Patents

Literature

158results about How to "Shorten the ripening time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

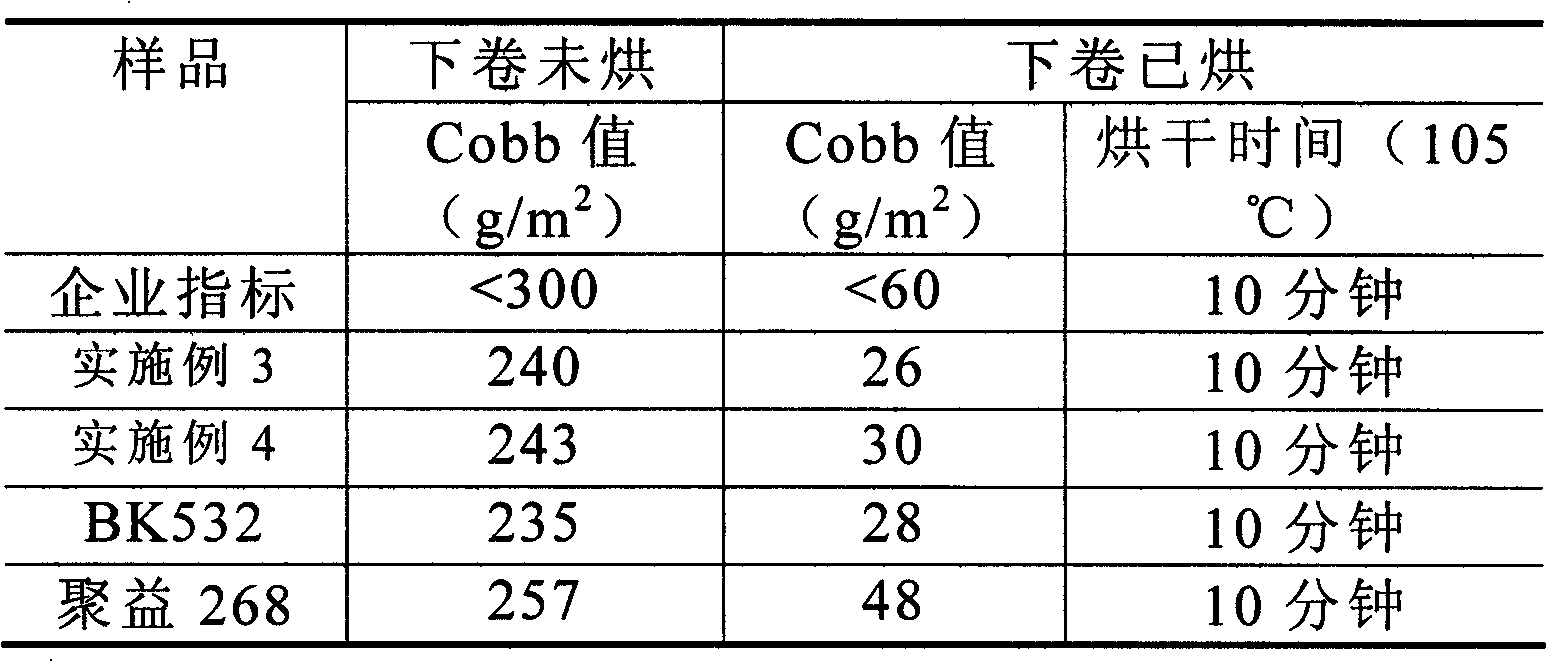

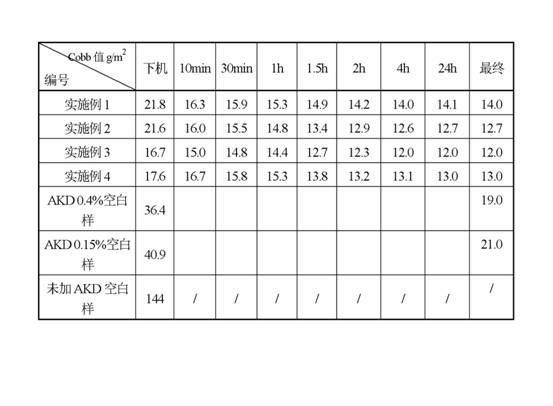

Method for preparing paraffin/AKD composite neutral paper-making glue blending agent

InactiveCN101168940AImprove retentionLittle impact on physical propertiesWater-repelling agents additionComplex typeParaffin wax

The invention relates to a preparation method of paraffin wax / AKD complex type neutral paper-making sizing agent. The step is as follows: firstly, AKD and paraffin wax powder are melted in AKD solution; secondly, compound emulsifying agent after being heated is added in melted AKD solution and mixed with a quick shearing mixing machine; thirdly, a rotating speed of the quick shearing blending machine is improved and preheating water is added to lead the formed AKD solution to performing emulsification nearby a W / O to O / W inversion point; quick mixing is performed and the preheating water is added and the mixing is continuously performed; fourthly, the water solution of flocculating agent PAC is added, and the mixing is continuously performed; fifthly, the mixing is stopped and the cold water is used for quickly performing cooling and cool down, and then the finished product of the paraffin wax / AKD complex-typed neutral paper-making sizing agent emulsion is produced. The complex-typed neutral sizing agent produced by the invention has the advantages that the holding rate is high, the effect on the physical property of the paper is small, and the emulsion is stable.

Owner:TIANJIN UNIV OF SCI & TECH

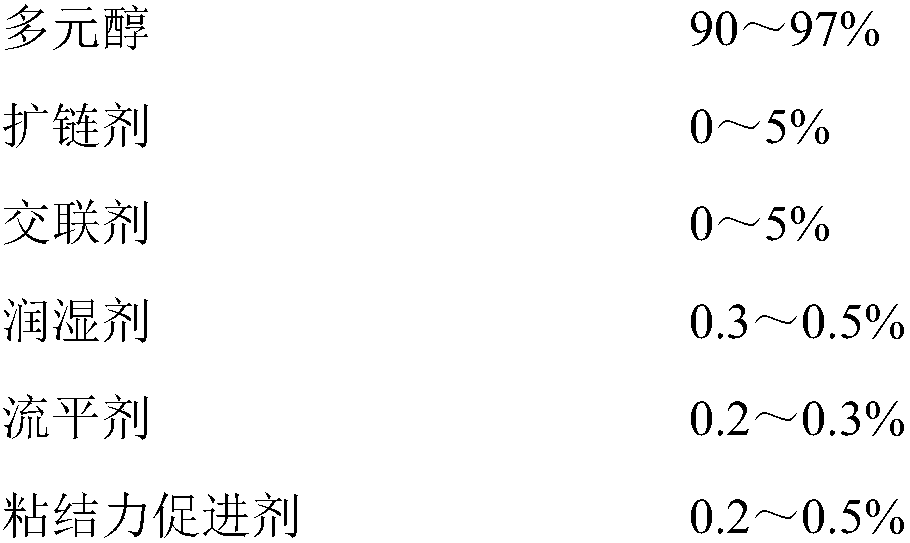

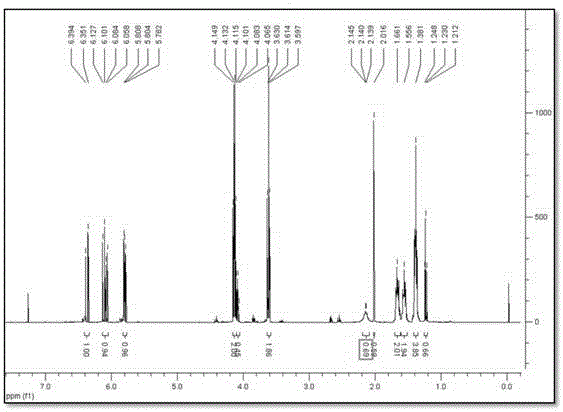

Quick-drying solvent-free polyurethane adhesive and preparation method thereof

InactiveCN108329883AHigh peel strengthImprove heat resistancePolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses a quick-drying solvent-free polyurethane adhesive and a preparation method thereof. The quick-drying solvent-free polyurethane adhesive comprises an isocyanate-terminated prepolymer as a component A and a hydroxy compound as a component B, wherein the isocyanate-terminated prepolymer is generated from polyol and polyisocyanates through a reaction; the hydroxy compound as the component B is prepared from polyol, a chain extender, a crosslinking agent, a wetting agent, a leveling agent and an adhesion promotor. The quick-drying solvent-free polyurethane adhesive has the advantages of low viscosity, high curing speed, high peel strength and capabilities of being cut in two hours and resisting steaming at high temperature of 121 DEG C, and has good application prospectand market potential.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD

Method for preparing liquid smoking spice for meat from pecan shells

ActiveCN101999618ATake advantage ofRich diversityFood preparationBiotechnologyPolycyclic aromatic hydrocarbon

The invention relates to a method for preparing liquid smoking spice for meat from pecan shells. In the method, the byproduct shells of wild pecans in China are used as the materials. The method comprises the following steps: selecting the material, pulverizing, carrying out dry distillation, filtering, fractionating, and aging at variant temperatures to obtain the stable finished product. The liquid smoking spice can be used for meat. The content of smoking characteristic flavoring substance 2,6-dimethoxyphenol is up to 8.0-18.0 (mg / mL), and the content of polycyclic aromatic hydrocarbon 3,4-benzopyrene is controlled within 2.0 mu g / kg, thereby enriching the diversity of smoking spice products and fully utilizing the pecan shells. By combining variant temperature aging with micro-filtering to remove precipitated tar, the aging time is shorted to 4 days, which is shortened by more than half as compared with the current like products, thereby greatly enhancing the production efficiency.

Owner:HEFEI UNIV OF TECH

Preparation method of single-component water-based polyurethane adhesive for use in flexible package compounding

ActiveCN103881640AImprove performanceEasy to useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterEpoxy

The invention discloses a preparation method of a single-component water-based polyurethane adhesive for use in flexible package compounding. The method comprises the following steps: reacting polyisocyanate with polyester polyol and polyether polyol, adding a chain extender, and continually reacting to obtain a polyurethane prepolymer; continually reacting epoxy resin with a modifier of a silane coupling agent to obtain a modified polyurethane prepolymer; cooling the modified prepolymer, neutralizing and salifying, and adding water for high-speed dispersion to obtain the single-component water-based polyurethane adhesive for use in flexible package compounding. The method is simple in preparation process, and the obtained single-component water-based polyurethane adhesive is convenient to use.

Owner:SHANDONG HUACHENG HIGH TECH ADHESIVE

Method for producing bioorganic fertilizer from pig manure

InactiveCN101565331AReduce nutrient lossShorten the ripening timeBio-organic fraction processingClimate change adaptationNitrogenOrganic fertilizer

The invention discloses a method for producing a bioorganic fertilizer from pig manure, which comprises that: fresh pig manure of which the water content is about 65 percent is mixed with sawdust in proper proportion to make the ratio of carbon to nitrogen be between 16 and 25; the mixture is evenly stirred with geotrichum or Bacillus stearothermophilus zymophyte; composting fermentation is carried out; and the heap is turned regularly, when the temperature of the materials is reduced to the ambient temperature, and the materials are baked or dried by air and crushed to become the finished product of the bioorganic fertilizer. The bioorganic fertilizer has the nutrient content of 7 percent and the organic content of over 50 percent.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Fresh-keeping agent for peach and its fresh-keeping method

InactiveCN1788577AReduce breathing intensityReduce respirationFruit and vegetables preservationChloridePre treatment

The present invention relates to fruit preserving technology. The fresh peach preserving agent contains potassium permanganate in 0.5-1.5 weight portions, nanometer silver in 1-3 weight portions and sepiolite powder in 3-9 weight portions. The fresh peach preserving process with the fresh peach preserving agent includes the steps of: the pre-treatment of spraying 0.4-0.6 % concentration calcium chloride solution before picking; pre-cooling treatment of cooling the picked peach to storing temperature; sorting and bagging to pack sorted peach inside preserving bag with the fresh peach preserving agent; and storing in cold warehouse at humidity of 85-90 % and certain storing temperature. The present invention has the active effect of lowering peach breath strength, delaying post-mature and prolonging preservation period. Compared with available preserving agent, the present invention has 10-20 days longer preservation period.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Polyethyleneimine-modified AKD sizing agent and preparation method thereof

InactiveCN101949108AHydrolysis phenomenon solvedAdd lessWater-repelling agents additionEmulsionMaterials science

The invention relates to a preparation method of a polyethyleneimine-modified AKD sizing agent. The method comprises the following steps of: stirring and reacting raw materials at the temperature of between 65 and 90 DEG C for 2 hours; preparing a cationic emulsifier from 0.8 to 1.4 weight parts of CTA cationic starch by synthesis reaction, wherein pH value is adjusted to be 5 with formic acid; heating and melting 1 weight part of AKD raw powder (alkyl ketene dimer) in a melting kettle, and stirring and melting the material at the temperature of between 65 and 85 DEG C; and placing 0.8 to 1.2weight parts of obtained emulsifier and 1 weight part of AKD raw powder into an emulsion synthesis kettle, and adding 0.015 to 0.03 weight part of polyethyleneimine, 0.002 to 0.005 weight part of glutaraldehyde and hot water into the kettle with high-shear stirring for 0.8 to 2 hours. The sizing agent and the preparation method have the advantages that: the curing time is reduced by over 80 percent compared with the conventional curing time, namely the curing time is reduced to be 4 to 8 hours from 72 hours, the application of the AKD glue to coating paper in a low weighing machine is extended, the hydrolysis phenomenon of the AKD glue is solved, and the amount of the glue applied to one ton of paper is reduced by 25 to 30 percent.

