Adjustable gel propellant three-time jet flow impact atomizing device

A technology of gel propellant and atomization device, which is applied in jet propulsion device, rocket engine device, machine/engine, etc., can solve the problems of secondary atomization, affecting atomization effect, and ineffectiveness of gel propellant. , to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

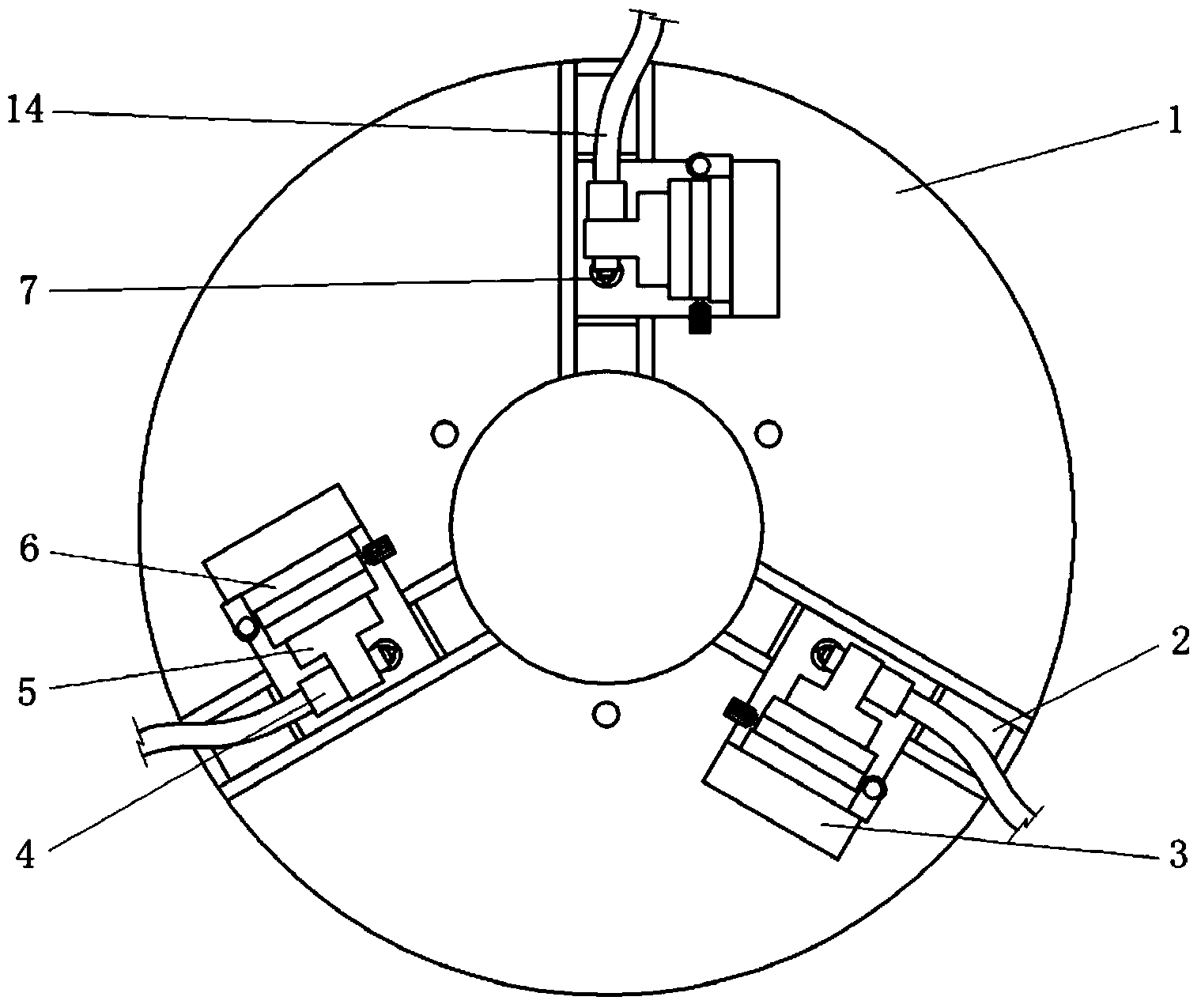

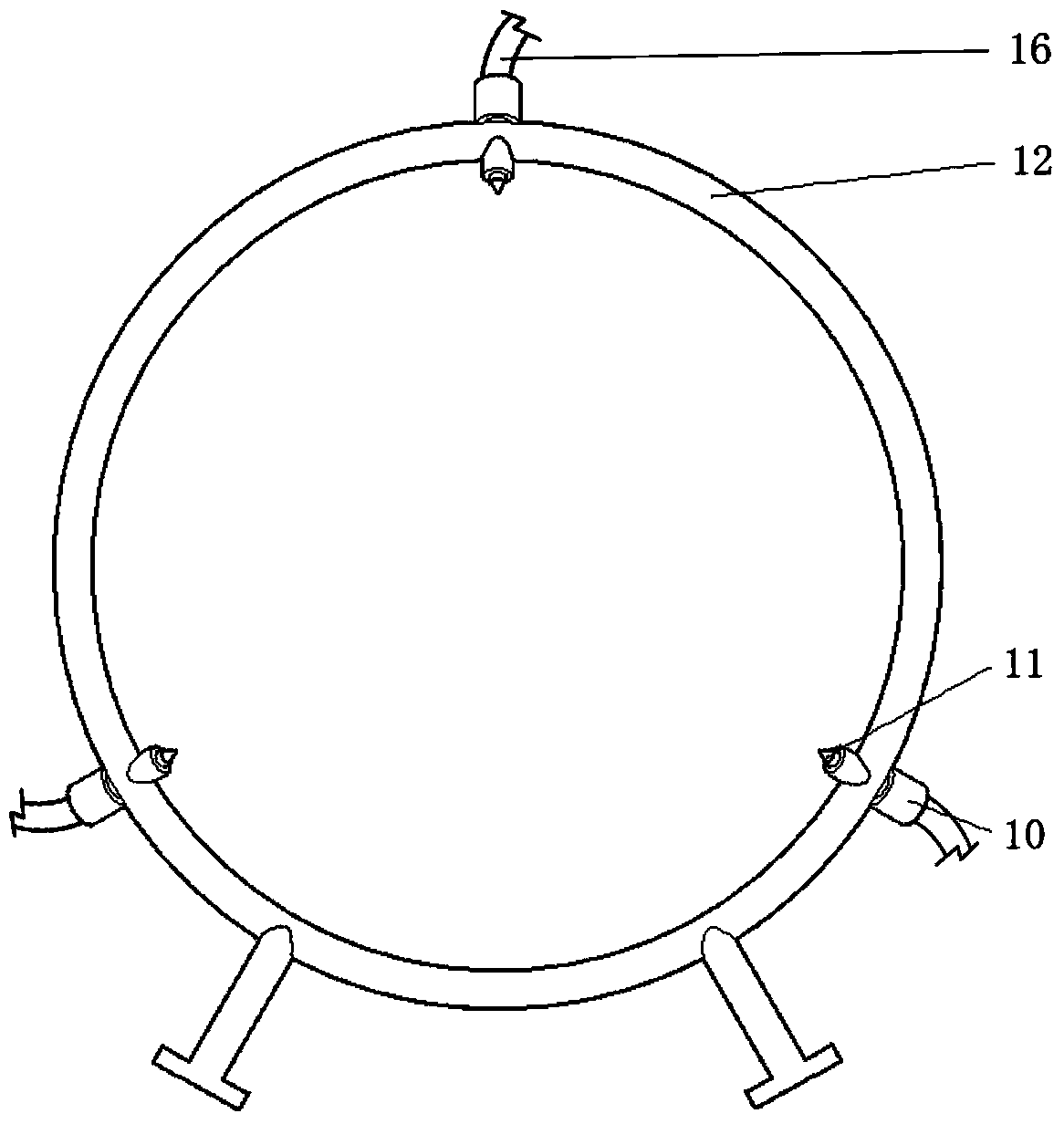

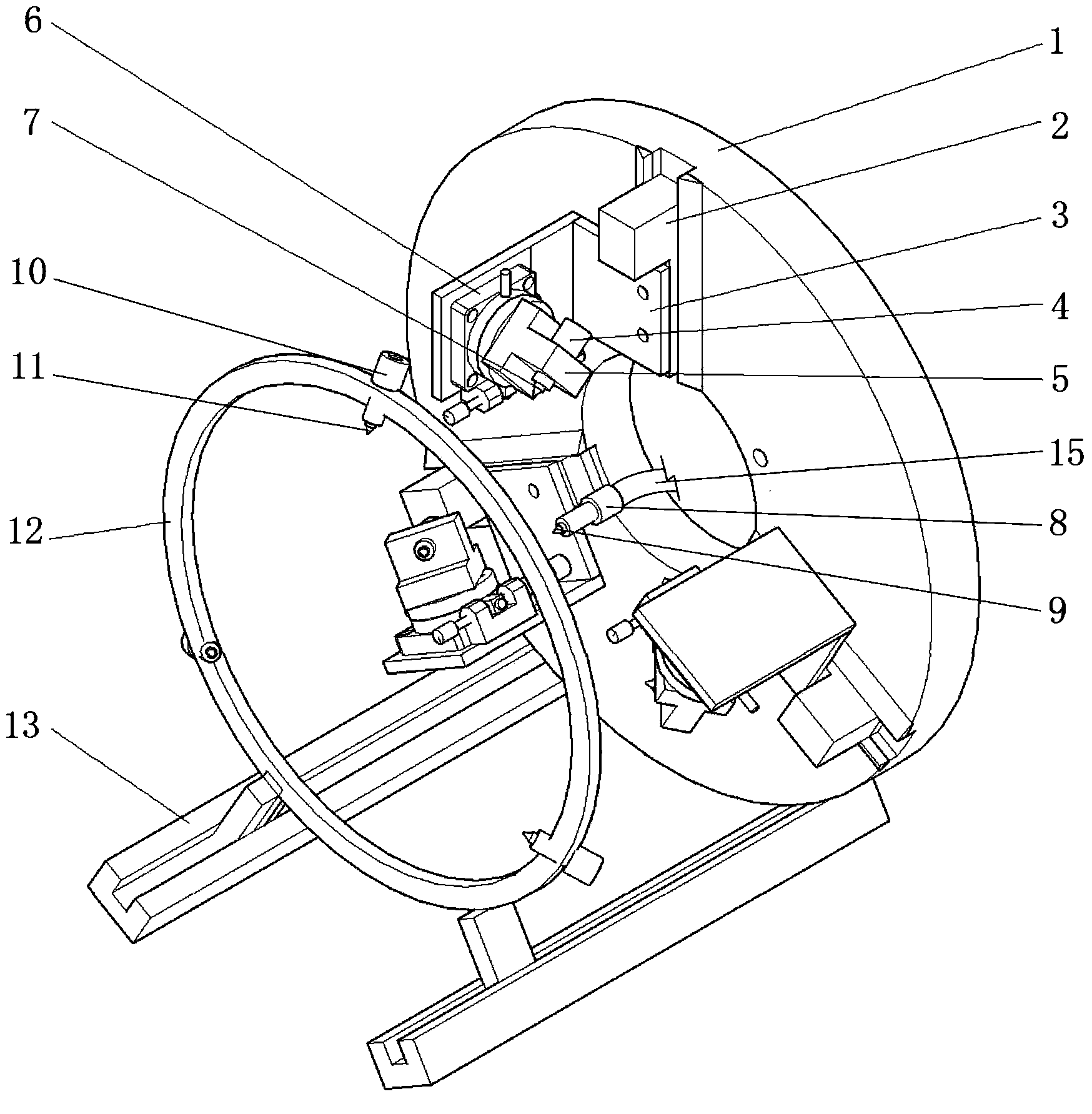

[0034] combine Figure 1 to Figure 5 , an adjustable three-jet impingement atomization device for gel propellants, including a base, a liquid jet impingement injector, a gas jet secondary injector and a gas jet triple impingement injector.

[0035] The base includes a disk-shaped base 1 and a spacing adjustment slider 2. There are three slide grooves on the disk-shaped base 1 that are evenly distributed in a 120° circumferential direction, and the spacing adjustment slider 2 is embedded in the slide grooves. Each chute side is engraved with a scale, and the spacing adjustment slider 2 is also engraved with a scale on the side of the chute that is engraved with a scale, so as to facilitate the adjustment of the movement distances of the three spacing adjustment sliders 2 respectively.

[0036] The liquid jet impact injector includes an L-shaped support frame 3, an impact angle adjustment platform 6, a nozzle fixing block 5, a liquid jet nozzle conduit connecting sleeve 4, a liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com