Patents

Literature

122 results about "Total fat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Your daily intake of total fat should equal 25 to 35 percent of your total daily calories. If you aim for the average, or 30 percent of daily calories from fat, then a 1,500-calorie-a-day diet would include 50 grams of total fat.

Infant formulas for early brain development

Disclosed are infant formulas comprising fat, protein, carbohydrate, vitamins, and minerals, including on an as-fed basis, at least about 5 mg / L of gangliosides, at least about 150 mg / L of phospholipids, at least about 70 mg / L of total sialic acid with at least about 2.5% as lipid-bound sialic acid, at least about 0.13% docosahexaenoic acid by weight of total fatty acids, and at least about 0.25% arachidonic acid by weight of total fatty acids. Also disclosed are methods of accelerating brain development, neural migration, and cognitive development in an infant by administering the infant formulas during the first 2-4 months of life, preferably as a sole source of nutrition.

Owner:ABBOTT LAB INC

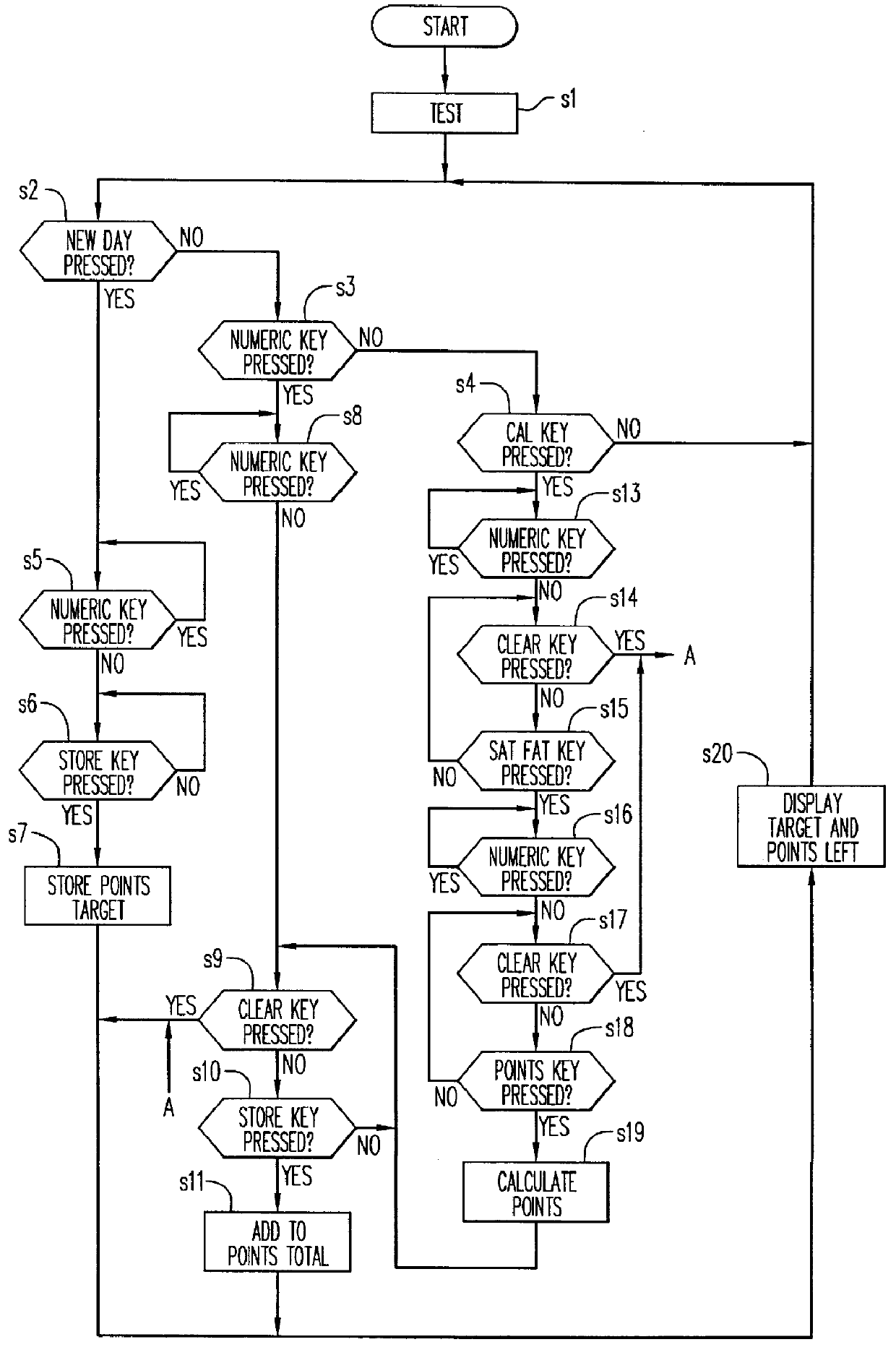

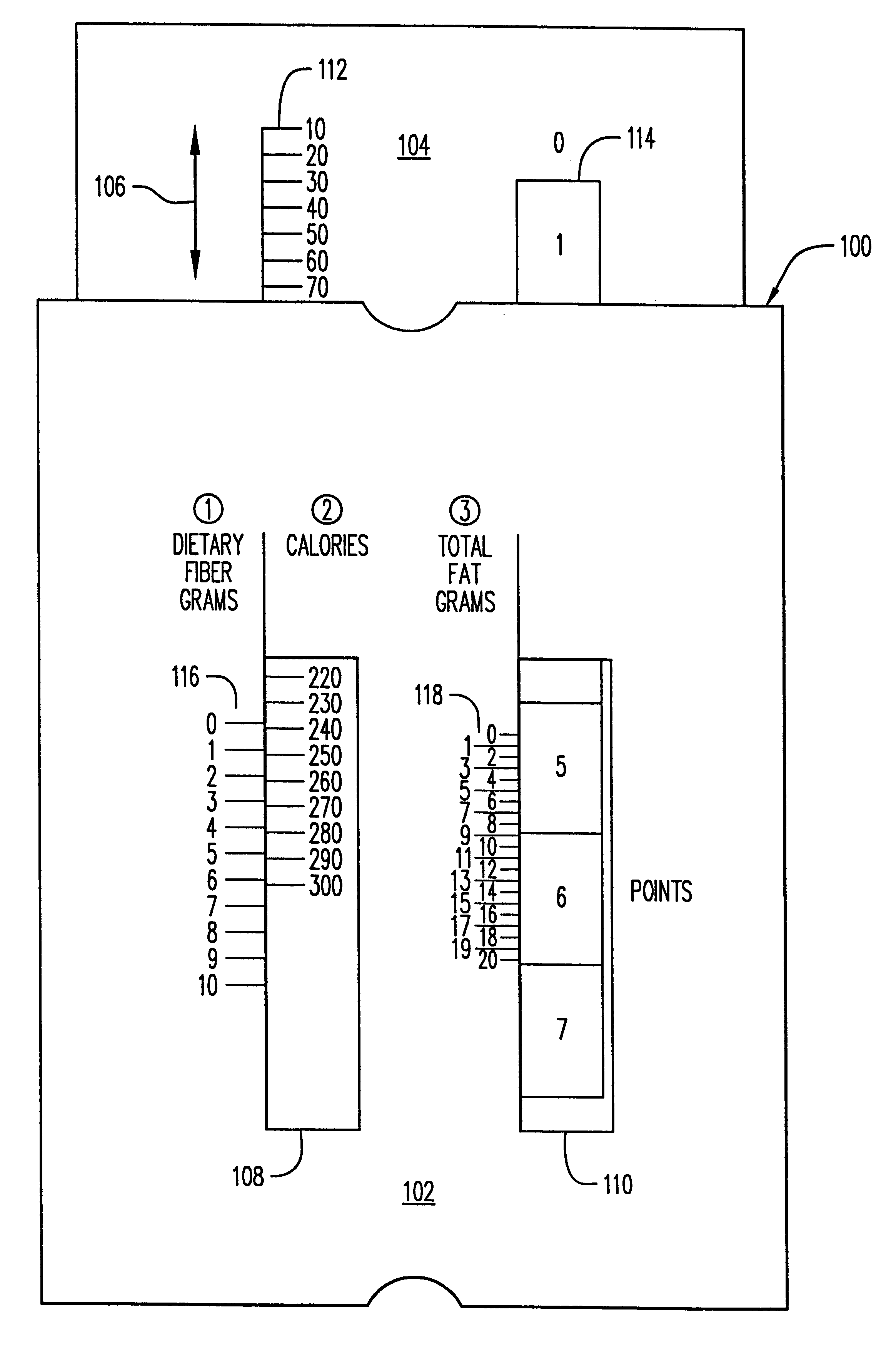

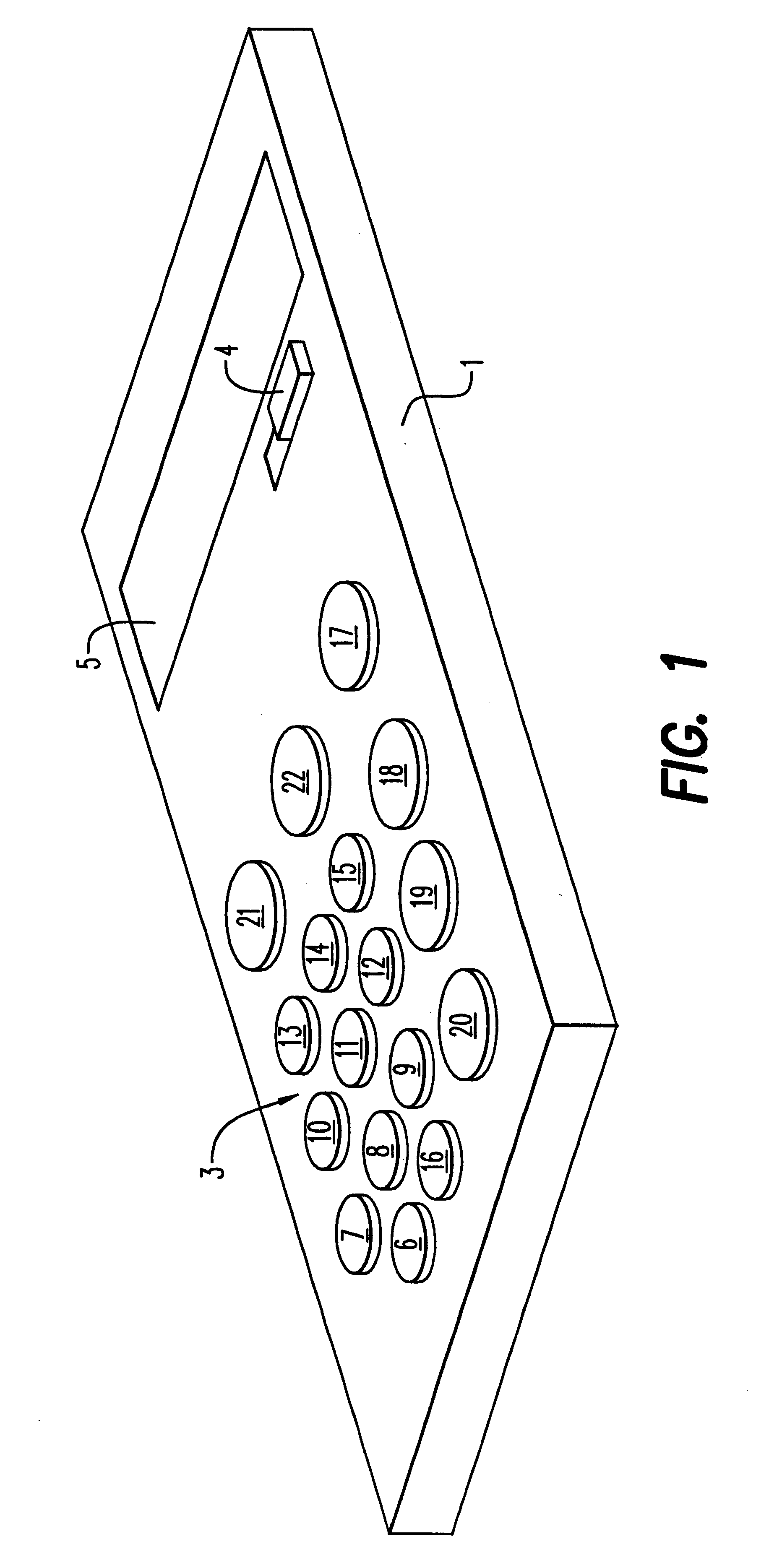

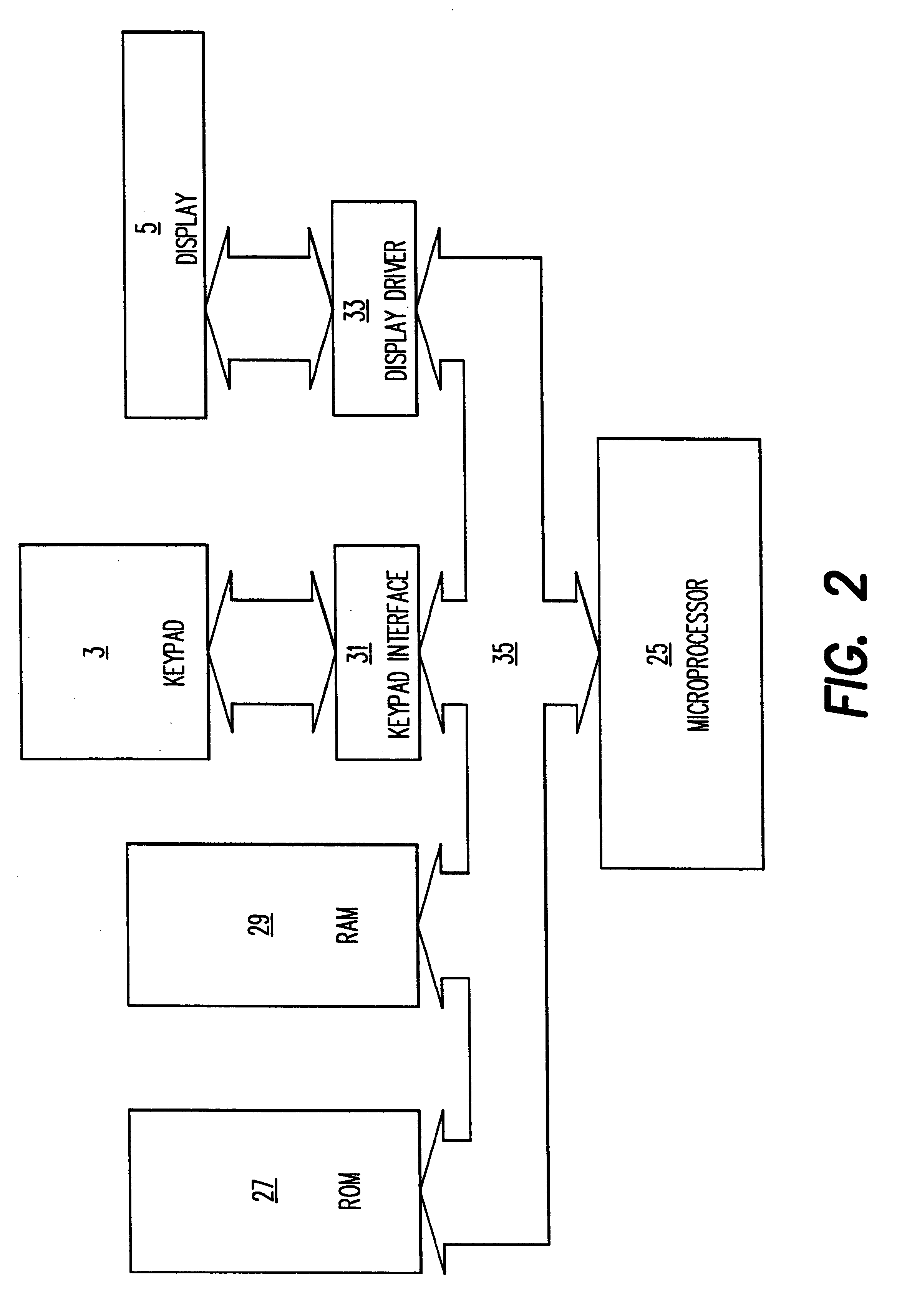

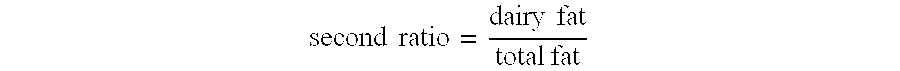

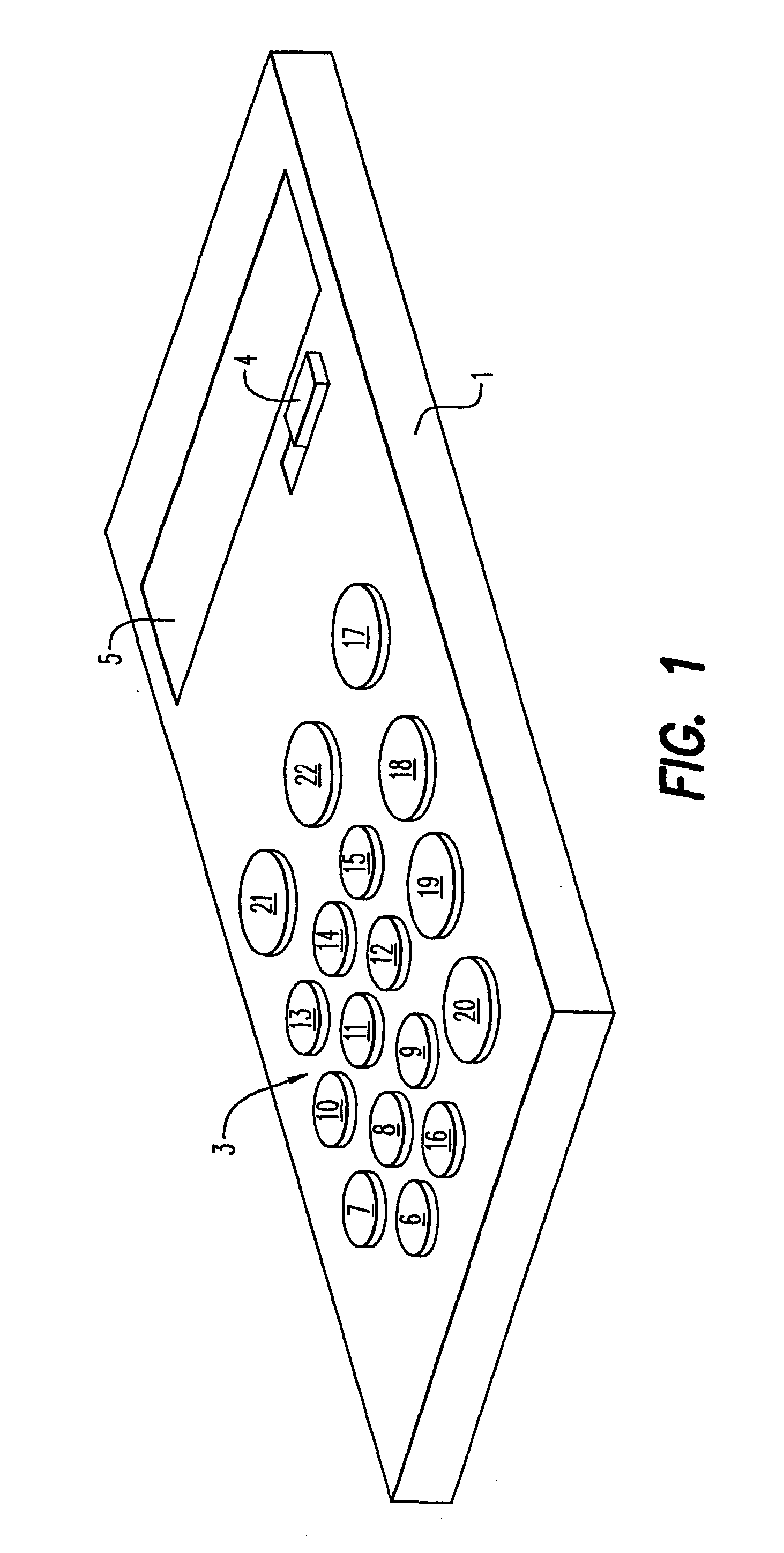

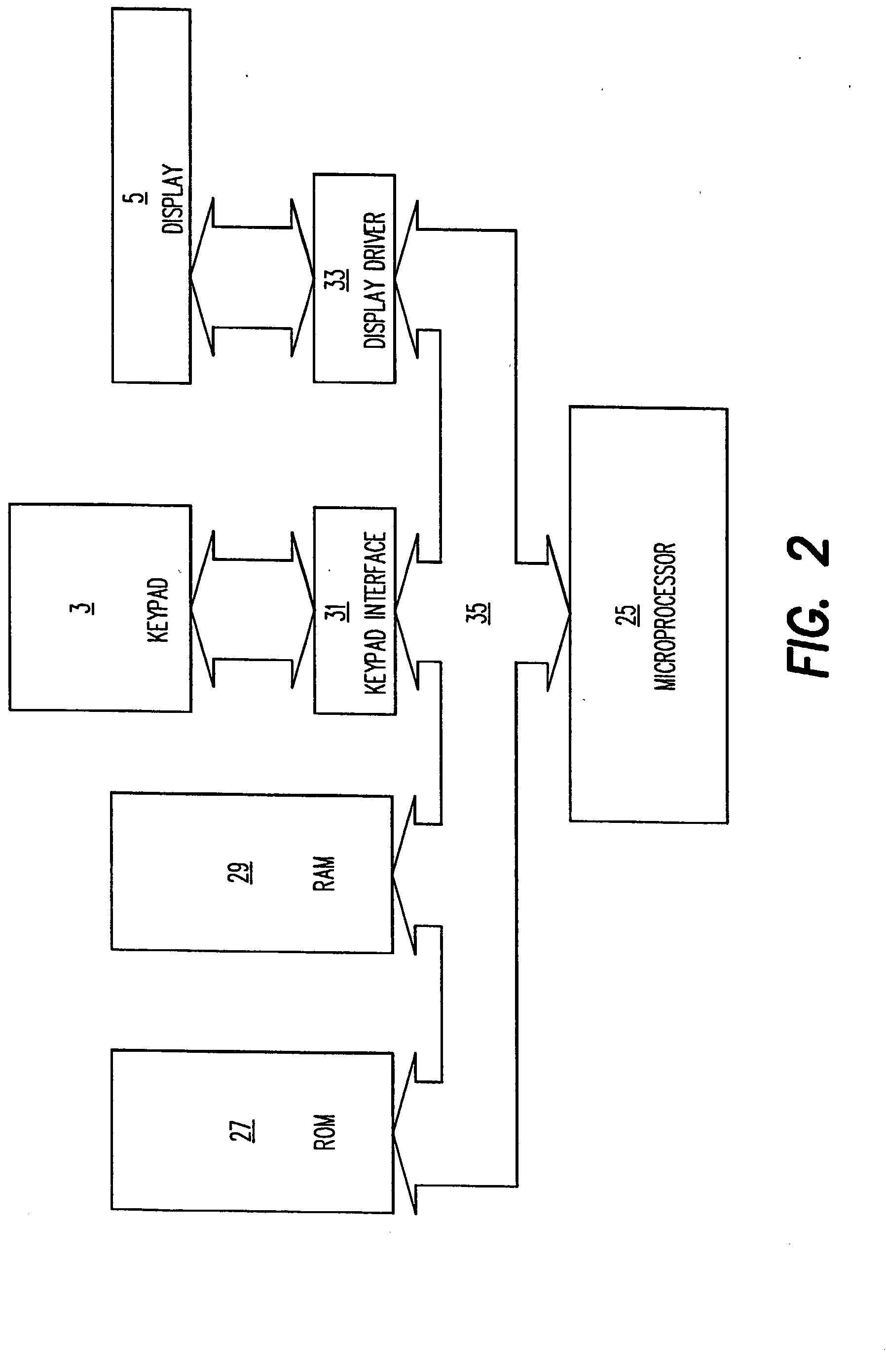

Process for controlling body weight

InactiveUS6436036B1Easy to masterMinimal computationPhysical therapies and activitiesLocal control/monitoringBody part weightWeight change

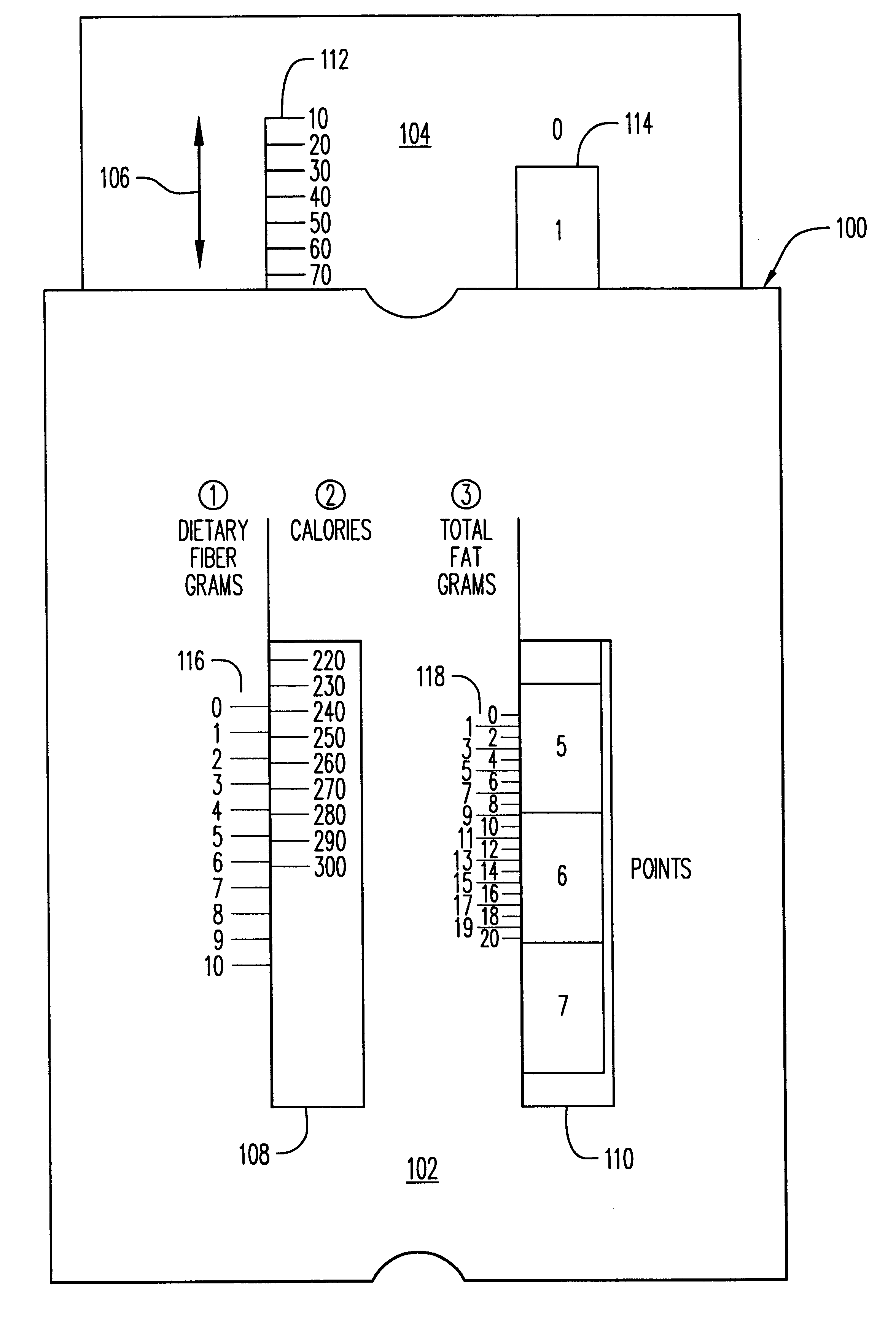

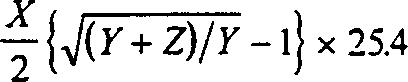

The disclosure relates to a process for controlling body weight in which selection of food servings is based on a calculated point value and a range of allotted daily points which is adjusted for weight change. The calculated point value is a function of measured calories, total fat and dietary fiber for serving sizes specified in readily estimatable units. A range or maximum number of points allotted per day may be calculated based on current body weight, caloric reduction to be achieved, physical activity level, and physical activity duration.

Owner:WEIGHT WATCHERS INT

Process for controlling body weight

InactiveUS6040531AEasy to masterMinimal computationLocal control/monitoringSurgeryBody part weightDietary fiber

The disclosure relates to a process for controlling body weight in which selection of food servings is based on a calculated point value and a range of allotted daily POINTS which is adjusted for weight change. The calculated POINT value is a function of measured calories, total fat and dietary fiber for serving sizes specified in readily estimatable units.

Owner:WEIGHT WATCHERS INT

Process for controlling body weight

InactiveUS6663564B2Easy to implementEasy to masterPhysical therapies and activitiesSurgeryBody part weightWeight change

The disclosure relates to a process for controlling body weight in which selection of food servings is based on a calculated point value and a range of allotted daily points which is adjusted for weight change. The calculated point value is a function of measured calories, total fat and dietary fiber for serving sizes specified in readily estimatable units. A range or maximum number of points allotted per day may be calculated based on current body weight, caloric reduction to be achieved, physical activity level, and physical activity duration.

Owner:WEIGHT WATCHERS INT

Fat compositions for infant formula and methods therefor

InactiveUS20040013787A1Improve the level ofLower levelVitamin food ingredientsFood preparationPhysiologyLinoleic acid

Fat compositions and infant formulas containing oleic acid in an amount of at least about 50% by weight of total fatty acids, lauric acid in an amount of at least about 10% by weight, palmitic acid in an amount of not more than about 10% by weight and, in certain embodiments, linoleic acid in an amount of not more than about 16% by weight. The fat compositions can be prepared to contain one or more oleic acid oils in a total amount of at least about 50% by weight, one or more linoleic acid oils in a total amount of not more than about 18% by weight and, in certain embodiments, one or more lauric acid oils in an amount of at least about 20% by weight. Also disclosed are methods of making the fat compositions and infant formulas and methods for providing a fat component to infant diets.

Owner:THEUER RICHARD C

Low Fiber Yellow Canola Seeds Comprising High Oleic, Low Linolenic Oil

