Patents

Literature

80results about How to "Adjust color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ultrafine platy copper-zinc alloy powder

The invention relates to a method for preparing ultrafine platy copper-zinc alloy powder by using a horizontal stirring and grinding method, belonging to the technical field of preparation of metal powder material. The method comprises the steps of: mixing the copper-zinc alloy powder, grinding media and various grinding aids, putting the mixture into a sealed grinding bin of a horizontal high-energy stirring machine, introducing a protective atmosphere which mainly contains inert gas such as nitrogen and argon and the like, introducing water or oil with the temperature of 15-100 DEG C into a water cooling sleeve of a ball milling machine, controlling the rotating speeds at different stages, grinding, dispersing, modifying and grading the alloy powder to finally obtain copper alloy powder with the meshes of minus 300. In the method, the annealing process of the traditional method is abolished, and proper grinding process parameters are adopted, and the method has the advantages of short production process, high production efficiency, stable process and the like, and the prepared powder material has good platy effect and surface performance. The method also can be used for zinc-aluminum mixing ball milling and the production of powder such as zinc-aluminum alloy powder and the like, in which the degree of oxidation needs to be controlled.

Owner:KUNMING UNIV OF SCI & TECH

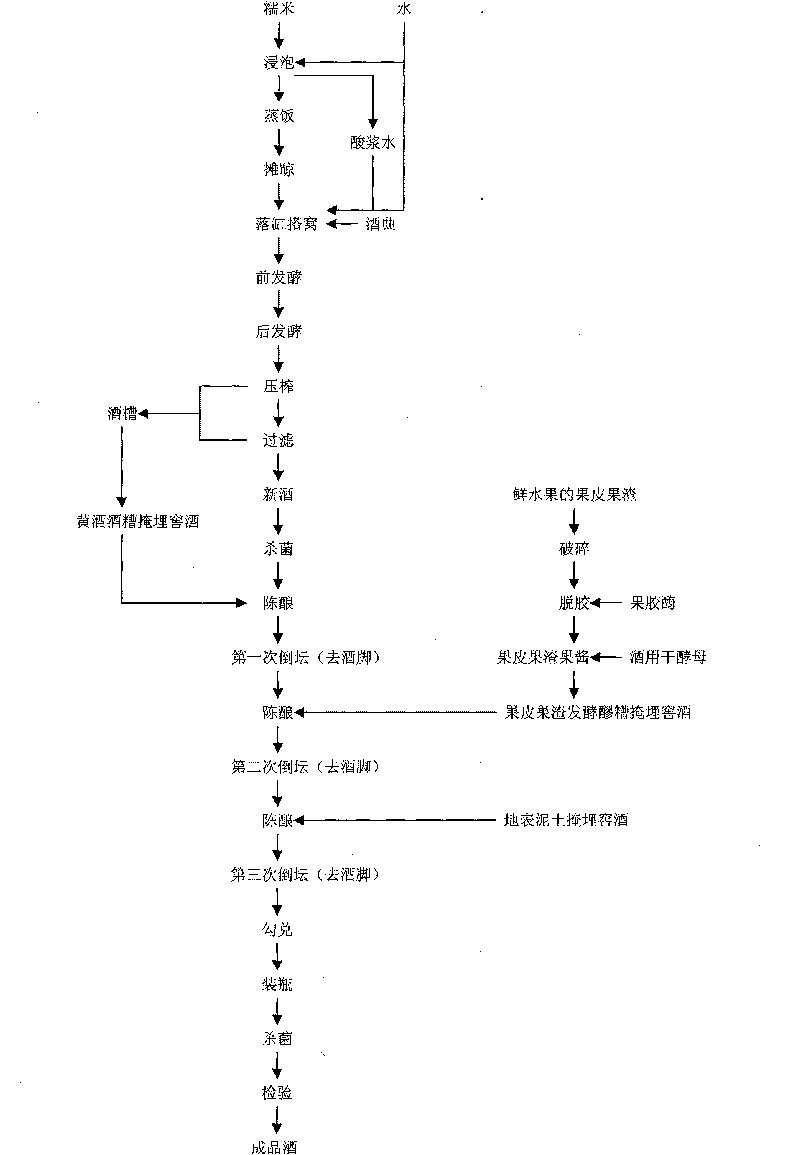

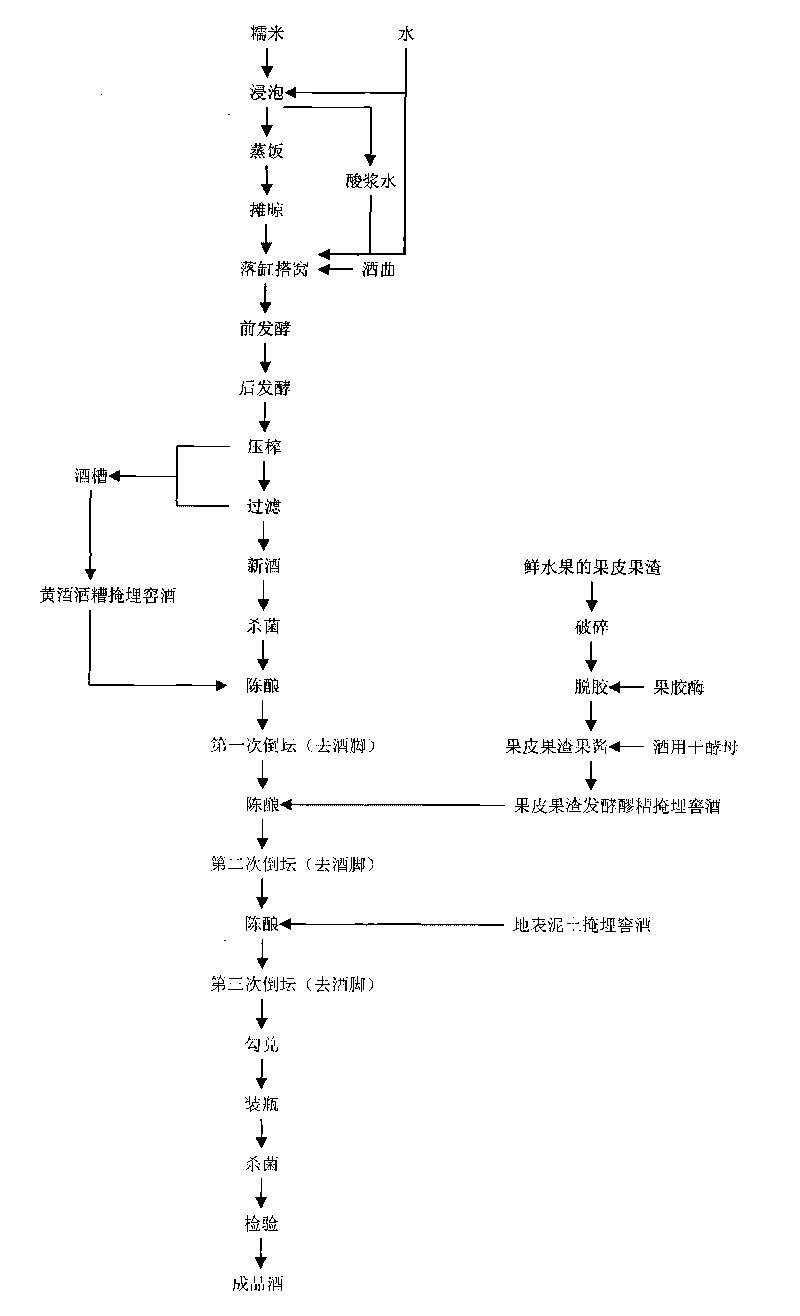

Buried type wine cellaring method

The invention discloses a buried type wine cellaring method, which aims to overcome shortcomings that the common storage method for a yellow wine has technical problems on shortening the storage period, adding aroma, improving mouthfeel, coordinating alcohol blending degree and the like. The invention adopts the following technical scheme: because an earthen jar (pot or vat) has characteristic of good air permeability when used to accommodate wine, yellow wine vinasse, fruit skin and fruit residue fermented glutinous rice wine and surficial soil are used for burying a cellared wine respectively for three times to effectively form favorable conditions, such as a microcirculatory respiratory system, a cold and hot interactive mechanism and a microbiological ecological environment, in the cellared wine; and combined with the natural environmental conditions of a cave (or an underground cellar), such as a constant temperature and a proper humidity, the alcoholization and aging of the yellow wine can be quickened, and the aims of shortening the storage period, improving the wine quality, increasing the aroma and the taste, improving the mouthfeel, coordinate the alcohol blending degree, reducing the wine storage cost and maintaining the quality of the wine after long-term storage are achieved.

Owner:刘名汉

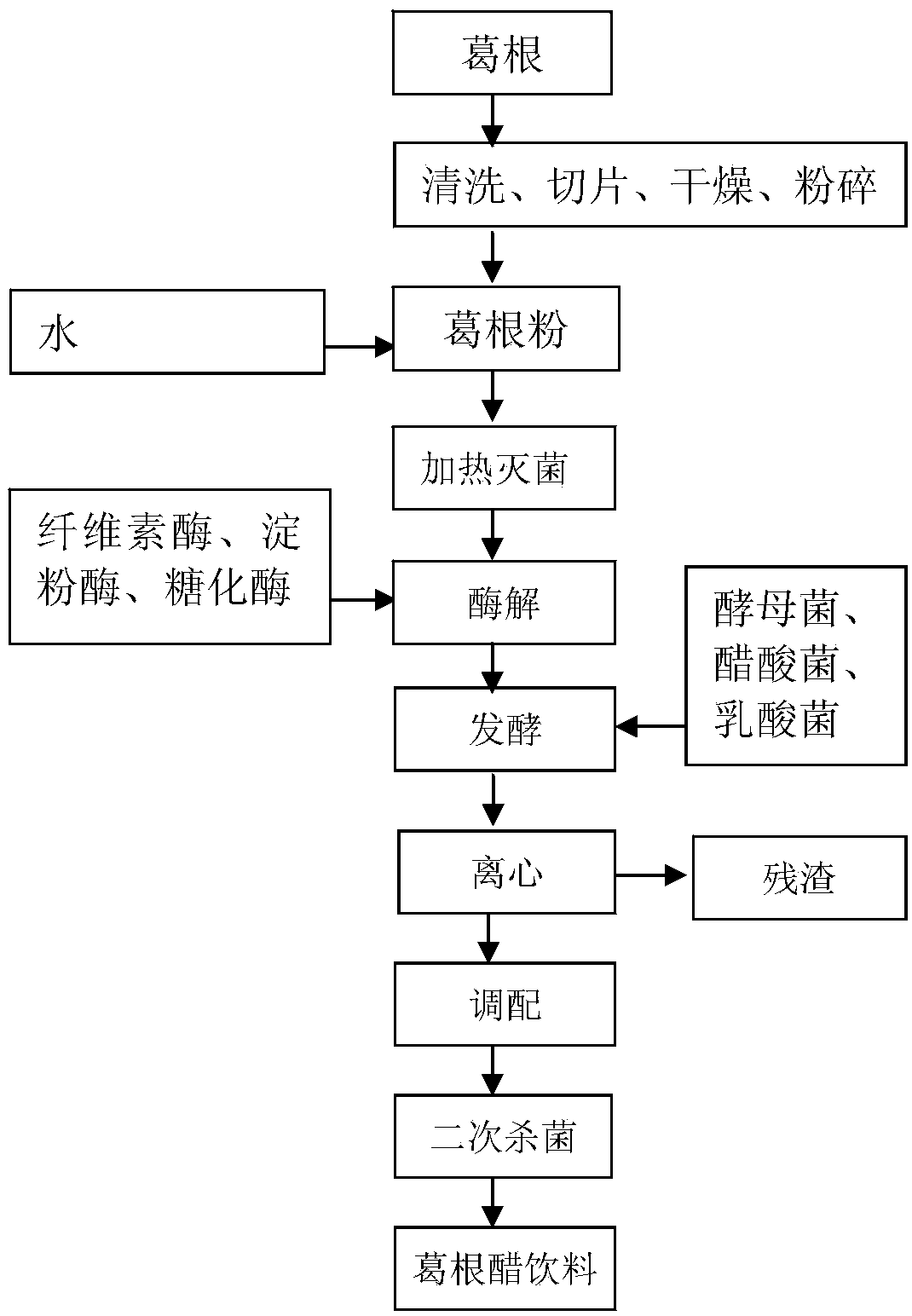

Preparation method of kudzu vine vinegar beverage

ActiveCN103829339AIncrease profitHigh extraction rateFood ingredient as thickening agentBiotechnologyAmylase

The invention discloses a preparation method of a kudzu vine vinegar beverage. The preparation method comprises the following steps of crushing kudzu vines, sterilizing, adding cellulose, amylase and saccharifying enzyme for carrying out synergetic enzymatic hydrolysis; then, adding mixed strains of lactic acid bacteria, saccharomycetes and acetic bacteria for carrying out multi-strain fermentation, filtering and mixing so as to obtain the kudzu vine vinegar beverage finally. According to the invention, the kudzu vine vinegar beverage is high in isoflavone extraction rate, brown orange, clear and transparent, palatable in acidity, soft, mellow and full-bodied in mouthfeel, and has specific flavor of the kudzu vine vinegar beverage.

Owner:JIANGSU UNIV +1

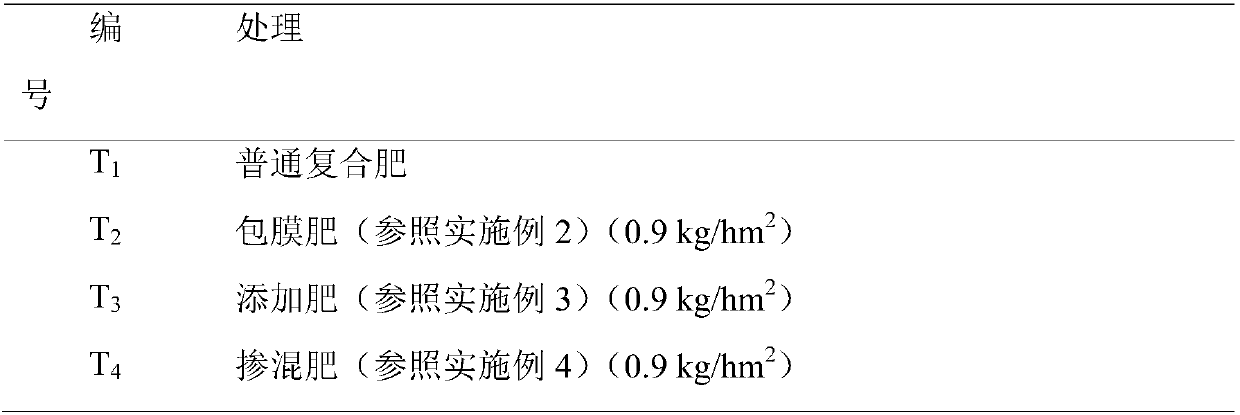

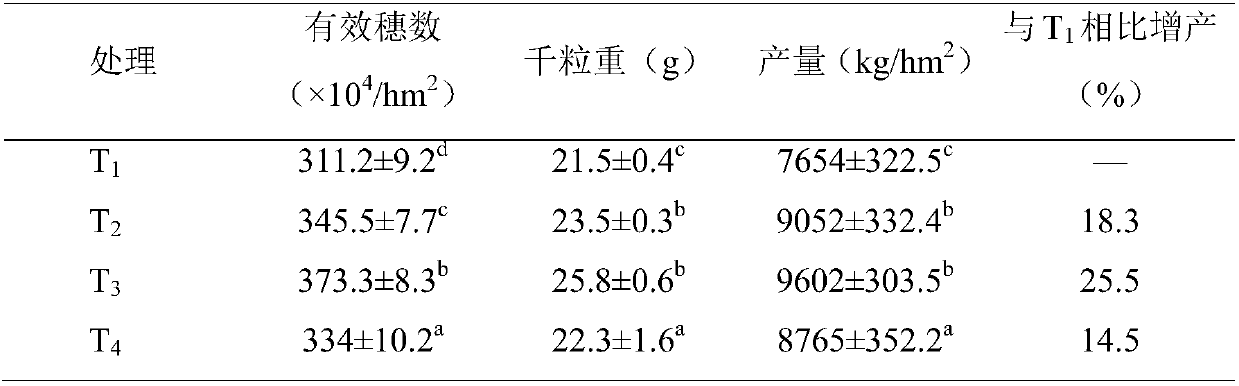

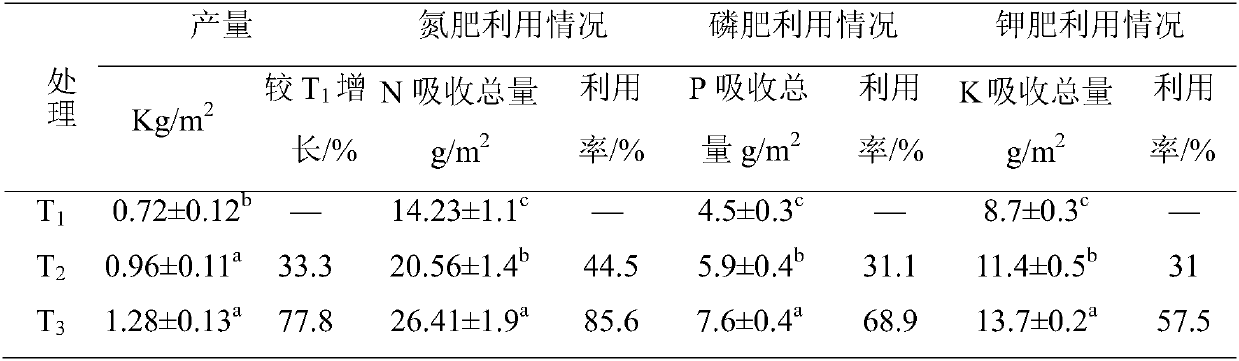

Composite synergist containing polyglutamic acid and potassium fulvic acid and application of composite synergist

PendingCN107641045AIncrease contentIncrease the Vc content in melon and fruit cropsFertilizer mixturesLeafy vegetablesPotassium

The present invention discloses a composite synergist containing polyglutamic acid and potassium fulvic acid. The composite synergist comprises the polyglutamic acid and the potassium fulvic acid, wherein the weight ratio of the polyglutamic acid to the potassium fulvic acid is 1:(0.001-0.5). The invention also discloses an application of the above composite synergist containing the polyglutamic acid and the potassium fulvic acid. The synergistic fertilizer prepared by using the composite fertilizer synergist provided by the invention effectively promotes the growth and development of crops, increases the yields of food crops, leafy vegetables and melon and fruit economic crops, and significantly improves the utilization rate of the fertilizer.

