Patents

Literature

95 results about "Inspirator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An inspirator is a device, similar to a venturi tube and an orifice plate, which mixes a fuel gas with atmospheric air in a precise ratio to regulate burn characteristics. Only the pressure of the fuel gas is used to draw in and mix the air. They are the most simple and common type of mixing device for gas stoves and furnaces. Burners using an inspirator are considered to be naturally aspirated.

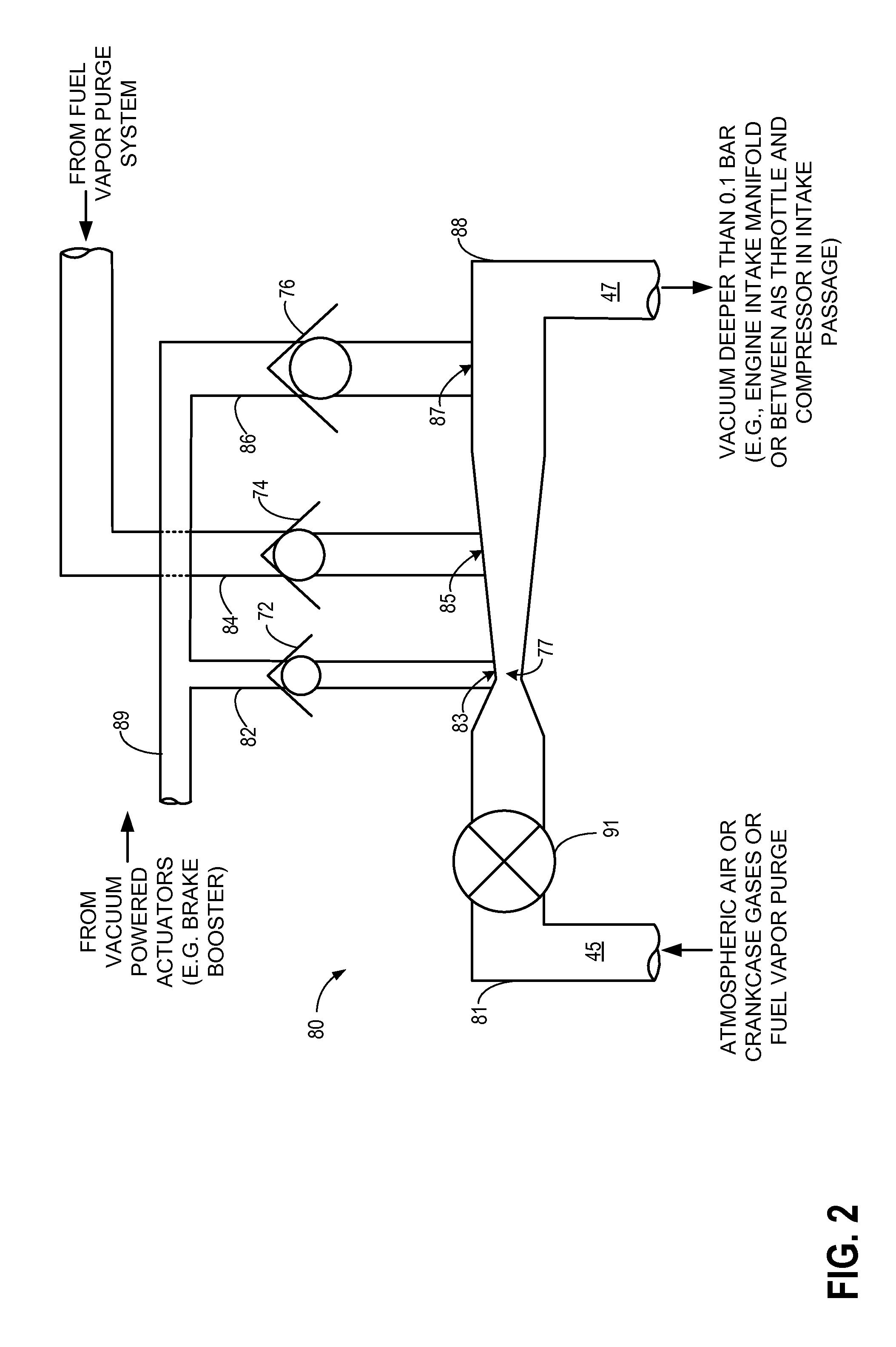

Crankcase ventilation and vacuum generation

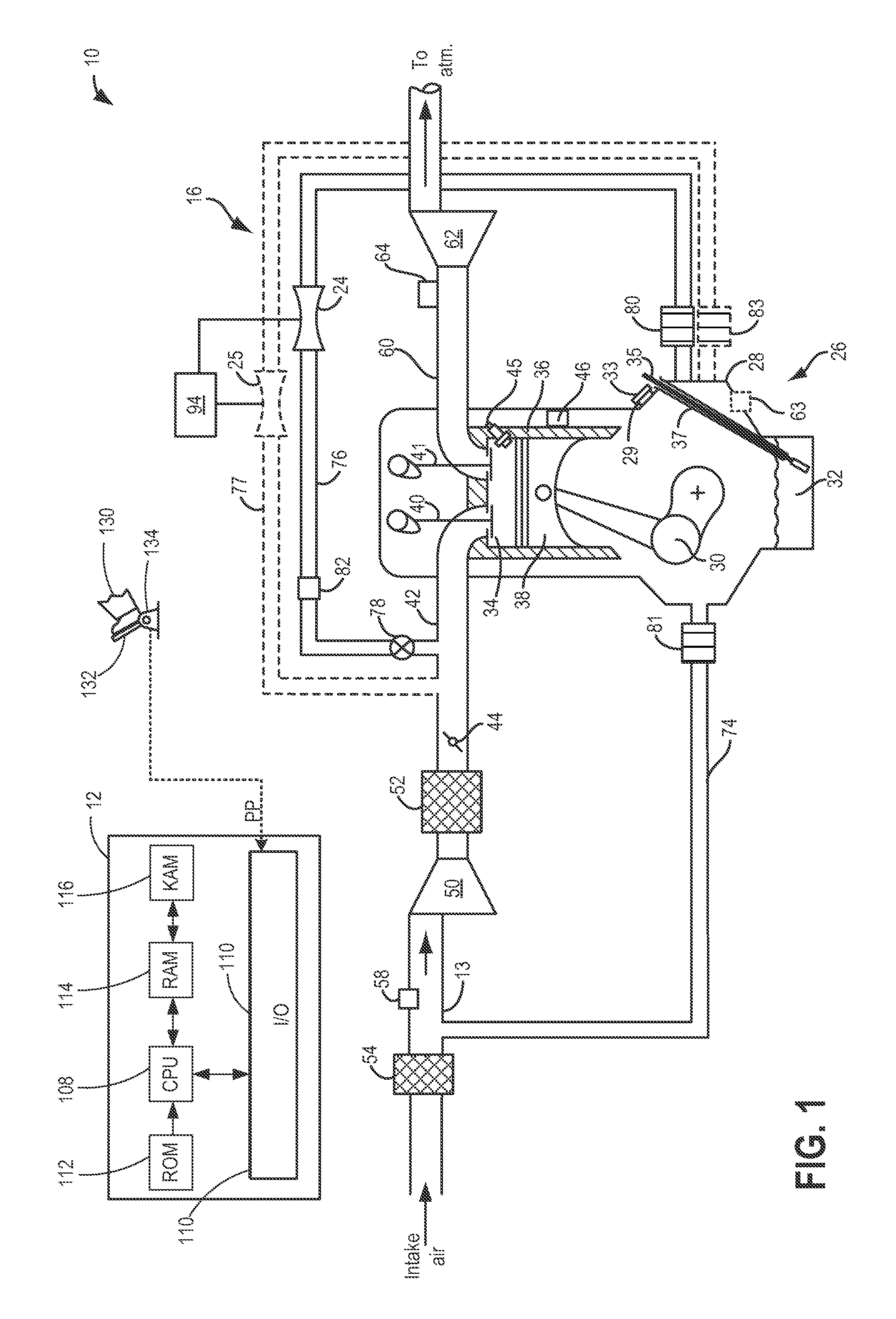

InactiveUS20130340732A1Increase vacuum generationImprove power generation efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelInspiratorProcess engineering

