Patents

Literature

286results about "Fluid pressure control with auxillary non-electric power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

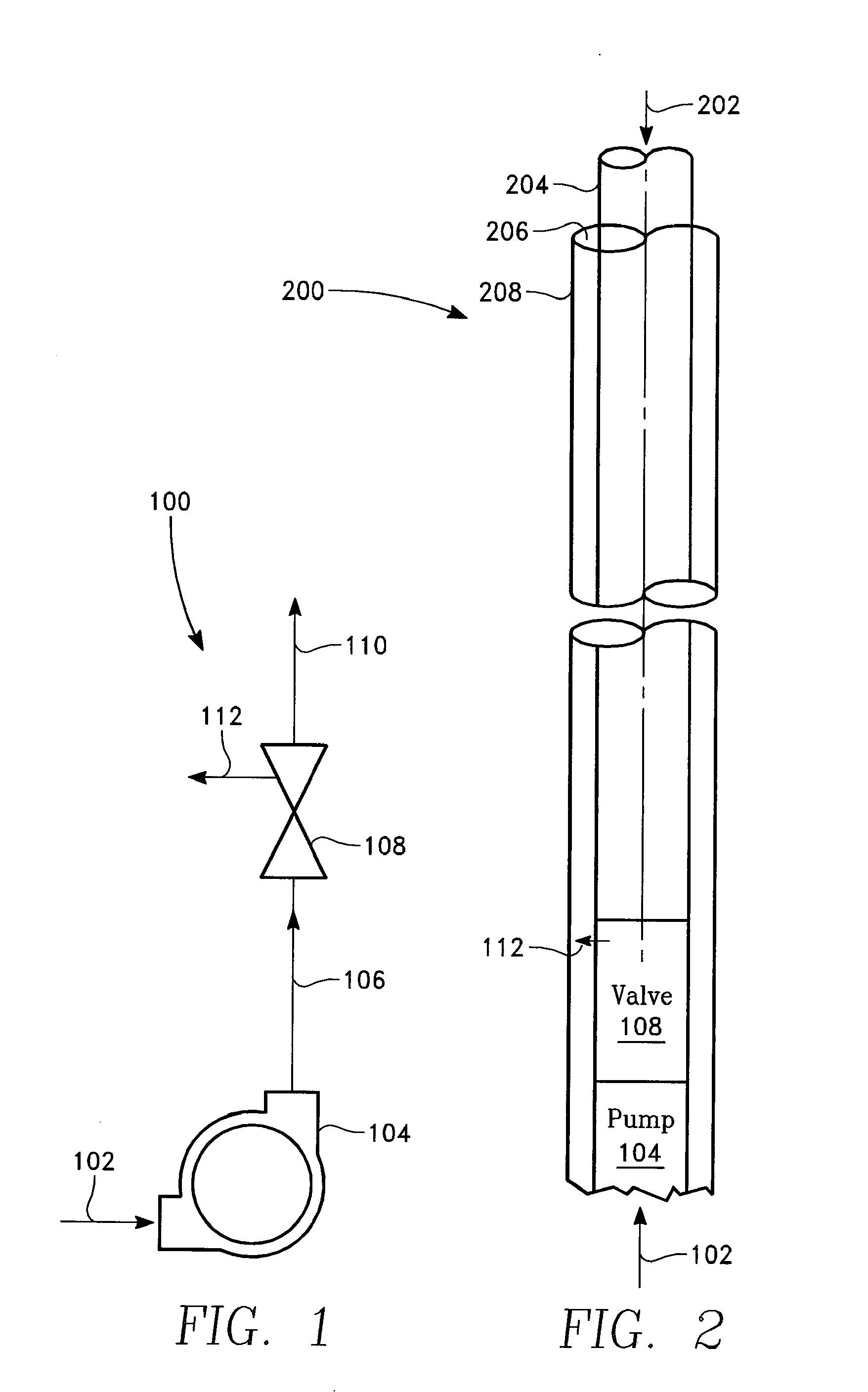

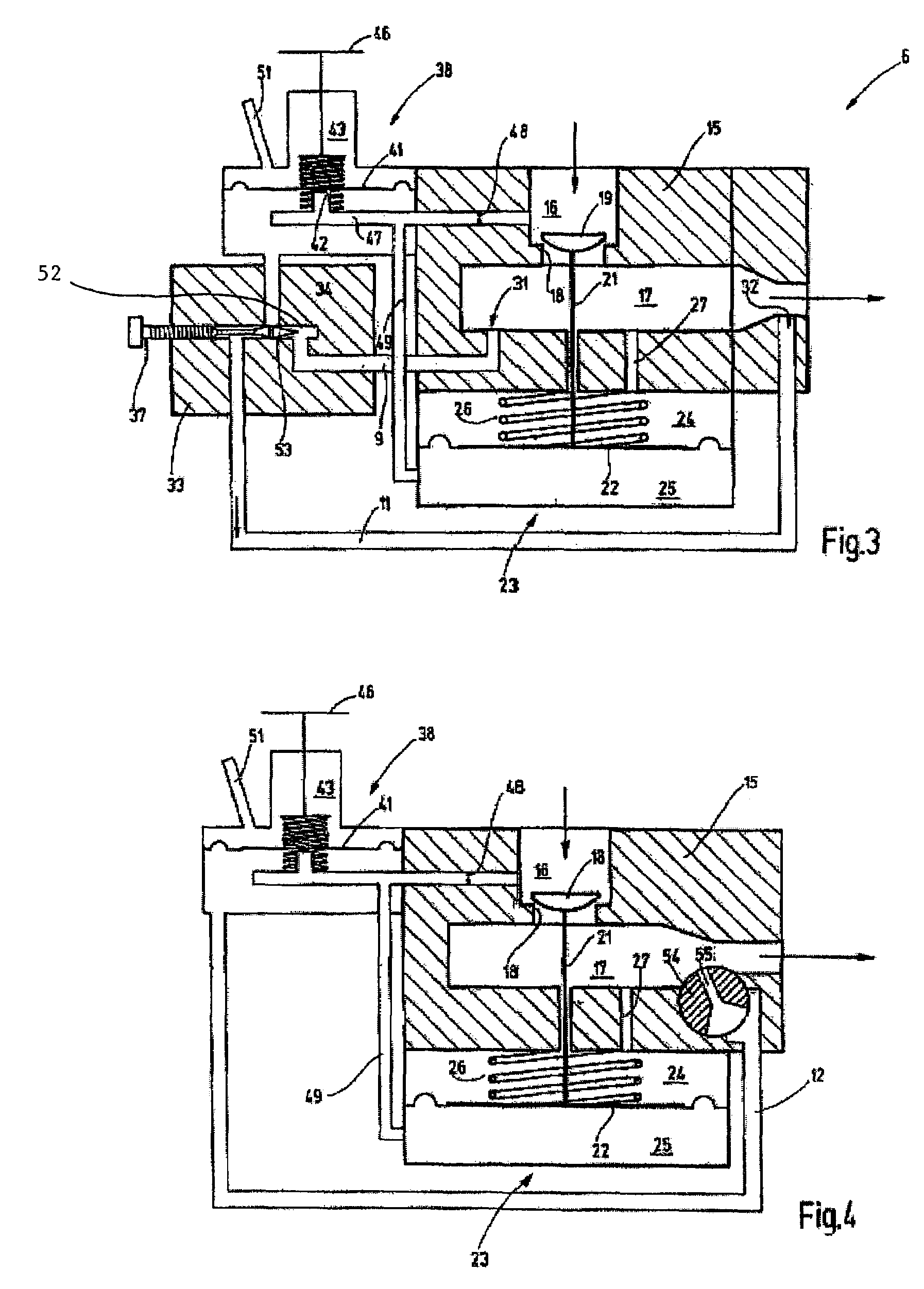

Device, method, and system for controlling fluid flow

InactiveUS20050150552A1Operating means/releasing devices for valvesVolume/mass flow measurementEngineeringAtmospheric pressure

A flow control device may include an inlet for passing fluid into the device, an outlet for passing fluid from the device, a pneumatic pressure controlling portion, a fluid flow control valve actuated by pneumatic pressure supplied via the pneumatic pressure controlling portion, a flow meter configured to measure flow rate of the fluid, and a controller configured to control the pneumatic pressure controlling portion at least according to the flow rate measured by the flow meter. Actuation of the fluid flow control valve may cause adjustment of the flow rate.

Owner:BOC EDWARDS

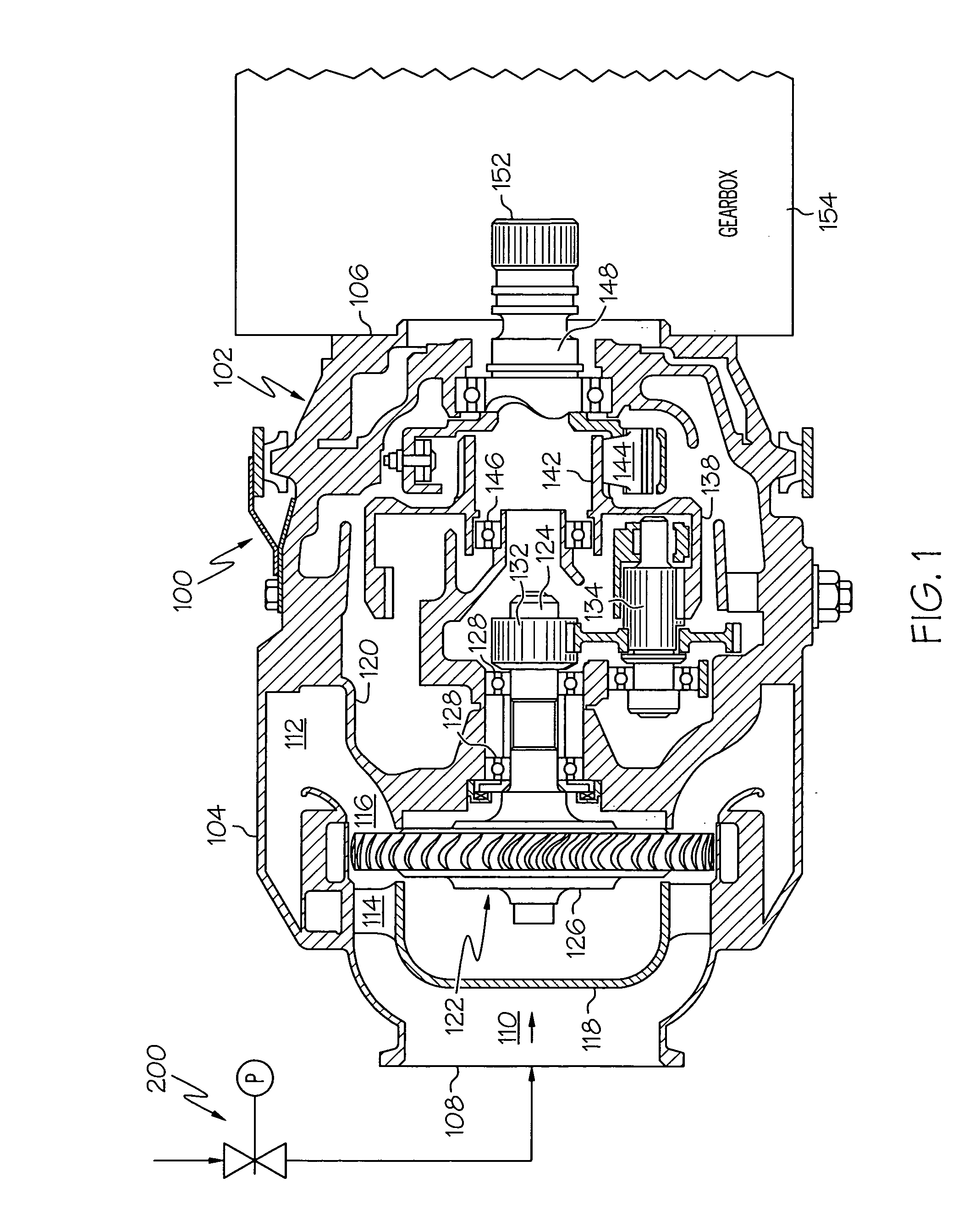

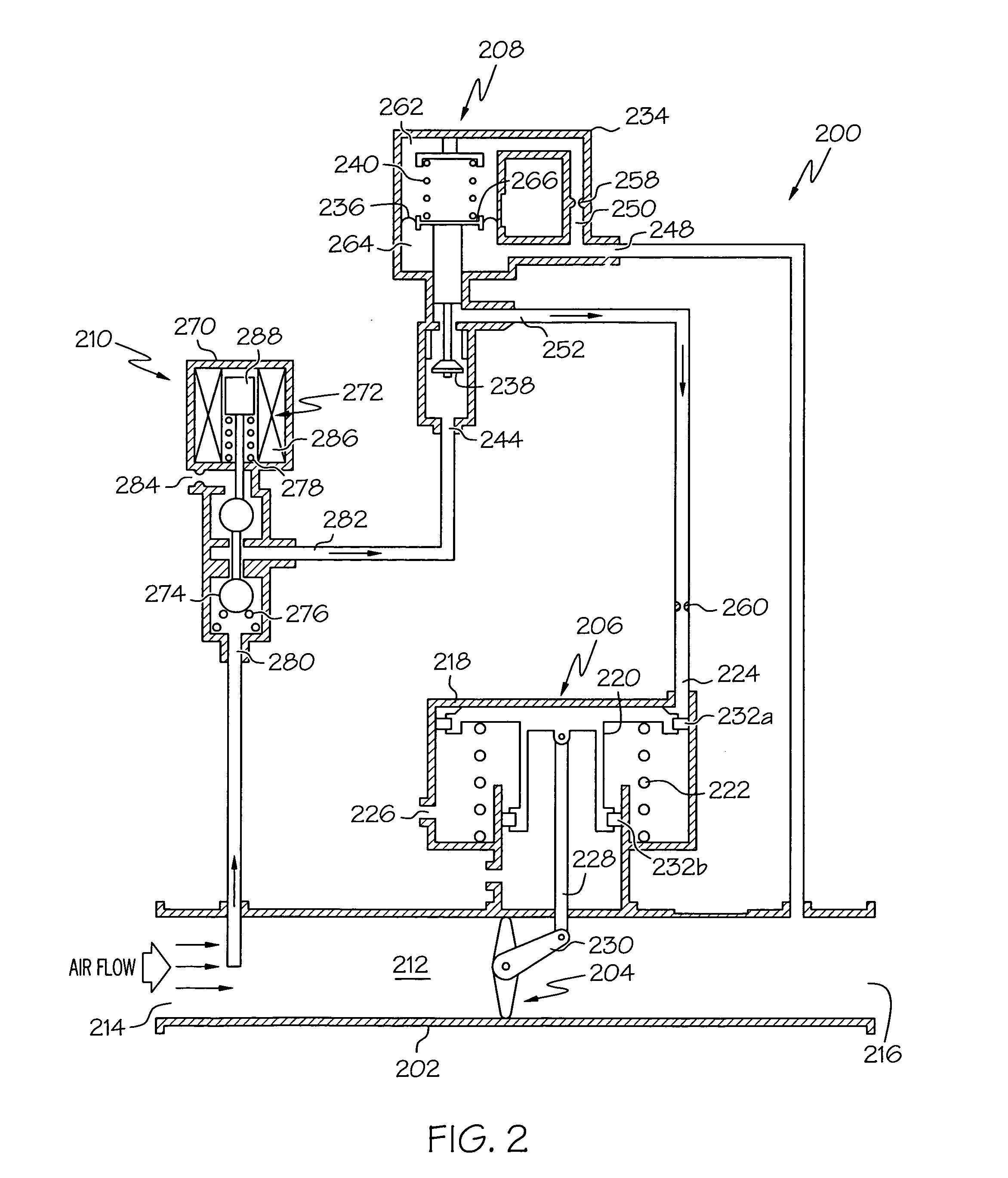

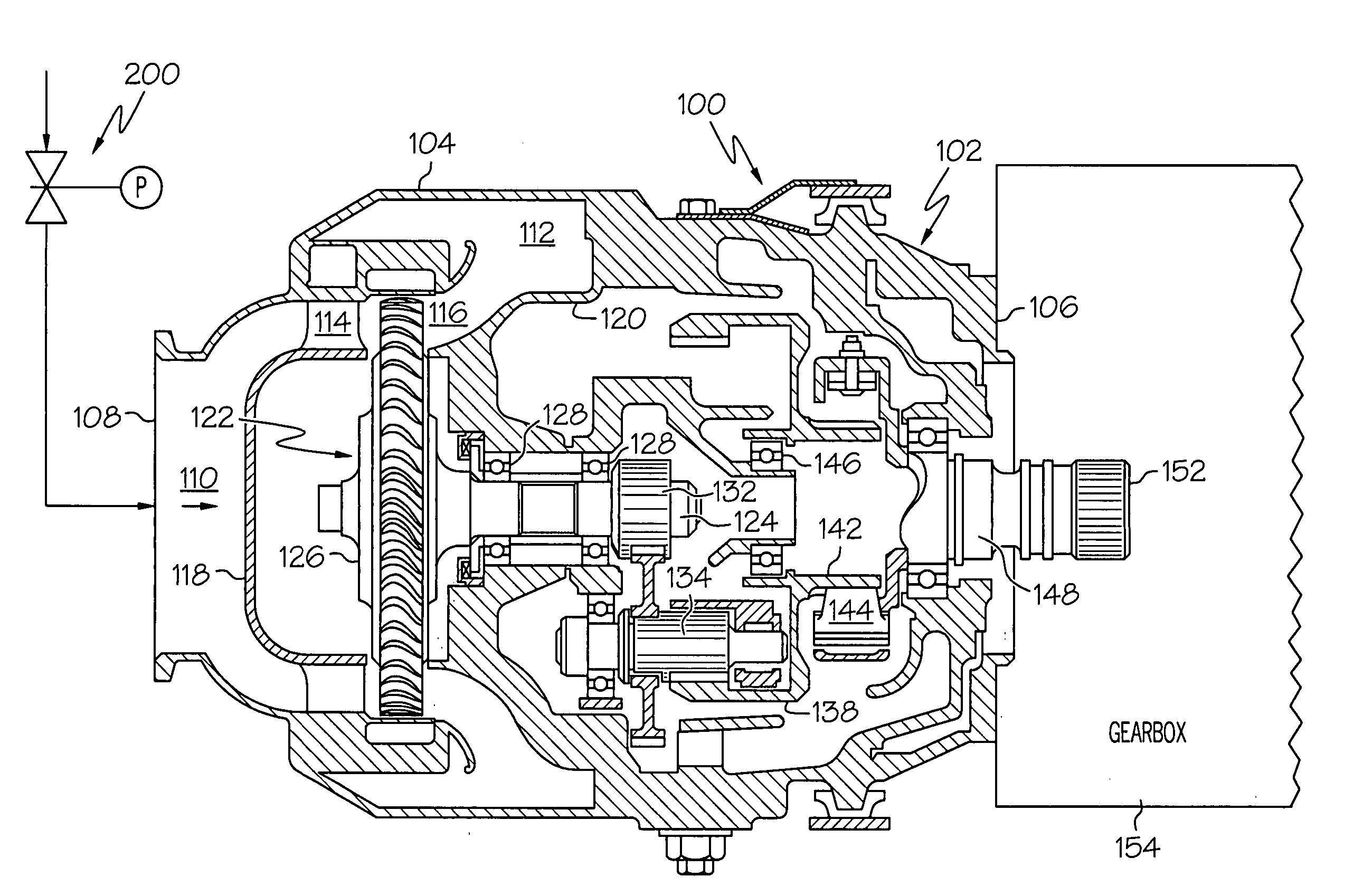

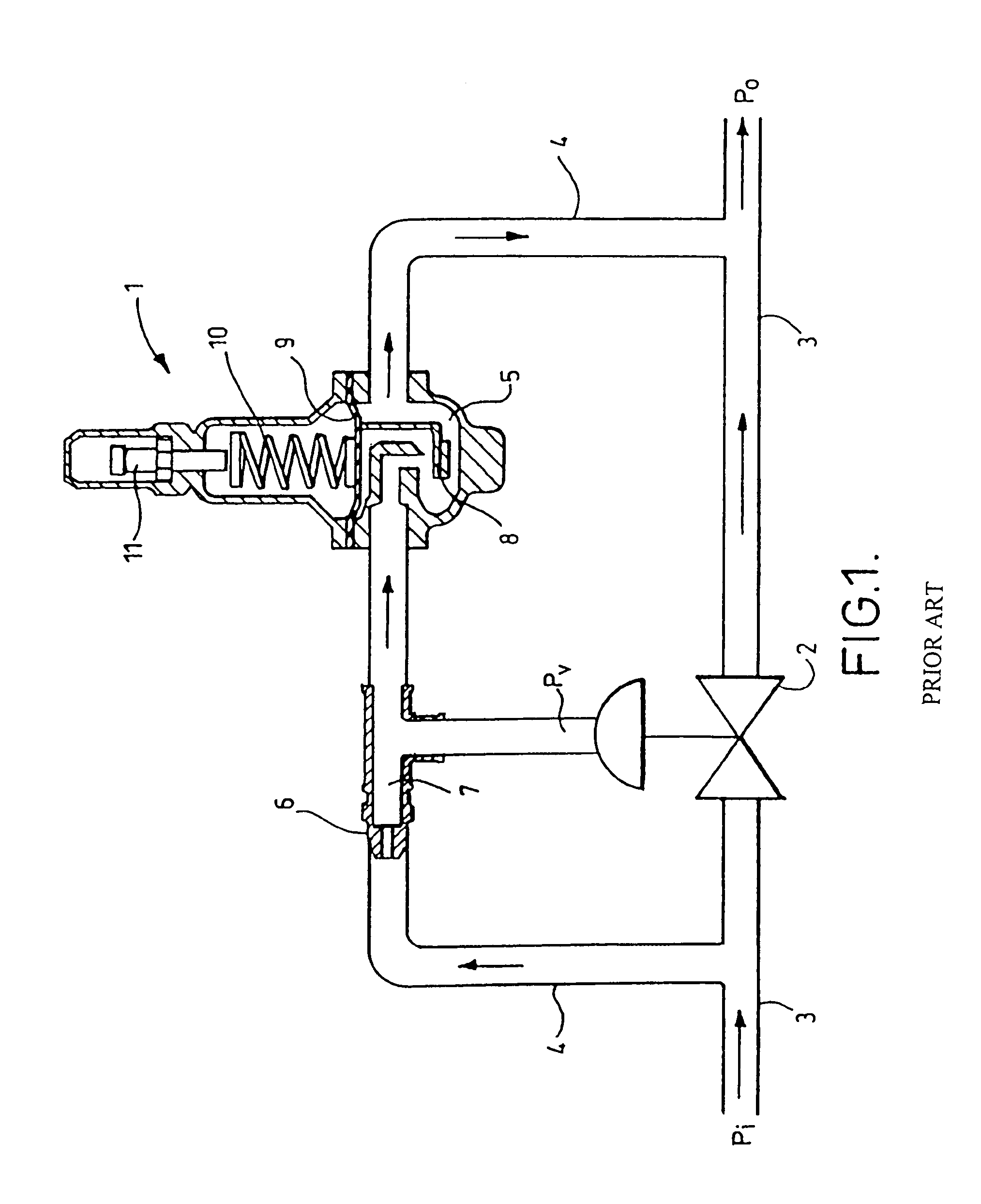

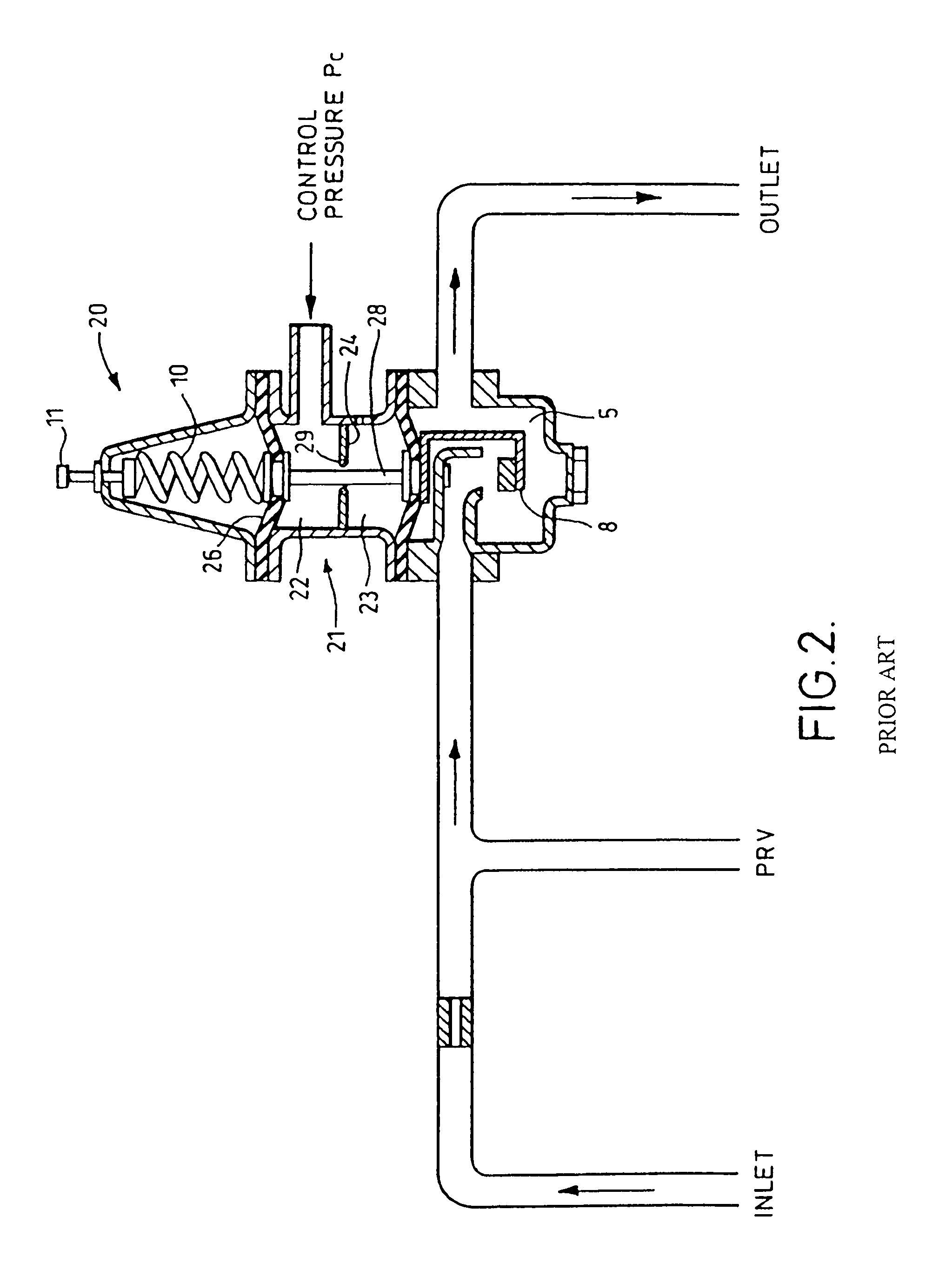

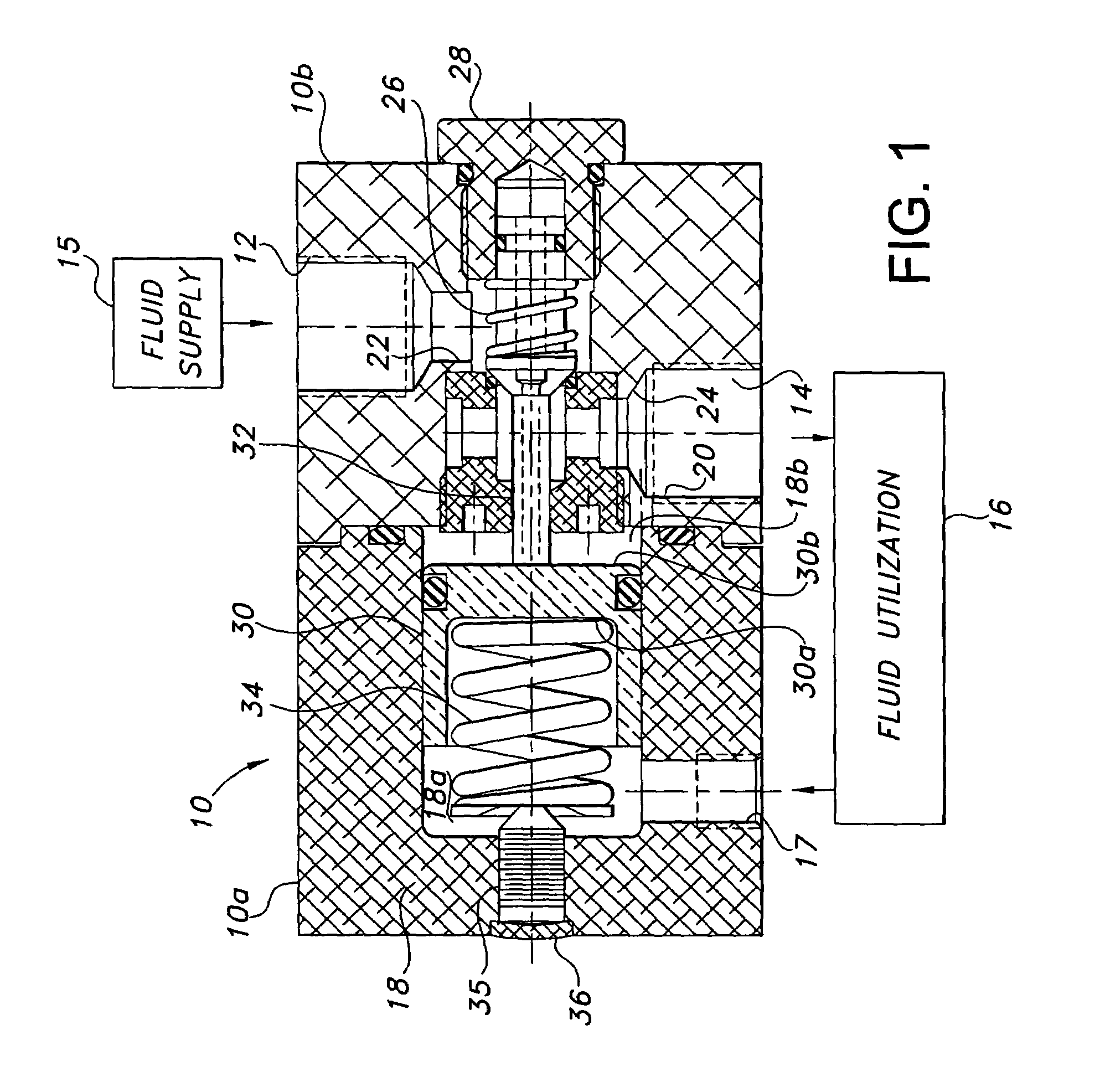

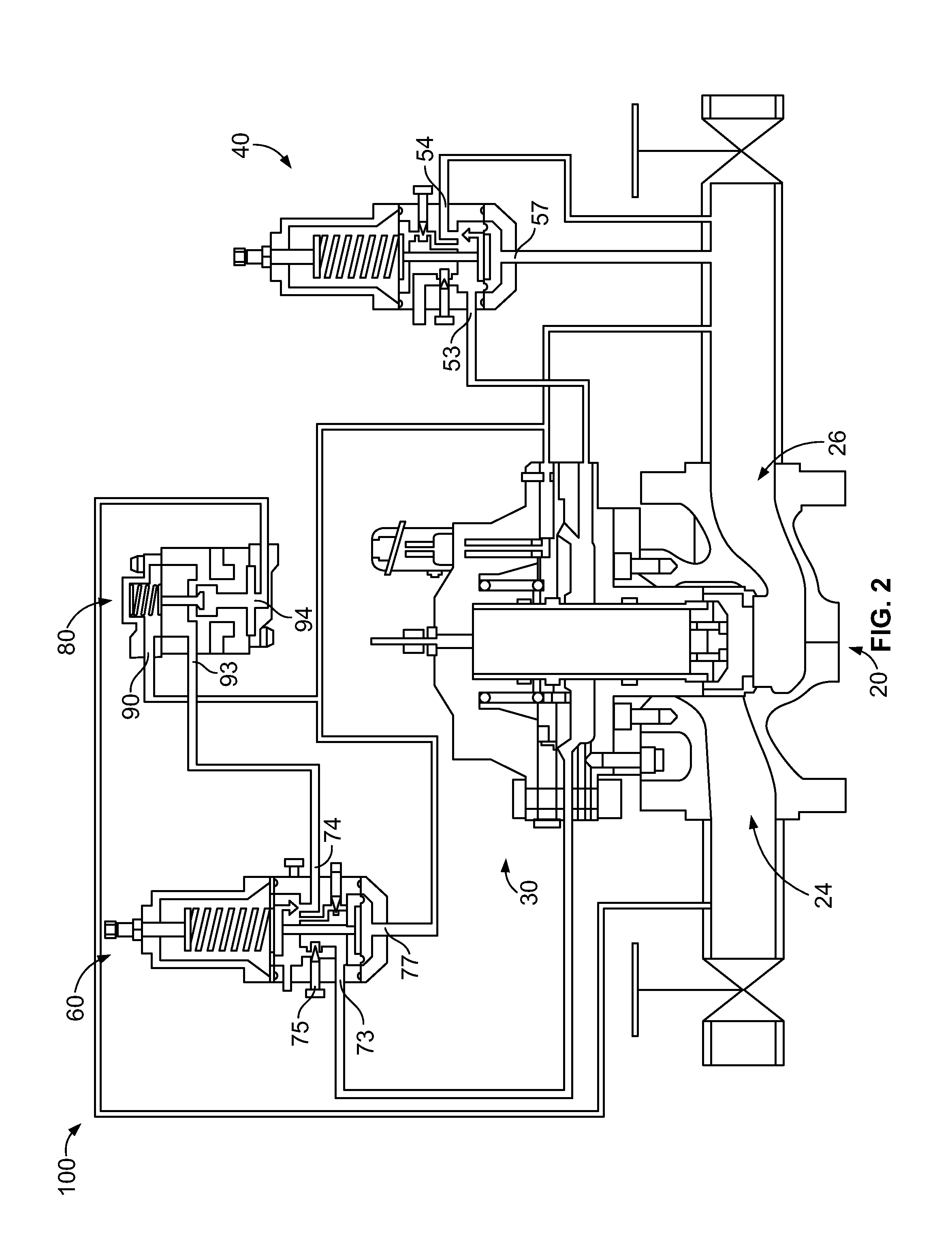

Pneumatic valve control having improved opening characteristics and an air turbine starter incorporating the same

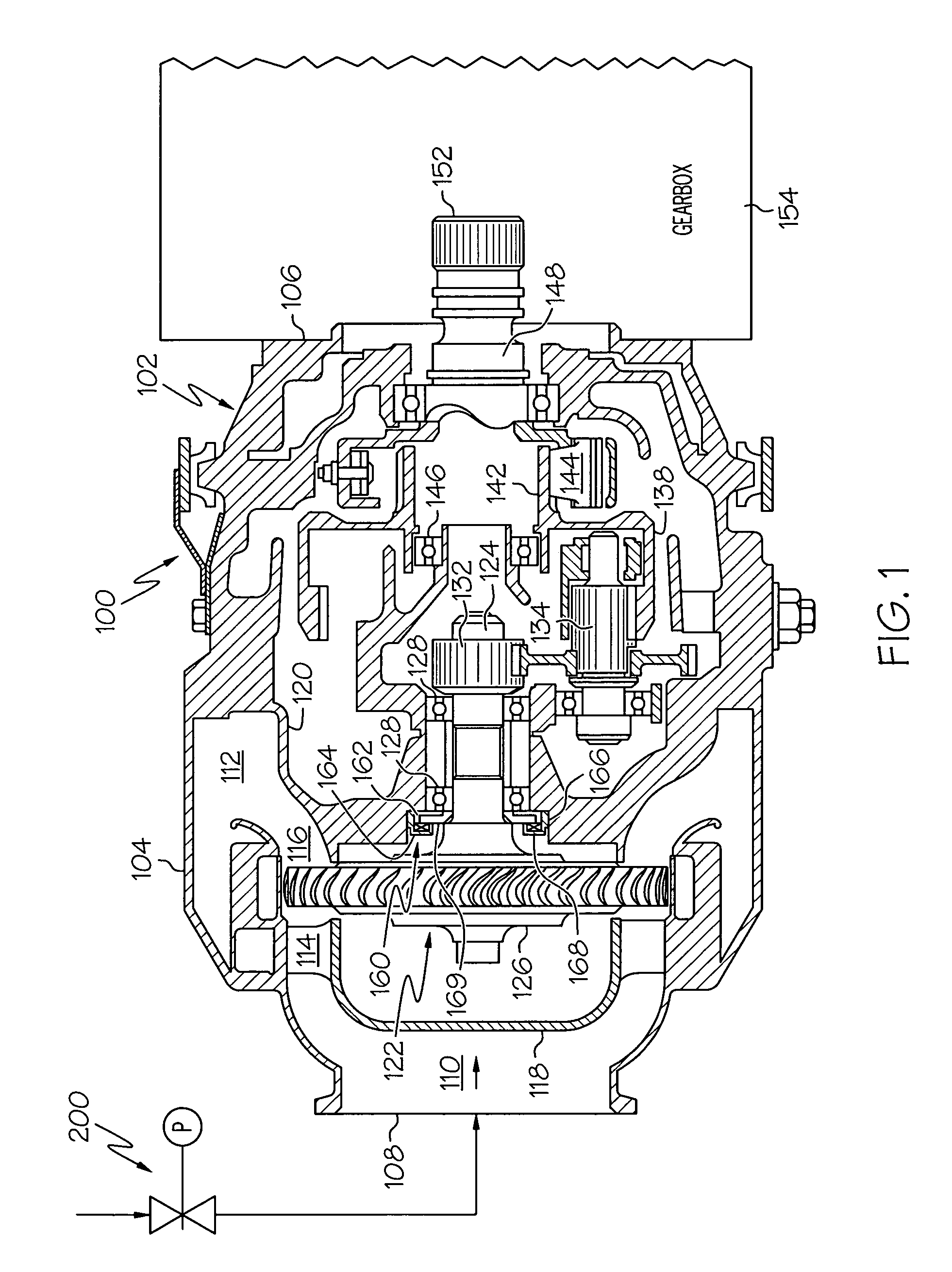

A starter air valve assembly includes a valve body, a flow control valve, a rate control servo mechanism, and a valve actuator. The valve body defines a flow passage having at least an inlet port and an outlet port. The valve is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The rate control servo mechanism is adapted to receive pressurized fluid and is configured, upon receipt thereof, to supply a controlled flow of the pressurized fluid. The valve actuator is coupled to the valve and is in fluid communication with the rate control servo to thereby receive the controlled flow of the pressurized fluid. The valve actuator is configured, upon receipt of the controlled flow of the pressurized fluid, to move the valve between the closed position and the open position at a substantially controlled rate.

