Patents

Literature

329 results about "Infrared reflectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reflected infrared In remote sensing, infrared which is solar-generated electromagnetic radiation that has been reflected from an object. Characteristically, reflected infrared radiation has a wavelength between 0.7 μm and 3 μm and is therefore near-infrared.

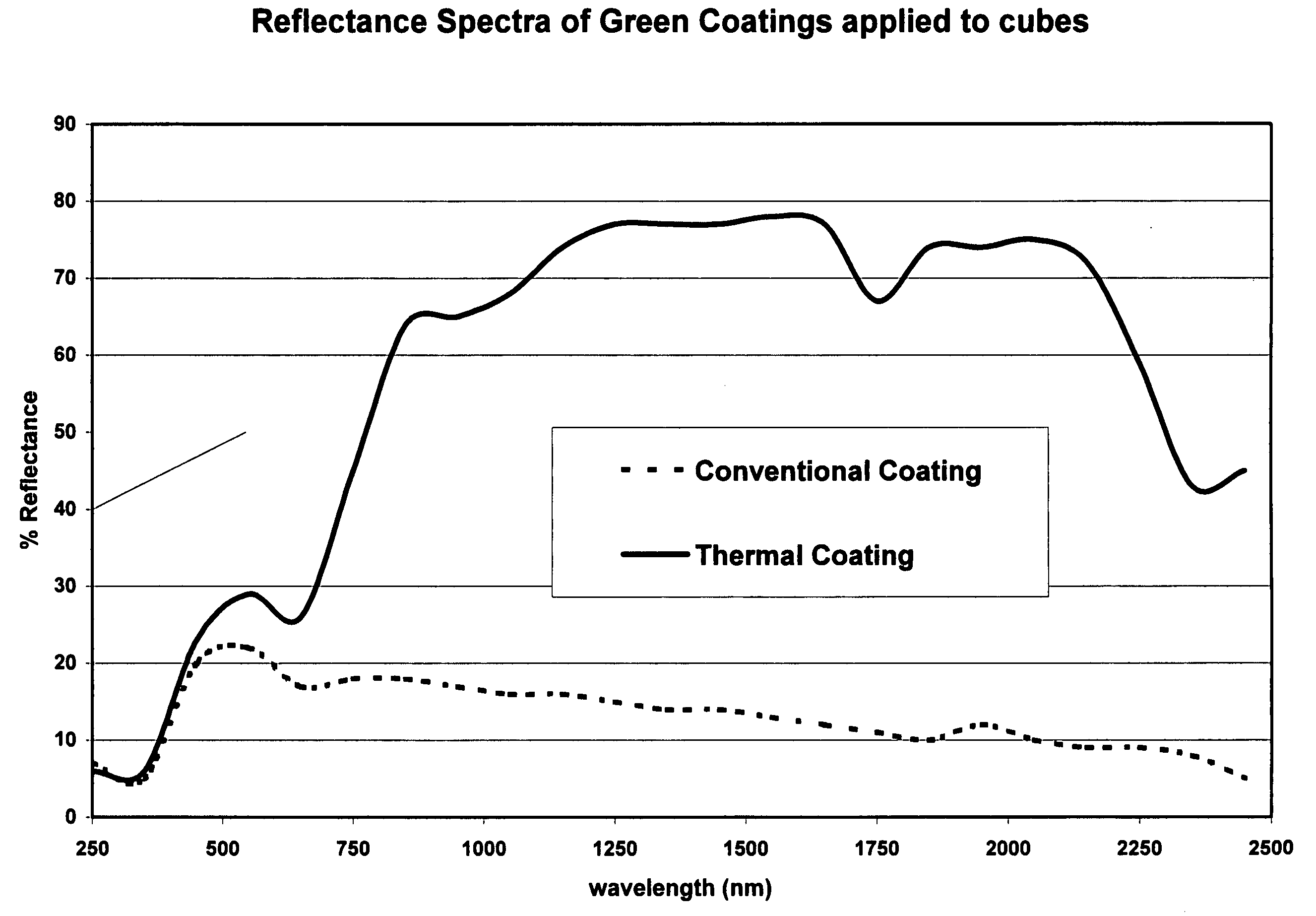

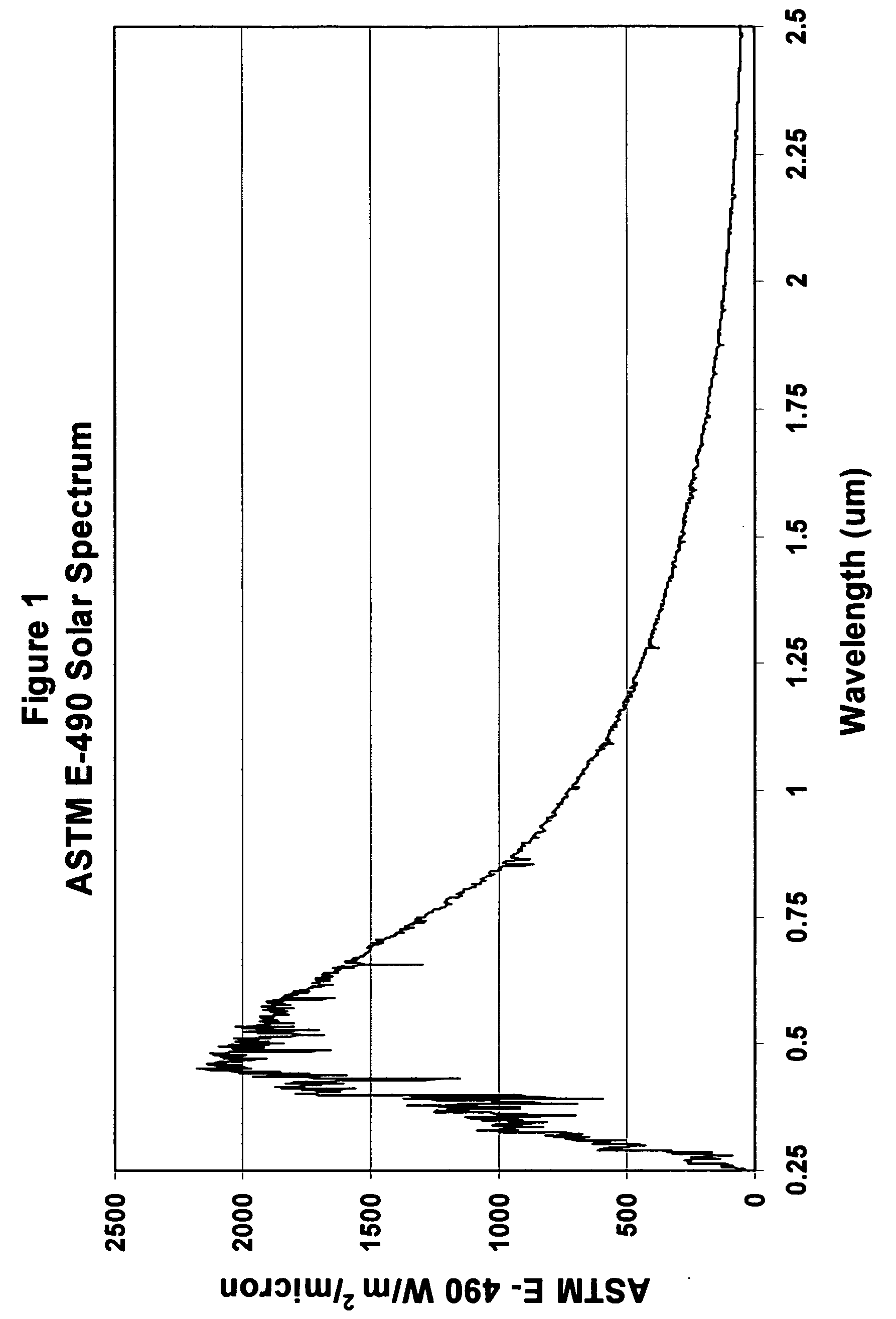

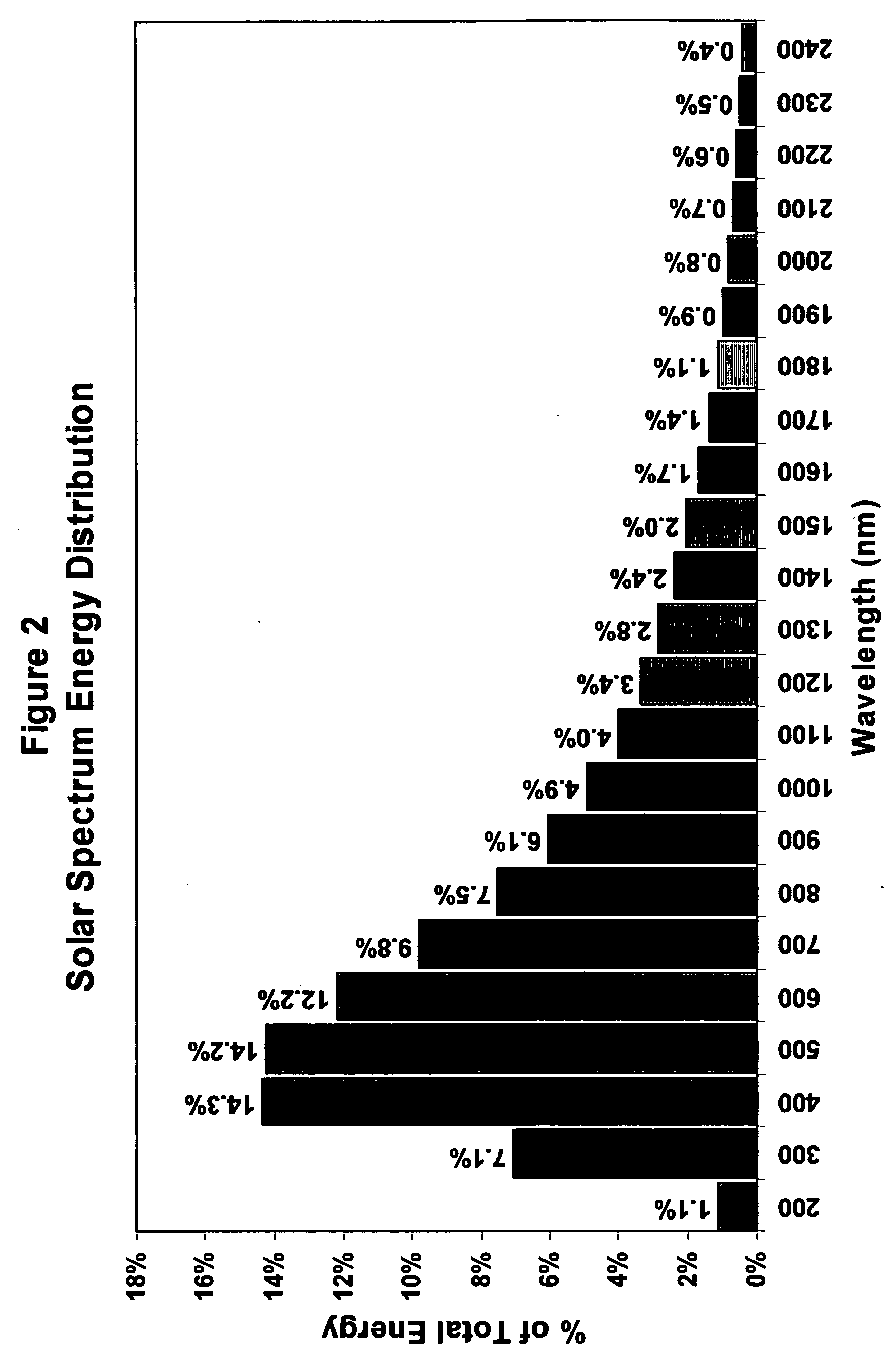

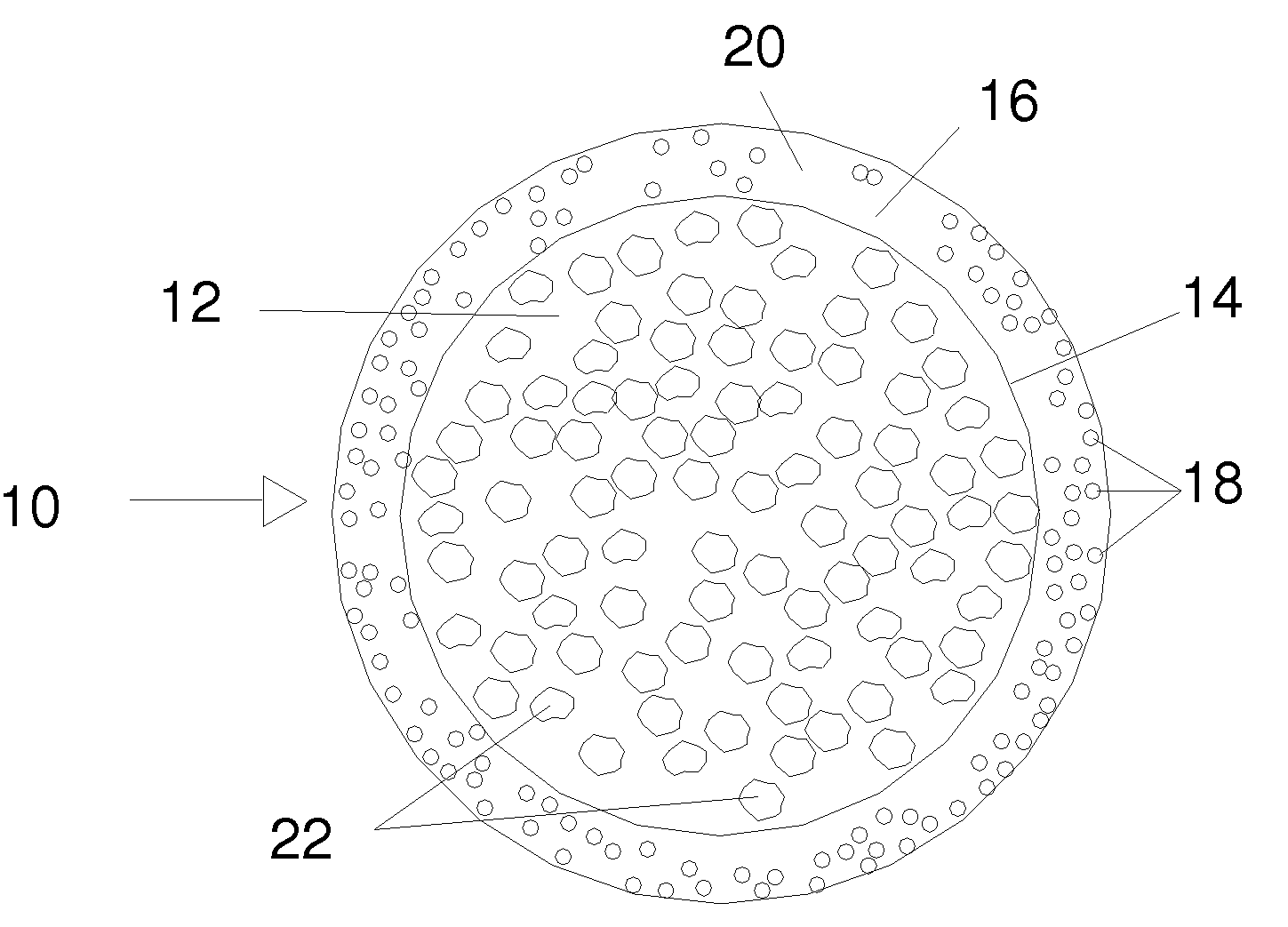

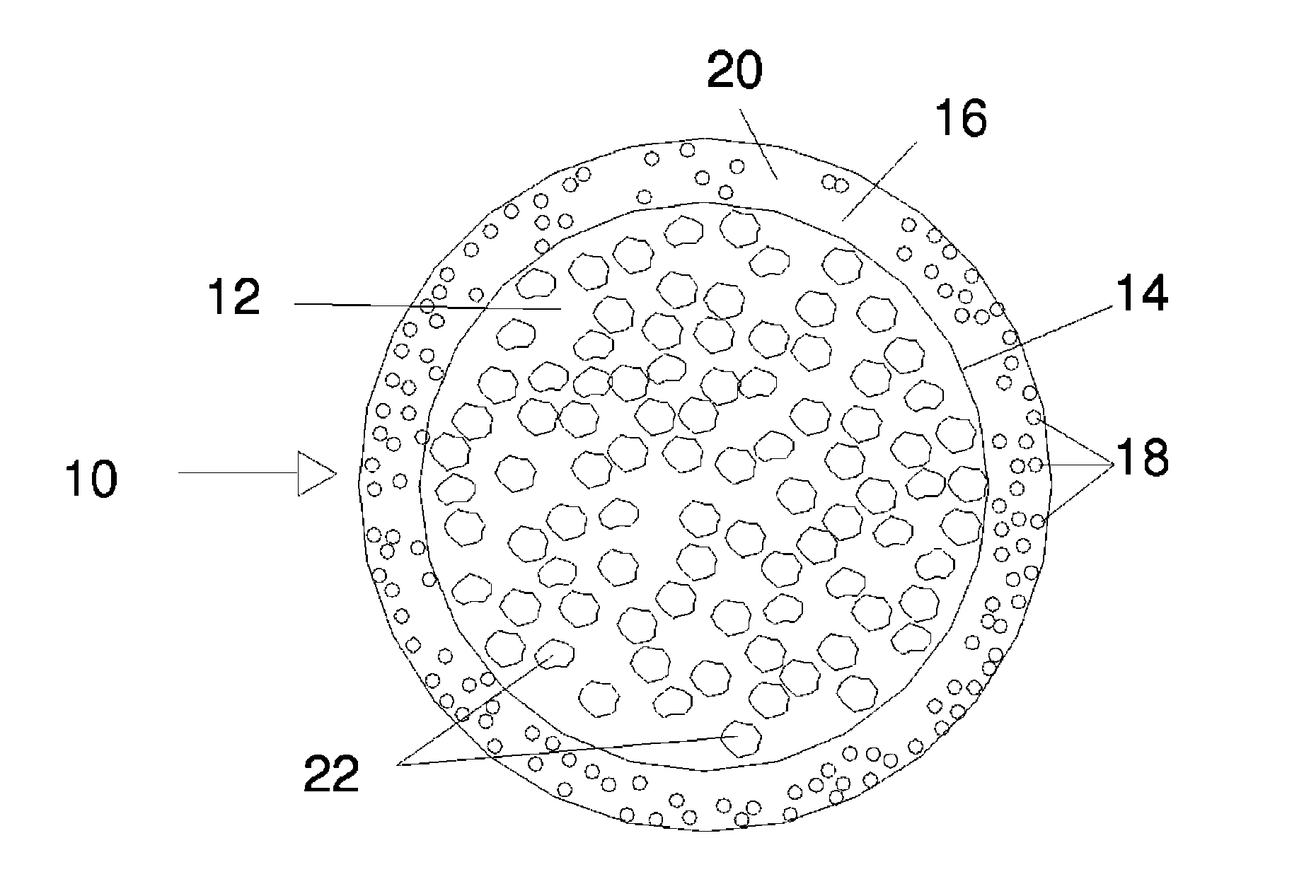

Composition of a thermaly insulating coating system

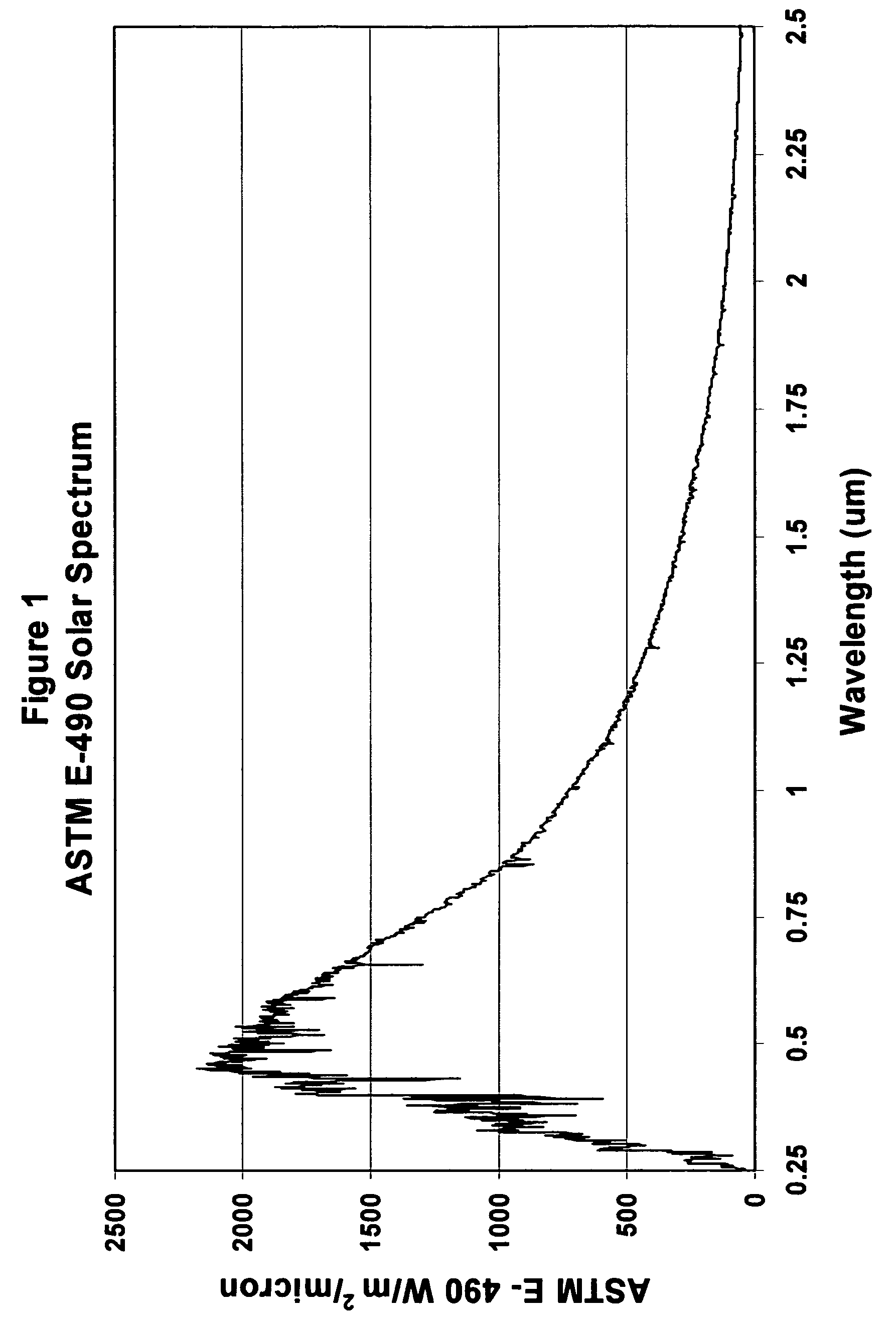

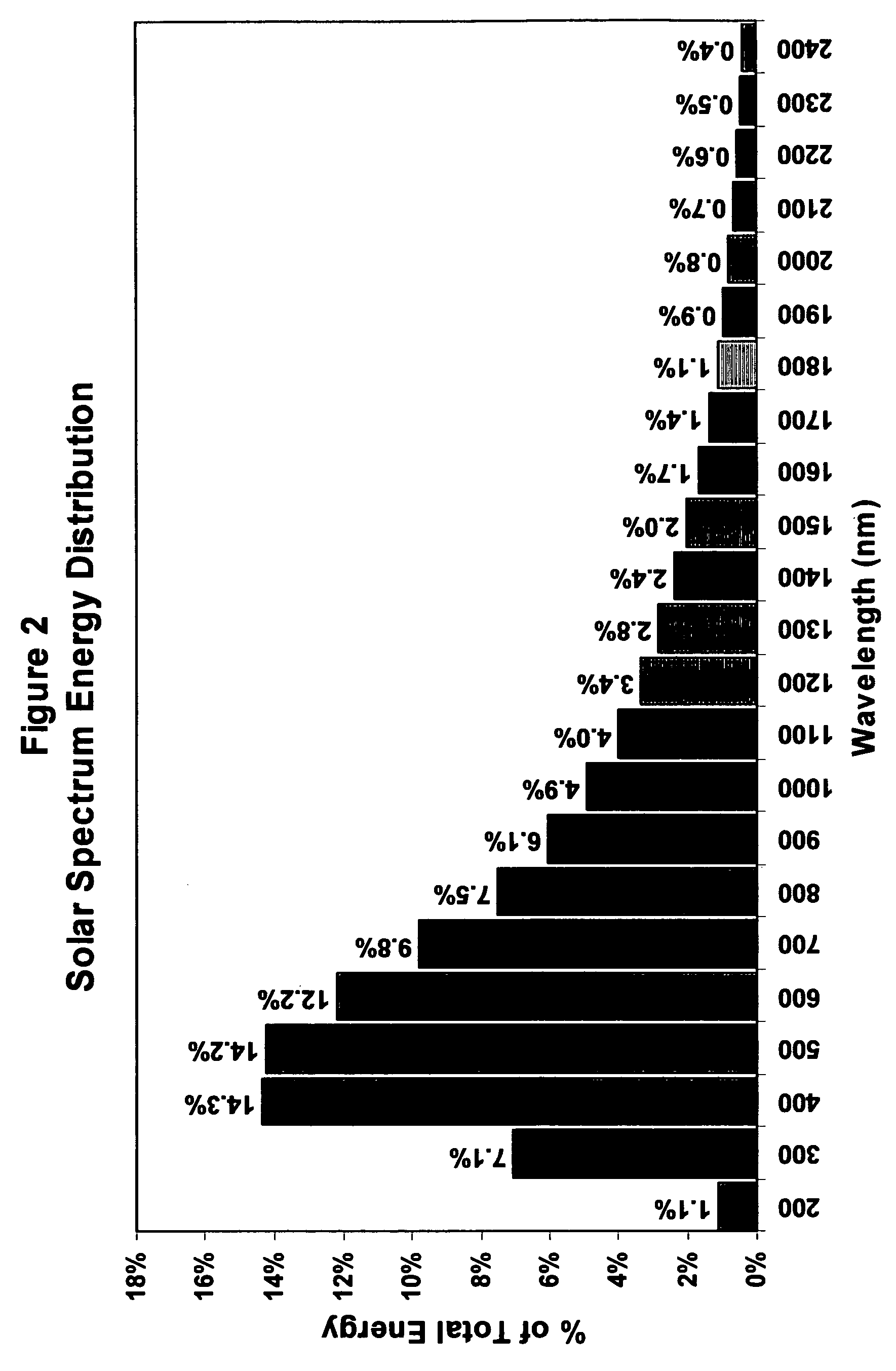

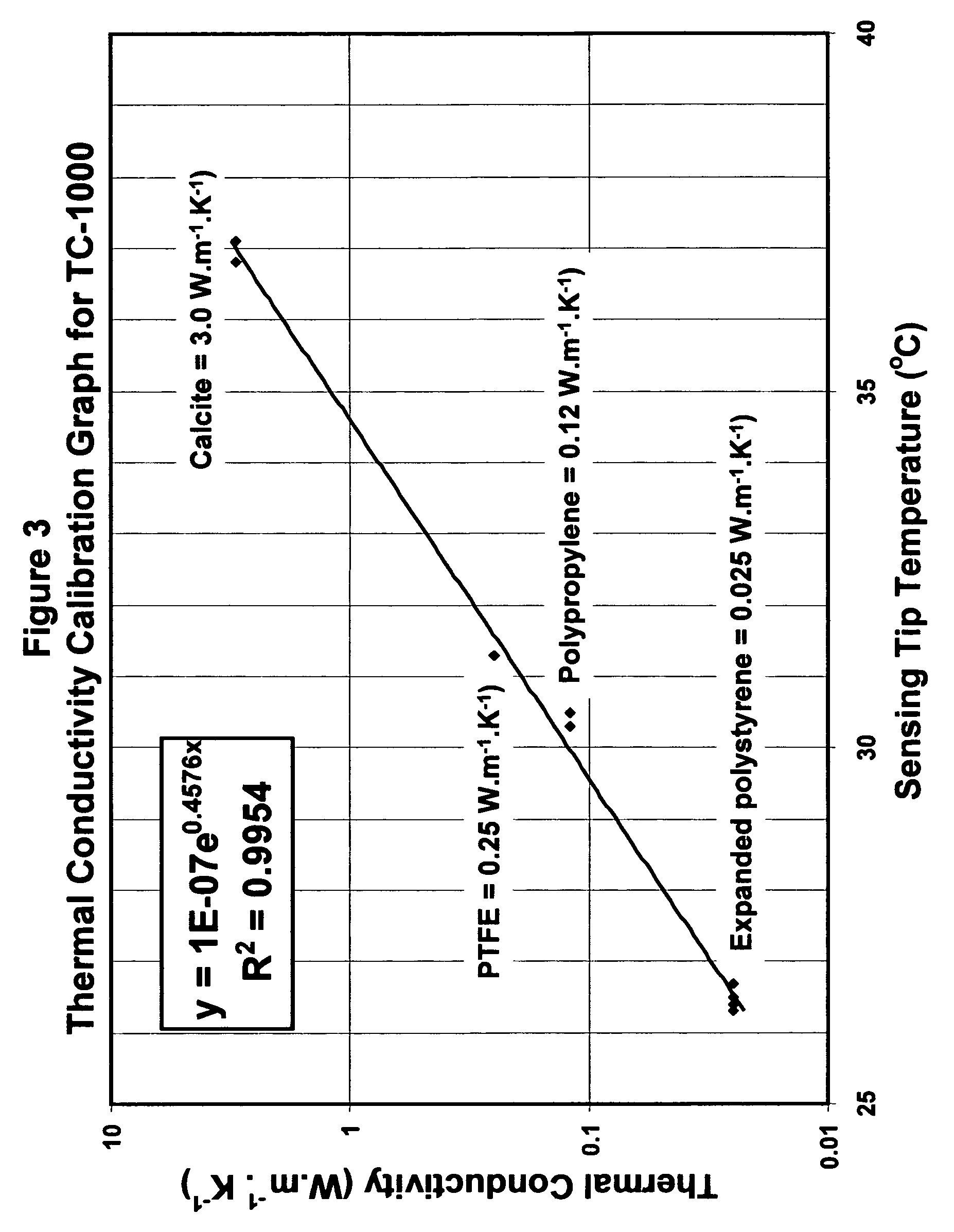

InactiveUS20050126441A1High infrared reflectivityLow thermal conductivityPigmenting treatmentCeramic layered productsCoating systemSolar spectra

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

Roofing granules with high solar reflectance, roofing materials with high solar reflectance, and the process of making the same

ActiveUS20100151199A1Uniform applicationHigh opacityLiquid surface applicatorsRoof improvementNear infrared reflectanceTransmittance

Roofing granules include a core having an average ultraviolet transmission of greater than sixty percent and an average near infrared reflectance of greater than sixty percent and a UV coating layer on the exterior surface. The coating provides UV opacity, while the core provides near infrared reflectance.

Owner:CERTAINTEED CORP

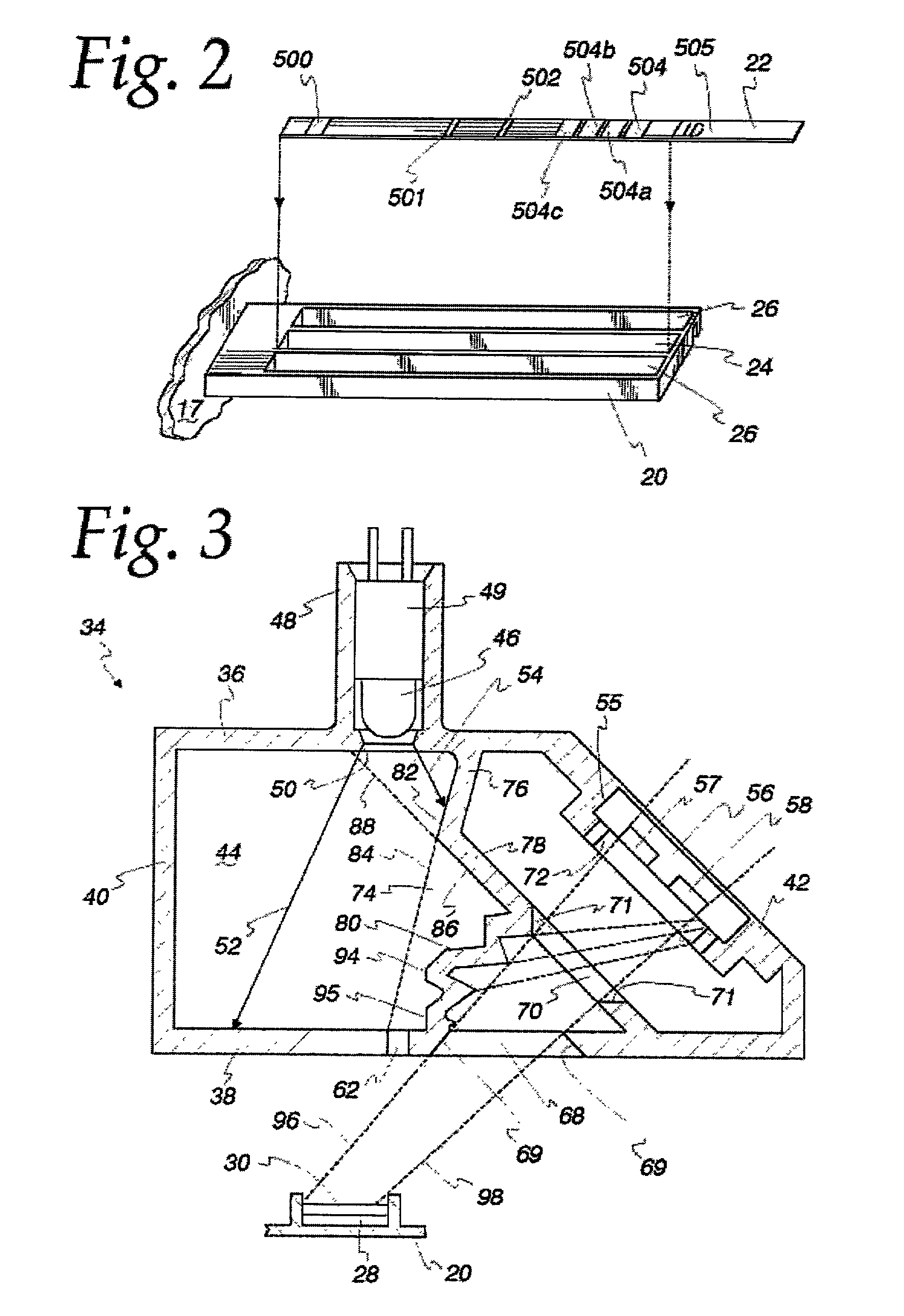

Photoacoustic imaging devices and methods of imaging

ActiveUS20100268058A1Improve image contrastFast processingUltrasonic/sonic/infrasonic diagnosticsCatheterFiberUltrasonic sensor

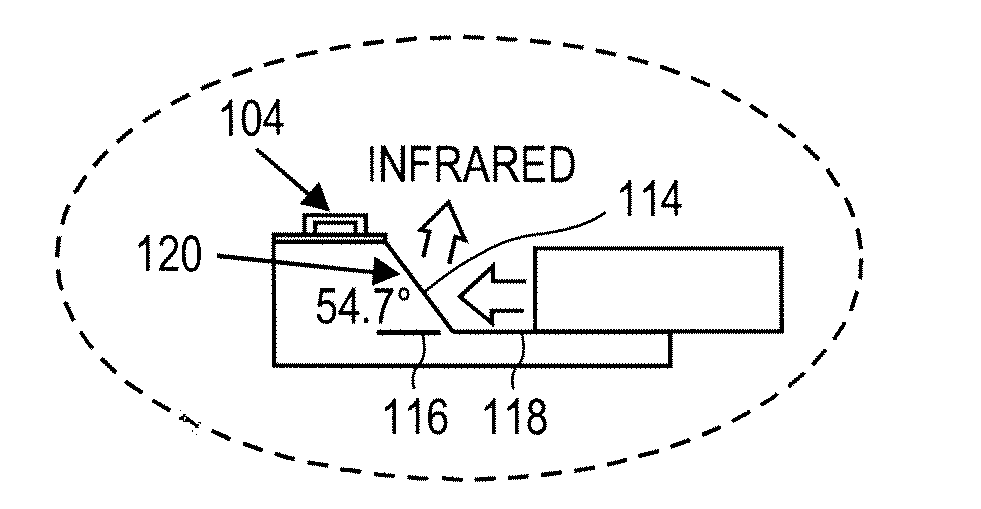

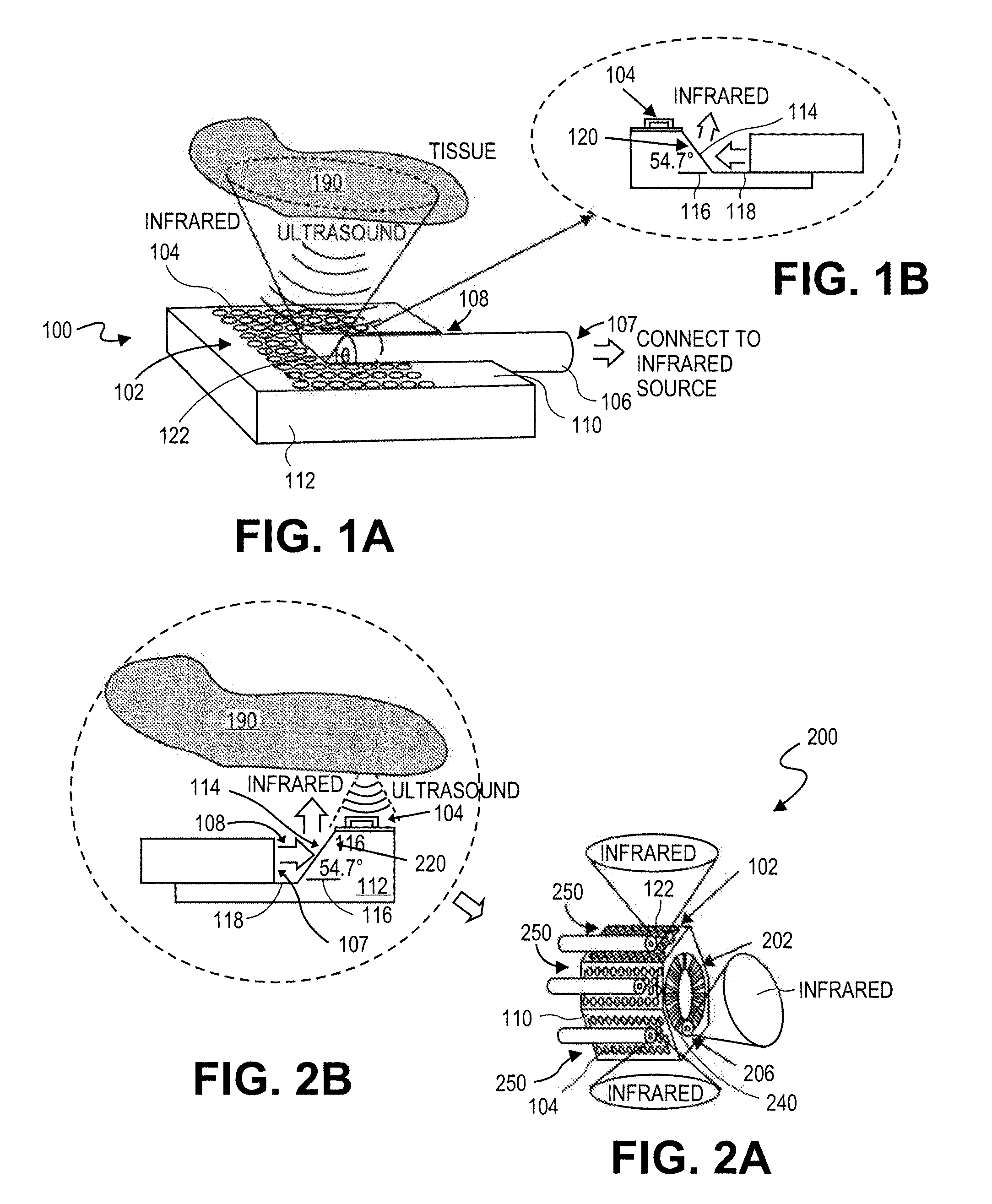

A photoacoustic medical imaging device may include a substrate, an array of ultrasonic transducers on the substrate, at least one groove etched on the substrate, at least one optical fiber, and at least one facet. Each optical fiber is disposed in one of the grooves. Each facet is etched in one of the grooves and coated with a layer of metal having high infrared reflectivity. Each optical fiber is configured to guide infrared light from a light source through the fiber and toward the respective facet. The facet is configured to reflect the infrared light toward a target.

Owner:STC UNM

Artificial suede-type leather and process for producing the same

InactiveUS20060035556A1Good light fastnessBrilliant colorationSynthetic resin layered productsWoven fabricsPolyesterLight irradiation

This invention relates to a suede-like artificial leather using ultra-fine polyester fibers and a polyurethane, and provides a suede-like artificial leather free from the occurrence of specking and having graceful surface appearance and high light fastness. The suede-like artificial leather comprising a fiber-entangled substrate mainly containing ultra-fine polyester fibers with a fiber fineness of 0.7 dtex or less and a polyurethane, and is dyed, and is wherein said polyurethane contains at least one each of yellow pigments, red pigments and blue pigments, and that said artificial leather satisfies all of the following properties (1) through (3) as measured by the methods described in the specification; (1) The infrared reflectance at 850 nm is 60% or more; (2) The surface temperature during light irradiation is 105° C or lower; (3) The light fastness is class 3 or better. Especially since the suede-like artificial leather of this invention has high light fastness, it can be most suitably used for car seats.