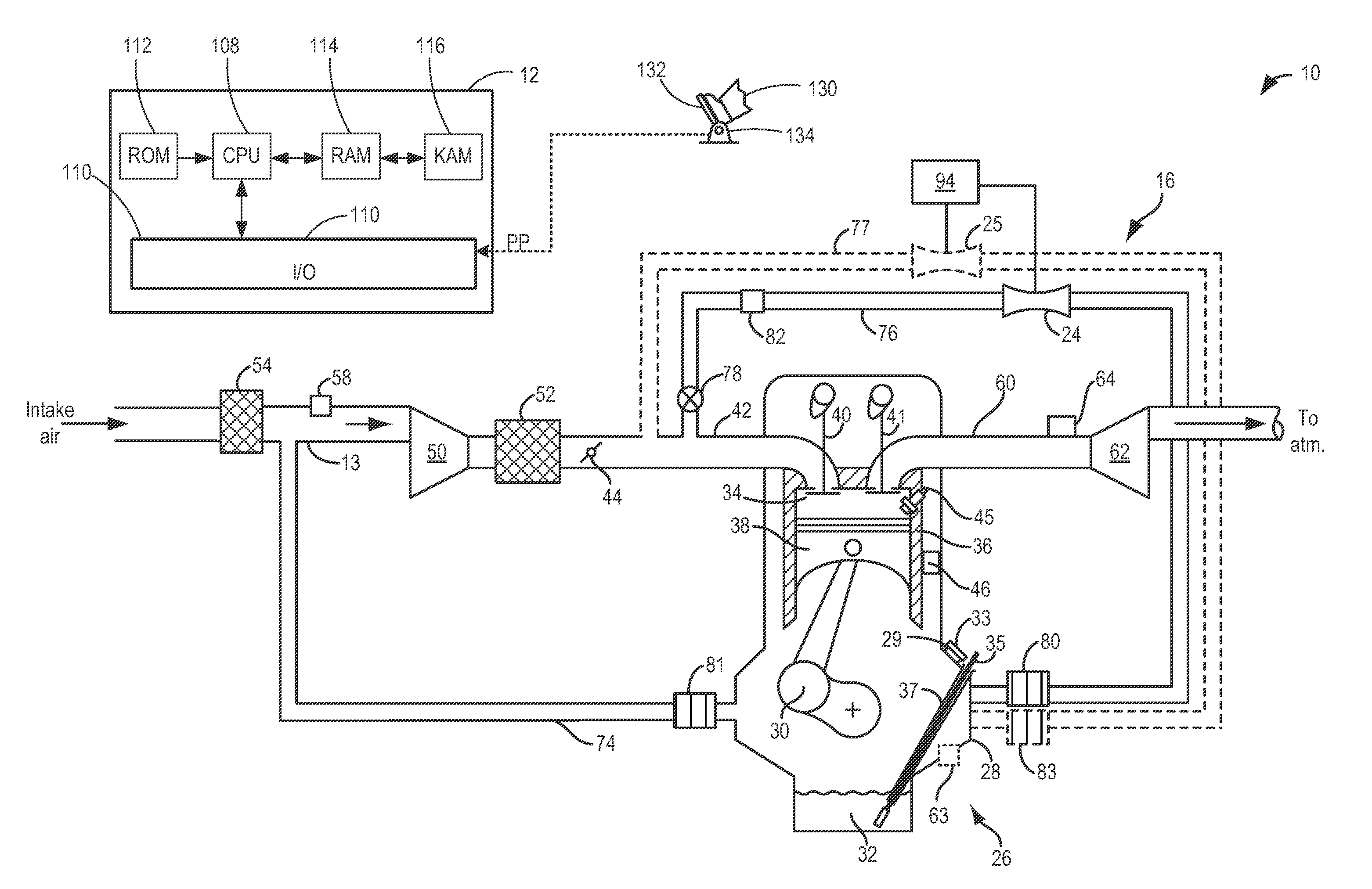

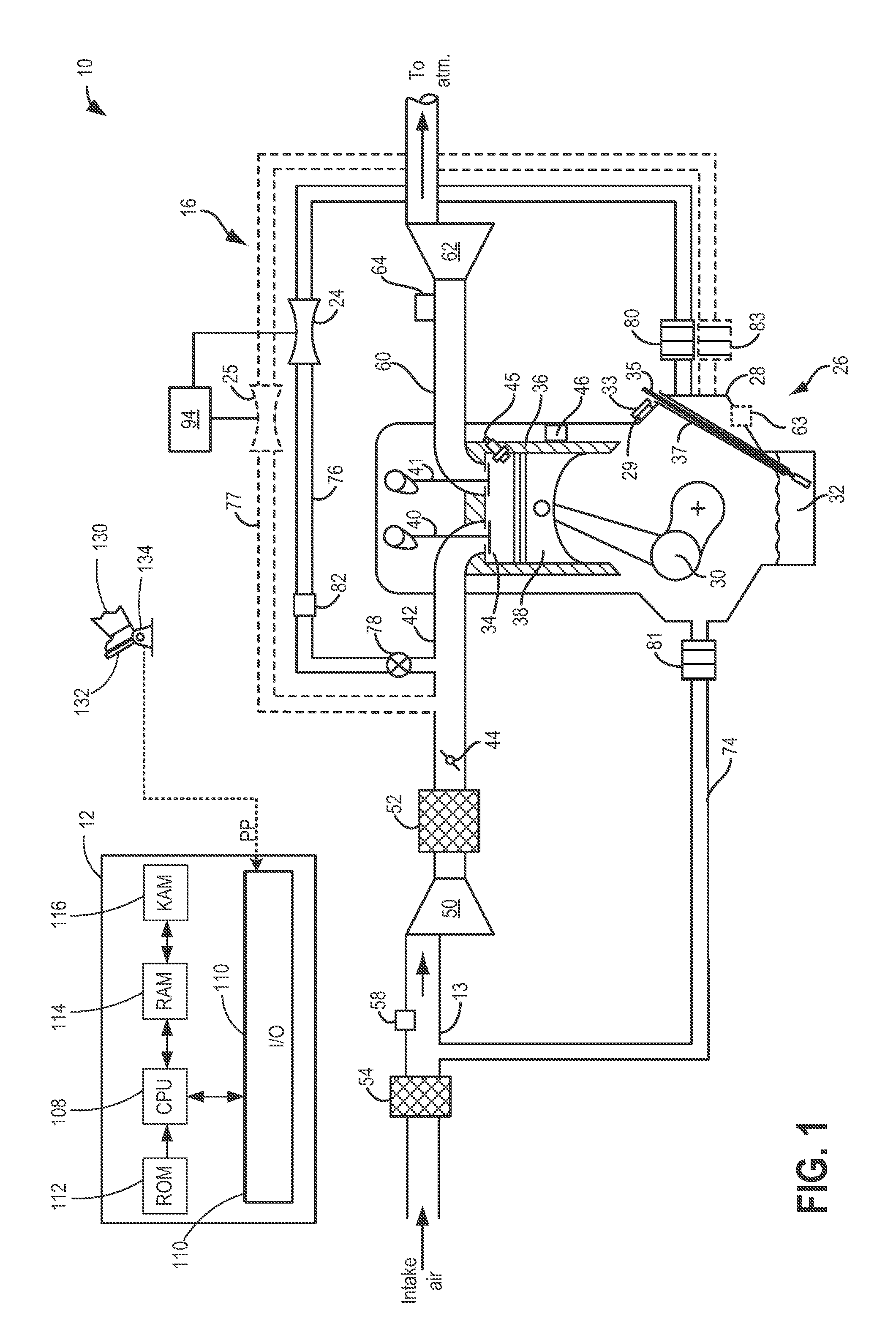

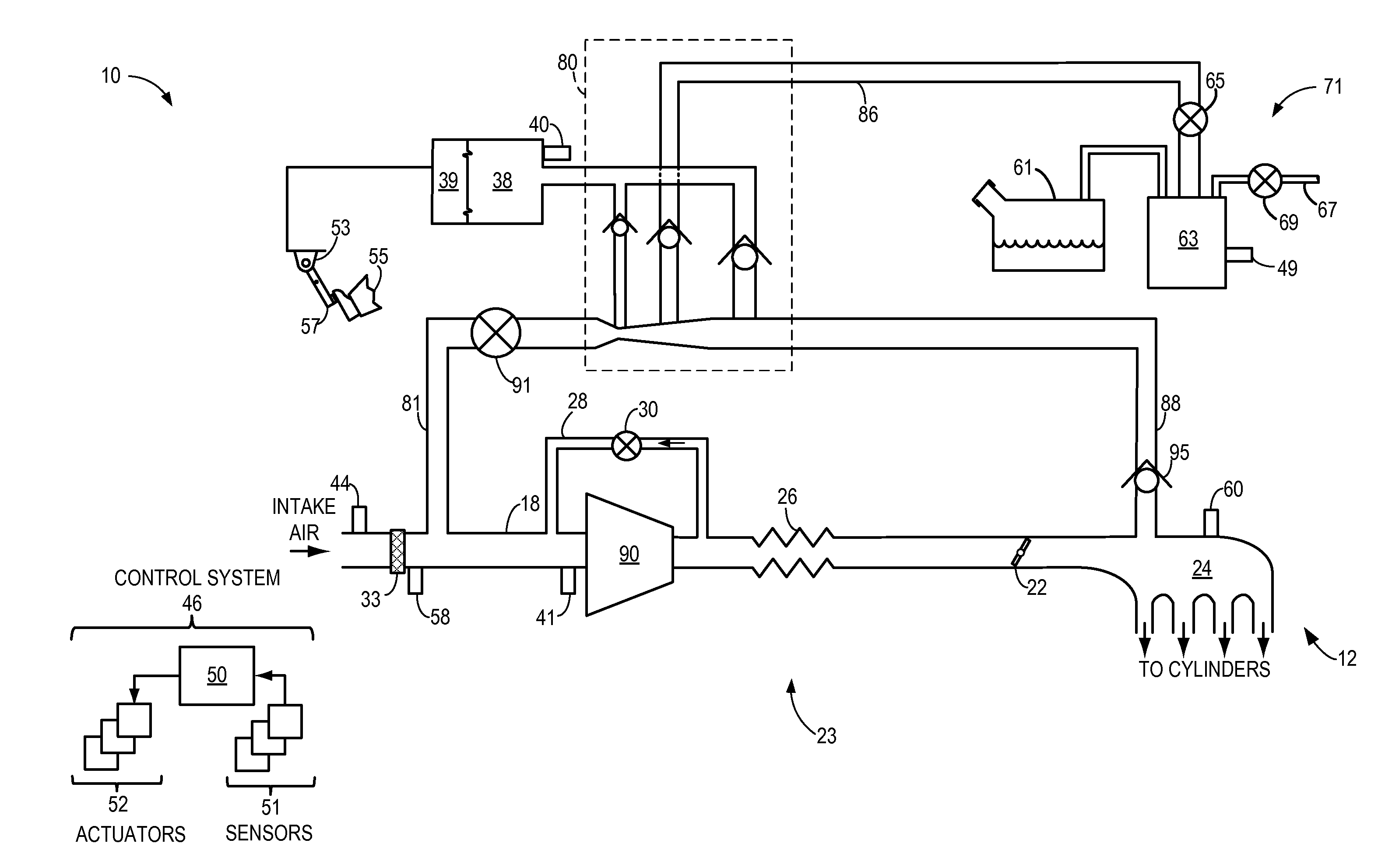

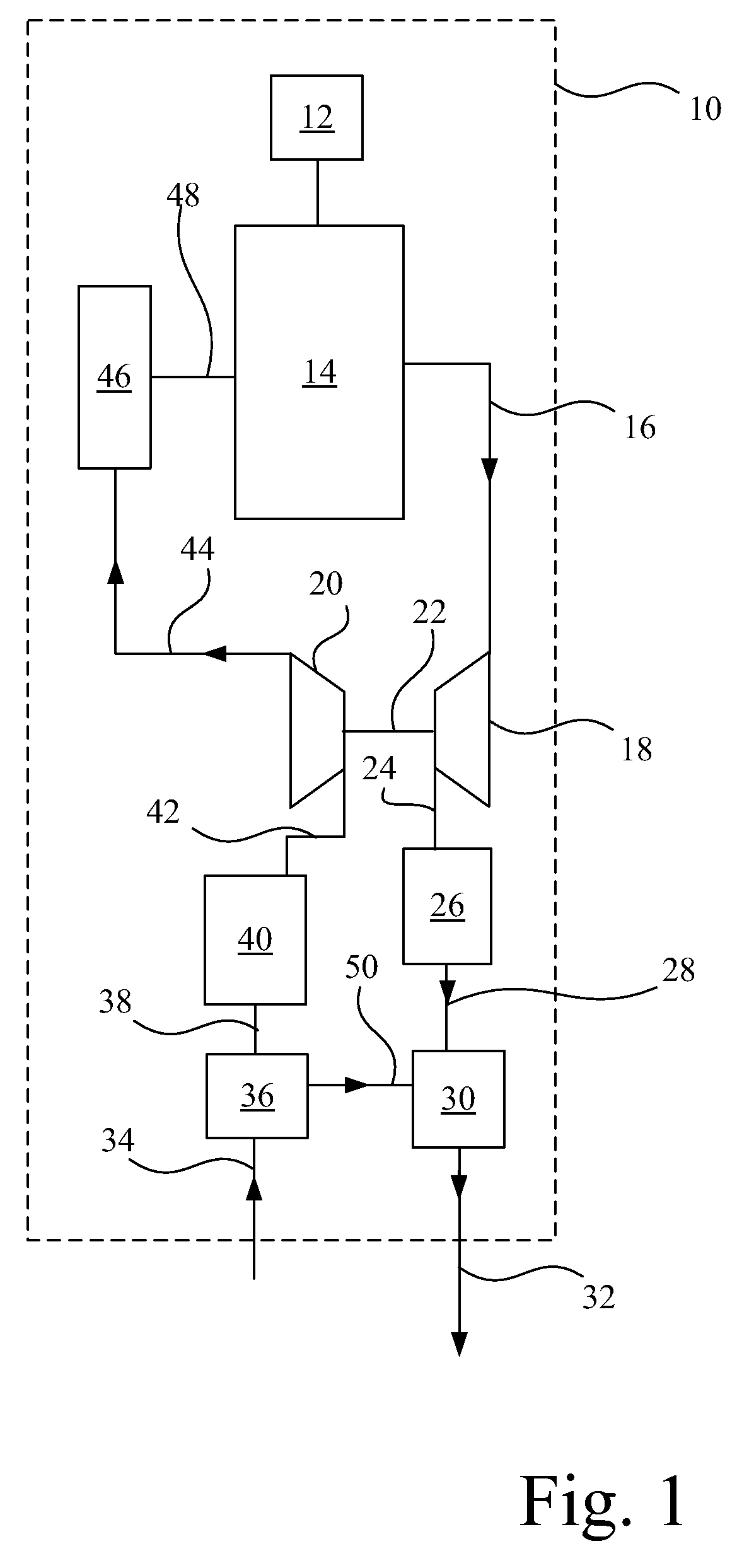

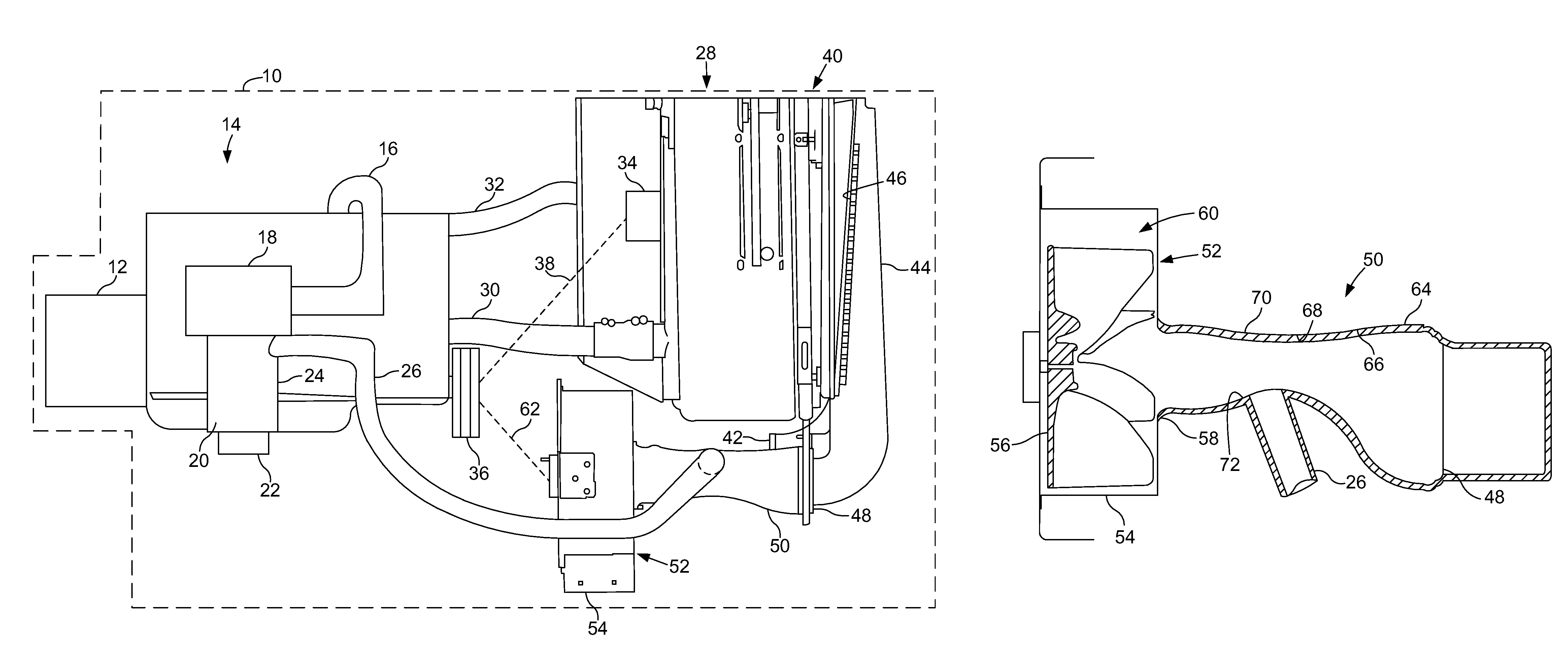

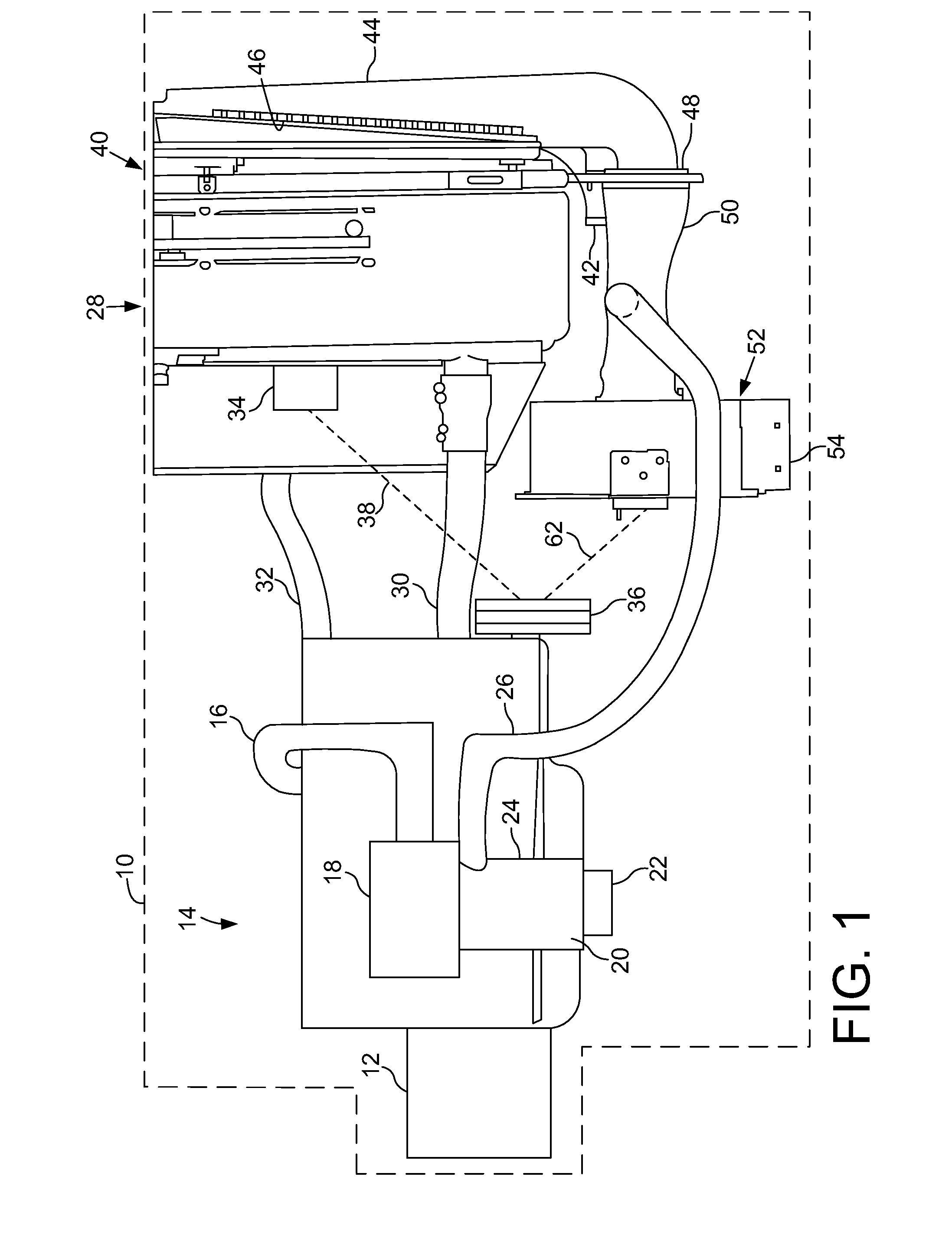

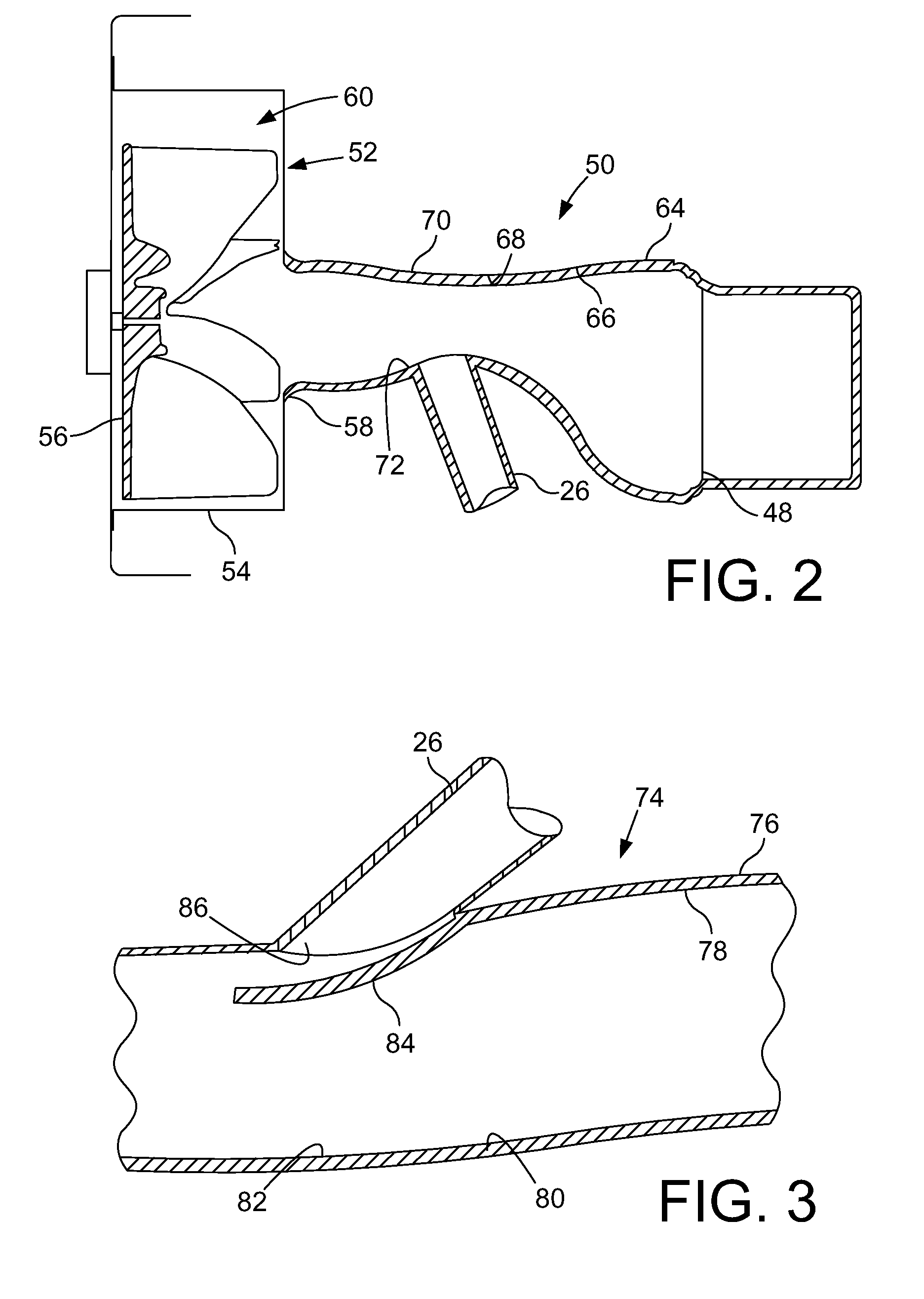

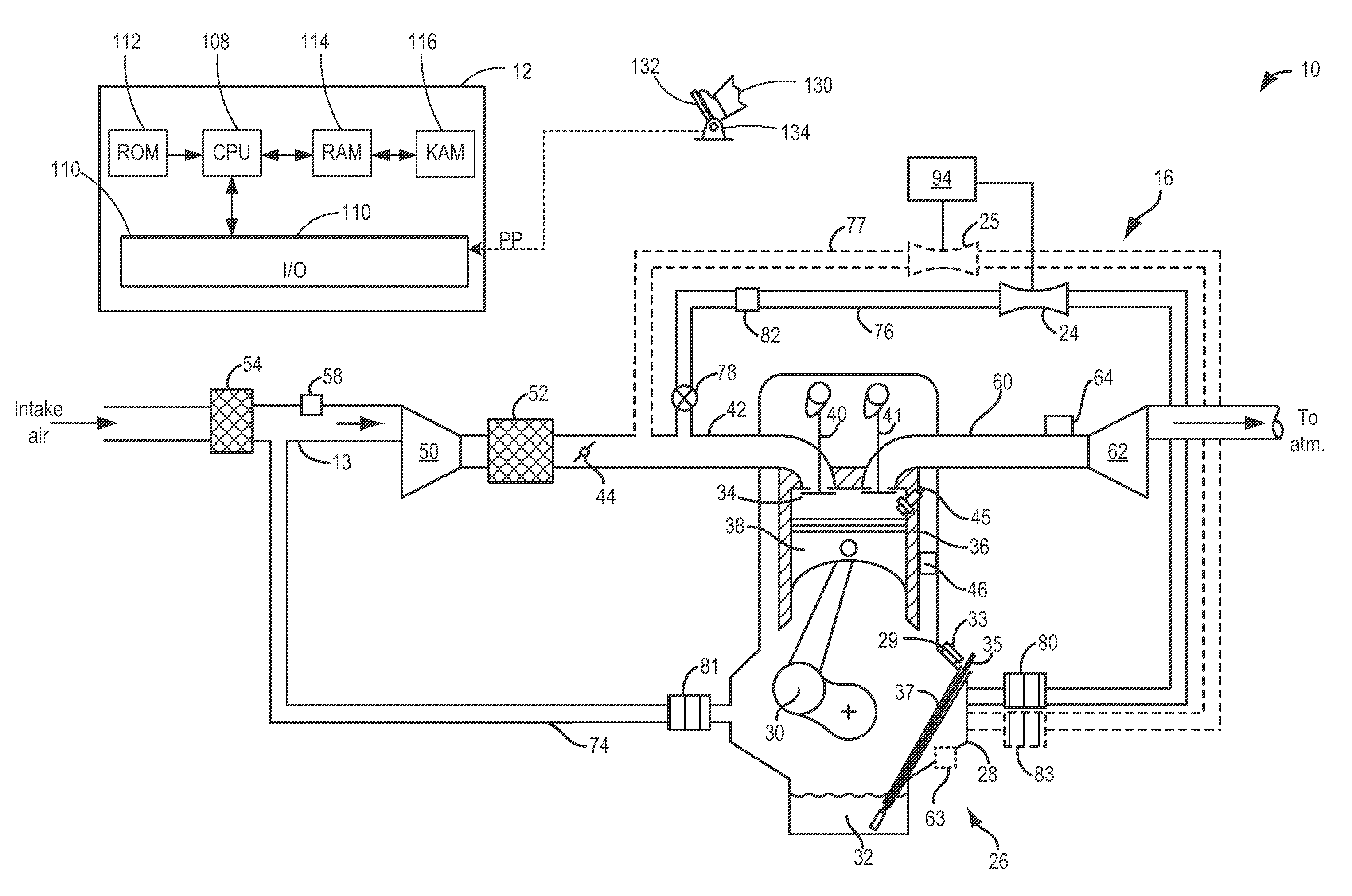

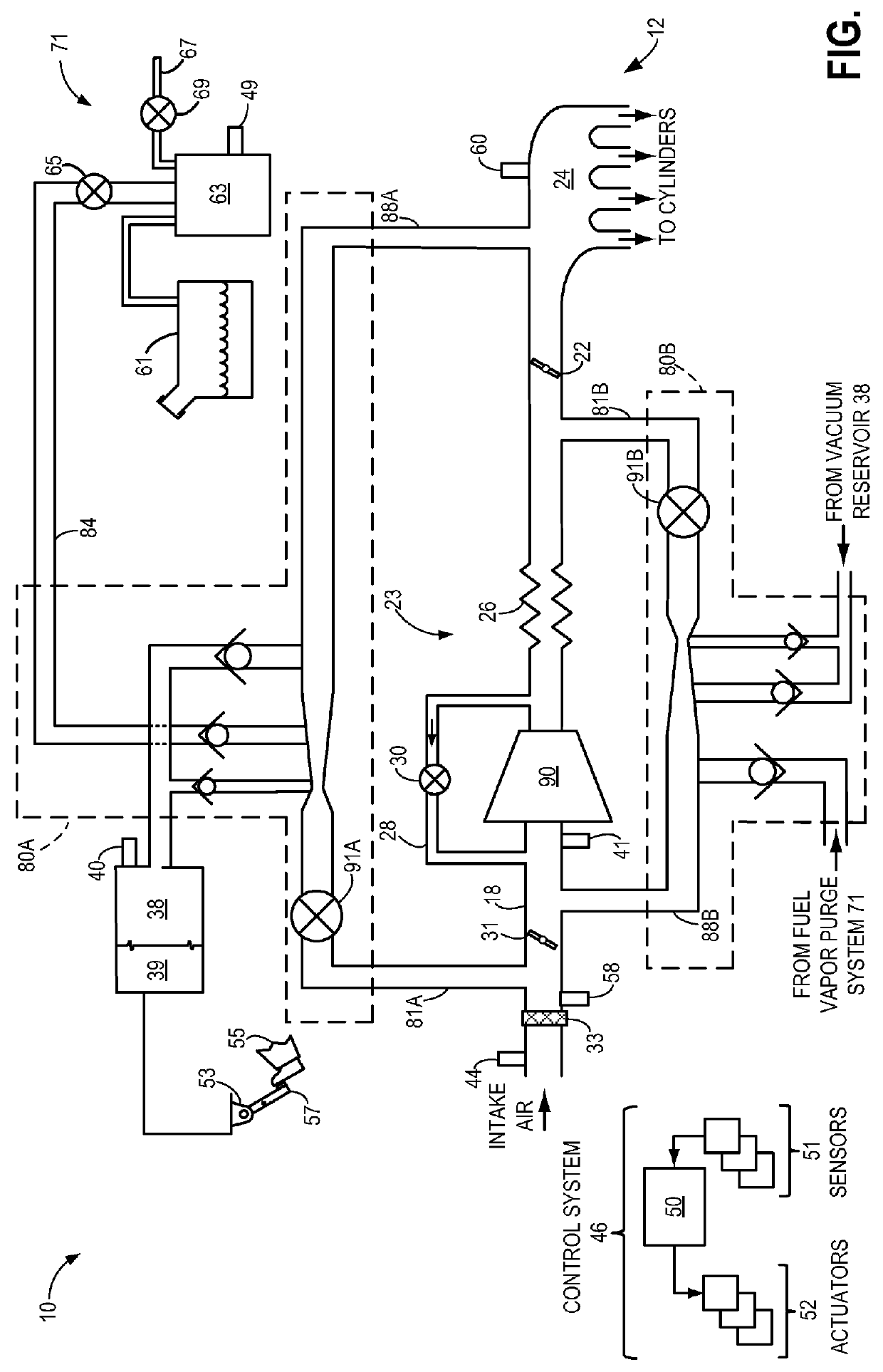

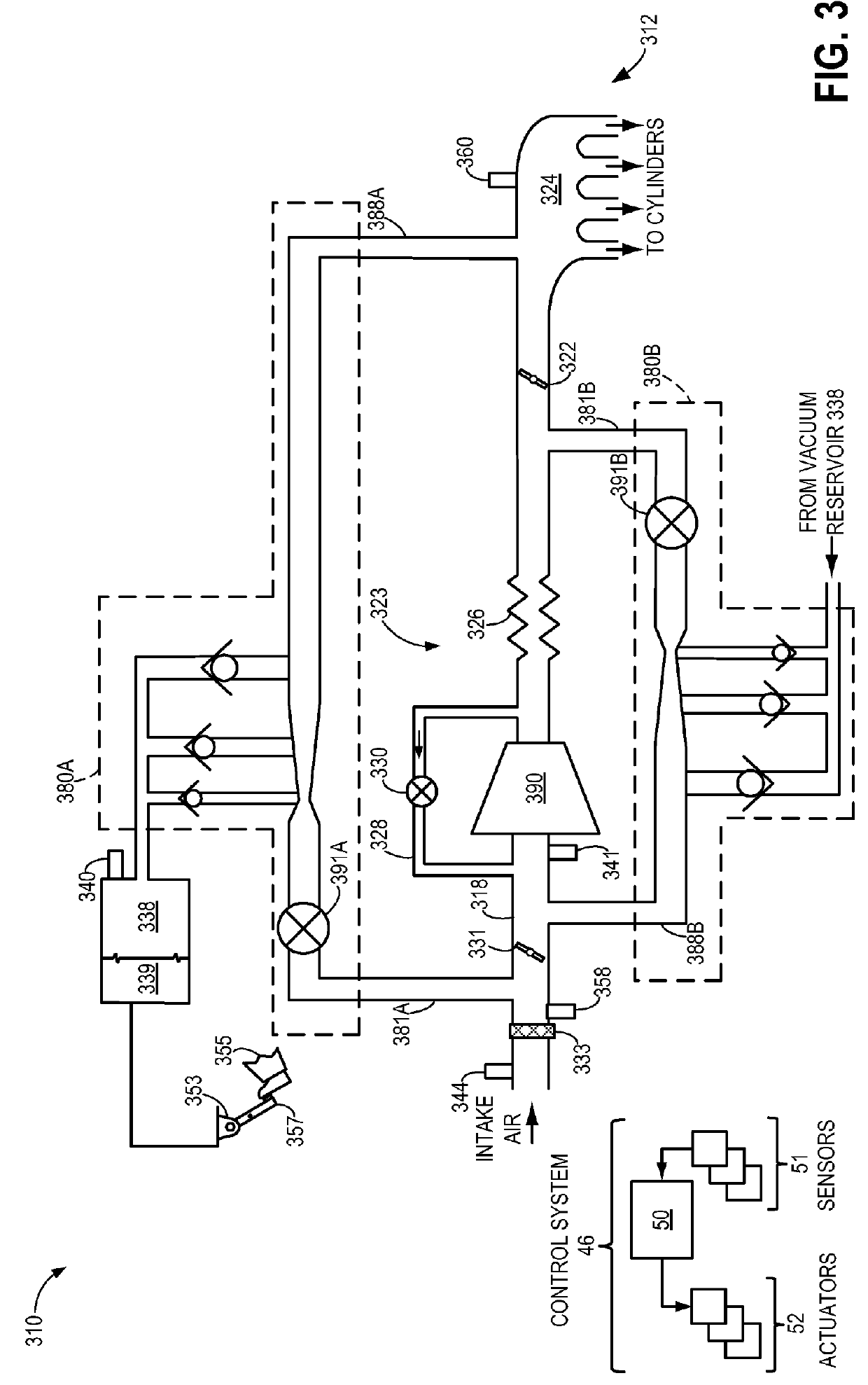

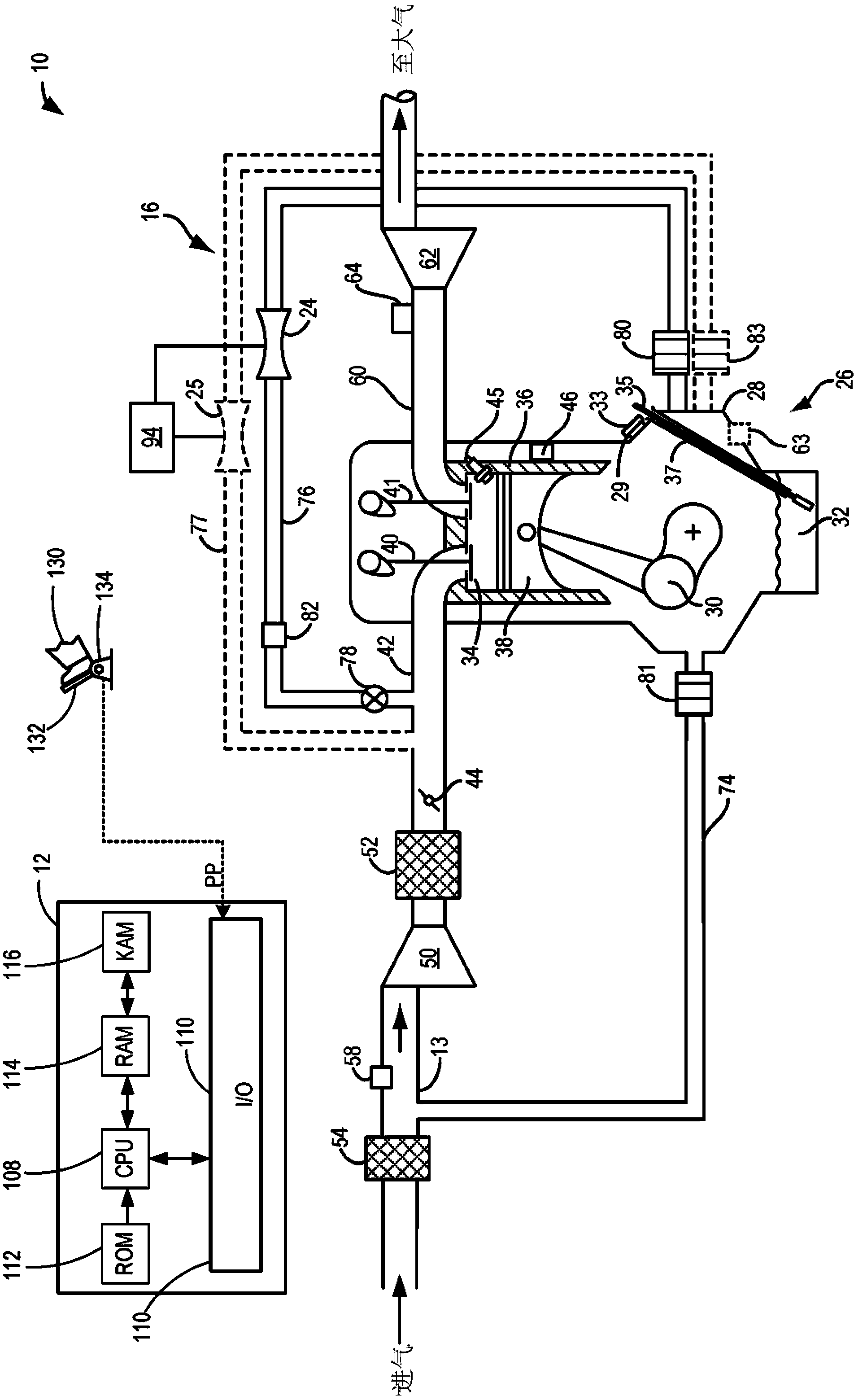

Methods and systems are provided for generating vacuum from crankcase ventilation flow. During both directions of gas flow between an engine intake manifold and a crankcase, gases are directed through one or more aspirators to produce vacuum. The drawn vacuum may then be used to operate various engine vacuum actuators.

Owner:FORD GLOBAL TECH LLC

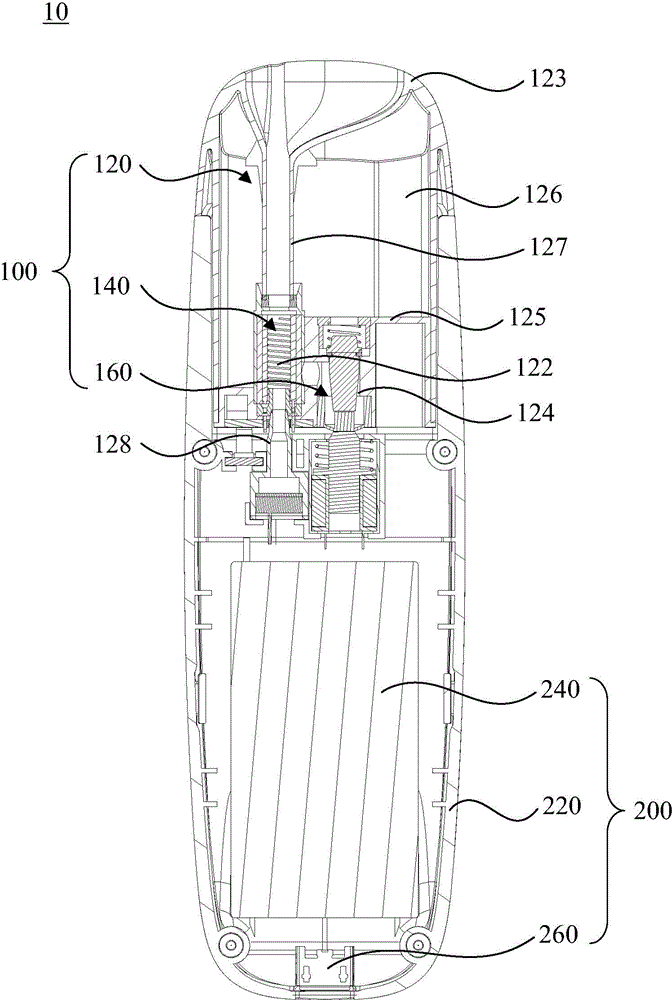

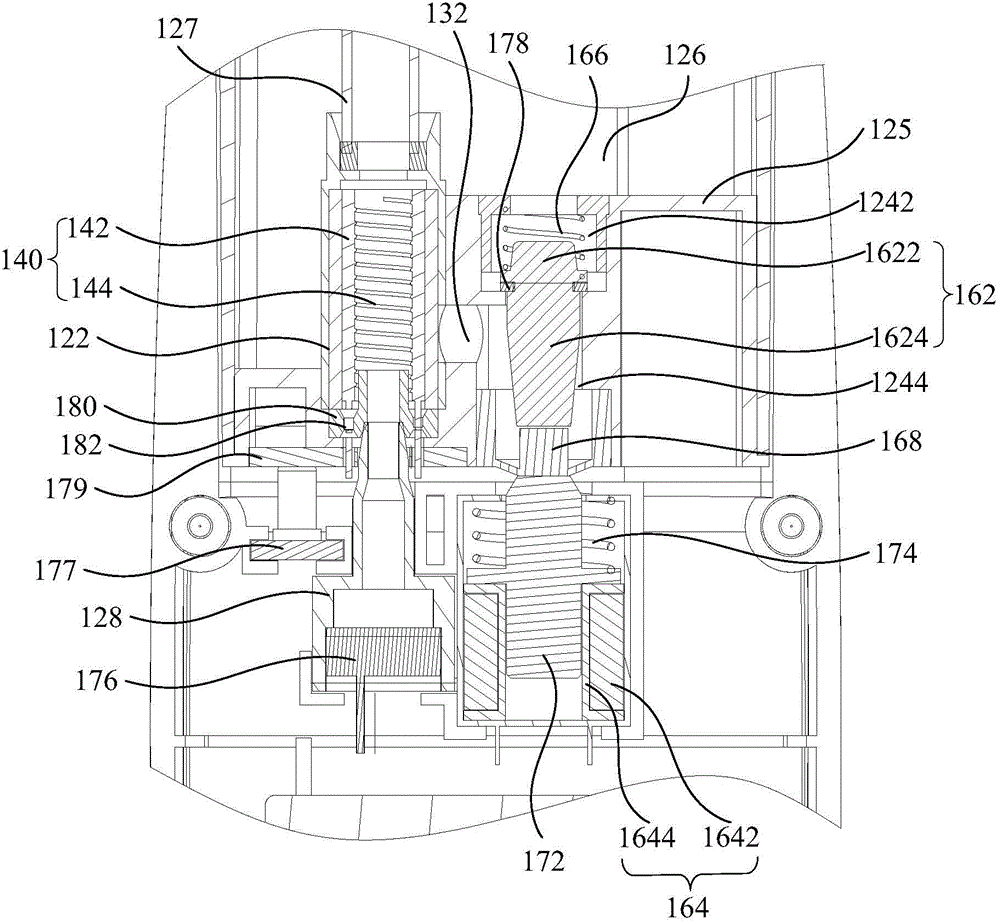

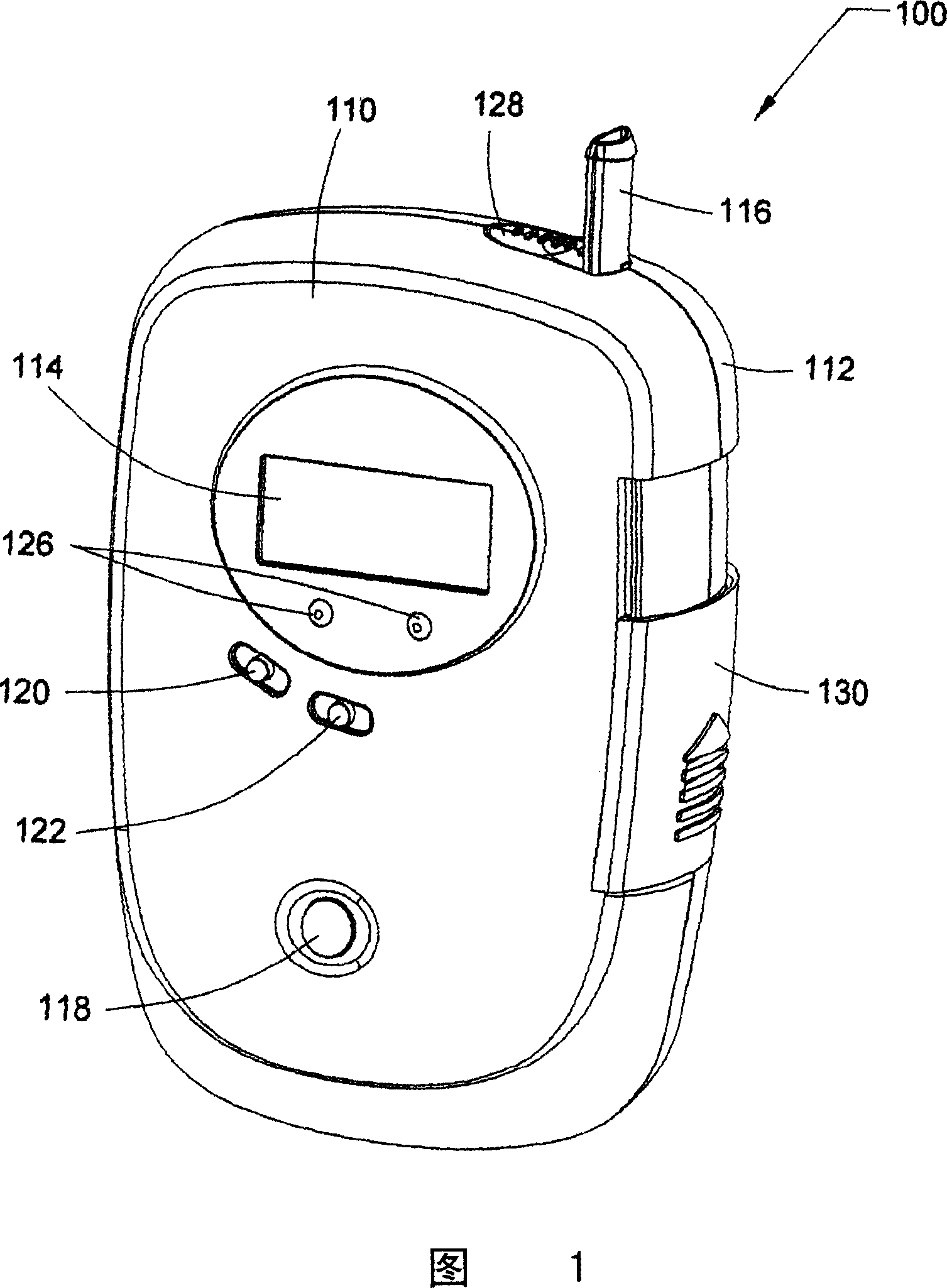

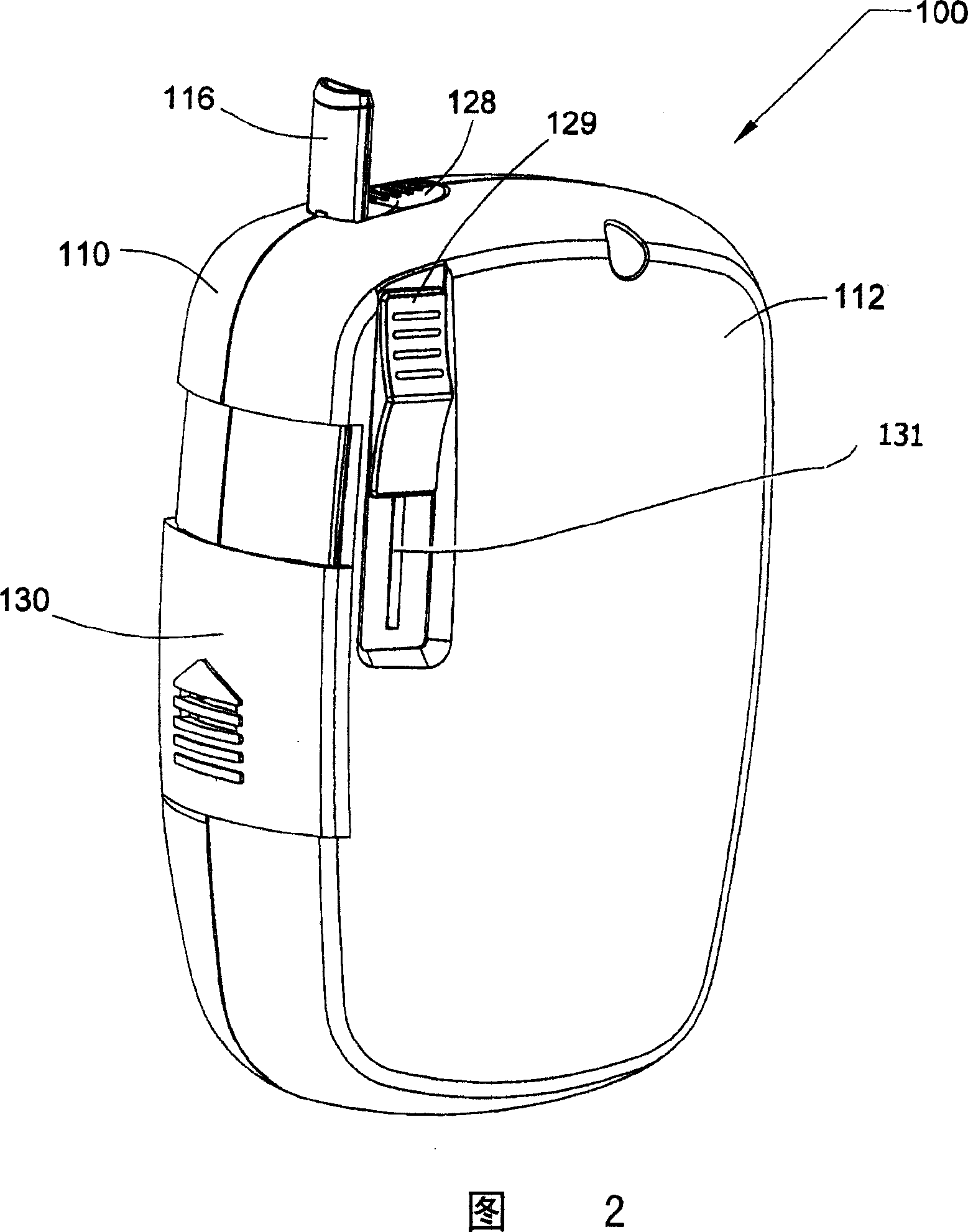

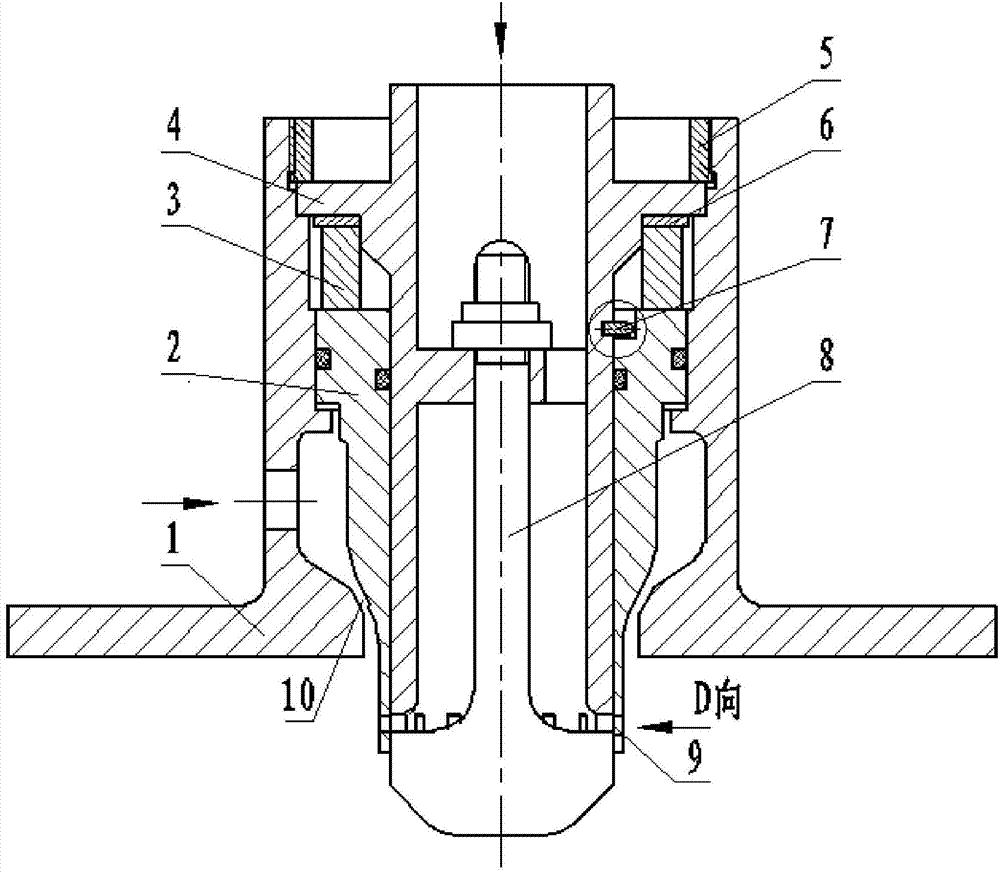

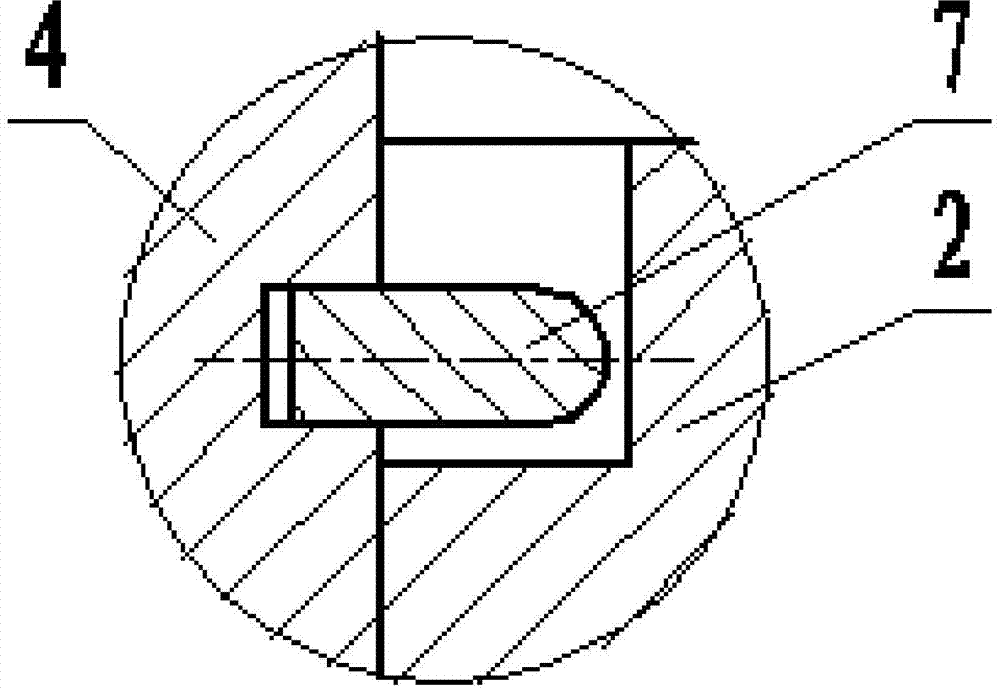

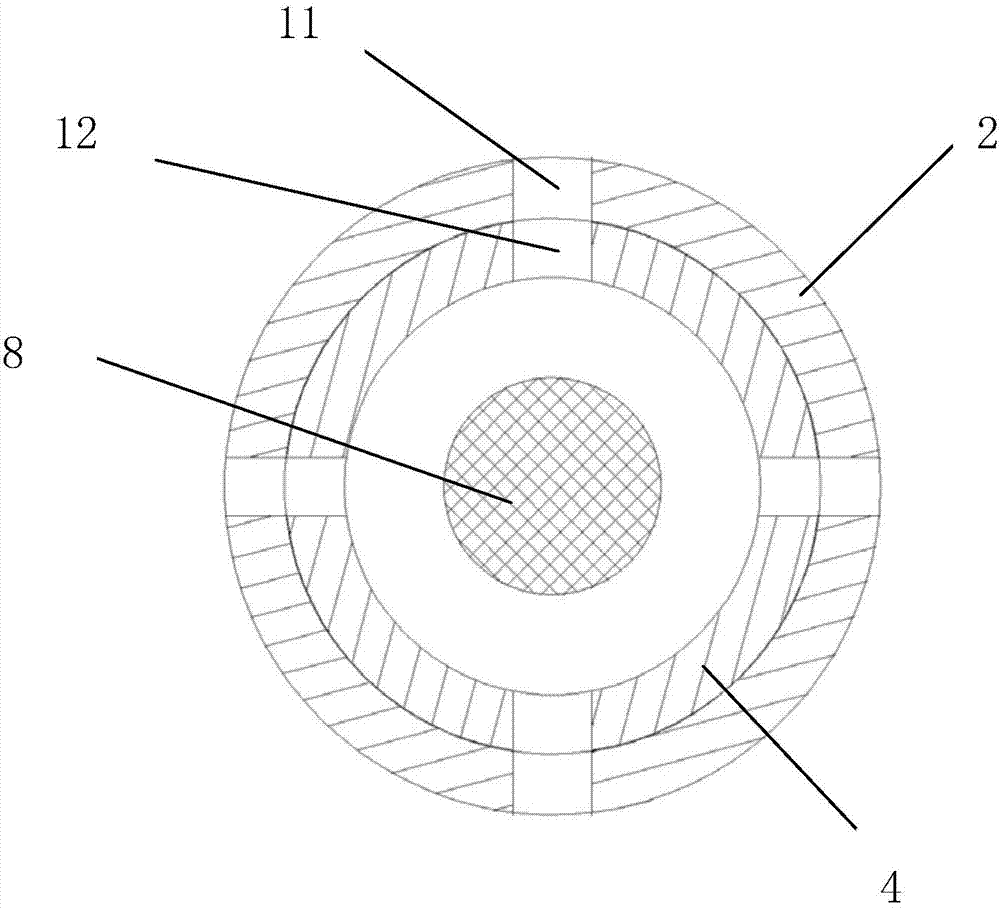

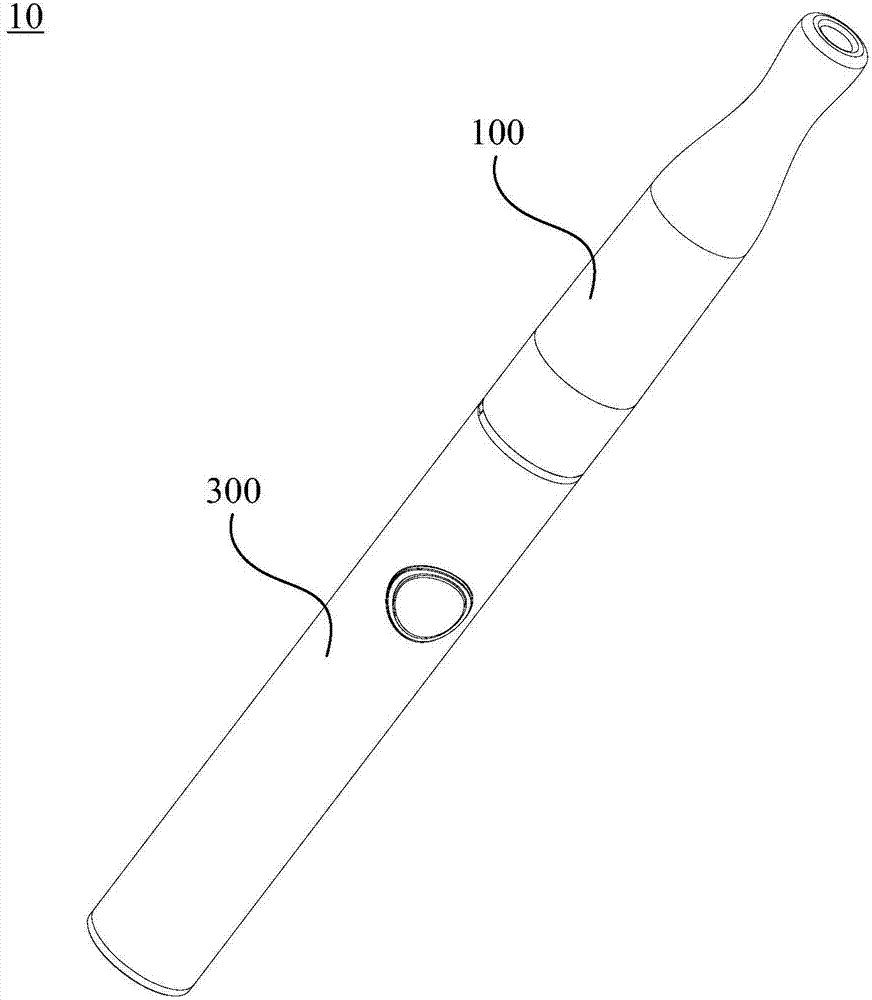

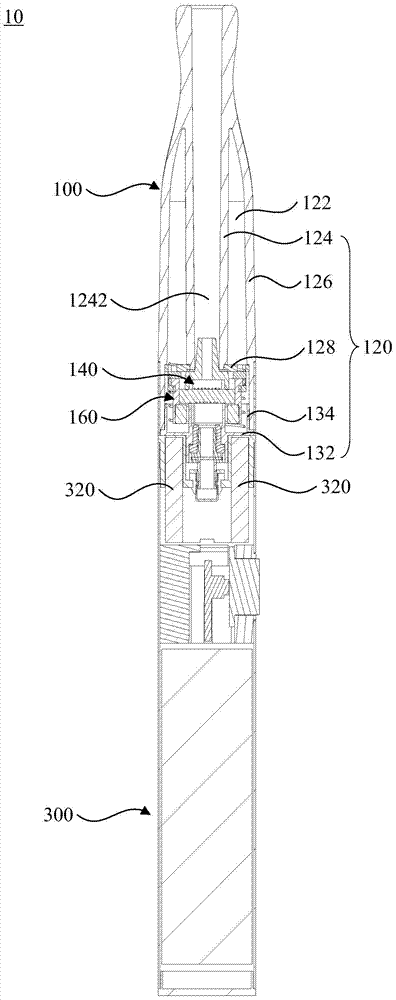

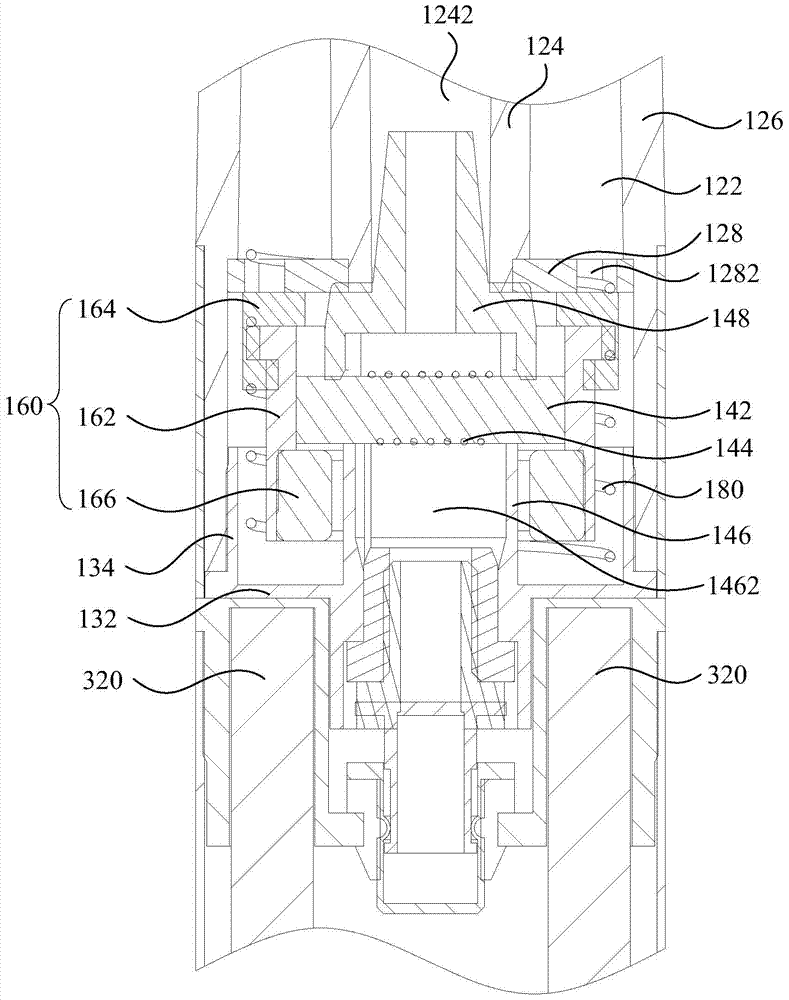

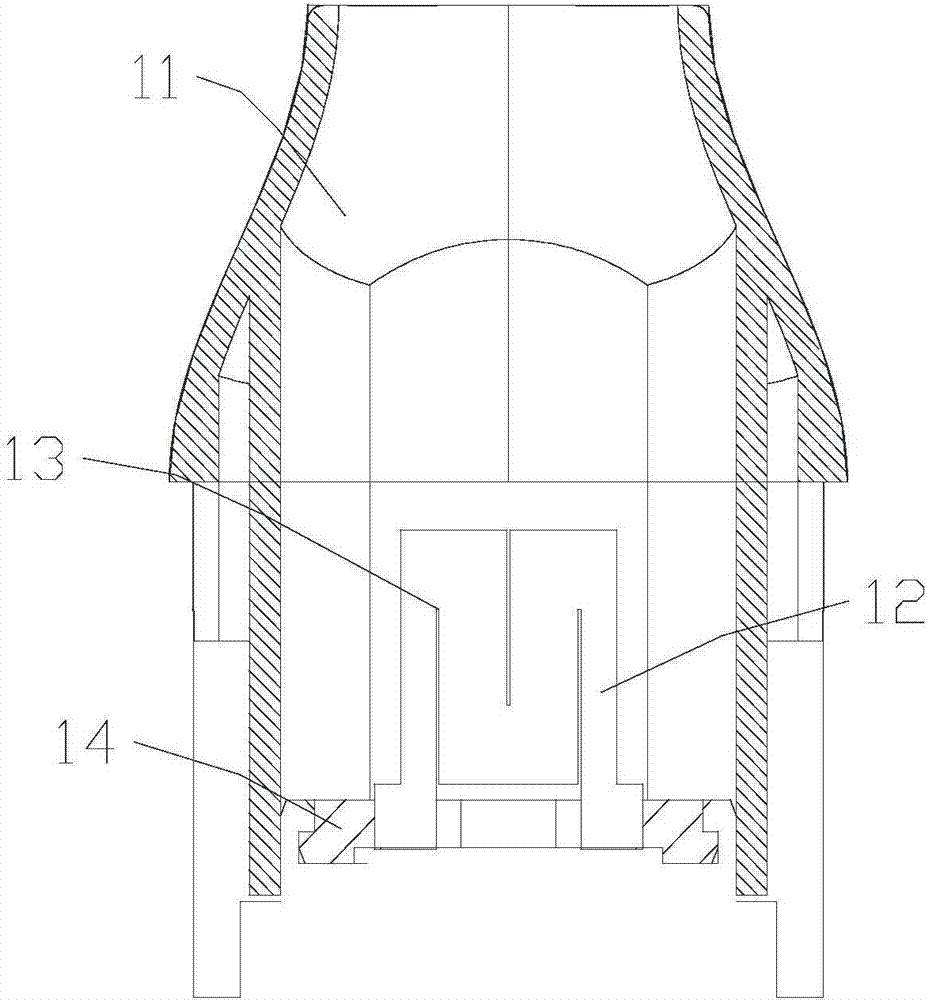

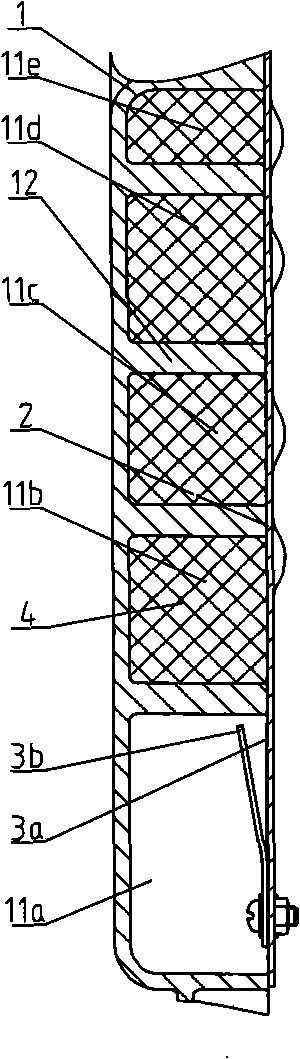

Inspirator and atomization component thereof

ActiveCN104544570APrevent volatilizationGuaranteed tasteTobacco devicesInhalatorsInspiratorElectronic cigarette

The invention relates to an inspirator and an atomization component thereof. The atomization component comprises a casing, an atomization element and a switching valve. An atomization chamber, a liquid guide channel and a liquid storage chamber for storing liquids are formed in the casing. The atomization chamber is communicated with the liquid guide channel which is communicated with the liquid storage chamber. The atomization element is arranged in the atomization chamber and is used for atomizing liquids. At least part of the switching valve is arranged in the liquid guide channel and is used for controlling on or off of the liquid guide channel. By means of the inspirator and the atomization component thereof, the switching valve is arranged in the liquid guide channel between the atomization chamber and the liquid storage chamber, and on or off of the liquid guide channel is controlled through the switching valve. When the inspirator is not used, the switching valve cuts off the liquid guide channel, the atomization chamber and the liquid storage chamber are sealed relatively, and accordingly, liquids in the liquid storage chamber are volatilized through the atomization element, and the taste of electronic cigarettes and the medical atomization inspirator effect cannot get worse for being put for a long time.

