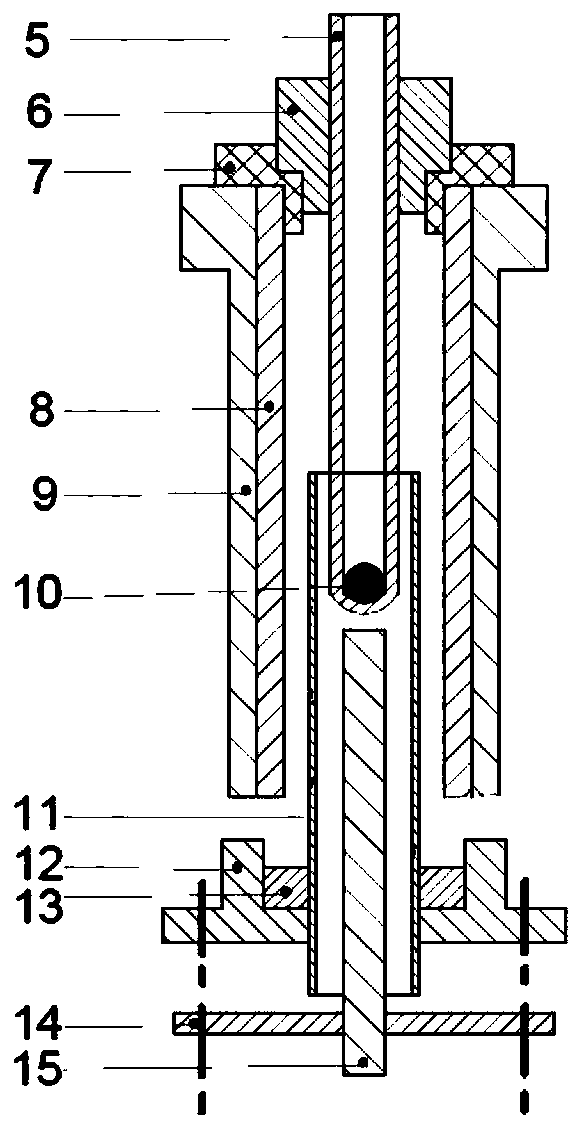

Low-temperature polymer electrical tree initiation method under electromagnetic field combined effect and low-temperature polymer electrical tree initiation device thereof

The invention relates to the technology of superconducting magnet insulation reliability, aims at realizing the electrical tree observation and image acquisition functions of a simulation superconducting magnet system in a strong magnetic field environment and a low temperature environment, and provides a low-temperature polymer electrical tree initiation method under the electromagnetic field combined effect and a low-temperature polymer electrical tree initiation device thereof. The low-temperature polymer electrical tree initiation device comprises a digital microscope imaging system, a temperature control system, a constant temperature box, a controllable high-voltage pulse power supply and a magnetic field generation device. The temperature control system controls temperature of the constant temperature box through a liquid nitrogen cooling device. The magnetic field generation device is composed of a constant current electromagnetic field generator and an electromagnet. The electromagnet uses a single-yoke U-shaped structure. The polymer is a polymer sampling for performing electrical tree aging. The polymer is arranged in the middle position of the single-yoke U-shaped structure, and the two ends are connected with the controllable high-voltage pulse power supply arranged outside the constant temperature box through a pin-plate electrode structure. The digital microscope imaging system observes the growing situation of the electrical tree in an epoxy resin sample in real time. The low-temperature polymer electrical tree initiation method under the electromagnetic field combined effect and the low-temperature polymer electrical tree initiation device thereof are mainly applied to the occasion of superconducting magnet insulation.

Owner:TIANJIN UNIV

Method for preparing half-crosslinked powdered butadiene-acrylonitrile rubber

The invention provides a method for preparing half-crosslinked powdered butadiene-acrylonitrile rubber, which belongs to the field of rubber polymer science. The method prepares half-crosslinked powdered butadiene-acrylonitrile rubber by a two-step process. The first step is to put blocky butadiene-acrylonitrile rubber, a starter, an aid crosslinking agent, an anti-aging agent, an anti-yellowing agent and a parting agent into an internal mixer, control the reaction temperature and the speed of a rotor of the internal mixer, react for a certain time period, cool and discharge to obtain half-crosslinked butadiene-acrylonitrile rubber. The second step is to grind the half-crosslinked butadiene-acrylonitrile rubber with a rubber grinder with a liquid nitrogen cooling system to obtain half-crosslinked butadiene-acrylonitrile rubber. The prepared half-crosslinked butadiene-acrylonitrile rubber can be widely used as a toughness modifier for polymers such as polyvinyl chloride for sealing workpieces, shoe material and the like to improve the elasticity, toughness, oil resistance and cold resistance of composite materials. The method disclosed by the method is simple, environment-friendly, favorable for large-scale production and capable of making product quality controllable and product performance stable, and thus has a wide application prospect.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Magnetic material processing device capable of reaching 1600 DEG C