The subject invention provides low fiber, yellow-seeded canola, and related canola meal and animal feed. Oil produced from this seed has at least 68% oleic acid and no more than 3% linolenic acid, relative to the total fatty acids in the oil. Specific canola lines exhibiting these characteristics are also provided. Canola seed offering the combined advantages of excellent oil together with high-quality meal has not heretofore been provided

Owner:AGRI & AGRI FOOD +1

Process for preparing hypoallergenic and reduced fat foods

InactiveUS7147882B2Reduced fat peanut butter compositionFrozen sweetsAlcoholic beverage preparationVitaminLiquid nitrogen

Common allergenic foods are made hypoallergenic by treatment with super critical fluid or critical liquid gas such as super critical carbon dioxide or liquid nitrogen. The treatment of foods with liquid nitrogen or super critical carbon dioxide also enhances the functionality of fat, so that the total fat in the food can be reduced while retaining the good taste of the food. Compositions and methods for the oral delivery of a medicament or vitamin are also provided.

Owner:IMMUNOPATH PROFILE INC A CORP OF PA

Process for preparing hypoallergenic and reduced fat foods

InactiveUS20120164306A1Reduced fat peanut butter compositionCocoaOther dairy technologyLiquid nitrogenVitamin

Common allergenic foods are made hypoallergenic with super critical fluid or critical liquid gas such as super critical carbon dioxide or liquid nitrogen. The treatment of foods with liquid nitrogen or super critical carbon dioxide also enhances the functionality of fat, so that the total fat in the food can be reduced while retaining the good taste of the food. Compositions and methods for oral delivery of a medicament or vitamin are also provided.

Owner:IMMUNOPATH PROFILE INC A CORP OF PA

Dasheen clear juice beverage and preparation method thereof

ActiveCN103704841AReduce contentRich in nutrientsFood ingredient as clouding agentFood homogenisationBiotechnologyEnzymatic hydrolysis

The invention relates to a preparation method of a dasheen clear juice beverage. The total solid content of the dasheen clear juice beverage is over 5 percent, the total fat content is less than 2 percent, and the sodium content is less than 0.1g / 100mL. The preparation method comprises the specific steps of (1) pretreating dasheens, water, composite enzymes, condiments, a stabilizing agent and a preservative, which serve as raw materials, to obtain clean dasheens; (2) performing grinding and gelatinization to obtain mashed dasheen; (3) preparing dasheen normal juice by an enzyme method to obtain the dasheen normal juice; (4) clarifying the rough dasheen normal juice to obtain clarified dasheen normal juice; (5) performing mixing, homogenizing and sterilizing to obtain the dasheen clear juice beverage. According to the preparation method disclosed by the invention, the dasheen clear juice beverage is prepared by a two-enzyme method, so that the enzymatic hydrolysis of the dasheens is increased; silicone soil is adopted for fine filtering, so that the problem that a dasheen clear juice beverage is turbid after a certain period of time is solved. The dasheen clear juice beverage prepared by the preparation method disclosed by the invention smells harmoniously good, tastes smooth, is uniform and stable and has a long storage period.

Owner:HEFEI UNIV OF TECH

Frozen aerated products and methods for preparation thereof

A frozen aerated product comprising water, 0.1 to 35 w / w % sweetener and 2 to 20 w / w % vegetable fat component of which up to 20% by weight of the fatty acids are polyunsaturated fatty acids, less than 15% by weight of the fatty acid is linoleic acid and up to 50% by weight of the fatty acids are saturated fatty acids; said frozen aerated product being characterised in that the amount of de-emulsified fat expressed as a percentage of the total fat present is greater than 20% by weight.

Owner:GOOD HUMOR BREYERS ICE CREAM DIV OF CONOPCO

Process for preparing hypoallergenic and reduced fat foods

Common allergenic foods are made hypoallergenic by treatment with super critical fluid or critical liquid gas such as super critical carbon dioxide or liquid nitrogen. The treatment of foods with liquid nitrogen or super critical carbon dioxide also enhances the functionality of fat, so that the total fat in the food can be reduced while retaining the good taste of the food. Compositions and methods for the oral delivery of a medicament or vitamin are also provided.