Owner:SHENZHEN SMOORE TECH LTD

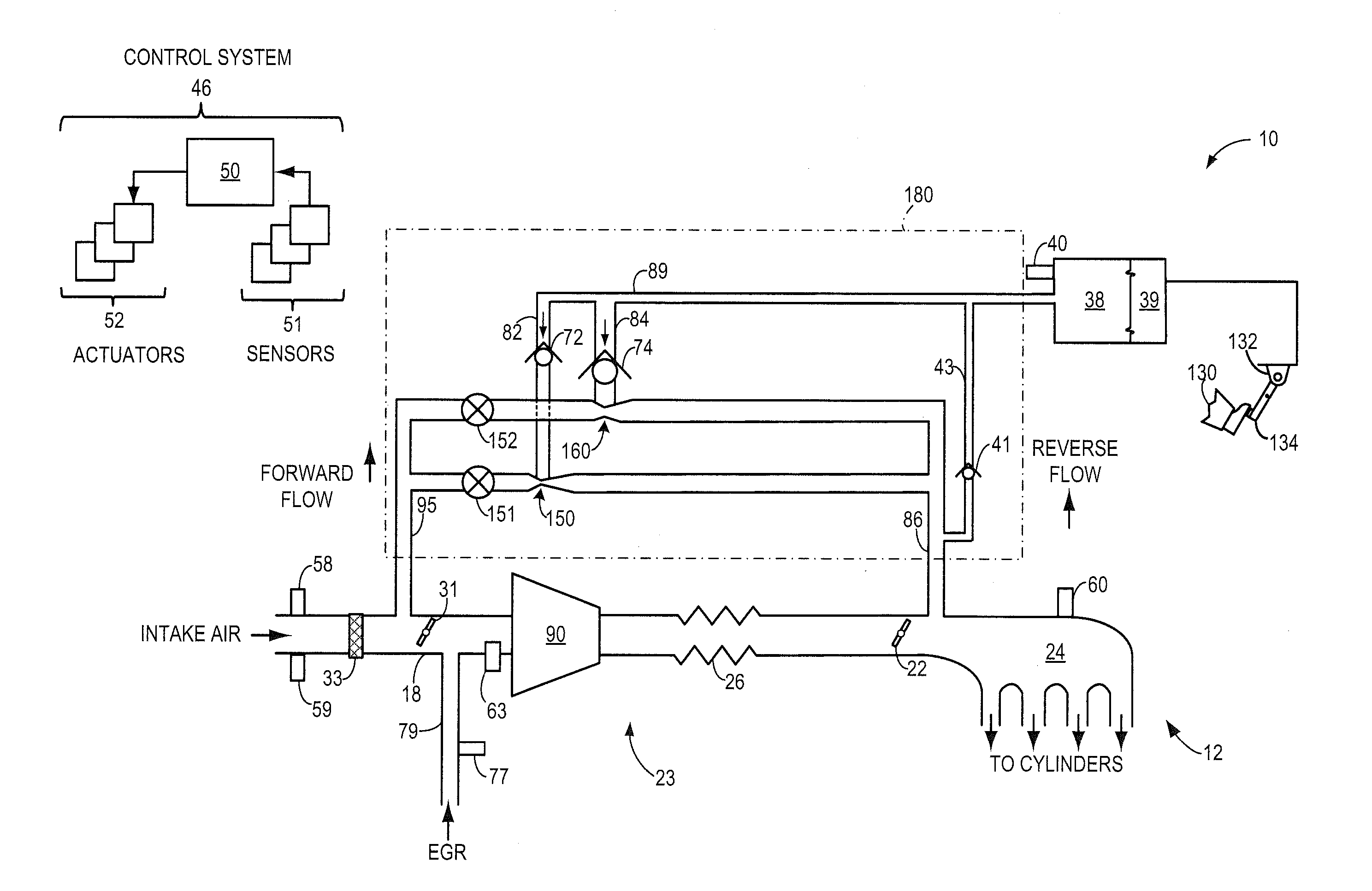

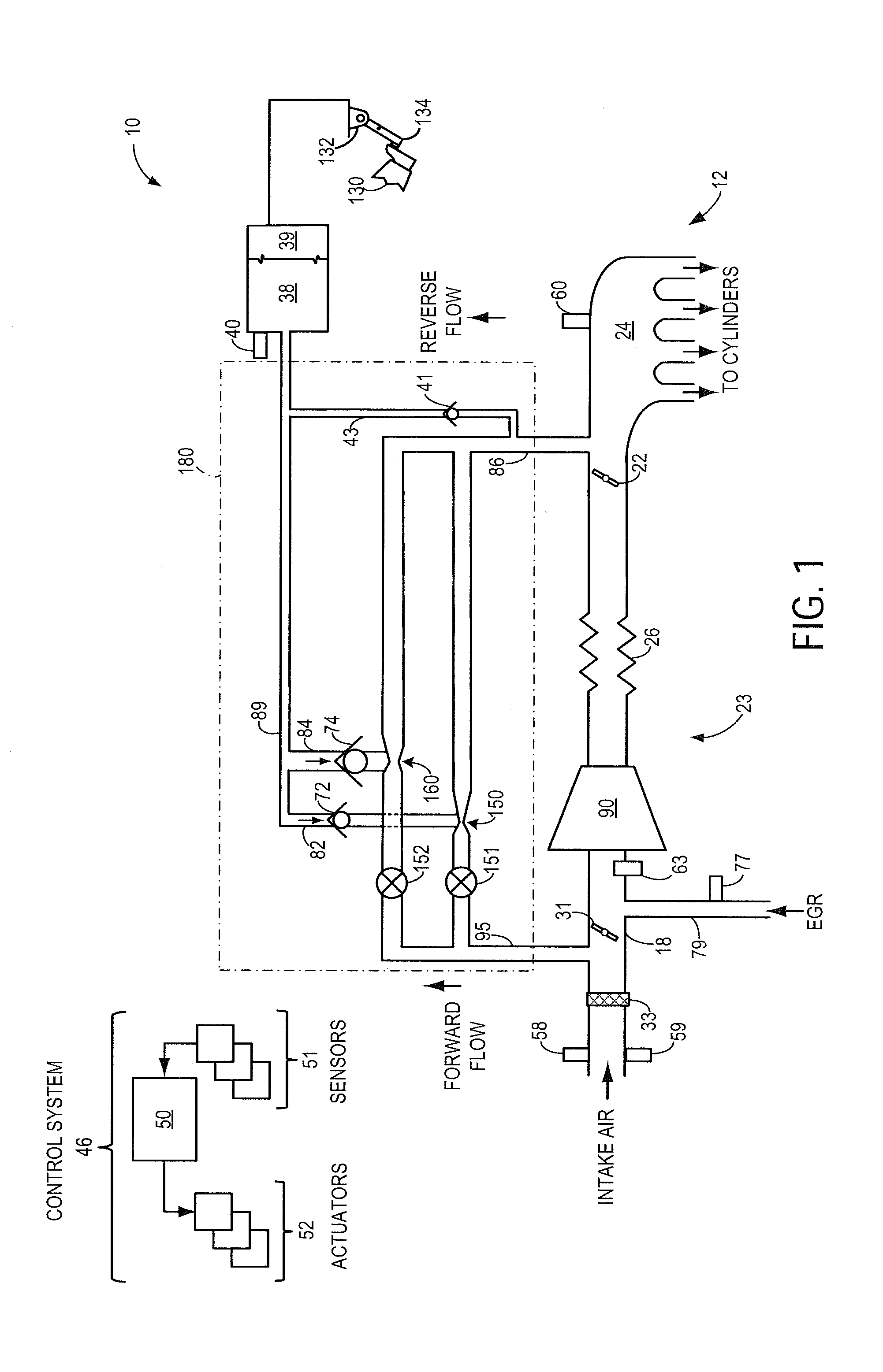

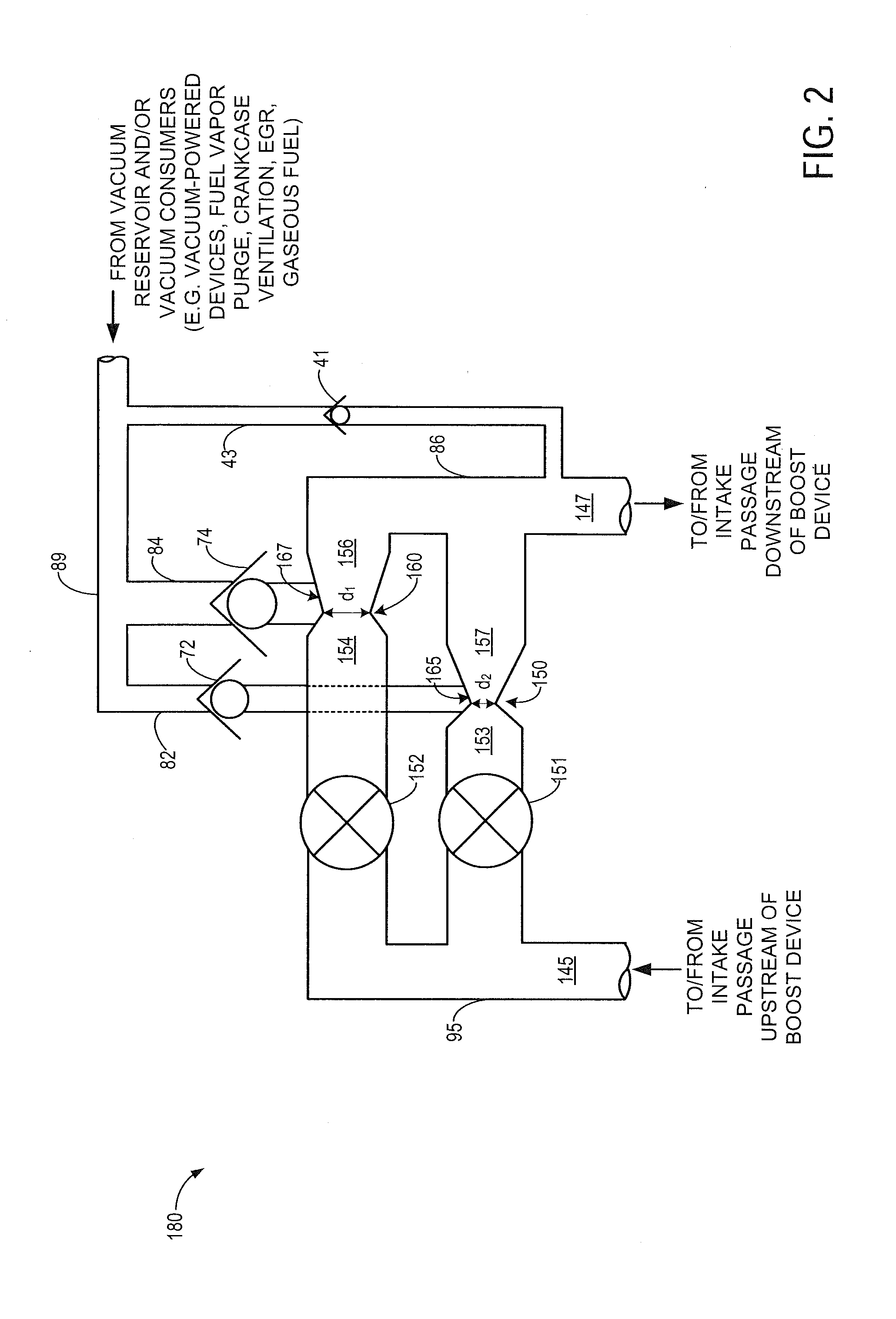

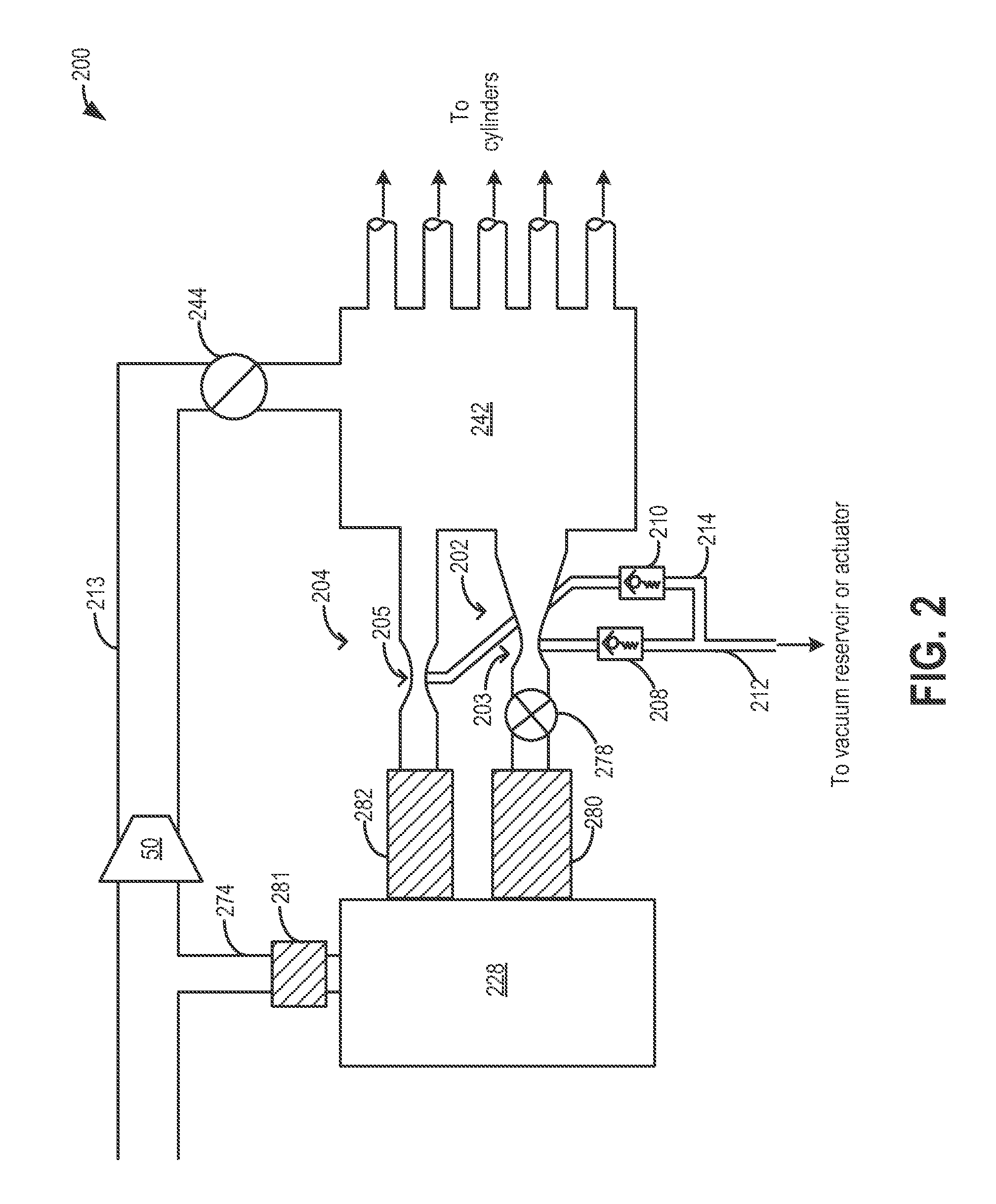

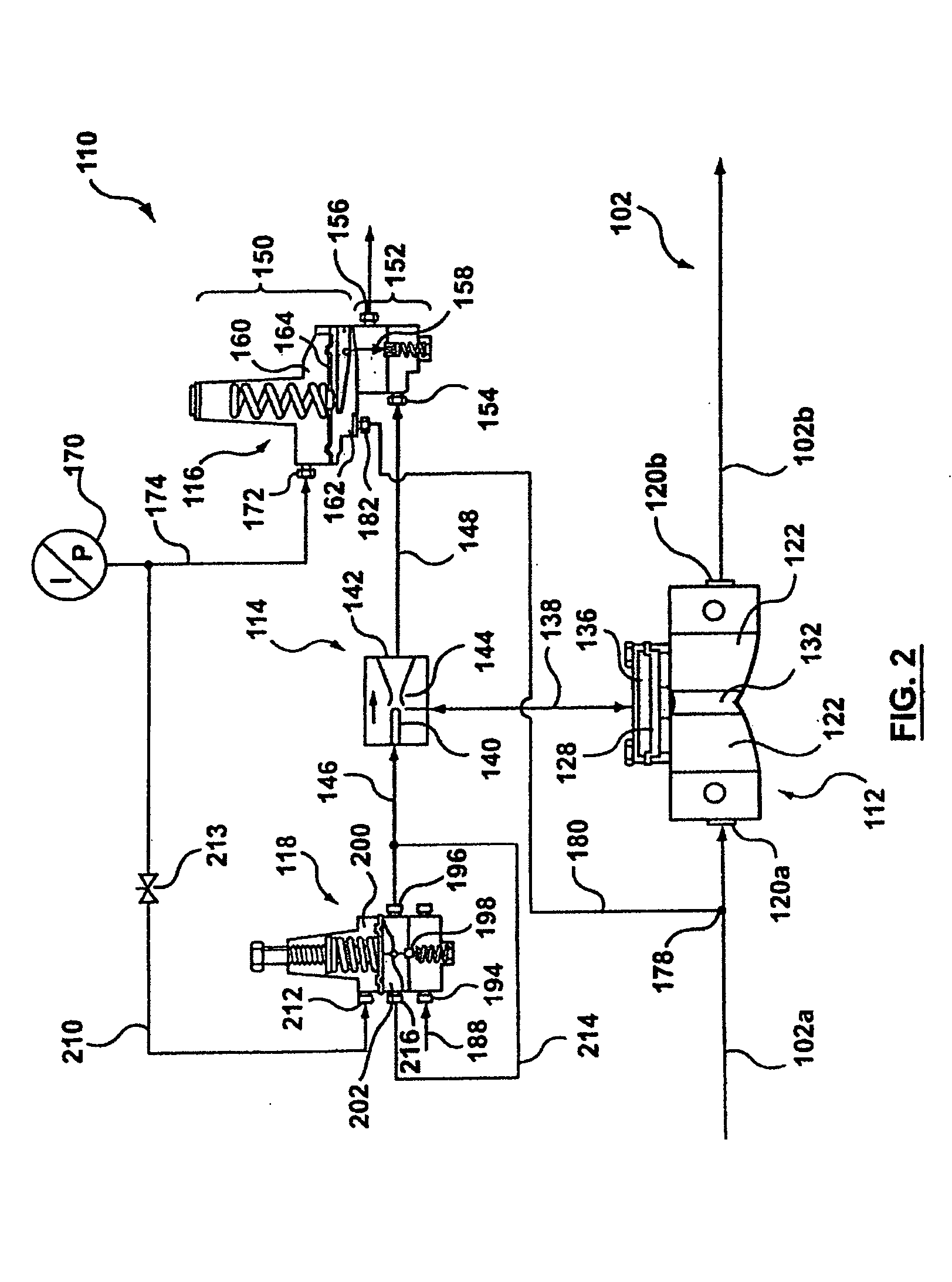

Parallel aspirator arrangement for vacuum generation and compressor bypass

InactiveUS20150083094A1Expand business scopePrevent objectionable audible noiseInternal combustion piston enginesCombustion-air/fuel-air treatmentInspiratorEngineering

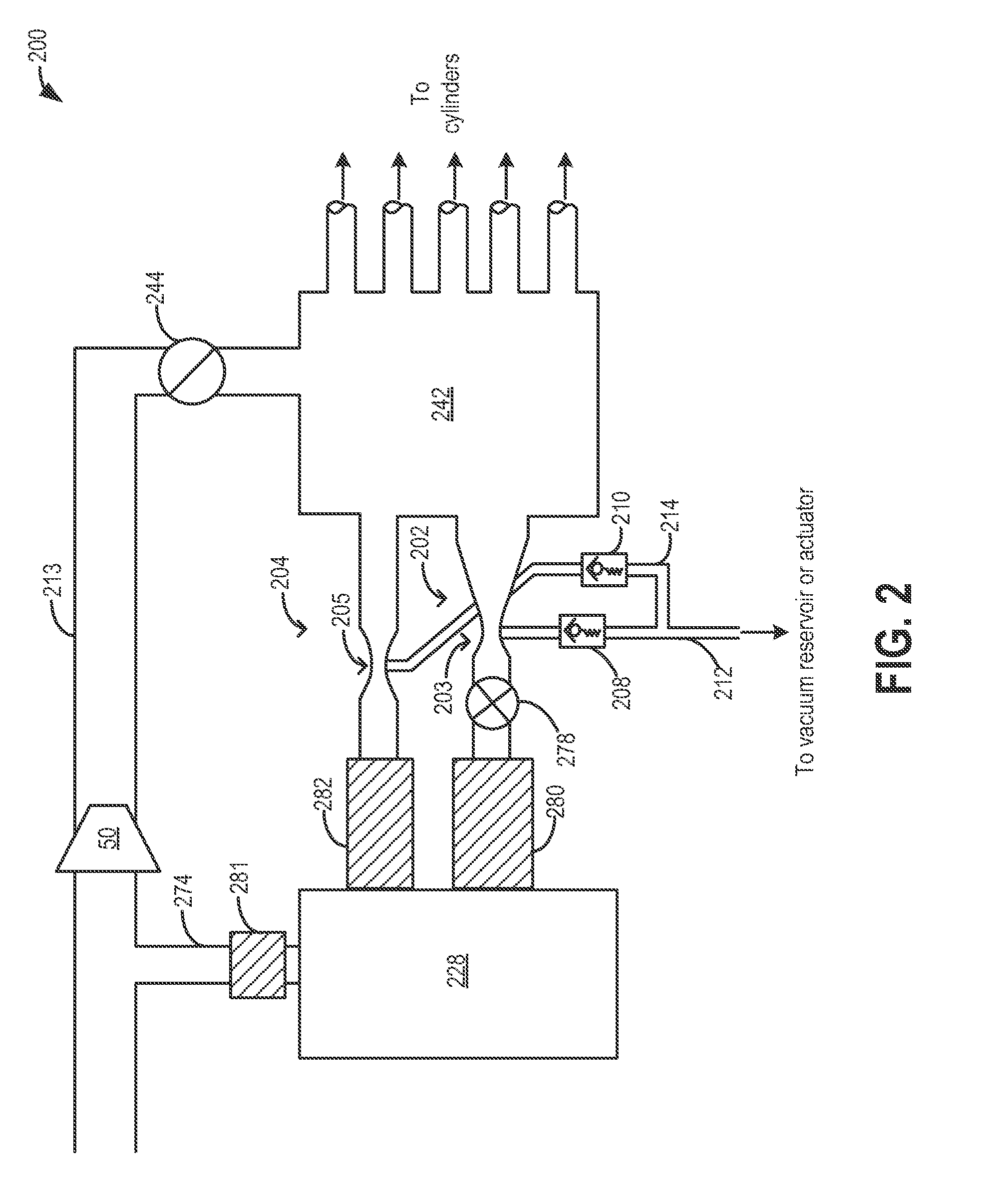

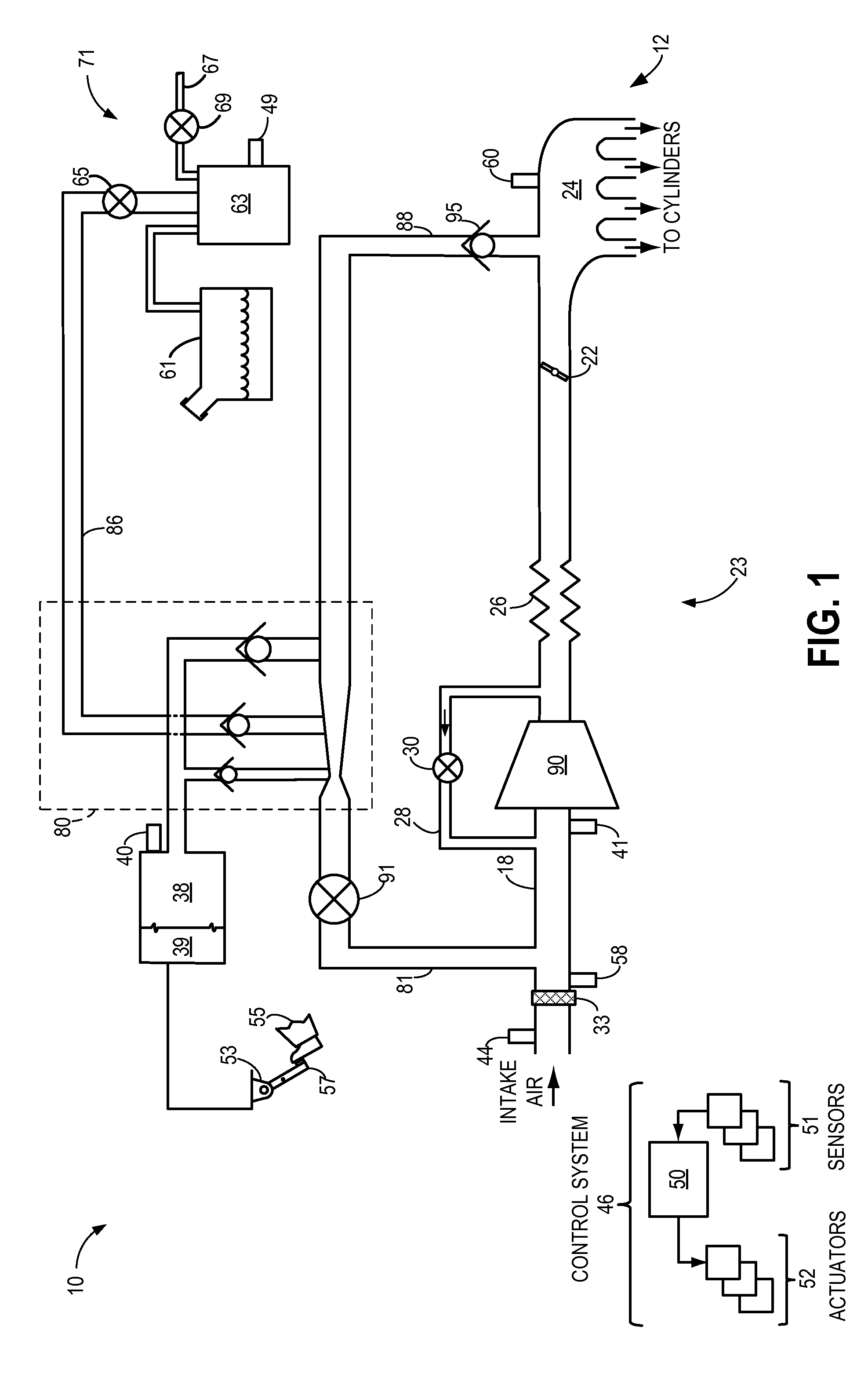

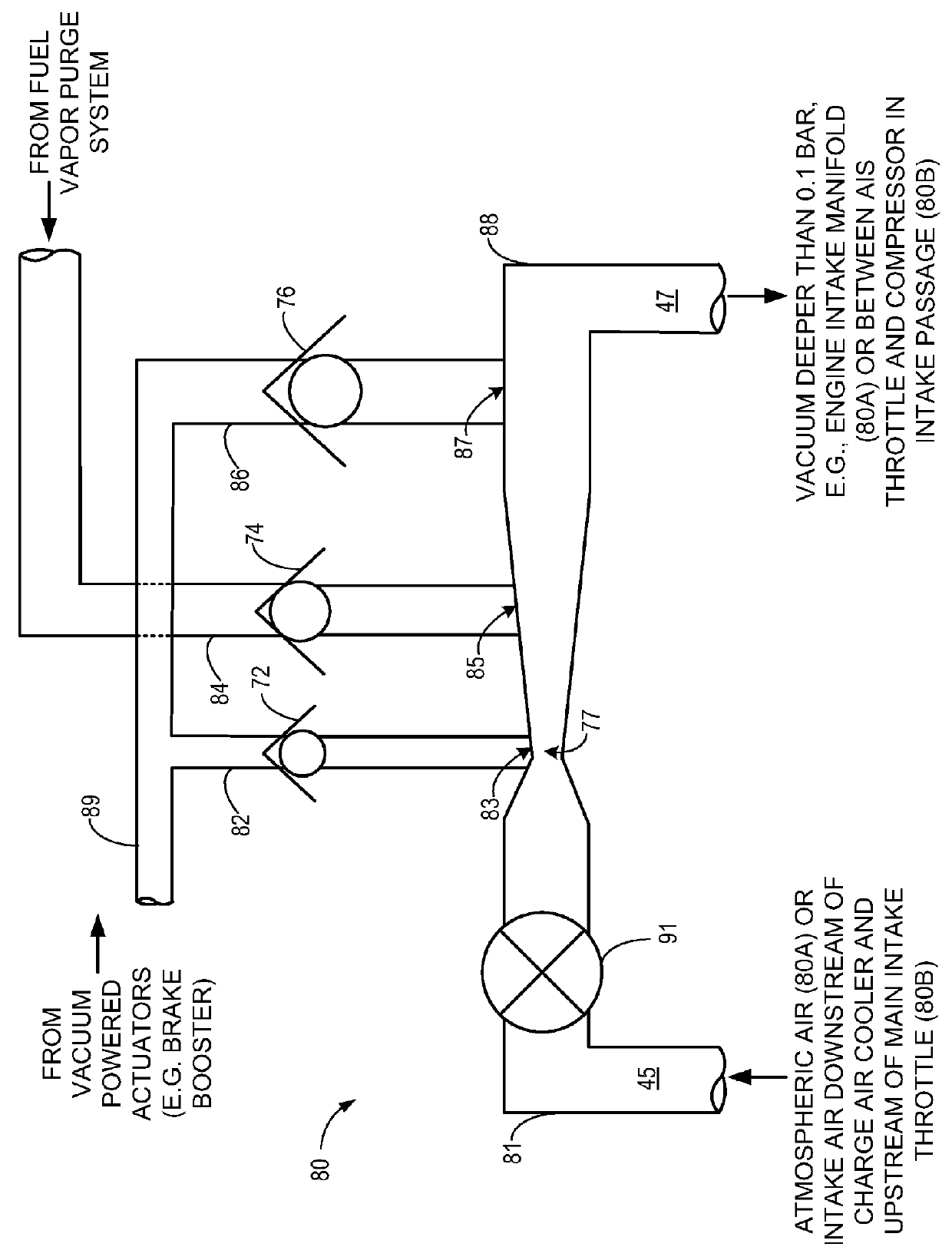

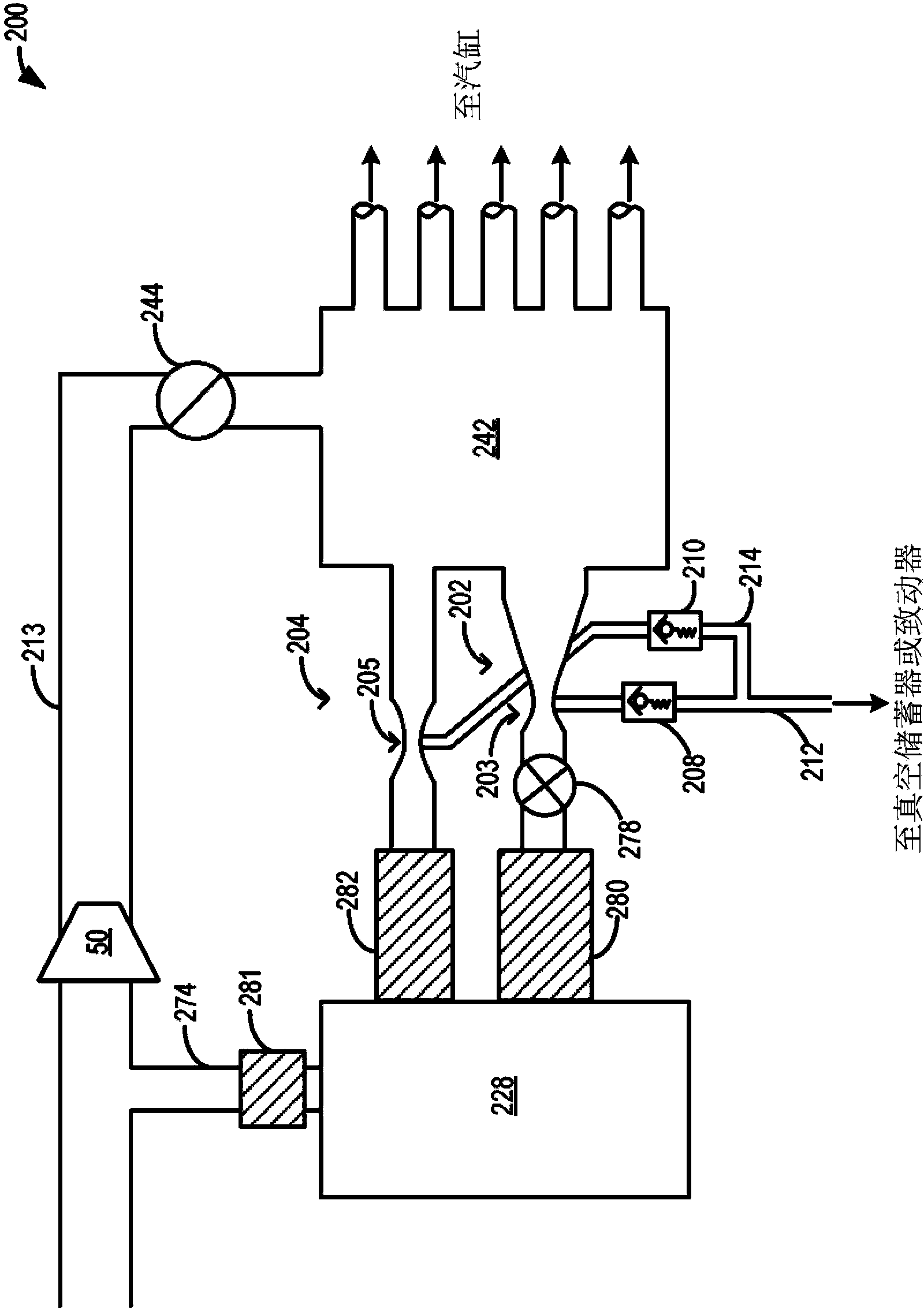

Methods and systems are provided for a parallel arrangement of at least two aspirators bypassing an intake compressor in an engine system, the aspirator arrangement including an aspirator shut-off valve arranged in series with each aspirator. The aspirator shut-off valves may be controlled based on engine vacuum needs as well as based on intake manifold pressure, during non-boost conditions, and compressor surge, during boost conditions. For example, during boost conditions, the aspirator shut-off valves may be controlled to enable a selectable discrete compressor recirculation flow rate, whereas during non-boost conditions the aspirator shut-off valves may be controlled to enable a selectable, discrete level of vacuum generation for use by various engine vacuum consumers.

