Method for increasing content of mogroside substances

A mogroside and substance content technology, applied in the fields of botanical equipment and methods, chemicals for biological control, food science, etc., can solve the problems of extremely limited improvement in after-ripening quality, shorten after-ripening time, improve Content, the effect of eliminating bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

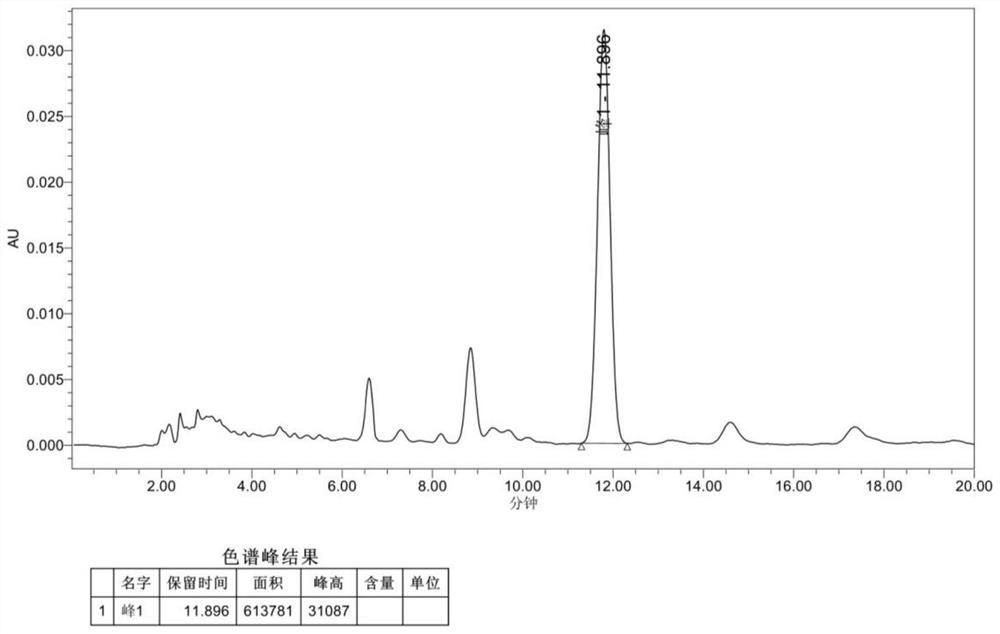

Image

Examples

Embodiment 1

[0030] (1) Sterilization: Put fresh Luo Han Guo in the upper and lower UV intensity of 100μW / cm 2 Irradiate for 20s under certain conditions for rapid sterilization;

[0031] (2) Shell breaking: place the sterilized Luo Han Guo in a sterile room, and directly press to break the shell, and the shell will crack until no juice flows out;

[0032] (3) Enzyme-containing ripening agent treatment: place the broken Luo Han Guo in a sterilization chamber, and spray the enzyme-containing ripening agent. Among the enzyme-containing ripening agents, β-fructofuranosidase preparation and glucosyltransferase preparation The mass proportion of cysteine, glutathione is 10:15:0.2:0.1; In the described enzyme-containing ripening agent, the addition amount of sterile water is such that the β-in the enzyme-containing ripening agent The concentration of fructofuranosidase preparation and glucosyltransferase preparation is 0.05%;

[0033] (4) Post-ripening treatment: Put the Momordica grosvenori s...

Embodiment 2

[0036] (1) Sterilization: Put fresh Luo Han Guo in the upper and lower UV intensity of 90μW / cm 2 Irradiate for 25s under certain conditions for rapid sterilization;

[0037] (2) Shell breaking: place the sterilized Luo Han Guo in a sterile room, and directly press to break the shell, and the shell will crack until no juice flows out;

[0038] (3) Enzyme-containing ripening agent treatment: place the broken Luo Han Guo in a sterilization chamber, and spray the enzyme-containing ripening agent. Among the enzyme-containing ripening agents, β-fructofuranosidase preparation and glucosyltransferase preparation The mass ratio of cysteine, glutathione is 10:4:20:0.4:0.3; In the ripening agent, the addition of sterile water is such that the β-furan fruit in the ripening agent The concentration of glycosidase preparation and glucosyltransferase preparation is 0.03%;

[0039] (4) Post-ripening treatment: Put the Momordica grosvenori sprayed with enzyme-containing ripening agent in the ...

Embodiment 3

[0042] (1) Sterilization: Put fresh Luo Han Guo under the condition of upper and lower ultraviolet intensity of 150μW / cm2 and irradiate for 15s for rapid sterilization;

[0043] (2) Shell breaking: place the sterilized Luo Han Guo in a sterile room, and directly press to break the shell, and the shell will crack until no juice flows out;

[0044] (3) Enzyme-containing ripening agent treatment: place the broken-shelled Luo Han Guo in a sterilization chamber, and spray an enzyme-containing ripening agent. Among the enzyme-containing ripening agents, β-fructofuranosidase, glucosyltransferase, semi The mass ratio of cystine and glutathione is 10:7:25:0.3:0.1; in the described enzyme-containing ripening agent, the addition amount of sterile water is such that the β- The concentration of fructofuranosidase preparation and glucosyltransferase preparation is 0.08%;

[0045] (4) Post-ripening treatment: Put the Momordica grosvenori sprayed with enzyme-containing ripening agent in the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com