Owner:NANJING SHINEKING BIOTECH CO LTD

Doping pearlescent pigment and preparation thereof

The invention discloses a doped pearlescent pigment and a preparation method thereof. The pigment uses a glass flake as a substrate; the surface of the glass flake is coated with a SiO2 or SnO2 coating; the surface of the SiO2 or SnO2 coating is coated with a doped metallic oxide coating; the doped metallic oxide coating is a coating of metallic oxide doped with at least one metallic element compound, nonmetallic element compound or the combination of the two. The glass flake after SiO2 or SnO2 coating treatment is directly coated with the doped metallic oxide coating and then calcined once so as to form the doped pearlescent pigment. The invention relates to the pearlescent pigment containing the doped metallic oxide coating. By doping the metallic oxide with different metallic element compounds and / or nonmetallic compounds, the color and glossiness of the doped pigment are adjusted; therefore, both a high-glossiness colorful twinkling effect and a soft-glossiness effect can be obtained. Moreover, the pearlescent pigment has good hiding rate as well.

Owner:SUZHOU TAIZHU TECH DEV

Processing method of wheat seedings as well as instant wheat seeding powder and wheat seeding fiber powder prepared from same

InactiveCN103300293AGrassy odor reductionGrassy smell will not appearFood preparationAgricultural engineeringSpray dried

The invention discloses a processing method of wheat seedings as well as instant wheat seeding powder and wheat seeding fiber powder prepared from the same, and aims to solve the problem that the wheat seedings can be protruded during the processing by adopting the existing wheat seeding juice powder preparation process, for example, in part of methods, hot air being 145-165 DEG C is used for drying, the processing time is slightly long, and the product quality is seriously influenced. The wheat seedings are processed by adopting a wall-adhering-resisting spray control drying method, the blanching temperature can achieve 95 DEG C-98 DEG C, and enzyme and functionality components in the seedlings are greatly destroyed. The processing method comprises the following steps of: preprocessing, color protecting, pulping, filtering, homogenizing and spray drying. The processing method provided by the invention is capable of effectively reducing the blanching temperature, the functionality components are reserved to be maximum extent, meanwhile, wheat seeding juice is directly sprayed, a relatively good spraying effect is obtained through controlling spraying process parameters, the process is simple, the operating method is simple, the spraying time is short, and a product is not easy to block.

Owner:SICHUAN AGRI UNIV

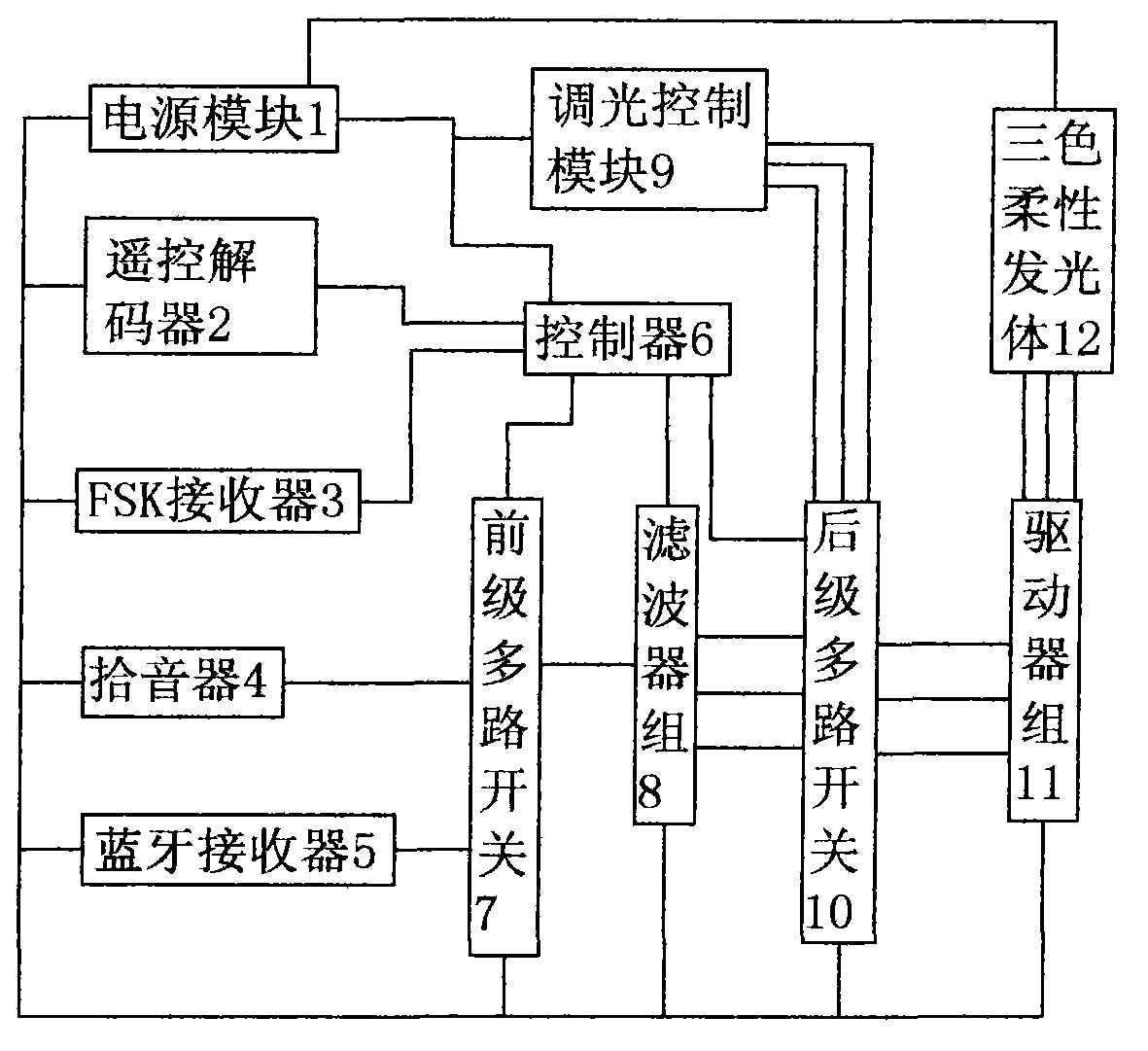

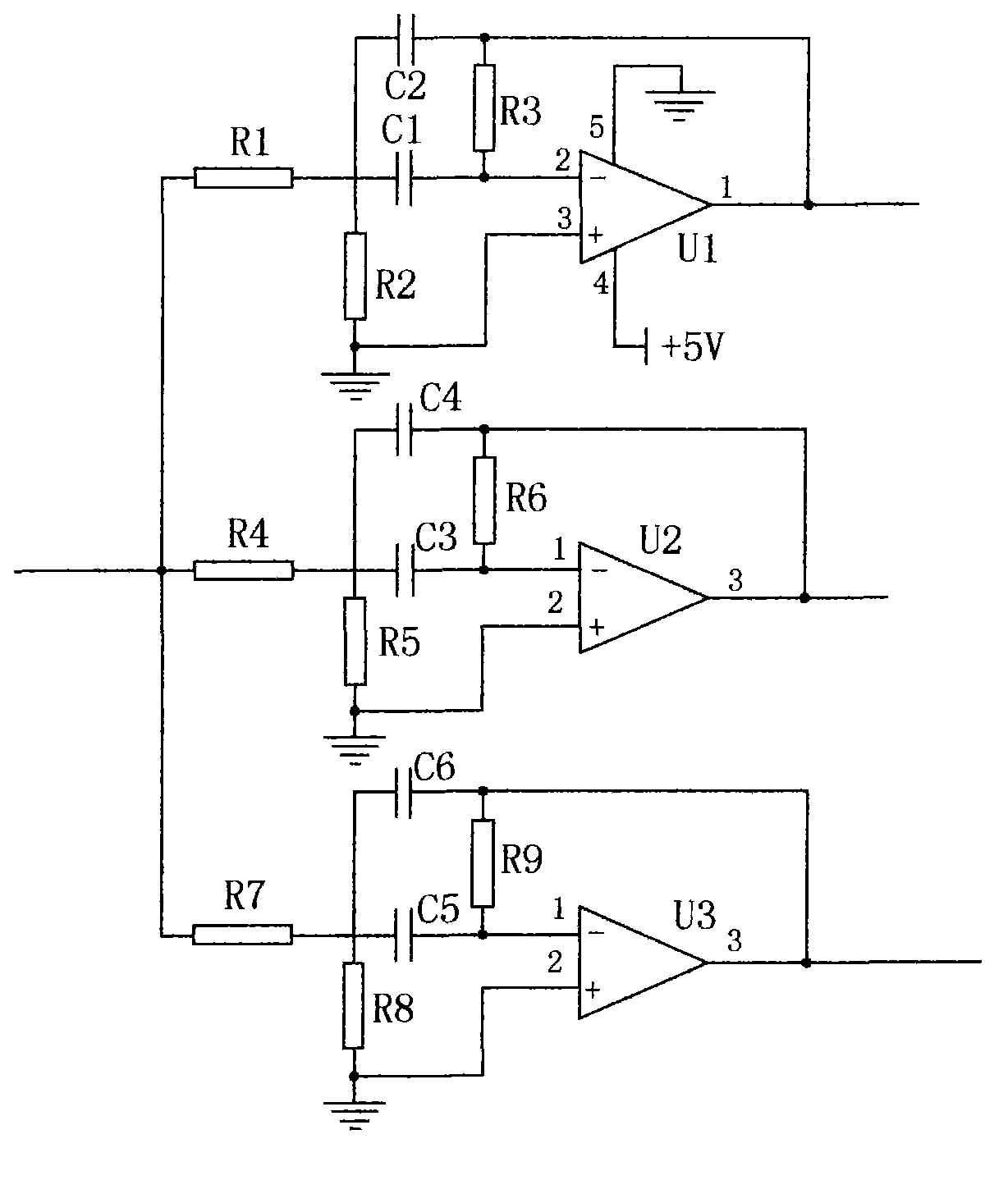

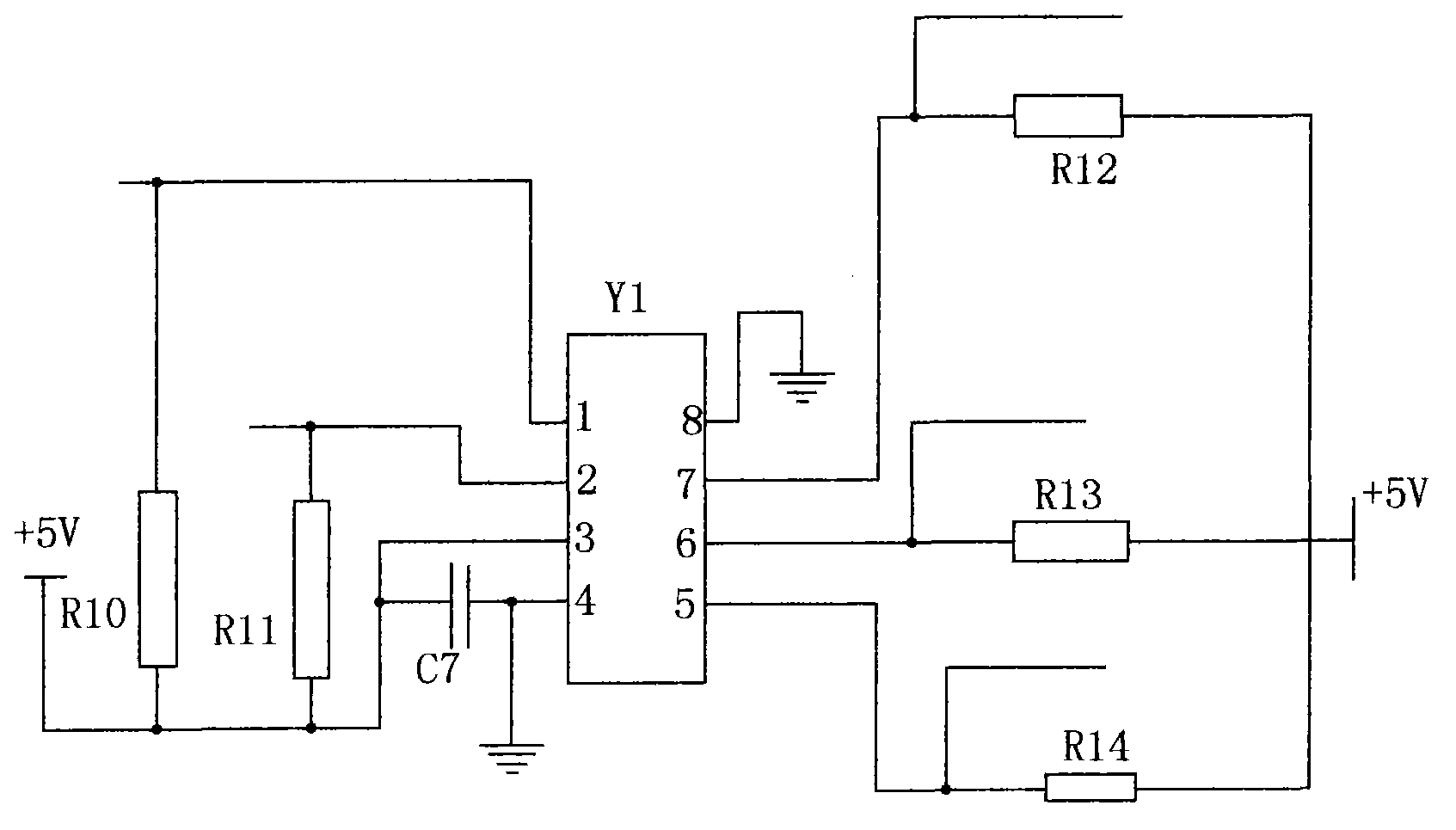

Intelligent drive control device for LED lamps

InactiveCN102802321AFlexible controlHigh degree of intelligenceElectric light circuit arrangementEnergy saving control techniquesTransceiverWireless control

The invention discloses an intelligent drive control device for LED lamps, relating to the field of LED illumination drive control. The intelligent drive control device is characterized in that a controller is respectively connected with a remote control decoder, an FSK (Frequency Shift Keying) transceiver, a front-stage multiway switch, a filter group and a back-stage multiway switch; the front-stage multiway switch is connected with the filter group; the filter group is connected with the back-stage multiway switch; the back-stage multiway switch is respectively connected with a dimming control module and a driver group; and the driver group is connected with a three-color flexible luminophor. A power supply module supplies power to other modules; the remote control decoder receives control signals from a wireless remote controller and selects a working mode; the FSK transceiver receives wireless control signals of a PC (Personal Computer), a sound pick-up acquires external sound signals, and a bluetooth receiver receives bluetooth music signals; and after filtering of the filter group, the back-stage multiway switch controls the driver group to drive the three-color luminophor to emit light of different colors and brightness along with changes of sound and music frequency and volume. The intelligent drive control device disclosed by the invention is flexible and diversified in control mode, high in intelligentization degree and convenient to use.