Owner:FORD GLOBAL TECH LLC

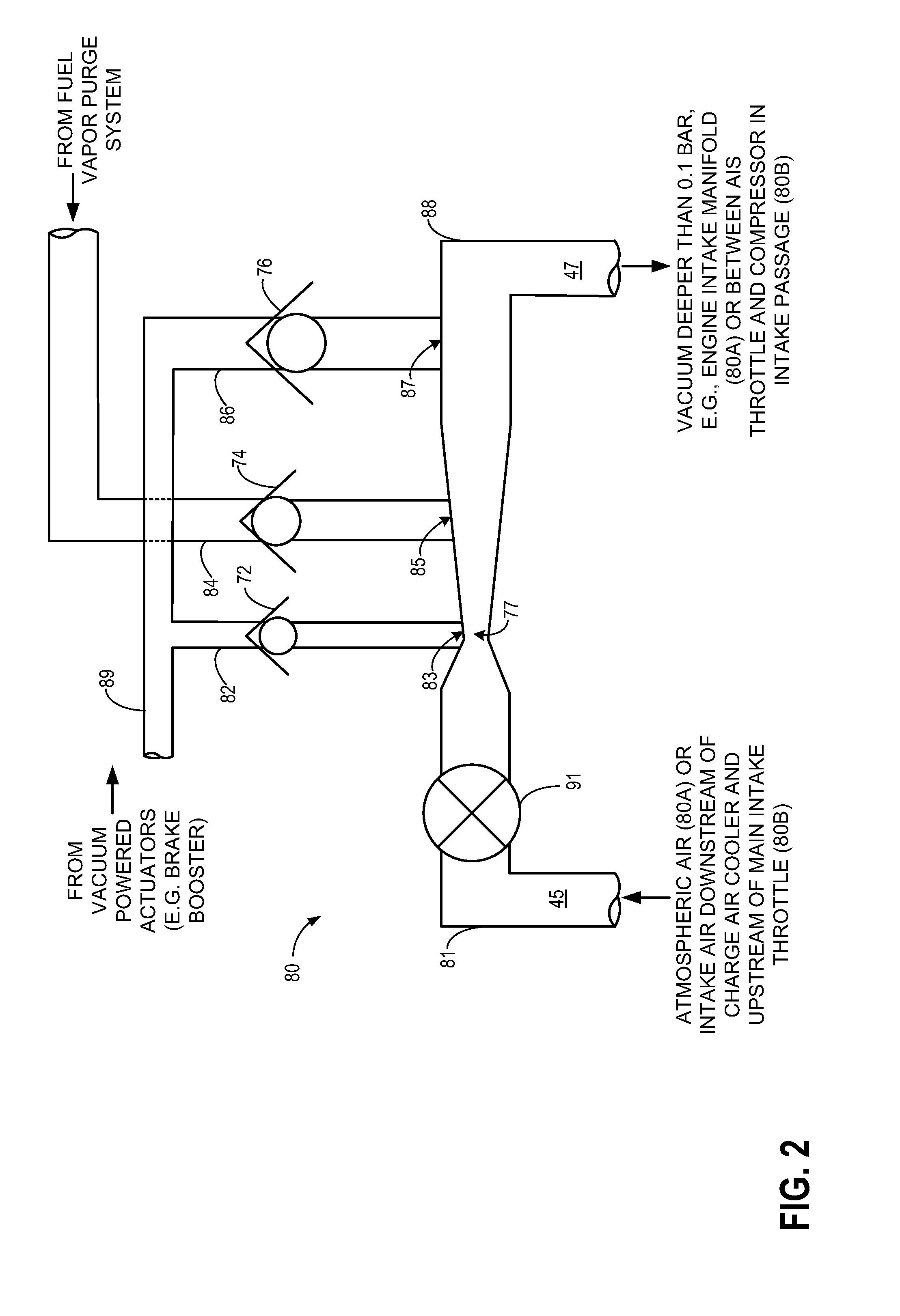

Aspirator motive flow control for vacuum generation and compressor bypass

ActiveUS20150114350A1Expand business scopePrevent objectionable audible noiseNon-fuel substance addition to fuelInternal combustion piston enginesInspiratorEngineering

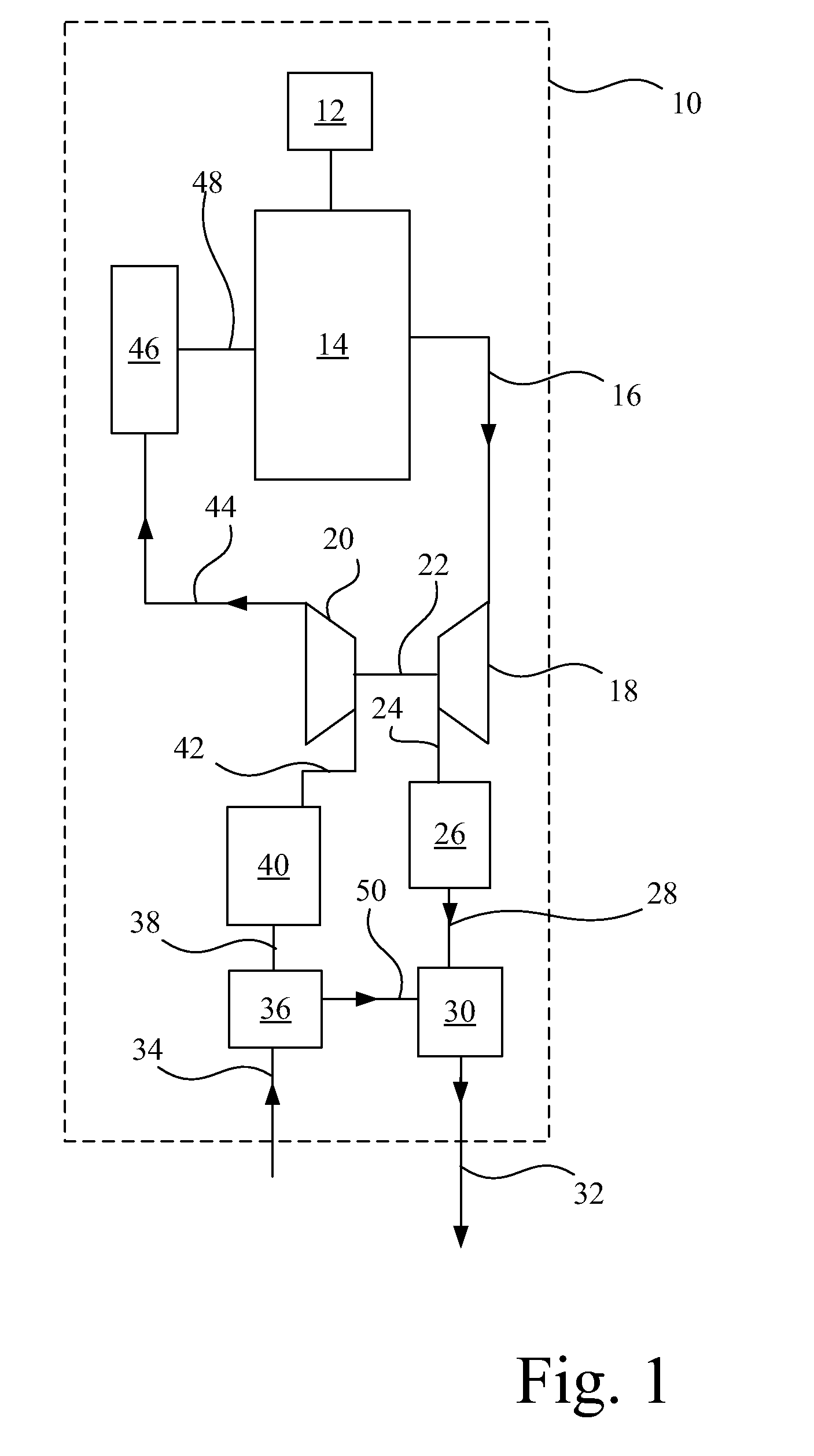

Systems and methods are provided for engine systems including a first multiple tap aspirator with a motive inlet coupled to an intake upstream of an air induction system throttle and a mixed flow outlet coupled to an intake manifold, and a second multiple tap aspirator with a motive inlet coupled to the intake upstream of a main throttle and a mixed flow outlet coupled to the intake downstream of the air induction system throttle. During non-boost conditions, intake air may be selectably diverted around a compressor and through the first and / or second aspirator based on desired vacuum generation. During boost conditions, the first and second aspirators may function as compressor bypass valves, and intake air may be selectably directed from downstream of the compressor to upstream of the compressor via the first and / or second aspirator based on a desired compressor bypass flow.

Owner:FORD GLOBAL TECH LLC

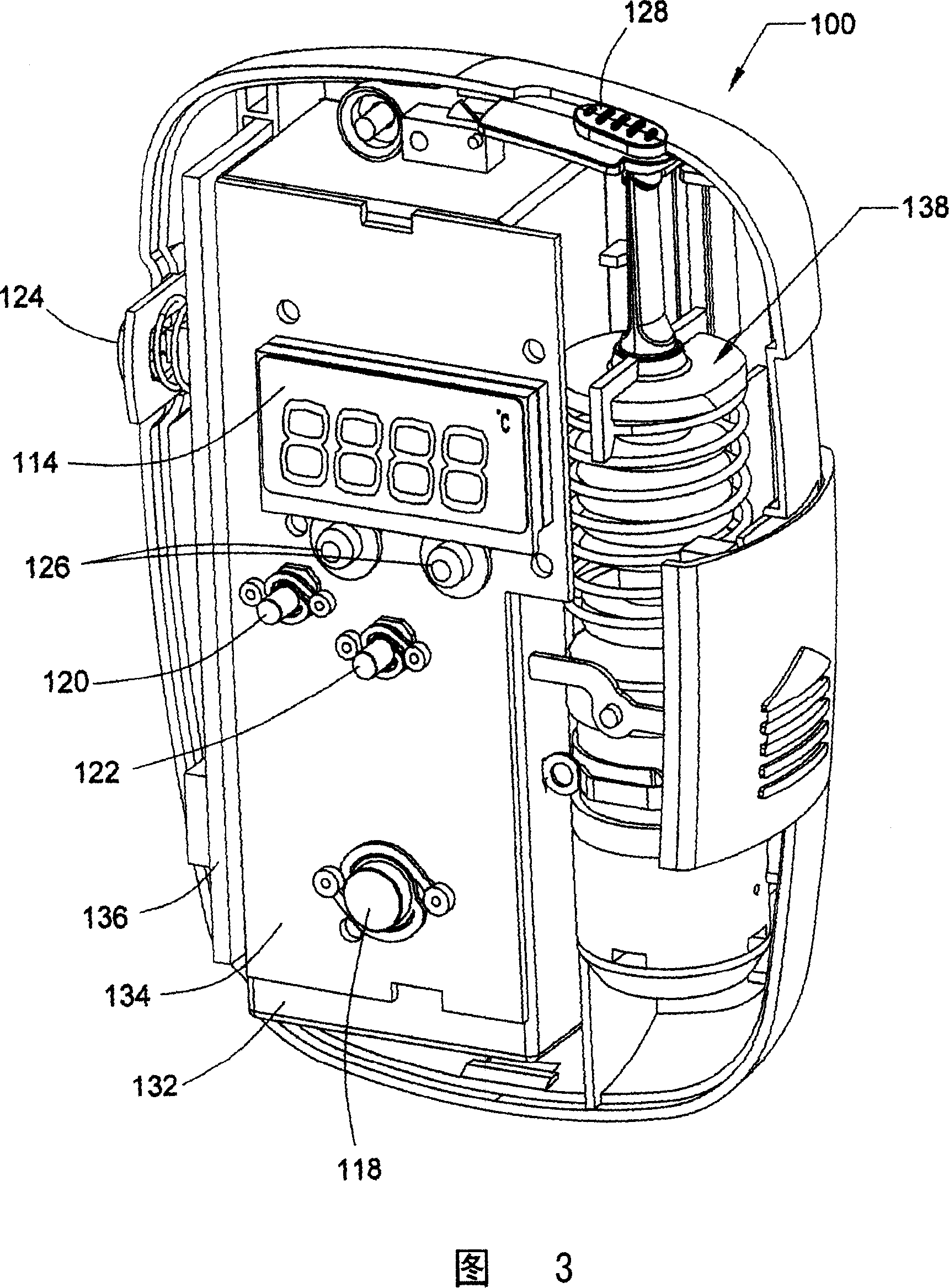

Portable minitype distillation inspirator and control method thereof

The invention discloses a portable microsize distilling inhalator and controlling method, which comprises the following parts: case, volatile element group in the case with sucker, heating element, heating chamber between the sucker and heating element, control device to control the operation of the heating element. The controlling method comprises the following steps: designing the temperature of heating chamber higher than the preset temperature; locking the heating chamber lid on the sealing position of the case; stopping the operation of heating element when the heating chamber reaches the first preset temperature or when the heating element reaches the second preset temperature. The invention has smart appearance to carry and use conveniently, which improves the security and reliability effectively.

Owner:王志群

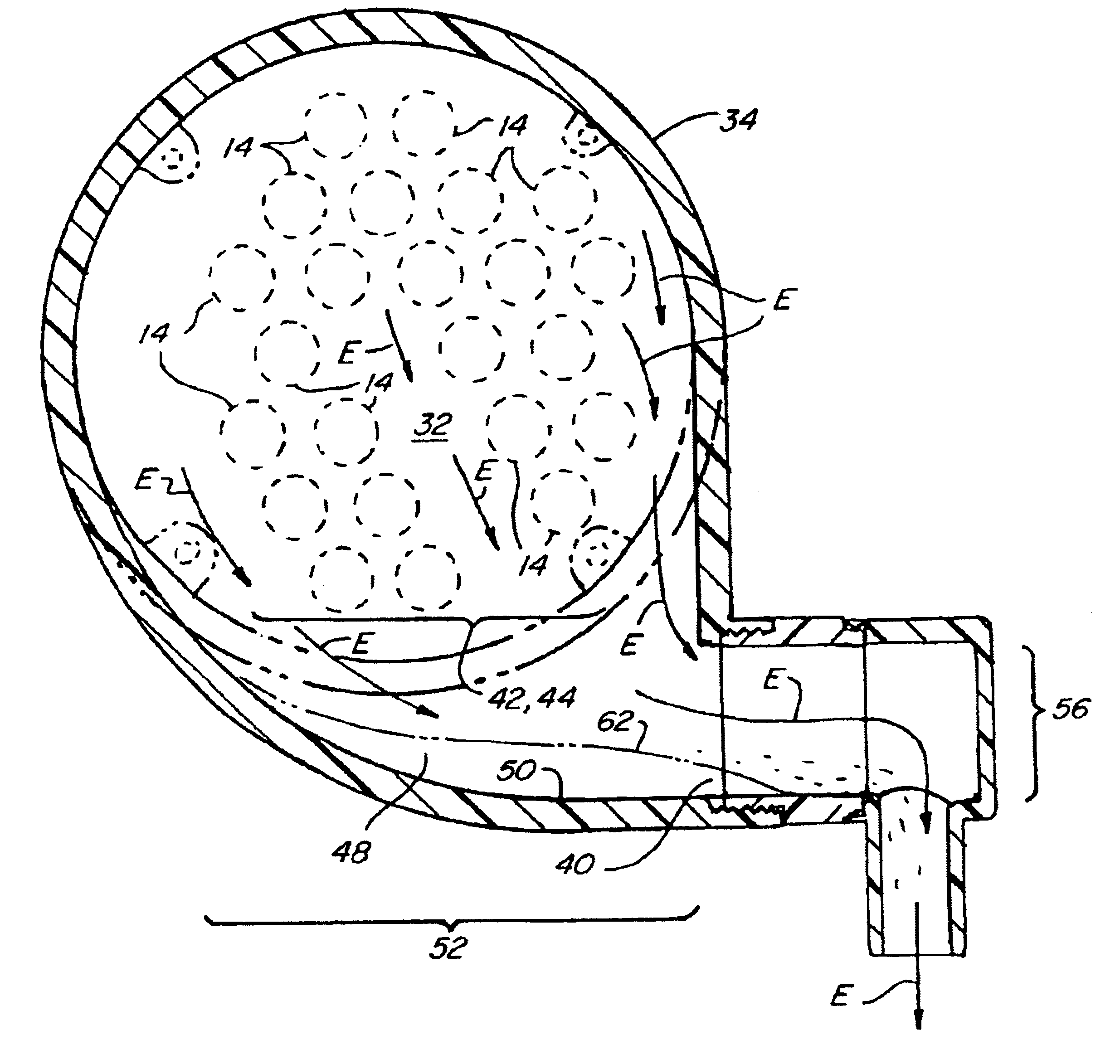

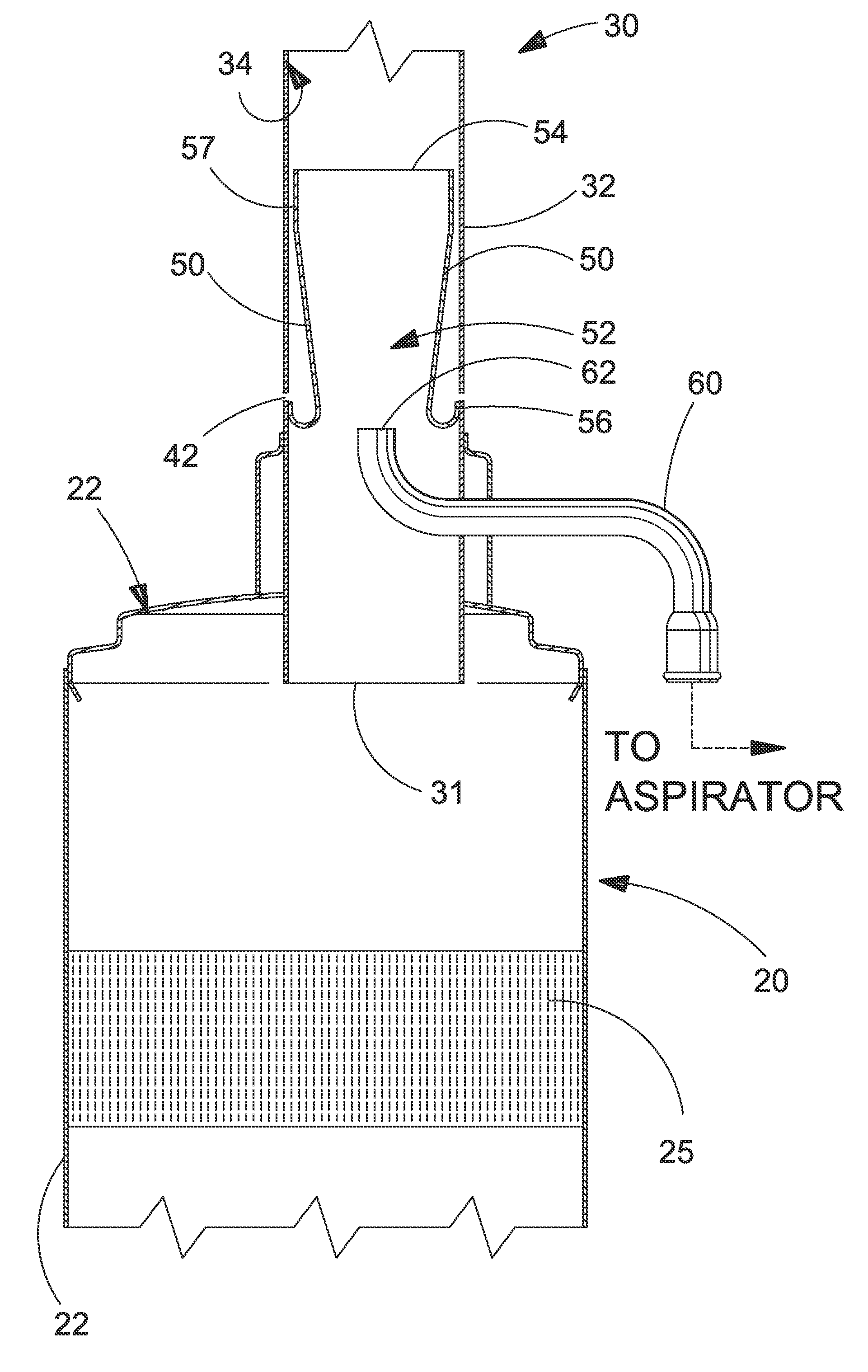

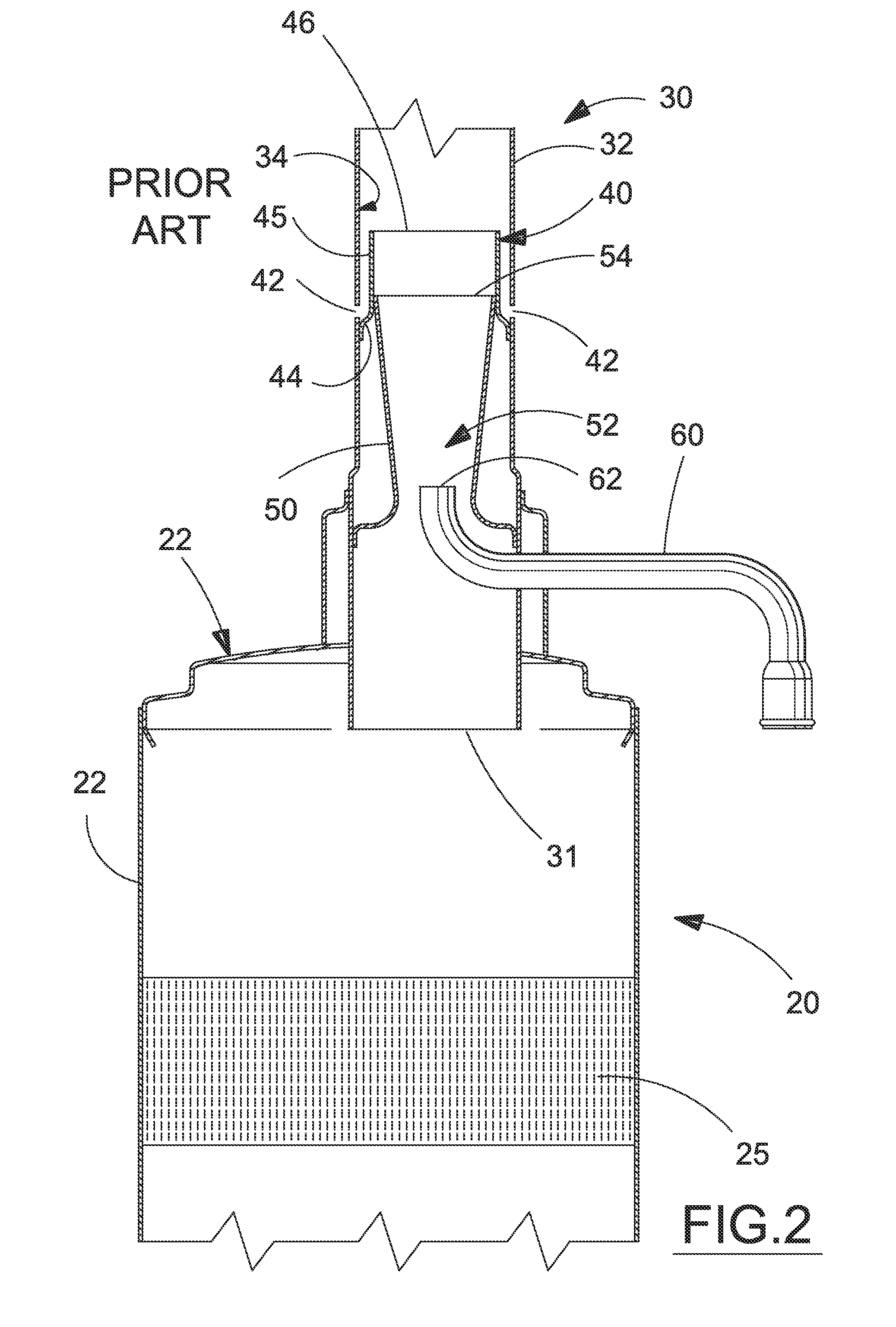

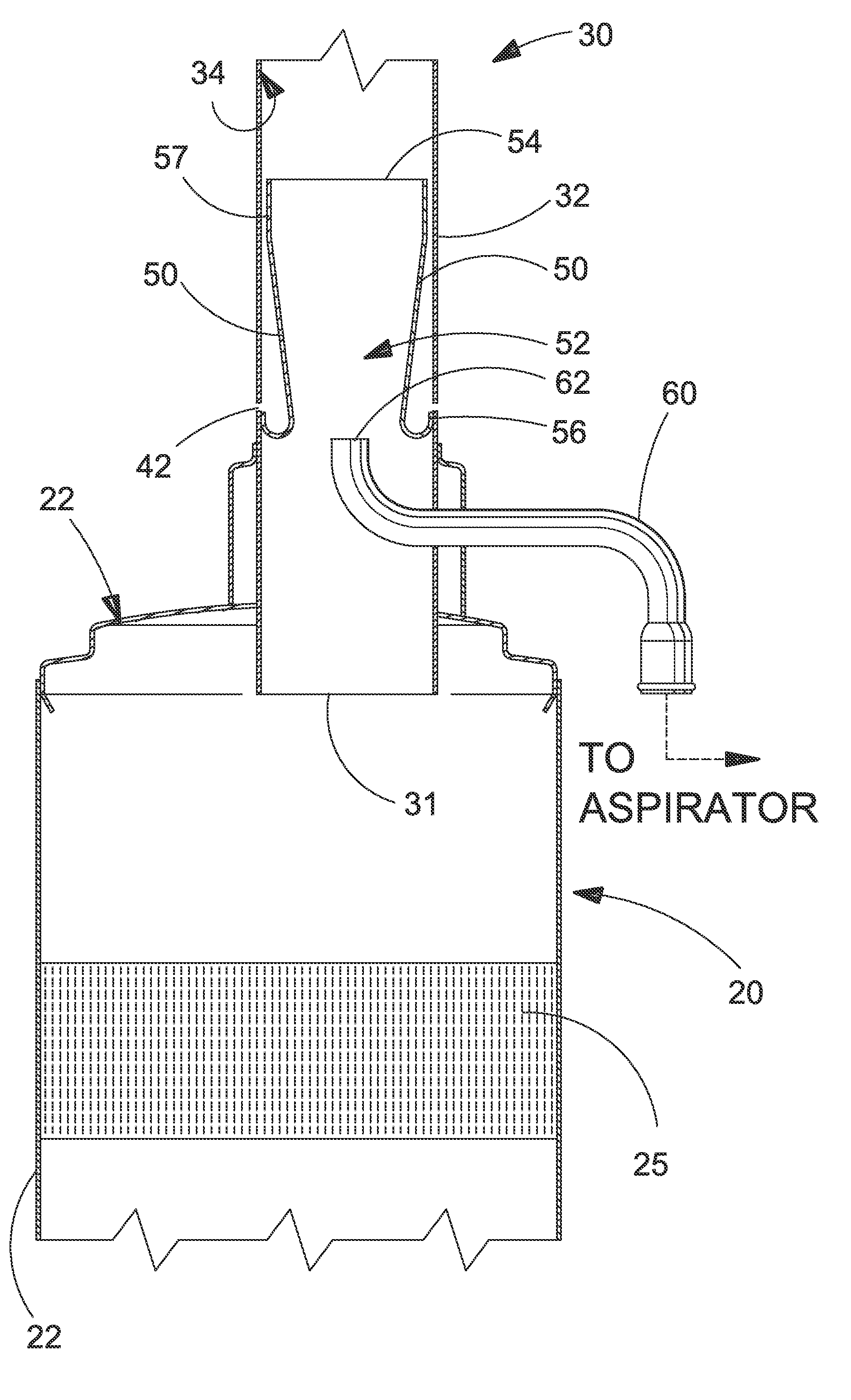

Intake air pre-cleaner with aspirator port chamber for collecting and holding particles for later aspiration

InactiveUS7004987B2Avoid cloggingIncrease intervalHuman health protectionCombination devicesInspiratorParticulates

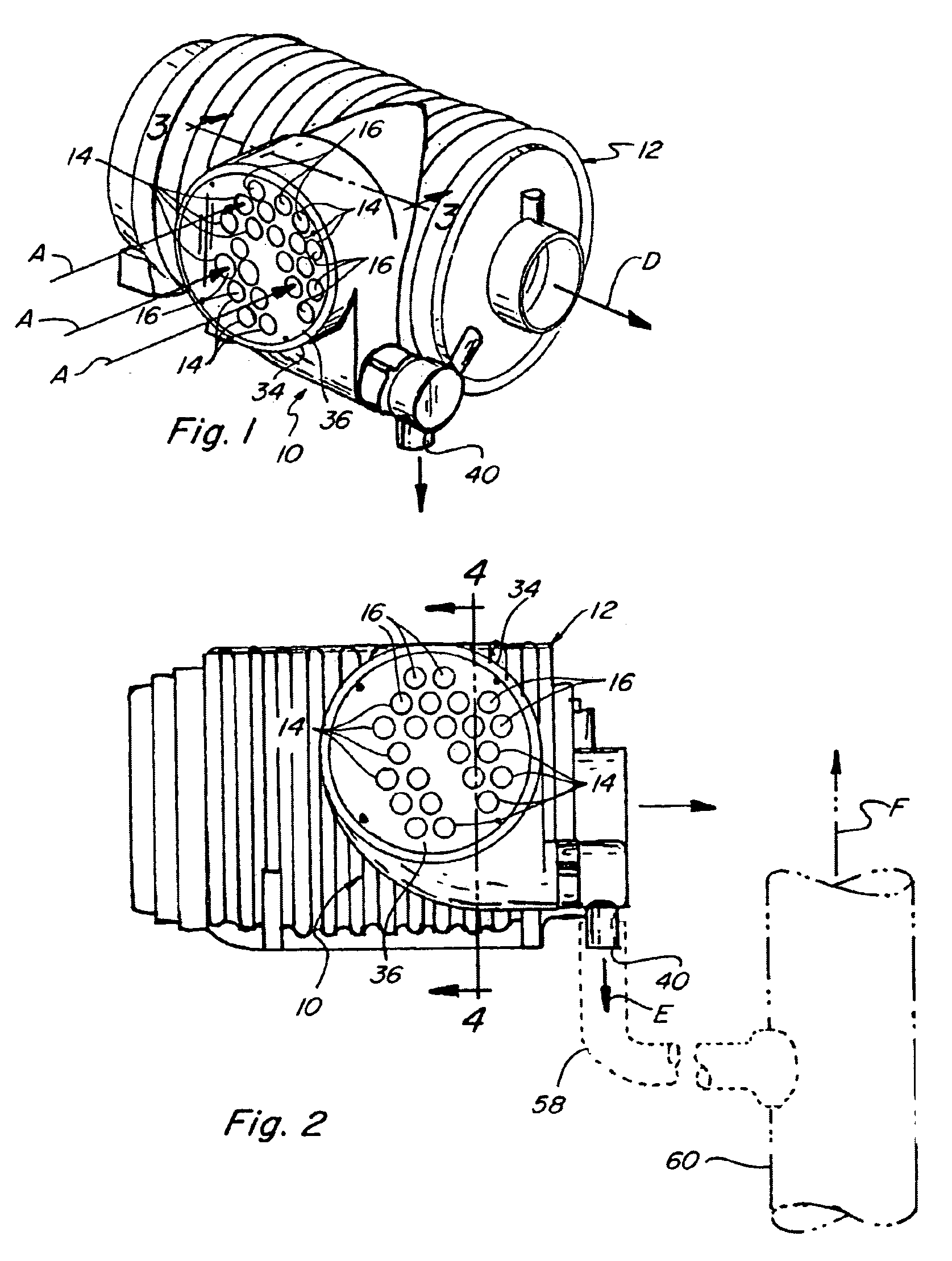

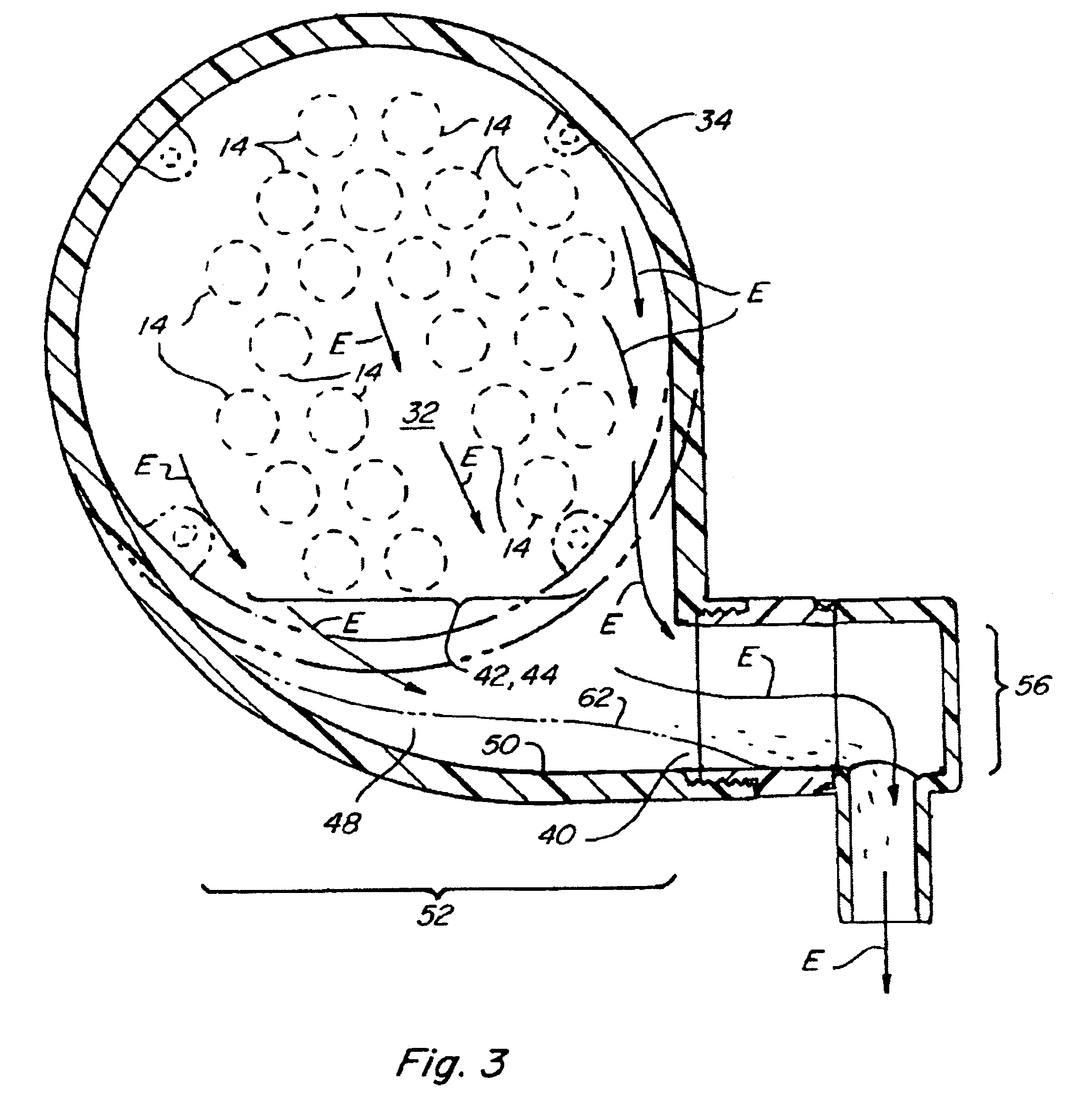

A pre-cleaner for an air induction system of an internal combustion engine including a housing enclosing an upper chamber and an aspirator port chamber, the upper chamber containing a plurality of particulate separator tubes for removing particles from air flowing through the tubes en route to the engine. The aspirator port chamber is located beneath and is upwardly open to the particulate outlets such that discharged particles can fall or flow from the tubes into the aspirator port chamber, the aspirator port chamber containing a large capacity upwardly facing particle collecting surface or trough for receiving the particles, and the housing including a generally horizontally facing aspirator port connecting to the aspirator port chamber adjacent to the particle collecting surface or trough, the aspirator port having a predetermined vertical extent and the particle collecting surface or trough having a horizontal extent in a direction substantially directly facing or aligned with the aspirator port sufficiently greater than the vertical extent of the aspirator port such that during periods when the particles are not aspirated into the aspirator port the particles can collect and settle on the particle collecting surface or trough for later aspiration when conditions improve.