Owner:天津市奥东化工有限公司

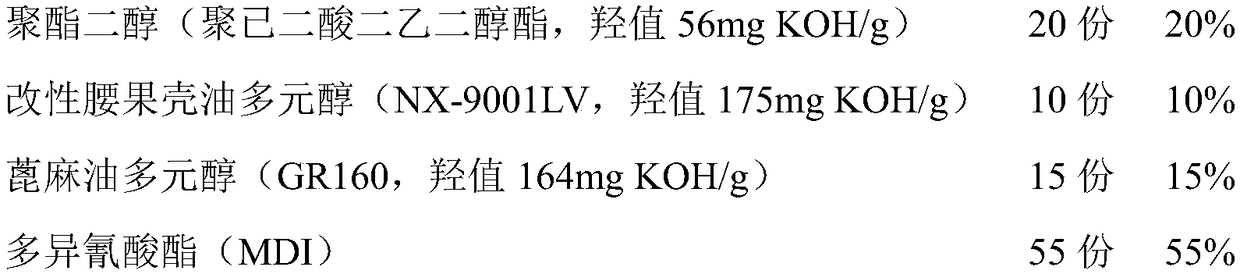

Production method of biobased solvent-free polyurethane synthetic leather

ActiveCN107012692AWith double foam technologyImprove controllabilityTextiles and paperProduction lineSolvent free

A production method of biobased solvent-free polyurethane synthetic leather comprising the steps of adding a hydroxyl containing component A and an isocyanate group containing component B into a reaction kettle, stirring for reaction to form foaming slurry, applying the foaming slurry to release paper in a scraping manner by using a dry synthetic leather production line to form a coating, laminating the coating with base cloth in a clearance laminating manner by using a laminating machine, putting in an oven for curing, and performing cooling and stripping to form the biobased solvent-free polyurethane synthetic leather. The biobased solvent-free polyurethane synthetic leather is produced by using a double foaming technology, an in-situ polyurethane polymerize technology, a heat-sensitive catalyst asynchronous catalysis technology and a single-knife constant temperature thermal scraping application technology; a production technology is environment-friendly, concise and stable; the product quality is good; biomass that is cheap and easy to obtain serves as a raw material; the use of a fossil raw material can be reduced; and environmental protection is facilitated.

Owner:聊城市鑫润达塑胶制品有限公司

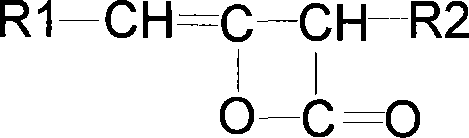

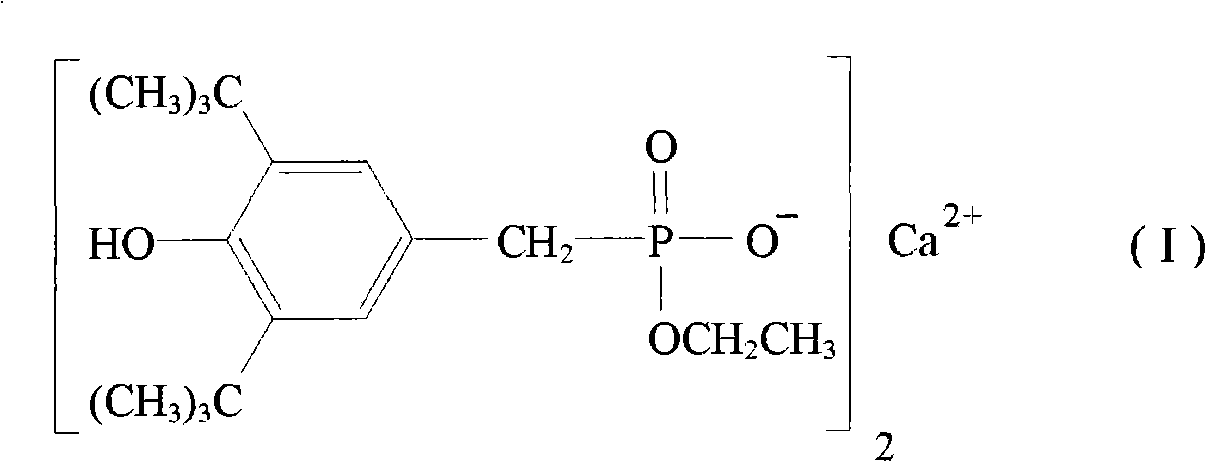

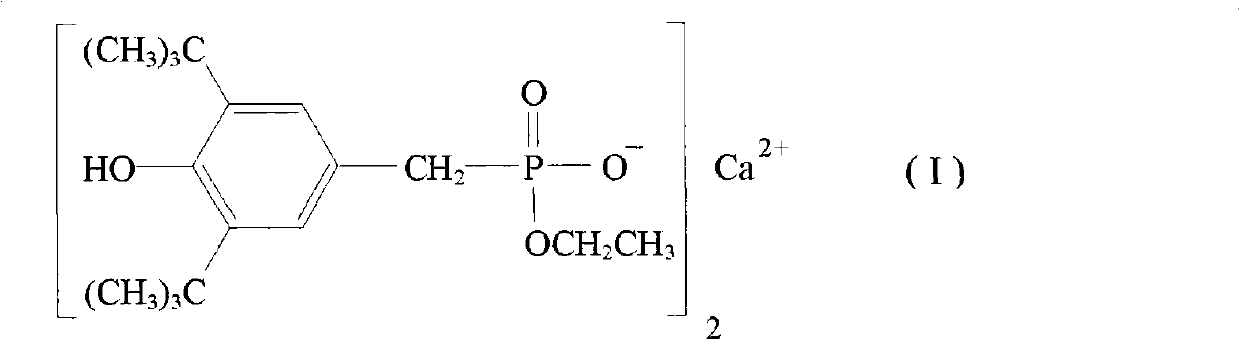

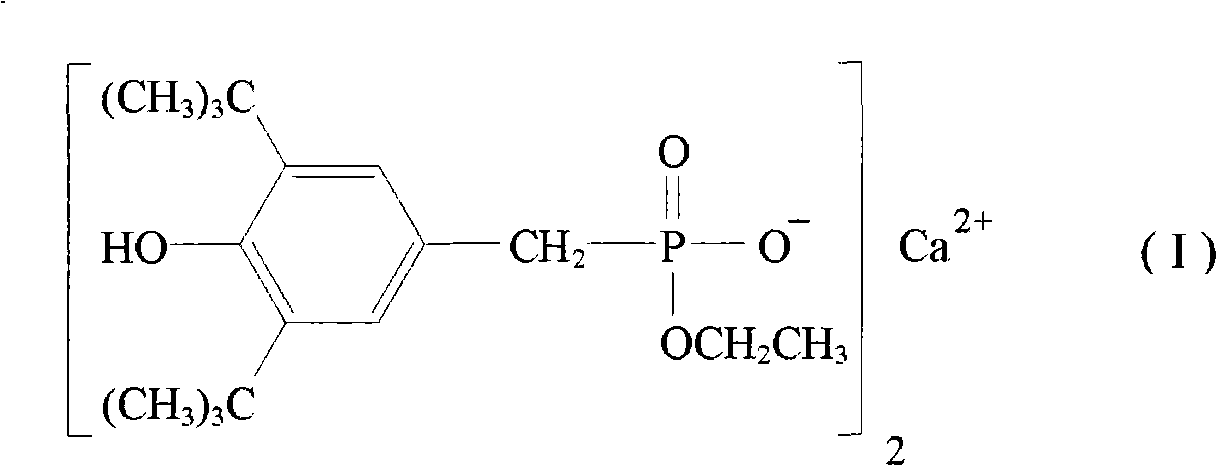

Polyethylene terephthalate (PET) polyester composition not containing antimony and cobalt elements

The invention discloses a polyethylene terephthalate (PET) polyester composition, which has the advantages of high solid polymerization reaction speed and relatively low regeneration amounts of aldehyde and cyclic oligomer during processing. In a polymerization process, a titanium element-containing compound is taken as a condensation polymerization catalyst, and a phosphorus element-containing stabilizing agent and an organic dye are added to avoid a yellow phase of polyester; and a phosphorus and calcium-containing compound shown as a structural formula (I) is added to increase the solid polymerization reaction speed of PET prepolymer and enhance the processing quality of a synthesized PET polyester composition; and when the polyester composition is used for processing and manufacturing a bottle mold, the regeneration amounts of the aldehyde and the cyclic oligomer are relatively low.

Owner:NANYA PLASTICS CORP

Coix seed barley buckwheat coarse cereal noodle and production method thereof

InactiveCN104323129AChange rheological propertiesOvercome the monotonous tasteFood preparationBiotechnologyPolygonum fagopyrum

The invention discloses a coix seed barley buckwheat coarse cereal noodle and a production method thereof. According to the invention, wheat flour, coix seed flour, barley flour, buckwheat flour, wheat gluten, eggs and other raw materials are selected to prepare the coarse cereal noodle with the nutrition and health care efficacy of coix seed, barley and buckwheat, good taste, and reasonable nutrition collocation. The noodle product has slight red color, is smooth and delicate, has good molding properties, is chewy and elastic, and has a breaking rate of less than 5%, a hint of coarse cereal flavor, and good palatability. The noodle provided by the invention has the advantages that: 1. the coix seed, barley, buckwheat and other coarse cereals are selected to overcome the disadvantages of single taste and low nutritional value in traditional noodles, and the product has the characteristics of reasonable diet, and good nutrition and health care functions; 2. the wheat gluten is added to the product raw materials to change the noodle rheological properties, improve the water absorption of stock, shorten the curing time and reduce the breaking rate, so that the noodle can be delicate, chewy, rich in nutrition, and has the health care functions.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Feed for promoting maturation of parent sea cucumber of stichopus japonicus

ActiveCN101912062AMeet growth needsShorten the ripening timeClimate change adaptationAnimal feeding stuffYolkRaw material

The invention discloses a feed for promoting maturation of parent sea cucumber of stichopus japonicus, comprising the following raw materials in weight percentage: 60%-70% of see mud, 17%-23% of fresh algae extract, 3%-5% of yolk powder, 1.5%-2.5% of fish meal, 0.4%-0.8% of yeast, 0.15%-0.25% of shell powder, 0.25%-0.4% of sodium alga acid, 0.25%-0.4% of immune polysaccharide of Chinese herbal medicine and 0.1%-0.2% of complex vitamin. The feed has comprehensive nutrition and can meet the personal growth requirement of the stichopus japonicus through the mutual fit of the raw materials. Compared with stichopus japonicus fed with the traditional feed, the feed can shorten the maturation-promoting time of the parent sea cucumber, increase the personal brood amount, improve the quality of ova and raise the survival rate of stichopus japonicus seedlings.

