Oil surface spreading agent

A technology of spreading agent and surfactant, applied in fire prevention equipment and other directions, can solve the problems of the destruction of the earth's ozone layer, environmental pollution, threats to human living environment, etc., and achieve the effect of reducing the use concentration and surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

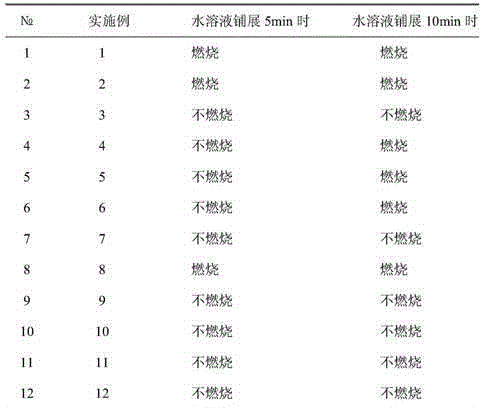

Embodiment 1

[0043] Example 1 Spreading film-forming agent aqueous solution The mass percentage of each component (w%, the same below): 0.01% A, 0.01% B-1000, 0.1% sodium dodecyl sulfate (SDS). Put 25mL93 in a glass petri dish (diameter 9cm, height 1.4cm) # For gasoline, use a 10mL syringe to drop the aqueous solution onto the oil surface to measure the gasoline volatilization. After 5 minutes of spreading, the coverage of the aqueous solution on the gasoline surface is 30.8%.

Embodiment 2

[0044] Example 2 Spreading film-forming agent aqueous solution The mass percentage of each component: 2.5% A, 0.5% B-1000, 0.1% sodium dodecylbenzenesulfonate (SDBS), 0.5% decanol. Put 25mL93 in a glass petri dish (diameter 9cm, height 1.4cm) #For gasoline, use a 10mL syringe to drop the aqueous solution onto the oil surface to measure the gasoline volatilization. After 5 minutes of spreading, the coverage of the aqueous solution on the gasoline surface is 85.1%.

Embodiment 3

[0045] Example 3 Spreading film-forming agent aqueous solution mass percent of each component: 1.0%A, 0.5%C-10, 1.0%C 12 ~C 14 Fatty Alcohol Sulfate (FAS), 0.5% Decyl Alcohol. Put 25mL kerosene in a glass Petri dish (diameter 9cm, height 1.4cm), use a 10mL syringe to drip the aqueous solution onto the oil surface, and measure the kerosene volatilization. After 5 minutes of spreading, the coverage of the aqueous solution on the kerosene surface is 99.2%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com