Patents

Literature

100results about How to "Promote loose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing method for water tank type dish washer

ActiveCN104983379AAvoid collisionIncrease flushing powerTableware washing/rinsing machinesHome appliance efficiency improvementElectricityPulp and paper industry

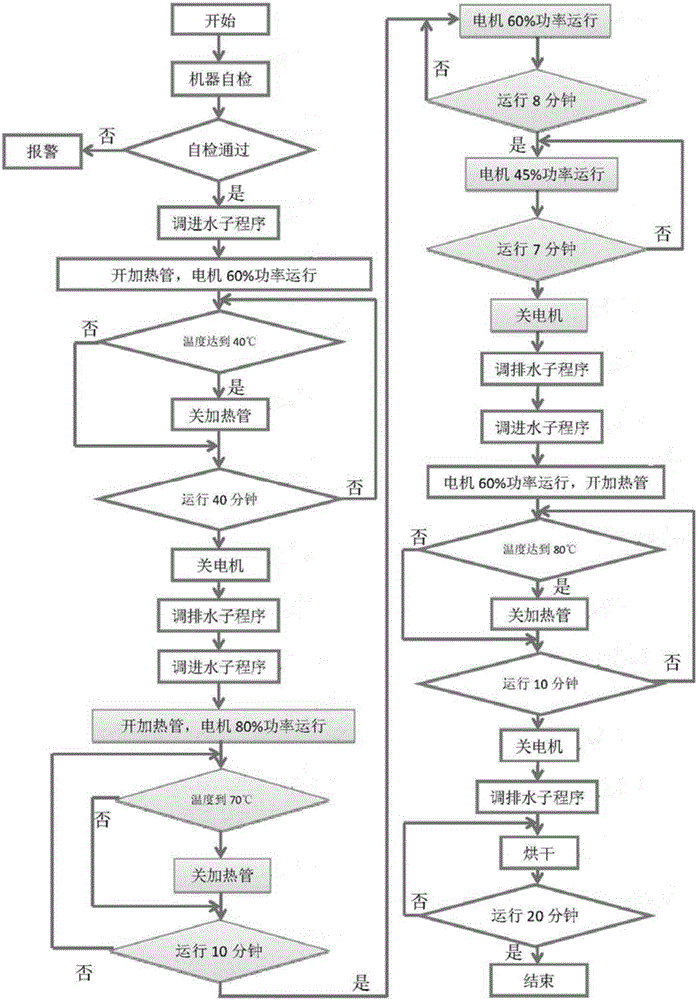

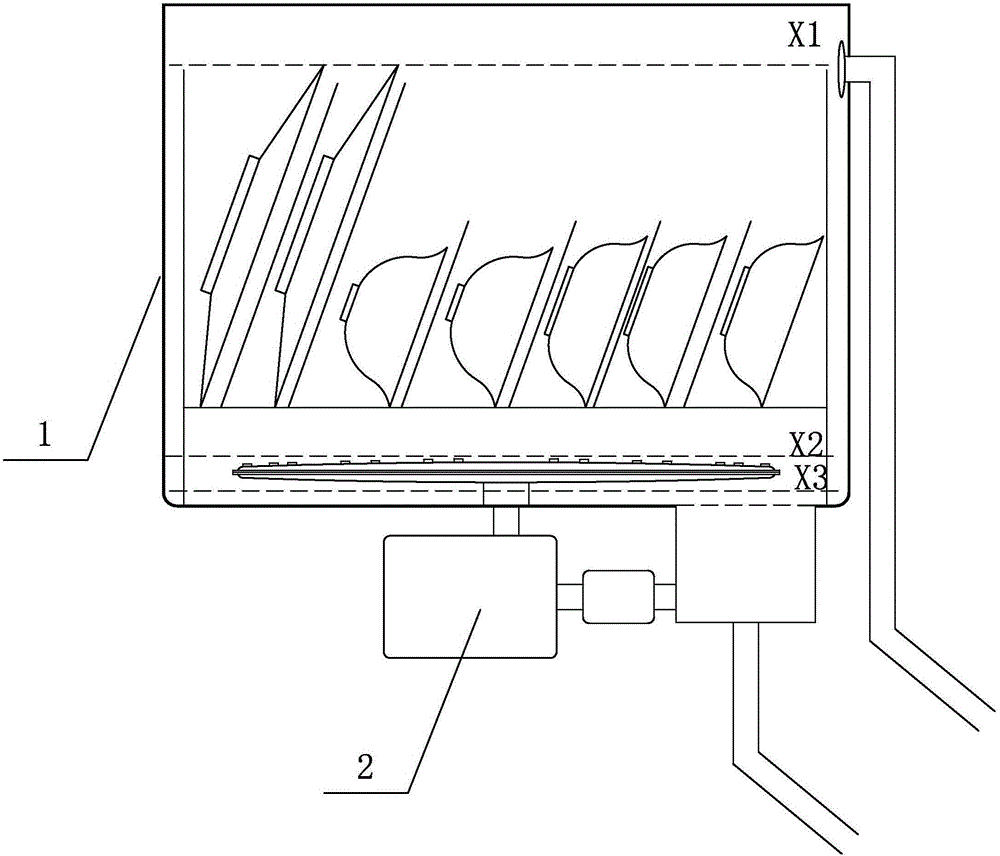

The invention discloses a washing method for a water tank type dish washer. The method includes the following steps that firstly, at the prewashing stage, water is injected, heating is started when the amount of injected water reaches a preset water amount, a circulating water pump starts running at the power accounting for 50% to 60% of the rated power, and eddy stirring is conducted through fins arranged on the upper surfaces of rotating spraying arms; secondly, at the main washing stage, the amount of injected water is controlled to be the preset water amount below the rotating spraying arms, heating is started, and the rotating spraying arms are driven to conduct spraying of different spraying strengths and different spraying angles in a segmented mode by setting the rated power of the circulating water pump in a segmented mode and setting the execution time in a segmented time; thirdly, at the rinsing stage, the amount of injected water is controlled to be the preset water amount below the rotating spraying arms, heating is started, and the rotating spraying arms are driven to conduct rinsing spraying. The washing method for the water tank type dish washer can solve various problems of Chinese style dishes, the washing efficiency can be effectively improved, more water and electricity are saved, and a mixing program is obtained.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD

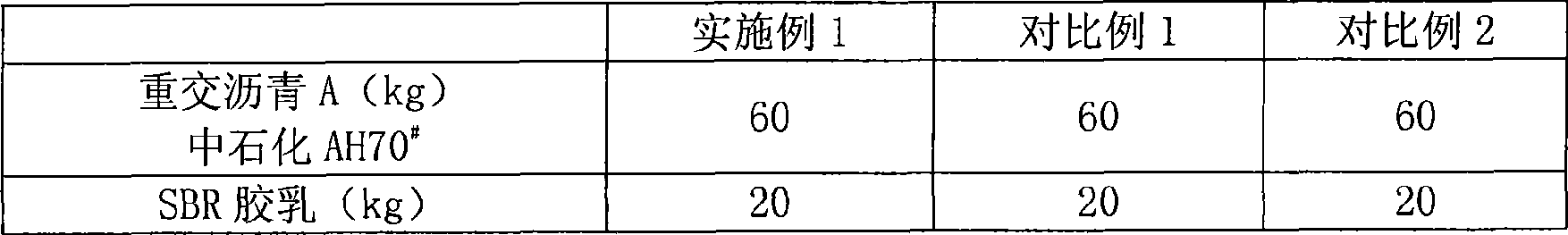

High strength cold state asphalt fissure cementation water-proof glue and preparation thereof

ActiveCN101475748AGood anti-aging performanceImprove high temperature performanceOther chemical processesBuilding insulationsTO-18Adhesive

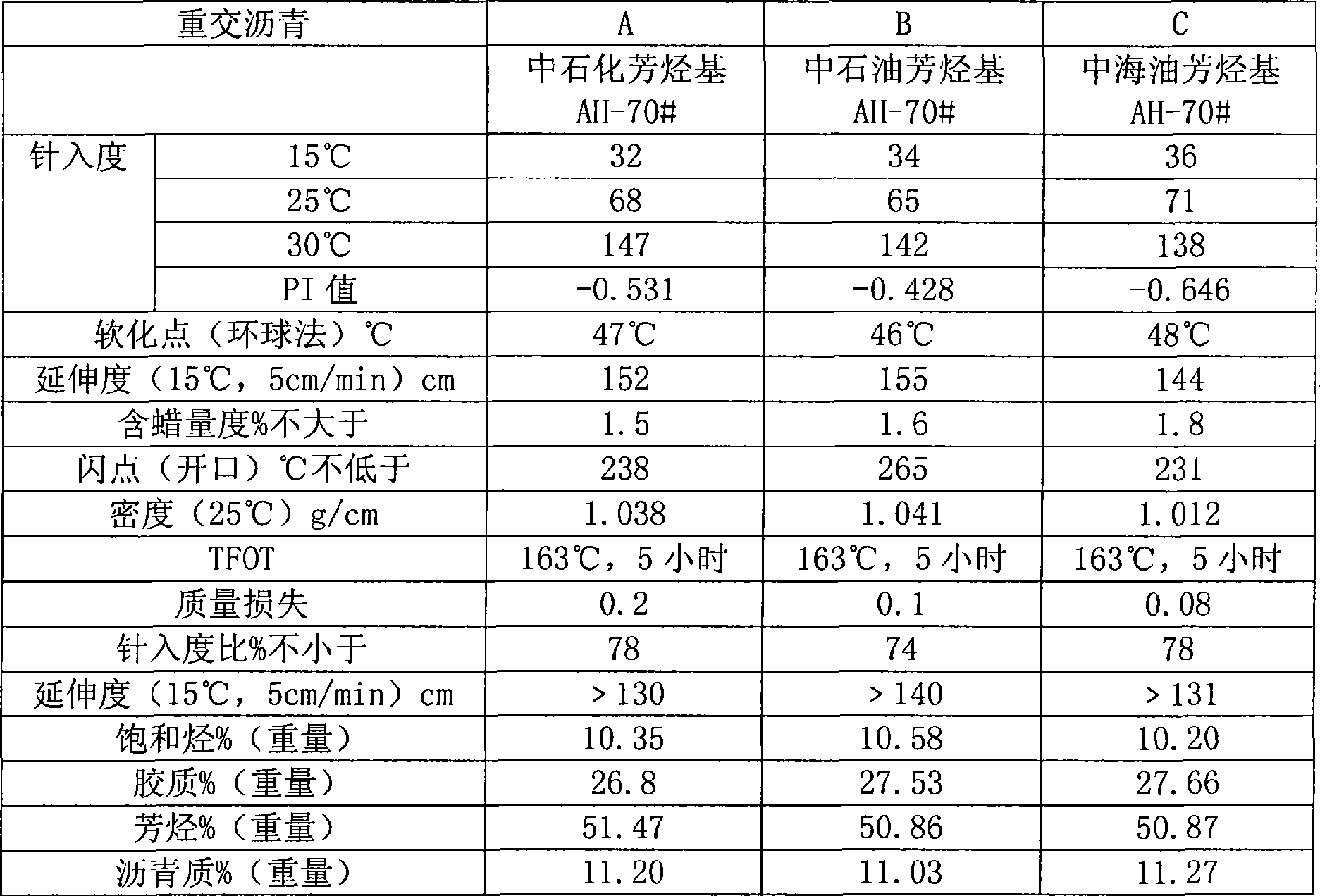

The invention relates to high-strength cold asphalt crack-pouring waterproof adhesive and a preparation method thereof. The waterproof adhesive comprises the following components in portion by weight: 15 to 20 portions of modifier polymer, 2.0 to 3 portions of dispersant, 0.5 to 2.0 portions of stabilizing agent, 50 to 60 portions of heavy rubber asphalt, 1.5 to 2.0 portions of emulsifying agent, 15 to 18 portions of purified water, and 4 to 16 portions of curing agent. The waterproof adhesive has the advantages of simple preparation, reliability and excellent properties, can be widely applied to crack pouring for large traffics in cities and countryside, heavy loading high-grade roads, stress absorbing structural layers, waterproof and mist sealing layers or layer sealing mat coats and the like, and remarkably improves water proofing, skid resistance, flatness and abrasion resistances of the roads.

Owner:钦兰成

Water-soluble fertilizer containing chitin and humic acid and production method thereof

InactiveCN101638333AHigh activityImprove fertilizer efficiencyFertilizer mixturesDiseaseContinuous cropping

The invention discloses a water-soluble fertilizer containing chitin and humic acid and a production method thereof. The method is characterized by degrading chitin, a natural high polymer, and then mixing chitin with humic acid solution and nitrogen fertilizer to produce the water-soluble fertilizer containing chitin and humic acid. The produced water-soluble fertilizer contains 20-40g / l of chitin, 20-40g / l of nitrogen, 170-190g / l of humic acid and 1-5g / l of plant growth regulators. The method is simple, easy to operate and high in feasibility of implementation. The produced water-soluble fertilizer integrates the functions of nutrition supplement, bacteria immunity and virus immunity, improves soil conditions, prevents hardening, raises ground temperature, promotes prematurity, resists diseases and tolerates stress, resists continuous cropping and balances nutrition, and features stable status and lasting fertilizer efficiency.

