Ceramic products with transparent heat reflection coat on surface and preparation method thereof

A technology for heat-reflective coatings and ceramic products, applied in the field of ceramic products and their preparation, can solve the problems of poor uniformity of film formation, high ultrasonic frequency, unstable aerosol, etc., and achieve low carrier gas pressure and good uniformity of film formation , good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (ATO / SiO 2 )-Rotary coated ceramic products

[0033] The film structure is ATO / SiO 2 / Ceramic substrate, the preparation method is as follows:

[0034] ① Preparation of silica sol: add 50ml of ethyl orthosilicate to 200ml of ethanol, and adjust the pH of the solution to 2-3 with 17% HCl. Stir and react at room temperature for 2h to obtain a silica sol with a concentration of 1.2mol / l .

[0035] ②ATO sol preparation: take 13.54g SnCl 2 ·2H 2 Dissolve O in 50ml absolute ethanol and 50ml acetic acid, add 5ml acetylacetone as stabilizer, stir and react at 70℃ for 2h; then weigh SbCl 3 Dissolve in 25ml absolute ethanol and 25ml acetic acid, make the molar ratio of Sb ion to Sn ion reach 10%, stir and react at 70℃ for 2h; then react with SnCl 2 The solution is mixed and stirred for 2 hours, and finally aged for 24 hours to form an antimony-doped tin oxide sol.

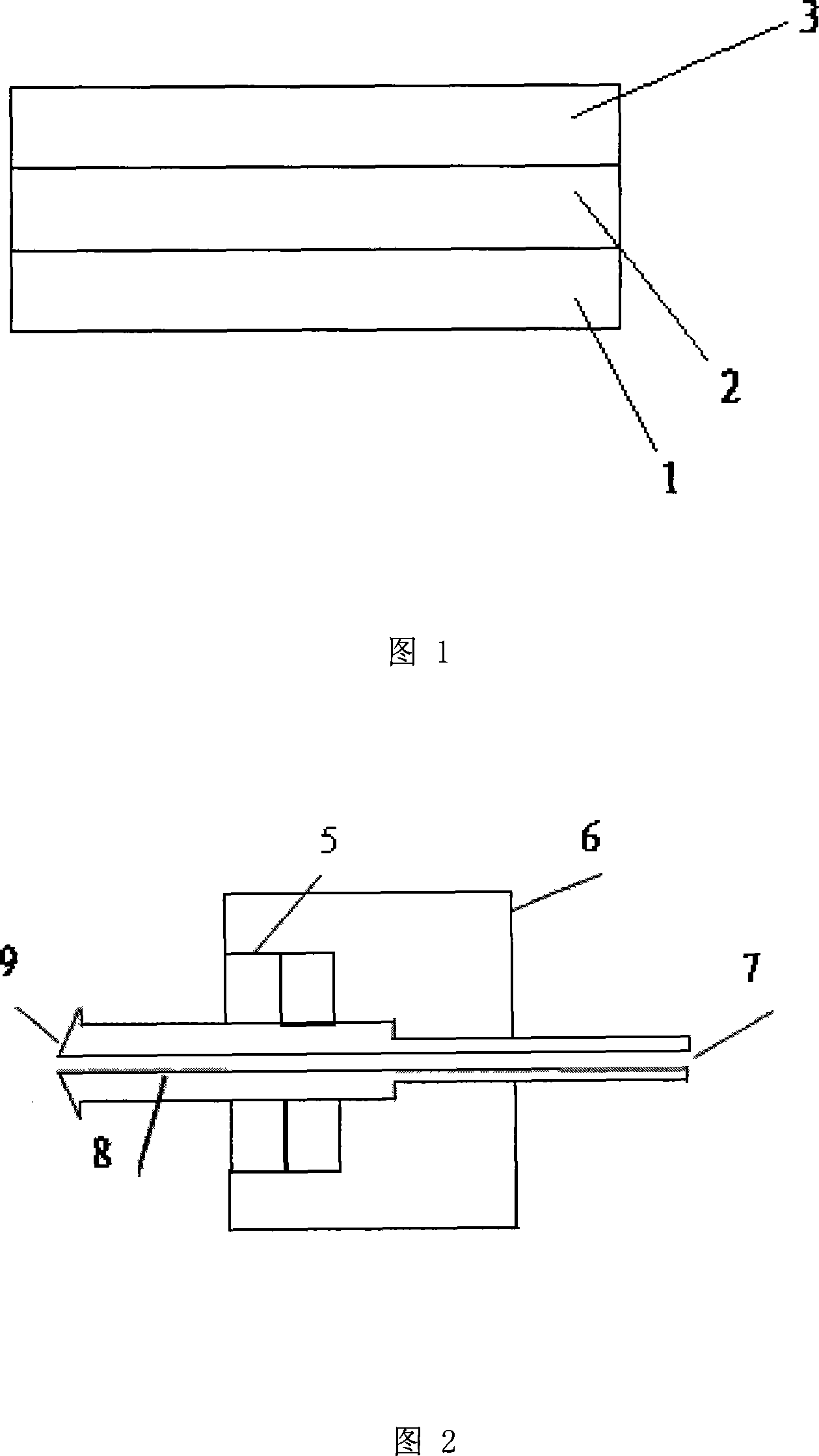

[0036] ③Spin coating and heat treatment: Fix the ceramic substrate 1 on the rotating table. When the substrate temperat...

Embodiment 2

[0037] Example 2 (ITO / SiO2)-spin coating

[0038] The film structure is ITO / SiO 2 / Ceramic substrate, the preparation method of ITO sol is as follows, and the rest is the same as in Example 1.

[0039] ITO sol preparation method: take 2g InCl 3 ·4H 2 Dissolve O in 100ml of absolute ethanol, add 1m of acetylacetone as stabilizer, stir and react at 60℃ for 2h; then weigh SnCl 4 Dissolve in 25ml of absolute ethanol, make the molar ratio of Sn ions to In ions reach 5:100, stir and react at 60℃ for 2h; then react with SnCl 4 The solution is mixed and stirred for 2 hours, and finally aged for 24 hours to form tin-doped indium oxide sol.

Embodiment 3

[0040] Example 3 (ITO / SiO2)-spin coating

[0041] The film structure is ITO / SiO 2 The preparation methods of ceramic substrate and ITO sol are as follows, and the rest are the same as in Example 1.

[0042] Take 10g InCl 3 ·4H 2 O was dissolved in 100ml of absolute ethanol, 5ml of diethanolamine was added as a stabilizer, and the reaction was stirred at 70℃ for 2h; then SnCl was weighed 4 Dissolve in 25ml of absolute ethanol, make the molar ratio of Sn ion to In ion reach 12:100, stir and react at 70℃ for 2h; then react with SnCl 4 The solution is mixed and stirred for 2 hours, and finally aged for 24 hours to form tin-doped indium oxide sol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com