Owner:DALIAN HAIBAO FISHERY

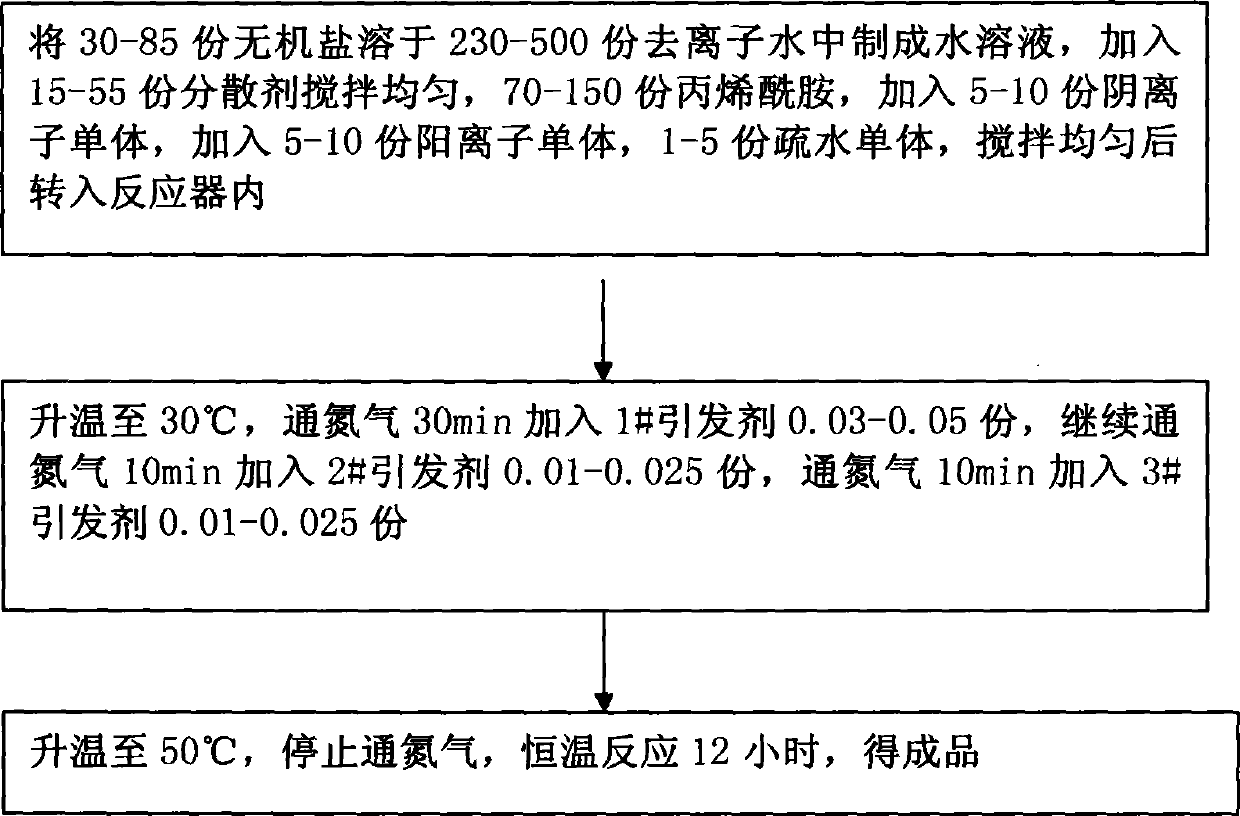

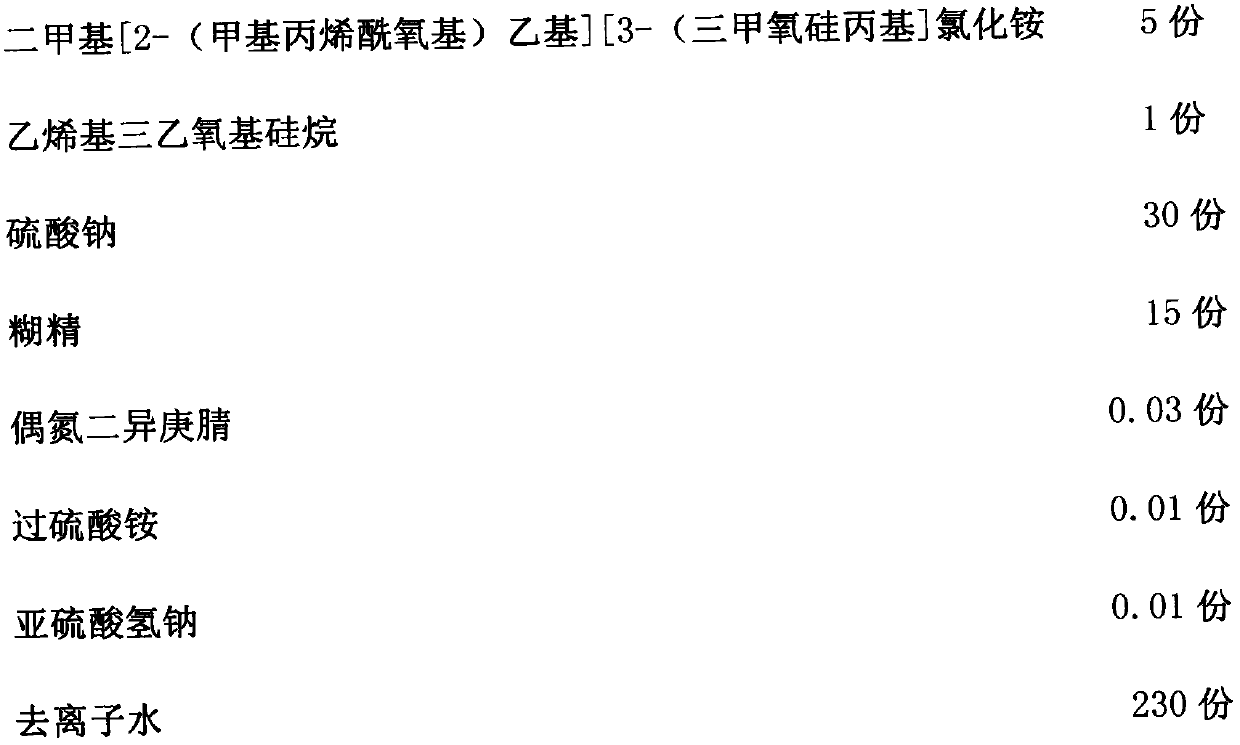

Water dispersible profile control agent for oil extraction and preparation method thereof

InactiveCN104194753AIncrease flow resistanceShorten the ripening timeDrilling compositionWater dispersiblePolyacrylamide

The invention discloses a water dispersible profile control agent for oil extraction and a preparation method thereof. The water dispersible profile control agent comprises the following components in parts by weight: 70-150 parts of acrylamide, 5-10 parts of anionic monomer, 5-10 parts of cationic monomer, 1-5 parts of hydrophobic monomer, 15-55 parts of dispersant, 30-85 parts of inorganic salt and 230-500 parts of deionized water. By virtue of water in water dispersion polymerization, the product is instant, so that the liquid preparation time and the curing time of a conventional polyacrylamide solution are shortened. A cationic chain link is introduced based on a conventional gel, so that gel molecules and rocks with negative electricity firmly adsorb so as to increase the flow resistance of water and improve the scouring resistance of the gel. The water dispersible profile control agent is low in initial viscosity, good in pumping property, simple in construction process and small in environmental damage. The water dispersible profile control agent is good in biological stability, and the profile control period of validity is over half a year. The product is obtained by virtue of water in water dispersion polymerization and is instant in the using process.

Owner:大庆高新区华龙祥化工有限公司

Preparation method for paper nanometer level surface sizing agents capable of realizing fast curing

ActiveCN102351973AOvercome the disadvantage of strong water absorptionIncrease the effective contact areaWater-repelling agents additionFiberPolyamide

The invention relates to a paper surface sizing agent, in particular to a preparation method for paper nanometer level surface sizing agents capable of improving the paper water resistance, surface intensity and annular pressure intensity and realizing the fast curing, which belongs to the technical field of chemical engineering and solves the technical problems of poor product quality and the like in the prior art. The surface sizing agent is prepared by the method of firstly preparing cation type polymer emulsifying agents and then preparing nanometer styrene-acrylates microemulsion. The method has the advantages that the defect of strong self water absorption performance of small molecular emulsifying agents is overcome, and in addition, the effective contact area between the surface sizing agent and the paper surface fiber is greatly improved, so the curing speed after the paper surface sizing and the sizing effect can be respectively and obviously accelerated and improved. The characteristic that paper making wet reinforcing agents of polyamide propylene oxide chloride resin can be fast combined with the fiber, and the cation type polymer emulsifying agents are adopted for taking reaction with epoxy chloropropane to obtain cation charges, so the fast combination of products with the paper surface fiber in the sizing process is promoted, and the curing speed is accelerated.

Owner:ZHEJIANG KESIKE CHEM NEW MATERIAL CO LTD

Flavor haw cake and manufacturing method thereof

The present invention discloses a novel flavor haw jelly and a manufacturing method. The gradients and formulation (calculated with weights) are that: haw 40 to 50 kg, xylose 10 to 20 kg, white granulated sugar 15 to 20 kg and other ingredients (Osmanthus 5 to 8 kg, dried orange peel 5 to 10 kg, black tea leaves 3 to 6 kg and mint 2 to 5 kg). The present invention replaces traditional water bath stewing with micro wave curing, which can prevent the loss of nutrient substances such as the flavone and so on and prevent the damage of the pigment and shorten the curing time greatly; the adoptions of an auto casting and shaping machine and a vacuum dry drier ensure the quality of the product and improve the production efficiency and ensure traditional craft studios production to be transformed into the high-tech large scale mechanized production. The present invention needless of any gum or alum, therefore, is a natural and low sugar food which is nutrient and health. The product is not only taken as a special snack food but also taken as a pie core.

Owner:山西汉波食品股份有限公司

Preparation method of meat-flavor essence

The invention relates to a preparation method of a meat-flavor essence. The method comprises the following steps: in a reactive kettle, successively adding a sulfocompound, an amino acid mixture, reducing sugar, hydrolyzed plant protein, enzyme-dispersed animal protein and yeast extract for maillard reaction to obtain a reaction essence base; with salad oil as the solvent, successively adding zanthoxylum oil, anise oil, cinnamon oil, geranium oil and ginger oil to obtain spicy essence base; with trimethylene glycol as the solvent, successively adding 4-methyl-4-sulfydryl-2-pentanone, 4-methyl-5-ethoxyl thiazole, 2-acetylpyrazine, ethyl maltol and vanillin to obtain a meat-flavor essence base; taking the reaction essence base, the spicy essence base and the meat-flavor essence, and adding table salt, monosodium glutamate, white granulated sugar and a thickening agent, uniformly mixing, and using a homogenizer and a colloid mill to prepare a pasty essence; and stirring the prepared pasty essence under the constant temperature of 50-100 DEG C for 10-60min to obtain the finished product. The essence is more plump in flavor and more natural, and has more cooking sensation.

Owner:TIANJIN CHUNFA BIO TECH GRP

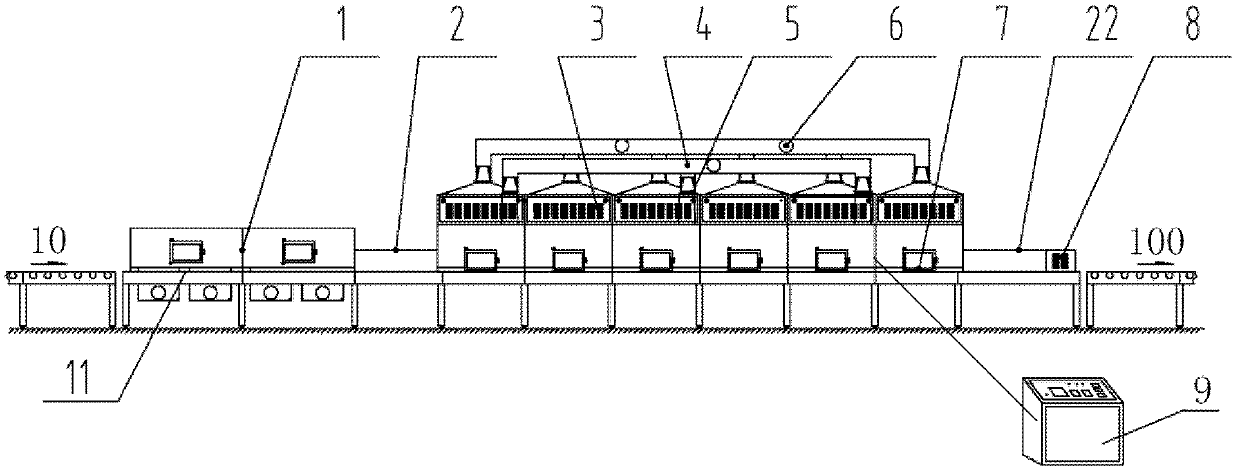

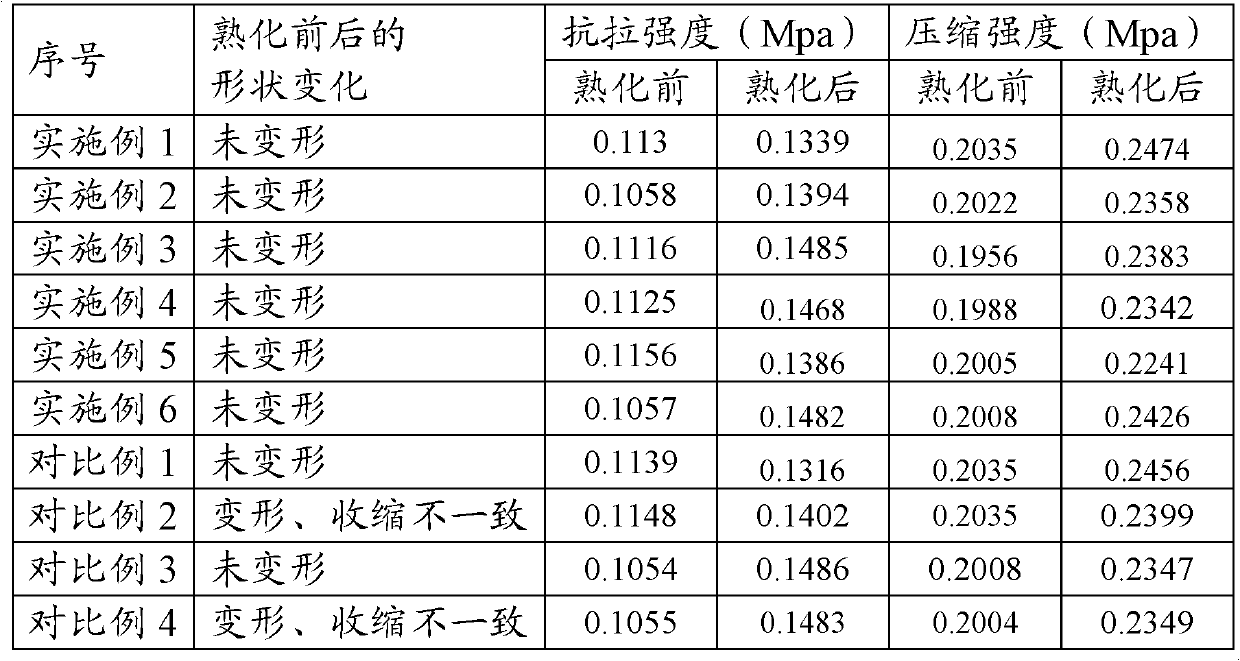

Method and equipment for curing phenolic aldehyde foam material

The invention discloses a method and equipment for curing a phenolic aldehyde foam material. The method for curing the phenolic aldehyde foam material comprises the steps of radiating the phenolic aldehyde foam material to be cured by using microwaves and cooling the phenolic aldehyde foam material. The equipment for curing the phenolic aldehyde foam material has the advantages that moisture, residual foaming agents and formaldehyde inside the phenolic aldehyde foam material are evaporated rapidly, and a chemical reaction inside the phenolic aldehyde foam material is greatly accelerated, so that the curing time is shortened. The microwaves are penetrable, so that the surface and inside of the phenolic aldehyde foam material are subjected to microwave radiation at the same time; and polar molecules absorb the energy of electromagnetic waves and generate uniform heat, so that the product quality is guaranteed, and the phenomenon that the phenolic aldehyde foam material shrinks discordantly, cracks or deforms is avoided.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