Owner:山东润华联邦农业科技有限公司

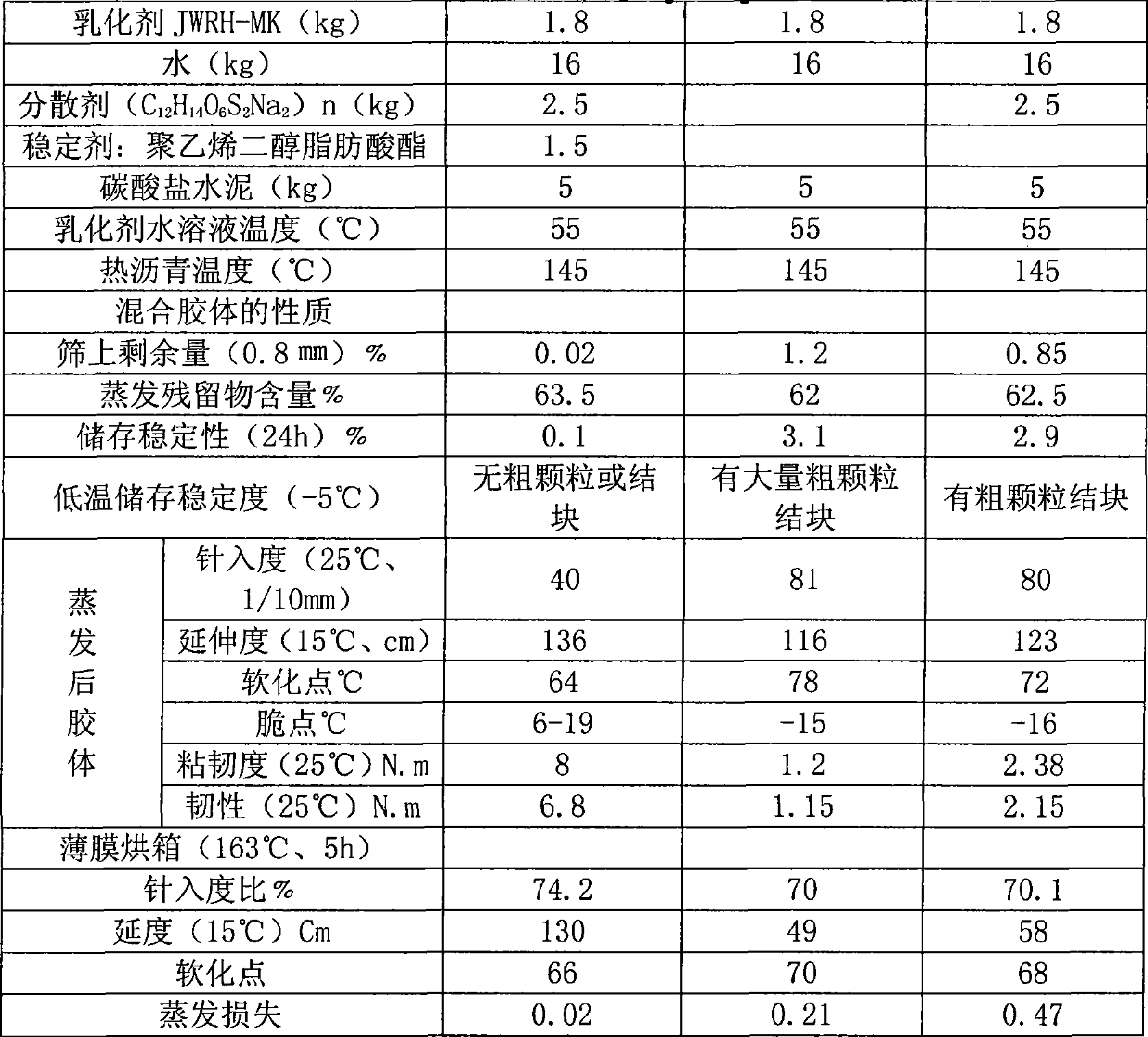

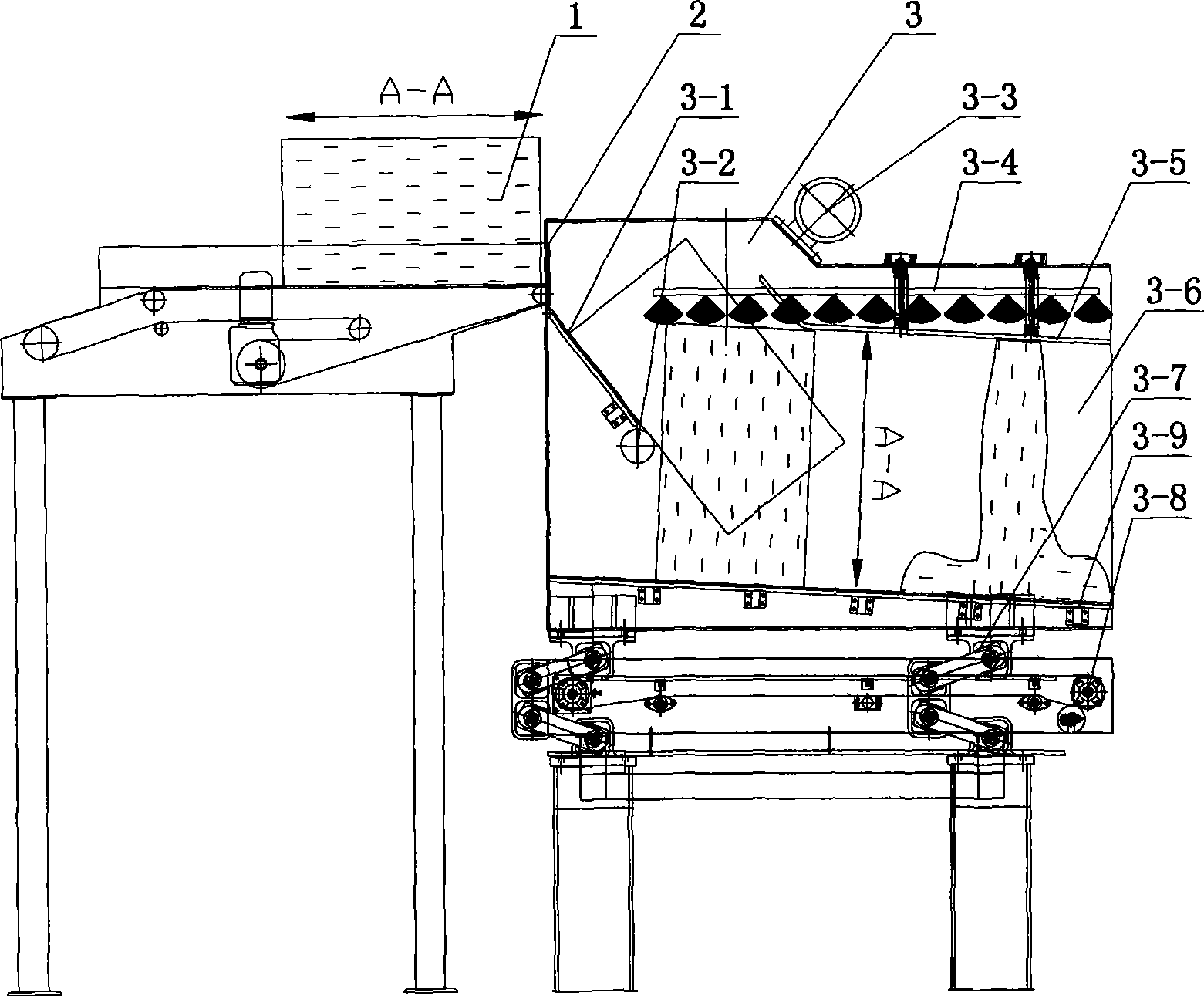

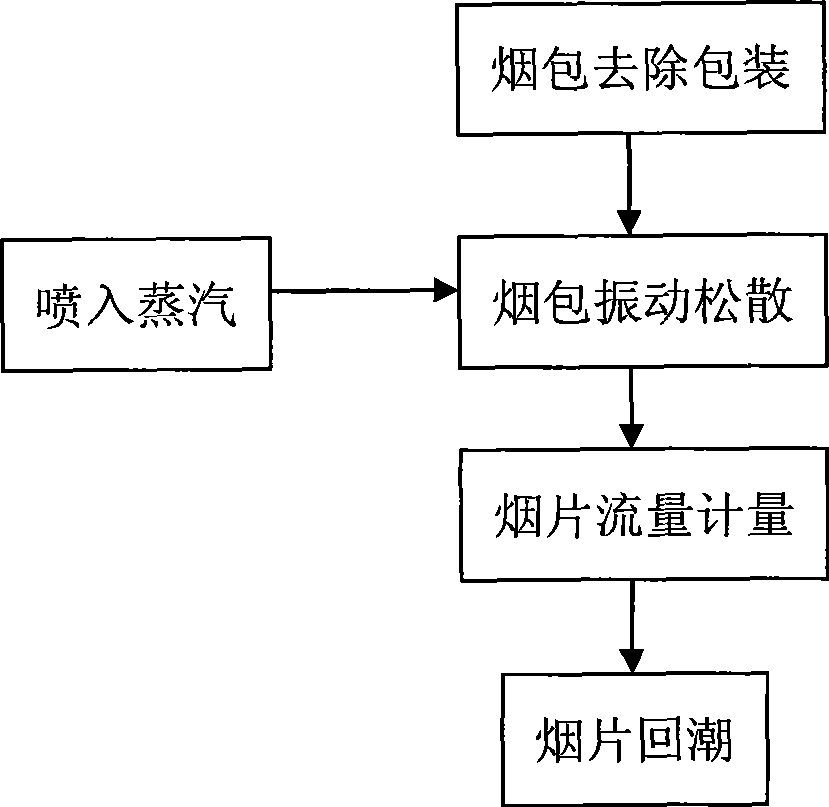

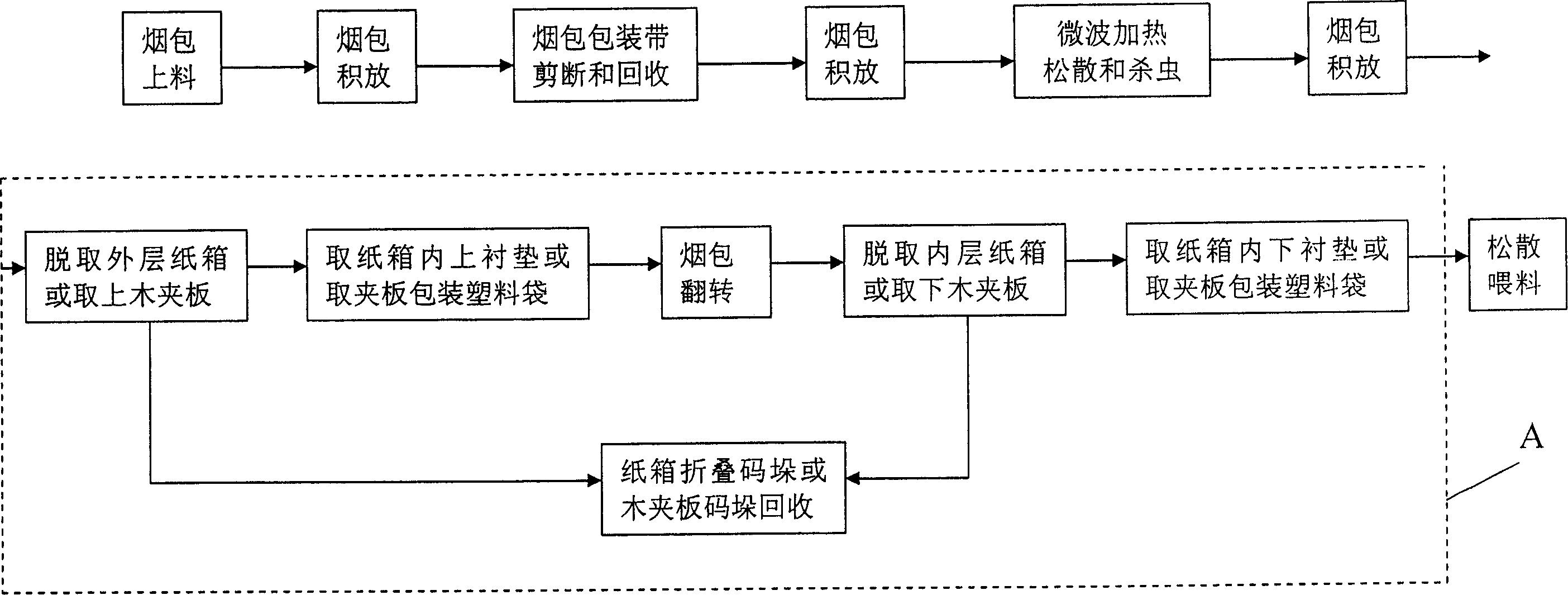

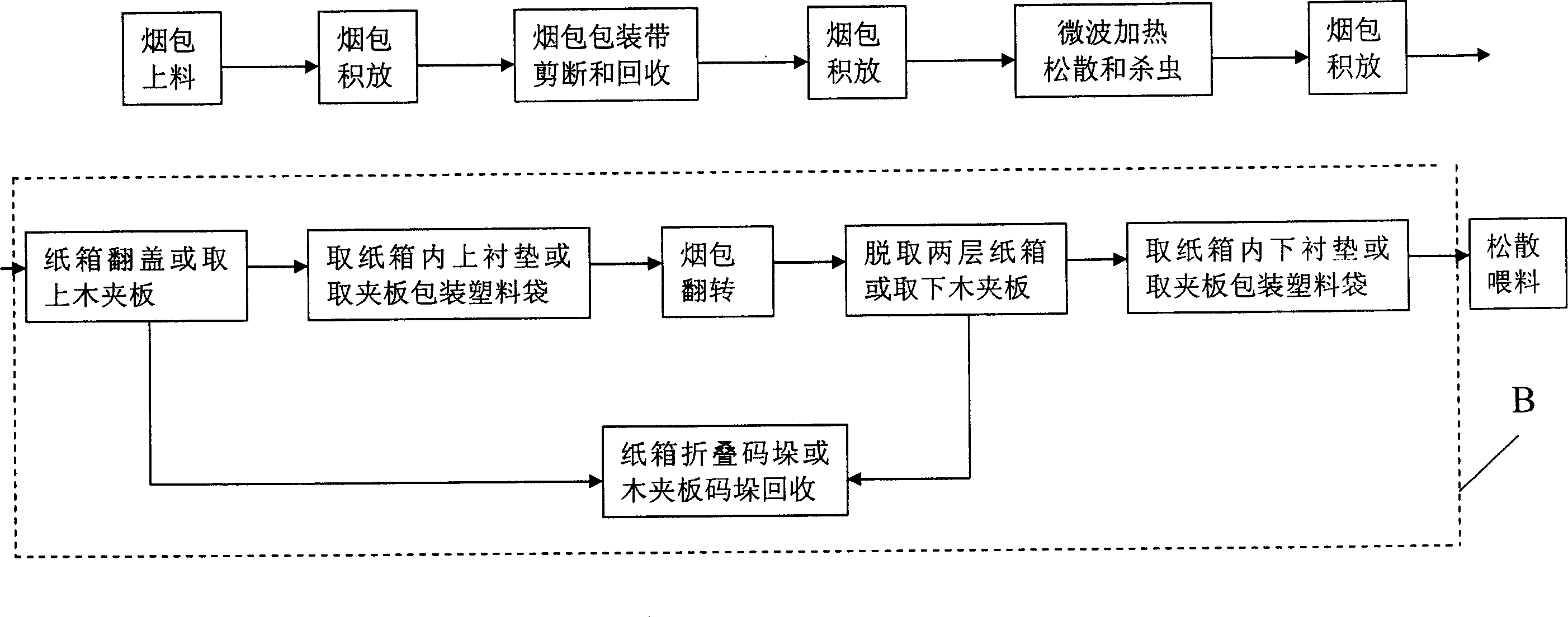

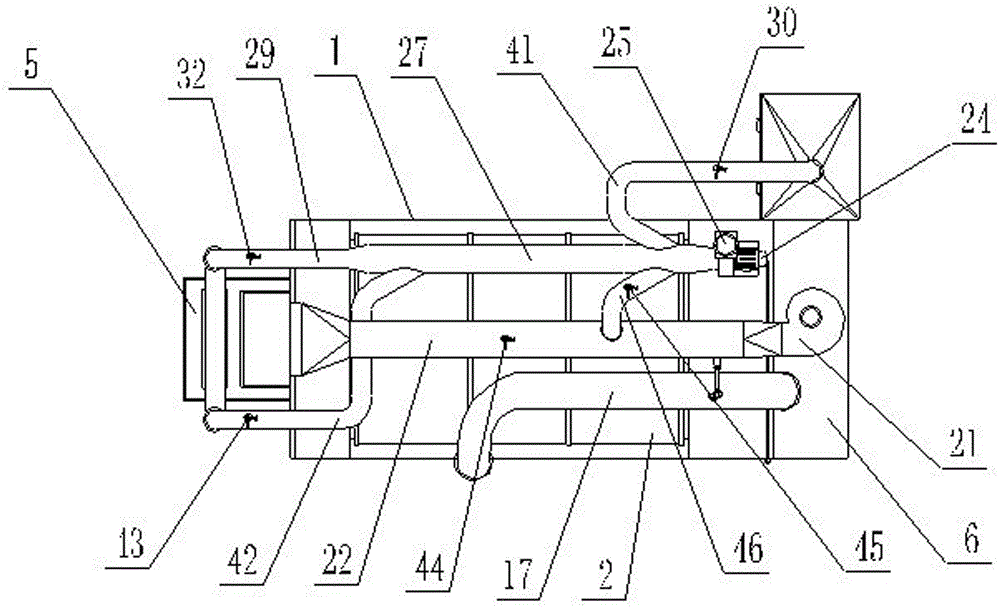

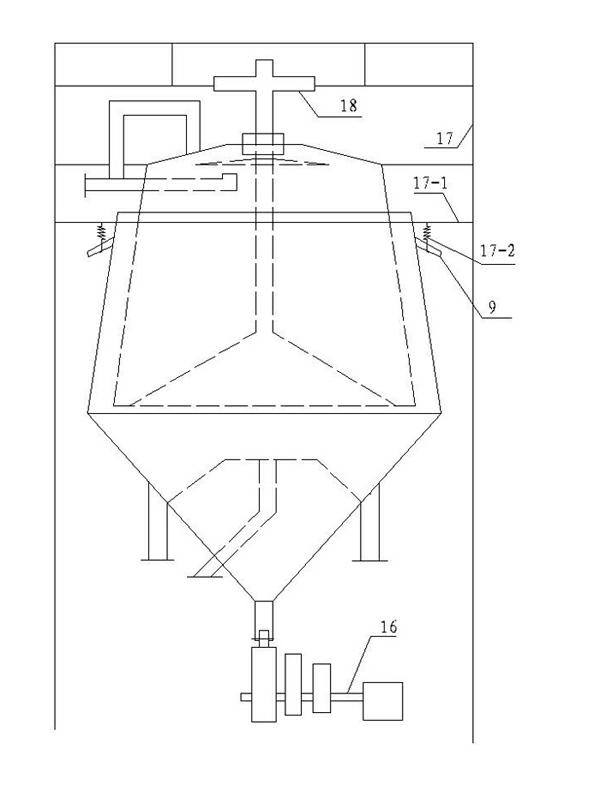

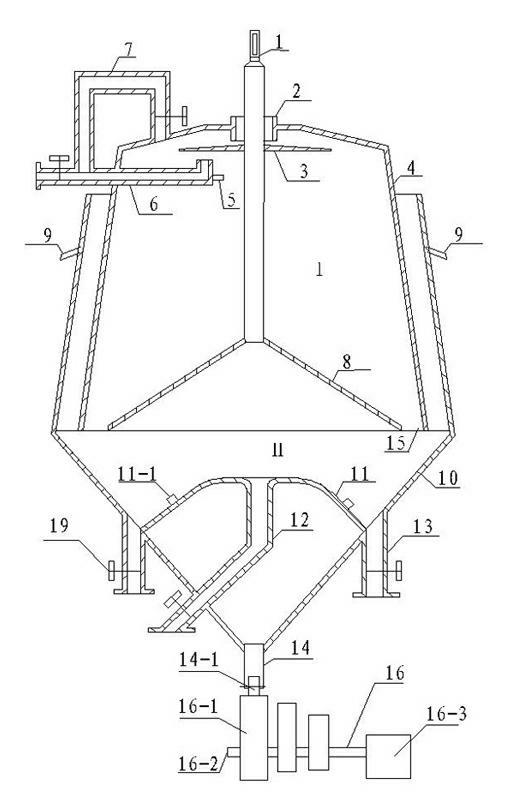

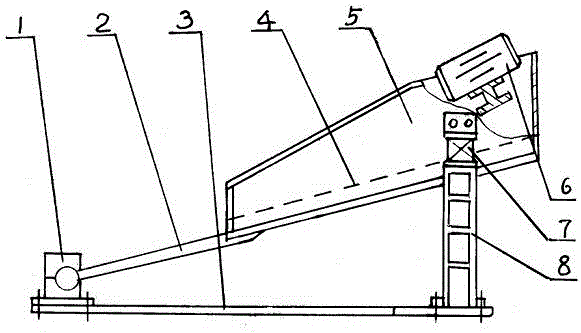

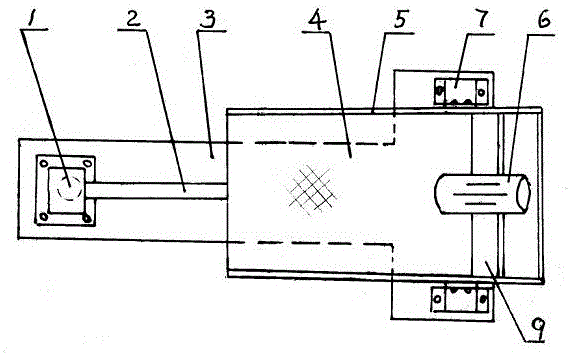

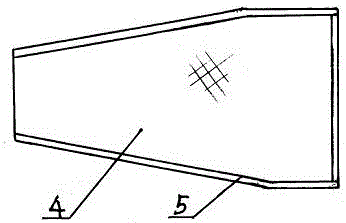

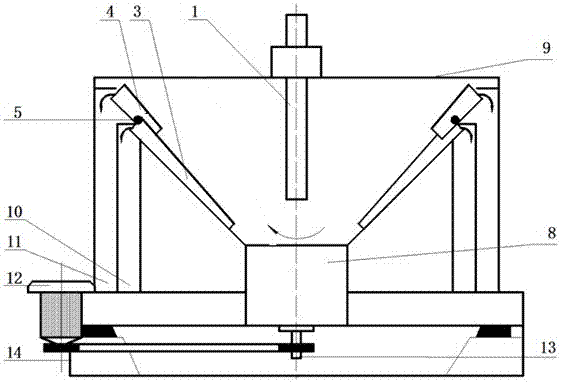

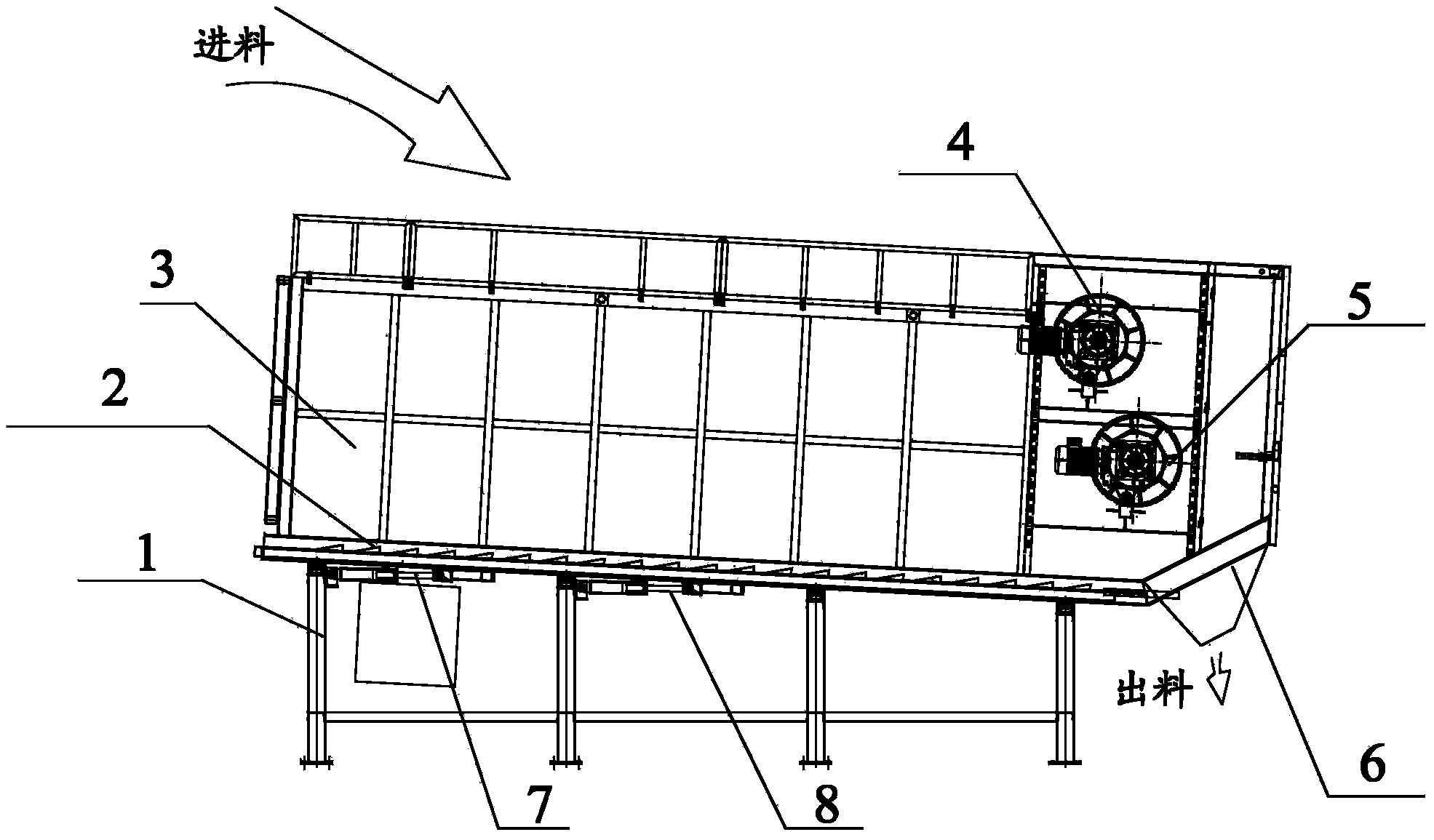

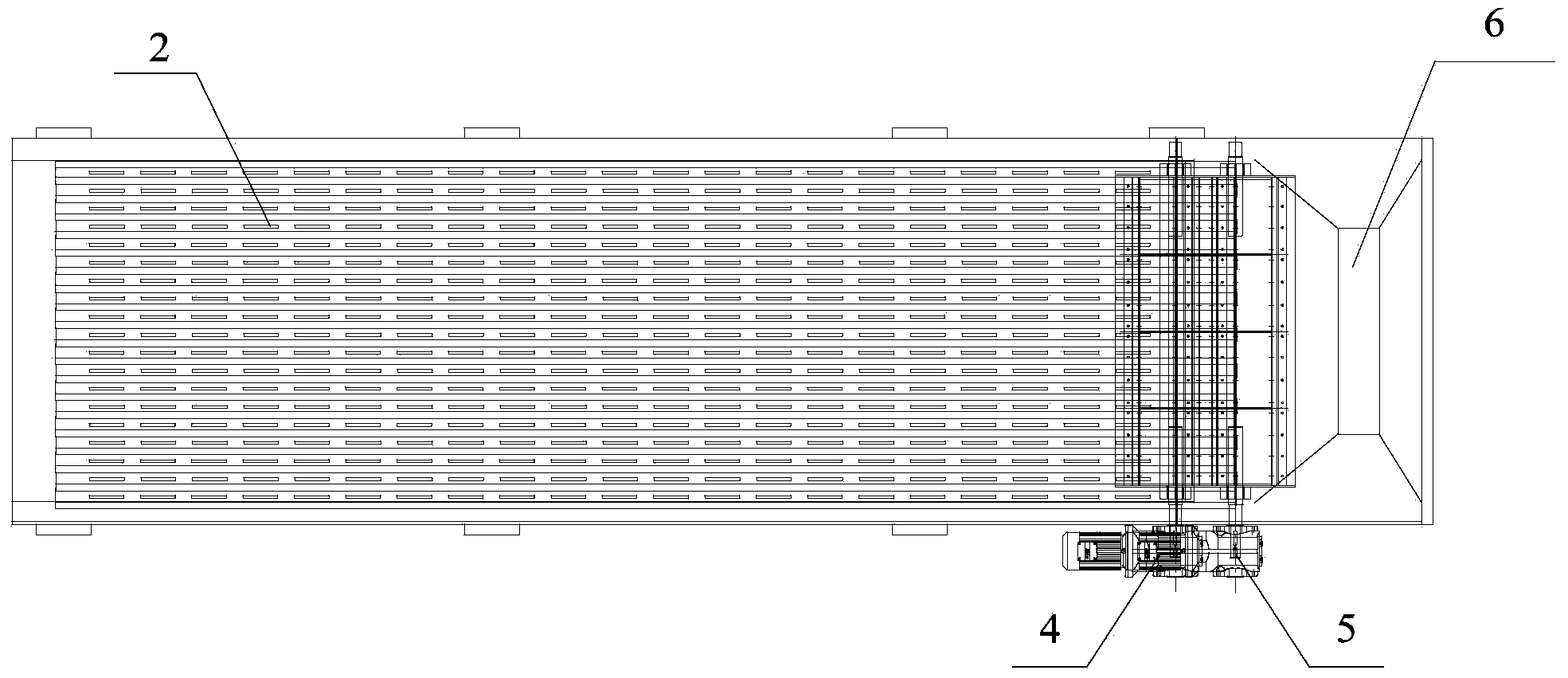

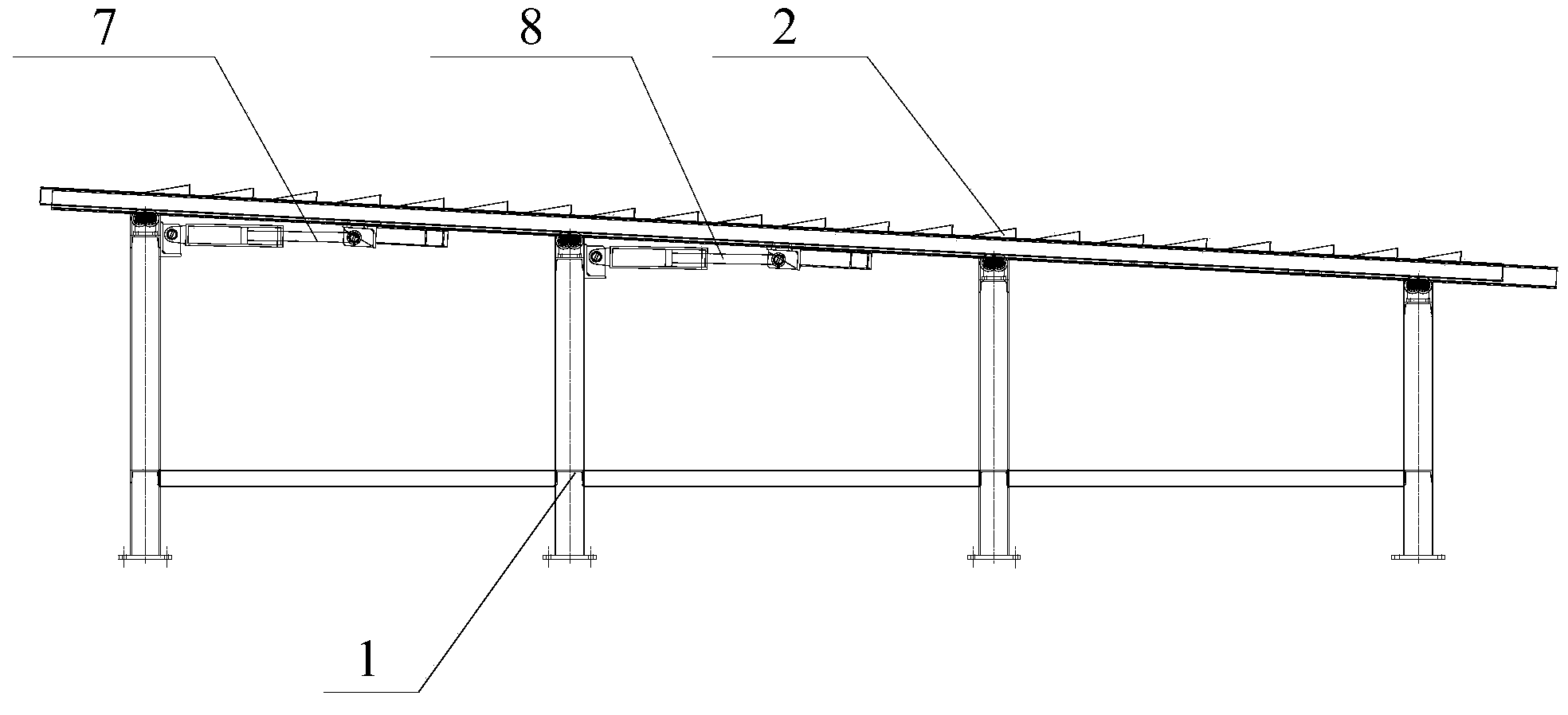

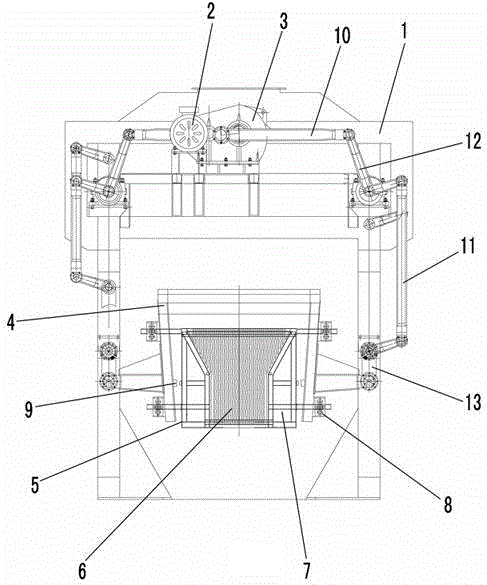

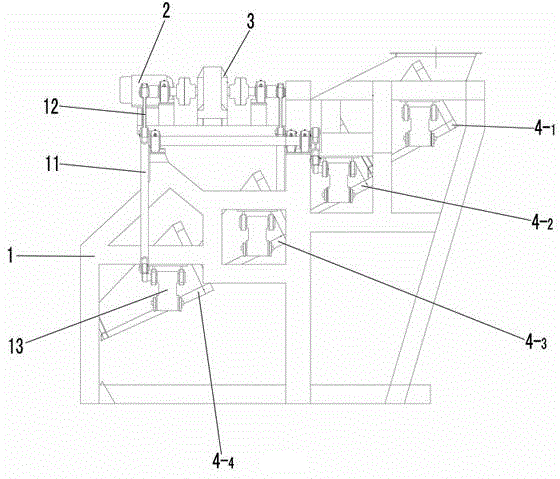

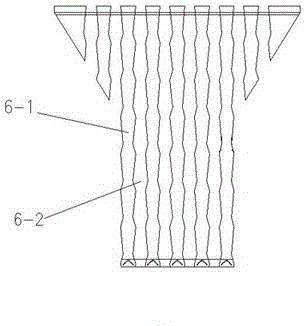

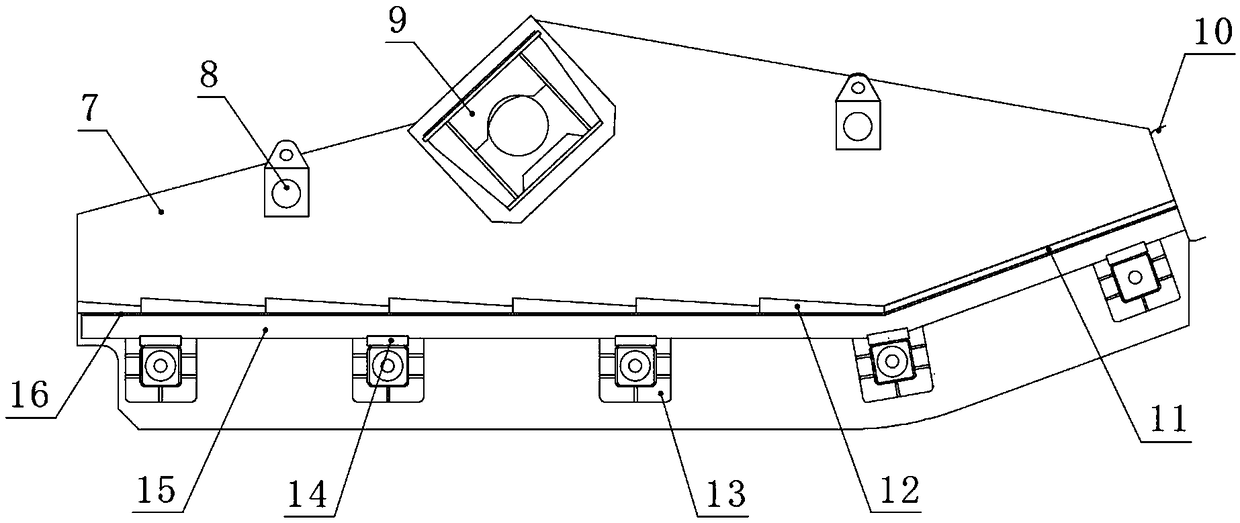

Tobacco bale loose treatment device and tobacco bale loosening reversion processing method