Owner:武汉巨正环保科技有限公司

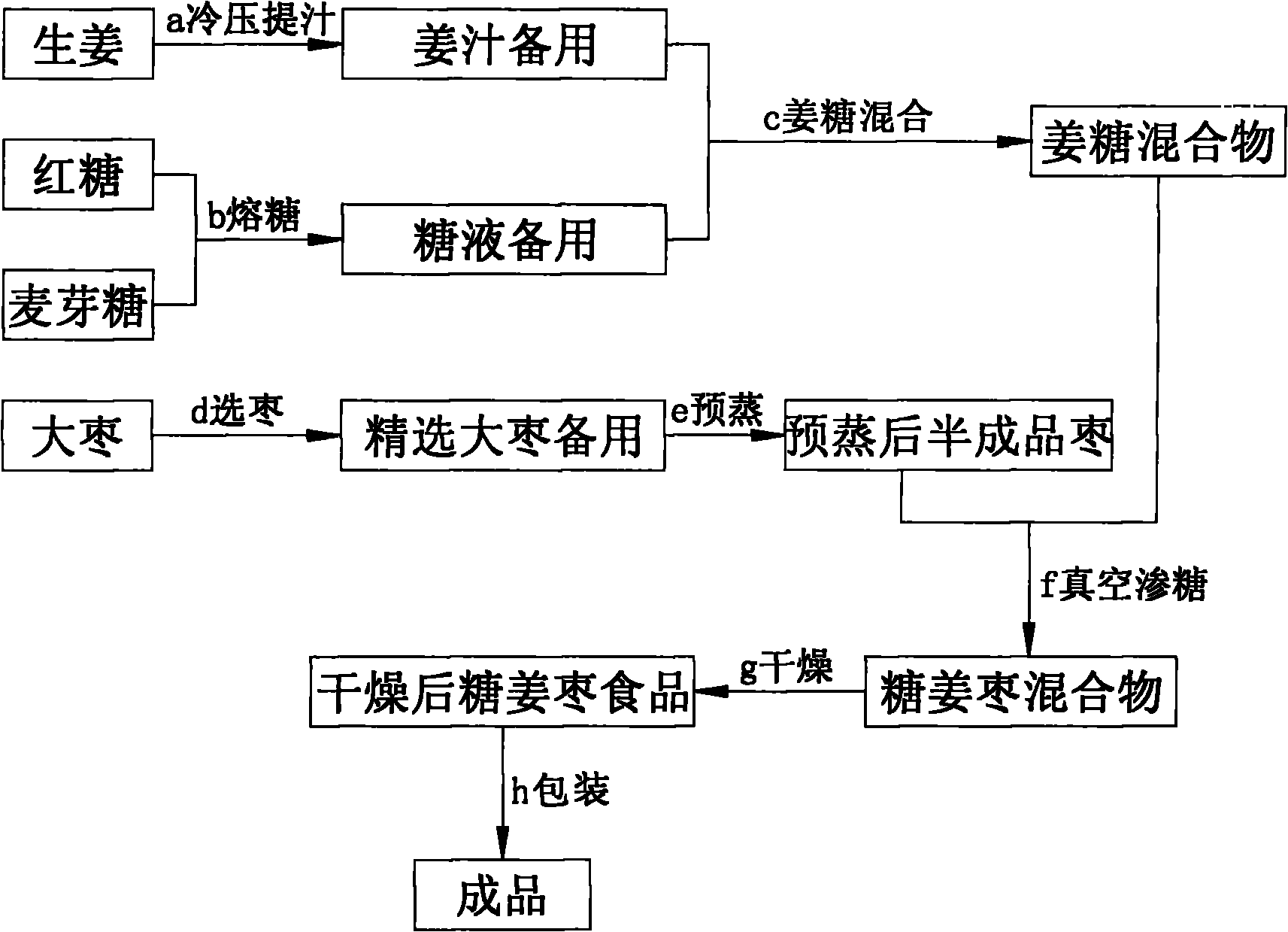

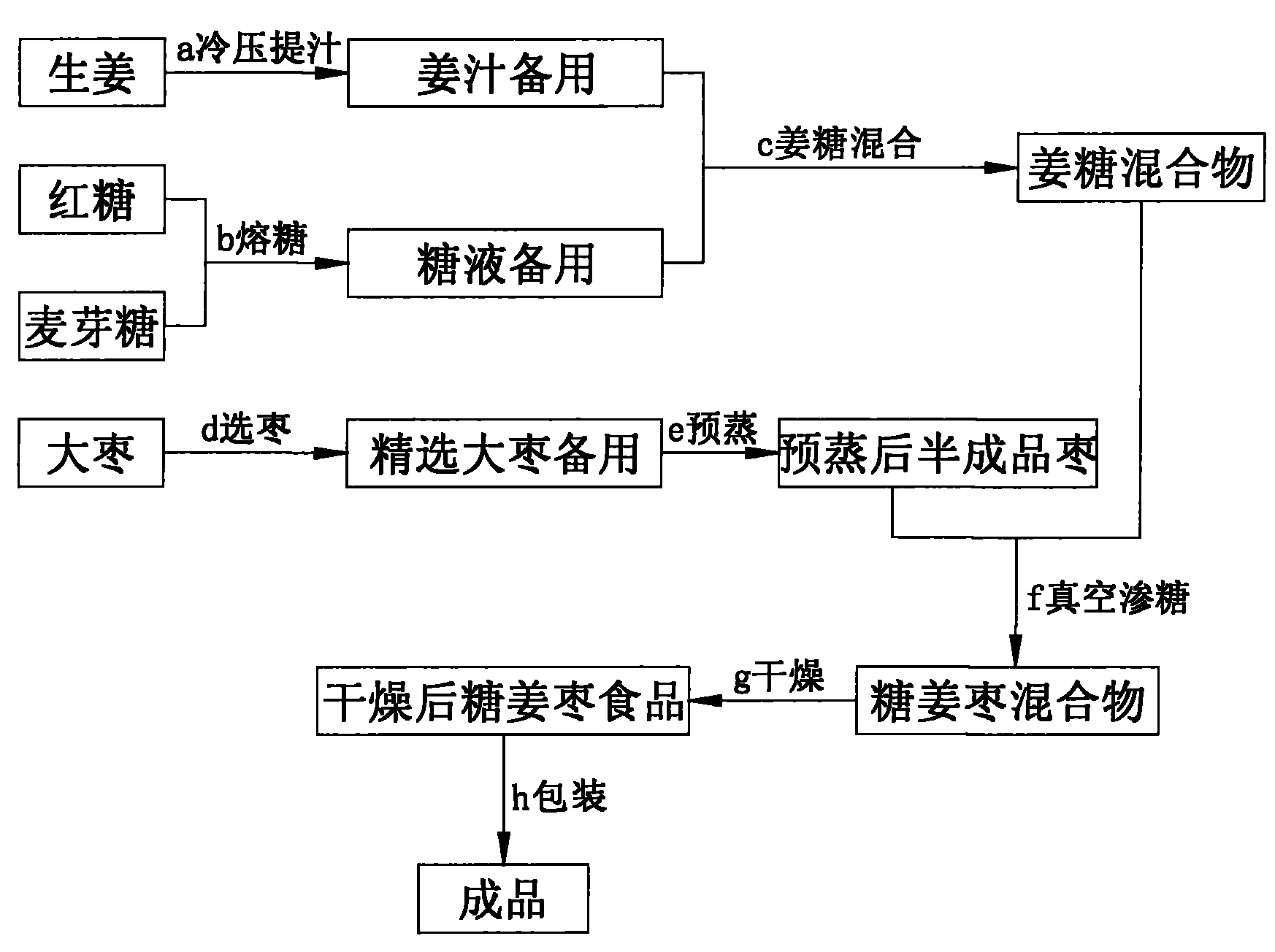

Preparation process of brown sugar, ginger and jujube food

InactiveCN101836734AAdjust colorPure colorConfectionerySweetmeatsZiziphus jujubaSurface-active agents

The invention relates to a preparation process of a brown sugar, ginger and jujube food, which comprises the following steps that: juice is extracted from ginger by cold pressing, and the ginger juice is prepared to be used; sugar is melted, and sugar liquid is prepared to be used; the ginger liquid and the sugar liquid are mixed into a ginger and sugar mixture; jujube is cleaned and selected, and jujube cores are removed; under vacuum conditions, the selected jujube is pre-steamed to form semi-finished product jujube; under the conditions of vacuum and temperature of 65 DEG C, the vacuum sugar permeation is carried out for the ginger and sugar mixture and the semi-finished product jujube after being pre-steamed to form a sugar, ginger and jujube mixture; the sugar, ginger and jujube mixture is put in a microwave vacuum dryer to be dried into a sugar, ginger and jujube food; and the sugar, ginger and jujube good after being dried is packaged into finished products by nitrogen filling. The sugar, ginger and jujube good comprises the following components of raw materials by weight part: 20-30 parts of brown sugar, 10-15 parts of maltose, 10-20 parts of ginger, 30-40 parts of jujube and 10-20 of water. The sugar, ginger and jujube good prepared by the process integrates health care and food therapy, and reserves the active ingredients of ginger and jujube to the utmost extent; and simultaneously, any preservatives, mildew preventives and other surface active agents are not added in the entire preparation process, and so the non-pollution, health and safety of the food are ensured.

Owner:薛青

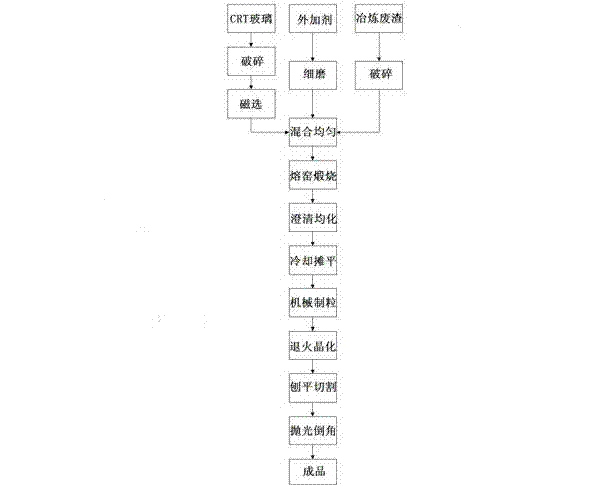

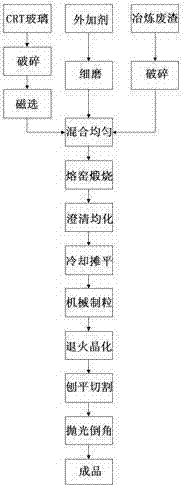

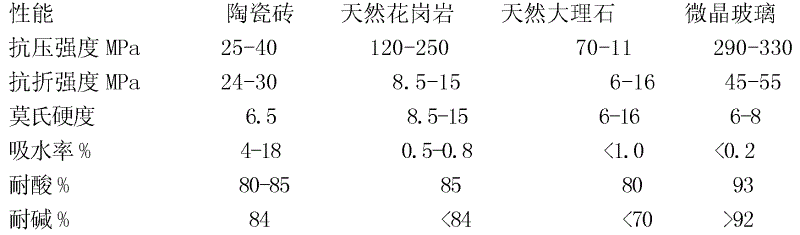

Method for manufacturing microcrystalline glass utilizing smelting waste slag and CRT (Cathode Ray Tube) waste glass

The invention relates to microcrystalline glass manufactured utilizing smelting waste slag and CRT (Cathode Ray Tube) waste glass. The microcrystalline glass is characterized in that: the process formula is designed according to the product requirements, and the raw materials comprise the following components according to a weight ratio: 45% of smelting waste slag, 45% of CRT waste glass, 3-5% of calcite ash, 5% of quartz sand and 0.5-1% of additive; and the process can be properly adjusted according to the process requirements, chemical composition of the raw materials, color and the like. According to the invention, industrial smelting waste slag and CRT waste glass are sufficiently utilized to replace natural stones and clay mineral resources, thus the mine exploitation is avoided, resources are saved, wastes are changed into valuable, pollution is prevented, environment is protected, building material products with high added value are produced and social wealth is created.

Owner:CHENZHOU WANRONG METAL PROCESSING

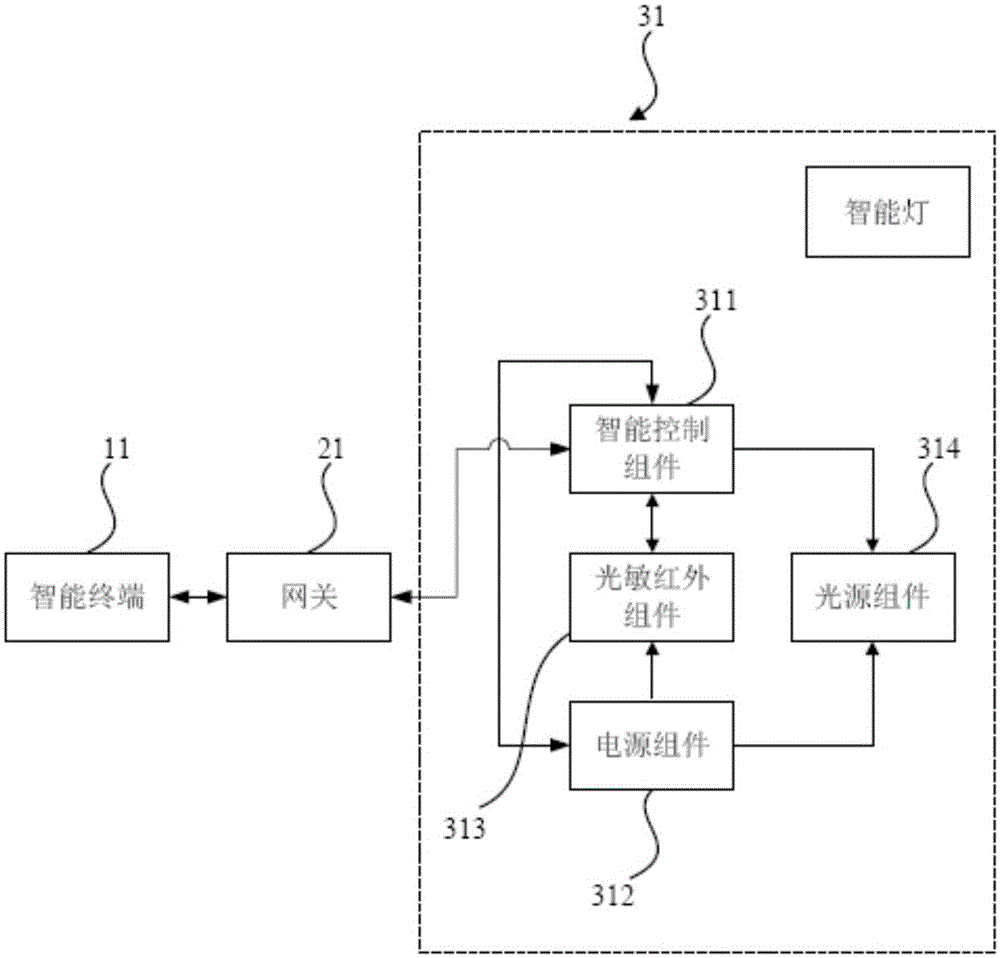

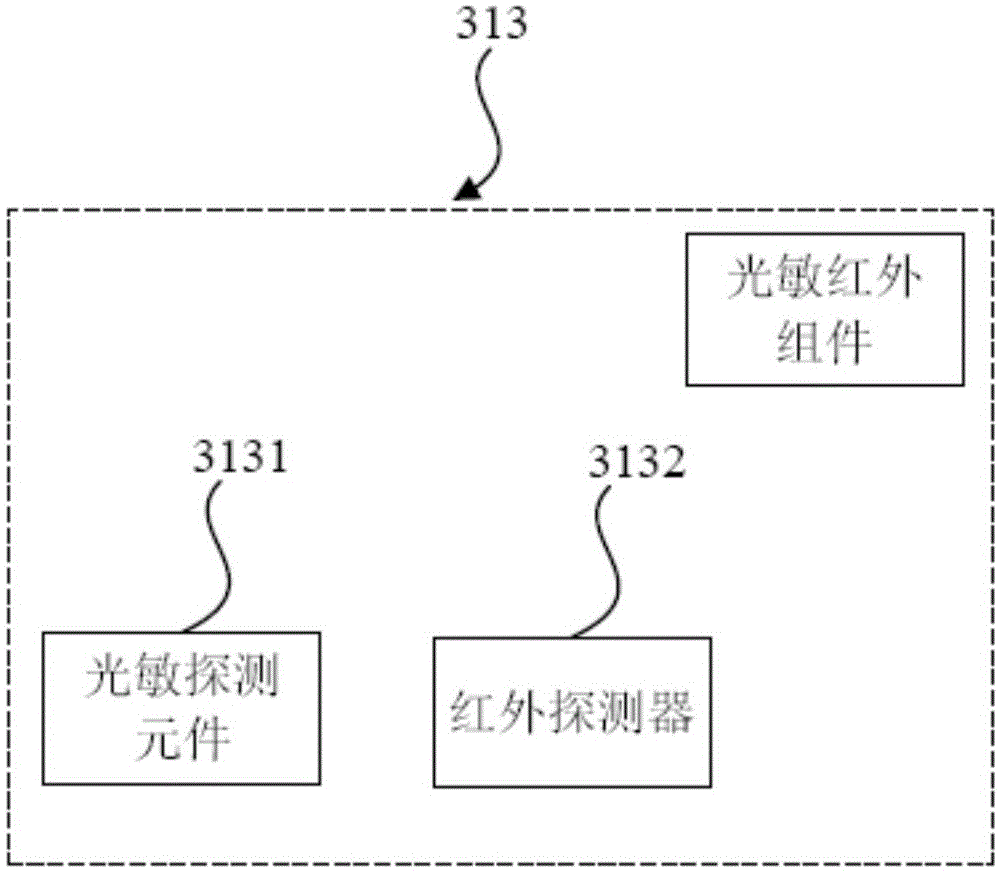

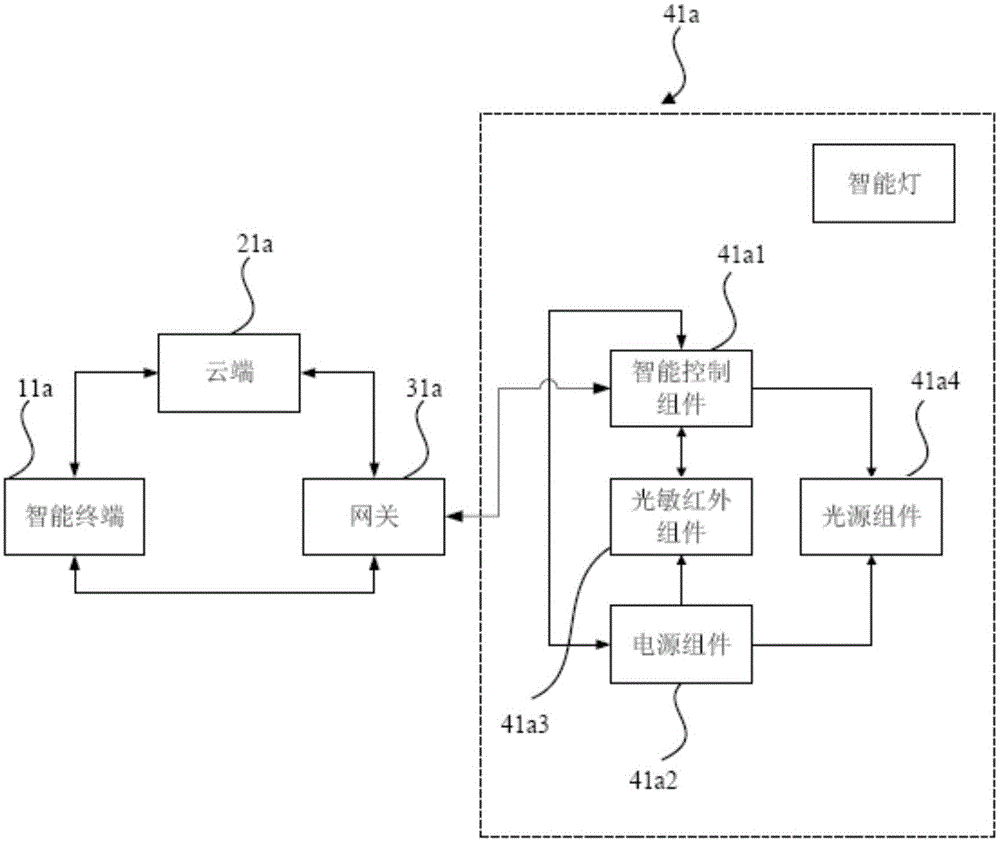

Intelligent lamp and intelligent control system

ActiveCN105142264AIntelligent control statusAdjust colorElectric light circuit arrangementEnergy saving control techniquesIntelligent control systemCalculated data

The invention provides an intelligent lamp and an intelligent control system. The intelligent lamp comprises a power supply assembly, a photosensitive infrared assembly, a light source assembly and an intelligent control assembly, wherein the intelligent control assembly is used for connecting and controlling the power supply assembly, the photosensitive infrared assembly and the light source assembly; the intelligent control system comprises the intelligent lamp, an intelligent terminal, a gateway and a cloud terminal; the cloud terminal is used for receiving, storing and analyzing operating data, fed back by the gateway, of the intelligent lamp; and the intelligent control assembly in the intelligent lamp can control the power supply assembly and the light source assembly, and can also adjust the color and the light intensity of the light source assembly, so as to achieve the energy-saving effect. In addition, the analyzed and calculated data are displayed through the intelligent terminal; and a user can be helped improve the bad living habits, so that the living quality is improved.