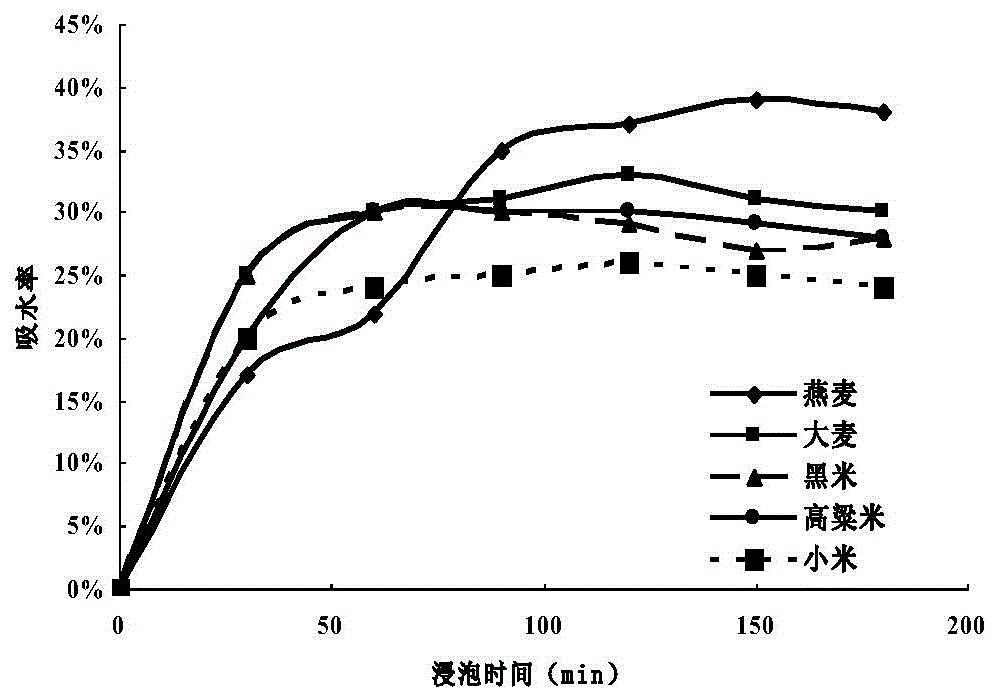

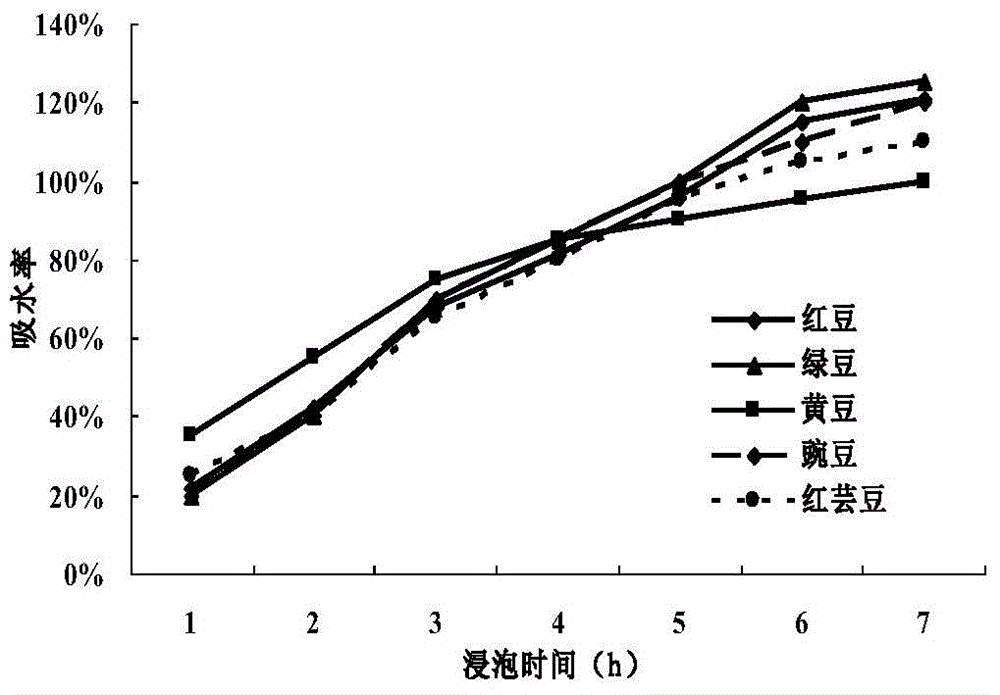

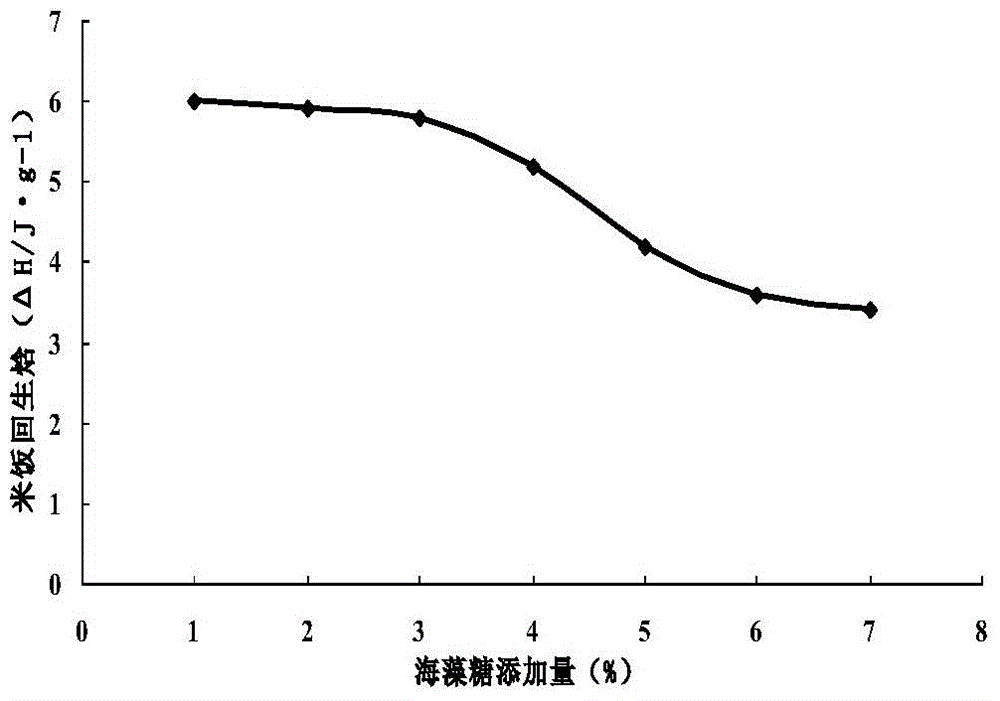

Preparation method and application of fast cooked anti-aging instant food grain rice

ActiveCN104431803AShorten the ripening timeStop agingFood thermal treatmentFood ultrasonic treatmentPre treatmentRice dishes

The invention discloses a preparation method and application of fast cooked anti-aging instant grain rice, and belongs to the technical field of food processing. The method provided by the invention comprises the following steps: soaking, steaming food grains and carrying out microwave drying treatment on the food grains by taking pretreated polished round-grained rice as a raw material and food grains as an auxiliary material, carrying out auxiliary soaking treatment by utilizing ultrasonic waves, steaming after treatment, dispersing by utilizing a dispersing liquid after steaming, filling quantitatively after dispersing, and finally carrying out steaming sterilization so as to obtain a finished product. The method provided by the invention can be used for solving the problems of dry and hardened rice and the like due to food grain starch aging and preventing the problem of decreasing of the quality of food grains in the sales and storage processes, and the fast cooked anti-aging instant grain rice is prepared and is suitable for industrial popularization and application.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

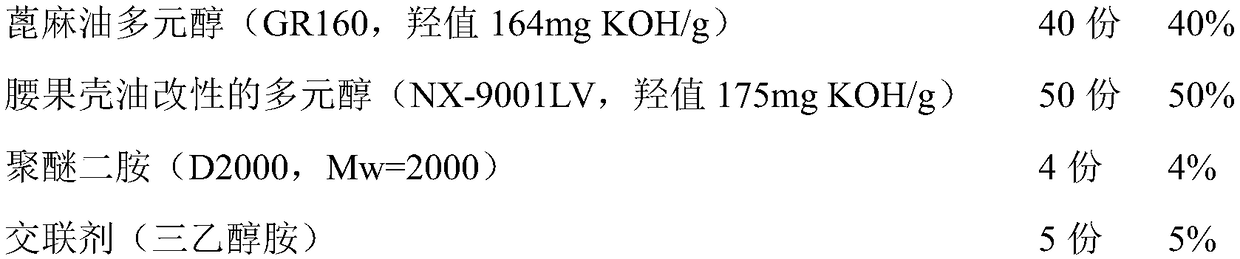

Production method of waterproof organosilicon modified solvent-free polyurethane synthetic leather

InactiveCN107268290AImprove controllabilityImprove waterproof performanceWaterborne vesselsTextiles and paperPolymer scienceIn situ polymerization

The invention discloses a production method of waterproof organosilicon modified solvent-free polyurethane synthetic leather. The production method comprises the following steps: firstly, adding a component A containing hydroxyl and a component B containing an isocyanate group into a reaction still, and reacting by stirring to obtain foaming slurry; secondly, adopting a dry process production line of the synthetic leather, blade coating the foaming slurry on release paper to form a coating, and then laminating the coating with a base fabric by a gap fitting mode through a laminating machine; thirdly, feeding a mixture into a drying oven for cooking to obtain the waterproof organosilicon modified solvent-free polyurethane synthetic leather. According to the production method disclosed by the invention, the waterproof organosilicon modified solvent-free polyurethane synthetic leather is produced by adopting a double foaming technology, a polyurethane in-situ polymerization waterproof technology, a heat-sensitive catalyst asynchronous catalysis technology and a single-pole constant temperature heating scrape coating technology; the production technology is environmentally friendly, simple, and stable; the quality of a product is good; a contact angle of water droplets on the surface of the synthetic leather is as high as 107 degrees, and static water seepage prevention can be kept for 15 days; the waterproof organosilicon modified solvent-free polyurethane synthetic leather can be used as a high-end functional yacht seat covering material.