InactiveCN101444326AReduce breakageKeep the aromaTobacco preparationEngineeringMechanical engineering

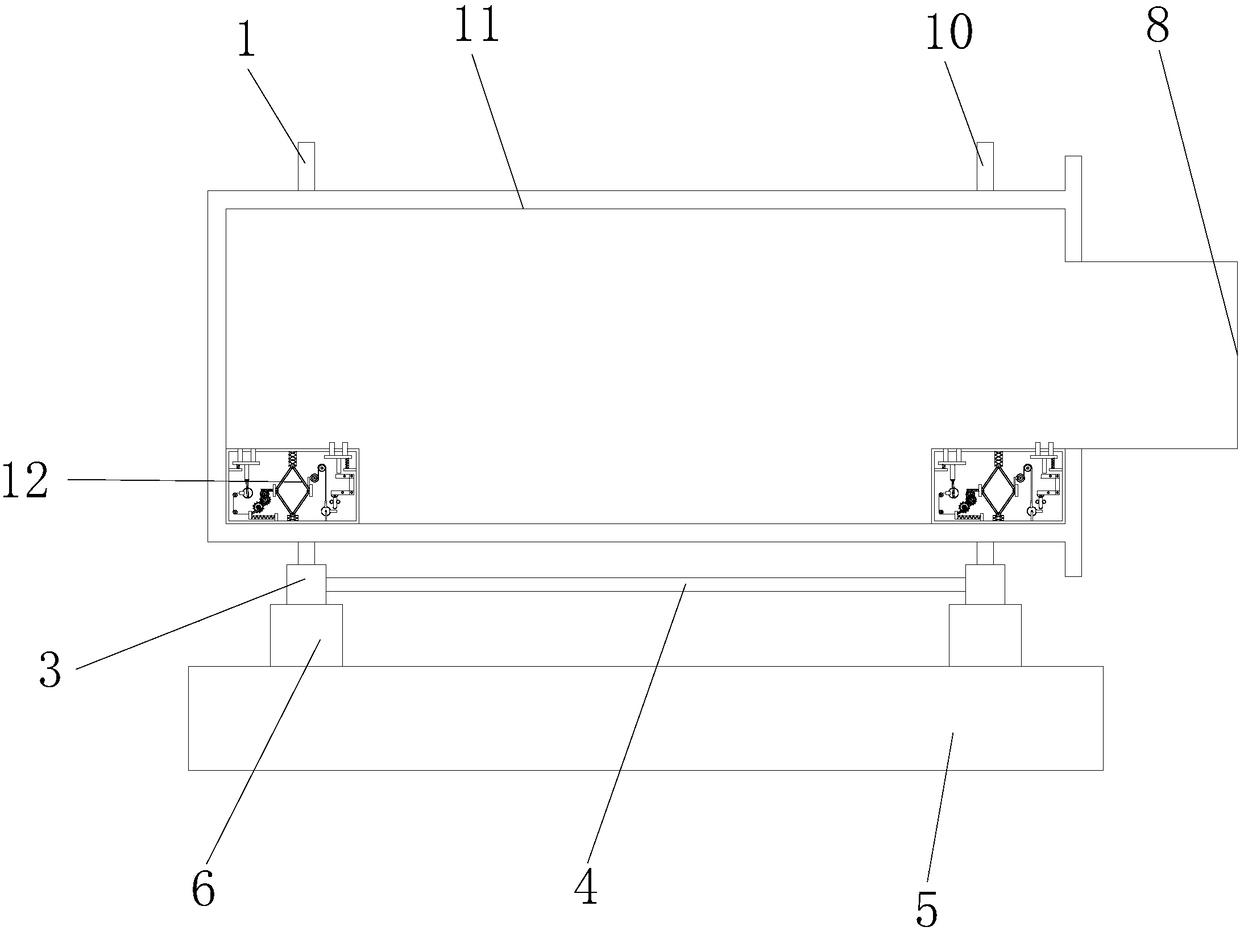

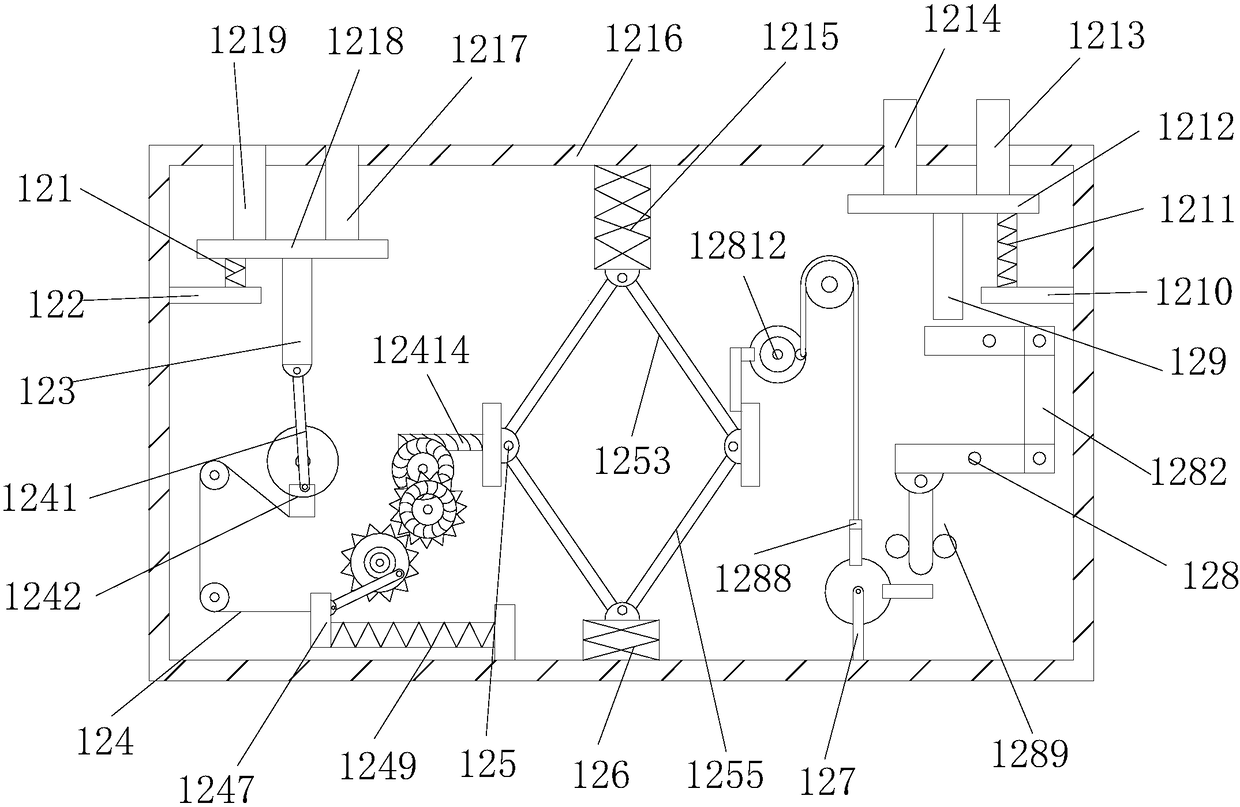

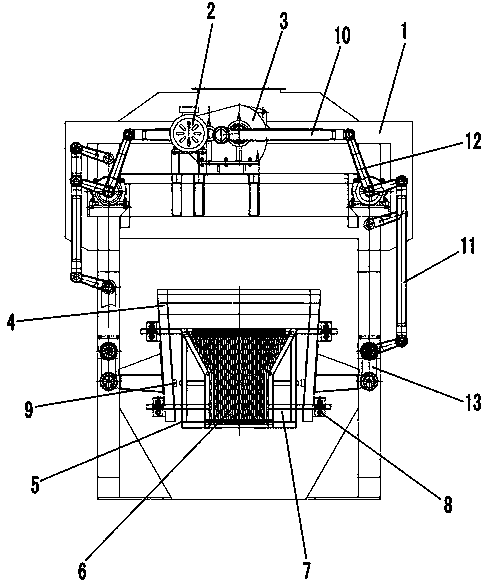

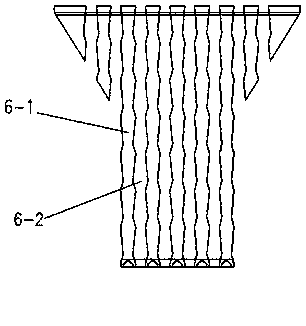

The invention provides a tobacco bale loosening treatment device which has higher loosening rate and lower process cost on the premise that the lower breaking rate is retained and a tobacco bale loosening reversion processing method thereof. The tobacco bale loosening treatment device comprises a tobacco delivery device, a loosening device and a tobacco flake delivery device. The loosening device is a vibrating thrasher and comprises a vibrating box body for containing a tobacco bale; a plurality of supporting plates are laid at the bottom part of the vibrating box body; an elastic tobacco bale stable pressing plate is mounted at the upper part of the vibrating box body to press the top part of the tobacco bale, so that the direction of a tobacco flake lamina is perpendicular to a supporting plated surface; the tobacco flake delivery device is mounted under the supporting plates; and a plurality of vibrating elastic supporting members are mounted at the bottom part of the vibrating box body and drives the vibrating box body to vibrate by a vibrating motor. The tobacco bale loosening reversion processing method comprises the following steps: removing packages, loosening the tobacco bale and reversing tobacco flakes; and the tobacco bale is vibrated and loosened by the vibrating thrasher. When the invention is used for loosening the tobacco bale, not only the flake is not required to be cut, but also the mechanical type strong loosening is not required to be conducted by a polygon rake; and the tobacco flake is completely and naturally stripped through vibration, so that the broken flaky tobaccos are greatly reduced.

