Patents

Literature

88 results about "Surface spreading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Illumination apparatus

Owner:EPISTAR CORP

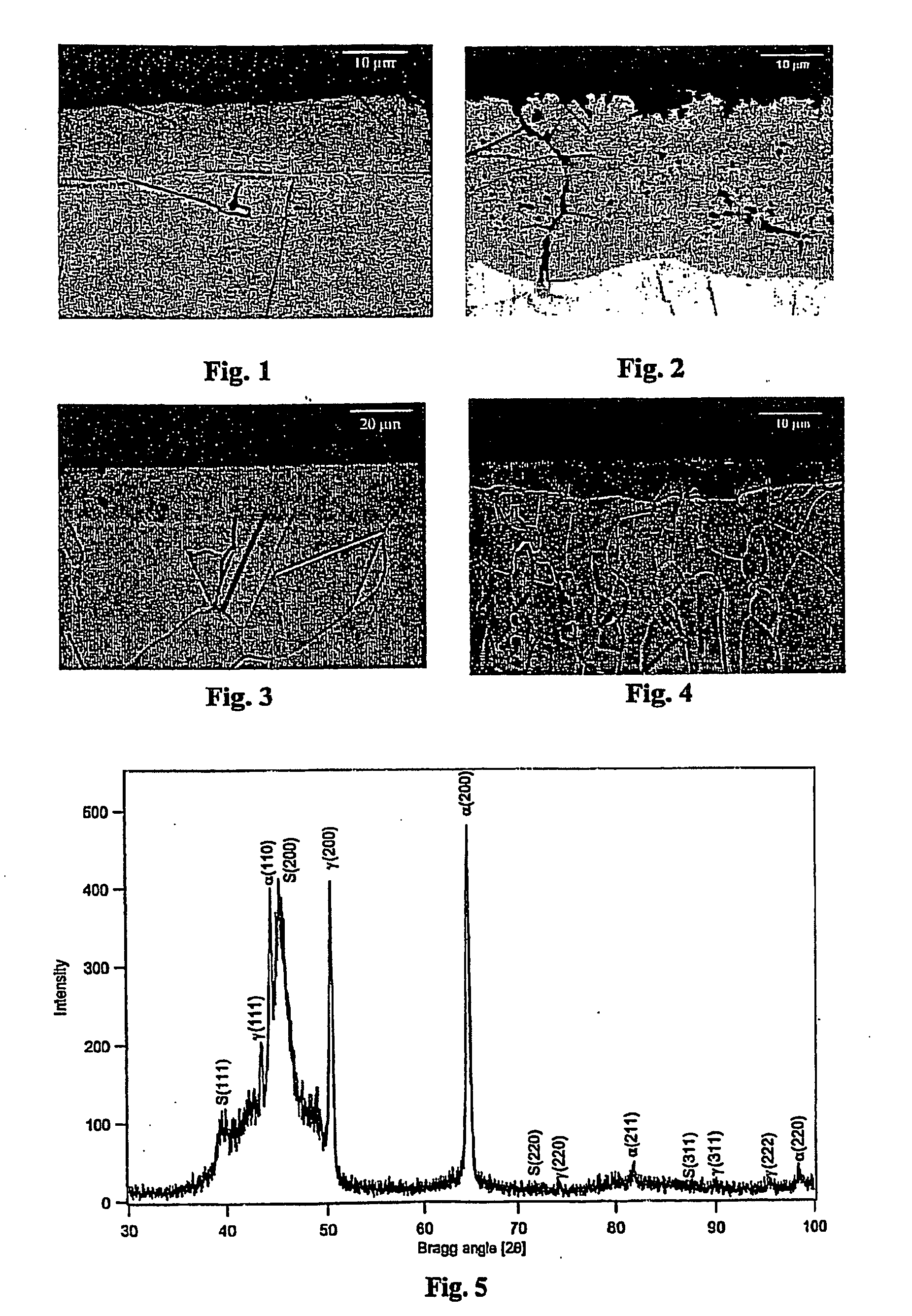

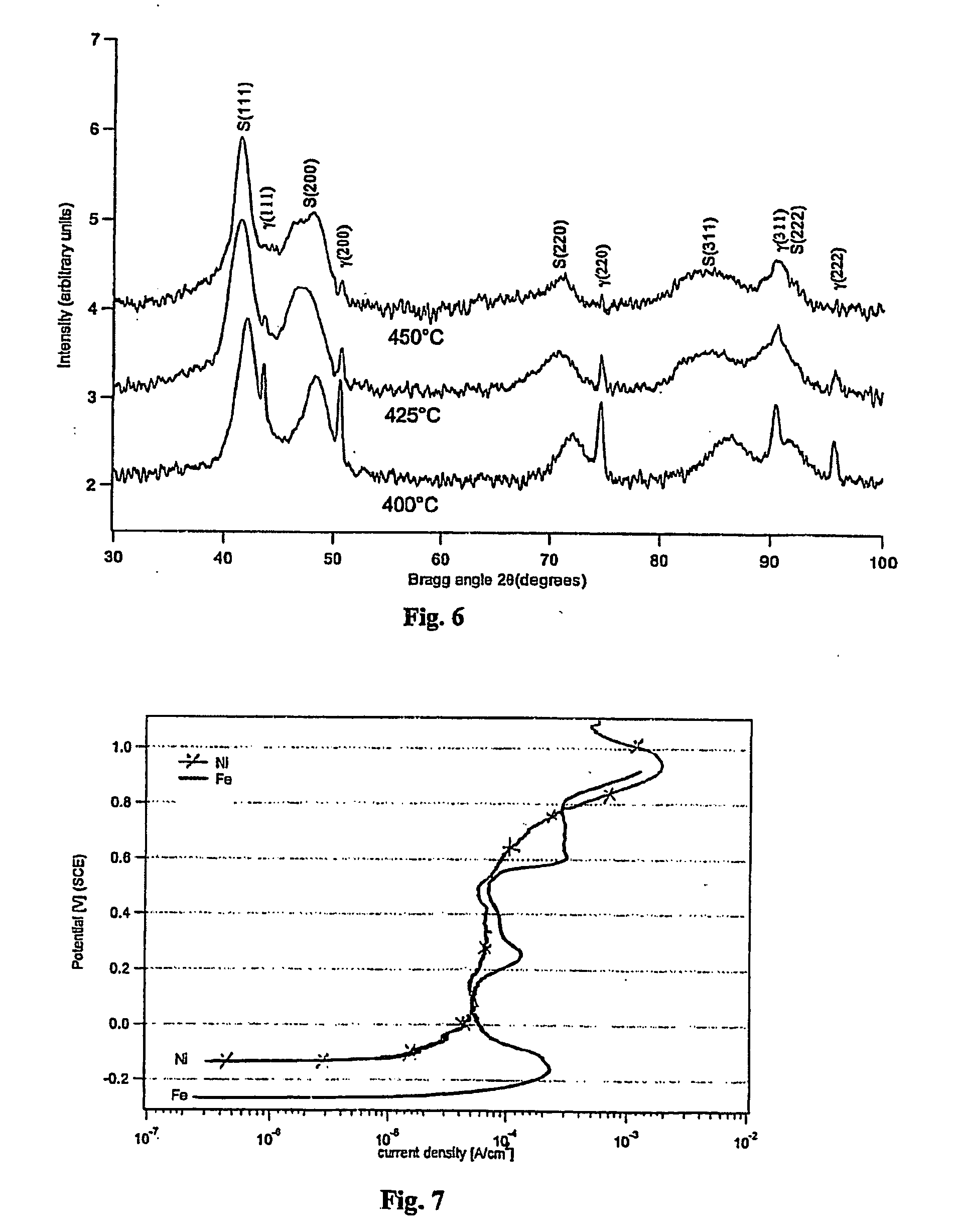

Case-hardening of stainless steel

InactiveUS20060090817A1Prevent oxidationReasonable time periodMaterial nanotechnologySolid state diffusion coatingDecompositionSurface spreading

The invention relates to case-hardening of a stainless steel article by means of gas including carbon and / or nitrogen, whereby carbon and / or nitrogen atoms diffuse through the surface into the article. The method includes activating the surface of the article, applying a top layer on the activated surface to prevent repassivation. The top layer includes metal which is catalytic to the decomposition of the gas.

Owner:DANMARKS TEKNISKE UNIV DTU LEDELSESSEKRETARIATET

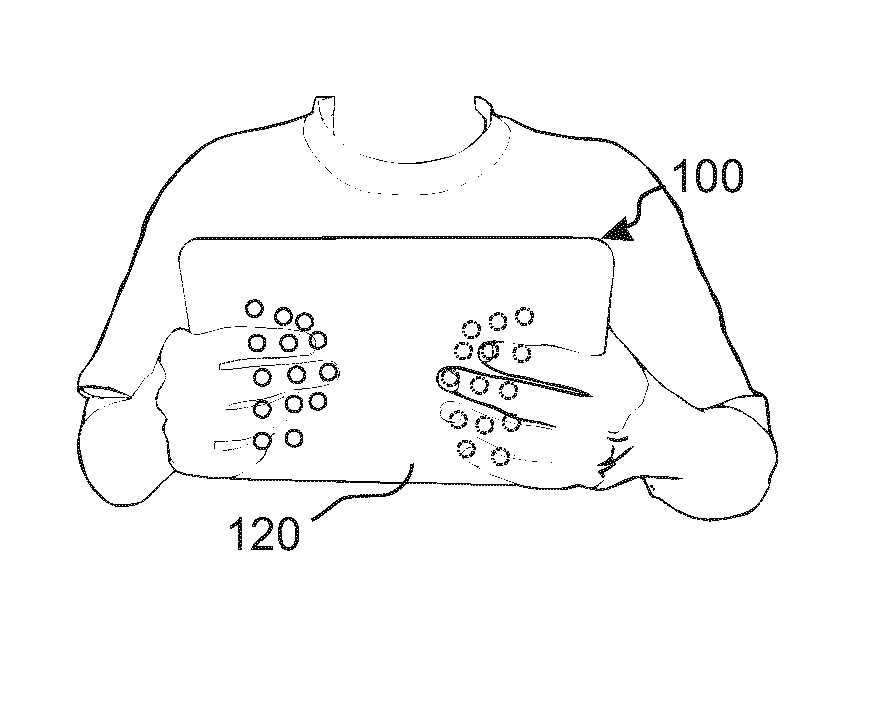

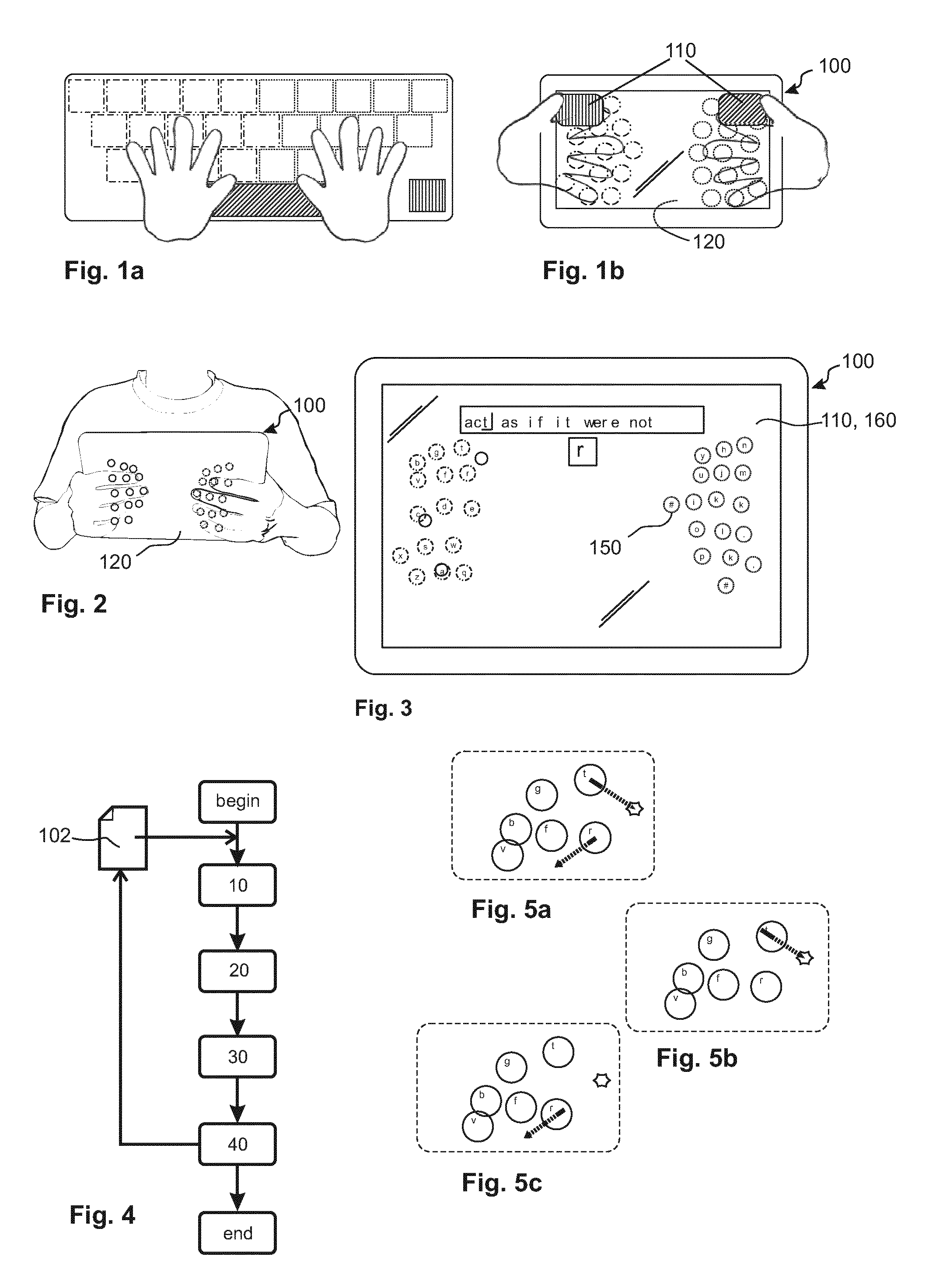

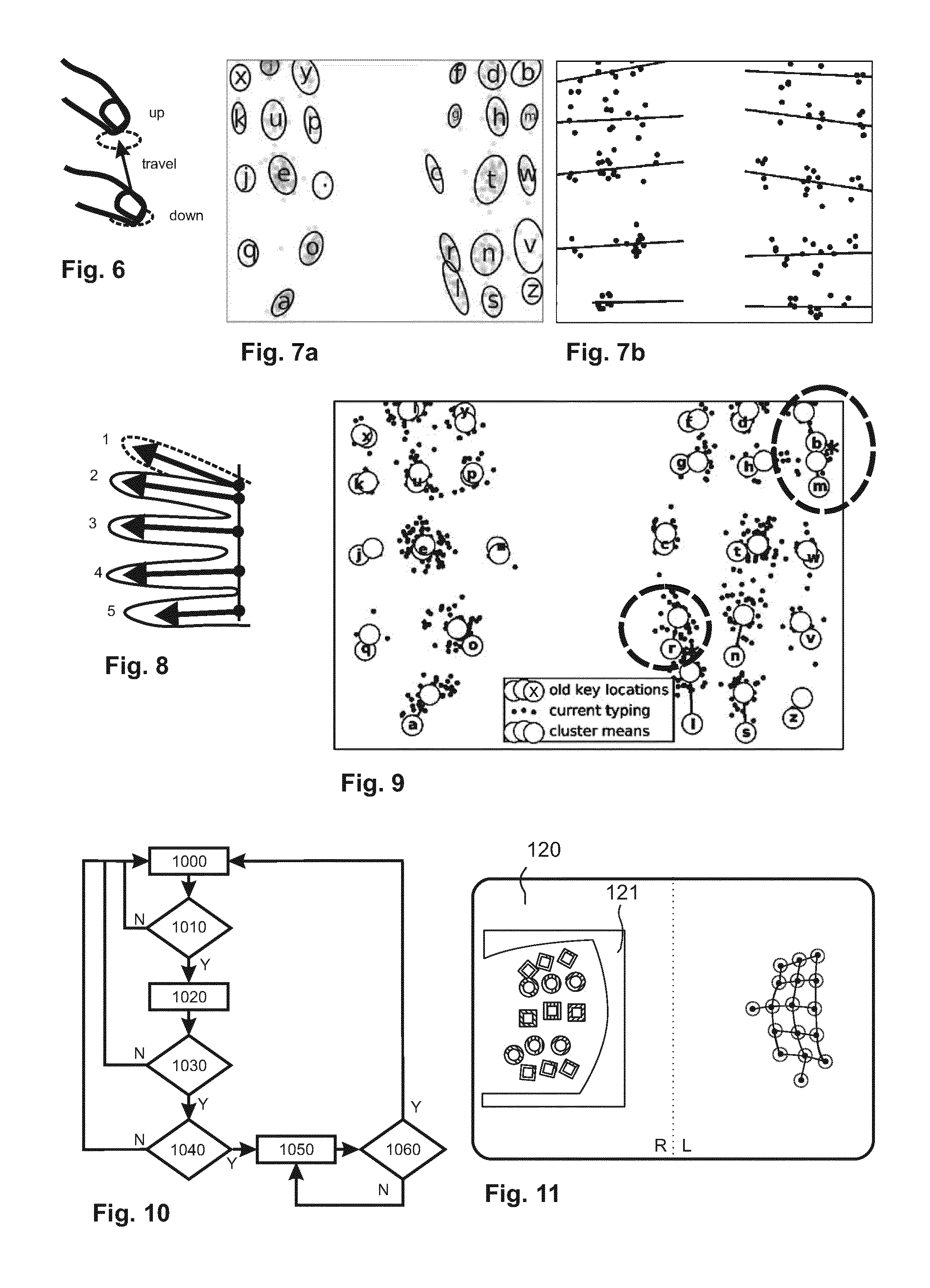

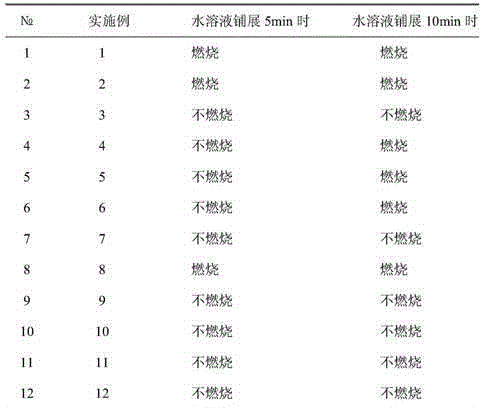

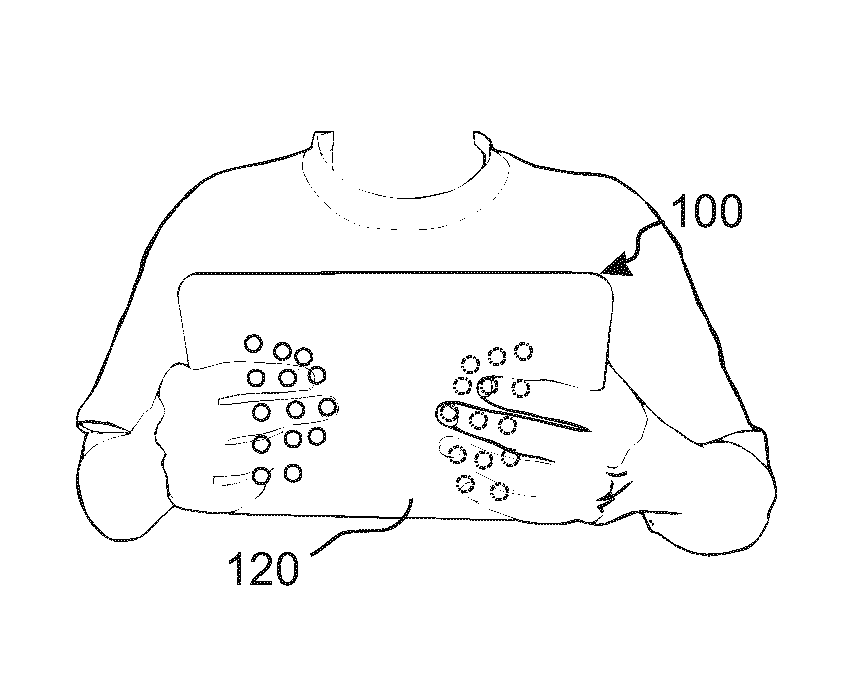

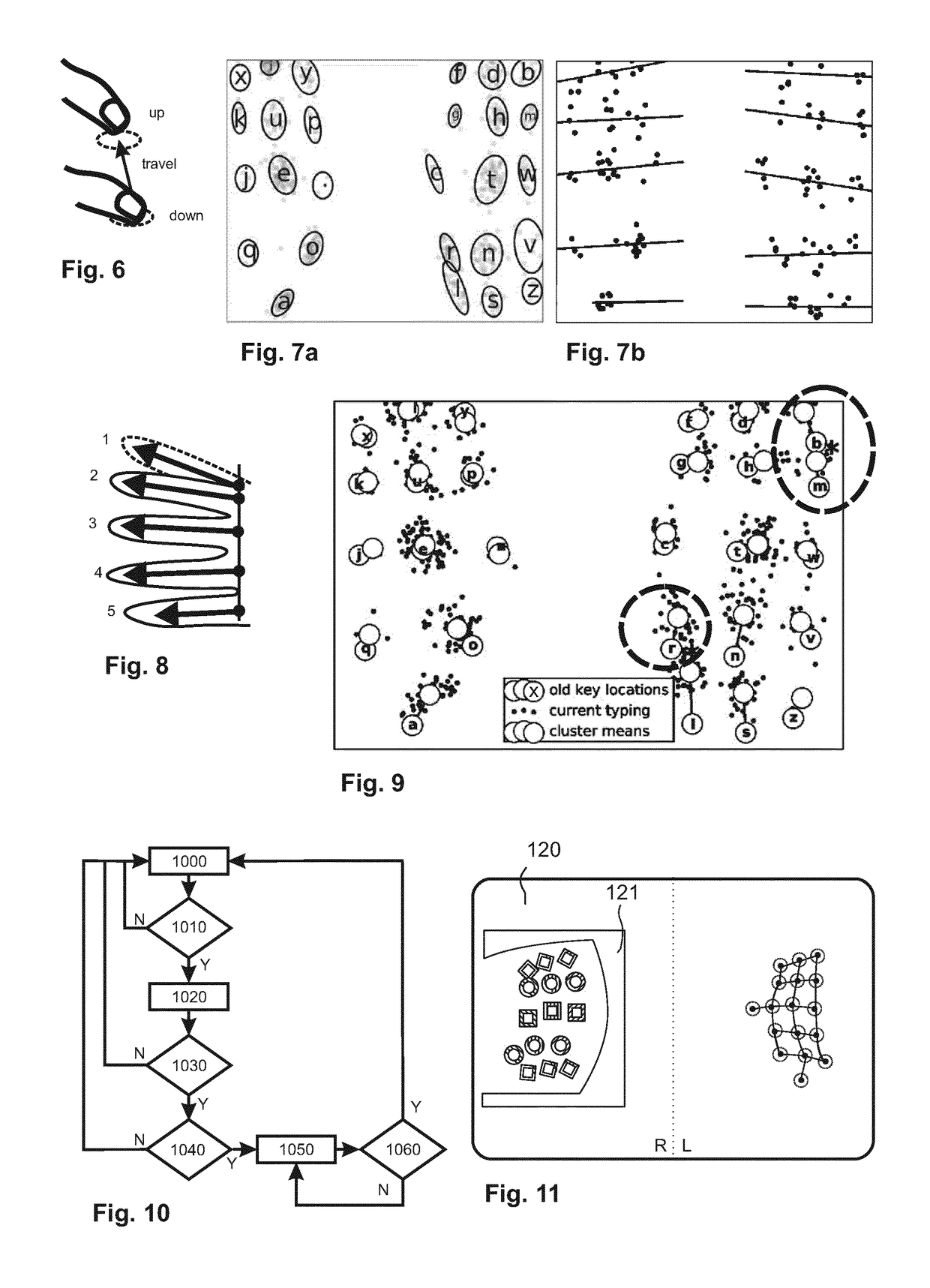

Method and Device for Typing on Mobile Computing Devices

InactiveUS20150293695A1Low economic overheadImprove productivityInput/output processes for data processingSurface spreadingText entry

The present invention relates to a method and a mobile computing device for reliable and fast text entry. The method relies on a virtual keyboard layout that has a multi-touch interaction surface spread out on both the front and rear sides of a handheld computing device. A user-adaptive updating algorithm allows the virtual keyboard layout to adapt to the user's handling of the device.