Owner:IMMUNOPATH PROFILE INC A CORP OF PA

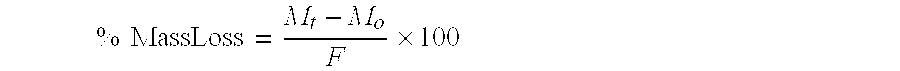

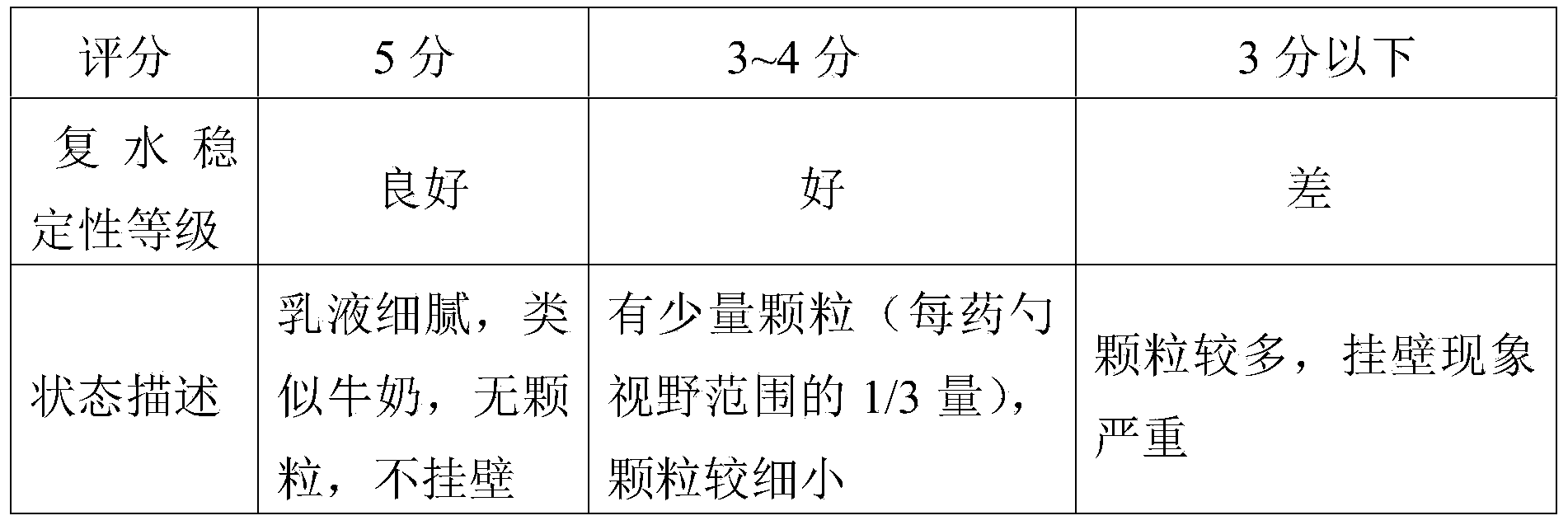

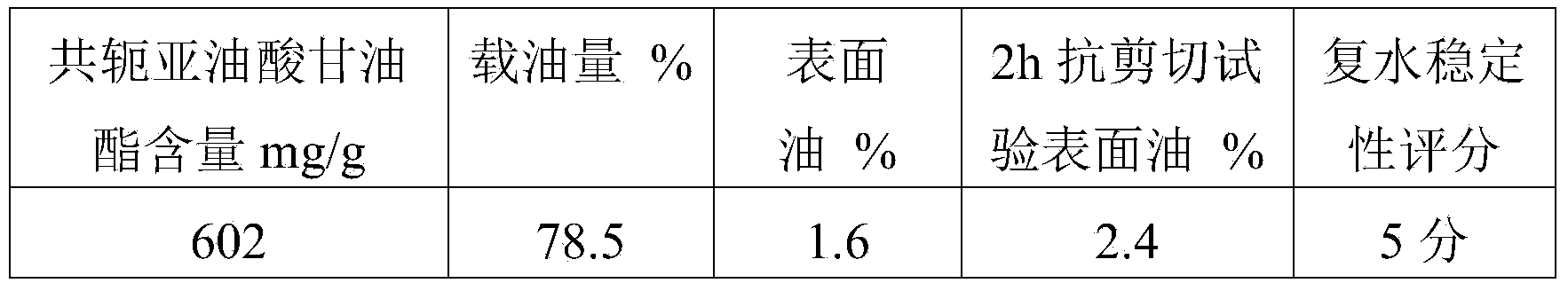

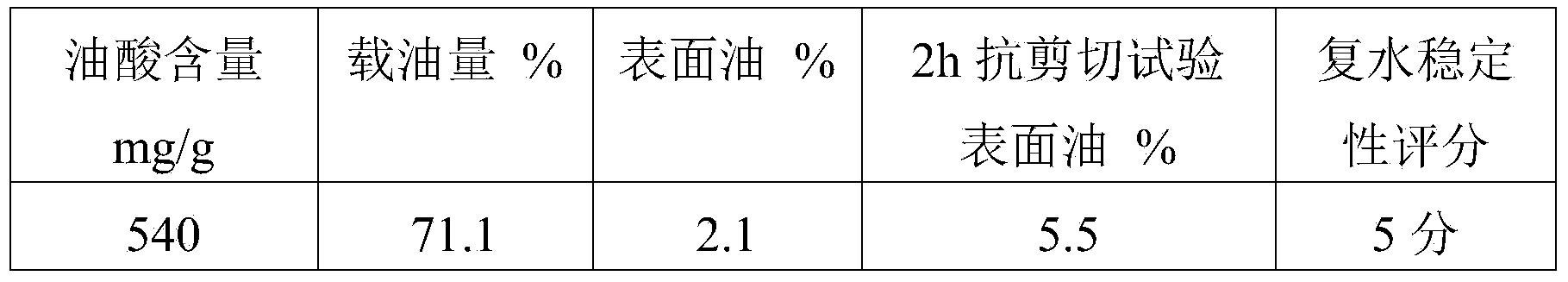

Preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring

InactiveCN104304838ASolve the fragile problemReduce dosageSugar food ingredientsVitamin food ingredientsBiotechnologyDairy foods

The invention provides a preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring. The preparation method comprises the following steps: adding protein type wall materials into water, stirring for dissolving the materials at 40-70 DEG C, adjusting the pH of an obtained solution to 7.0-12.0, reacting under the condition of 40-70 DEG C for 0.5-4 hours, adding sugar type wall materials and a stabilizing agent into an obtained reaction solution, and stirring for dissolving, thereby obtaining a water phase solution; adding an antioxidant and an emulsifier into nutrition lipid type core materials, and stirring for dissolving at 40-70 DEG C, thereby obtaining an oil phase solution; and mixing the water phase solution with the oil phase solution, emulsifying and homogenizing, and spray-drying, thereby obtaining the micro-capsule powder. The content of total fat in the micro-capsule powder reaches up to 60%-85%, and the content of surface oil in the micro-capsule powder is lower than 5%. The micro-capsule powder has tolerance to mechanical force, is good in self-emulsifying capability, can be dissolved to form uniform and stable fine emulsion without floating particles and sediments, can be applied to the field of food, and can be added to food such as bread, cookies, nutrition bars and milk products and also be taken as solid granules.