Owner:ZHISI HLDG GRP

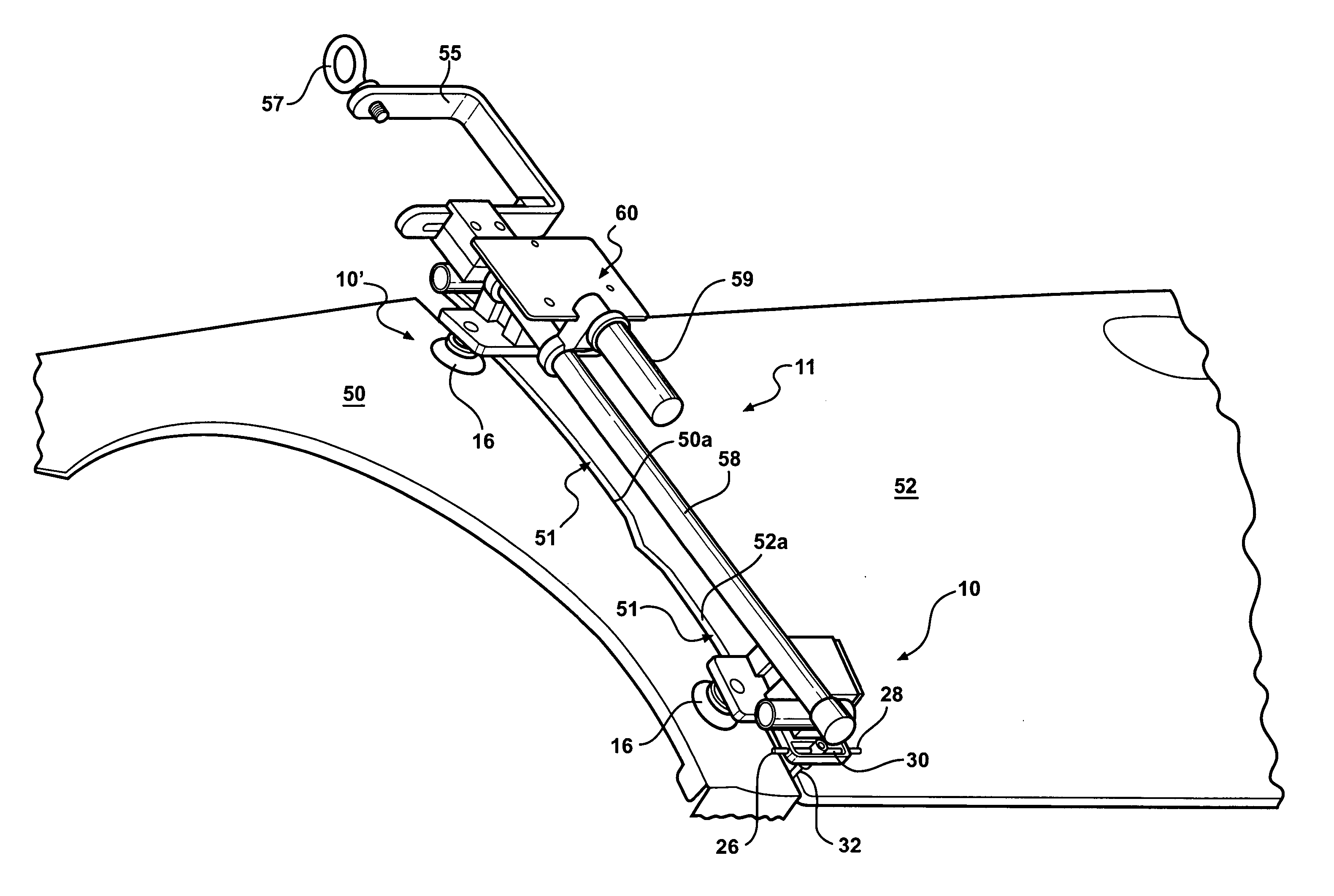

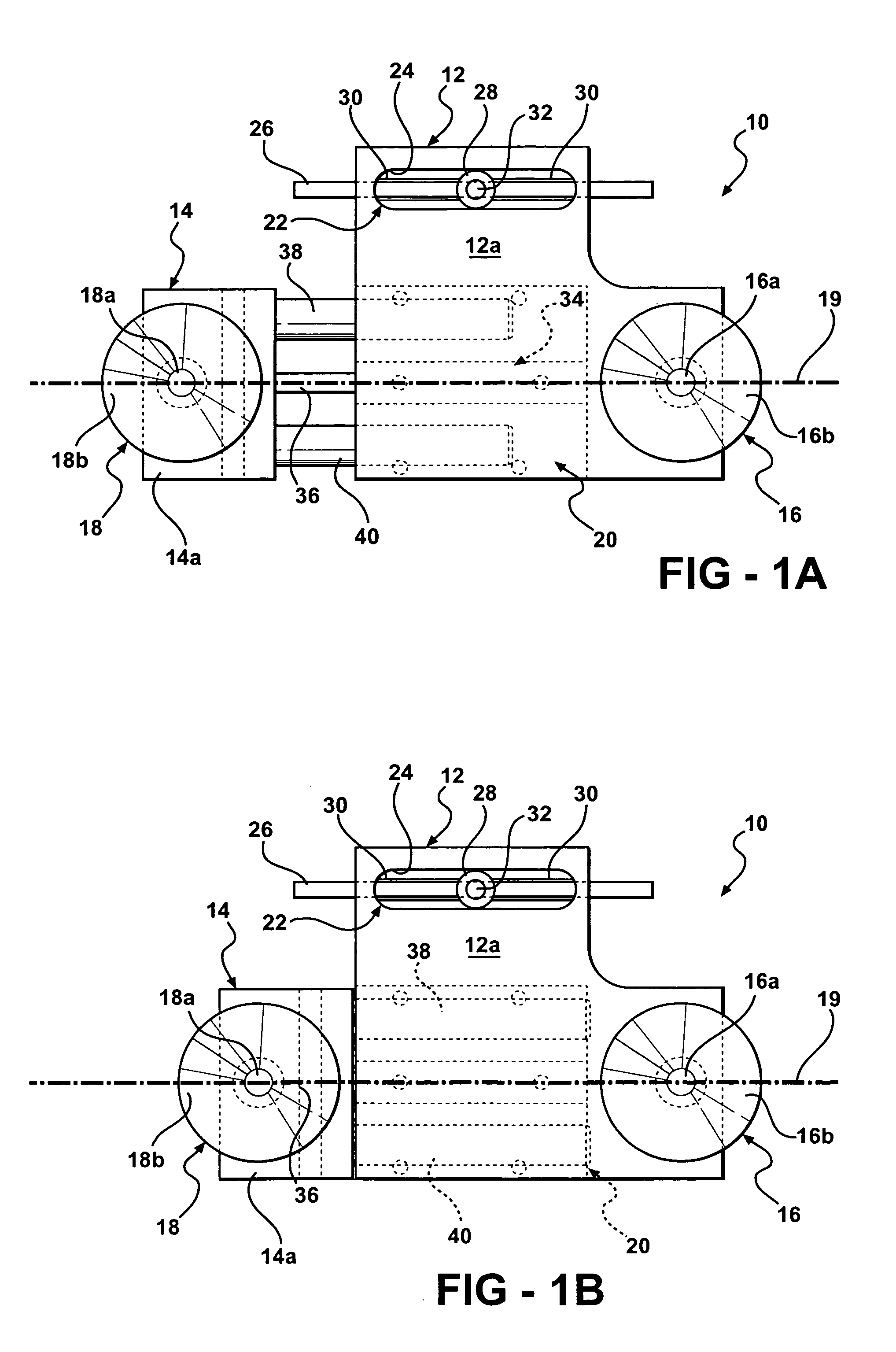

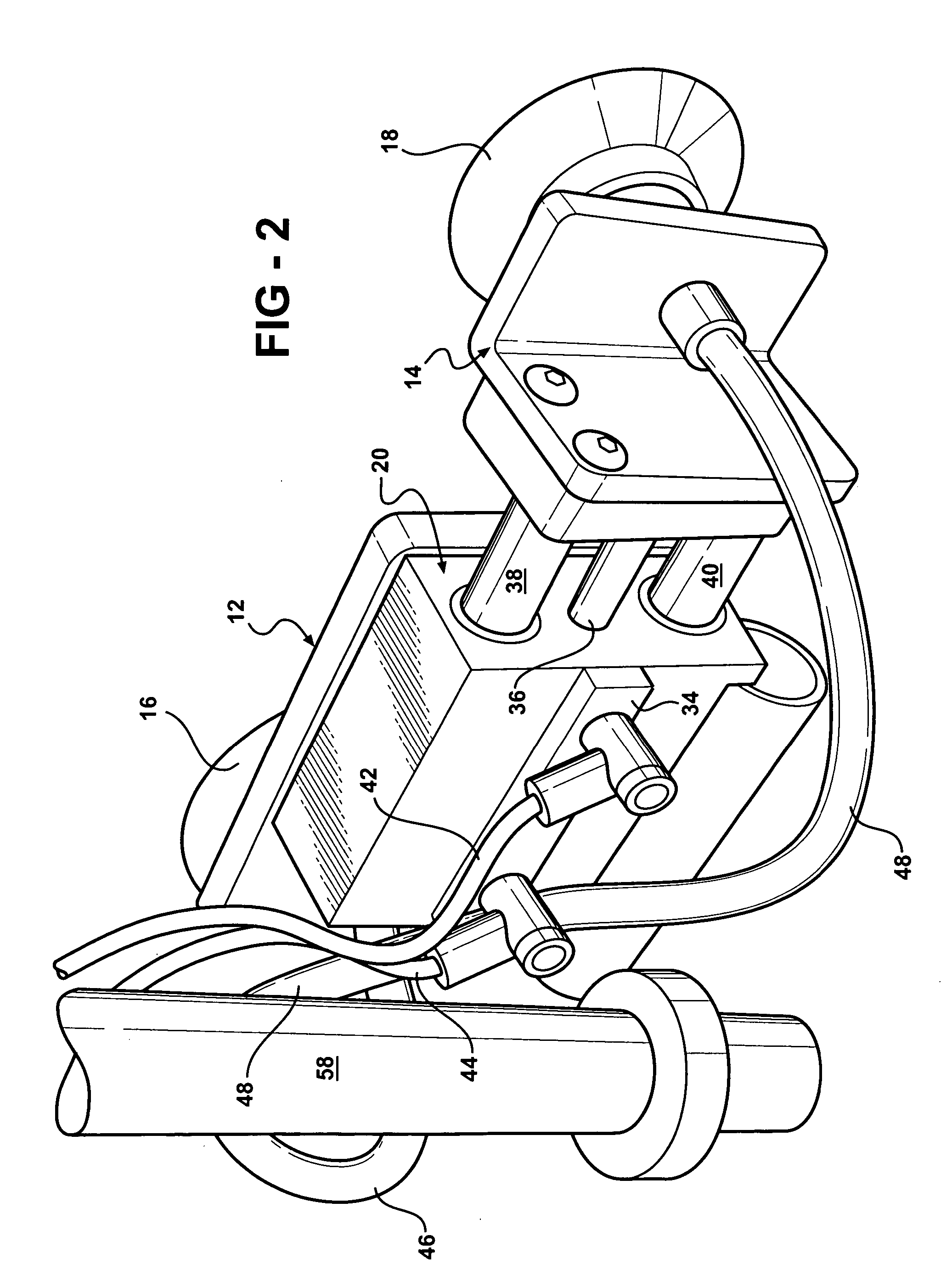

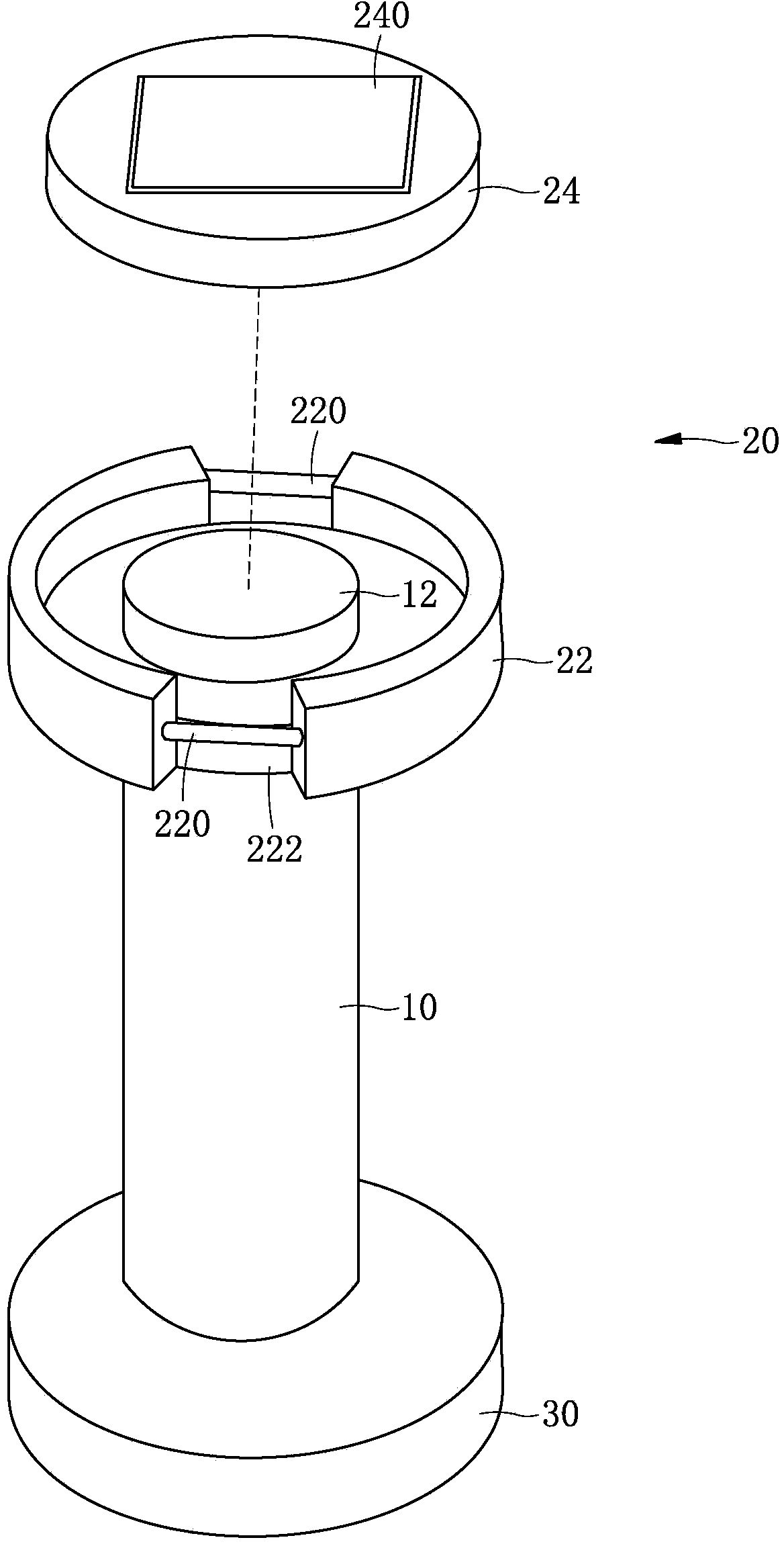

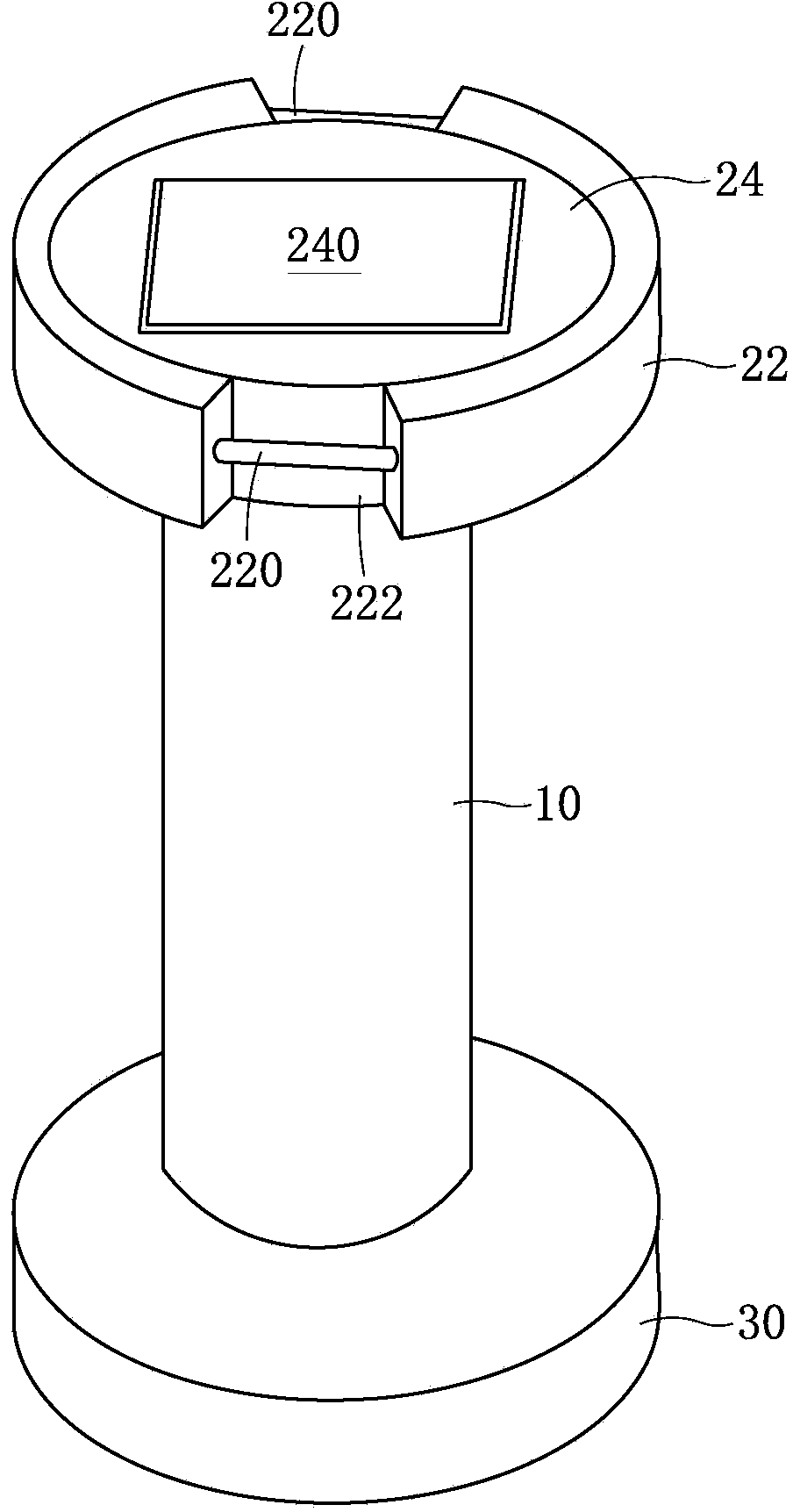

Gap setting tool and method of operating same

InactiveUS20050177991A1Improve efficiencyQuality improvementWork holdersVehicle componentsEngineeringSurface plate

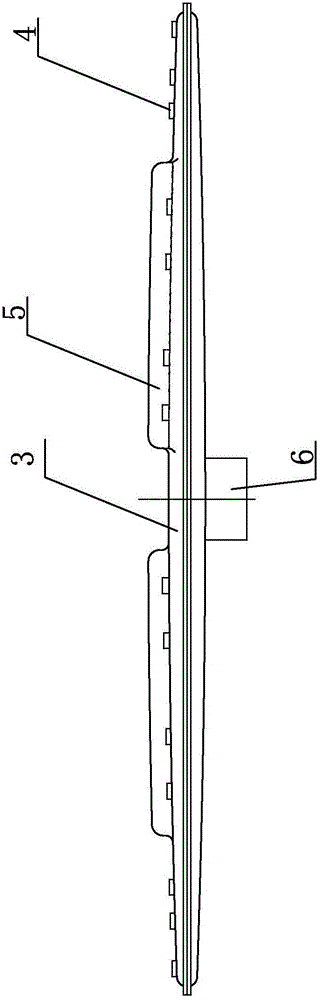

A gap setting tool for setting a gap between a pair of panels includes a first body portion, a second body portion, and a pin having a predetermined diameter. The first body portion, the second body portion, and the pin are movable relative to one another. One of the panels is fixed and the other panel is movably mounted adjacent thereto. The body portions are operable to be attached to respective ones of the pair of panels, such as by vacuum cups or the like, and drawn toward one another with the pin in the gap until the panels contact the pin.

Owner:GM GLOBAL TECH OPERATIONS LLC

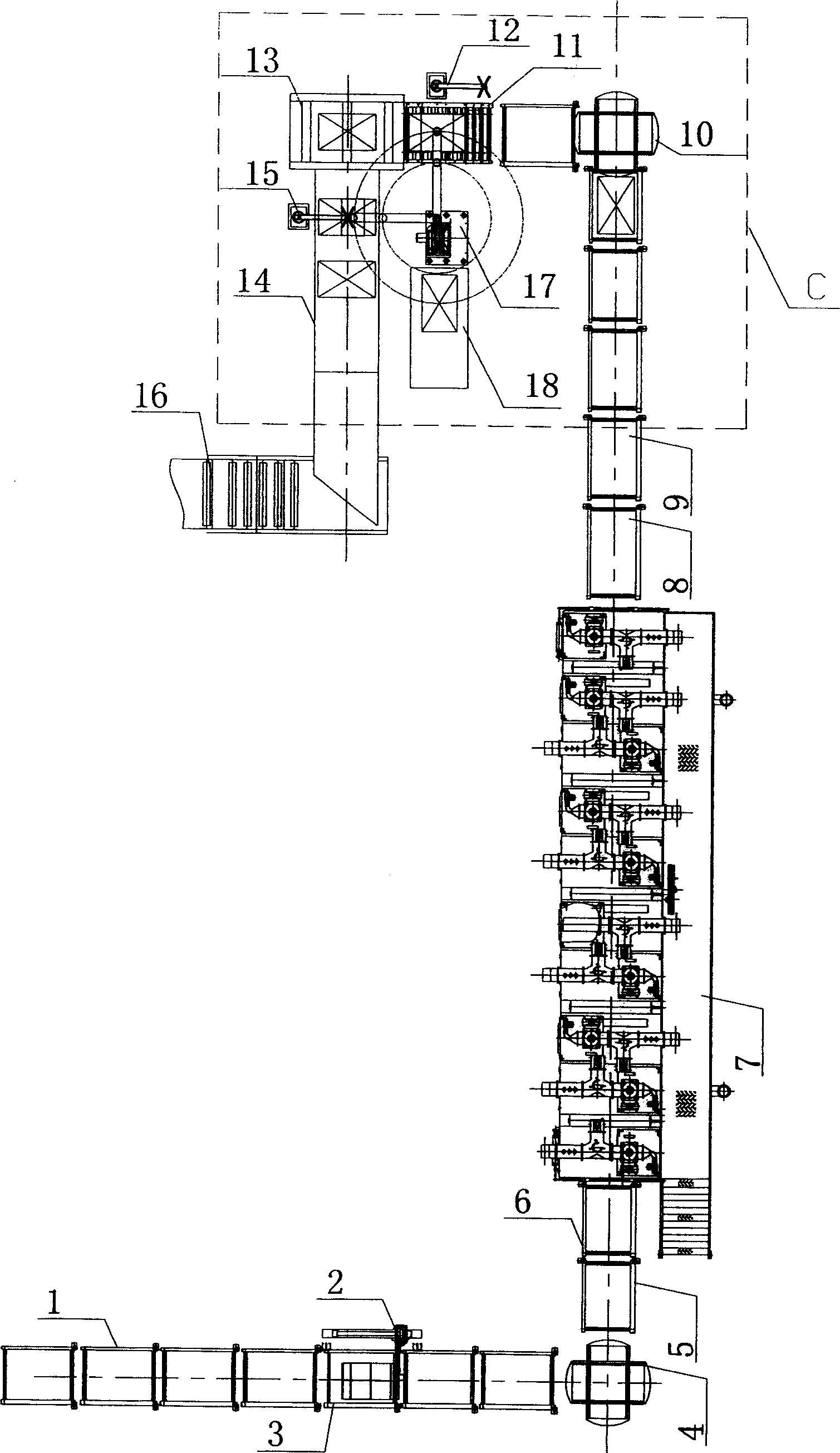

Tobacco leaf cut-tobacco-making pretreating process and production line

InactiveCN1709168ASimple processIncrease productivityTobacco preparationPre treatmentManufacturing line

The present invention relates to a pretreatment process for making tobacco shreds by using tobacco leaf and its production line. Said pretreatment process includes the following procedures: tobacco bale charging, stacking, cutting packaging band and recovering said packaging band, stacking broken tobacco bale, microwave heating, loosening and killing insects, stacking loosened tobacco bale, opening bale and loosely feeding material. Said production line includes several conveyer equipments, microwave heating, loosening and insects-killing equipment, bale-breaking and bale-opening equipment, packaging band cutting and recovering equipment and loosely material-feeding equipment, etc.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

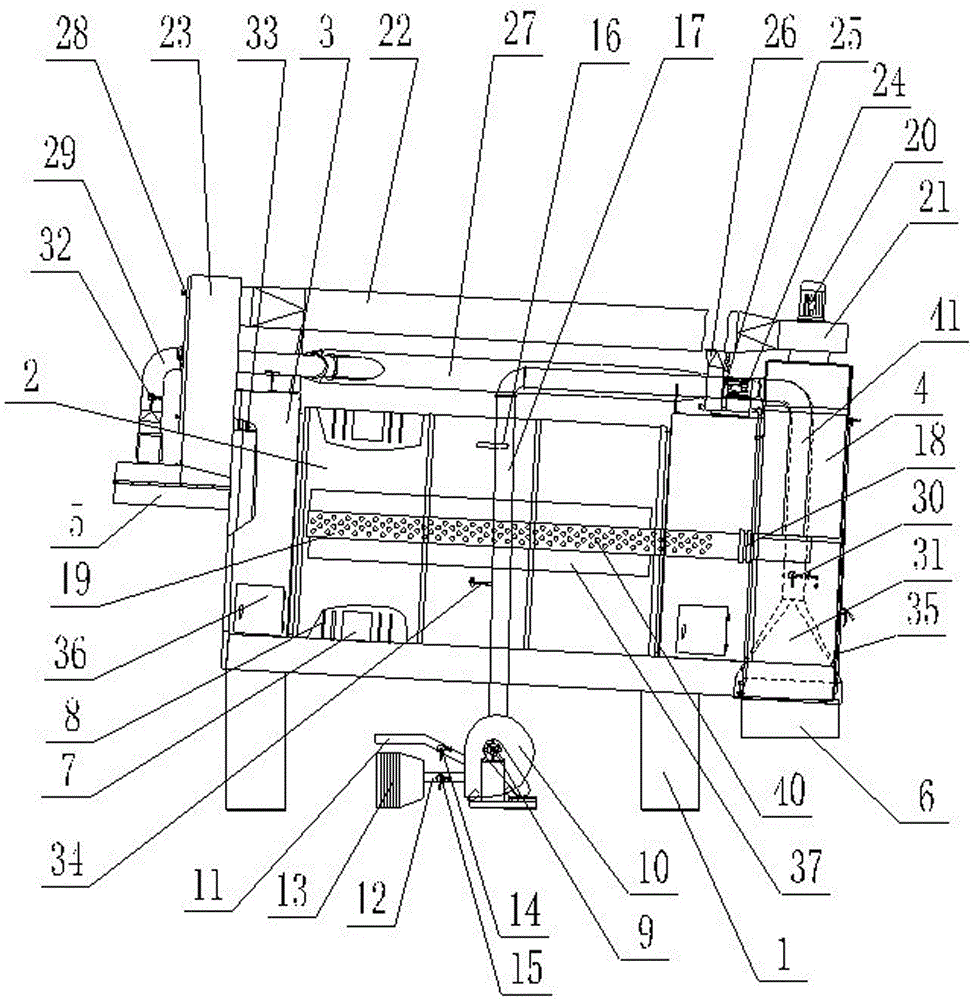

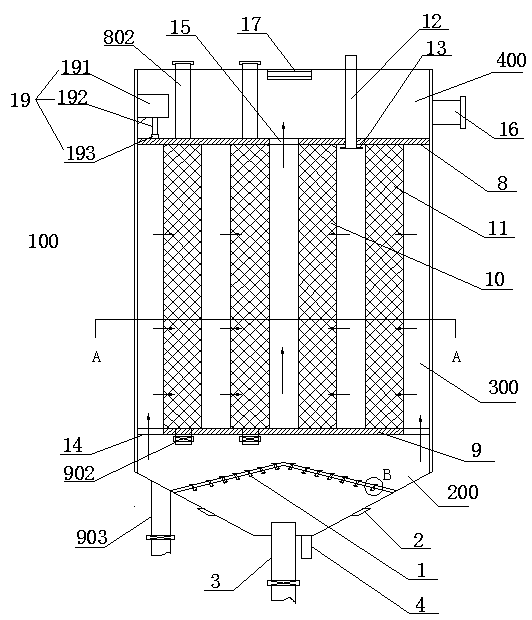

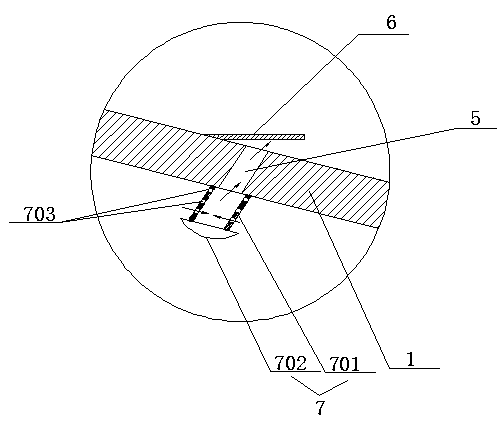

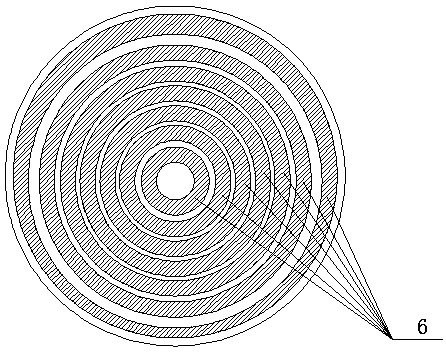

Moisture regain machine capable of improving warming and humidifying uniformity of tobacco leaves and reducing breakage

ActiveCN105533786AImprove the uniformity of warming and humidificationQuality improvementTobacco preparationPulp and paper industryMoisture regain

The invention relates to a moisture regain machine capable of improving the warming and humidifying uniformity of tobacco leaves and reducing breakage. A hot air pipeline system, a moisture removal pipeline system and a circulating air pipeline system are additionally arranged in the roller tobacco leaf moisture regain machine, a hot air outlet pipeline is provided with fins and rake nails, and through the fins and the rake nails arranged in a staggered mode, tobacco blocks can be better loosened, and the problem that the tobacco blocks which are not fully loosened still exist at an outlet of the roller type tobacco leaf moisture regain machine is solved. The material falling distance is divided into two segments through the fins of the hot air pipeline, and the material falling impact force is decreased; the 'air cushion' effect is formed through cross flowing of hot air and the materials, and the buffering effect on material falling is achieved; the falling materials are loosened and supported through conical shoveling nails arranged on the pipelines, and the purpose of improving the warming and humidifying uniformity of the materials is achieved, and the comprehensive quality and processing resistance of the tobacco leaves are integrally improved.

Owner:CHINA TOBACCO HENAN IND

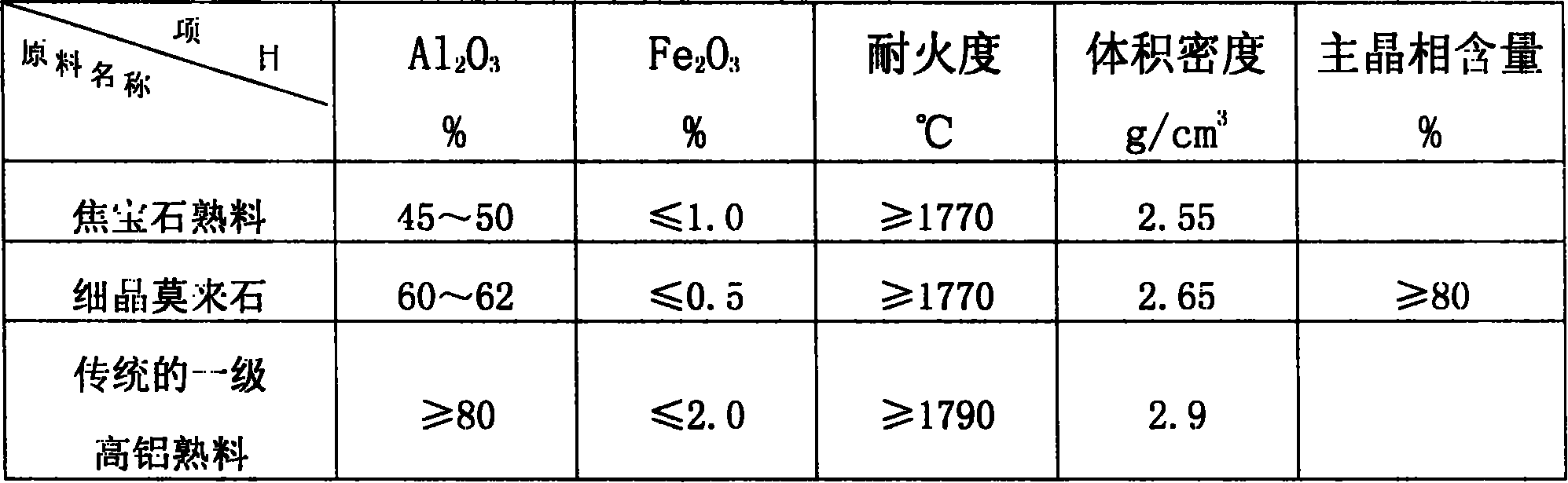

Flame-proof pouring material for hydroted alumina gas suspending roasting furnace furnace liner

The present invention provides a fire-resistant castable material of furnace lining for aluminum hydroxide gas suspension baking furnace. The fire-resistant castable material is a mixture of sintered coke sapphire chamotte and fine-grained mullite of good crystal structure in the sintering process, binder and composite additive according to different proportions; the lining of a main furnace body for aluminum hydroxide gas suspension baking furnace is prepared after furnace building, furnace baking and sintering. Wherein, the percentage of composition of raw materials is: 27 to 33 percent of coke sapphire chamotte less than 3mm, 25 to 30 percent of coke sapphire chamotte with a particle size between 3mm and 5mm, 8 to 15 percent of coke sapphire chamotte with a particle size between 5mm and 8mm, and 15 to 25 percent of fine-grained mullite powder with a particle size less than 0.074mm. The binder uses activated alumina of rho- Al2O3 of 5 to 8 percent; the composite additive uses high-dispersion oxidated alpha-Al2O3, superfine powder and silicon oxide SiO2; the contents of the superfine powder and the silicon oxide are respectively 2 to 5 percent; the particle size of the superfine powder is less than 5 Mu m; the content of sodium tripolyphosphate is 0.1 to 0.3 percent.