Owner:TORAY IND INC

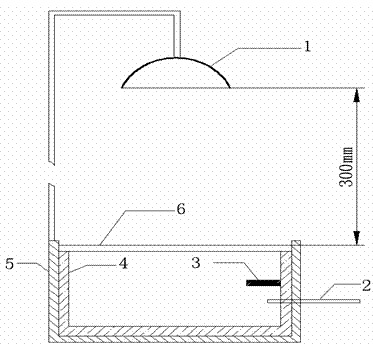

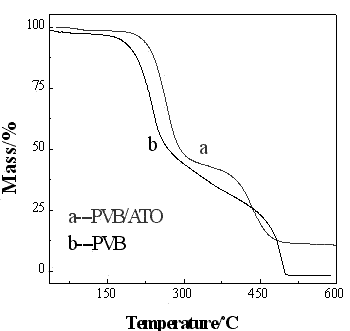

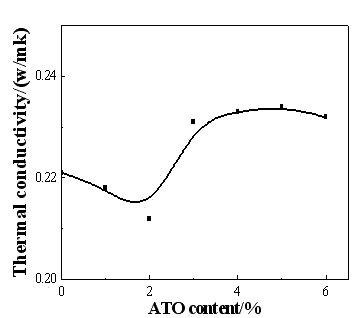

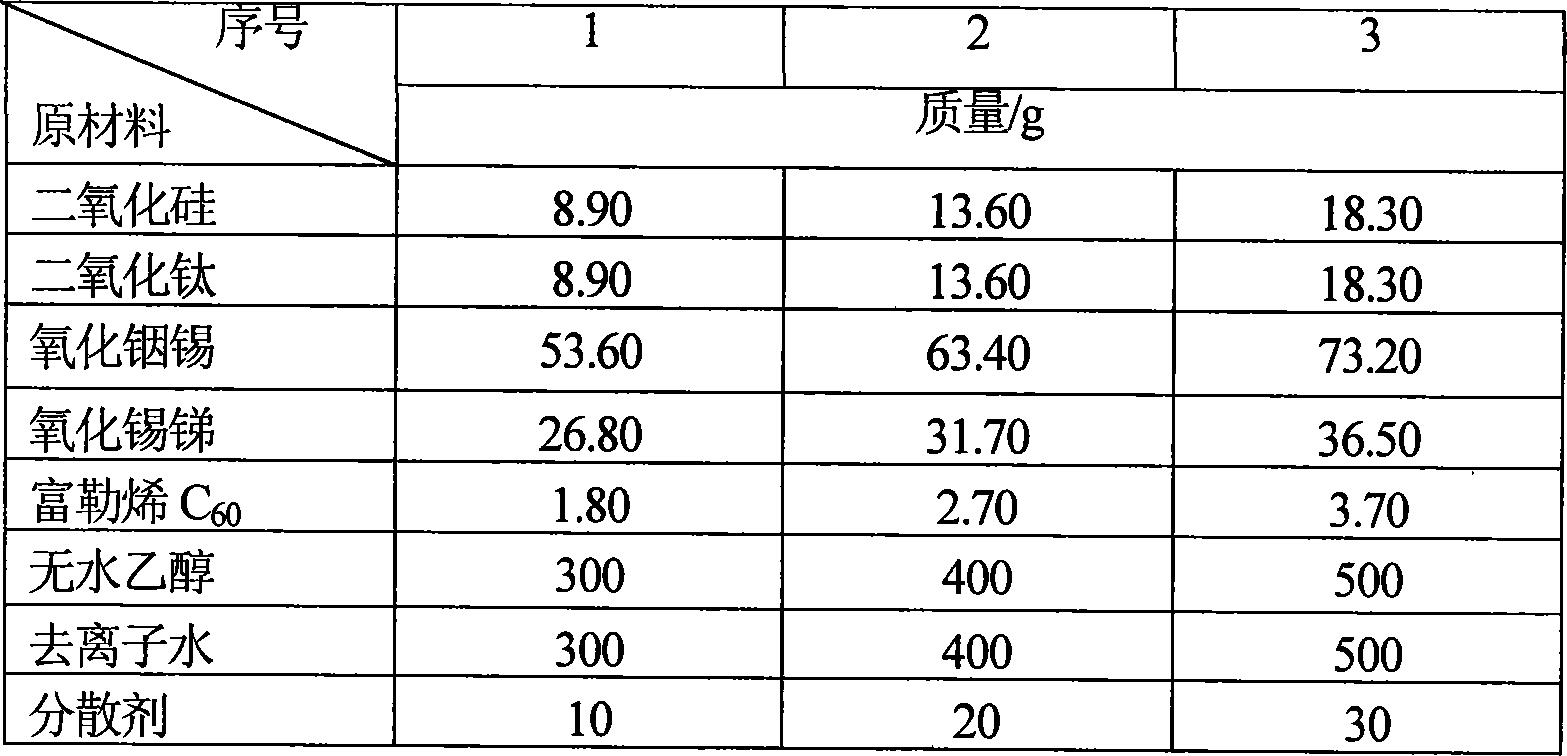

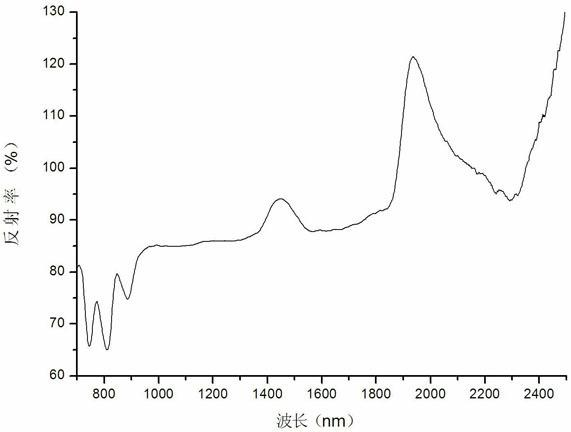

Polyvinyl butyral transparent film and preparation method thereof

ActiveCN102863917ANon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceComposite film

The invention belongs to the field of polymer / nanoparticle composite materials, and relates to an infrared thermal reflection and anti-ultraviolet polyvinyl butyral (PVB) transparent film for laminated safety glass and a preparation method thereof. According to the method, nano-indium stannum oxide (ATO) is selected as functional particles, is subjected to double processing through a coupling agent and a dispersing agent and is poured into a mold to be formed and compounded after being directly and uniformly mixed with purchased or self-made polyvinyl butyral, plasticizer, antioxidant and filming agent by means of ultrasonic wave to prepare a heat-insulating PVB nano composite film. The nano-ATO particles are subjected to the double processing and the special ultrasonic dispersion process, so that the problem of agglomeration of the ATO is effectively improved; and the prepared PVB nano composite film has superior mechanical property and higher infrared reflectivity and visible light transmittance, and can be directly used for processing and producing heat-insulating, sound-insulating, anti-ultraviolet, transparent and impact-resistant multi-functional safety glass.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Process for making anti-infrared multifunctional camouflaged color cloth

InactiveCN101397708AShort production processHue once goodFibre treatmentSingeingFiberTextile printer

The invention relates to a textile printing and dyeing technique, in particular to a manufacturing technique of an infrared ray resistant multi-functional camouflage fabric. The technique flow is as follows: original cloth seaming, singeing, old rolling, 180 pre-treatment, shaping, mercerizing, ground dyeing, pattern printing, baking, aging, stentering of post treatment, examination and acceptance; wherein, the ground dyeing flow is as follows: padding liquor, two groups of infrared rays and drying; a formula adopted in the ground dyeing flow comprises 2g / l to 10g / l of dispersion dyes, 5g / l to 15g / l of vat dyes and 0.01g / l to 1.0g / l of infrared ray resistant regulators; the formula of pattern printing is as follows: 2kg to 15.7kg of dispersion material, 2. kg / l to 10.5kg / l of vat material and 0.01kg to 2.5kg of infrared ray resistant regulators; post treatment has the function compatibility of multiple functions which are water proofing, oil repellence, ventilation, crease resistance and static resistance. The technique has the advantages of having short production procedure, color phase with good uniformity, stable infrared reflectivity, low cost, multiple functions, mainly using environment friendly dyes and being suitable for infrared ray resistant camouflage fabric products with different fibers and different specifications.