Owner:INNOBIO CORP LTD

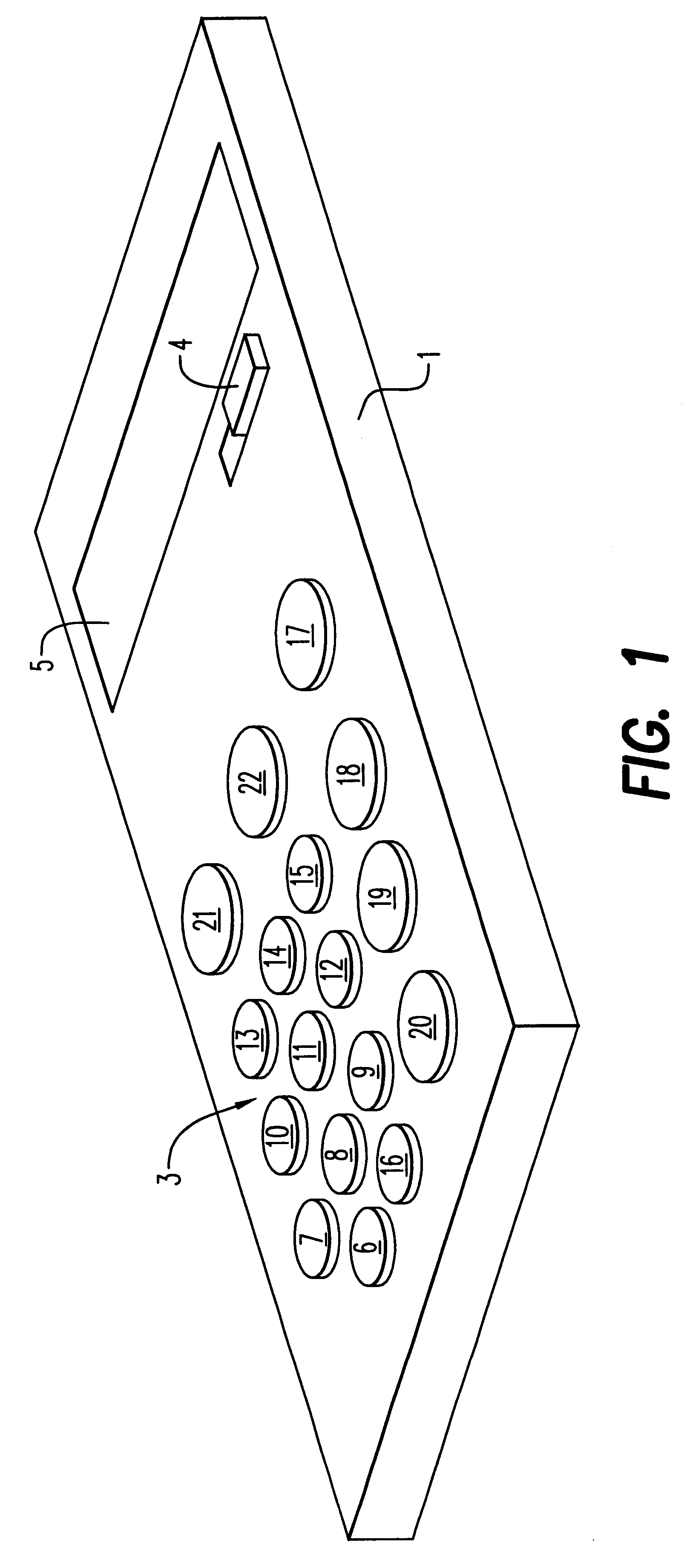

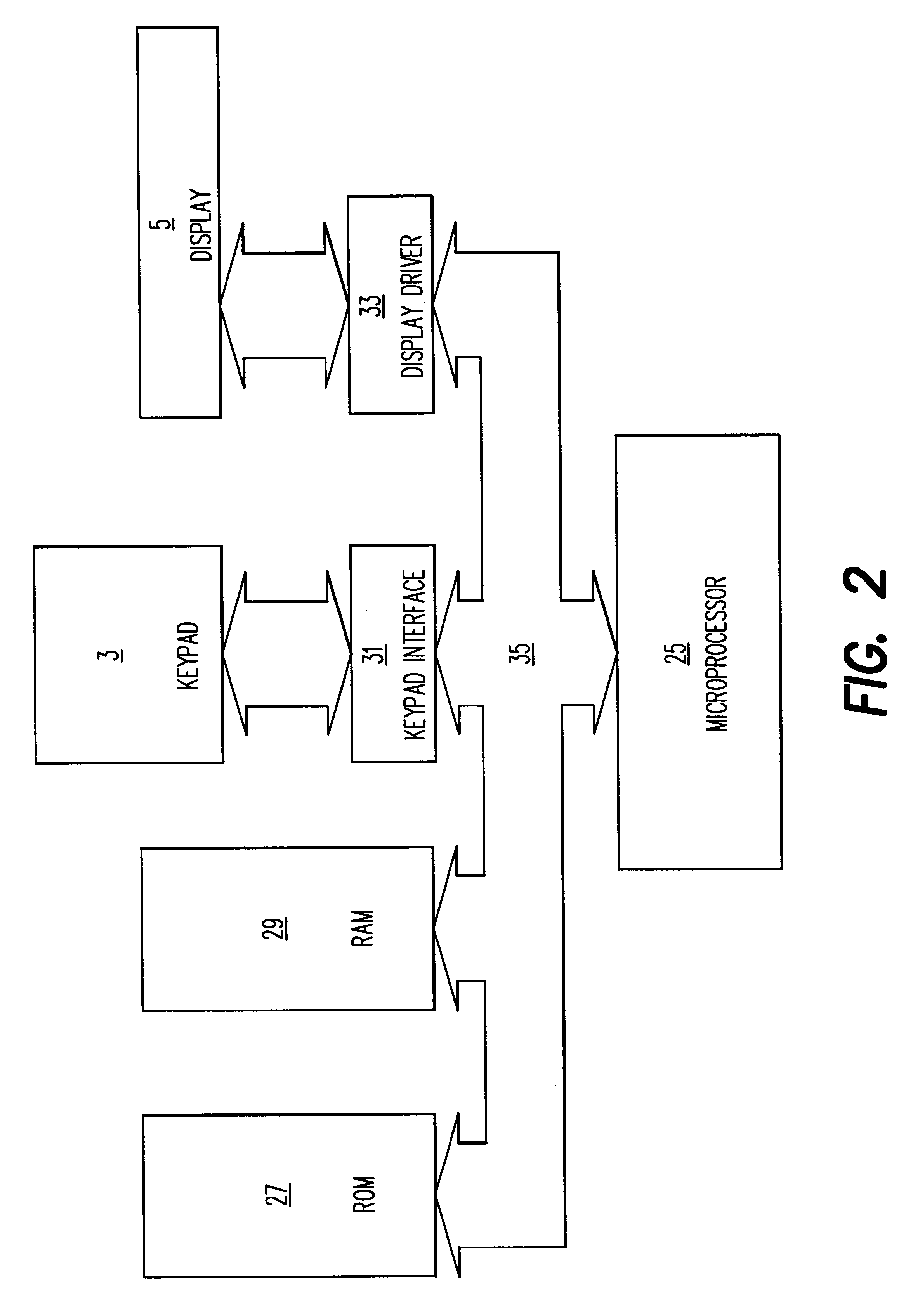

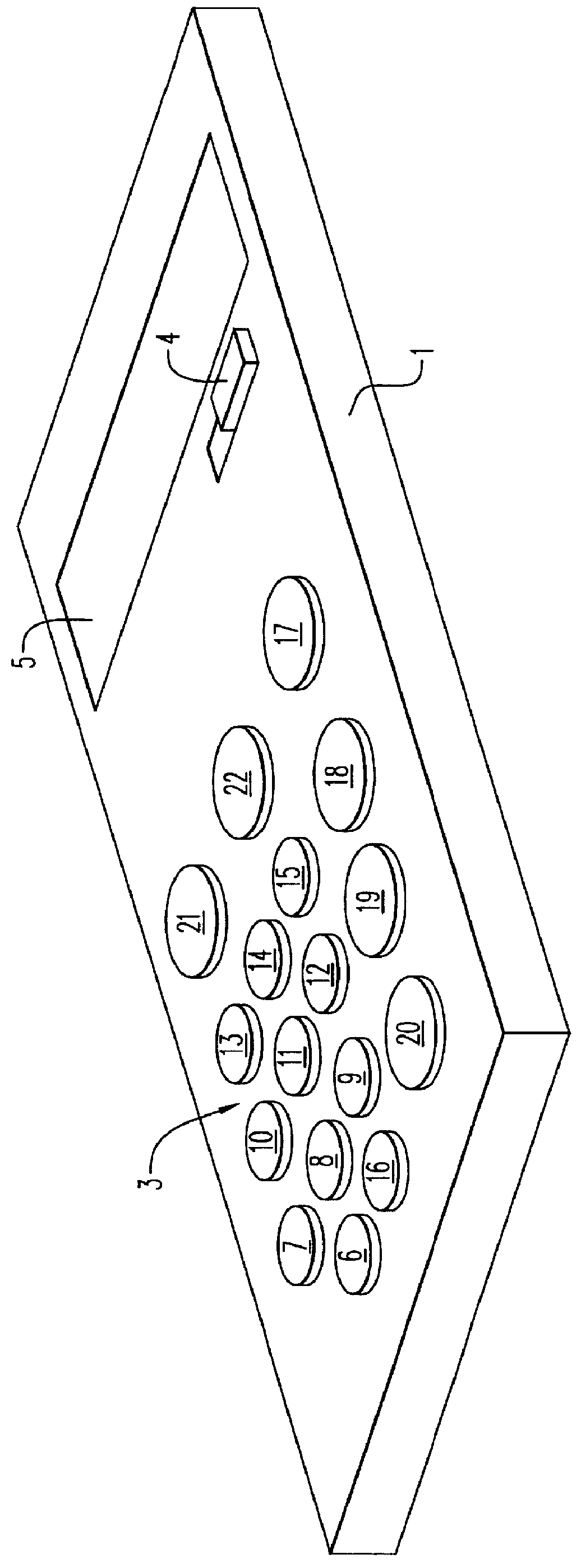

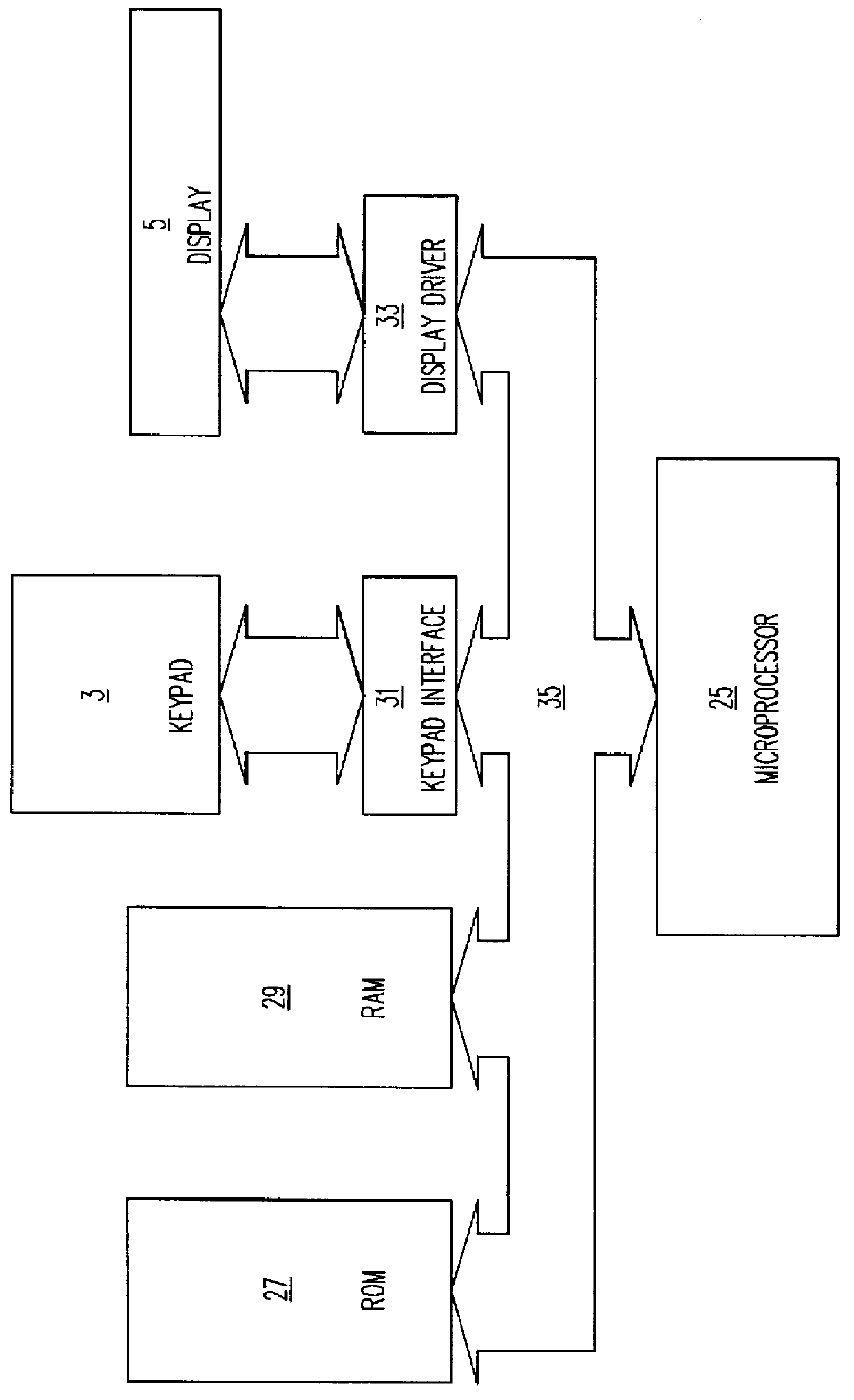

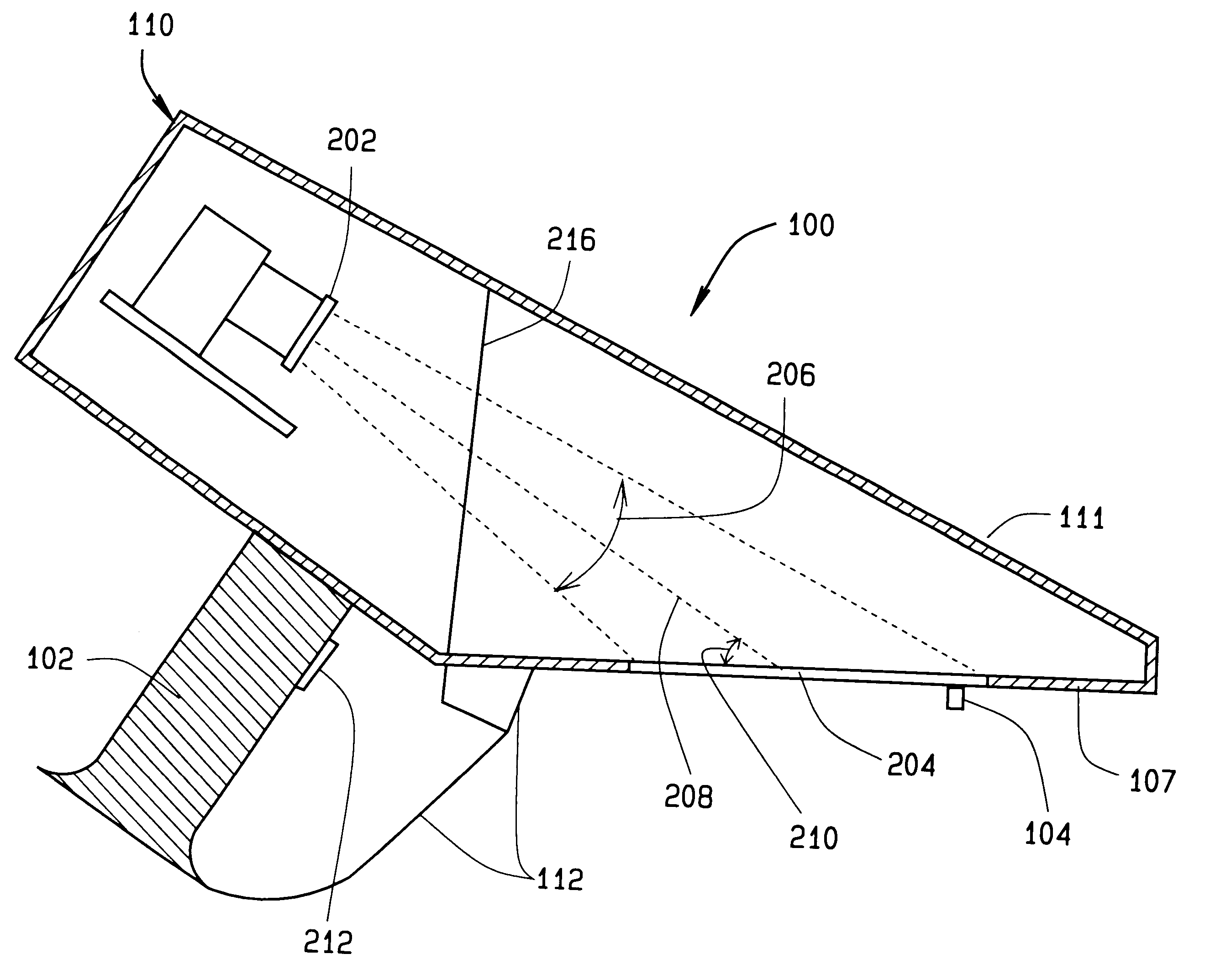

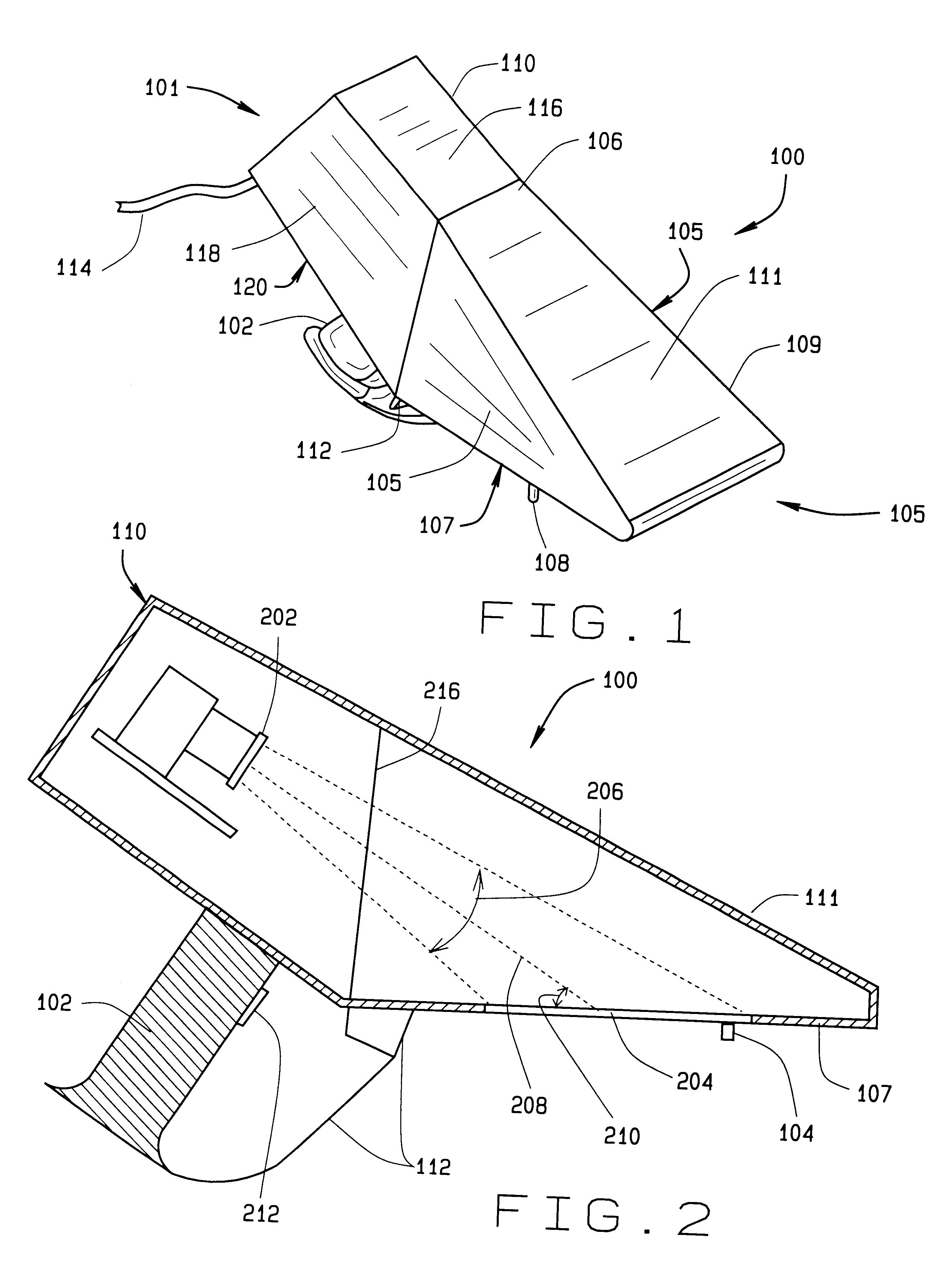

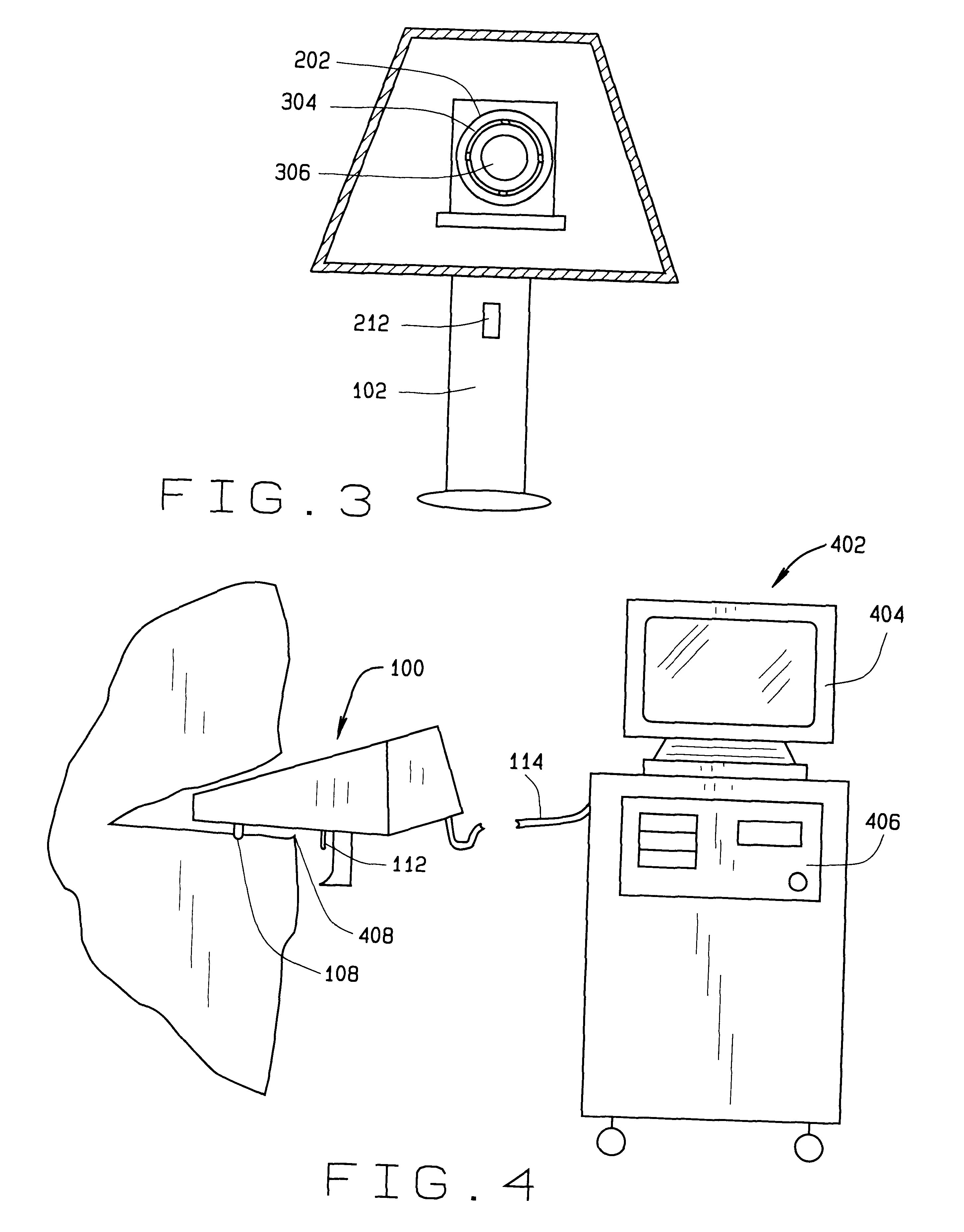

Image analysis systems for grading of meat, predicting quality of meat and/or predicting meat yield of an animal carcass

InactiveUS6751364B2Improve abilitiesEasy to insertImage enhancementImage analysisLean meatImaging analysis

The invention is an image analysis system and method for grading of meat, predicting quality of meat and / or predicting meat yield of an animal. One embodiment of the invention is particularly designed to capture an image of the 12rib cross section of the ribeye and perform an image analysis of the ribeye for grading purposes. The image capturing camera portion of the system has a wedged shaped camera housing for ease of insertion into the ribbed incision. The image capturing portion of the system further comprises a camera with a flash for consistent lighting. The camera is positioned such that it views the ribeye cross section at an angle to accommodate the wedge shape of the camera housing for ease of insertion in the incision. The camera housing also has various alignment means to facilitate the user's ability to capture images in a consistent manner. Once the image is captured either digitally or captured and converted to a digital image, an image analysis is performed on the digital image to determine parameters such as the percentage lean, total area of the ribeye, total fat area, total lean area, percent marbling, and thickness of fat adjacent to the ribeye, and other parameters. These parameters are used to predict value determining traits of the carcass.