Owner:阮克胜

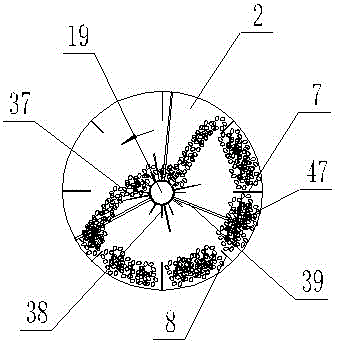

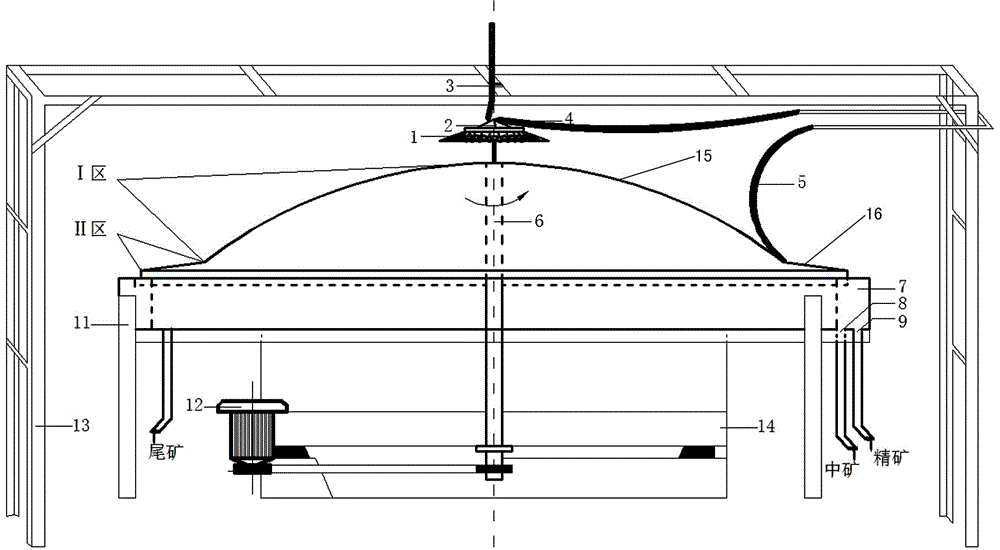

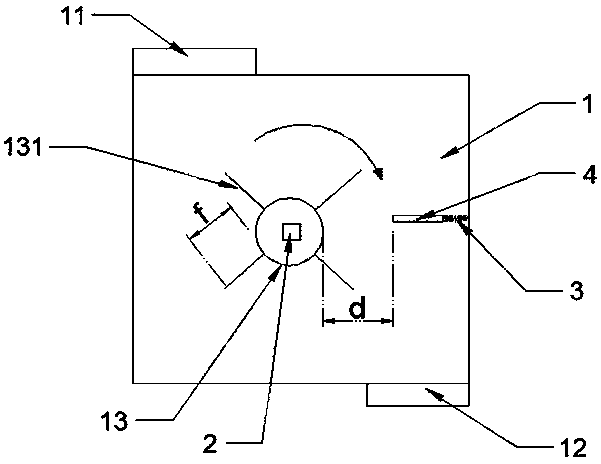

Method and equipment for processing mineral by jointly using gravity, centrifugal force and vibration force

InactiveCN102091669ASolving Intermittent Job ProblemsIncrease productivityWet separationEngineeringGravitational force

The invention disclose a method and equipment for processing mineral by jointly using gravity, centrifugal force and vibration force, belonging to the technical field of industrial mineral separation. The equipment comprises an upper conic cylinder and a lower conic cylinder which are perpendicular to each other; a rotating shaft is arranged in the upper conic cylinder along the center axis of the upper conic cylinder; the upper conic cylinder is fixed on a support; the lower conic cylinder is movably connected with the support; the lower part of the upper conic cylinder is sleeved in the upper part of the lower conic cylinder; the upper end of the rotating shaft can be rotationally fixed on the support; a stream guide disc is fixed on the middle part of the rotating shaft; a conic rotating disc is fixed on the lower end of the rotating shaft; a gap is left between the edge of the conic rotating disc and the inner wall of the upper conic cylinder to form a circular seam; the upper part of the upper conic cylinder is provided with an air intake pipe; the inlet of an upper tailing pipe is provided with a slurry measuring sensor; a vibration table is fixed in the lower conic cylinder; a material measuring sensor is arranged on the vibration table; a concentrate pipe is connected to the wall of the lower conic cylinder; a vibration joint is fixed on the lower end of the lower conic cylinder; and the vibration joint is connected with a vibration mechanism.

Owner:XUZHOU INST OF ARCHITECTURAL TECH

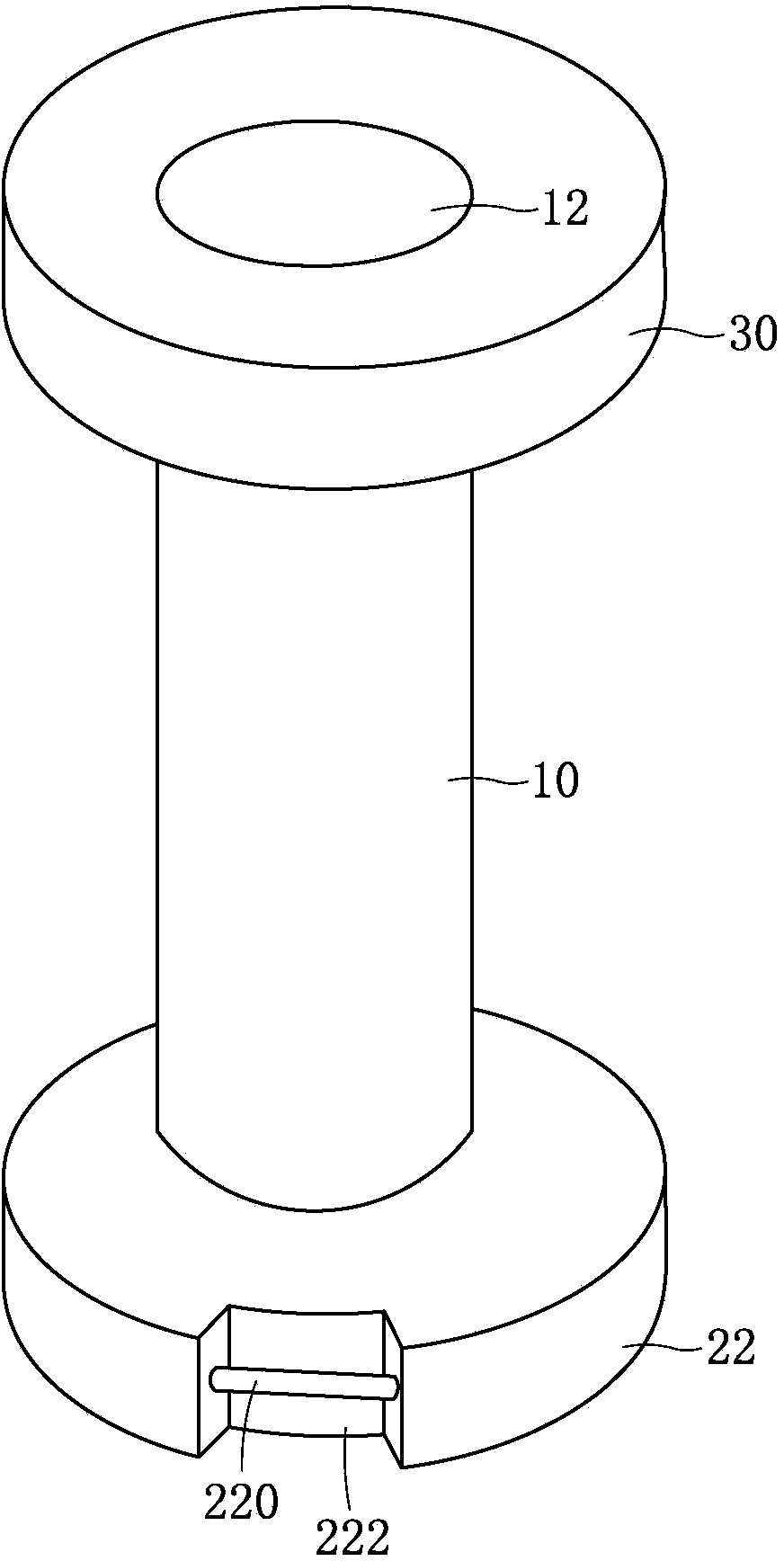

Textile machine bobbin

The invention discloses a textile machine bobbin, and relates to the technical field of textile machines. The textile machine bobbin comprises a cylindrical bobbin body, an axle hole penetrating through the two ends of the bobbin body is formed in the center of the bobbin body, a first edge disc and a second edge disc are arranged at the two ends of the bobbin body respectively, the axle hole extends to the outer side of the first edge disc and the outer side of the second edge disc, the first edge disc comprises an edge disc body fixedly connected with the bobbin body, grooves are formed in the edge part of the edge disc body, a yarn plugging rod is arranged in each groove, and the two ends of each yarn plugging rod are fixed to the two opposite side walls of the corresponding groove respectively. The textile machine bobbin solves the technical problems that yarns wound on the bobbin are prone to loosening and difficult to distinguish in the prior art. The textile machine bobbin is reasonable in structure and capable of preventing yarns from loosening, workers can distinguish the varieties of the yarns easily, production efficiency and the working efficiency of the workers are improved effectively, and the labor intensity of the workers is relieved.

Owner:CHANGYI XINDA ELECTROACOUSTIC TECH

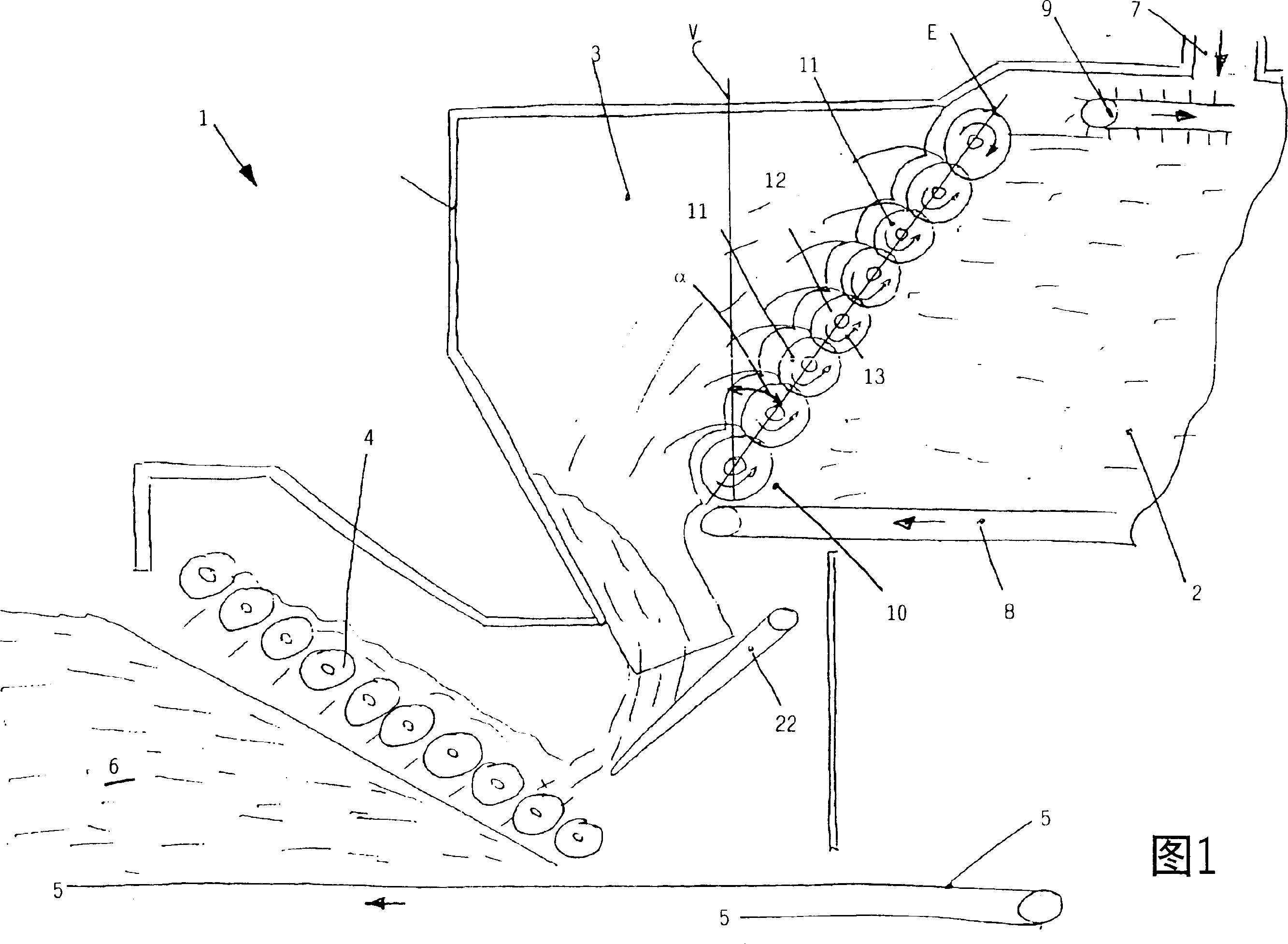

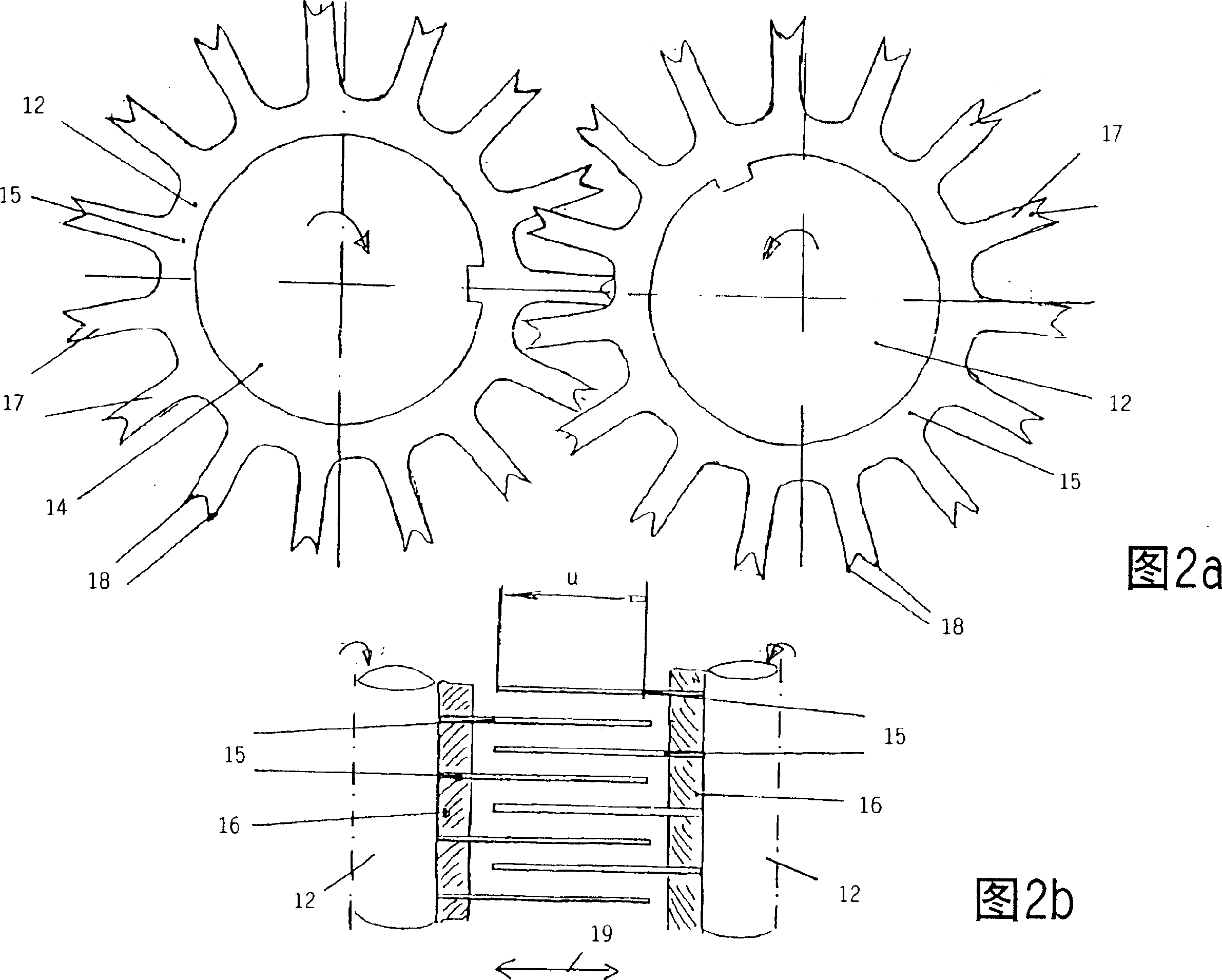

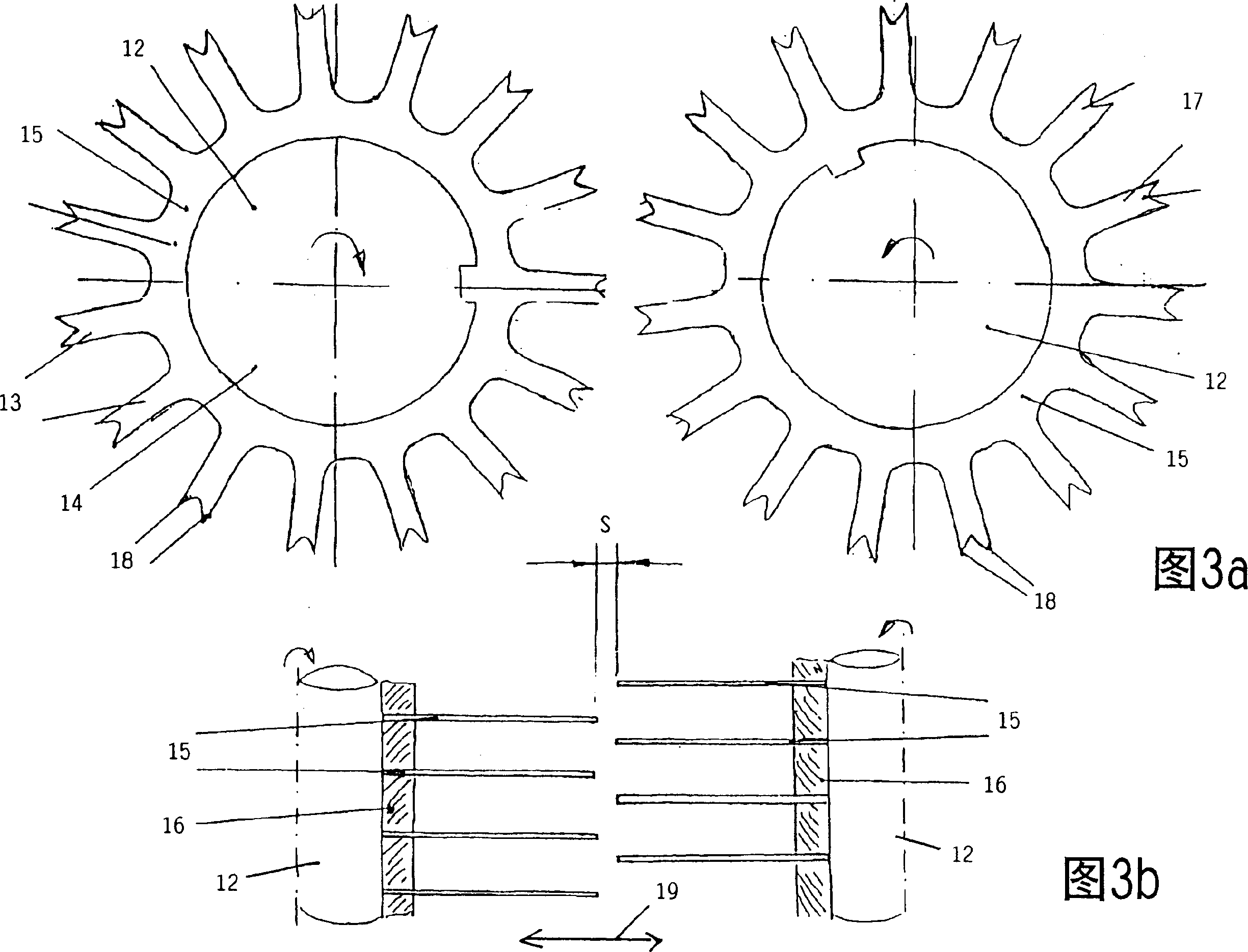

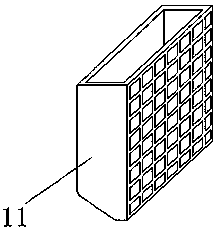

Device for distributing granular material onto a continuously travelling support and bunker for granular material

InactiveCN1532032ASatisfy the function of loose materialReduce the height of the structureDomestic articlesFlat articlesBunkerEngineering

The scattering apparatus (1) includes a roller arrangement (11) which is arranged in the discharge section (10) of a metering hopper (2). The roller arrangement processes the scattered grits. An Independent claim is also included for a hopper.

Owner:DIEFFENBACHER GMBH & CO KG

Carbonization treatment method of wood plate

ActiveCN107160519APromote looseIncreasing the thicknessPressure wood treatmentWood treatment detailsSurface layerCarbonization

The invention discloses a carbonization treatment method of a wood plate. The carbonization treatment method comprises the following steps of (1) plate cleaning, (2) surface modification treatment, (3) soaking treatment, (4) carbonization treatment, and (5) cooling treatment. According to the carbonization treatment method, the carbonization effect on the wood plate can be effectively improved, the thickness of a surface carbonization layer of the wood plate is effectively increased, the carbonization rate of a surface layer material of the wood plate is also well increased, meanwhile, reasonably-added nanometer silica enhances the density and mechanical property of the surface layer, the machining defective rate is obviously decreased, and good service value is achieved.

