Construction setting out method for high speed rotary road curved surface spreading

A high-speed ring road and construction method technology, applied in the field of building construction, can solve the problems of mismatching received signals, inability to meet the paving work of bridge paver, cumbersome stakeout work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

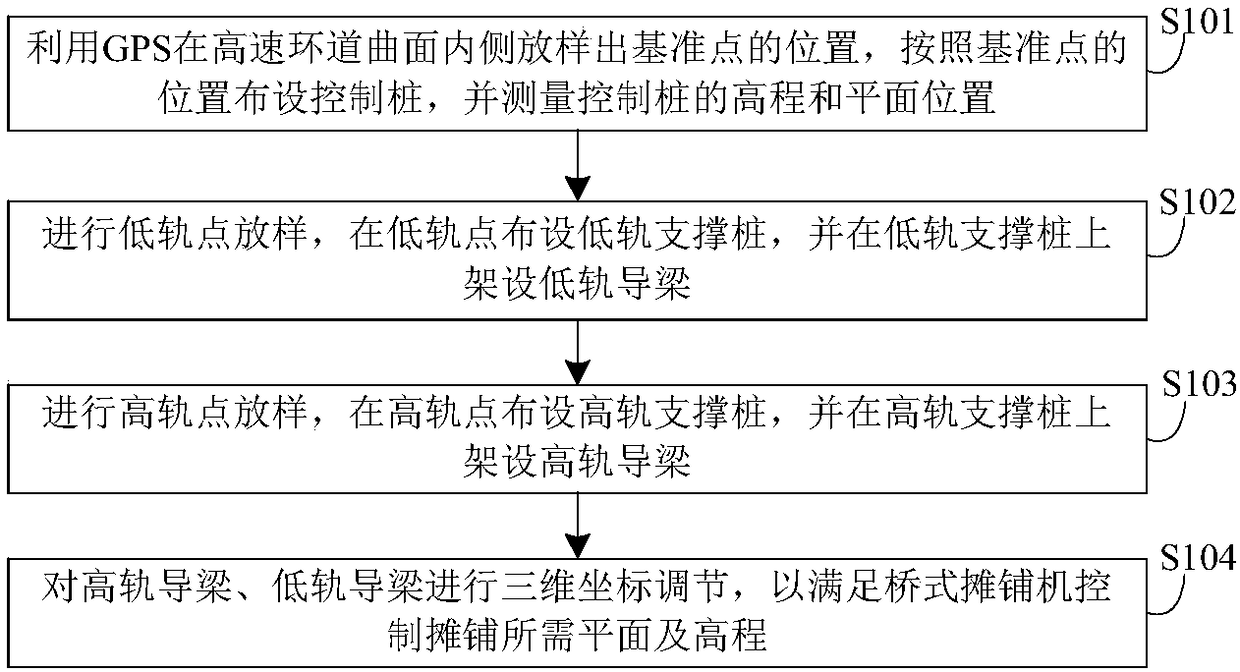

[0057] In order to further illustrate the features of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are for reference and description only, and are not intended to limit the protection scope of the present invention.

[0058] This embodiment solves the problem of repeated lofting in the traditional full-section paving technology by providing a lofting construction method for paving curved surfaces of high-speed ring roads.

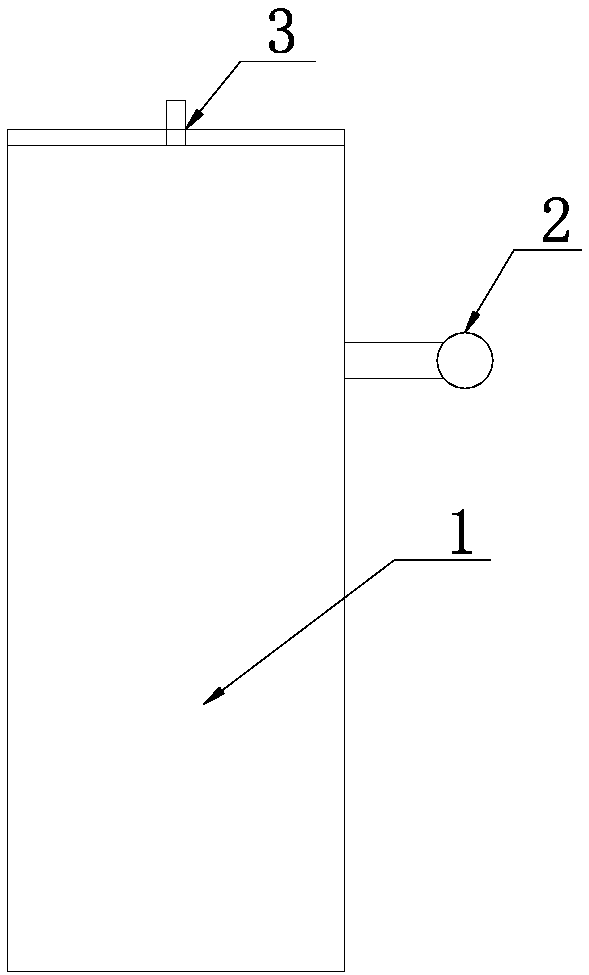

[0059]In order to solve the above-mentioned problems, the general idea of the scheme of this embodiment is: install the high-rail guide beam and the low-rail guide beam necessary for erecting bridge-type paving on the upper and lower parts of the curved surface of the high-speed ring road respectively, and the upper part refers to It is the outer side of Diding Road, and the lower part refers to the inner side of the parking lane. The low rail guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com