Owner:HONEYWELL INT INC

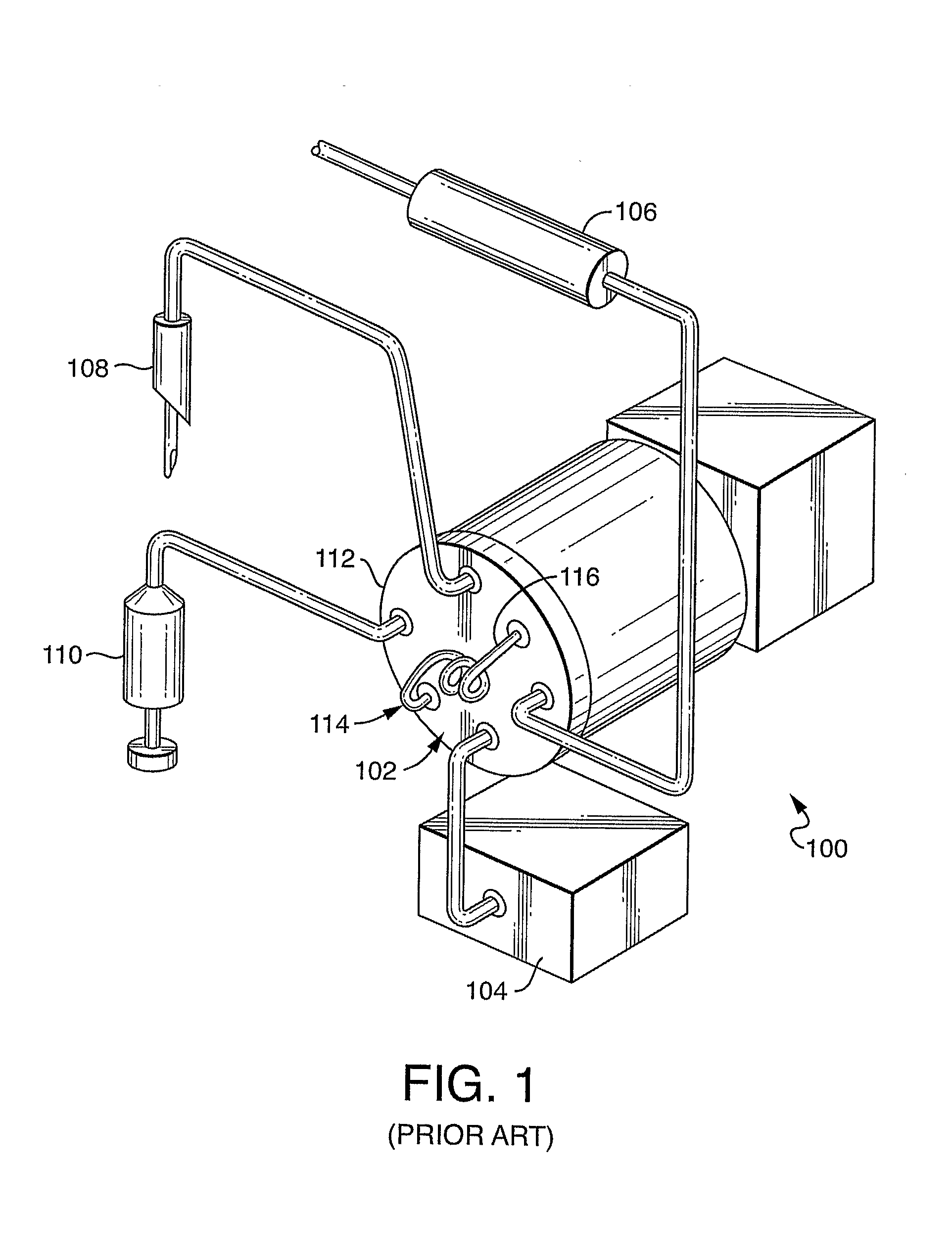

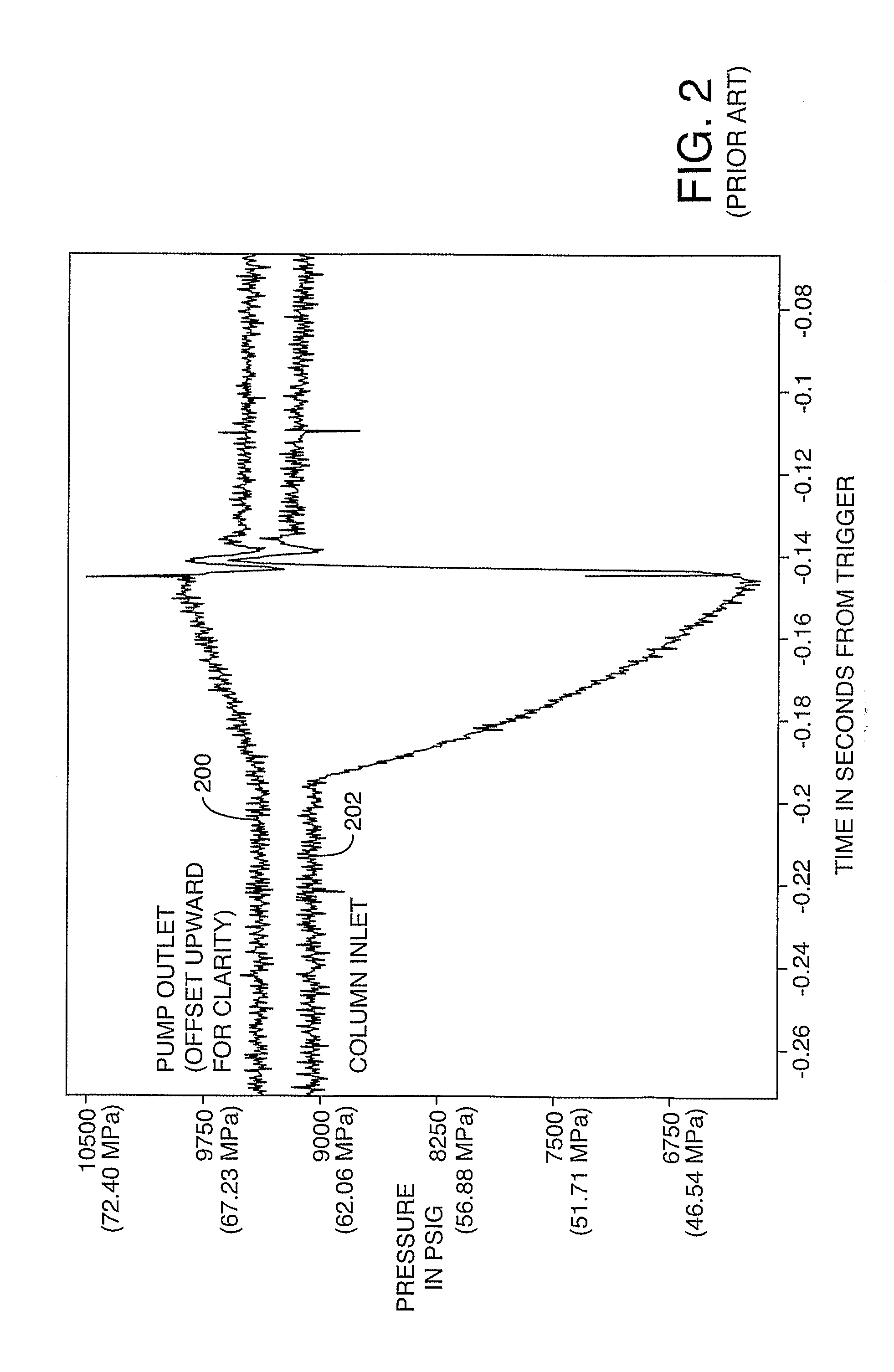

Method and apparatus for sample injection in liquid chromatography

Owner:WATERS TECH CORP

Valve with shuttle for use in a flow management system

Owner:ANYTHING FOR A BUCK INC

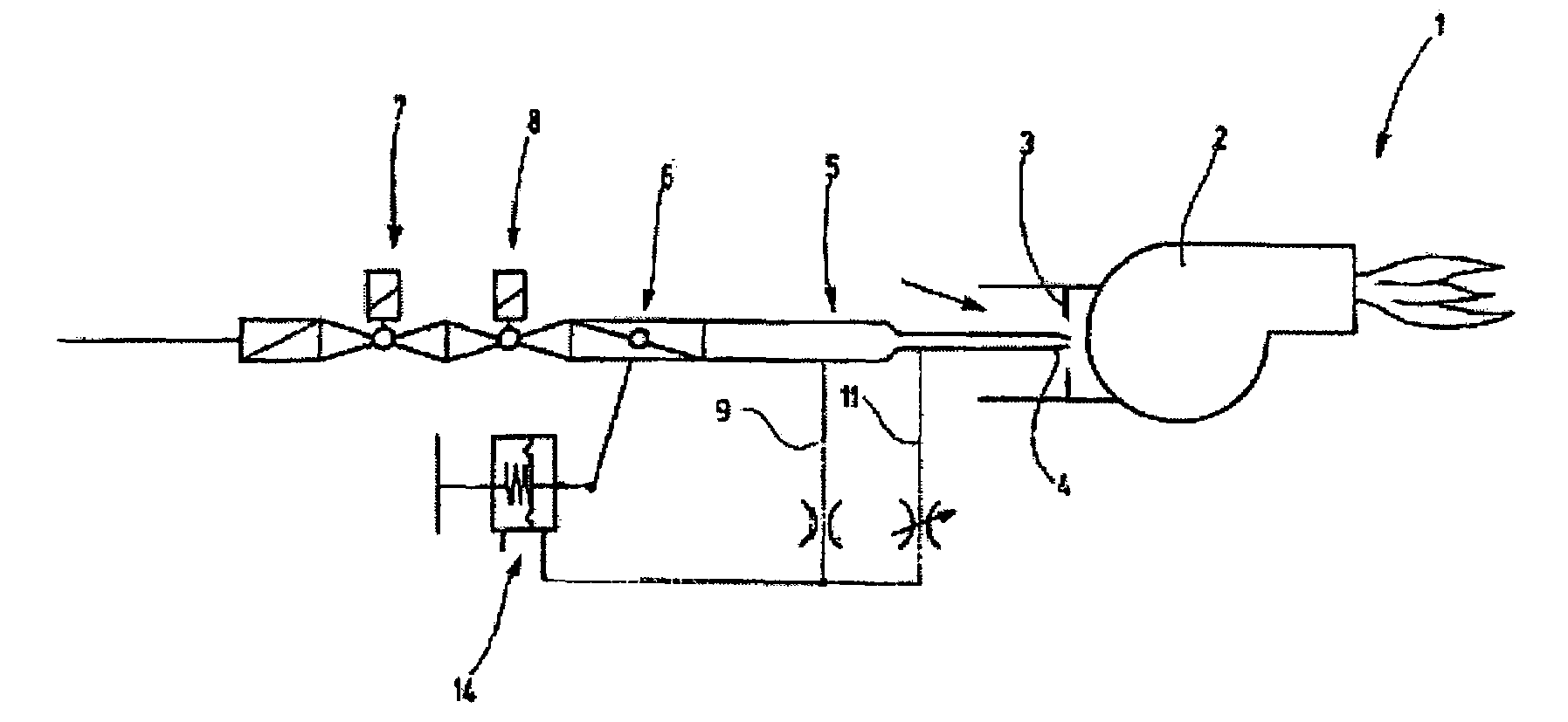

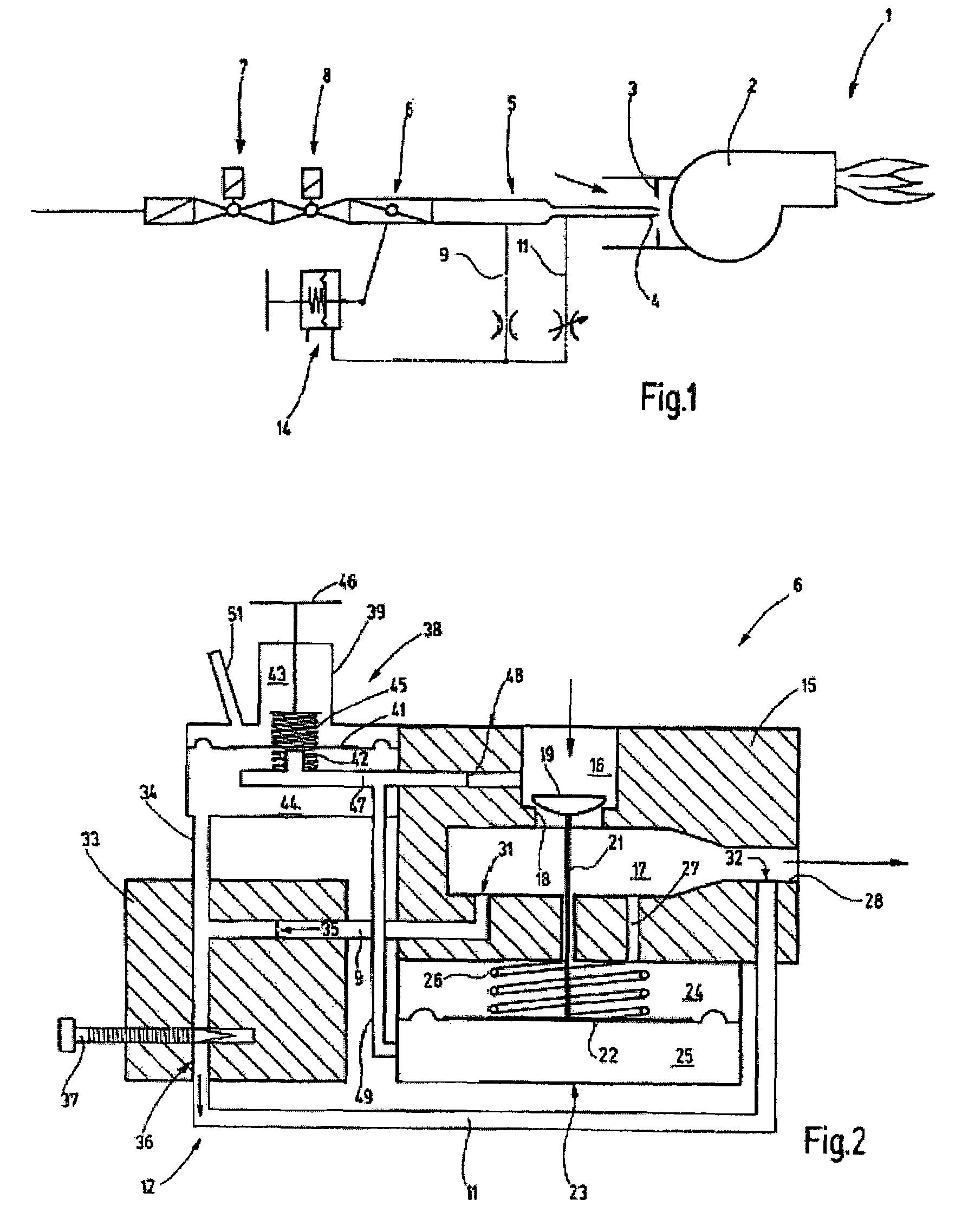

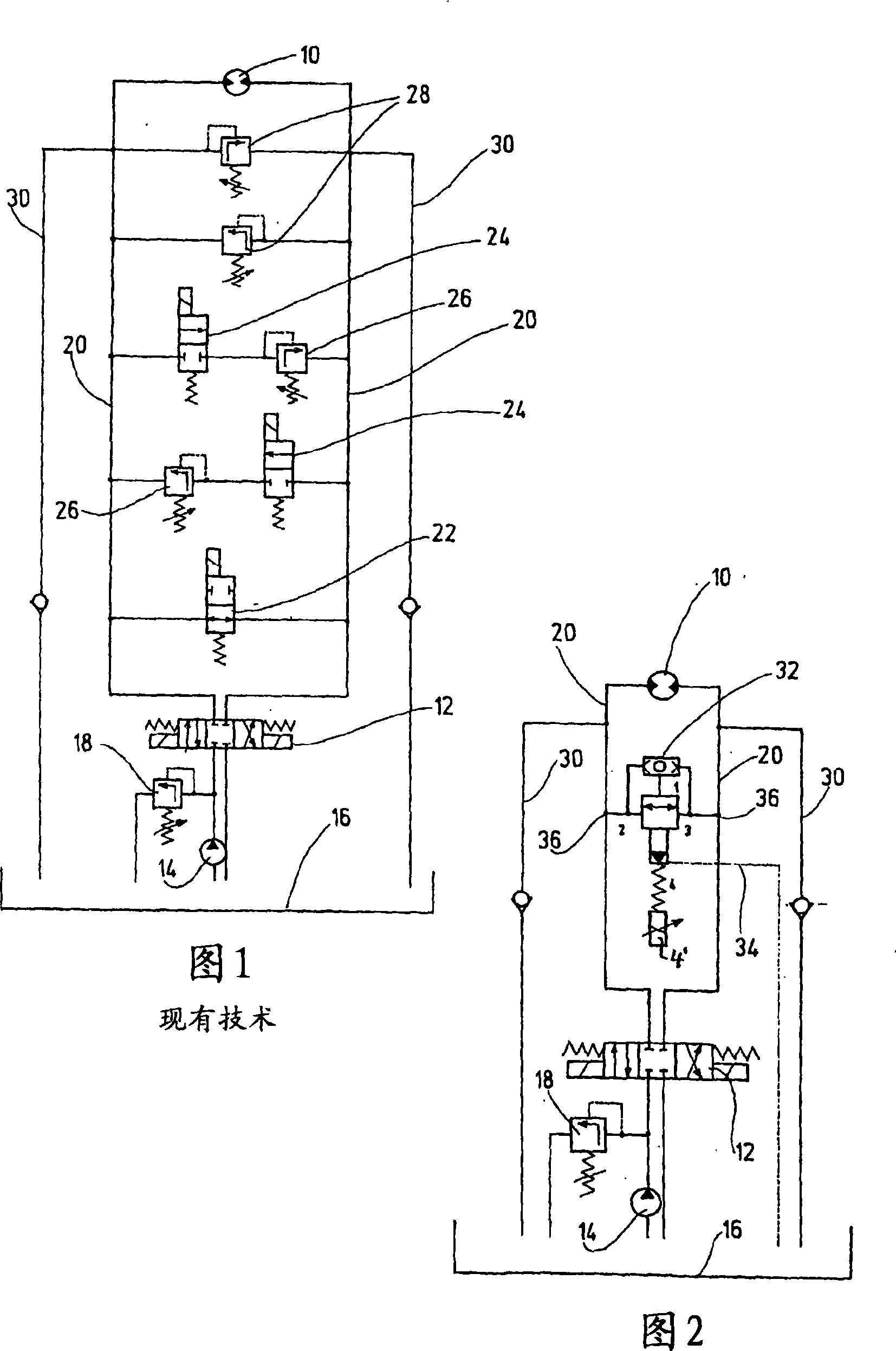

Ratio controller with dynamic ratio formation

InactiveUS7249610B2Fuel supply regulationOperating means/releasing devices for valvesCombustion chamberCombustor

For adjustment of a desired burner gas-air ratio over the broadest possible load range without additional pressure tapping of the burner, combustion chamber, or air lines, a ratio controller is provided that permits adjustment of the gas flow as a function of counterpressure. For adjustment, the ratio controller has at least one position-variable measurement site, or at least two measurement sites, connected directly or indirectly via a pilot valve, to an actuating diaphragm via a valve block or throttle valve block. Depending on whether the control pressure is picked up more from one or more from the other measurement site, the gas flow and therefore the gas-air ratio can be adjusted to be larger or smaller.

Owner:KARL DUNGS

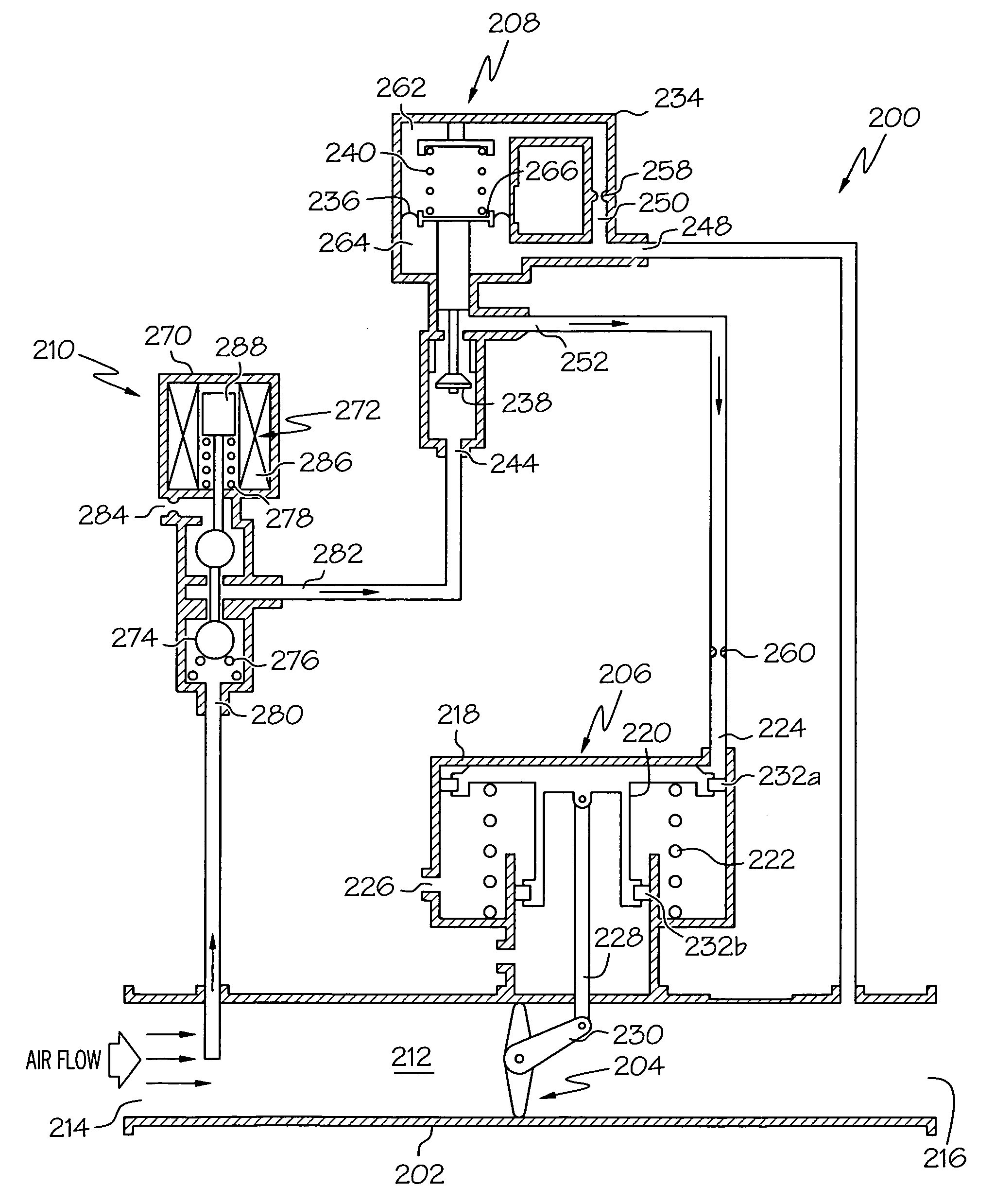

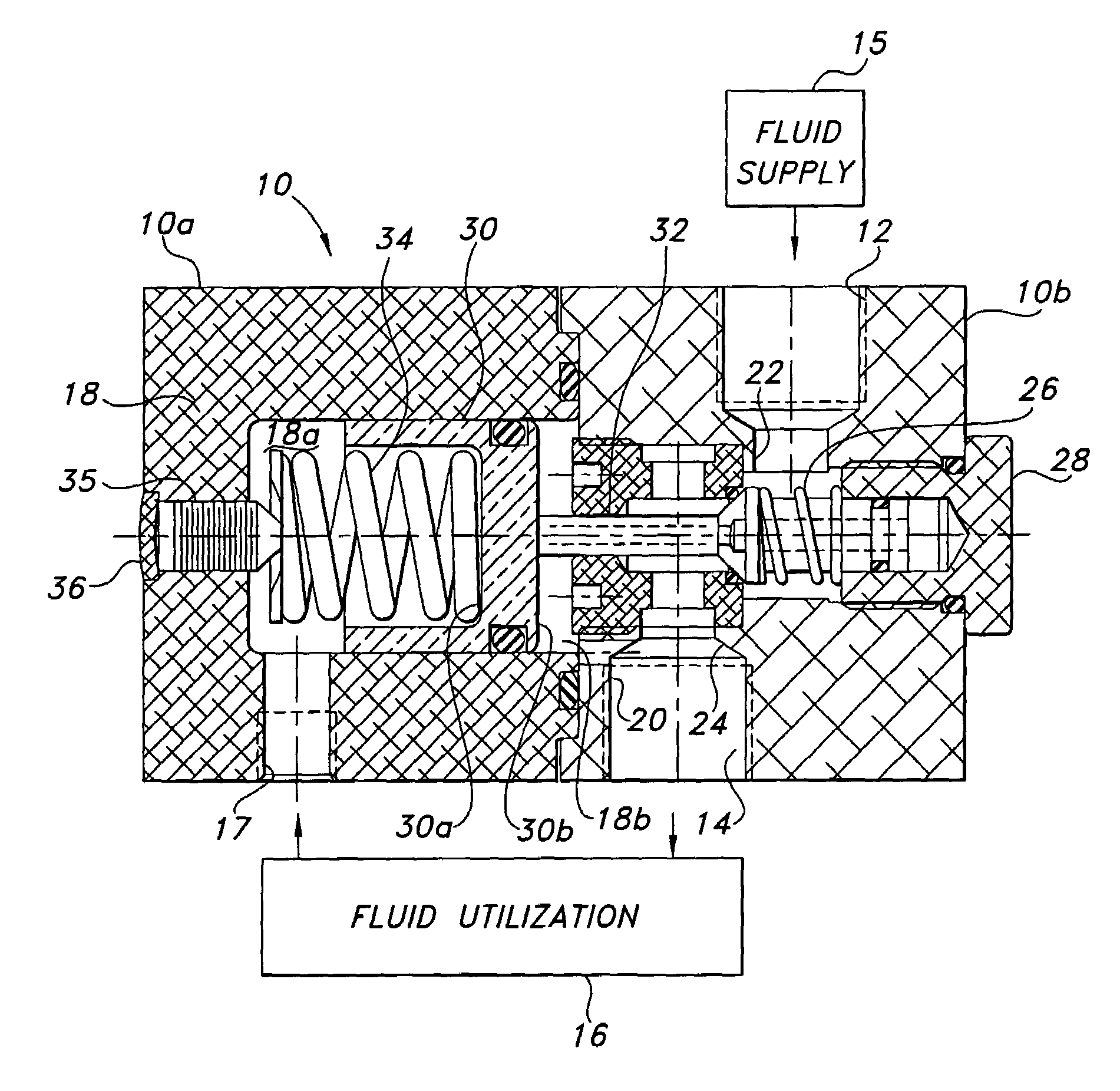

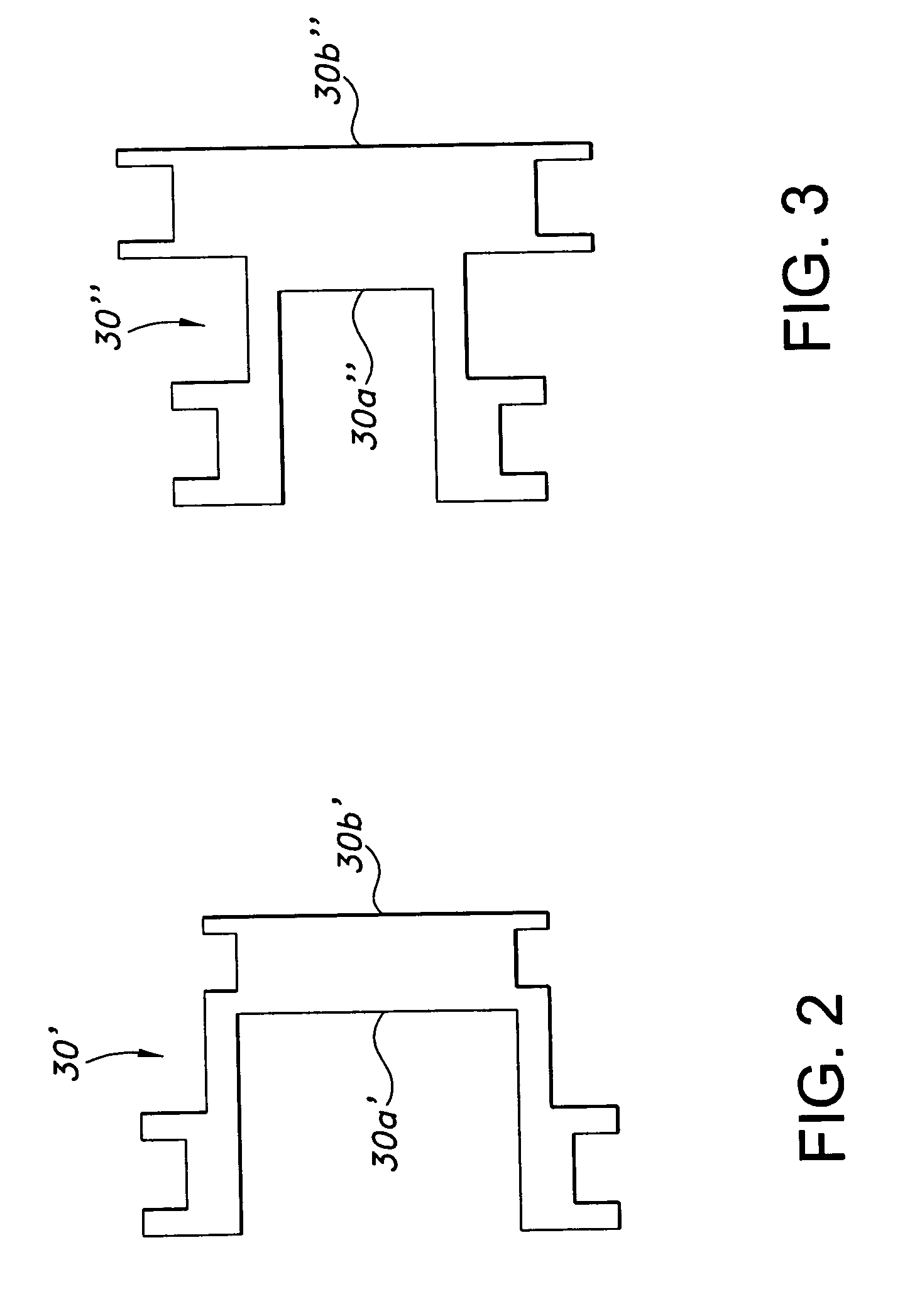

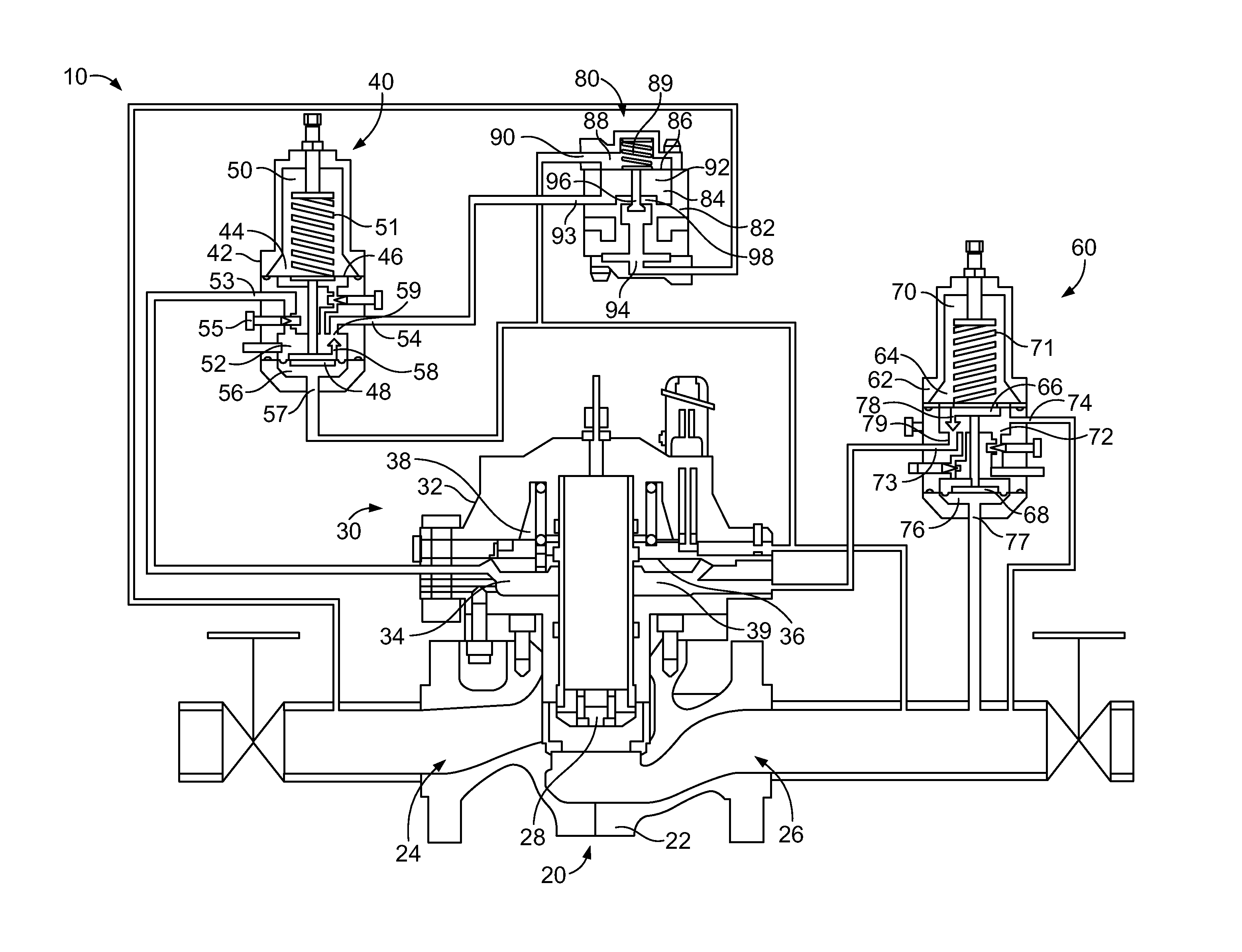

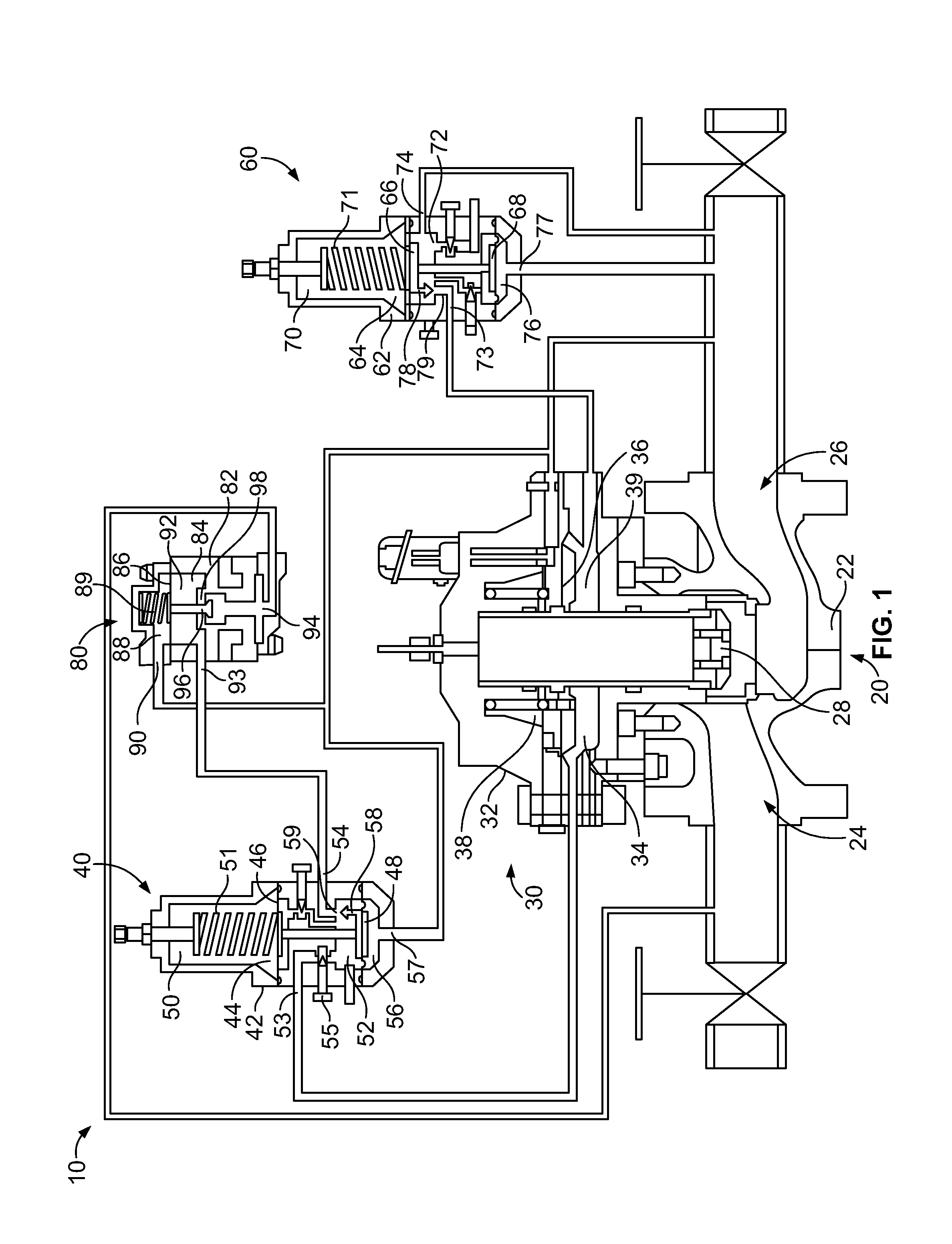

Pneumatic valve control using downstream pressure feedback and an air turbine starter incorporating the same

