Low emissivity glass

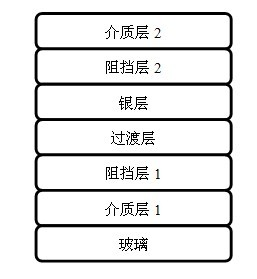

A low-emissivity glass and glass substrate technology, applied in the field of low-emission glass, can solve problems such as difficulty in ensuring consistency of film thickness, unsatisfactory low-emission effect, and long-term use of glass, and achieve good industrial application prospects and high visible light Good transmittance and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

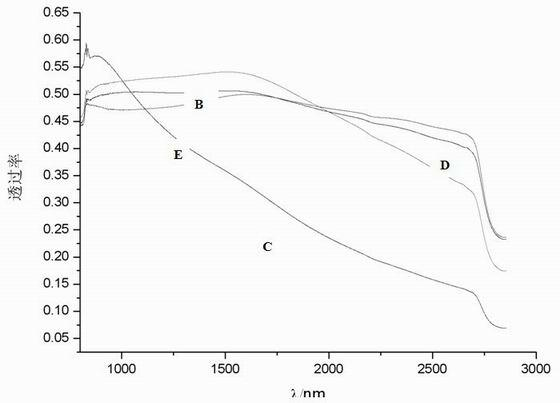

[0032] (1) Use magnetron sputtering to plate each film layer separately, and determine the optimal condition of sputtering by comparing their transmission in the spectral range; then measure its thickness to calculate its optimal condition sputtering rate. The optional parameters are as follows:

[0033]

[0034](2). First, the dielectric layer 1 is plated on the transparent glass surface, the sputtering time is 5, 6, 7, and 8 minutes, and the thickness is 38.7nm, 46.44nm, 54.18nm, and 61.92nm respectively; followed by the barrier layer 1 , the sputtering time of the barrier layer 1 is NiOx——7s, CrOx——6s, the thickness is NiOx——1nm, CrOx——1nm; moreover, the sputtering time of the transition layer is 2s, and the thickness is 3.49nm Next, the metal silver layer is plated, the sputtering time of the metal silver layer is 4s, and the thickness is 13.12nm; then it is still a barrier layer 2, and its plating method and time are the same as the previous barrier layer 1; each film...

Embodiment 2

[0039] Dielectric layer 1 (ZnO) is plated on the surface of transparent glass, the sputtering time is 7 minutes, and the thickness is 54.18nm; followed by barrier layer 1, the sputtering time of barrier layer 1 is NiOx - 3.5s, CrOx - 3s , the thickness is NiOx——0.5nm, CrOx——0.5nm; Furthermore, the transition layer (Zn) is plated, the sputtering time of the transition layer (Zn) is 2s, and the thickness is 3nm; next, the metal silver layer is plated, and the metal silver layer The sputtering time is 2s, 3s, 4s, 5s, the thickness is 6.56nm, 9.84nm, 13.12nm, 16.4nm, and then it is the barrier layer 2. The plating method and time of the barrier layer 2 are the same as the previous barrier layer 1; They are plated by magnetron sputtering. In addition, each film layer is not independent, and their adjacent surfaces penetrate each other, so they have a good bonding force.

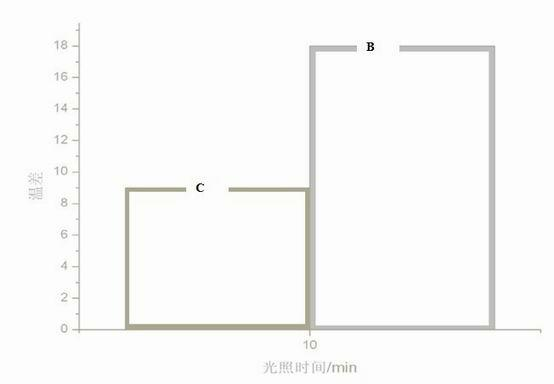

[0040] In this example, the effect of the thickness of the metal layer on the infrared radiation performance i...

Embodiment 3

[0042] Dielectric layer 1 (SnO 2 ), the sputtering time is 6 minutes, and the thickness is 46.44nm; followed by the barrier layer 1, the sputtering time of the barrier layer 1 is NiOx——14s, CrOx——6s, and the thickness is NiOx——2nm, CrOx——1nm; Furthermore, the transition layer (Ni) is plated, the sputtering time of the transition layer is 3.5s, and the thickness is 6nm; then the metallic silver layer is plated, the sputtering time of the metallic silver layer is 4s, and the thickness is 13.12nm. The metal layer is plated at different temperatures, that is, one is plated at 200 ° C, and the other is plated at room temperature; then it is the barrier layer 2, and its plating method and time are the same as before; each film layer is used Plated by magnetron sputtering method. In addition, each film layer is not independent, and their adjacent surfaces penetrate each other, so they have a good bonding force.

[0043] Such as Figure 4 As shown, F represents that the metal layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com