Owner:XIANYANG JIHUA NEW 30 DYEING & PRINTING

Transparent heat insulating dope and preparation method thereof

InactiveCN101186781AHigh visible light transmittanceHigh infrared reflectivityFireproof paintsPolyurea/polyurethane coatingsUltravioletSolvent

The invention discloses a transparent heat insulation coating and process for preparation. A mixed solvent of dispersant, defoaming agent, deionized water and absolute ethyl alcohol and nano-powder are put into a beaker, the PH value is regulated to 6.5 to 7.4, and homogenate of 30 minutes to 60 minutes is implemented on a high speed homogenizer, and 20 to 30 times of ultrasonic dispersion is performed. Ultrasonic agitation is conducted, and when the ultrasonic agitation is stopped, cold air is let in. Further, water polyurethane dispersoid, the defoaming agents, thickening agents and texanol are added in, the PH value is regulated to 6.5 to 7.5, the homogenate of 20 to 30 minutes is conducted on the high speed homogenizer, and the transparent heat insulation coating is obtained. The invention is simple in preparation and needs no investment of expensive large-scale equipment, the preparation and construction technology is simple and convenient, which effectively reduces the manufacture costs and is favorable for popularization in markets. The transparent heat insulation coating of the invention has the advantages of comparatively high visible light transmittance, infrared reflectivity, transparent and uniform appearance of painting film, high rigidity, good adhesive force, strong wash resistance and ultraviolet ray aging resistance.

Owner:SOUTH CHINA UNIV OF TECH

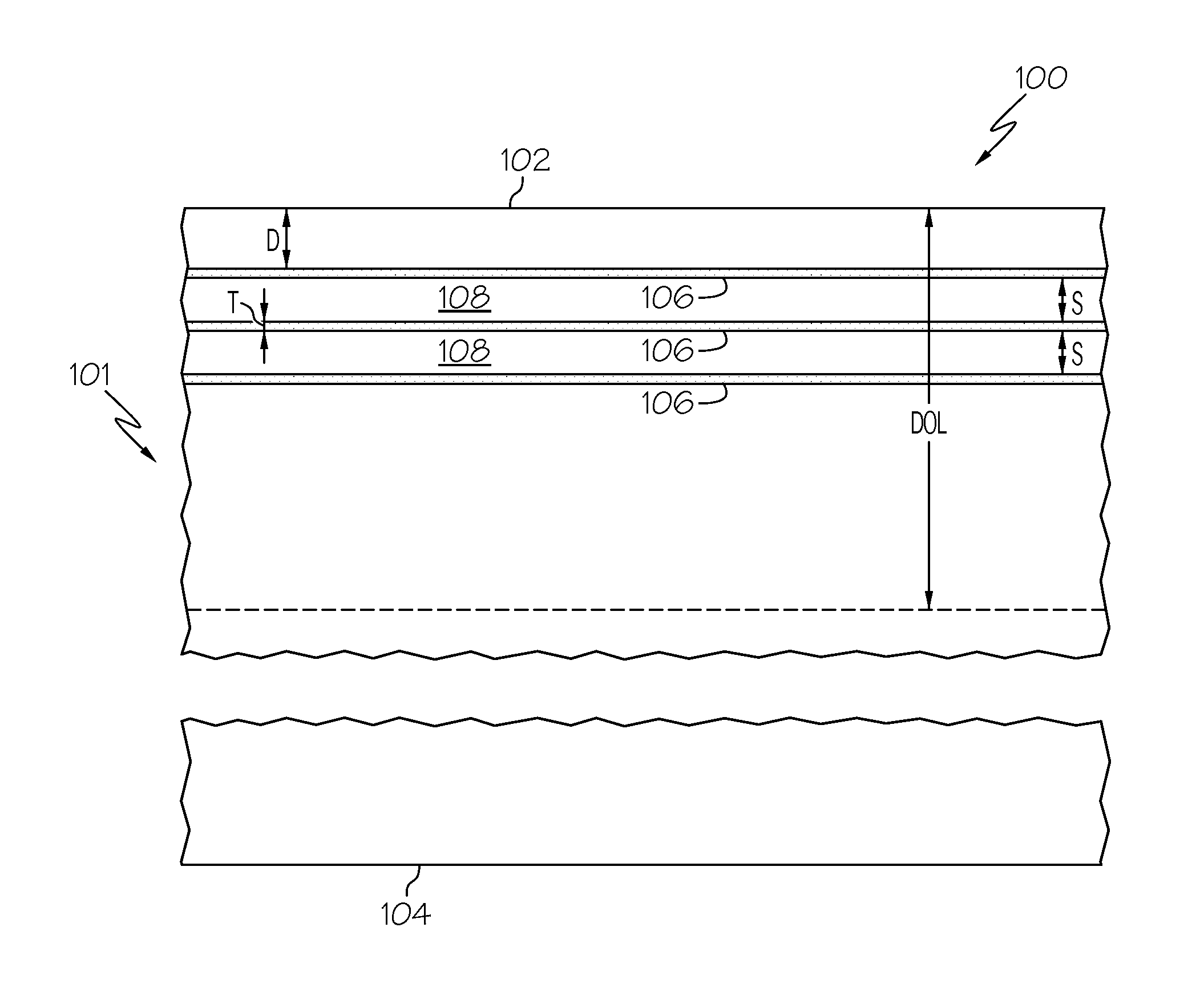

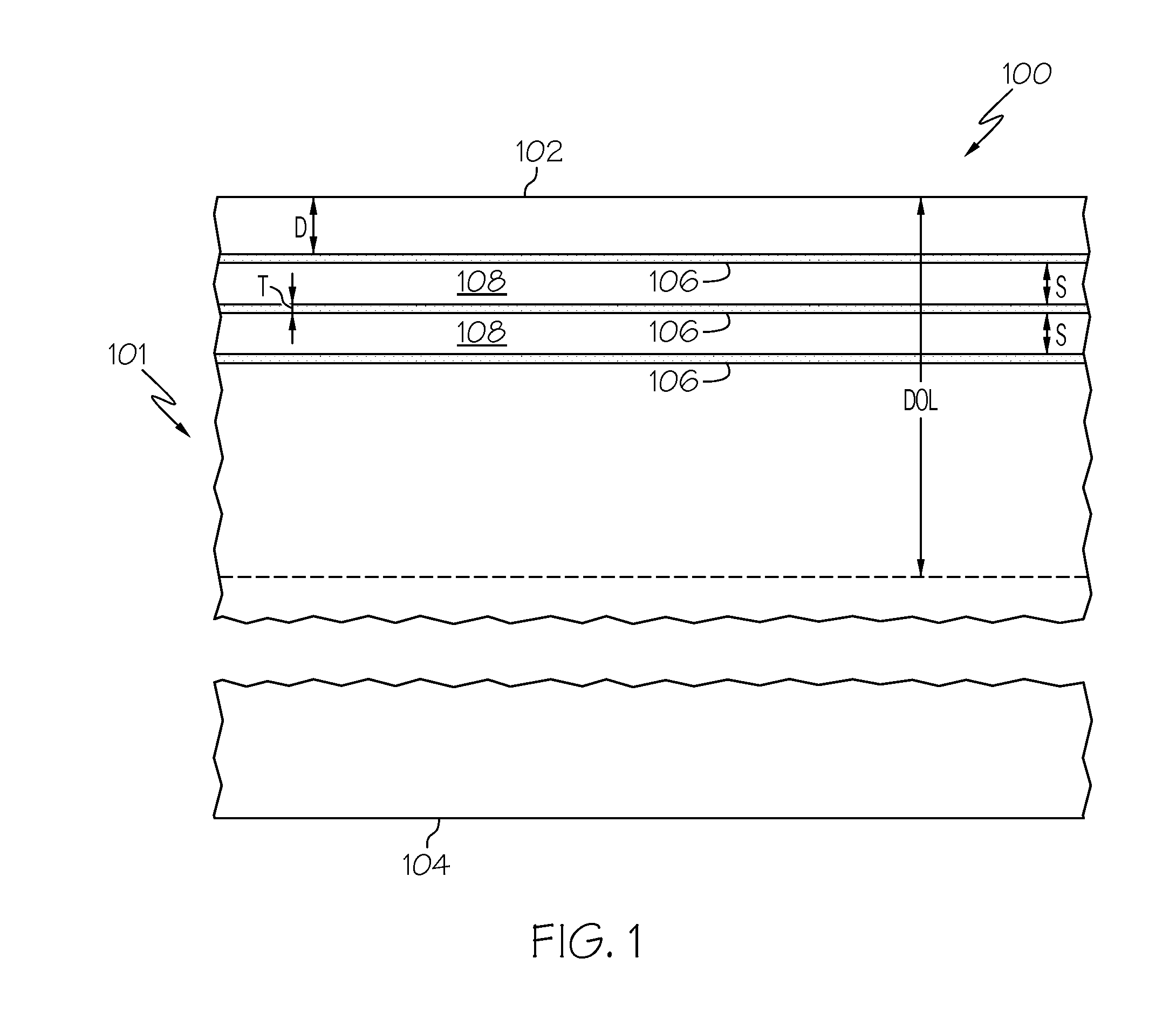

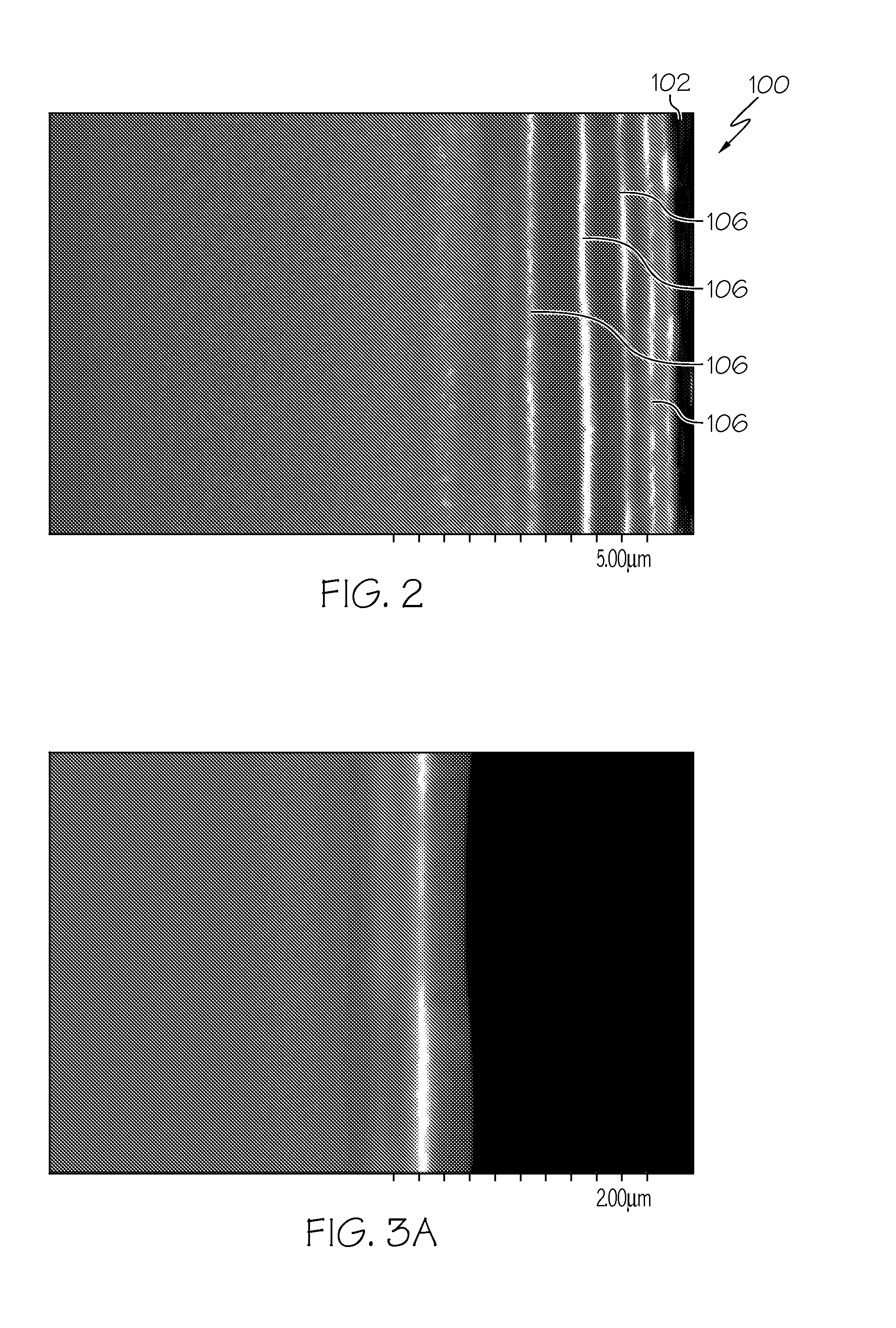

Glass articles with infrared reflectivity and methods for making the same

Glass articles with infrared reflectivity and methods for making the same are disclosed herein. In one embodiment, glass article having infrared reflectivity includes a first surface, a second surface and a body extending between the first and second surfaces. A plurality of discrete layers of metallic silver are formed in the body creating at least one optical cavity in the body. Each discrete layer may have a thickness T such that 100 nm≦T≦250 nm and may be spaced apart from adjacent layers of metallic silver by a spacing S≦500. The glass article reflects at least a portion of electromagnetic radiation incident on the glass article having a wavelength from 800 nm to 2500 nm and transmits at least a portion of electromagnetic radiation incident on the glass article having a wavelength from 390 nm to 750 nm.

