Antifogging toughened glass and preparation method thereof

A tempered glass and glass technology, applied in the field of anti-fog tempered glass and its preparation, can solve problems such as affecting the display effect of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

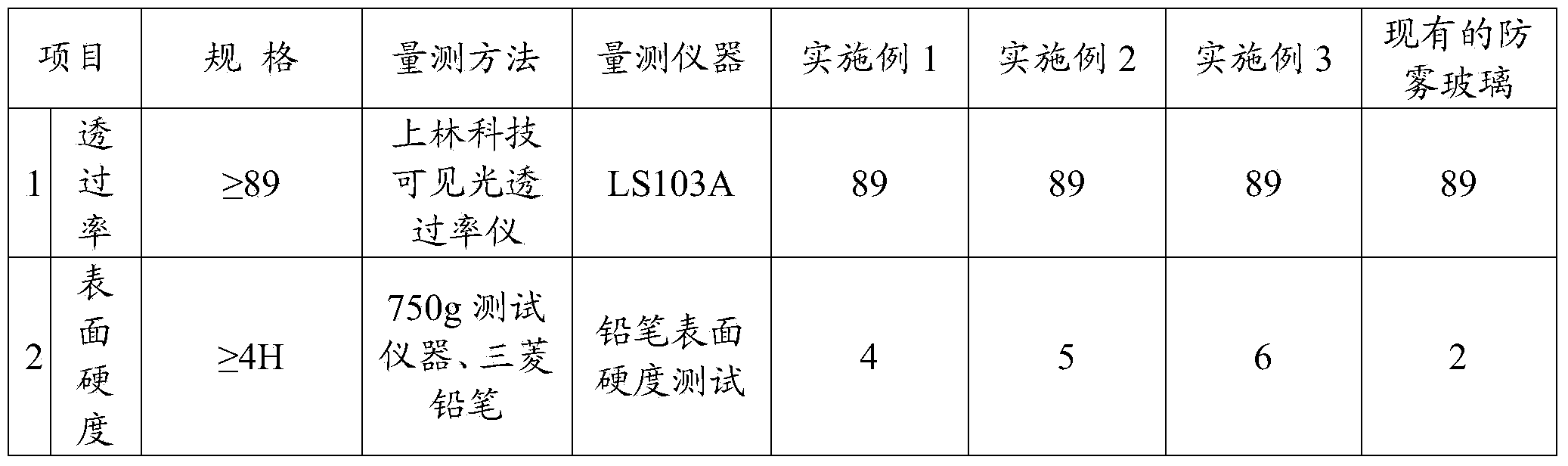

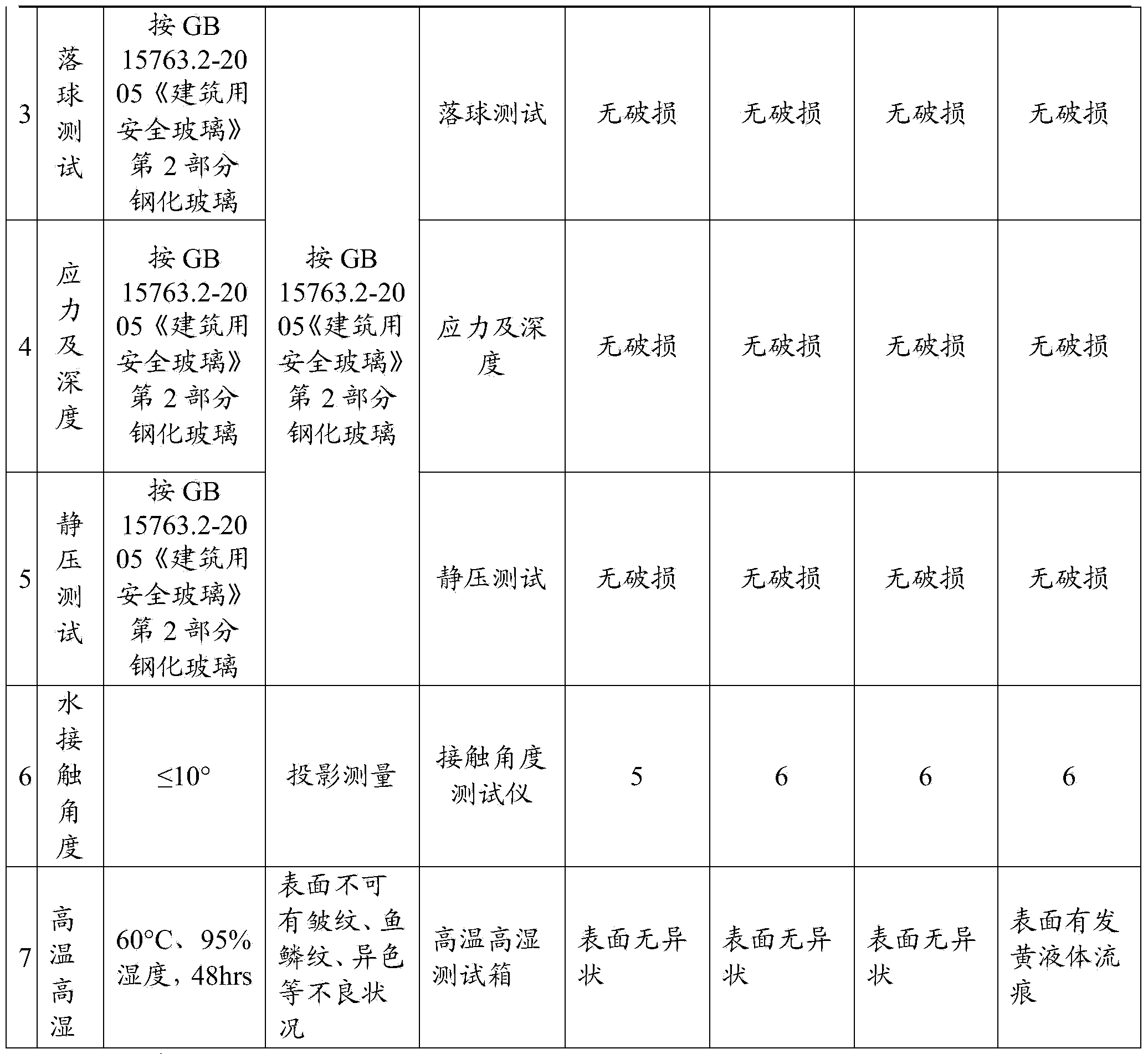

Examples

Embodiment 1

[0038] A preparation method of anti-fog tempered glass, comprising the steps of:

[0039] (1) Cut and edge-grind the original glass sheet according to the design requirements;

[0040] (2) Tempering the glass cut and ground in step (1), the steps of the tempering treatment are: heating the glass in a tempering furnace at a temperature of 680°C for 120-125 seconds, and then quenching to obtain Tempered glass, then put it into the washing machine for cleaning, the water temperature is 25°C;

[0041] (3) Spray coating the cleaned tempered glass, the operating parameters of the spray coating are: air pressure 0.4-0.5MPa, spraying distance 20-25cm;

[0042] The raw material composition of described antifogging agent is: hydrophilic acrylic resin 10wt%, film-forming material 10wt%, water 10wt%, ethanol 40wt%, fluorocarbon leveling agent 0.5wt%, additive 0.5wt%, volume ratio is 1 The mixed solvent 29wt% that the Virahol of 1 and ethanol form;

[0043] (4) Put the coated tempered g...

Embodiment 2

[0046] A preparation method of anti-fog tempered glass, comprising the steps of:

[0047] (1) Cut and edge-grind the original glass sheet according to the design requirements;