Owner:FUNAN NATURE ARTS & CRAFTS

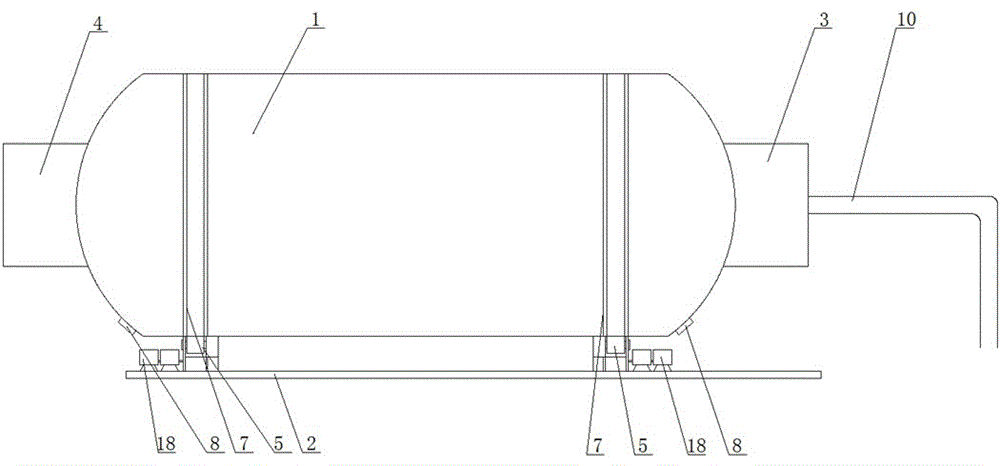

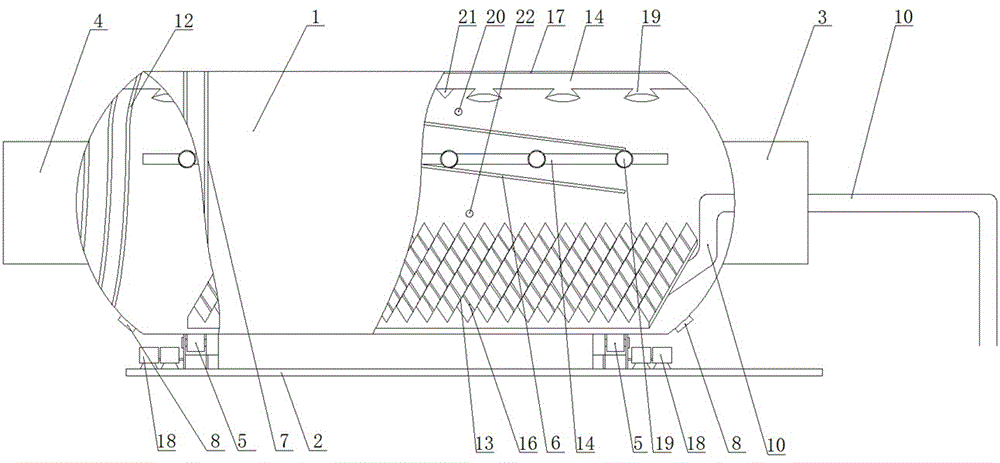

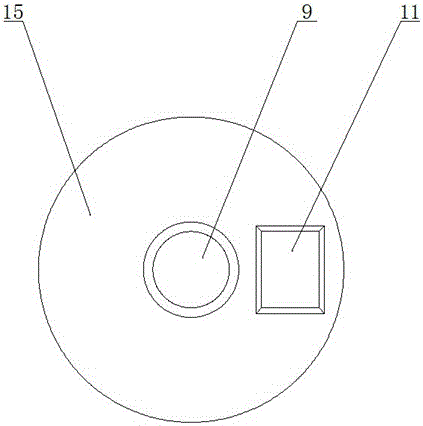

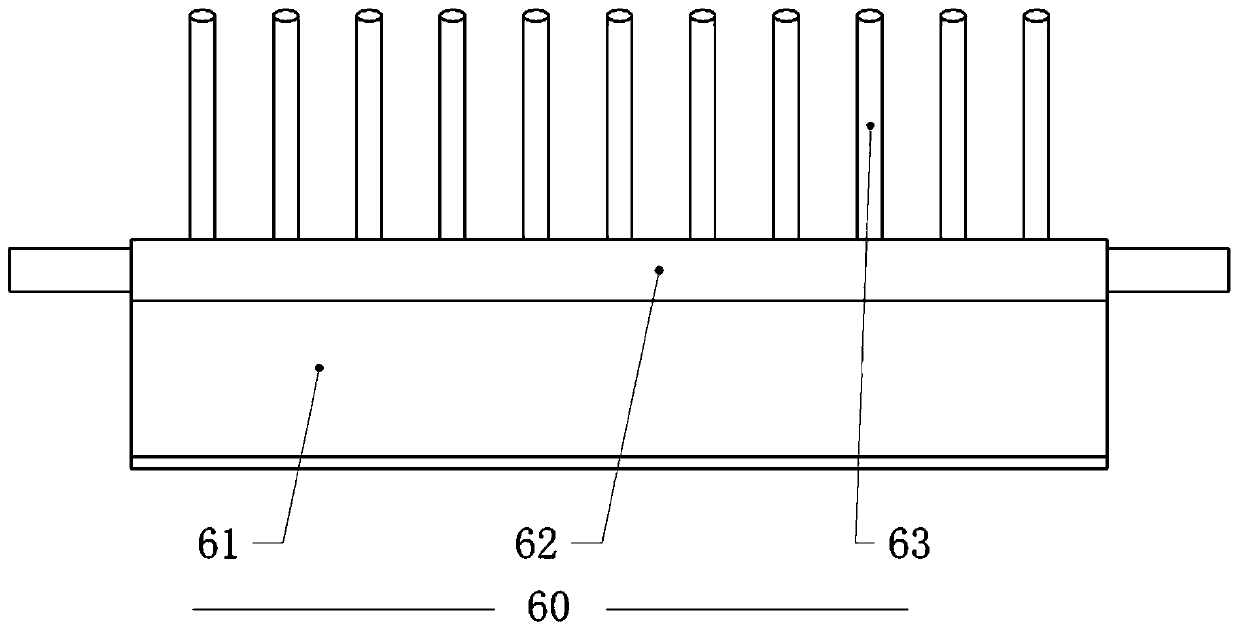

Biological fermentation all-in-one machine

InactiveCN106318862AReduce wearReduce chance of deflectionBioreactor/fermenter combinationsBiological substance pretreatmentsFermentationLeather belt

The invention discloses a biological fermentation all-in-one machine. The biological fermentation all-in-one machine comprises a drum. The drum is movably supported on an underframe by four supporting wheels at two ends of the underframe, a feeding port is formed in one end face of the drum, a discharging port is formed in the other end face of the drum, and a plurality of shovelling plates forming included angles with the axis of the drum are arranged on the inner wall of the middle of the drum. A feeding device corresponding to the feeding port is arranged at one end of the drum, two belt rings meshing with the supporting wheels arranged on the underframe are arranged at two outer ends of the drum circumferentially, and discharge outlets are formed in the edges of two ends of the drum respectively. A rolling shaft is arranged on the feeding port, communicated hoses are arranged inside and outside the rolling shaft, and the feeding port is provided with an observation window. A spiral guide-out device in tight fit with the drum is arranged inside the end of the discharging port, a serrated koji bed, spraying devices and sensors are arranged inside the drum, and a steel plate as heavy as the koji bed is welded inside the drum (1) and oppositely to the koji bed. The biological fermentation all-in-one machine is provided with an automatic spraying system and is simple to operate, convenient to run and capable of being stopped at a designated position at any time, monitoring interior conditions in real time and detecting the temperature, the humidity and pH values.

Owner:TIANJIN TIDAI MEDICINE SCI & TECH

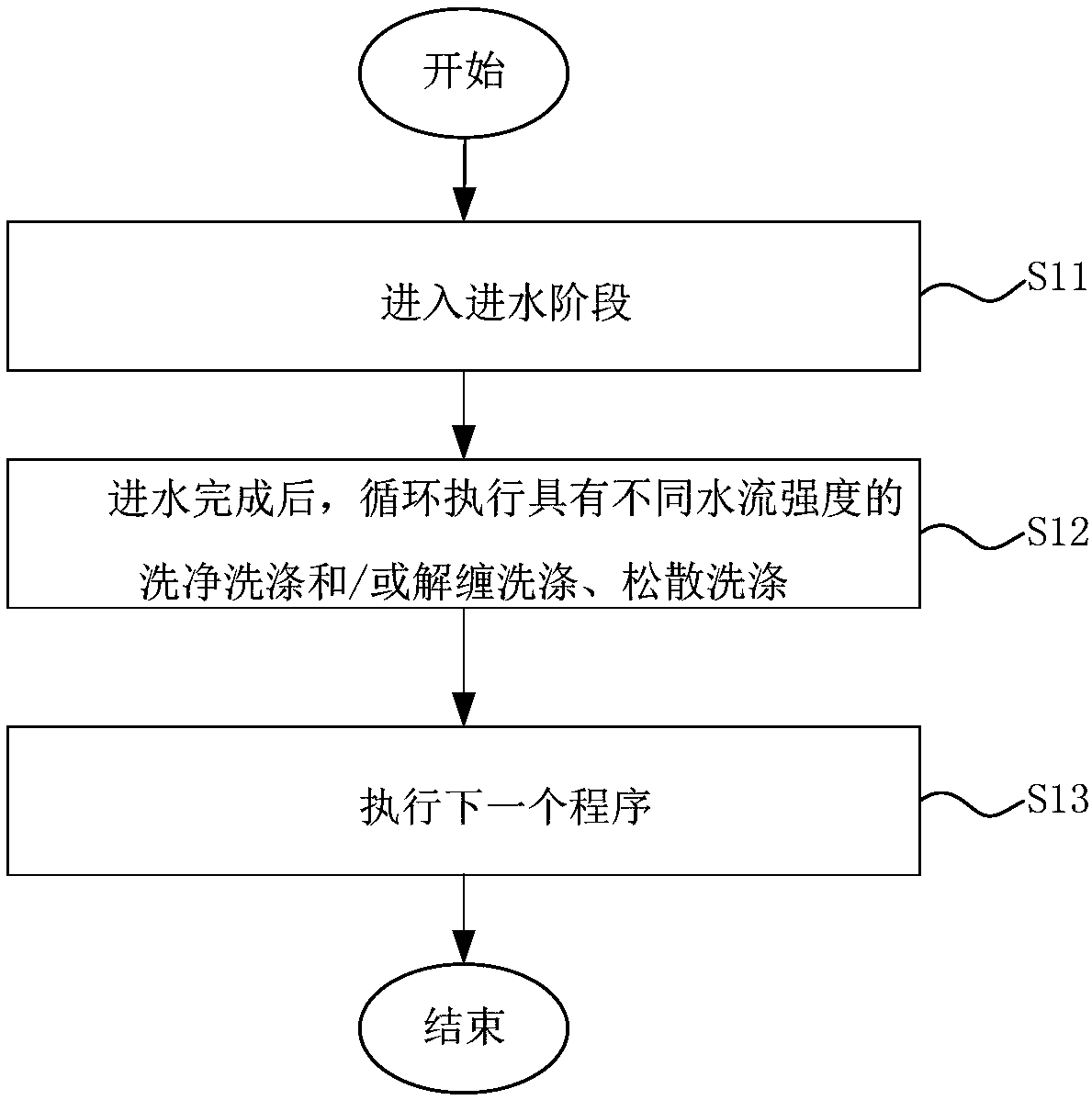

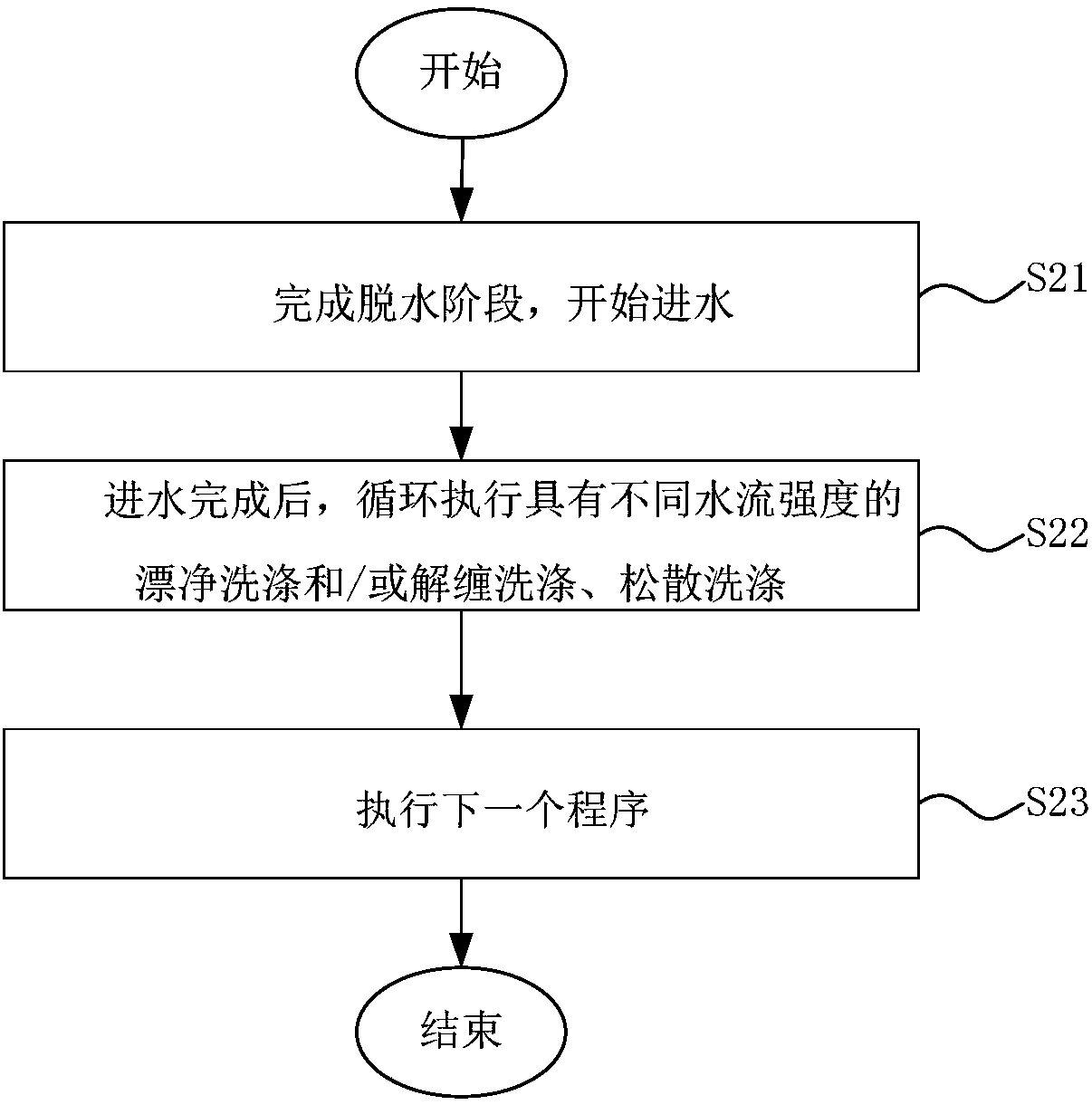

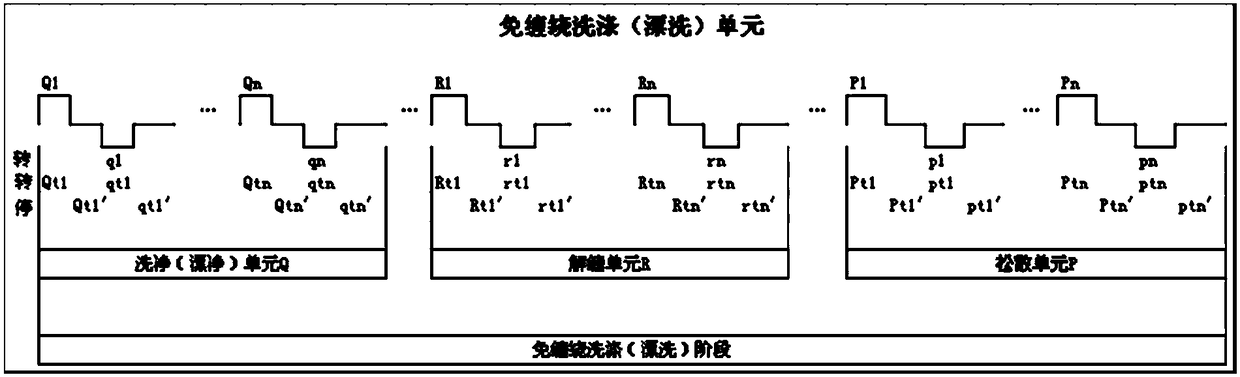

A pulsator washing machine and an entwining-preventing washing method thereof

InactiveCN108265458AIncrease the kneading areaWon't tangleOther washing machinesControl devices for washing apparatusWater dischargeWater flow

The embodiments of the invention provide a pulsator washing machine and an entwining-preventing washing method thereof. A washing process in the method includes a water inflow phase, a washing phase and water discharging phase, wherein in the washing phase, cleaning washing and / or disentanglement washing and loosening washing with different water current intensities are performed circularly. Thenthe next process is executed. A rinsing process in the method includes a spinning-drying phase, a water inflow phase, a rinsing phase and a water discharging phase, wherein in the rinsing phase, rinsing washing and / or disentanglement washing and loosening washing with different water current intensities are performed circularly. Then the next process is executed. The pulsator washing machine and the entwining-preventing washing method have the advantages that the rubbing area of relative movement among clothes and between clothes and water can be increased, the cleaning capability of the washing machine is improved, and the washing can achieve the effects of cleanness, evenness and looseness; clothes are prevented from entwining, so that the rinsing or spinning-drying in the next stage canbe performed conveniently; the entwining of clothes is effectively reduced, so that the experience of users is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

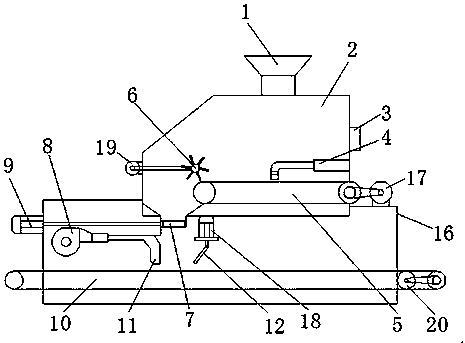

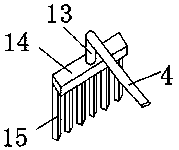

Spreading machine for wood fiber plate slab

The invention discloses a spreading machine for a wood fiber plate slab. The spreading machine comprises a machine body, and a feeding port is formed in the top end of the machine body. A material level indicator is fixedly mounted on the outer wall of the left end of the machine body, and the inner wall of the right end of an inner cavity of the machine body is fixedly connected with an electrictelescopic rod. The left end of the electric telescopic rod is fixedly connected with a connecting rod. The bottom end of the connecting rod is fixedly connected with a rake head, and rake teeth are fixedly mounted on the bottom end face of the rake head. The rake teeth are arranged to be triangular, and a first conveying belt is rotationally mounted at the bottom end of the machine body. The raketeeth are arranged above the first conveying belt and are not in contact with the top face of the first conveying belt, a second motor is fixedly mounted on the outer wall of the left end of the machine body, and the inner cavity of the machine body is fixedly connected with a shifter. The spreading machine for the wood fiber plate slab is used for loosening machine body fibers conveniently, it is avoided that the fibers are stacked into clusters and fiber plates in subsequent procedures are even in thickness, looses are avoided, and raw materials are saved.

Owner:沭阳县东泰木质纤维粉有限公司

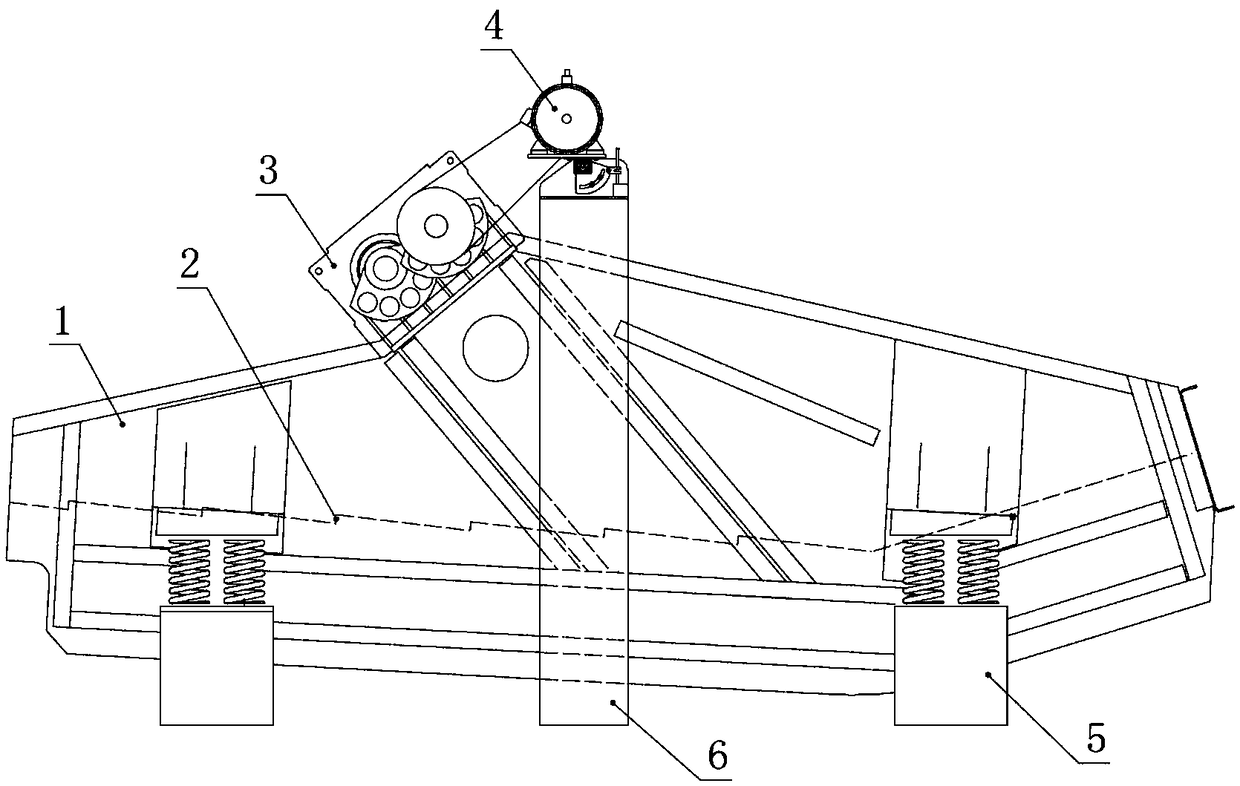

Conical trajectory vibrating screen

The invention discloses a conical trajectory vibrating screen, and belongs to the field of vibrating screening machines. Vibrating strength of a screening machine is matched with distribution of materials on a screen face. The vibrating screen is mainly composed of a screen box, the screen face, vibrators, a vibrating reduction supporting device and a base. The vibrators are mounted on the feeding end of the screen box, and the feeding end of the screen box is connected with the base through the vibrating reduction supporting device; the discharging end of the screen box is hinged to a spherical support fixed to the base through an elastic rod or connecting rod; the length of the elastic rod is smaller than the length of the screen box; and the vibrators are single-shaft vibrators, and the center line of a vibration shaft of each single-shaft vibrator passes through the center of the spherical support located on the base. The spherical support is in sliding connection or rolling connection with the elastic rod. According to the vibrating screen, the damage force of the resonance phenomenon to a screening machine during starting or closing down is greatly reduced; and the vibrating screen has the beneficial effects of being reasonable in structure, stable in work and high in screening efficiency, saving raw materials and energy and the like and is suitable for screening work of various materials.