Owner:JIANGXI MESMART INTERNET OF THINGS TECH

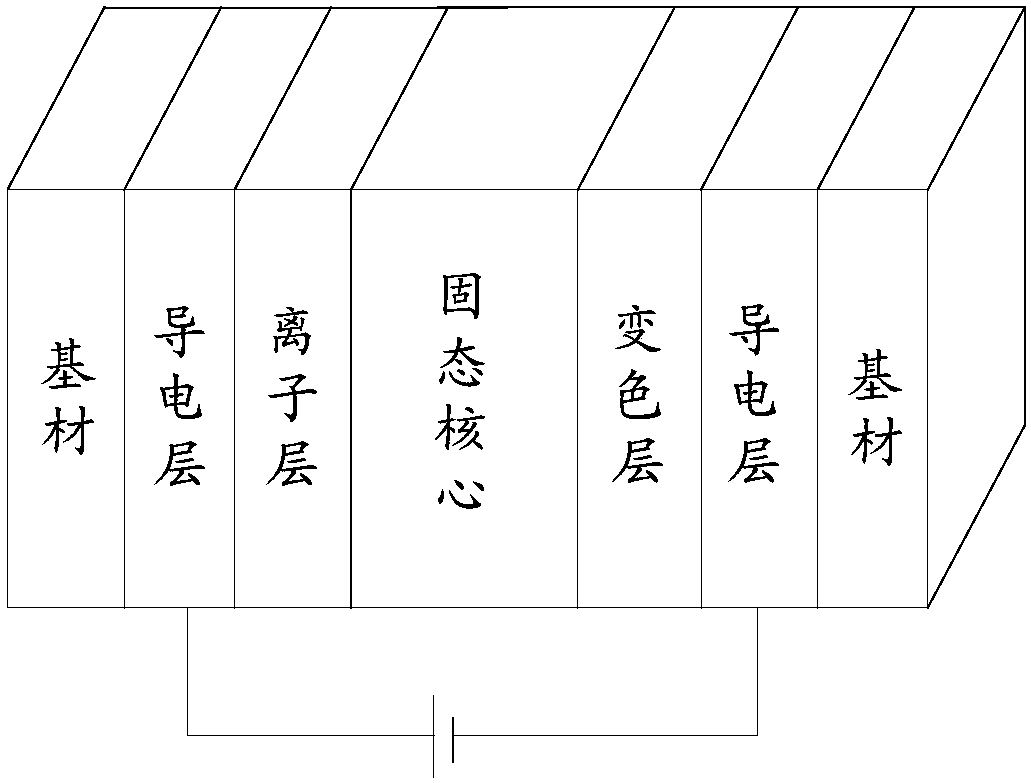

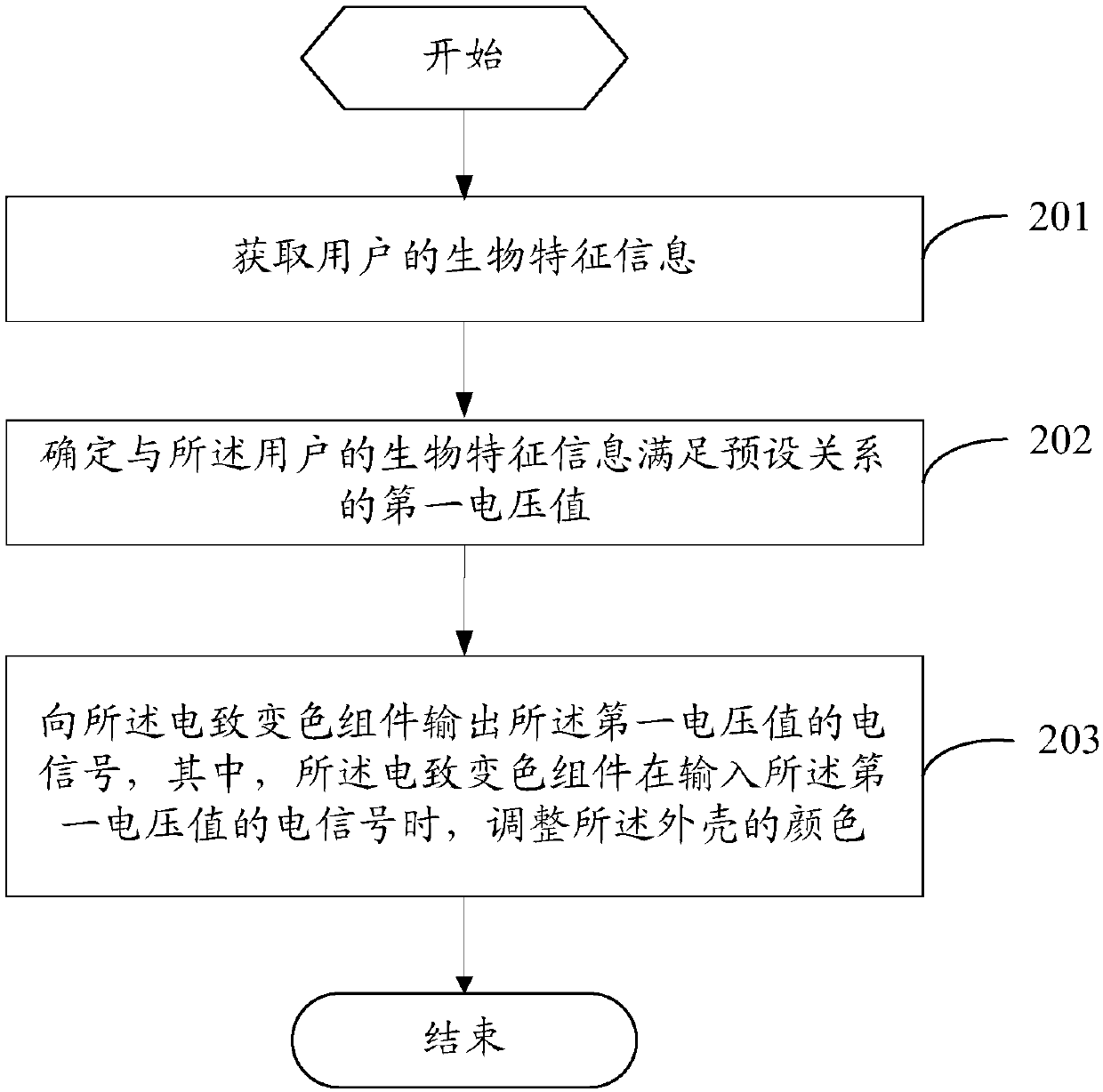

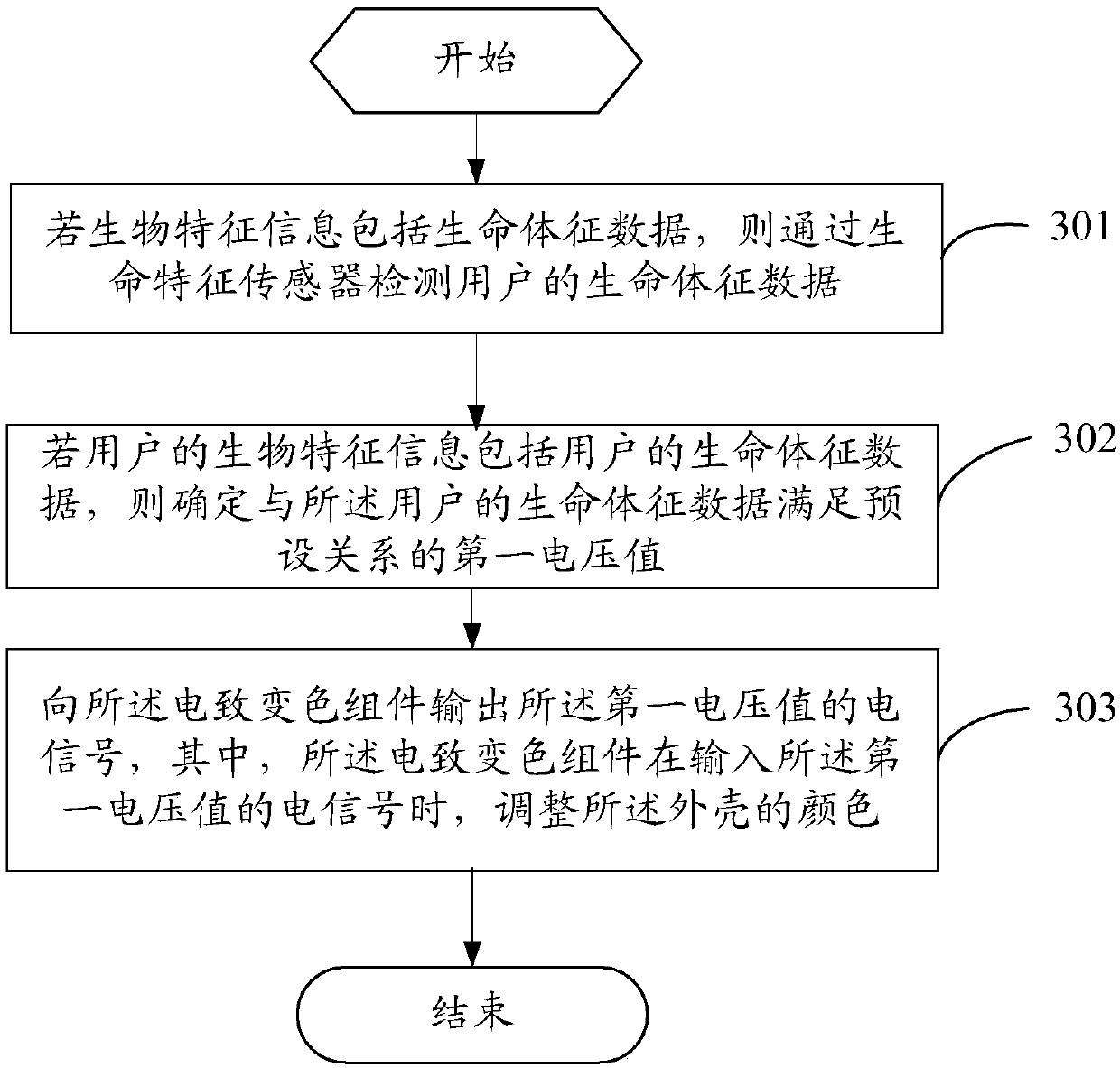

Mobile terminal shell color adjustment method and mobile terminal

InactiveCN107819902AAdjust colorRich and varied colorsTelephone set constructionsElectricityComputer terminal

The invention provides a mobile terminal shell color adjustment method and a mobile terminal. The method comprises the steps of acquiring biological characteristic information of a user; determining afirst voltage value meeting a preset relation with the biological characteristic information of the user; and outputting an electrical signal of a first voltage value to a electrochromic component, wherein the electrochromic component adjusts the color of a shell when the electrical signal of the first voltage value is input. As the electrochromic component display different colors when the different electrical signals are input, the color of the shell of the mobile terminal can be adjusted, and thus the shell of the mobile terminal is rich and variable in color.

Owner:VIVO MOBILE COMM CO LTD

High-color-changing-resistance golden copper alloy and preparation method

The invention discloses a high-color-changing-resistance golden copper alloy and a preparation method. The alloy comprises Zn, Al, Co, Ce, B and the balance Cu. The preparation process comprises the steps of casting, hot rolling, cold rolling, solution hardening, cold finish and rough rolling, cold finish rolling and finished product annealing. The golden degree of the produced alloy is high, thehot processing performance and the cold processing performance are both excellent, and resistance to deformation is small; and the alloy includes no precious metal elements, and cost is low. The components of the alloy are reasonable and simple, the golden degree of the alloy is improved through reasonable matching of cheap aluminum and zinc, the casting process is simple through the simple alloycomponents, through reasonable matching of cerium and boron, the processing property is improved, and color changing resistance is improved; and the binding energy of trace cobalt and the vacancy in the copper alloy is low, binding with the vacancy in the copper alloy can be achieved effectively, a Zn atom diffusion channel is blocked, and dezinc corrosion corrosion of the alloy is improved. The alloy is simple in production process, low in production cost, good in processing performance and good in golden degree and is suitable for industrial production.

Owner:CENT SOUTH UNIV +1

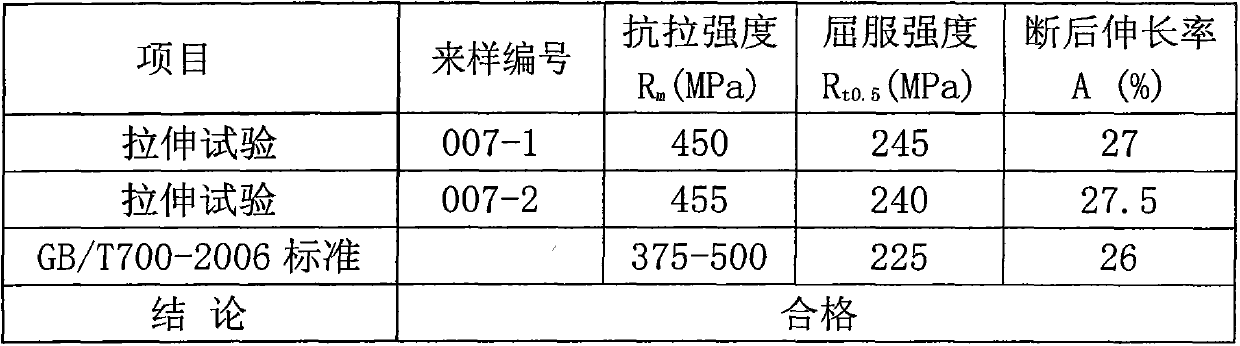

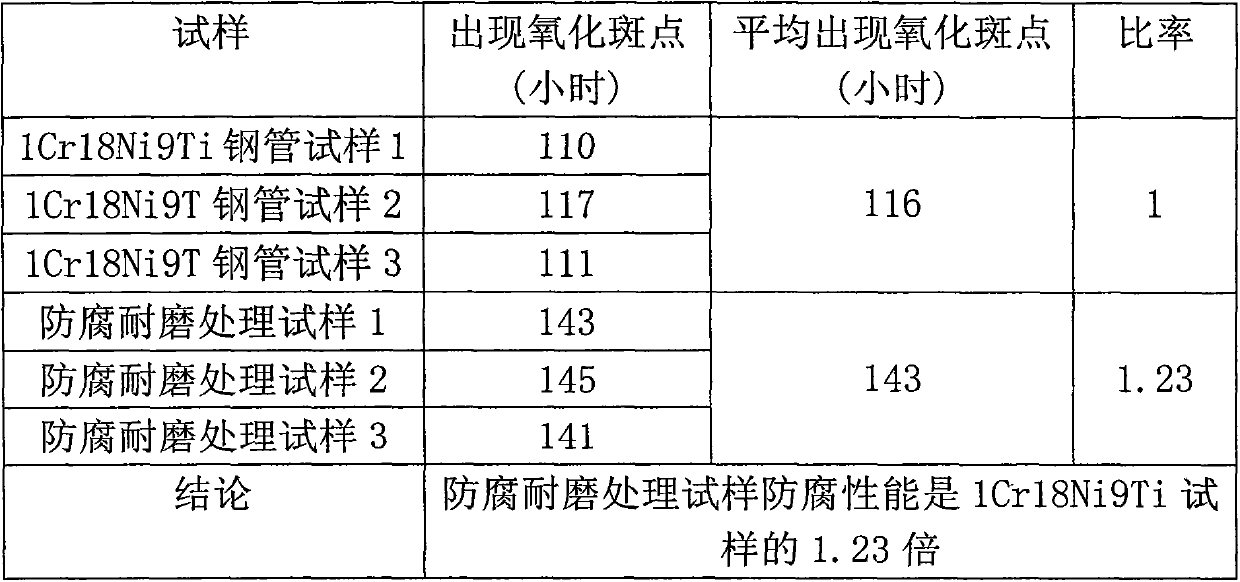

Process for preparing novel corrosion-resistant and wear-resistant color steel pipe

ActiveCN104195505AHigh hardnessImprove anti-corrosion performanceSolid state diffusion coatingWear resistantSeam welding

The invention relates to a process for preparing a novel corrosion-resistant and wear-resistant color steel pipe and belongs to the technical field of surface modification and heat treatment of steel pipes. The process is mainly characterized in that the inner and outer surfaces of the steel pipe are subjected to oil removal and cleaning treatment, steel pipe preheating treatment, steel pipe secondary polishing treatment, steel pipe third polishing treatment and liquid ion nitriding and corrosion-resistant and wear-resistant heat treatment process and then subjected to liquid ion oxidizing and coloring and fine polishing treatment and a 10mu m-100mu m corrosion-resistant and wear-resistant layer is formed on each of the inner and outer surfaces of the steel pipe, wherein the corrosion-resistant and wear-resistant layer mainly and sequentially comprises a compound layer and a nitrogen-containing austenite layer, the steel pipe is A3, Q235 or other carbon steels and the original state of the steel pipe can be a seamless steel pipe and can also be a straight-seam welded steel pipe. The steel pipe produced by the process disclosed by the invention has the advantages of relatively high corrosion resistance and wear resistance and since the outer surface of the steel pipe can show different colors, such as silver, bronze, black, and navy blue, the steel pipe can replace Cr-containing and Ni-containing stainless steel color steel pipes.

