Functional factor containing pearl milk tea beverage and production method thereof

A technology of functional factors and production methods, which is applied in the field of pearl milk tea beverage and its production, can solve the problems of seldom considering nutrition, increasing serum total fat and low-density cholesterol levels, and not improving health, so as to prolong the residence time and enhance anti-oxidation effect, effect of increasing appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

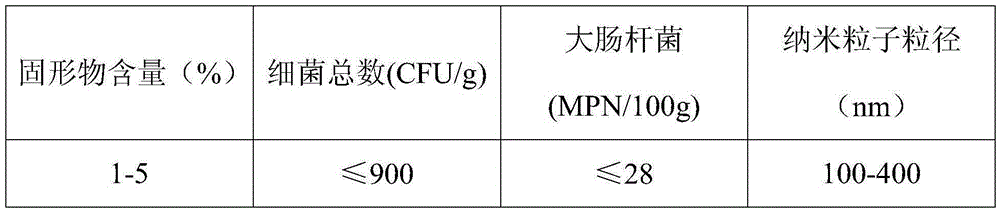

Image

Examples

Embodiment 1

[0031] 1) Dissolving zein and fat-soluble functional factors in a binary solution of ethanol-water with a mass concentration of 65% according to a mass ratio of 3:1, and stirring evenly;

[0032] 2) After adding sodium alginate aqueous solution to the solution prepared in step 1), the mixed solution is subjected to high-speed shear mixing or stirring mixing, and the amount of sodium alginate aqueous solution added is 0.3 times the amount of zein;

[0033] 3) Place the solution prepared in step 2) in a negative pressure evaporator to remove ethanol by evaporating under reduced pressure at a temperature of 10-40° C. to obtain a zein nanoparticle suspension loaded with fat-soluble functional factors stabilized by polysaccharides ;

[0034] 4) Disperse the zein nanoparticle suspension loaded with fat-soluble functional factors prepared in step 3) into a corresponding amount of CaCl through a distributor. 2 Cross-linking is carried out in the solution to obtain polysaccharide bead...

Embodiment 2

[0036] 1) Dissolving zein and fat-soluble functional factors in a binary solution with a mass concentration of 80% ethanol-water according to a mass ratio of 12:1, and stirring evenly;

[0037] 2) After adding sodium alginate aqueous solution to the solution prepared in step 1), high-speed shear mixing or stirring mixing is performed on the mixed solution, and the amount of sodium alginate aqueous solution added is 1.2 times the amount of zein;

[0038] 3) Place the solution prepared in step 2) in a negative pressure evaporator to remove ethanol by evaporating under reduced pressure at a temperature of 10-40° C. to obtain a zein nanoparticle suspension loaded with fat-soluble functional factors stabilized by polysaccharides ;

[0039] 4) Disperse the zein nanoparticle suspension loaded with fat-soluble functional factors prepared in step 3) to a concentration containing a corresponding amount of CaCl through a distributor. 2 Cross-linking is carried out in the solution to obt...

Embodiment 3

[0041] 1) Dissolving zein and fat-soluble functional factors in a binary solution with a mass concentration of 90% ethanol-water according to a mass ratio of 20:1, and stirring evenly;

[0042] 2) After adding sodium alginate aqueous solution to the solution prepared in step 1), the mixed solution is subjected to high-speed shear mixing or stirring mixing, and the amount of sodium alginate aqueous solution added is 2.0 times the amount of zein;

[0043] 3) Place the solution prepared in step 2) in a negative pressure evaporator to remove ethanol by evaporating under reduced pressure at a temperature of 10-40° C. to obtain a zein nanoparticle suspension loaded with fat-soluble functional factors stabilized by polysaccharides ;

[0044] 4) Disperse the zein nanoparticle suspension loaded with fat-soluble functional factors prepared in step 3) to a concentration containing a corresponding amount of CaCl through a distributor. 2 Cross-linking is carried out in the solution to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com