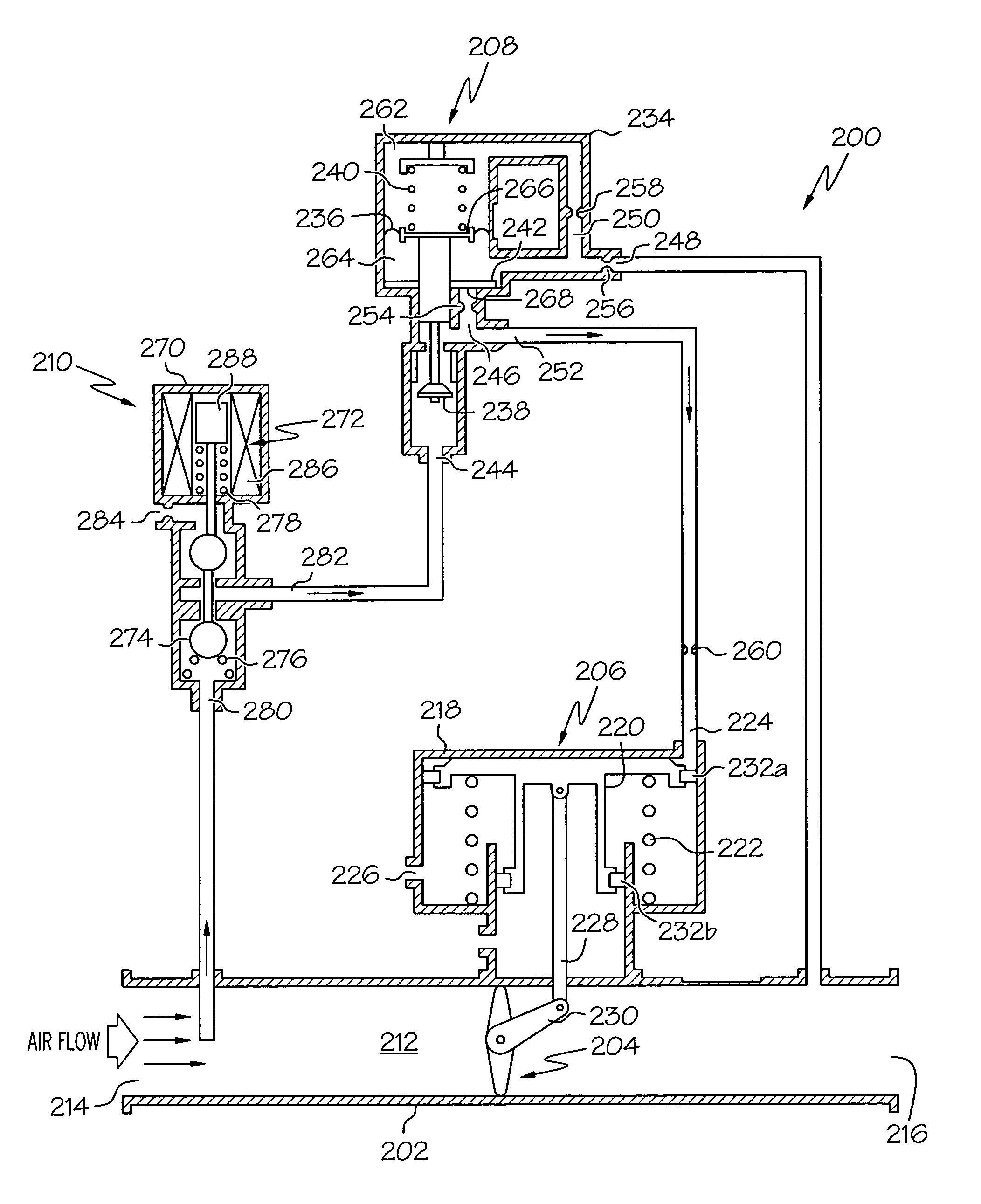

A starter air valve assembly includes a valve body, a flow control valve, a rate control servo mechanism, and a valve actuator. The valve body defines a flow passage having at least an inlet port and an outlet port. The valve is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The rate control servo mechanism is adapted to receive pressurized fluid and is configured, upon receipt of the pressurized fluid, to supply a controlled flow of the pressurized fluid. The valve actuator is coupled to the valve and is in fluid communication with the rate control servo to thereby receive the controlled flow of the pressurized fluid. The valve actuator is configured, upon receipt of the controlled flow of the pressurized fluid, to move the valve between the closed position and the open position at a substantially controlled rate.

Owner:HONEYWELL INT INC

Pneumatic valve control using downstream pressure feedback and an air turbine starter incorporating the same

ActiveUS20050276685A1Improved valve opening characteristicImprove featuresWind motor controlPump componentsControl flowValve actuator

A starter air valve assembly includes a valve body, a flow control valve, a rate control servo mechanism, and a valve actuator. The valve body defines a flow passage having at least an inlet port and an outlet port. The valve is disposed at least partially within the flow passage and is moveable between an open position and a closed position. The rate control servo mechanism is adapted to receive pressurized fluid and is configured, upon receipt of the pressurized fluid, to supply a controlled flow of the pressurized fluid. The valve actuator is coupled to the valve and is in fluid communication with the rate control servo to thereby receive the controlled flow of the pressurized fluid. The valve actuator is configured, upon receipt of the controlled flow of the pressurized fluid, to move the valve between the closed position and the open position at a substantially controlled rate.

Owner:HONEYWELL INT INC

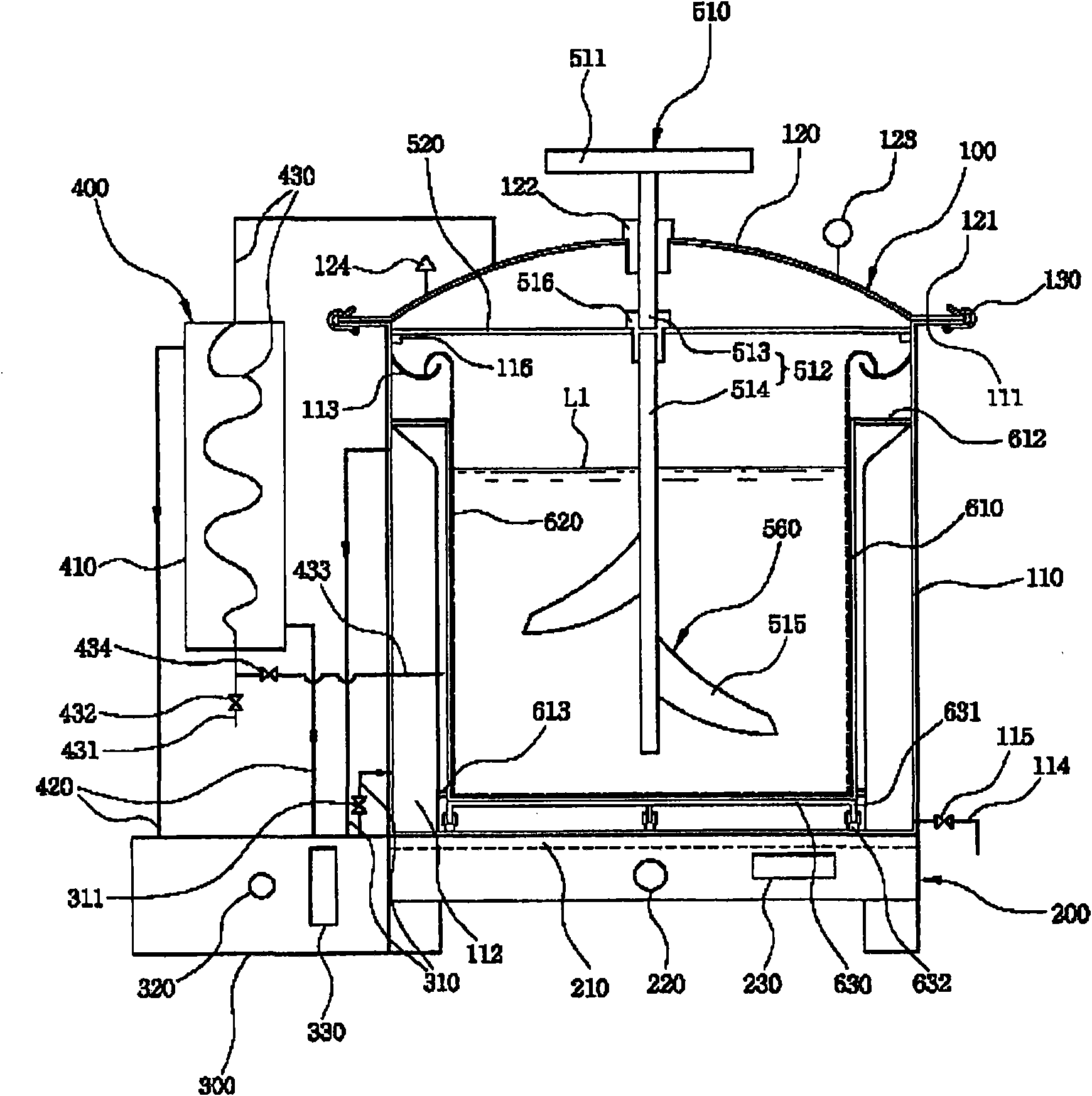

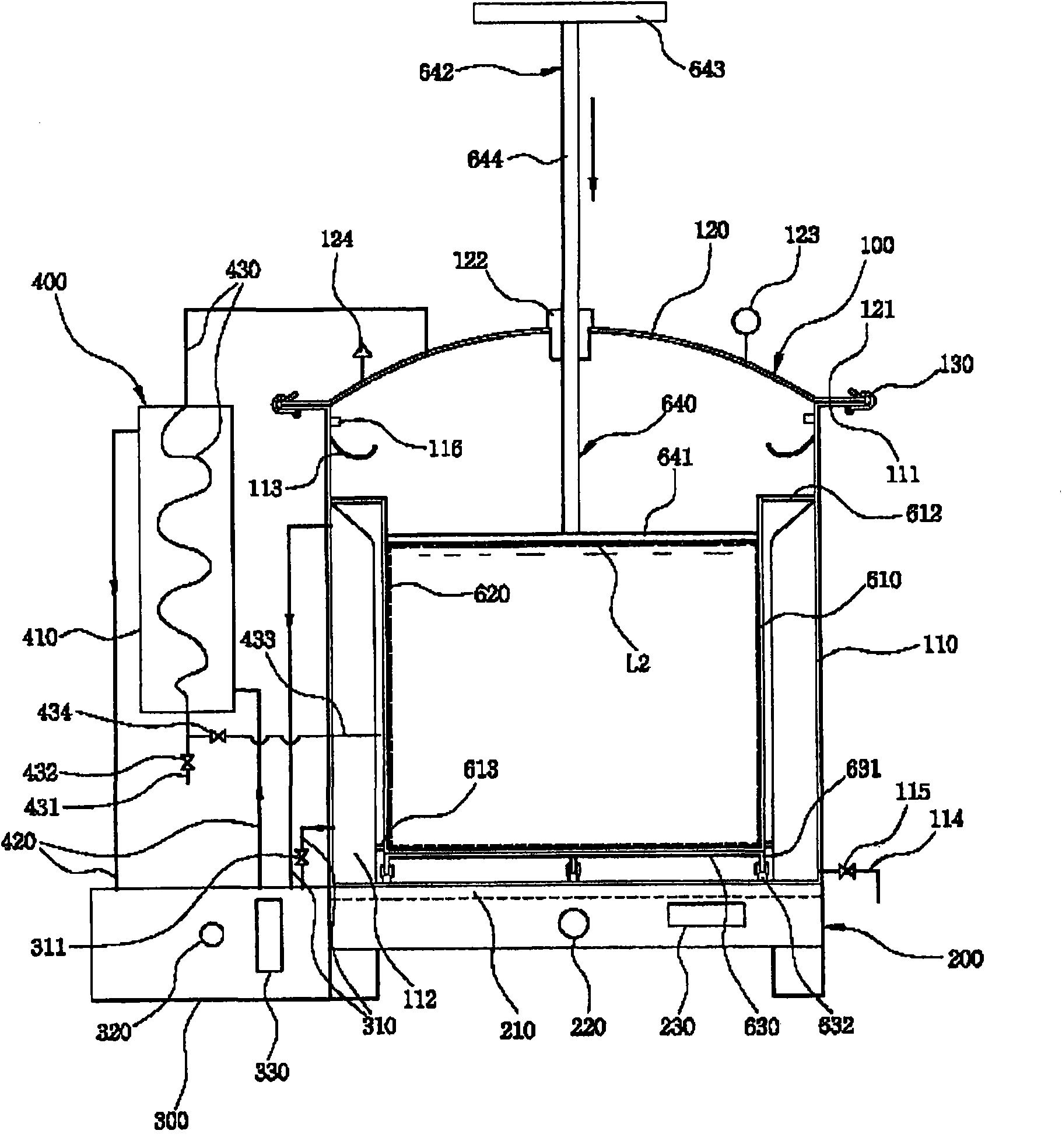

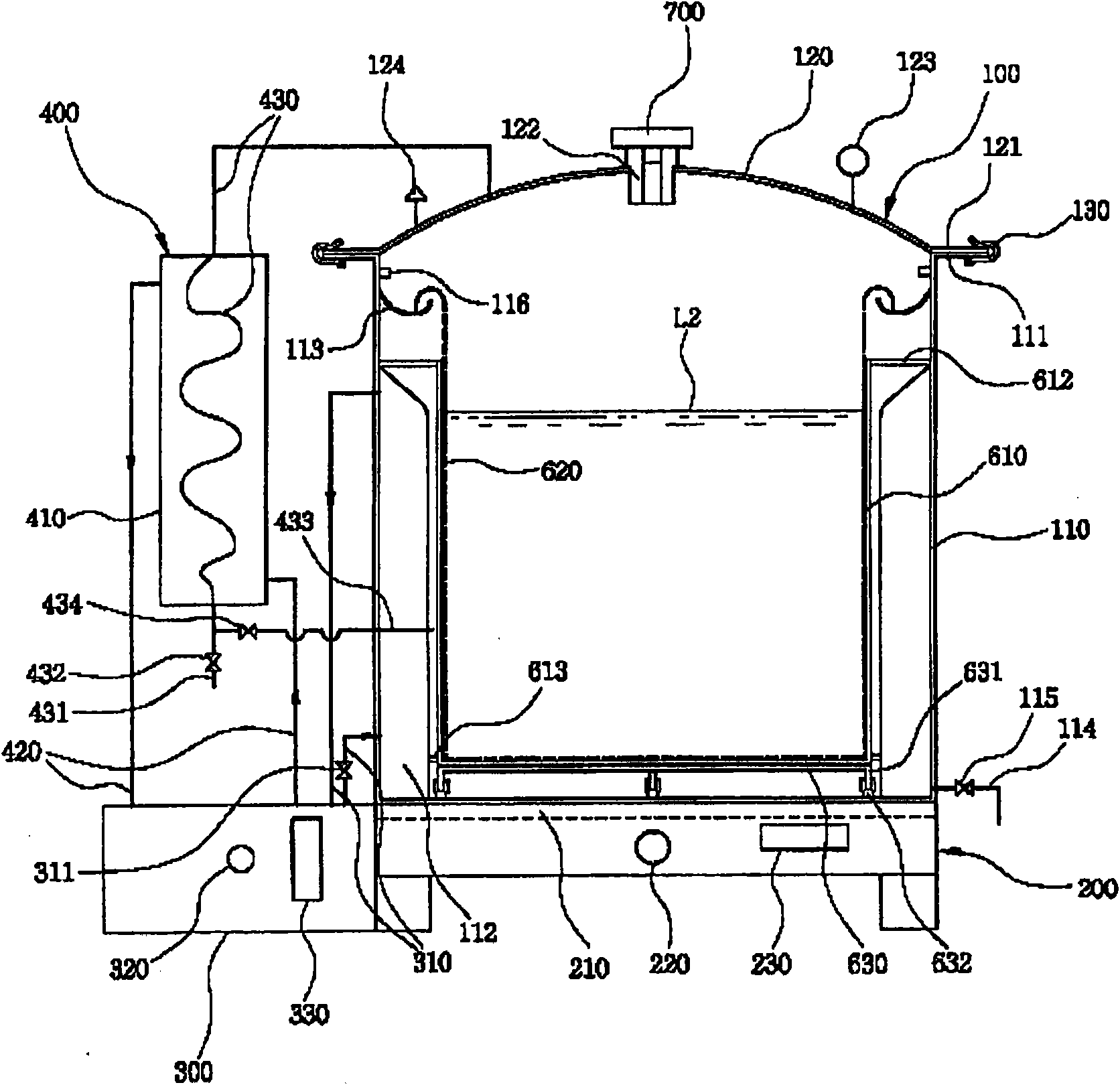

Home-brewed liquor manufacturing apparatus

ActiveCN101679928AEasy to manufactureEasy to operateFermented solutions distillation/rectificationTemperature control using plurality of sensorsComing outDistillation

The present invention relates to a liquor manufacturing apparatus for home use. Particularly, the present invention relates to a liquor manufacturing apparatus for home use, which includes a single device consisting of a heater, the cooler, the condenser, the stirrer and the filter to enable to perform all processes required for liquor preparation and which enables anyone to easily make desired liquor even in general homes using grains, fruits or other plant materials. The liquor manufacturing apparatus for home use comprises: a combined fermentation and distillation tank including a tank body having a cooling jacket mounted at the inside wall surface thereof so as to allow cooling water to be filled therein and to pass therethrough and a lid being adapted to hermetically seal the top portion of the tank body; an electric heater adapted to heat the tank body; a cooler adapted to supply the cooling water to the cooling jacket so as to cool the tank body; a condenser adapted to cool steam and volatile substance coming out of the combined fermentation and distillation tank; a combined steaming and filtering container disposed inside the tank body; a fabric filter disposed inside the combined steaming and filtering container and adapted to contain contents produced in the liquor preparing process; and a stirrer adapted to stir the contents inside the fabric filter during fermentation.

Owner:DAEBONG LS CO LTD

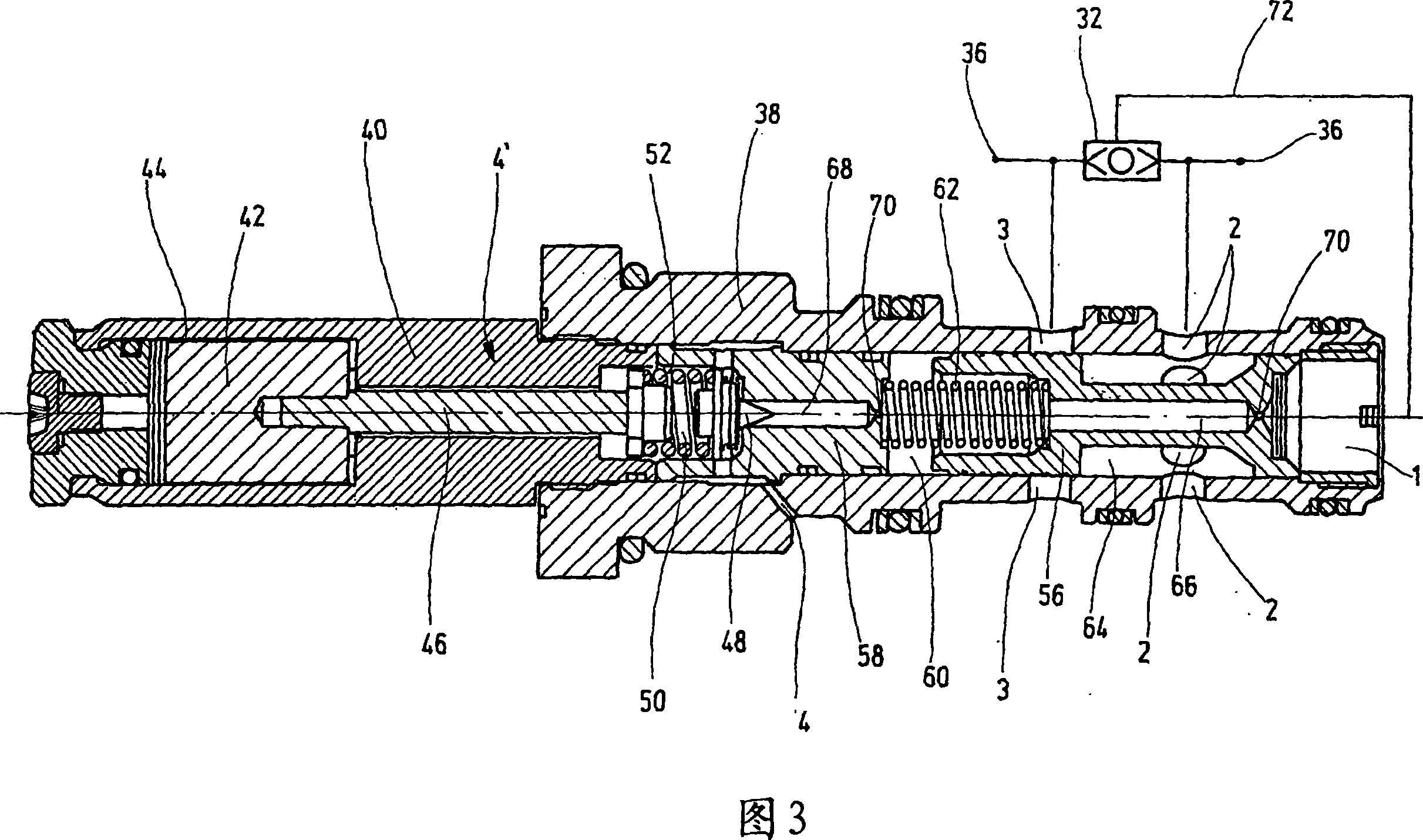

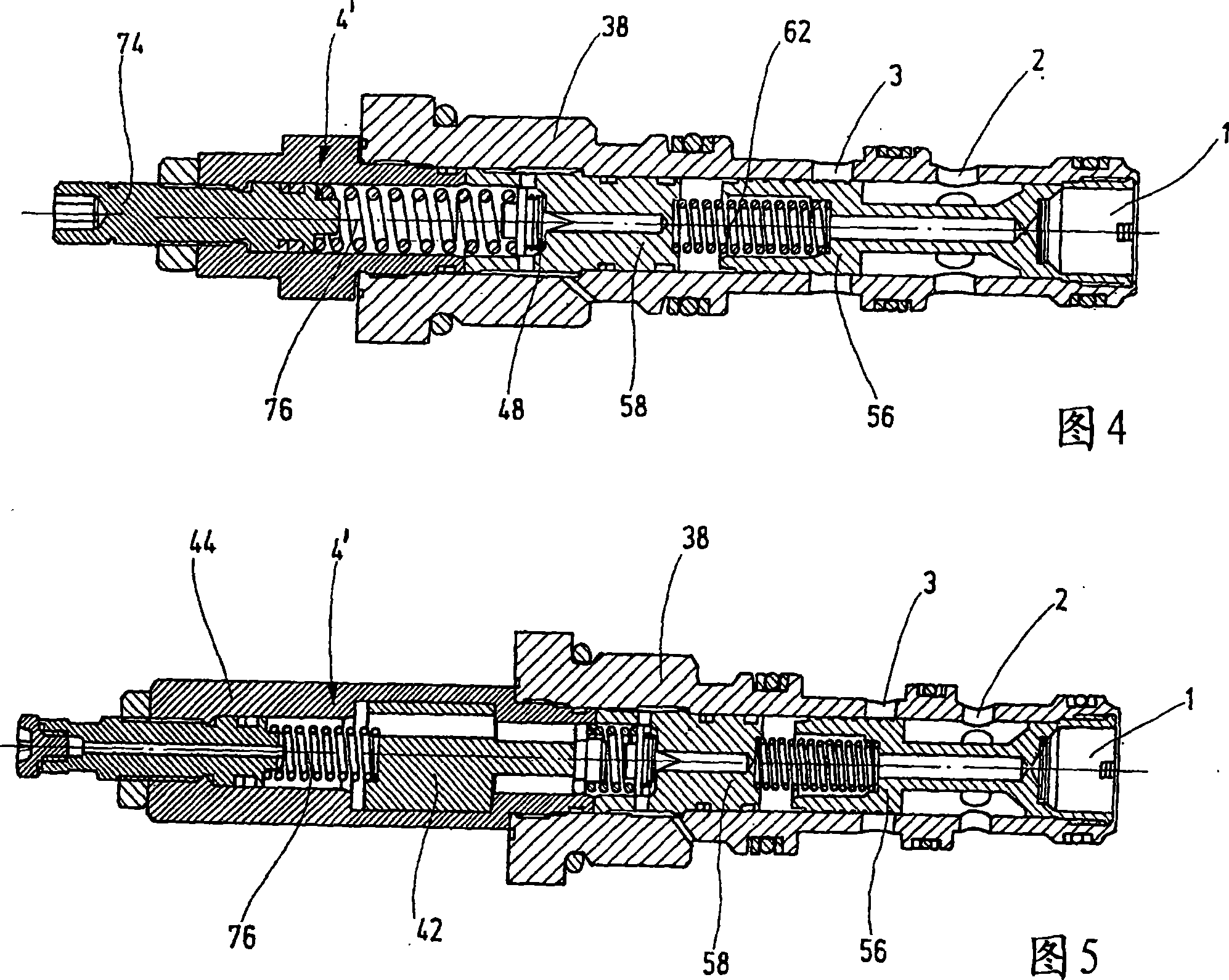

Valve, especially proportional pressure control valve

InactiveCN101124525AReliable valve switching functionReliable switching functionServomotor componentsEqualizing valvesEngineeringPressure controlled ventilation

A proportional pressure control valve includes a valve housing (38) with at least three fluid connections (1, 2, 3). The valve can be connected to a hydraulic drive system with a pre-determinable consumer pressure. The valve can perform reliable valve switching functions even for low-viscous fluid media, and can reduce its susceptibility to disturbance variables. A valve piston (56) actively connected to a pilot seat (5) by an energy accumulator (62) can be controlled by a control device (40). The consumer pressure on a fluid connection (1) acts on the valve piston (56) such that, according to the consumer pressure and the actuating force of the control device (40), a fluid can flow between the two other fluid connections (2 and 3) in both directions inside the valve housing (38).