Owner:SHAANXI TIEMA FORGING

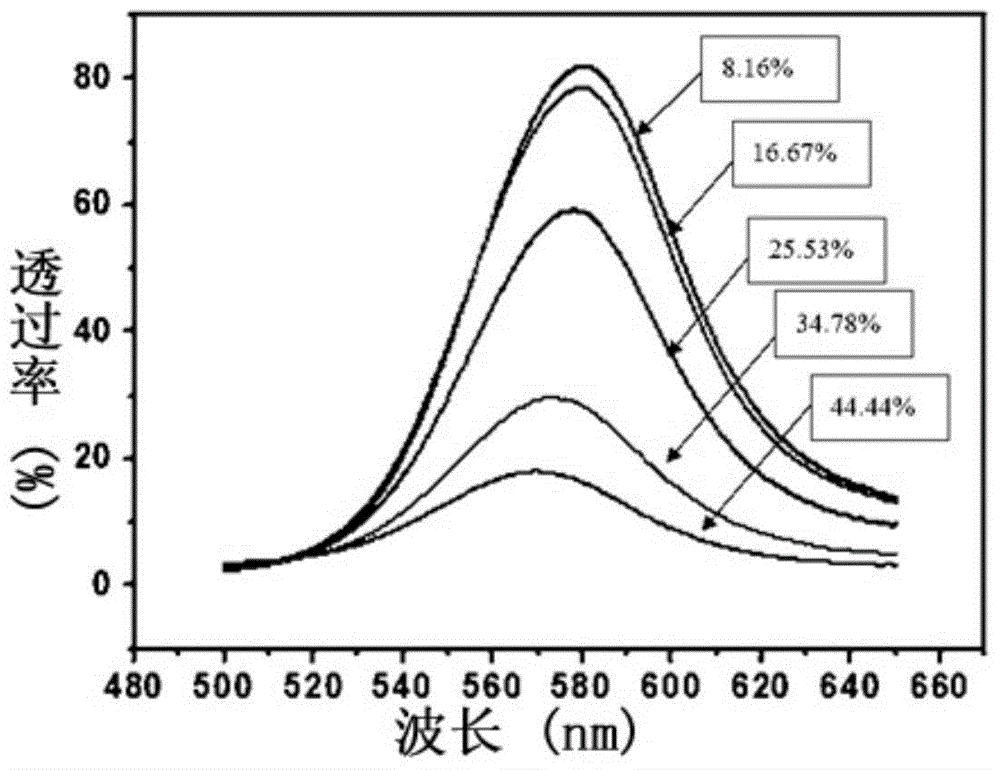

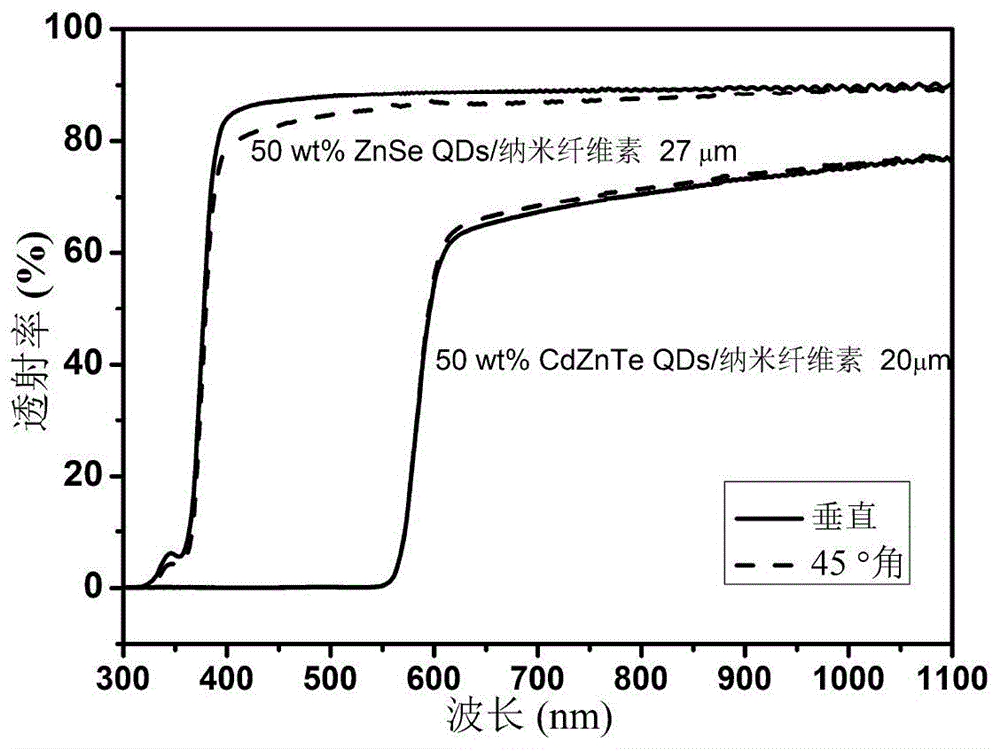

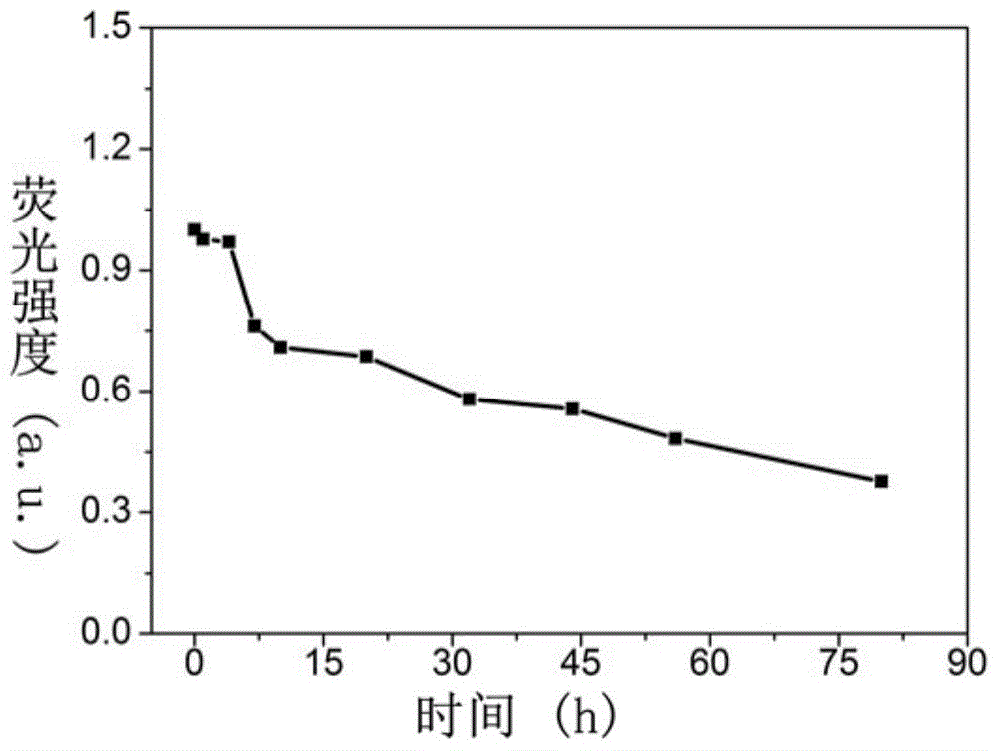

Quantum-dot strengthened composite light conversion film and preparation method thereof

The invention relates to a quantum-dot strengthened composite light conversion film and a preparation method thereof, belonging to the field of photoelectric-function high-polymer technical materials. The film material with adjustable flexibility, transparency, luminescent intensity and color is composed of nano cellulose, a plasticizer and water-soluble quantum dots, wherein polyalcohol is used as the plasticizer of the nano cellulose for regulating the flexibility of the film, and the water-soluble quantum dots can account for 0.1-50 wt% of the composite material; and the film has adjustable transparency, flexibility and luminescent color, controllable thickness and cuttable area. The thickness and area of the film material can be scaled up according to application demands. The quantum-dot strengthened composite light conversion film prepared by the method has the advantages of high composite material doping amount, high transparency and high flexibility, and is cuttable and flexible; the luminescent color and luminescent intensity can be adjusted according to the type, size and proportioning of the quantum dots; and the addition of the glycerol can further optimize the flexibility of the film material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Highly-color-change-resistant golden brass alloy and preparation method

The invention discloses a highly-color-change-resistant golden brass alloy and preparation method. The highly-color-change-resistant golden brass alloy comprises the following components of Mn, Sn, Ni, Zn, Sr, Ce, B, Si and the balance Cu and inevitable impurities. The preparation process comprises the following steps of casting, hot rolling, cold rolling, intermediate annealing, cold finish roughrolling, cold finish rolling and finished product annealing. The alloy produced by the method is high in golden degree, good in color-change resistance, excellent in hot and cold machining performance, small in deformation resistance, free of precious metal elements and relatively low in cost; the alloy produced by the method is reasonable in component, the golden degree of the alloy is improvedthrough reasonable matching of cheap manganese, nickel, zinc and tin, the zinc content is lower than 20% so that dezincification corrosion can be avoided, through the reasonable combination strontium,cerium, boron and silicon, the process performance can be improved, and the color-change resistance can be improved; according to the alloy, the production process is simple, the production cost is low, the machining performance is good, the golden degree is high, the color-change resistance is excellent in the environment of salt mist, high humidity, synthetic perspiration and the like, and thealloy is suitable for industrial production.

Owner:CENT SOUTH UNIV +1

High discoloration resistance and low-cost gold bronze alloy and preparation method thereof

The invention provides a high discoloration resistance and low-cost gold bronze alloy and a preparation method thereof. The high discoloration resistance and low-cost gold bronze alloy comprises the following components of Mn, Al, Ni, Si, Ce, Sr, P and B, and the balance Cu and inevitable impurities. The preparation method comprises the steps of smelting, semi-continuous casting, hot rolling, surface milling, cold rolling, intermediate annealing, cold finish rough rolling, cold finish rolling and finished product annealing. The alloy produced by the method has high gold color, good discoloration resistance performance, excellent hot and cold working properties and small deformation resistance, and does not contain noble metal elements, so that the alloy is relatively low in cost. The alloyhas reasonable components, and the gold degree of the alloy is improved through reasonable matching of cheap manganese, aluminum, nickel and silicon. The reasonable collocation of strontium, cerium,phosphorus and silicon can improve the technological performance and the discoloration resistance. The alloy is low in price of raw materials, simple in production process, environment-friendly, low in production cost, good in processing performance, high in the gold degree, excellent in discoloration resistance performance in environments such as salt mist, high-humidity and artificial sweat, andsuitable for industrial production.

Owner:CENT SOUTH UNIV

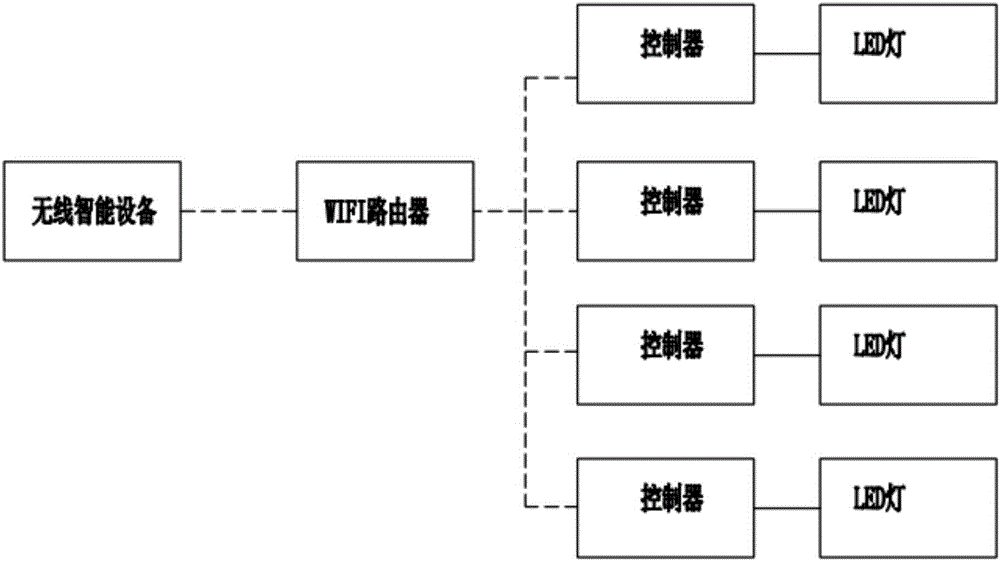

WIFI multi-point controller of LED lamp and method for controlling LED lamp through WIFI

InactiveCN106304514ABrightness adjustableAdjust colorElectrical apparatusElectroluminescent light sourcesEngineeringLED lamp

The invention provides a WIFI multi-point controller of an LED lamp. The WIFI multi-point controller is characterized in that the controller comprises a wireless intelligent device, a WIFI router, and one or more LED lamps, each LED lamp is connected with a controller capable of emitting and receiving WIFI signals, and the controllers control the LED lamps. The invention also provides a method for controlling the LED lamp through WIFI. According to the controller and the method, the structure is simple, and the usage is convenient; users do not need to separately press buttons to control the LED lamps but through the control of a cellphone; the cellphone is connected with the WIFI router so that turn-on / turn-off is controlled by the cellphone, and the brightness, the color, the color temperature, the music and the timing function of the lamps are adjusted; WiFi has larger coverage and higher transmission rate so that the application of multiple devices can be controlled in a remote manner, and other functions of the cellphone are not influenced.

Owner:XIAMEN JIER ELECTRICAL APPLIANCES CO LTD

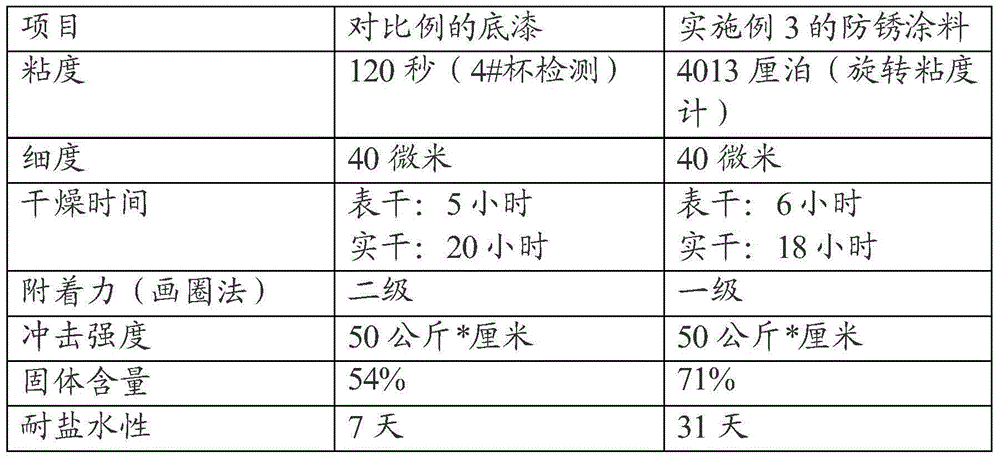

Rust-proof coating

InactiveCN104449201AImprove adsorption capacityAdjust colorAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses a rust-proof coating. The coating comprises a component A and a component B in the weight ratio of 5: 1, wherein the component A comprises the following components in parts by weight: 18-22 parts of first epoxy resin, 18-24 parts of second epoxy resin, 10-15 parts of magnet powder, 2-10 parts of iron oxide red, 3-6 parts of zinc phosphate, 1-6 parts of zinc powder, 0.1-0.2 part of a dispersant, 0.2-0.3 part of an assistant and 12-15 parts of a diluent; and the component B comprises the following components in parts by weight: 56-62 parts of a first amine curing agent, 12-18 parts of a second amine curing agent and 20-30 parts of ethanol. The rust-proof coating adopts two different types of epoxy resin and curing agents to form a film by crosslinking and curing. The film-forming mechanism is that active H<+> is contained in the amine curing agents and can react with epoxy groups in epoxy resin at normal temperature and form a reticular structure by crosslinking; and the reticular structure is dense and hard, good in anti-corrosion performance, strong in adhesion and outstanding in chemical resistance.