Owner:CNH IND AMERICA LLC +1

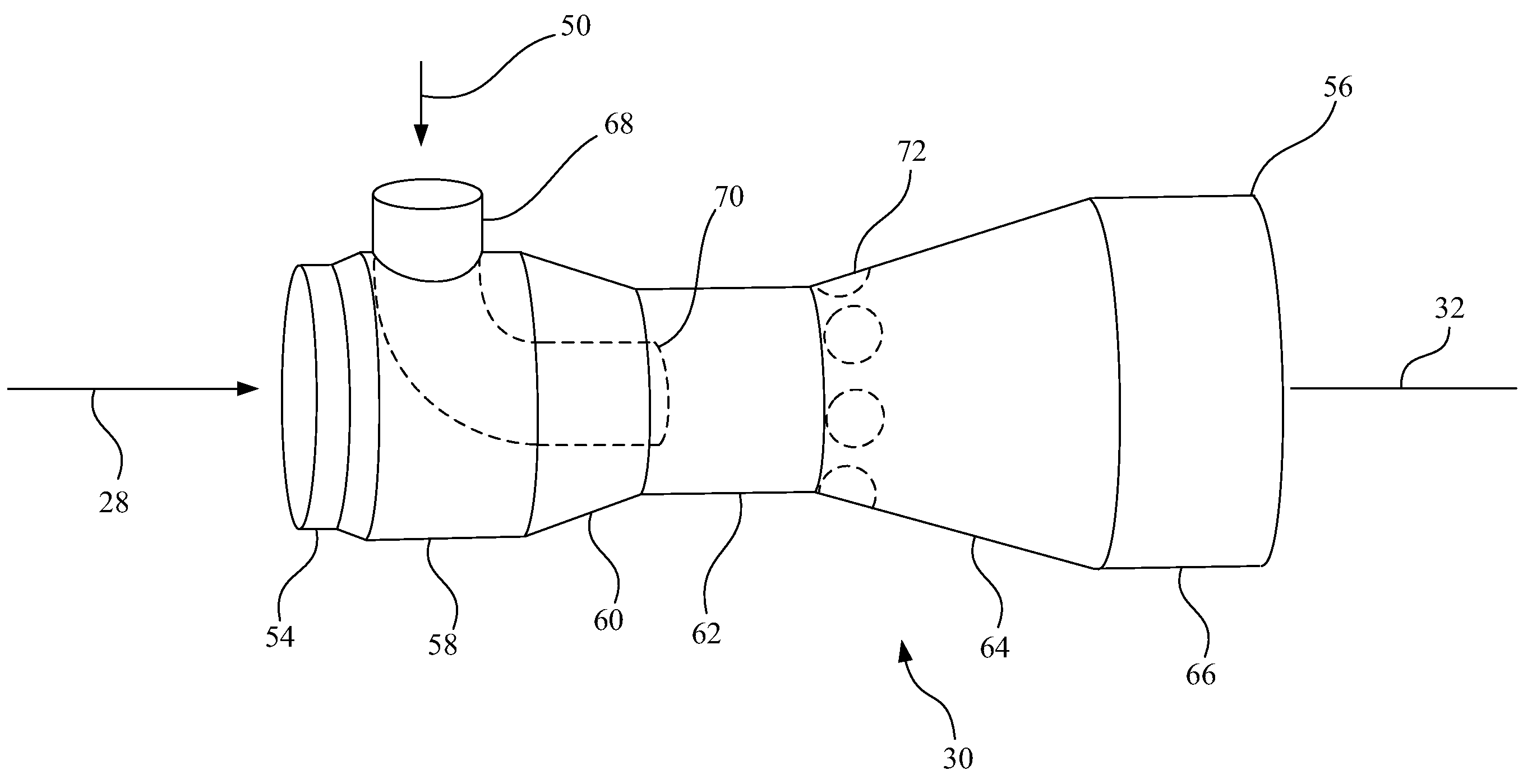

Multiple tap aspirator

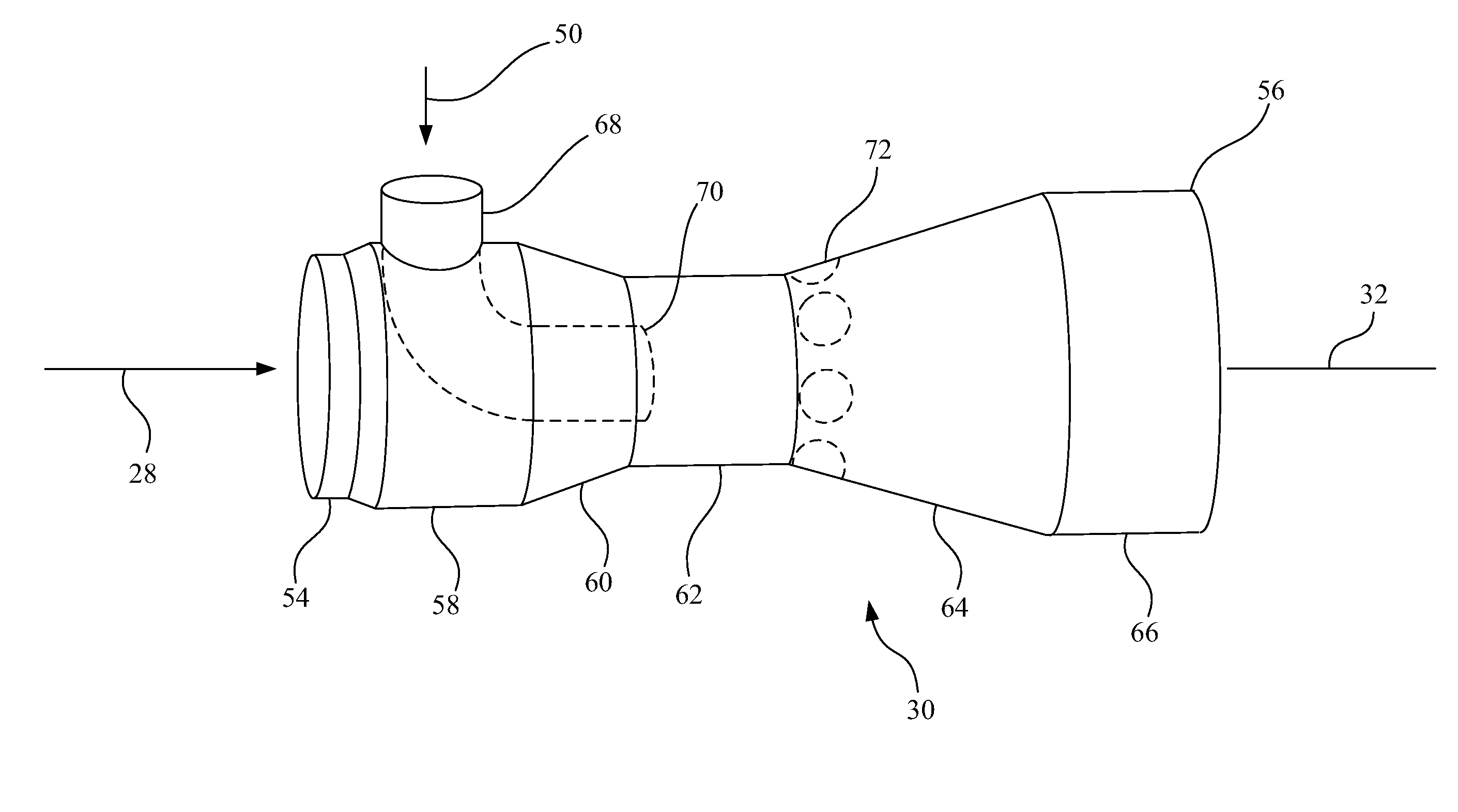

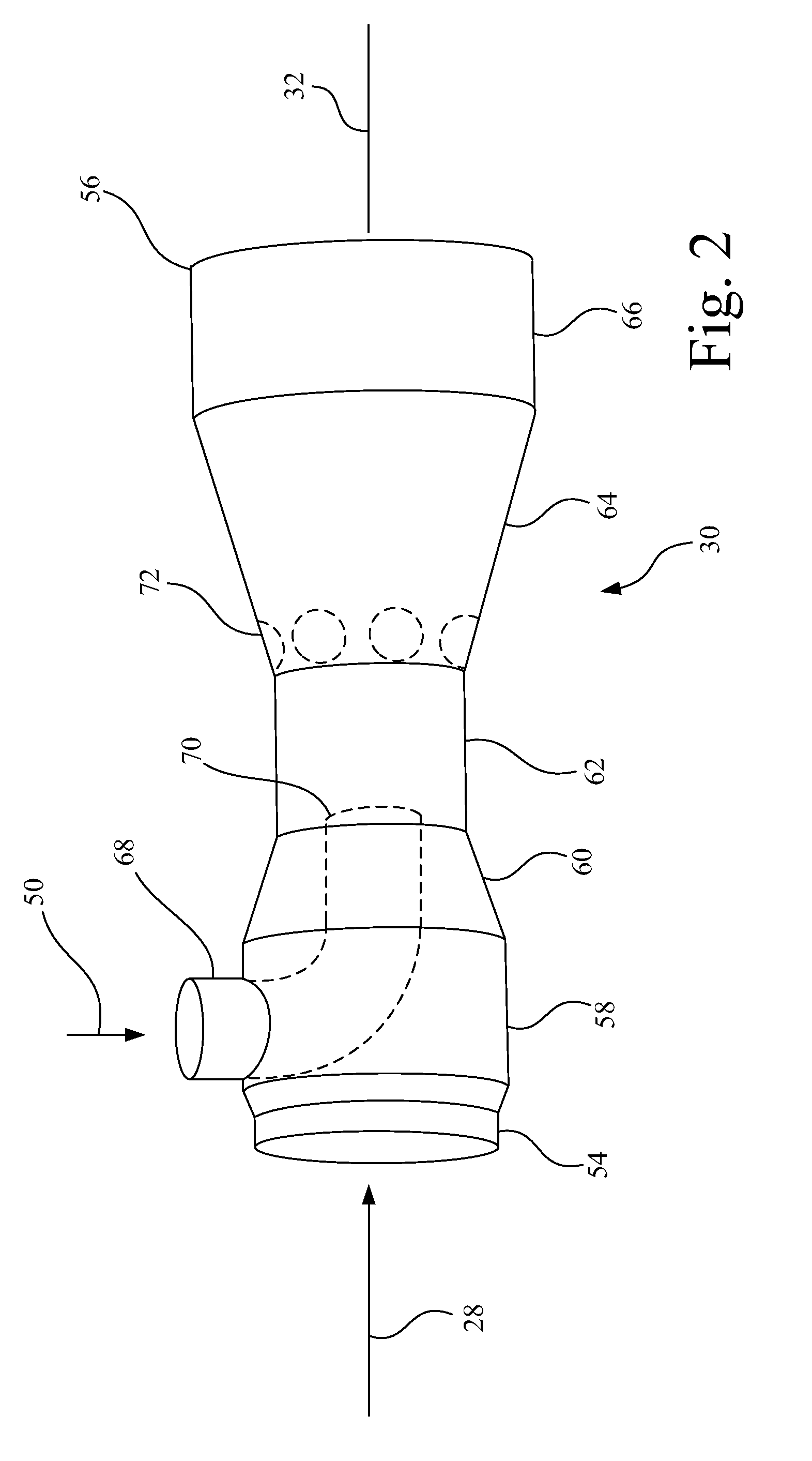

ActiveUS20150114348A1Low-cost vacuum generationFast pull-downAuxillary drivesNon-fuel substance addition to fuelInspiratorVacuum level

Systems and methods are provided for engine systems including a vacuum-powered multiple tap aspirator coupled between atmospheric, an engine crankcase, or another source and a vacuum source such as a compressor inlet or engine intake manifold. The multiple tap aspirator includes a suction tap arranged in a throat of the aspirator, a suction tap arranged in a diverging cone of the aspirator, and a suction tap arranged in a straight exit tube downstream of the diverging cone of the aspirator. The aspirator provides vacuum generation and suction flow over a range of vacuum levels at the suction taps, and suction flow only passes through a single check valve before entering the aspirator.

Owner:FORD GLOBAL TECH LLC

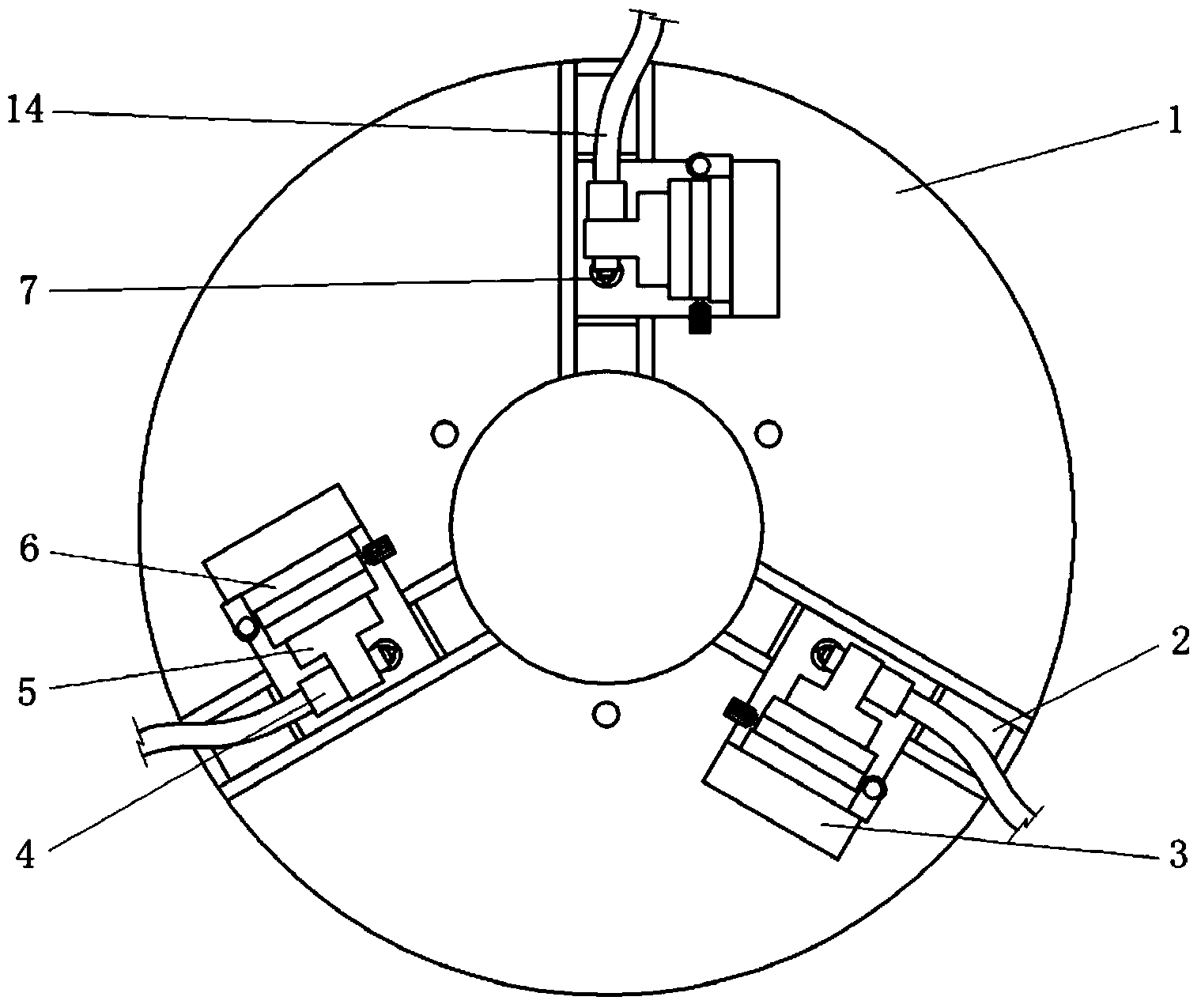

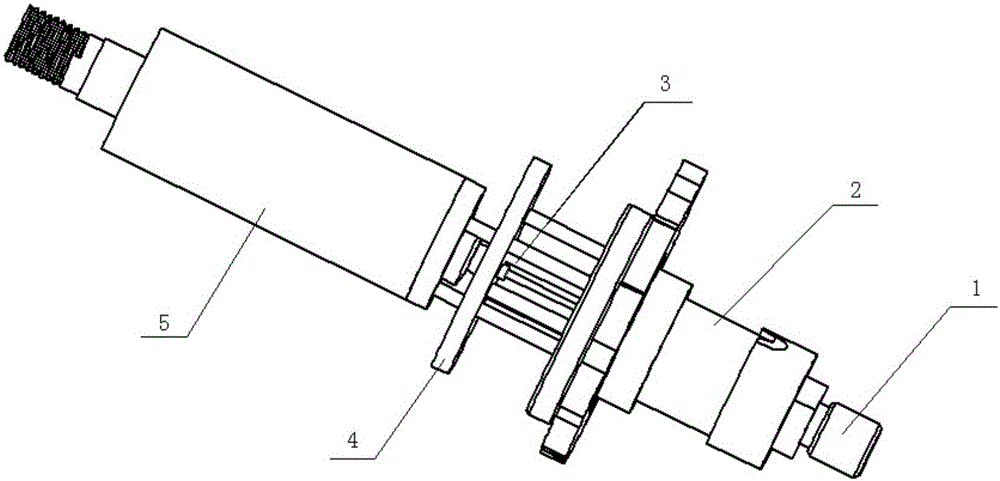

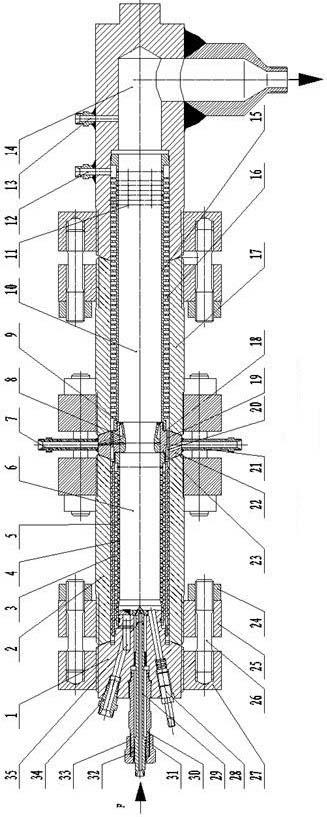

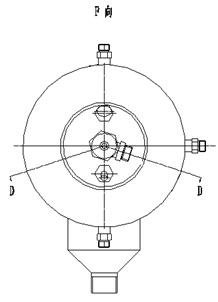

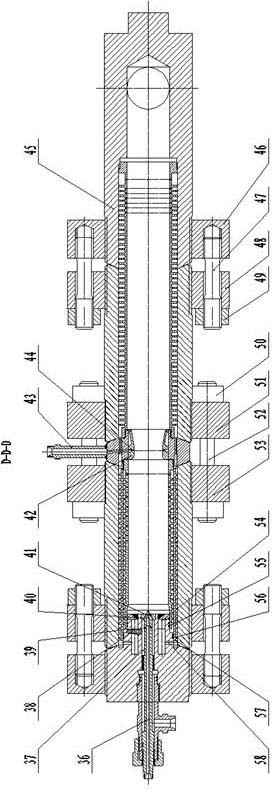

Adjustable coaxial double-slotting bolt type inspirator

The invention relates to an adjustable coaxial double-slotting bolt type inspirator. A needle valve is also arranged between a shell and a center tube, the lower end of the center tube is provided with center tube slots, the lower end of the needle valve is provided with needle valve slots corresponding to the center tube, a passage is formed between a center rod and the inner wall of the center tube, and the center tube slots, the needle valve slots and the passage formed by the center rod and the inner wall of the center tube jointly form a center path nozzle. The invention provides the adjustable coaxial double-slotting bolt type inspirator which has the advantages that excellent mixing of a propellant is ensured, the solid boundary of jet flow is increased, and the combustion efficiency is improved.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

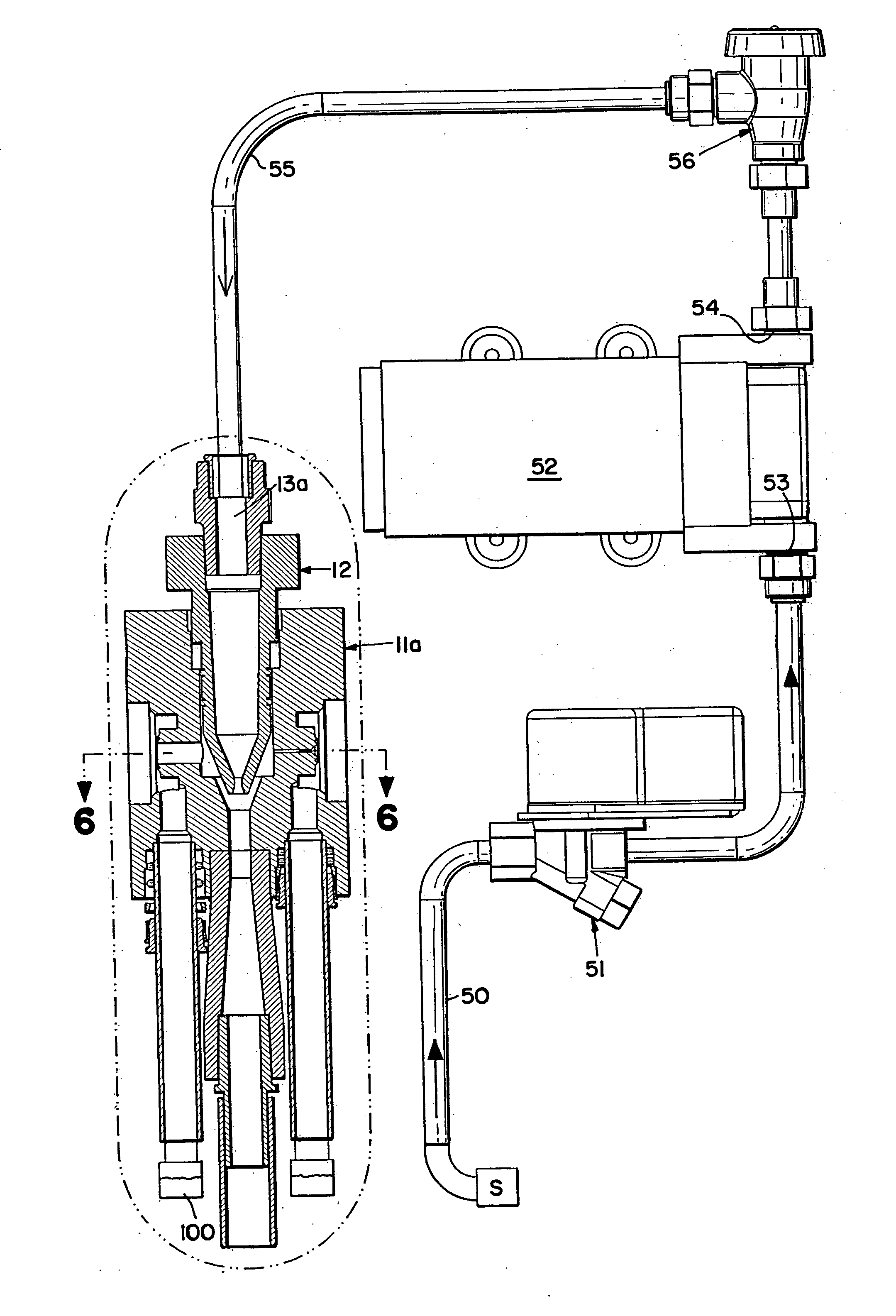

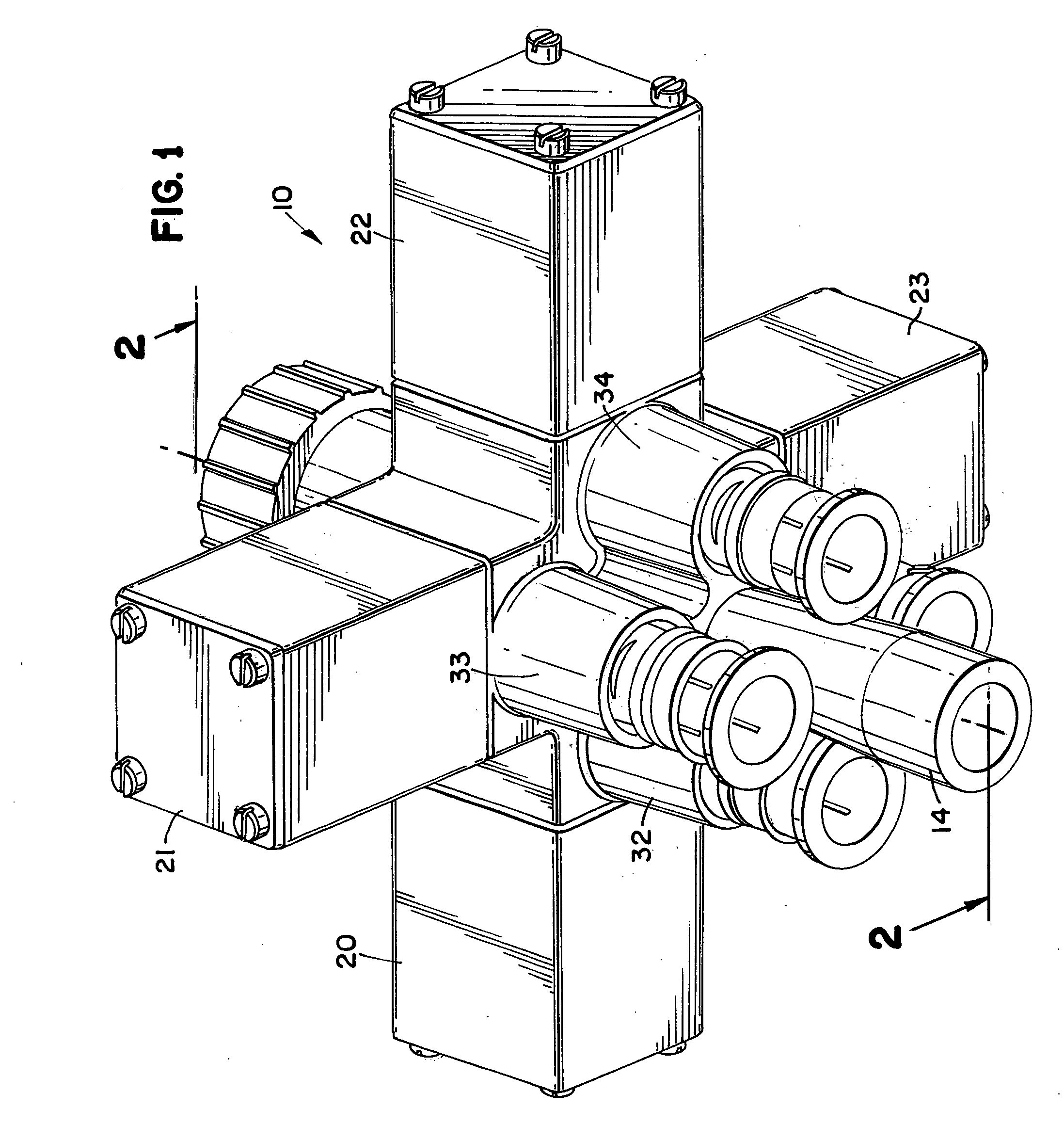

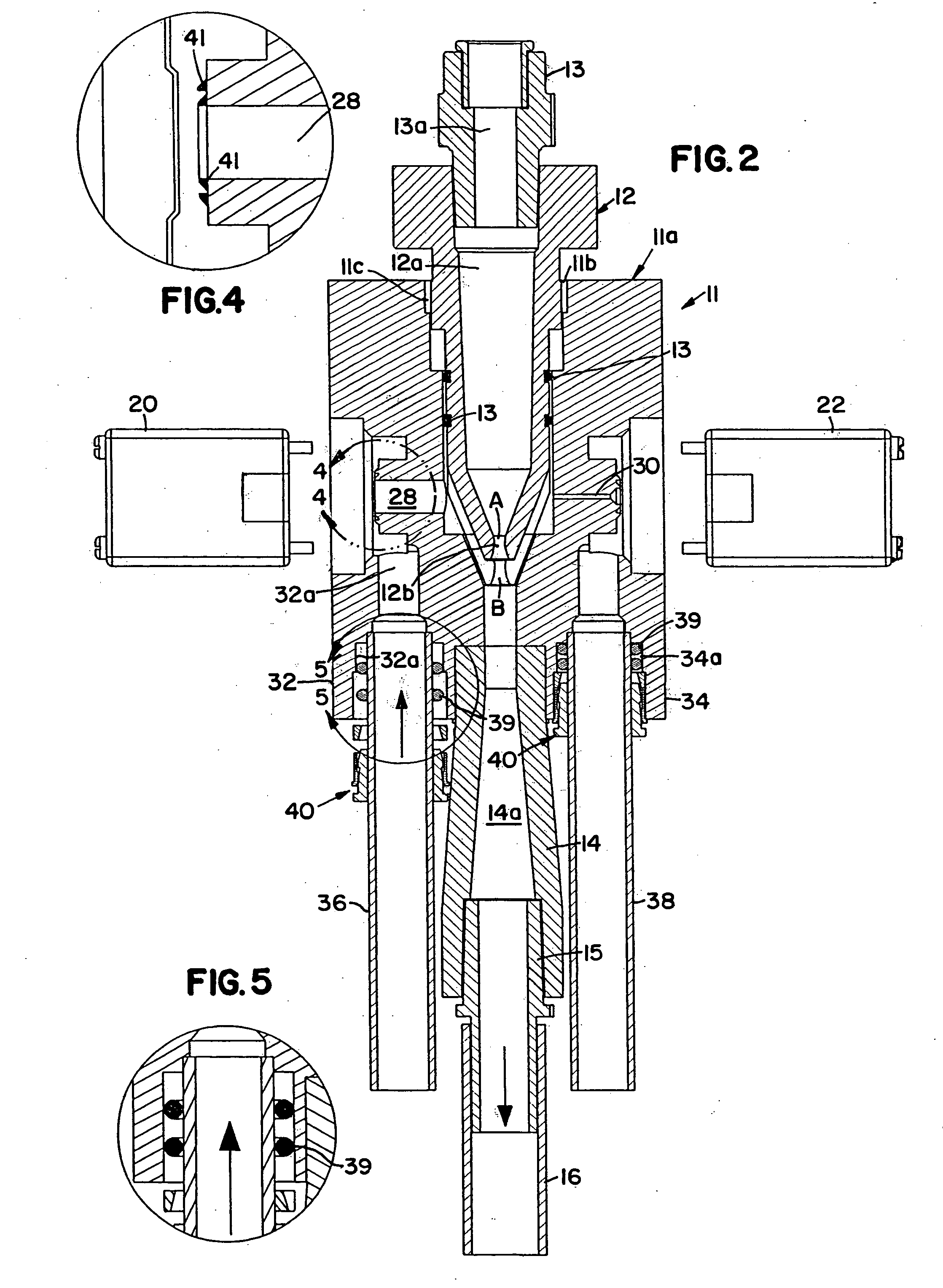

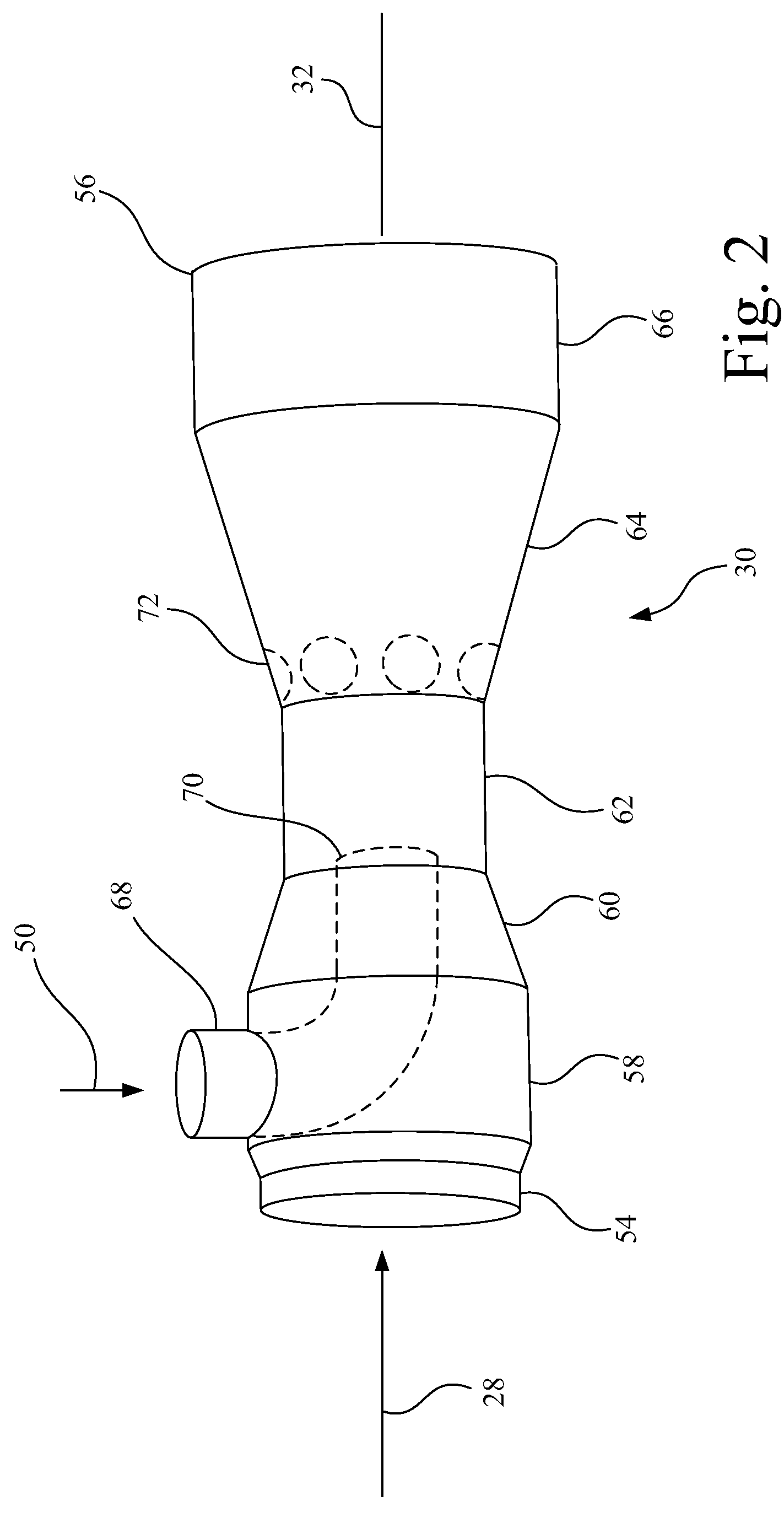

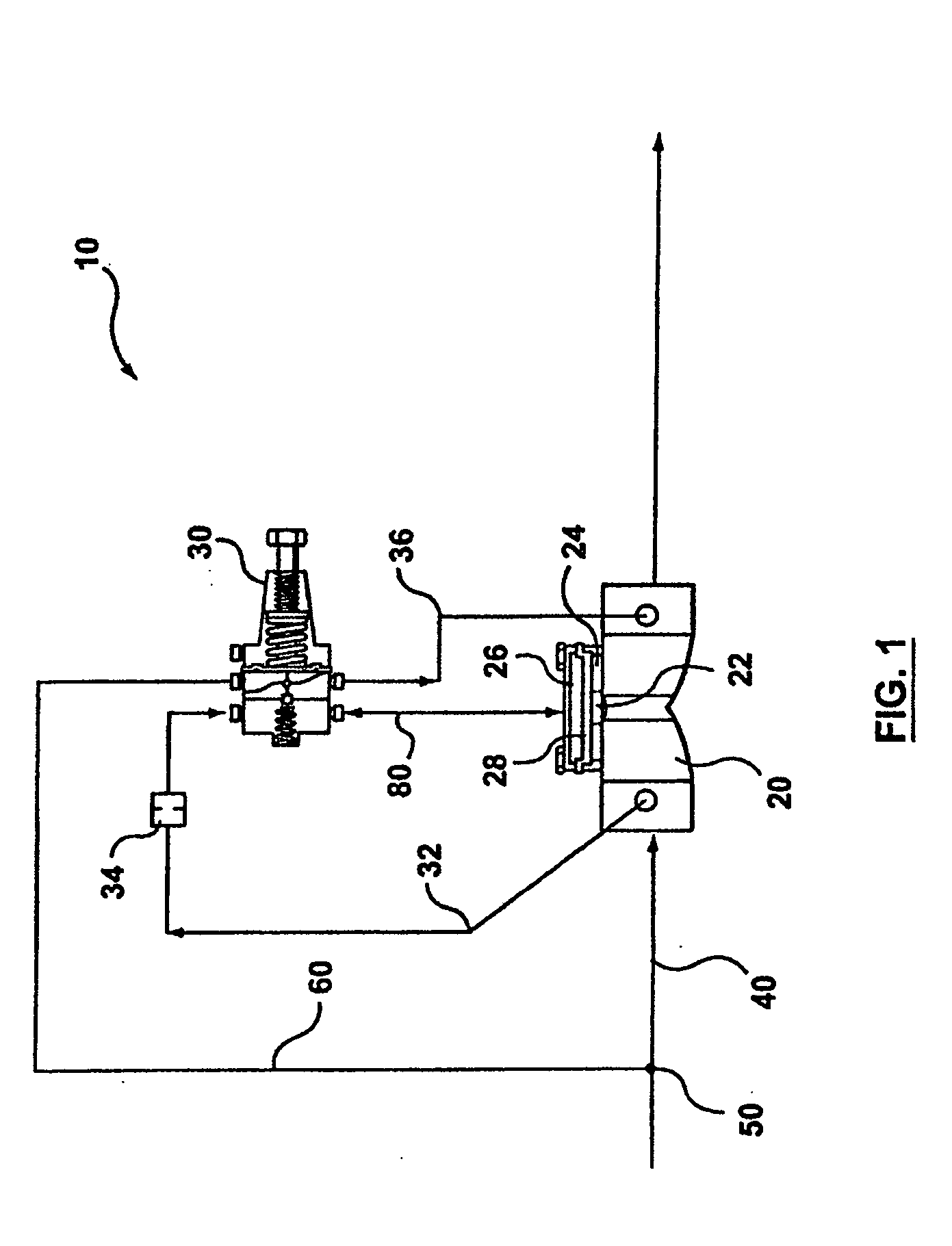

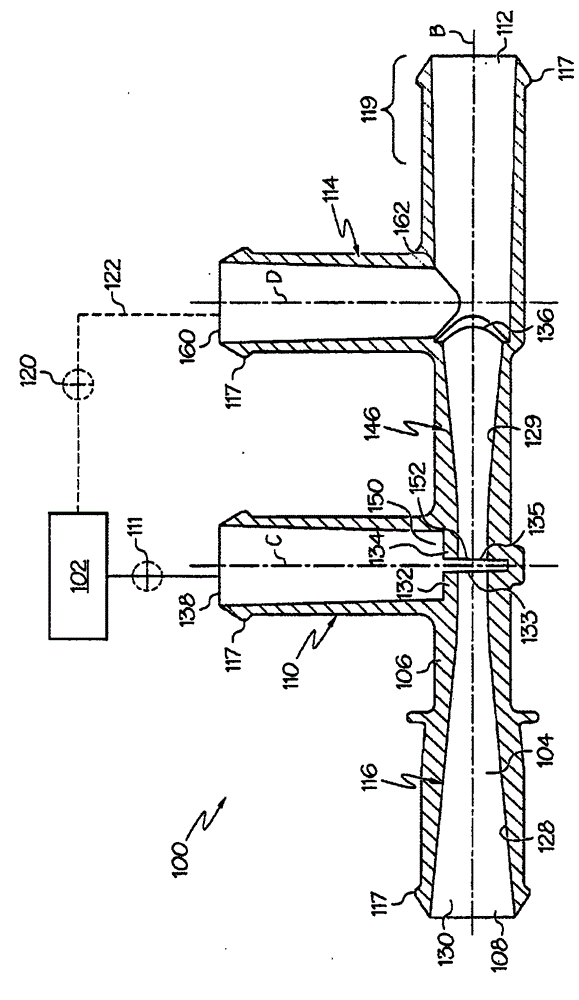

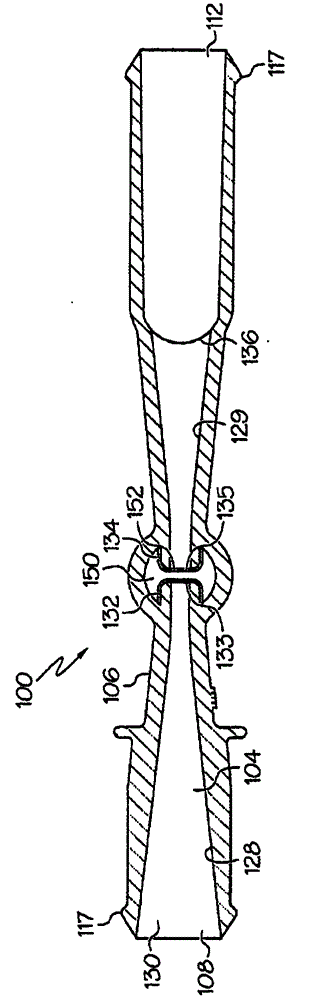

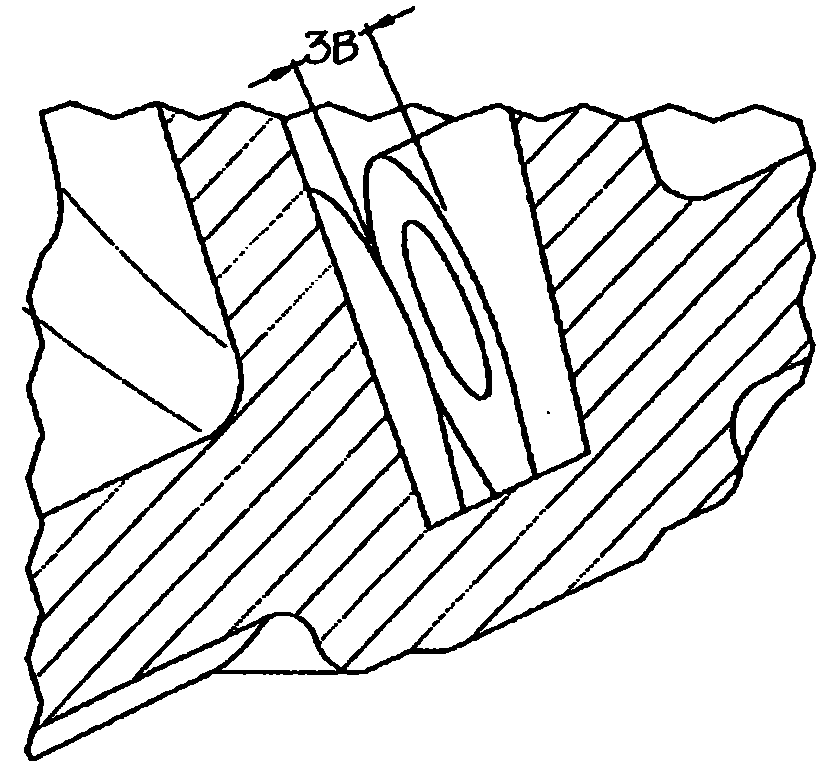

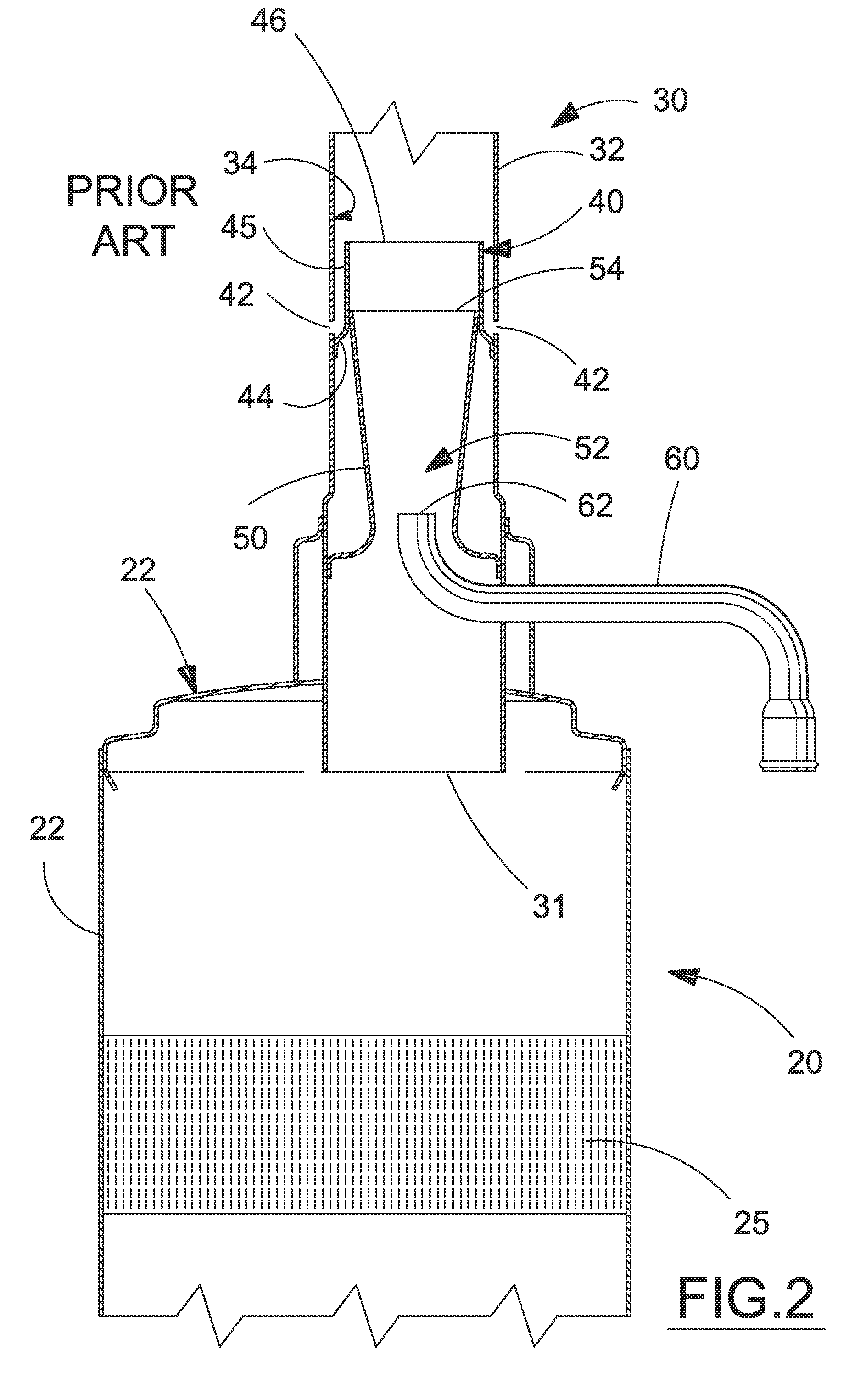

Method and apparatus for dispensing a use solution

A method and apparatus provides for dispensing a liquid concentrate. The source pressure of a liquid diluent is changed by a boost pump (52) to bring the pressure of the diluent to an elevated pressure. The diluent then enters an aspirator assembly (10) wherein the concentrate and diluent are mixed to form a use solution. The dynamic pressure of the diluent entering the aspirator assembly (10) is sufficient so that the amount of concentrate delivered over time is more constant.