Owner:HYDAC FLUITECHNIK GMBH

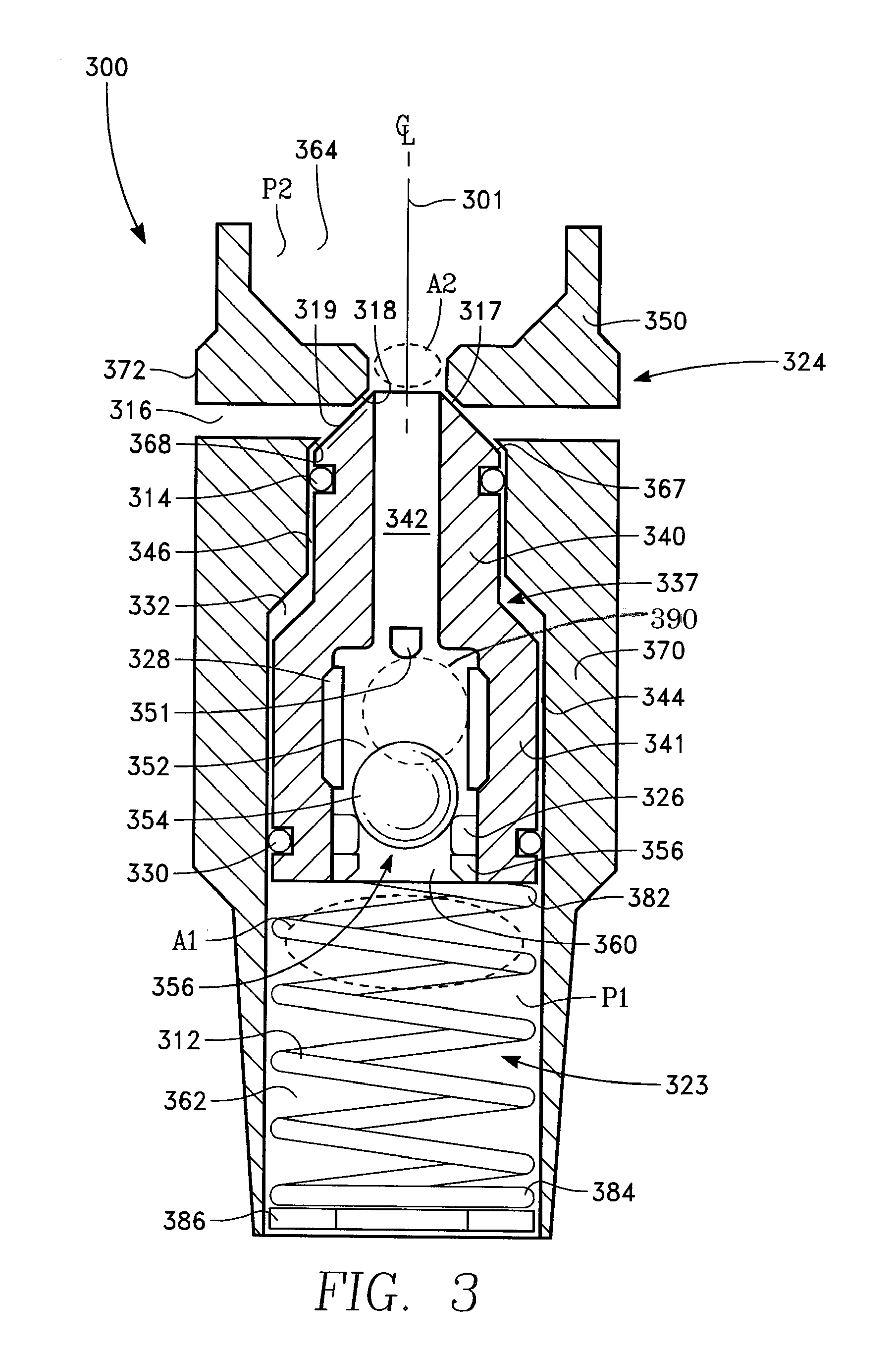

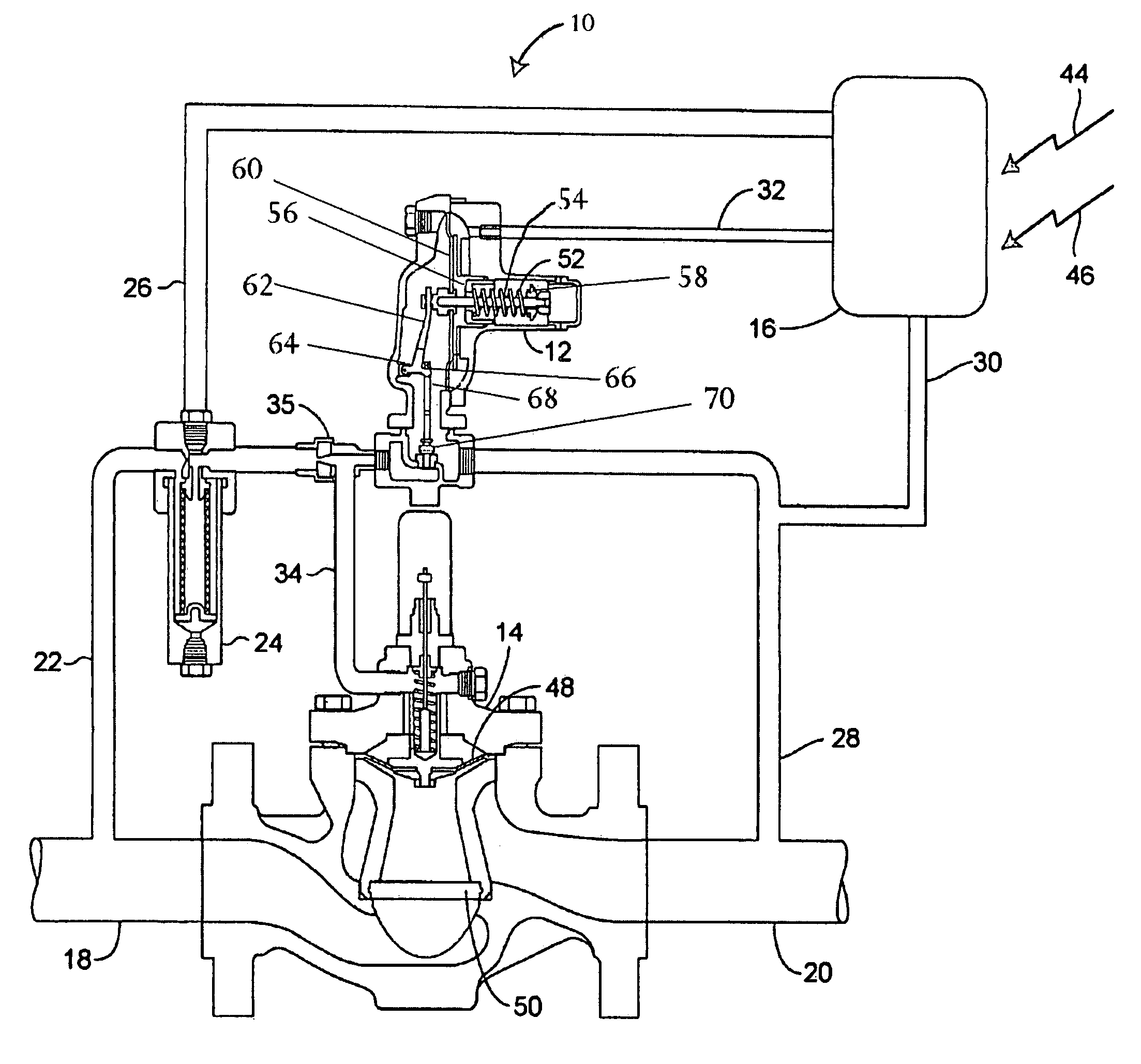

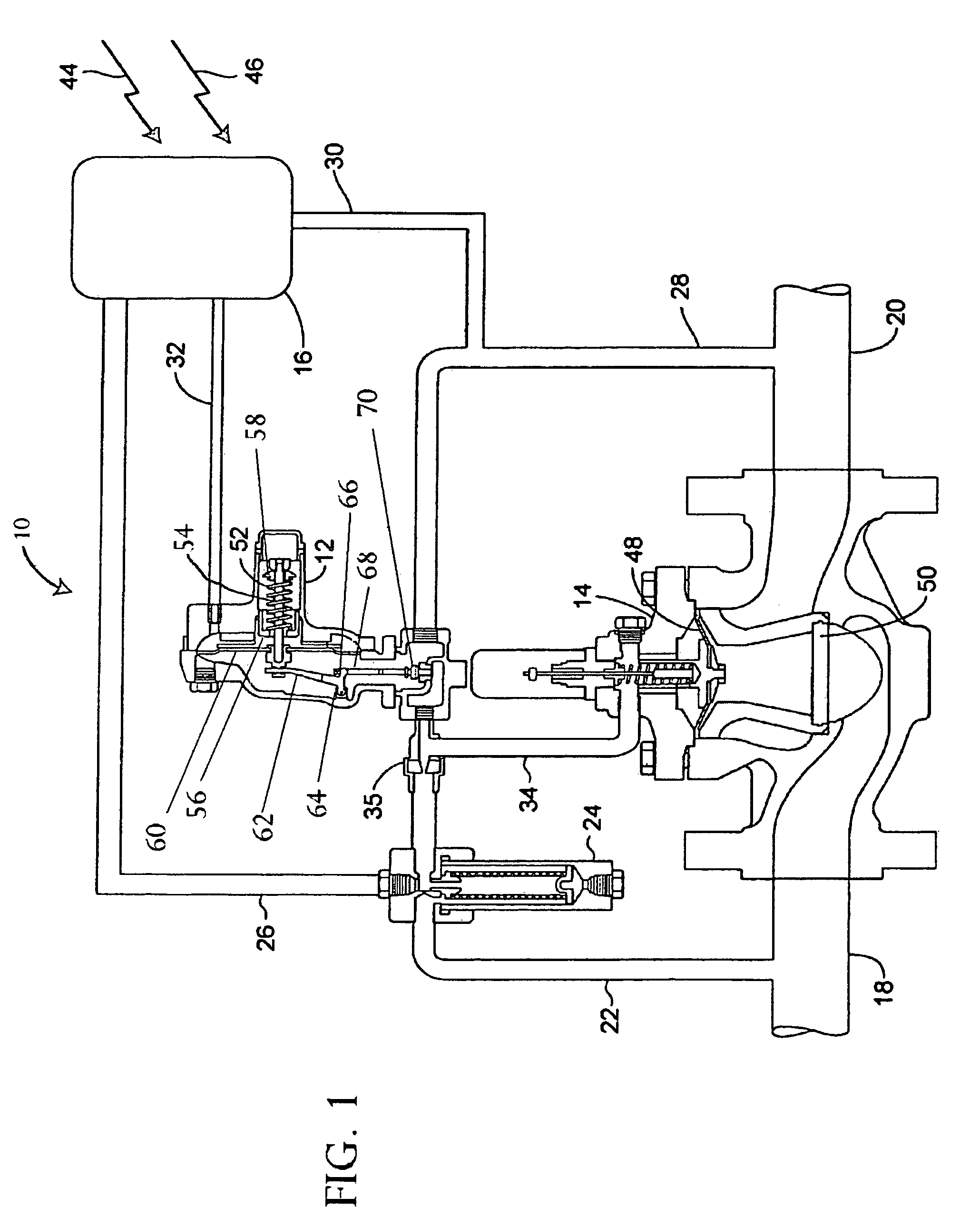

Pressure loaded pilot system and method for a regulator without atmospheric bleed

ActiveUS7318447B2Operating means/releasing devices for valvesServomotor componentsPilot systemAtmospheric air

A pressure loaded pilot valve system and method for a regulator valve is provided. The system includes a regulator valve connecting an inlet line to an outlet line, a servo control valve assembly, and a pilot valve assembly. A supply line is connected to the servo control valve, and a pilot loading pressure line connects the servo control valve to the pilot valve assembly An exhaust line connects the servo control valve to the outlet line, thereby avoiding waste, pollution, etc. associated with bleeding excess pilot pressure to the atmosphere.

Owner:FISHER CONTROLS INT LLC

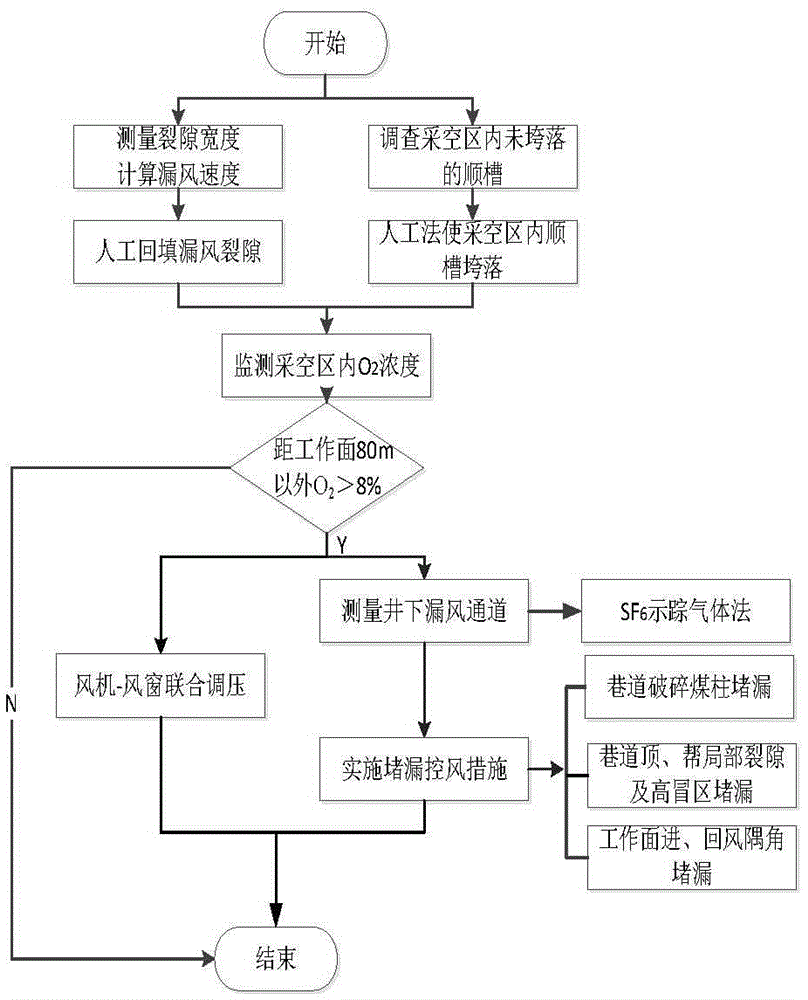

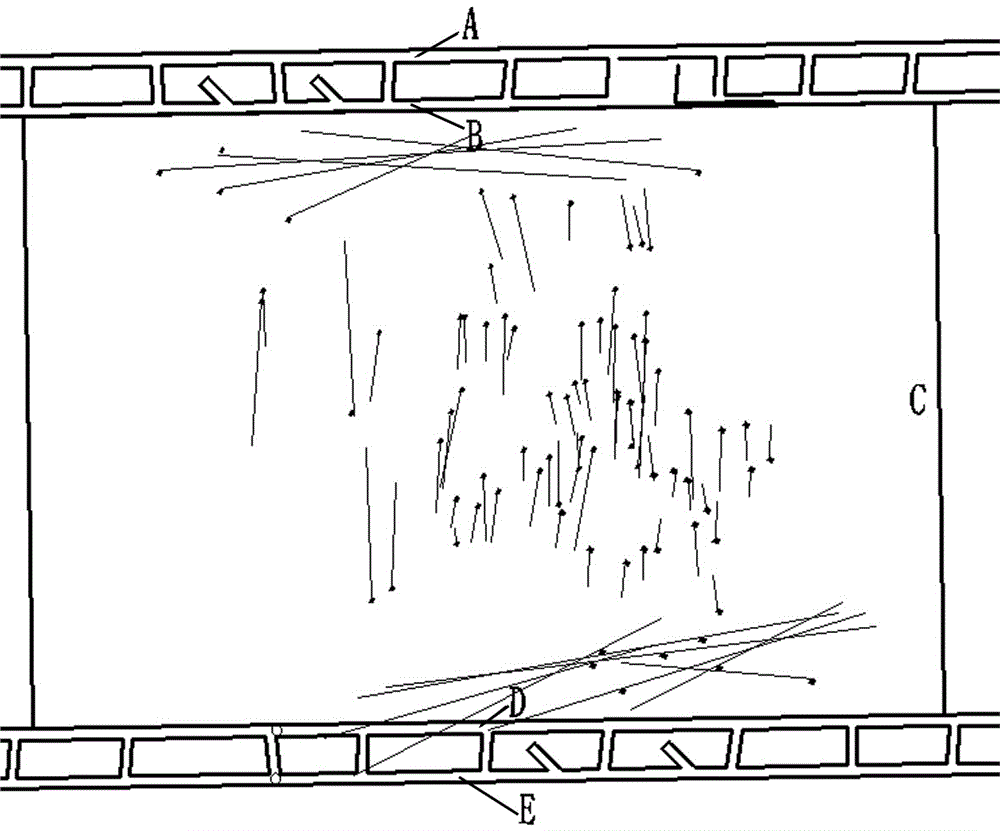

Method for controlling goaf air leakage in exploitation process of shallow buried close-range coal seam

InactiveCN106593523ASafe and Efficient MiningImprove reliabilityDetection of fluid at leakage pointFluid pressure control with auxillary non-electric powerCoal spontaneous combustionMonitoring system

The invention provides a method for controlling goaf air leakage in the exploitation process of a shallow buried close-range coal seam. The method mainly comprises technologies such as plugging of earth surface air leaking fractures and detecting and plugging of downhole air leaking channel, namely, first, the widths of earth surface mining-induced fractures are measured and the speed of fracture air leaking is calculated; the fractures with the widths and the air leaking air speeds being out of gauge are plugged, an air inlet roadway and an air outlet roadway which are difficult to cave by a roof in a goaf is caved by a manual way, and air leaking toward the goaf is reduced; next, a beam tube monitoring system is used for monitoring the concentration of O2 in the goaf, and whether air leaking exists or not in the goaf is judged according to the concentration of O2; then, a tracer gas method is used for detecting air leaking channels of downhole coal pillars, the air inlet roadway, the air outlet roadway and the like, and corresponding plugging measures are adopted; and at the time of plugging, a fan-air-window combined pressure regulating method is used for balancing air pressure of the goaf and a working face, goaf air leaking is reduced, and coal spontaneous combustion in the goaf is avoided.

Owner:CHINA UNIV OF MINING & TECH

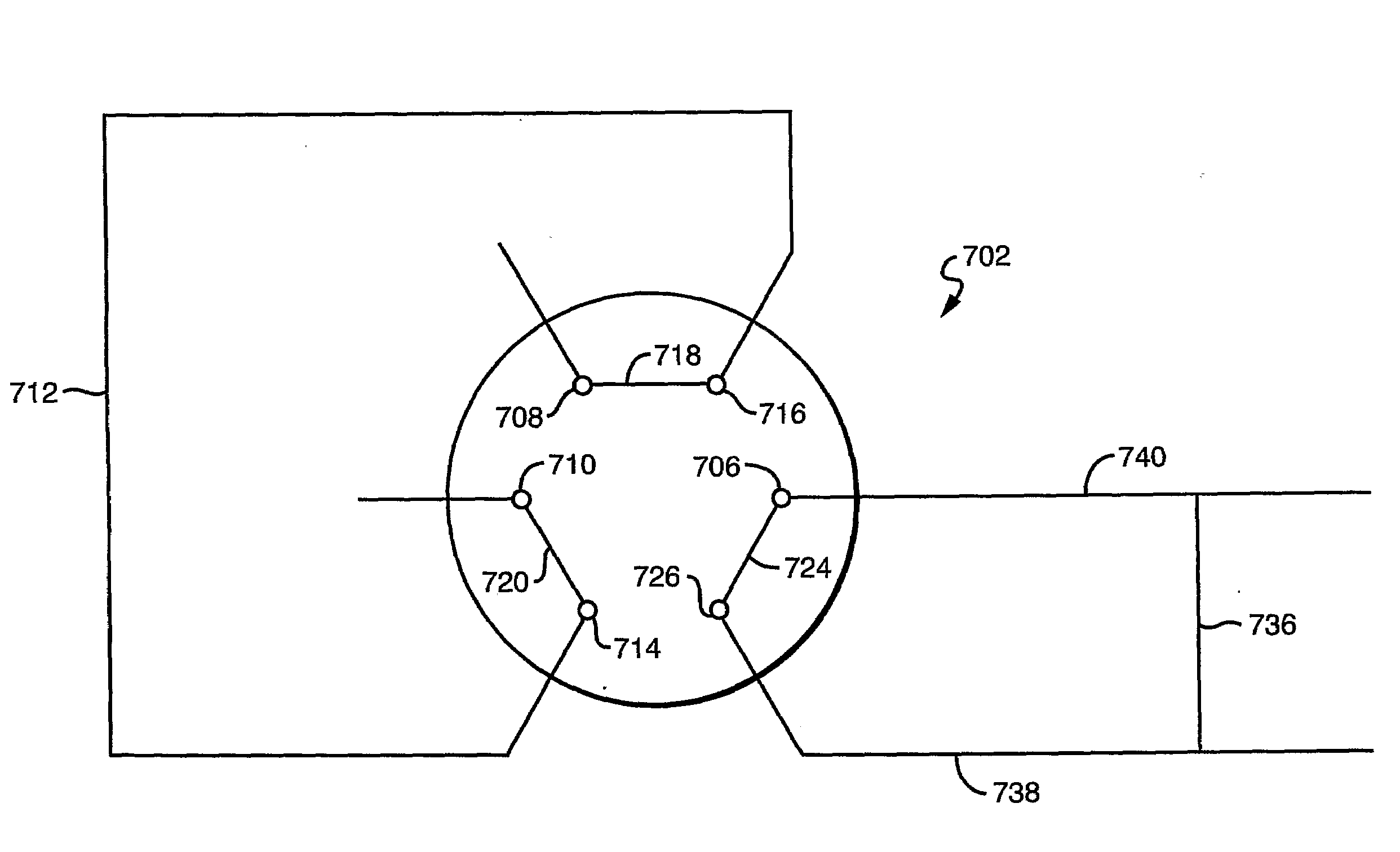

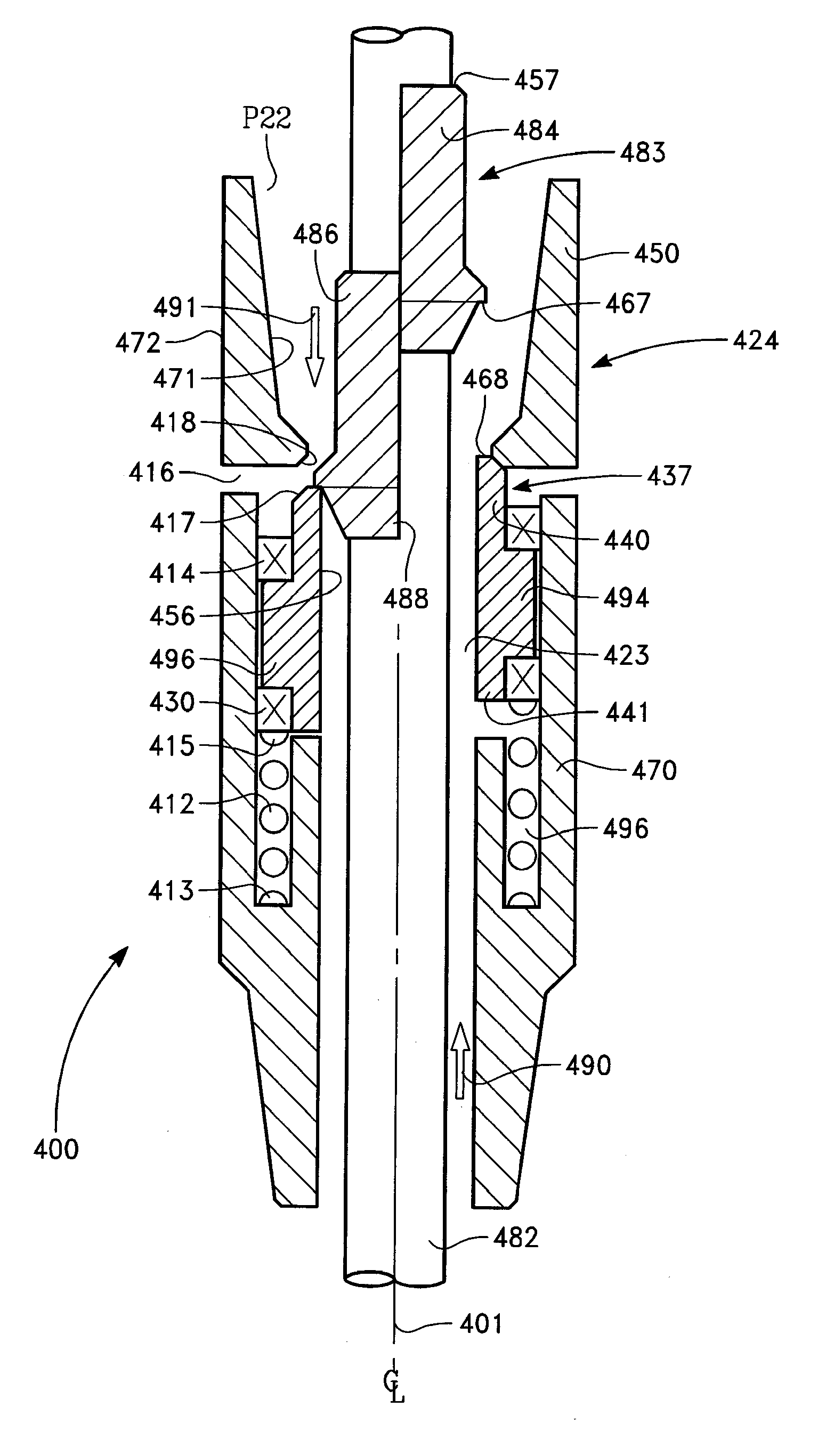

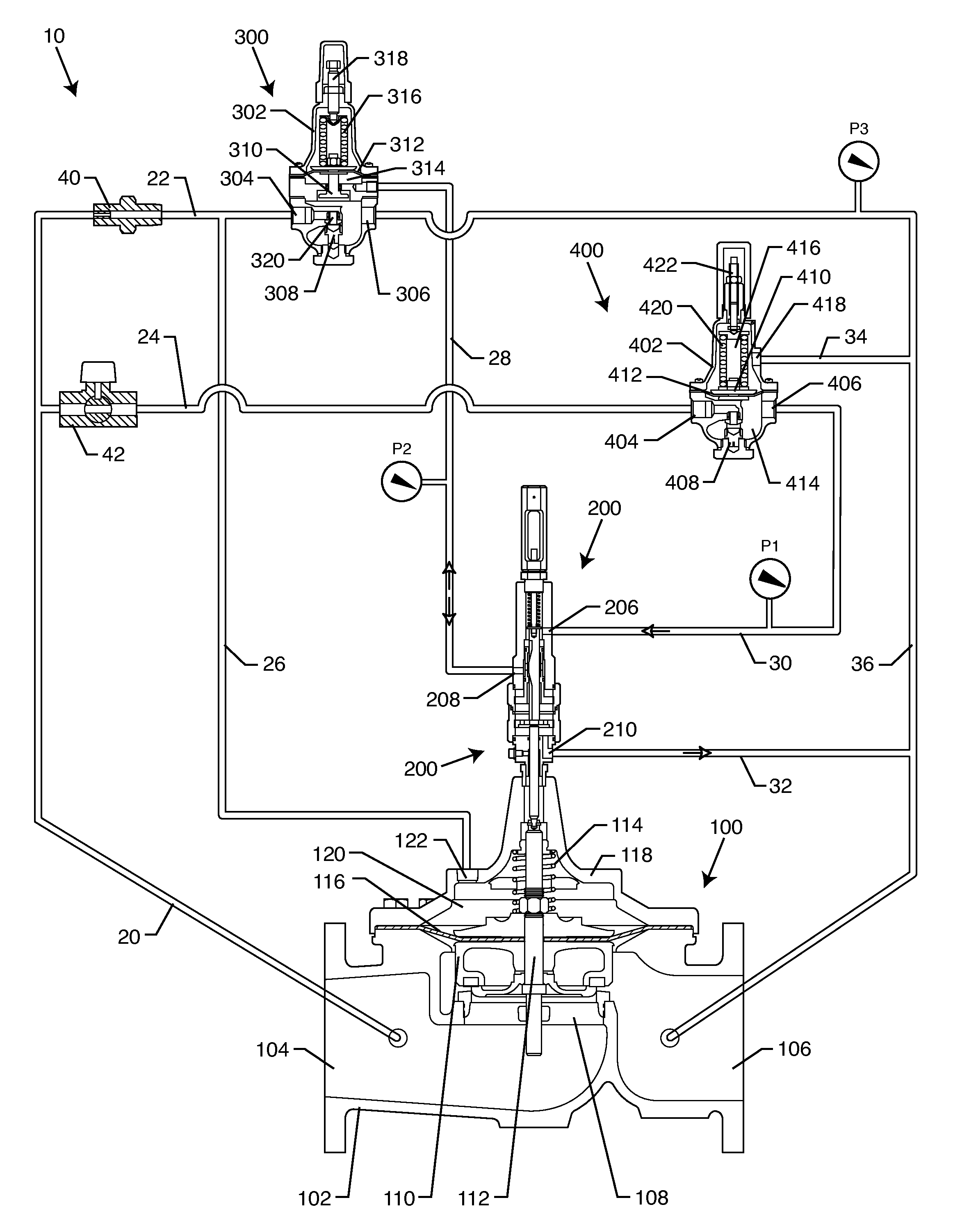

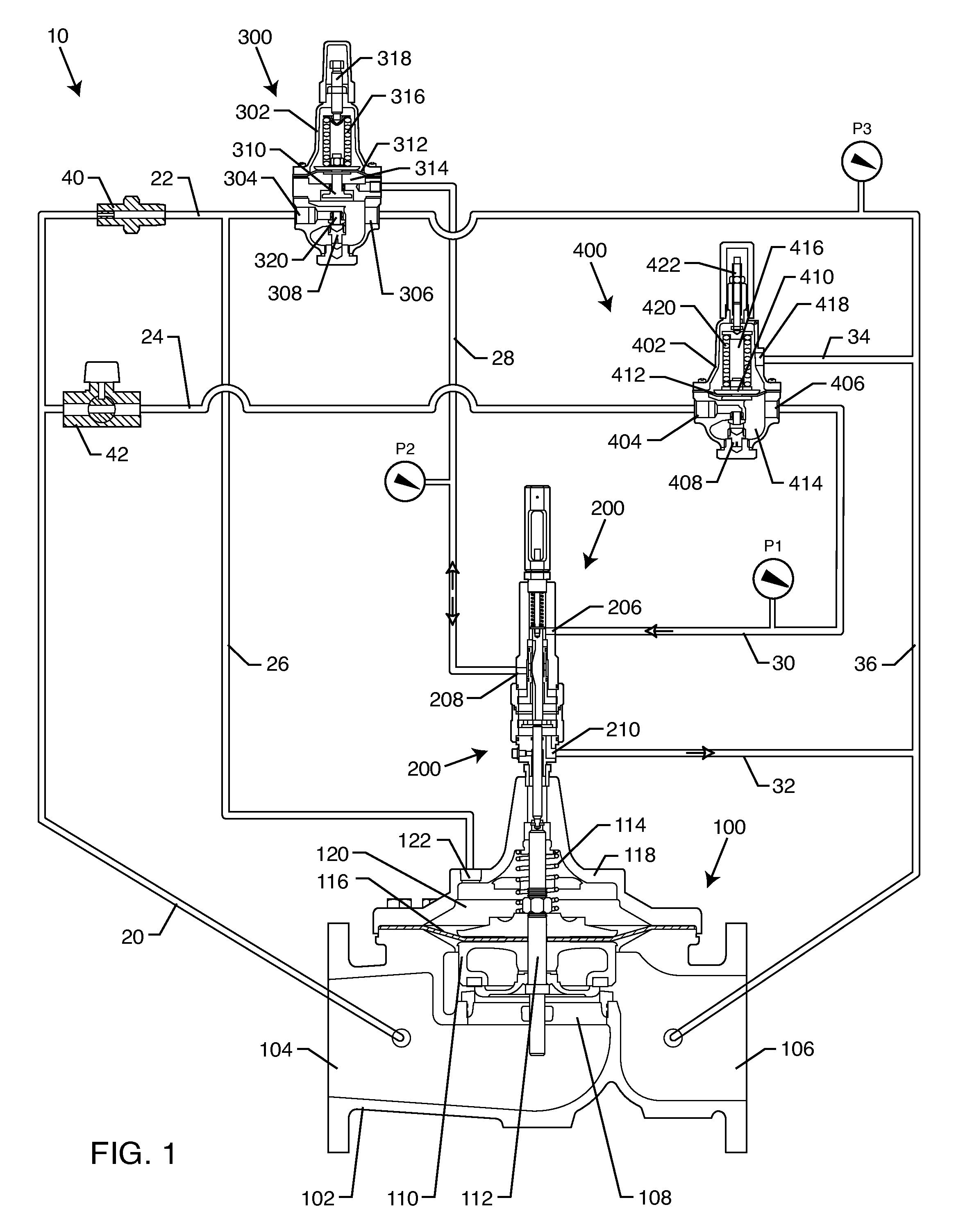

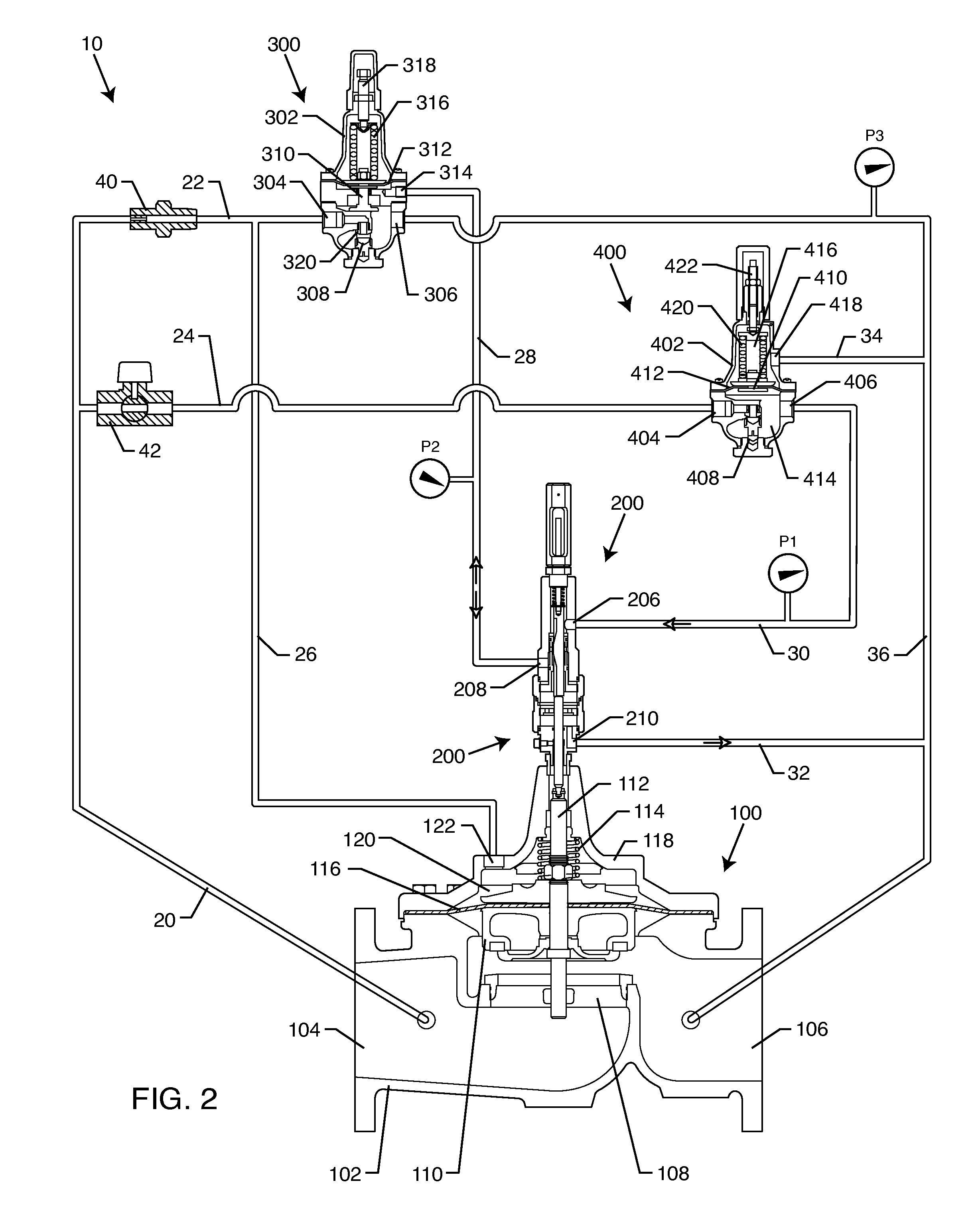

System, including a variable orifice assembly, for hydraulically managing pressure in a fluid distribution system between pressure set points

InactiveUS20100071787A1Reduction of amount of water lossOperating means/releasing devices for valvesServomotor componentsDistribution systemEngineering

A system for hydraulically managing fluid pressure in a fluid distribution system between pressure set points includes a main valve having a fluid inlet and outlet. The main valve is configured to open to increase fluid flow therethrough and to close to reduce the fluid flow therethrough. A variable orifice assembly is coupled to the main valve and has fluid apertures formed in a housing thereof to create a fluid flow pathway therebetween. A valve stem is variably positioned within the housing to alter the fluid flow between the fluid apertures. A first control pilot is in fluid communication with the main valve and a first fluid aperture of the variable orifice assembly. A second control pilot is in fluid communication with the main valve and a second fluid aperture of the variable orifice assembly. The valve position and fluid flow are variable as the main valve opens and closes.