Owner:SHAANXI UNIV OF SCI & TECH

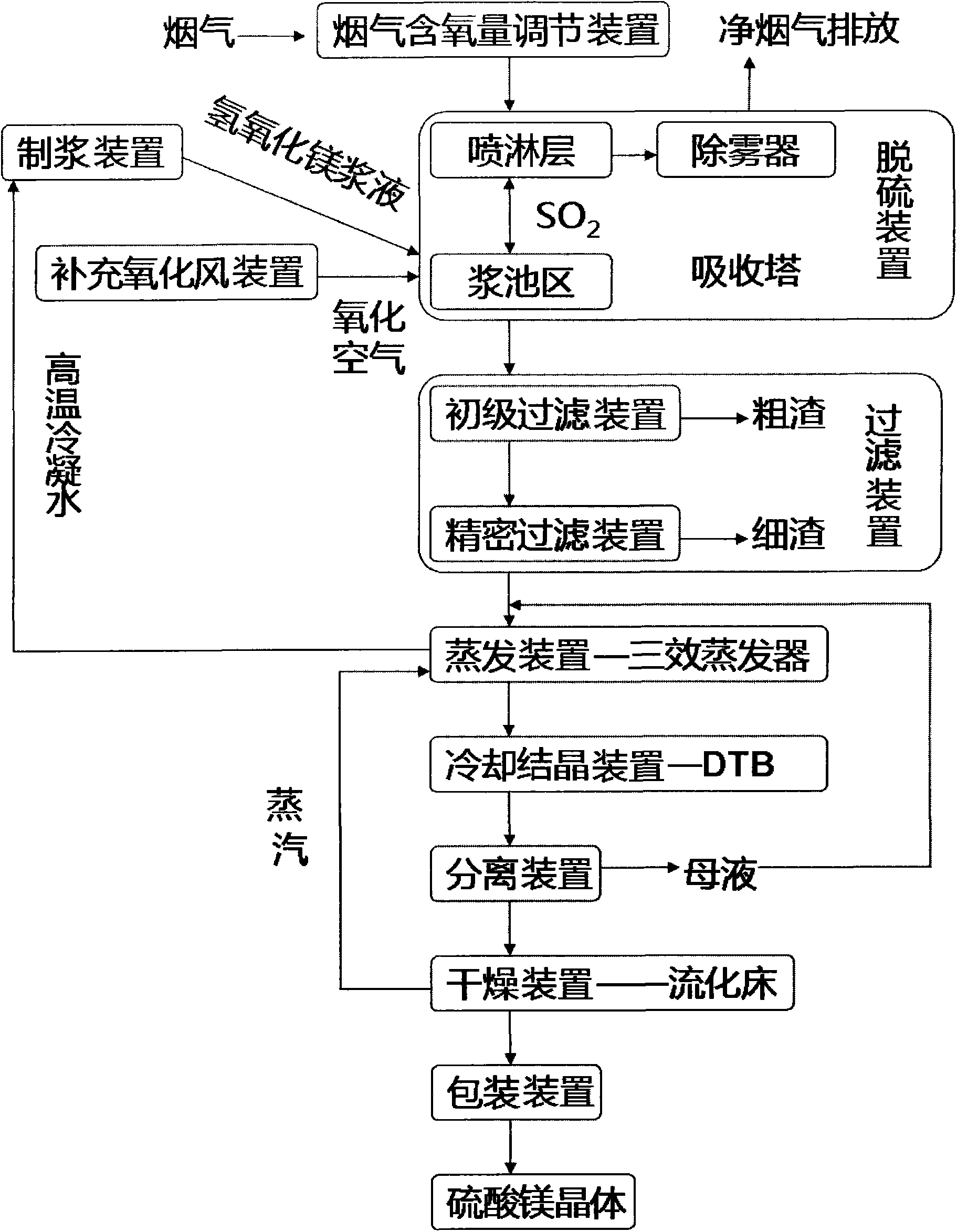

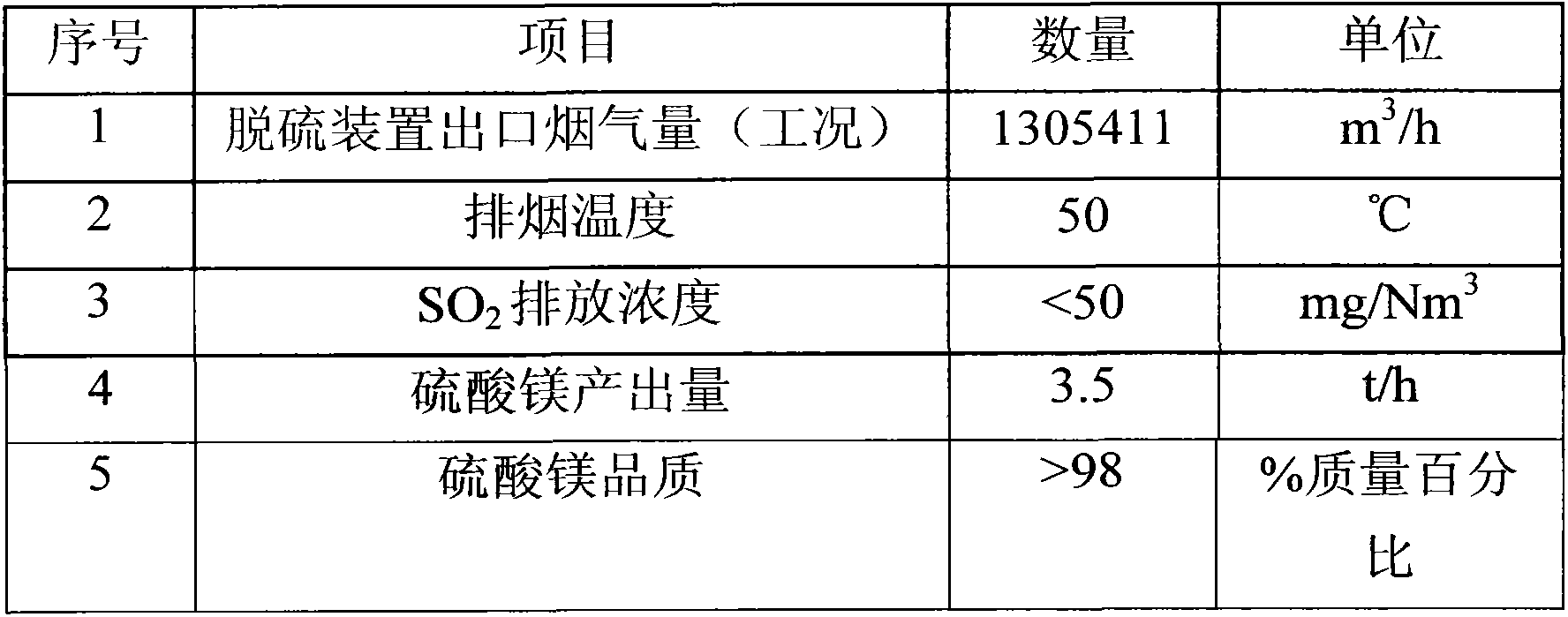

Magnesium sulfate preparation system

ActiveCN103588230AImprove conversion efficiencyImprove qualityMagnesium sulfatesFlue gasOxygen content

The invention discloses a magnesium sulfate preparation system. The system comprises a pulping device, a flue gas oxygen content adjusting device, a desulphurization device, a supplementary oxidation device, a filtering device, an evaporating device, a cooling crystallization device and a separator. The flue gas oxygen content adjusting device is used for controlling the oxygen content of a flue gas before desulphurization in a range of 15-25vt%; and the evaporating device and the cooling crystallization device are arranged in a separate manner. The method can simultaneously realize the efficient desulphurization of the magnesium oxide flue gas and the preparation of the high-quality magnesium sulfate product, and avoids the secondary pollution problem caused by landfill treatment of gypsum which is a common wet calcium method desulphurization byproduct.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Meat flavor

The invention relates to a meat flavor which is prepared by the following method from the following raw materials in parts by weight: 20-60 parts of reaction base, 0.1-5 parts of spicy base, 0.1-5 parts of meat-flavor base, and other auxiliary materials, and the raw materials are mixed uniformly and processed by a homogenizer and a colloid mill to obtain a pasty flavor; and then the obtained pasty flavor is stirred at a constant temperature of 50-100 DEG C for 10-60 minutes to obtain the ultimate meat flavor finished product. The flavor retains the pure meat flavor original in the flavor, so that the flavor is more full and closer to nature, and gives more cooking sensation.

Owner:TIANJIN CHUNFA BIO TECH GRP

Bladeless stirrer

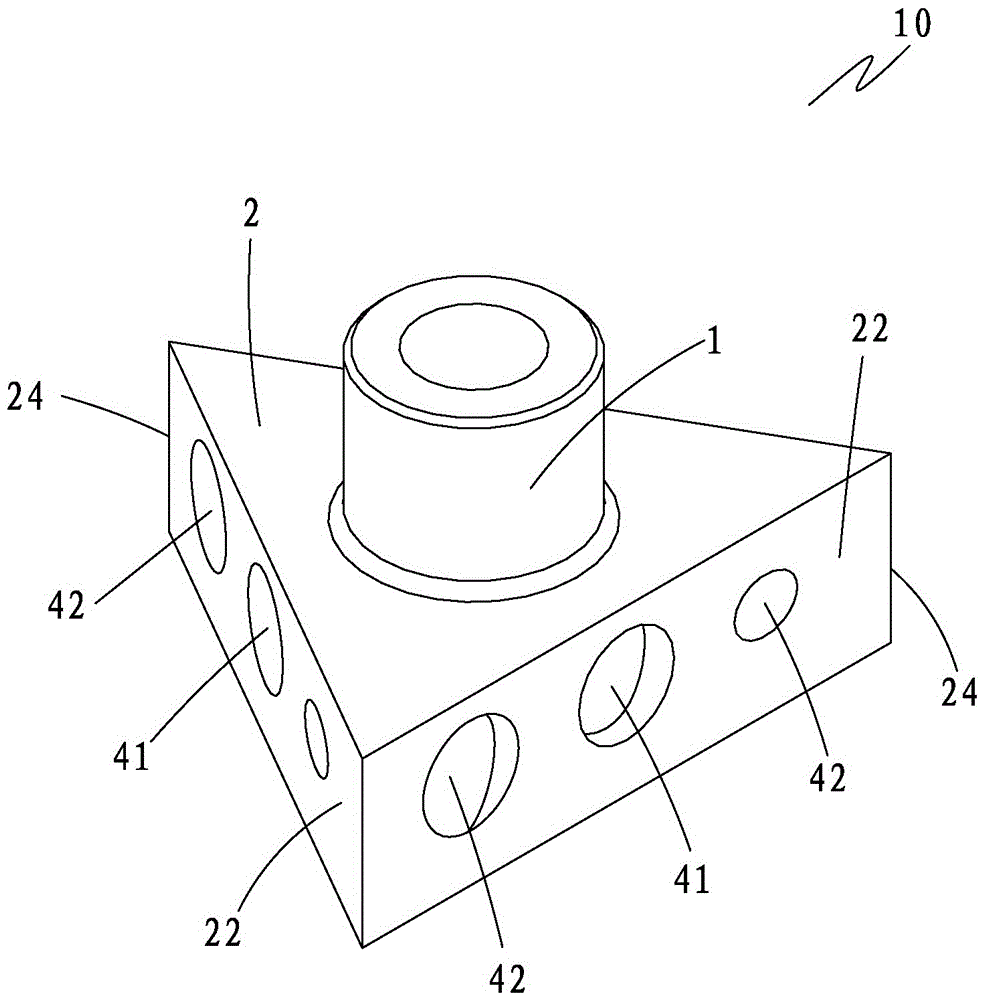

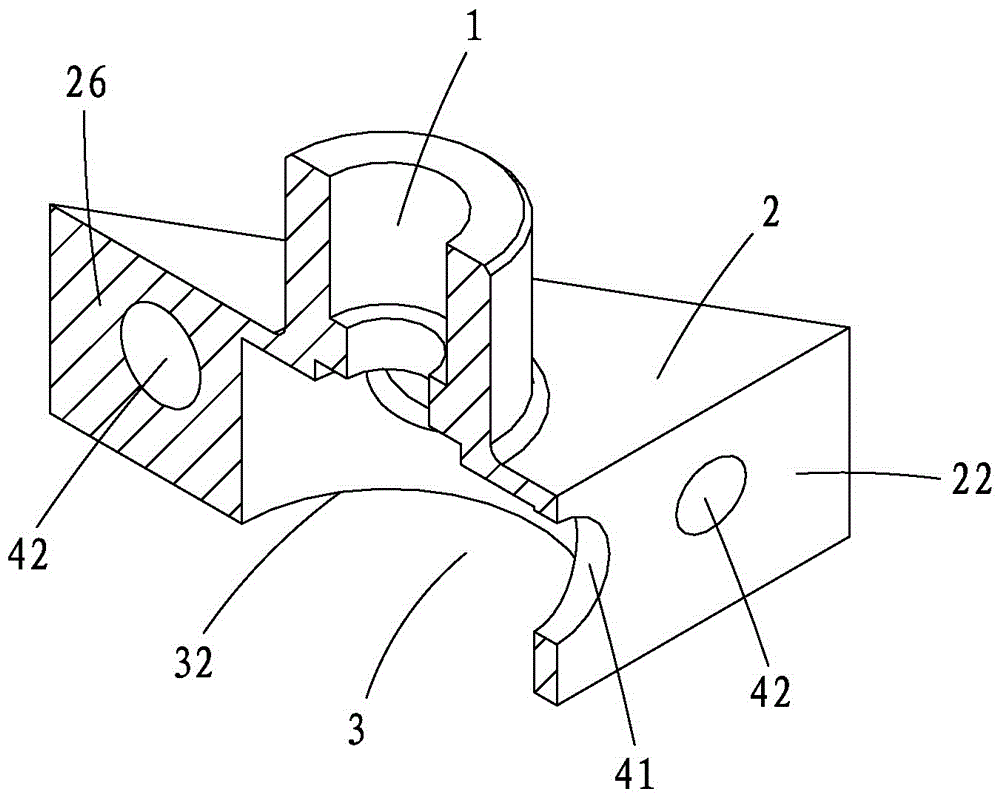

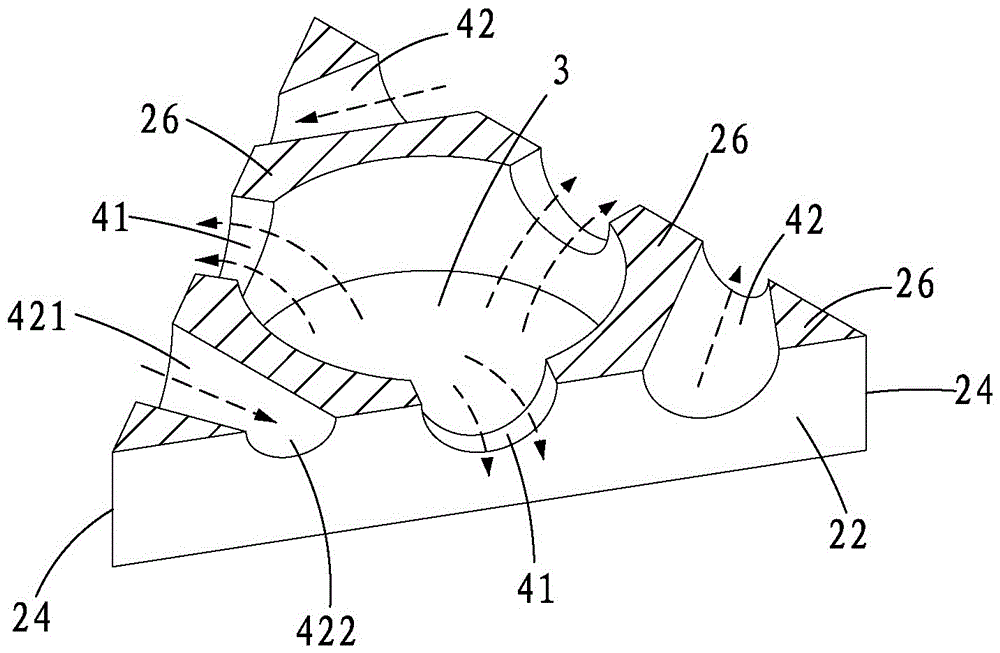

ActiveCN106731950AShorten the ripening timeEffective liftingRotary stirring mixersTransportation and packagingCircular discWater flow

The invention provides a bladeless stirrer which comprises a shaft sleeve and a disc body, wherein the disc body is connected with a stirring shaft of the stirrer through a shaft sleeve; the disc body is free of stirring blades; the outer side surface of the disc body consists of a plurality of planes which are connected in sequence; a stirring ridge is formed at connecting parts of every two planes; a cavity and water flow through holes are further formed in the disc body; the water flow through holes consist of middle ejection holes and lateral flow through holes; the middle ejection holes are communicated with the cavity; the lateral flow through holes penetrate through the side wall of the disc body. The bladeless stirrer is not provided with blades and is not of a smooth disc structure, either, but a compromise proposal is adopted, that is, stirring ridges are formed on the disc body, so that on one hand, problems caused by stirring blades can be solved, and on the other hand, a stirring effect can be enhanced through the stirring ridges. Due to the water flow through holes in the disc body, centrifugal ejection flow and annular ejection flow can be integrated in the stirring process, and the stirring efficiency can be greatly improved.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

