High heat insulation transparent SiO2 aerogel film material and preparation method thereof

A thin film material and airgel technology, which is applied in the field of high thermal insulation transparent SiO2 airgel thin film material and its preparation, can solve the problems of unfavorable transparency, reduce the light transmittance of SiO airgel thin film, etc., and achieve moderate viscosity , low density, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

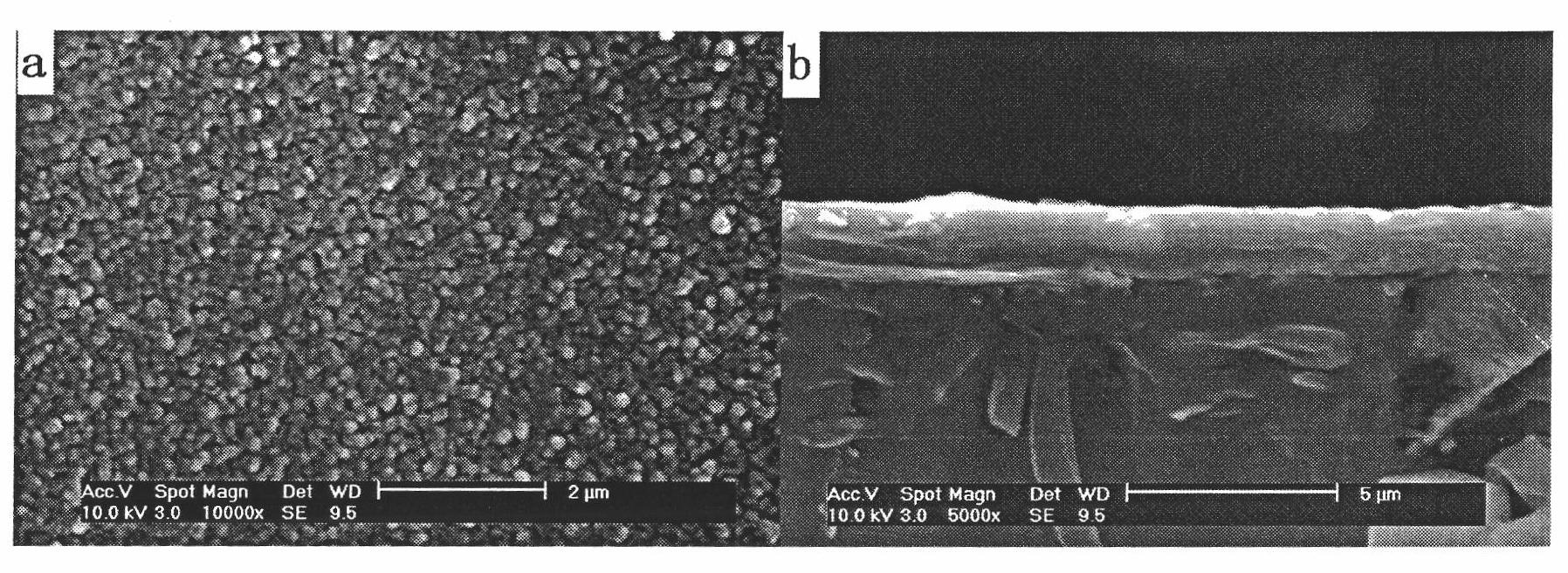

Image

Examples

Embodiment 1

[0029] (1) Preparation of acid catalyst solution and alkali catalyst solution

[0030] Measure 0.0418mL of concentrated hydrochloric acid (HCl) and 7.44mL of concentrated ammonia (NH 4 OH), were dissolved in 99.9164ml of absolute ethanol (CH 3 CH 2 OH) and 92.56ml deionized water (H 2 (0) in, be prepared into concentration and be the dilute ammonia solution of the hydrochloric acid dehydrated alcohol solution of 0.01mol / L and 1mol / L.

[0031] (2) SiO 2 Preparation of precursor sol

[0032] A. Add 40ml of tetraethyl orthosilicate, 14.66ml of absolute ethanol and 2.72ml of deionized water to a dry and clean beaker and mix them in turn. Stir vigorously at room temperature with a magnetic stirrer for 35 minutes of hydrolysis / polycondensation reaction; add 2.5 ml of hydrochloric acid absolute ethanol solution, and continuously stirred for 60 min to obtain the acid-catalyzed reaction product;

[0033] B. Add 1.76ml of dilute ammonia solution to the acid-catalyzed reaction prod...

Embodiment 2

[0046] (1) Preparation of acid catalyst solution and alkali catalyst solution

[0047] Measure 0.0418mL of concentrated hydrochloric acid (HCl) and 7.44mL of concentrated ammonia (NH 4 OH), were dissolved in 99.9164ml of absolute ethanol (CH 3 CH 2 OH) and 92.56ml deionized water (H 2 (0) in, be prepared into concentration and be the dilute ammonia solution of the hydrochloric acid dehydrated alcohol solution of 0.01mol / L and 1mol / L.

[0048] (2) SiO 2 Preparation of precursor sol

[0049] A. Add 30ml of tetraethyl orthosilicate, 11.43ml of absolute ethanol and 2.38ml of deionized water to a dry and clean beaker and mix them in sequence. Stir vigorously at room temperature with a magnetic stirrer for 30 minutes of hydrolysis / polycondensation reaction; add 2.06 ml of hydrochloric acid absolute ethanol solution, and continuously stirred for 80 minutes to obtain the acid-catalyzed reaction product;

[0050] B. Add 1.41ml of dilute ammonia solution to the acid-catalyzed reac...

Embodiment 3

[0062] (1) Preparation of acid catalyst solution and alkali catalyst solution

[0063] Measure 0.0418mL of concentrated hydrochloric acid (HCl) and 7.44mL of concentrated ammonia (NH 4 OH), were dissolved in 99.9164ml of absolute ethanol (CH 3 CH 2 OH) and 92.56ml deionized water (H 2 (0) in, be prepared into concentration and be the dilute ammonia solution of the hydrochloric acid dehydrated alcohol solution of 0.01mol / L and 1mol / L.

[0064] (2) SiO 2 Preparation of precursor sol

[0065] A. Add 50ml of tetraethyl orthosilicate, 19.79ml of absolute ethanol and 4.52ml of deionized water to a dry and clean beaker and mix them in turn. Stir vigorously at room temperature with a magnetic stirrer to carry out hydrolysis / polycondensation reaction for 45 minutes; add 3.77 ml of hydrochloric acid absolute ethanol solution, and continuously stirred for 66 minutes to obtain the acid-catalyzed reaction product;

[0066] B. Add 2.27ml dilute ammonia solution to the acid-catalyzed r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com