Owner:ECOLAB USA INC

Engine exhaust cooler and air pre-cleaner aspirator

Owner:DEERE & CO

Inspirator and atomization component thereof

The invention relates to an inspirator and an atomization component thereof. The atomization component and a battery component of the inspirator are removably connected, and the atomization component comprises a liquid storage structure, an atomization core and a movable piece; the inner part of the liquid storage structure is provided with a liquid storage cavity used for storing liquid, the atomization core is fixedly connected with the liquid storage structure, the atomization core comprises a liquid absorbing core and the movable piece is movably connected with the liquid storage structure; when the atomization component is not connected with the battery component, the liquid storage structure is blocked by the movable piece so that liquid in the liquid storage cavity is separated from the liquid absorbing core to prevent the liquid in the liquid storage cavity from being absorbed and volatized by the liquid absorbing core; when the atomization component is connected with the battery component, the movable piece moves to the battery component so that the liquid storage cavity is communicated with the liquid absorbing core and the liquid absorbing core is used for absorbing the liquid for atomization; when the inspirator is not in use for a long time, the atomization component and the battery component can be separated, and the liquid storage structure can be locked by the movable piece so as to prevent the liquid in the liquid storage cavity from volatizing.

Owner:SHENZHEN SMOORE TECH LTD

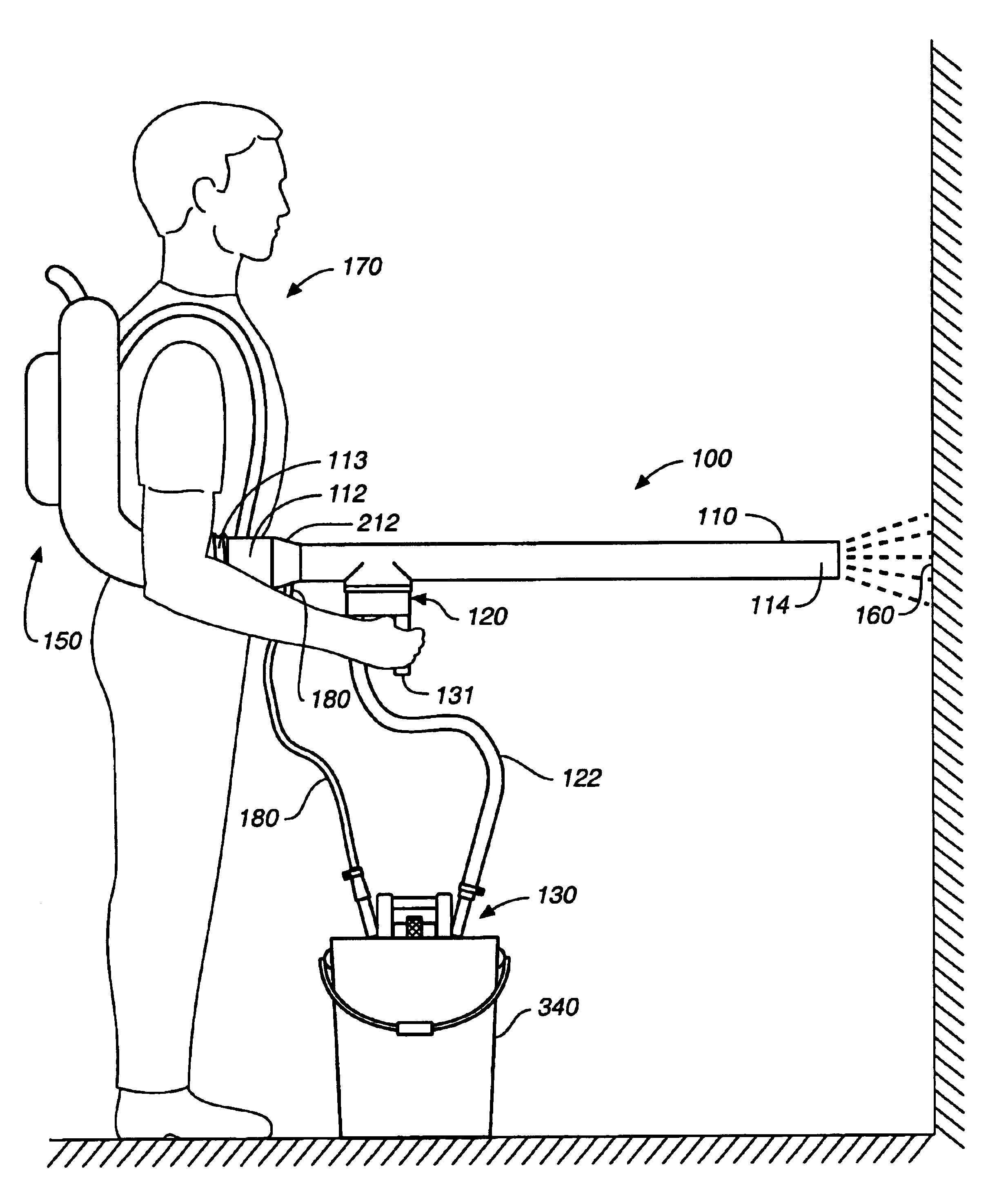

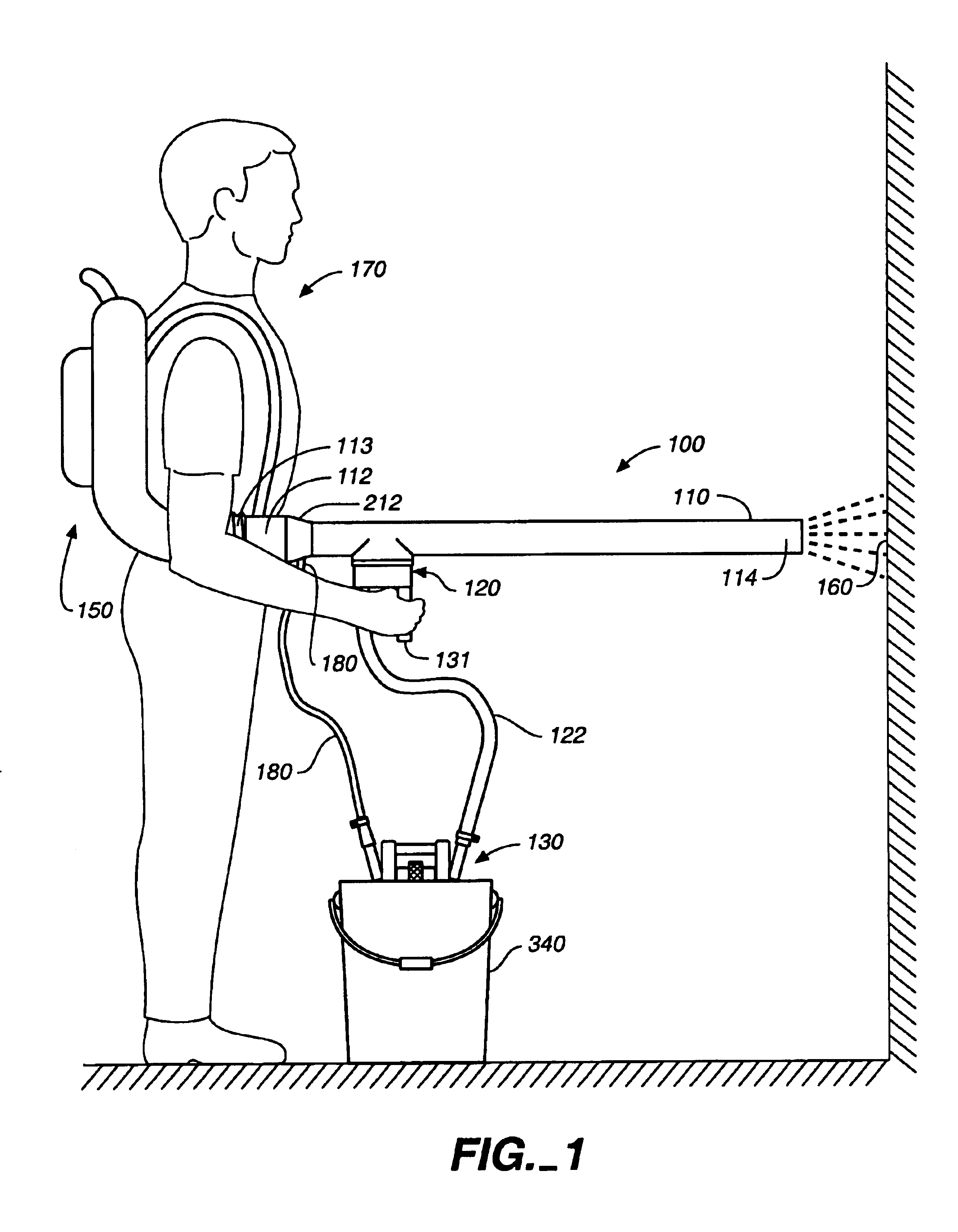

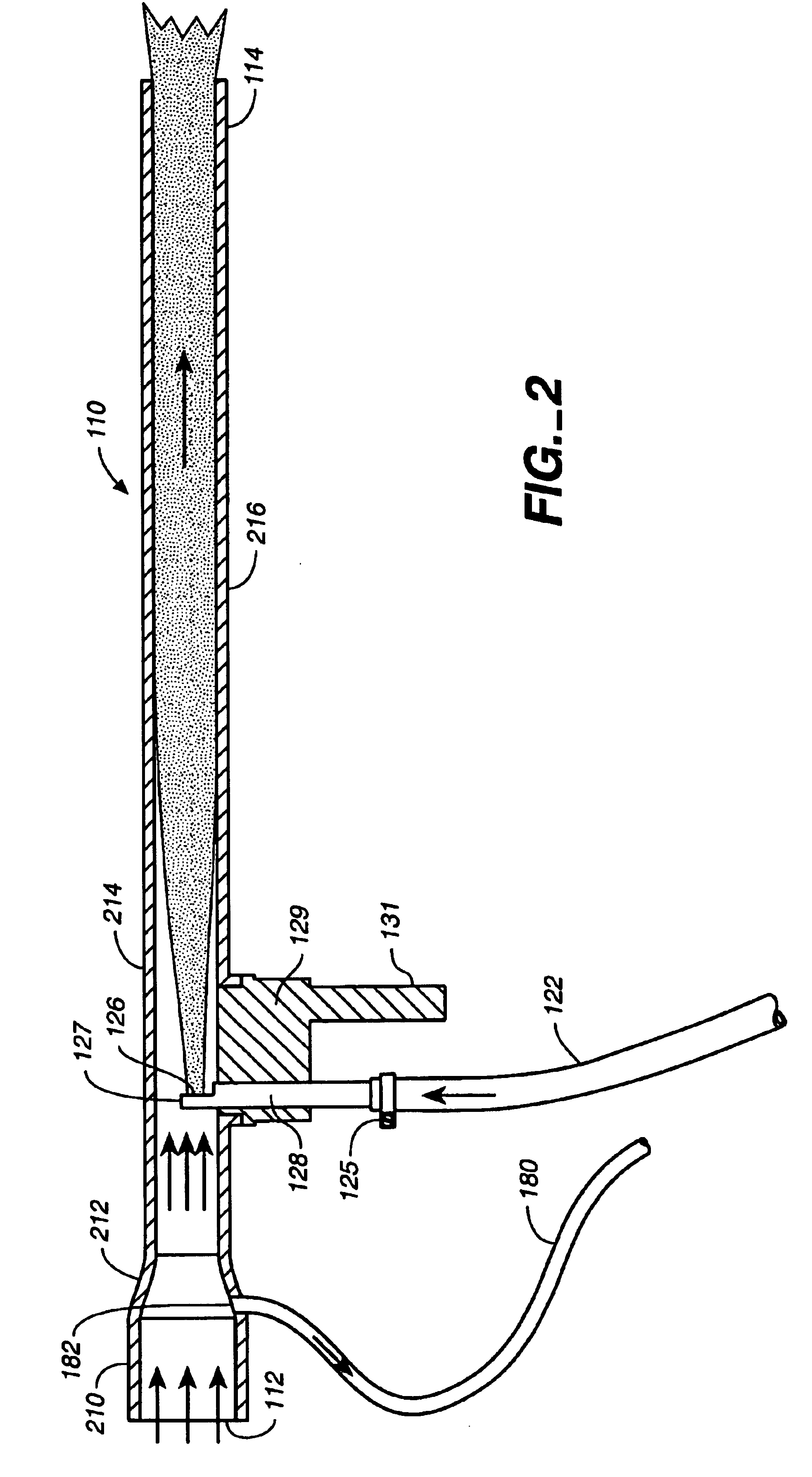

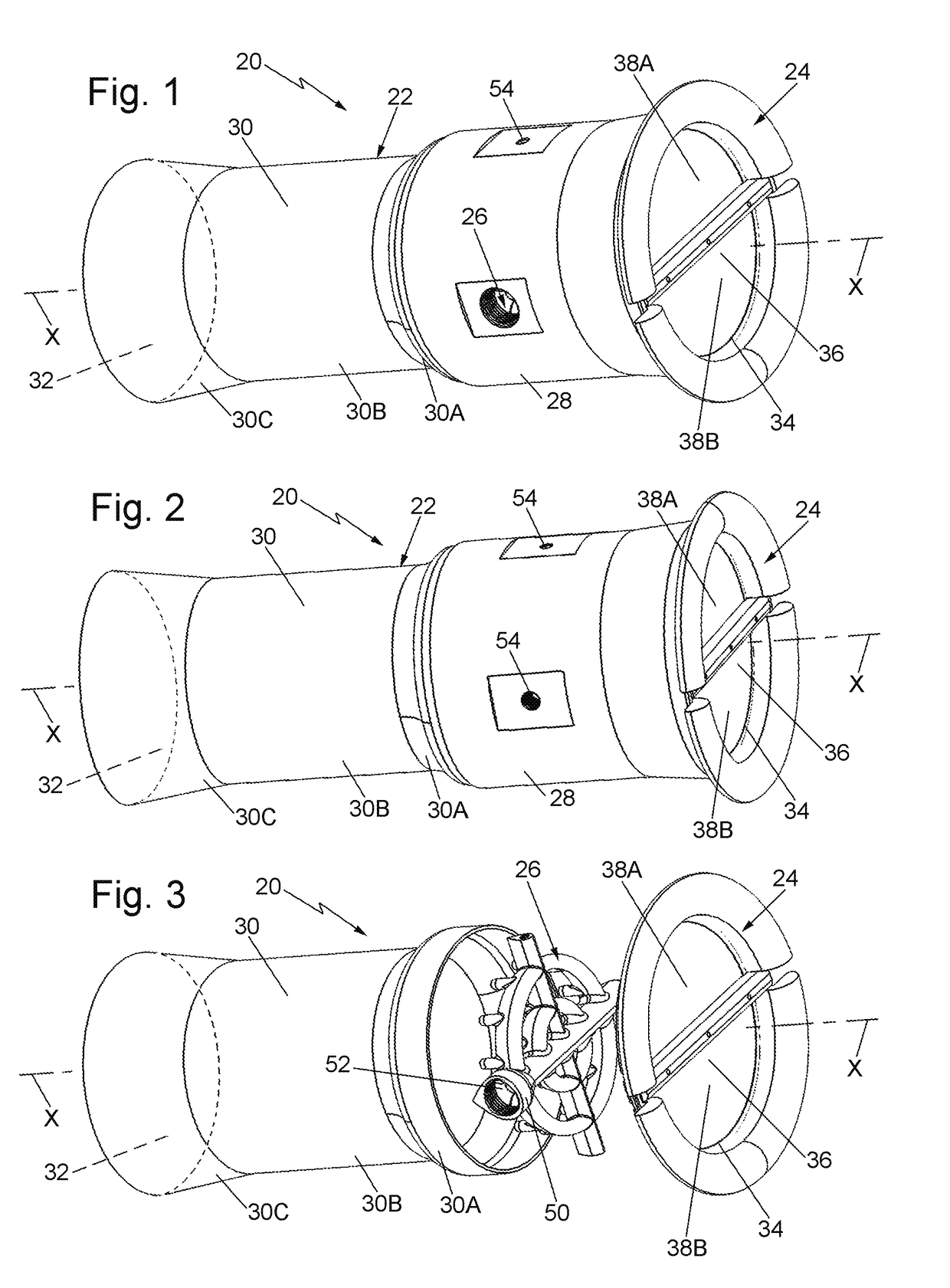

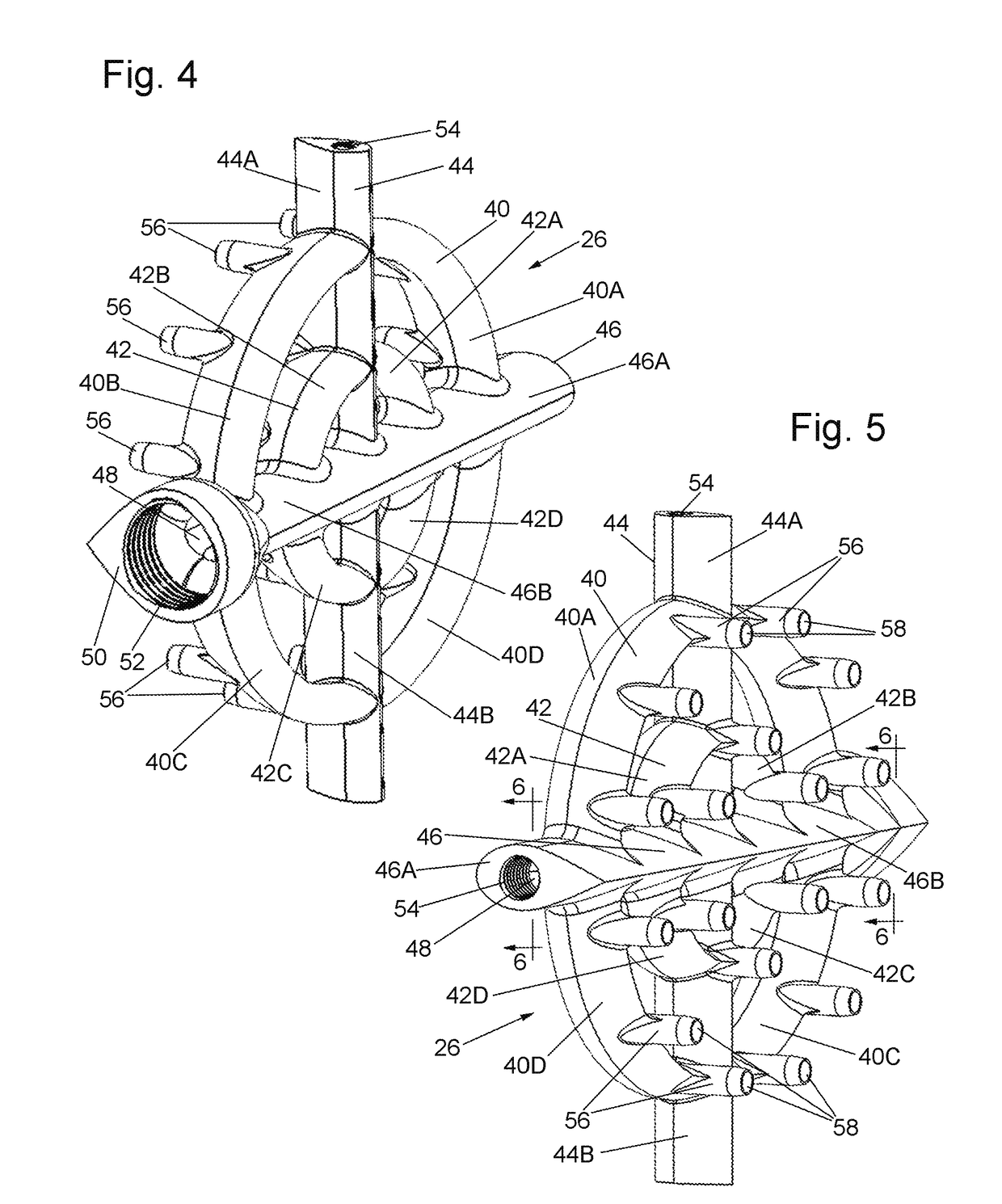

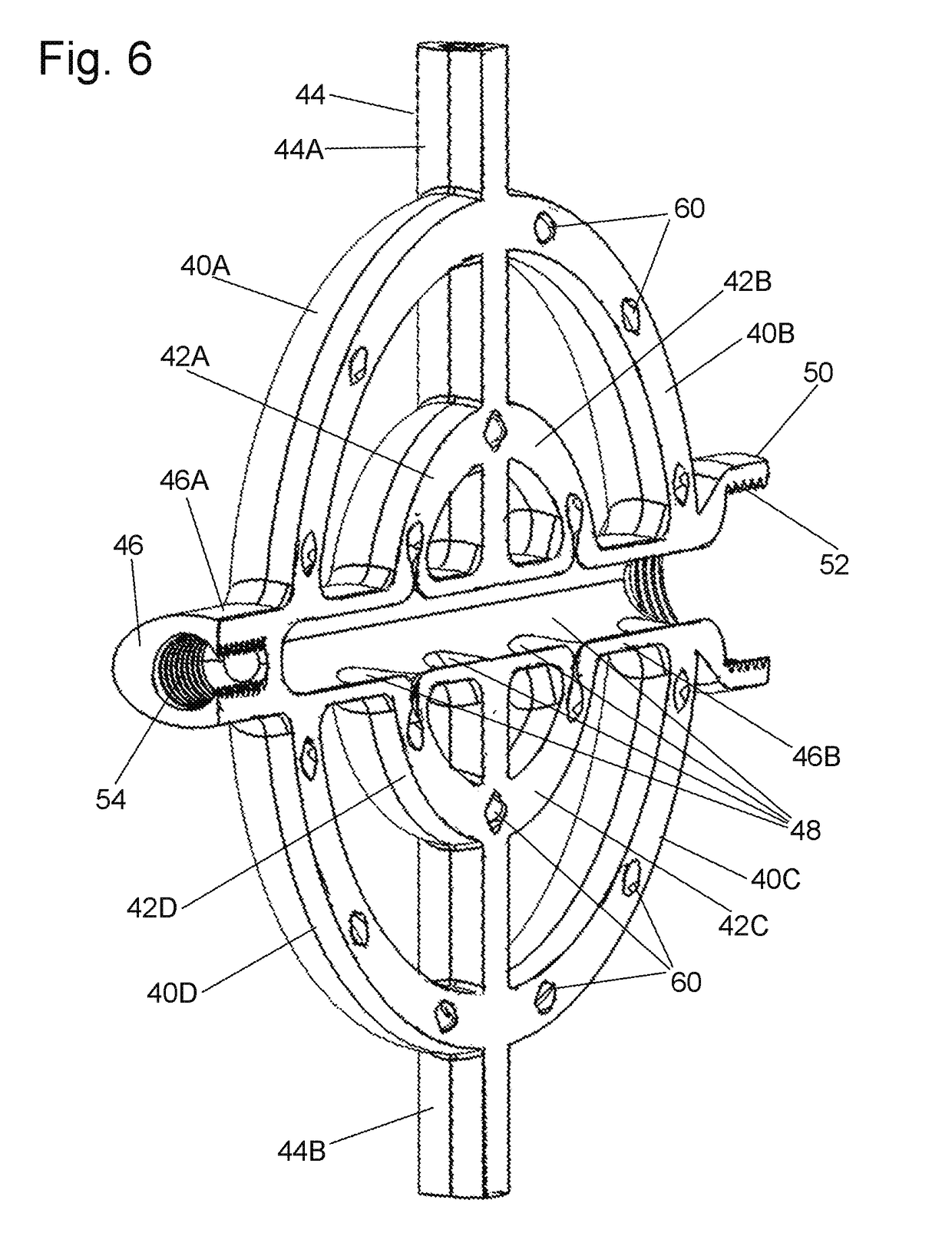

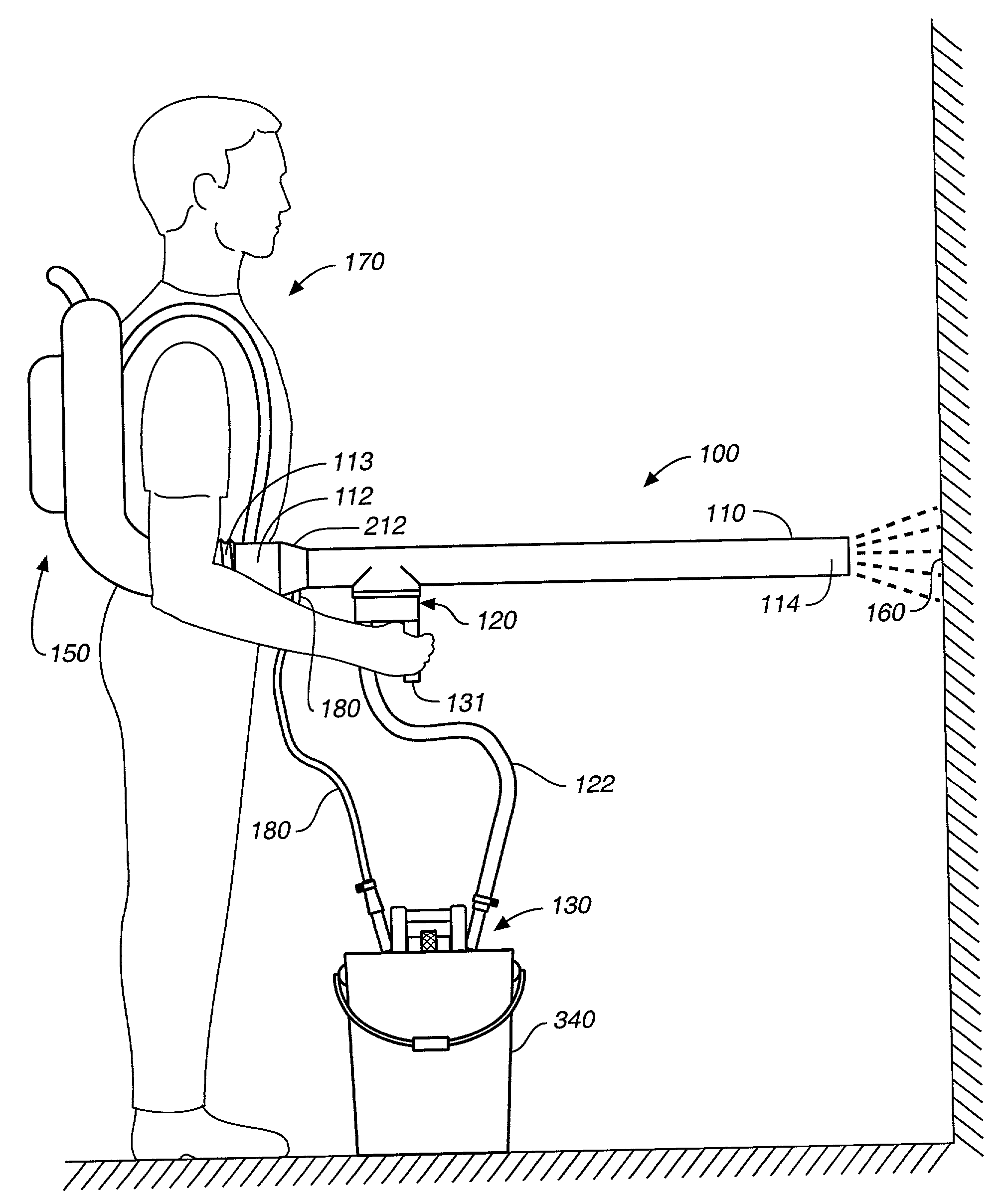

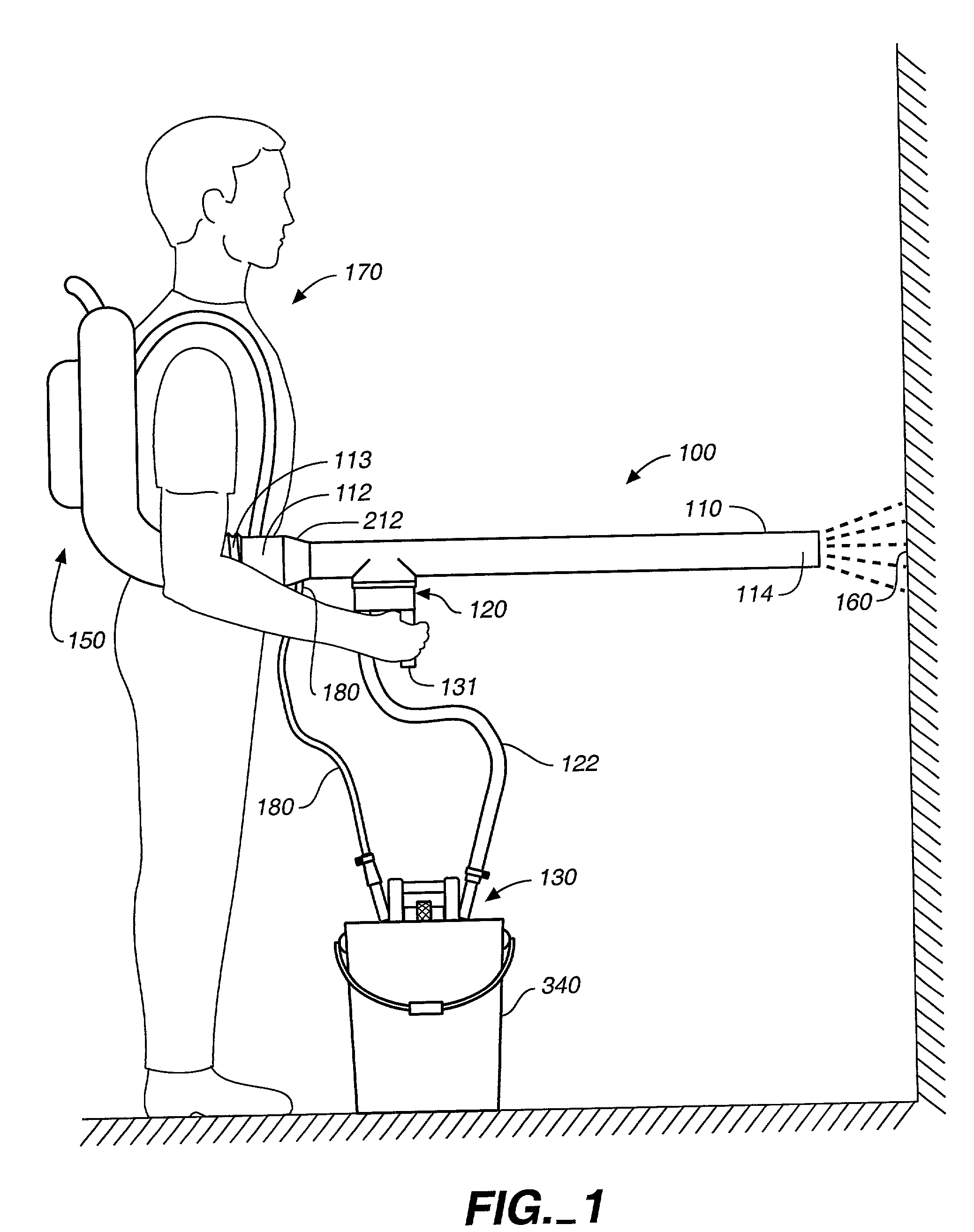

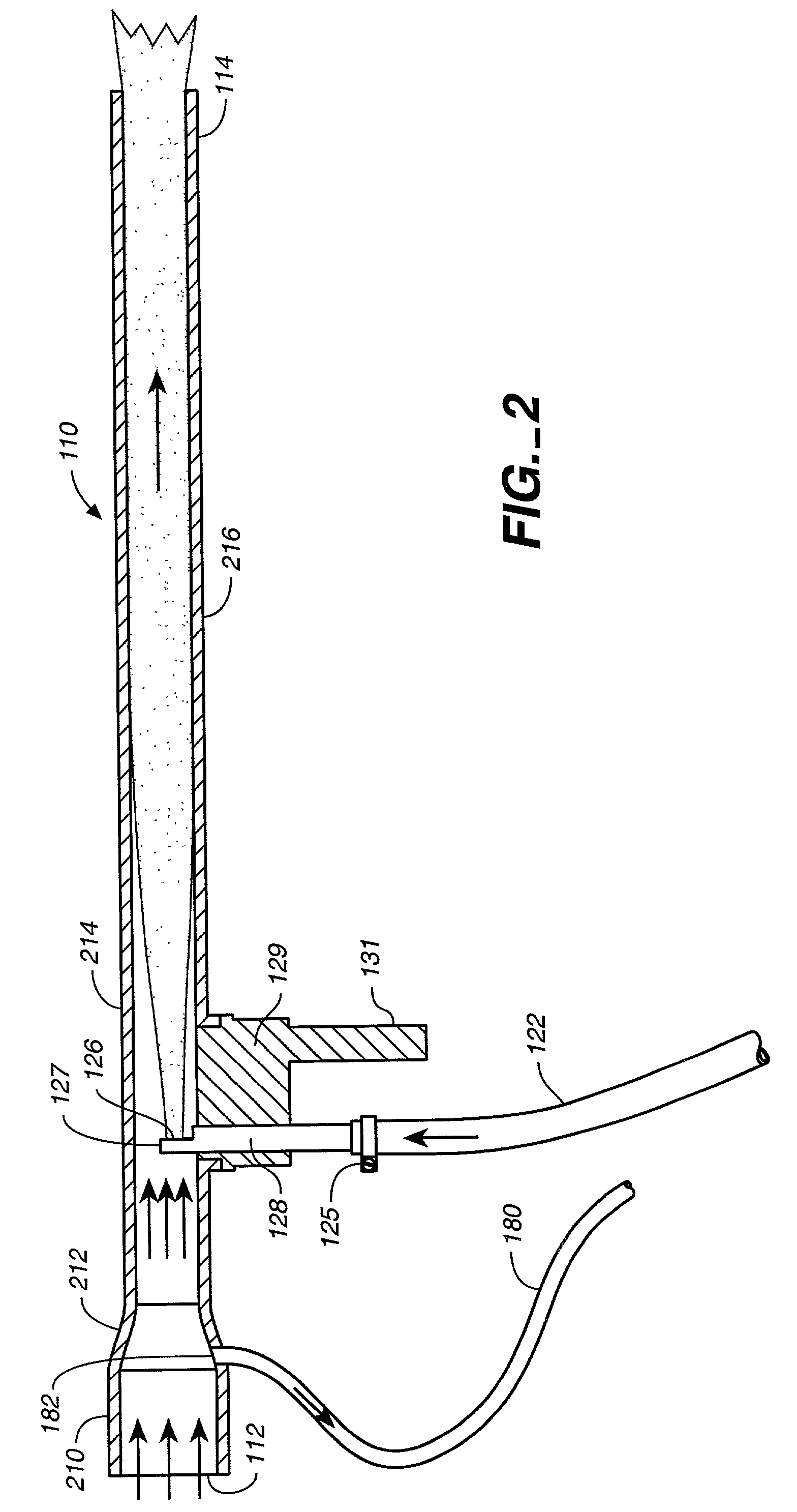

Particulate blaster assembly and aspirator

A particulate blaster assembly (100) for use as an attachment to a portable air blower (150) includes an air directing tube (110), a vacuum generating assembly (120), and a particulate material aspirator (130). The air directing tube (110) has an inlet end (112) formed for coupling to the air blower (150) to receive air discharged therefrom and a movable exhaust end (114) formed for discharge of air and particulate material (212) entrained in the air toward a target site (160). The vacuum assembly (120) is coupled to the air directing tube (110) and formed to produce a partial vacuum as air passes in the tube (110) over the vacuum generating assembly (120). The particulate material aspirator (130) is coupled to the vacuum assembly (120) and is responsive to the partial vacuum generated by the vacuum generating assembly (120) to aspirate a particulate material (212) from a particulate material source (340) into the air directing tube (110) for acceleration and discharge of the entrained particulate material (212). Preferably, a positive pressure, generating assembly (182) communicates positive pressure to aspirator (130) for cooperation with the partial vacuum at the aspirator (130) to aspirate particulate material (212) into the air directing tube (110).