Owner:CORNING INC

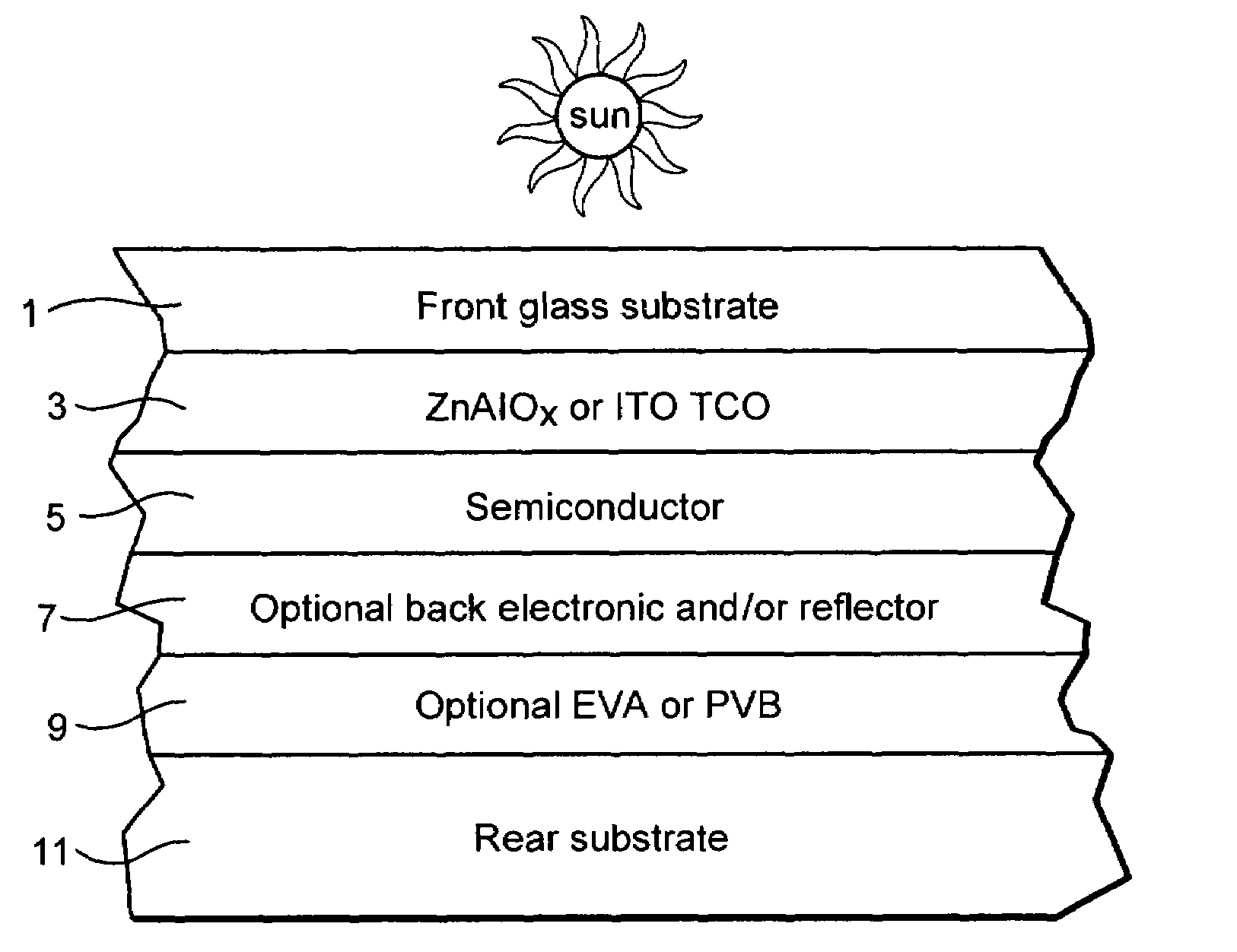

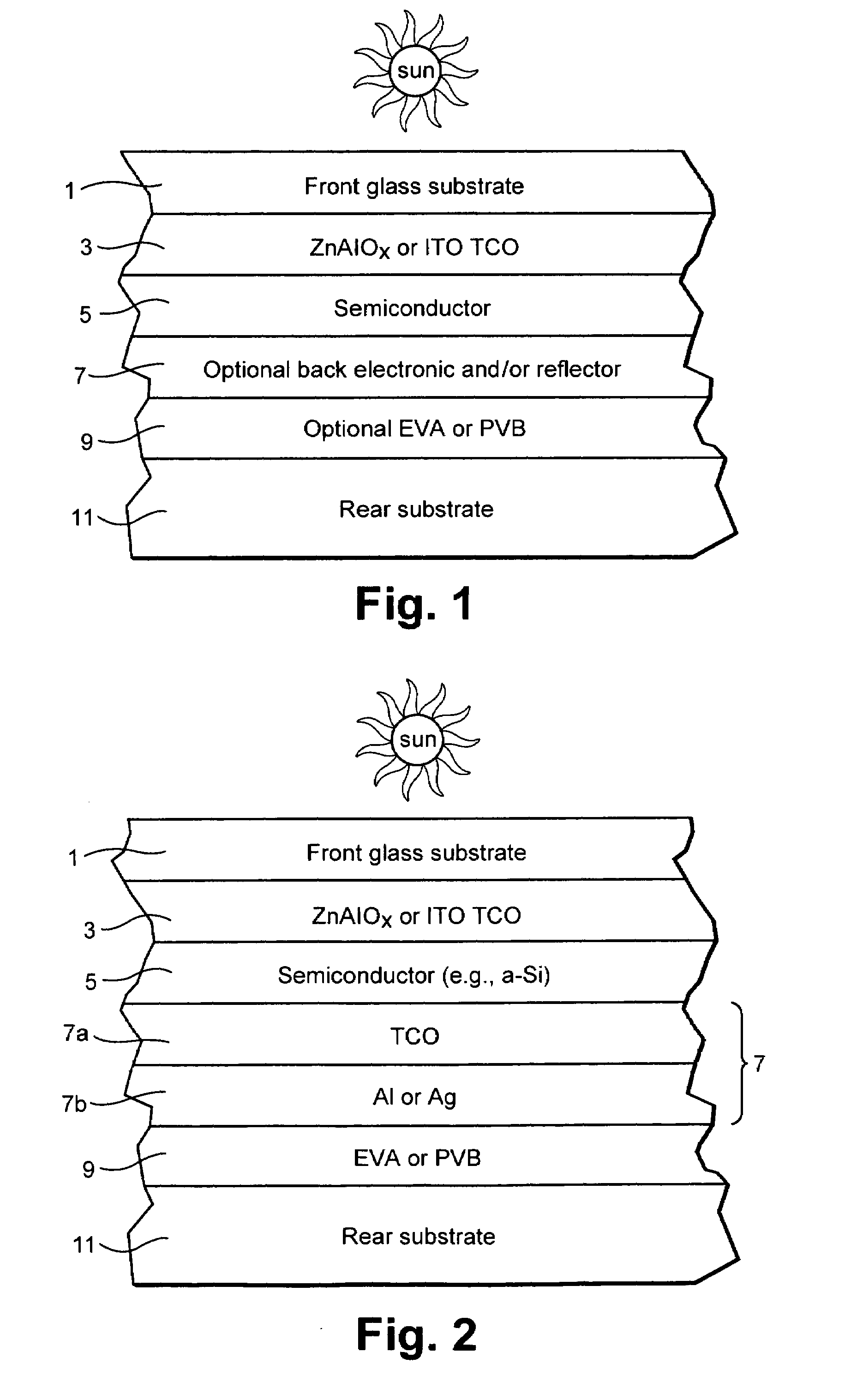

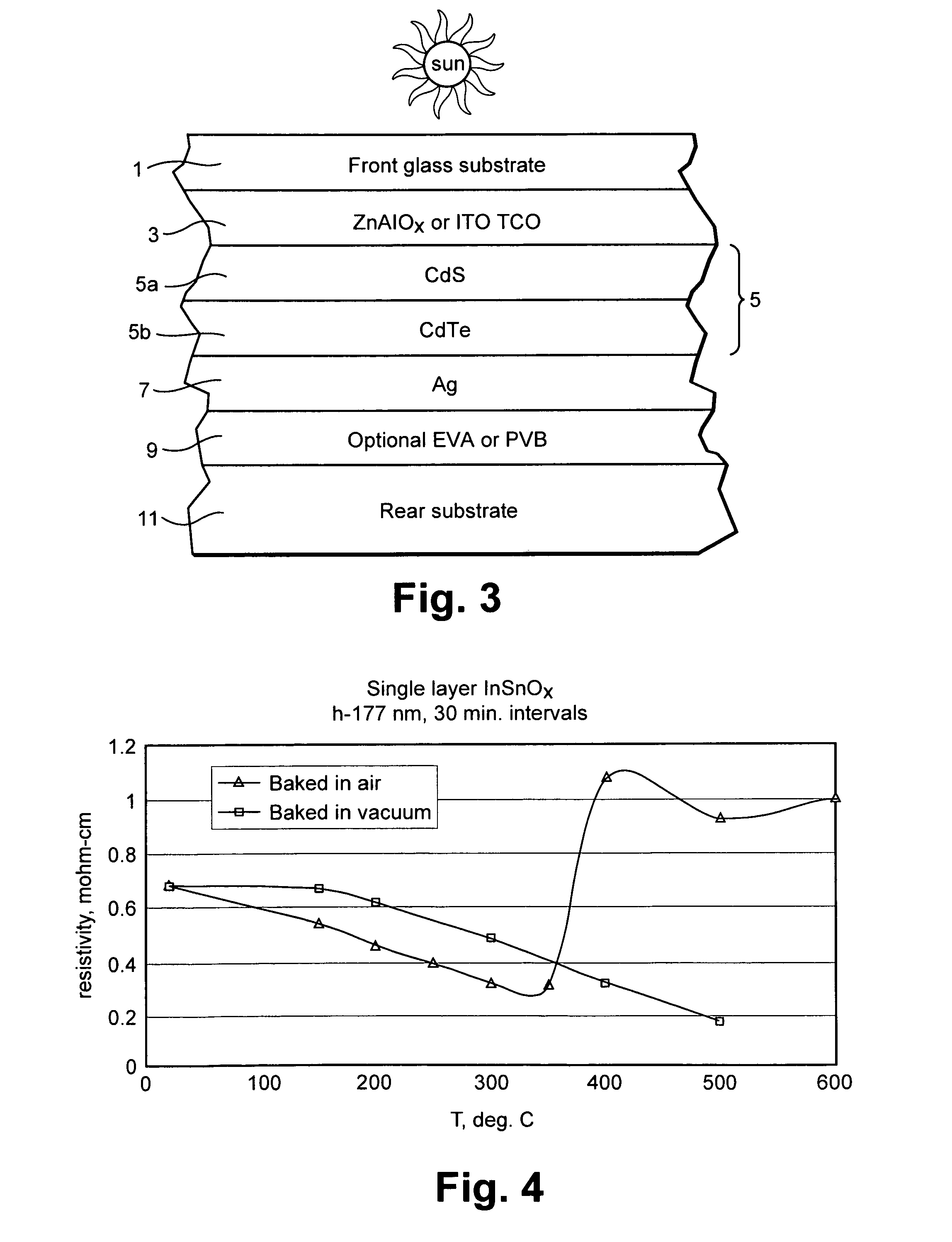

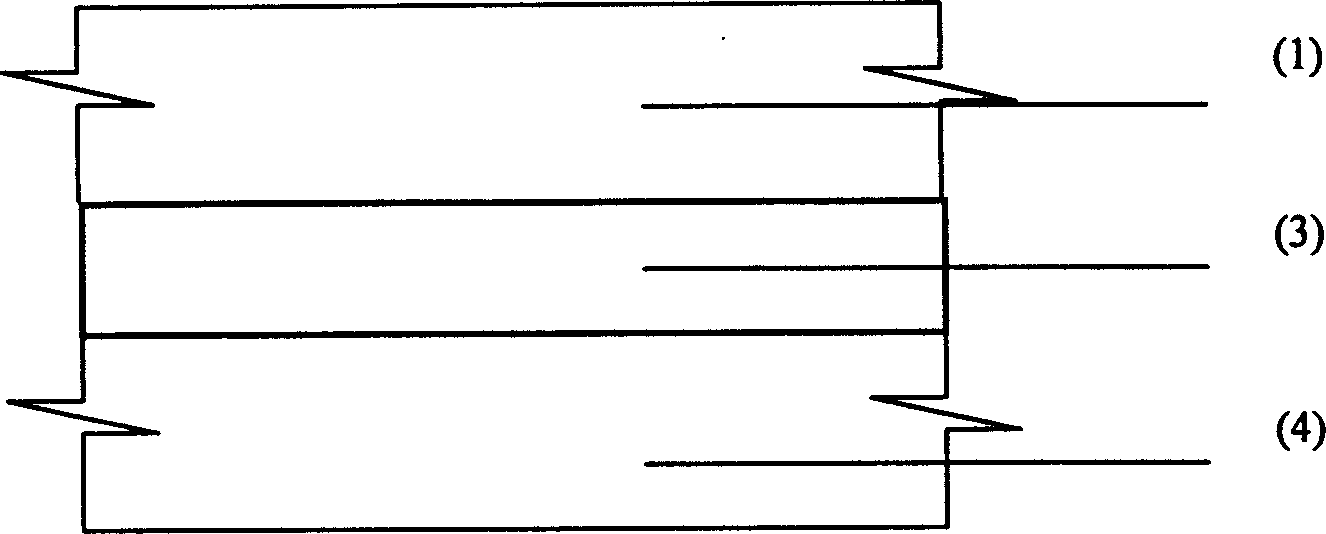

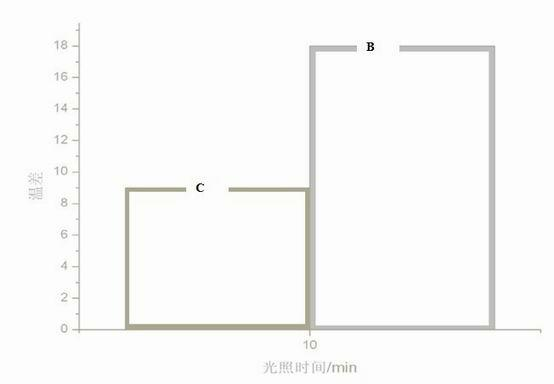

Method of enhancing the conductive and optical properties of deposited indium tin oxide (ITO) thin films

InactiveUS20100304523A1Improve conductivityReduce sheet resistanceMuffle furnacesMaintainance of heating chambersOptical propertyIndium tin oxide

Certain example embodiments of this invention relate to a method of activating an indium tin oxide (ITO) thin film deposited, directly or indirectly, on a substrate. The ITO thin film is baked in a low oxygen environment at a temperature of at least 450 degrees C. for at least 10 minutes so as to provide for (1) a post-baked resistivity of the ITO thin film that is below a resistivity of a corresponding air-baked ITO thin film, (2) a post-baked visible spectrum absorption and transmission of the ITO thin film that respectively are below and above the absorption and transmission of the corresponding air-baked ITO thin film, and (3) a post-baked infrared reflectivity of the ITO thin film that is above the reflectivity of the corresponding air-baked ITO thin film. The substrate with the activated ITO thin film may be used in a photovoltaic device, for example.

Owner:GUARDIAN GLASS LLC

Autombobile windshield glass possessing infrared reflection performance and its preparation method

InactiveCN1555989AImprove transmittanceWith thermal insulation performanceWindowsWindscreensIndiumSilicon oxide

An anti-fogging insulating windshield with high infrared reflectivity (more than 70%) features that a semiconductor oxide film, which may be the indium oxide film doped by tin oxide or the zinc oxide film doped by at least one of aluminium oxide, silicon oxide, boron oxide, dysprosium oxide and gallium oxide, is arranged between PVB film and the internal or external surface of glass. Its preparing processis also disclosed.

Owner:TSINGHUA UNIV

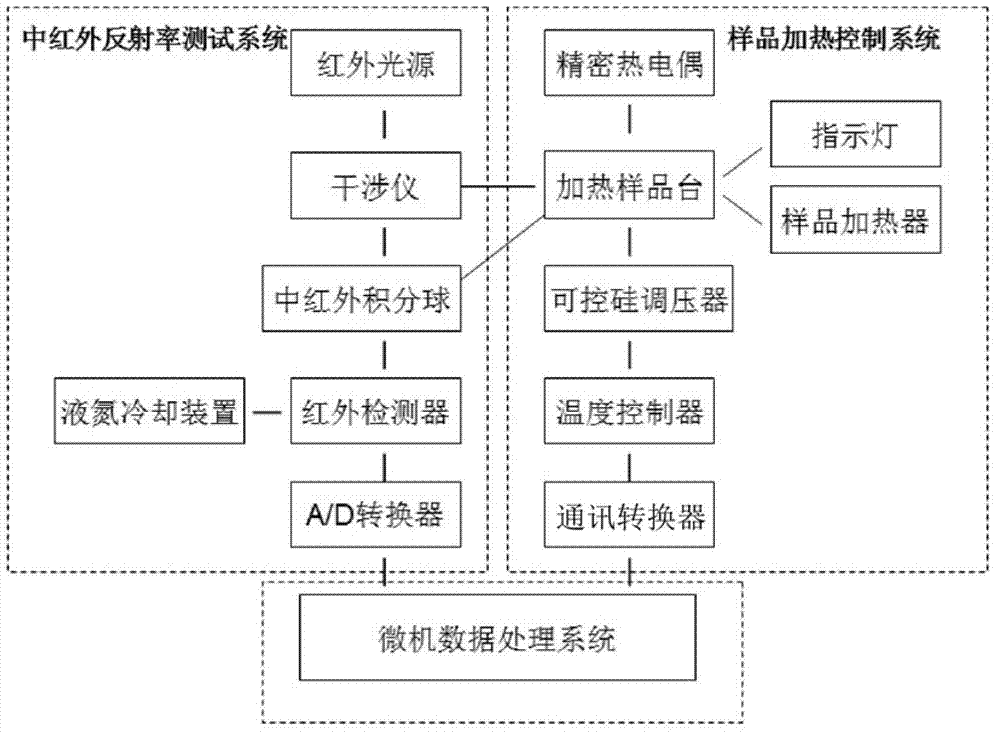

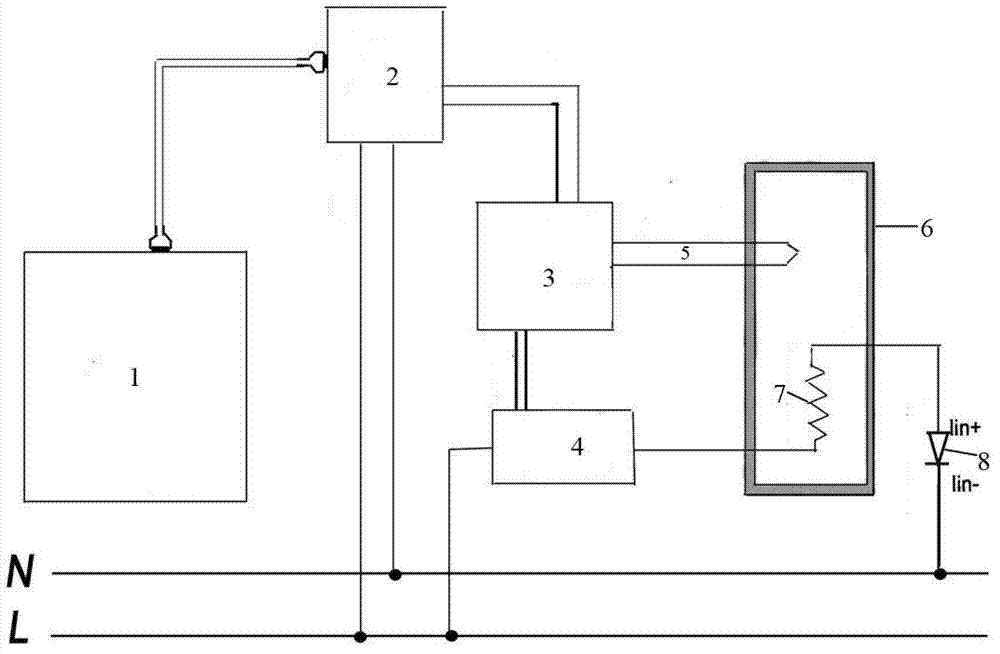

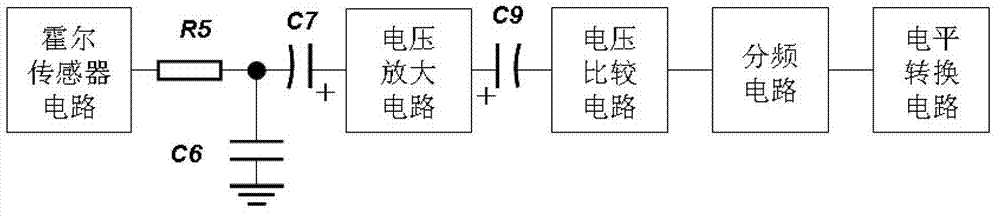

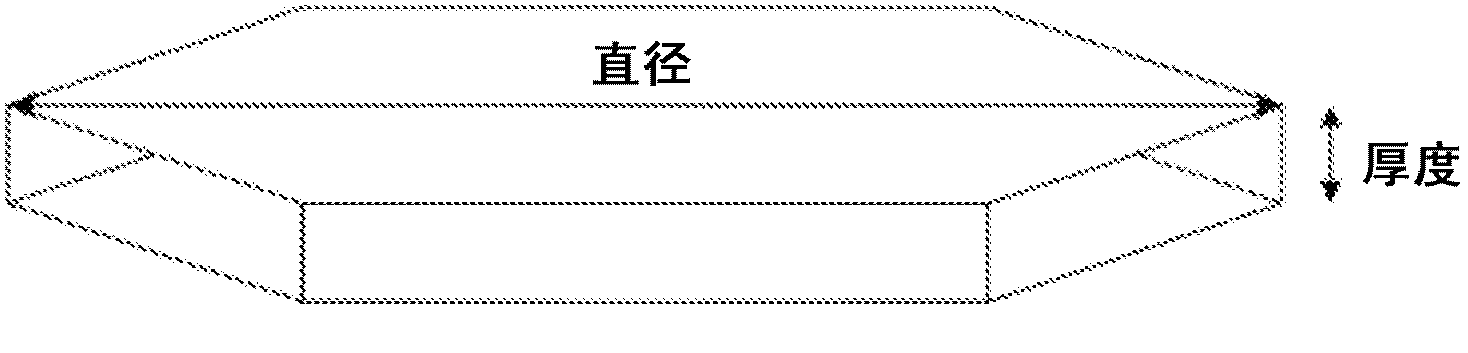

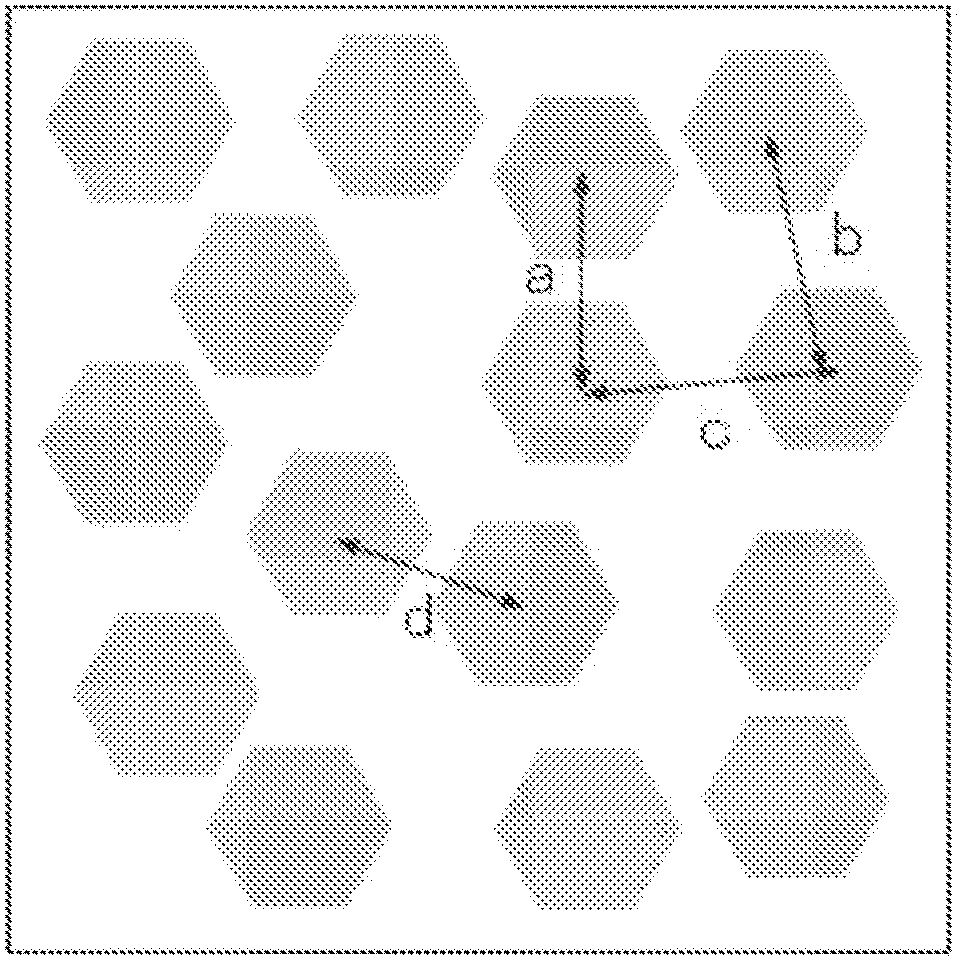

Middle/high-temperature infrared emissivity testing device

ActiveCN102830064AEasy to operateRelaxed test conditionsMaterial analysis by optical meansMaterial thermal analysisLiquid nitrogen coolingData treatment

The invention discloses a middle / high-temperature infrared emissivity testing device. The middle / high-temperature infrared emissivity testing device comprises an infrared reflectivity testing system, a sample heating control system and a microcomputer data processing system. The infrared reflectivity testing system comprises an infrared source, an interferometer, an intermediate infrared integrating sphere, an infrared detector, an A / D convertor and a liquid nitrogen cooling device. The sample heating control system comprises a sample heating table, a communication convertor, a temperature controller, a silicon-controlled voltage regulator, a sample heater and an indicator light, wherein the communication convertor, the temperature controller, the silicon-controlled voltage regulator, the sample heater and the indicator light are orderly connected. The temperature controller is connected to a precision thermocouple. The microcomputer data processing system is used for inputting preset parameters and acquiring and treating data. The middle / high-temperature infrared emissivity testing device is simple, can be used conveniently, can realize fast and accurate measurement of infrared emissivity of a material in a middle / high-temperature range of 20 to 600 DEG C, and can be used for the field of key development of middle / high-temperature solar photo-thermal coatings.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

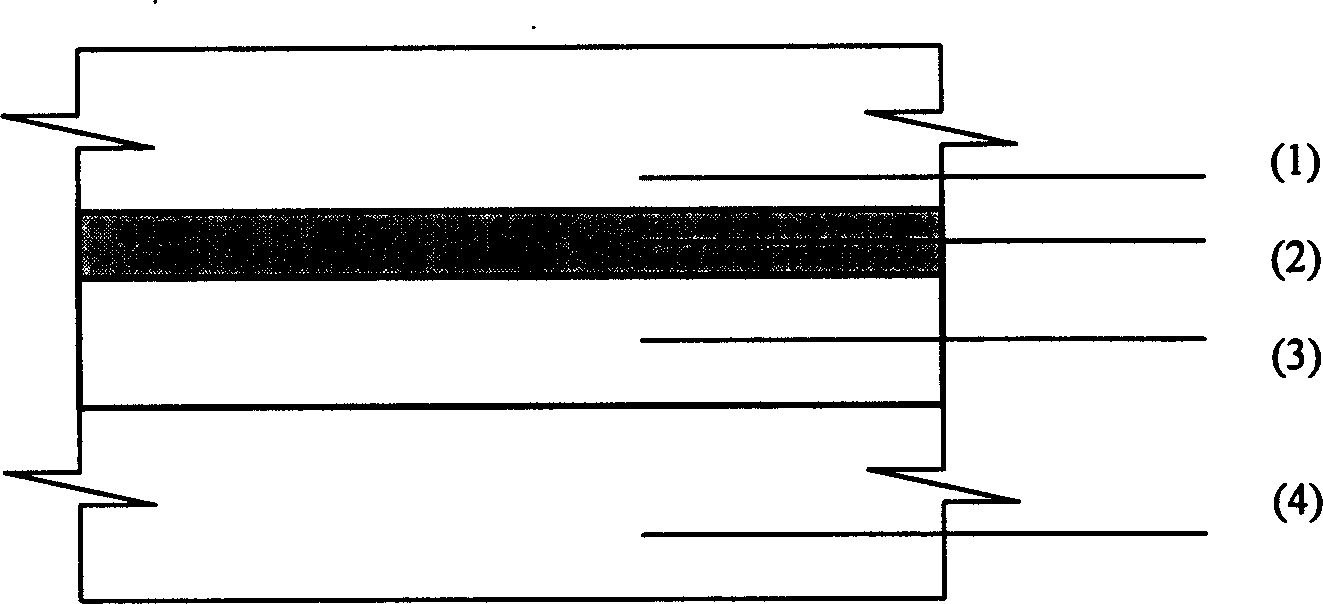

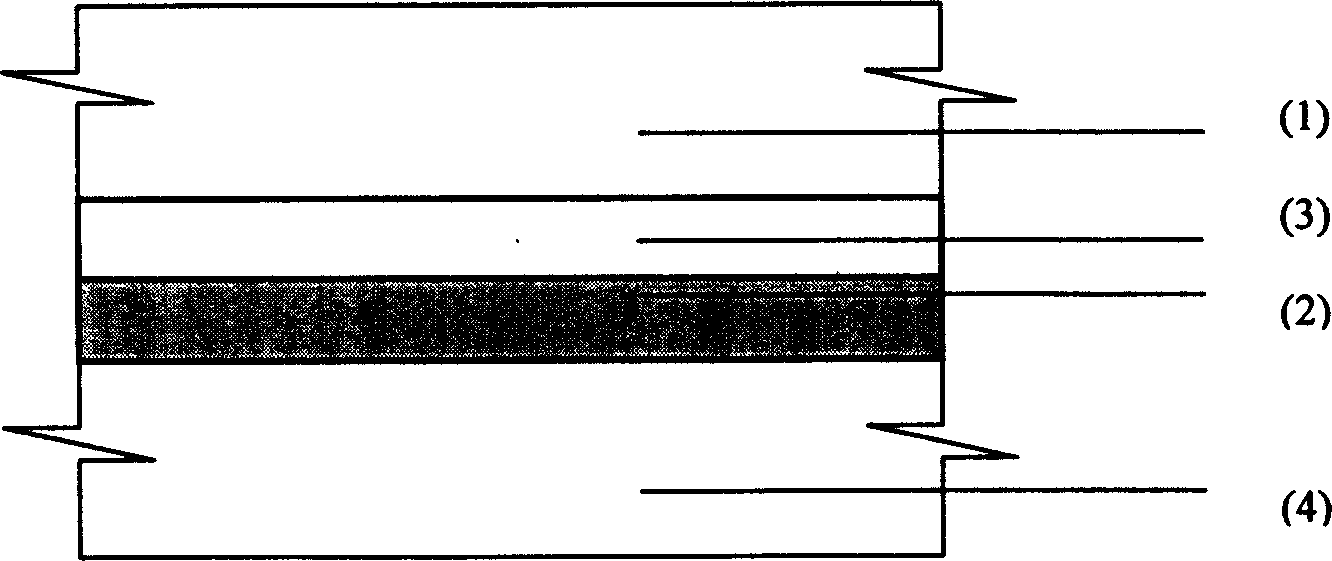

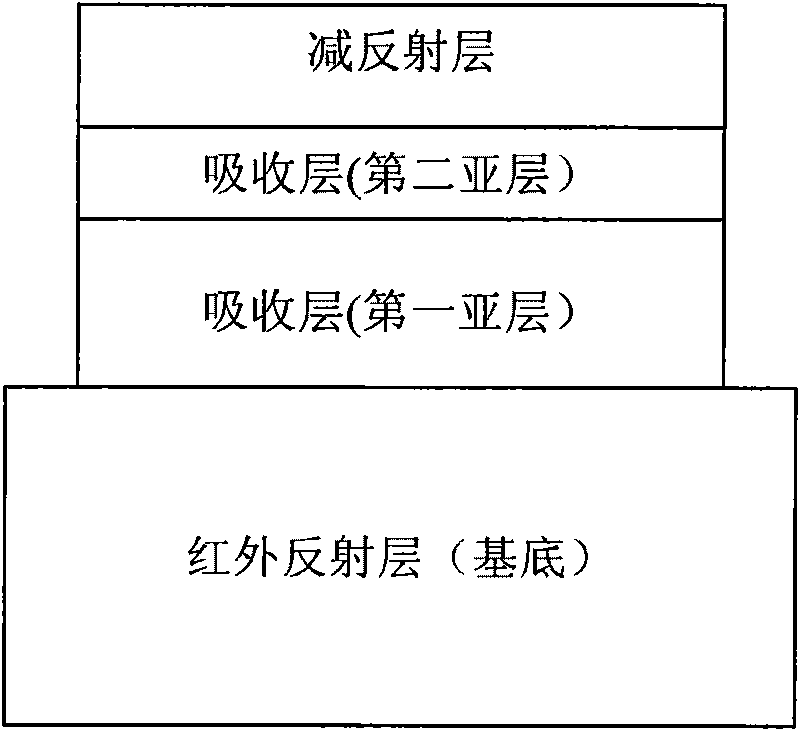

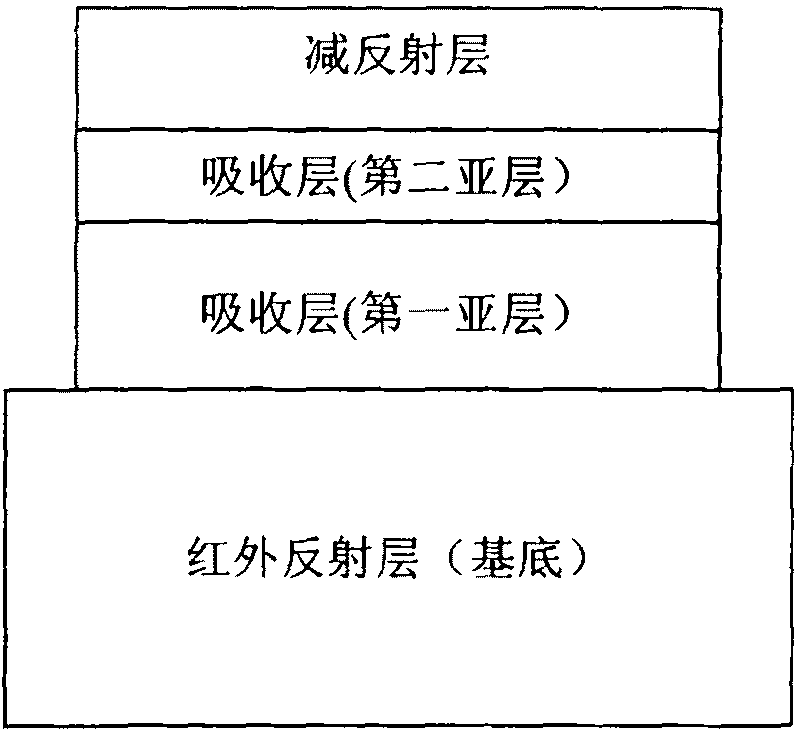

Solar spectrum selective absorbing coating and preparation method thereof

ActiveCN101737983AImprove thermal stabilityMeet the requirements of sustainable developmentSolar heat devicesLayered productsRefractive indexAlloy