Owner:鞍山鞍重矿山机械有限公司

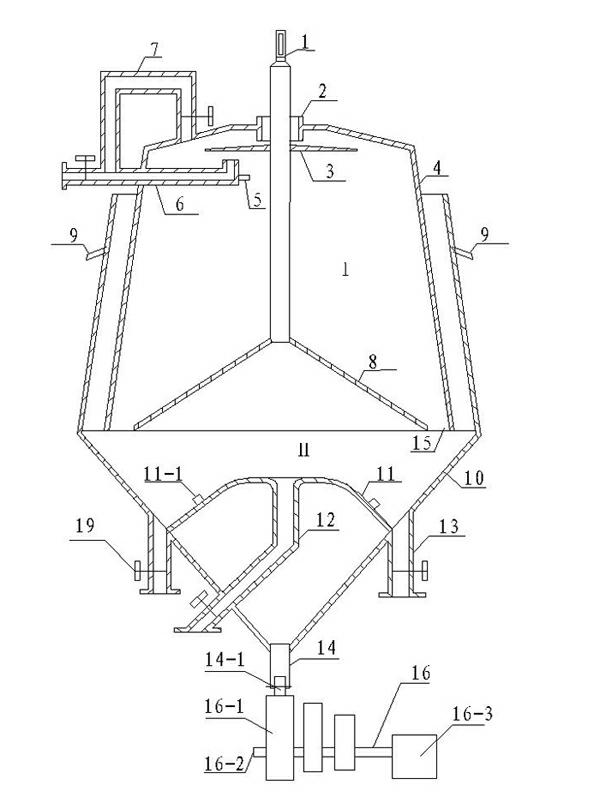

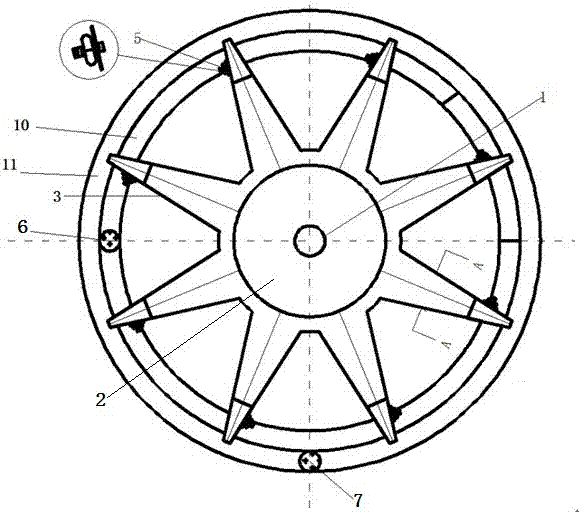

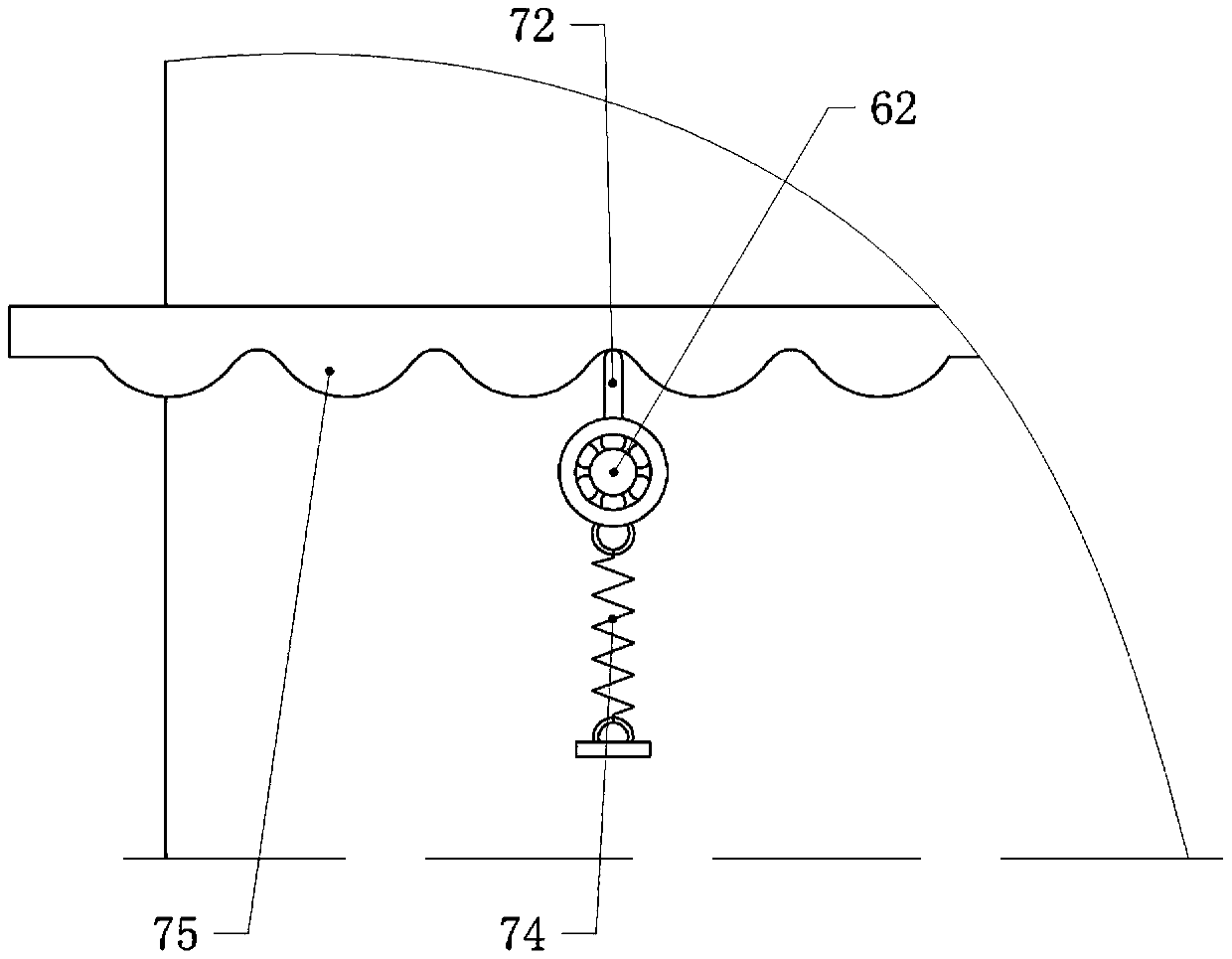

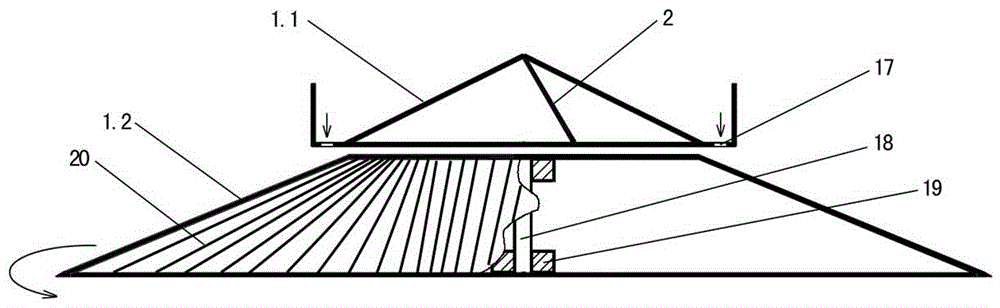

Tapered centrifugal beneficiation equipment

ActiveCN106925436APromote loosePromote stratificationRotary centrifugesElectric machineClassical mechanics

The invention discloses tapered centrifugal beneficiation equipment. The tapered centrifugal beneficiation equipment comprises a central ore feeding pipe, a centrifugal rotating drum, shunting grooves, intercepting grooves, a hollow shaft rotating platform, a shell, a concentrate groove, a tailing groove, a driving motor, a hollow shaft and a machine frame, wherein the centrifugal rotating drum, the intercepting grooves, the hollow shaft rotating platform, the concentrate groove and the tailing groove are arranged in the shell, the centrifugal rotating drum is located in the center of the interior of the shell, the central ore feeding pipe penetrates through the shell from outside to be right opposite to the bottom of the centrifugal rotating drum, the shunting grooves are uniformly formed in the periphery of the centrifugal rotating drum, the intercepting grooves are formed in the tail ends of the shunting grooves, the concentrate groove is formed in the outlets of the shunting grooves, the tailing groove is formed in the outlets of the intercepting grooves, the centrifugal rotating drum is arranged on the hollow shaft rotating platform, the hollow shaft rotating platform is connected with the hollow shaft, the hollow shaft is connected with the driving motor, and the driving motor is arranged on the machine frame. The tapered centrifugal beneficiation equipment is environment-friendly, efficient, energy-saving, capable of automatically and continuously discharging concentrate and tailings, high in efficiency, low in cost and suitable for high-efficiency sorting of fine-grain mineral so that the sustainable development of resources can be realized.

Owner:KUNMING UNIV OF SCI & TECH

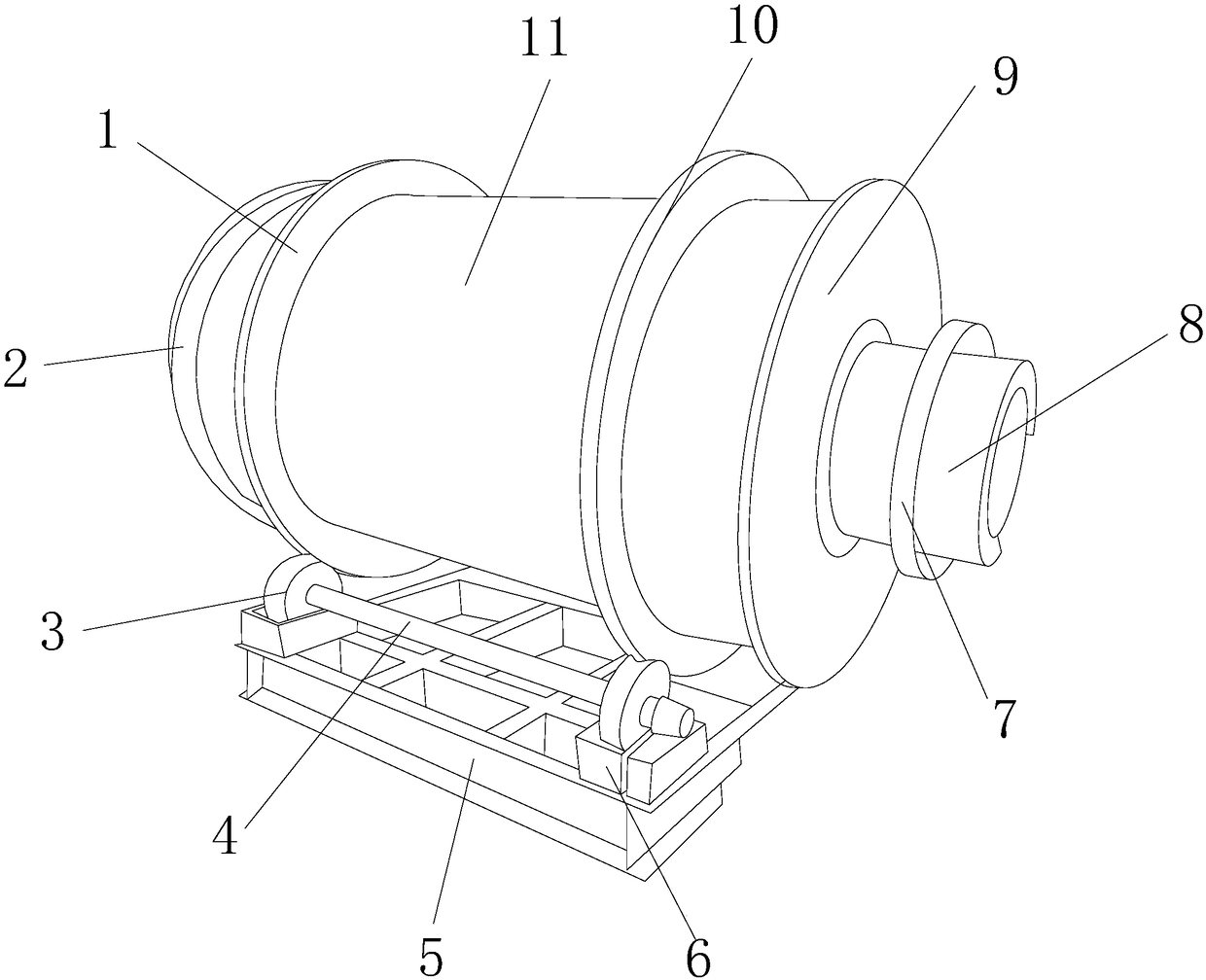

Rare earth efficient drying device for rare earth waste recovery

InactiveCN108444242AKeep dryPromote looseDrying chambers/containersDrying solid materialsRare earthEngineering

The invention discloses a rare earth efficient drying device for rare earth waste recovery. The rare earth efficient drying device for rare earth waste recovery structurally comprises a first fixed guide rail, a rear protective cover, supporting rolling wheels, a rolling wheel connecting transverse rod, a supporting base, rolling wheel limiting grooves, an adjustment supporting frame, a feeding pipe opening, a top end protective cover, a second fixed guide rail, a protective making shell and an adjustment loosening device. The outer surface of the feeding pipe opening is installed on the innerwall of the adjustment supporting frame in an integral structure manner. The left end of the feeding pipe opening is welded to the middle of the right end of the top end protective cover. The rare earth efficient drying device for rare earth waste recovery has the beneficial effects that because the adjustment loosening device is additionally arranged on the device, when the device carries out rare earth waste recovery drying operation, integrated regulation of rare earth can be carried out inside the device, that rare earth in the device can be in the loose state surely when being dried, rare earth can be dried quicker, the drying efficiency of the device is improved while it is guaranteed that the rare earth is dry, and the rare earth efficient drying device for rare earth waste recovery is practical.

Owner:刘志坤

Organic planting method for red-heart grapefruits

InactiveCN106233950APromote growthPromote respirationCultivating equipmentsHorticultureRapeseedSoil fertility

The invention discloses an organic planting method for red-heart grapefruits. The organic planting method includes the steps that red-heart grapefruit seedlings obtained after seedling culture are planted in blended soil, base fertilizer is applied during seedling culture and soil preparation, and the base fertilizer is prepared from 20-35 parts of soybean meal, 25-35 parts of rapeseed residues, 20-25 parts of earthworm soil and 25-30 parts of plant ash. The organic planting method has the advantages that the base fertilizer is applied to a nursery garden, which is beneficial for improving soil fertility in the nursery garden to promote seedling growth and increase the survival rate of the seedlings; humus in the soil can be increased by using the rapeseed residues, which is beneficial for the respiration of seeds or the roots of the seedlings, necessary elements needed by seed or seedling growth are supplemented, and the effect of promoting growth can be achieved.

Owner:CHENGDU ECOLOGICAL AGRI HUIFENG TECHCO

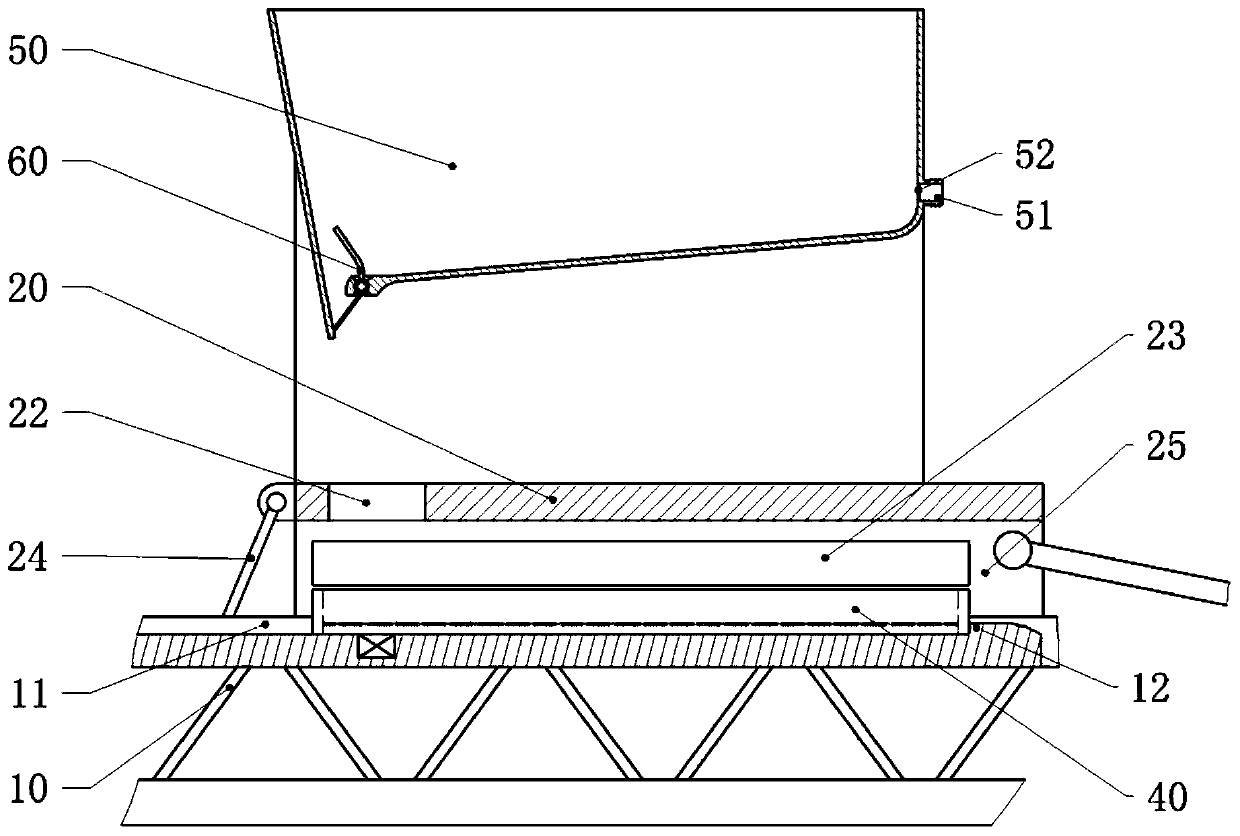

Tea spreading and cooling device

ActiveCN110892923AImprove loose stateAvoid blockingPre-extraction tea treatmentClimate change adaptationMechanical engineeringTea leaf

The application relates to a tea processing device, and particularly discloses a tea spreading and cooling device. The tea spreading and cooling device comprises a frame body, a spreading and coolingmechanism and a driving mechanism, wherein the spreading and cooling mechanism is arranged above the frame body, and the driving mechanism is arranged on the frame body; the frame body is provided with a track in the transverse direction; the spreading and cooling mechanism comprises a reciprocating sliding seat glidingly connected with the track; a hopper is fixed onto the reciprocating sliding seat; a strip-shaped discharge hole arranged in the longitudinal direction is formed in the bottom part of the hopper; the side wall of the strip-shaped discharge hole is hinged with a baffle through arotating shaft; the rotating shaft is provided with a torsional spring so as to make a material stop part seal the strip-shaped discharge hole through the torque of the torsional spring; the drivingmechanism drives the reciprocating sliding seat to do reciprocating sliding on the track; when the reciprocating sliding seat slides to the right, the baffle is in a vibrating state and opens the strip-shaped discharge hole intermittently; when the reciprocating sliding seat slides to the left, the baffle seals the strip-shaped discharge hole; a through slot arranged in the transverse direction and used for holding a spreading and cooling net is formed in the bottom face of the reciprocating sliding seat; and a spreading and cooling hole communicating with the through slot and opposite to thestrip-shaped discharge hole is formed in the upper part of the reciprocating sliding seat. The tea spreading and cooling device can automatically spread and cool tea in batches.

Owner:河南献民茶业有限公司

Special paint spray room cleaning device for effectively purifying and preventing clogging

InactiveCN109012019AExtended stayImprove purification effectGas treatmentDispersed particle separationOrganic solventTower

The invention relates to a special paint spray room cleaning device for effectively purifying and preventing clogging, and the special paint spray room cleaning device comprises a vertical purification tower. The vertical purification tower comprises a cone-shaped air inlet chamber, a purification chamber and an air outlet chamber from bottom to top in turn, the cone-shaped air inlet chamber is internally provided with a conical air diffusion plate, a cooling component, an air inlet pipe and a condensation discharge pipe. The purifying room is internally provided with an upper fixed plate, a lower fixed plate, an inner purifying layer and an outer purifying layer. One side of the air outlet chamber is connected with an air outlet pipe. The invention provides a special purifying device forpaint spraying room which can effectively purify and prevent blockage. The special paint spray room cleaning device is specially used for waste gas treatment in a paint spraying room after paint spraying treatment, can improve the effect of waste gas treatment and effectively purify organic solvents in waste gas. At the same time, the special paint spray room cleaning device can avoid blockage ofan adsorbent by the waste gas, has good adsorption and purification effect, fast speed, high adsorbent utilization rate, and large overall treatment capacity.

Owner:江苏亚一智能装备有限公司

Hydraulic rubbing type material storing and pushing bin equipment

The invention discloses hydraulic rubbing type material storing and pushing bin equipment which comprises a fixed support and a washboard type material pushing device which is mounted on the fixed support and is used for pushing materials forwards. The washboard type material pushing device is provided with a material box, and a material outlet is formed in the rear end of the washboard type material pushing device. Material evening devices which prevent the materials from arching and are used for scattering and evening the materials are mounted at the rear end of the material box and placed above the washboard type material pushing device. In the using process, solid materials conveyed by a conveying vehicle (or a conveying belt) enter a material bin, two sets of material pushing plates which are obliquely arranged at the bottom of the material bin make interaction movement through two hydraulic cylinders, and the materials are pushed forwards to the material outlet step by step. The material outlet is provided with two sets of the material evening devices, and the materials can be smoothly and evenly conveyed to the next conveying belt from the material outlet. The hydraulic rubbing type storing and pushing material bin equipment is suitable for solid waste treatment projects and capable of achieving the effects of temporarily storing the materials and pushing the materials to be conveyed smoothly.

Owner:SHAANXI XINYU SURFACE ENG

Fertilizer special for foxtail millet in dry farmland and preparation method thereof

InactiveCN105461490AIncrease productionHelps water retentionCalcareous fertilisersExcrement fertilisersBiotechnologyBulrush millet

The invention relates to a fertilizer special for foxtail millet in dry farmland and a preparation method thereof, and belongs to the technical field of fertilizers special for foxtail millet. The fertilizer is prepared from 30-50 parts of straw, 2-10 parts of weeds, 2-10 parts of fallen leaves, 30-70 parts of sheep manure, 5-15 parts of calcium oxide, 5-15 parts of potash fertilizer, 5-15 parts of urea, 10-20 parts of sterilized mellow soil, 5-15 parts of bran, 0.5-2 parts of sodium selenite, 0.2-2 parts of an EM bacterium stock solution and 100-230 parts of water. The fertilizer special for foxtail millet in dry farmland can increase the yield of foxtail millet and has the drought resisting and seedling strengthening effects.

Owner:ZIBO BEIYUANFU FOOD CO LTD

Coal screening machine low energy-consumption and high efficiency

The invention provides a coal screening machine with low energy-consumption and high efficiency. The coal screening machine comprises a rack, a screen body driving mechanism and a transmission mechanism. The coal screening machine is improved as follows: screen bodies are mounted on the frame in a transverse reciprocating motion manner, the transmission mechanism is composed of a connecting rod component which can drive the screen bodies to perform reciprocating swing transversally, or is composed of a connecting rod component and a connecting lever component hinged to the frame; collision heads or hard springs which are used for colliding the screen bodies so as to enable the screen bodies to be pulled back are arranged on the frames on the two sides of each screen body or screen body bearing bodies; a multi-stage screen body structure is composed of a plurality of screen bodies which swing independently and are longitudinally arranged in a one-list and stepped manner; a plurality of sieve meshes are formed between adjacent screen strips; the sieve meshes are communicated with one another, and become larger gradually and then become smaller suddenly from the coal-in direction to the coal-out direction; the screen strips are mounted in an up and down malposed manner. The coal screening machine has the benefits as follows: the condition for reducing installed power is created, the adaptability for screening inferior coal with large ash content and high water content is improved, the requirements of screening efficiency can be met under any working condition, the coal screening machine is a such coal screening machine that mostly corresponding to a screening mechanism, and the installed power and construction cost are the lowest under the condition of same labor force consumed.