[0048] (2) Tempering the glass cut and ground in step (1), the steps of the tempering treatment are: heating the glass in a tempering furnace at a temperature of 685°C for 120-125 seconds, and then quenching to obtain Tempered glass, then put it into the washing machine for cleaning, the water temperature is 35 °C;

[0049] (3) Spray coating the cleaned tempered glass, the operating parameters of the spray coating are: air pressure 0.4-0.5MPa, spraying distance 20-25cm;

[0050] The raw material composition of described antifogging agent is: hydrophilic acrylic resin 12wt%, film-forming material 8wt%, water 12wt%, ethanol 36wt%, fluorocarbon leveling agent 0.4wt%, additive 0.6wt%, volume ratio is 1 : 1 mixed solvent 31wt% of isopropanol and ethanol composition;

[0051] (4) Put the coated tempered g...

Embodiment 3

[0054] A preparation method of anti-fog tempered glass, comprising the steps of:

[0055] (1) Cut and edge-grind the original glass sheet according to the design requirements;

[0056](2) Tempering the glass cut and ground in step (1), the steps of the tempering treatment are: heating the glass in a tempering furnace at a temperature of 683°C for 120-125 seconds, and then quenching to obtain Tempered glass, and then put it into the washing machine for washing, the water temperature is 30°C;

[0057] (3) Spray coating the cleaned tempered glass, the operating parameters of the spray coating are: air pressure 0.4-0.5MPa, spraying distance 20-25cm;

[0058] The raw material composition of described antifogging agent is: waterborne acrylic acid 8wt%, film-forming material (acrylic resin) 12wt%, water 8wt%, ethanol 44wt%, fluorocarbon leveling agent 0.4wt%, additive 0.6wt%, volume ratio is 1:1 mixed solvent 27wt% of isopropanol and ethanol;

[0059] (4) Put the coated tempered g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com