Owner:DANIEL DORCE L

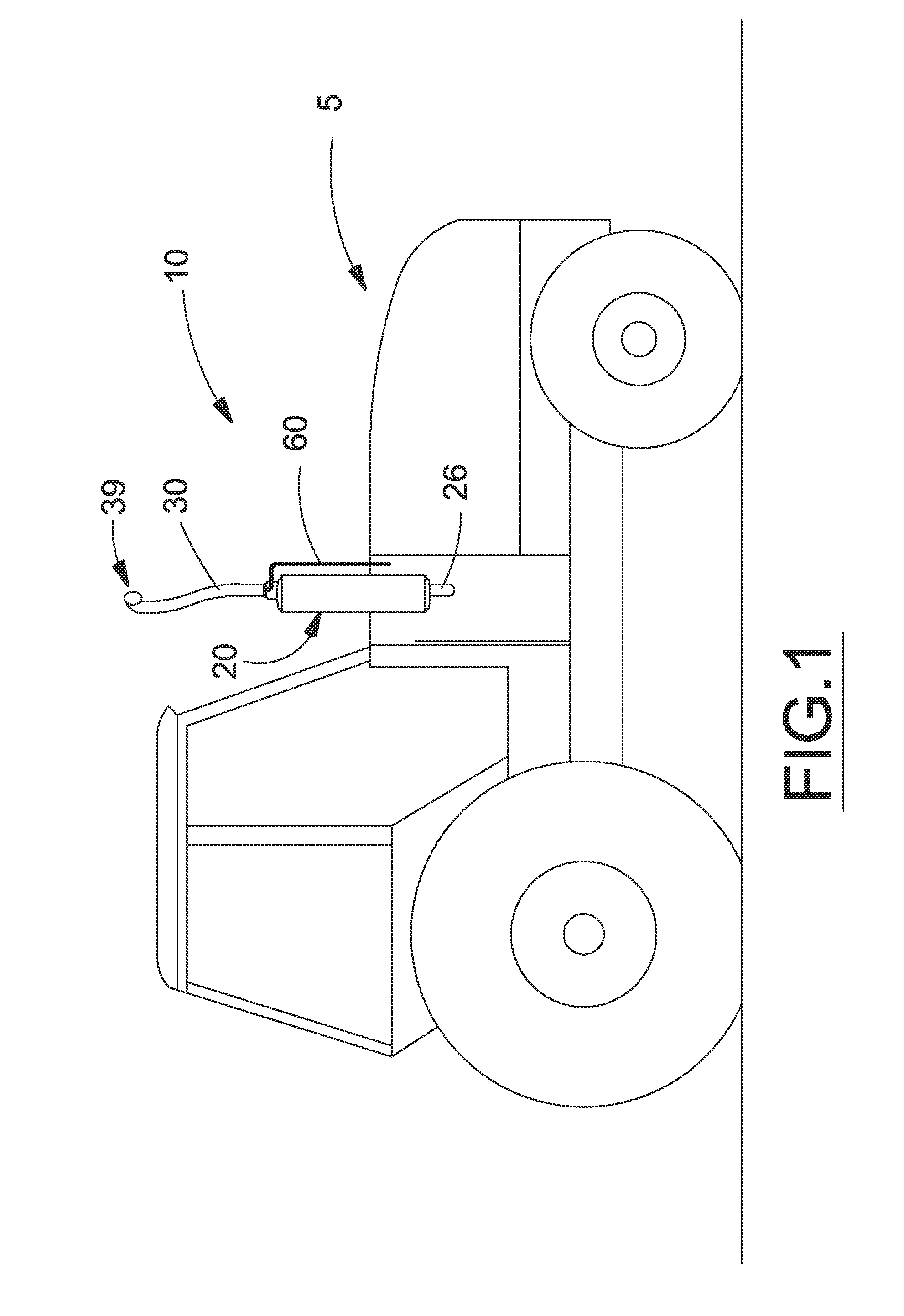

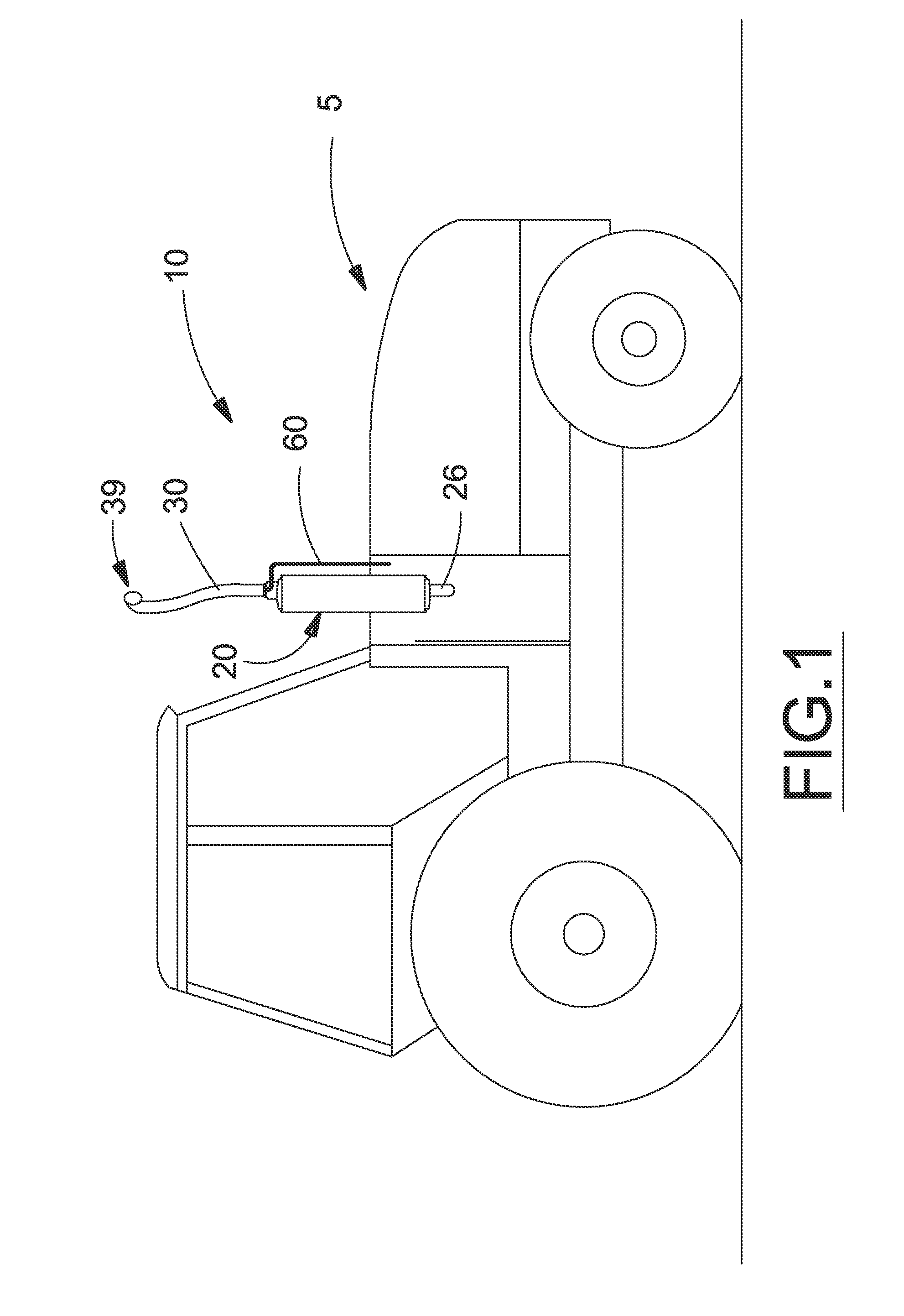

Engine cooling flow debris cleaner and air pre-cleaner aspirator

A work vehicle operating in a highly contaminated environment has a radiator with a rotary screen debris removal device upstream of the radiator. The debris thus removed passes through a fan for disposal away from the work machine. The engine is an air breathing fuel consuming engine and has a pre-cleaner for removing larger particles of air delivered to the engine for combustion. A conduit extends from the intake air pre-cleaner to a venturi device adjacent to and upstream of the fan for continuously and effectively removing particles from the engine air pre-cleaner.

Owner:DEERE & CO

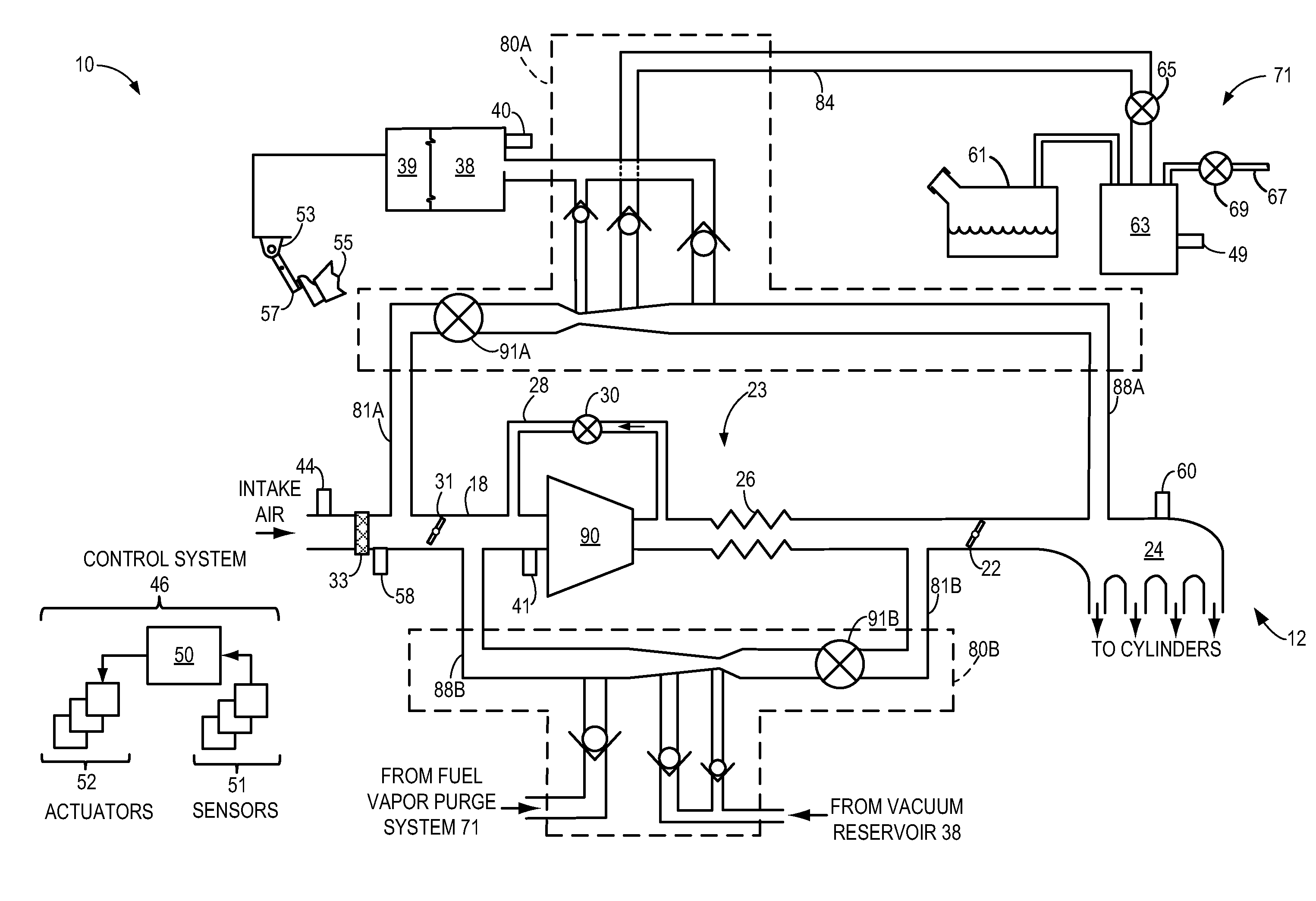

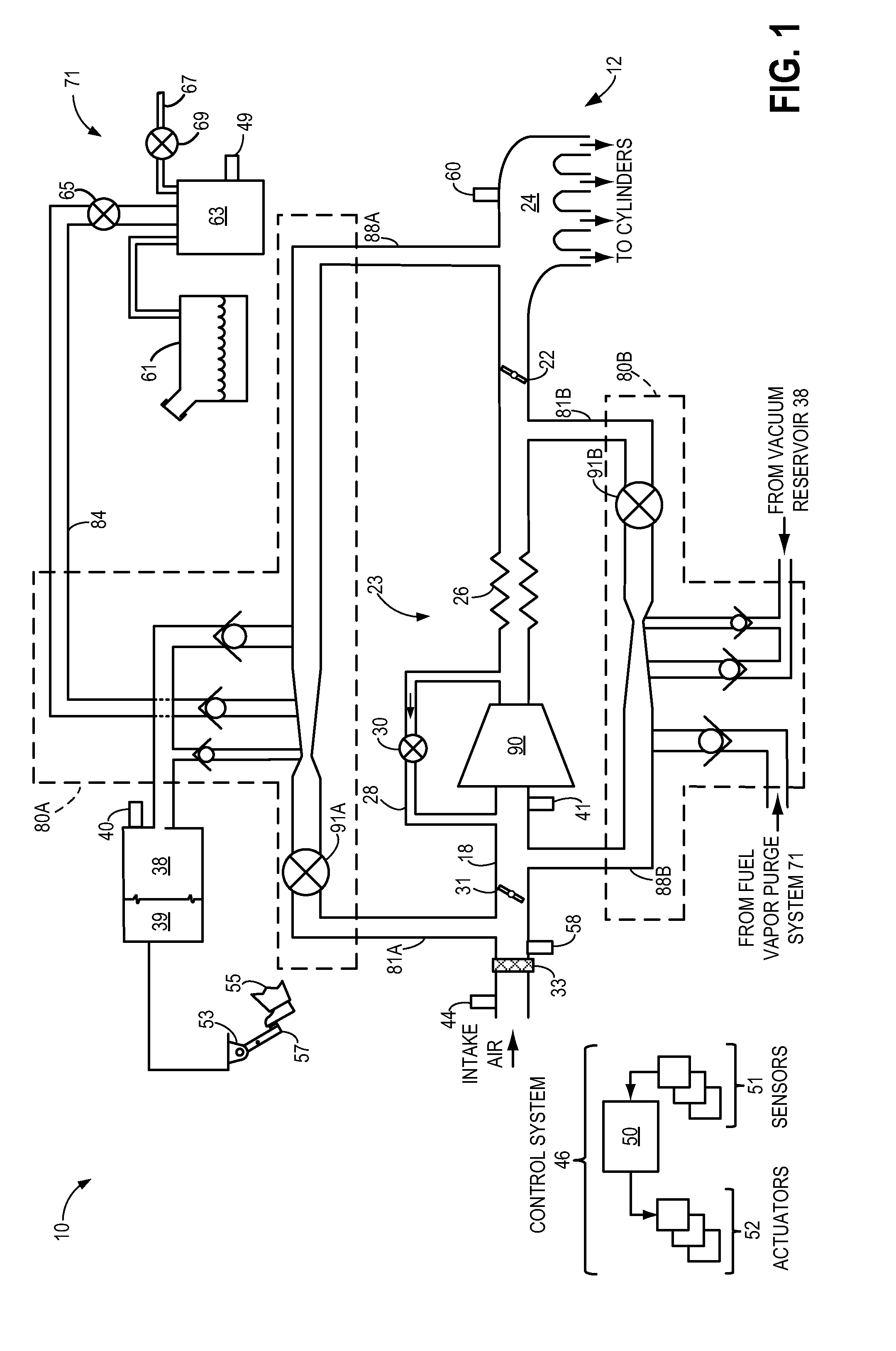

Crankcase ventilation and vacuum generation

InactiveUS9027536B2Improve power generation efficiencyMinimum controllable airflow budget of the engine is not affectedInternal combustion piston enginesNon-fuel substance addition to fuelInspiratorCrankcase

Methods and systems are provided for generating vacuum from crankcase ventilation flow. During both directions of gas flow between an engine intake manifold and a crankcase, gases are directed through one or more aspirators to produce vacuum. The drawn vacuum may then be used to operate various engine vacuum actuators.

Owner:FORD GLOBAL TECH LLC

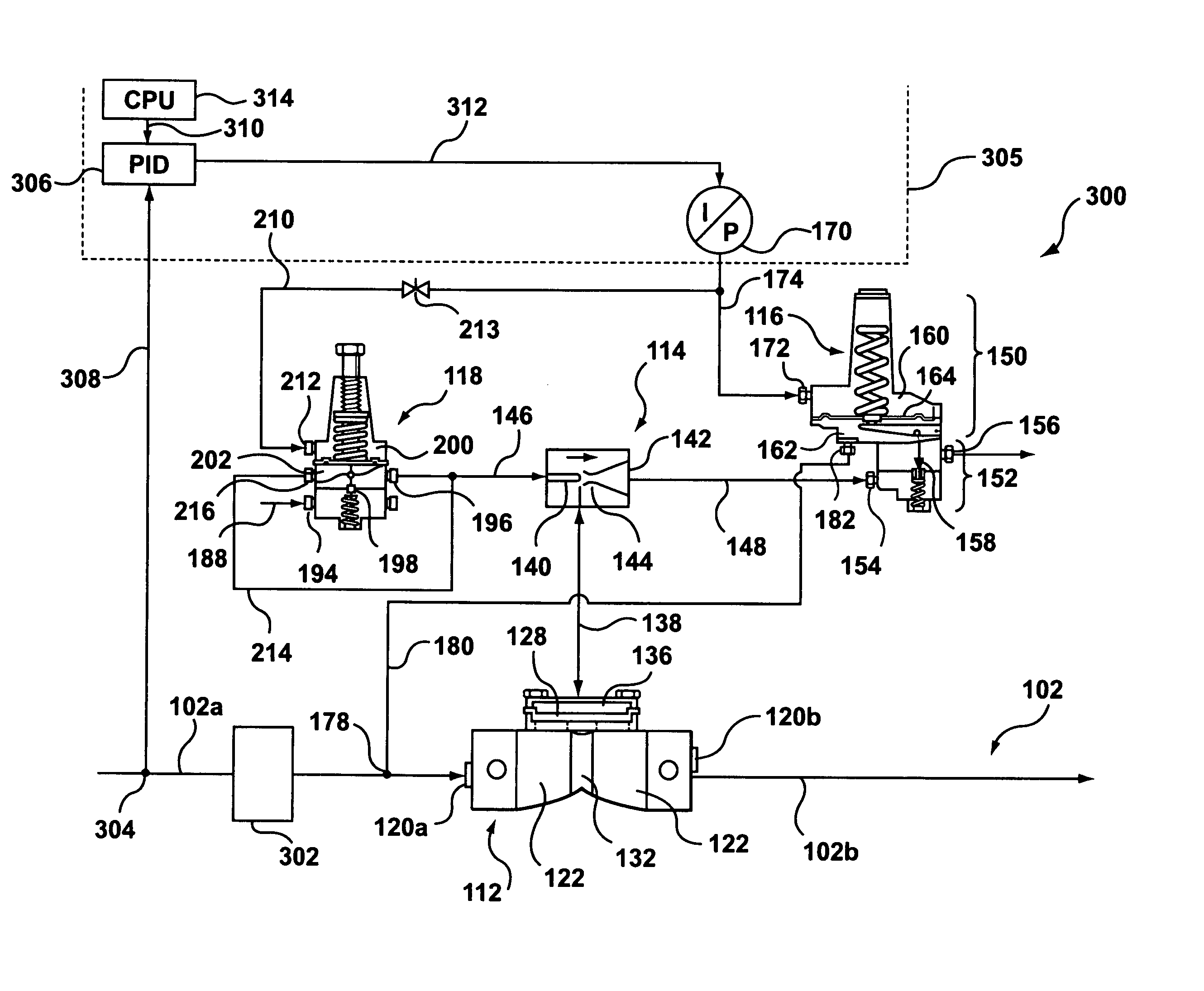

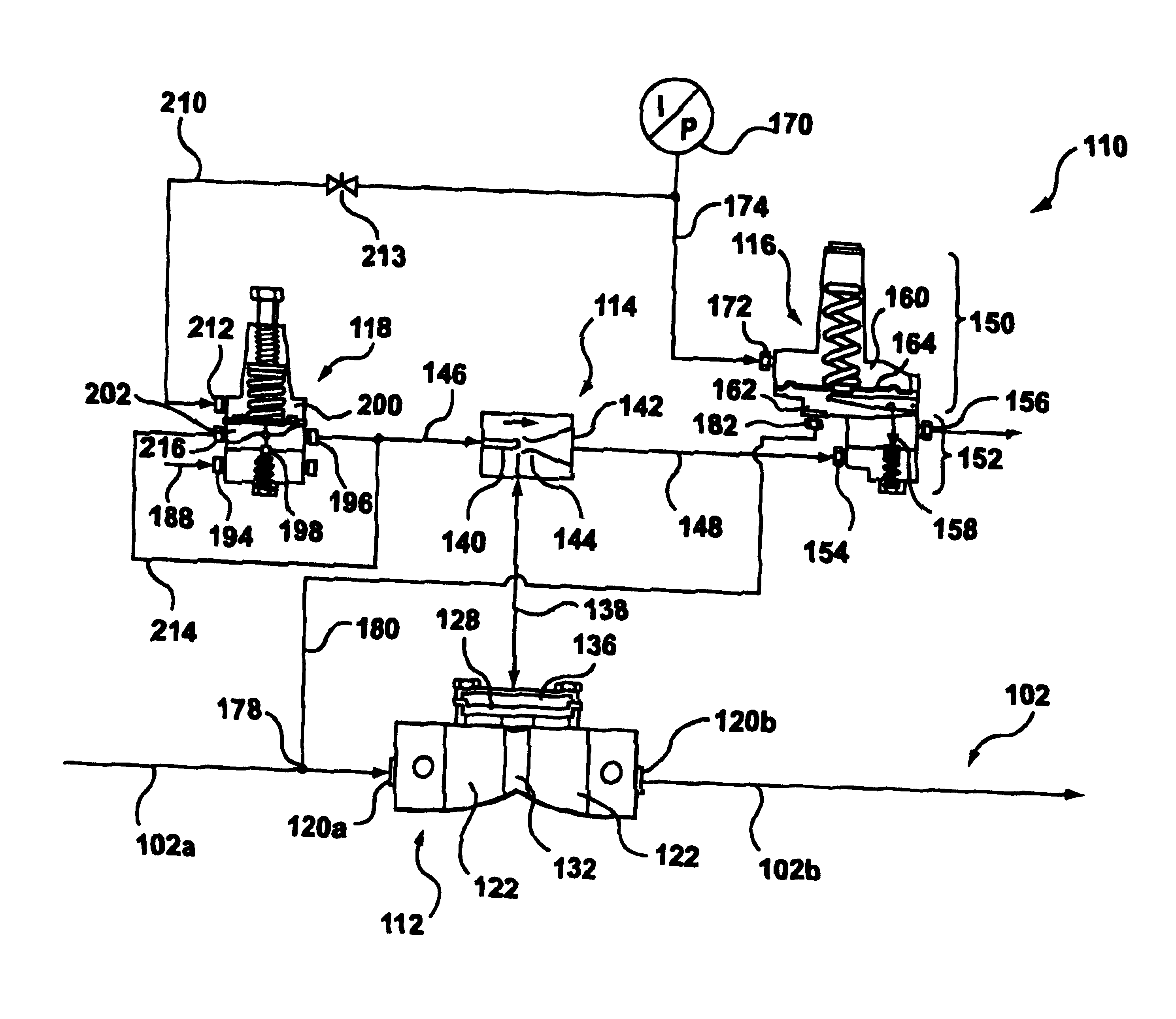

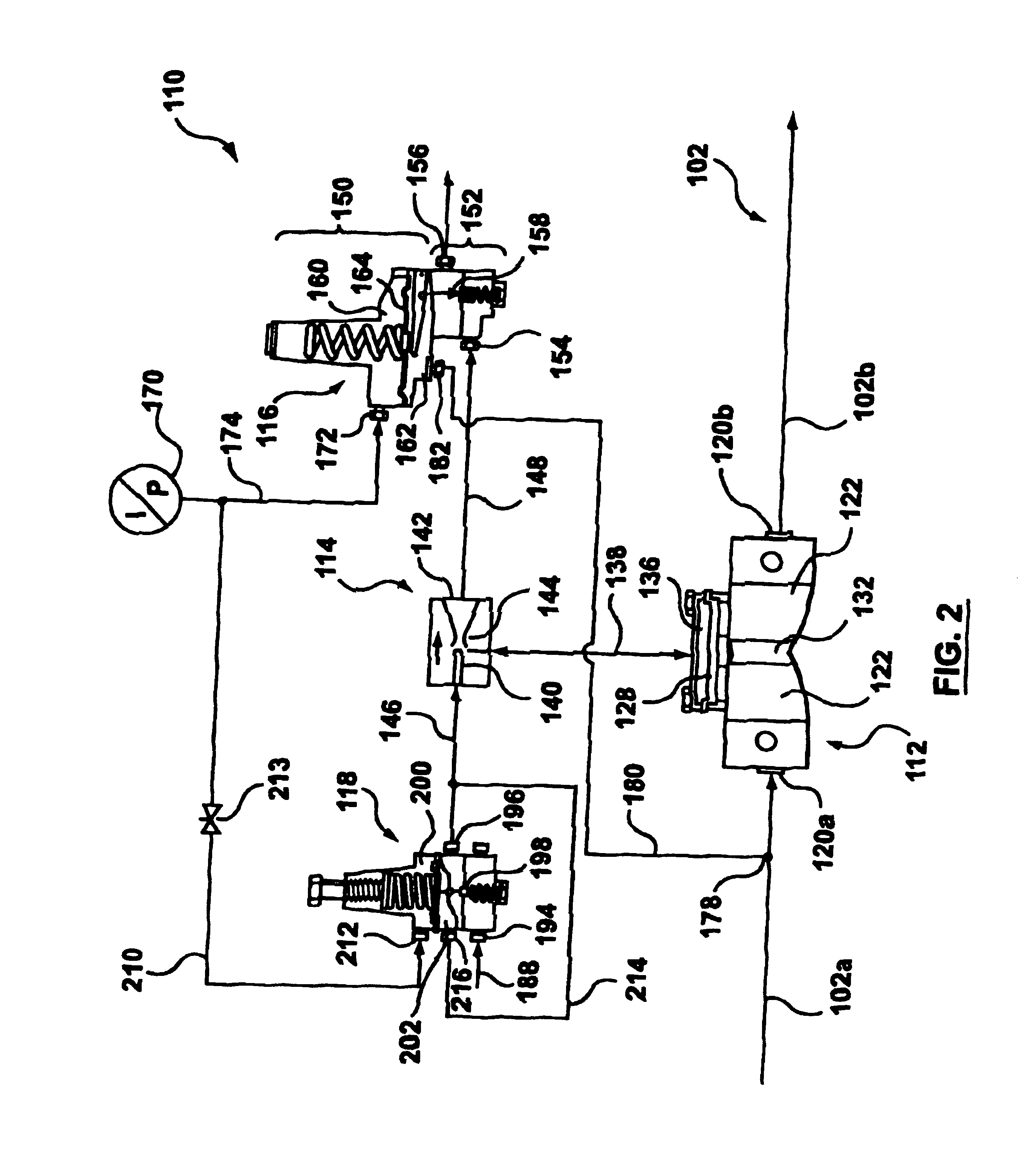

Pressure control system for low pressure high flow operation

InactiveUS20050268968A1Operating means/releasing devices for valvesFluid pressure control with auxillary non-electric powerInspiratorAutomatic control

A pressure control system for controlling the pressure of a process fluid stream at a certain location, comprising: a pressure regulator disposed in the process fluid stream, through which the process fluid stream flows; a first pilot controller adapted to sense the pressure of the process fluid at the said location and receive a control pressure from a control source; a second pilot controller adapted to receive same control pressure from the control source and provide added pressure; an inspirator adapted to receive the added pressure from the second pilot controller and generate a differential pressure; wherein the differential pressure is used to control the pressure of the process fluid stream within the pressure regulator. The pressure regulator comprises a first chamber and a second chamber therein separated by a flexible element and a divider is disposed in the first chamber and operative to abut against the flexible element to divide the first chamber into separate spaces. Preferably, the pressure regulator is disposed such that the flexible element extends substantially in vertical direction and the divider extends substantially in horizontal direction. The pressure control system further comprises an automatic control system including an electronic proportional-integral-derivative controller adapted to control the process fluid pressure based on pressure measurements received from a pressure transducer.

Owner:HYDROGENICS CORP

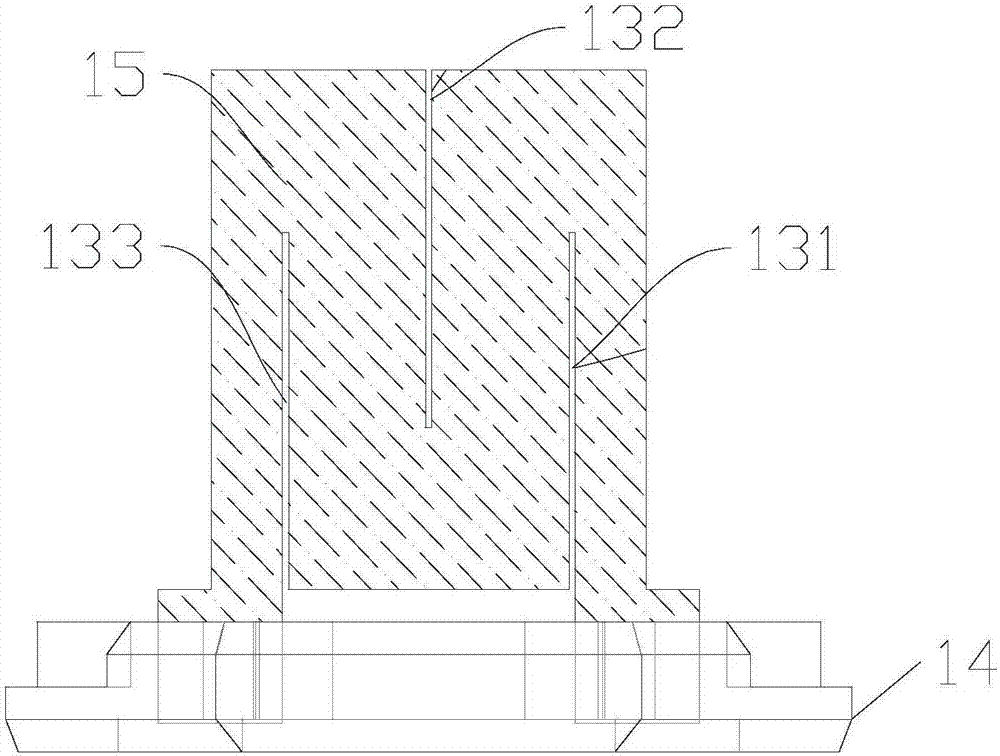

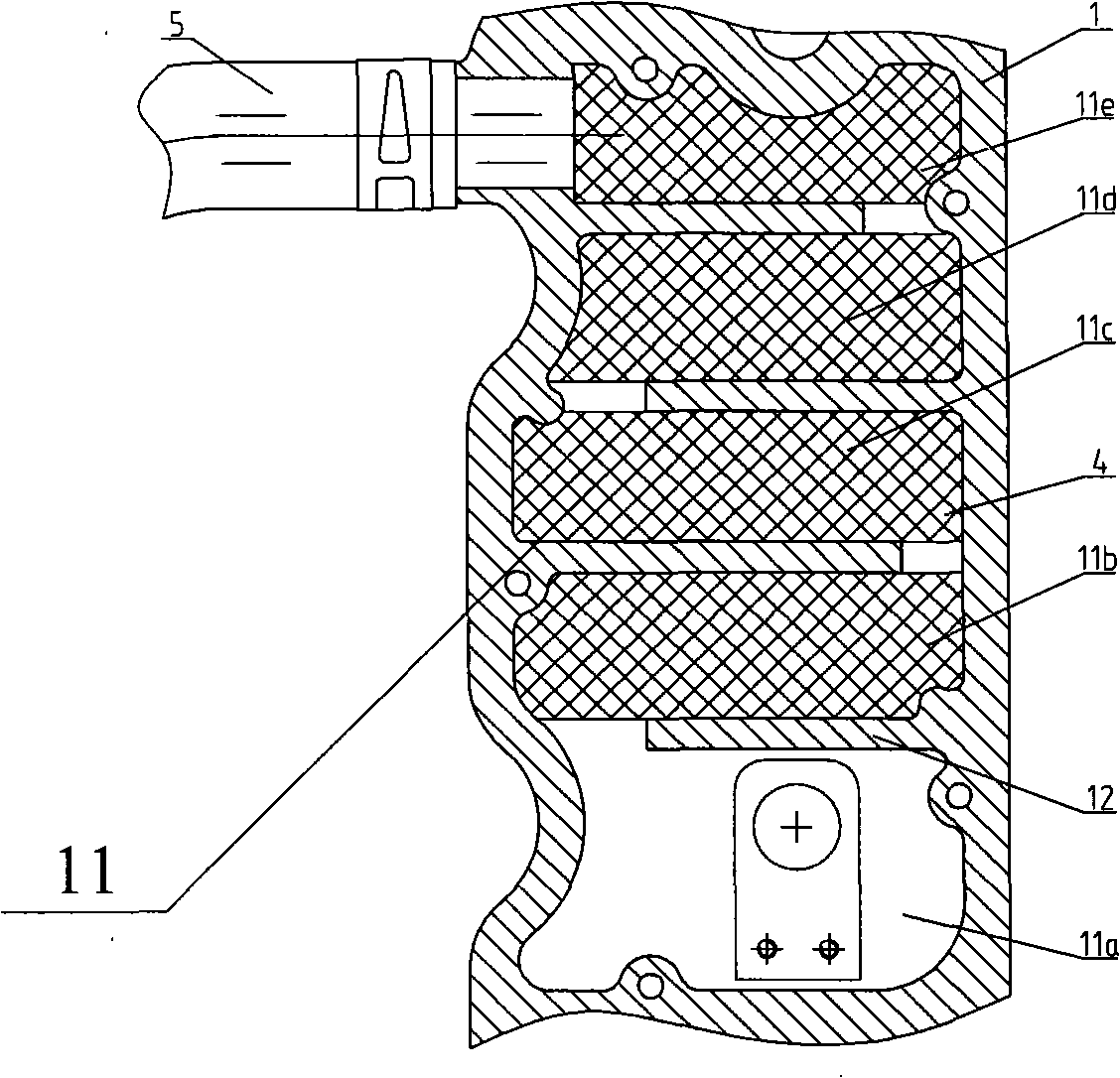

Heating type inspirator and heating assembly thereof

The invention discloses a heating assembly for a heating type inspirator. The heating assembly includes a cylindrical housing, and a fixing seat arranged in the housing; the heating assembly also includes a heating piece which is detachably arranged on the fixing seat; the heating piece includes a heating portion and an electrical connection portion connected to the heating portion; and the heating portion includes at least one gap structure for guiding the flow direction of current so as to allow even heating. The invention discloses an improved heating assembly and a heating type inspirator. The heating assembly is easy to clean, is simple in structure, is low in cost, is even in heating, is good in heating effect, will not damage the heating piece, and is long in service life.

Owner:SHENZHEN MERIT TECH CO LTD

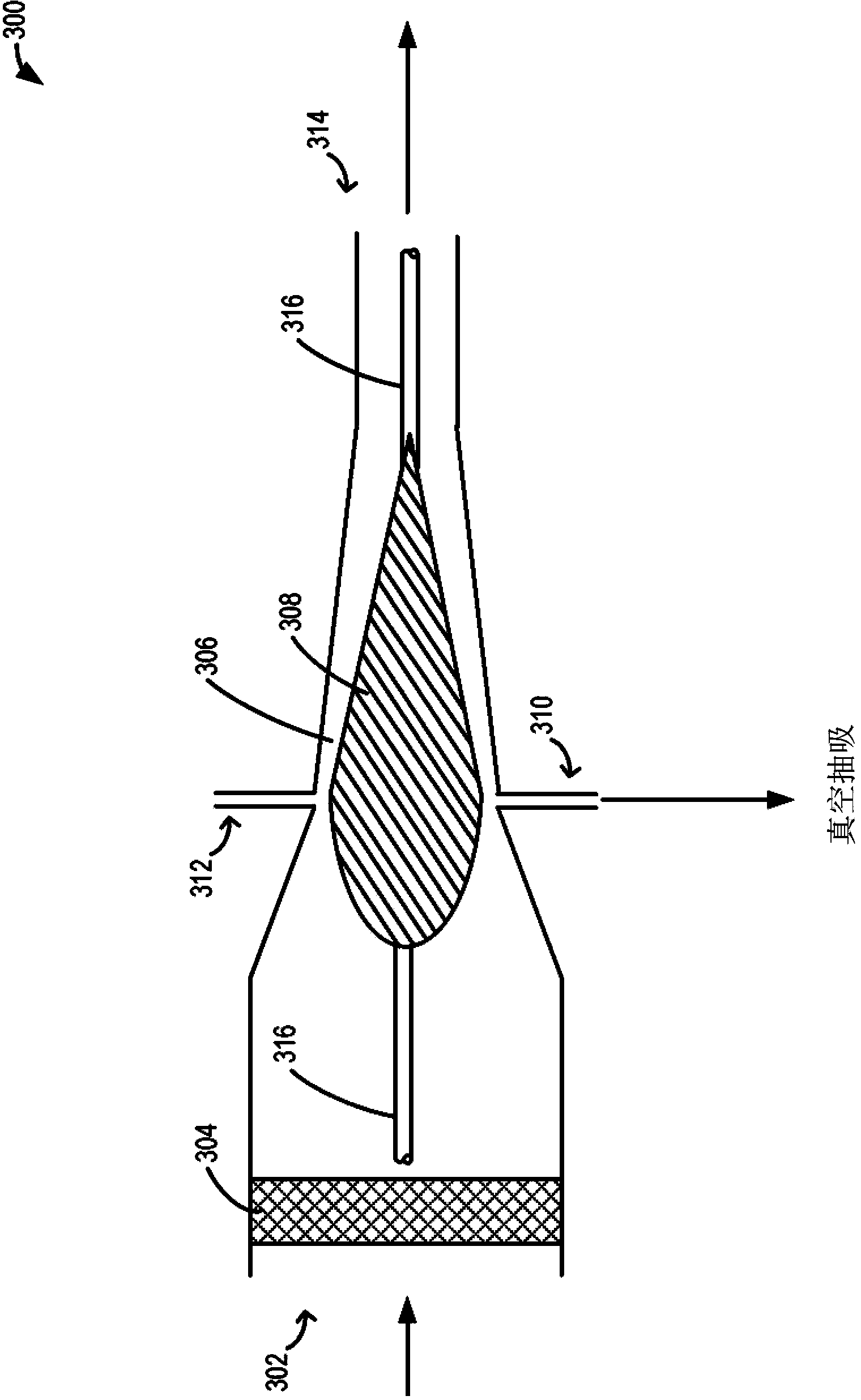

Aspirators for producing vacuum using the Venturi effect

Aspirators are disclosed herein that include a body defining a Venturi gap between an outlet end of a converging motive section and an inlet end of a diverging discharge section and have a suction port in fluid communication with the Venturi gap. The converging motive section defines a circular-shaped motive inlet and defines an elliptical- or polygonal-shaped motive outlet, and the diverging discharge section defines an elliptical- or polygonal-shaped discharge inlet. In one embodiment, the converging motive section defines an inner passageway that transitions as a hyperbolic function from the circular-shaped motive inlet to the elliptical- or polygonal-shaped motive outlet and the elliptical- or polygonal-shaped motive outlet has an area that is less than the area of the circular-shaped motive inlet.