Owner:马奎山

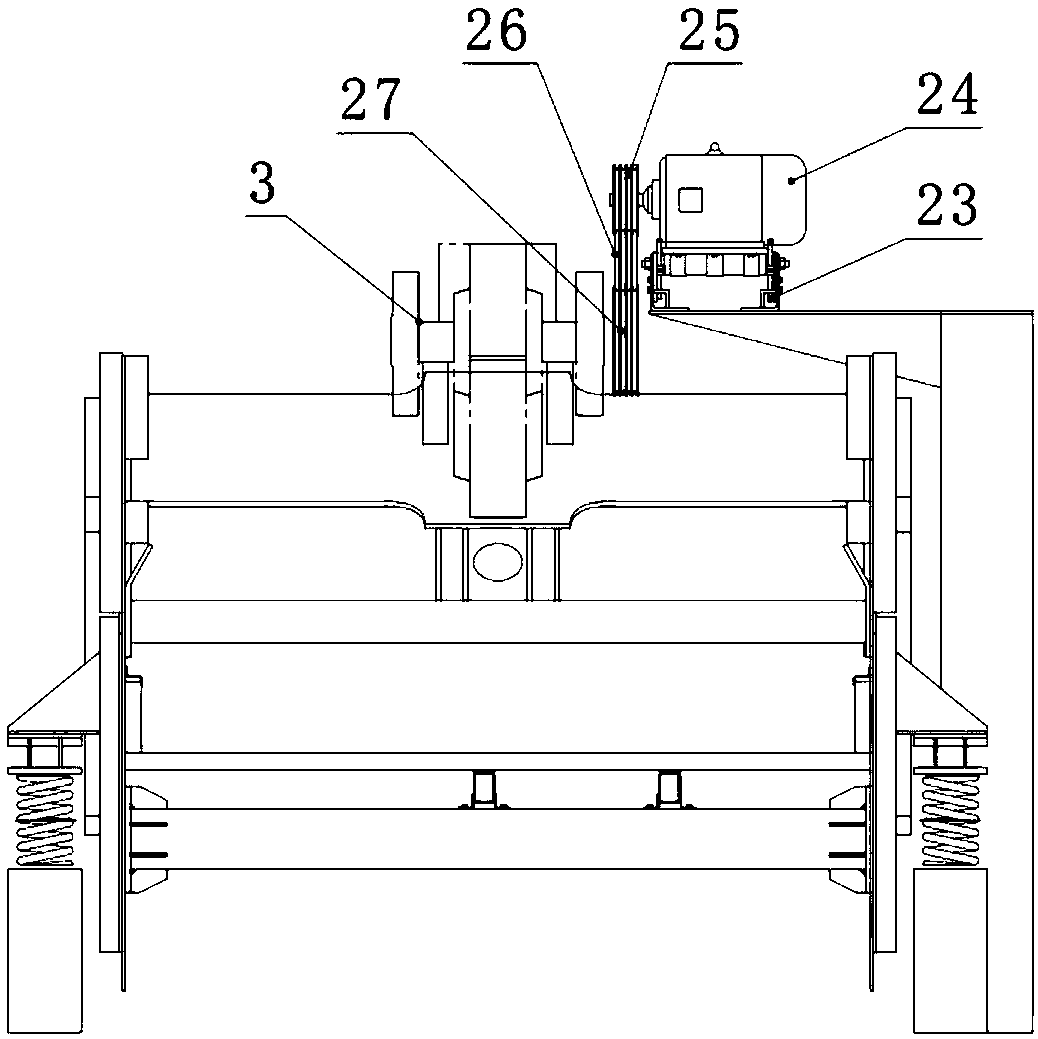

High frequency vibrating screen

ActiveCN108906600APromote looseImprove dehydration effectSievingScreeningButt jointVibration exciter

The invention discloses a high frequency vibrating screen which comprises a screen box, a screen plate, a box type vibration exciter and a driving system. The screen box comprises two side plates, a plurality of transverse beams and a driving beam, the two side plates are installed on a support through springs, the lower edges of the two side plates are connected through the multiple parallel transverse beams, the upper portions of the middles of the two side plates are connected through the driving beam, the box type vibration exciter is installed on the driving beam and is connected with thedriving system, the screen plate is fixed to the upper portions of the transverse beams and is formed by butt joint of a slope screen plate with a positive inclined angle and a step-shaped screen plate with a negative inclined angle, the slope screen plate is located on the back portion of the step-shaped screen plate, and a feeding baffle is arranged at the back end of the slope screen plate. According to the high frequency vibrating screen, the staged type screen plate formed by the slope screen plate and the step-shaped screen plate is adopted, the forced synchronization type box type vibration exciter is used as a vibration exciting source, coal slime scattering and layering and further dewatering can be promoted, material stacking and water running can be effectively prevented, the dewatering effect of the slime water is improved, the fault rate is low, and the screen machine running reliability is greatly improved.

Owner:TIANDI TANGSHAN MINING TECH +1

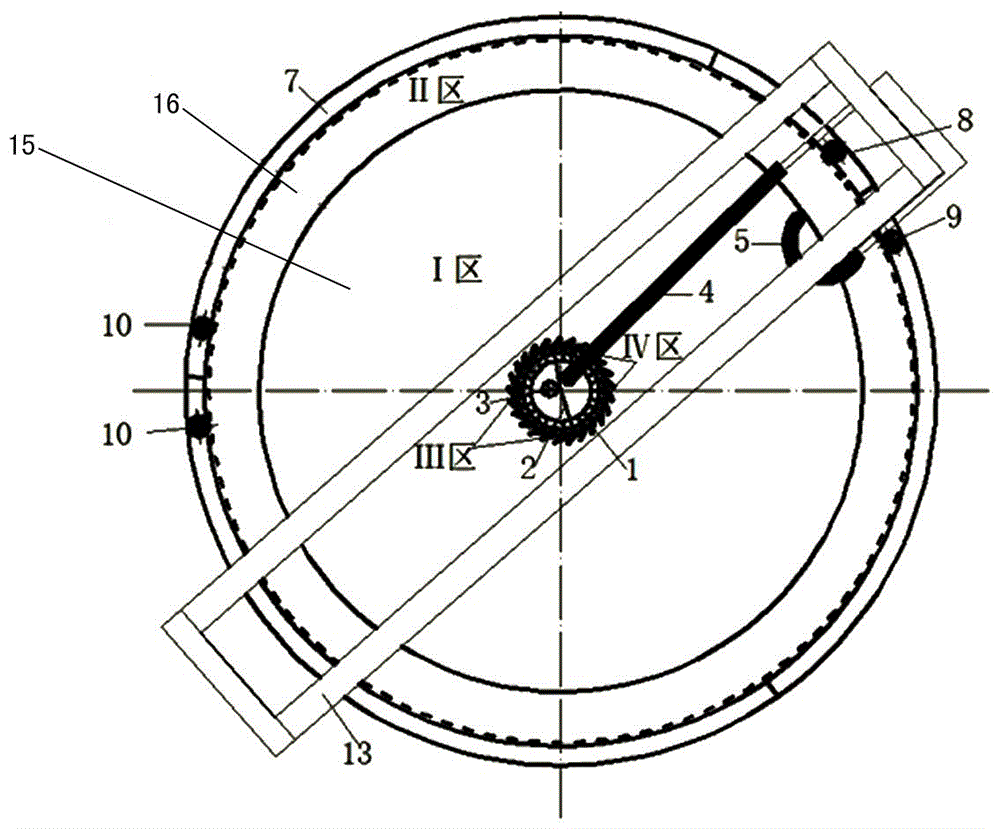

Arc surface spreading flow film sorting machine

ActiveCN106824500AIncrease centrifugal accelerationRaise the lower limit of granularityWet separationSurface spreadingEngineering

The invention discloses an arc surface spreading flow film sorting machine, and relates to equipment capable of continuously sorting fine-particle refractory minerals under combined effect of gravity and turning force. The equipment mainly consists of a rotary sorting disc driven by a driving device, an ore and water feeding device and an ore receiving and discharge device; the upper surface of the sorting disc is a spherical arc surface with a curvature radius of 0.58-2.27 m; the outer edge of the spherical arc surface is connected with a lap of annular inclined surface for forming an angle of 3-8 degrees with the horizontal plane; a flushing water pipe is mounted on the annular inclined surface; an ore receiving groove below the sorting disc in the flushing water pipe is provided with middling, concentrate and tailing discharge ports in sequence at intervals; an ore separation flushing disc is arranged rightly above the sorting disc; the upper part of the disc is a conical surface fixed disc, and the lower part is a movable disc provided with a rotating shaft; an ore feeding pipe mouth and a water feeding pipe mouth are aligned to the fixed disc; a series of leakage holes are formed in the bottom of the fixed disc, and are aligned to the movable disc; and a series of baffle plates aslant dispersed are arranged on the surface of the movable disc. The machine is suitable for environment-friendly, efficient, energy-saved and continuous sorting of 0.2-0.037 mm fine-particle valuable minerals.

Owner:昆明理工凯吉思科技有限公司

Polymer aqueous asphalt colloid and preparation method thereof

InactiveCN108165030AImprove aging performanceImprove high temperature performanceBuilding insulationsPolymer scienceRoad surface

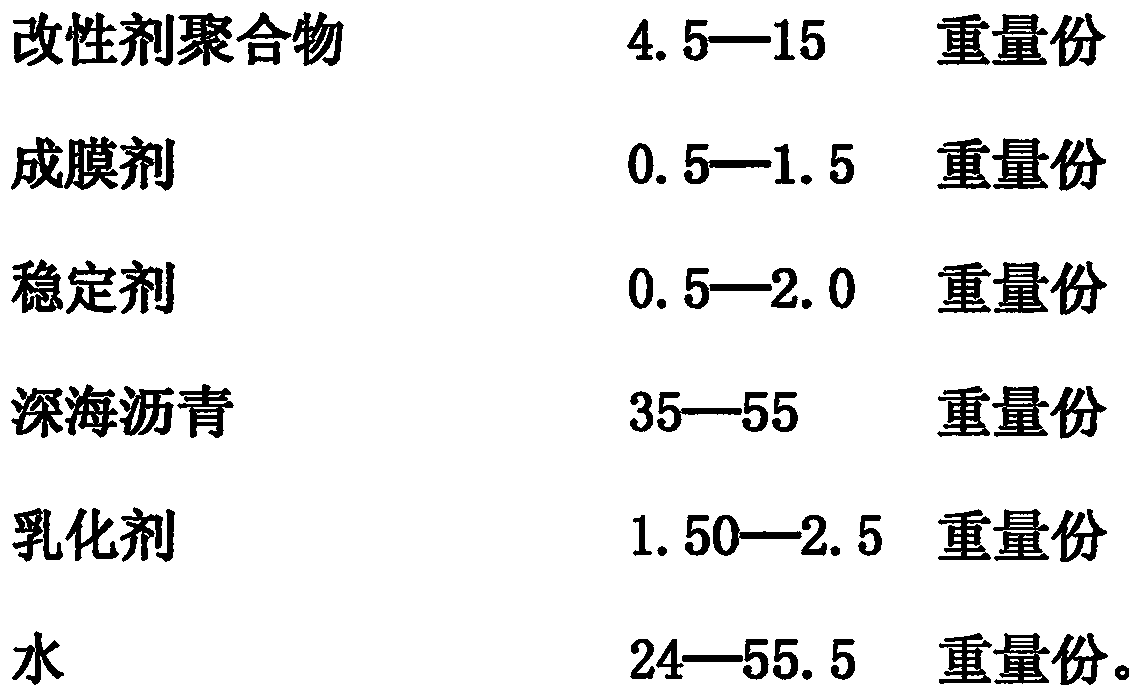

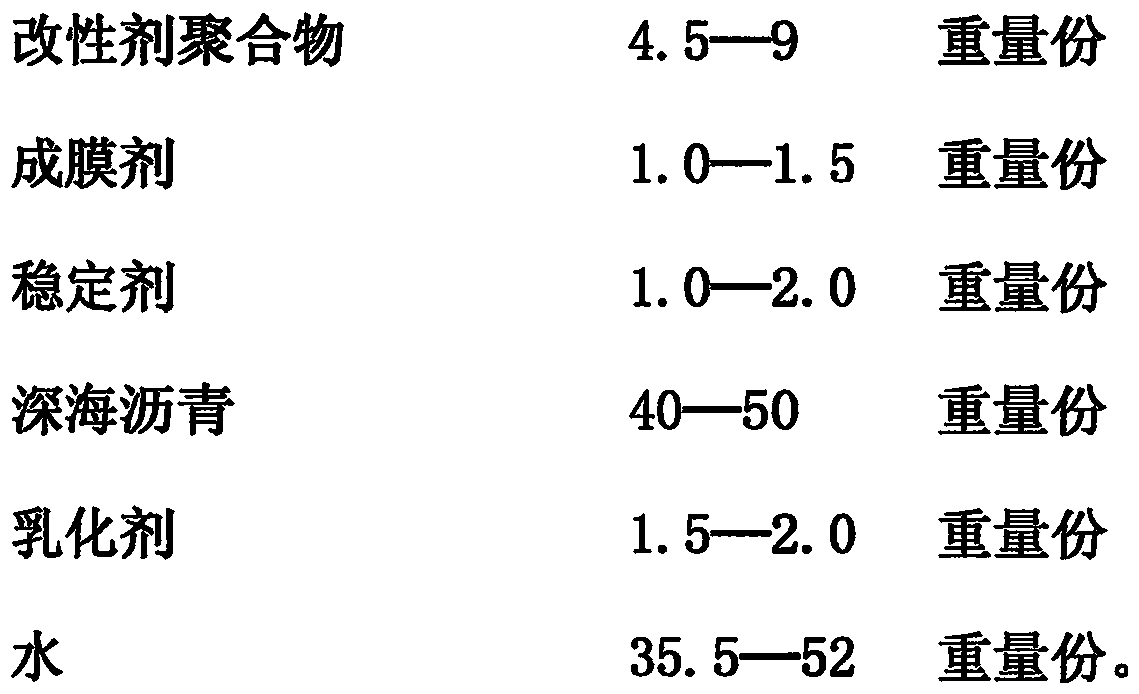

The invention relates to a polymer aqueous asphalt colloid and a preparation method thereof, wherein the polymer aqueous asphalt colloid comprises, by weight, 4.5-15 parts of a modified polymer, 0.5-1.5 parts of a film forming agent, 0.5-2.0 parts of a stabilizer, 35-55 parts of deep sea asphalt, 1.0-2.5 parts of an emulsifier, and 25-56 parts of water, and mixing, emulsifying, shearing and colloid milling are performed to obtain the polymer aqueous asphalt colloid. According to the present invention, the polymer aqueous asphalt colloid has advantages of simple and reliable preparation, excellent performance, good film forming property, excellent high-temperature resistance and excellent low-temperature resistance, can significantly improve the water resistance, the slip resistance, the flatness and the wear resistance of pavement, and can be widely used in the micro-surface positions of urban and rural traffic heavy-duty high-grade pavements, or the sealing layer cover surfaces of newroads, and the like.

Owner:江苏荣成路桥材料有限公司

Low-power-consumption efficient coal screening machine

InactiveCN103801509APromote loosePromote stratificationSievingScreeningEngineeringMechanical engineering

A low-power-consumption efficient coal screening machine comprises a rack, a screen body driving mechanism and a transmission mechanism. The coal screening machine is characterized in that side projections of screen strips forming screen faces are curves, a strip-shaped screen hole is formed by linking multiple unit screen hole sections formed by the adjacent screen strips in an opposite mode, each unit screen hole section is wide gradually and becomes narrow suddenly from the feeding direction of coal to the discharging direction of the coal, and the screen strips are installed on each screen body in a high and low stagger mode at selected intervals. On the coal screening machine with the screen bodies swinging at low frequency, a collision head or a hard spring is arranged on the rack and retraced when impacting the screen bodies. Generally the coal screening machine with the multiple-stage screen bodies is composed of the multiple screen bodies which swing independently and are arrayed longitudinally in a stepped mode. The low-power-consumption efficient coal screening machine has the advantages that in the work process, the screen faces swing transversely at low frequency with a large amplitude, the effect that the special screen faces and screen bodies are impacted to be retraced in the swing process is combined, loosening and delamination of the coal are facilitated, the screening process of the coal is improved substantially, the screen faces are not blocked or stuck by the coal, the maximum screening capacity and the maximum screening efficiency are obtained, and the screen through rate for screening inferior coal high in ash content and water content is improved substantially.

Owner:马奎山

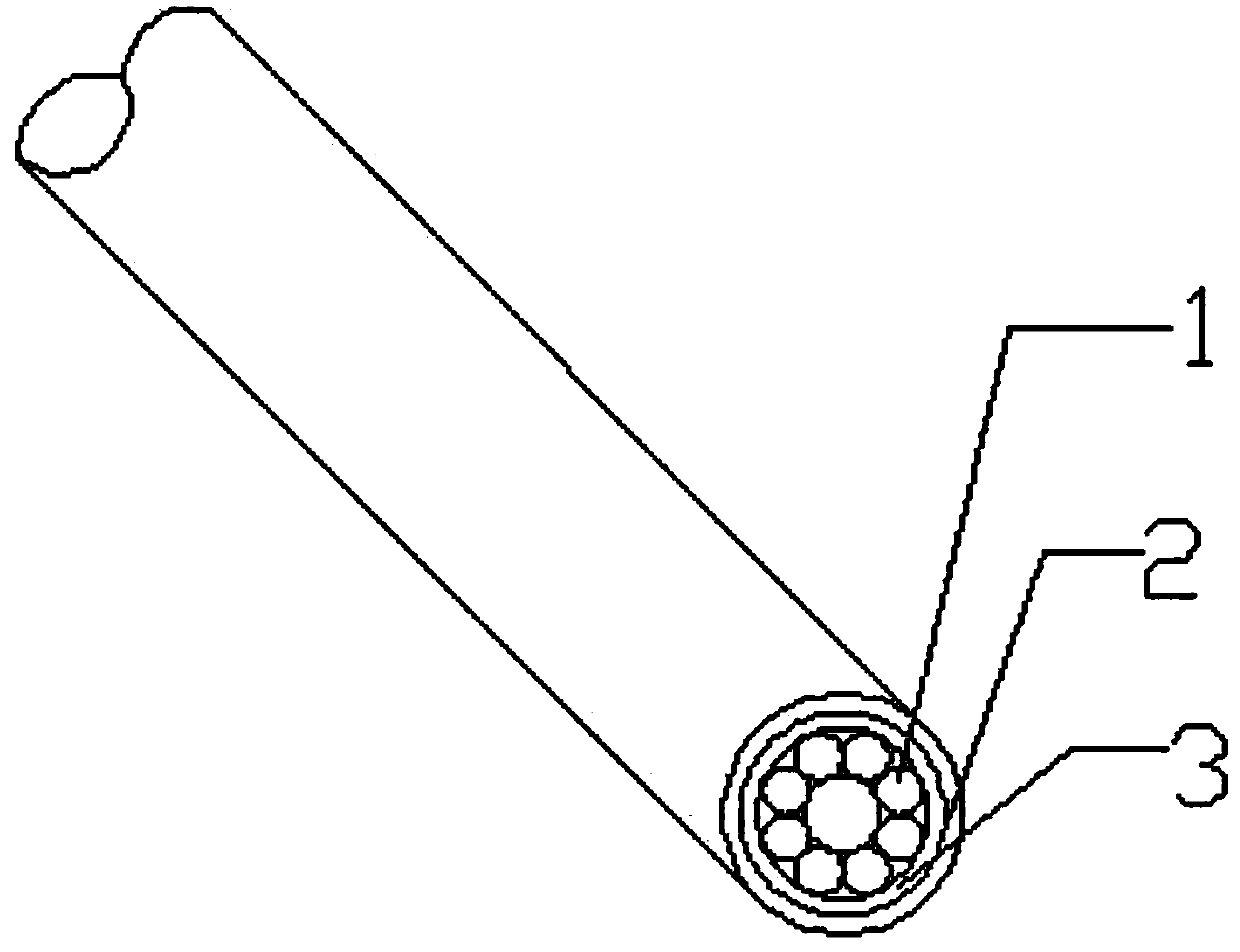

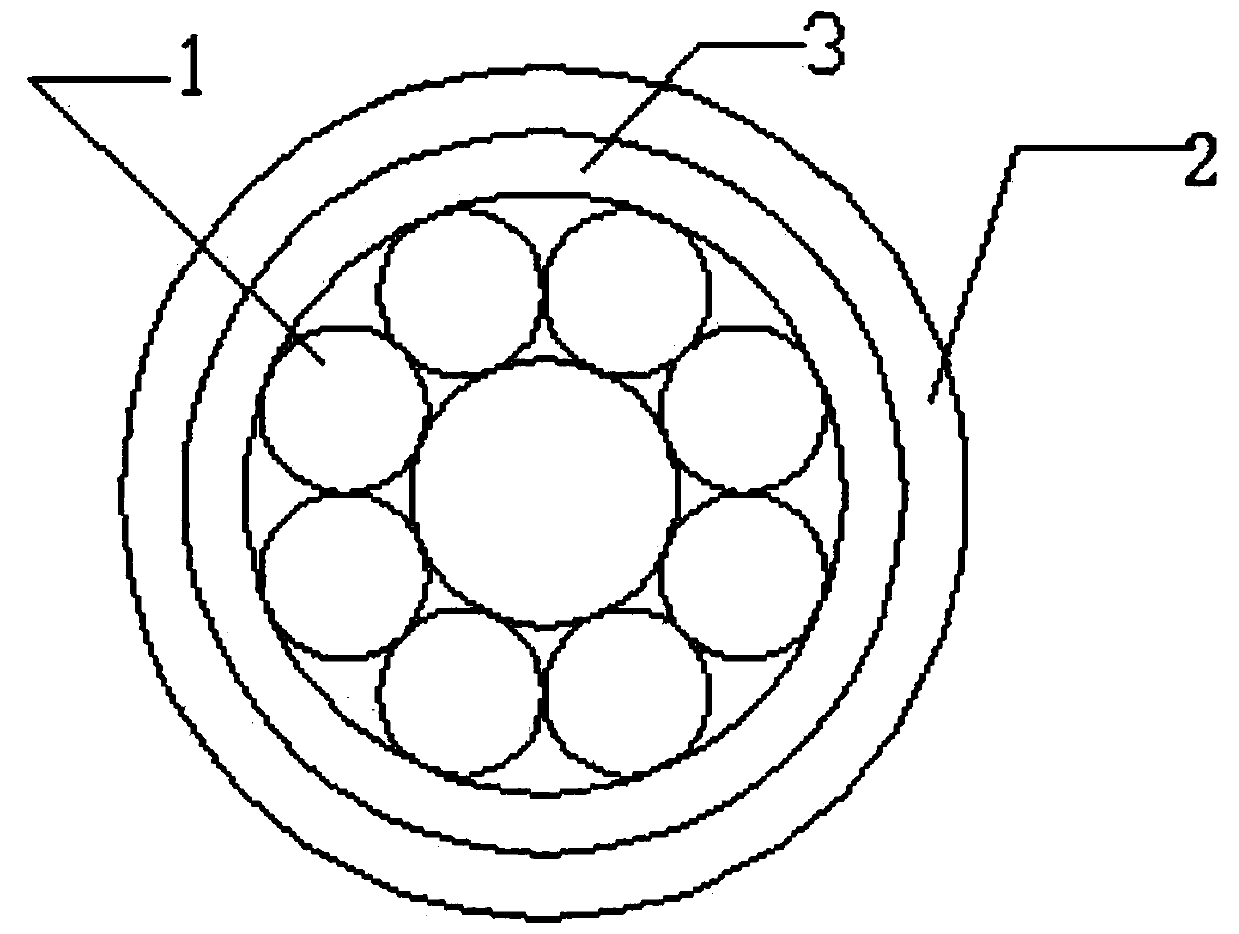

Mountaineering rope with high safety

InactiveCN107916588AGuarantee the safety of useImprove the safety of useTextile cablesYarnEngineering

The invention discloses a mountaineering rope, and particularly relates to a mountaineering rope with high safety. The mountaineering rope with high safety comprises a rope core, a rope skin and an intermediate film, wherein the intermediate film is arranged between the rope core and the rope skin; the rope core is arranged in the intermediate film and is woven by polyamide filaments; and eight polyamide filaments are originally twisted to obtain plied yarns, sixteen plied yarns are secondarily twisted to obtain eight strands, and the eight strands are used as the rope core. In the technical scheme, the rope core and the rope skin are integrated. By the rope, sliding and clustering of the rope skin are further avoided, the use safety of the rope is further ensured, even if the rope skin isbroken completely, a user can still pass through safely, and thus, the user cannot be trapped on the rope.

Owner:宁波泰芸电气有限公司

Efficient stirring device used for fertilizers

InactiveCN107670561APromote looseAvoid clumpingShaking/oscillating/vibrating mixersTransportation and packagingShake upEngineering

The invention discloses an efficient stirring device used for fertilizers. The efficient stirring device used for the fertilizers comprises a stirring barrel, a feeding port, a discharging port, a rotating shaft, stirring blades, a vibration spring, a vibration plate and a heater. The efficient stirring device used for the fertilizers has the following beneficial effects: (1) the set of the heatercan make moisture in a raw material mixture in the mixing barrel properly volatilized, so that the raw material mixture is in a loose state and is much easier to mix uniformly; and (2) the raw material mixture falling on the surface of the vibration plate will shake up and down with the elastic force of the vibration spring, so that the phenomena of agglomeration and clustering of the raw material mixture are avoided, the raw material mixture is well loosened, and the mixing and stirring efficiency is improved.

Owner:ANHUI JIAFENG FERTILIZER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com