Soilless lawn substrate production method, and its product and apparatus

A soilless lawn and production method technology, applied in soilless cultivation, botany equipment and methods, horticulture, etc., can solve the problems of short life cycle of flowers and plants, low technological content, poor working environment, etc., to achieve large-scale production, Improve the working environment and save the effect of manual processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

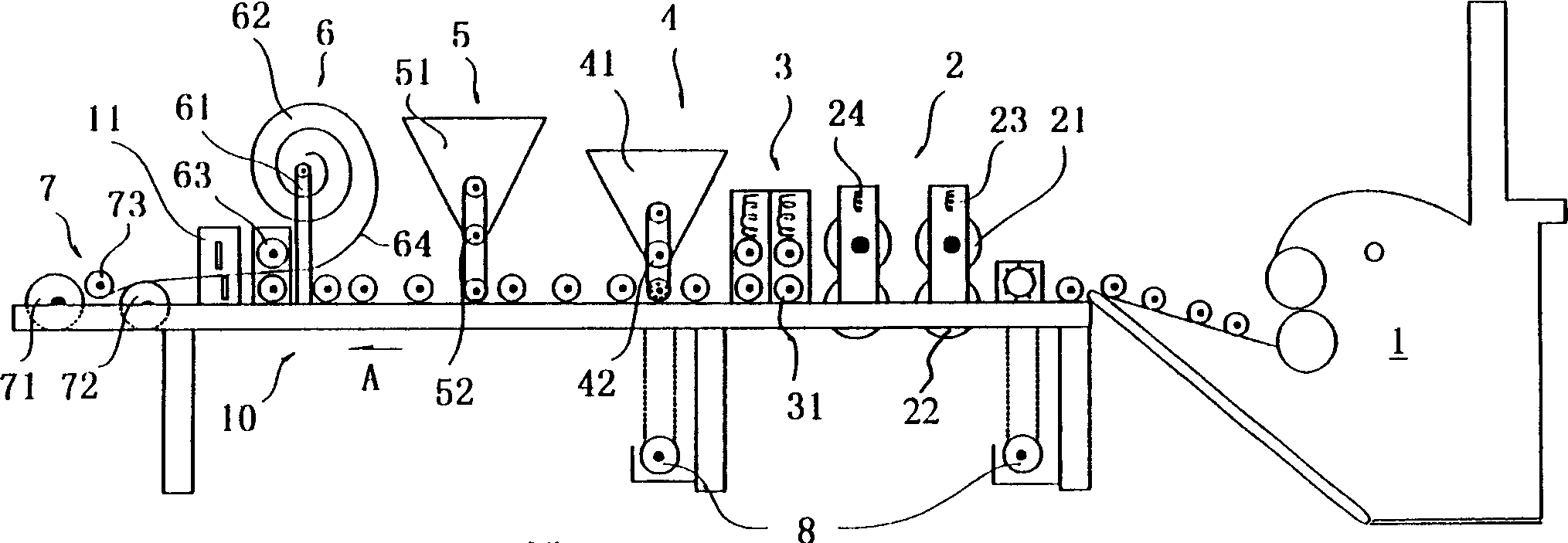

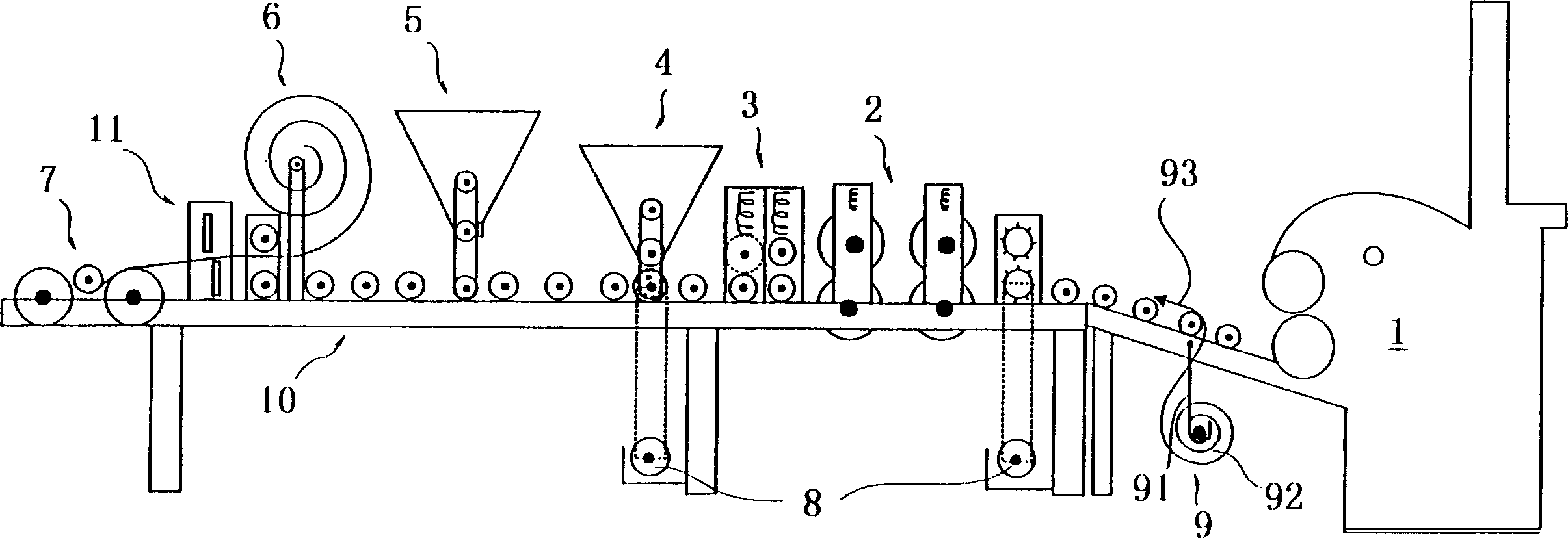

[0029] Refer to attached figure 1 , which illustrates a production plant for a soilless lawn substrate.

[0030] In the production method provided by the invention, comprise the following steps:

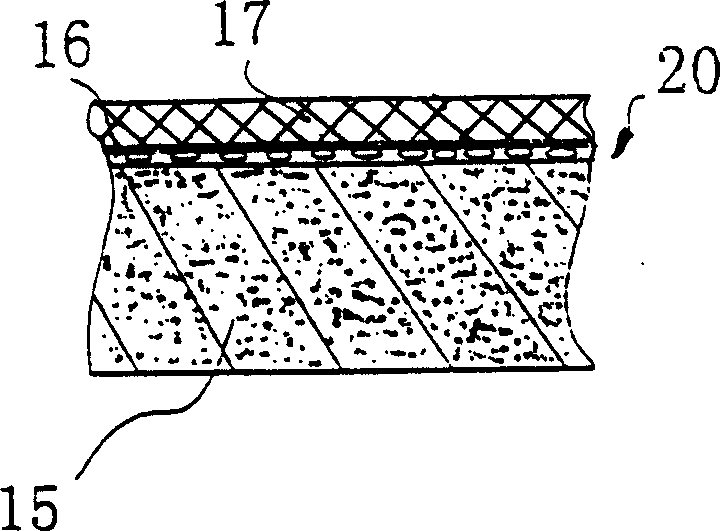

[0031] Stirring, combing, and shaping one or more of the crushed plant fibers, animal fibers, or man-made fibers to form a continuous mat-like material 15 with a thickness of 6-10 cm;

[0032] Apply pressure to the continuous mat-like material, the pressure range is 40-80kgf / cm 2 , so that it is thinned to a thin base layer 15 with a thickness of 1-2cm;

[0033] Cut longitudinally along the thin cushion bottom layer 15, so that the width of each thin cushion bottom layer 15 is 80-220cm;

[0034] Apply an appropriate amount of grass seeds 16 on the upper surface of the thin cushion bottom layer 15, according to different varieties, its spreading rate is 0.012-0.035kg / m 2 ;

[0035] On the thin base layer 15 with an appropriate amount of grass seeds on the upper surface, the cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com