Tobacco bale loose treatment device and tobacco bale loosening reversion processing method

A technology for processing equipment and loosening moisture, which is applied in tobacco, tobacco preparation, application, etc., can solve the problems of high cost, complicated process, high crushing rate, etc., and achieve improvement of various indicators, simple equipment structure, and reduced crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

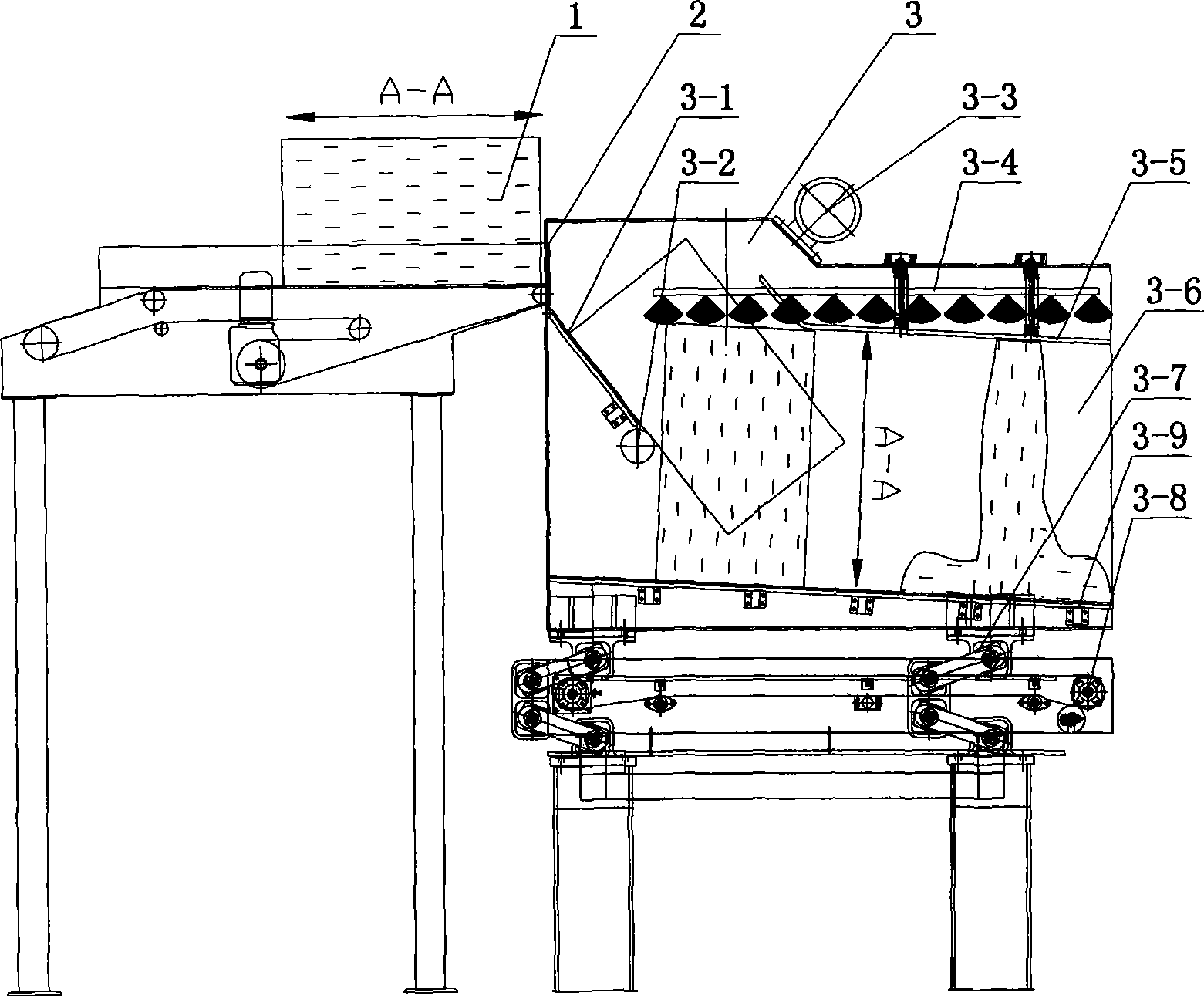

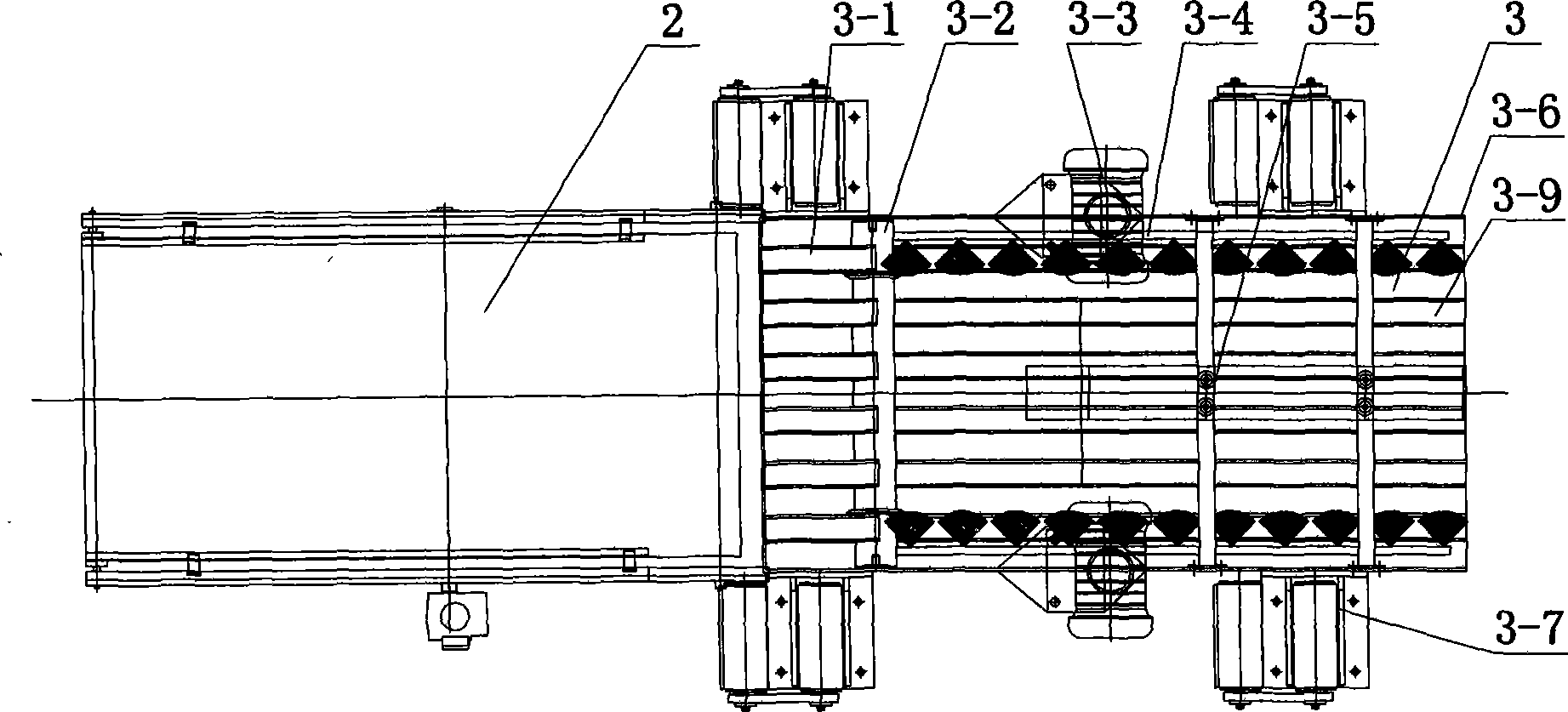

Method used

Image

Examples

Embodiment 1

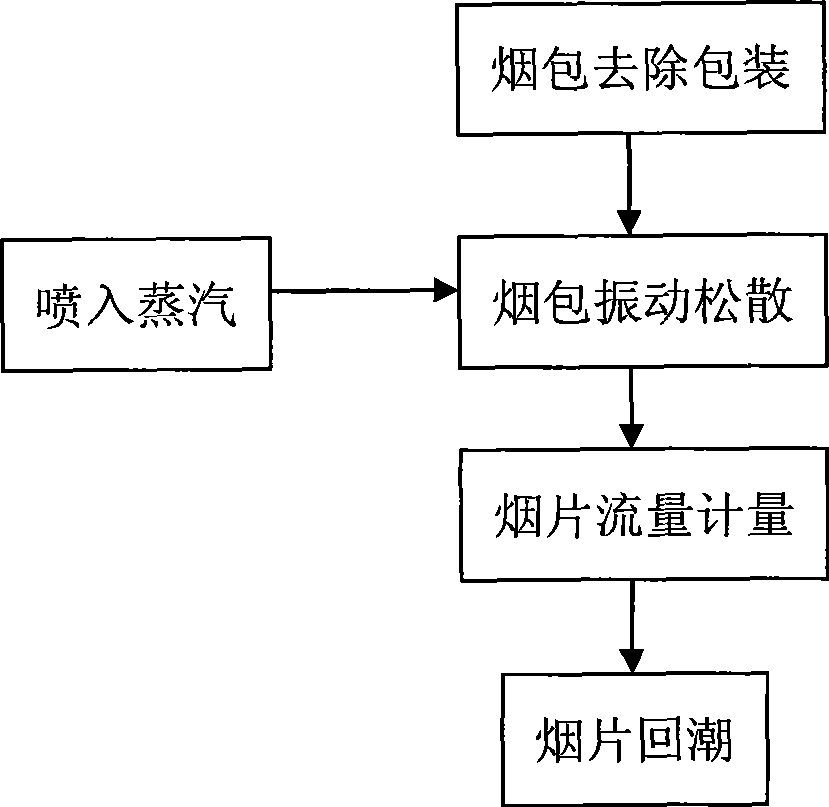

[0034] Example 1: as image 3 As shown in the figure, the cigarette packs are first unpacked by an unpacking machine and then sent to a vibration loosening machine for vibration loosening. During the vibration loosening process, water vapor is injected, and the steam temperature should not be higher than 200 °C; The unit is sent to the reconditioning machine for reconditioning. This method is suitable for loosening and regaining moisture of high-grade tobacco.

Embodiment 2

[0035] Example 2: as Figure 4 As shown in the figure, the cigarette packs are first heated and loosened by a microwave cigarette pack loosening machine; then, after being unpacked by an unpacking machine, they are sent to a vibration loosening machine for vibration loosening, and water vapor is sprayed during the vibration loosening process; Tobacco flakes are sent to the reconditioning machine through the metering unit for reconditioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com