PendingCN110118679ACharacterizing phase transitionSimple structurePreparing sample for investigationSusceptibility measurementsMagnetic susceptibilityInsulation layer

The invention relates to a magnetic material processing device capable of reaching 1600 DEG C. A water cooling machine is connected with a compressor; the compressor is connected with the input end and the output end of a liquid nitrogen cooling nozzle of a superconducting magnet; an excitation power supply is connected with the superconducting magnet; the lower end of a quartz tube passes througha copper bush, and is arranged in a heating body; the upper end of a thermocouple passes through a thermocouple fixing plate, and is arranged in the heating body; the heating body is positioned in athermal insulation layer; the thermal insulation layer is positioned in a water cooling layer; the water cooling layer is positioned in the superconducting magnet; an infrared probe, a test tube clampand a balance form a balance magnetic susceptibility measurement system; and the infrared probe and the balance are connected with a computer through a conducting wire and a conversion interface. Themagnetic material processing device capable of reaching 1600 DEG C disclosed by the invention is simple in structure, convenient to use and operate, and easy to disassemble; the cavity space of the superconducting magnet is large; furthermore, the reachable magnetic field intensity is high; therefore, the range increasing size of processed materials can be increased; the size of a contained sample is convenient for later testing of various performances; and thus, experiment and test analysis integration can be realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ultrasonic gas or cluter injector

ActiveCN1941216AMake the density distribution peakReduce recyclingNuclear energy generationThermonuclear fusion reactorPlasma densityLiquid nitrogen cooling

A loading device for nuclear plant is composed by a valve part which is fixed to the flange on the pipe of the circulation vacuum chamber and is of a gas rejection valve with Laval nozzle, the gas rejection valve is linked to high pressure gas pipe and with liquid nitrogen cooling trap to outside then a magnetic screen. The injector prevents injected particles disperse and increase the injected amount and depth, so to increase plasma density and improve its inhibition character.