Owner:湖南中汉高分子材料科技有限公司

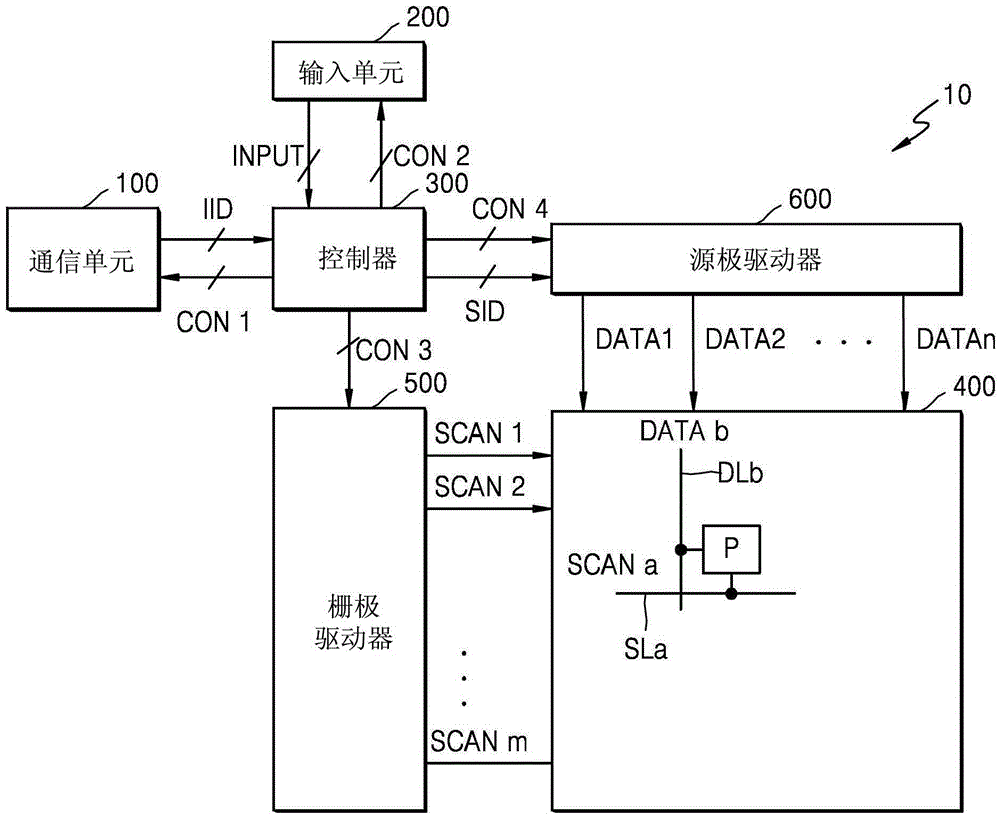

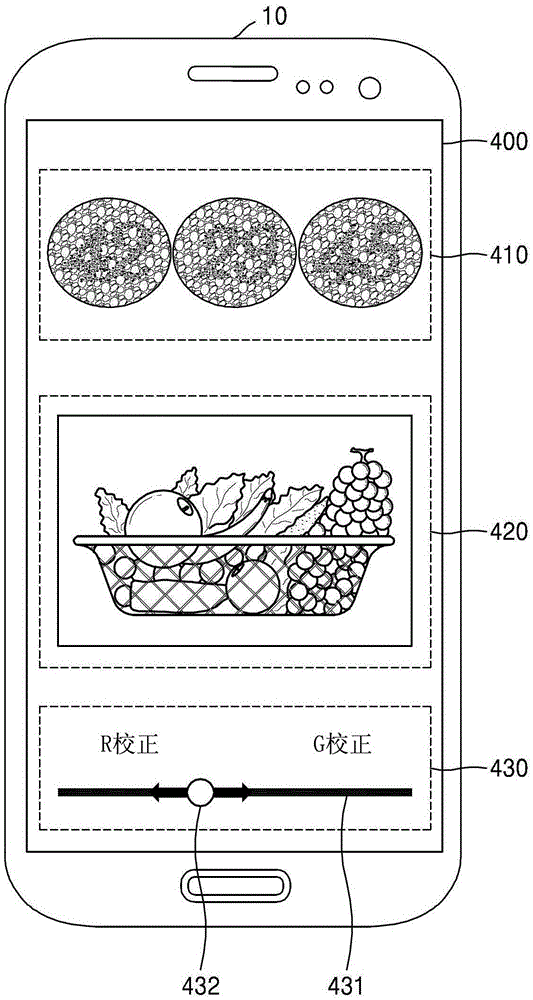

Display apparatus and method of driving the same

ActiveCN106251799AAdjust colorReal-time adjustmentStatic indicating devicesInput/output processes for data processingColor vision testComputer graphics (images)

A method of driving a display device includes displaying both a natural image and a color vision test image on the display unit. The color vision test image is an image used to determine whether a person has a color vision impairment. A color adjustment user interface for adjusting color of the display unit is displayed on the display unit. A color adjustment instruction that instructs to adjust color of the display unit is received via an input unit. Supply image data supplied to the display unit is adjusted based on the color adjustment instruction by using a controller.

Owner:SAMSUNG DISPLAY CO LTD +1

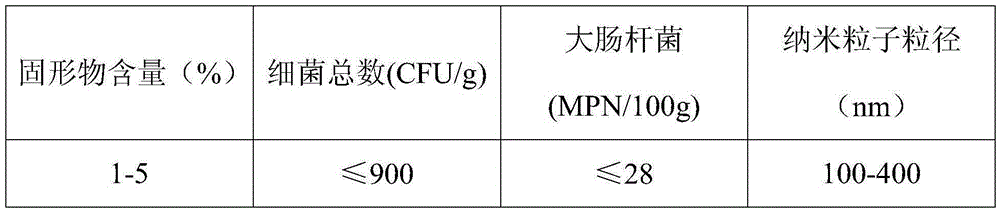

Functional factor containing pearl milk tea beverage and production method thereof

InactiveCN105230788AExtended stayBoost free radicalsMilk preparationPre-extraction tea treatmentWater insolubleNanoparticle

The present invention relates to a pearl milk tea beverage and a production method thereof, in particular relates to a functional factor containing pearl milk tea beverage and a production method thereof. The pearl milk tea beverage is composed of coagulated beads and milk tea. The coagulated beads are prepared by using zein to contain fat-soluble functional factors and are prepared by the following steps: anionic polysaccharide aqueous solution is used to stabilize zein loaded nanoparticles, which enables water-insoluble fat-soluble functional factors to be uniformly suspended in the aqueous phase. A crosslinking agent is used to enable anionic polysaccharide to form the coagulated beads, then the coagulated beads are poured into the milk tea to form the functional factor containing pearl milk tea beverage. The fat-soluble functional factors can follow the milk tea to enter into human body to improve human body functions. Besides, tea polyphenols in milk tea and fat-soluble functional factors can also generate synergistic reactions to remove human body free radicals and improve human health.

Owner:SHENYANG NORMAL UNIV

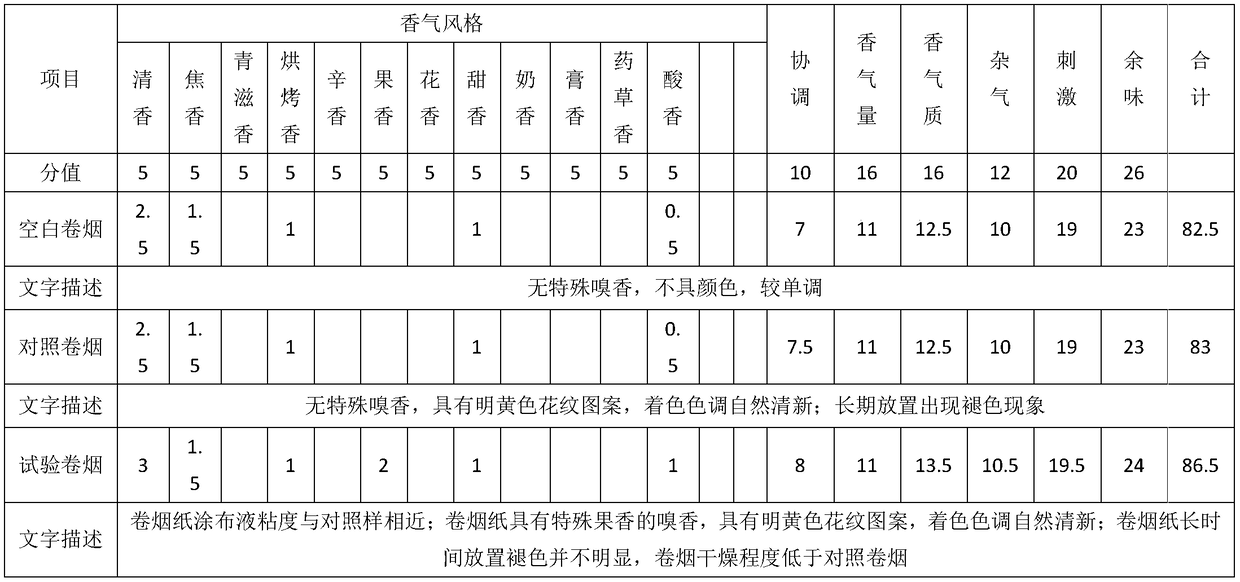

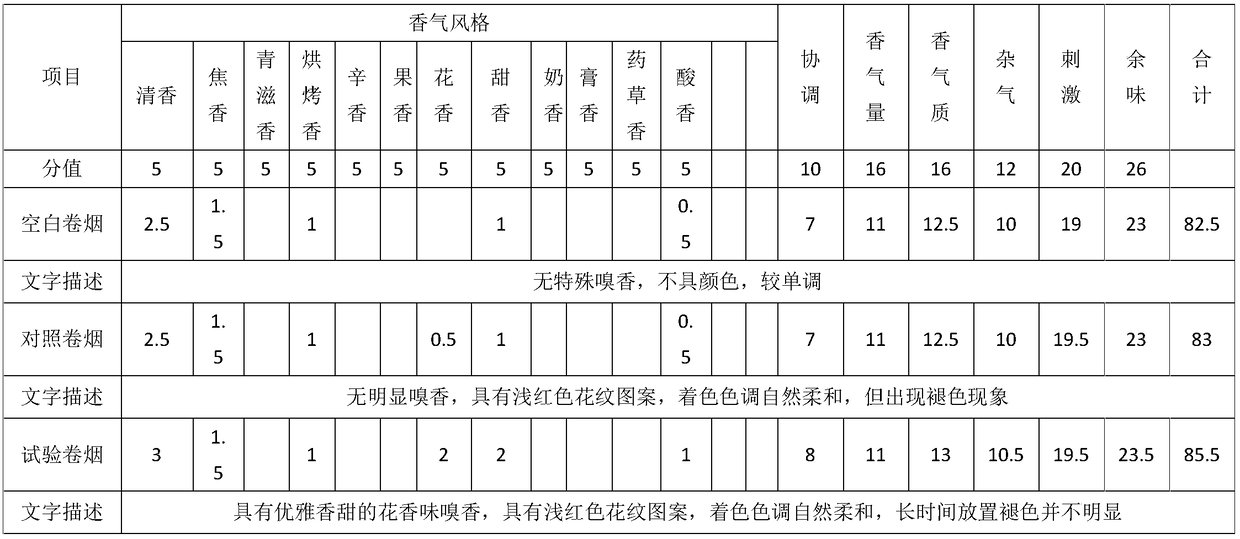

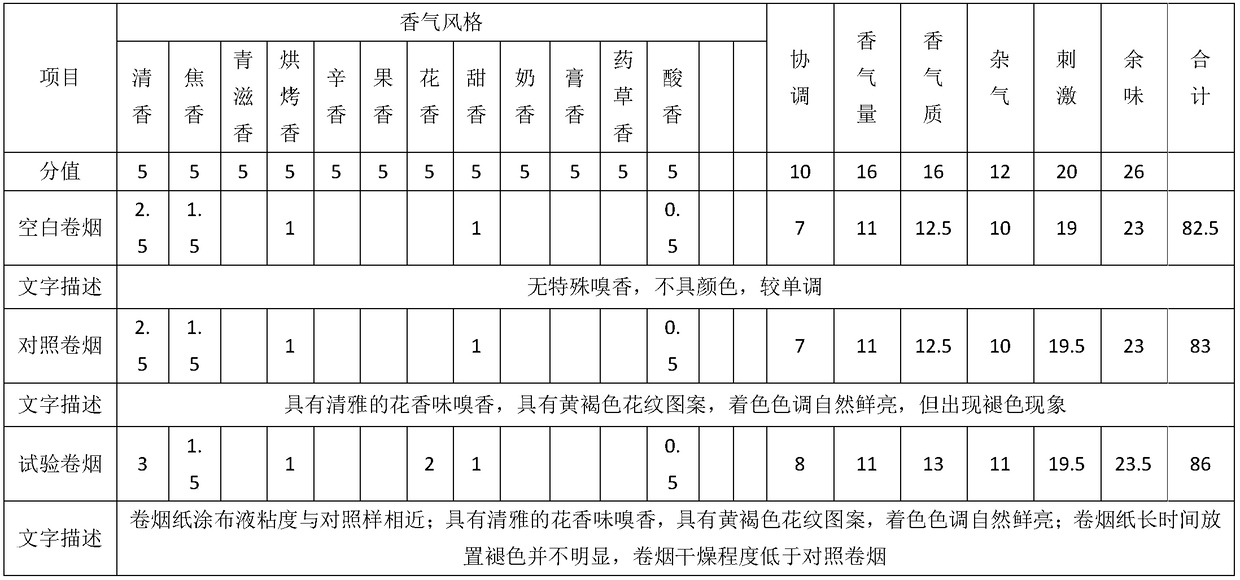

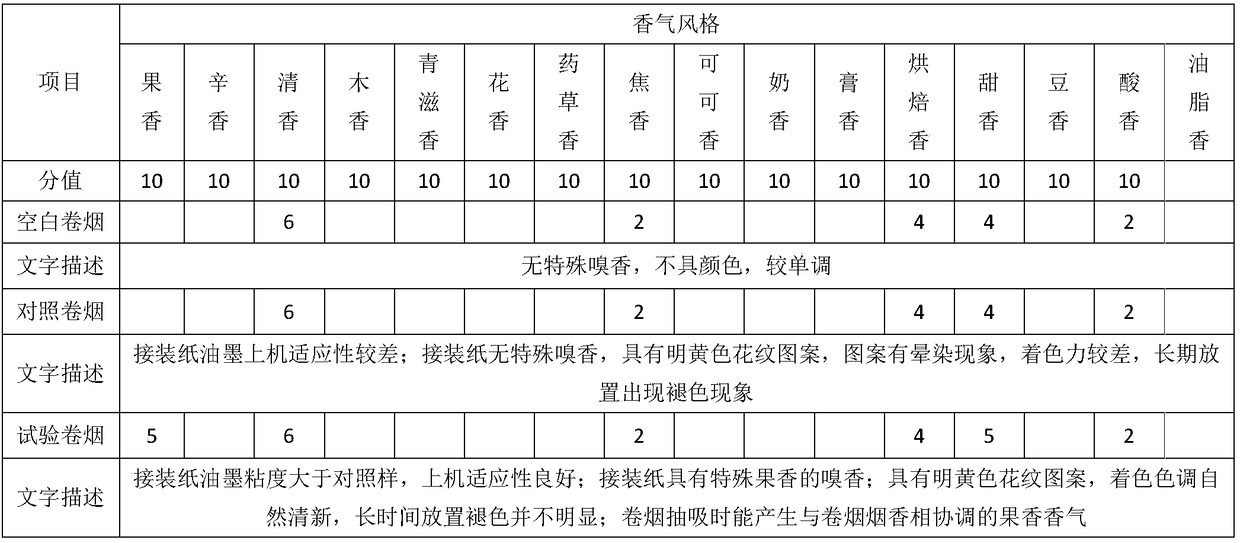

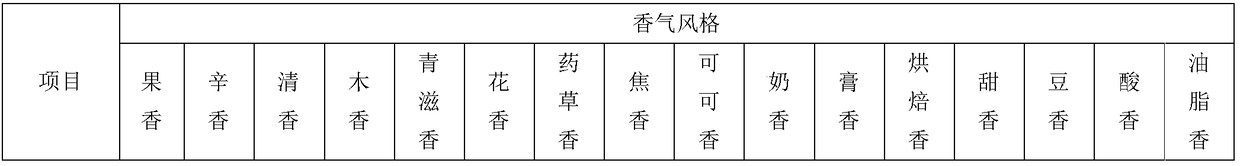

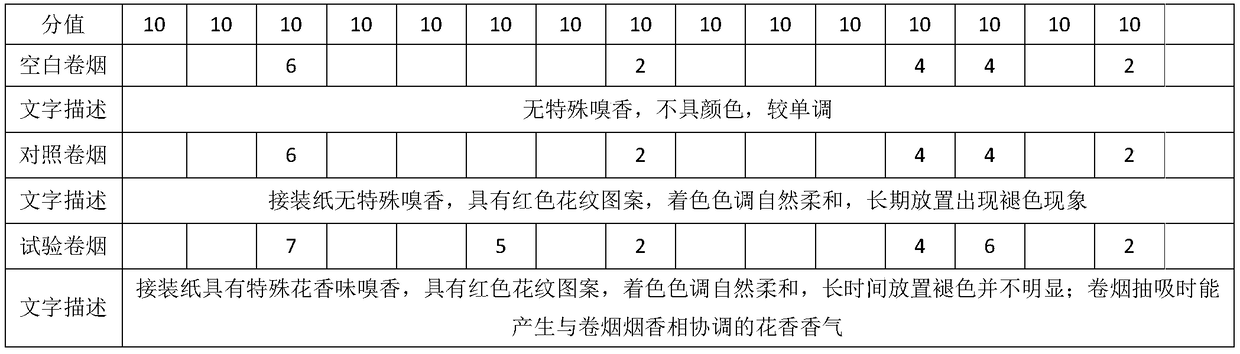

Colored cigarette paper coating solution with specific fragrance and application thereof

ActiveCN108797214APreserve the coloring functionAdjust colors flexiblySurface covering paperNon-fibrous pulp additionSocial benefitsEconomic benefits

The invention discloses a colored cigarette paper coating solution with specific fragrance and application thereof. The colored cigarette paper coating solution is prepared through the following steps: taking plants containing natural pigment as raw materials, and fermenting plant powder or pulp by sequentially using an aspergillus oryzae YNCA 9804 strain and a bacillus subtilis Van3 strain, thusforming an aroma component; carrying out solvent extraction and concentration purification; mixing the aroma component with coating solutions such as fungal polysaccharide, thus preparing a finished product. According to the colored cigarette paper coating solution disclosed by the invention, the characteristic of pleasant fragrance of the colored cigarette paper coating solution is given while acoloring function of the natural pigment is reserved; pigment powder with the fragrance obtained through treatment is independently compounded, mutually compounded or compounded with other natural pigment for use, so that the color of the colored cigarette paper coating solution can be flexibly regulated; synthetic pigment is replaced, dual sense experience on vision and olfaction can be obtainedby a cigarette product while the safety is improved, diversified color developing and fragrance increment of a tobacco paper base can be realized, and good social benefit and economic benefit are obtained.