Owner:SCHONLEBEN OLIVER +2

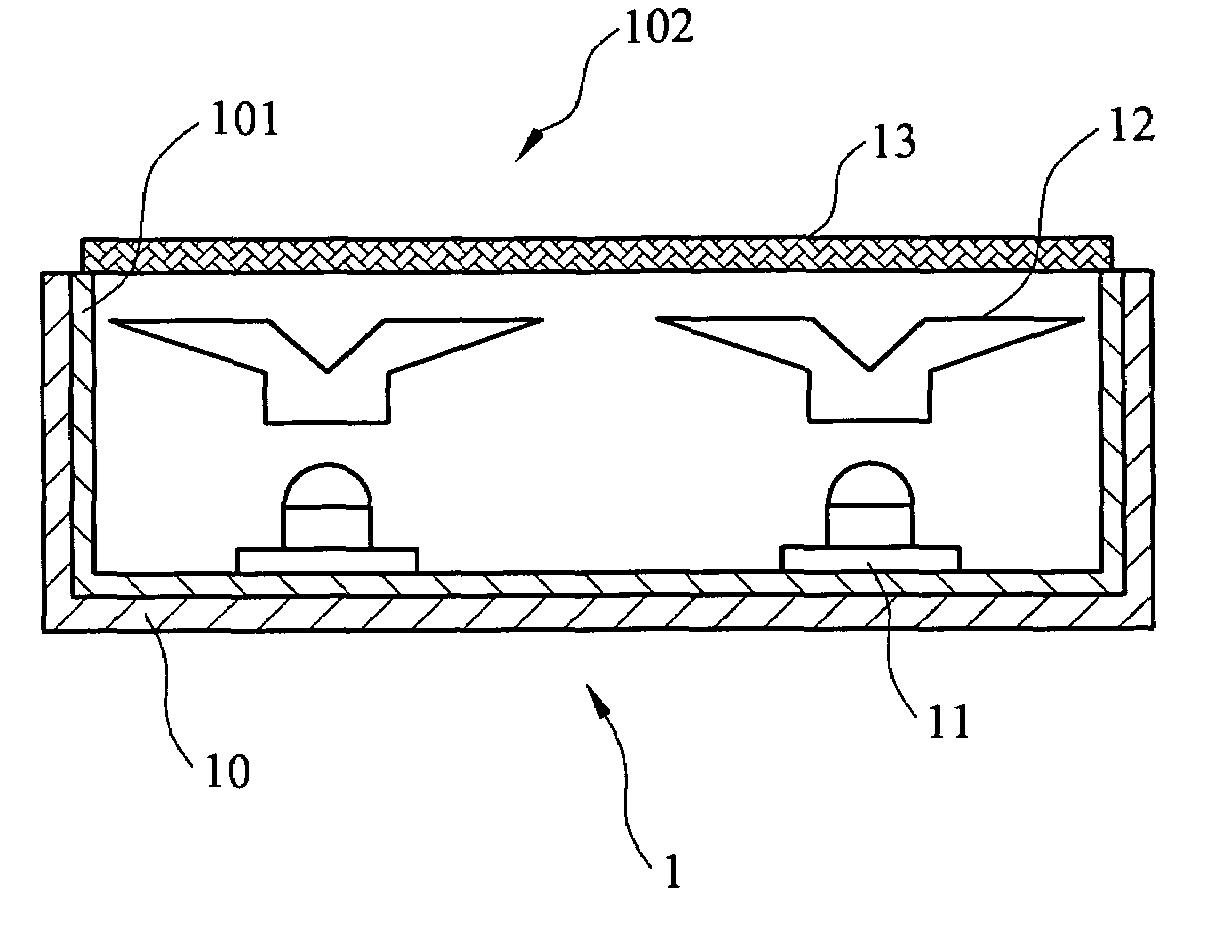

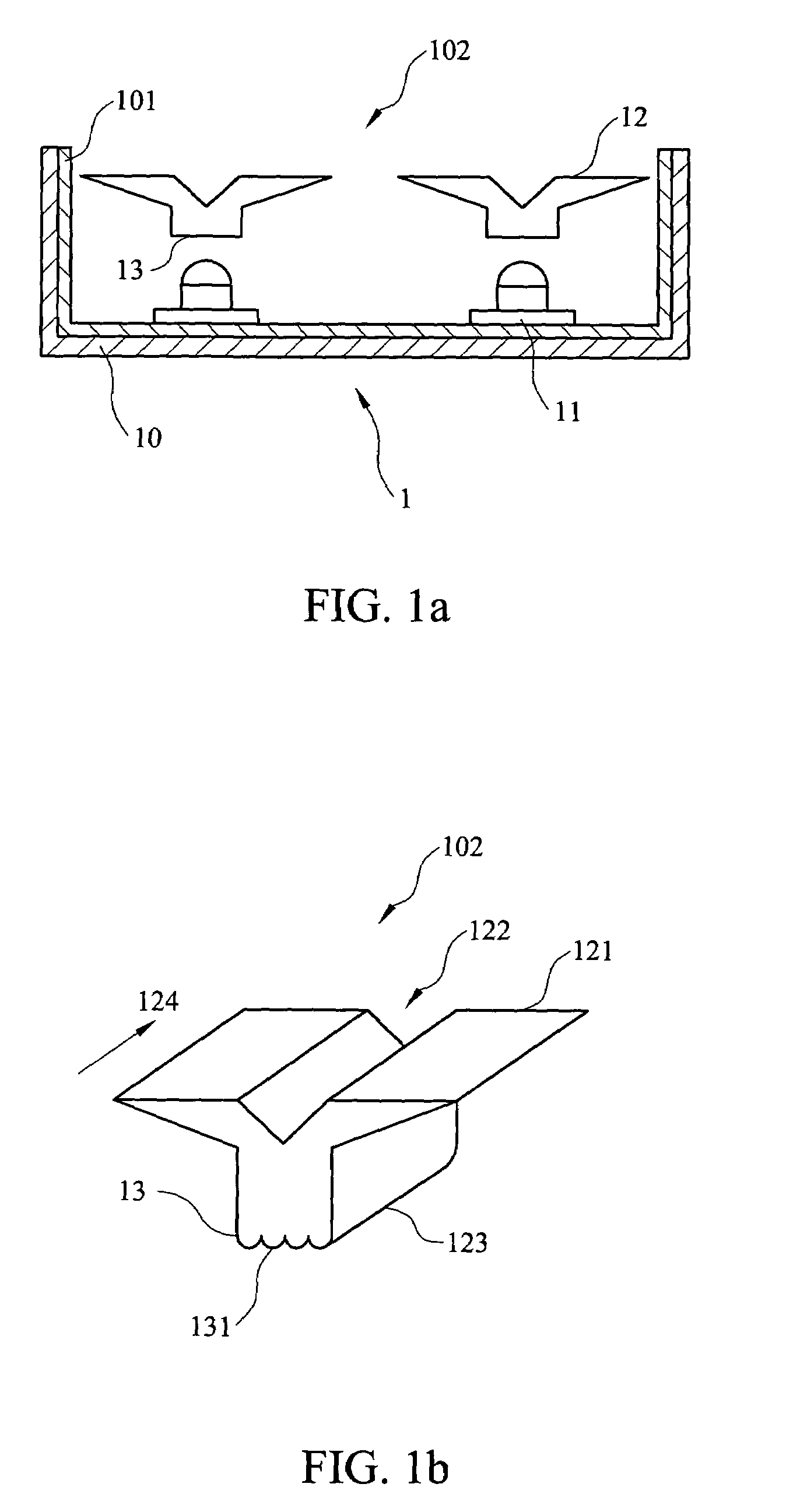

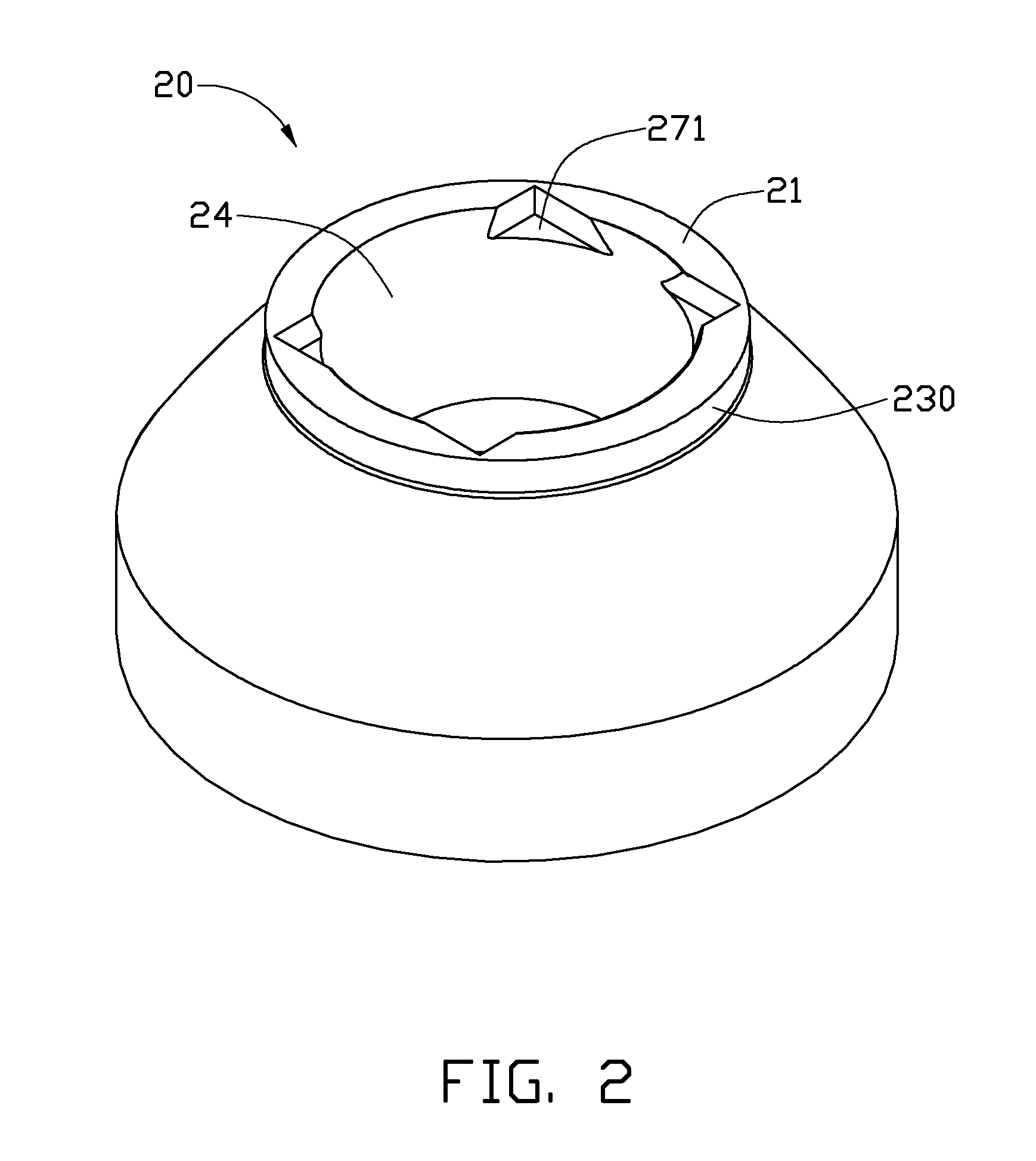

LED module

Owner:FU ZHUN PRECISION IND SHENZHEN +1

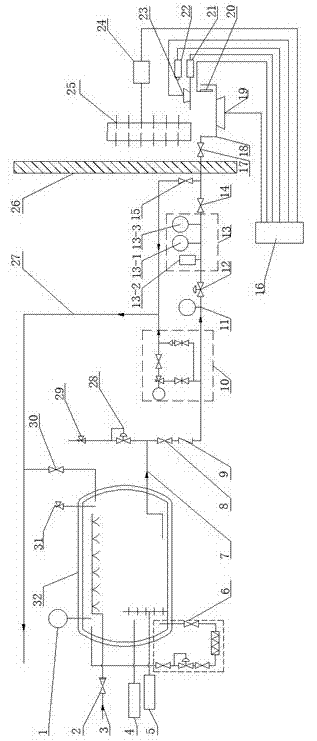

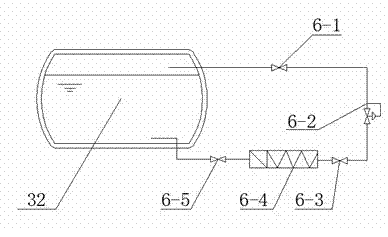

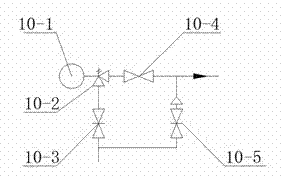

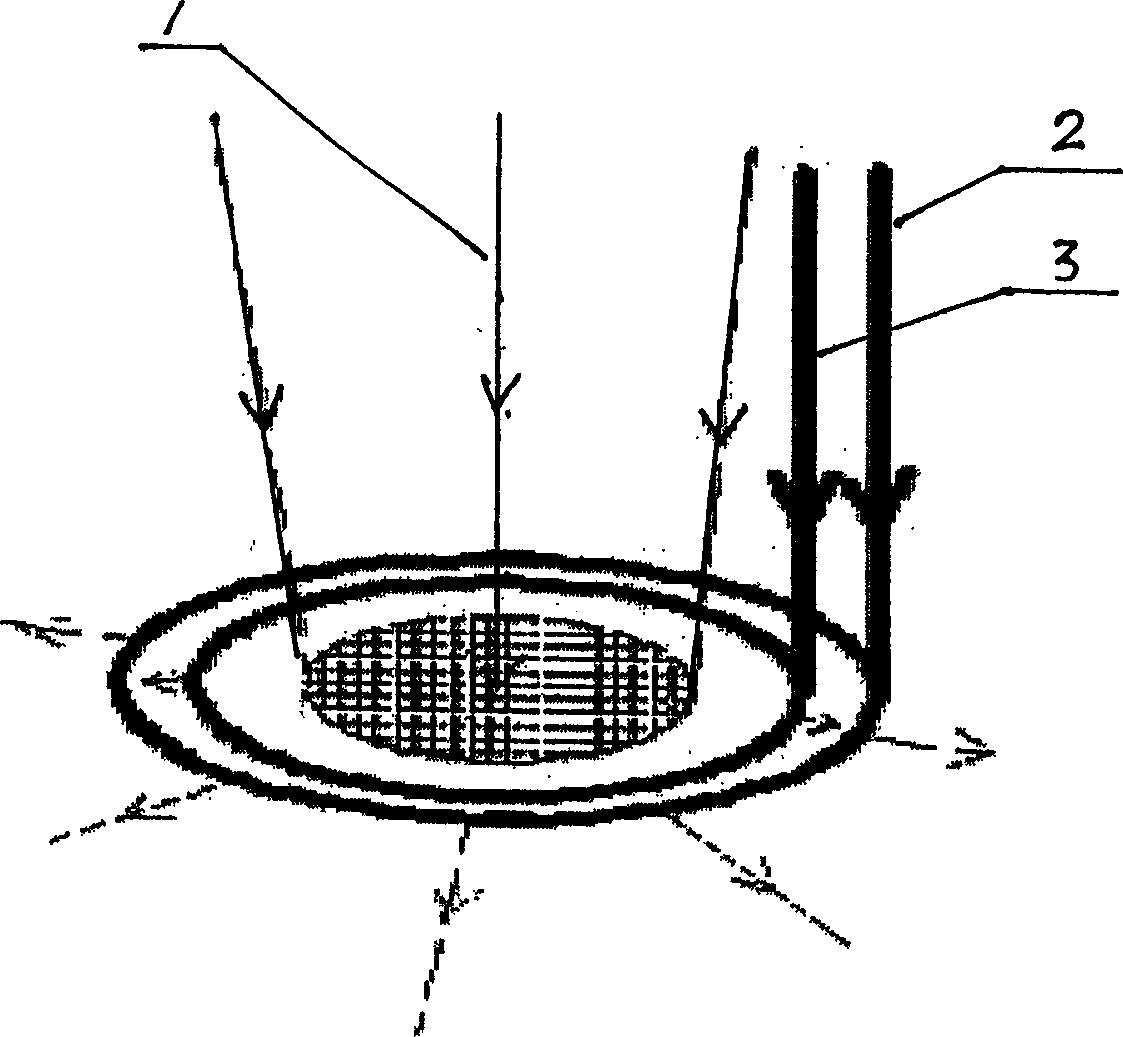

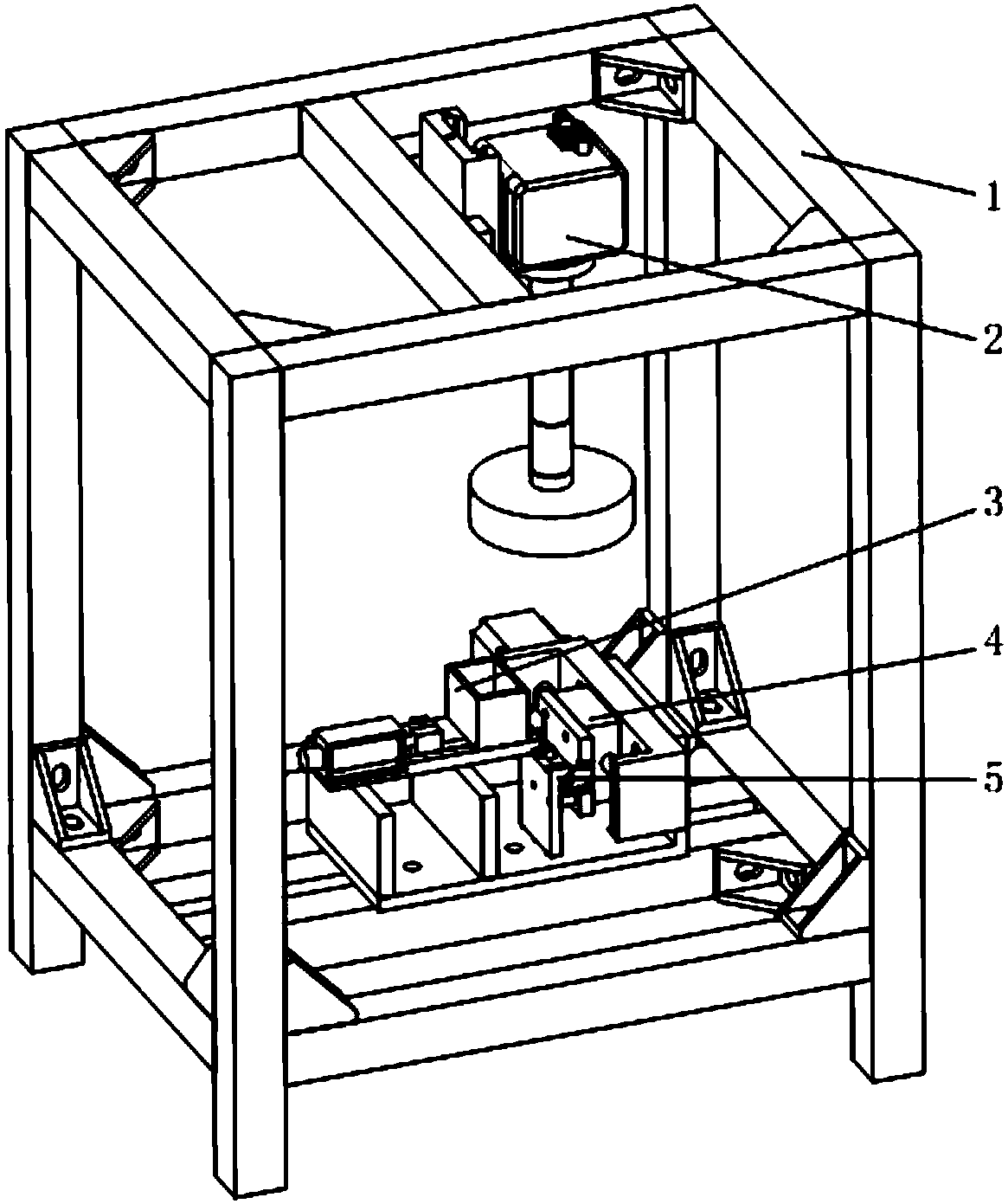

Liquefied natural gas (LNG) drain diffusion and pool fire combustion simulated experimental platform and LNG drain diffusion and pool fire combustion simulated experimental method

ActiveCN102879305AAvoid suffocation damageAvoid cold damageSurface/boundary effectData acquisitionEngineering

The invention relates to a liquefied natural gas (LNG) drain diffusion and pool fire combustion simulated experimental platform and an LNG drain diffusion and pool fire combustion simulated experimental method. The platform comprises an experimental system, a testing system and a control system, wherein the experimental system consists of an LNG storage tank, heat-insulation pipes, experimental devices and an anti-explosion isolating wall; the testing system consists of an electronic balance, an ignition system, a methane concentration detector, a thermocouple tree, a data acquirer and a camera; and the control system consists of a programmable logic controller (PLC) system, various display instruments and a control valve. By designing an angle-adjustable LNG surface spreading experimental device with a changeable surface material, spreading and gasification diffusion experimental simulation of LNG on surfaces of different substances and at different flowing speeds can be carried out; and by matching the ignition system and the methane concentration detector, LNG gas cloud concentration change monitoring and gas cloud ignition can be realized, and data and images are acquired automatically. The platform has the advantages of short experimental time, low cost, high experimental efficiency and the like. By the design, experimental steps are less, experimental safety is guaranteed under the condition of severe monitoring and control, the platform is easy and convenient to operate, and experimental repeatability is high.

Owner:应急管理部天津消防研究所

Process for making high simulation ultra-fine fabric leather based cloth

One high simulation superfine fiber leather base cloth production method, uses the double component altogether to mix spinning production law produce island superfine fiber, then makes the adhesive-bonded base cloth material, first contains soaks half polyether polyurethane resin or the polyester polyurethane resin, then blows in base cloth the surface spreads gathers the carbonic ether polyurethane resin or the entire polyether polyurethane resin, then carries on coagulation processing using the DMF solution after the polyurethane resin, then uses the lukewarm water completely to wash DMF, use toluene solution island superfine fiber's in 'sea' ingredient extract comes out, then carries on alkali decrement processing. This invention produce base cloth which has thickness direction from trapezoidal density distribution structure, the dermis feeling is strong, may further enhance the artificial leather product the scale.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