The invention relates to a solar spectrum selective absorbing coating which is prepared by adopting magnetron sputtering technology. The absorber of the coating comprises the following three layers of films from substrate to top: a first layer adopts copper with infrared reflectivity or aluminium substrate as an infrared reflecting layer; a second layer uses a metalloid layer and a medium type layer which have different refractive indexes and thicknesses; and a third layer uses SiON film as an antireflection layer. The preparation method comprises the following steps: the first layer (infrared reflecting layer): cleaning copper or aluminium sheets with ultrasonic wave or polishing the copper or aluminium sheets; the metalloid layer of second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the medium type layer of the second layer: using two metals as alloy target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting DC electrical source to perform reactive sputtering; the third layer (antireflection layer): uses SiN as target, argon gas as sputtering gas and nitrogen and oxygen gas as reaction gas and adopting radio frequency power source to perform reactive sputtering; and finally obtaining the absorber.

Owner:安徽科鑫光热技术有限公司

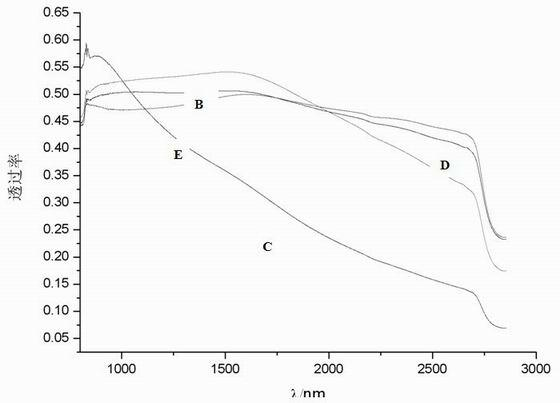

Low-reflection high-sunshade low radiation coated glass with double-silver composite structure and technique

InactiveCN101148329AStrong reflexesLow surface emissivityVacuum evaporation coatingSputtering coatingRadianceTransmittance

The present invention is one kind of coated glass with double silver layer structure and possessing low reflectivity, high shading coefficient and low insolation, and its coating process. The film structure on the glass includes one first dielectric layer, one composite absorption layer, one first silver layer, one first protecting layer, one composite dielectric layer, one second silver layer, one second protecting layer and one second dielectric layer arranged successively on the glass. The glass with the film structure has the advantages of high infrared reflectivity, low surface radiance, high shading performance, medium visible light transmittance, medium visible light reflectivity, etc.

Owner:江门耀皮工程玻璃有限公司

Composition of a thermaly insulating coating system

InactiveUS8287998B2High infrared reflectivityReduce absorptionPigmenting treatmentCeramic layered productsParticulatesCoating system

A composition for a Coating System (paint) which forms an insulating material being designed to both reflect infrared radiation and have reduced thermal conductivity. The coating system may be either a single Thermal Coating or may be a Thermal Coating used in combination with a Thermal Primer. The Thermal Coating is formulated using conventional techniques and a resin used in paint manufacture, but utilizes primary pigments and extender mineral pigments which preferentially reflect in the infra red area of the solar spectrum. A method of characterizing particulate materials for their infra red reflectivity is described, which provides a means for preferential selection of particulate additives based on their relative visible light and infrared reflectivity. Additionally the incorporation of hollow micro-spheres is desired to reduce thermal conductivity. The Thermal Primer is designed to provide adhesion between the Thermal Coating and the substrate on which it is applied and uses conventional techniques to achieve those properties. However it has been found advantageous to incorporate hollow micro-spheres with low thermal conductivity, such as glass, ceramic or polymeric micro-spheres and / or an extender pigment with low thermal conductivity such as calcined clay to further reduce heat flow through the Coating System.

Owner:ANTHONY DAVID SKELHORN

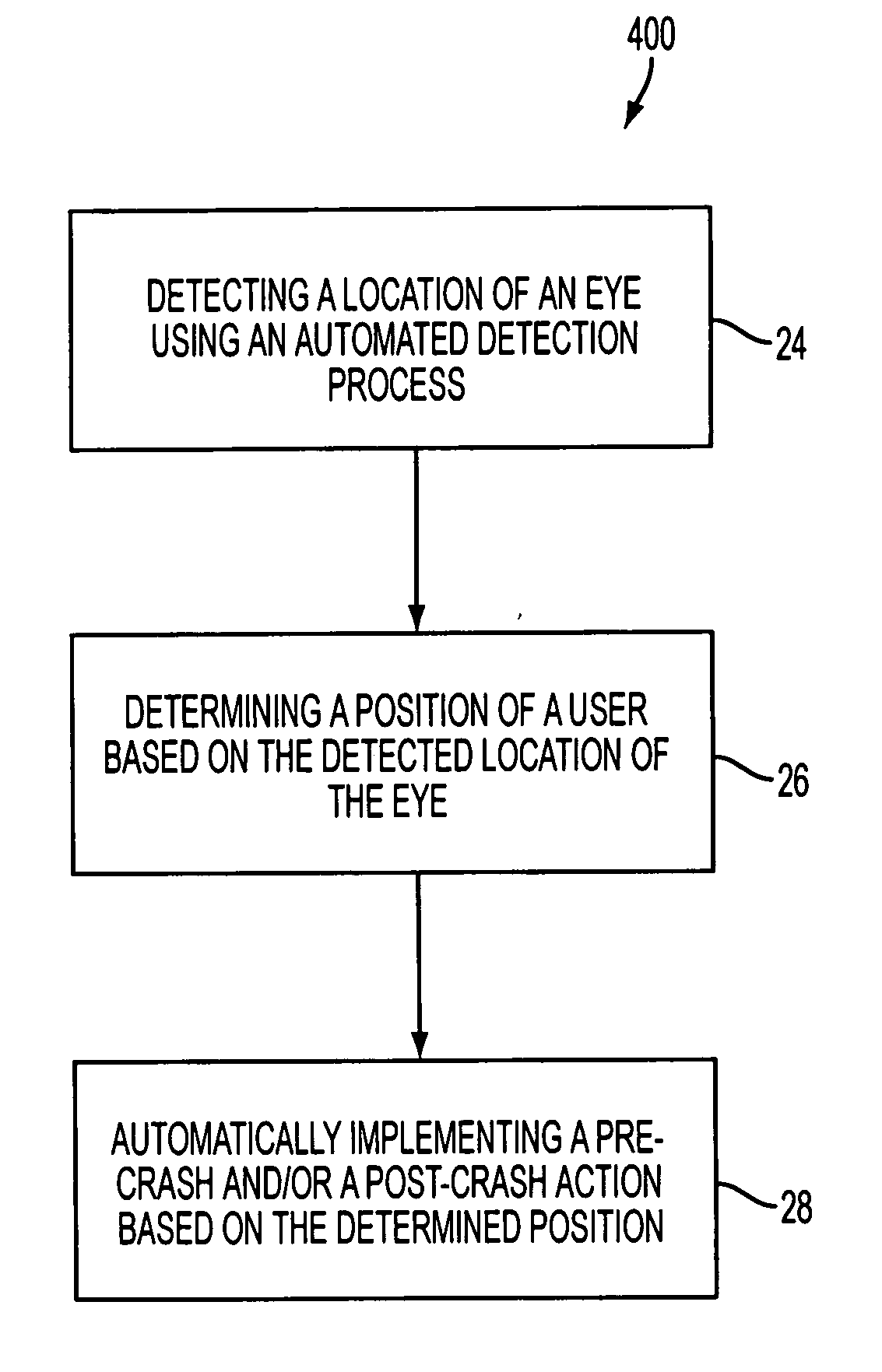

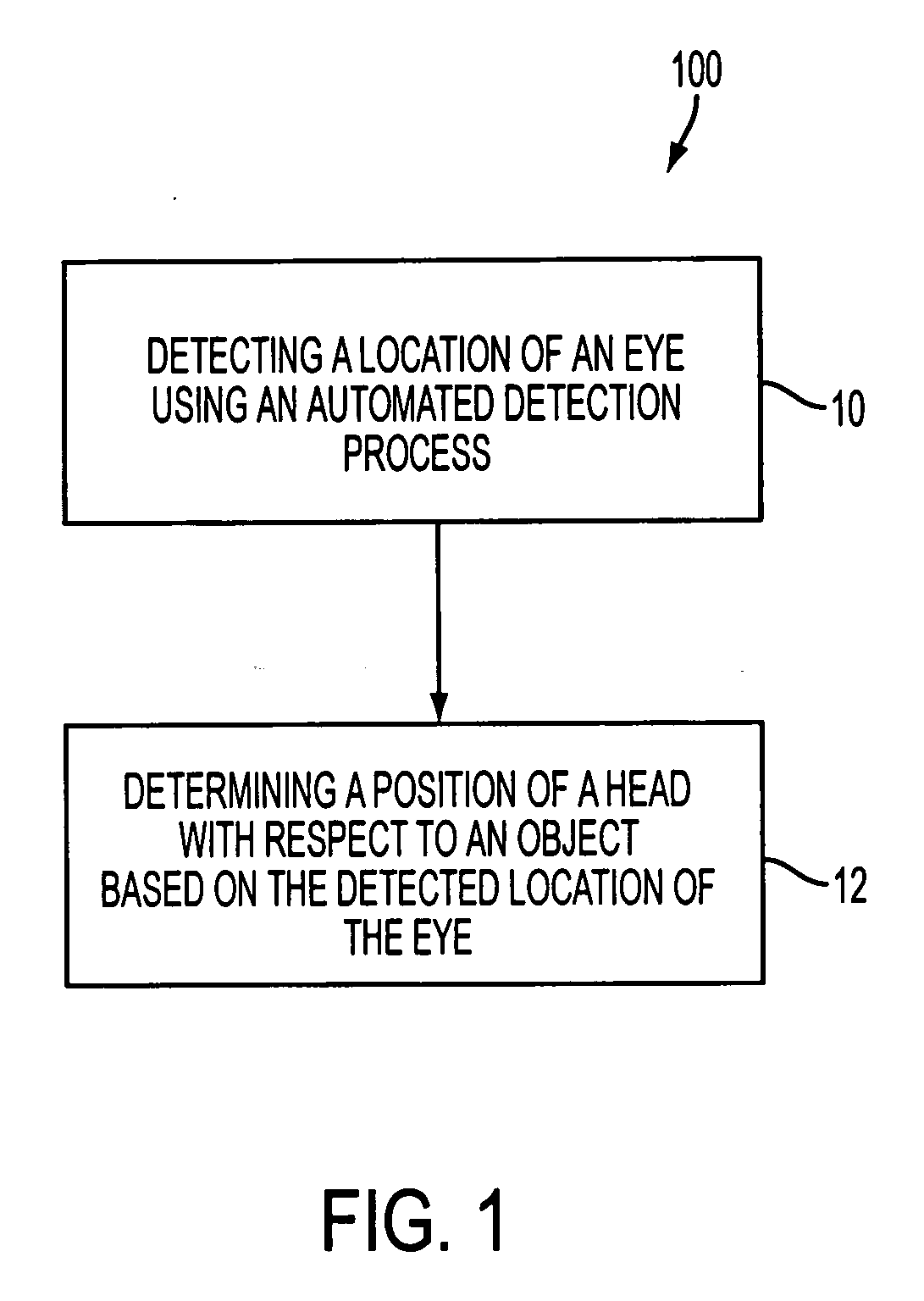

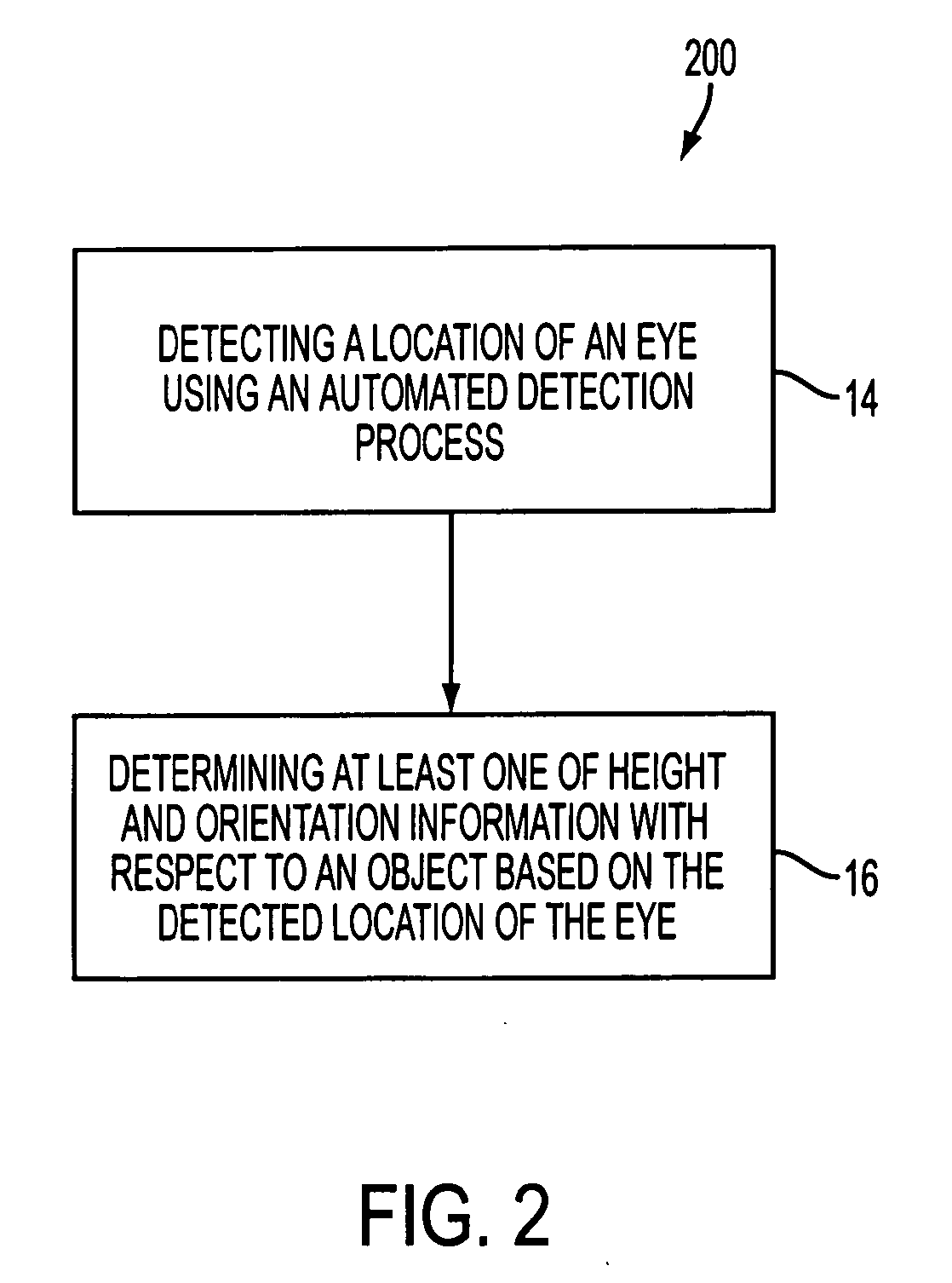

Detecting an eye of a user and determining location and blinking state of the user

InactiveUS20060149426A1Digital data processing detailsAnti-theft devicesObject basedComputer science

A method and apparatus for detecting a location of an eye of a user using an automated detection process, and automatically determining a position of a head of the user with respect to an object based on the detected location of the eye. A location of an eye of a user inside a vehicle is detected using the automated detection process, at least one of height and orientation information of the user is automatically determined based on the detected location of the eye, and a mechanical device inside the vehicle is controlled in accordance with the determined information. Moreover, an eye blinking pattern of a user is detected using an infrared reflectivity of an eye of the user, and messages are transmitted from the user in accordance with the detected eye blinking pattern of the user.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

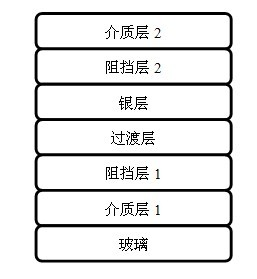

Low emissivity glass

The invention discloses low emissivity glass. The low emissivity glass contains a glass substrate, a first dielectric layer, a first barrier layer, a transition layer, a metal layer and a second barrier layer in turn from bottom to top, wherein preferably, a second dielectric layer can be plated on the second barrier layer; the transition layer is adopted to promote the growth of the metal layer and ensure that the metal layer can grow to form a continuous structure, thus the glass can have high infrared reflectivity and visible light transmittance; and the barrier layers can fully protect the metal layer to ensure that the high infrared reflectivity of the metal layer can be utilized. The low emissivity glass has low production cost and very good industrial application prospect; and the energy can be effectively saved.

Owner:HUAZHONG UNIV OF SCI & TECH

Estimation method for content of copper in soil on basis of visible-light near-infrared spectrum technology

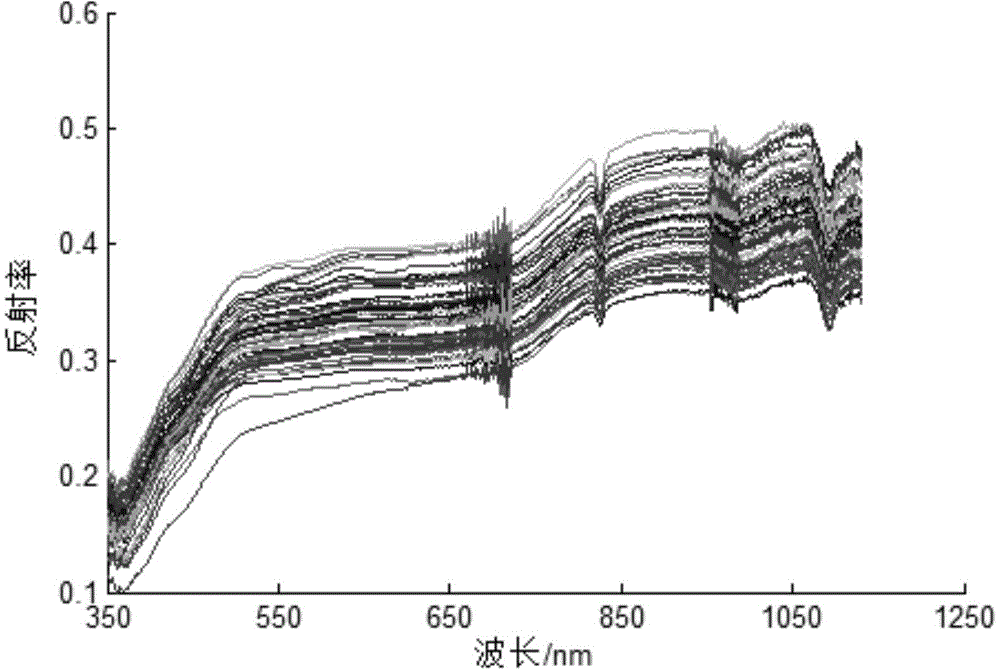

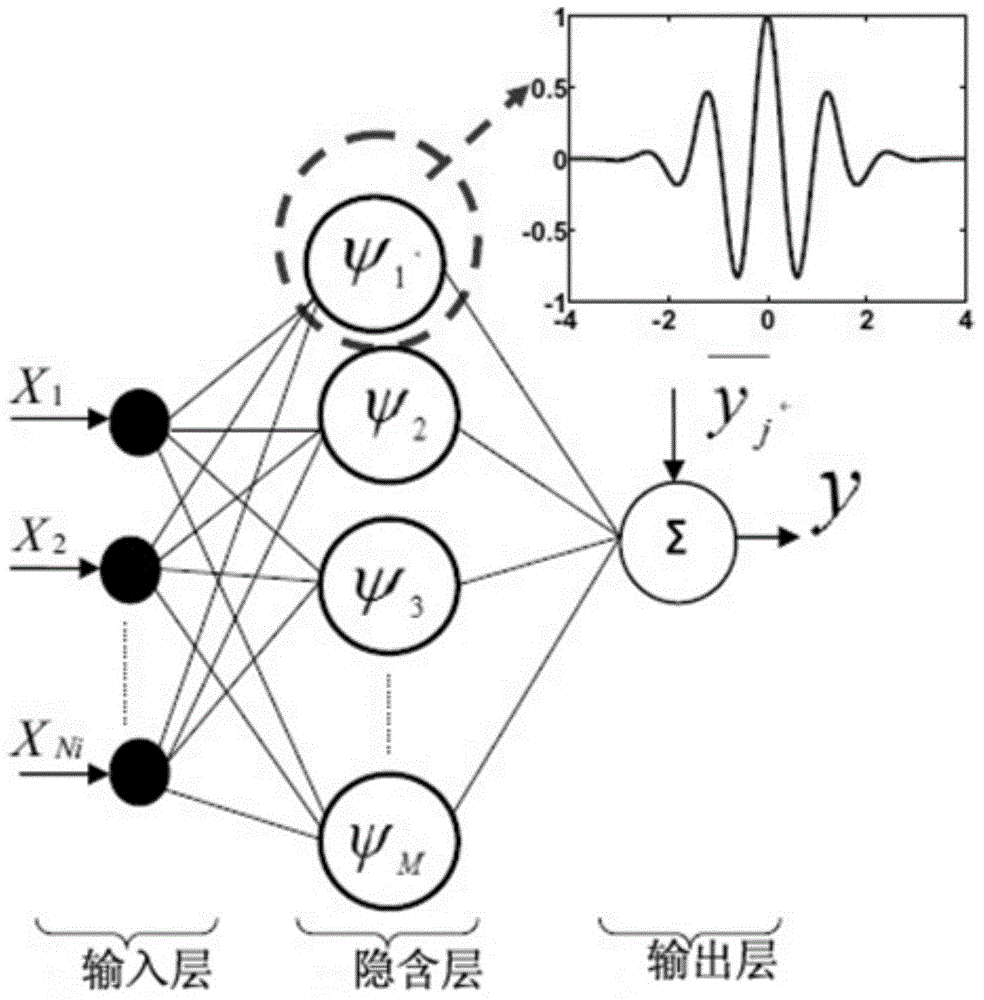

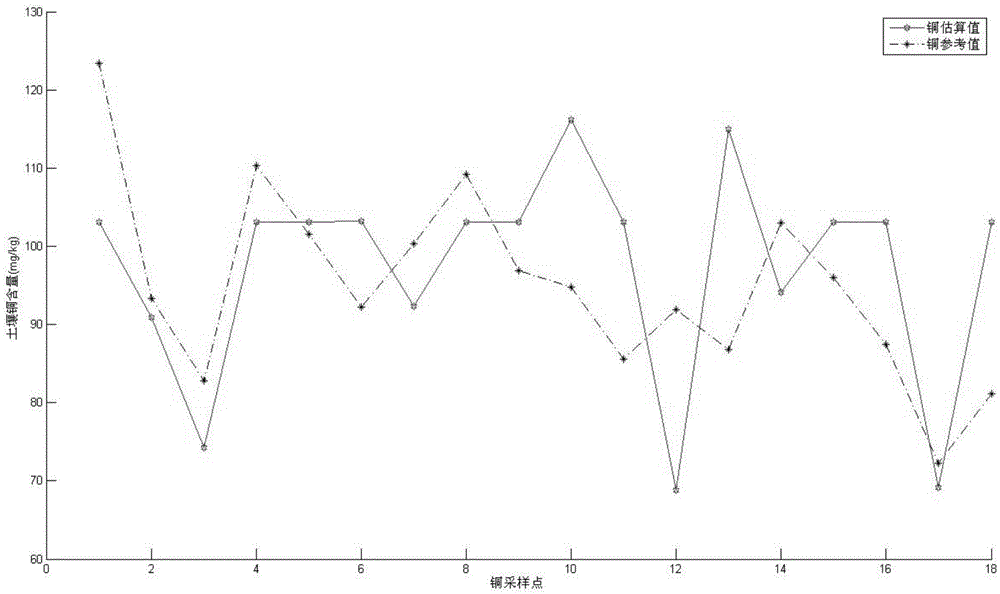

InactiveCN104596957ACalculation method is simpleReduce running timeColor/spectral properties measurementsPollutionLight spectrum