Owner:TYSON FRESH MEATS +1

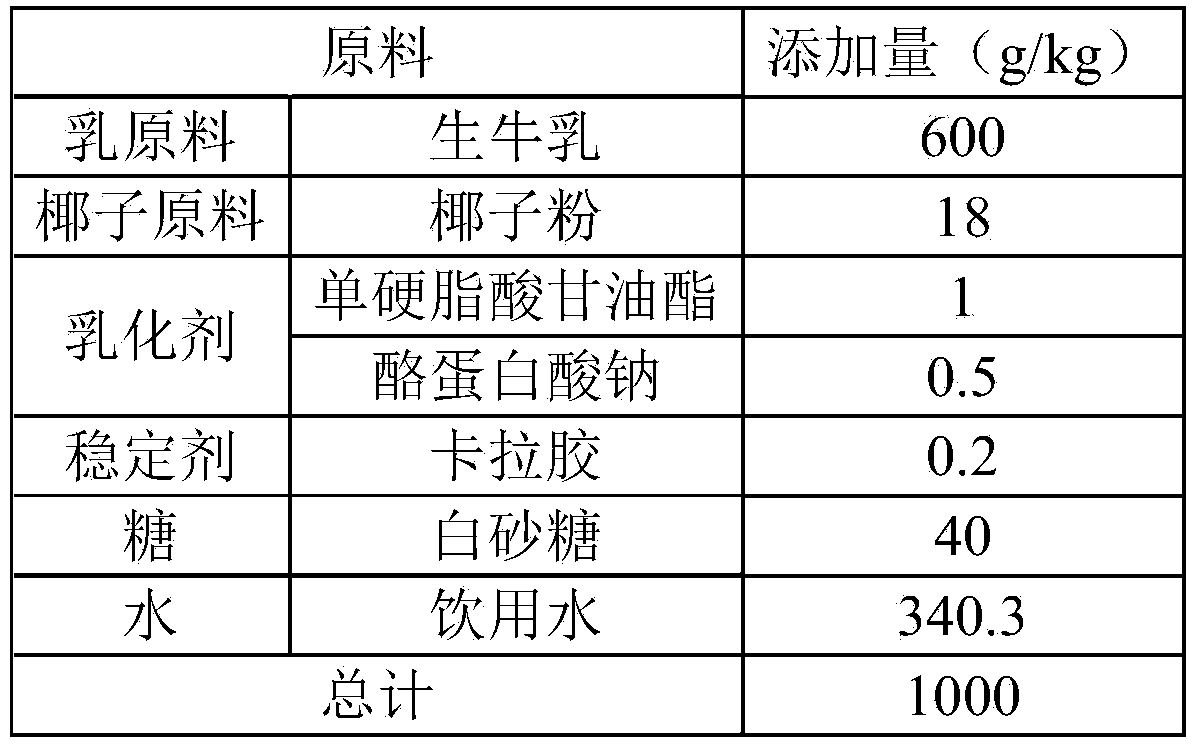

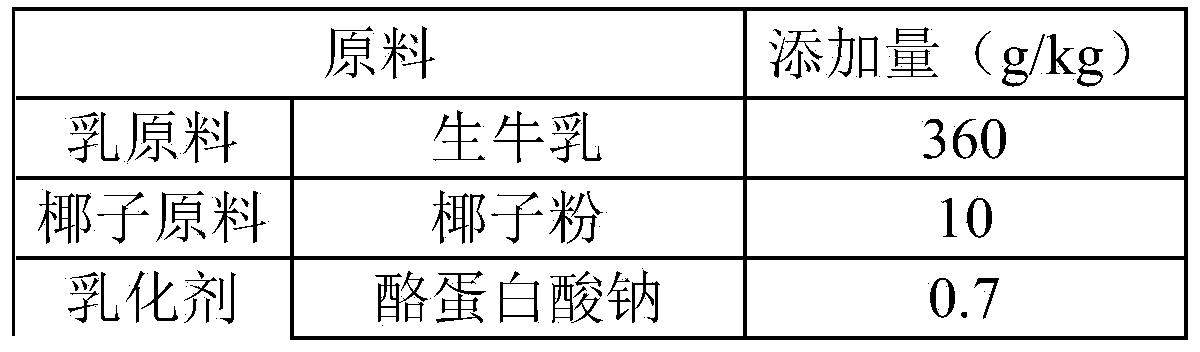

Coconut cow milk beverage and preparation method thereof

The invention discloses a coconut cow milk beverage and a preparation method thereof. The coconut cow milk beverage comprises the following raw materials in percentage by weight: 3%-60% of a milk raw material, 1%-6% of a coconut raw material and 0.05%-0.15% of an emulsifier, a stabilizer, a sweetener and water, wherein protein with the protein content of 1.1%-2.0% is milk protein and fat with the fat content being 1.5%-3.0% and the total fat content more than 35% is fat in the coconut raw material. The preparation method comprises the following steps: uniformly mixing the raw materials, homogenizing, sterilizing, cooling to 10-30 DEG C, filling, and standing at 8-10 DEG C for 3-7 days for maturing. The coconut cow milk beverage prepared by using the method fuses the coconut fragrance with the milk fragrance, and is coordinated and full in flavor, good in mouth feel and rich in nutrition.

Owner:BRIGHT DAIRY & FOOD

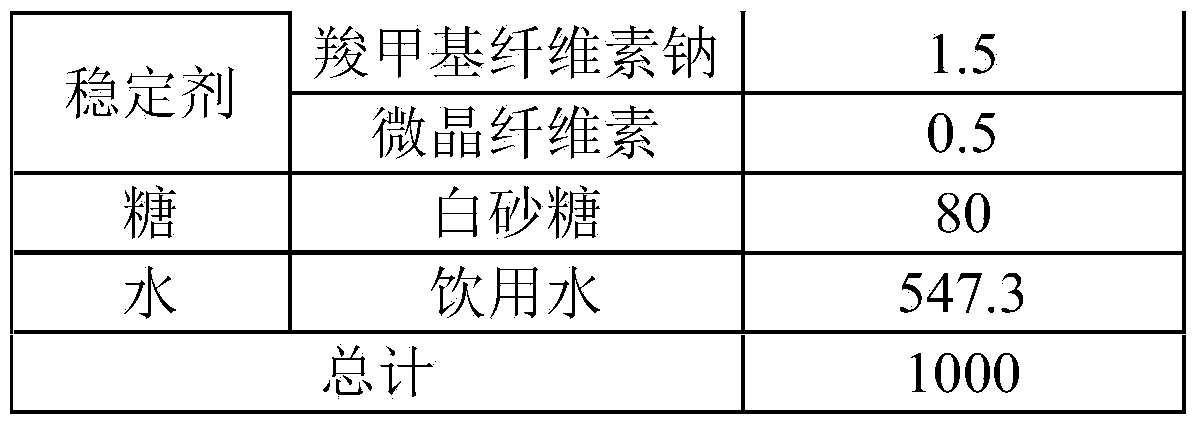

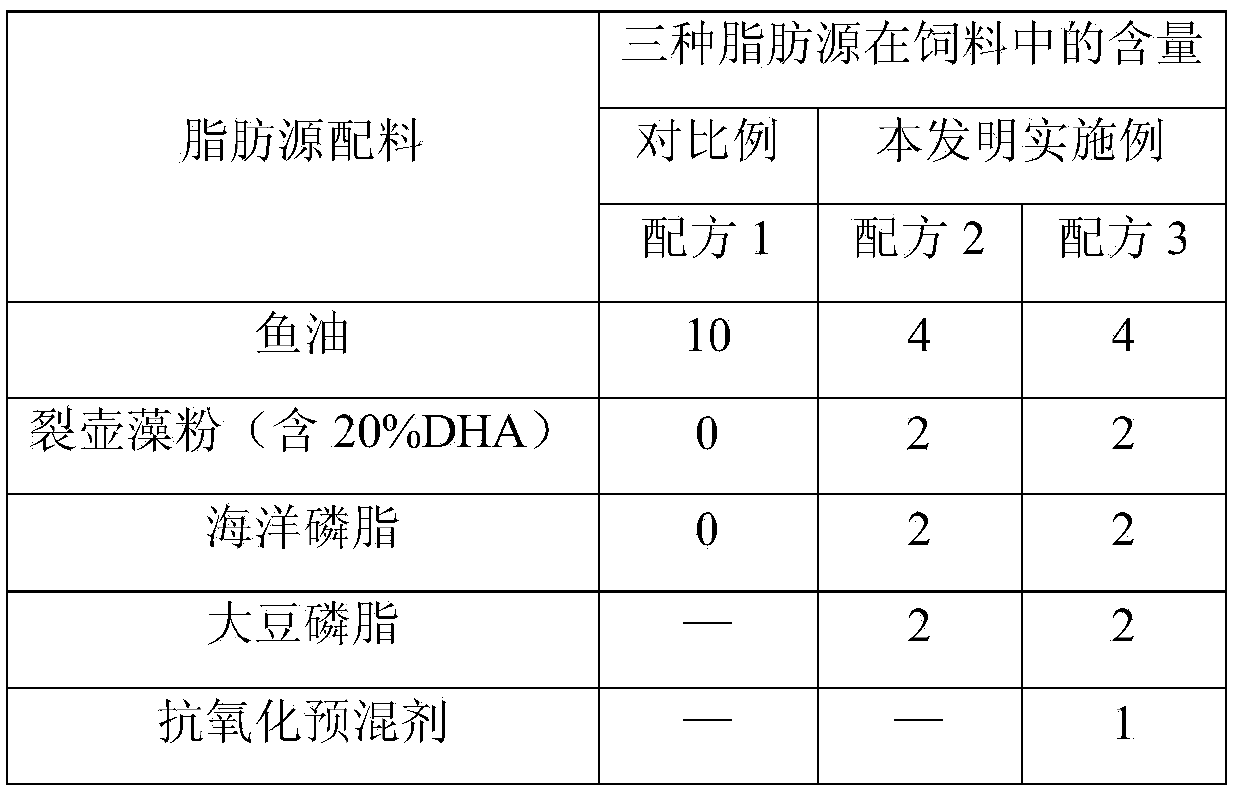

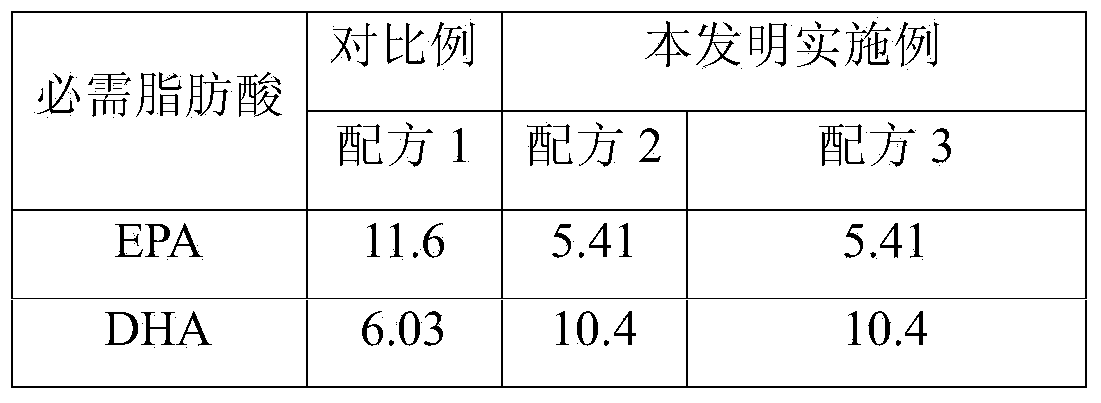

Parent sturgeon feed

The invention relates to a parent sturgeon feed. Through experiments, the use amounts of two essential fatty acids including EPA (Eicosapentaenoic acid) and DHA (docosahexaenoic acid) in a parent sturgeon feed, the weight part ratio of the two fatty acids and the content of the essential fatty acids in the total fat of the feed are confirmed, and comparison is carried out on organic trace elements and inorganic trace elements. The invention further provides a basic nutrition formula of the parent feed. Experiments prove that the feed disclosed by the invention is capable of obviously promoting secretion of female hormone in the parent sturgeon breeding period, and increasing the brood amount, egg hatchability and fertility rate of parent sturgeons, the growth speed, the weight and the survival rate of fries.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Heat treated, whippable oil in water emulsion

The invention relates to a heat treated, whippable oil in water emulsion comprising a fat phase and at least one emulsifier, whereby the fat phase comprises a fat blend, characterised in that the fat blend has a solid fat content of at least 10% at 40° C. and at least 40% at 30° C. and at least 60% at 10° C, and the fat blend comprises from 5 to 49 wt % fatty acids with 14 carbon atoms or less on total fatty acid content of the fat blend. The specific fat phase makes the composition stable upon storage at temperatures up to 35° C. while the composition still shows good whippability.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