Owner:CLA VAL

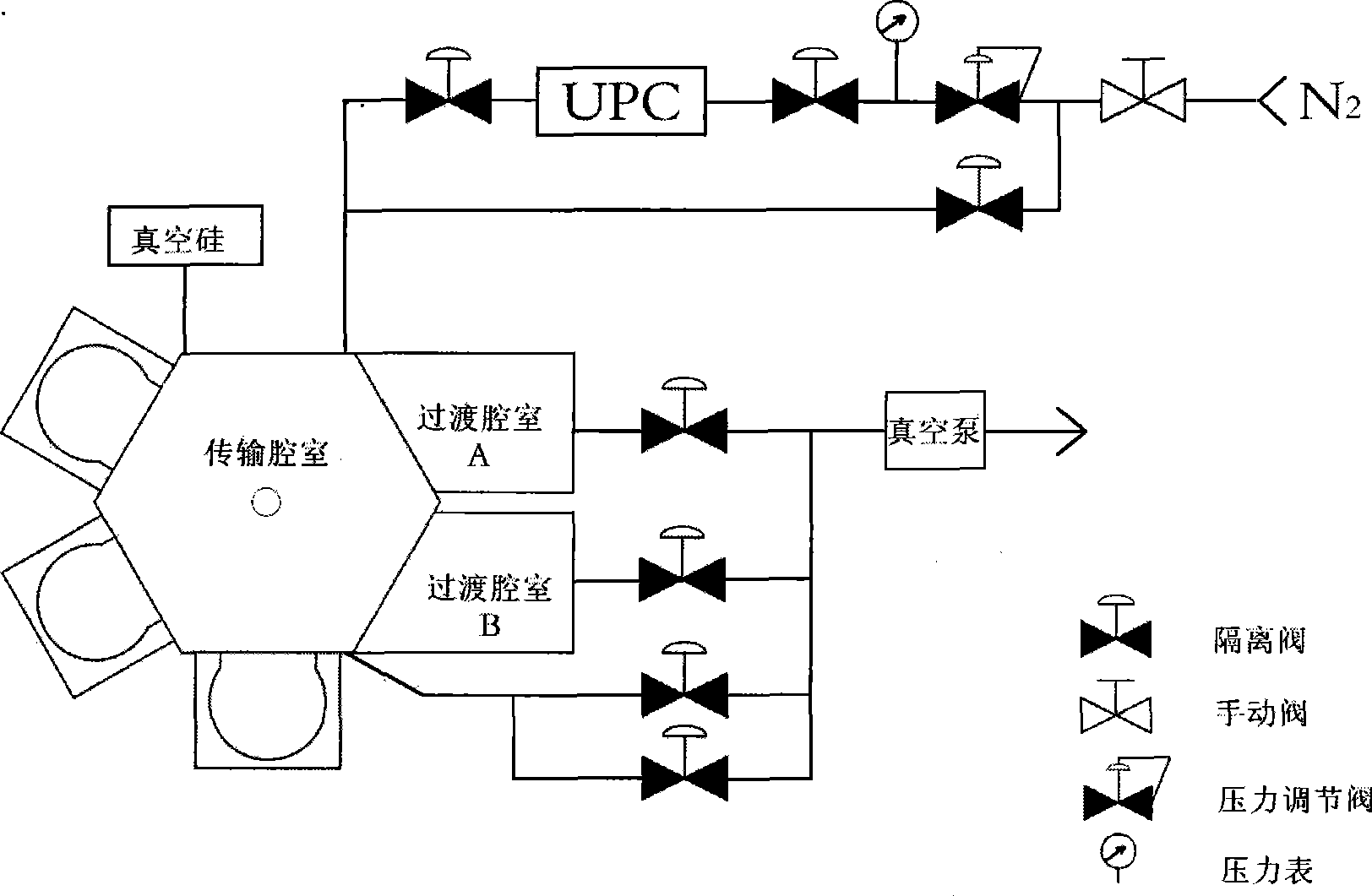

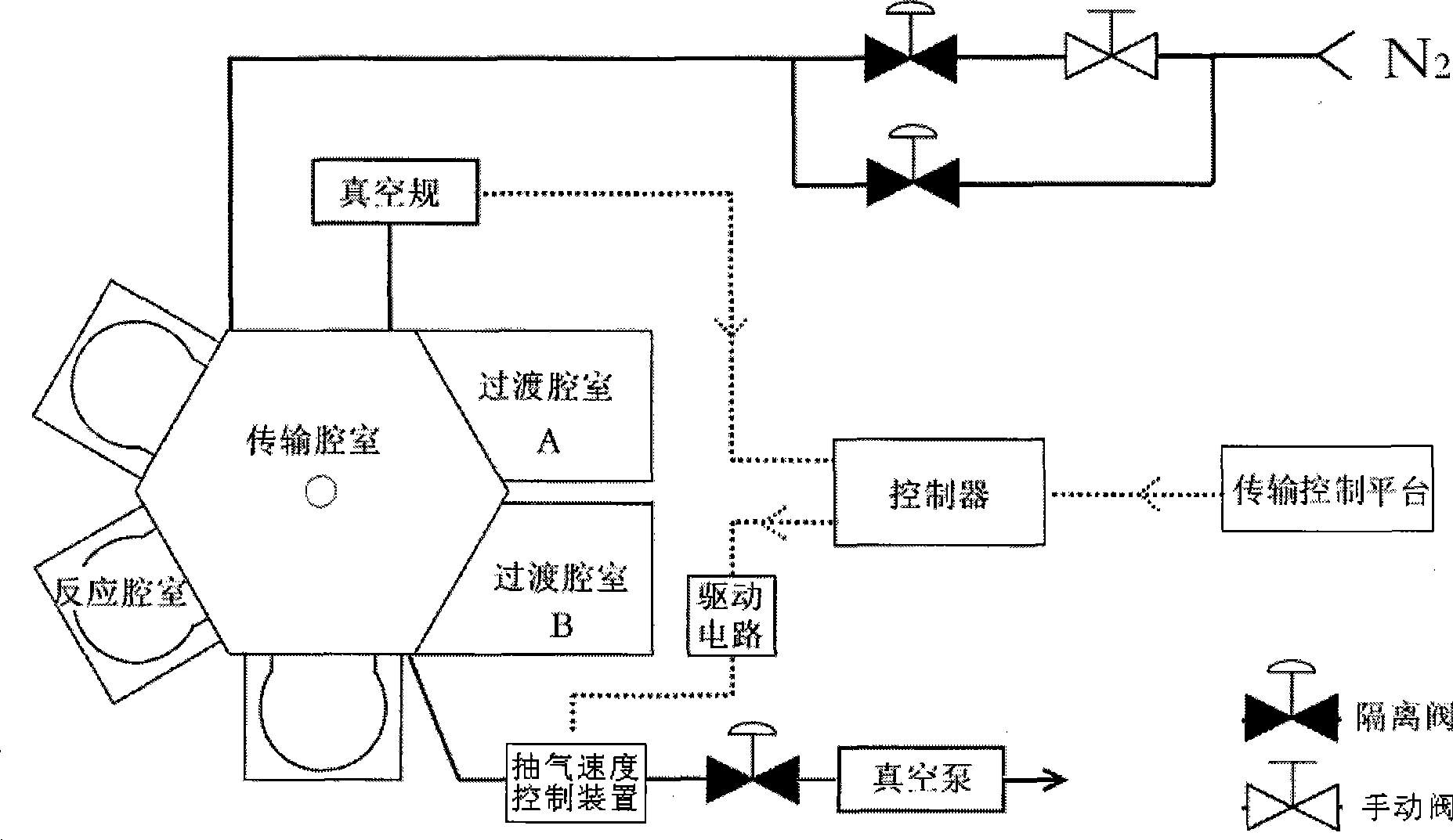

Transmission cavity pressure control system and method

InactiveCN101470447AReduce consumptionStable pressureFluid pressure control with auxillary non-electric powerFluid pressure control using electric meansLoop controlControl system

The invention discloses a pressure control system of a transmission chamber and a method thereof. The transmission chamber is equipped with a charging air passage and an evacuating air passage, wherein the evacuating air passage is provided with an evacuating speed control device, and pressure in the transmission chamber is controlled through controlling evacuating speed of the evacuating air passage in the transmission chamber. The evacuating speed control device is connected with a controller, the transmission chamber is equipped with a pressure sensor connected with the controller, firstly detecting pressure signals in the transmission chamber, then comparing the pressure signals with the set pressure parameters, and on-line adjusting the evacuating speed of the evacuating air passage in real time through closed-loop control algorithms such as PID and the like, finally, the purpose of control pressure in the transmission chamber is achieved. Besides, the system is stable in pressure control and low in nitrogen consumption.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

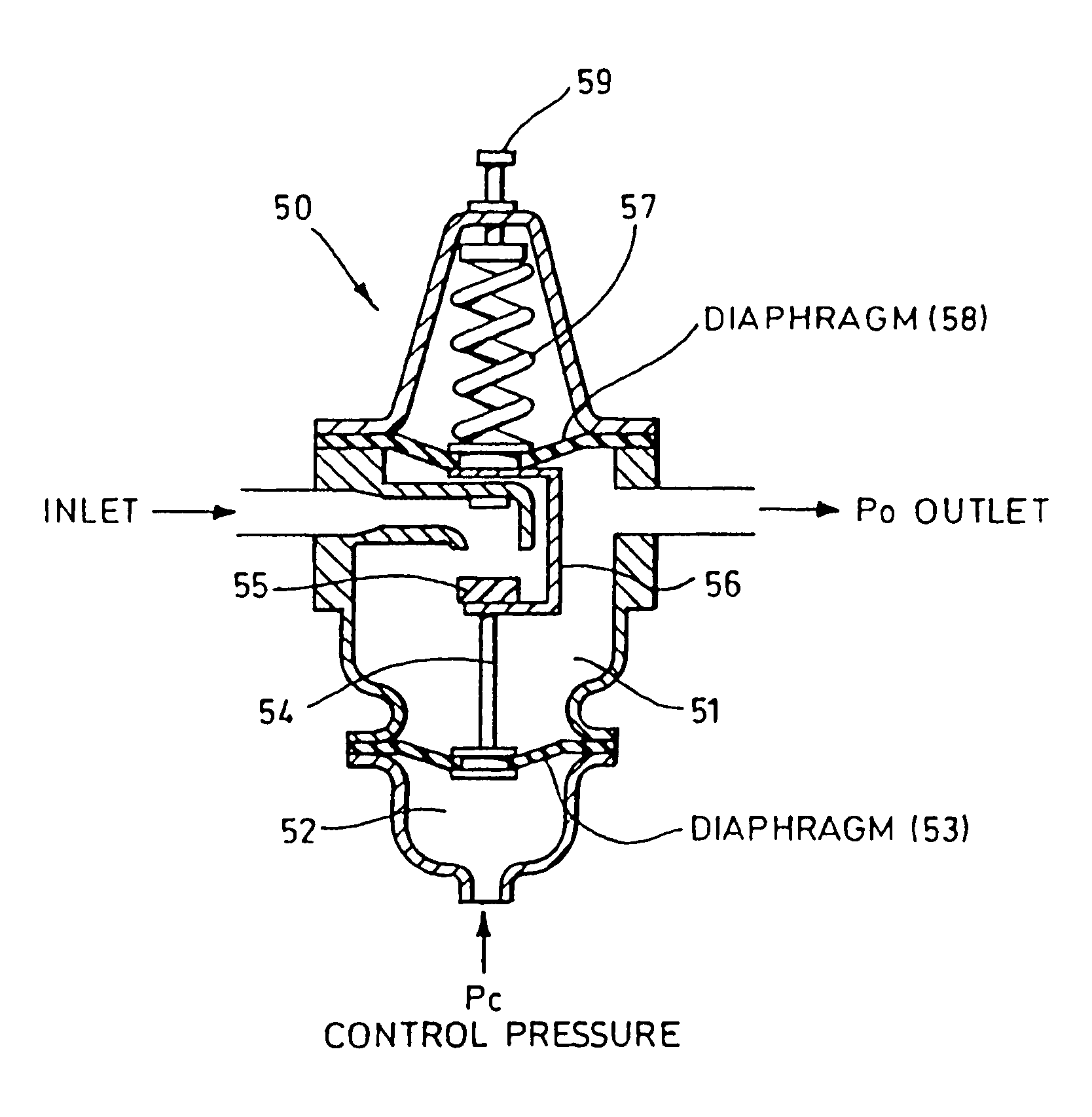

Pilot valve

InactiveUS6935362B1Reduce flowAvoid the needOperating means/releasing devices for valvesFluid pressure control with auxillary non-electric powerEngineeringGas supply

There is provided a pilot valve (50), suitable for use in water and gas supply systems, the valve including biassing means (57), to control a gate (55), for controlling fluid flow through a control chamber (51), and a second chamber (52), which is sealed by a diaphragm (53), the second chamber (52), in use, receiving a control pressure for controlling the operation of the gate (55), such that an increase in control pressure acts to reduce fluid flow through the gate (55). The side of the diaphragm (53), against which the control pressure is not applied, is in fluid communication with the control chamber (51).

Owner:TECHNOLOG

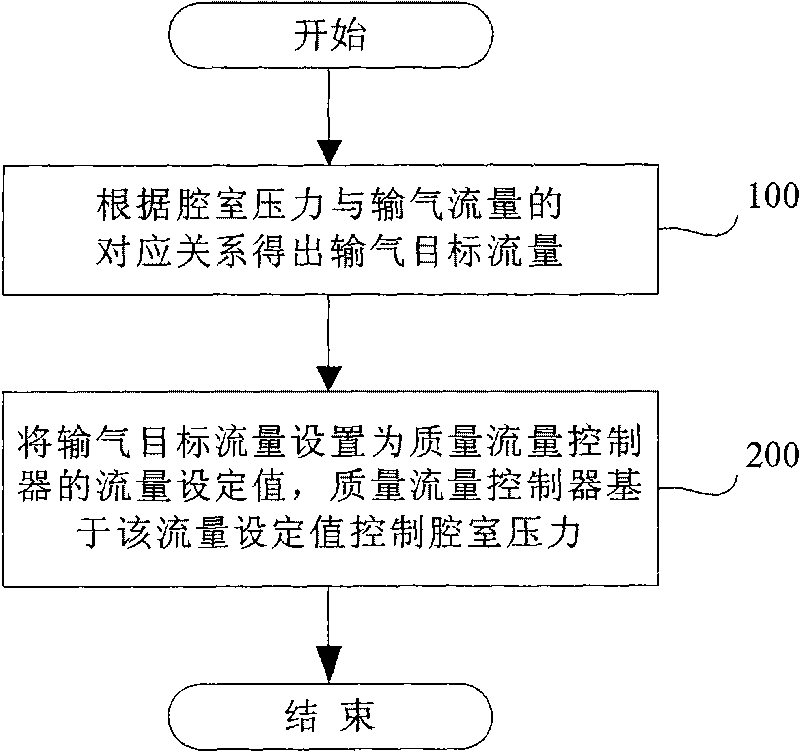

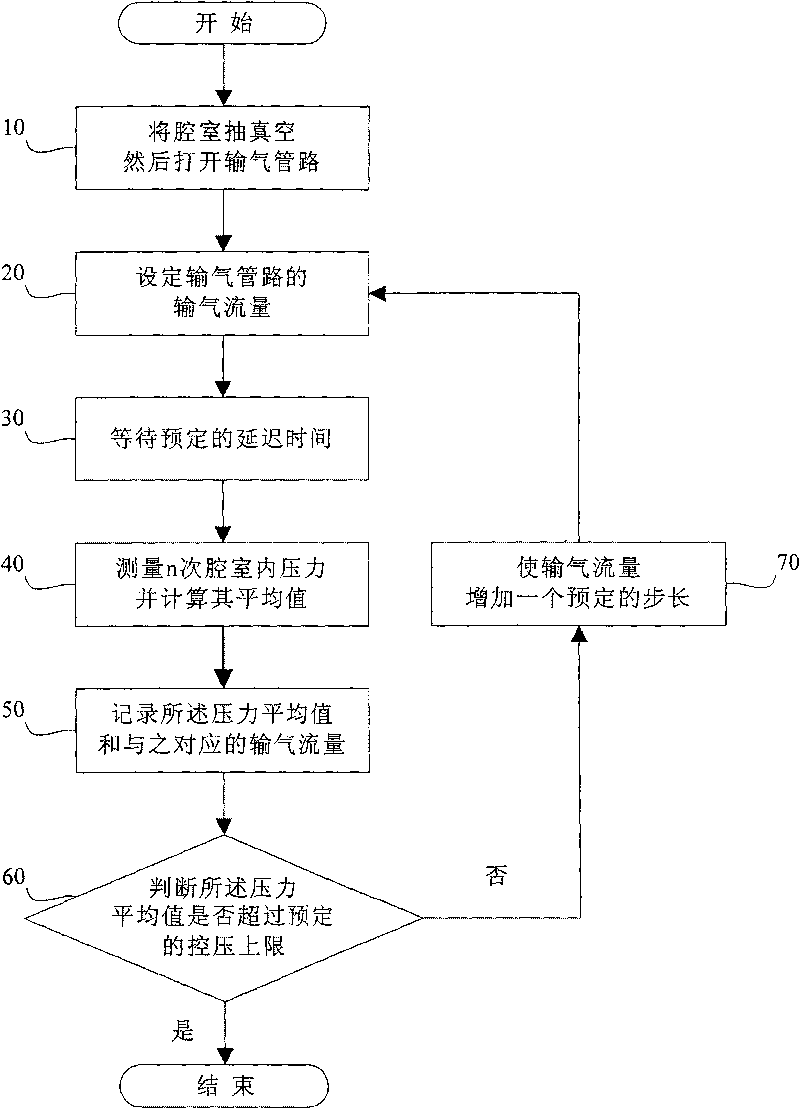

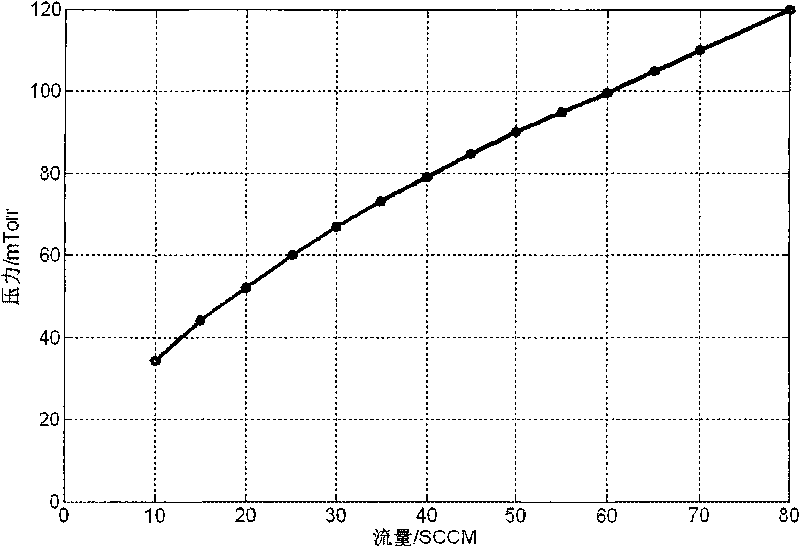

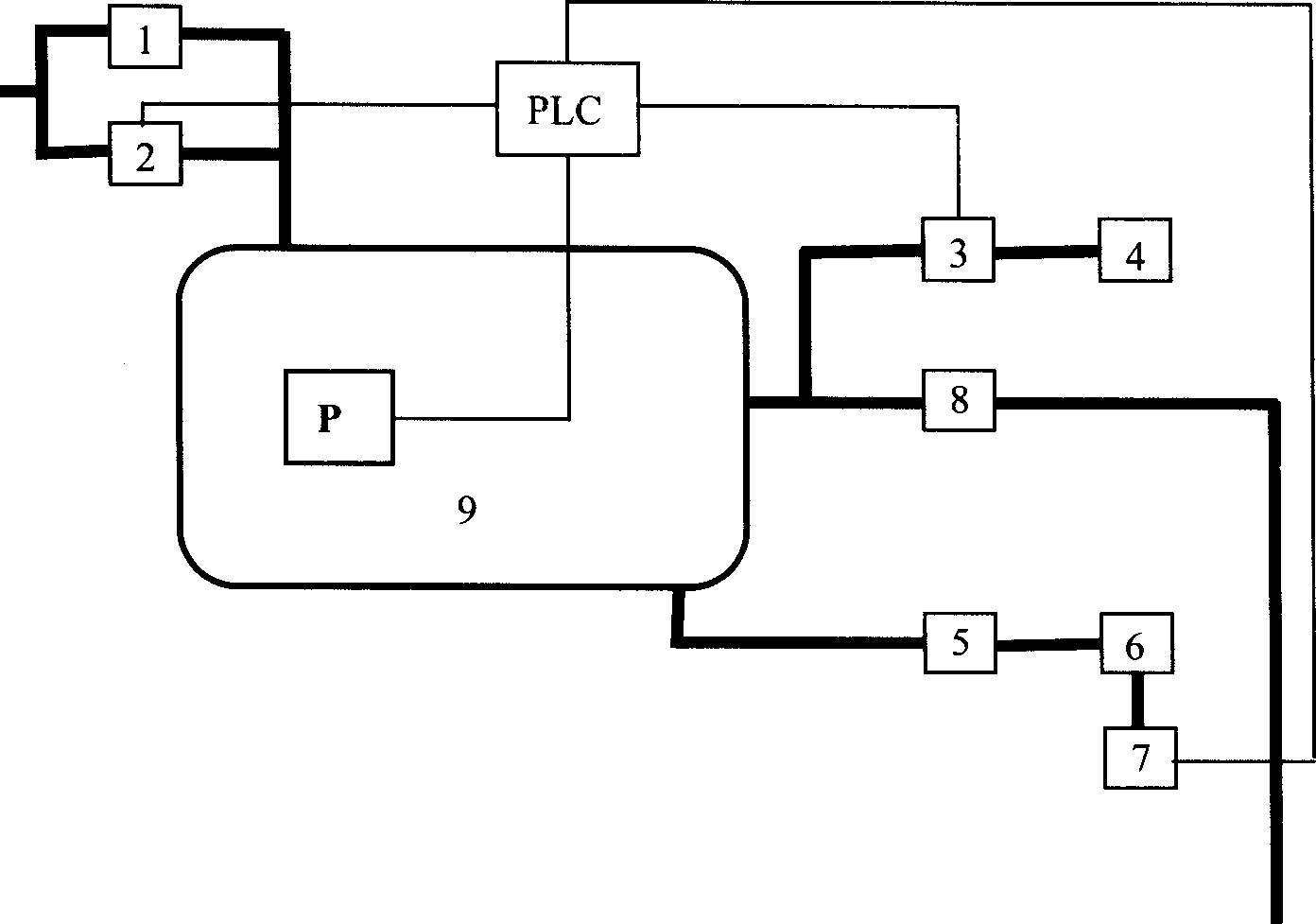

Method, device and system for chamber pressure control

ActiveCN101727111AEffective pressure controlLow costSemiconductor/solid-state device manufacturingFluid pressure control with auxillary non-electric powerControl systemEngineering

The invention provides a chamber pressure control method, which comprises: step 100, acquiring air delivery target flow required when a chamber is in a target pressure according to a corresponding relationship between the pressure of the chamber and the air delivery flow; and step 200, setting the air delivery target flow as a flow setting value of a mass flow controller, wherein the mass flow controller implements air delivery operation on the chamber based on the flow setting value and controls the pressure of the chamber within the target pressure range. The method for controlling the pressure of the chamber also comprises a step of acquiring the corresponding relationship between the pressure of the chamber and the air delivery flow. In addition, the invention also provides a chamber pressure control device, a chamber pressure control system using the method and the chamber pressure control system using the device. An expensive pressure control valve is replaced by adopting the cheaper mass flow controller and the simple control step, and the cost of the process / equipment is saved while effectively controlling the pressure of the chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Device and method for controlling atmosphere content and pressure balance in negative pressure container

InactiveCN1862435AControl gas impurity contentEasy to operateFluid pressure control with auxillary non-electric powerFluid pressure control using electric meansGas analysisGas composition

The present invention discloses a negative pressure container interior gas composition and pressure balance control equipment and method required for making rare earth permanent magnetic material. Said invention adopts pump-valve coupled structure, utilizes gas analysis equipment and makes it be connected with PLC controller to control gas intake and gas exhaust balance so as to attain the goal of stabilizing pressure and monitoring gas composition in negative pressure container interior.

Owner:绵阳西磁科技开发公司

Slurry tolerant pilot operated relief valve

ActiveUS20070001134A1Avoid flowOperating means/releasing devices for valvesEqualizing valvesFluid controlEngineering

Cartridge-style fluid control devices are provided that are static pressure independent and capable of repeatable, reliable, particulate insensitive performance in service conditions typical of downhole intervention environments.

Owner:EXXONMOBIL UPSTREAM RES CO

Fluid flow pressure regulator

InactiveUS6986338B2Operating means/releasing devices for valvesLow-pressure fuel injectionSteam pressureEngineering

A fuel vapor pressure regulator by which the input pressure of an input fluid is regulated by the opening and closing of a valve unit controlled by a piston pressure sensor, the operation of which is, in turn, controlled by a movement of a preset bias, the output pressure of the fluid delivered by the regulator, and a biasing pressure that reflects the operating demands of the utilization unit to which the fluid is delivered.