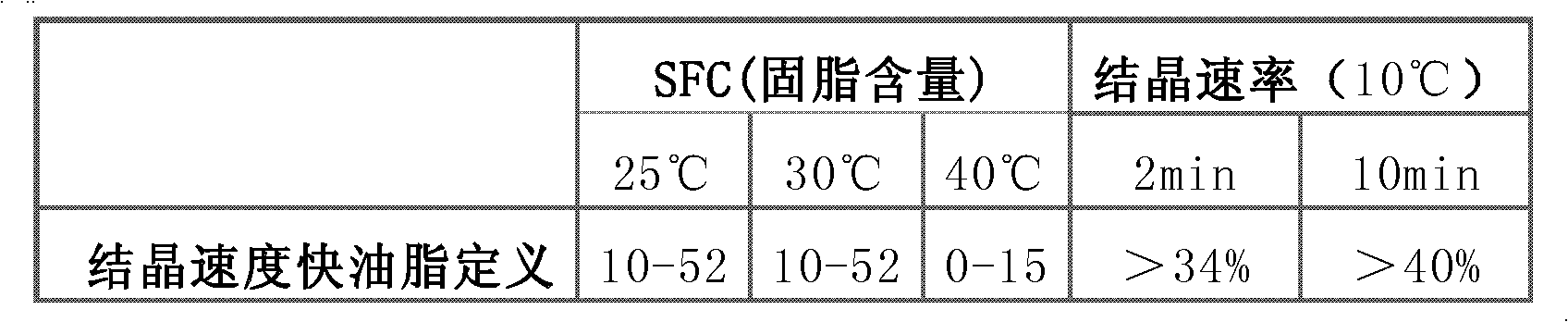

Grease composition, composite grease composition, product and preparation method thereof

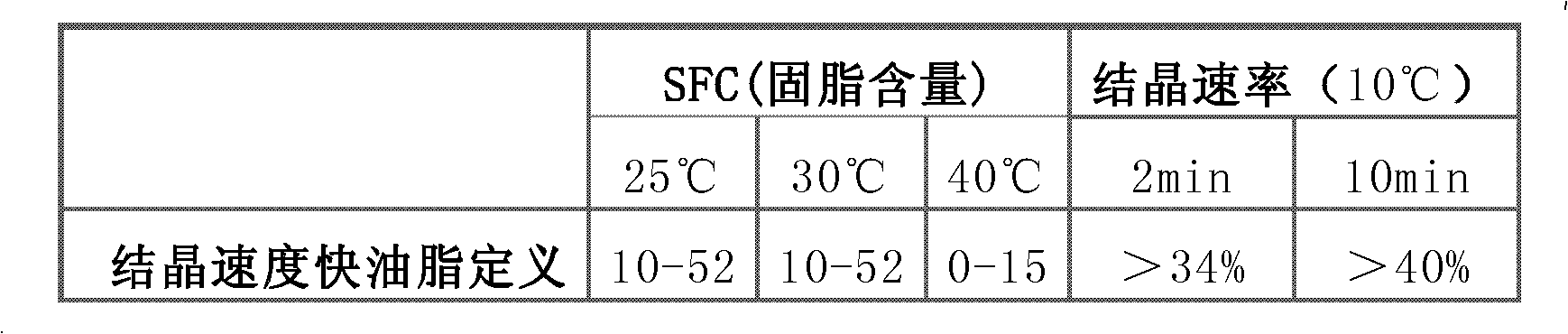

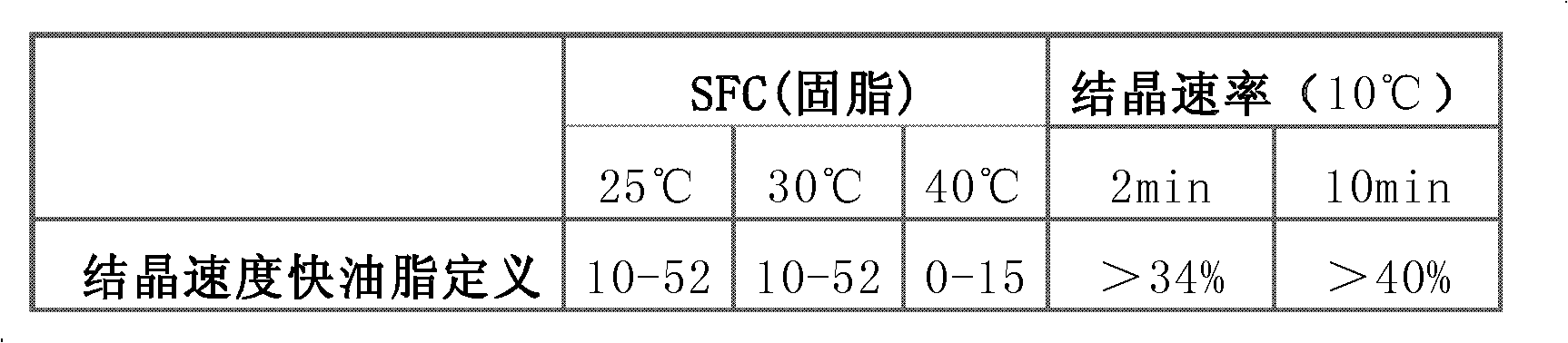

InactiveCN103181417AShorten the ripening timeDoes not affect other performanceEdible oils/fats production/working-upNutritive valuesTrans esterification

The invention provides a grease composition, which comprises a triglyceride composition obtained by an ester exchange treatment. In terms of the weight of the total fatty acids constituting the grease composition, the content of saturated fatty acid is 30%-100%; in terms of the weight of the total fatty acids constituting the grease composition, the content of fatty acid with a carbon atom number of less than 11 is 0-60%; and in terms of the weight of the total fatty acids constituting the grease composition, the content of fatty acid with a carbon atom number of greater than 19 is 0-60%. The invention also provides grease prepared from the grease composition and a preparation method thereof. The grease composition provided in the invention has a low content of trans-fatty acids, a solid fat content in line with the requirement, a fast crystallization speed, and higher nutritive value, and can be used for making a grease composition of plastic grease.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