Owner:CHINA TOBACCO YUNNAN IND

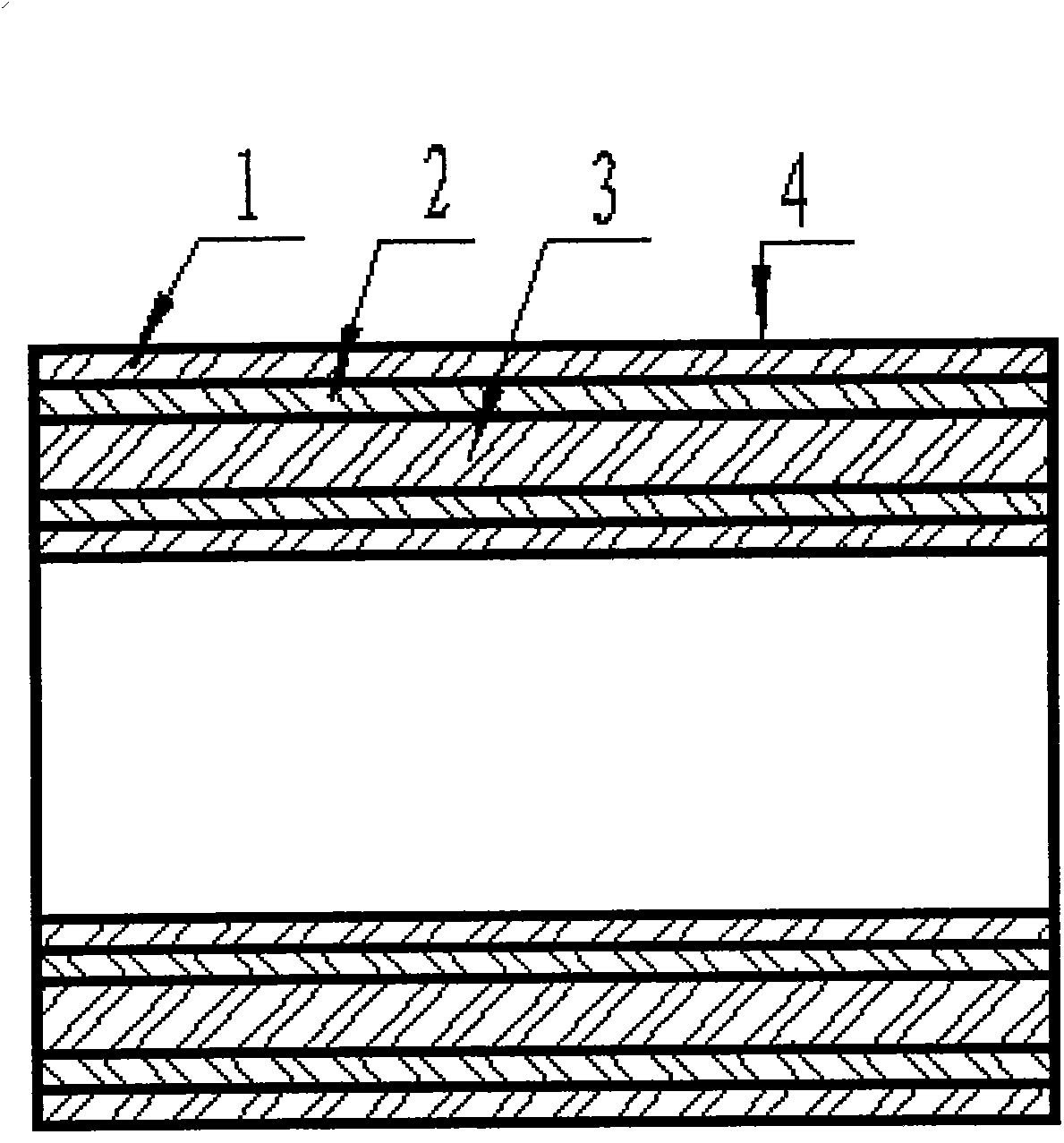

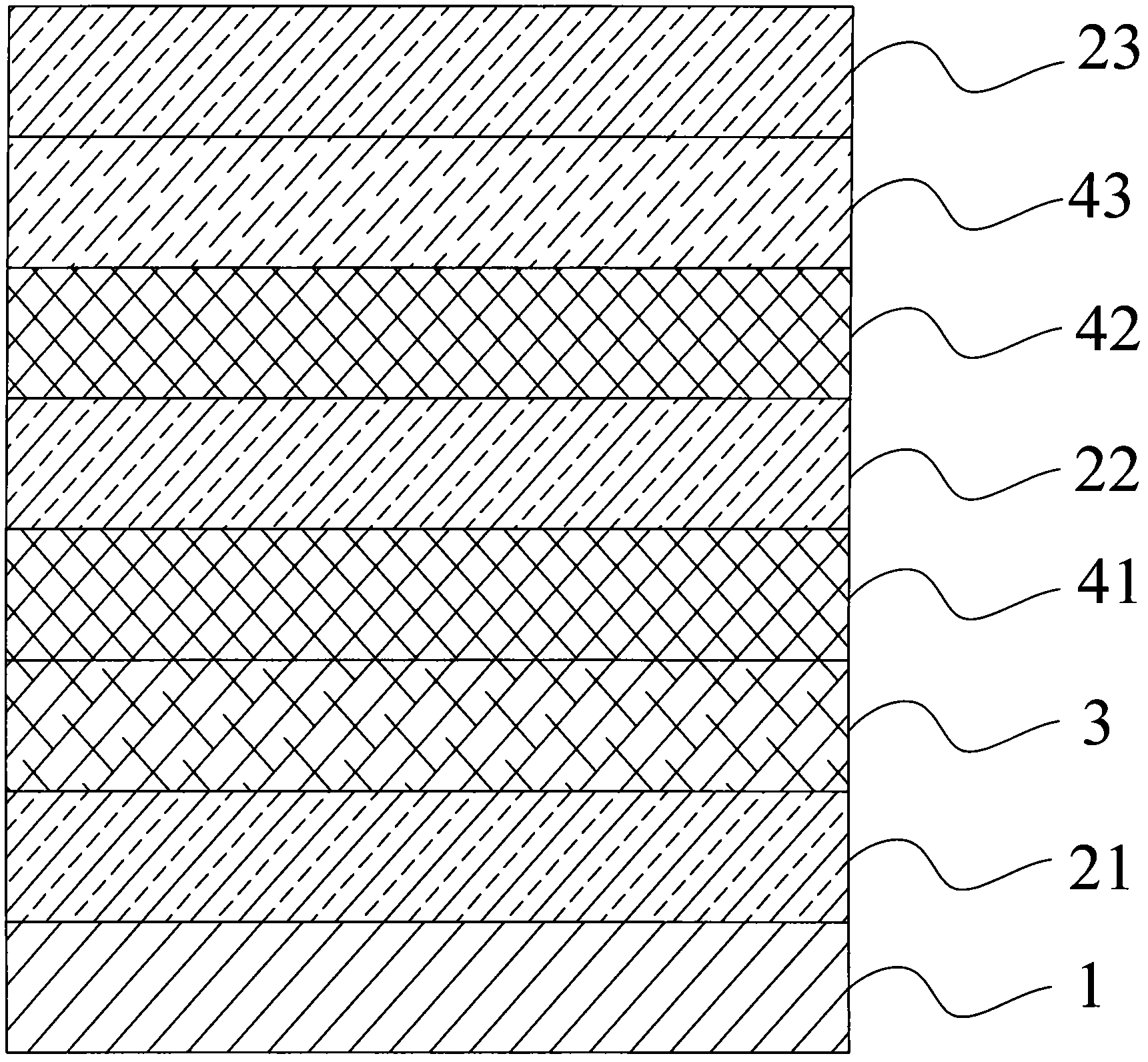

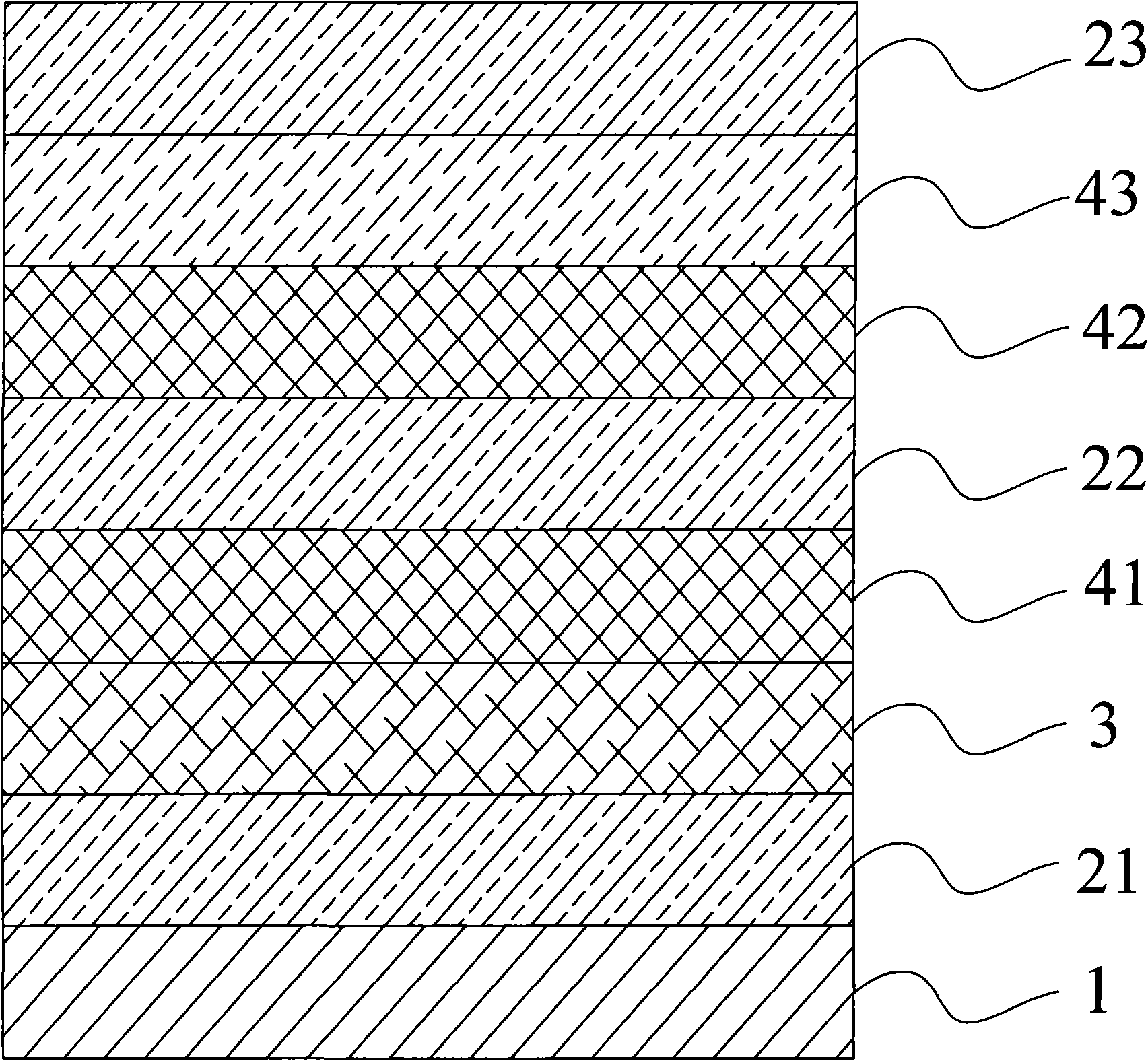

Low-emissivity coated glass

The invention discloses low-emissivity coated glass, sequentially comprising glass, a first dielectric layer, a silver layer, a first shielding layer, a second dielectric layer, a second shielding layer, a third shielding layer and a third dielectric layer from inside to outside. In the invention, since three medium layers are adopted, the protection on the silver layer is enhanced, and the transmittance, the reflectivity and the colour of the low-emissivity coated glass can be effectively regulated by regulating the thicknesses of the three medium layers so as to widen the colour range of a product and beautify the product. The three shielding layers are adopted, wherein a dielectric layer is sandwiched between the first shielding layer and the second shielding layer, therefore, the inoxidizability of the silver layer in the low-emissivity coated glass is effectively improved; Meanwhile, the transmittance and the reflectivity can be regulated by regulating the thicknesses of the three dielectric layers, so that the film system can be used for producing multiple colours of sunshading low-emissivity glass with the radiation rate of 0.05-0.15 and the transmittance of 10-60%.