Owner:ITT MFG ENTERPRISES LLC

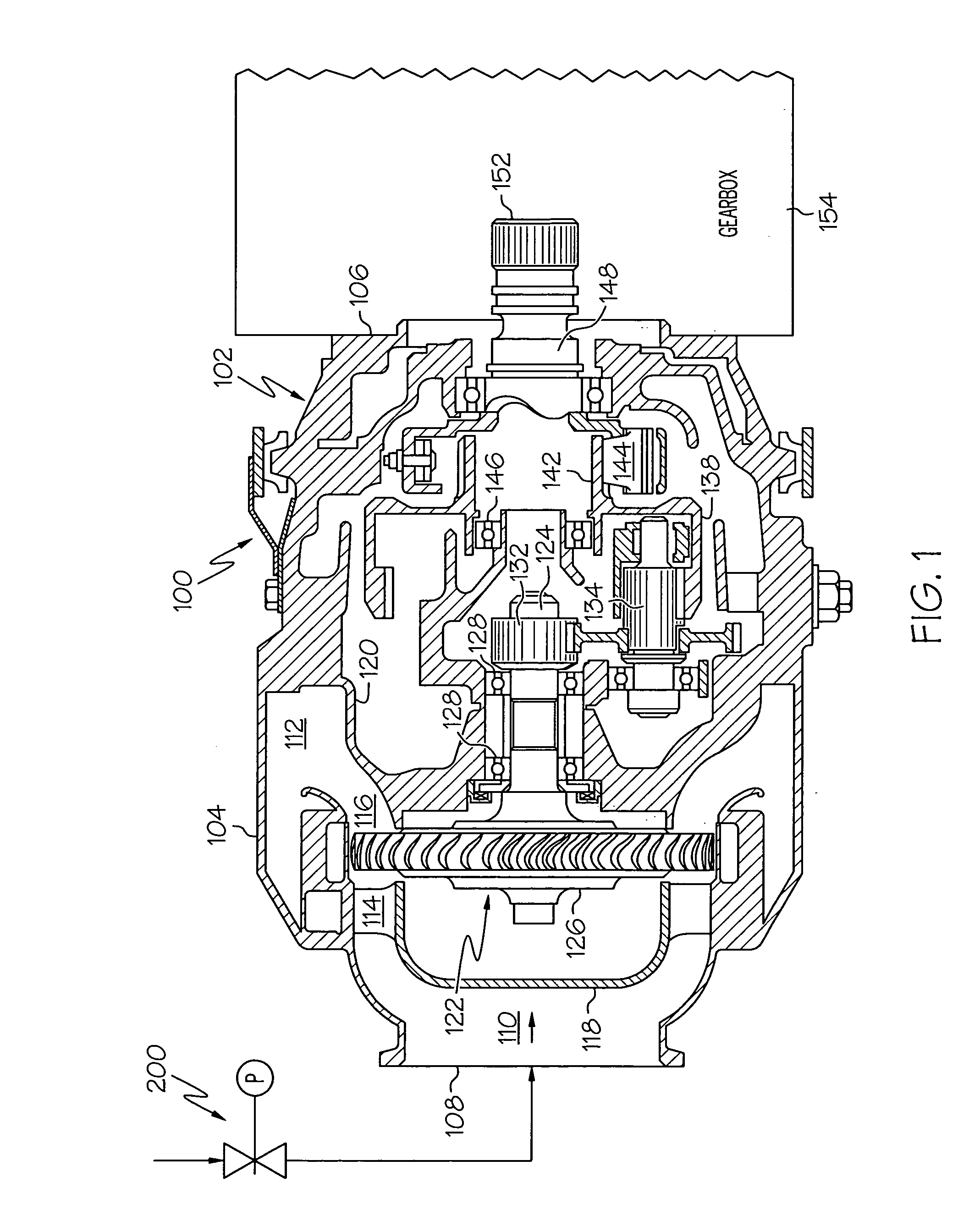

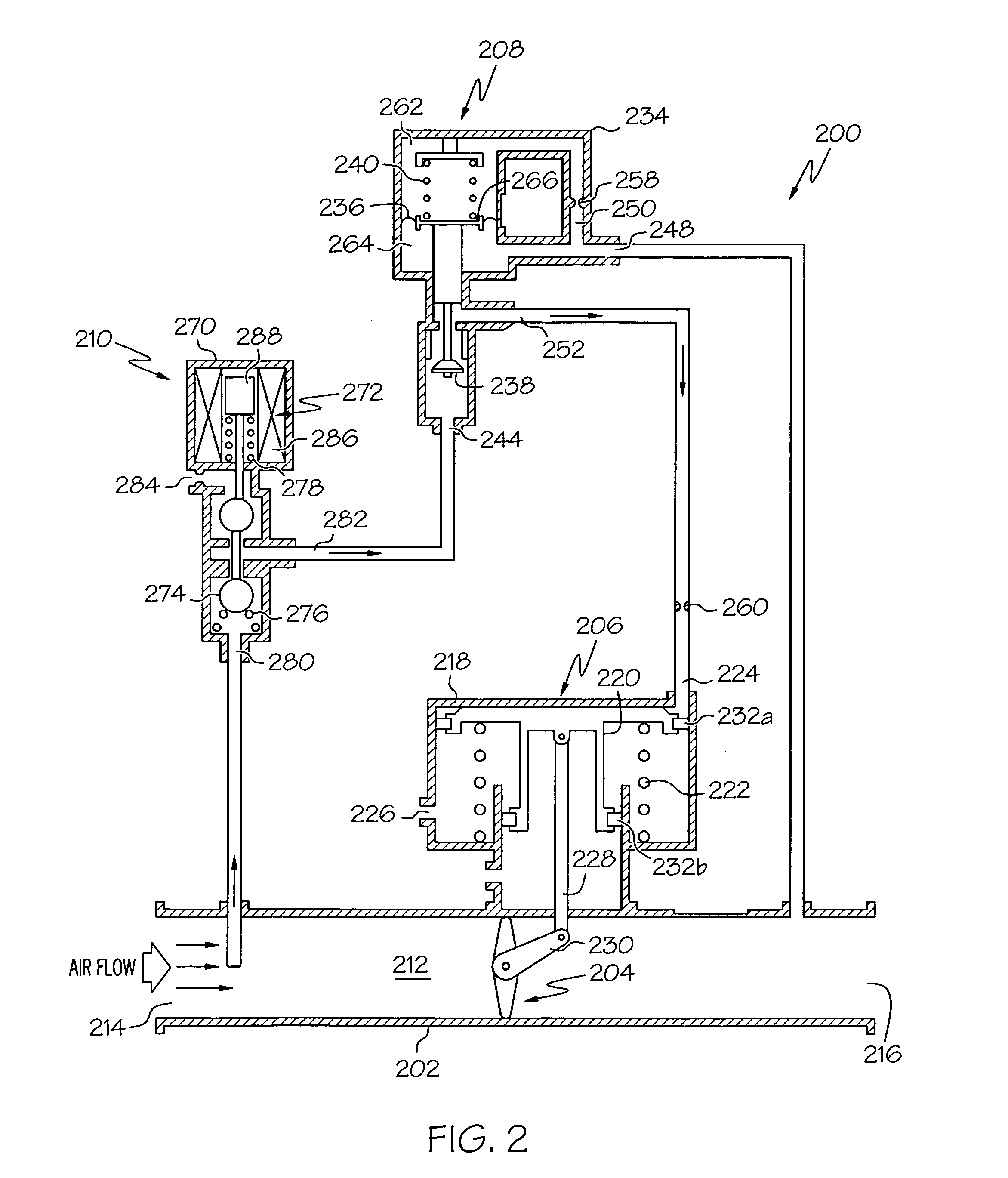

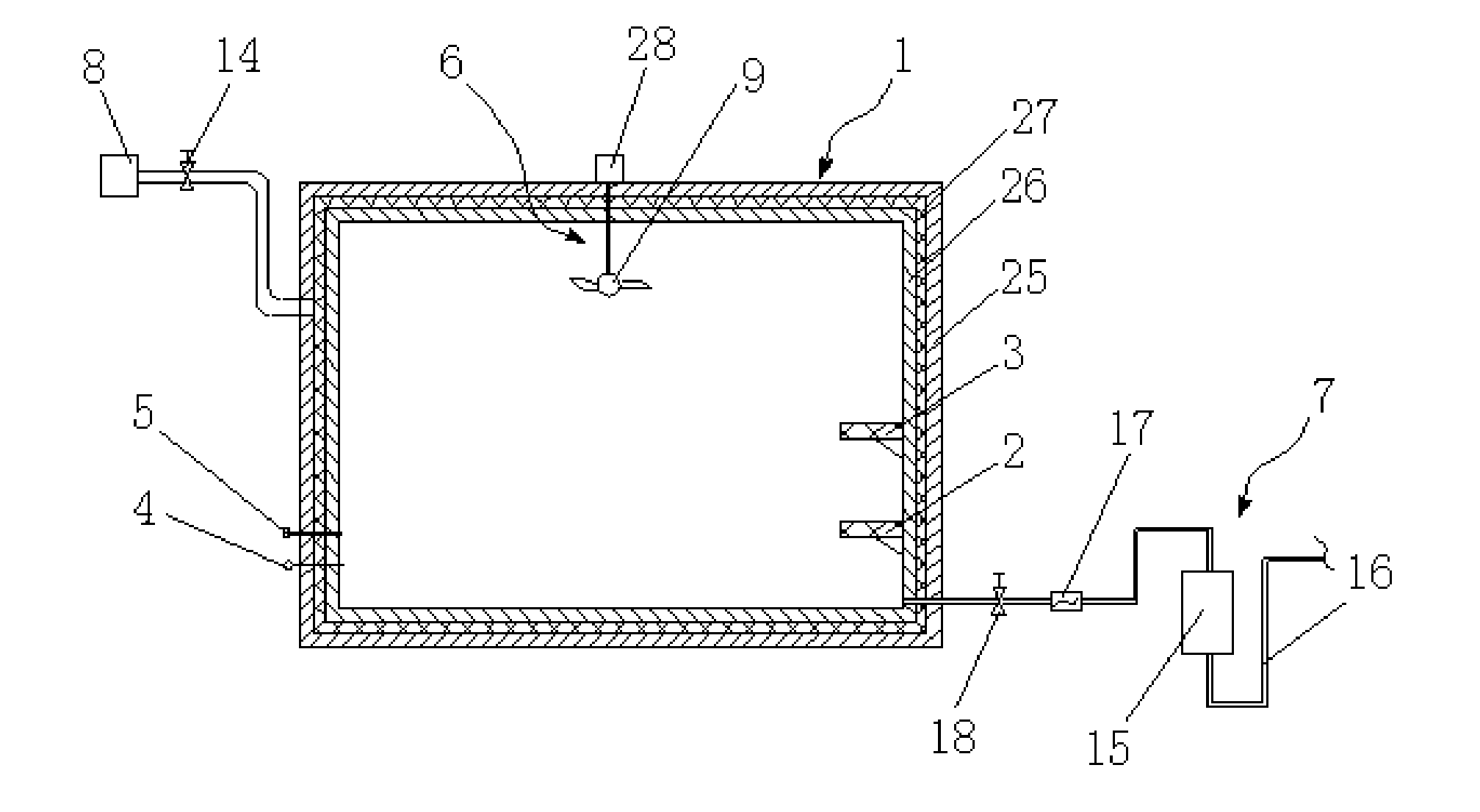

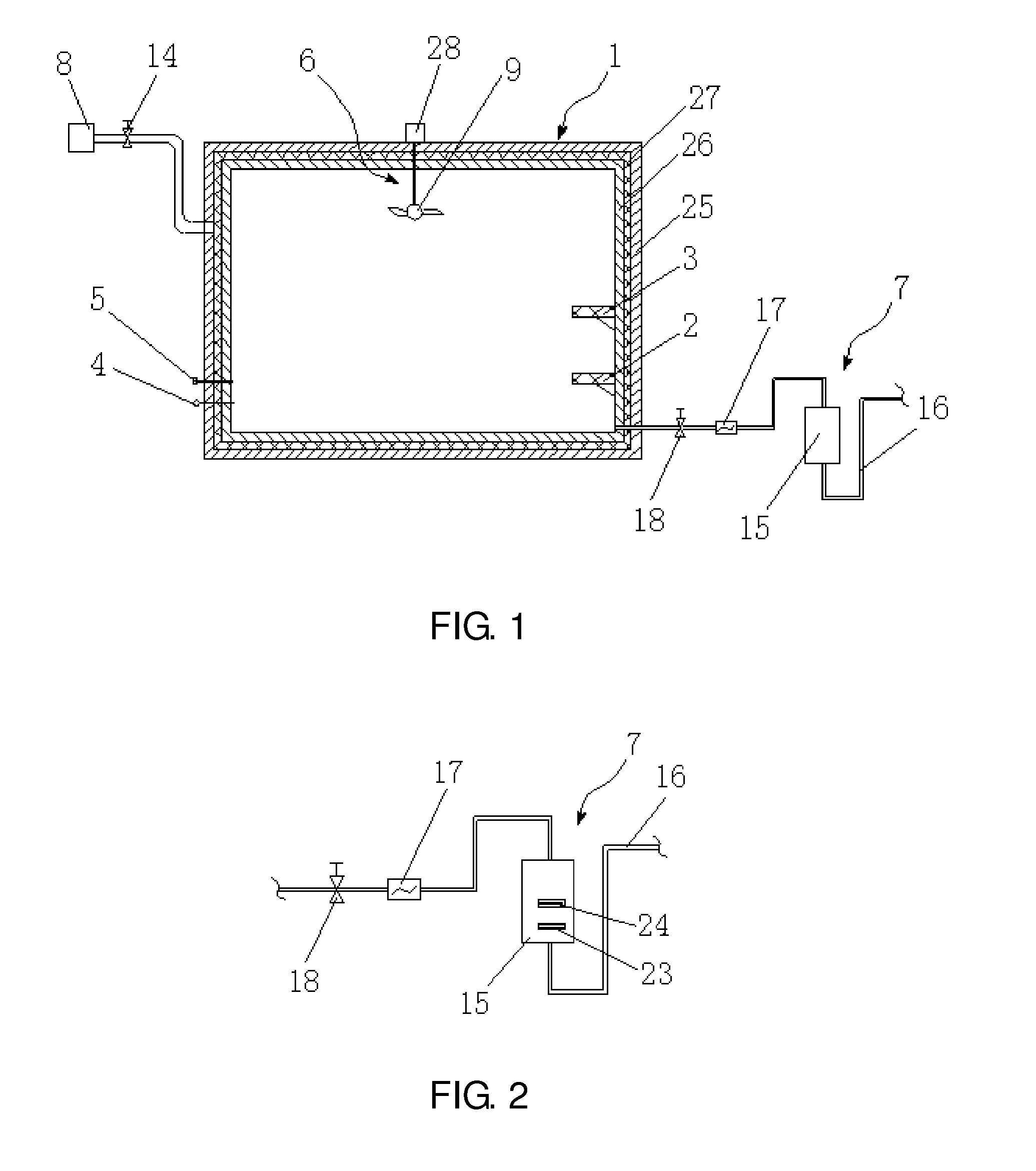

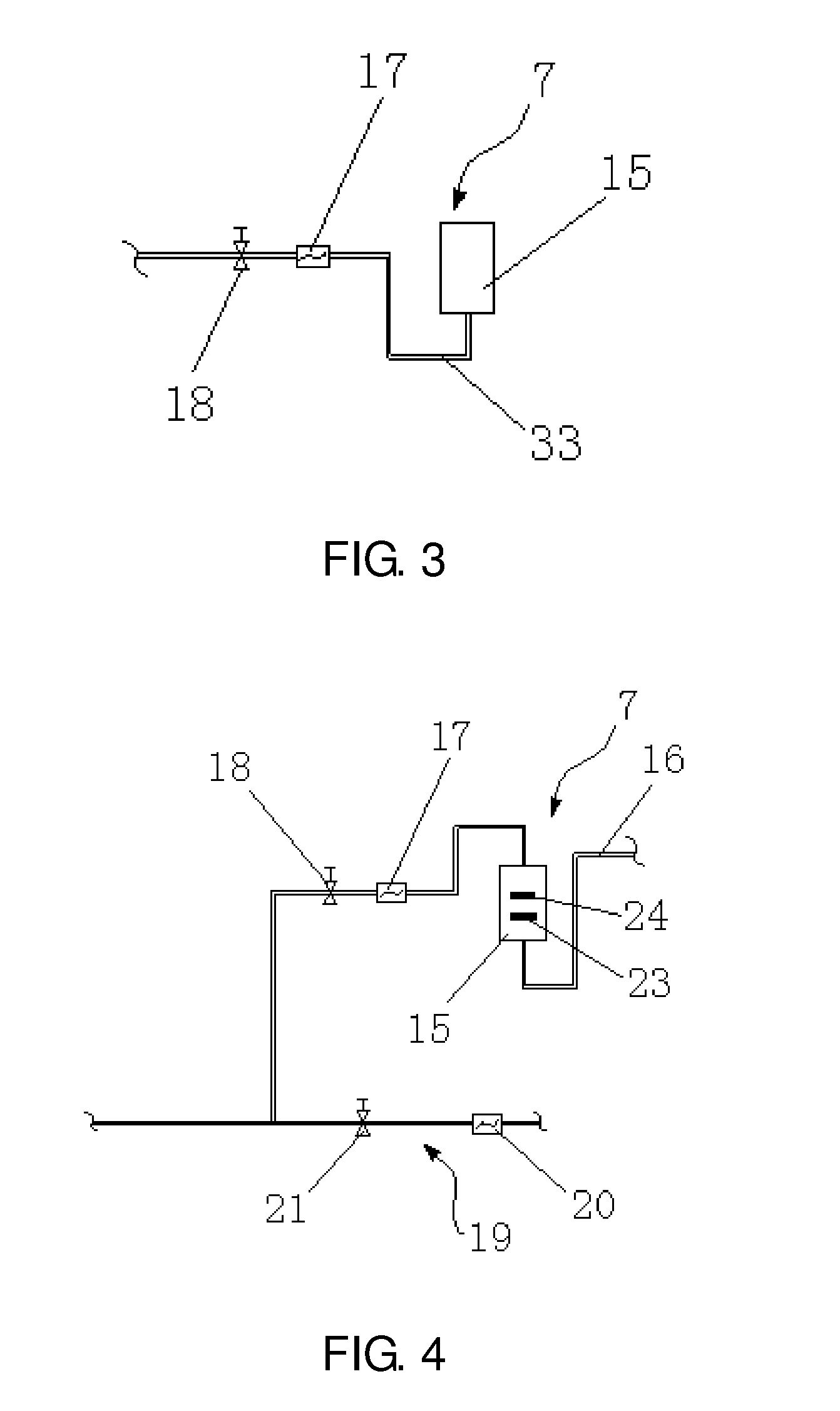

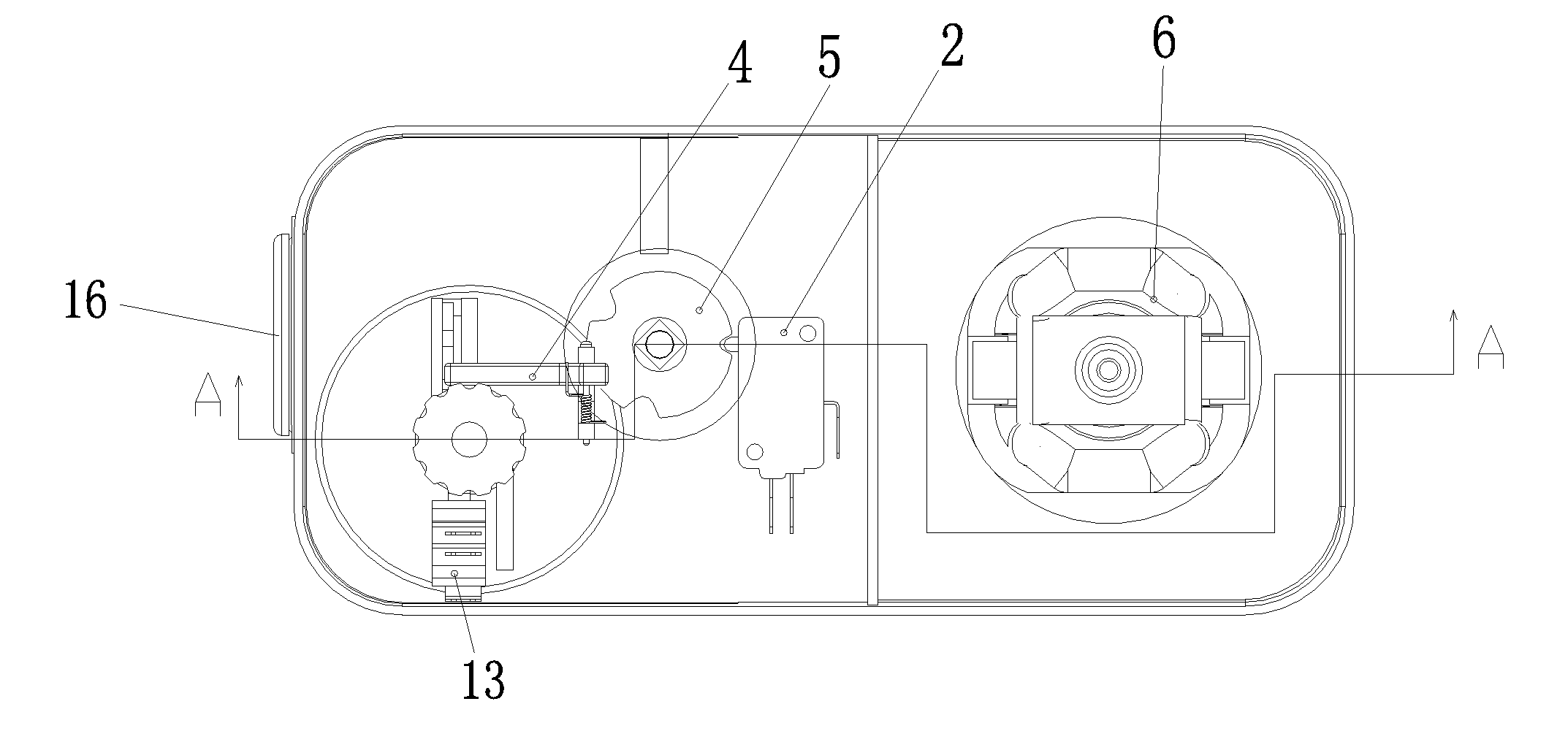

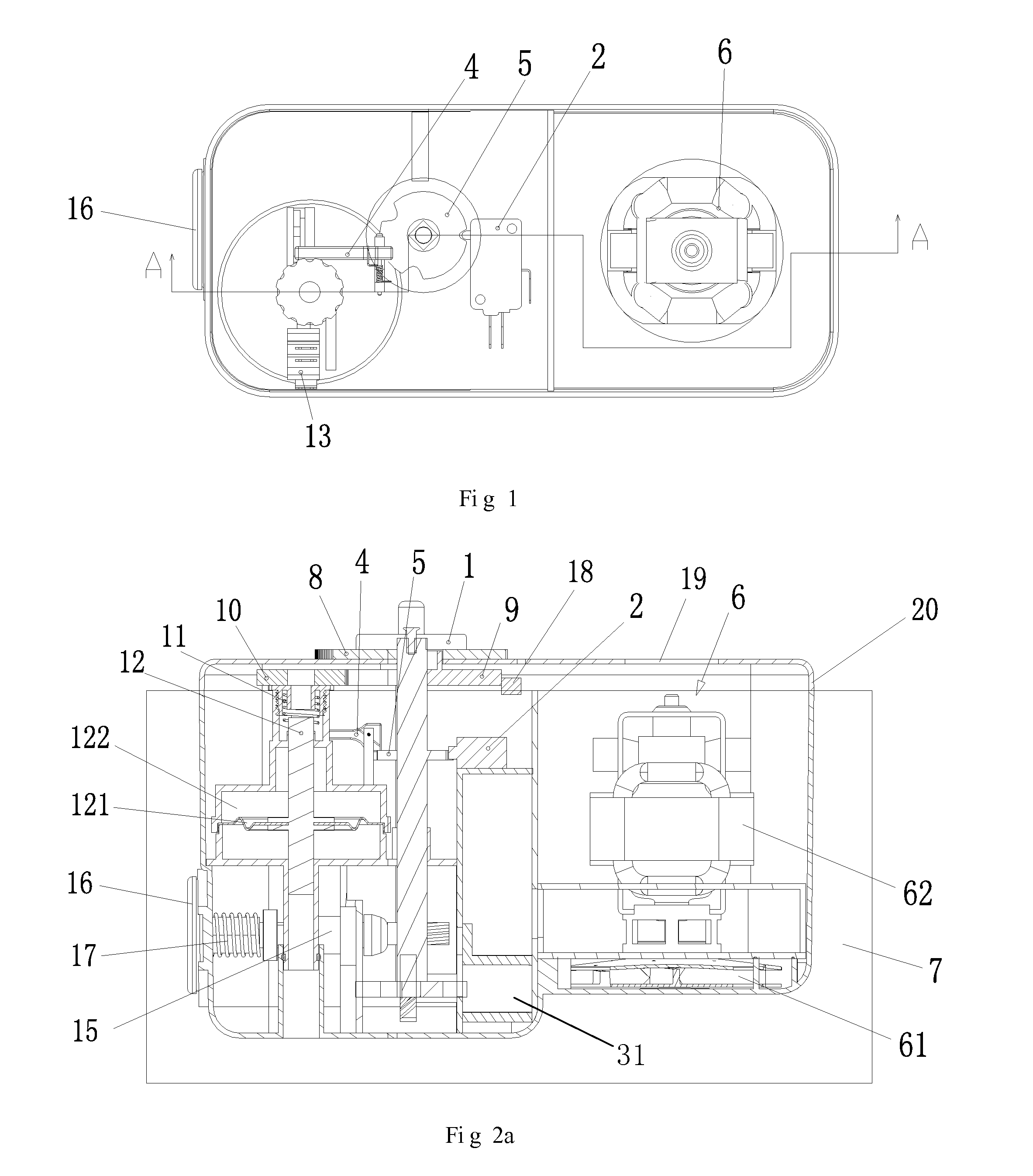

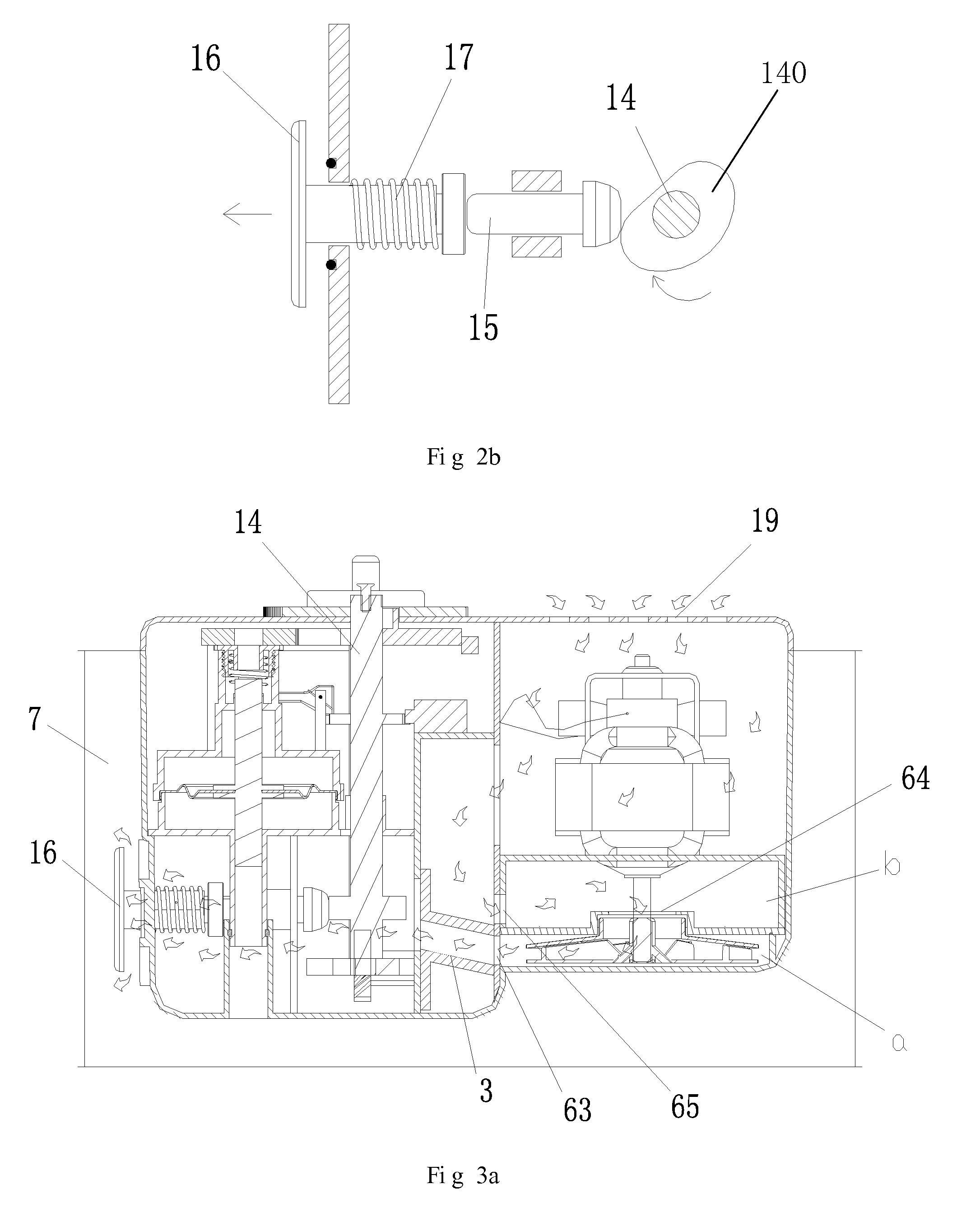

Low pressure and high-low temperature test box capable of controlling humidity

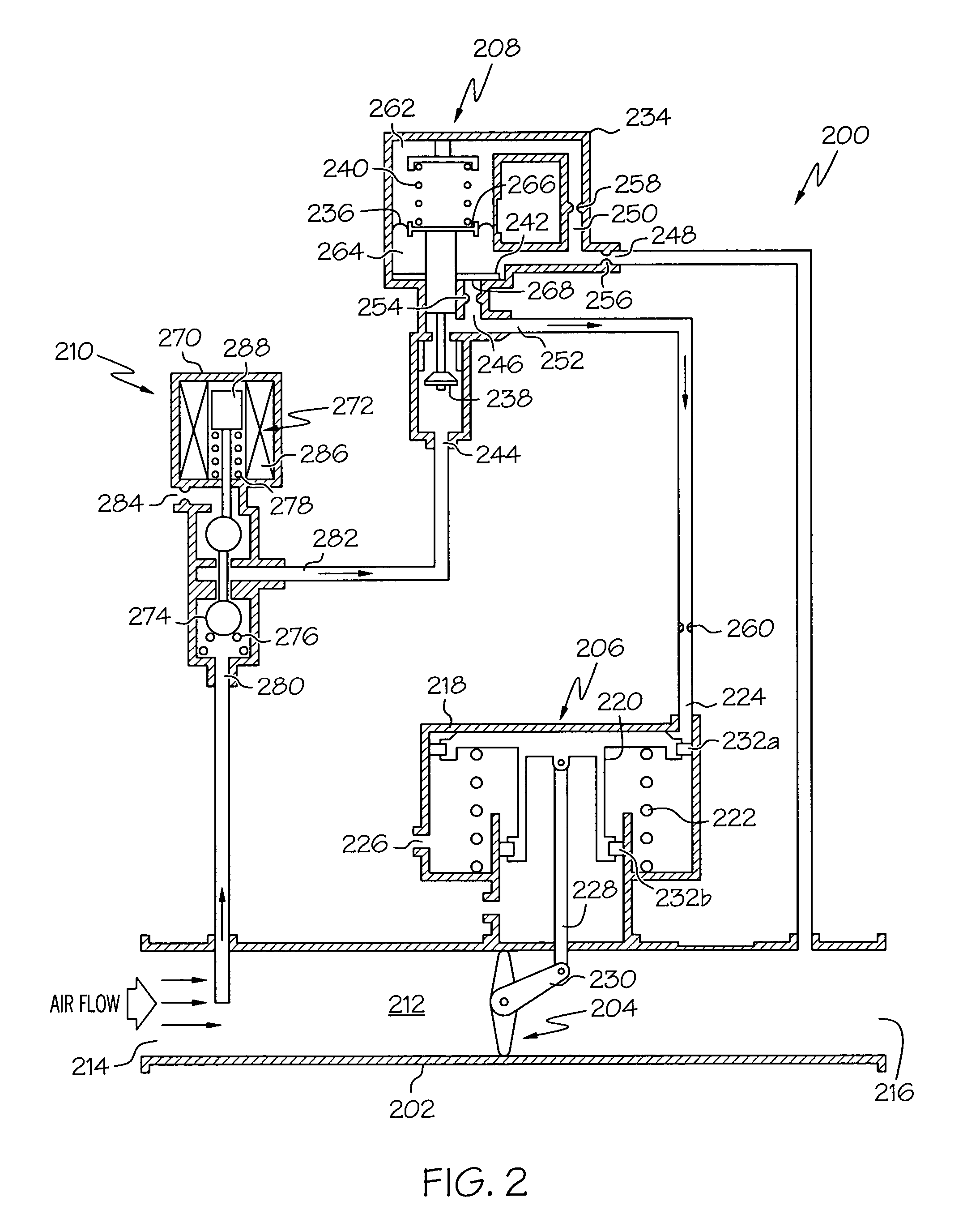

ActiveUS20130193219A1Efficiently meetImprove detection accuracyAir-treating devicesWeather/light/corrosion resistanceAir cycleVacuum pressure

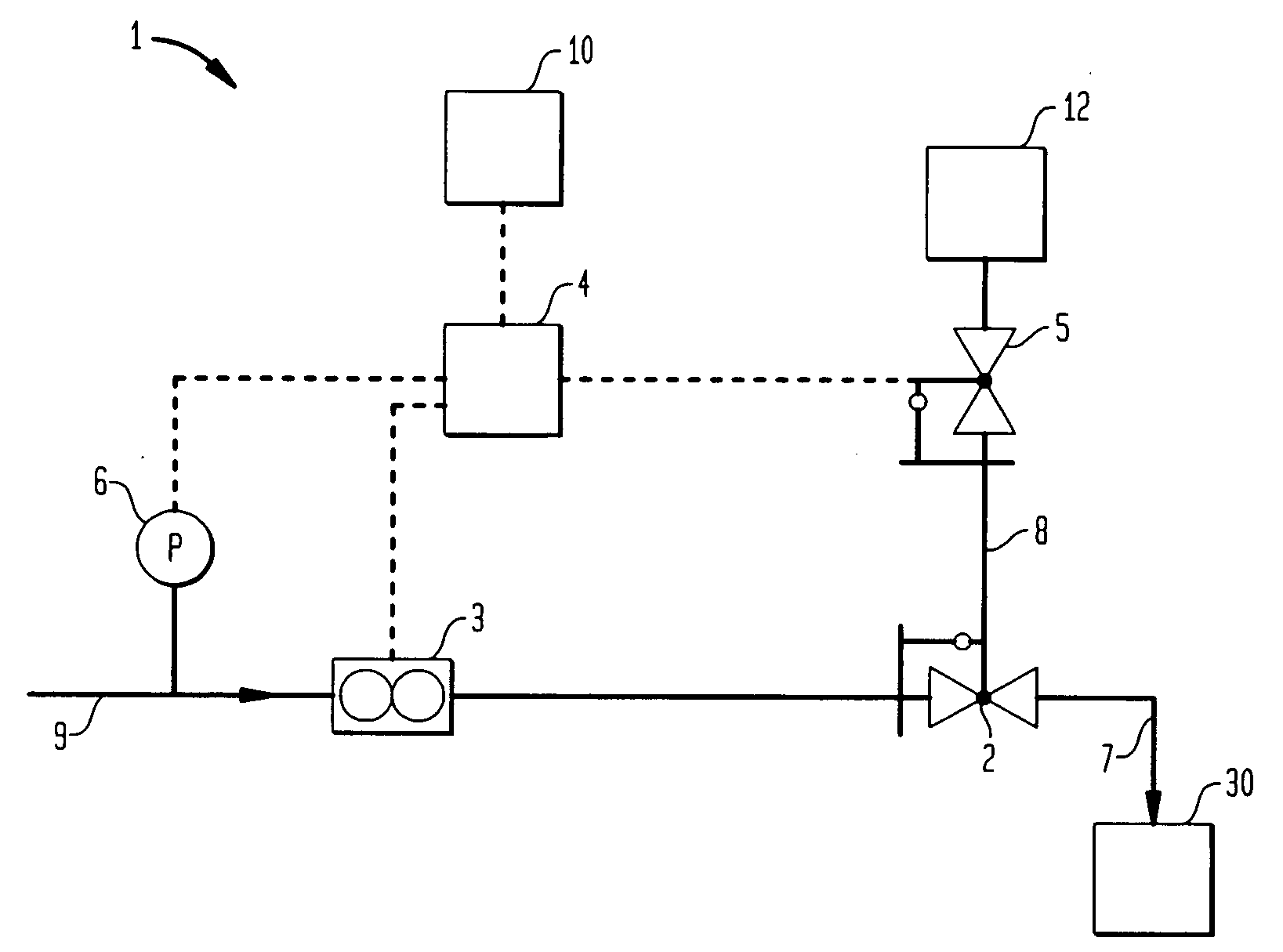

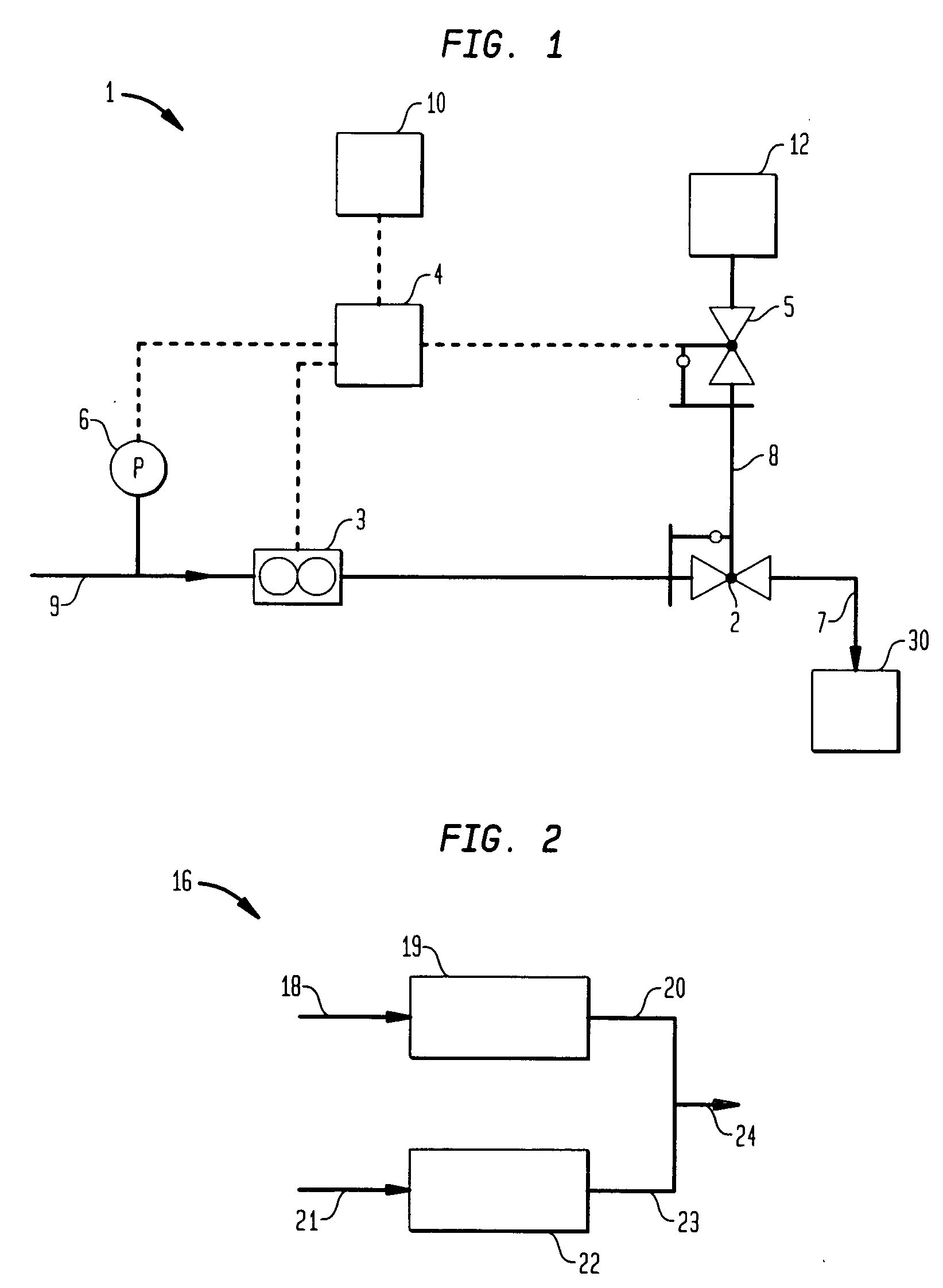

A low pressure and high-low temperature test box capable of controlling humidity comprises a test box body (1), a first heater (2) and a first evaporator (3) which are installed in the test box body (1), a humiture sensor (4) for detecting the humiture inside the test box body (1) and a vacuum manometer (5) for detecting the pressure inside the test box body (1) which are both installed on the test box body (1), an air circulation device (6) for circulating the air inside the test box body (1), and a humidity adjusting device (7) which is connected to the test box body (1) and used for adjusting the humidity inside the test box body (1). A vacuum pump (8) for vacuumizing the test box body (1) is also provided on the test box body (1).

Owner:DONGGUAN CITY SIMPLEWELL TECH

Slurry tolerant pilot operated relief valve

ActiveUS7467778B2Operating means/releasing devices for valvesEqualizing valvesFluid controlEngineering