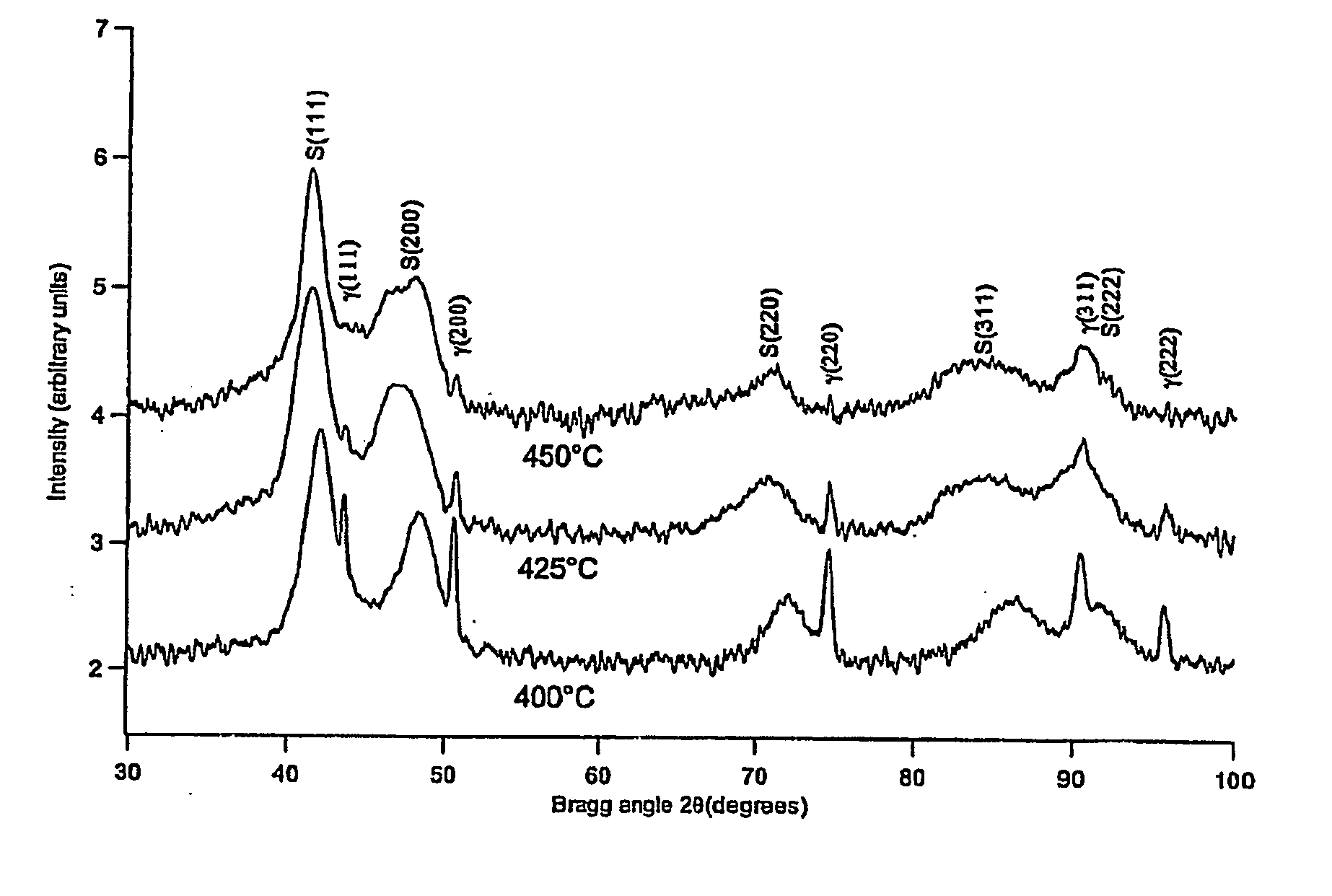

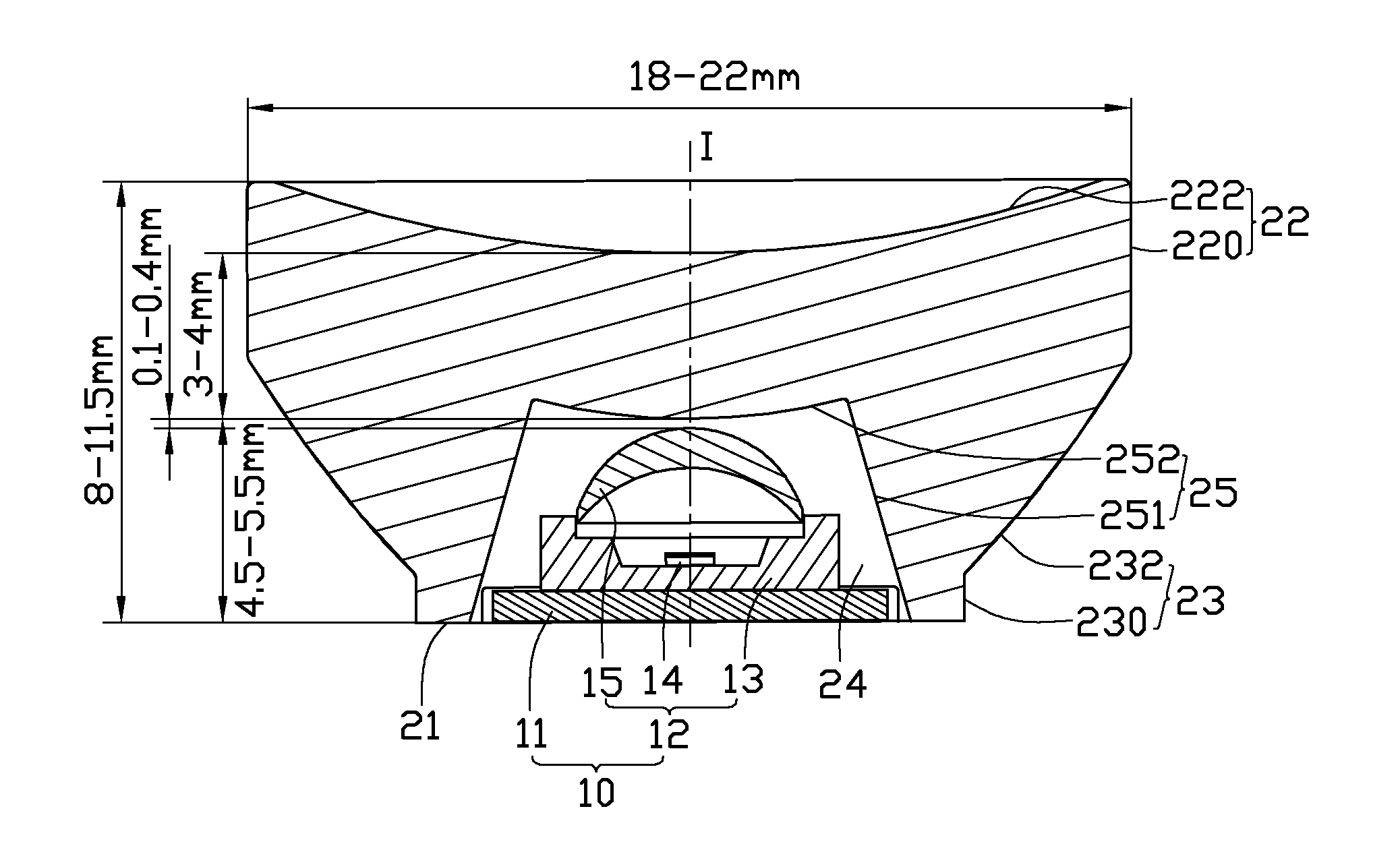

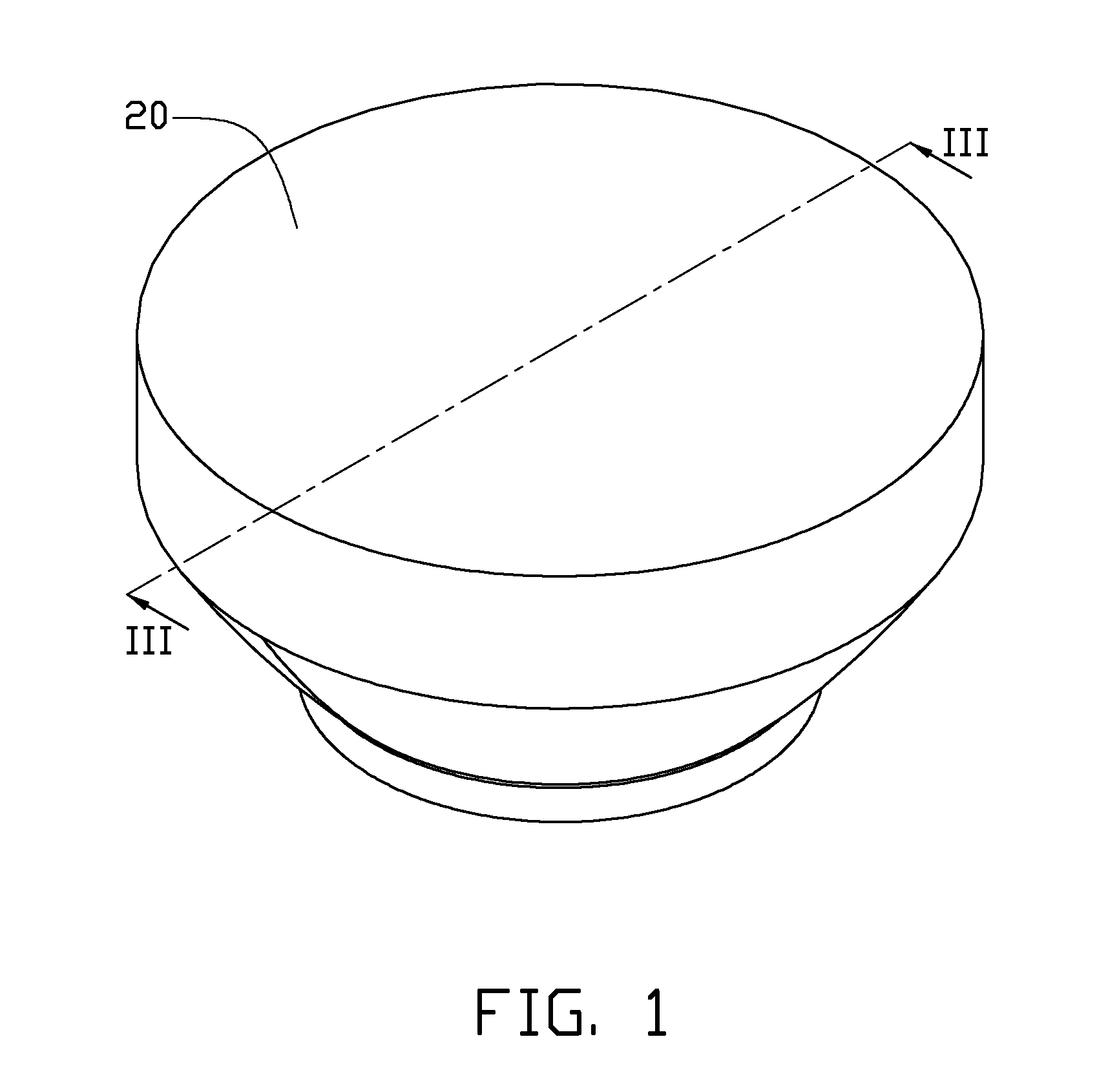

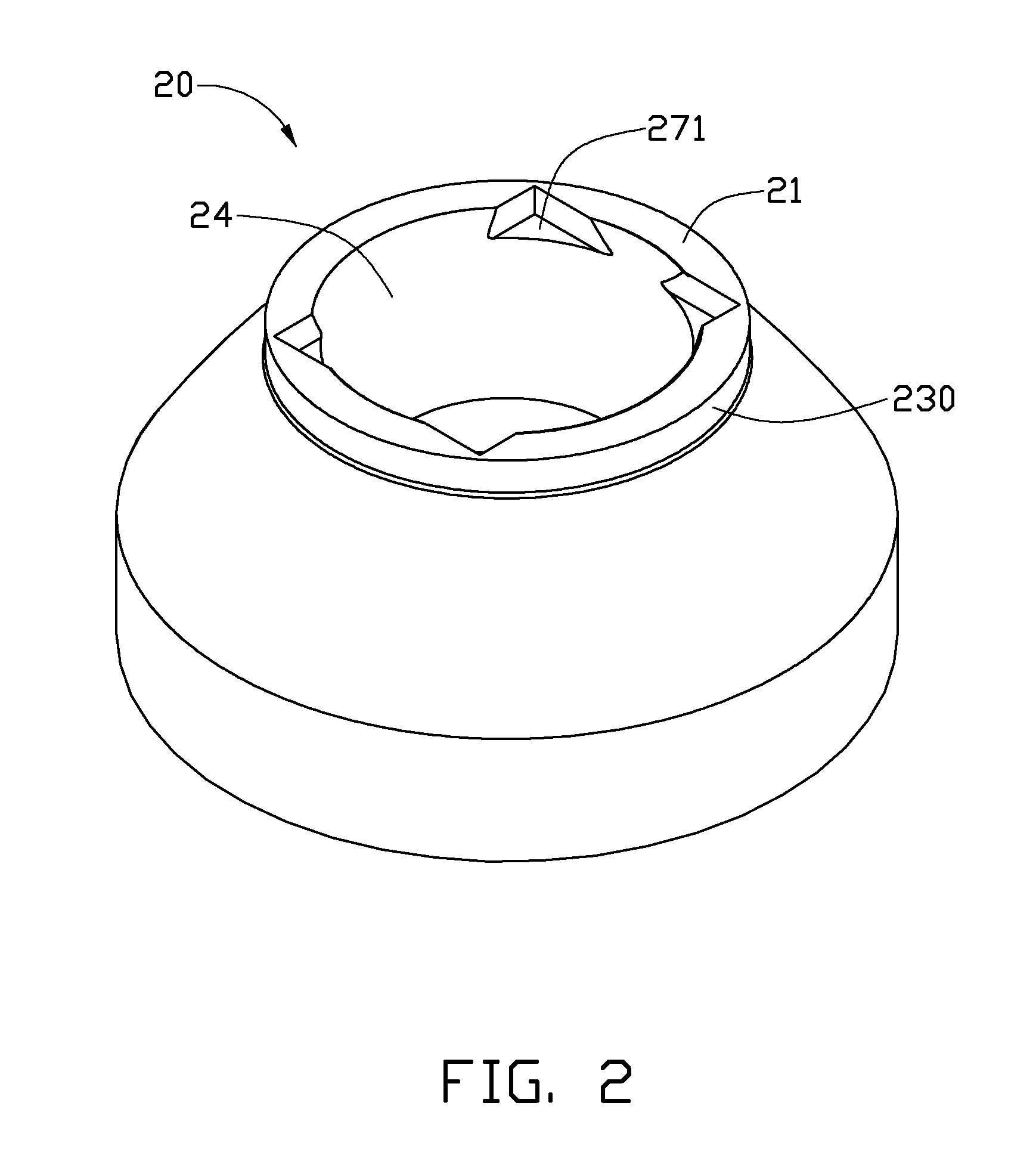

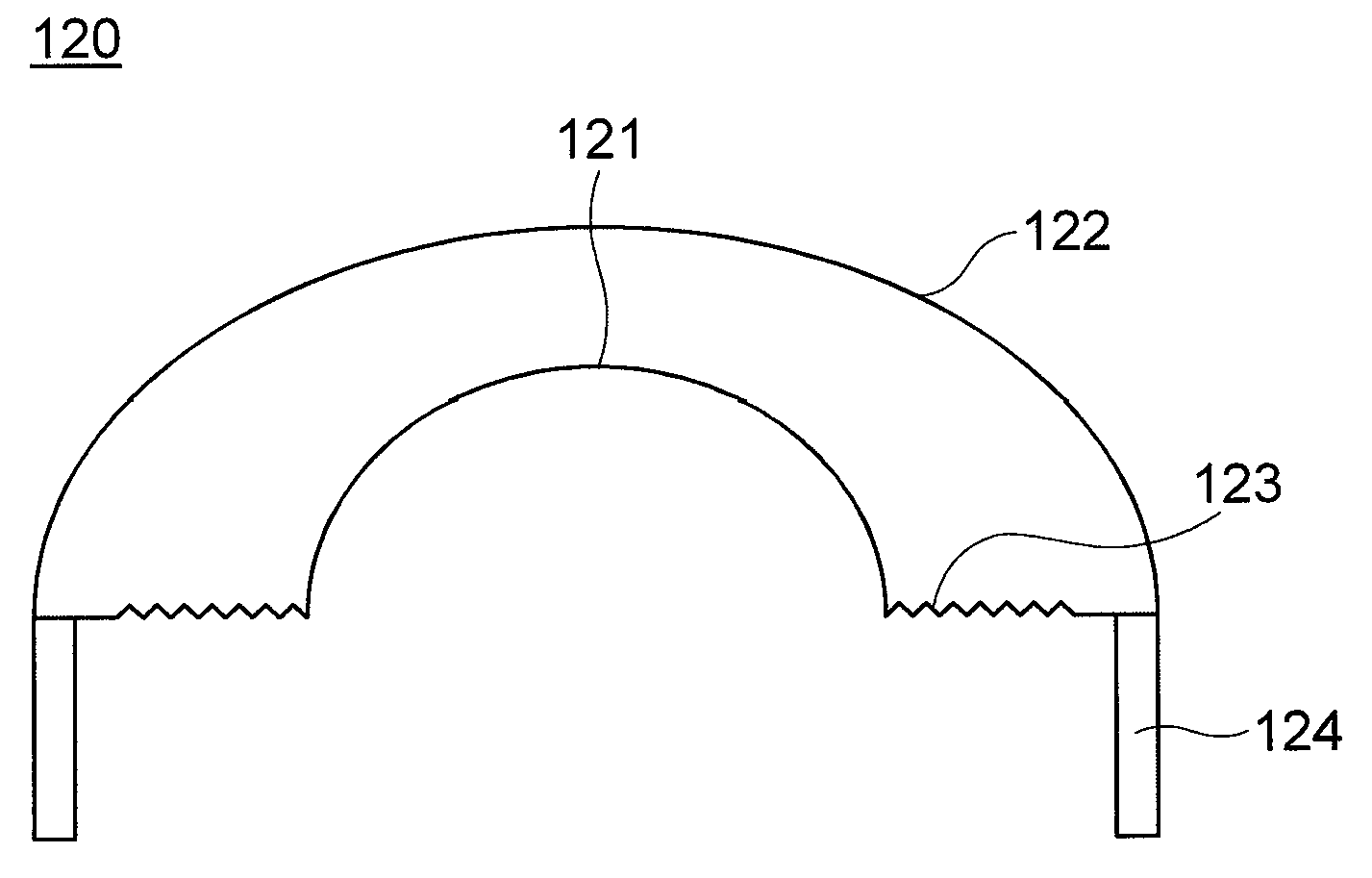

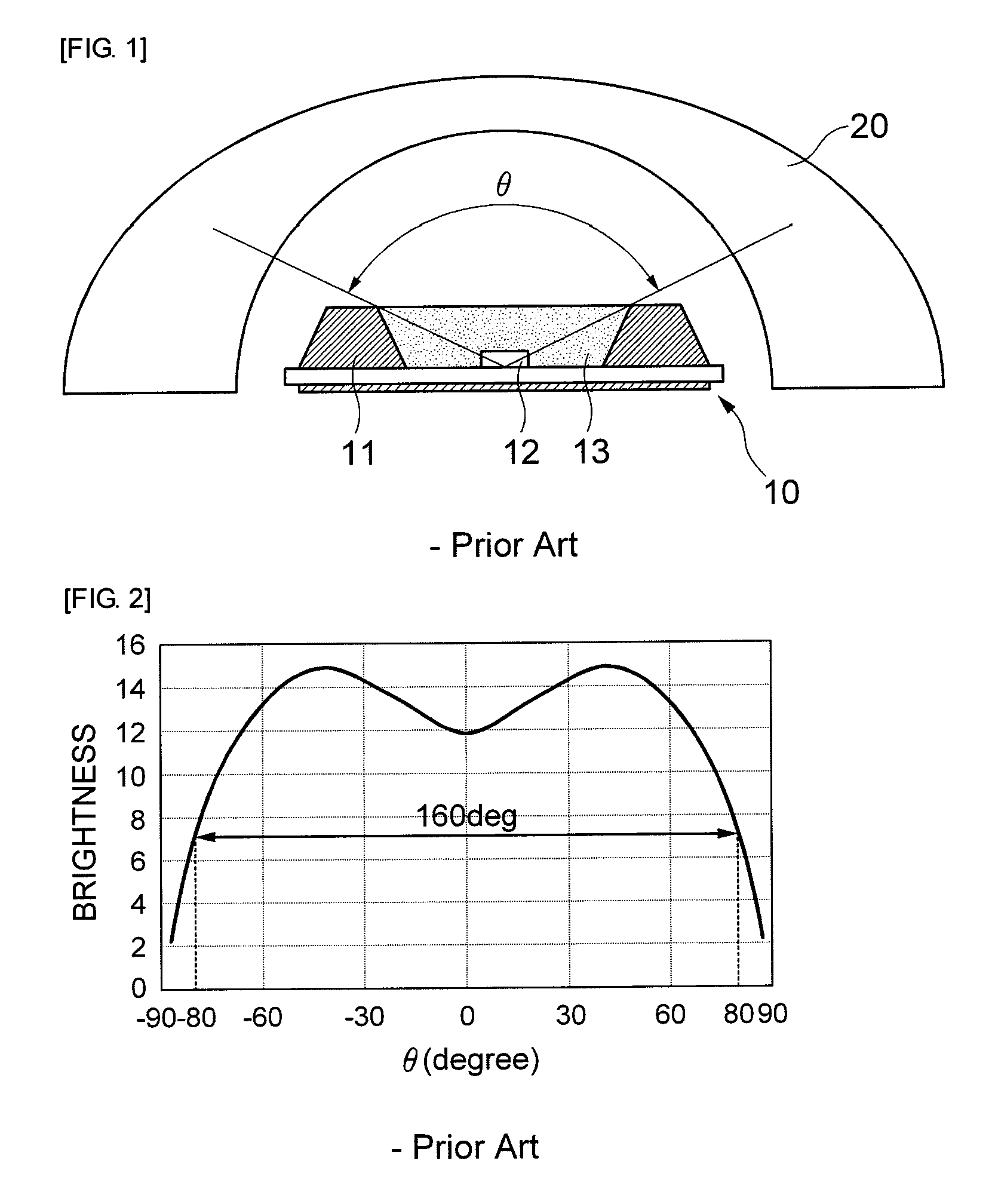

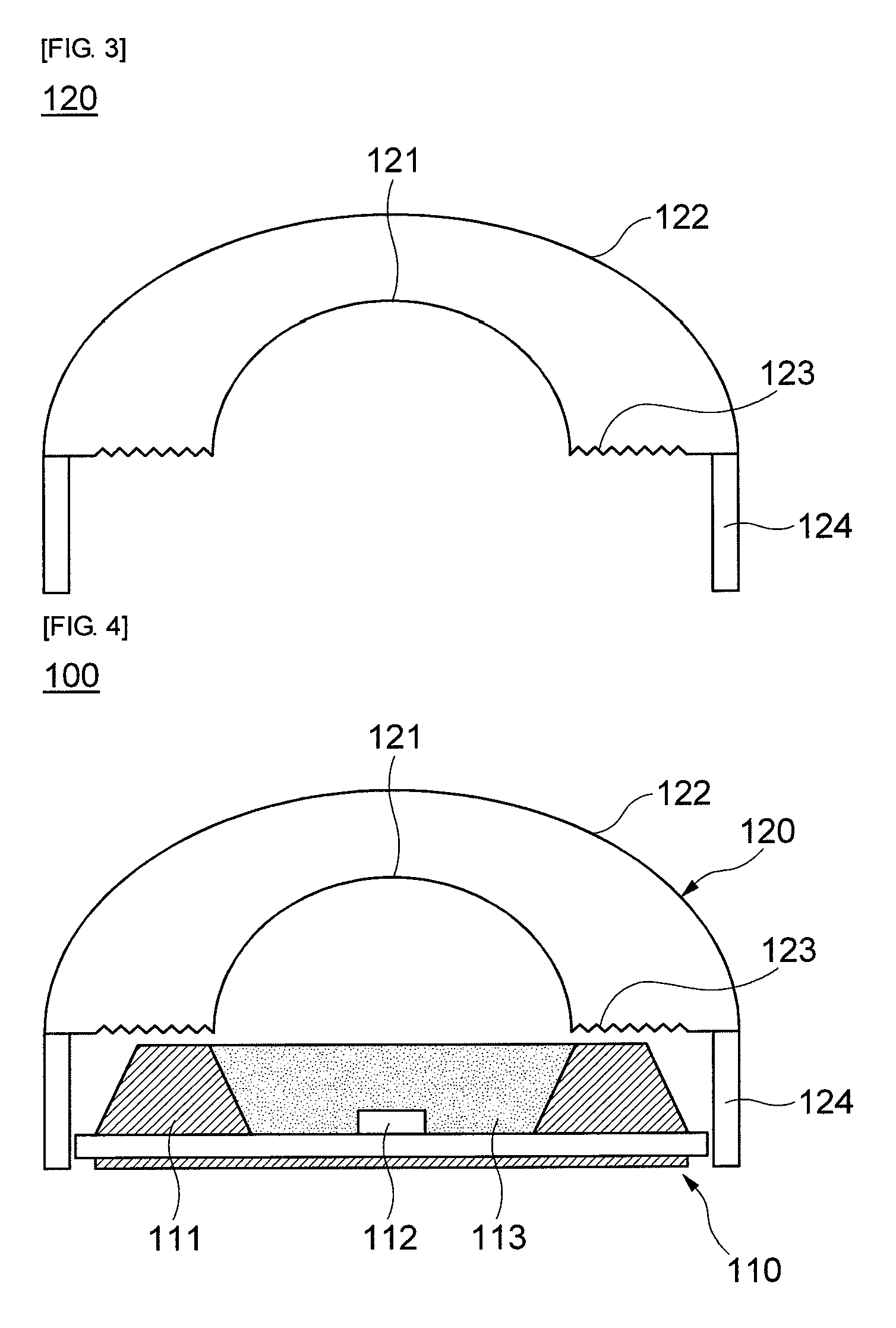

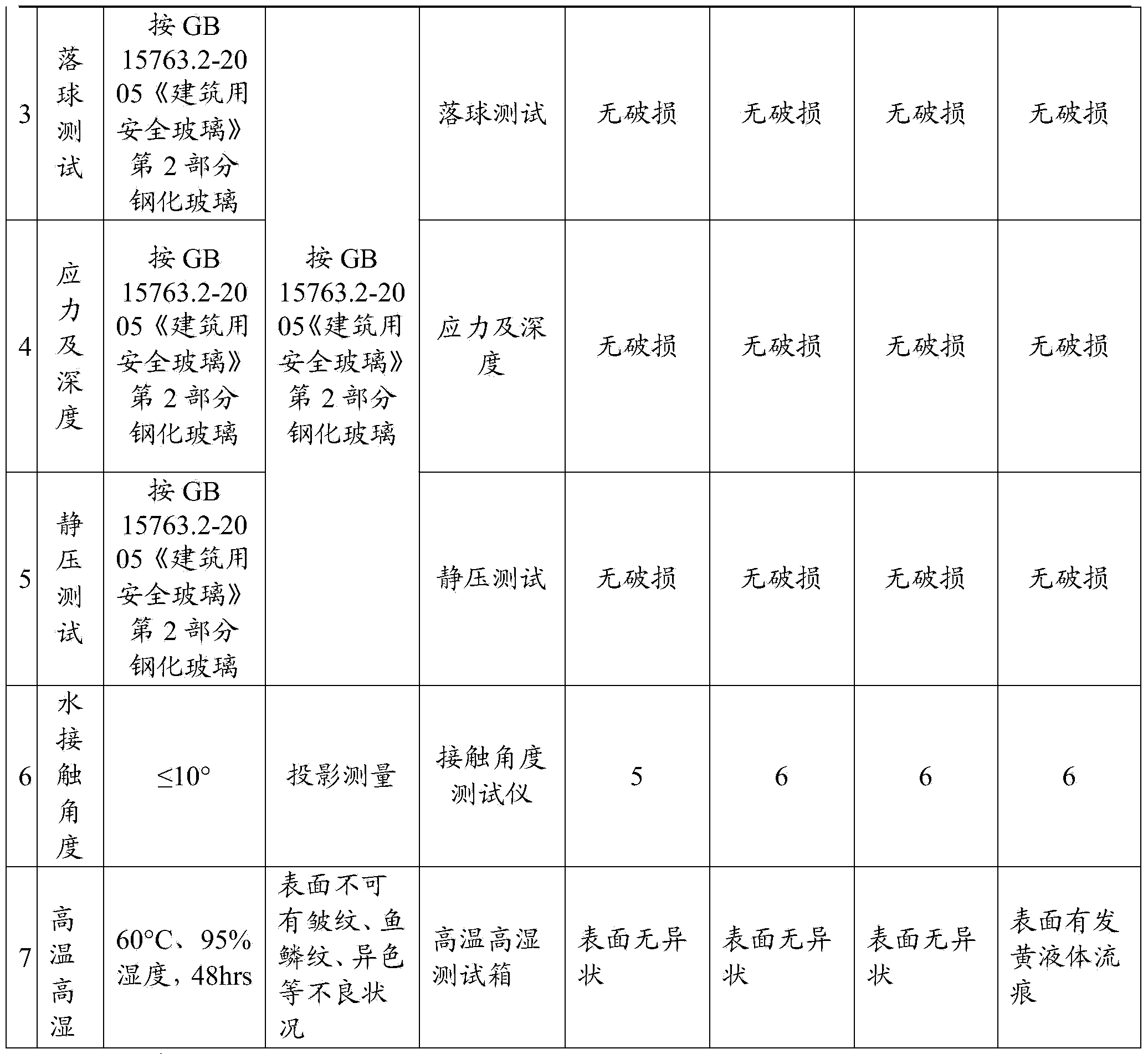

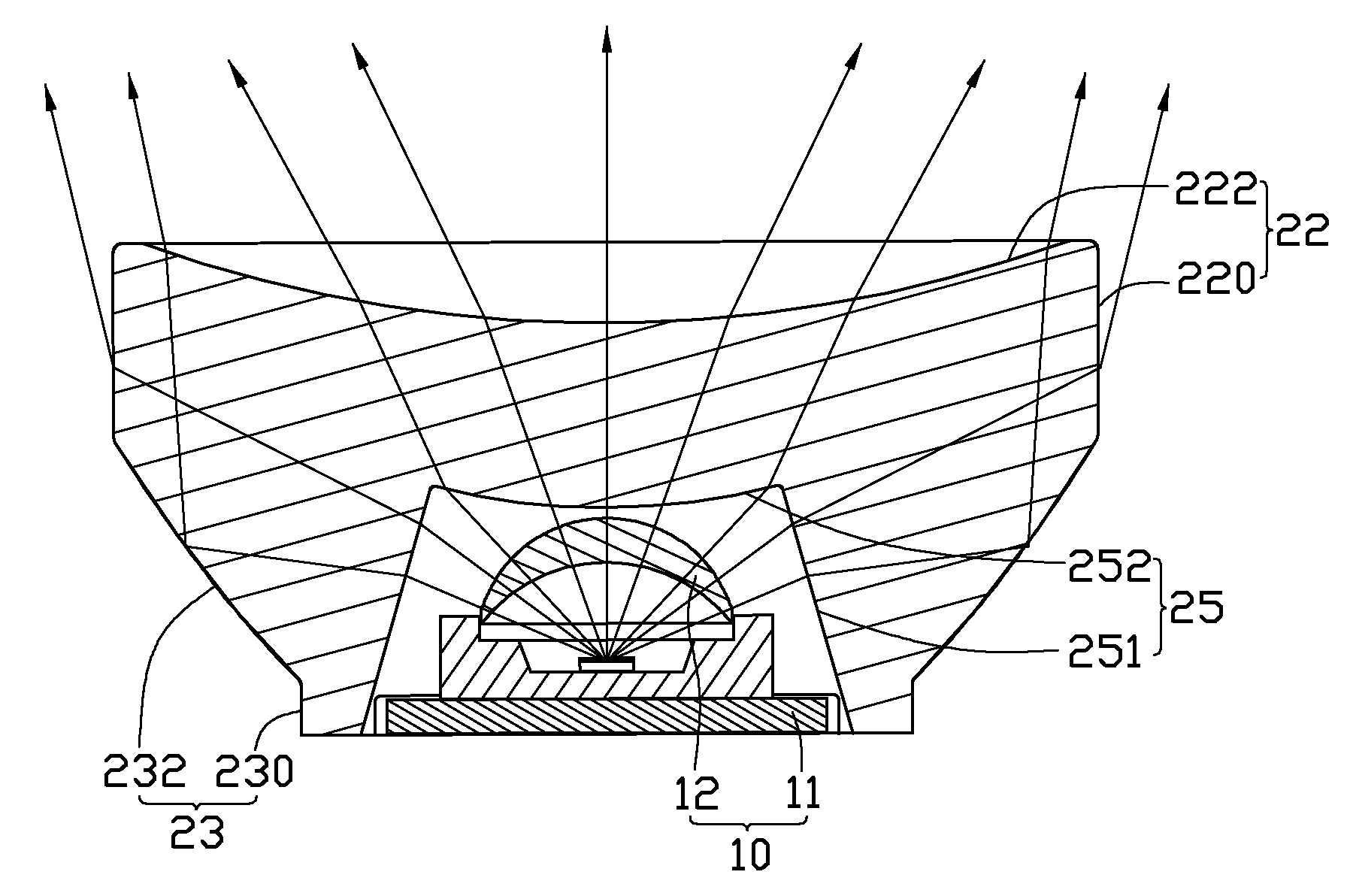

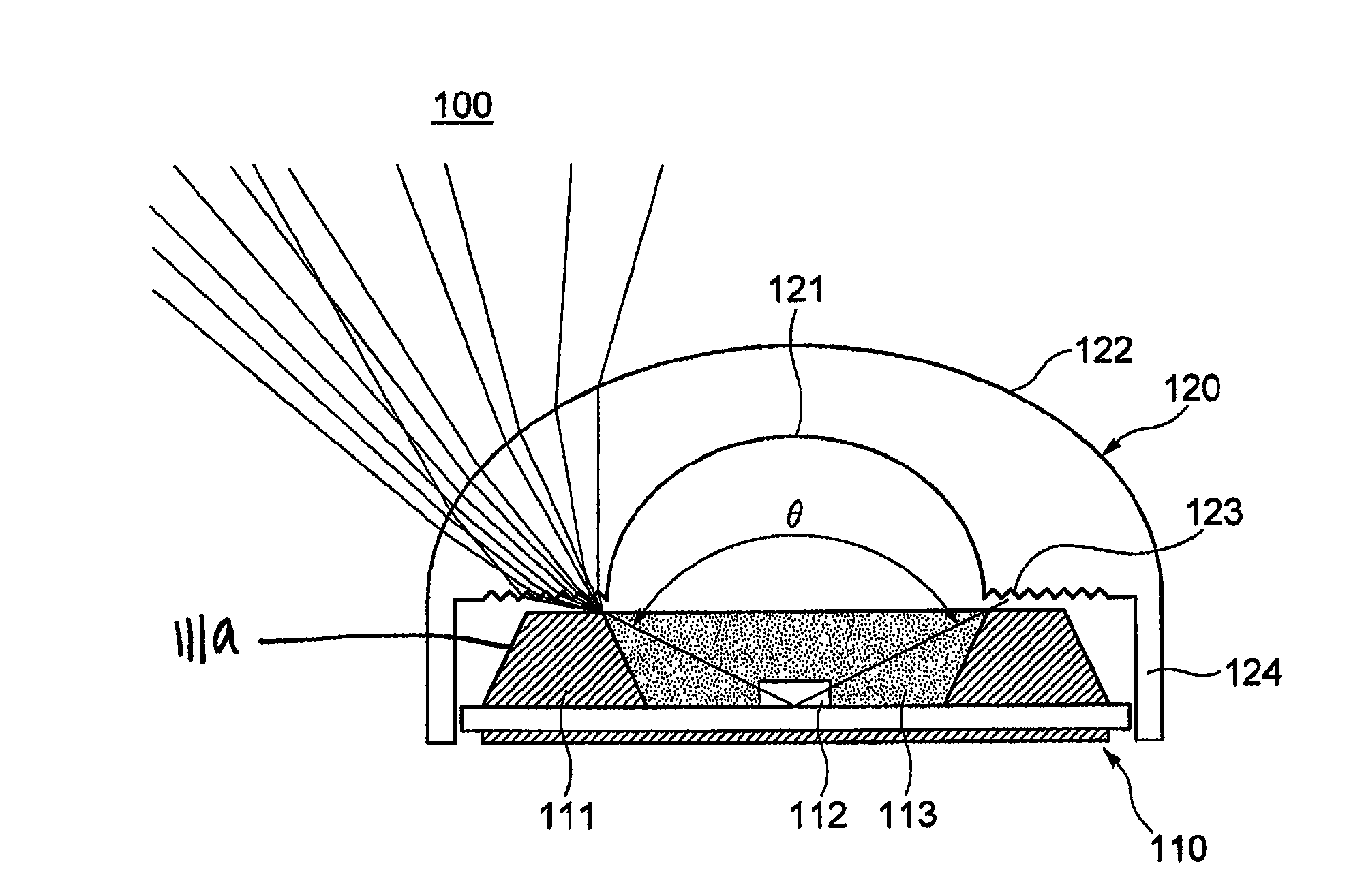

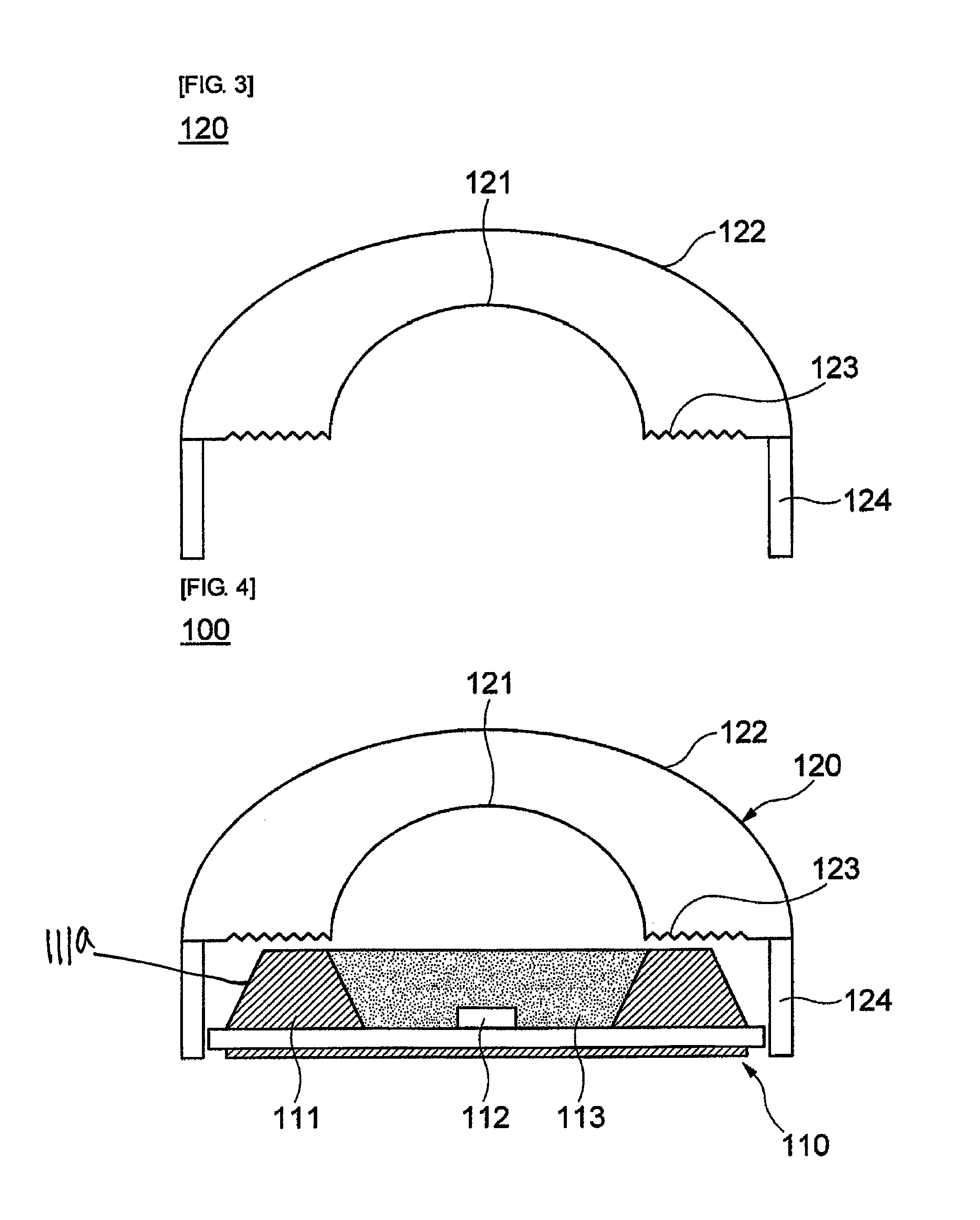

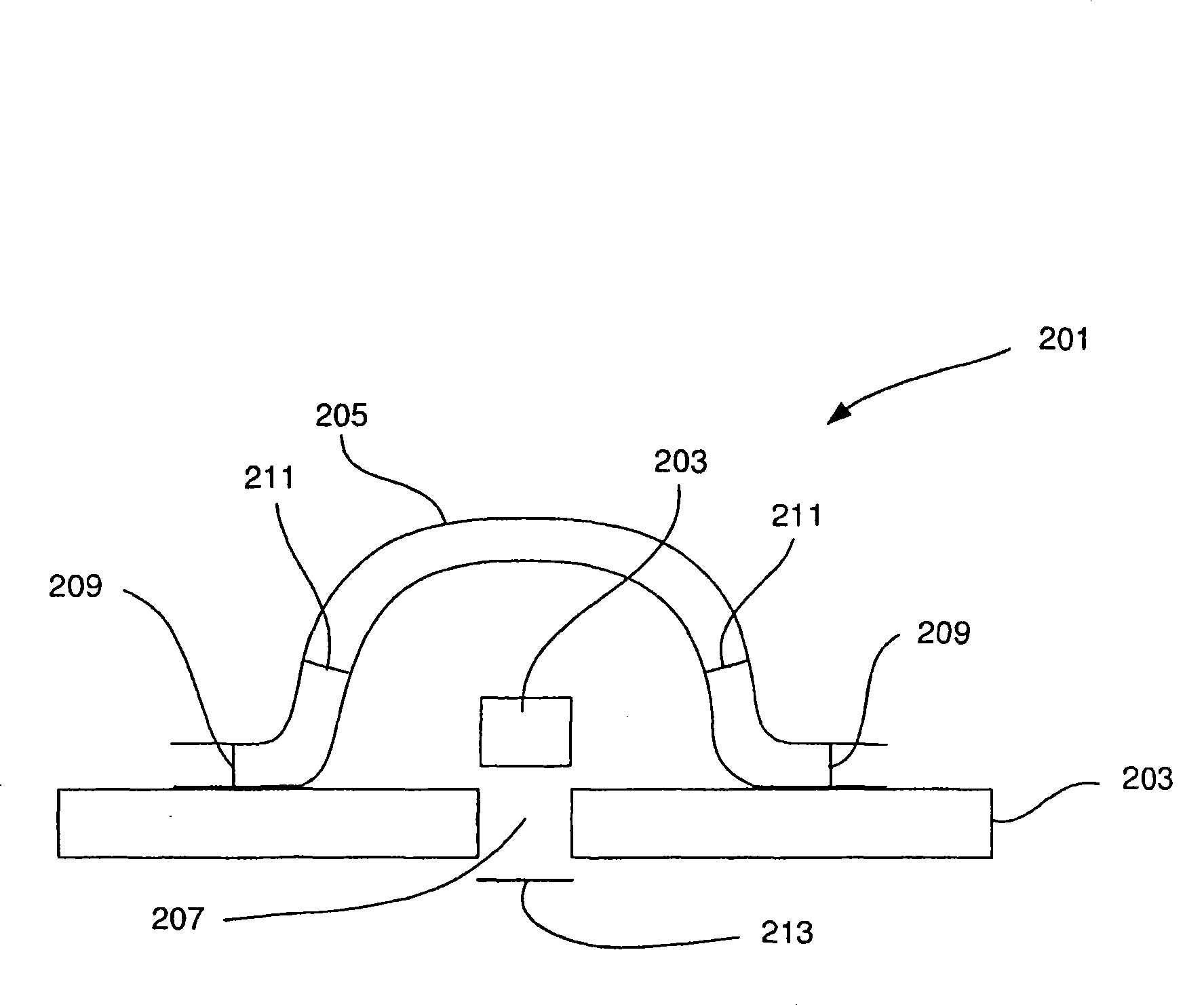

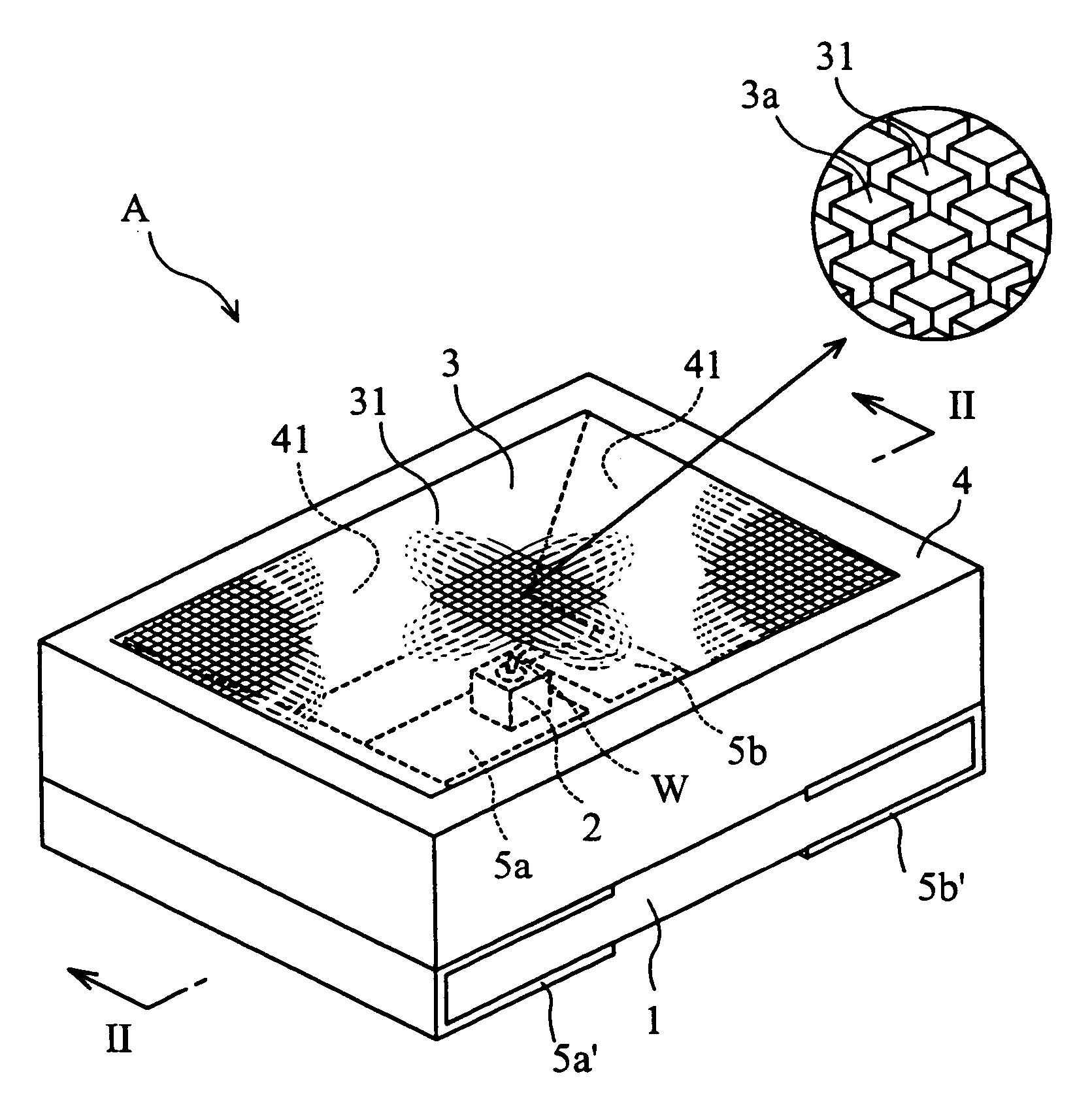

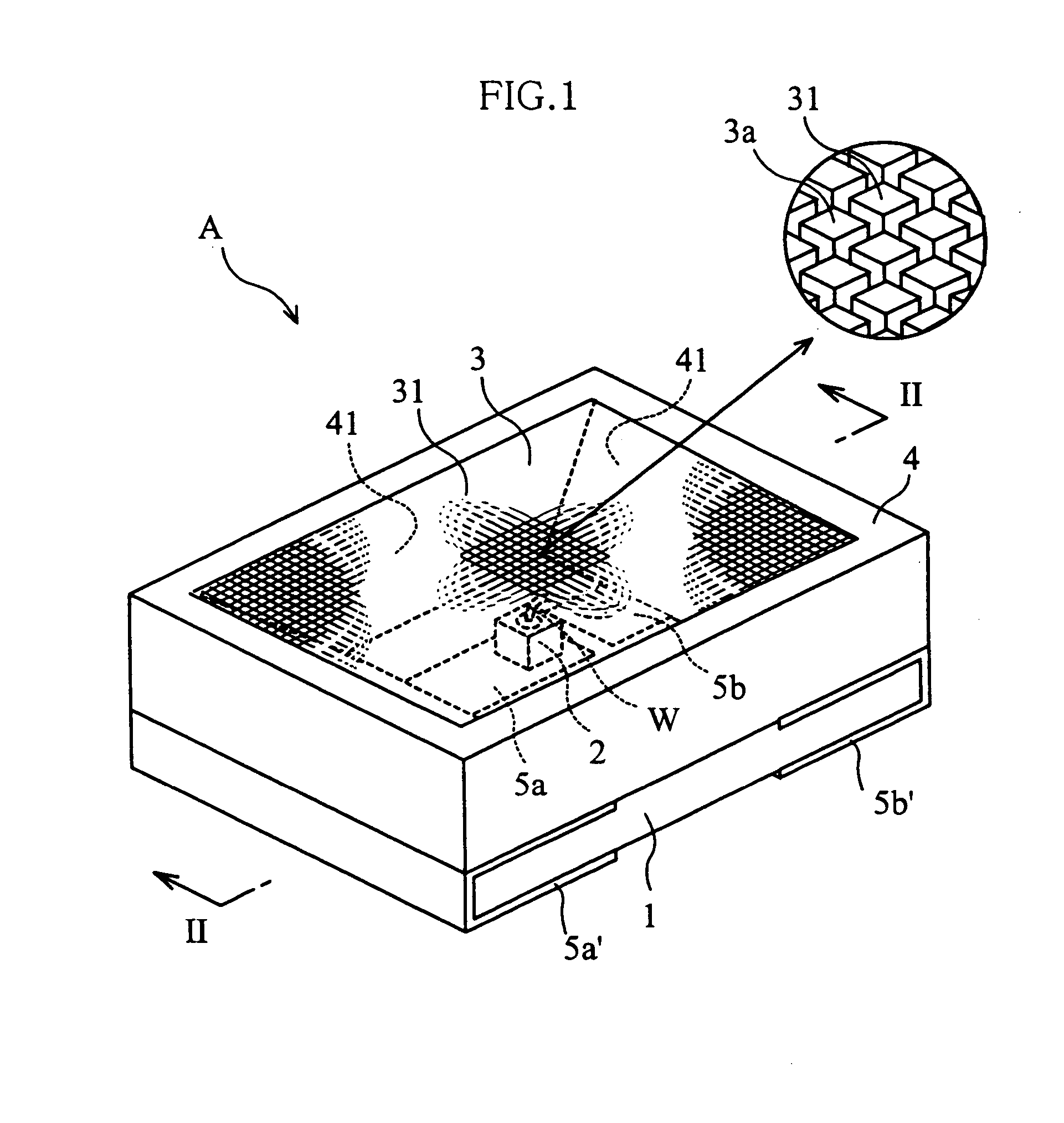

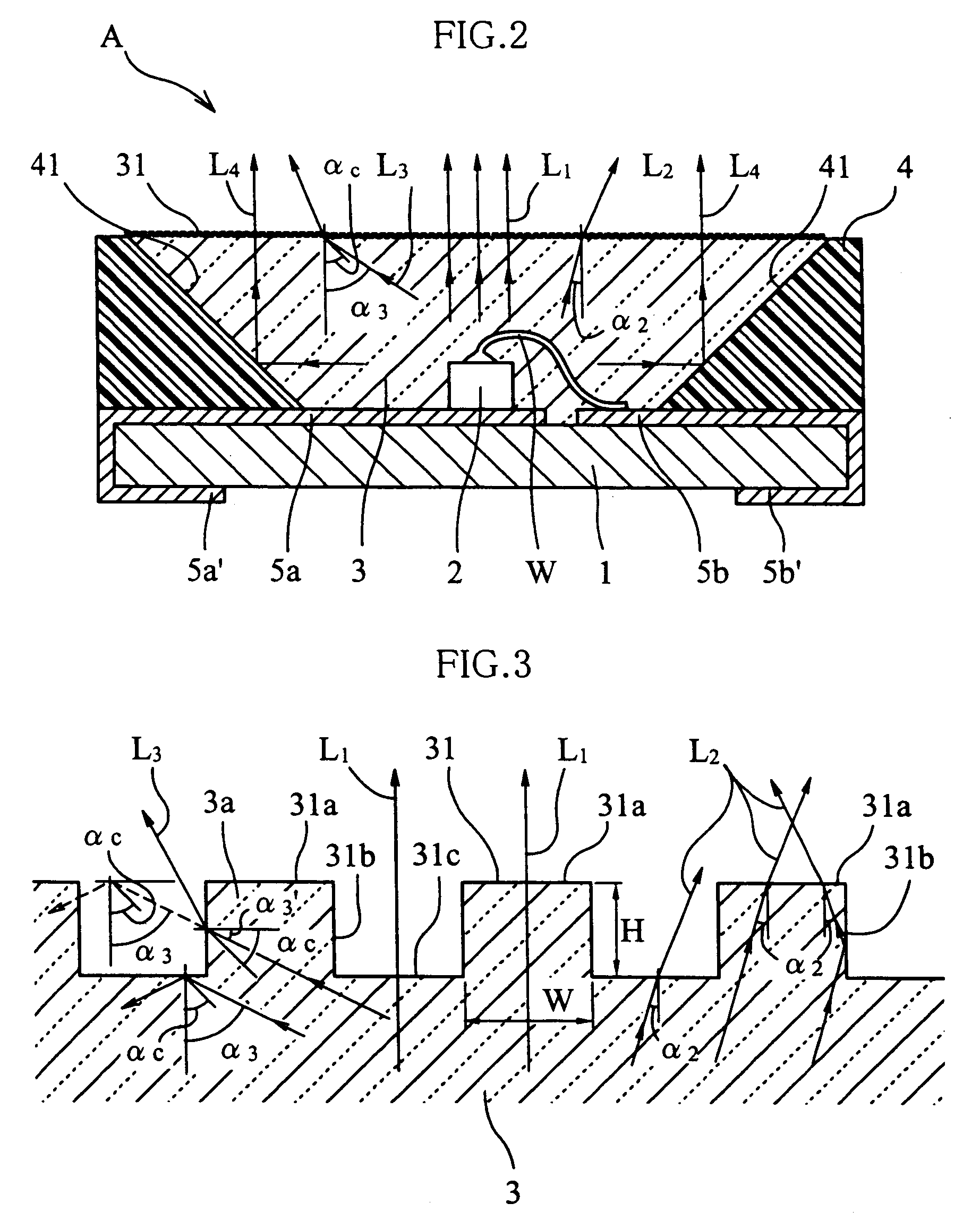

Spread lens and lighting device assembly using the same

ActiveUS20090296405A1Improved Diffusion PropertiesMechanical apparatusDischarge tube luminescnet screensSurface spreadingEffect light

The present invention relates to a spread lens and a light emitting device assembly using the spread lens for miniaturization and improving a spread characteristic of a lens.In accordance with the present invention, a spread lens spreading light emitted from a light emitting device may include a first lens surface through which the emitted light from the light emitting device is inputted; a second lens surface spreading the light inputted through the first lens surface to an outside; refraction parts which extend between both side ends of each of the first and second lens surfaces, are formed in a concave-convex shape, and refract the emitted light from the light emitting device; and support parts which extend at both side ends of the second lens surface and separate the refraction parts and the light emitting device from each other.

Owner:SAMSUNG ELECTRONICS CO LTD

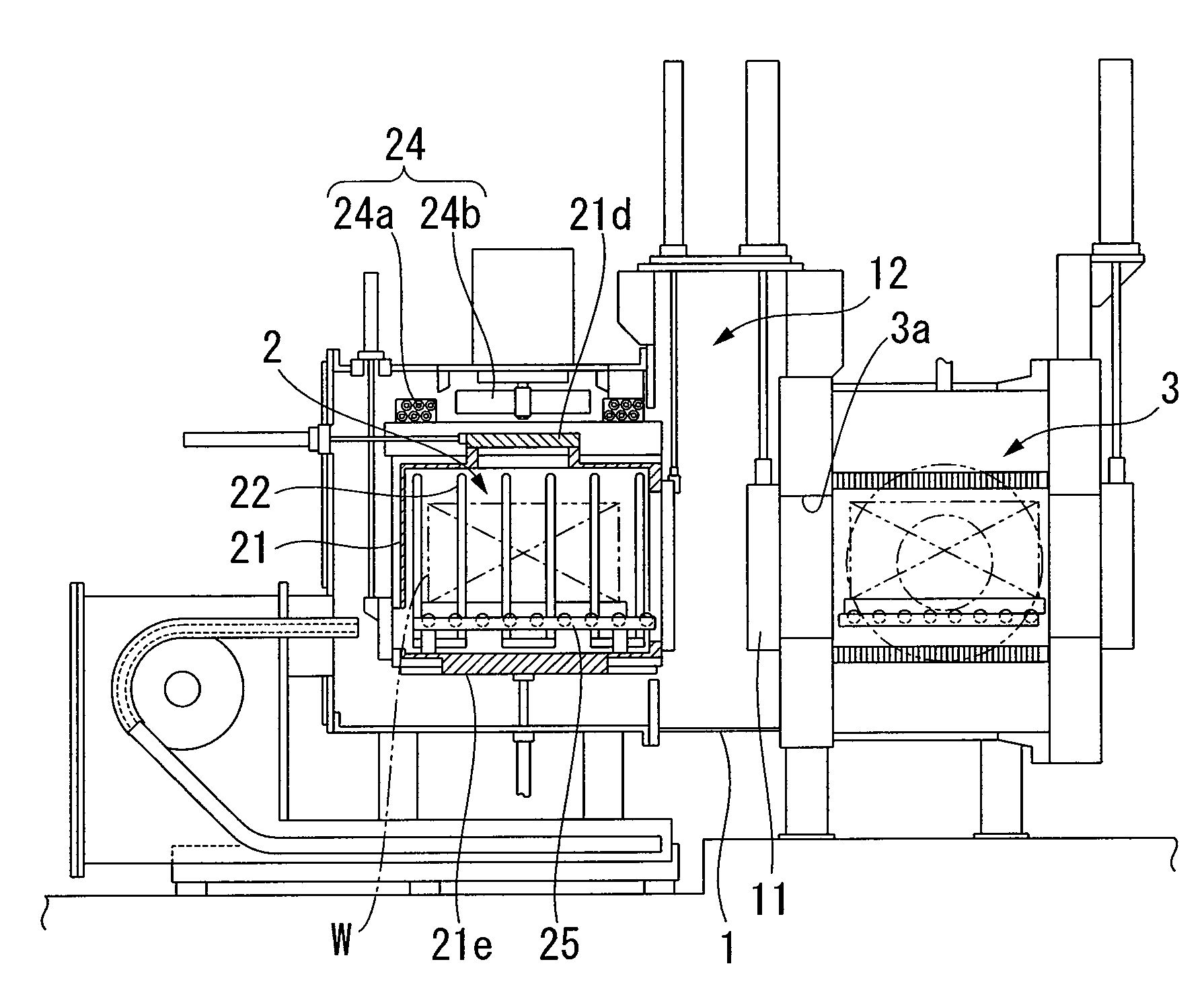

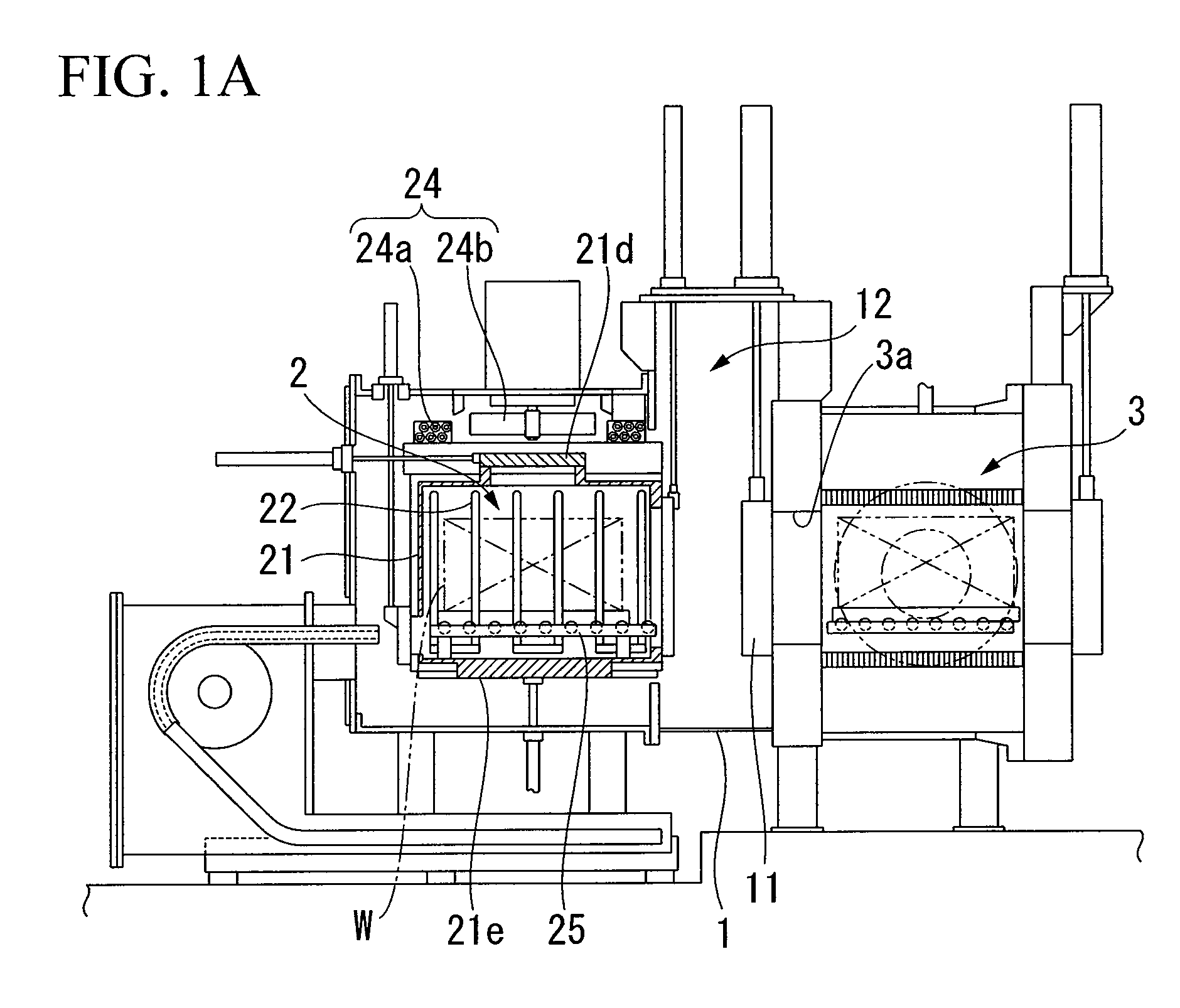

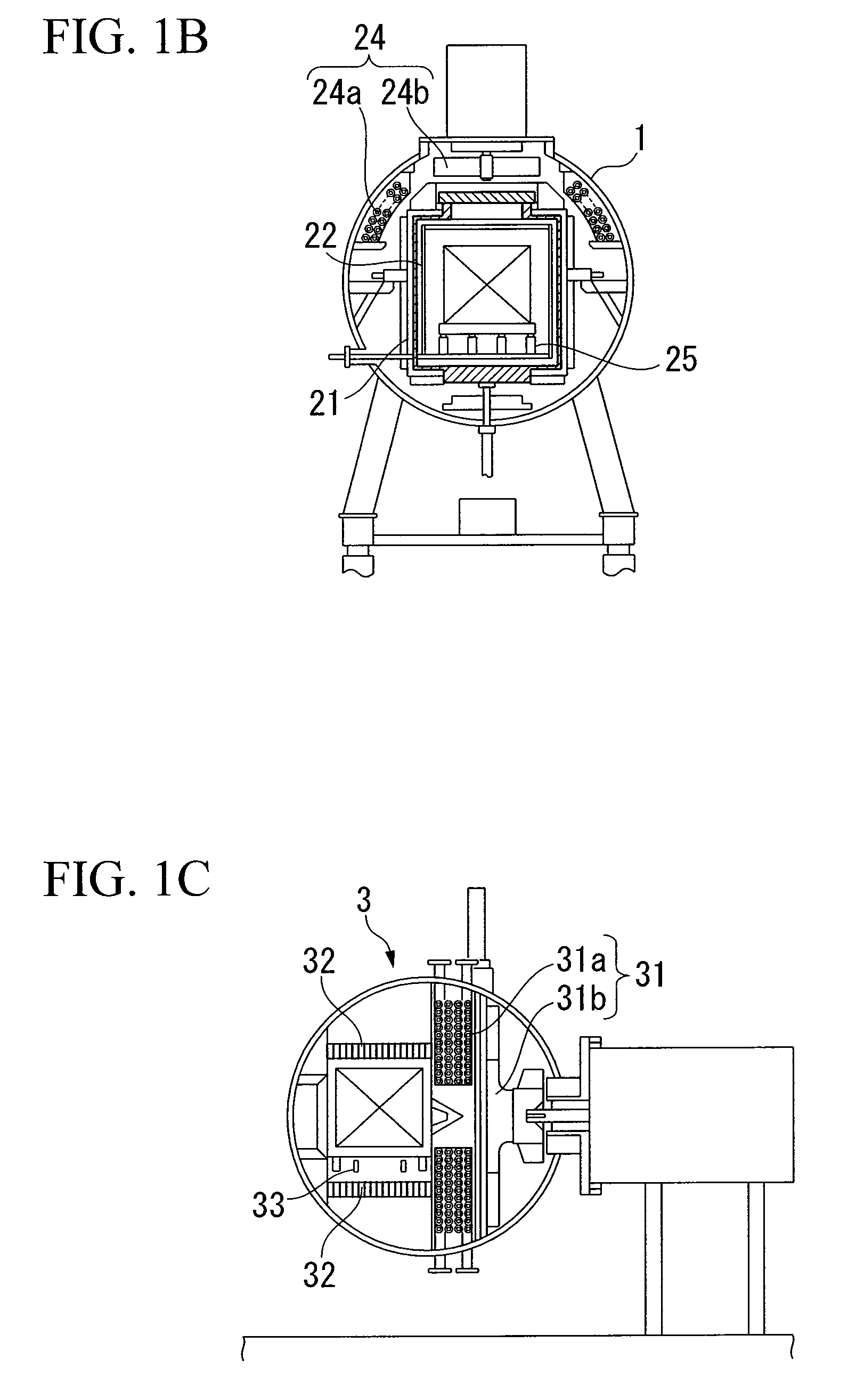

Vacuum carburization processing method and vacuum carburization processing apparatus

ActiveUS20080073001A1Increase temperatureReduce the temperatureMuffle furnacesSolid state diffusion coatingSurface spreadingQuenching