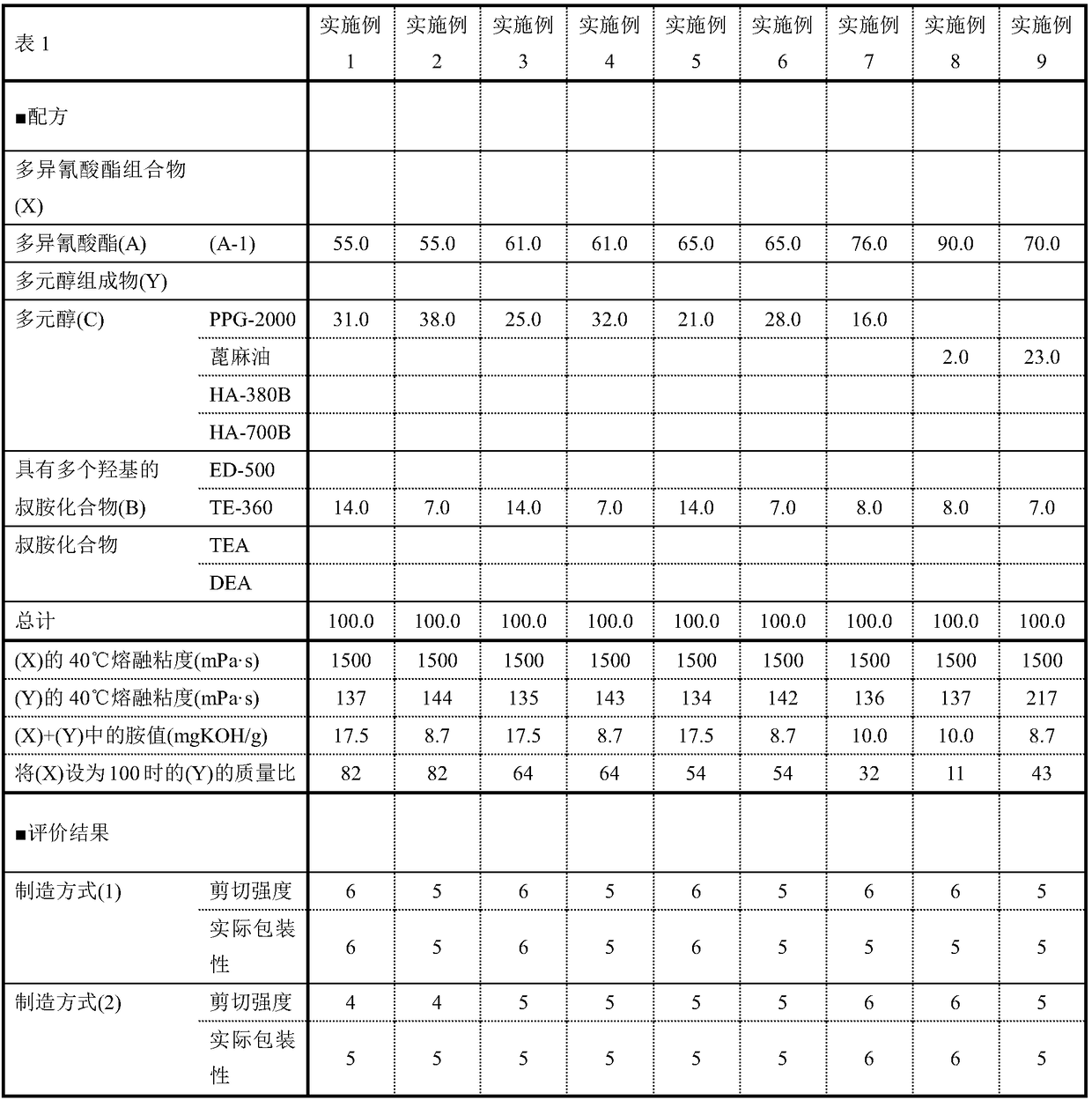

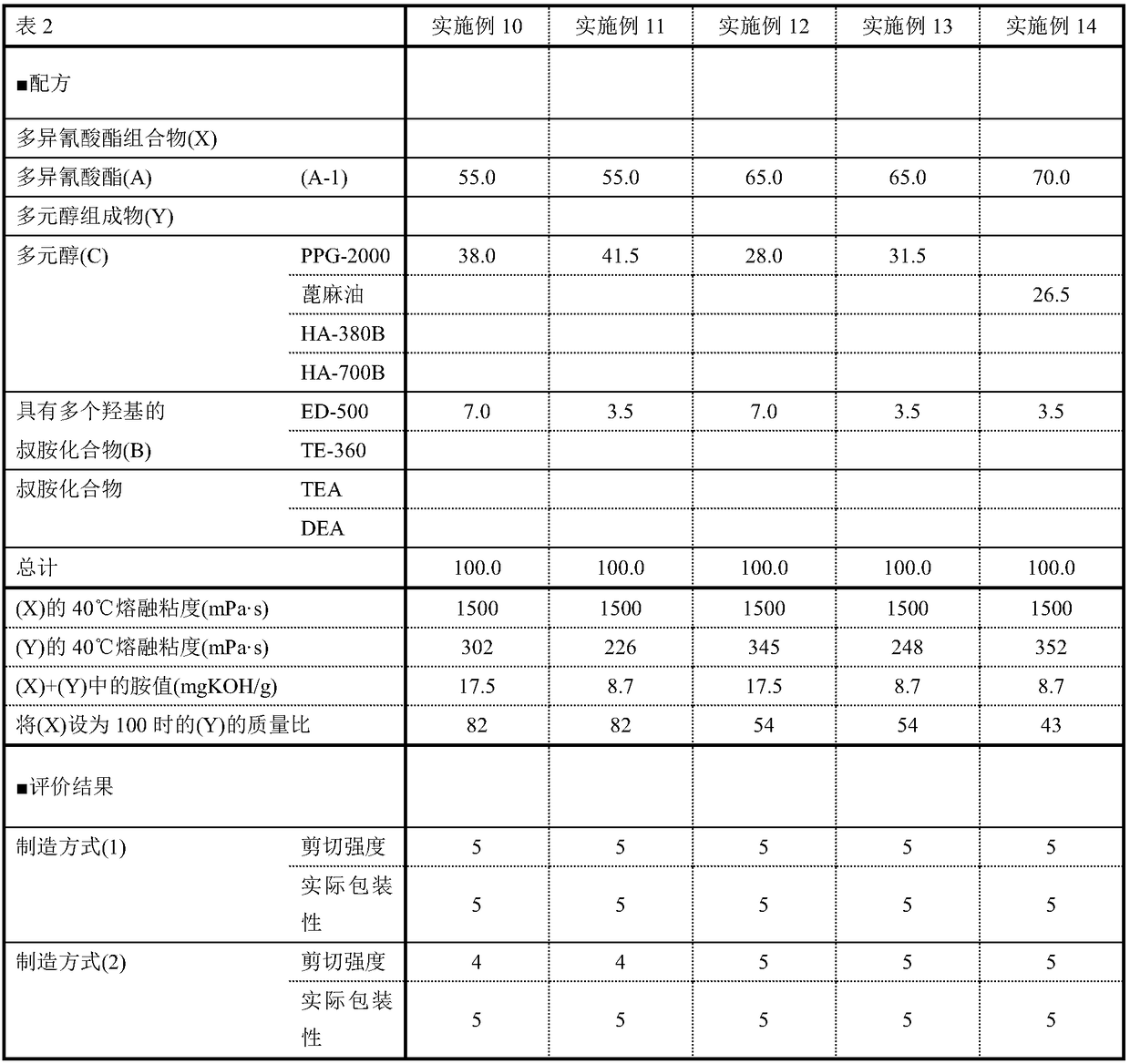

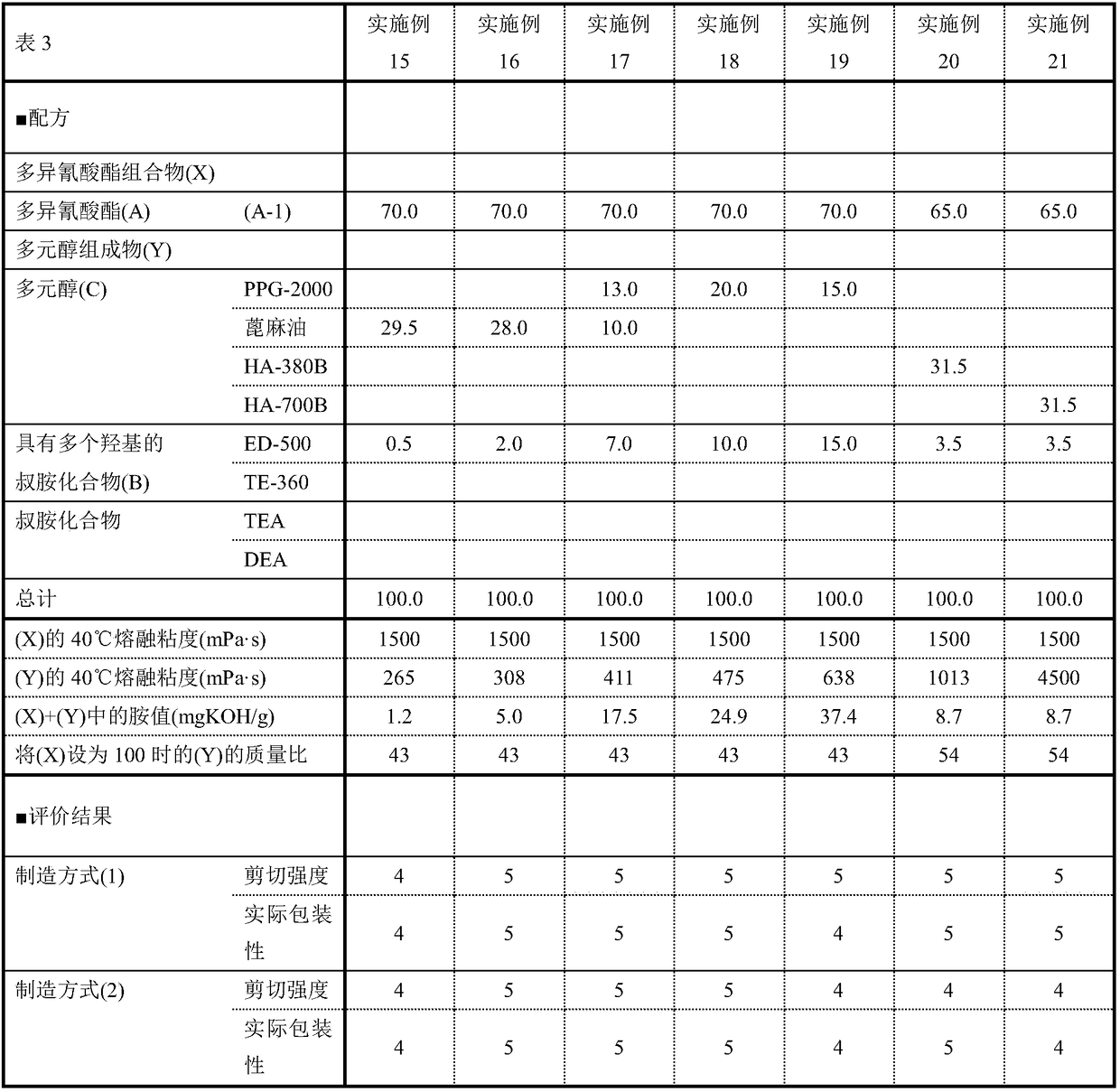

Adhesive, laminated film using the same and polyol composition for adhesive

PendingCN108463478AImprove productivityEasy to packPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyolAdhesive

Owner:DIC CORP

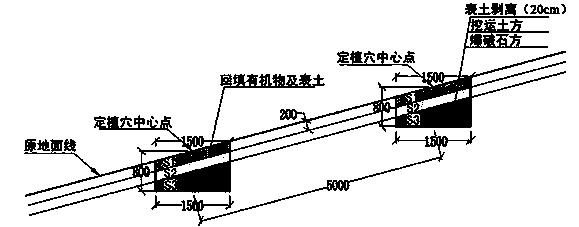

Planting pit soil improving method for fast ripening of soil in newly built citrus orchard in three gorges reservoir area

ActiveCN103918521AReduce construction costsShorten the ripening timeCultivating equipmentsSoil-working methodsSurface layerRipening

The invention discloses a planting pit soil improving method for fast ripening of soil in a newly built citrus orchard in the three gorges reservoir area. The method comprises the first step of planning a planting pit; the second step of stripping surface soil with the area ranging from 8 m<2> to 10 m<2> and with the center of the planting pit as the original point, wherein the stripping thickness ranges from 18 cm to 22 cm, and the soil is stacked locally after stripping; the third step of digging the planting pit; the step of refilling the planting pit with the surface soil and carrying out improvement of soil fertility, wherein the refilling is carried out in three layers, the bottom layer is refilled with the mixture of coarse stuff and surface soil, the middle layer is refilled with the mixture of the fine stuff and surface soil, the surface layer is refilled with mixture of organic fertilizer and surface soil, the planting pit is filled with the refilling stuff, and the stacked refilling stuff is higher than the original ground by 0.1-0.2 m. According to the planting pit soil improving method, the soil improvement work amount accounts for 20-30 percent of the common soil improvement work amount, the soil improvement work amount and establishing cost are greatly reduced, and the planting pit soil improving method has good ecological benefits. The ripening time of soil in the citrus orchard is shortened, and the ripening time based on the method is only one month while the ripening time based on a traditional method is about half year.

Owner:SOUTHWEST UNIV

Crosslinked material capable of promoting curing of alkyl ketene dimer and preparation method thereof

InactiveCN102101918AIncrease the degree of sizingReduce penetrationWater-repelling agents additionWater solubleGuar gum

The invention discloses a crosslinked material capable of promoting curing of alkyl ketene dimer(AKD) and a preparation method thereof. The crosslinked material is characterized by comprising guar gum, synthetic water soluble polymer, cationic assistant, crosslinking agent and water. The preparation is implemented by the following steps: dissolving the guar gum in water, adding the crosslinking agent, stirring, regulating the pH value of the mixed reaction system by using NaOH, raising the temperature to perform a cross-linking reaction, adding the synthetic water soluble polymer and the cationic assistant, cooling to obtain the crosslinked material capable of promoting the curing of the alkyl ketene dimer. The crosslinked material of the invention can improve the degree of sizing of paper, reduces infiltration capacity of liquid, and helps to produce high water resistance. The crosslinked material of the invention reduces the sizing curing time of AKD to 2 hours from the original 2 weeks, improves the utilization rate of paper machine and reduces storage time.

Owner:NANTONG TONGDI BIOTECH CO LTD +1

Pressure-sensitive adhesive composition

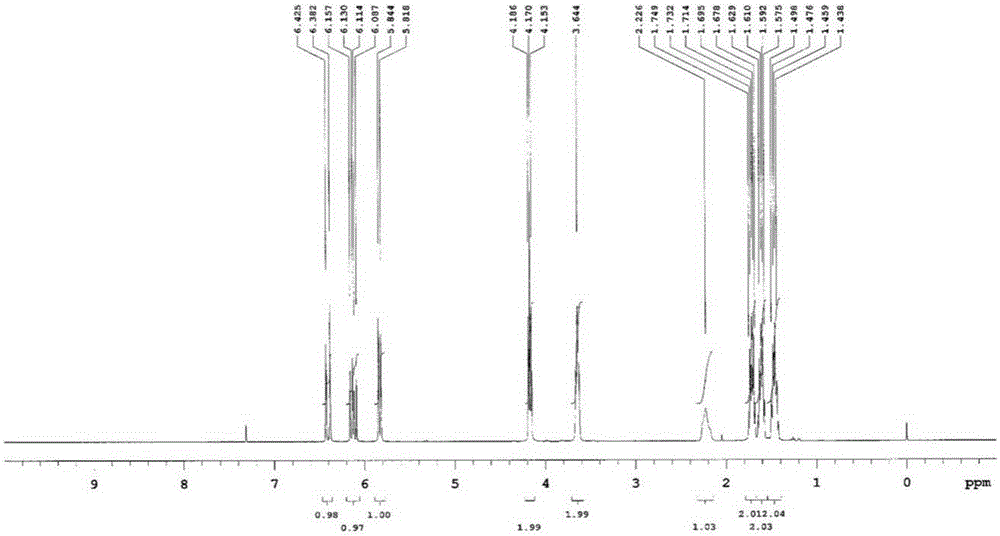

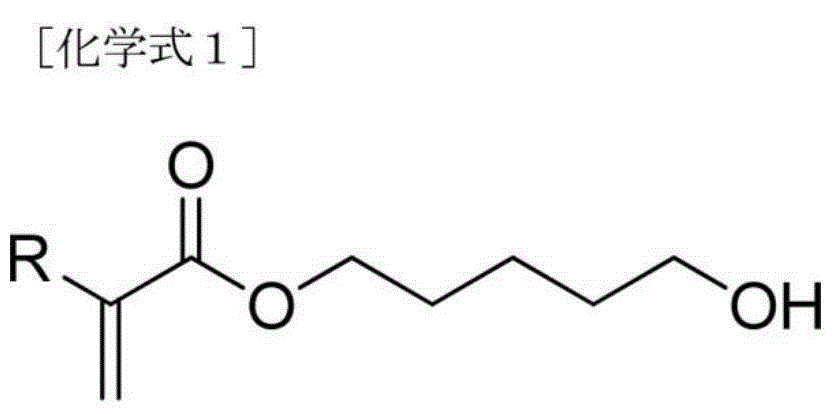

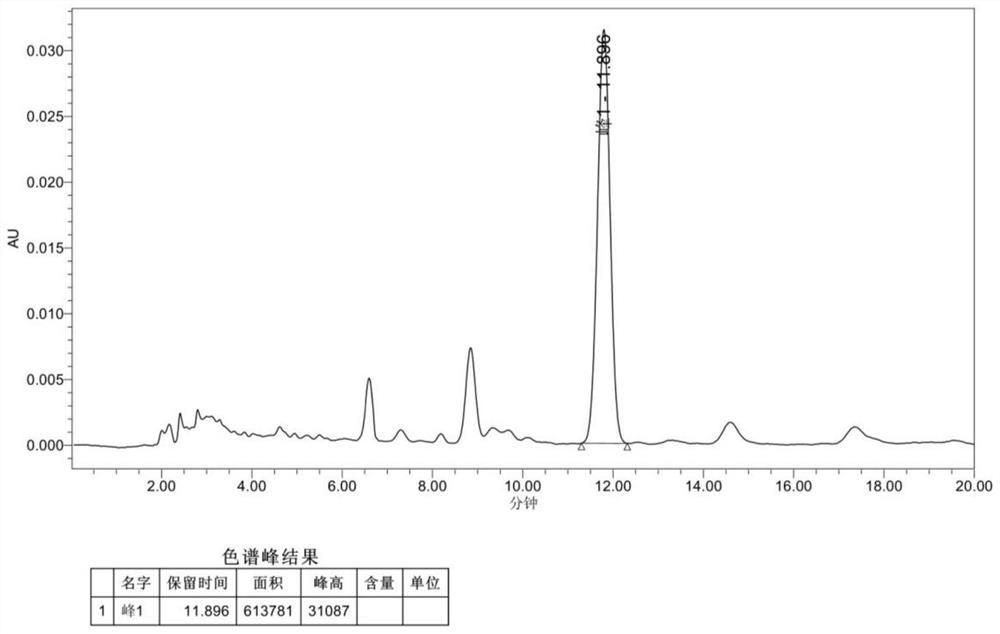

ActiveCN105462524AShorten the ripening timeGood spreadabilityNon-macromolecular adhesive additivesFilm/foil adhesivesCopolymerOrganic anion

The present invention relates to a pressure-sensitive adhesive composition comprising: an acrylic copolymer including more than or equal to 30 wt% of n-butylacrylate with respect to the total weight of monomers, and polymerized by including compounds represented by chemical formula 1; a polyfunctional isothiocyanate-based cross linking agent; an ionic anti-static agent including one or more types of positive ions of alkali metal positive ions and onium positive ions, and one or more types of negative ions of fluroine-containing organic negative ions and fluroine-containing inorganic negative ions; and a silane coupling agent having an electrophilic substituent or a nucleophilic substituent, thereby implementing short curing time, excellent coating properties, reworkability, durability, and anti-static properties, and anti-static properties over time.

Owner:DONGWOO FINE CHEM CO LTD +1

Method for increasing content of mogroside substances

The invention discloses a method for increasing the content of mogroside substances. The method comprises the following steps: (1) performing sterilizing; (2) performing shell crushing; (3) performingtreatment with a ripening agent; and (4) performing indoor microenvironment factor adjusting treatment. The method breaks through a conventional method for promoting after-ripening of momordica grosvenori and increasing the content of the mogroside only by adjusting external temperature and illumination conditions, starts from an after-ripening endogenous mechanism of the momordica grosvenori, creatively aims at an after-ripening key limiting factor of the momordica grosvenori, adds an exogenous ripening acceleration intervention measure, and cooperates with external environment factor adjustment, so that the high-efficiency and rapid after-ripening of the momordica grosvenori is realized. Compared with the prior art, the method disclosed by the invention has the advantages that the increase amplitude of the content of the mogroside is large, after-ripening time is short and bitterness can be eliminated.