Owner:HUANGHUA RONGDA GLASS

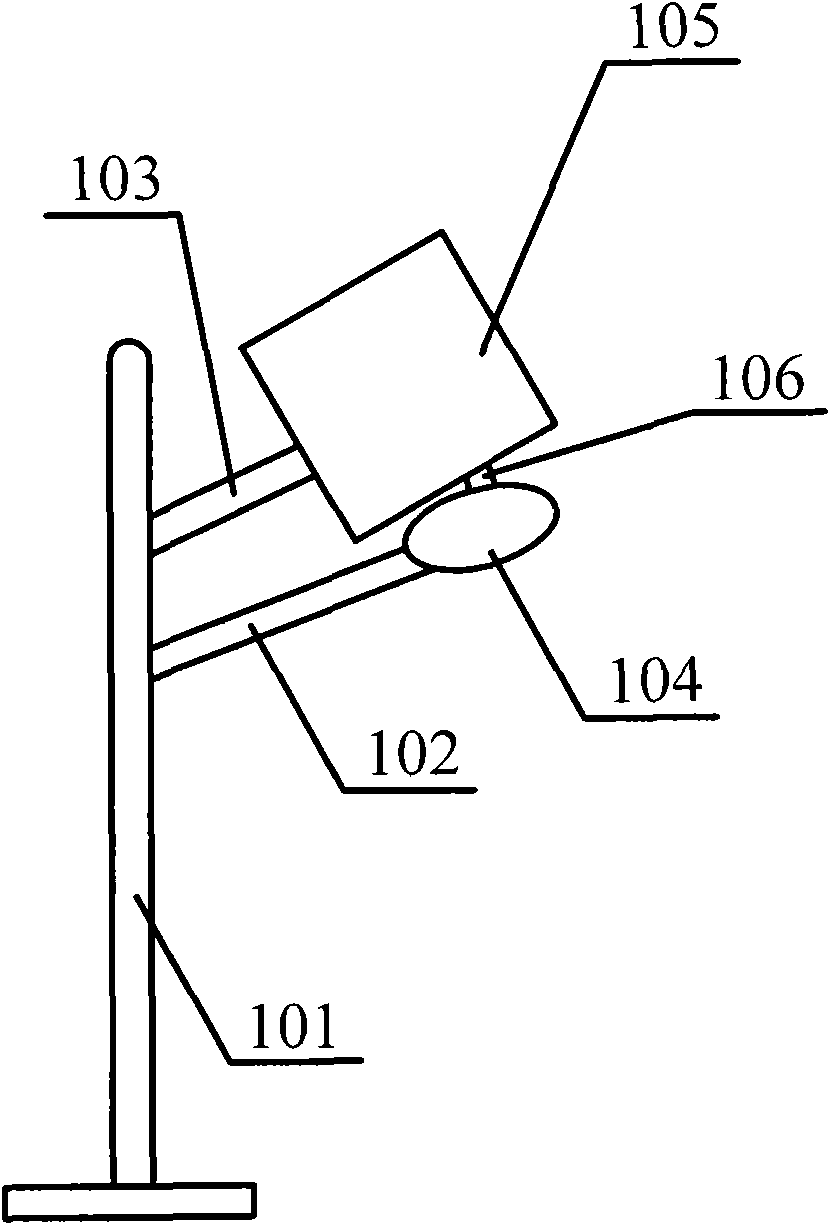

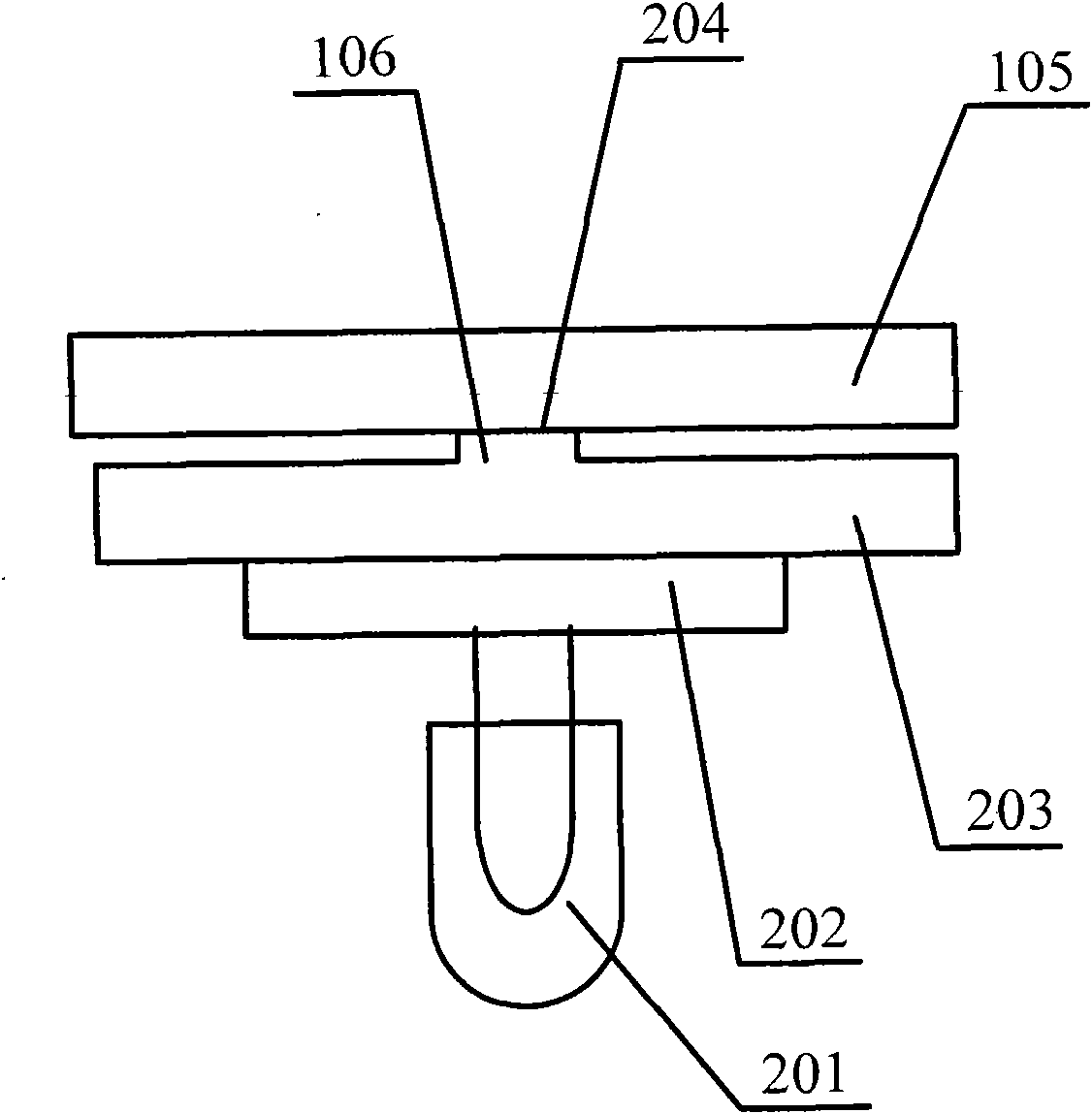

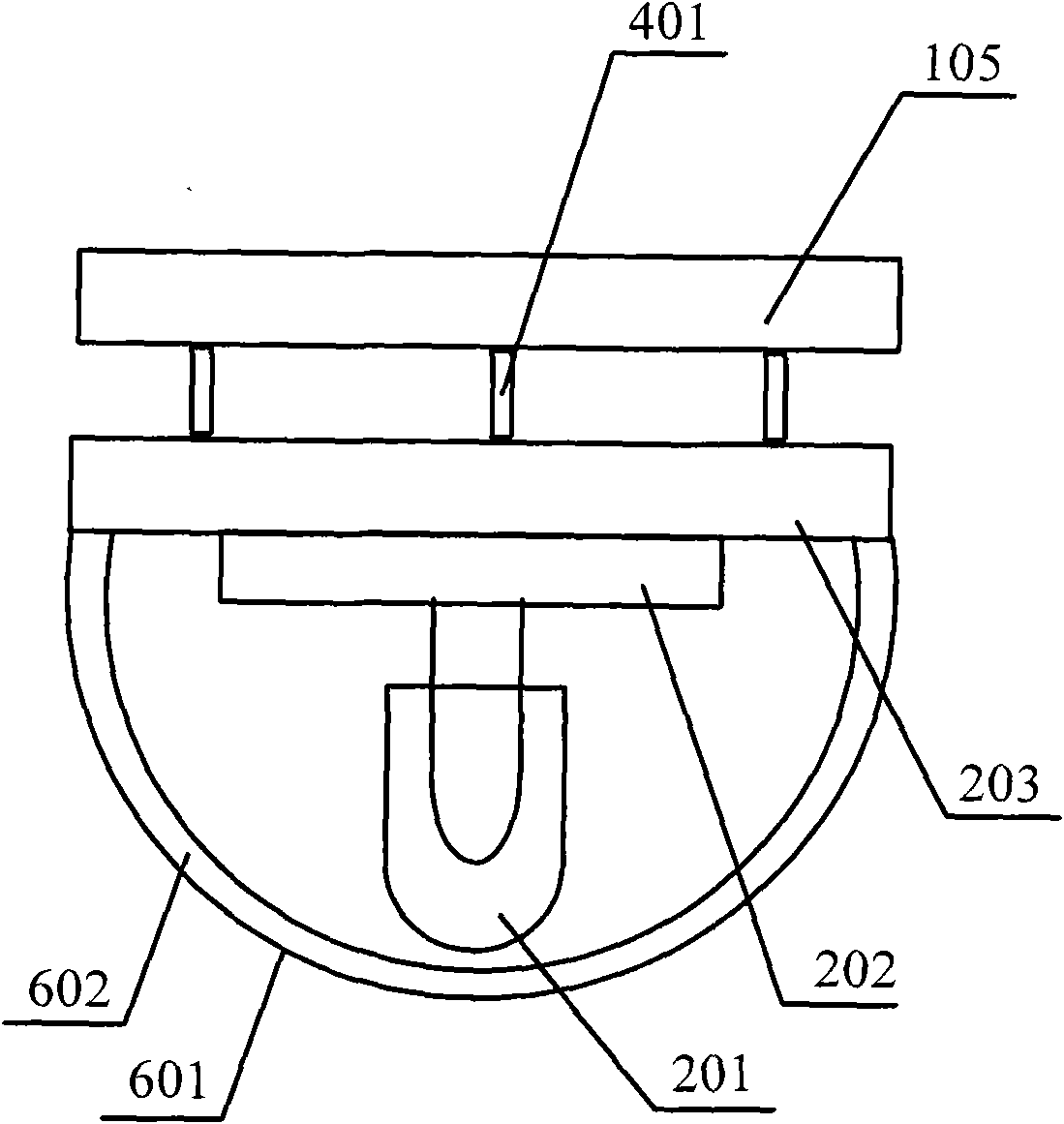

LED solar street lamp

InactiveCN101625099AAdjust colorBrightness adjustableBatteries circuit arrangementsPoint-like light sourceElectricityEngineering

The invention discloses a solar LED street lamp which comprises a lamp post, a lamp body fixed on the lamp post, a solar device, a control device, and at least one overheating protection switch, wherein the solar device comprises a solar panel, an accumulator and an electric control switch; the solar panel is provided with at least one fixing device; the lamp body comprises at least one group of LEDs (light emitting diodes) and control modules of the LEDs; the lamp body is arranged right below the solar panel and is fixedly connected with the solar panel through the fixing device; after passing through the electric control switch and the control modules sequentially, the accumulator is electrically connected with all groups of LEDs for providing voltage so as to drive all groups of LEDs. The solar LED street lamp has the advantages of simple structure, and firmer installation of the solar device and the lamp body.

Owner:SHENZHEN HUAHAI CHENGXIN ELECTRONICS DISPLAY TECH

Crab shell powder chemical treatment method, enhanced polylactic acid 3D printing material and preparation method thereof

InactiveCN110698571AEfficient recyclingIncrease added valueAdditive manufacturing apparatusChemical treatmentWaste treatment

The invention belongs to the fields of solid waste treatment and fused deposition modeling 3D printing technologies and particularly relates to a crab shell powder chemical treatment method. Accordingto the method, surfaces of crab shells are cleaned, the crab shells are smashed to obtain brown crab shell powder, the crab shell powder is soaked in a container containing a dilute acid solution, the solution is filtered, washed and dried to obtain orange crab shell powder, multiple steps can be sequentially performed subsequently to obtain light-red crab shell powder, light-yellow crab shell powder and milk-white crab shell powder respectively, and the chemically treated crab shell powder is mixed with polylactic acid, a flexibilizer and a lubricant for 3D printing. Through the method, waste crab shells are chemically treated, then a polylactic acid 3D printing material is prepared, the preparation process is simple, added value of crabs is increased, environmental pollution is relieved, and the prepared polylactic acid 3D printing material not only has good mechanical properties and printing properties but also is environment-friendly and unique in color.

Owner:SOUTH CHINA AGRI UNIV

Method for inhibiting side reaction of tetrahydrofuran in polymerizing process

The invention relates to a method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process. According to the method, in the process of preparing a polymer by using terephthalic acid and 1,4-butanediol as main raw materials, ester, titanium-silicon-cobalt composite catalyst dispersant and pH regulator are generated by adding the terephthalic acid and dihydric alcohol in the esterifying stage, the molar ratio of the terephthalic acid to the 1,4-butanediol is controlled to be 1:(1.05-1.10) to inhibit the side reaction of tetrahydrofuran, so that the content of tetrahydrofuranin the polymer is less than or equal to 10wt%; the dispersing medium in the titanium-silicon-cobalt composite catalyst dispersant is 1,4-butanediol, and the titanium-silicon-cobalt composite catalystis prepared by combining a titanium-silicon composite catalyst and a cobalt catalyst, and the titanium-silicon composite catalyst is prepared from a silicon catalyst-supported titanium catalyst. According to the method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process, the final product has concentrated molecular weight distribution, few byproduct and high quality, andhas a great application prospect.

Owner:DONGHUA UNIV

Preparing method of aluminum alloy surface colorful ceramic film

The invention particularly relates to a method for preparing an aluminum alloy surface colorful ceramic film through a micro-arc oxidation method, and belongs to the technical field of surface treatment. The method comprises the steps that firstly, dirt removing and oil removing treatment is carried out on the surface of an aluminum alloy base body, cleaning is thorough, and drying is carried out; secondly, an electrolyte containing NaH2PO4, NaF, NH4F, Na2B4O7 and a coloring agent is prepared; and thirdly, the aluminum alloy base body in the first step serves as an anode, the electrolyte prepared in the second step serves as the electrolyte, a corresponding cathode is arranged, the micro-arc oxidation reaction is conducted under the voltage of 125-155 V, and when it is monitored that the current is smaller than 0.5 A, the reaction is over, and the aluminum alloy surface colorful ceramic film is obtained. The method is simple in technology, the later paint spraying treatment technology is omitted, efficiency is high, and cost is low.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

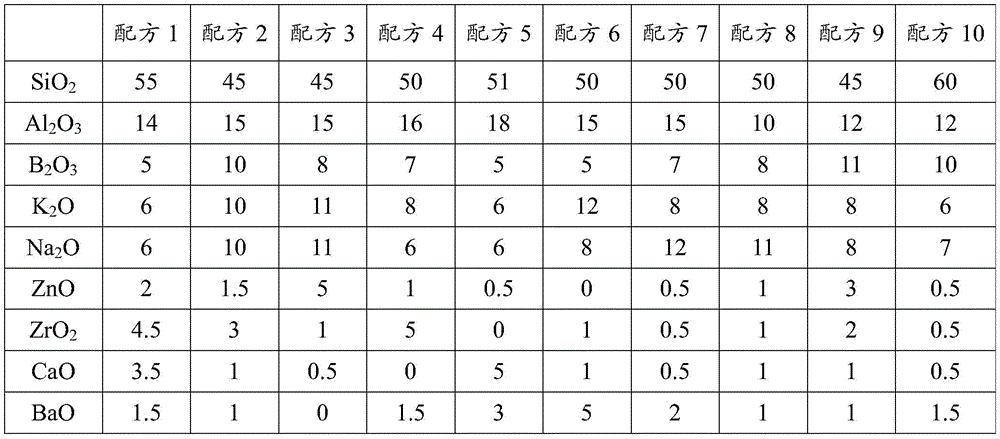

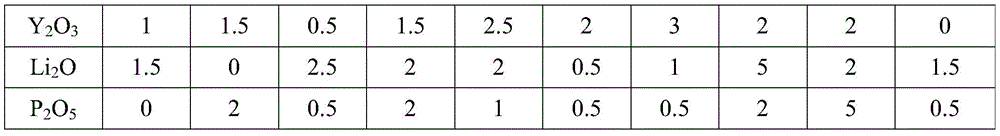

Baked porcelain powder for zirconium-oxide all-ceramic crown and preparing method thereof

InactiveCN105686955AEvenly dispersedStrong Color AccuracyImpression capsDentistry preparationsBiocompatibility TestingAll ceramic

The invention discloses baked porcelain powder for a zirconium-oxide all-ceramic crown. The baked porcelain powder comprises bonding porcelain powder, body porcelain powder and glaze porcelain powder. The bonding porcelain powder comprises, by weight, 90%-99.5% of basis bonding porcelain powder, 0.1%-5% of nanometer second phase A and 0.1%-5% of pigment A; the body porcelain powder comprises, by weight, 90%-99.5% of basis body porcelain powder, 0.1%-5% of nanometer second phase B and 0.1%-5% of pigment B. When the baked porcelain powder is sintered on the zirconium-oxide all-ceramic crown, an obtained ceramic substrate-baked porcelain compound is even in baked-porcelain-powder dispersion; after a ceramic substrate is sintered to porcelain, binding force between the porcelain and the ceramic substrate is high, the biocompatibility between the porcelain and the ceramic substrate is excellent, and wear resistance and corrosion resistance are good; meanwhile, in appearance, the baked porcelain powder has the advantages of being high in color accuracy, even in coloring, natural and lifelike in color and the like. Meanwhile, the invention further discloses a preparing method of the baked porcelain powder for the zirconium-oxide all-ceramic crown.

Owner:CHAOZHOU THREE CIRCLE GRP

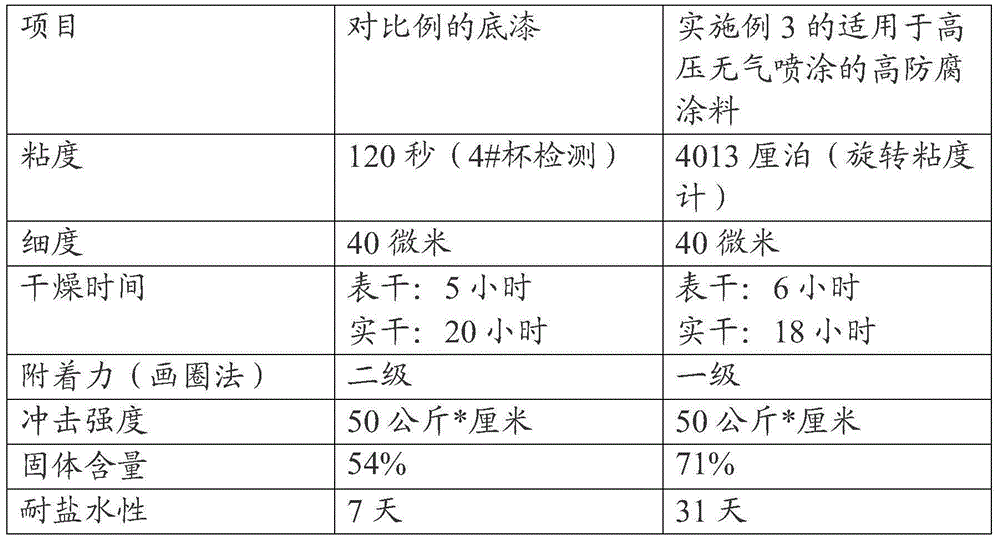

High anti-corrosion coating suitable for high-pressure airless spraying

InactiveCN104449202AImprove thixotropyHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyHigh pressure

The invention discloses a high anti-corrosion coating suitable for high-pressure airless spraying. The coating comprises a component A and a component B in the weight ratio of 5: 1, and the component A comprises the following components in parts by weight: 18-22 parts of first epoxy resin, 18-24 parts of second epoxy resin, 10-15 parts of magnet powder, 2-10 parts of iron oxide red, 0.2-0.5 part of polyvinyl butyral resin, 0.1-0.2 part of a dispersant, 0.5-0.7 part of modified bentonite, 0.2-0.4 part of nano-silicon dioxide, 0.2-0.3 part of an assistant and 12-15 parts of a diluent; and the component B comprises the following components in parts by weight: 56-62 parts of a first amine curing agent, 12-18 parts of a second amine curing agent and 20-30 parts of ethanol. The high anti-corrosion coating suitable for high-pressure airless spraying adopts two different types of epoxy resin and curing agents to form a film by crosslinking and curing. The film-forming mechanism is that active H<+> is contained in the amine curing agents and can react with epoxy groups in epoxy resin at normal temperature and form a reticular structure by crosslinking; and the reticular structure is dense and hard, good in anti-corrosion performance, strong in adhesion and outstanding in chemical resistance.

Owner:湖南中汉高分子材料科技有限公司

Solid cleaning adhesive and preparation method thereof

ActiveCN102533171BImprove sticky effectImprove reliabilityEster polymer adhesivesHydrocarbon polymer adhesivesAdhesiveMicroparticle

Owner:CHANGZHOU INST OF CHEM

Aromatic color ink and application thereof to tipping paper

ActiveCN108727897APreserve the coloring functionAdjust colors flexiblyInksSocial benefitsEconomic benefits

The invention discloses aromatic color ink and application thereof to tipping paper. The plants containing natural pigments are used as raw materials; aspergillus oryzae YNCA 9804 strains and bacillussubtilis Van3 stains are sequentially used for fermenting plant powder or slurry; aroma forming ingredients are formed; then, through solvent extraction and concentration refining, the aroma formingingredients are mixed with ink ingredients such as fungal polysaccharides to obtain a product. The coloring function of the natural pigments is maintained; meanwhile, the pleasant aroma features are given to the ink. The aromatic color pigment powder obtained through treatment is singly or mutually compounded or is compounded with other natural pigments to be used; the color of the ink of the tipping paper can be flexibly regulated. The aromatic color ink is used for replacing synthetic pigment; the safety is improved; meanwhile, the cigarette products have the duplex sensing experience of visual effects and smell feelings; the diversified color showing and aroma enhancement of tobacco paper bases can be realized; good social benefits and economic benefits are realized.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com