A vacuum carburization processing method includes a preparatory heating step of increasing the temperature of a workpiece in a heating chamber to a first temperature, a carburizing step of carburizing the workpiece by supplying carburizing gas into the heating chamber from a state where the pressure inside the heating chamber is reduced to an extremely low pressure, a diffusing step of terminating the supply of the carburizing gas and making carbon diffuse from a surface of the workpiece into its internal part, and a quenching step of abruptly cooling the temperature of the workpiece from a state where the temperature of the workpiece is at a second temperature; and also includes, between the diffusing step and the quenching step, a normalizing step of reducing the temperature of the workpiece so that the temperature history of the workpiece from the first temperature to a predetermined temperature satisfies predetermined conditions, a post-normalization maintaining step, performed after the normalizing step, of miniaturizing crystal grains of the workpiece by maintaining the workpiece at the predetermined temperature for a predetermined time so that the entire workpiece reaches the predetermined temperature, and a reheating step, performed after the post-normalization maintaining step, of increasing the temperature of the workpiece to the second temperature.

Owner:IHI CORP

Metal laser deep-layer quenching process

InactiveCN1603425AAvoid deformationSolve the problem of shallow depthLaser quenchingLaser processing

One kind of metal laser deep layer quenching craft, through must process the area surface spreading alloy extinction coating after the metal, according to processes the area choice certain facula the light beam to carry on laser processing, simultaneously, blows the metal surface laser partial with the certain current capacity gas sphere of action, and with the liquid cooling laser sphere of action periphery, causes the metal hardening level quenching depth to achieve 0.7~~3mm. The invention has solved the metal induction heating time deformation, enhanced the metal skin hardness, simultaneously has solved an ordinary laser quenching hardening depth shallower problem.

