Efficient stirring device used for fertilizers

A stirring device, high-efficiency technology, applied in the direction of mixer accessories, transportation and packaging, dissolution, etc., can solve the problems of uneven mixing, wet adhesion, agglomeration, etc., achieve easy mixing, good loosening, and improve mixing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

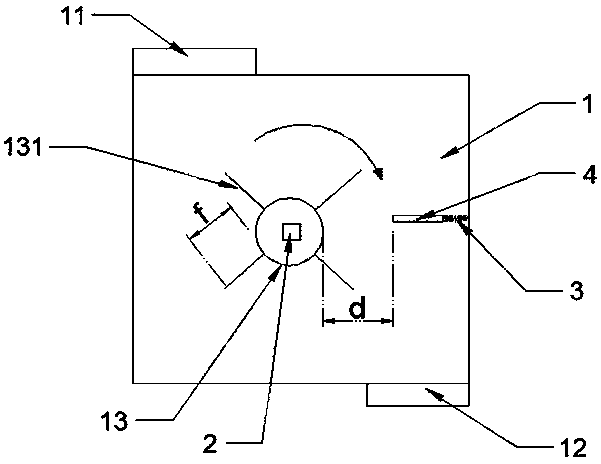

[0012] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0013] as attached figure 1 As shown, a high-efficiency stirring device for fertilizers includes a mixing tank 1, a feed port 11, a discharge port 12, a rotating shaft 13, a stirring blade 131, a vibrating spring 3, a vibrating plate 4, and a heater 2;

[0014] The top side of the mixing bucket 1 is provided with the feed inlet 11, and the other side below the mixing bucket 1 is provided with the discharge opening 12; the rotating shaft 13 is horizontally arranged in the mixing bucket 1, so that The heater 2 is arranged inside the rotating shaft 13 , and the rotating shaft 13 and the heater 2 are coaxially arranged on the center line. After the heater 2 is heated, the raw material mixture on the outer wall of the rotating shaft 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com