Predigested soyfood

A pre-digested food and pre-digestion technology, applied in food preparation, food science, application, etc., can solve problems such as unconfirmed evidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Take 10 kg of dehulled soybeans, add water and soak overnight (about 10-12 hours) at room temperature, and take the soybeans to fully absorb water and swell as the degree;

[0118] Steam the fully water-swelling soybeans in a pressure cooker at 120°C for 25 minutes;

[0119] Drain, cool, keep the temperature at 37°C, add 1% food grade lactic acid to acidify according to wet weight;

[0120] Dilute the prepared Rhizopus oligospora fermented liquid in proportion to 1% of the base mass with sterile water, and evenly mix it into the acidified soybeans;

[0121] Put the inoculated matrix into a fermentation vessel and ferment at 33-35°C for 26-28 hours;

[0122] Dry the fermented soybeans with hot air at 60-70°C, crush them and pass them through a 100-mesh sieve;

[0123] The pulverized fermented soybean powder is vacuum-packed, 50 grams per packet, to obtain 190 bags of the product of the present invention.

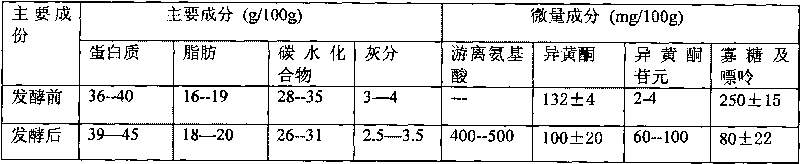

[0124] The prepared product was sent for inspection, and the r...

Embodiment 2

[0126] Take 20 kg of dehulled soybeans, add water and soak overnight (about 10-12 hours) at room temperature, and the degree of swelling is based on the fact that the soybeans fully absorb water;

[0127] Put the fully water-swelling soybeans in a pressure cooker, heat until the pressure reaches 1.5 atmospheres (120°C), and steam for 24-26 minutes;

[0128] Take out soybeans, drain and cool, keep the temperature at 37-38°C, add 1.1% food grade acetic acid according to wet weight to acidify;

[0129] Take 1.5 kg of fermented soybeans, grind them to form a suspension, and mix the prepared suspension evenly into the acidified soybeans;

[0130] After inoculation, the matrix is put into a fermentation container and fermented at 34-36°C for 27-30 hours;

[0131] The fermented soybeans are freeze-dried, crushed and passed through a 100-mesh sieve;

[0132] The pulverized fermented soybean powder is vacuum-packed, 50 grams per packet, to obtain 385 bags of the product of the pres...

Embodiment 3

[0135] Take 15 kilograms of dehulled soybeans, add water and soak overnight (about 10-12 hours) at room temperature, and take the soybeans to fully absorb water and swell as the degree;

[0136] Steam the fully water-swelling soybeans in a pressure cooker at 120°C for 25-27 minutes;

[0137] Take it out, drain it, cool it down, keep the temperature at 37-40°C, and add 1.1% (calculated as acetic acid) by wet weight for edible acetic acidification;

[0138] Take 1 kg of fermented soybeans, grind them to form a suspension, and mix the prepared suspension evenly into the acidified soybeans;

[0139] After inoculation, the matrix is put into a fermentation container and fermented at 36--37°C for 28-30 hours;

[0140] The fermented soybeans are added to cold boiled water in an amount 8 times the weight of the matrix, homogenized and then spray-dried.

[0141] Add sucrose to the fermented soybean powder after drying according to the ratio of 3:2 by weight of the soybean powder, v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com