Owner:ZHEJIANG UNIV OF TECH

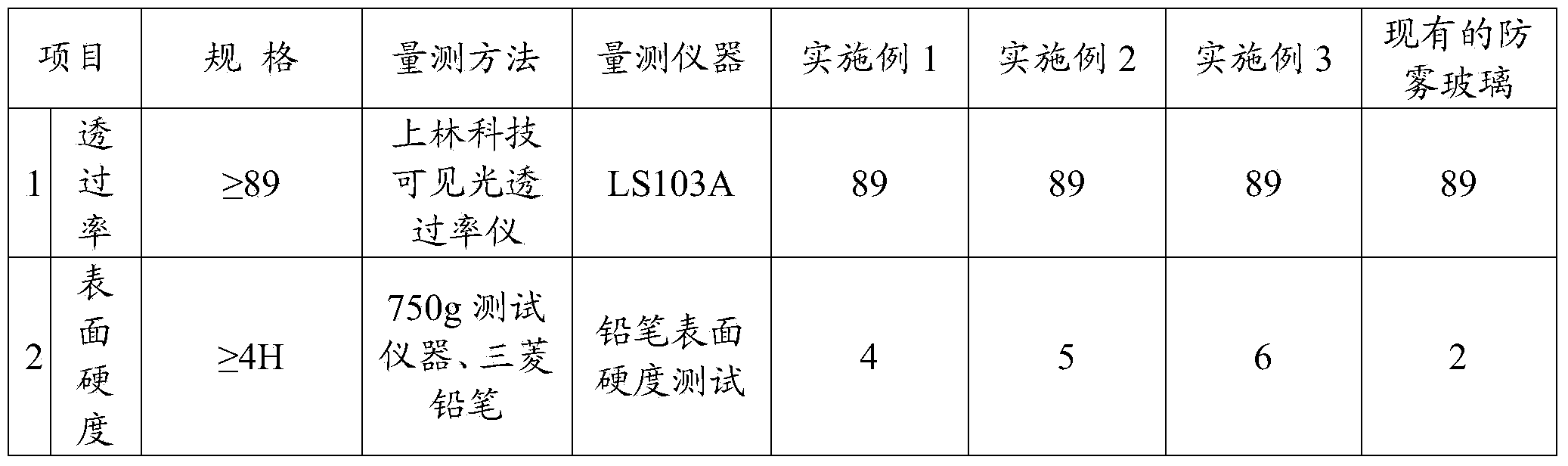

Antifogging toughened glass and preparation method thereof

The invention discloses an antifogging toughened glass and a preparation method thereof. The preparation method comprises the following steps: cutting glass, toughening, cleaning, spray-coating, baking, and cleaning. A water-soluble acrylic resin is used as the antifogging agent of a film forming material according to a hydrophilic principle, and an antifogging film is formed on the surface of toughened glass by adopting a spray coating technology and a baking technology, and the film is hydrophilic, can reduce the contact angle of the surface of the glass to water, makes small water drops coagulating on the surface spread on the surface to form a film not tiny water drops, and reduces the diffuse reflection of light.

Owner:GUANGZHOU SHIZHEN INFORMATION TECH CO LTD

LED module

Owner:FU ZHUN PRECISION IND SHENZHEN +1

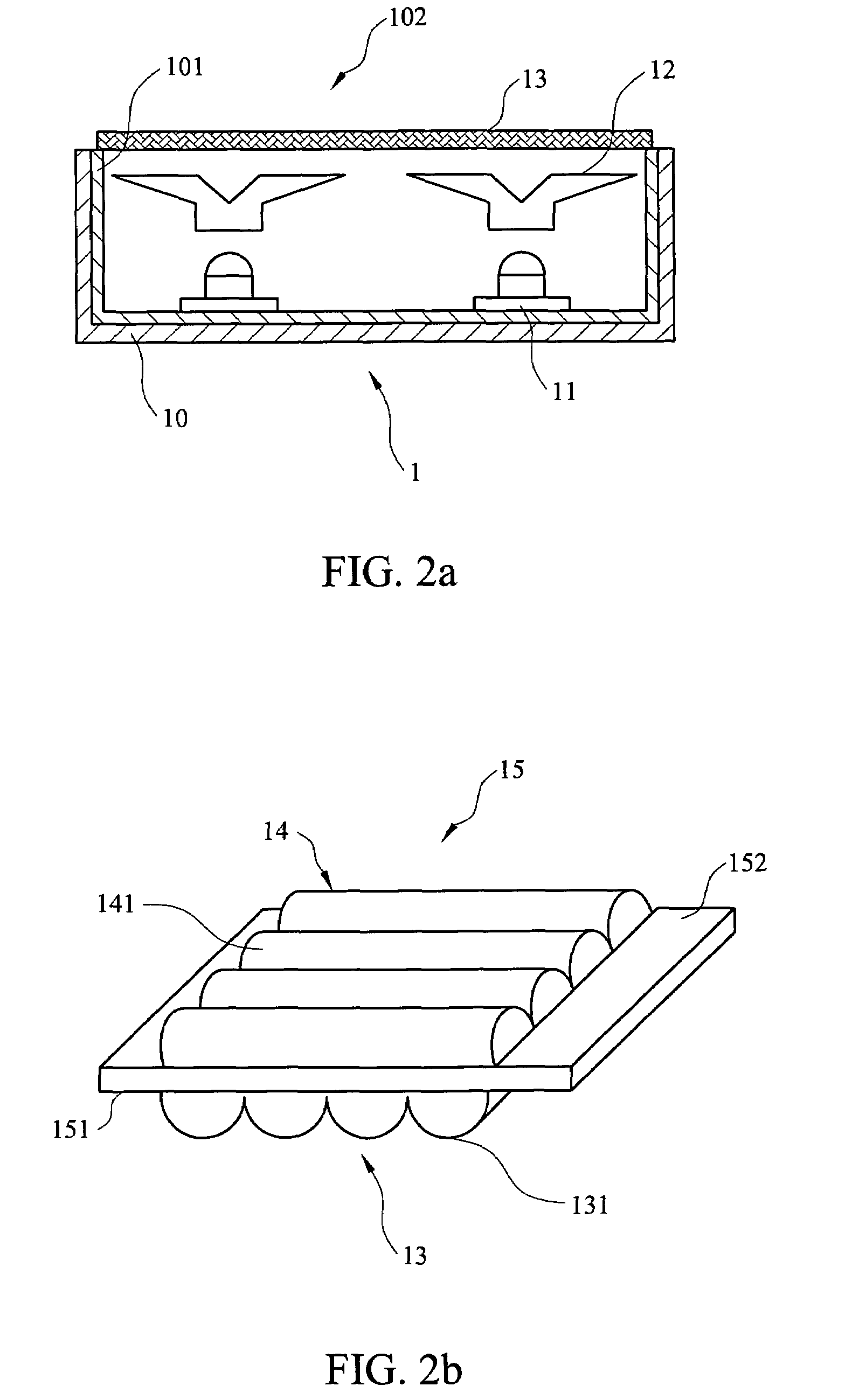

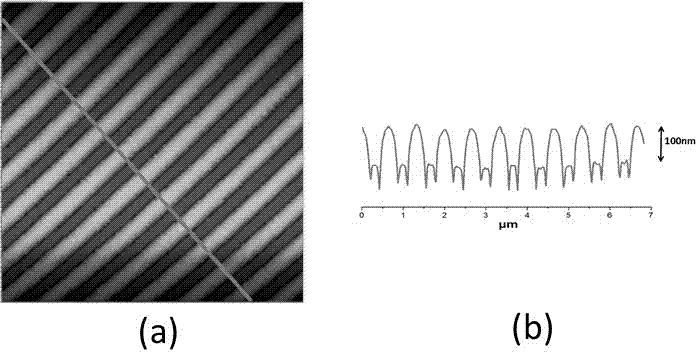

Rough black metal film for absorbing terahertz radiation and preparation method of rough black metal film

ActiveCN102998725AIncreased radiation absorptionImprove absorption rateOptical elementsEtchingTerahertz radiation

The invention discloses a rough black metal film for absorbing terahertz radiation and a preparation method of the rough black metal film. An ultra-thin metal film is bombarded by plasma of a metal active etching agent, such as fluoro, and the surface of the metal film is rough through the physical bombardment of fluoro plasma. Simultaneously, the fluorinion energy and the fluorinion concentration are adjusted during the etching, the fluorinion is attached to the rough surface of the metal film, is diffused on the surface and reacts, and the metal film with enriched fluorinion is obtained. A large number of crystal defects of fluorinion are generated on the rough metal film surface after etching, the metal film surface is black, the structure of the black and rough metal film surface has the high surface-to-volume ratio and low reflectivity, the absorption performance and the efficiency of the terahertz radiation are effectively improved, the preparation process is simple, the Micro Electronic Mechanical System (MEMS) and the process are compatible, and the metal film and the method can be applied to the terahertz detection and imaging filed widely.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

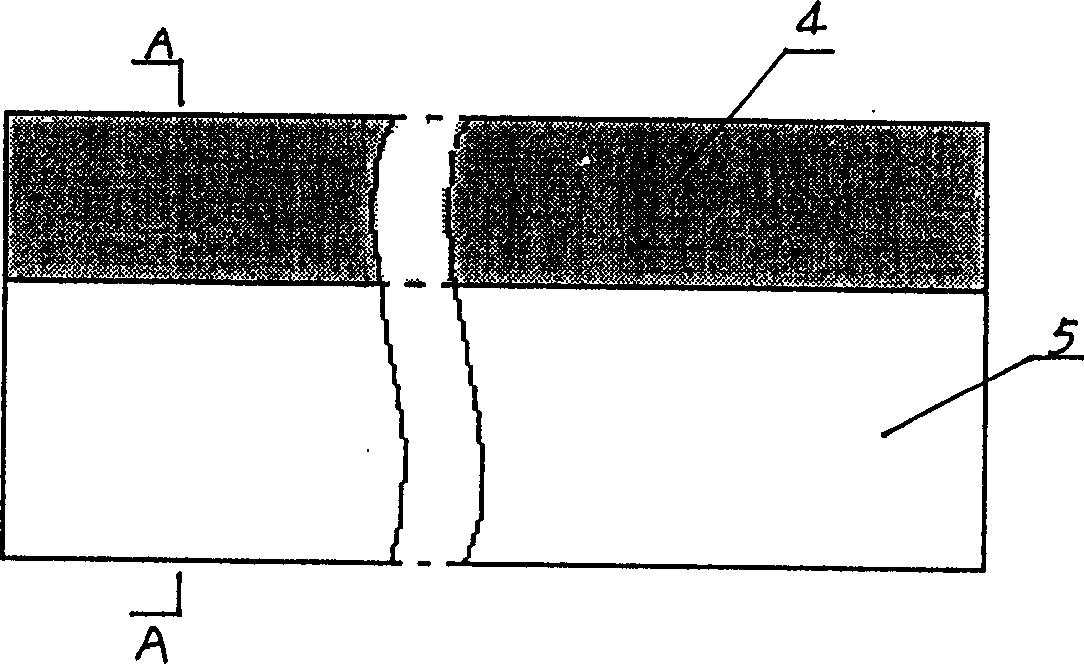

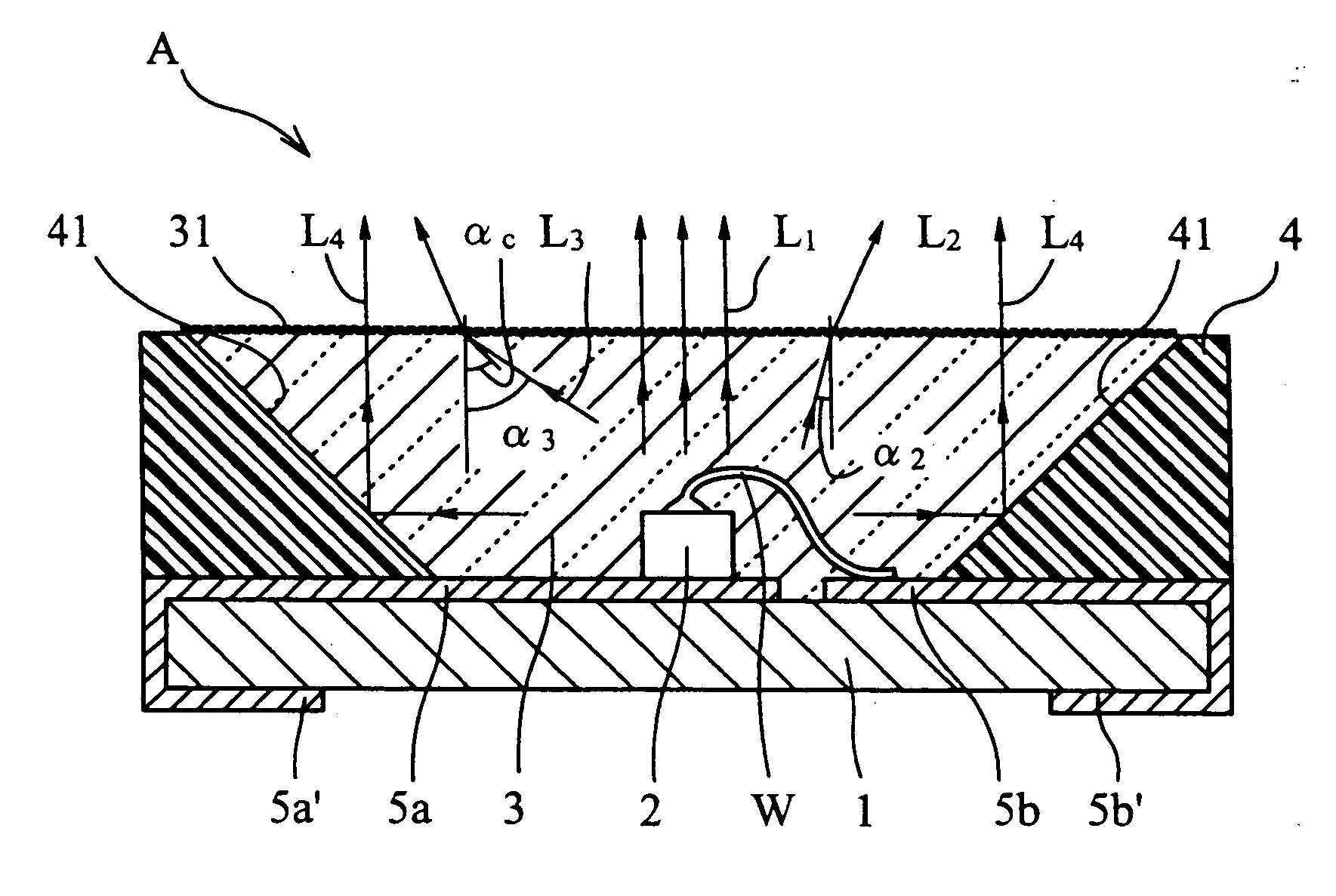

Spread lens with refraction parts, and lighting device

ActiveUS8128260B2Improved Diffusion PropertiesMechanical apparatusDischarge tube luminescnet screensSurface spreadingLight emitting device

A spread lens including a first lens surface through which the emitted light from the light emitting device is inputted; a second lens surface spreading the inputted light to an outside; refraction parts which extend between both side ends of each of the first and second lens surfaces, are formed in a concave-convex shape, and refract the emitted light from the light emitting device; and support parts which extend at both side ends of the second lens surface and separate the refraction parts and the light emitting device from each other.

Owner:SAMSUNG ELECTRONICS CO LTD

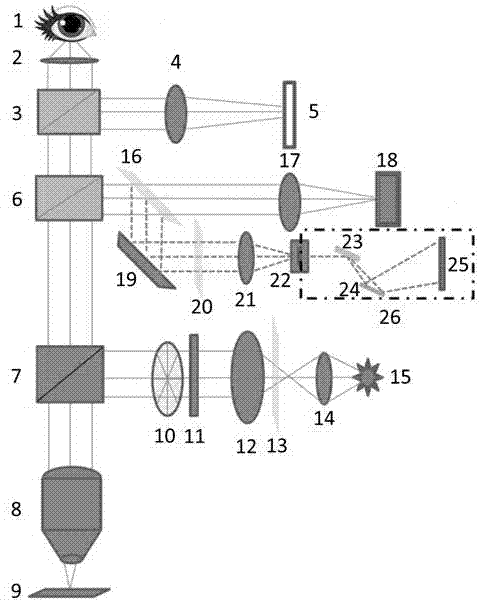

Microscopic imaging technique compounding surface plasma resonance and surface enhanced raman

ActiveCN106896095AStrong practicabilityLow costRaman scatteringGratingSurface plasmon resonance imaging

The invention discloses a microscopic imaging technique compounding surface plasma resonance (SPR) and surface enhanced Raman scattering (SERS) and relates to the field of surface plasma elements and surface enhanced Raman scattering. The technical key point disclosed by the invention is as follows: an SPR-SERS comprehensive microscopic imaging system is assembled, and SPR and SERS are excited and detected by a nano slit array raster bi-model structure; an SPR system judges change of an exciting angle by measuring movement of an SPR peak position to determine change of the surface effective refractive index induced by a biomolecular reaction on the surface of a chip; the SERS system directly differentiates the biomolecules by measuring the Raman spectrum; efficient and high-sensitive detection of SPR and Raman is dependent on the nano slit array raster bi-model structure: the excitation wavelength efficiently excites SPR through the raster structure; SPR generates dipole vibration in nanogaps in a metal surface spreading process, and the surface electric field generated by SPR and the nano silt dipole jointly act to enhance the surface local electric field to acquire an enhanced Raman signal.

Owner:SICHUAN UNIV

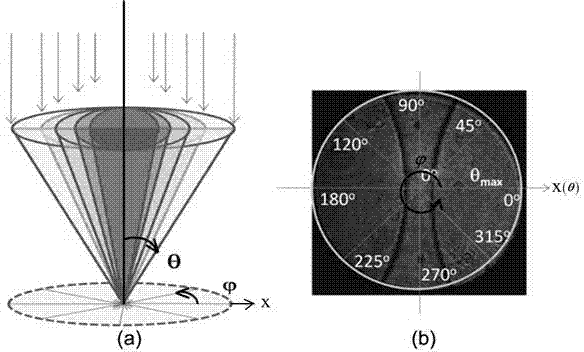

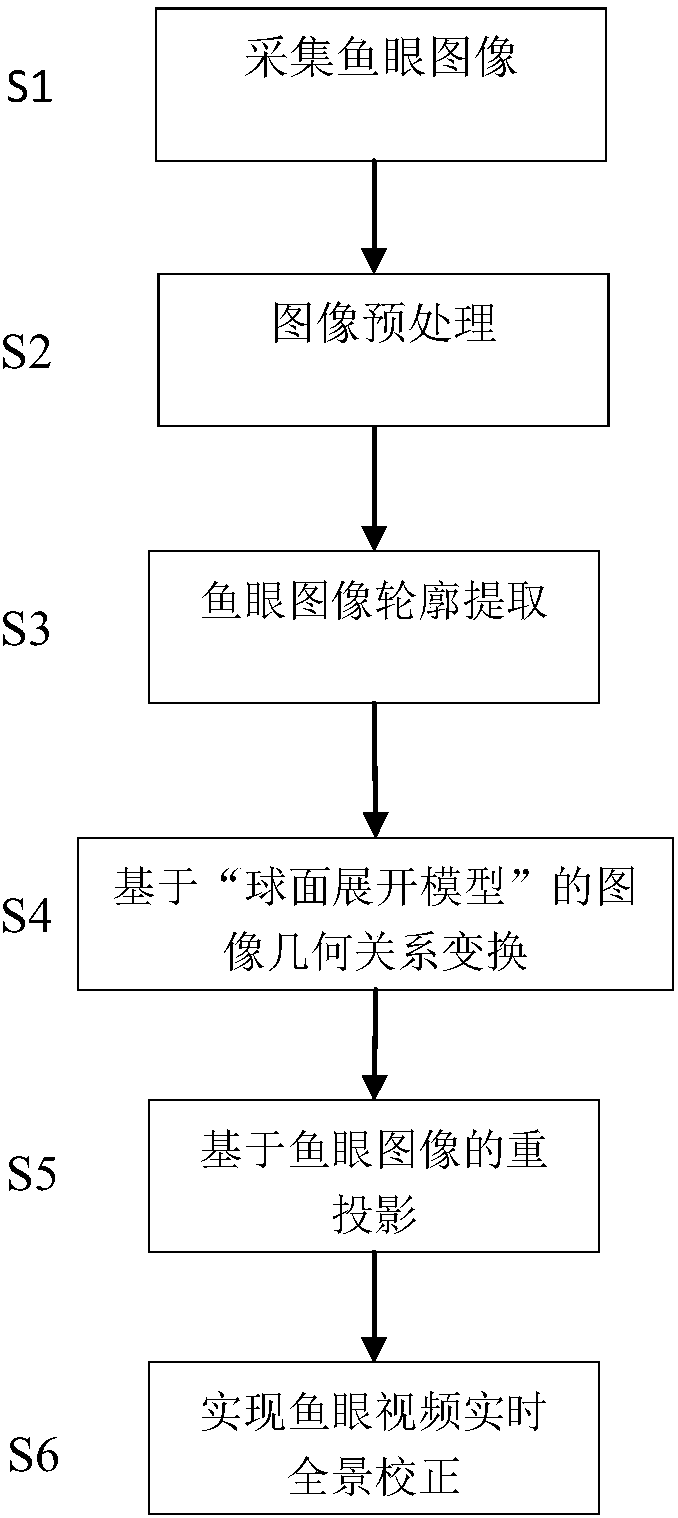

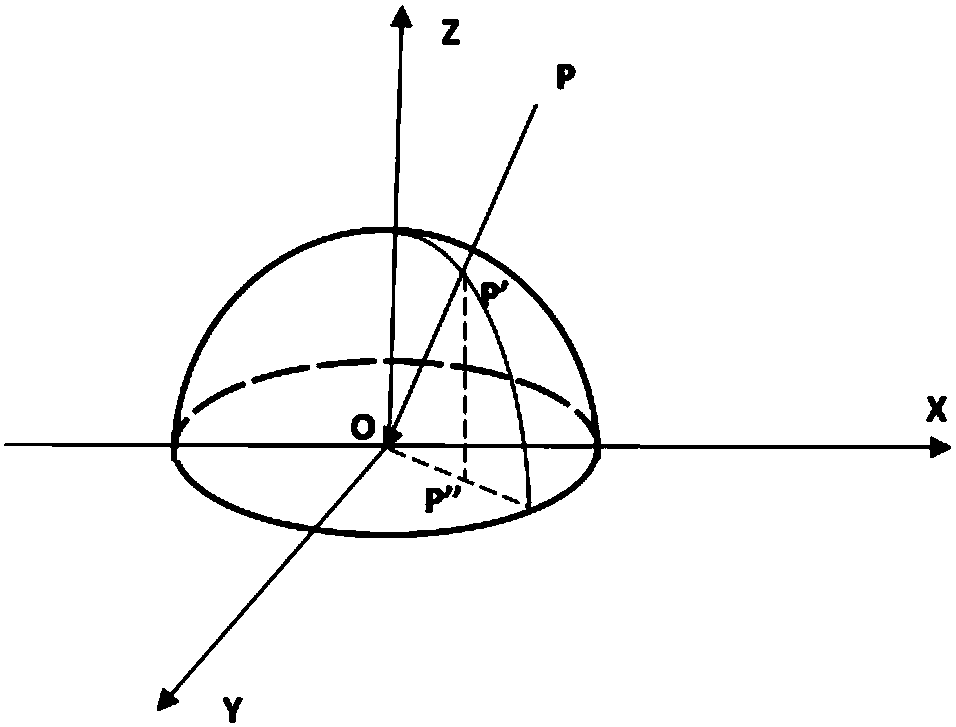

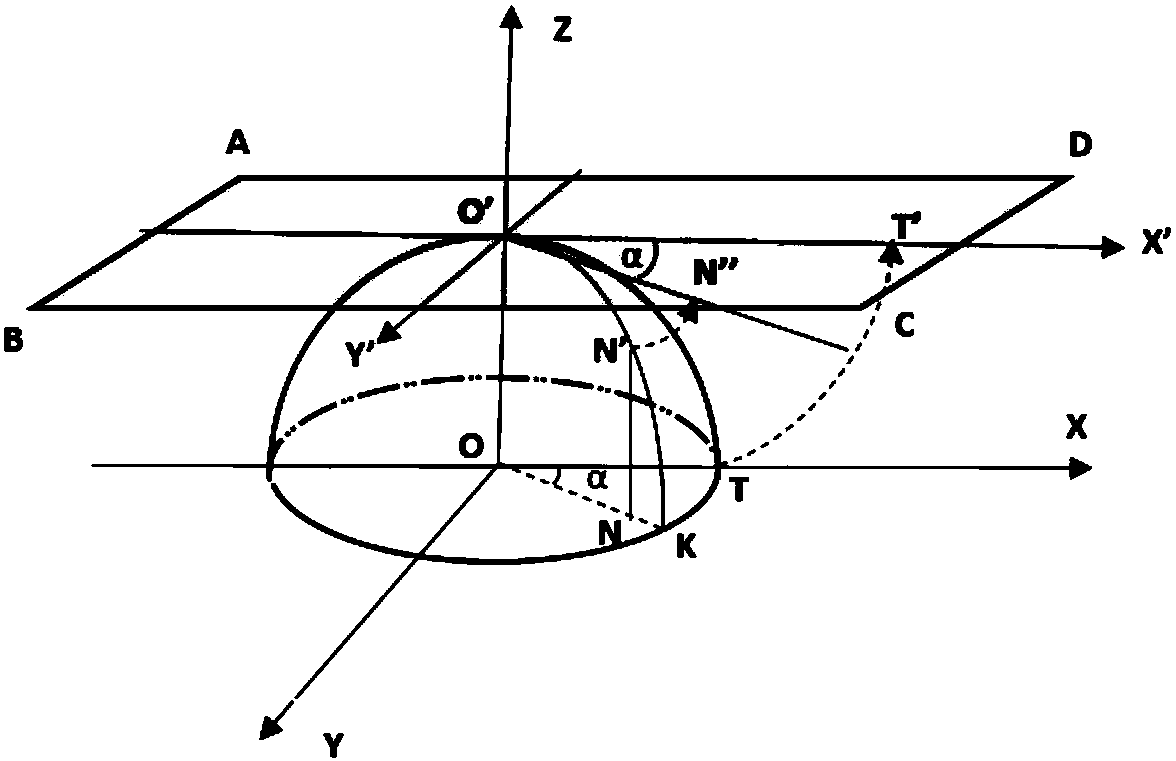

Fish eye video real-time panoramic correction method based on spherical surface spreading model

InactiveCN106920210AAchieve wide viewing angleAchieve correctionGeometric image transformationCamera lensFisheye lens

The invention provides a fish eye video real-time panoramic correction method based on a spherical surface spreading model and belongs to the field of image video processing. The method includes the following steps: fish eye image acquisition, fish eye image pre-processing, fish eye image profile extraction, image geometrical relation converting, re-projection based on fish eye image, and fish eye video roaming. According to the invention, the method includes the following specific steps: after acquiring a fish eye video, firstly resolving the radius of a corresponding "spherical model" of a fish eye image, then performing selection, and restoring each pixel of each frame of fish image to one "spherical model"; then expanding each pixel of the spherical surface to one correction plane according to a corresponding spherical arc; and finally conducting sampling and interpolation on the corrected pixels to obtain a corrected image of the fish eye image. According to the invention, compared with algorithms of same types, the method overcomes the limitation of wide viewing angle and timeliness, addresses unexpandability of the spherical surface, effectively increases image correction precision, achieves fish eye video panoramic expanding, meets real-time applications, has certain robustness for fish eye cameras of different models, and has strong practicality.