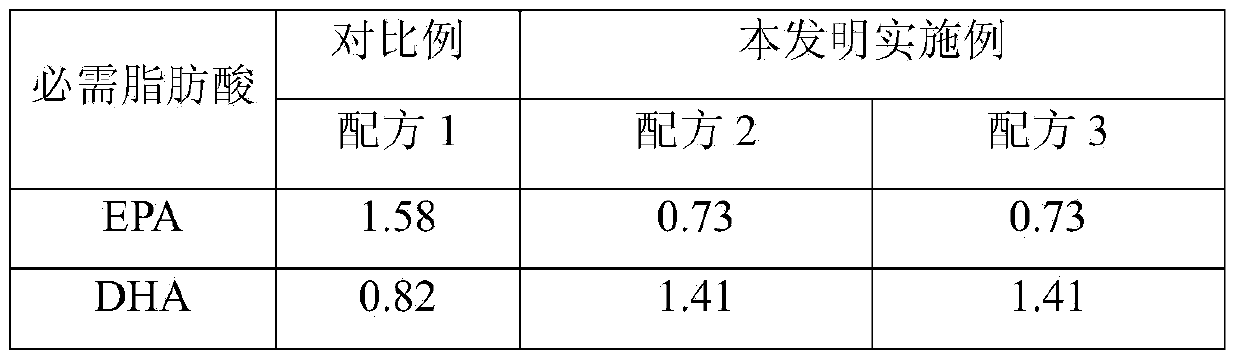

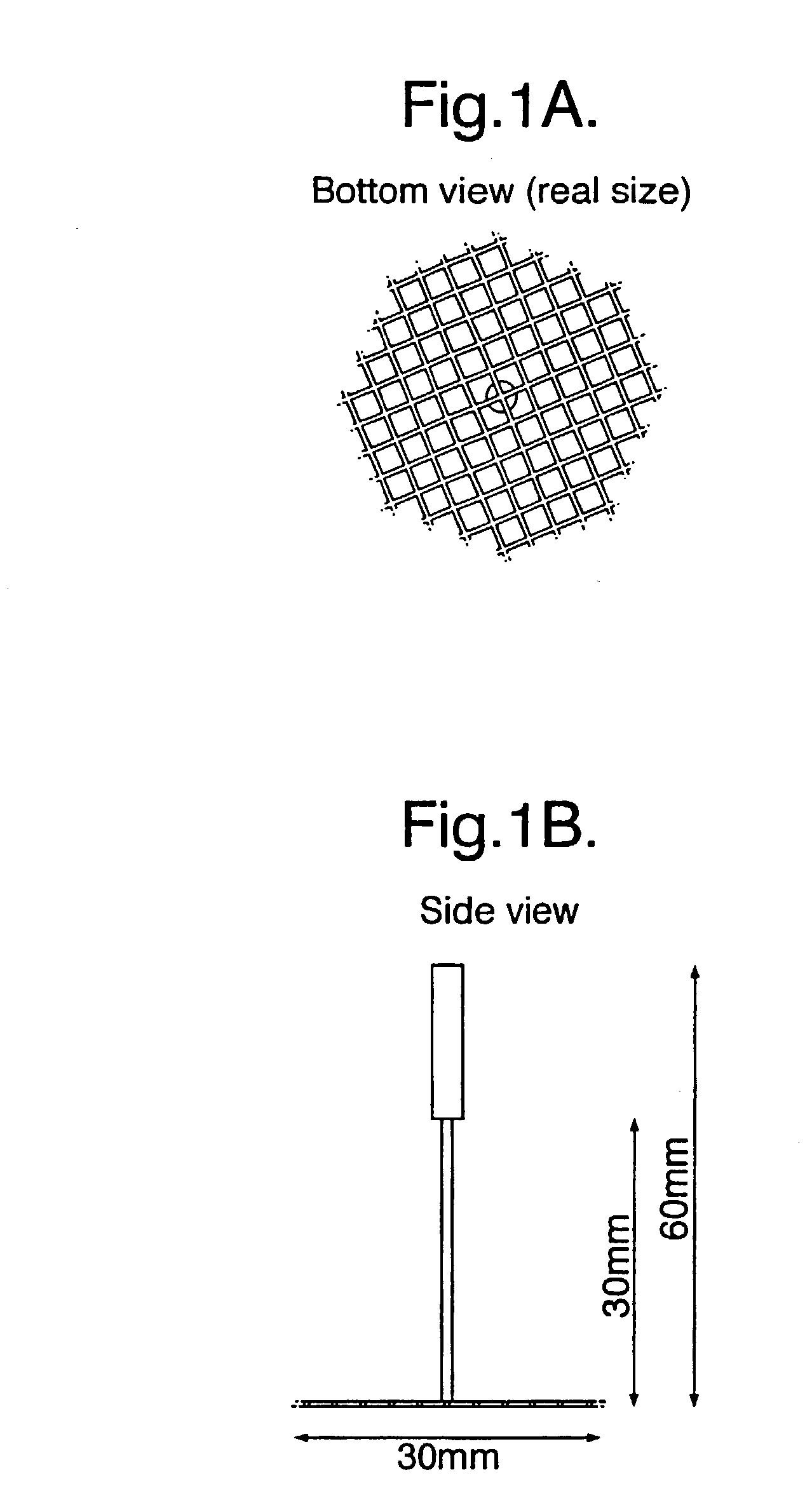

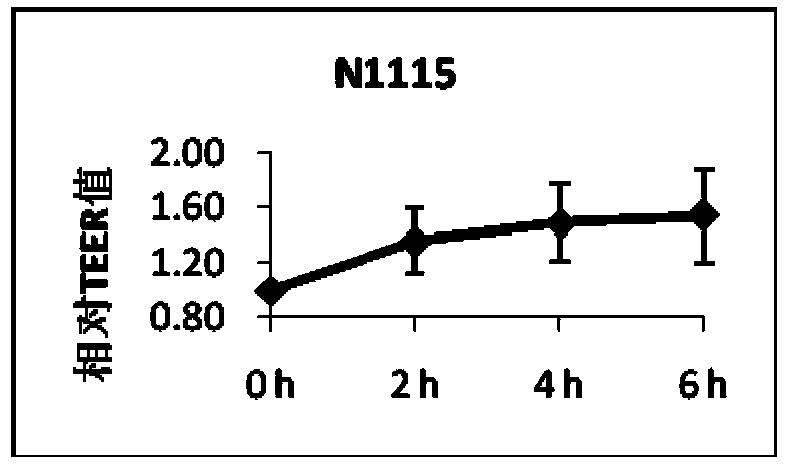

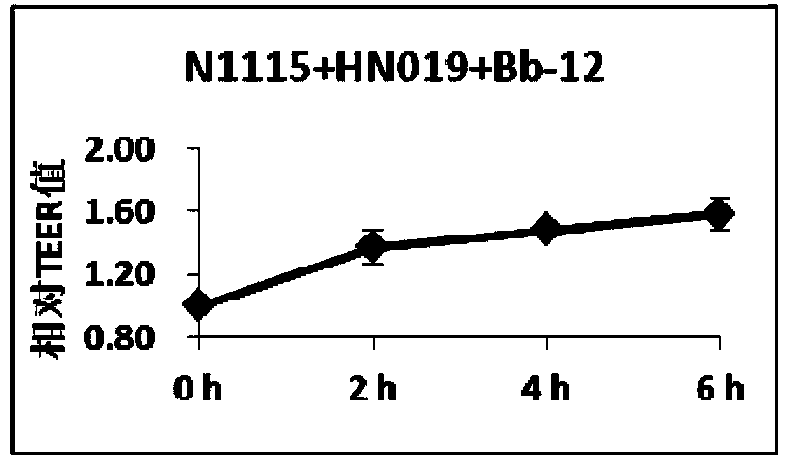

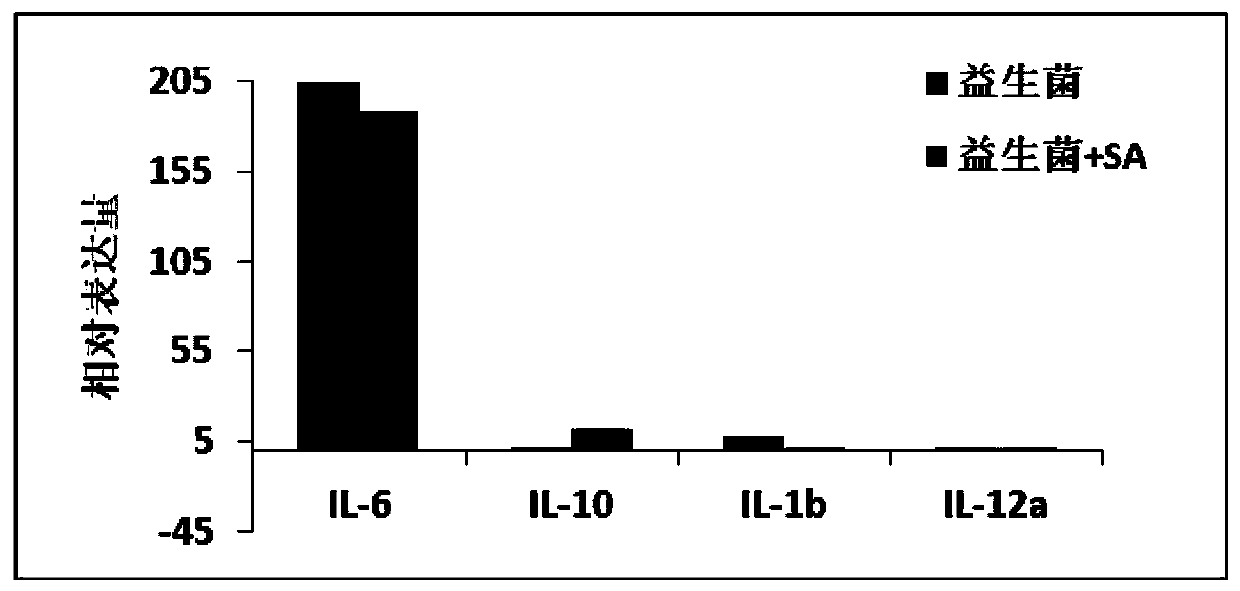

Probiotics-containing breast milk-like formula milk powder for infants and preparation method of milk powder

InactiveCN110506793APromote brain developmentImprove memoryMilk preparationBrain developmentDocosahexaenoic acid

The invention discloses a probiotics-containing breast milk-like formula milk powder for infants. Raw milk is used as a base material; according to nutrient differences of breast milk and raw milk, whey protein is added to adjust the ratio of whey protein to casein in a product to be close to 6:4; soybean oil is added to adjust deficiency of linoleic acid in milk fat, wherein linoleic acid accounts for about 12.8 percent of the total fat of the breast milk but only 2.2 percent of the total fat of raw milk; arachidonic acid (AA), docosahexaenoic acid (DHA), sialic acid (SA) and 3'-sialyllactose(3'-SL) are added to promote brain development of infants and improve memory and intelligence; and bifidobacterium lactis HN019, bifidobacterium animal Bb-12 and lactobacillus paracasei N1115 are added to regulate intestinal healthy development of infants. The invention also provides a preparation method of the milk powder. The milk powder is close to the nutrition index in the Chinese breast milk and is suitable for growth and development of infants in China.

Owner:JUNLEBAO DAIRY GRP CO LTD

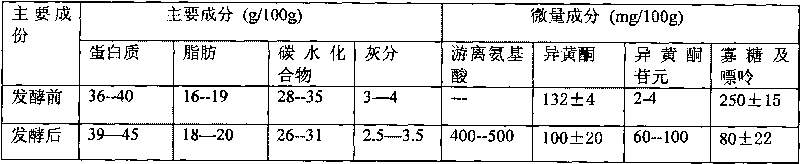

Predigested soyfood

The invention relates to a predigested soyfood, which is prepared by fermenting with a rhizopus and is characterized in that each 100g of finished product contains the following main nutrient components: 42+ / -3 g of protein, 19+ / -2 g of total fat, 28+ / -3 g of total carbohydrate and 3+ / -0.5 g of ash content. Because the components are subjected to enzymolysis through microbial fermentation, the soyfood is absorbed and used more easily; and simultaneously because the soyfood contains relatively rich lipase and protease, the soyfood can be used as a mate of a high-fat and high-protein food. The predigested soyfood of the invention also can be used for preparing a functional food for reducing LDP cholesterol and a functional food for releasing women's menopause syndrome.

Owner:张正生

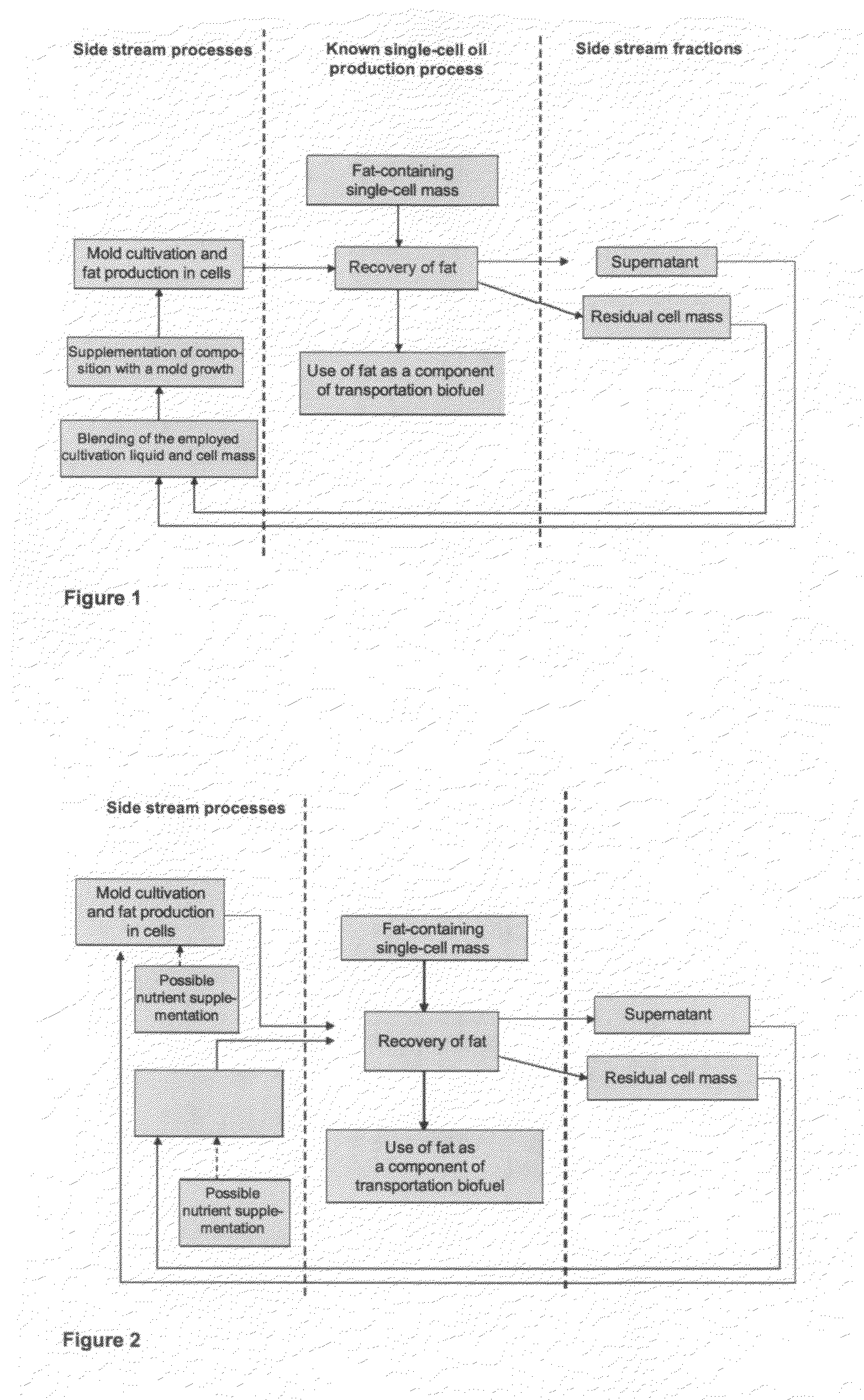

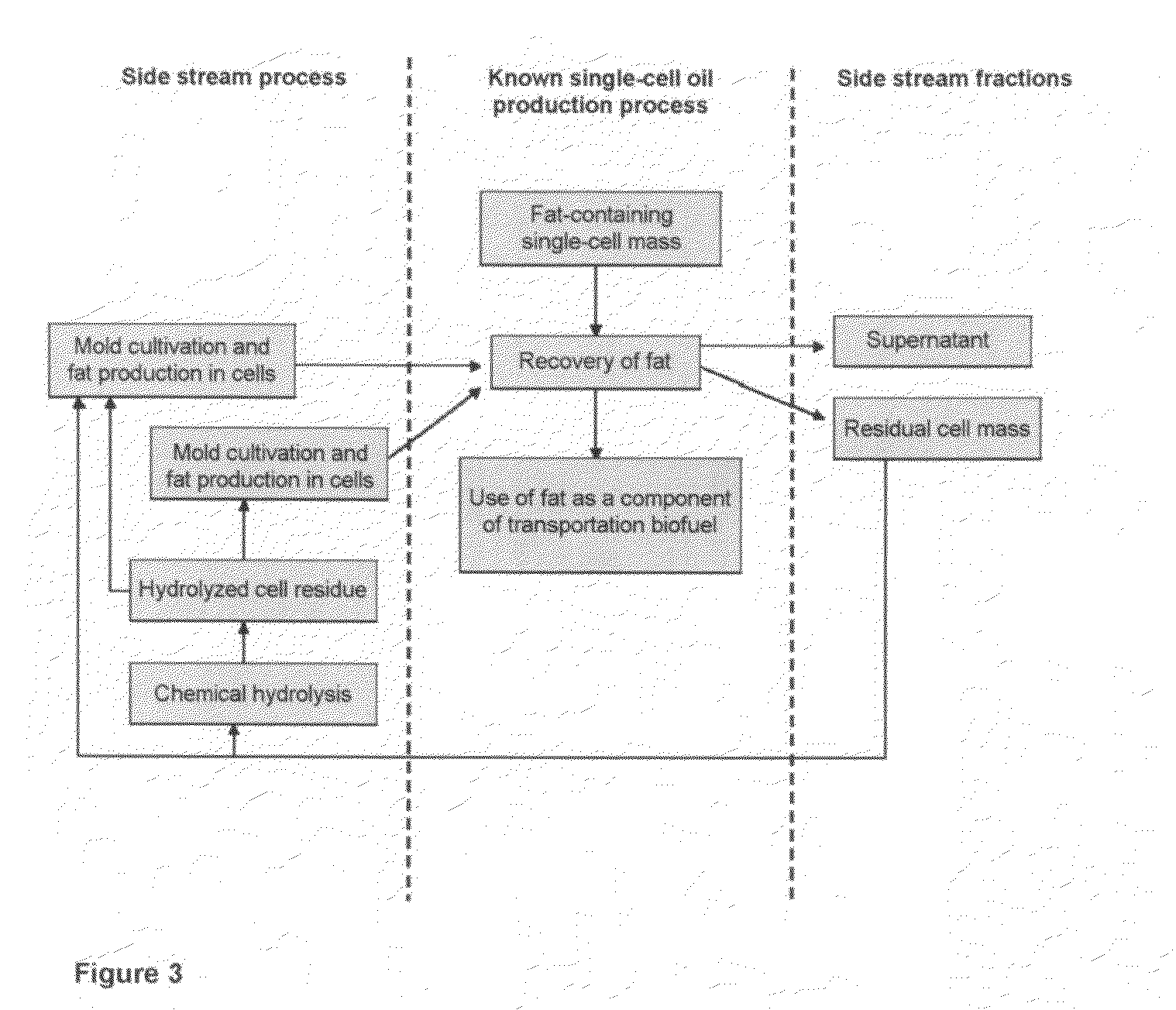

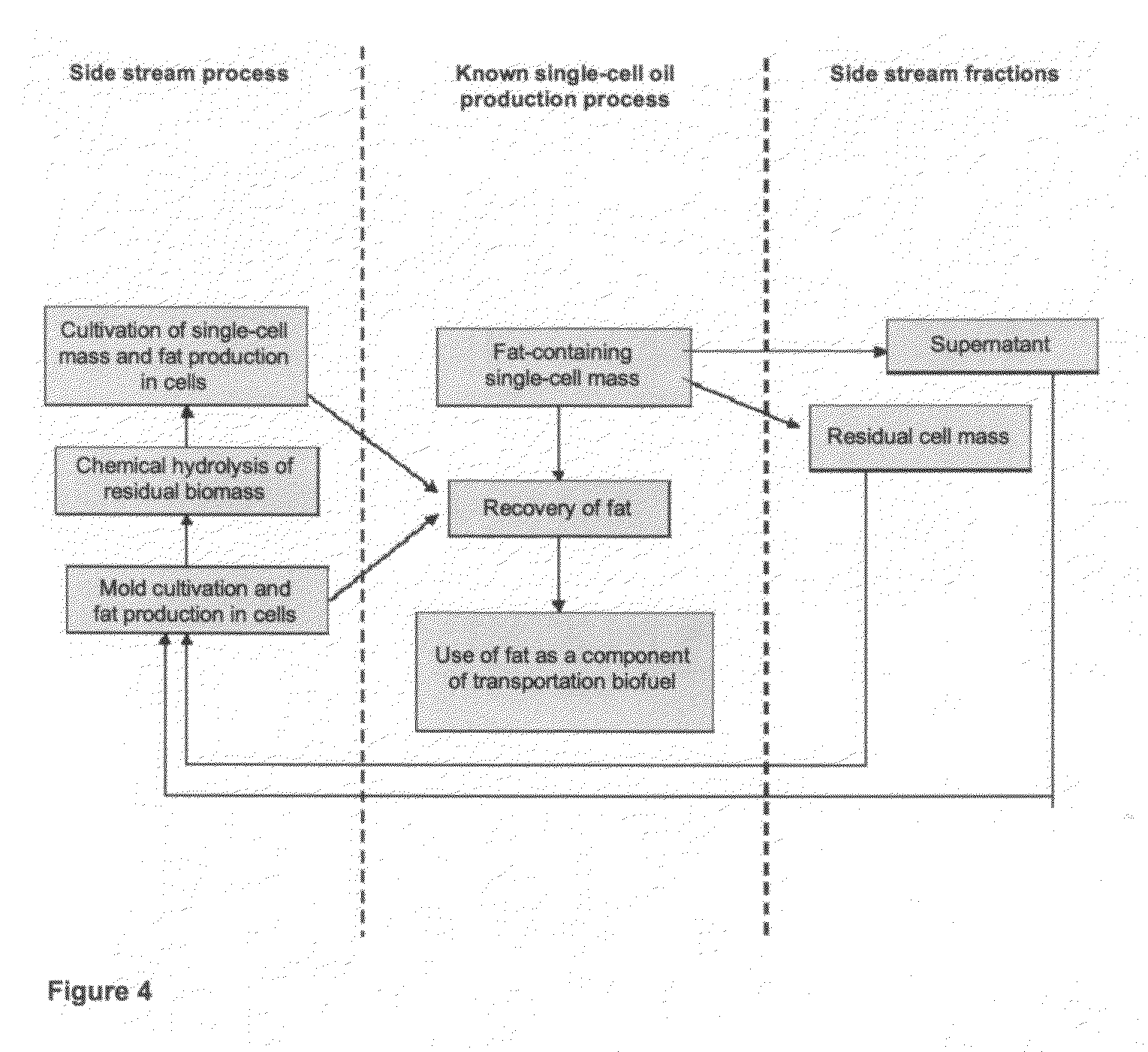

Method for the production of fat

ActiveUS20110065940A1Increase carbonImprove energy balanceFungiOrganic chemistryBiological bodyBiofuel

The present invention relates to a method for the production of fat with a principal application as transportation biofuel or a component or raw material therefor. According to the method, cell masses, cell suspensions and / or liquid phases formed in the production of single cell oil, and / or biomass-containing side streams or microorganism cell masses for another purpose and / or originating from other sources, are contacted with a fat-production capable microorganism and the organism is allowed to produce fat. The resulting fat is recovered or the microorganism mass is passed to a single-cell oil production process. By means of the invention, the organic matter present in the cell mass and side streams of single-cell oil can be re-utilized for the production of the single-cell oil, thereby improving a total fat yield, as well as reducing an organic load of the side streams.