Owner:SOUTHWESTERN INST OF PHYSICS

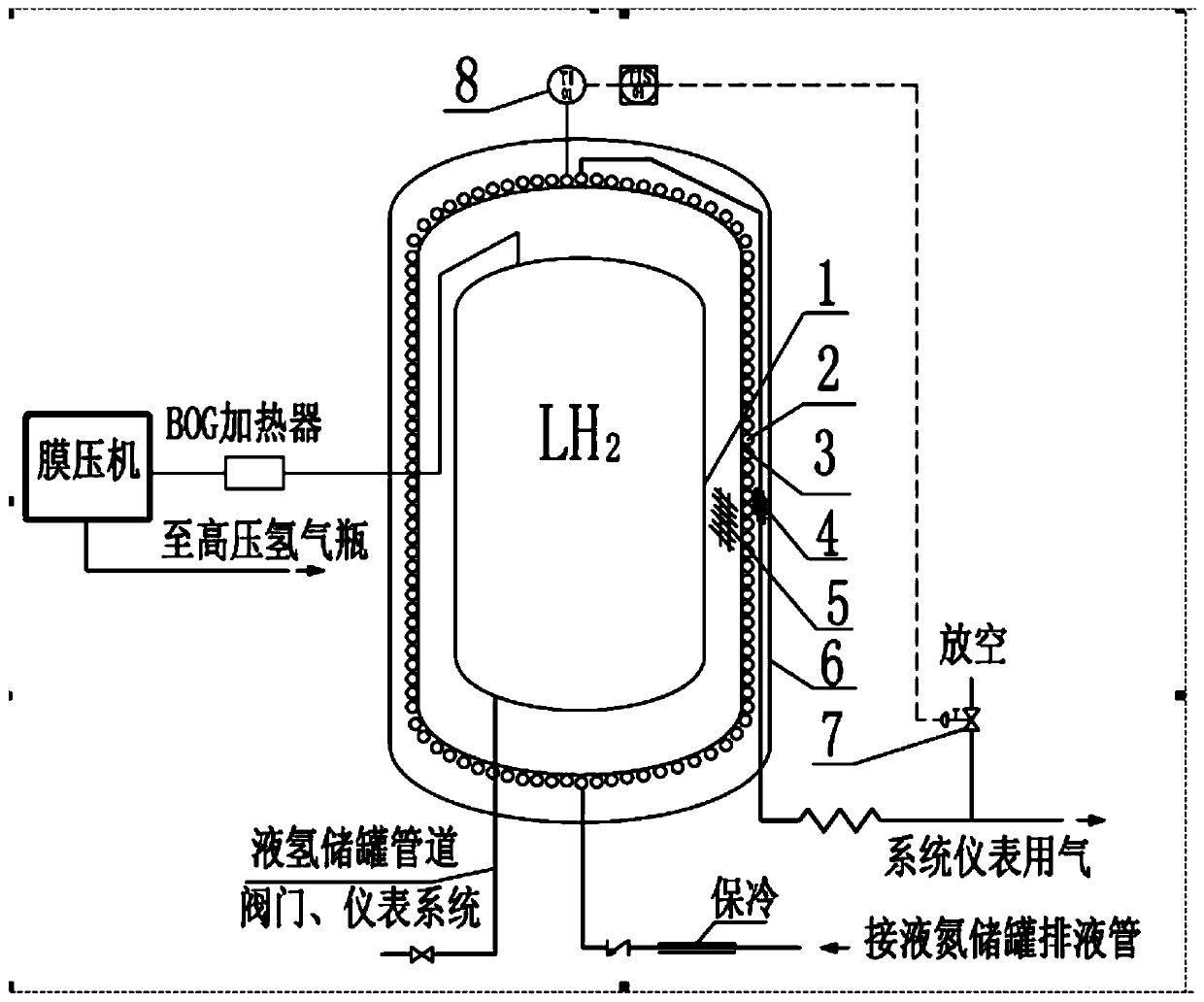

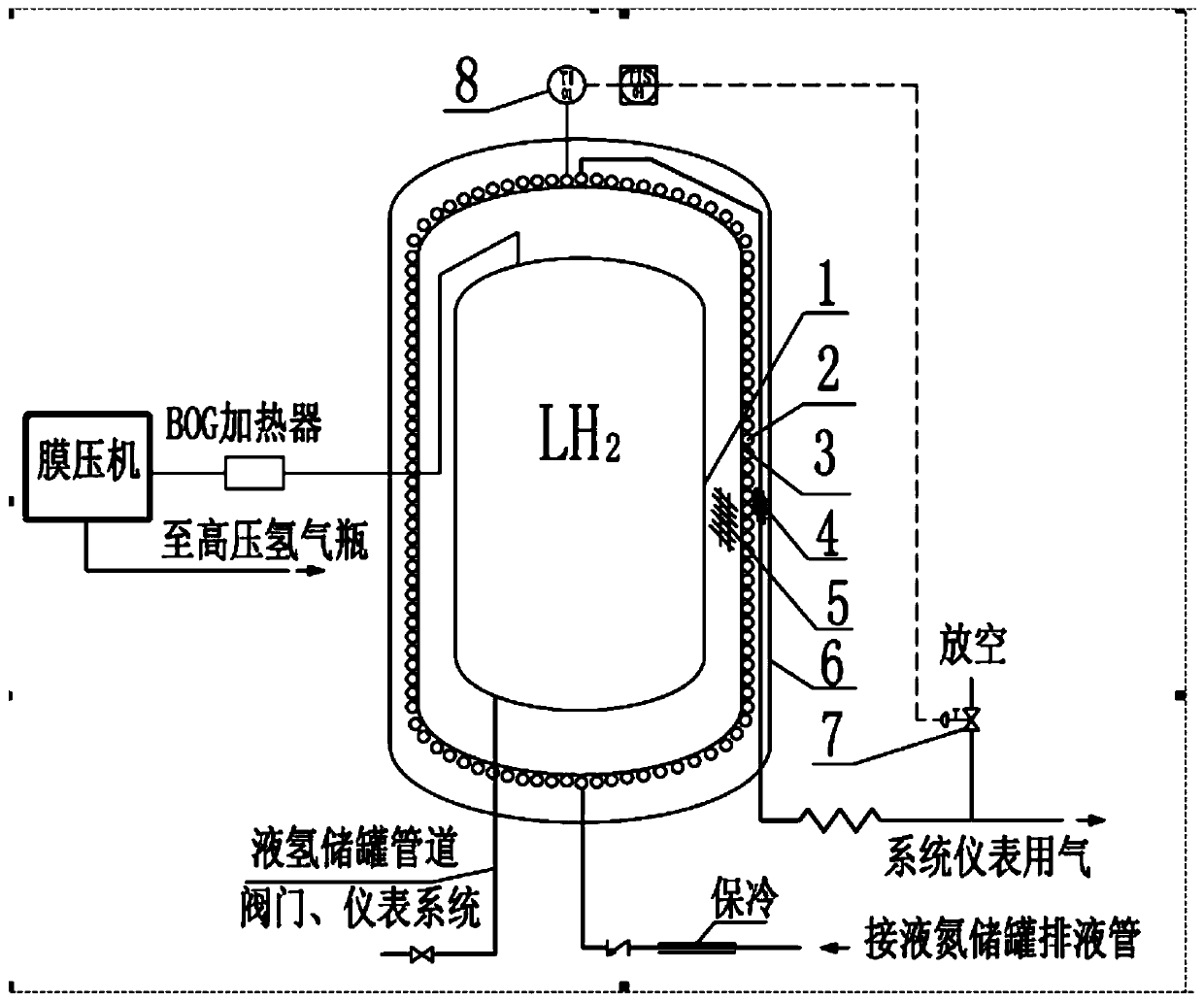

Device and method for reducing evaporation rate of liquid hydrogen storage tank by using liquid nitrogen cooling capacity

PendingCN110043791AConstant gas space temperatureGuaranteed efficiencyContainer filling methodsPressure vesselsInsulation layerLiquid nitrogen cooling

The invention discloses a device and a method for reducing the evaporation rate of a liquid hydrogen storage tank by using liquid nitrogen cooling capacity. The device comprises the liquid hydrogen storage tank, a liquid nitrogen storage tank and instrument gas, wherein the liquid hydrogen storage tank comprises a liquid hydrogen storage tank inner tank and a liquid hydrogen storage tank outer tank, high-vacuum multiple heat insulation layers are arranged between the liquid hydrogen storage tank inner tank and the liquid hydrogen storage tank outer tank, the liquid nitrogen storage tank is connected with the instrument gas through a liquid nitrogen liquid discharge pipe, the outer side wall of the liquid hydrogen storage tank outer tank is connected with a liquid nitrogen discharge pipe ina wound mode from top to bottom, the two ends of the liquid nitrogen discharge pipe are connected with the instrument gas and the liquid nitrogen liquid discharge pipe correspondingly, liquid nitrogen enters the liquid nitrogen liquid discharge pipe from the liquid nitrogen storage tank and then flows into the instrument gas through the liquid nitrogen discharge pipe, and the temperature of the liquid nitrogen in the liquid nitrogen discharge pipe is -150 DEG C or below. According to device and the method for reducing the evaporation rate of the liquid hydrogen storage tank by using the liquid nitrogen cooling capacity, heat transfer temperature difference of the liquid hydrogen storage tank can be effectively reduced, so that the effect of reducing the natural evaporation rate of the liquid hydrogen storage tank is achieved.