The invention relates to an estimation method for the content of copper in soil on the basis of visible-light near-infrared spectrum technology. The estimation method is realized by the following six steps: (1) collecting a soil sample; (2) determining a visible-light near-infrared spectrum; (3) pretreating the spectrum; (4) determining the reference value of the content of copper in soil; (5) establishing an estimation model; and (6) estimating the content of copper in an unknown soil sample. The estimation model between the visible-light neared-infrared reflectivity spectrum and the content of the copper is established by utilizing a wavelet neural network method on the basis of the visible-light near-infrared spectrum technology, so that the visible-light neared-infrared reflectivity spectrum of the unknown soil sample is substituted into the estimation model and further the content of the copper in the unknown soil sample is determined. The estimation method has the advantages that the determination can be performed without direct contact with the sample, and is complete non-destructive measurement, the operation process and the calculation method for the content of the copper in the soil are simple, the determination speed is greatly enhanced, no other chemical reagents need to be added and the like, so that the estimation method is environmental-friendly and pollution-free.

Owner:XIAN UNIV OF SCI & TECH

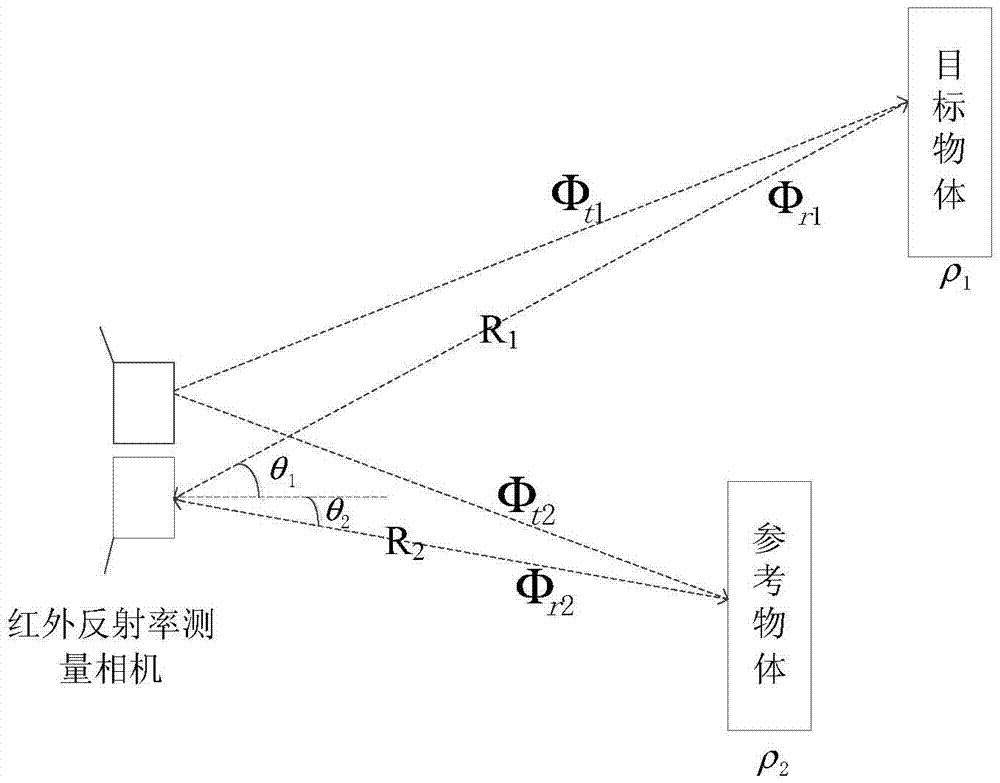

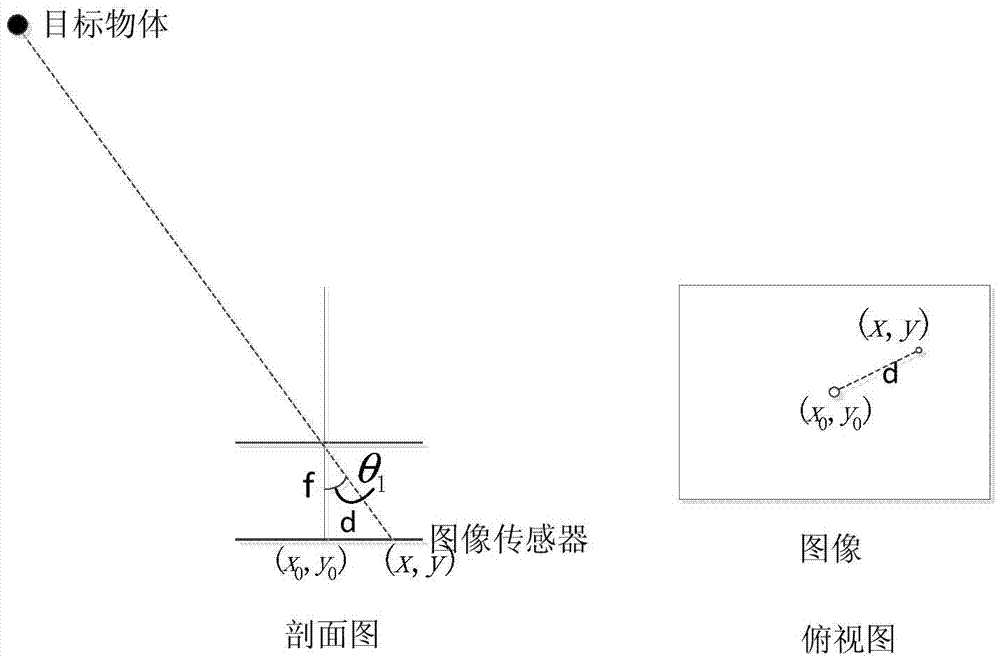

Method and device for measuring infrared reflectivity of target object

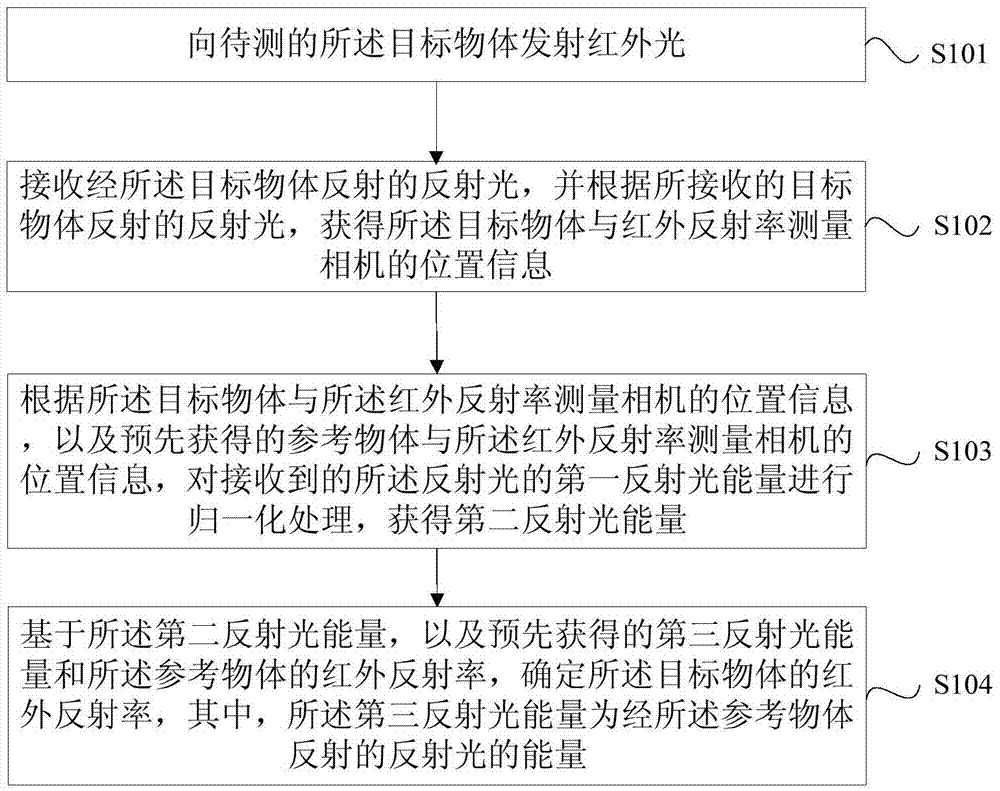

ActiveCN106996922AEasy to measureScattering properties measurementsLight energyInfrared reflectivity

The embodiment of the invention discloses a method and a device for measuring infrared reflectivity of a target object, which are applied to an infrared reflectivity measurement camera. The method comprises the following steps: emitting infrared light to the target object to be measured; reflecting reflected light reflected by the target object, and obtaining position information of the target object and the infrared reflectivity measurement camera according to the received reflected light reflected by the target object; according to the position information of the target object and the infrared reflectivity measurement camera and position information, obtained in advance, of a reference object and the infrared reflectivity measurement camera, performing normalization processing on first reflected light energy of the received reflected light, thus obtaining second reflected light energy; based on the second reflected light energy, and third reflected light energy and infrared reflectivity of the reference object, which are obtained in advance, determining the infrared reflectivity of the target object. According to the embodiment, the infrared reflectivity of the target object can be simply and conveniently measured.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Ceramic products with transparent heat reflection coat on surface and preparation method thereof

InactiveCN101215190AImprove conductivityHigh Visible Light TransmissionElectrical resistance and conductanceFilm-forming agent

The invention discloses a ceramic product which is provided with a transparent heat-reflective coating on surface. The invention uses ceramic as a substrate to coat sequentially a layer of ionic barrier layer thin film and a layer of transparent conductive oxidation thin film on the surface of the ceramics, or uses the ceramic as the substrate to coats sequentially a layer of ionic barrier layer thin film, a layer of metallic film and a layer of transparent conductive oxidation film on the surface of the ceramics. The invention further discloses a method for preparing the ceramic product. The transparent heat-reflective coating on the surface of the ceramic product provided by the invention does not contain macromolecular film-forming agent and has perfect conductivity property. And surface resistance of the coating can be below 100 omega / cm, resistivity is less than 1*10 -3omega,cm, and infrared reflectivity of the thin film can reach above 70 percent.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Roofing granules with high solar reflectance, roofing materials with high solar reflectance, and the process of making the same

ActiveUS8394498B2High opacityLow transparencyLiquid surface applicatorsRoof improvementTransmittanceNear infrared reflectance

Roofing granules include a core having an average ultraviolet transmission of greater than sixty percent and an average near infrared reflectance of greater than sixty percent and a UV coating layer on the exterior surface. The coating provides UV opacity, while the core provides near infrared reflectance.

Owner:CERTAINTEED CORP

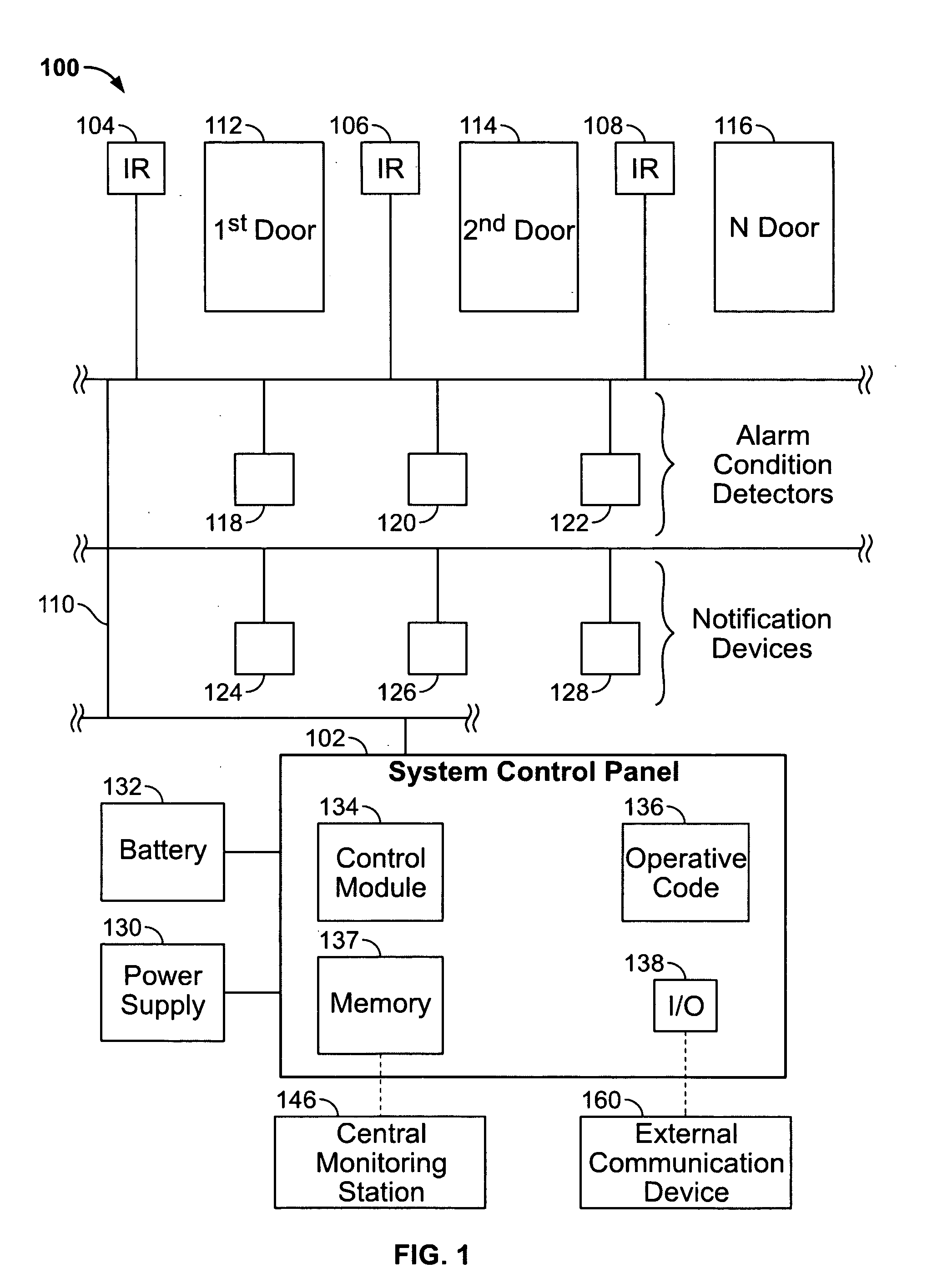

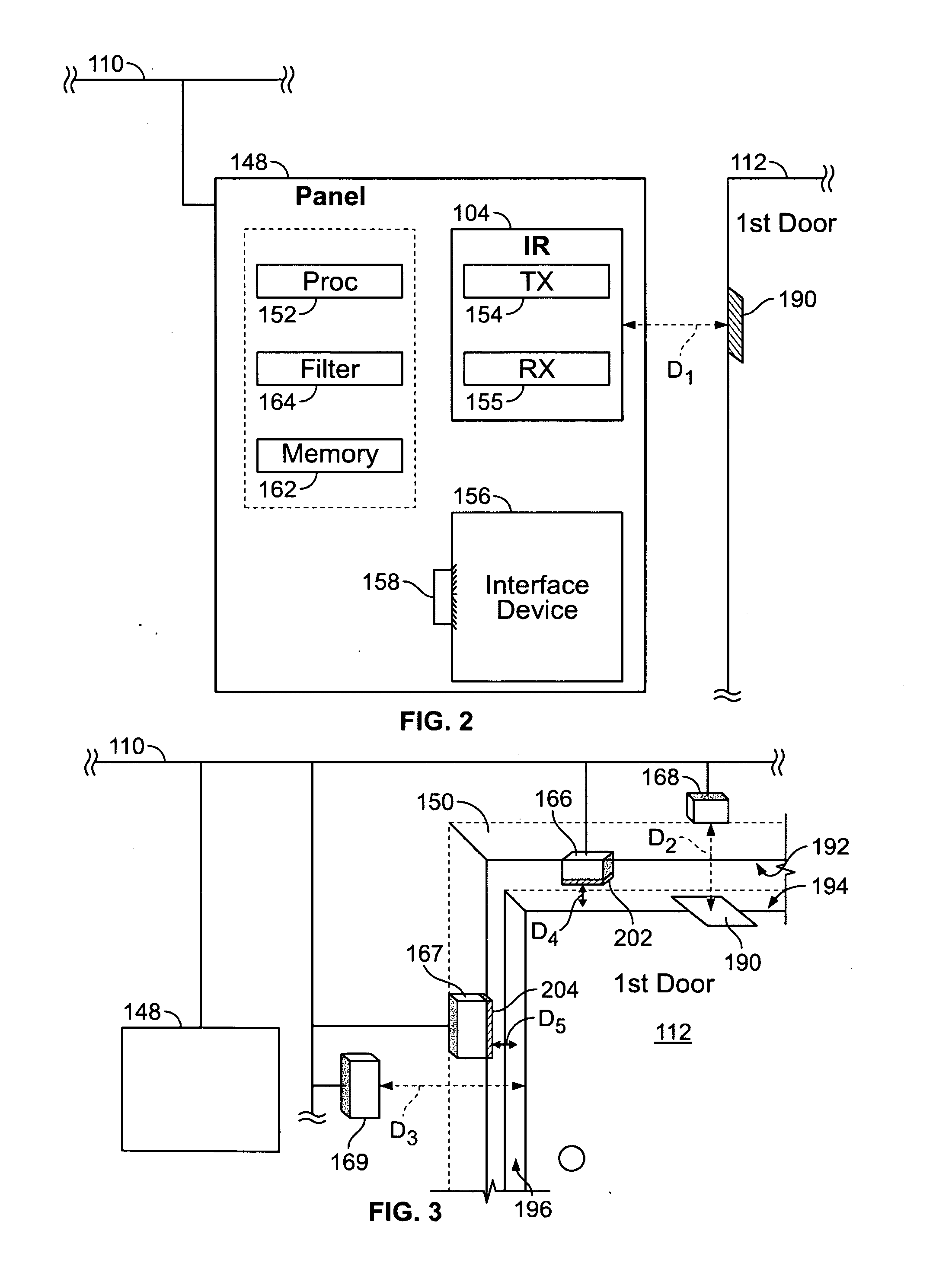

Method and apparatus for using an infrared reflectivity sensor in a security system

ActiveUS20080030328A1Burglar alarm by openingBurglar alarm short radiation actuationNetwork packetControl data

The IR sensor is configured to be mounted proximate to a door to be monitored. The IR sensor has an IR transmitter and an IR receiver. The IR transmitter has an active period and an idle period. The IR transmitter transmits control data packets which are provided by the processor during the active period. The IR receiver has an active period for detecting IR data and reflected data packets. Each of the reflected data packets has a packet IR reflectivity. The memory stores a door IR reflectivity associated with a door surface of the door, and the processor compares the packet IR reflectivity to the door IR reflectivity to determine at least a door position of the door.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