Owner:HUNAN HUACHENG BIOTECH

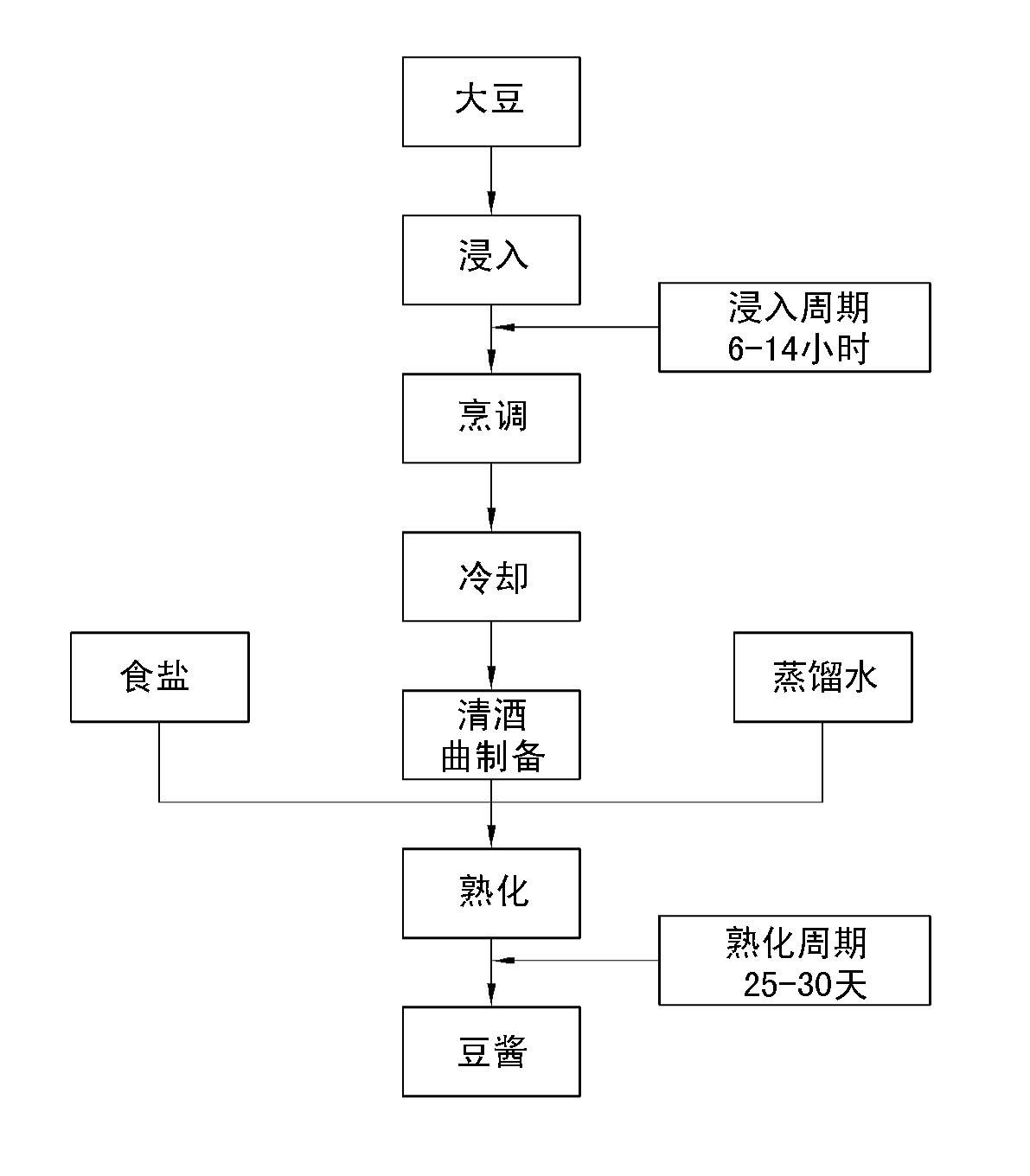

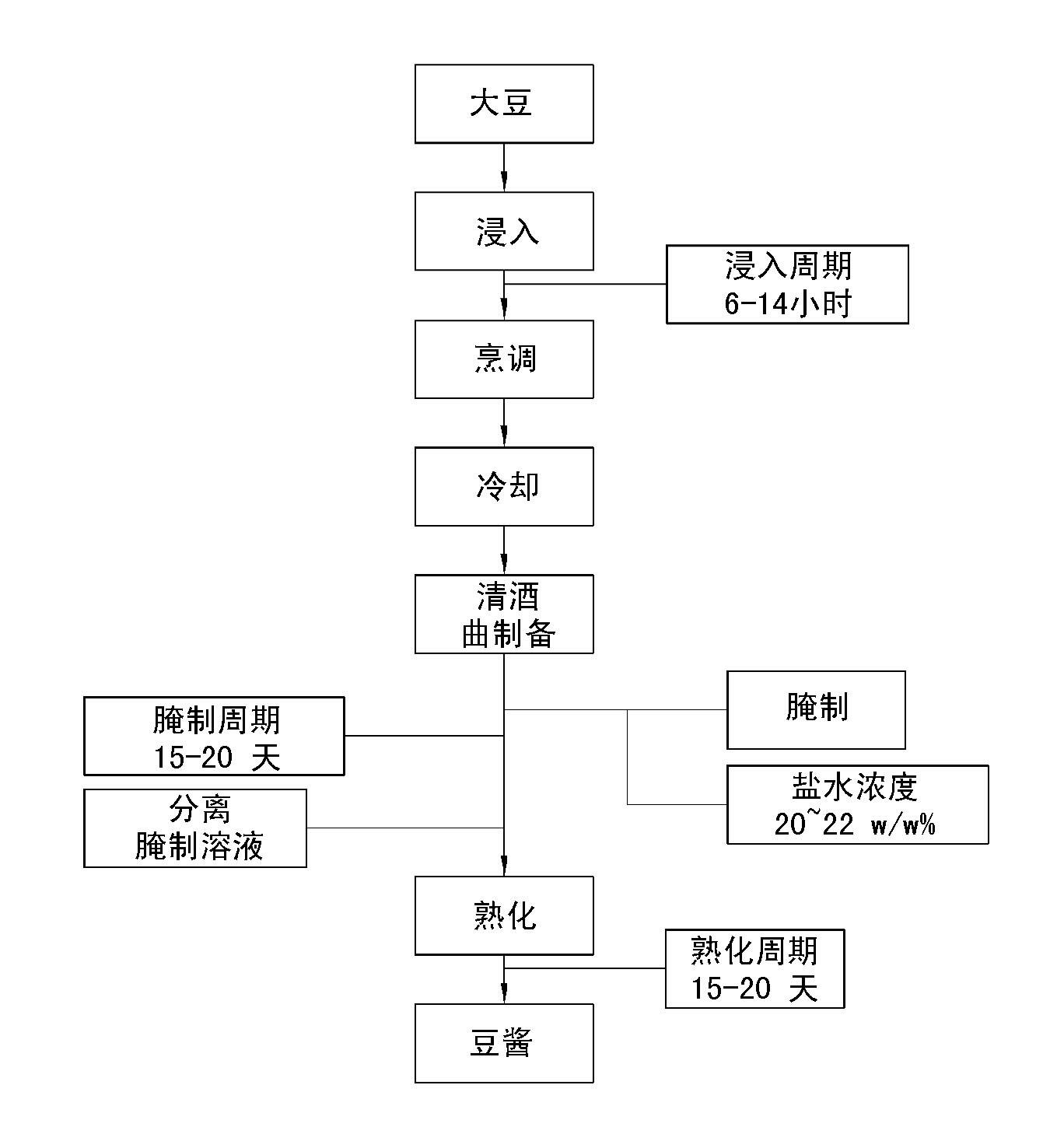

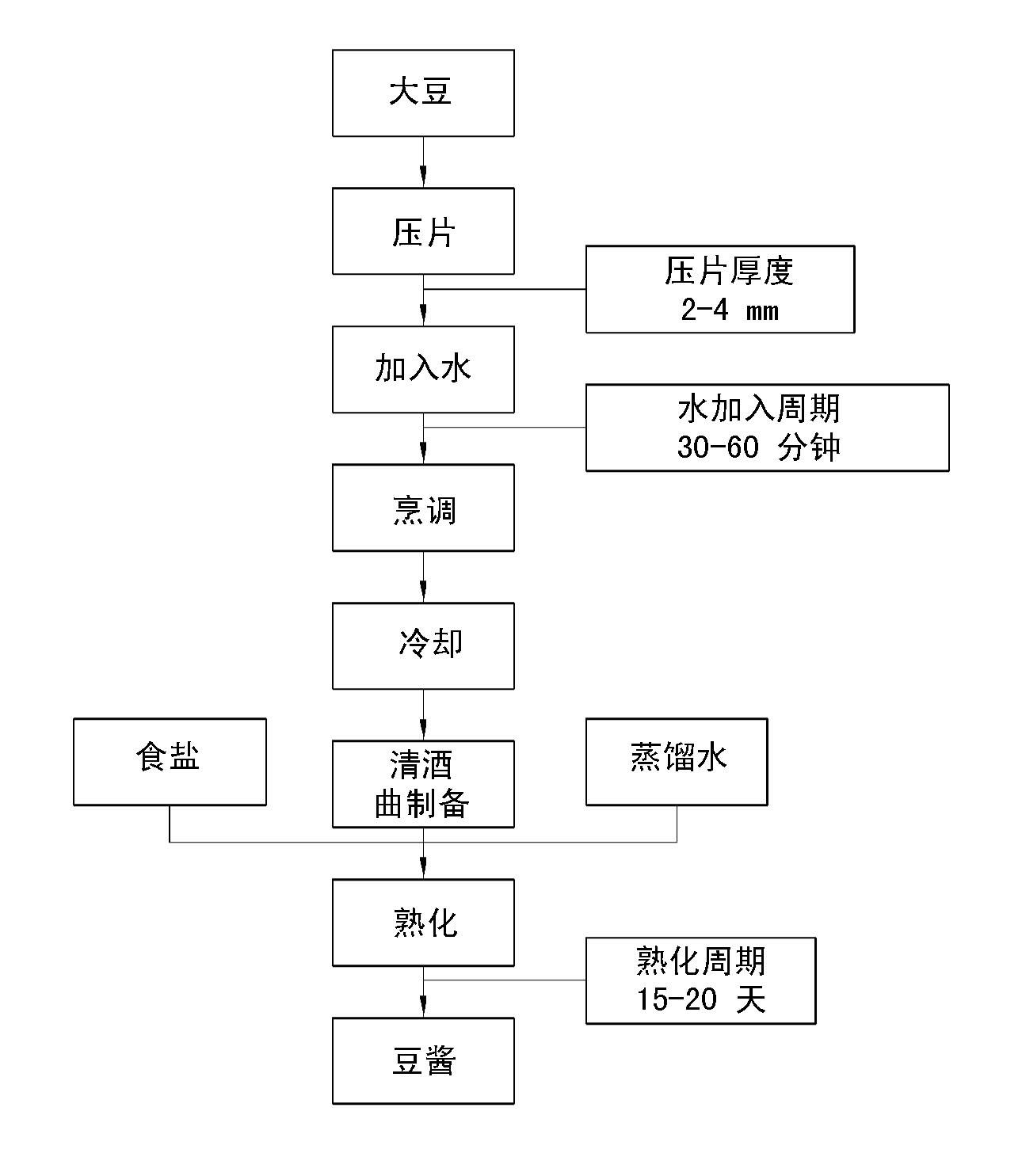

Method for preparing soybean paste

InactiveCN102612324AActivate growthSmall surface areaFood thermal treatmentFood dryingBiotechnologyMicroorganism

Disclosed is a method for preparing a soybean paste including: flaking or crushing raw soybeans, immersing the resulting flaked or crushed soybeans in water, followed by cooking and cooling, homogeneously mixing the soybeans with koji bacteria and a bean or grain powder, followed by fermenting and drying, and mixing the meju with table salt and distilled water and aging the resulting mixture. In accordance with the method, the soybeans are flaked or crushed to advantageously reduce hydrating and cooking periods of soybeans, form cracks on the soybean surfaces and increase surface areas, and allow beneficial microorganisms to easily use nutrients contained in soybeans, thus increase enzyme production, considerably reduce fermentation period of meju and aging period of soybean paste, obtain manufacturing soybean pastes with superior quality and improve production efficiency.

Owner:CJ CHEILJEDANG CORP

Starch glycosyl polyether glycol used for polyurethane rigid foam and preparation method thereof

The invention discloses a starch glycosyl polyether glycol, which has a higher molecular weight and is prepared from modified starch sugar, low molecular weight alcohols and propylene oxide. The molecular weight is within the range of 700 to 1200, the hydroxyl value (mg KOH / g) is 415 to 430, the viscosity (cSt, 25 DEG C) is 4500 to 6500, and density (gm / cc, 25 DEG C) is 1.0188 to 1.0218. The starch glycosyl polyether glycol has good compatibility with cyclopentane foaming agents. The polyurethane foam prepared with the starch glycosyl polyether glycol shows excellent dimensional stability, higher flowability and lower thermal conductivity. Besides, the application of the starch glycosyl polyether glycol can shorten curing time of the foam. The invention also discloses a preparation methodof the starch glycosyl polyether glycol.

Owner:江苏钟山新材料有限公司

Cheese and preparation method thereof

ActiveCN102047984AControlling "post-acid" issuesNo pollutionCheese manufactureWhey protein powderWhole milk

The invention relates to a cheese and a preparation method thereof. The cheese comprises the following components in parts by weight: 800-950 parts of fresh milk, 50-100 parts of white granulated sugar, 30-80 parts of sweetened condensed whole milk, 0-8 parts of whey protein powder, 0-15 parts of starch, 0-10 parts of thickening agent and 50-100 parts of lactococcus lactis. The cheese of the invention is prepared by the following procedures of burdening, homogenizing, sterilizing, cooling, adding the strains, heating on line, filling, fermenting, after-ripening and the like. The fresh little cheese produced by the invention conforms to the taste of Chinese people, and has tender and smooth mouth feel and rich nutrition, so that the cheese must be favored by domestic enterprises and consumers.

Owner:JUNLEBAO DAIRY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com