Owner:成都深冷科技有限公司

Quick quenching device and method for shaft parts

InactiveCN104775011ATemperature monitoringWon't soften the problemFurnace typesHeat treatment furnacesLaser quenchingLiquid nitrogen cooling

The invention discloses a quick quenching device and method for shaft parts. The quick quenching device for shaft parts is provided with a temperature monitoring device, a laser device, a liquid nitrogen cooling system, a workpiece clamp and a connecting plate assembly, wherein the connecting plate assembly is provided with a manipulator connecting plate, a connecting component and a spray nozzle connecting plate, a laser head is installed on the manipulator connecting plate, and a liquid nitrogen spray nozzle is installed on the spray nozzle connecting plate and is connected with a liquid nitrogen cooling system control valve through an air delivery pipe. The workpiece clamp is arranged under the connecting plate assembly and is provided with a chuck, a tip and a control system for controlling rotation of the chuck, and a workpiece is arranged between the chuck and the tip. The temperature monitoring device is arranged on one side of the connecting plate assembly and is used for monitoring the temperature of a laser quenching zone on the workpiece. By the adoption of the quick quenching device and method for shaft parts, the automation degree of surface laser strengthening of large shafts can be improved, working efficiency can be improved, shaft surface strengthening and near-net shaping can be also achieved, additional machining is not needed basically, and working procedures and cost are saved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com