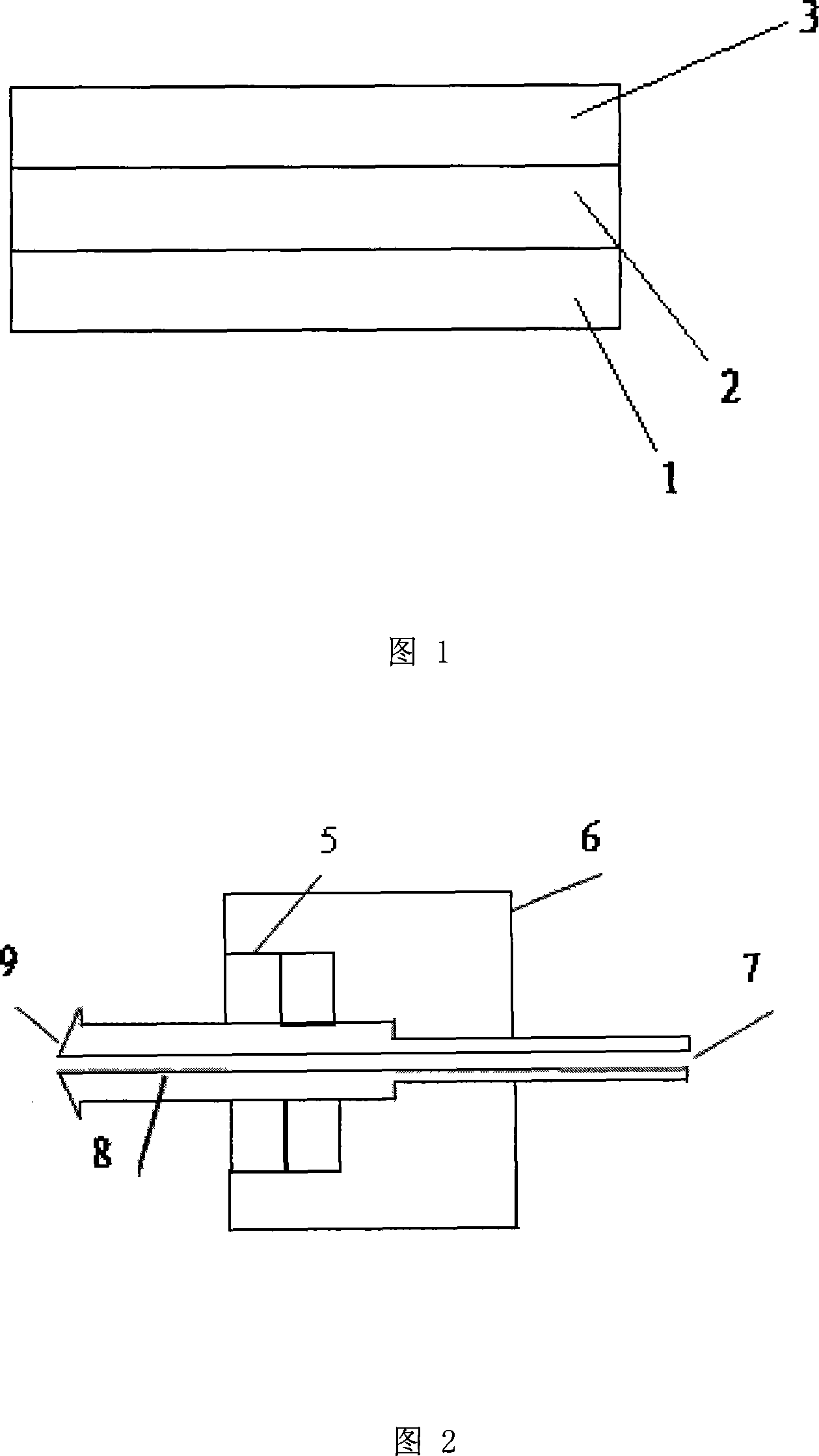

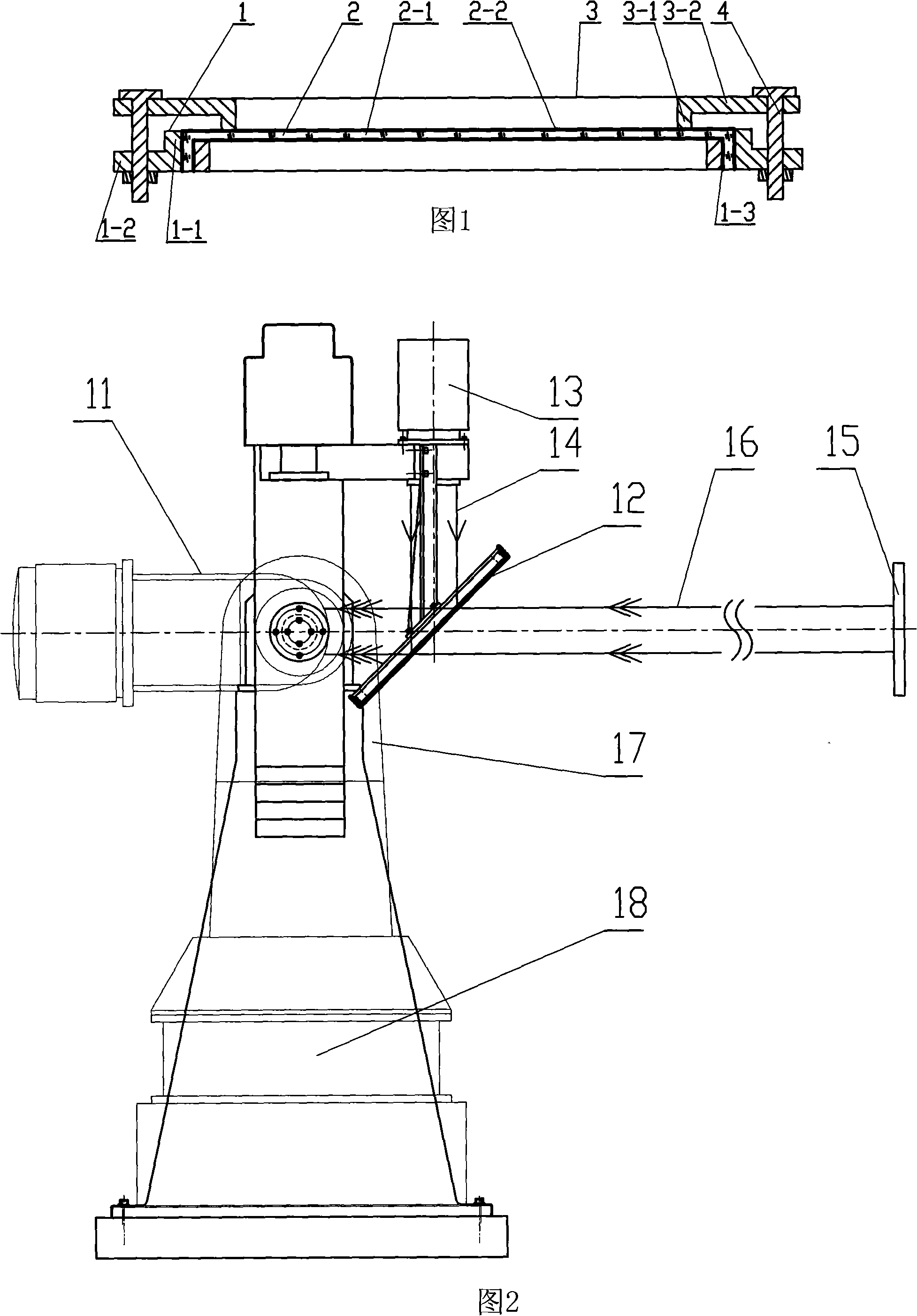

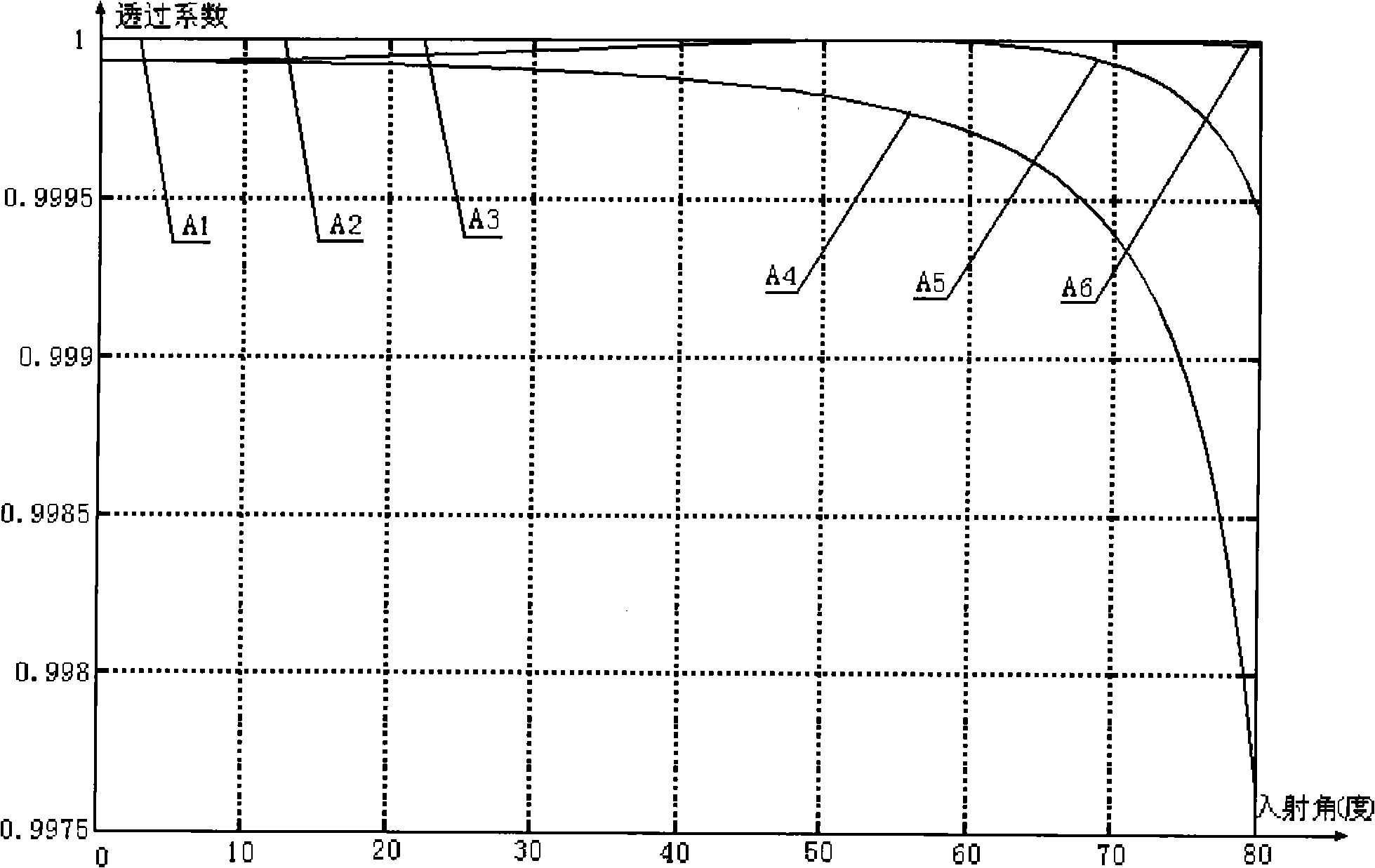

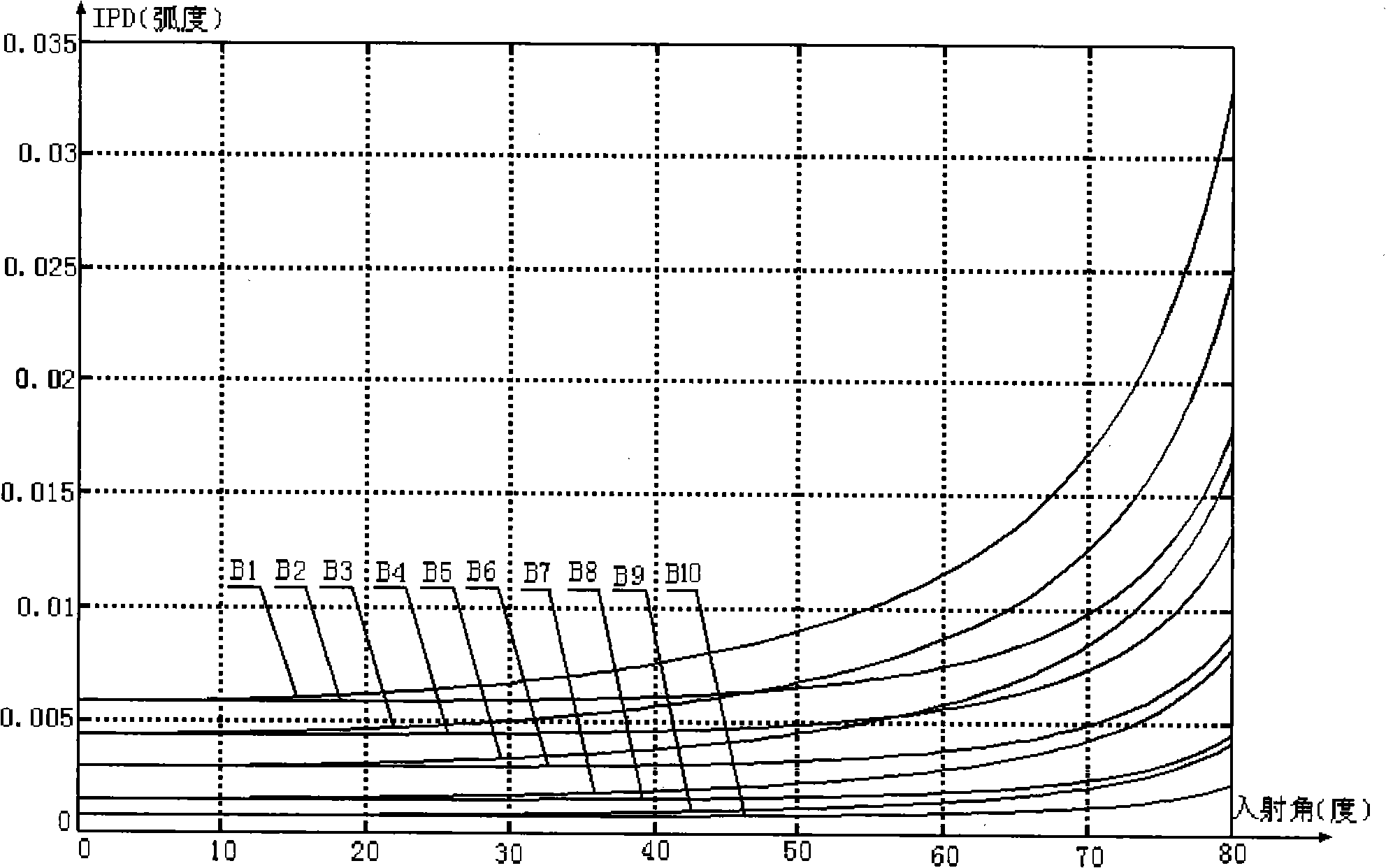

Thin film type infrared-radar beam synthesizer

ActiveCN101303407AImprove transmittanceHigh infrared reflectivityWave based measurement systemsTransmittanceAcoustics

A diaphragm type infra-red radar beam synthesizer relates to an infra-red radar beam synthesizer. The synthesizer of the invention solves the problems that the existing beam synthesizer produces comparatively large IPD (Insertion Phase Delay) to radar wave, thus leading to an impact on the testing precision and causing the existing beam synthesizer to be incapable of moving with a simulator. The beam synthesizer of the invention consists of a fixing adjustment mechanism, a beam synthesizing film (2); the beam synthesizing film (2) is fixedly arranged on the fixing adjustment mechanism. The synthesizer of the invention produces a small amount of IPD to radar wave and can move with an infrared simulator with high radar wave transmittance rate and infrared reflectivity rate.

Owner:深圳市睿诚光电科技有限公司

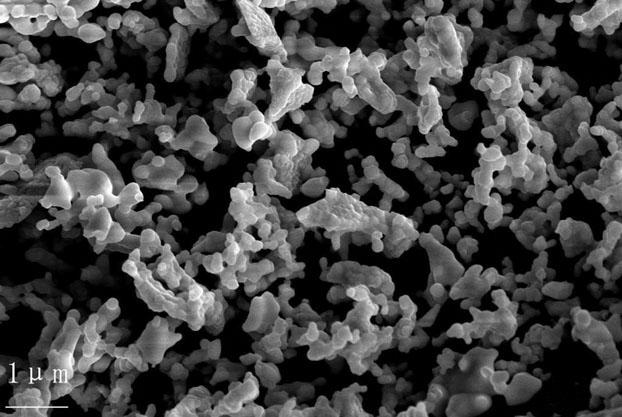

High near-infrared reflectivity nano-ceramic pigment and preparation method thereof

InactiveCN102659410AIncrease reflectionComplete structureInorganic pigment treatmentAir atmosphereSlurry

The invention discloses high near-infrared reflectivity nano-ceramic pigment and preparation method thereof. The preparation method includes the steps of using absolute ethyl alcohol as solvent to ball-mill and mix powders of yttrium oxide, neodymium oxide and molybdenum oxide for 30-40 minutes; drying slurry obtained by ball-milling and mixing at 50-80 DEG C under vacuum condition to obtain mixed powder; subjecting the mixed powder to non-pressure calcining in a heating furnace in the presence of air, and holding the temperature which rises to the highest calcining temperature of 1400-1600 DEG C for 60-180 minutes; allowing for natural cooling; and crushing and screening product of calcining to obtain pigment powder. By weight, the materials include 55-65 parts of yttrium oxide, 20-30 parts of neodymium oxide, and 15 parts of molybdenum oxide. The high near-infrared reflectivity nano-ceramic pigment has high near-infrared band reflectivity, is light yellow, and has d50 smaller than or equal to 200nm. The high near-infrared reflectivity nano-ceramic pigment can be used as ideal materials for military near-infrared stealth, house cooling, vehicle casing cooling coating, cooling coating of other casings and the like.