Owner:NESTE OIL OY

Fat composition

A vegetable fat composition comprises glycerides, wherein the triglyceride content of the composition is:6 to 20% SSS,5 to less than 20% SUS5 to less than 25% SSU10 to 39% SU2 andat least 20% U3,wherein S is a saturated fatty acid residue having 16 to 24 carbon atoms and U is an unsaturated fatty acid residue having at least 18 carbon atoms and all percentages are by weight based on the total triglycerides present in the composition,the weight ratio SUS / SSU is between 0.5 and 2.0,the weight ratio of (saturated fatty acid residues having 18 to 24 carbon atoms) / (saturated fatty acid residues having 16 carbon atoms) in the total S content of the triglycerides is less than 0.2,and the triglycerides contain less than 3% of arachidic and behenic acid residues based on the total fatty acid residue content of the triglycerides,and wherein the saturated fatty acid residue content of the triglycerides is less than 45% by weight of the total fatty acid residues in the triglycerides. The composition may be used to produce baked products and iced confectionery products.

Owner:LODERS CROKLAAN USA

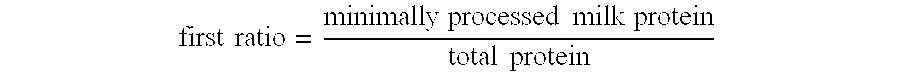

Nutritional non-cultured beverage composition

InactiveUS20050069618A1Improve qualityMaintain good propertiesMilk preparationFood preparationAdditive ingredientTotal protein

The present invention provides a high quality, ready-to-drink, non-cultured nutritional beverage comprising (1) a protein component, (2) an emulsified fat component, (3) a fortification component, and (4) an optional sweetener component. Preferably the protein component comprises minimally processed milk; the emulsified fat component comprises dairy fat; the beverage contains about 1.5 to 10 percent total protein and about 0.15 to about 5 percent total fat; the beverage has a first ratio of the minimally processed milk protein divided by the total protein which is greater than or equal to about 0.05; the beverage has a second ratio of the dairy fat divided by the total fat which is greater than or equal to about 0.15; and the fortification component provides at least 10 percent of the daily value per single beverage serving of at least 6 vitamins and minerals.

Owner:KRAFT FOODS INC

Process for controlling body weight

InactiveUS20030050540A1Easy to implementEasy to masterPhysical therapies and activitiesSurgeryBody part weightWeight change

The disclosure relates to a process for controlling body weight in which selection of food servings is based on a calculated point value and a range of allotted daily points which is adjusted for weight change. The calculated point value is a function of measured calories, total fat and dietary fiber for serving sizes specified in readily estimatable units. A range or maximum number of points allotted per day may be calculated based on current body weight, caloric reduction to be achieved, physical activity level, and physical activity duration.

Owner:WEIGHT WATCHERS INT

Natural rich vitamin blending edible oil and preparation method thereof

The invention discloses a natural rich vitamin blending edible oil and a preparation method thereof. The natural rich vitamin blending edible oil is prepared in such a way that 3 kinds of rice bran oil, semen lepidii oil, maize germ oil, tea seed oil and soya bean salad oil are used as main raw materials, wheat germ oil and prinsepia utilis royle oil, which contain rich natural vitamin, are addedto blend. The finished oil comprises various fatty acids accounting for the total fatty acid in percentage by weight: 30-45 percent of monounsaturated fatty acid, 30-45 percent of n-6 polyunsaturatedfatty acid, 2-9 percent of n-3 polyunsaturated fatty acid, 0.01-0.6mg / 100g of vitamin A, 0.01-0.05mg / 100g of vitamin D and 50-150mg / 100g of vitamin E. The defects of single nutrition component or unbalanced content and non-natural source and deficiency of vitamin of the edible oil and fat produced in the prior art are overcome, and the balance requirement of various unsaturated fatty acids and oilsoluble vitamins of a human body is met.

Owner:白新鹏

Mutton fermentation dry sausage and preparation method thereof

The invention discloses a high-grade mutton fermentation dry sausage with low fat and abundant exopolysaccharide. The mutton fermentation dry sausage comprises the following substances in parts by weight: 1-99 parts of mutton, 1-30 parts of sheep tail oil, 1-30 parts of konjac flour, 1-10 parts of other grease, 0.5-20 parts of leavening agent, 0.5-10 parts of sucrose, 0.2-1 part of ground pepper, 1-5 parts of salt, 0.00010-0.00030 part of nitrite, and 1-20 parts of auxiliary ingredients. The high-grade mutton fermentation dry sausage has the beneficial effects that the content of animal fat is obviously reduced, and the high-yield exopolysaccharide leavening agent is adopted to provide a safe and health-care dry fermentation product for consumers. According to the high-grade mutton fermentation dry sausage, the raw materials are creatively adopted, animal fat is partially replaced, the content of saturated fatty acid and total fat in the product can be reduced, and by adopting the high-yield exopolysaccharide leavening agent, the water activity of the product can be reduced through exopolysaccharide generated during the fermentation process while the pH value of the product can be reduced, thus achieving the purposes of being corrosion-resistant and controlling the quality of the product.

Owner:新疆顶泰食品科技有限公司

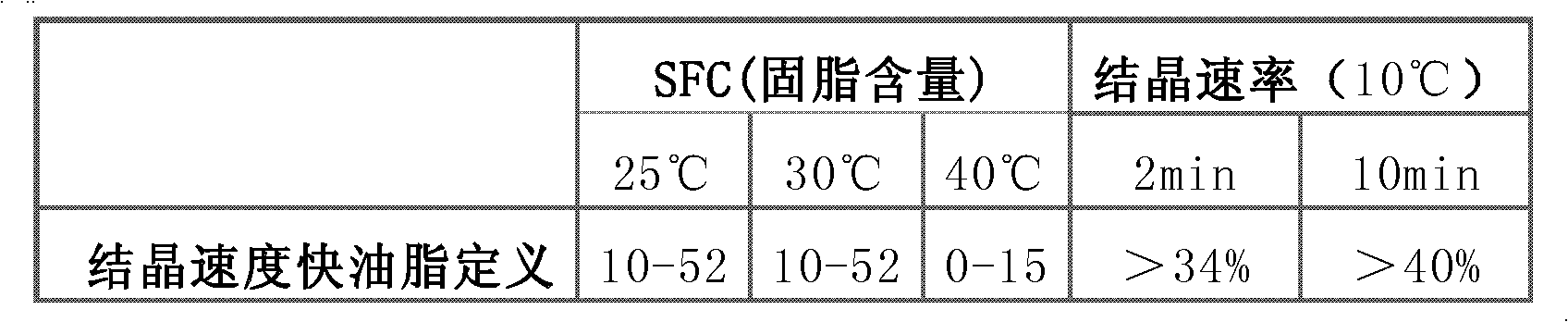

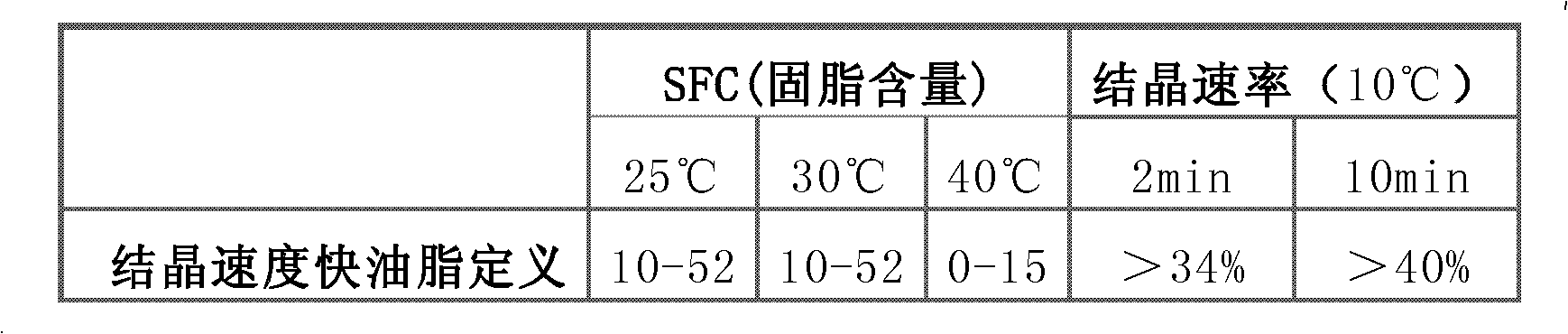

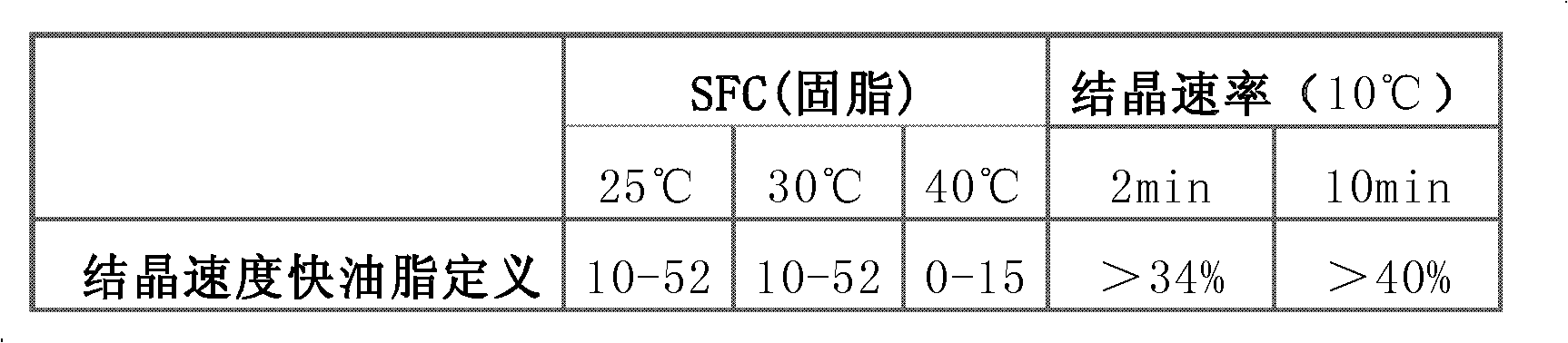

Grease composition, composite grease composition, product and preparation method thereof

InactiveCN103181417AShorten the ripening timeDoes not affect other performanceEdible oils/fats production/working-upNutritive valuesTrans esterification

The invention provides a grease composition, which comprises a triglyceride composition obtained by an ester exchange treatment. In terms of the weight of the total fatty acids constituting the grease composition, the content of saturated fatty acid is 30%-100%; in terms of the weight of the total fatty acids constituting the grease composition, the content of fatty acid with a carbon atom number of less than 11 is 0-60%; and in terms of the weight of the total fatty acids constituting the grease composition, the content of fatty acid with a carbon atom number of greater than 19 is 0-60%. The invention also provides grease prepared from the grease composition and a preparation method thereof. The grease composition provided in the invention has a low content of trans-fatty acids, a solid fat content in line with the requirement, a fast crystallization speed, and higher nutritive value, and can be used for making a grease composition of plastic grease.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