Owner:WUHAN UNIV

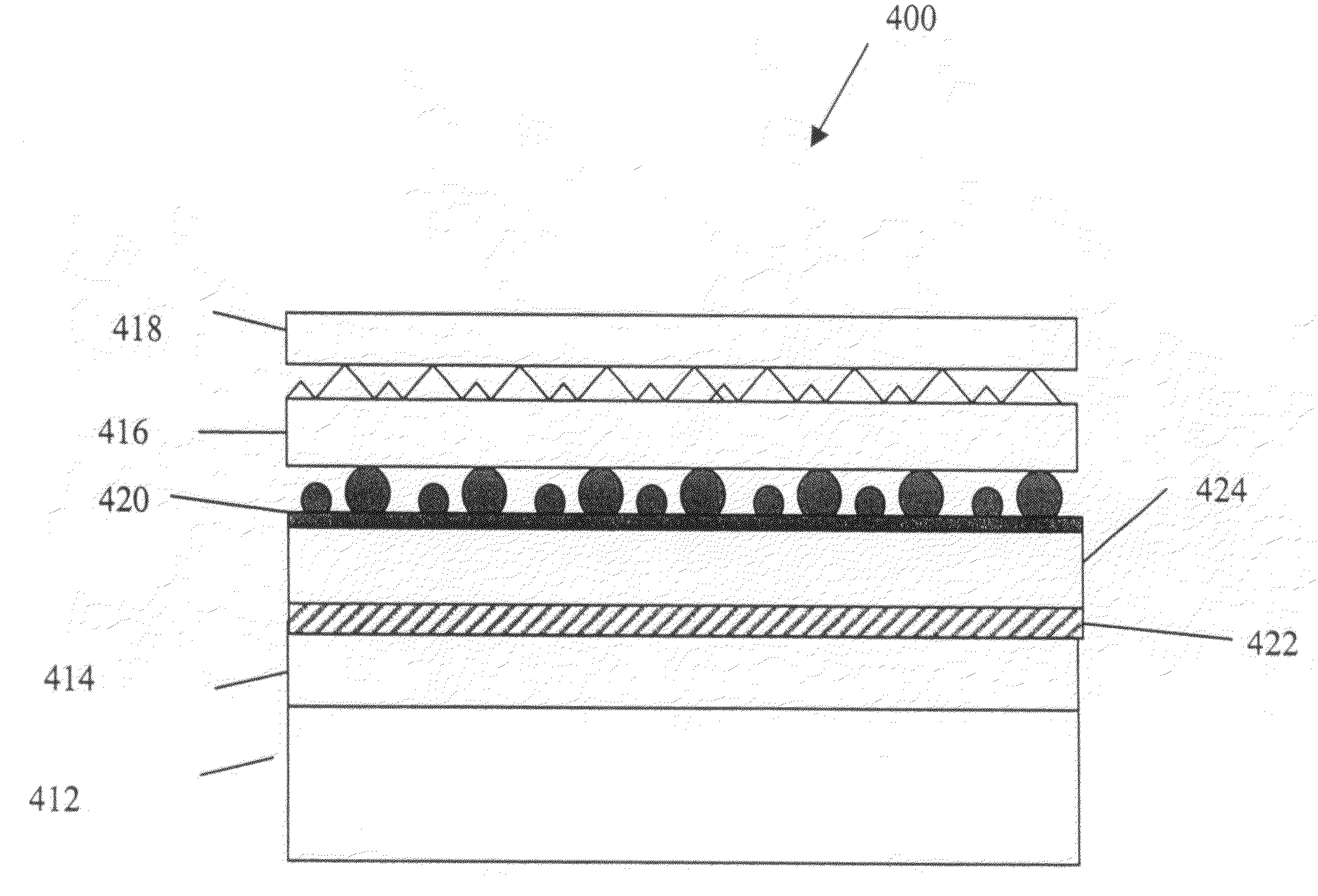

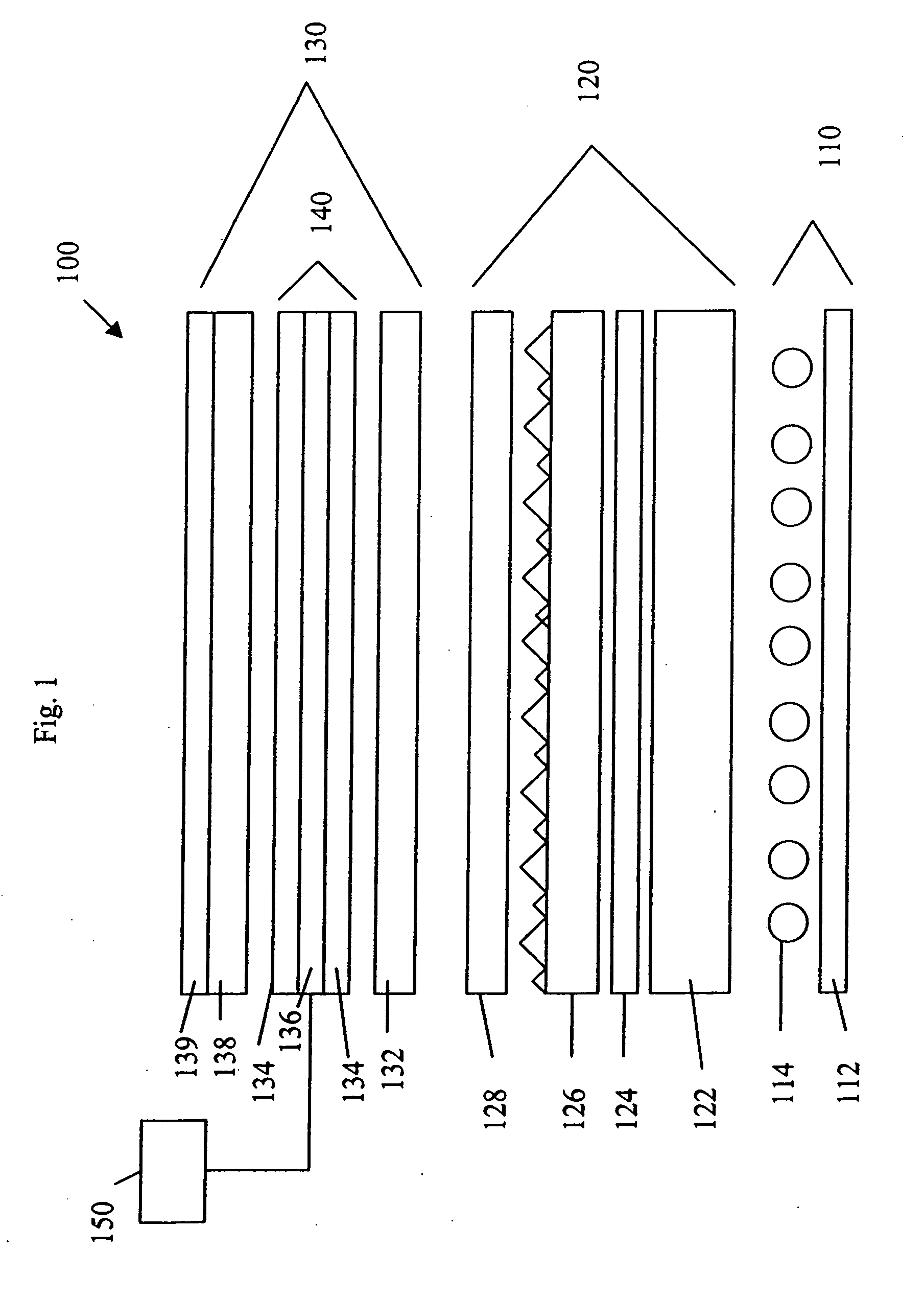

Thin film bulk and surface diffuser

A voided semi-crystalline polymeric integrated optical diffuser film is provided with surface beads. The film is useful when incorporated into a display device such as an LC display.

Owner:SKC HAAS DISPLAY FILMS CO LTD

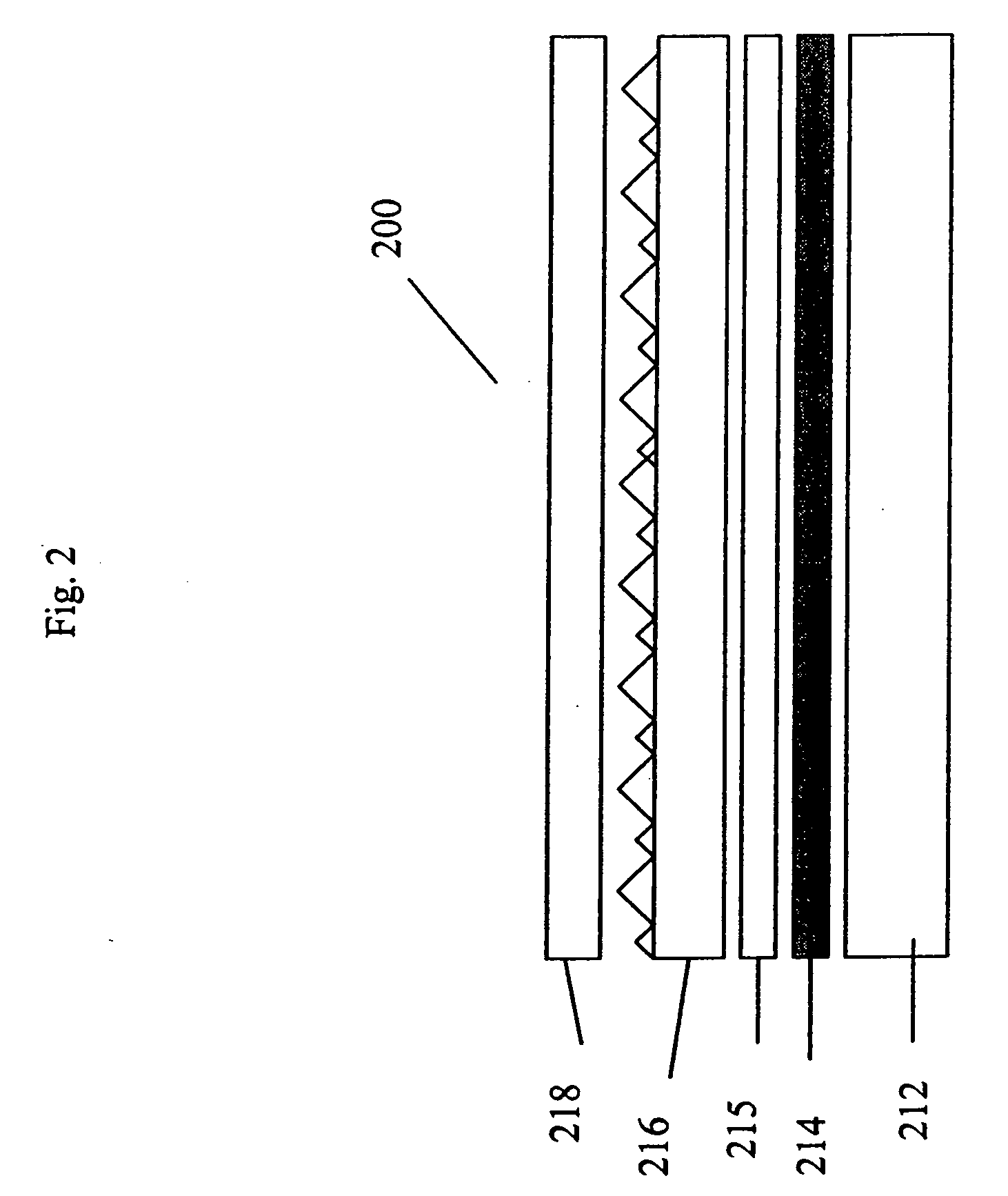

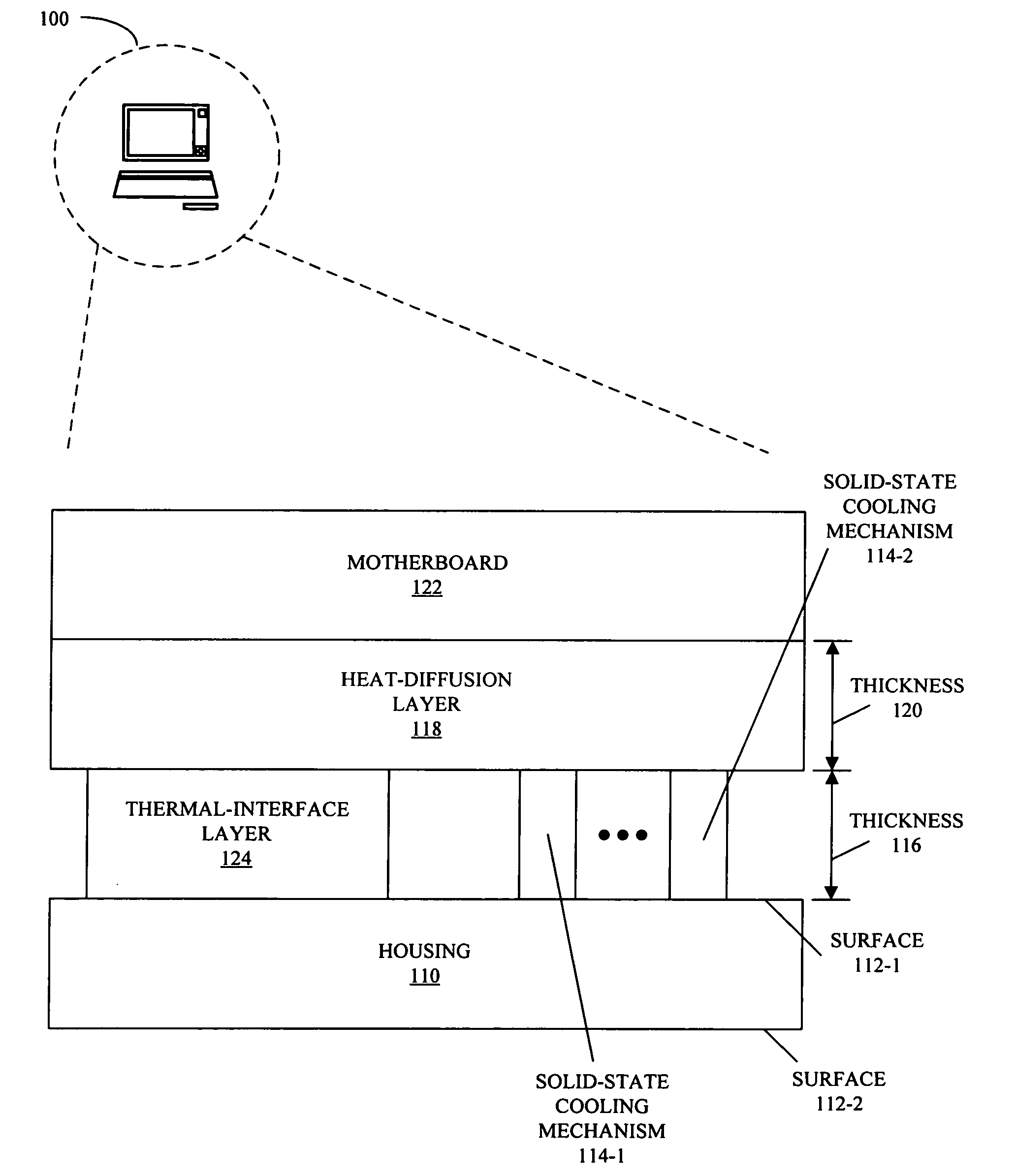

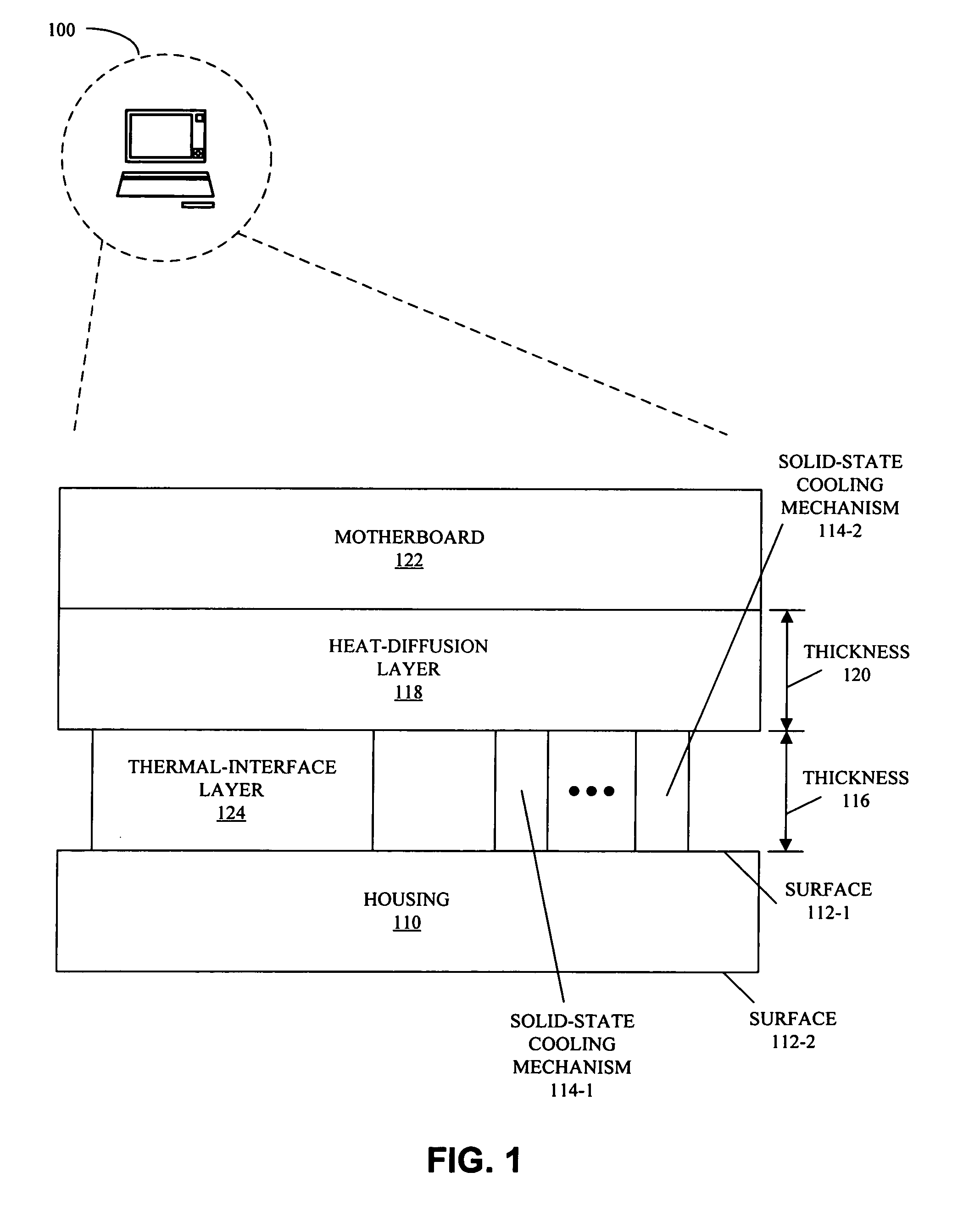

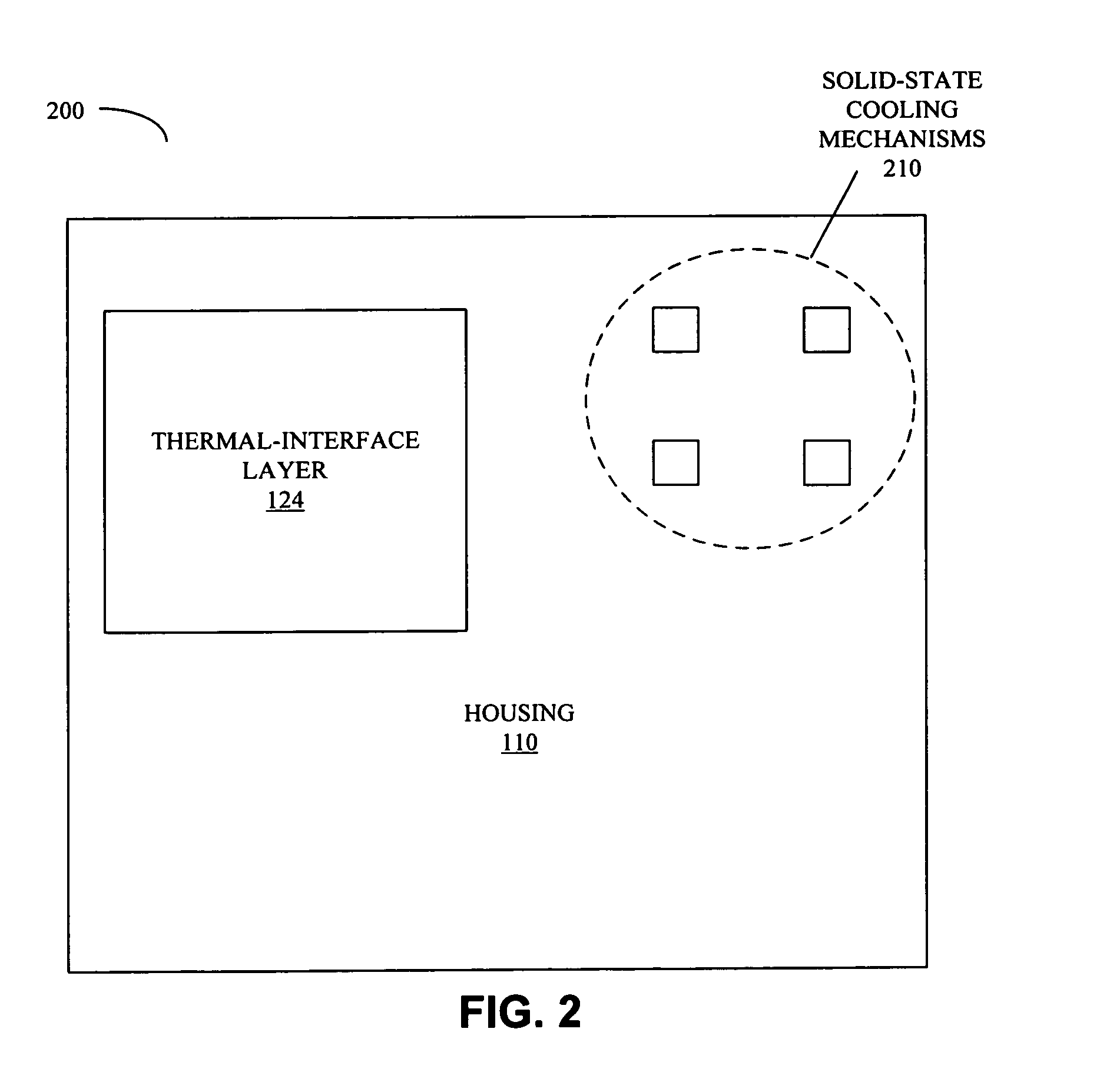

Embedded thermal-electric cooling modules for surface spreading of heat

ActiveUS20080101038A1Digital data processing detailsSemiconductor/solid-state device detailsThermoelectric coolingSurface spreading

A portable computing device includes a housing having an external surface and an inner surface. A solid-state cooling mechanism in the computing device is coupled to the inner surface. This solid-state cooling mechanism is configured to maintain a temperature difference across at least a portion of the external surface that is less than a pre-determined value.

Owner:APPLE INC

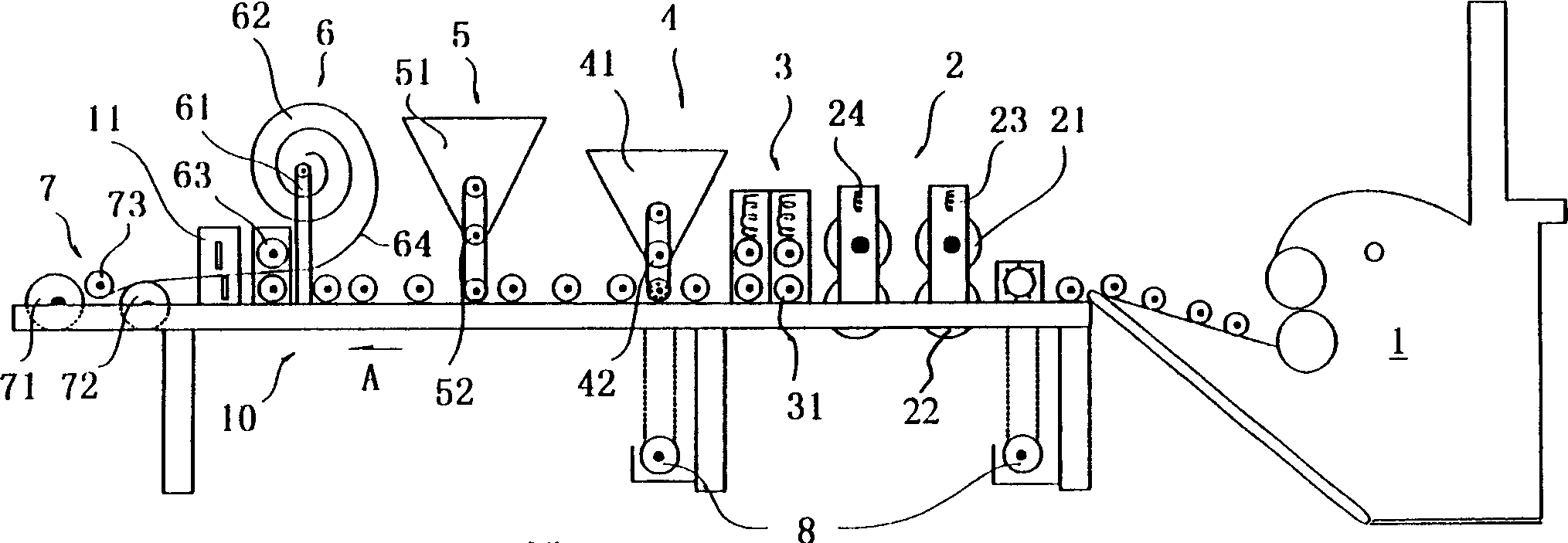

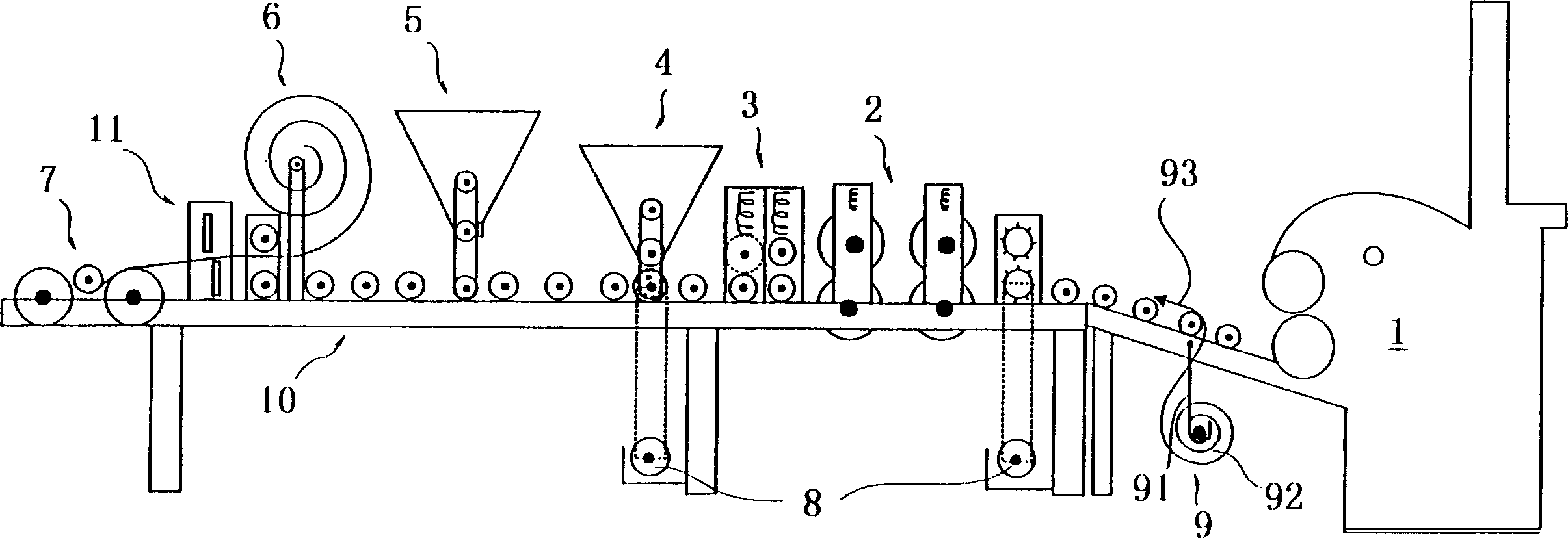

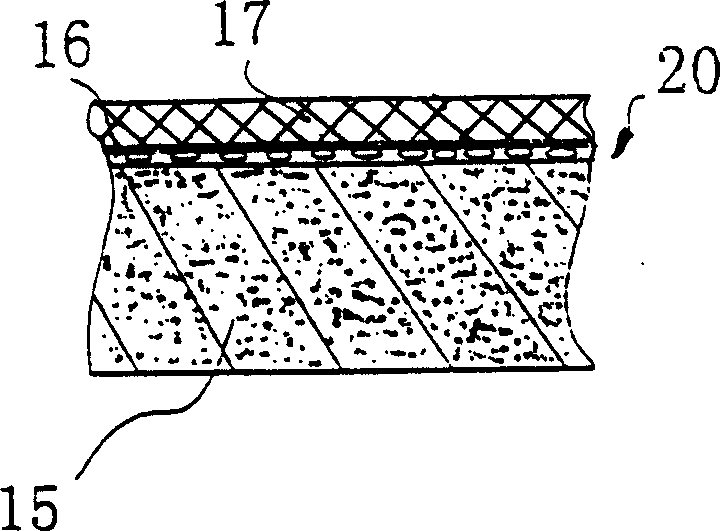

Soilless lawn substrate production method, and its product and apparatus

InactiveCN1611105AEasy to useEliminate heavy manual processesAgriculture gas emission reductionCultivating equipmentsThinningBran

The present invention discloses a production method of soilless lawn matrix, its product and equipment. Its production method includes the following steps: making pulverized plant fibre, animal fibre or artificial fibre undergo the procedures of stirring, carding and forming to obtain a continuous mat-shaped material; press-thinning said mat-shaped material and cutting along the longitudinal direction; on its upper surface spreading grass seeds and applying a mixture formed from peat and one of sawdust, pine needle, tree leaf, bran and straw or several kinds of them, fermenting and using the humic matter formed after fermentation and plantation covering material consisting of organic fertilizer, inorganic fertilizer and trace elements of form the soilless lawn matrix; covering its upper and lower surfaces with film and press-combining them; transverse cutting and rolling it to form matrix roll.