Owner:EXXONMOBIL UPSTREAM RES CO

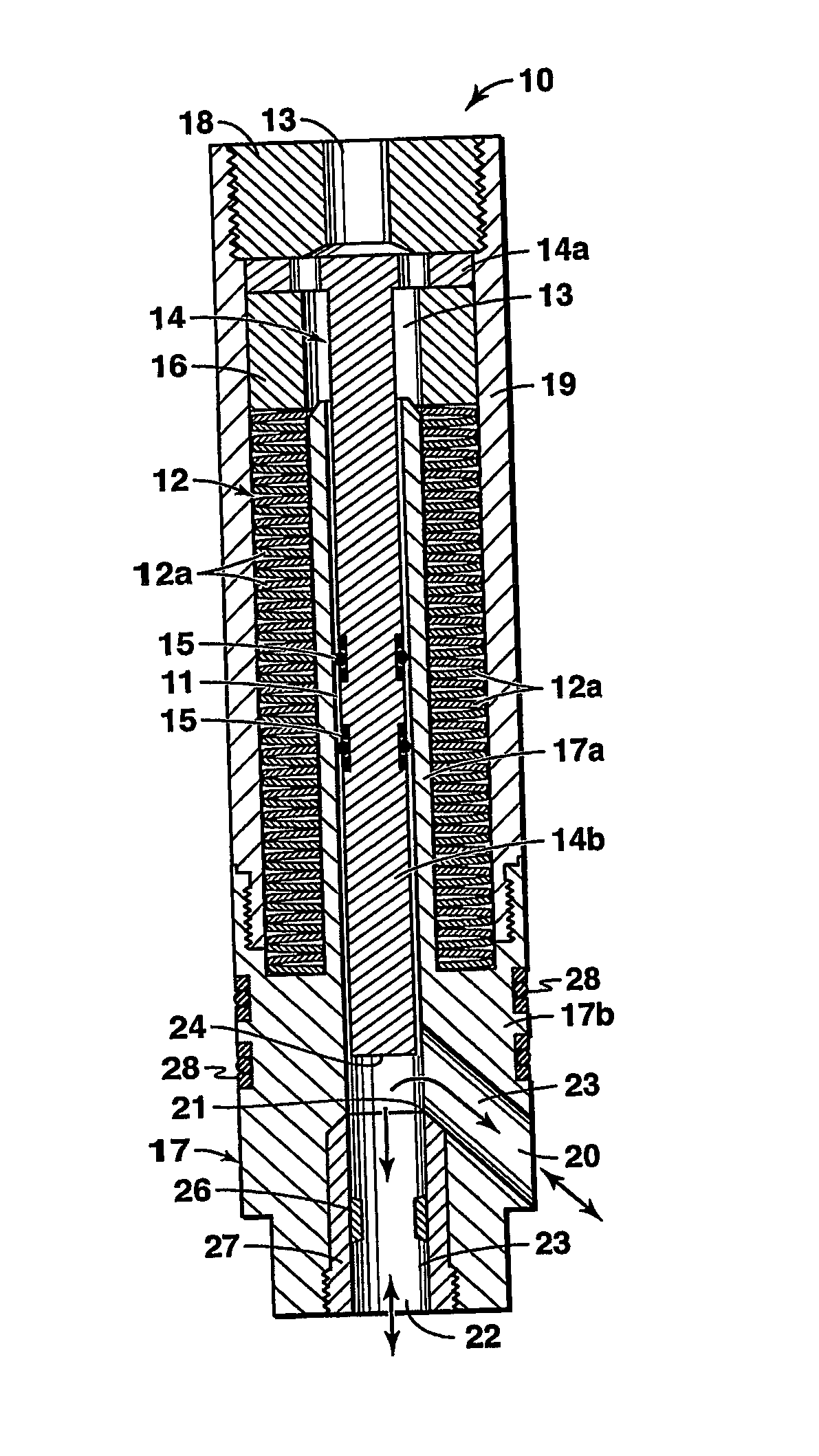

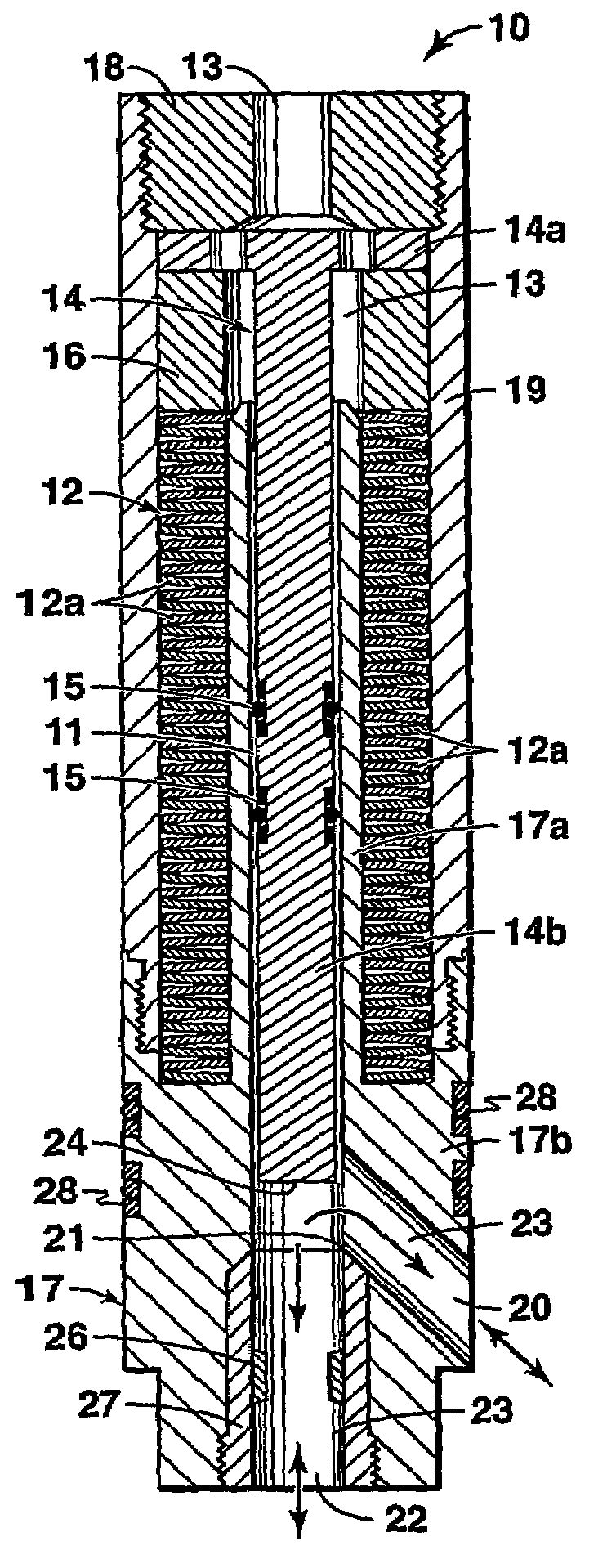

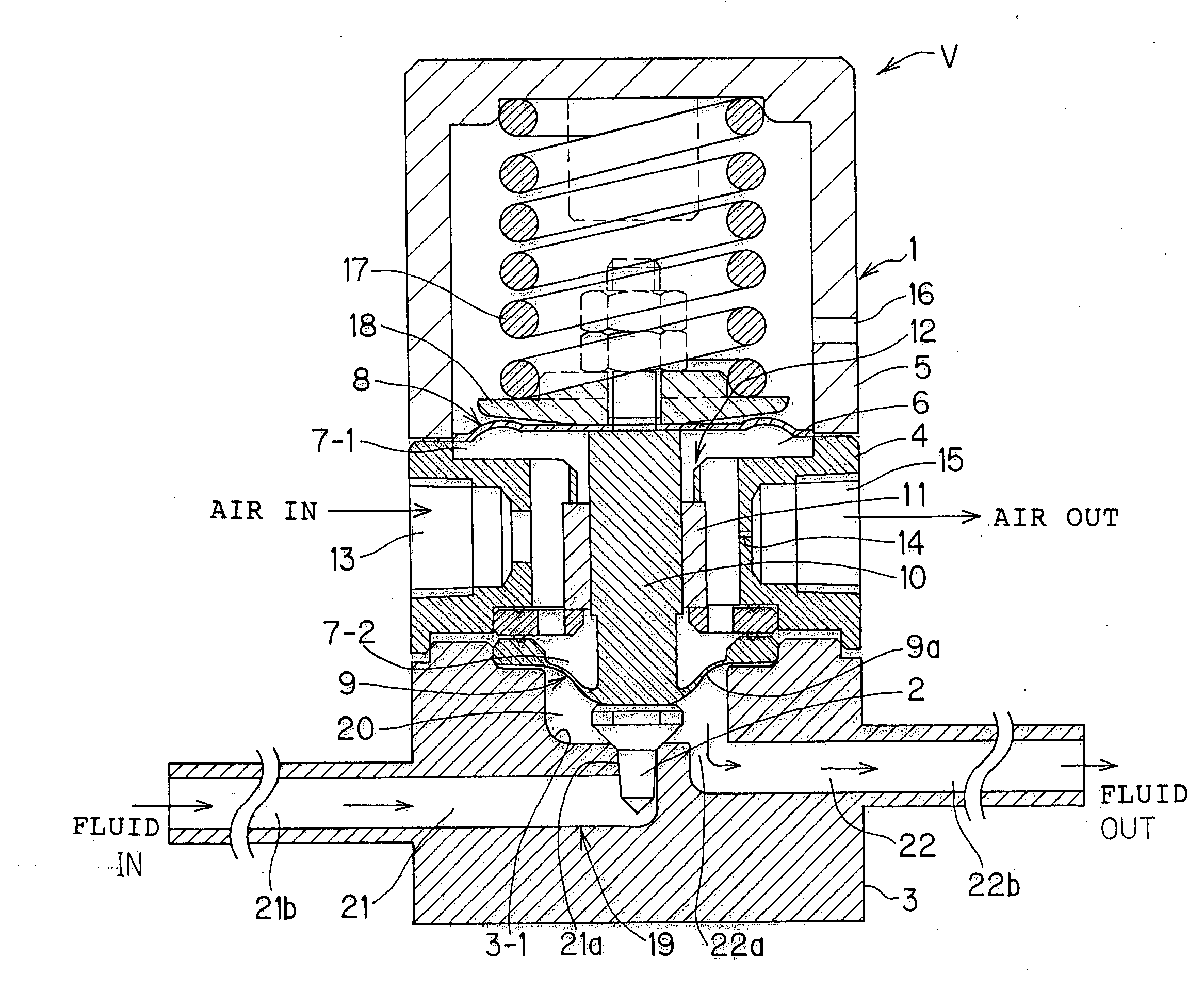

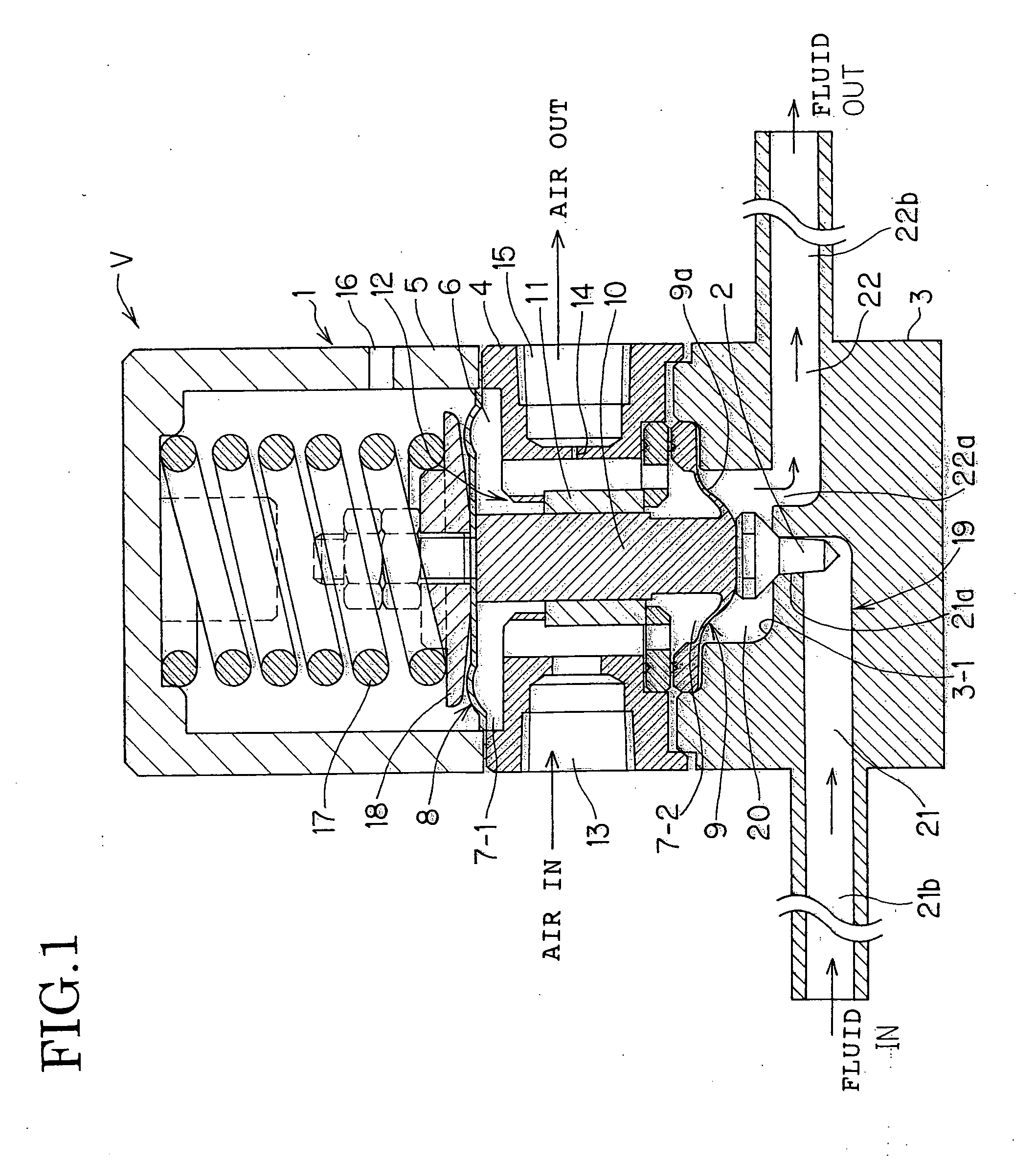

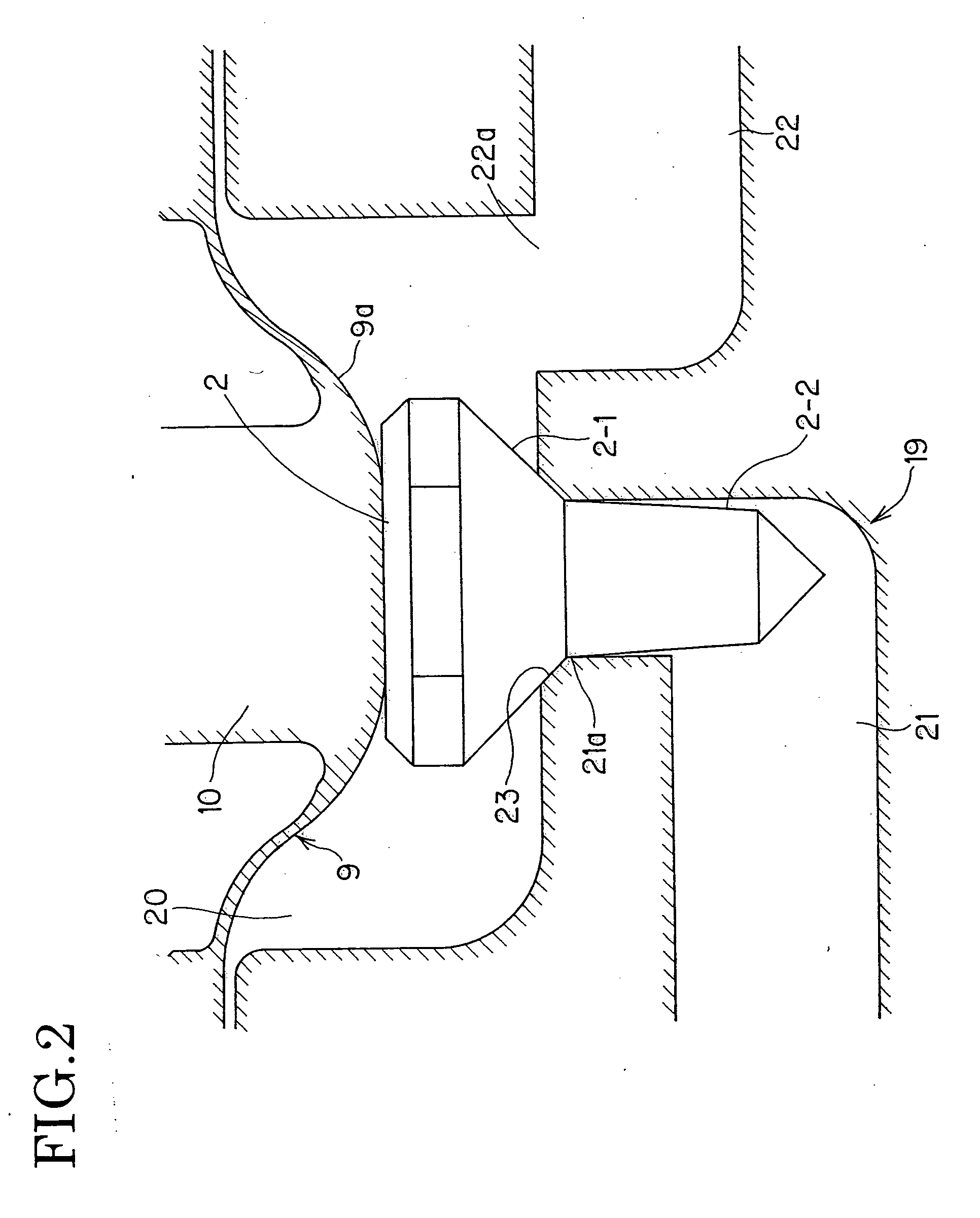

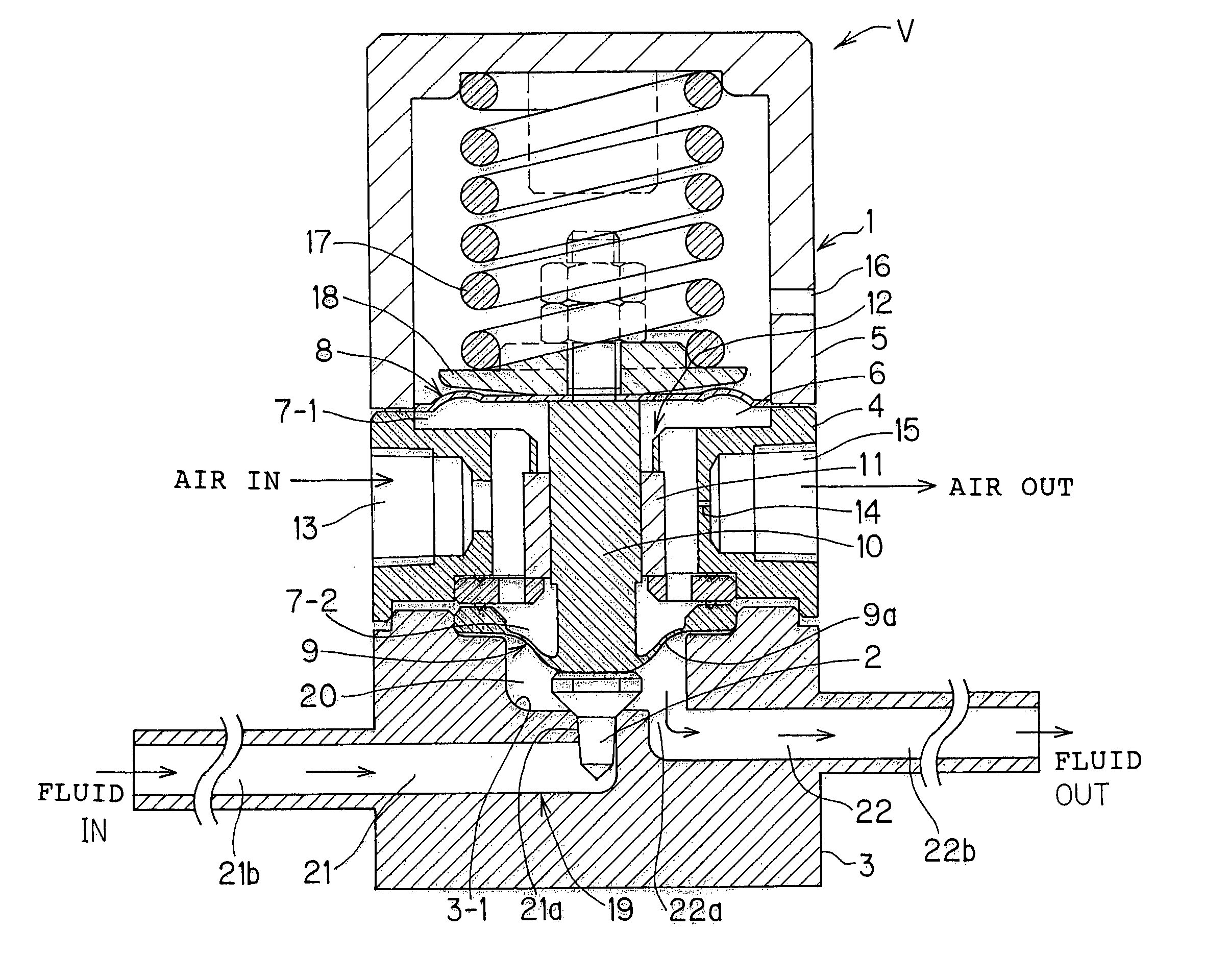

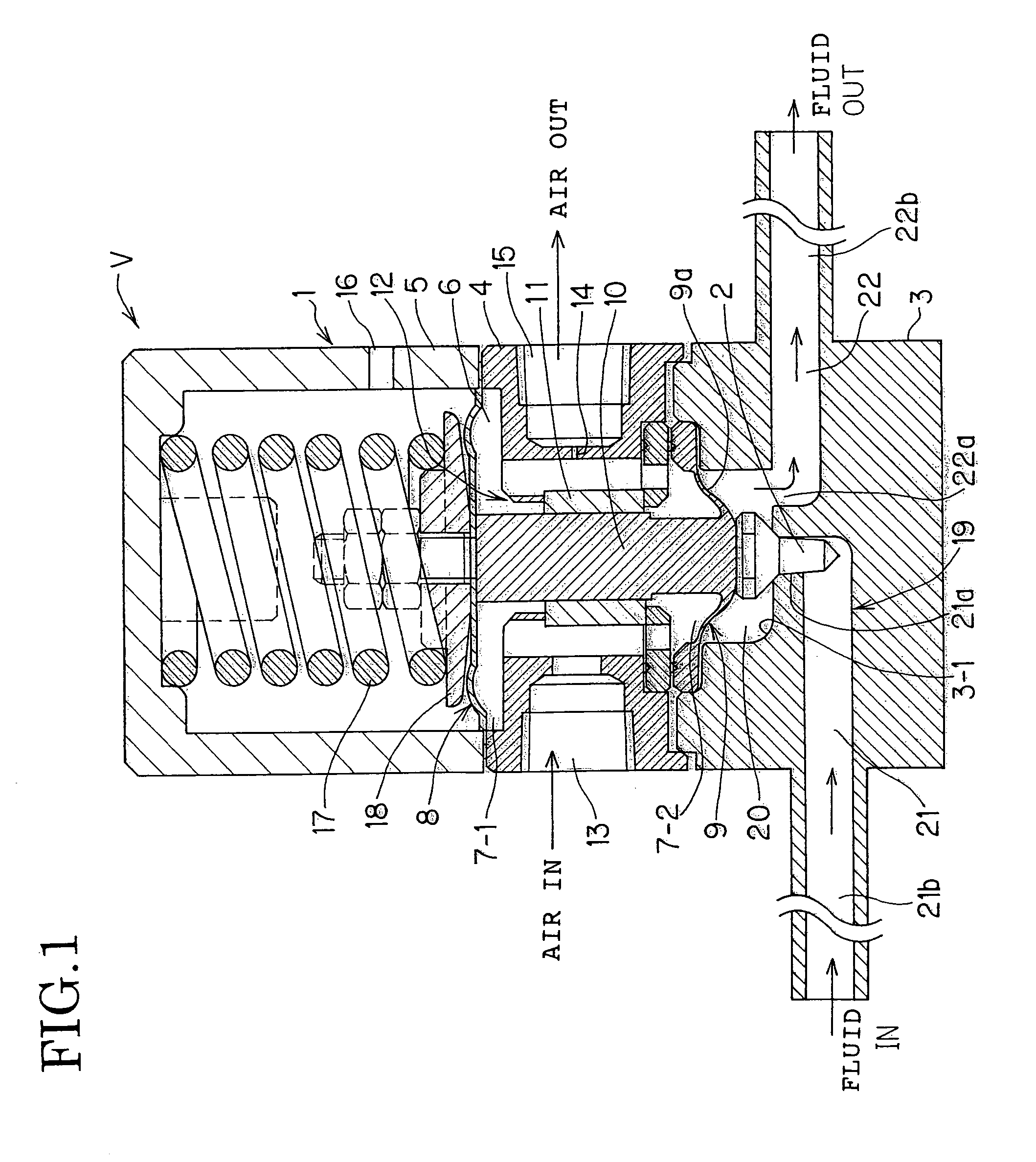

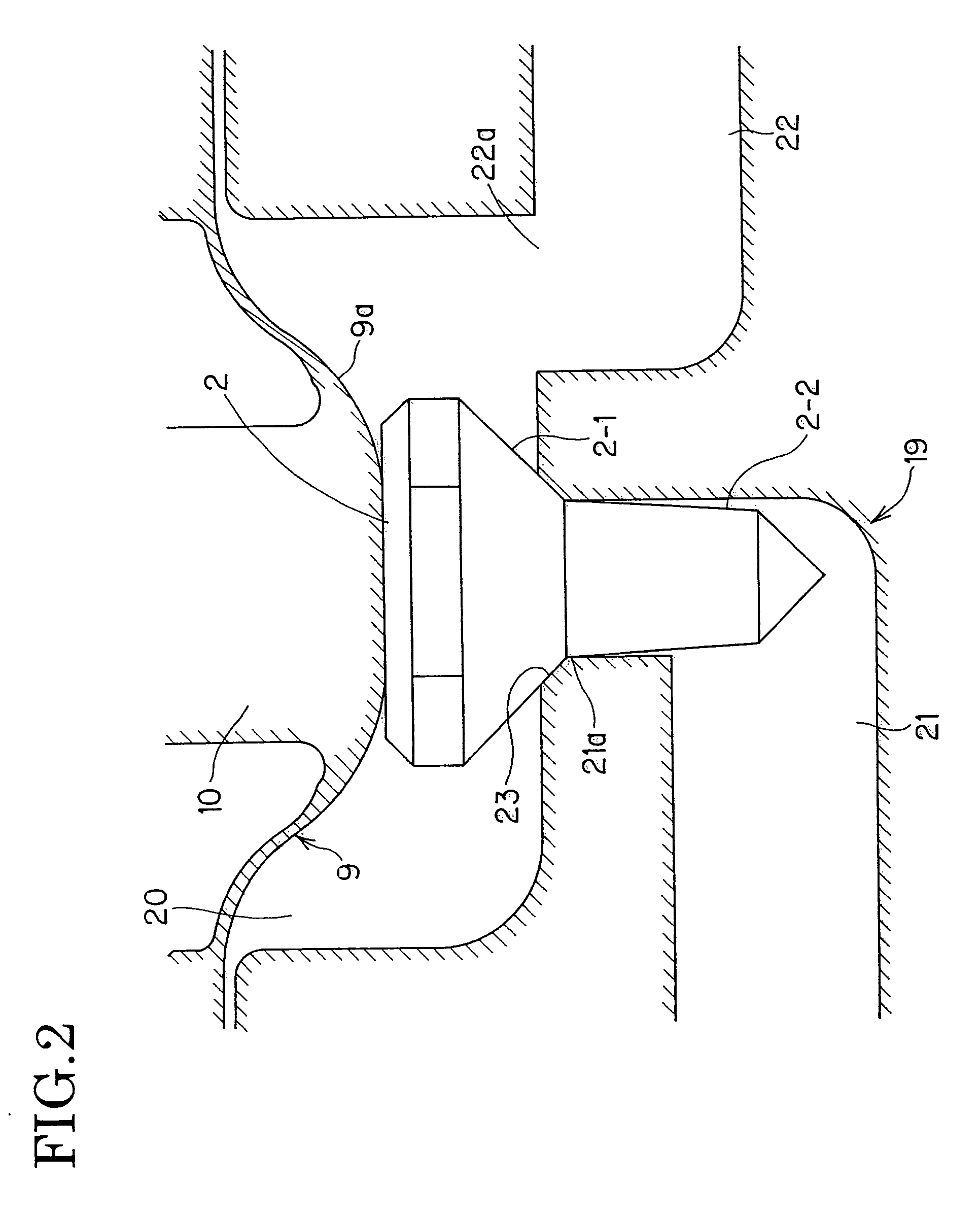

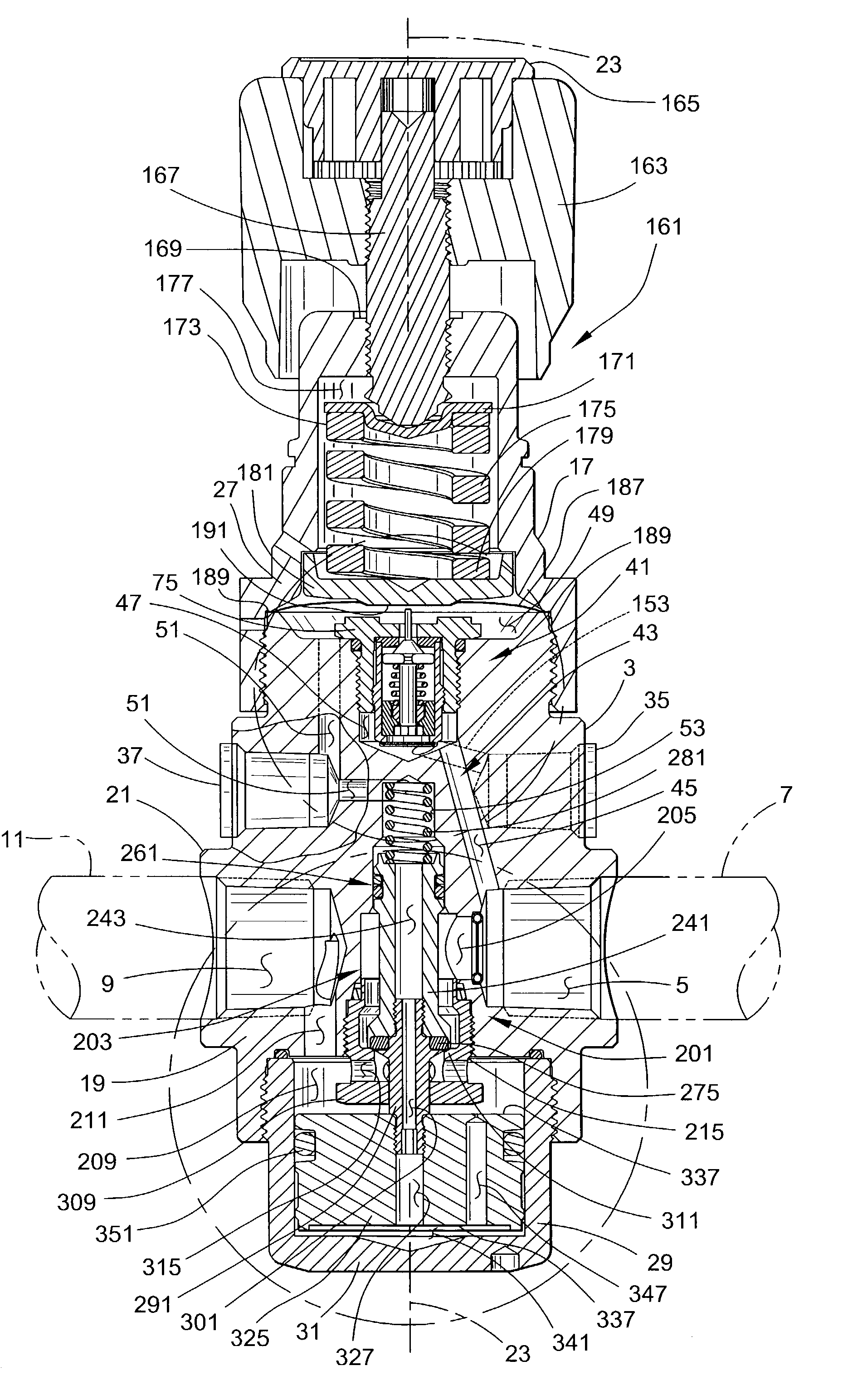

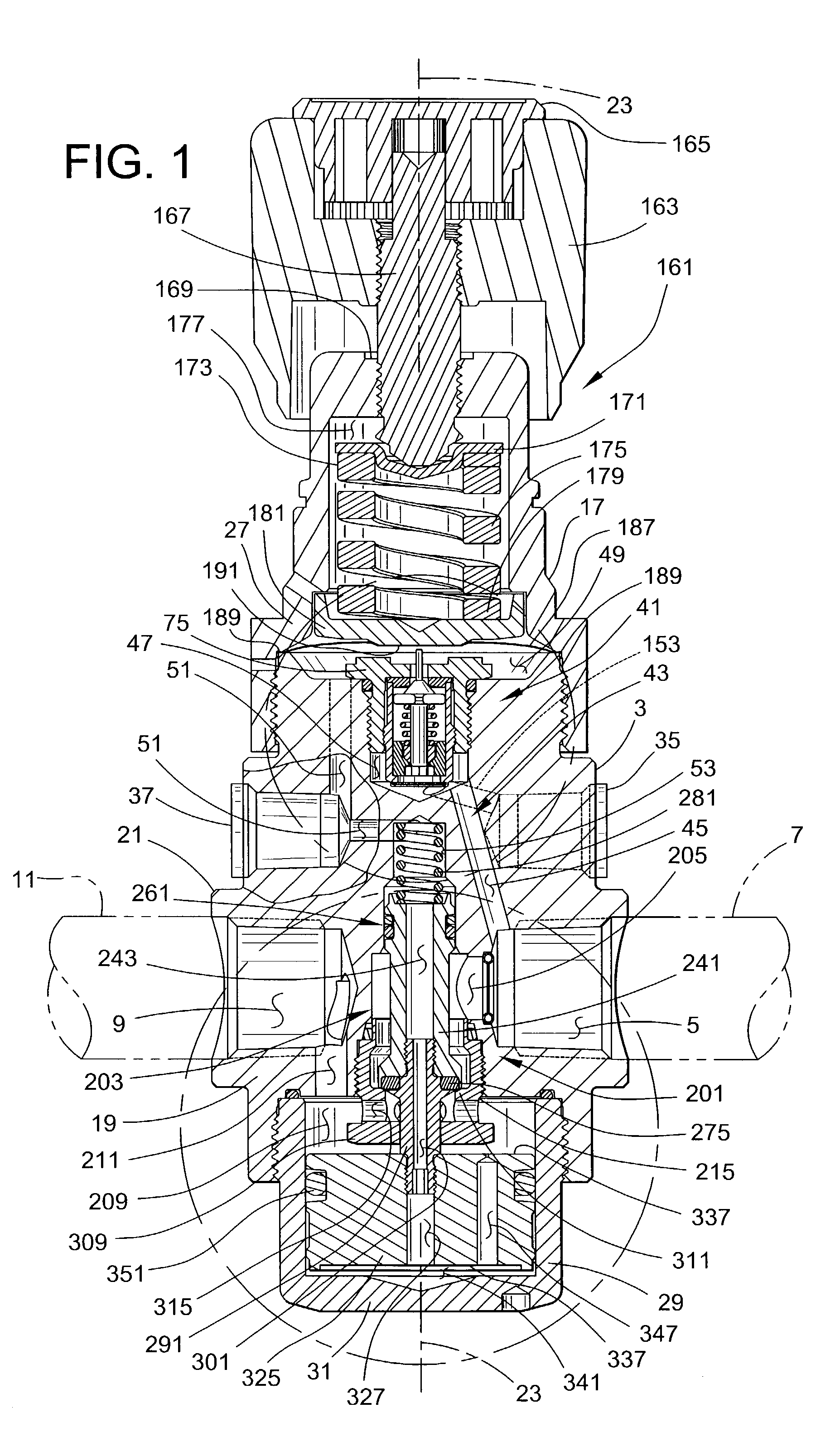

Flow control valve and flow control device

ActiveUS20050145278A1Increase and decrease flow rateHigh resolutionOperating means/releasing devices for valvesFlexible wall reciprocating enginesEngineeringControl valves

There are provided a flow control valve and a flow control device suitable for allowing flow control of a fluid with high accuracy. Diaphragms 8 and 9 are mounted to upper and lower openings, respectively, of an air chamber 6. The upper diaphragm 8 and the lower diaphragm 9 are connected by a connecting shaft 10 and have pressurized surfaces with different areas that receive pressure of the air chamber 6. This causes a difference between forces applied to the two diaphragms 8 and 9, and the difference causes the connecting shaft 10 and a valve body 2 mounted to an outer surface of the lower diaphragm 9 to slide and be separated from a valve seat 23.

Owner:TOFLO CORP

Flow control valve and flow control device

ActiveUS7163024B2Increase and decrease flow rateImprove accuracyOperating means/releasing devices for valvesFlexible wall reciprocating enginesFluid controlEngineering

There are provided a flow control valve and a flow control device suitable for allowing flow control of a fluid with high accuracy. Diaphragms 8 and 9 are mounted to upper and lower openings, respectively, of an air chamber 6. The upper diaphragm 8 and the lower diaphragm 9 are connected by a connecting shaft 10 and have pressurized surfaces with different areas that receive pressure of the air chamber 6. This causes a difference between forces applied to the two diaphragms 8 and 9, and the difference causes the connecting shaft 10 and a valve body 2 mounted to an outer surface of the lower diaphragm 9 to slide and be separated from a valve seat 23.

Owner:TOFLO CORP

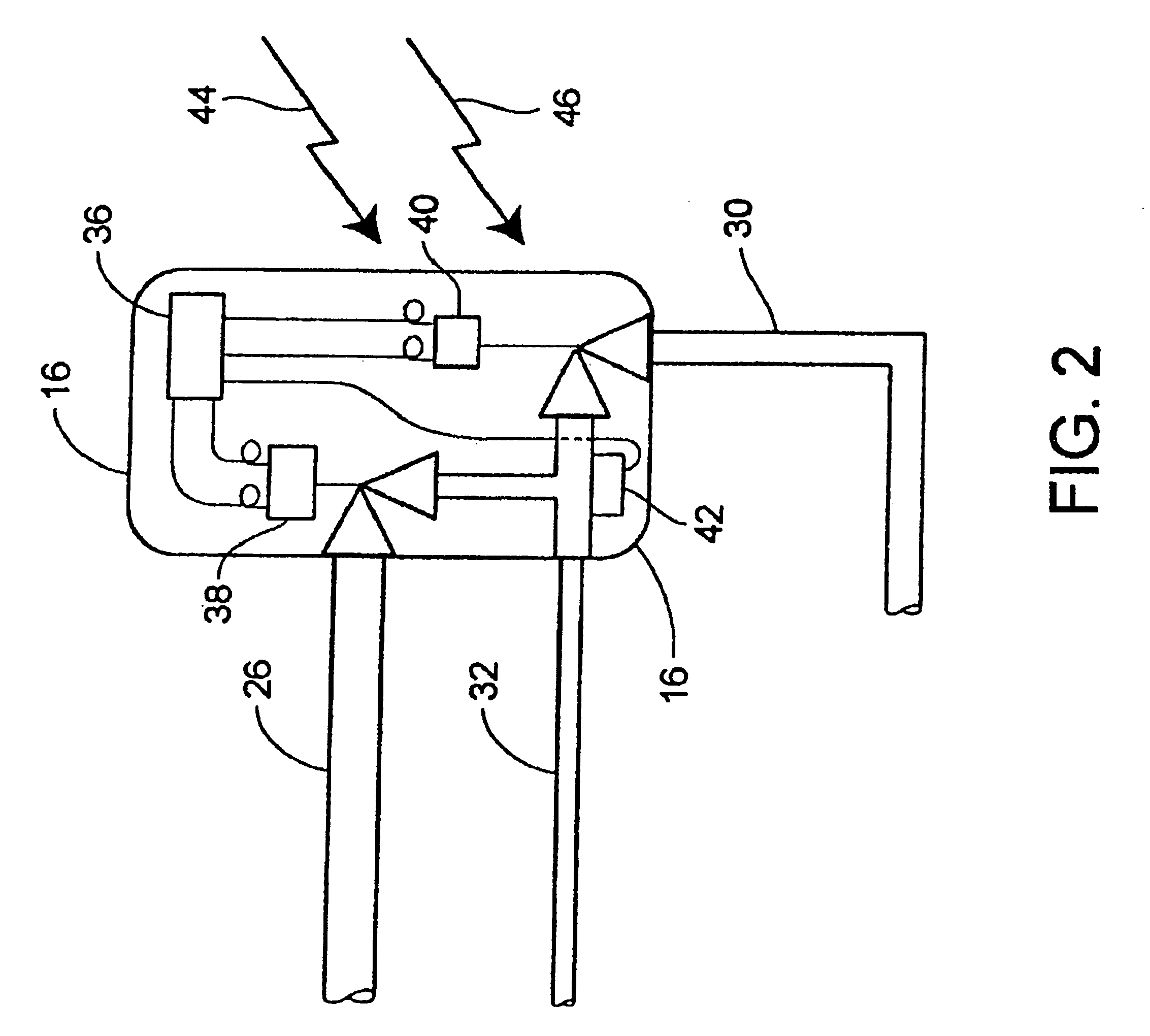

Inflating module for use with an inflatable object

ActiveUS20110284108A1Operating means/releasing devices for valvesPositive displacement pump componentsEngineeringAtmospheric pressure

An inflating module adapted to an inflatable object includes an air pump assembly selectively operable to deflate and inflate the inflatable object and a supplemental air pressure providing device automatically activated to provide supplemental air pressure to the inflatable object when the air pressure of the inflatable object is down and below a predetermined level so as to maintain air pressure of the inflatable object in a predetermined range.

Owner:TEAM WORLDWIDE

Gas pressure regulator

ActiveUS7134447B2Easy to installReduce leak pointsOperating means/releasing devices for valvesPressure relieving devices on sealing facesEngineeringAtmospheric pressure

A gas pressure regulator has an inlet for connection to an upstream gas line for flow of gas into the regulator under pressure and an outlet for connection to a downstream gas line for flow of gas out of the regulator at a reduced pressure. A pilot mechanism delivers a desired pilot gas pressure through a pilot passage. A main valve mechanism regulates the flow of gas through a main flow passage connecting the inlet and outlet of the regulator. The regulator has a piston chamber, and a piston operatively connected to the main valve mechanism and movable in the piston chamber. The main valve mechanism has a passageway between the piston chamber and the pilot passage whereby the pilot gas pressure is adapted to move the piston and thereby position the main valve mechanism to regulate the gas pressure at the outlet of the regulator.