Owner:SHANDONG UNIV

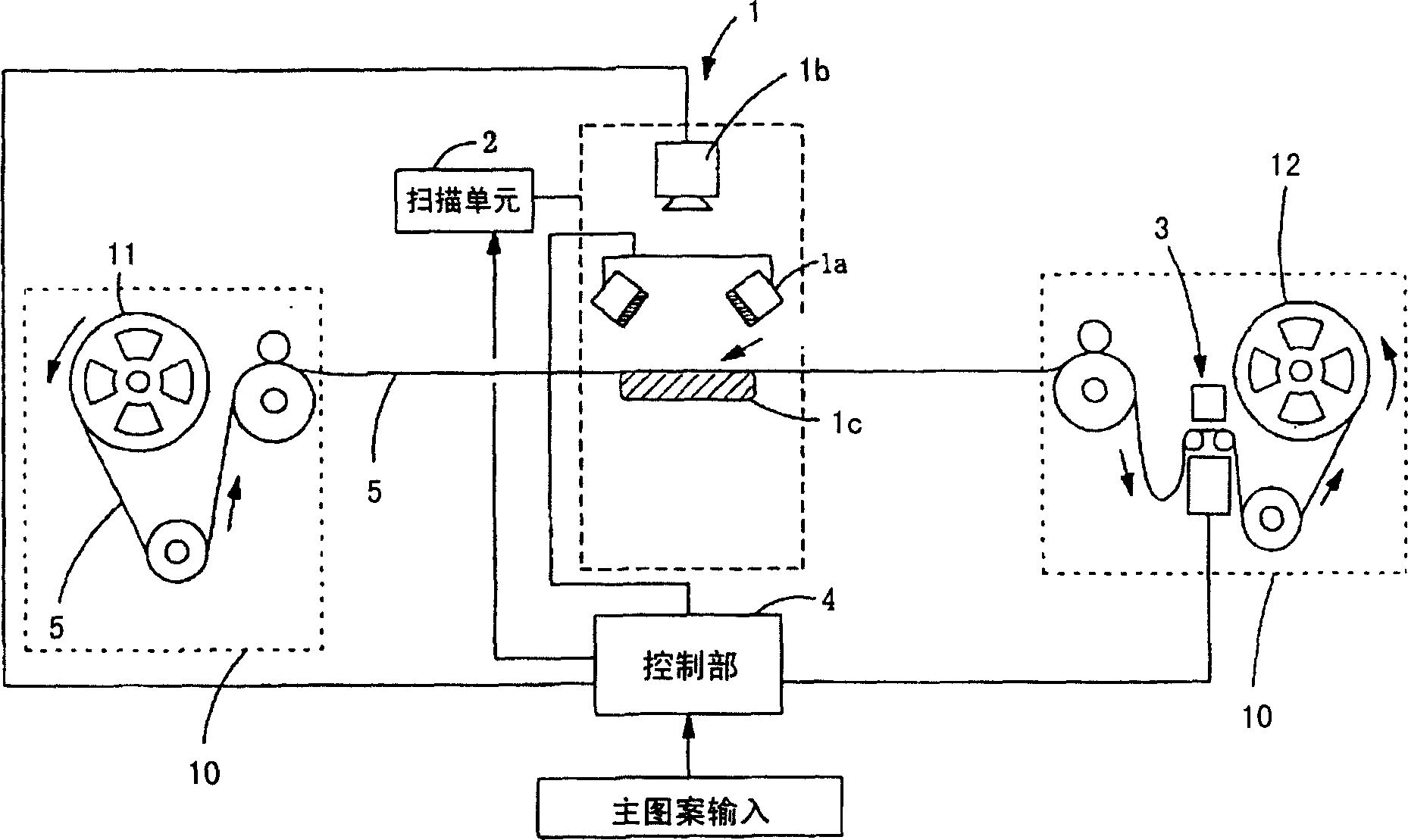

Pattern checking device

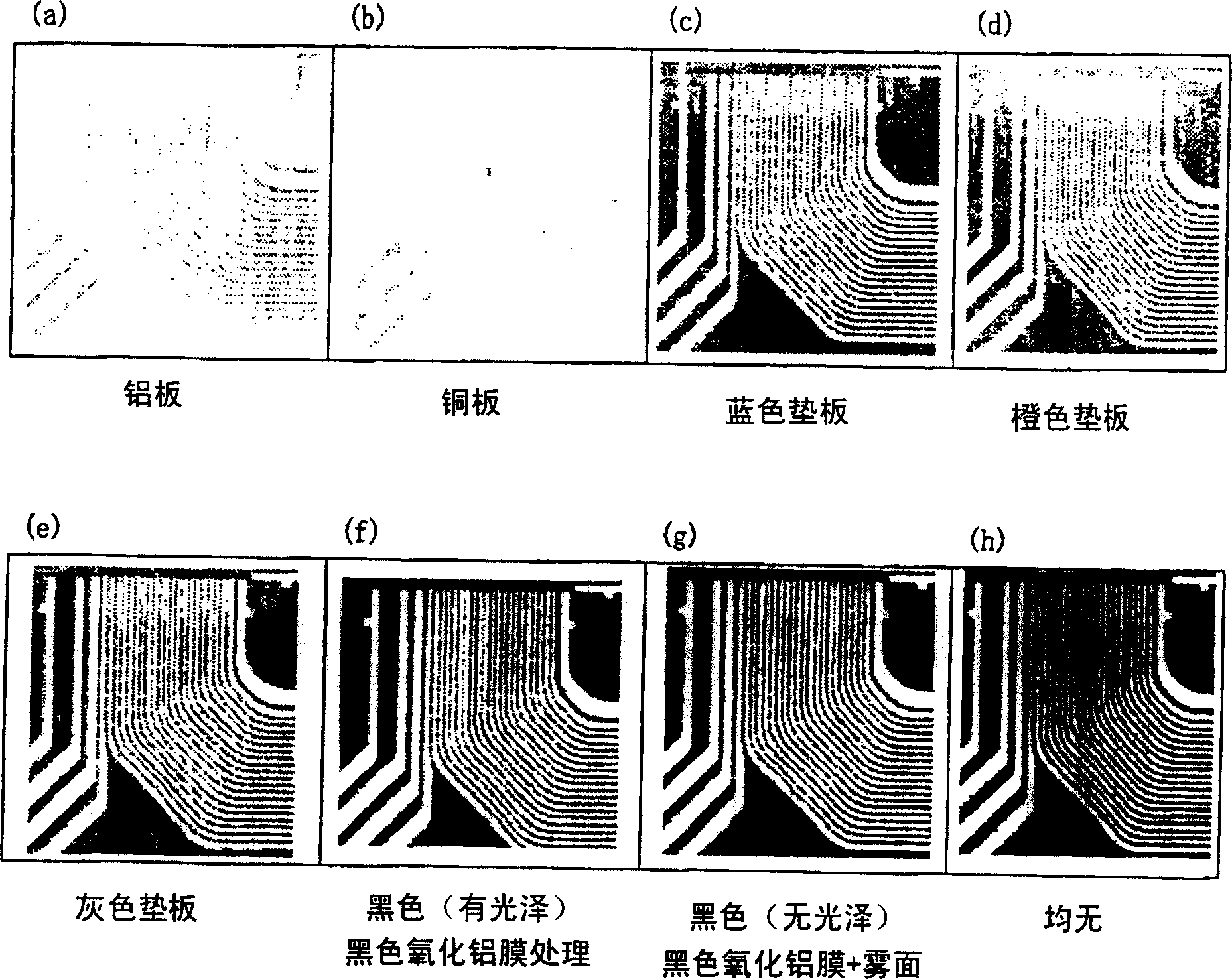

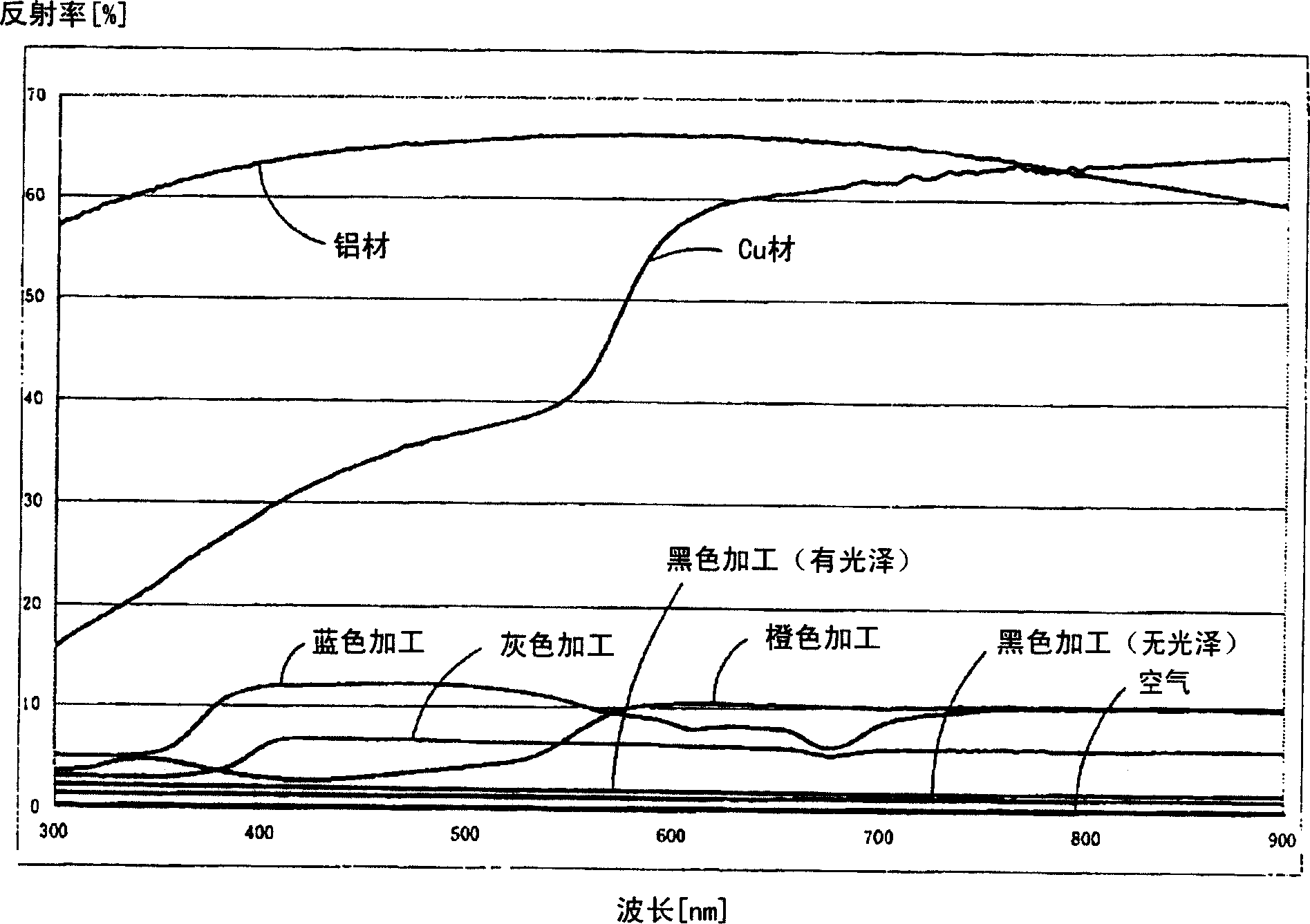

InactiveCN1763511AIncrease contrastReduce reflected light componentsSemiconductor/solid-state device testing/measurementMaterial analysis by optical meansReference patternsEngineering

To increase the contrast between a wiring part and a resin film part to easily detect a wiring pattern by reflective illumination. A TAB tape 5 having the wiring pattern formed thereon is unwound from a feed-out reel 11 to be fed to an inspection part 1 and illuminated by a reflective illumination means 1a to image the inspection pattern on the TAB tape 5 by an imaging means 1b in the inspection part 1. The image of the imaged inspection pattern is sent to a control part 4 and compared with a reference pattern to determine the quality of the pattern. The light source of the reflective illumination means 1a is, for example, an infrared LED for emitting only light with a wavelength of 500 nm or more. Since only the light with the wavelength of 500 nm or more which penetrates the TAB tape 5, an image of good contrast can be obtained. Further, if the infrared reflectivity of a stage 1c is set to be less than 10% and the stage 1c is provided, an image with better contrast can be obtained.

Owner:USHIO DENKI KK

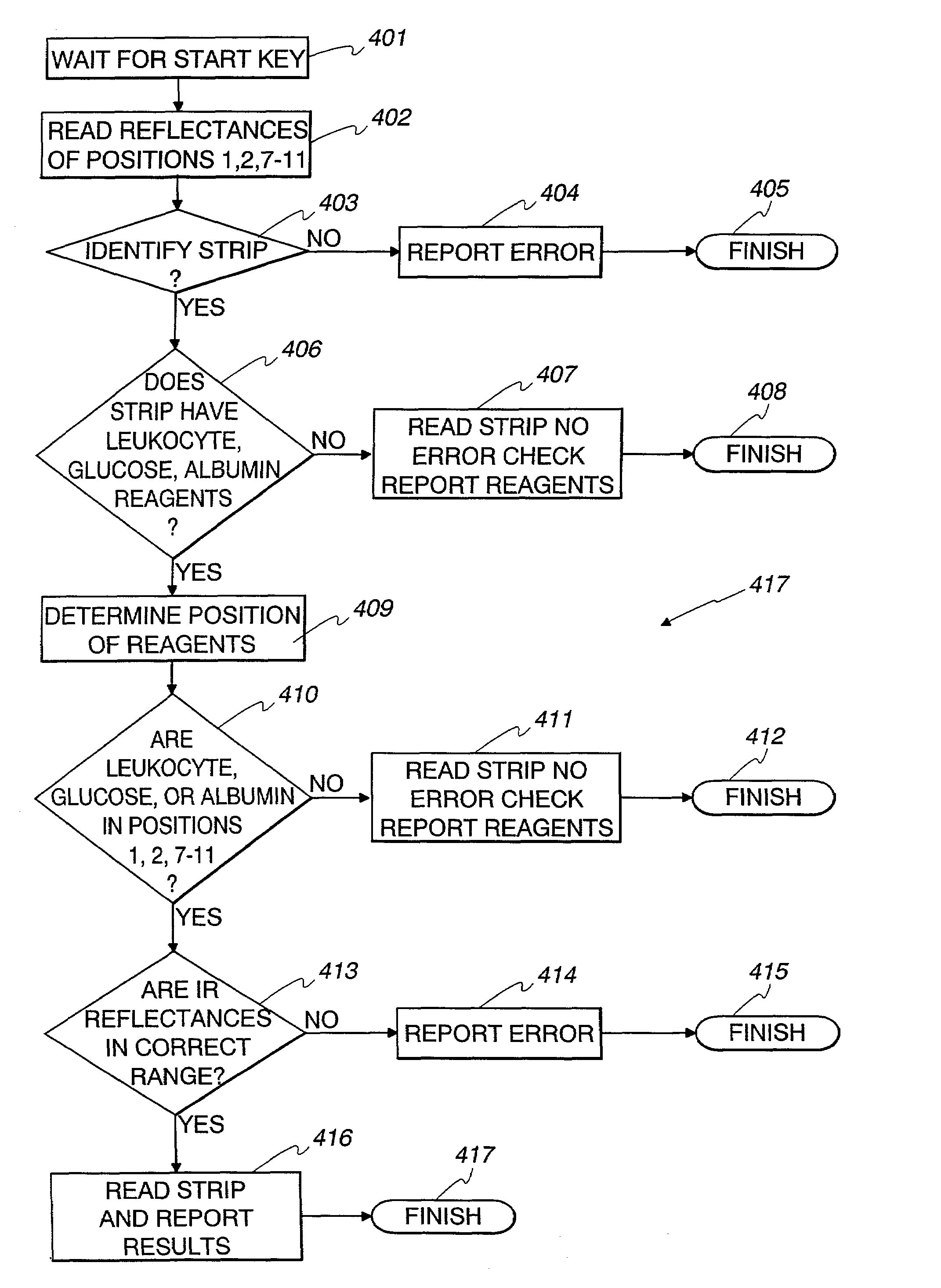

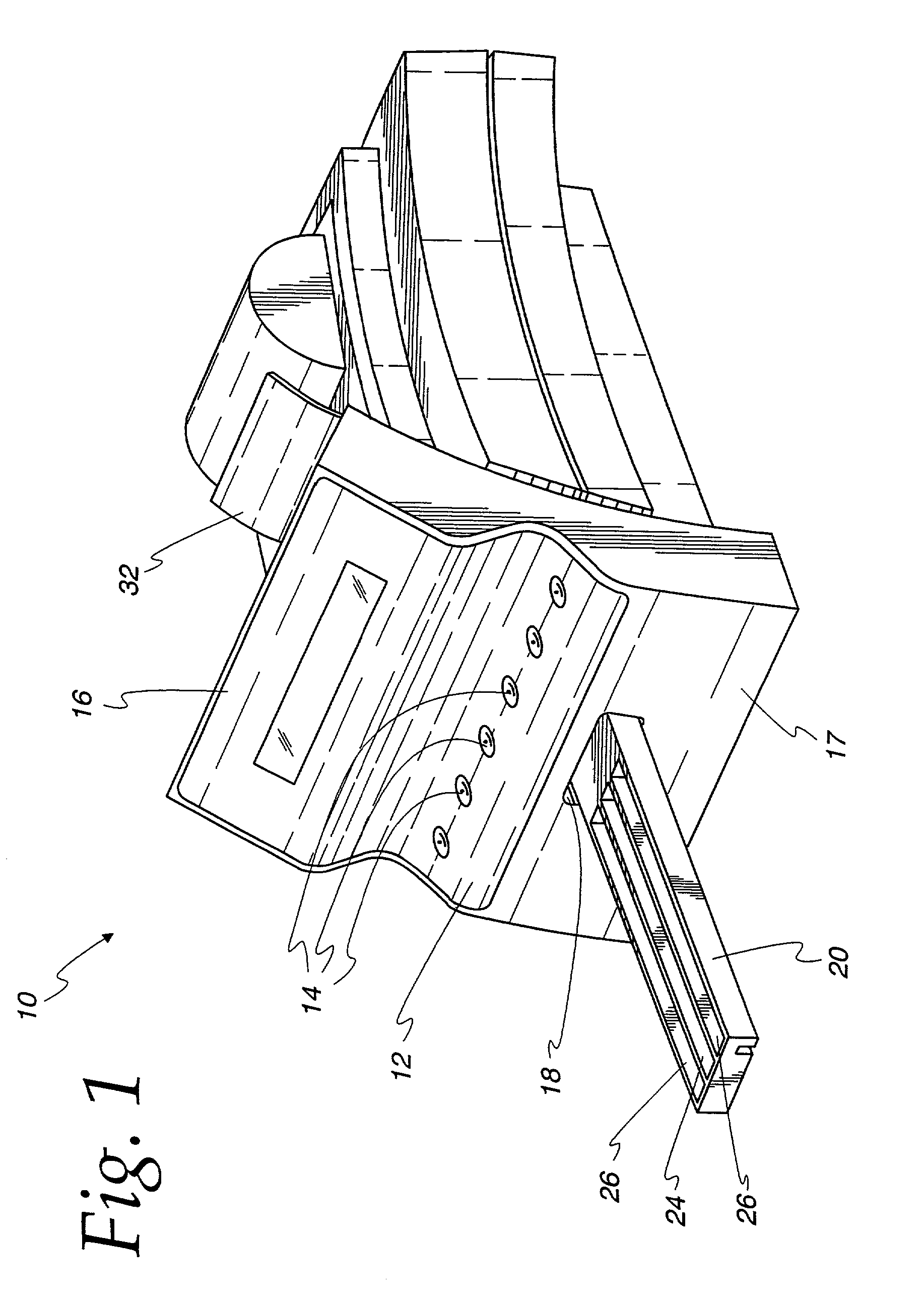

Method and apparatus for using infrared readings to detect misidentification of a diagnostic test strip in a reflectance spectrometer

ActiveUS7601544B2Analysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorTest stripsSpectrometer

A method and apparatus for using an infrared reading to detect the misidentification of a diagnostic test strip disposed on a feed table comprising the steps of determining if the test strip possesses specified reagents, reading the infrared reflectances from the reagent positions, determining if the reflectances are within an acceptable predetermined range and aborting the test if the infrared reflectances are not within the acceptable predetermined range.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

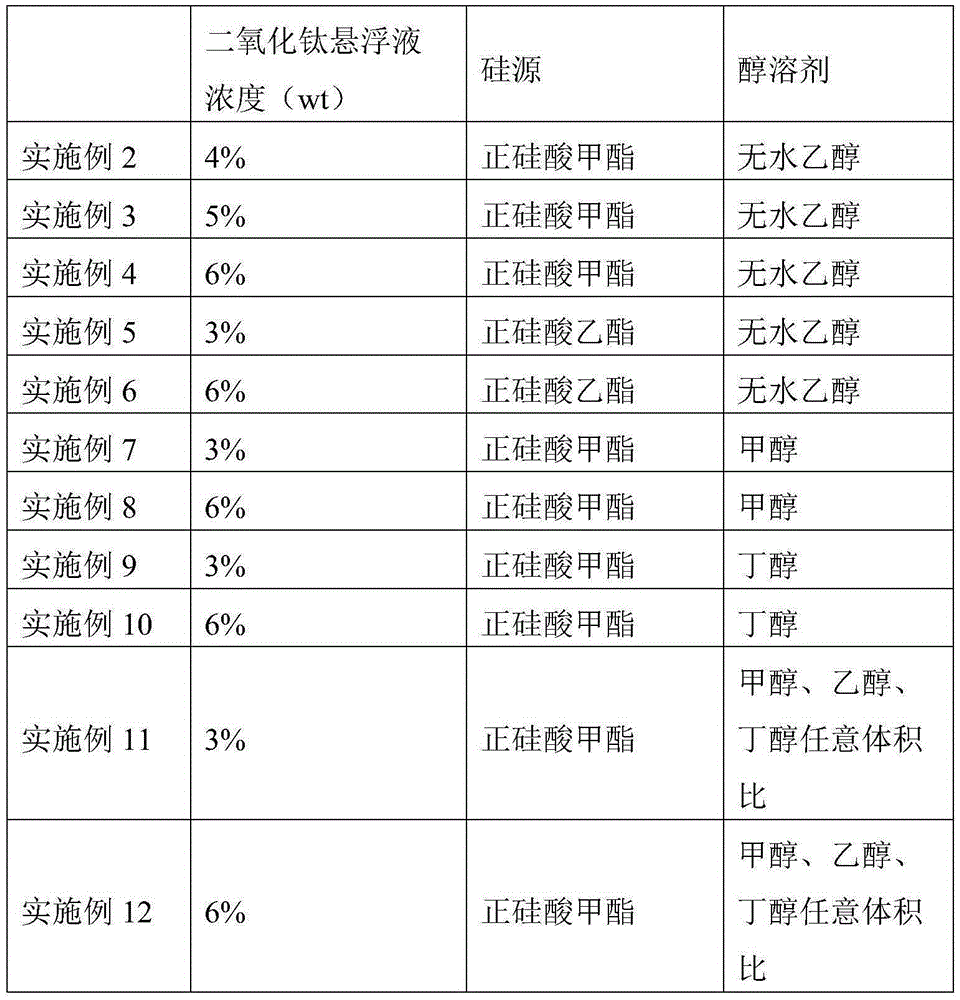

Improved Stober method for preparing tio2/sio2 aerogel microsphere

The invention relates to an improved Stober method for preparing a TiO2 / SiO2 aerogel microsphere. The improved Stober method comprises the steps of (1) preparing a titanium dioxide suspension liquid; (2) preparing mixed sol of tetramethoxysilane or tetraethoxysilane and alcohol; (3) preparing a mixed solution of ammonia water and ethanol; (4) reacting the mixed sol and the mixed solution; (5) adding fluoroalkyl silane self-assembly solution into the solution obtained in the step (4), and further reacting; and (6) centrifugally cleaning the solution obtained in the step (5), and drying to obtain the TiO2 / SiO2 aerogel microsphere. The improved Stober method provided by the invention is carried out at normal pressure and is mild in condition, low in reaction temperature not higher than 80 DEG C, not high in equipment requirement and capable of reducing production cost and improving production safety. The TiO2 / SiO2 aerogel microsphere prepared by using the method disclosed by the invention has the particle size of 200-750nm, is smooth in surface, relatively good in monodispersity, good in integrity and free of fragmentation or cracks, has the advantages of high transparency, good hydrophobicity and infrared reflectivity, low heat conductivity and the like and has a wide application prospect in the field of buildings such as coatings and coiled materials.

Owner:WUHAN UNIV OF TECH

Heat-ray shielding material

InactiveCN102933990AImprove reflectivityImprove transmittanceNon-insulated conductorsMetal-working apparatusMetal particleArea ratio

Owner:FUJIFILM CORP

Synthesis method of sodium hexatitanate whisker

ActiveCN101363136AImprove uniformityLow costPolycrystalline material growthSingle crystal growth detailsSynthesis methodsPotassium

The invention discloses a preparation method of potassium hexatitanate crystal whiskers, which adopts a technique of melting and quenching for synthesis and has convenient and feasible process flow. First, raw materials containing titanium and gallium are mixed with fluxing agent in a mixer, put into a crucible which is fixed onto a high-temperature furnace and sintered. The high-temperature furnace is leaned in order that the molten mass can flow out equably into special quenching equipment with cold water and water fog at the bottom for quenching. Then, the acid solution dissolves out a part of the sodion and is filtered, washed, soaked by surface active agent and then sintered for recrystallization, thereby obtaining the end product. No agglomeration and aggregation appears in the process of recrystallization. There is no pollution throughout the process. The potassium hexatitanate crystal whiskers produced by the synthetic method of the invention have an average length of 5 to 50um, an average diameter of 0.5 to 3um with a yield higher than 95%, and have the advantages of low thermal conductivity, high infrared reflectivity and low cost.

Owner:SHANGHAI JINGXU COMPOSITE MATERIAL +1

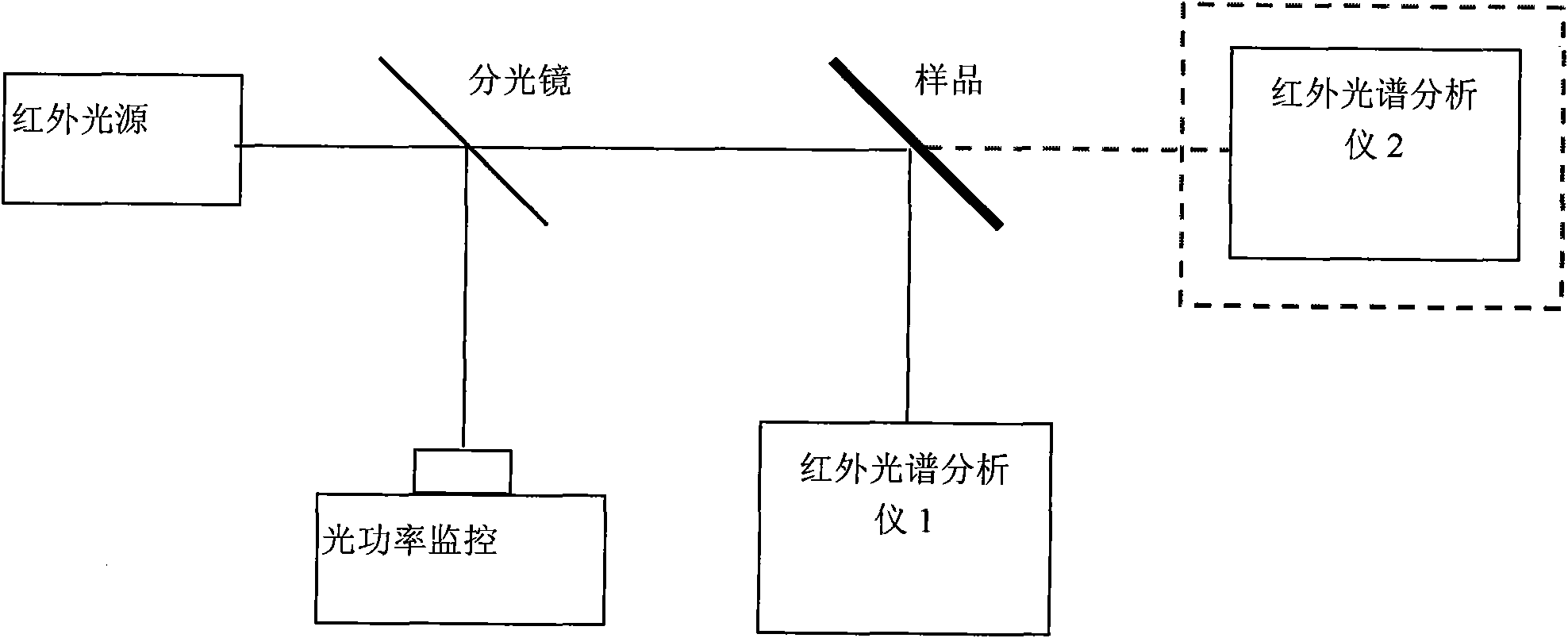

Method for testing coating infrared emittance with spectral reflectance method

InactiveCN102081037ASimple test setupRelaxed test conditionsColor/spectral properties measurementsLow emissivitySpectrograph

The invention relates to a method for testing coating infrared emittance with a spectral reflectance method, which is characterized in that light emitted by an infrared source is divided into two paths by a splitter, wherein one path serves as a measuring light beam, and the other path serves as a reference light beam; a standard sample with the known infrared reflectivity rho is placed in a test light path to store and record the measurement value rho' of a grating spectrum instrument; the sample to be tested, which is sprayed, is placed in the test light path; the plane of the sample to be tested and the incident light direction form an angle of 45 degrees, and the measurement value rho of the grating spectrum instrument is stored and recorded; a reflectivity spectrum is obtained by the grating spectrum instrument; and according to alpha=rho0 / rho0', 1-rho*alpha is obtained by calculation and is the infrared reflectivity of the surface of the sample to be measured. The test device is simple, and the test condition is wide; errors brought by reflection on surrounding irradiation by a tested sample can be eliminated, the sample with low emissivity can be measured, and emissivity at different temperatures can be measured; and thus the method is a practical test method.

Owner:FAW GROUP

Synthesis method of potassium hexatitanate whisker

ActiveCN101363135ALess non-acicular particlesLow costPolycrystalline material growthFrom normal temperature solutionsThermal insulationSynthesis methods

The invention discloses a preparation method of potassium hexatitanate crystal whiskers, which adopts a technique of melting and quenching for synthesis and has convenient and feasible process flow. First, raw materials containing titanium and gallium are mixed with fluxing agent, sintered in an elevated temperature vessel, taken out after being melted, and quenched on special quenching equipment, thereby producing well-proportioned fine powder with particle diameter less than 1mm. Then, the powder is put into a reactor with hot water; the quantity of potassium ion release is controlled by controlling the acidity of the solution. While the reaction is finished, the product is filtered, washed by deionized water at the temperature of 20 to 40 DEG C repeatedly, soaked by surface active agent, and sintered directly after being filtered, thereby obtaining the end product. There is no pollution throughout the process. The synthetic potassium hexatitanate crystal whiskers synthesized by the method have the advantages of few un-needle-shaped particles, low cost, low thermal conductivity, high infrared reflectivity and good sound-absorbing property at high temperature, with the average length of the crystal whiskers being 5 to 30um and the average diameter being 0.5-3um, can be used as reinforcing material, friction material, thermal insulation material and the like, and have a yield higher than 97%.

Owner:SHANGHAI JINGXU COMPOSITE MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com