Owner:毛宇 +1

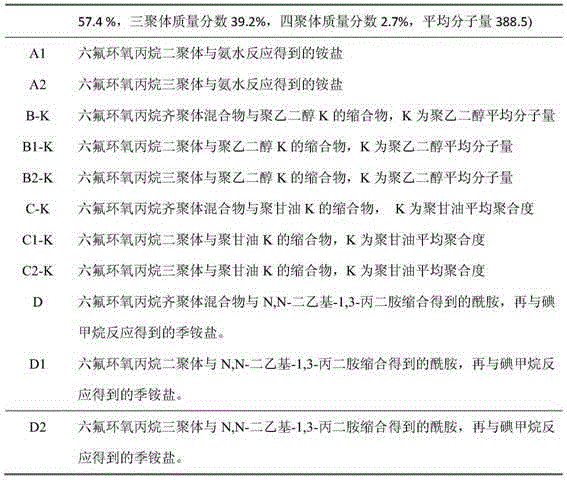

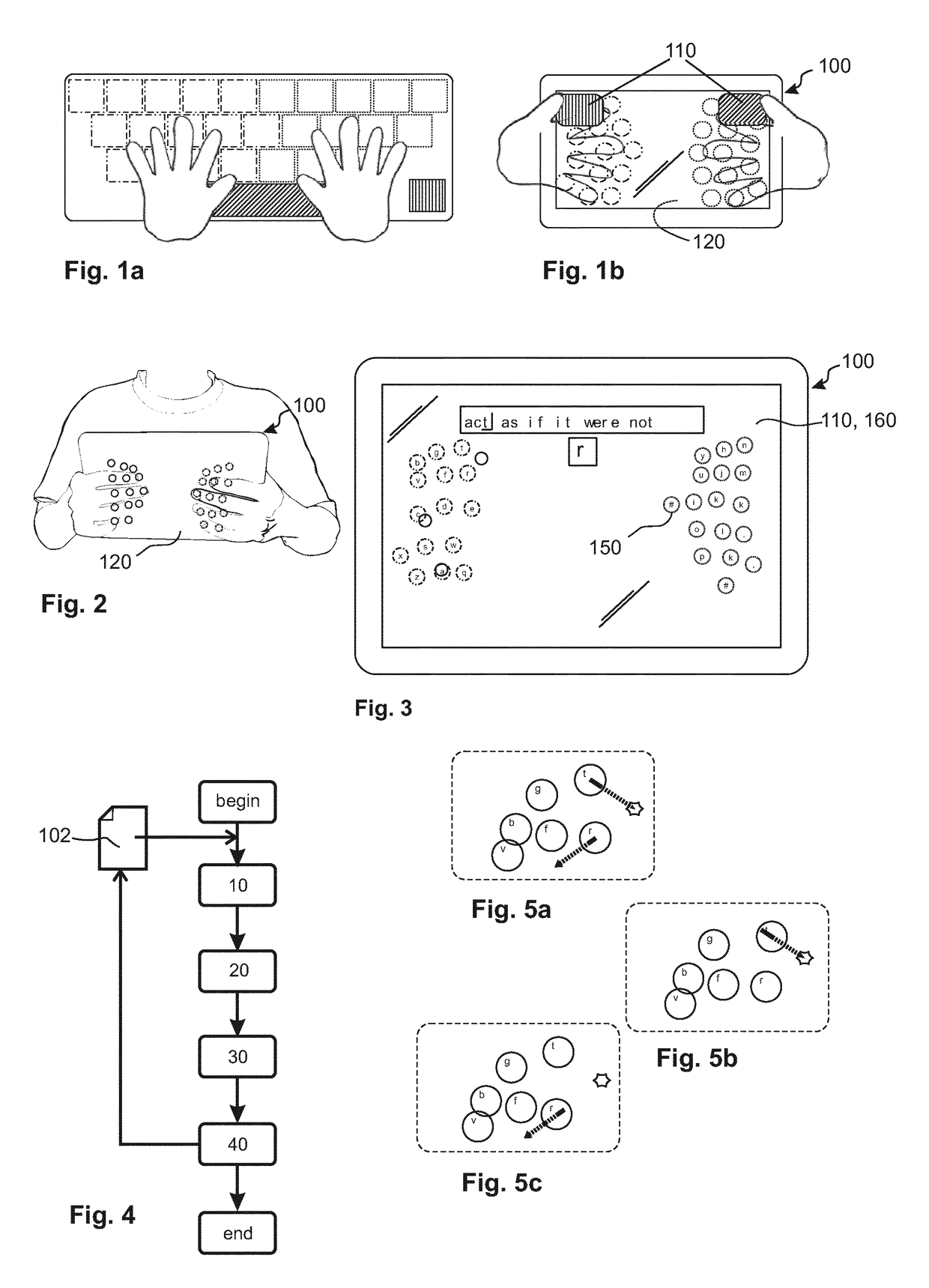

Oil surface spreading agent

ActiveCN103550897APrevent volatilizationInsulate the airFire extinguisherQuaternary ammonium cationHexafluoropropylene oxide

The invention discloses an oil surface spreading agent containing a fluorine containing surfactant, a hydrocarbon surfactant, an additive and water, wherein the fluorine containing surfactant is a combination of an anionic-type fluorine containing surfactant and a non-ionic or a cationic-type fluorine containing surfactant, and the anionic-type fluorine containing surfactant is an ammonium salt of hexafluoropropylene oxide oligomer, the non-ionic fluorine containing surfactant is a condensation product of the hexafluoropropylene oxide oligomer and a polyol polymer or polyoxyethylene polyoxypropylene ether, the cationic-type fluorine containing surfactant is a quaternary ammonium salt obtained by reacting an amide with methyl iodide, wherein the amide is prepared by concentration of the hexafluoropropylene oxide oligomer and a propane diamine compound; and in the oil surface spreading agent, the anionic-type fluorine containing surfactant concentration is 0.01w% ~ 10.0w%, the non-ionic or the cationic-type hydrocarbon surfactant concentration is 0.01w% ~ 5.0w%, the hydrocarbon surfactant concentration is 0.01w% ~ 20.0w% and the additive concentration is 0.00w% ~ 25.0w%.

Owner:菏泽建数智能科技有限公司

Method and device for typing on mobile computing devices

InactiveUS10013163B2Area maximizationIncrease chanceInput/output processes for data processingSurface spreadingText entry

The present invention relates to a method and a mobile computing device for reliable and fast text entry. The method relies on a virtual keyboard layout that has a multi-touch interaction surface spread out on both the front and rear sides of a handheld computing device. A user-adaptive updating algorithm allows the virtual keyboard layout to adapt to the user's handling of the device.

Owner:SCHONLEBEN OLIVER +2

Tin and Tin-Zinc plated substrates to improve Ni-Zn cell performance

An improved Ni-Zn cell with a negative electrode substrate plated with tin or tin and zinc during manufacturing has a reduced gassing rate. The copper or brass substrate is electrolytic cleaned, activated, electroplated with a matte surface to a defined thickness range, pasted with zinc oxide electrochemically active material, and baked. The defined plating thickness range of 40-80 muIn maximizes formation of an intermetallic compound Cu3Sn that helps to suppress the copper diffusion from under plating layer to the surface and eliminates formation of an intermetallic compound Cu6Sn5 during baking to provide adequate corrosion resistance during battery operation.

Owner:ZINCFIVE POWER INC

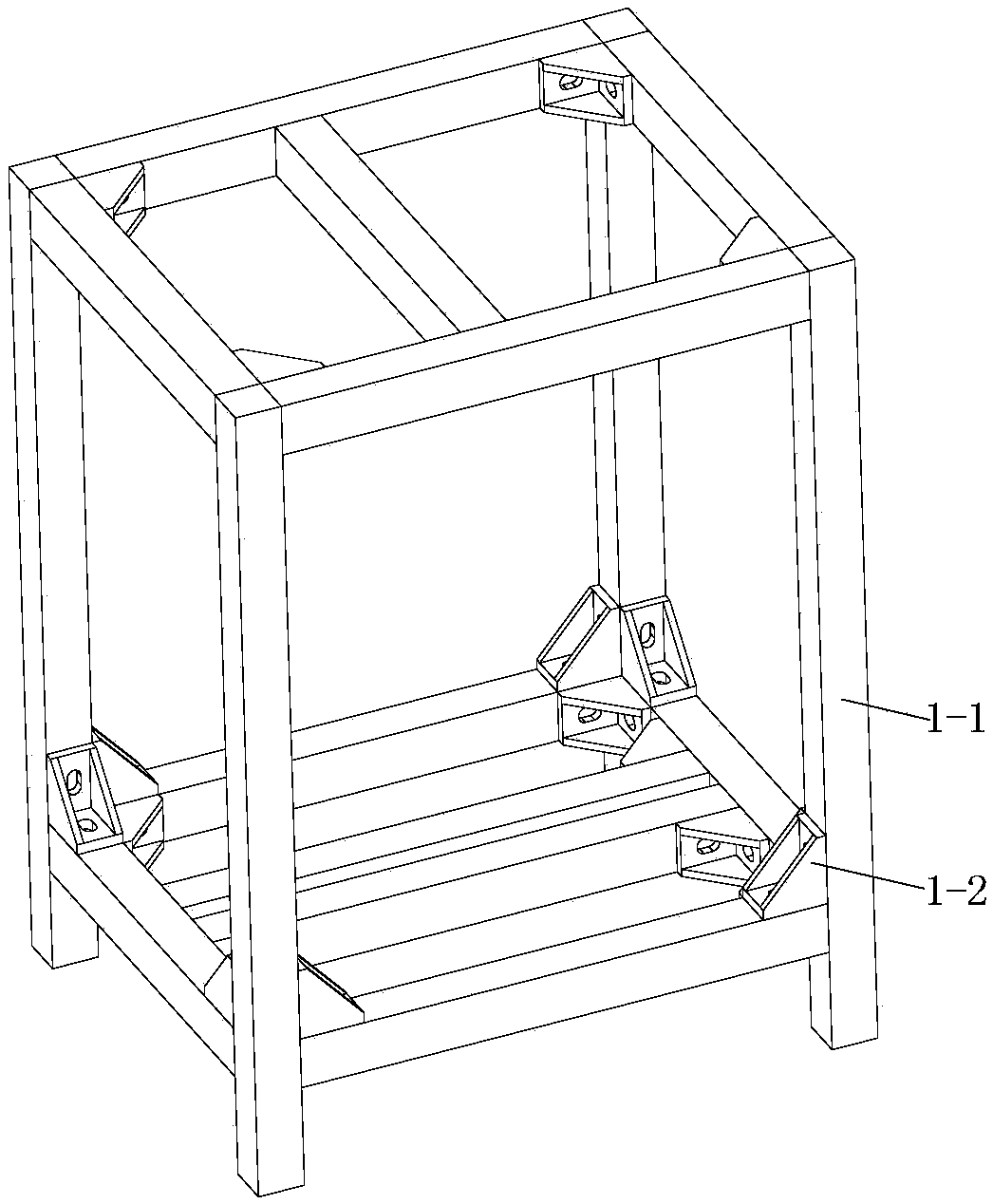

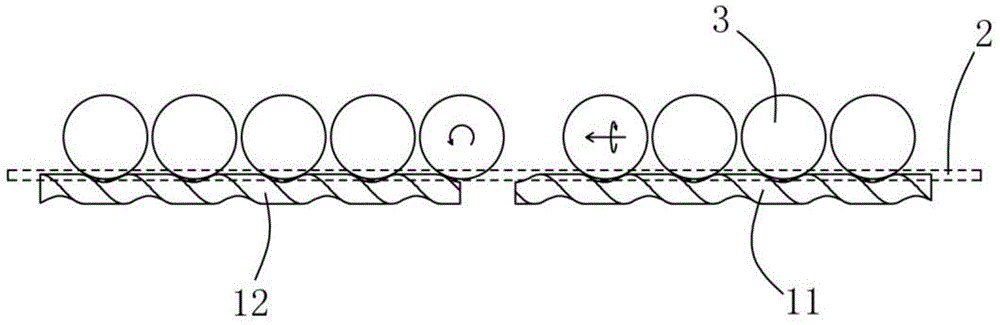

Bead detection sorting device and method

ActiveCN108405353ARealize automatic sortingOptically investigating flaws/contaminationSortingSurface spreadingComputer module

The invention discloses a bead detection sorting device and method. The bead detection sorting device comprises a fixing rack, an image acquisition module, a bead surface spreading module, a bead sorting module and a connecting piece, wherein the fixing rack is used for supporting and fixing the entire device; the image acquisition module is positioned at the upper part of the fixing rack; the connecting piece is positioned on the inner side of the fixing rack and is fixedly connected with the fixing rack; and the bead surface spreading module and the bead sorting module are fixed to the connecting piece. At present, surface defects of beads are manually detected, operation is complex, efficiency is low, and diameter and surface defects of the beads are judged and recognized without manualintervention through adoption of the bead detection sorting device; and detected beads are sent into material grooves corresponding to qualified products or various defect varieties through the beaddetection sorting device, the beads are automatically sorted, labor intensity is reduced, working efficiency is improved, and the bead detection sorting device has great practical significance.

Owner:扬州振光机械有限公司

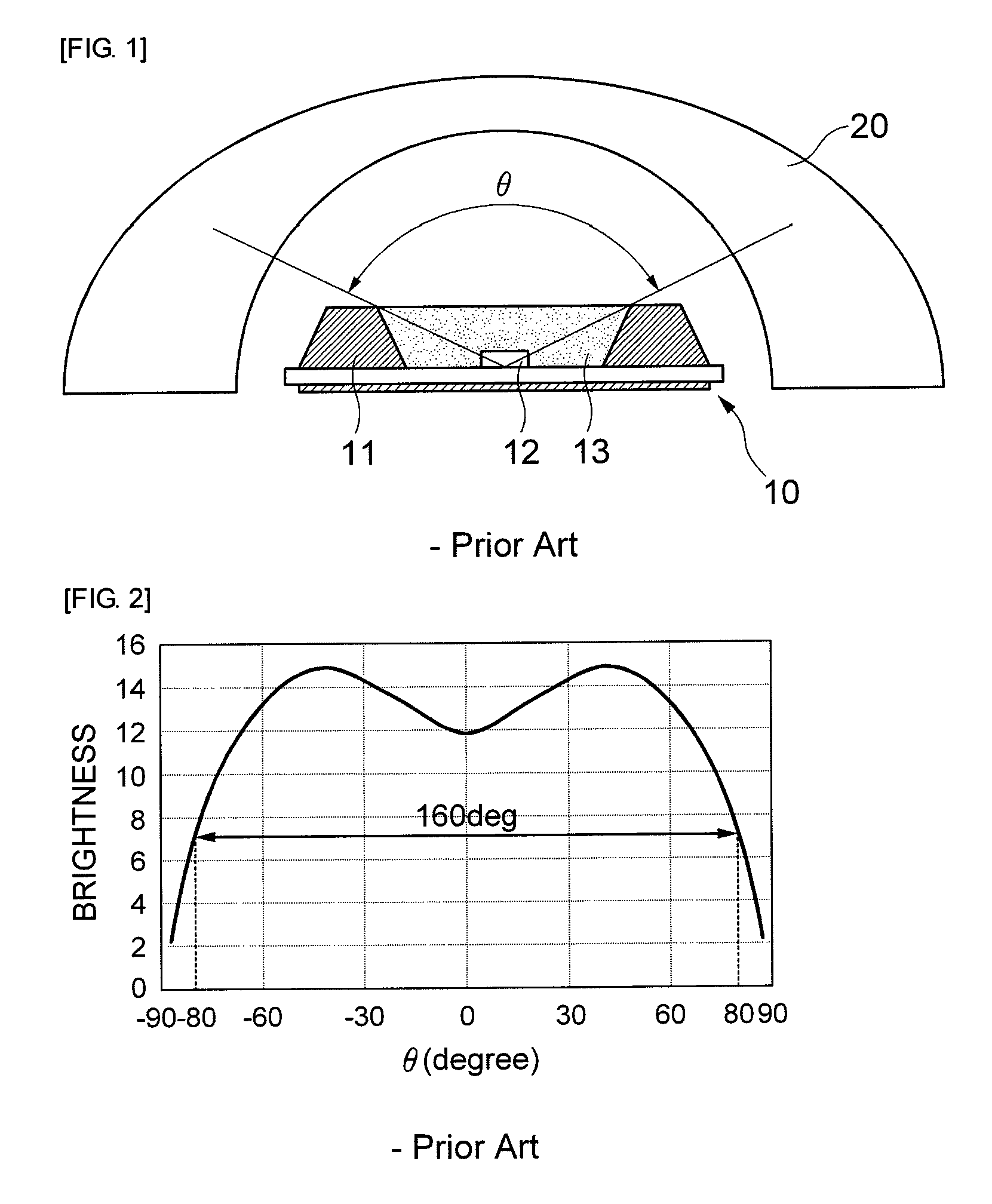

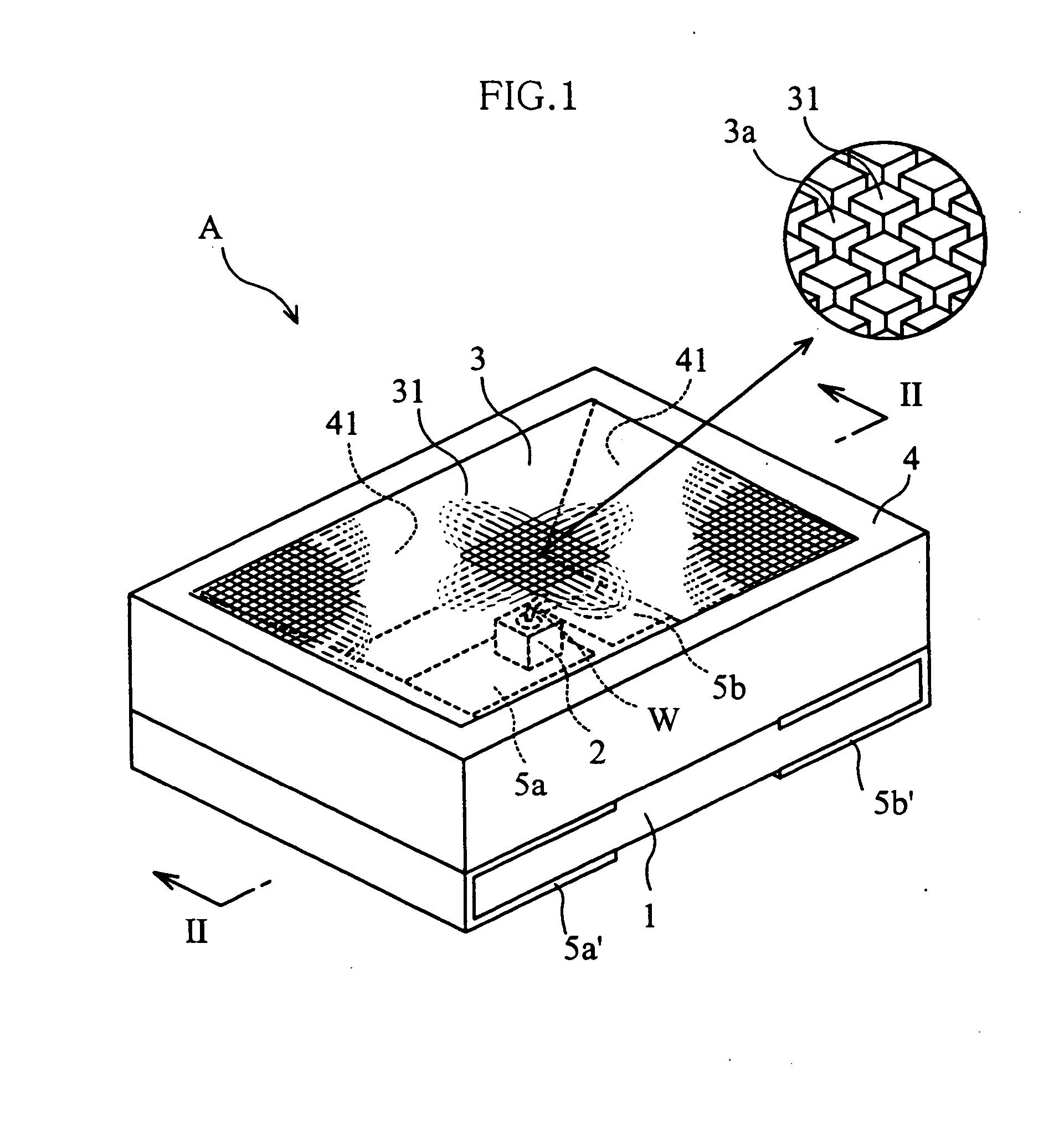

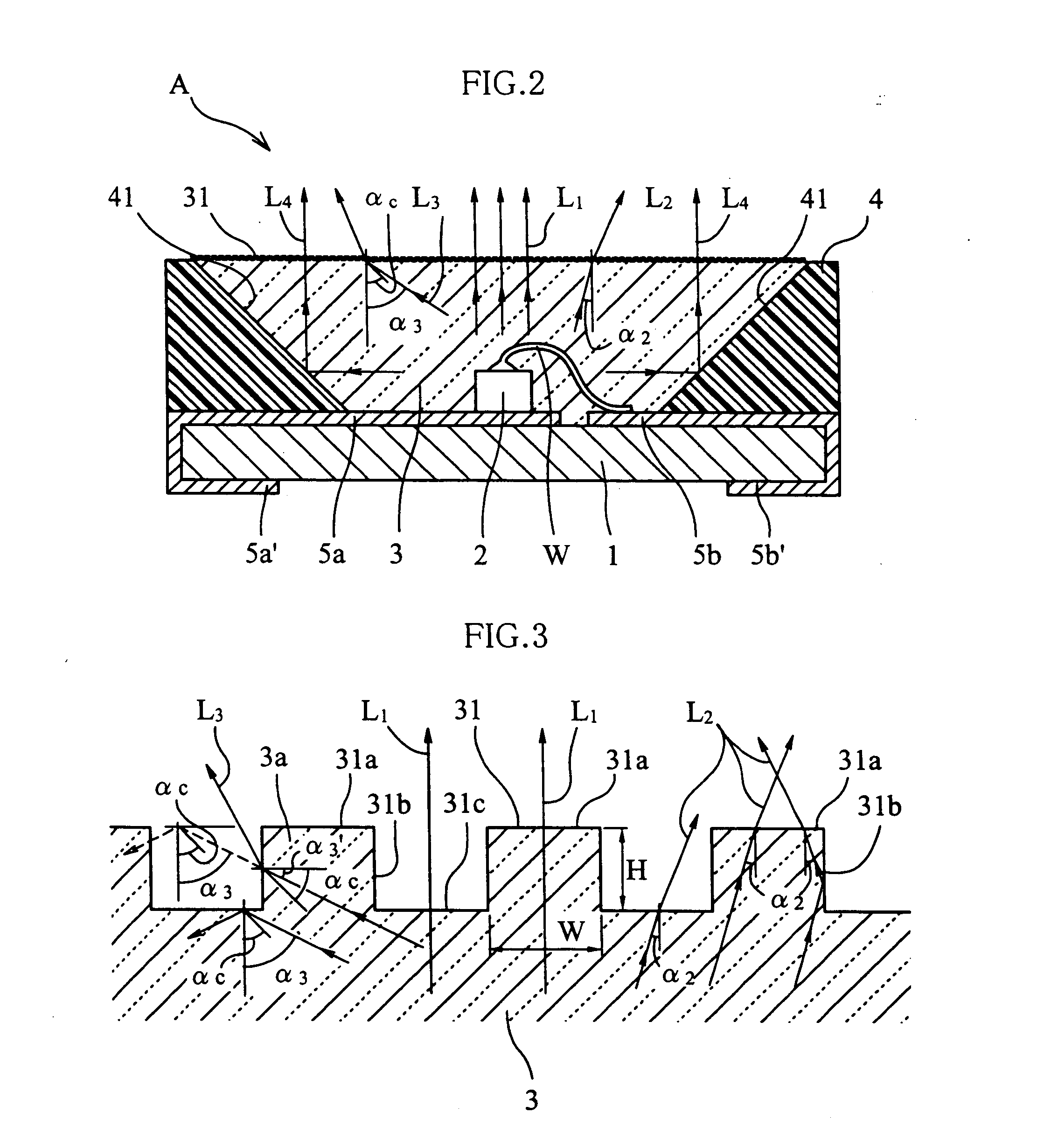

Optical semiconductor device

ActiveUS20050040405A1Increase brightnessIncrease power consumptionSolid-state devicesSemiconductor devicesComing outDevice material

An optical semiconductor device includes an optical semiconductor chip and a light permeable member covering the optical semiconductor chip. The light permeable member has a light emitting surface for emitting light coming out from the optical semiconductor chip to the outside. The light emitting surface includes a plurality of standing surfaces standing in a second direction which intersects a first direction in which the light emitting surface spreads.

Owner:ROHM CO LTD

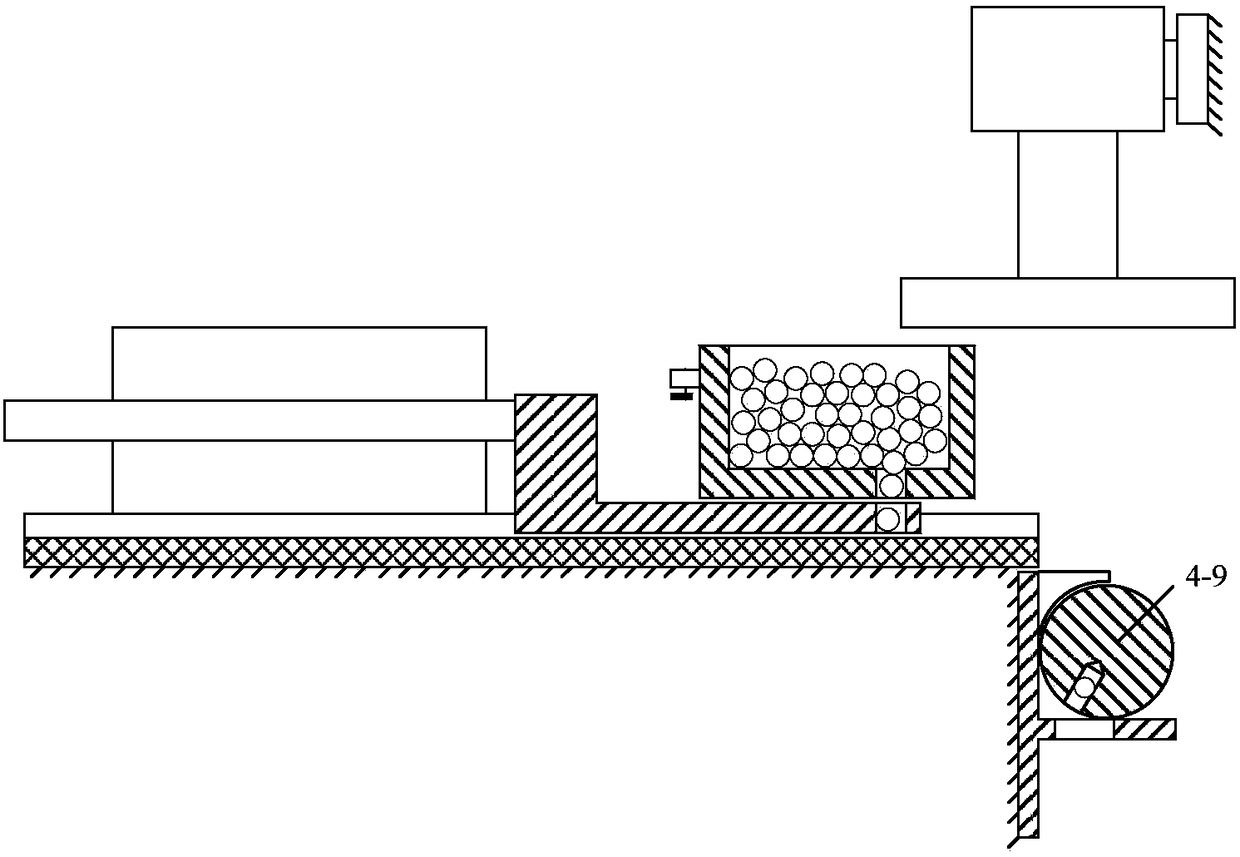

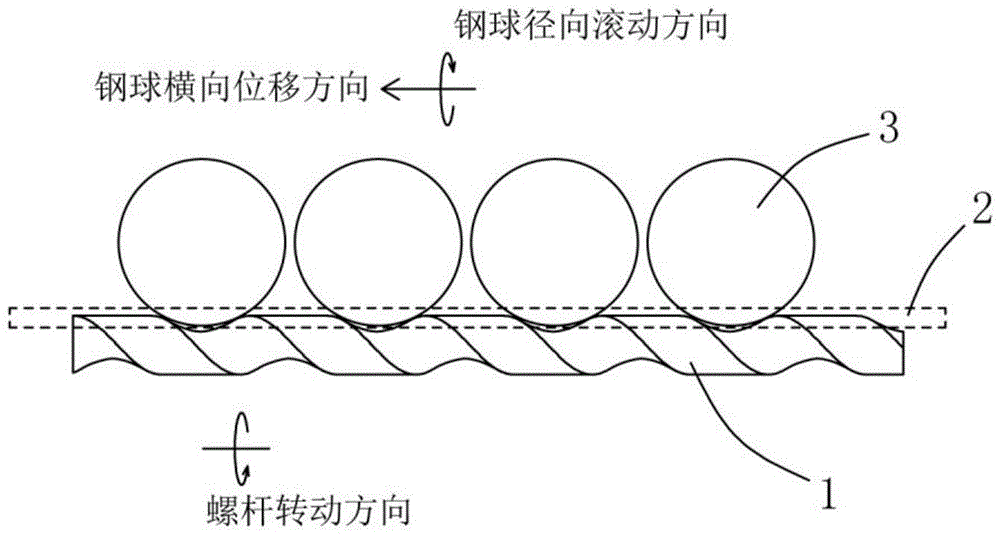

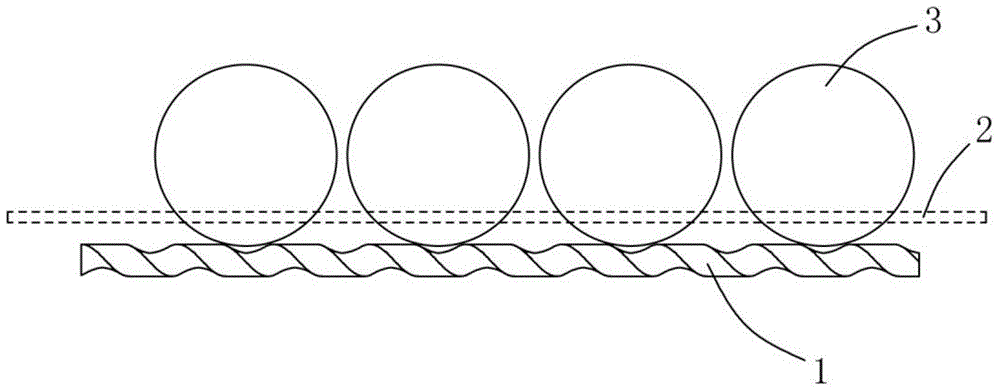

Steel ball surface spreading apparatus based on machine vision

ActiveCN104155309AAvoid situations where full scrolling is not possibleSimple structureMaterial analysis by optical meansSortingMachine visionSurface spreading