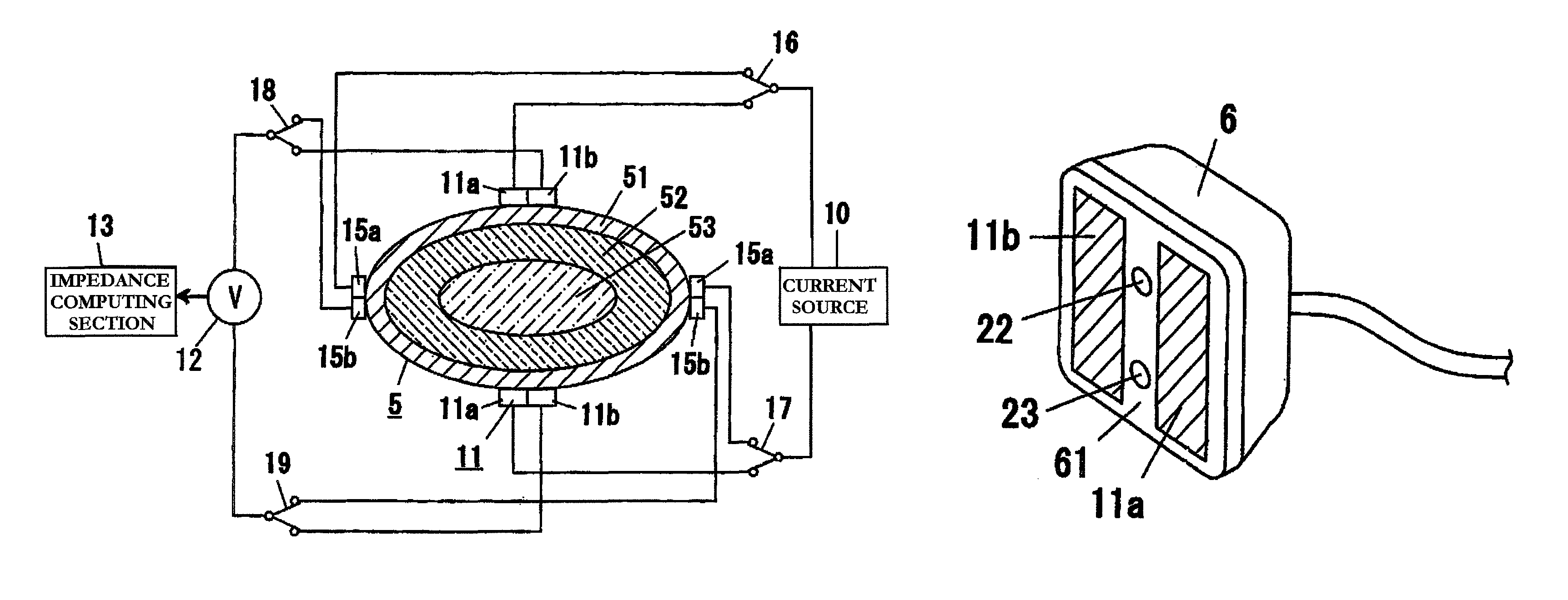

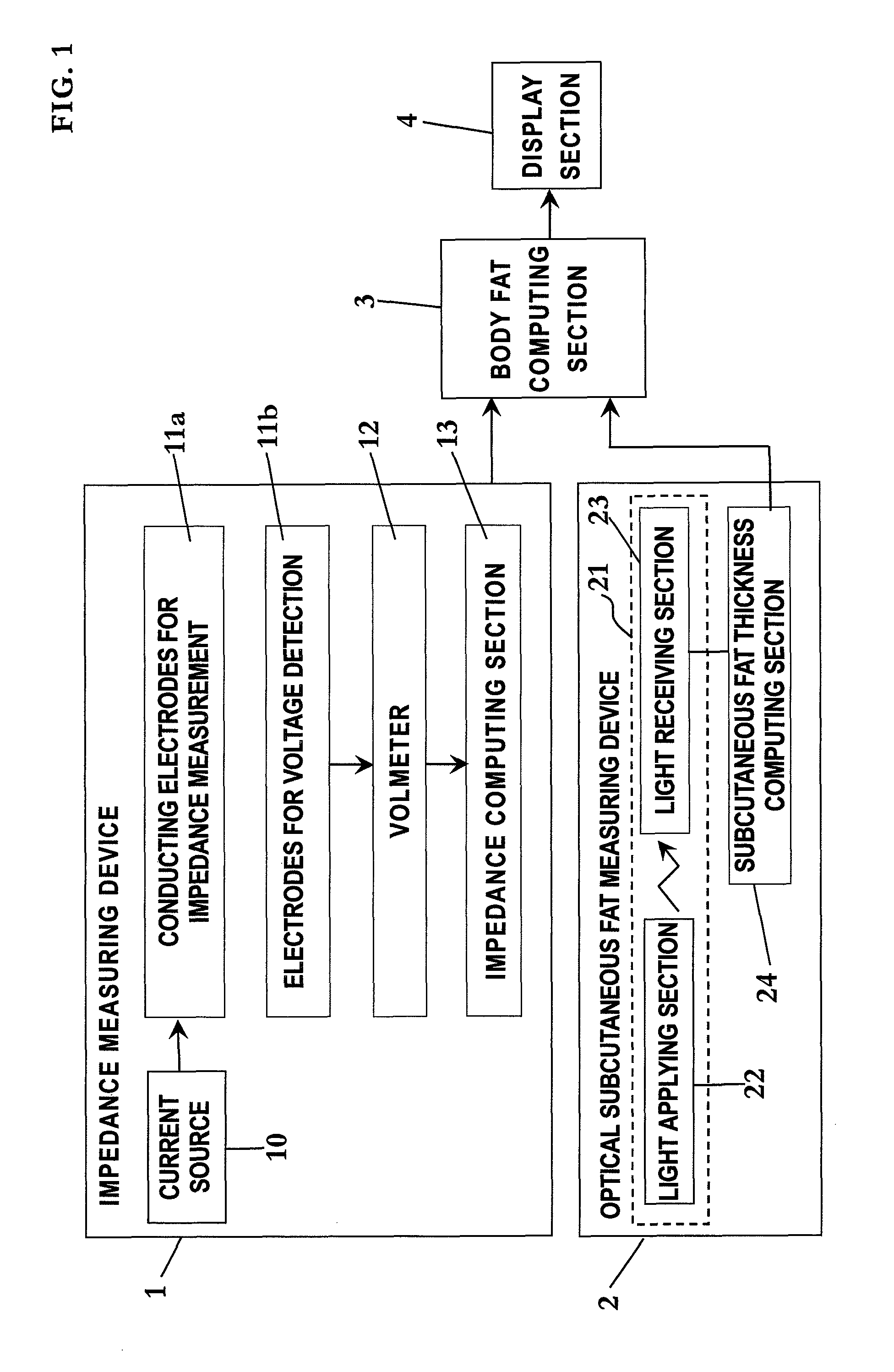

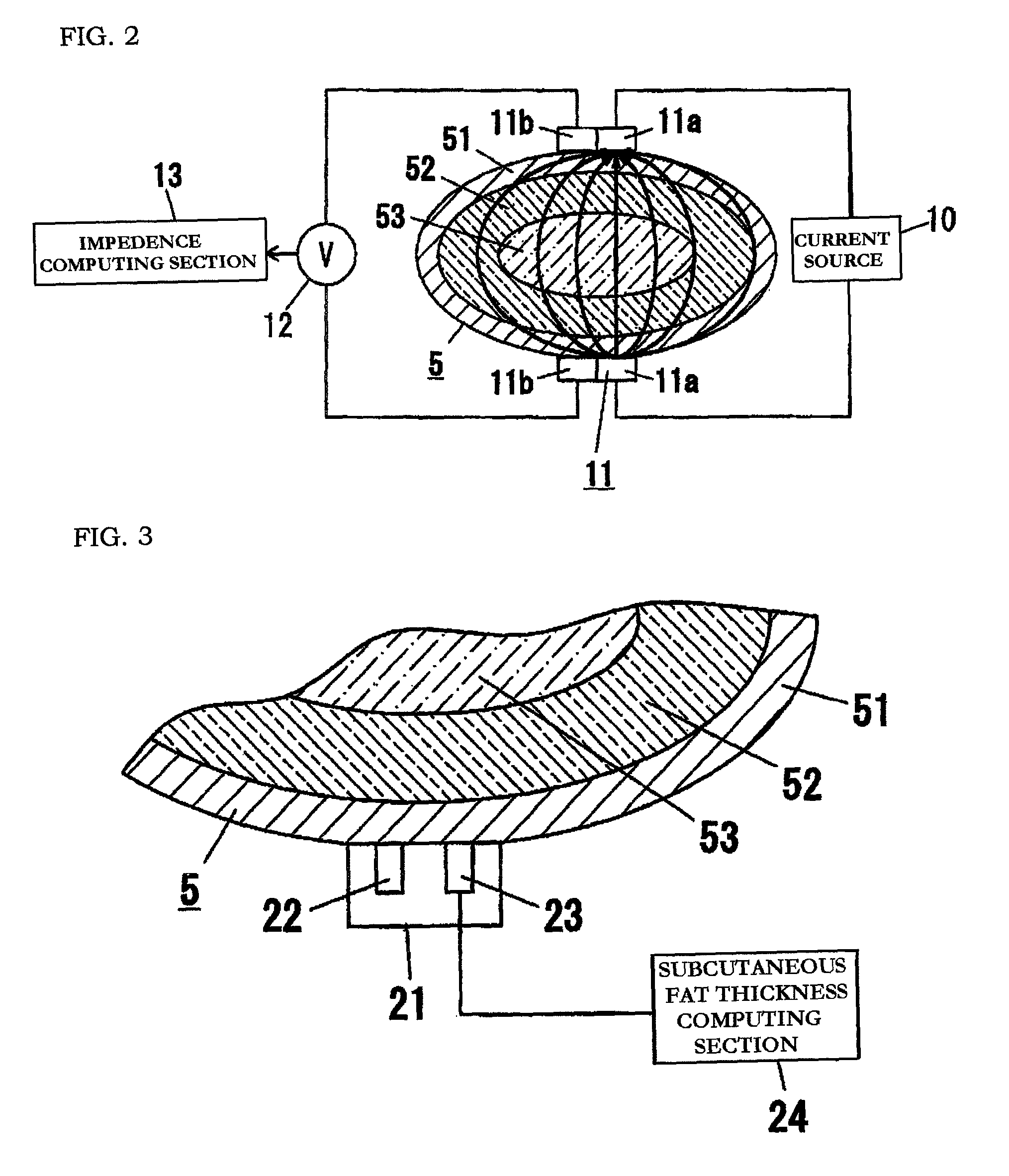

Body fat measuring device

InactiveUS8095211B2High measurement accuracyEasy to getDiagnostics using lightSensorsMeasurement deviceVisceral fat

A body fat measuring device comprises electrodes brought into contact with the waist portion of a subject, an optical sensor composed of a light applying section and a light receiving section, an impedance computing section for computing the impedance between the electrodes, a subcutaneous fat thickness computing section for computing the thickness of the subcutaneous fat of the subject from the value detected by the optical sensor, and a body fat computing section which subtracts the amount of subcutaneous fat determined using the thickness of the subcutaneous fat computed by the subcutaneous thickness computing section from the total fat amount of the subject determined using the impedance computed by the impedance computing section so as to determine the visceral fat amount of the subject. With this, not only the accuracy of measurement of the visceral fat amount is improved but also the visceral fat amount of the subject can be easily computed even without a database.

Owner:MATSUSHITA ELECTRIC WORKS LTD

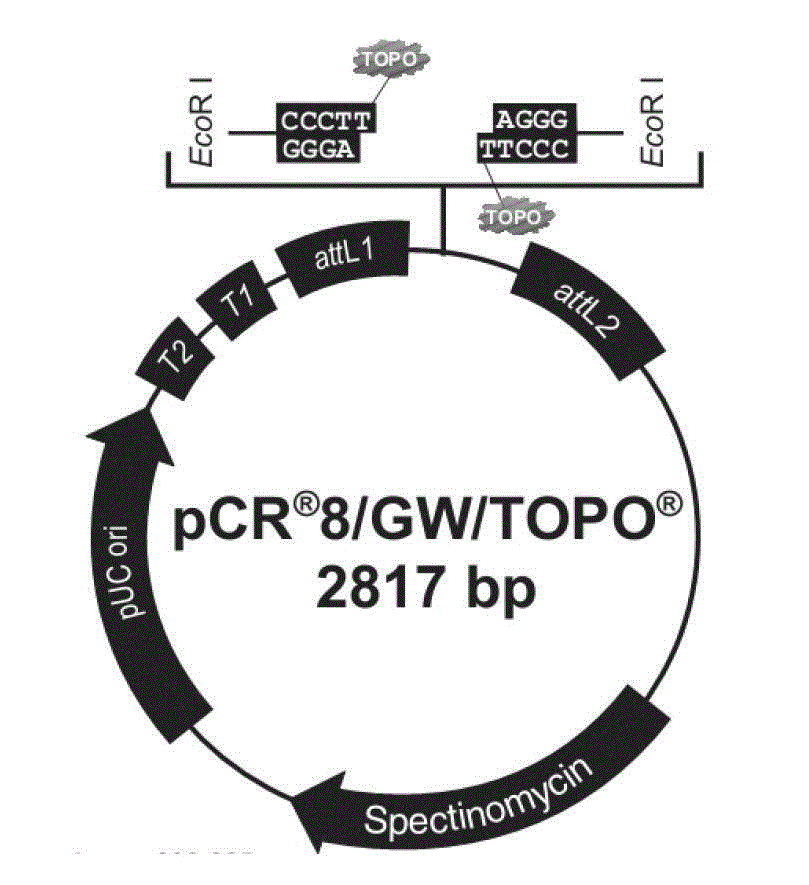

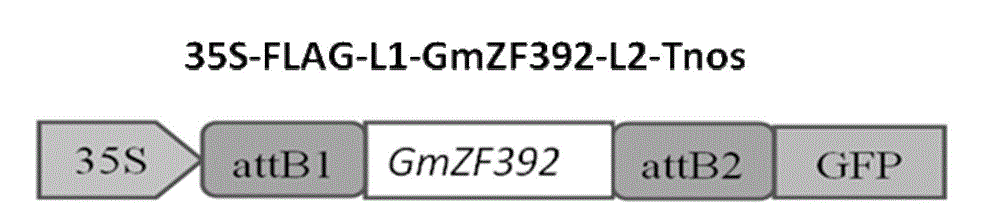

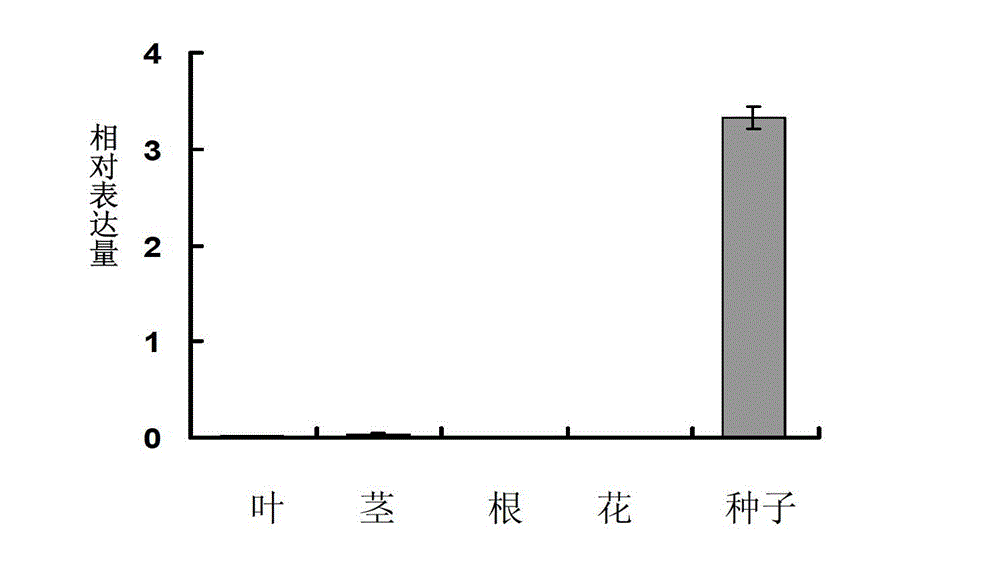

Protein GmZF 392 derived from soybeans and applications of related biomaterials in regulation and control of plant fat

ActiveCN104152485AVector-based foreign material introductionAngiosperms/flowering plantsHigh fatStearic acid

The invention discloses a protein GmZF 392 derived from soybeans and applications of related biomaterials in regulation and control of plant fat. One application is a method for cultivation of transgenic seed plants with a high total fat content and / or a high fatty acid content. The method comprises steps: a GmZF 392 gene is introduced into an acceptor seed plant and a transgenic seed plant with a total fat content being higher than the total fat content of the acceptor seed plant and / or a fatty acid content being higher than the total fatty acid content of the acceptor seed plant is obtained. The fatty acids are at least one of the followings: linolenic acid, linoleic acid, oleic acid, a fatty acid named after gongduosuan, sinapic acid, palmitic acid and stearic acid. The GmZF 392 encoding gene has important theoretical and practical significances to raise and improve crop fat components, especially to raise fat components in seeds of oil plants of soybeans and the like and to cultivate varieties with high fat.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

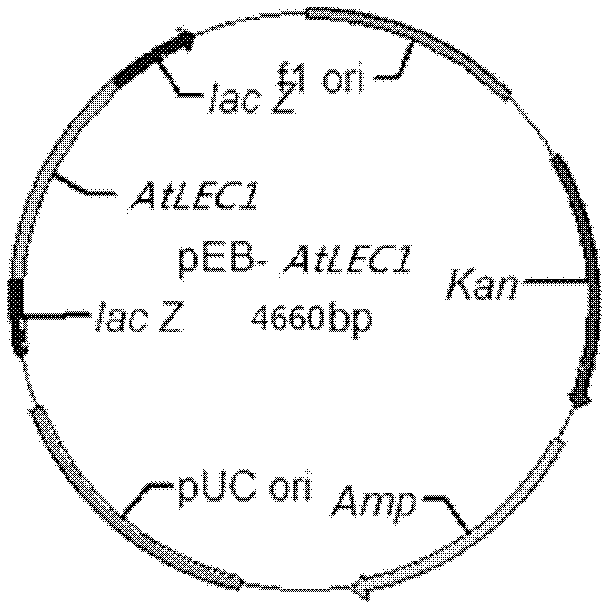

Method for increasing the content of total oil, linoleic acid or α-linolenic acid in chlorella

InactiveCN102277378AMicroorganism based processesVector-based foreign material introductionAgricultural scienceBiodiesel

The invention provides the use of an AtLEC1 gene in improvement on oil and fat content in chlorella. The gene is derived from Arabidopsis thaliana which is a member of CCAAT-Box binding factor HAP3 family. The AtLEC1 gene-transformed chlorella can improve the LA, oleic acid and ALA content and can improve the total oil and fat content of the chlorella strain. The method can be used in production of unsaturated fatty acid and biodiesel by an alga expression system and by using gene engineering technology.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Production method for low-fat yogurt ice cream

The invention provides a production method for a low-fat yogurt ice cream, wherein the method includes the steps: raw materials are mixed and fermented to obtain a material liquid after fermentation; the material liquid after fermentation is demulsified and aged, and a material liquid after aging is obtained; then the material liquid after aging is homogenized, and a material liquid after homogenization is obtained; and the material liquid after homogenization is agitated, wherein the total fat content of the raw materials is lower than 3%, and the homogenization pressure is 10-15 bar. The produced yogurt ice cream is strong in yogurt flavor and delicate in mouthfeel.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Oven-baked french fries having extended hold time

Coated French fried potatoes which maintain crispness for at least about 10 minutes. The French fries have at least a 0.1 mm starch-based surface coating and Texture Value of at least about 170 after an extended holding time. The holding time is a measurement based on (1) 4 minutes holding under a heat lamp, (2) 3 minutes holding under a heat lamp in Foodservice serving bags and (3) at least 3 minutes holding in a closed carry-out bag. The par-fries have specific properties which, upon oven-finishing, deliver a unique texture. The coated oven-finished French fries have about 28% to about 50% bulk moisture and from about 8% to about 25% total fat. The par-fried potato strips used to prepare the oven-finished French fried potatoes are coated with a starch suspension. The coating has a low water solubility starch fraction as one of its ingredients. The low water solubility starch fraction has a water solubility index of less than about 30%. The par-fries can be finished in a conventional oven in less than about 10 minutes. The time required to finish the par-fries in a forced air convection oven is less than about 5 minutes. The coated par-fried potato strips have a bulk moisture of about 30% to about 55%, and a total fat of about 6% to about 25%.

Owner:THE PROCTER & GAMBLE COMPANY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com