Owner:DAYCO IP HLDG

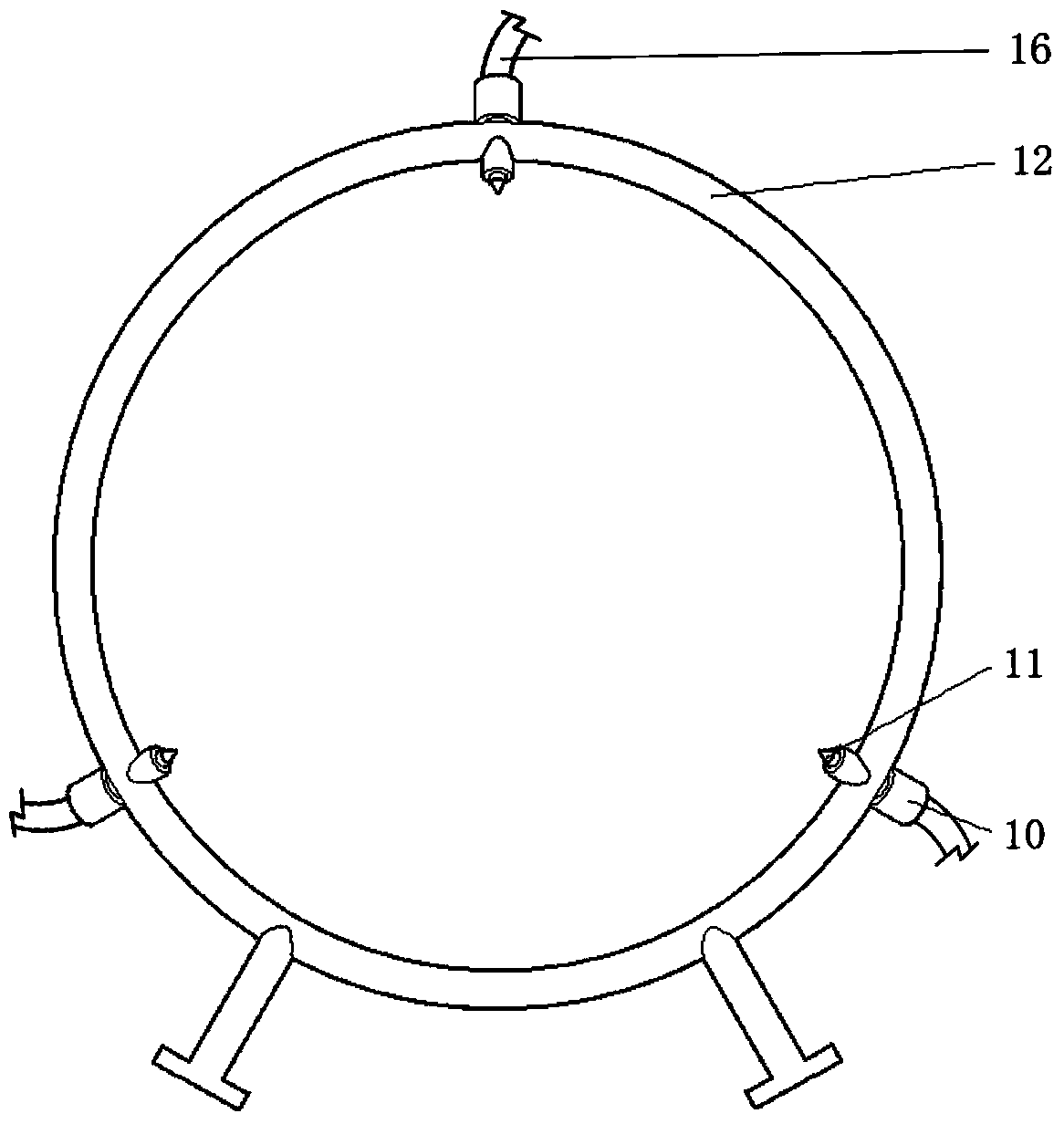

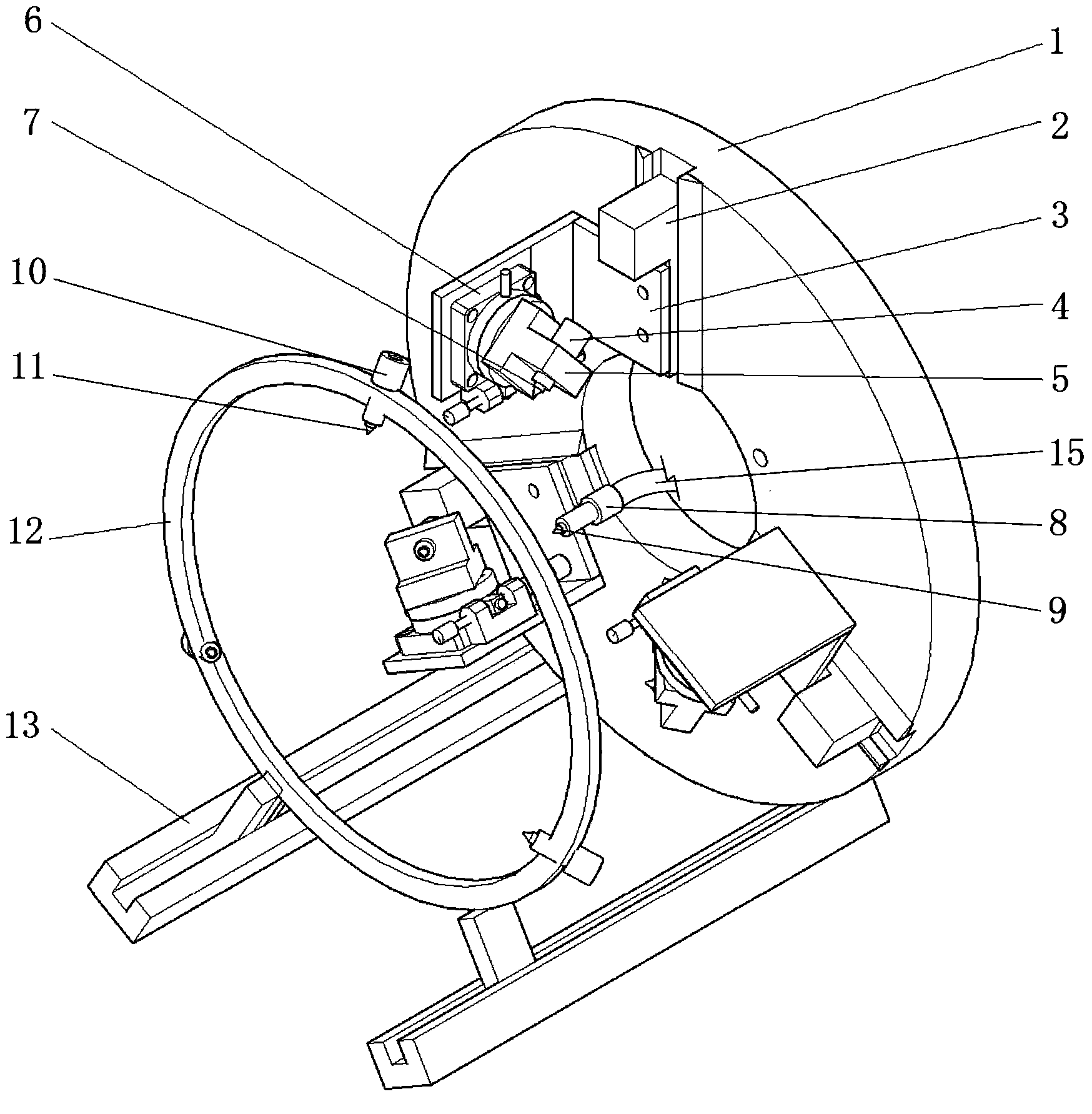

High efficiency aspirator for inflatable emergency slides

An aspirator assembly for inflating an emergency slide is disclosed. The aspirator assembly includes a bell housing, a mixing chamber, and a nozzle assembly. The bell housing includes a ring defining an inlet port at which a check valve is located and into which ambient air can flow. The mixing chamber has an outlet port. The nozzle assembly is located in the mixing chamber and includes plural passageway sections defining concentric rings and cross bars. The passageway sections include internal passageways in communication with plural nozzle jets through which a compressed air is introduced into the mixing chamber to mix with the ambient air. The passageway sections are of an airfoil shape cross-section having a rounded leading end directed towards the inlet port and a trailing end is directed toward the outlet port to reduce air turbulence within the mixing chamber.

Owner:ALTEVAC LLC

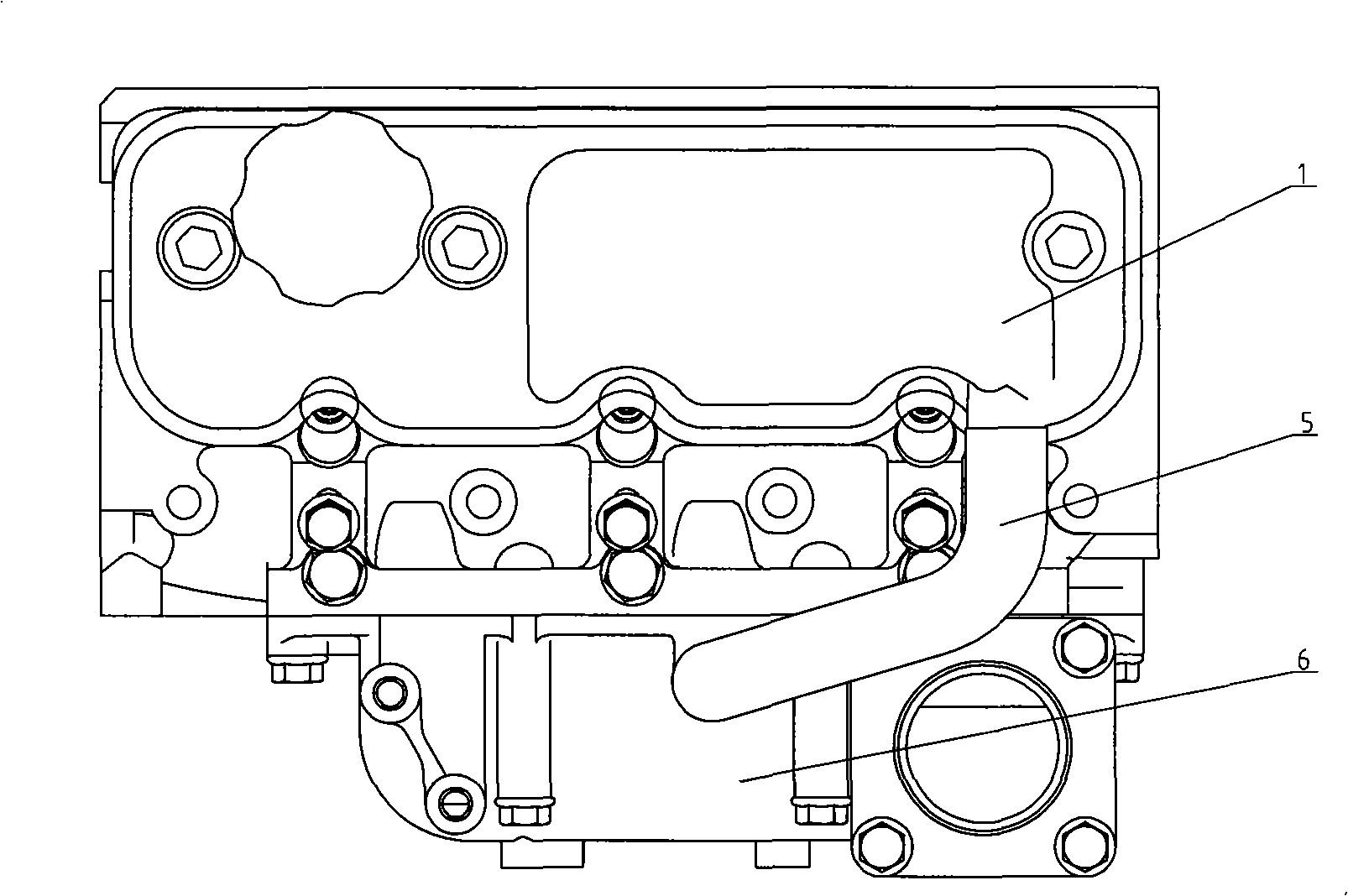

Engine ventilating device

InactiveCN101270684AAvoid dischargeEasy to captureMachines/enginesCrankcase ventillationInspiratorCombustion chamber

The invention relates to an engine breather for improving the performance of a whole internal-combustion engine and being favorable for environmental protection. The invention is characterized in that a cylinder cover is provided with a plurality of shutters and separation chambers filled with catch materials and covered by an inspirator cover. The inspirator cover is provided with an oil-gathering groove. The bottom of the oil-gathering groove is provided with a plurality of oil drain holes. The inspirator cover is provided with an inspirator pore that is a communication pore canal for a crankcase and an intake manifold. An inspirator spring piece and a spring piece binder plate are arranged in the inspirator pore. The engine breather can prevent oil mist in the crankcase of the engine from being discharged to outside, thus effectively stopping elaioplast in the oil mist from entering a combustion chamber and avoiding carbon and cold smoke caused by the oil burning of the engine. And the engine oil consumption and the discharge amount of carbon granule are increased.

Owner:WUXI KIPOR POWER CO LTD

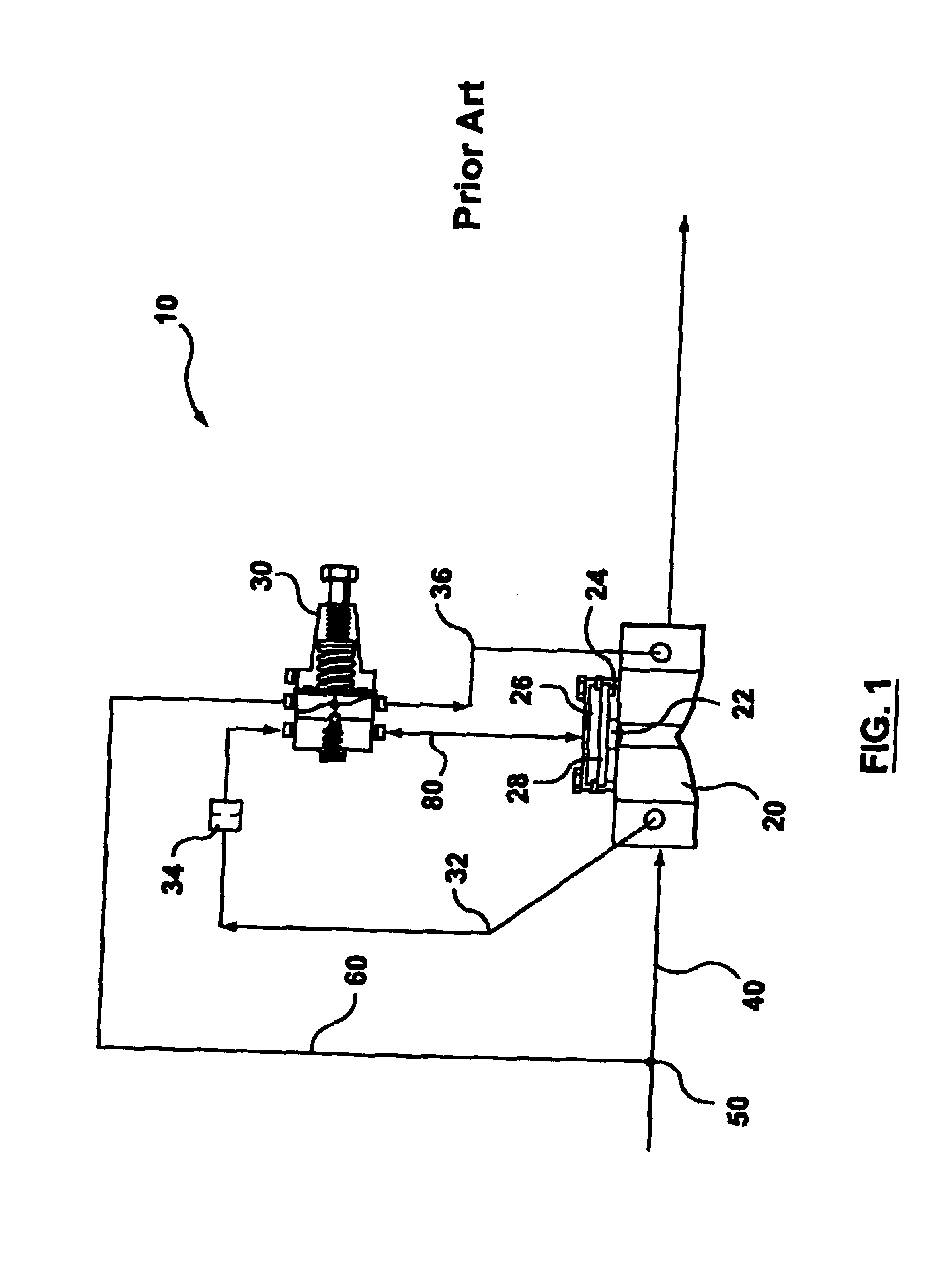

Pressure control system for low pressure operation

ActiveUS6935363B2Operating means/releasing devices for valvesFluid pressure control with auxillary non-electric powerInspiratorDifferential pressure

A pressure control system for controlling the pressure of a process fluid stream at a certain location having a pressure regulator disposed in the process fluid stream, through which the process fluid stream flows. A first pilot controller senses the pressure of the process fluid at the location and receives a control pressure from a control source. A second pilot controller receives the control pressure from the control source and provides added pressure. An inspirator receives the added pressure from the second pilot controller and generates a differential pressure. The differential pressure is used to control the pressure of the process fluid stream within the pressure regulator. The pressure regulator comprises a first chamber and a second chamber therein separated by a flexible element and a divider is disposed in the first chamber and operative to abut against the flexible element to divide the first chamber into separate spaces. Preferably, the pressure regulator is disposed such that the flexible element extends substantially in vertical direction and the divider extends substantially in horizontal direction.

Owner:HYDROGENICS CORP

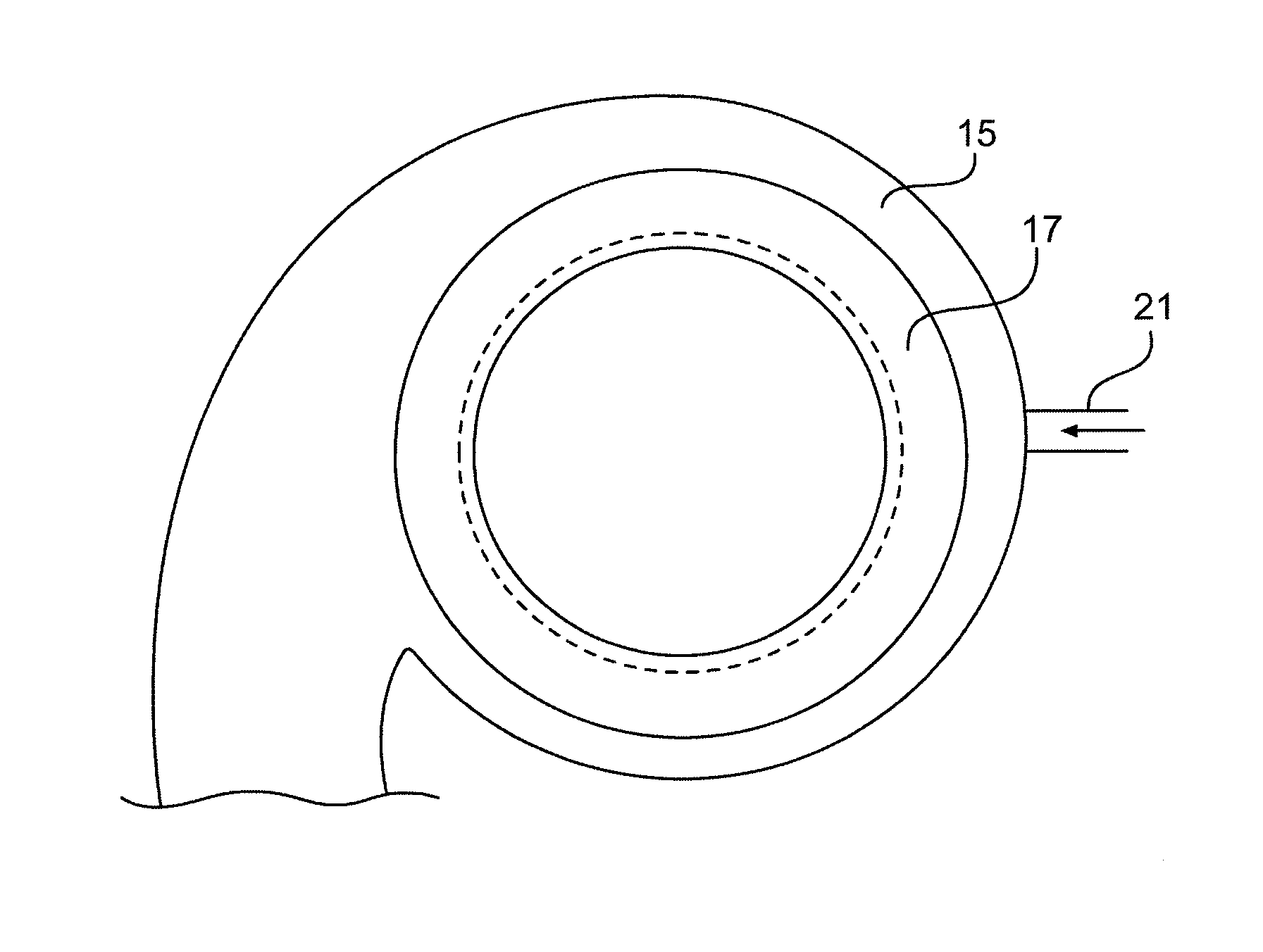

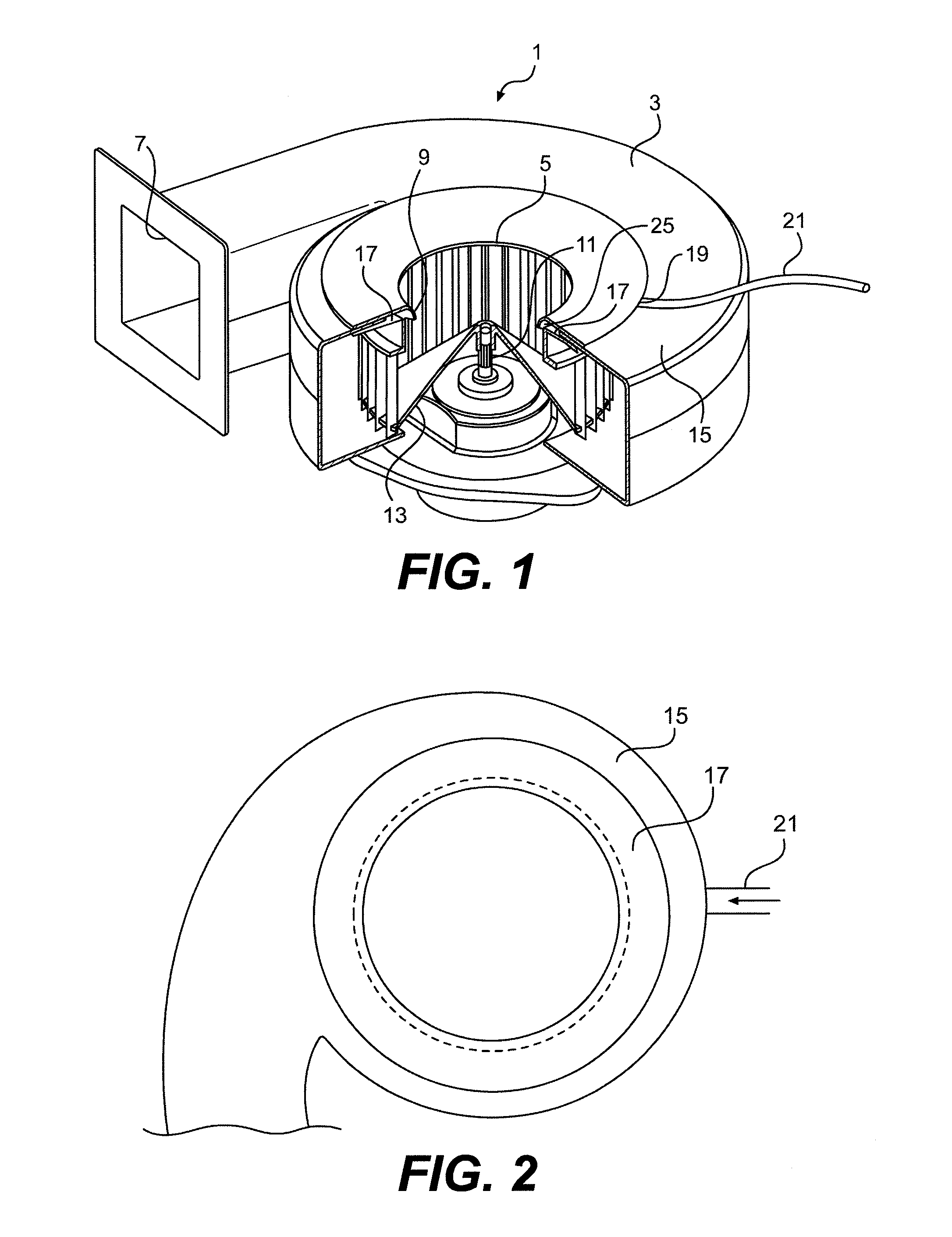

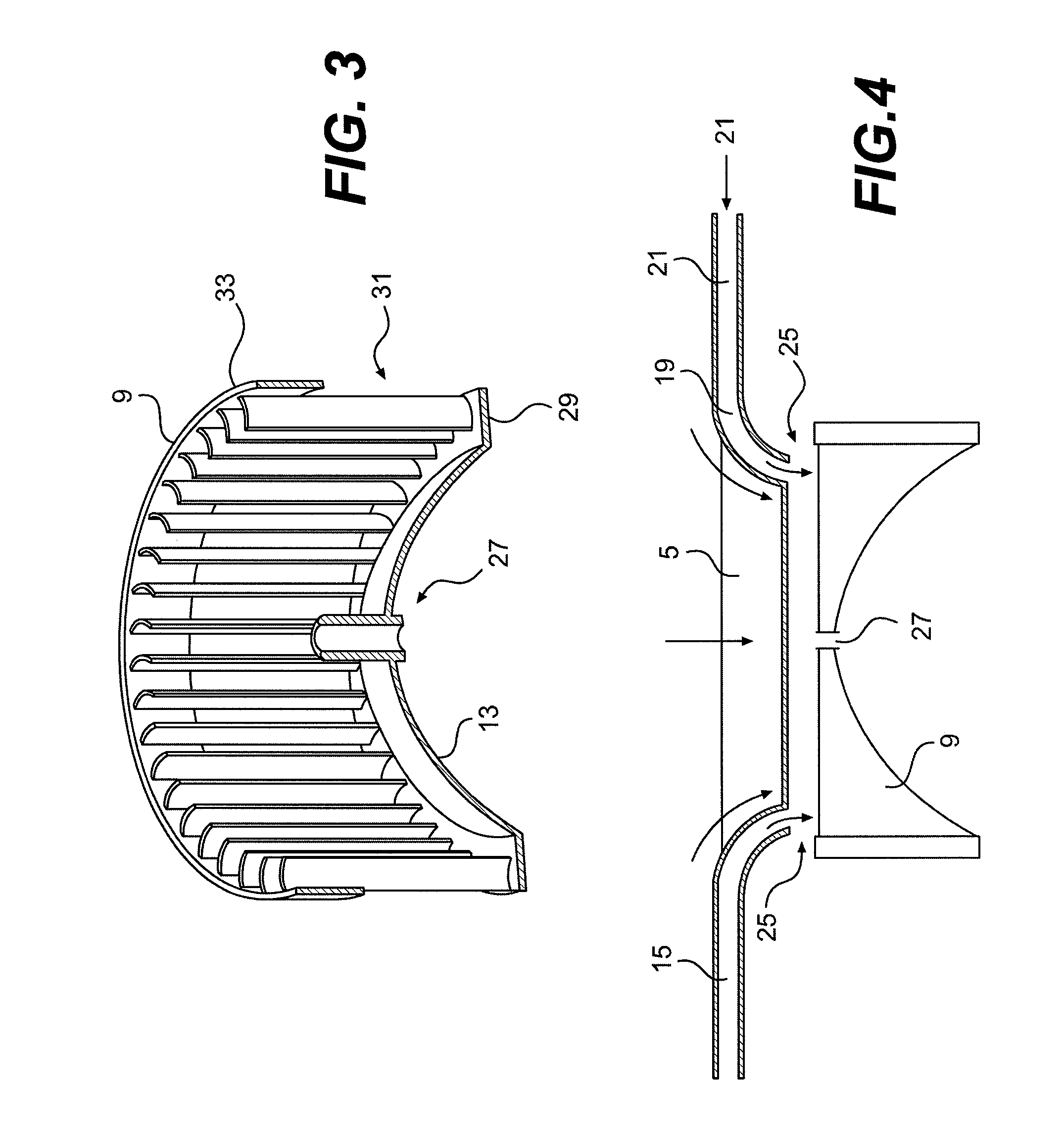

Blower scroll having an aspirator venturi

A blower assembly for use with an HVAC module is provided. The blower assembly includes a scroll or volute shaped housing having an air inlet in a wall of the housing for receiving air to be blown by an impeller, and an air outlet from which the blown air passes from the housing. A blower wheel is secured to a rotatable motor-driven shaft extending along a central axis of the air inlet. At least one venture is provided adjacent to the air inlet of the housing, the at least one venturi connectable to an aspirator that is in fluid communication with a sensor unit. Wherein, during operation, the blower wheel pulls air both through the air inlet to the housing and through the at least one venturi.

Owner:BEHR AMERICA

Adjustable gel propellant three-time jet flow impact atomizing device

InactiveCN103590921AOvercoming the problem of non-adjustable angleAdjustable impact angleRocket engine plantsLiquid jetInspirator

The invention discloses an adjustable gel propellant three-time jet flow impact atomizing device. The adjustable gel propellant three-jet-flow impact atomizing device comprises a plate-shaped base, liquid jet flow impact inspirators, a second air jet flow inspirator and a third air jet flow inspirator; the plate-shaped base comprises an executing mechanism which can be used for adjusting the distance between every two liquid jet flow impact inspirators, each liquid jet flow impact inspirator comprises an executing mechanism which can be used for adjusting the jet flow angle, and the third air jet flow inspirator comprises an executing mechanism which can be used for adjusting the axial position of an air flow mixed area. The adjustable gel propellant three-time jet flow impact atomizing device is designed on the basis of simple parts, has the advantages that the height of the liquid jet flow posture is adjustable in three-dimensional space, and the liquid jet flow impact inspirators are evenly distributed on the plate-shaped base, and can meet the requirement for atomization of various adhesive gel propellants.

Owner:NANJING UNIV OF SCI & TECH

Combined intake aspirator venturi tube and water trap in vertical exhaust outlet stack

ActiveUS20120124980A1Easy to adaptEfficient trappingSilencing apparatusMachines/enginesInspiratorWater trap

An integral water trap and venturi tube element for use in an exhaust stack on a vehicle, the exhaust stack being generally vertically oriented and having a catalyst element or other moisture-sensitive emission control component disposed below the water trap, the venturi tube having an aspirator tube disposed therein to provide a low pressure aspiration source for the vehicle, wherein the venturi tube is so disposed in the exhaust stack to also function as the water trap and allows capture and diversion of water entering the exhaust stack from above.

Owner:BLUE LEAF I P INC

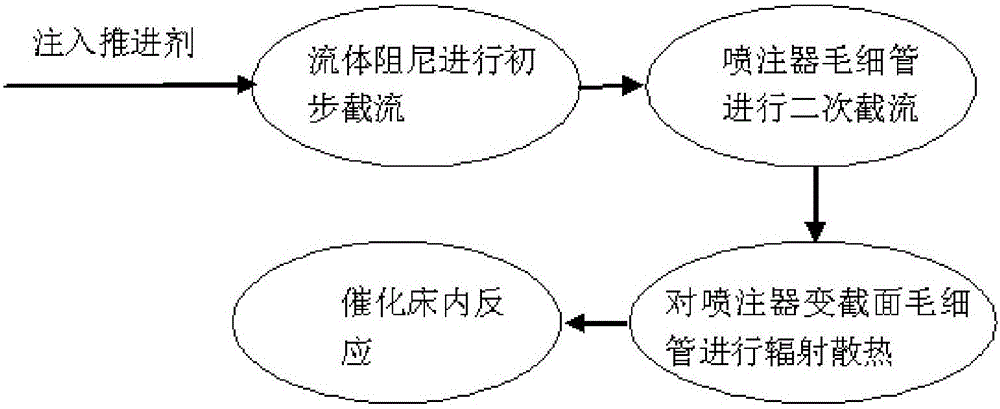

Flow control device and method

ActiveCN106014688AImprove anti-pollution performanceImprove machine lifeRocket engine plantsInspiratorEngineering

The invention discloses a flow control device and method. The flow control device comprises a fluid damper, an electromagnetic valve, an inspirator, a radiation fin and a catalytic bed. A fluid channel used for conducting throttling on a propellant is formed in the fluid damper. The fluid damper is connected with an inlet in one end of the electromagnetic valve. A propellant passageway is formed in the electromagnetic valve. The propellant passageway communicates with the fluid channel. The internal diameter of the propellant passageway in the electromagnetic valve is larger than that of the fluid channel in the fluid damper. The electromagnetic valve is connected with the catalytic bed through the inspirator. According to variable-section capillary tubes of the inspirator of the flow control device, by increasing the flow area of the root portions of the capillary tubes, the contamination resistance of the capillary tubes is improved, and the service life of a whole thruster is prolonged. Compared with an existing flow control device with the service life shorter than 50 hours, the service life of the flow control device can be prolonged to 500-1000 hours.

Owner:BEIJING INST OF CONTROL ENG

Particulate blaster assembly and aspirator

A particulate blaster assembly (100) for use as an attachment to a portable air blower (150) includes an air directing tube (110), a vacuum generating assembly (120), and a particulate material aspirator (130). The air directing tube (110) has an inlet end (112) formed for coupling to the air blower (150) to receive air discharged therefrom and a movable exhaust end (114) formed for discharge of air and particulate material (212) entrained in the air toward a target site (160). The vacuum assembly (120) is coupled to the air directing tube (110) and formed to produce a partial vacuum as air passes in the tube (110) over the vacuum generating assembly (120). The particulate material aspirator (130) is coupled to the vacuum assembly (120) and is responsive to the partial vacuum generated by the vacuum generating assembly (120) to aspirate a particulate material (212) from a particulate material source (340) into the air directing tube (110) for acceleration and discharge of the entrained particulate material (212). Preferably, a positive pressure, generating assembly (182) communicates positive pressure to aspirator (130) for cooperation with the partial vacuum at the aspirator (130) to aspirate particulate material (212) into the air directing tube (110).

Owner:DANIEL DORCE L

Aspirator motive flow control for vacuum generation and compressor bypass

ActiveUS9382882B2Expand business scopePrevent objectionable audible noiseInternal combustion piston enginesNon-fuel substance addition to fuelInspiratorMixed flow

Systems and methods are provided for engine systems including a first multiple tap aspirator with a motive inlet coupled to an intake upstream of an air induction system throttle and a mixed flow outlet coupled to an intake manifold, and a second multiple tap aspirator with a motive inlet coupled to the intake upstream of a main throttle and a mixed flow outlet coupled to the intake downstream of the air induction system throttle. During non-boost conditions, intake air may be selectably diverted around a compressor and through the first and / or second aspirator based on desired vacuum generation. During boost conditions, the first and second aspirators may function as compressor bypass valves, and intake air may be selectably directed from downstream of the compressor to upstream of the compressor via the first and / or second aspirator based on a desired compressor bypass flow.

Owner:FORD GLOBAL TECH LLC

Engine exhaust cooler and air pre-cleaner aspirator

ActiveUS20090293836A1Avoid flowCombination devicesLiquid degasificationInspiratorExternal combustion engine

A diffuser for a work machine having an air breathing fuel consuming internal combustion engine with an exhaust aftertreatment device periodically elevating the exhaust temperatures to a high level. The diffuser has a venturi section and the excess contaminants from an intake air pre-cleaner are directed to the throat of the venturi to aspirate and dispose of excess contaminants while cooling the exhaust flow. Additional openings in the divergent section of the diffuser assist in providing significant reductions in exhaust temperatures within a short axial envelope.

Owner:DEERE & CO

Crankcase ventilation and vacuum generation

InactiveCN103511025AImprove vacuum generation efficiencyDoes not compromise minimum controllable airflow budgetNon-fuel substance addition to fuelInternal combustion piston enginesInspiratorEngineering

The invention relates to methods and systems for generating vacuum from crankcase ventilation flow. During both directions of gas flow between an engine intake manifold and a crankcase, gases are directed through one or more aspirators to produce vacuum. The drawn vacuum may then be used to operate various engine vacuum actuators.

Owner:FORD GLOBAL TECH LLC

Supplementary combustion type supercritical pressure gas-liquid two-phase fuel generator combustion chamber

ActiveCN102287801AExtend your lifeFixing Air LeaksFluid removalSteam boilersInspiratorCombustion chamber

The invention provides a supplementary combustion chamber of a supercritical pressure gas-liquid fuel generator, and relates to oil extraction equipment in an oil field. The supplementary combustion chamber is characterized by comprising a pre-combustion chamber (6), a secondary combustion chamber (10) and a vaporizing chamber (14). A spouting mode of fuel of the supplementary combustion chamber is as follows: the pre-combustion chamber (6) only sprays part of the fuel and full air for oxygen-enriched combustion; the remaining fuel is sprayed into the secondary combustion chamber (10) from a supplementary combustion inspirator and completely combusted with oxygen-enriched gas from the pre-combustion chamber in the secondary combustion chamber (10). By the combustion chamber, simultaneous combustion of gas fuel and liquid fuel is realized, and heat transfer deterioration is prevented due to various cooling modes.

Owner:刘殿玺 +2

Combined intake aspirator venturi tube and water trap in vertical exhaust outlet stack

ActiveUS9103262B2Easy to adaptEfficient trappingSilencing apparatusMachines/enginesInspiratorWater trap

An integral water trap and venturi tube element for use in an exhaust stack on a vehicle, the exhaust stack being generally vertically oriented and having a catalyst element or other moisture-sensitive emission control component disposed below the water trap, the venturi tube having an aspirator tube disposed therein to provide a low pressure aspiration source for the vehicle, wherein the venturi tube is so disposed in the exhaust stack to also function as the water trap and allows capture and diversion of water entering the exhaust stack from above.

Owner:BLUE LEAF I P INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com