The invention discloses a steel ball surface spreading apparatus based on machine vision. The steel ball surface spreading apparatus comprises guide rails used for bearing steel balls, a screw which is parallely arranged below the guide rails and is in rolling fit with the steel balls and a drive unit driving the screw to rotate. When the steel balls pass through the guide rails above the screw, the steel balls carry out radial rolling and lateral displacement relative to the guide rails under driving of the screw and guiding of the guide rails, and the steel balls carry out radial rolling at least for one circle. According to the invention, the technical means of driving by the screw is employed for passive rolling spreading of the steel balls to mainly overcome the technical problem that active rolling spreading of two adjacent steel balls cannot be realized due to close contact of the two adjacent steel balls; intact surface images of steel balls can be shot, leak detection is avoided, a false drop rate is reduced and is 0.0001 to 0.0002, sorting efficiency is high, and the steel ball surface spreading apparatus is applicable to industrial batch sorting of steel balls.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

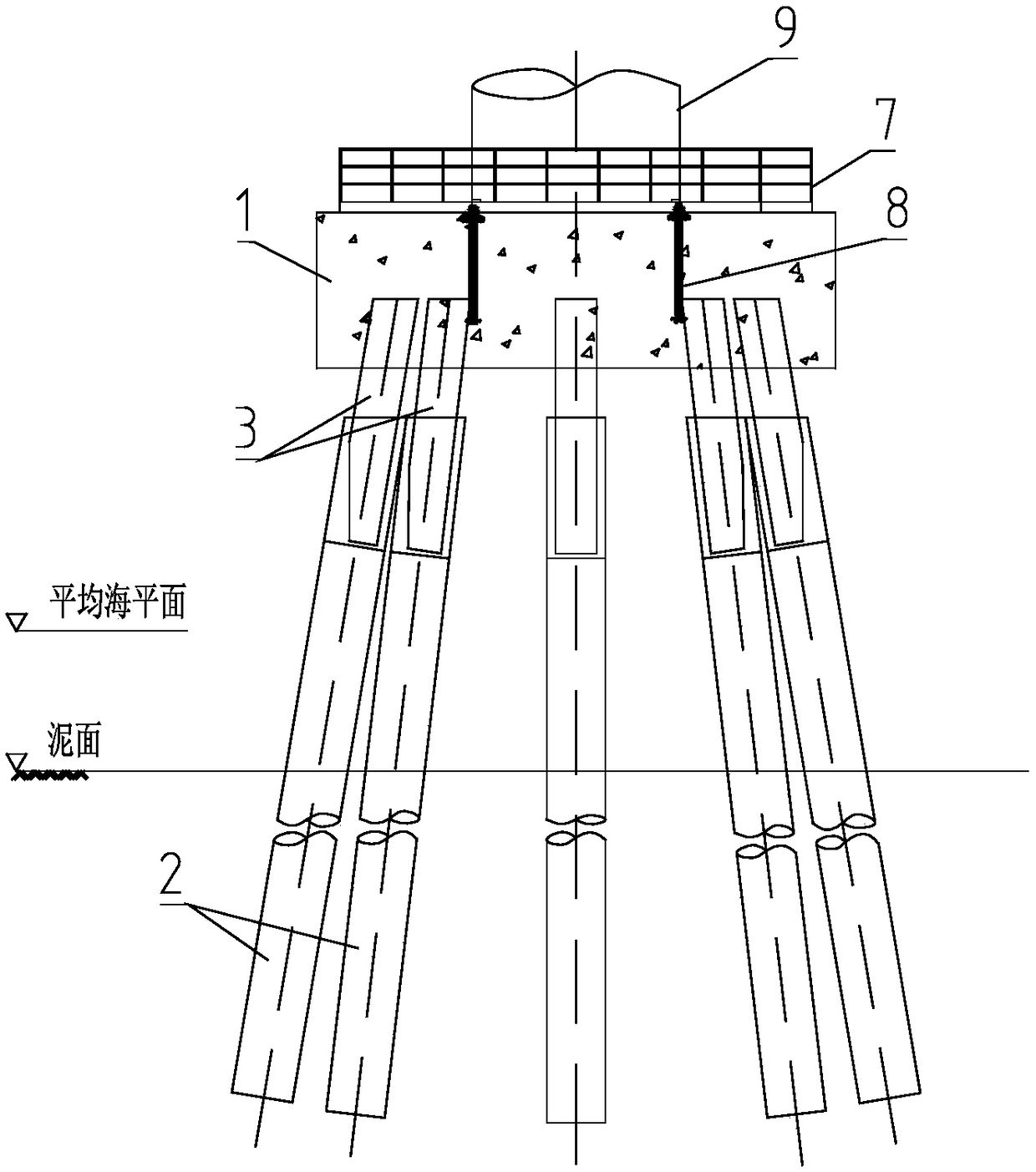

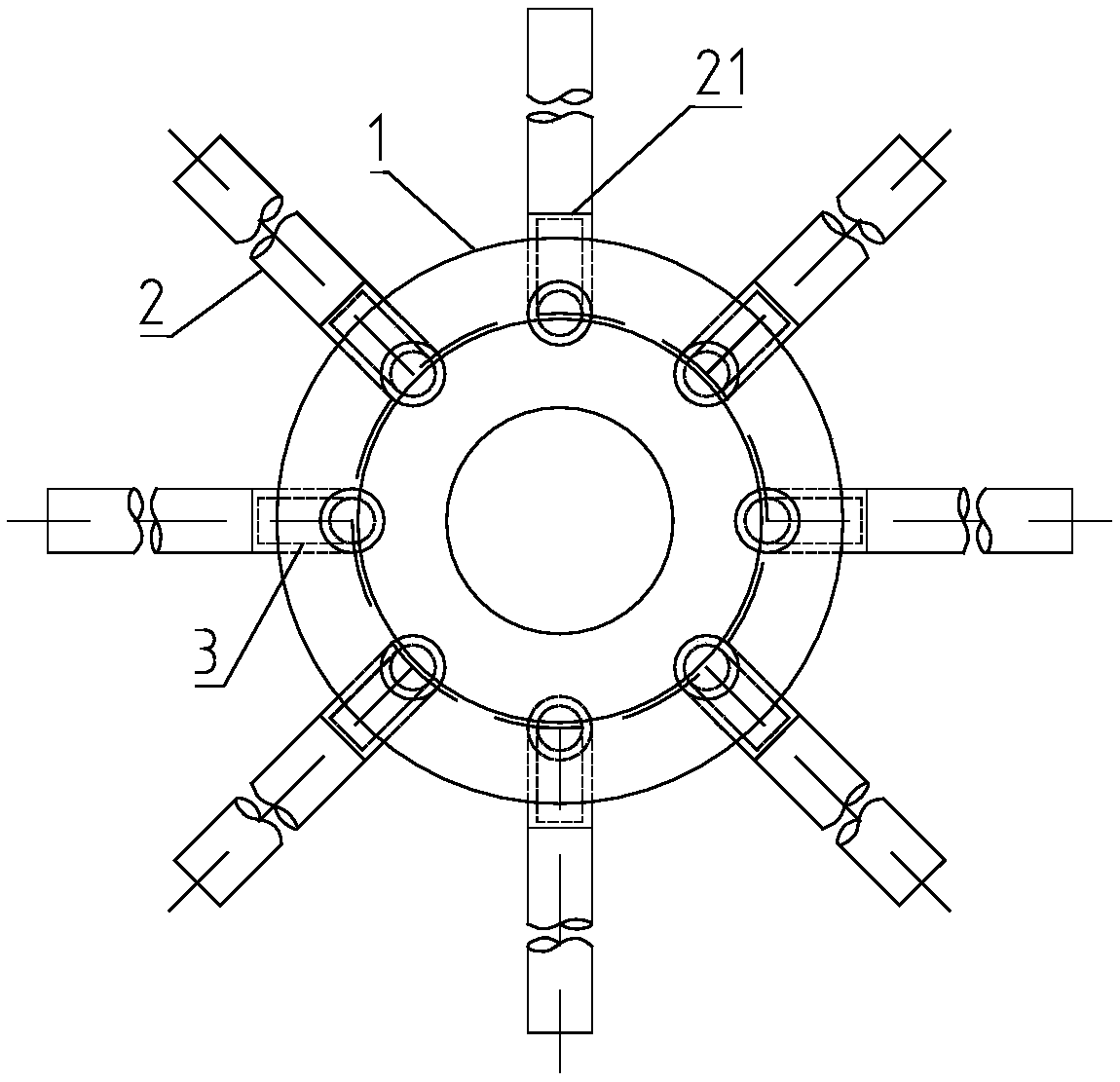

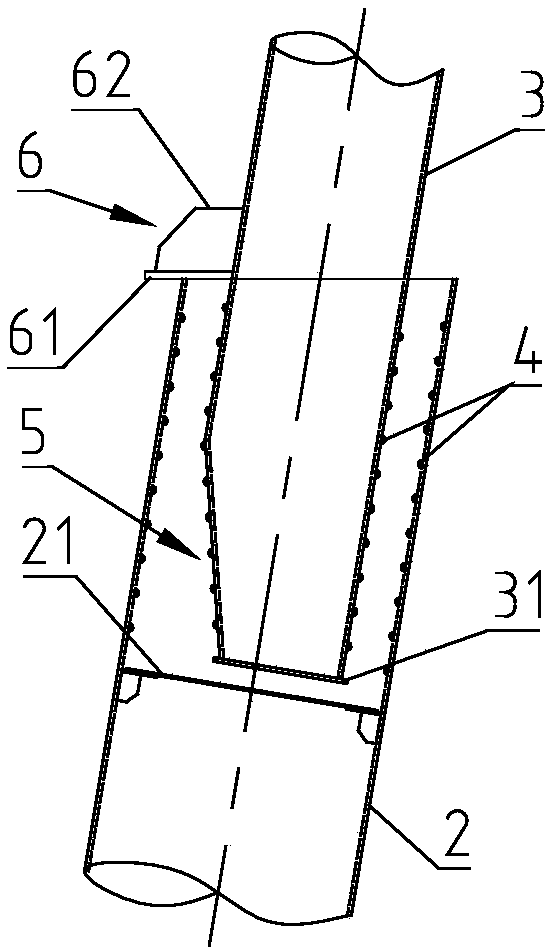

Offshore high-rise pile cap fan foundation and construction method

PendingCN108755738AQuality assuranceShorter working time at seaFoundation engineeringPile capReinforced concrete

The invention discloses an offshore grouting connection high-rise pile cap fan foundation. The offshore grouting connection high-rise pile cap fan foundation comprises a concrete pile cap and steel tube piles for supporting the concrete pile cap, wherein the concrete pile cap and the steel tube piles are connected through connecting steel tubes; the concrete pile cap is a precast member; upper segments of the connecting steel tubes are located in the concrete pile cap; lower segments of the connecting steel tubes are located in the top ends of the steel tube piles; and the connecting steel tubes and the steel tube piles are connected through grouting. The invention further provides a construction method of the offshore fan foundation. Offshore reinforcement assembling and concrete pouringconstructions are transferred to land, so that not only is lots of offshore operation time saved, but also multi-surface spreading in precasting of the concrete pile cap onshore can be realized. Multiple pile caps perform pouring simultaneously to ensure compact proceeding of the construction taking offshore operation as a critical path. Besides, onshore pouring and maintenance of the concrete pile cap are in favor of guaranteeing the quality of a reinforced concrete structure, achieving multiple purposes.

Owner:POWERCHINA ZHONGNAN ENG

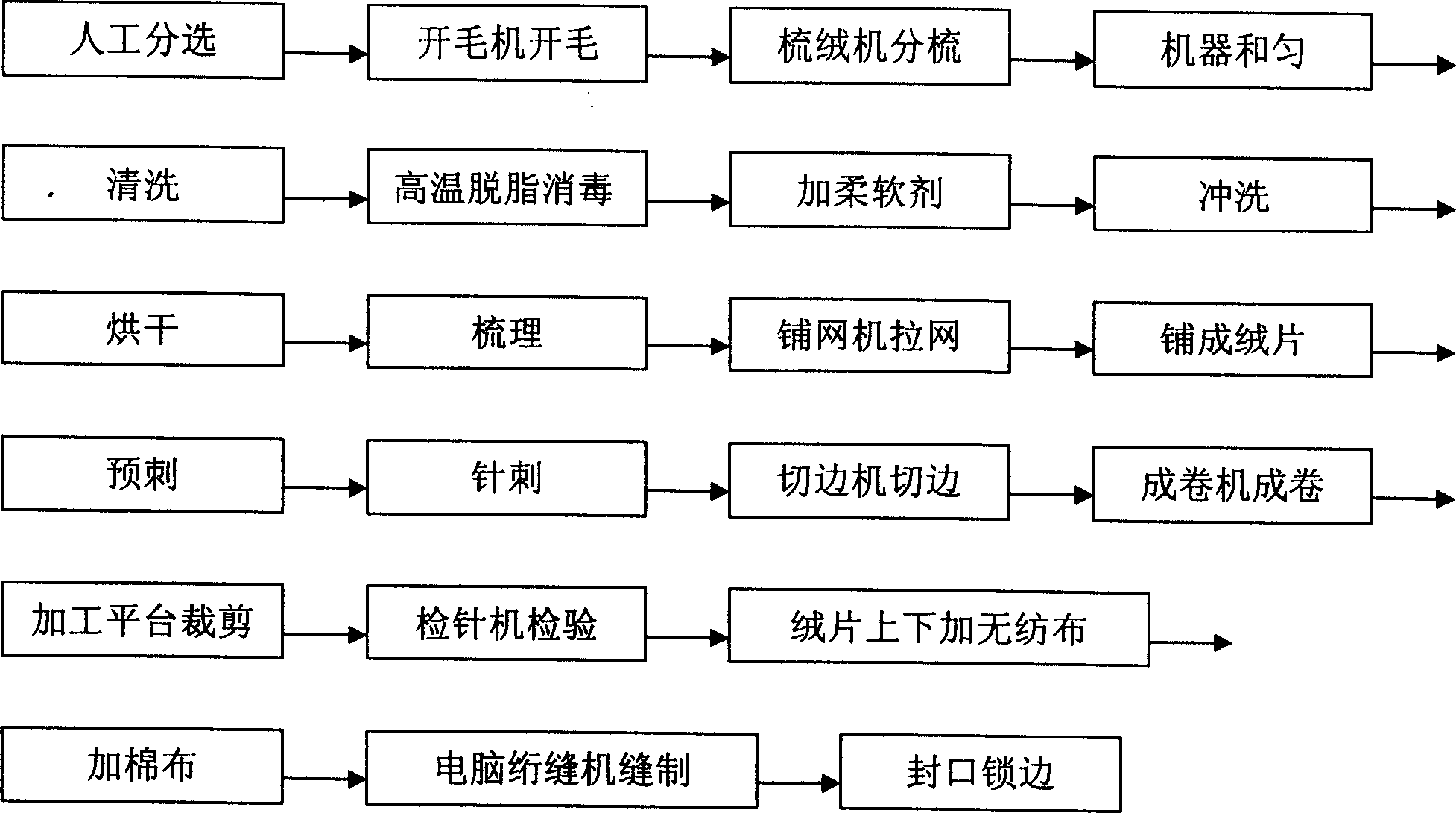

Down quilt and its processing method

InactiveCN1861518AImprove breathabilityGood warmth retentionUpholstery manufactureBed-coversSurface spreadingCotton cloth

A technology for manufacturing the quilt with downy wool of goat, camel, sheep, yak, rabbit, etc includes such steps as opening, combing, washing, high-temp defatting and disinfecting, adding softener, flushing, baking, combing, spreading, pre-needling, needling, cutting to remove edges, cutting by needed sizes, spreading the air-permeable non-woven cloth onto its both surface spreading cotton cloth and sewing.

Owner:杨魁武

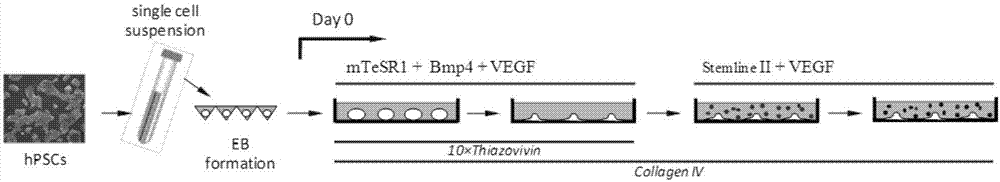

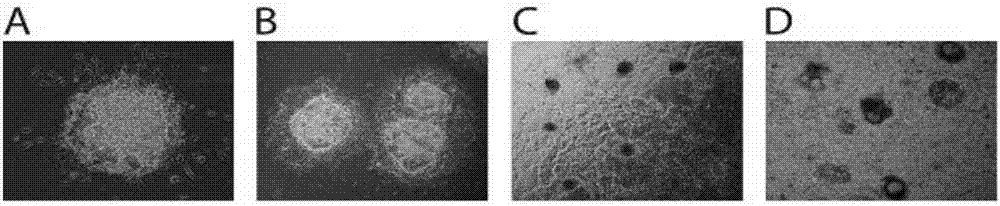

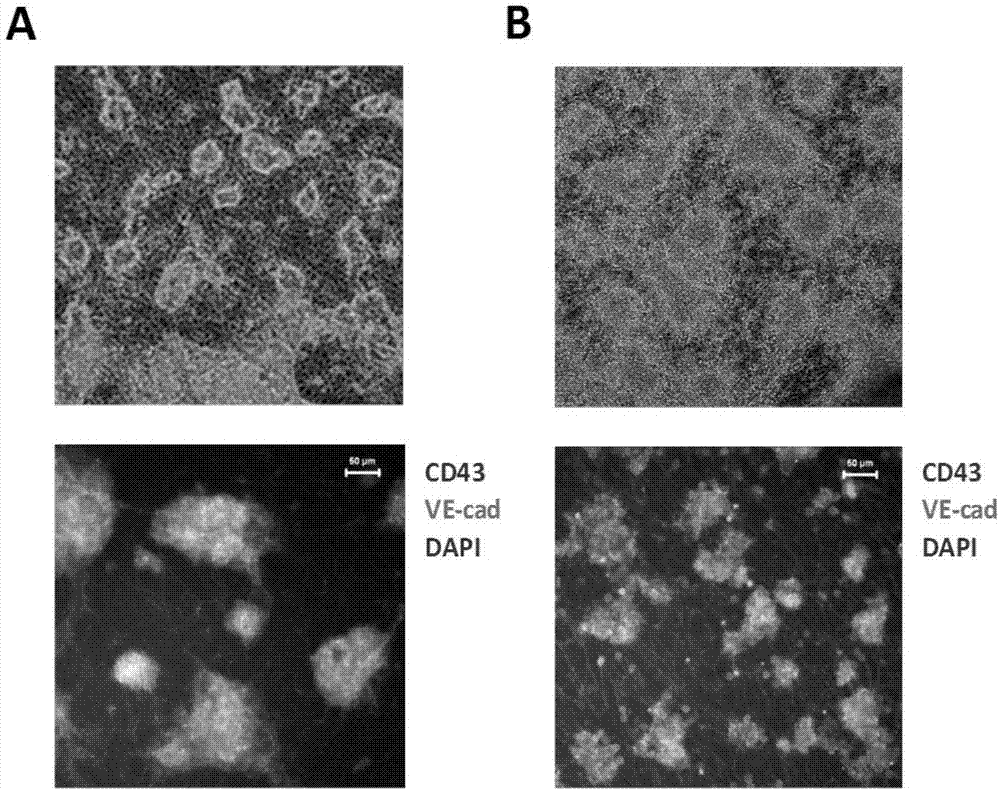

Pluripotent stem cells directional differentiation method

InactiveCN107488629AIncrease productionQuality improvementCulture processCell culture supports/coatingGerm layerProcess mechanism

The invention discloses a pluripotent stem cells directional differentiation method. The method is characterized in that pluripotent stem cells are cultured under cell culture environment of non exogenous hematopoietic cytokines, non serum, non matrix cells and clear component, after embryoid is formed, a vascular endothelial growth factor and bone morphogenetic protein 4 are added, the embryoid is attached on the surface spread with collagen IV, mesoderm differentiation is induced, and hemopoietic progenitor cells and blood corpuscles are generated. The cell culture system with determined component enables directional differentiation on the pluripotent stem cells, has the advantages of low cost, simple operation, high repeatability and ordered differentiation process, can massively generate hemopoietic progenitor cells and blood corpuscles, and has important meaning for researching a blood growth process mechanism.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI

Optical semiconductor device

ActiveUS7202507B2Increase brightnessReduce power consumptionSolid-state devicesSemiconductor devicesComing outSurface spreading

An optical semiconductor device includes an optical semiconductor chip and a light permeable member covering the optical semiconductor chip. The light permeable member has a light emitting surface for emitting light coming out from the optical semiconductor chip to the outside. The light emitting surface includes a plurality of standing surfaces standing in a second direction which intersects a first direction in which the light emitting surface spreads.

Owner:ROHM CO LTD

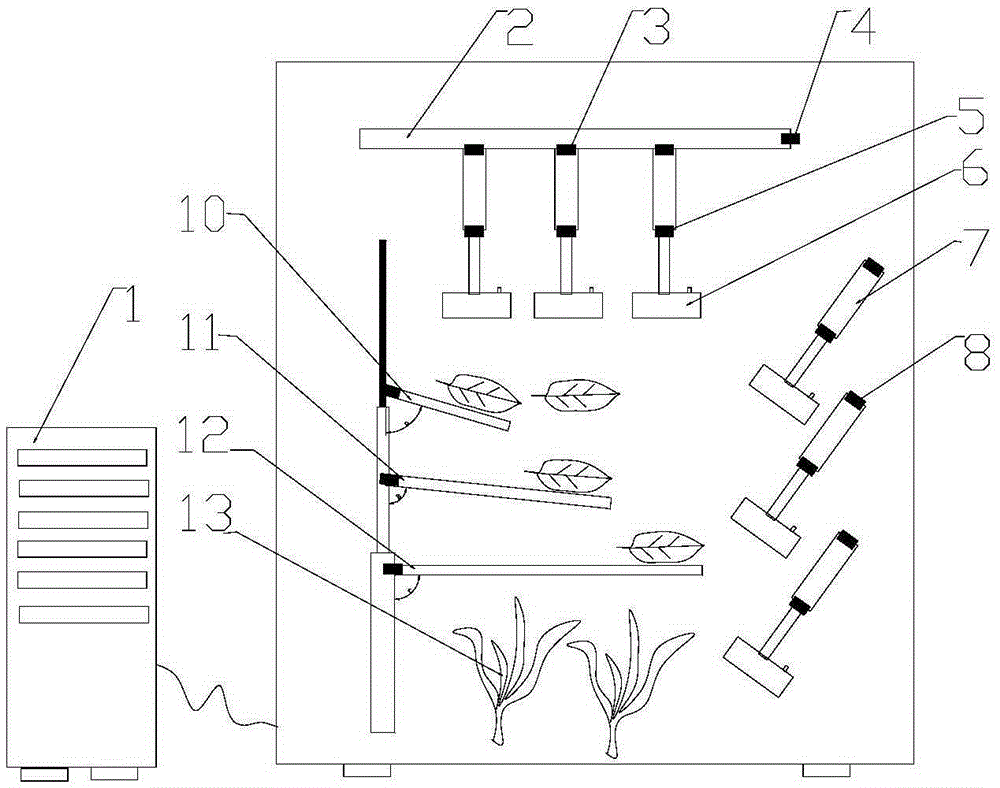

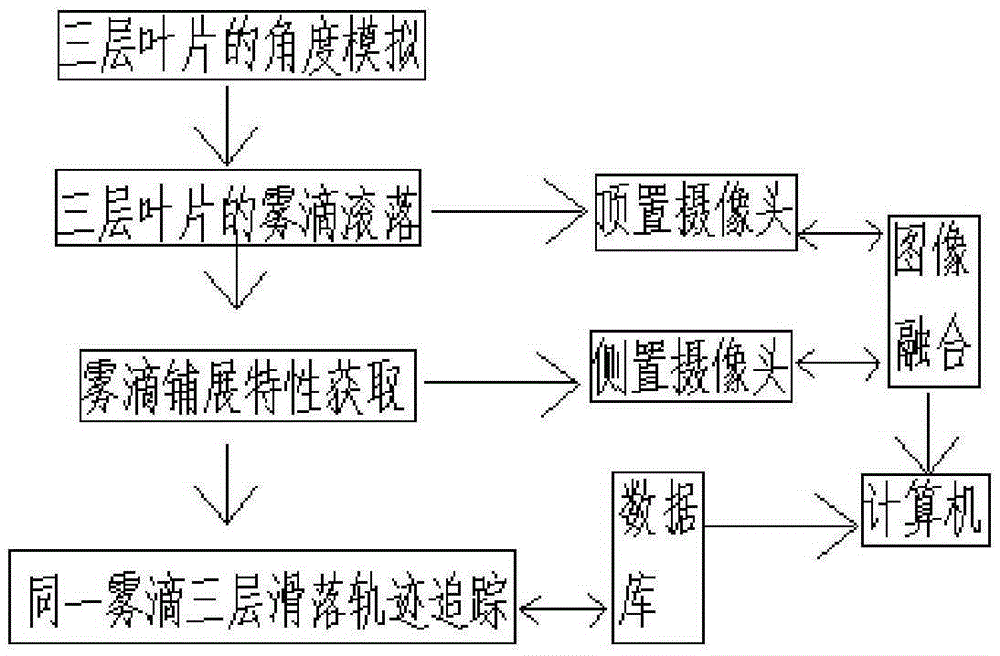

Method for obtaining leaf surface spreading characteristics of fog drops based on timestamp

The invention relates to the technical field of agriculture, in particular to a method for obtaining the leaf surface spreading characteristics of fog drops based on a timestamp. The method includes the steps that multiple layers of leaves are arranged above a target crop through leaf bracket devices, wherein angle simulation can be performed on the multiple layers of leaves; under the control of a computer control system, top cameras move horizontally and vertically to trace the fog drops on the multiple layers of leaves from the upper position, and meanwhile side cameras conduct angle rotation to trace the fog drops on the multiple layers of leaves from the side position; the fog drops are released to start to disperse after being generated on the top layer of leaves and then roll to the other layers of leaves from top to bottom, and during the process, the top cameras and the side cameras cooperate to collect rolling information and spreading characteristic information of the fog drops, and feed the collected information back to the computer control system at the same time; the computer control system establishes a spreading model of the fog drops through database information.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

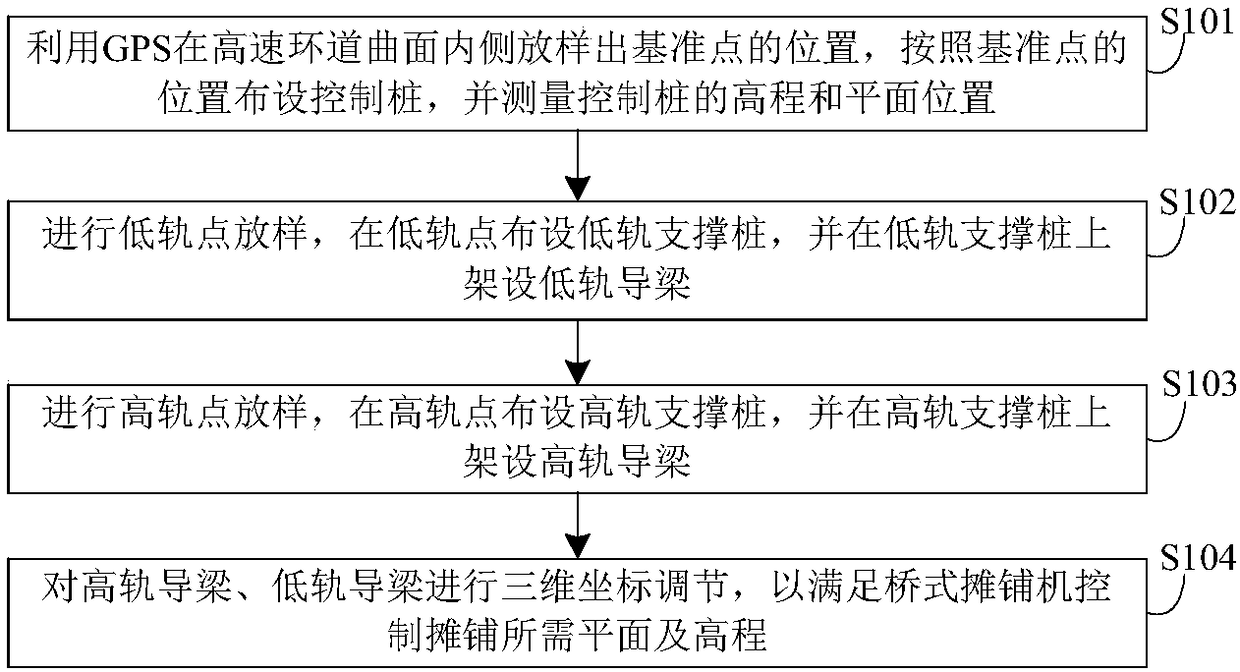

Construction setting out method for high speed rotary road curved surface spreading

The invention discloses a construction setting out method for high speed rotary road curved surface spreading, and belongs to the technical field of building construction. The method comprises the steps of using GPS to set out the positions of reference points on the inner side of a high speed rotary road curved surface, arranging control piles according to the positions of the reference points, and measuring the elevations and plane positions of the control piles; performing low track point setting out, arranging low track support piles at low track points, and erecting low track guide beamson the low track support piles; performing high track point setting out, arranging high track support at high track points, erecting high track guide beams on the high track support piles, and using abridge spreading machine to walk on the high track guide beams and low track guide beams for spreading work to meet the planes and elevations required for the bridge spreading machine to control spreading. When the method is used for curved surface spreading, it is not necessary to repeat the setting out, and the spreading precision is high.

Owner:THE FIRST ENG CO LTD OF CTCE GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com