Owner:VICTOR EQUIP

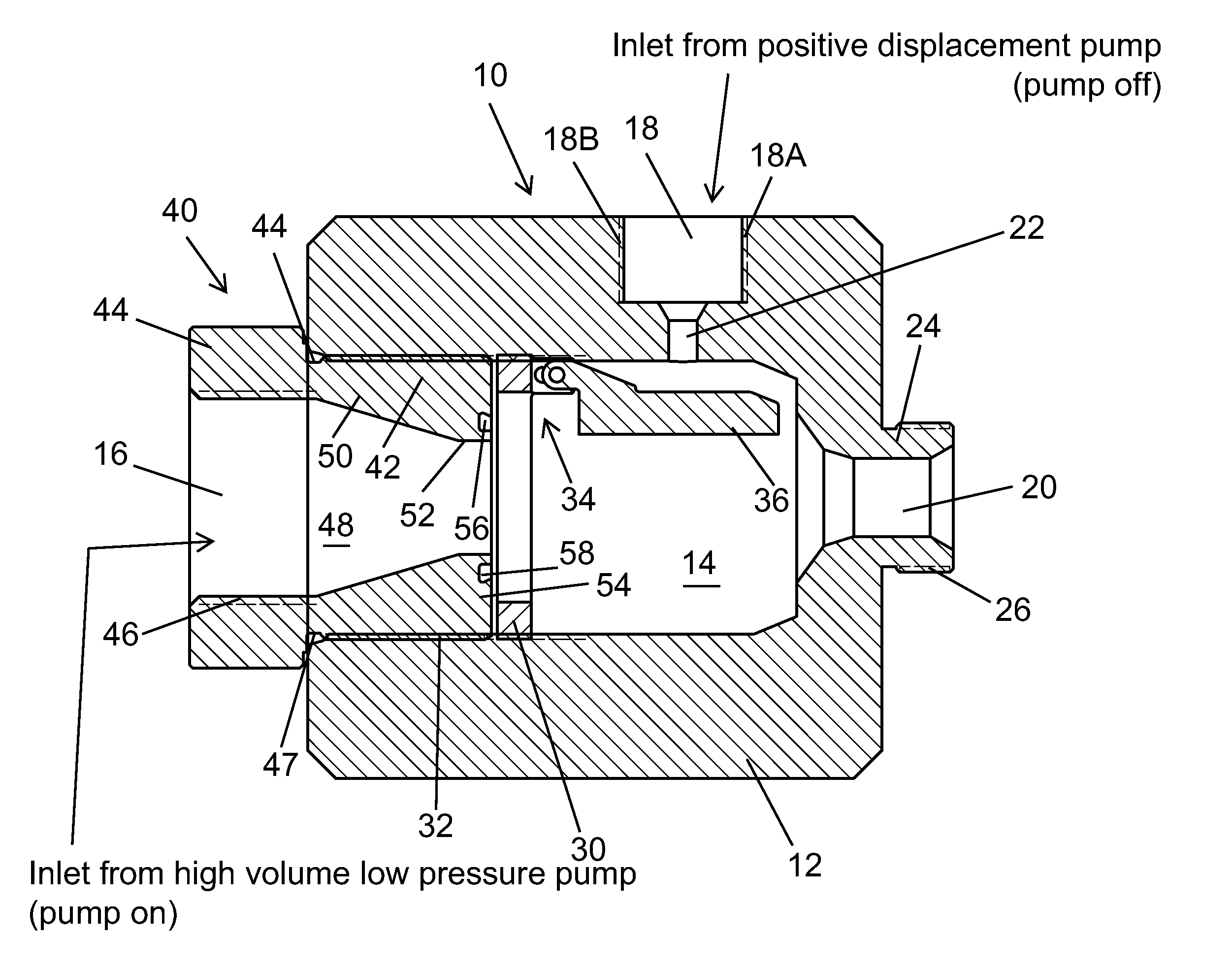

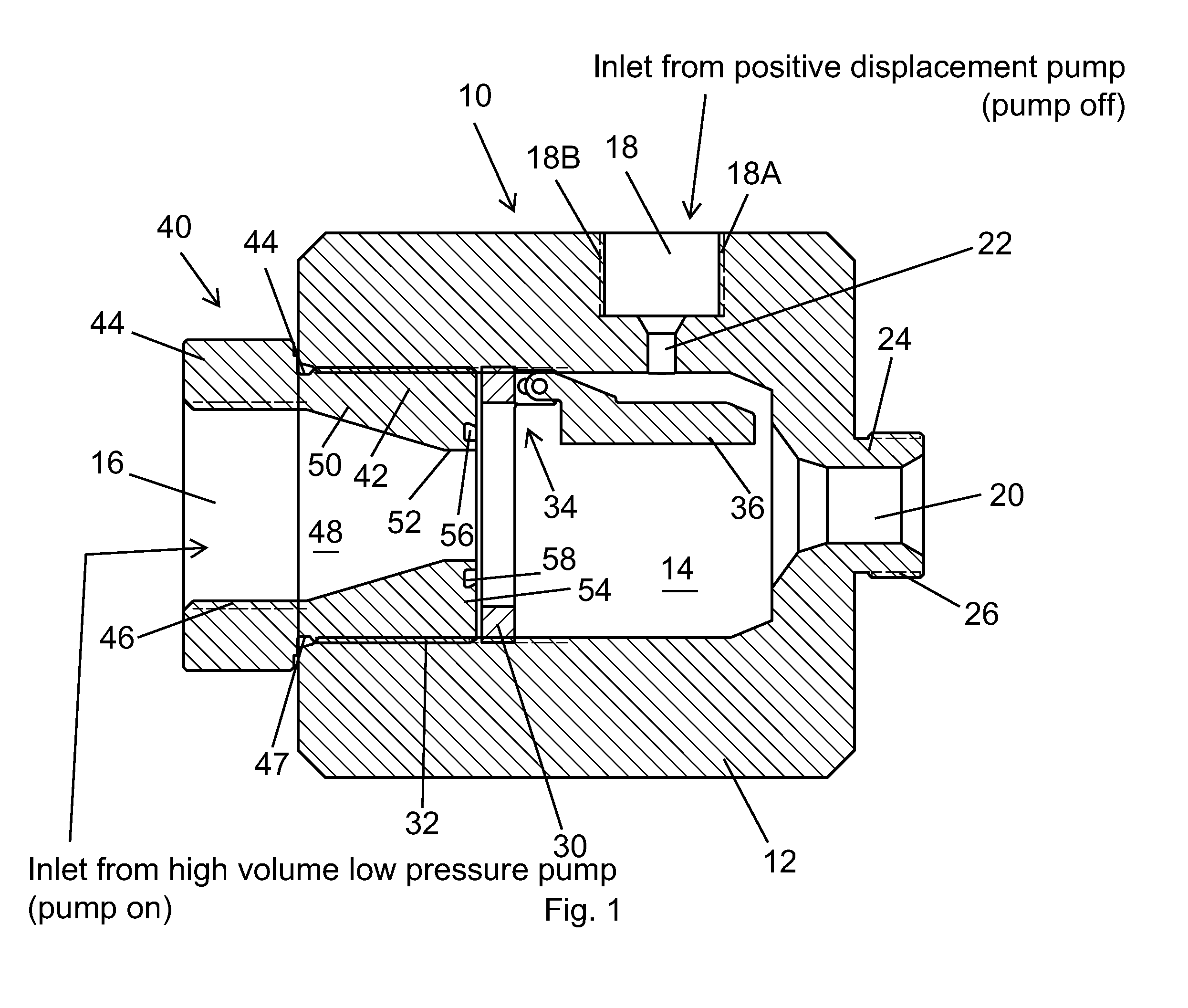

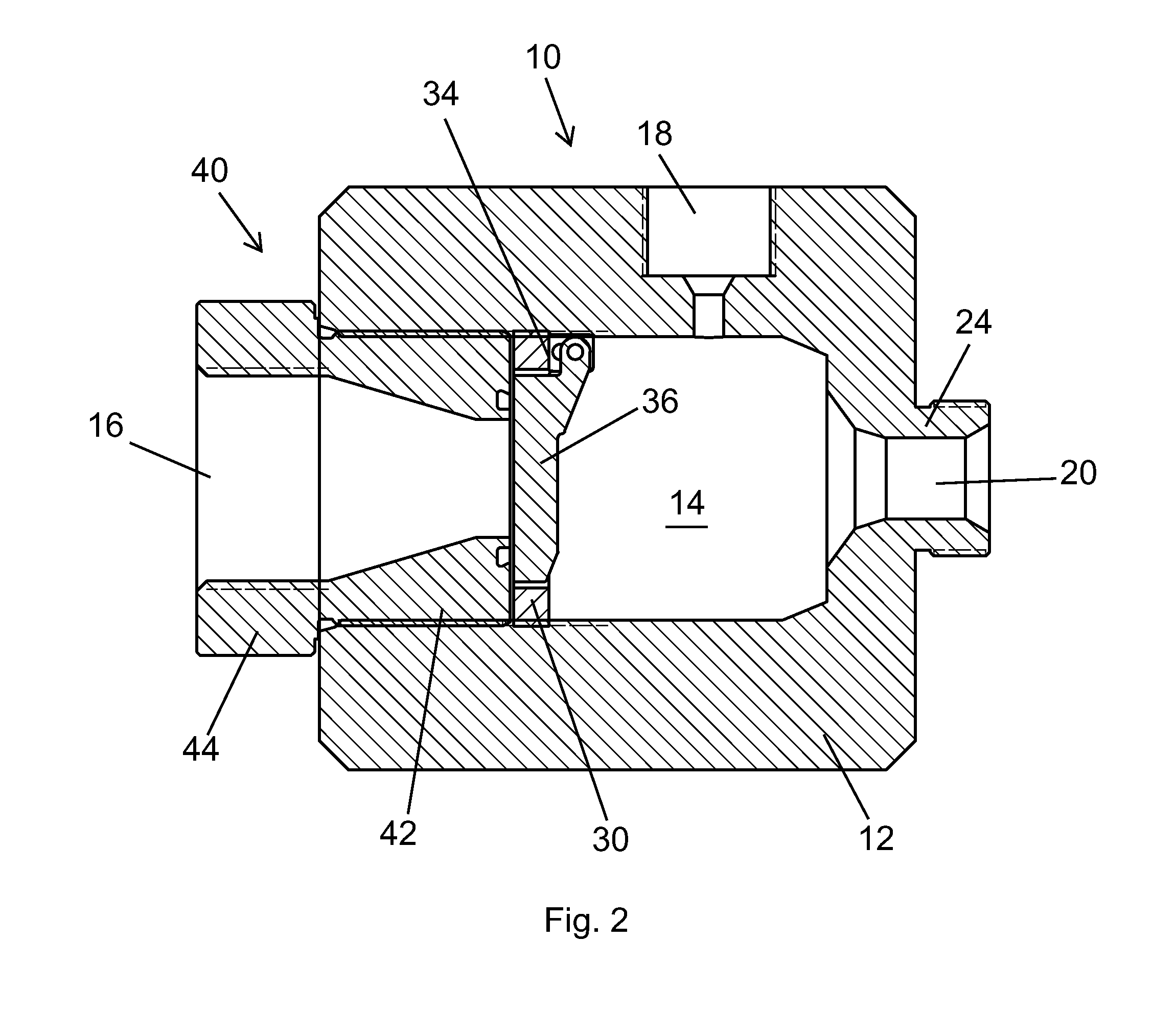

Dual Flow Check Valve

InactiveUS20160084392A1Operating means/releasing devices for valvesCheck valvesEngineeringCheck valve

A dual flow check valve having a check valve body with an interior chamber. There is a first inlet in open communication with the chamber and a second inlet in open communication with the chamber. There is also an outlet in open communication with the chamber. A pressure responsive valve element to permit one-way flow of a fluid through the first inlet into the chamber is mounted in the body.

Owner:HORTON BEN

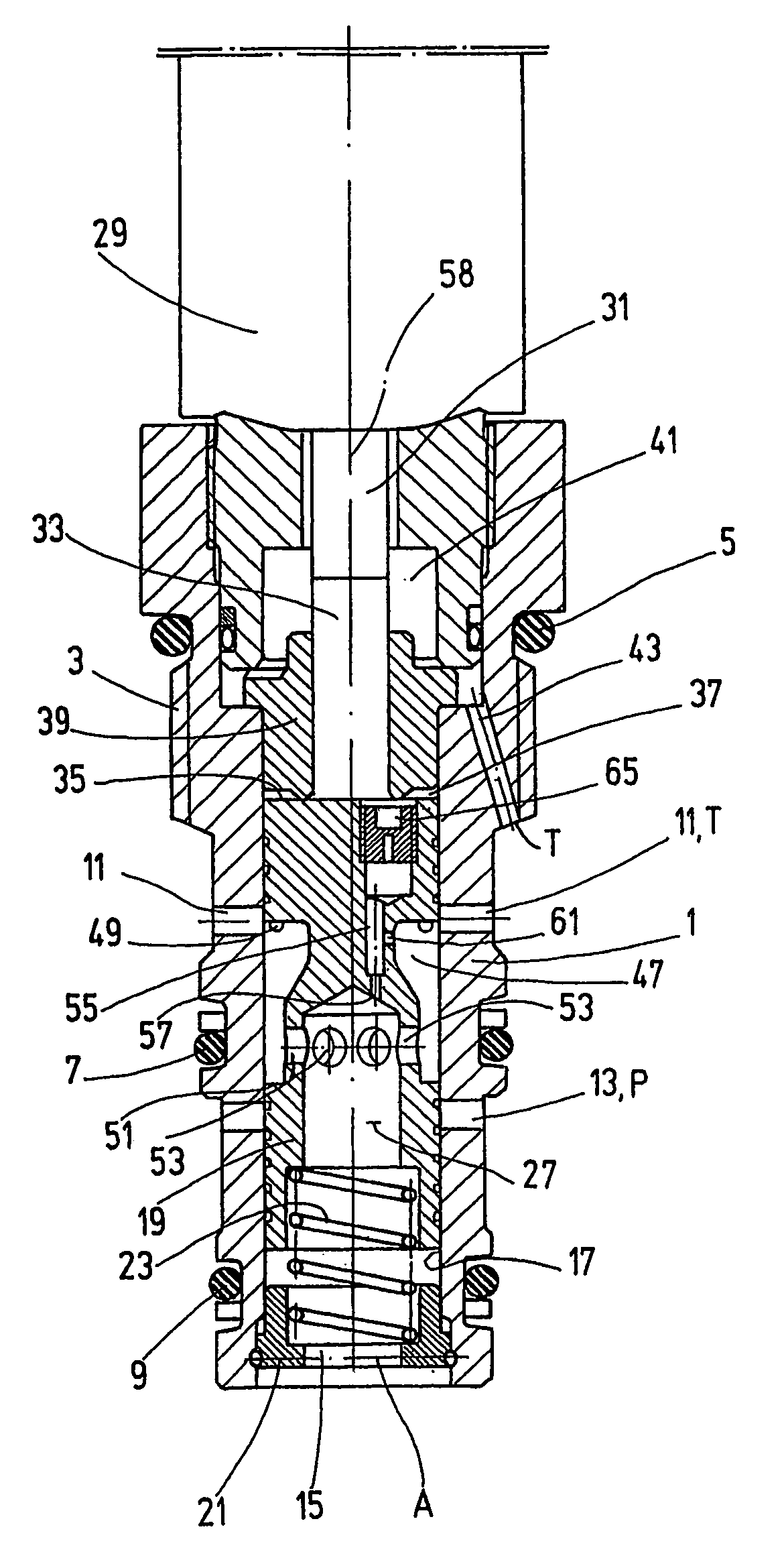

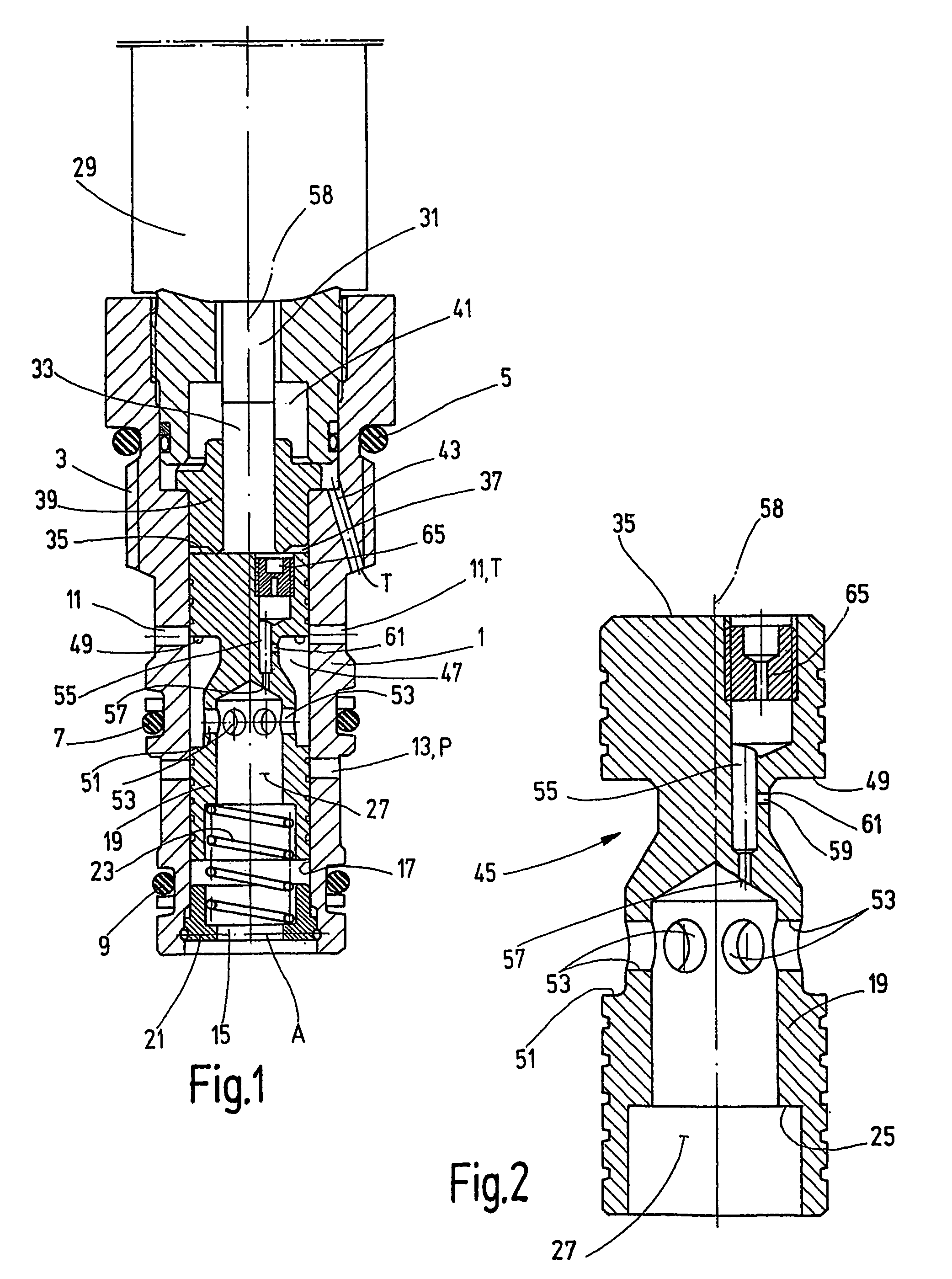

Pressure regulating valve, in particular proportional pressure regulating valve

InactiveUS7073533B2Easy to operateOperating means/releasing devices for valvesFluid pressure control with auxillary non-electric powerVALVE PORTPiston

A pressure regulating valve, in particular a proportional pressure regulating valve, includes a valve body (1) with at least a pump connection (P), a use connection (A) and a tank connection (T). A piston (19), capable of being displaced by a controllable actuating device (29), is guided in the valve body (1). At the periphery of the piston, a recess (45) is formed and defines a peripheral annular gap (47) delimited by the control edges (49, 51) of the piston (19). In the piston (19), a passage (55) provides fluid communication between the front surface of the piston (19), subjected to the use connection (A) pressure, and the rear surface (35) of the piston (19), adjacent to a pressure chamber (37) located behind. The passage (55) of the piston (19) has, in the region proximate to the piston front surface, a restriction zone (57). In a region away from the restriction zone (57) towards the rear of the piston surface (35), an orifice (59) faces the peripheral annular gap (47), and has a second restriction zone (61).

Owner:HYDAC FLUITECHNIK GMBH

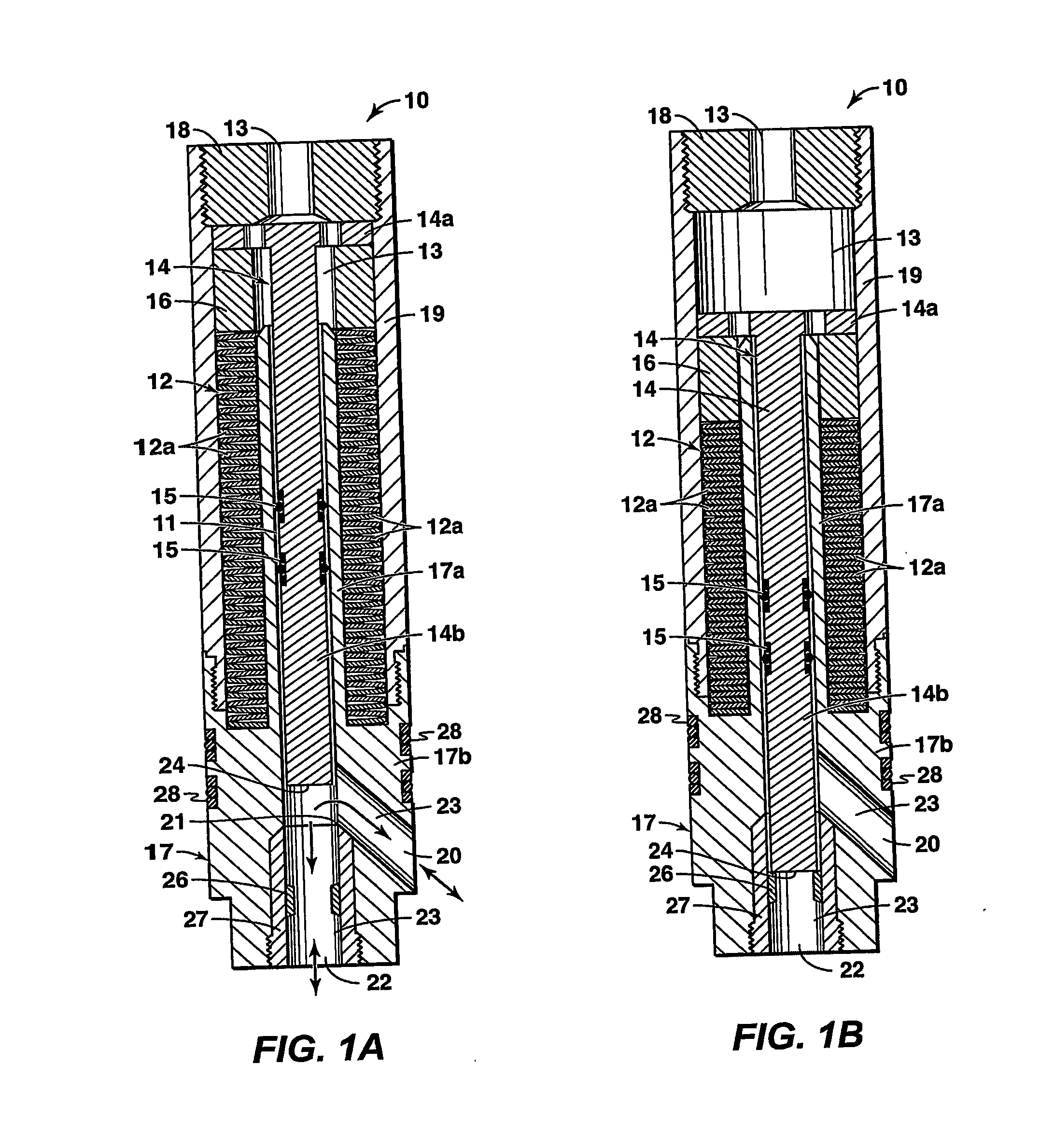

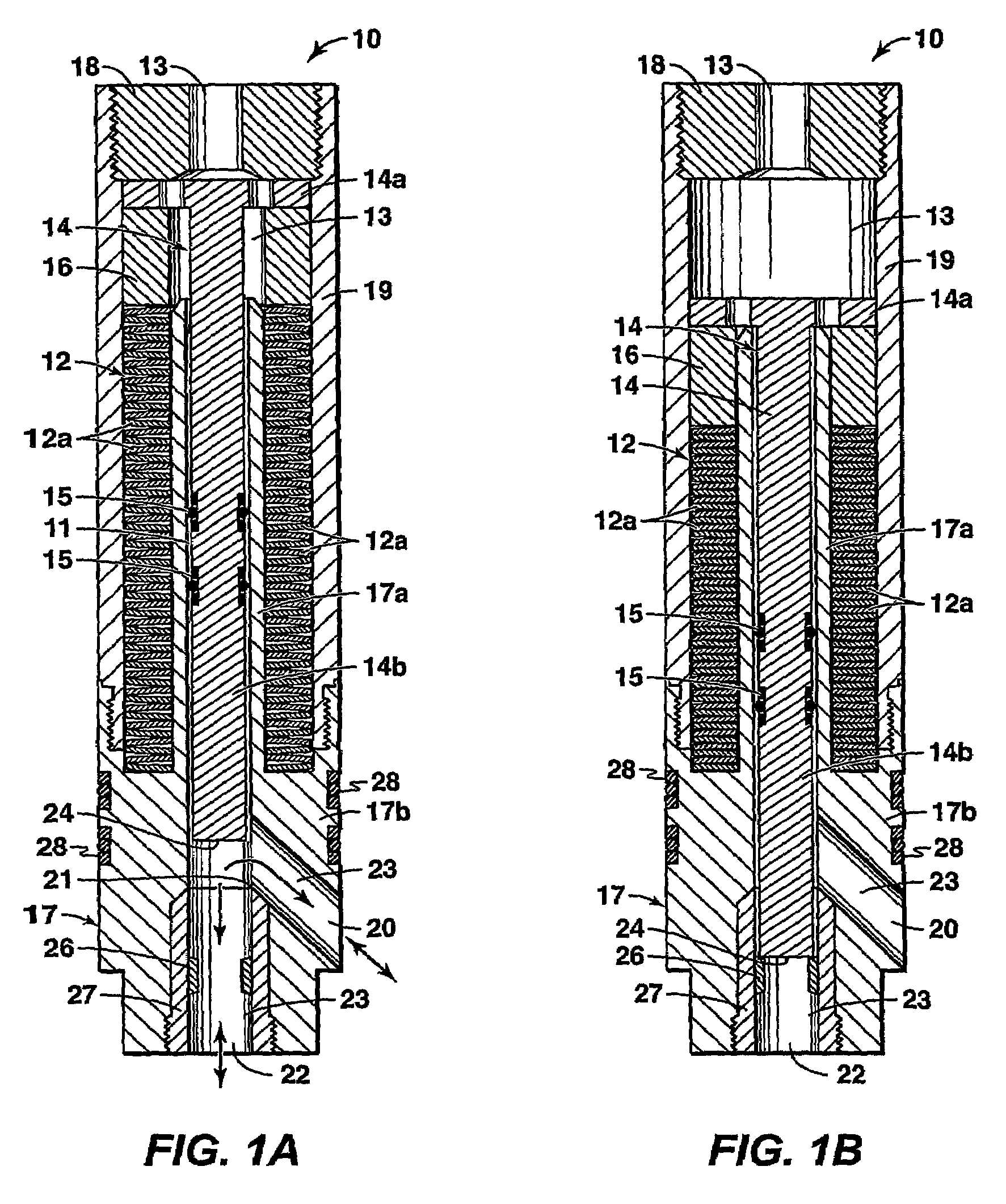

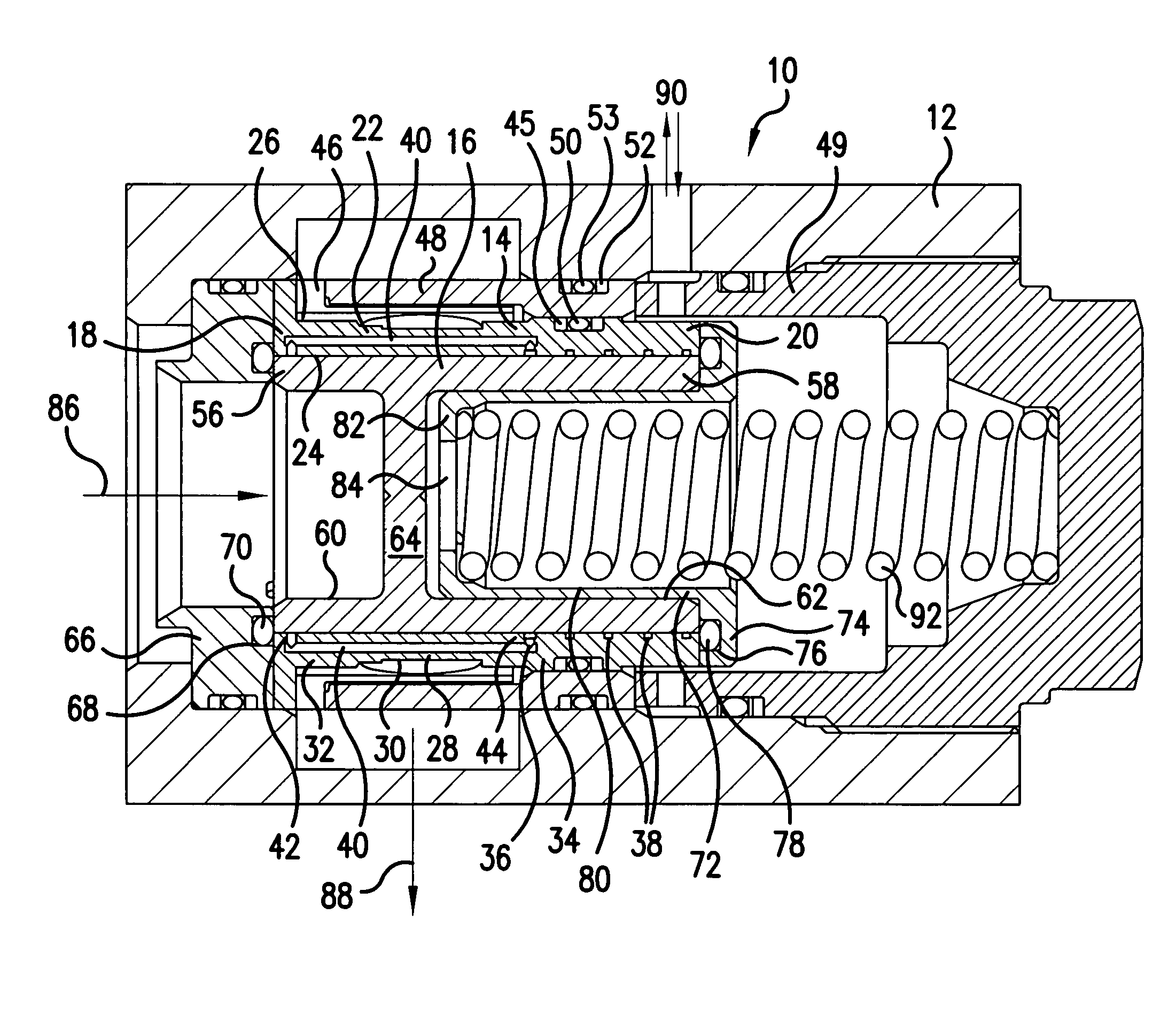

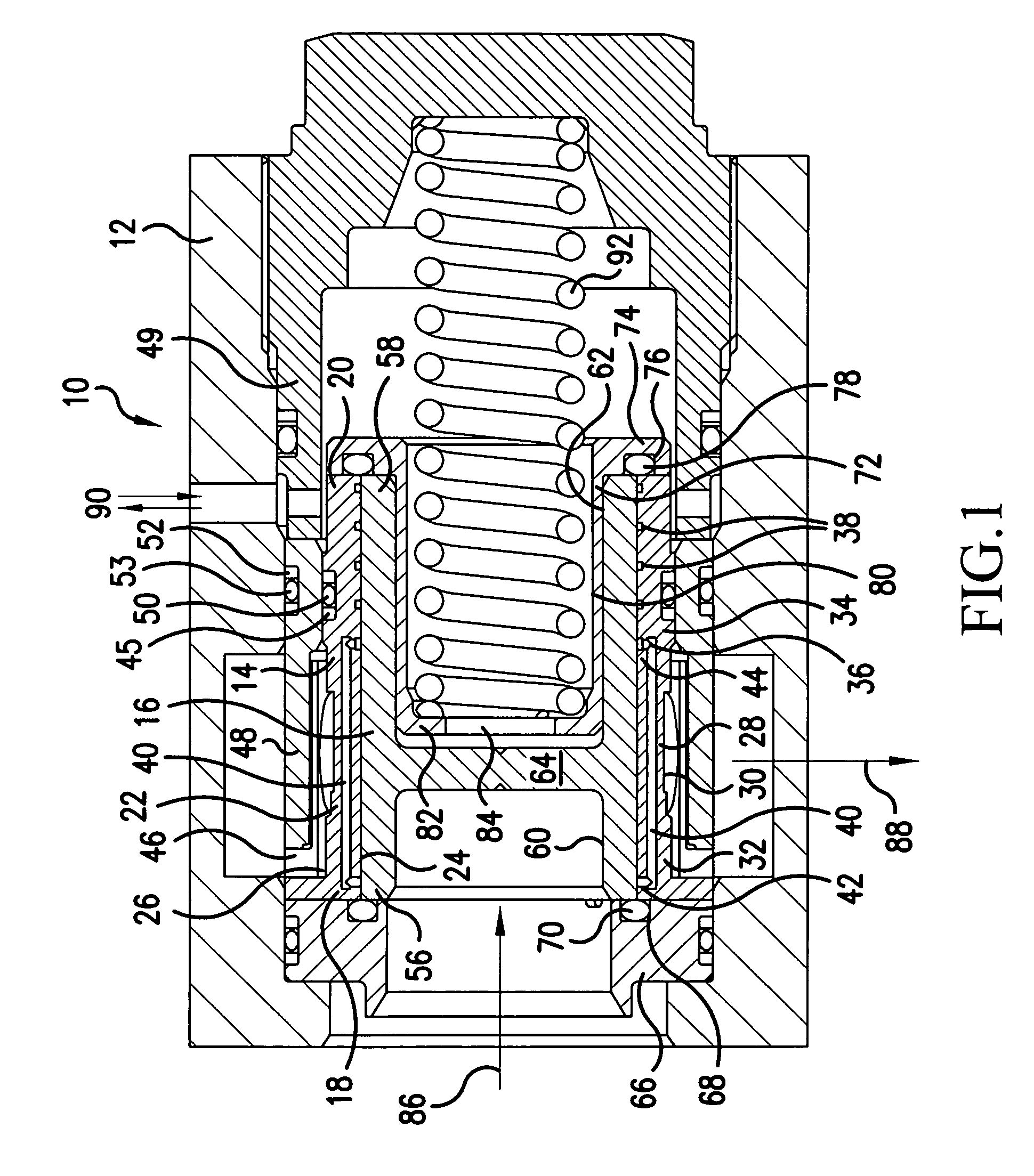

High accuracy low leakage valve for high pressure applications

ActiveUS7322373B2Easy to achieveImprove leakageCheck valvesTurbine/propulsion fuel valvesEngineeringLow leakage

A high pressure valve assembly (10) comprising a valve sleeve (14) and a valve body (16) slidably mounted in the valve sleeve (14) is disclosed, the valve body (16) and valve sleeve (14) each having first ends (18, 56) and second ends (20, 58). A sidewall (22) extends between the valve sleeve first end (18) and second end (20) which sidewall (22) has an inner surface (24) and an outer surface (26) and at least one opening (30) therethrough. The sidewall (22) also includes at least one channel (40) having a first end (42) facing the inner surface (24) at a first location closer to the first valve sleeve end (18) than to the second valve sleeve end (20) and a second end (44) facing the inner surface (24) at a second location closer to the second valve sleeve end (20) than to the first valve sleeve end (18). A method of using the valve assembly (10) is also disclosed.

Owner:HONEYWELL INT INC

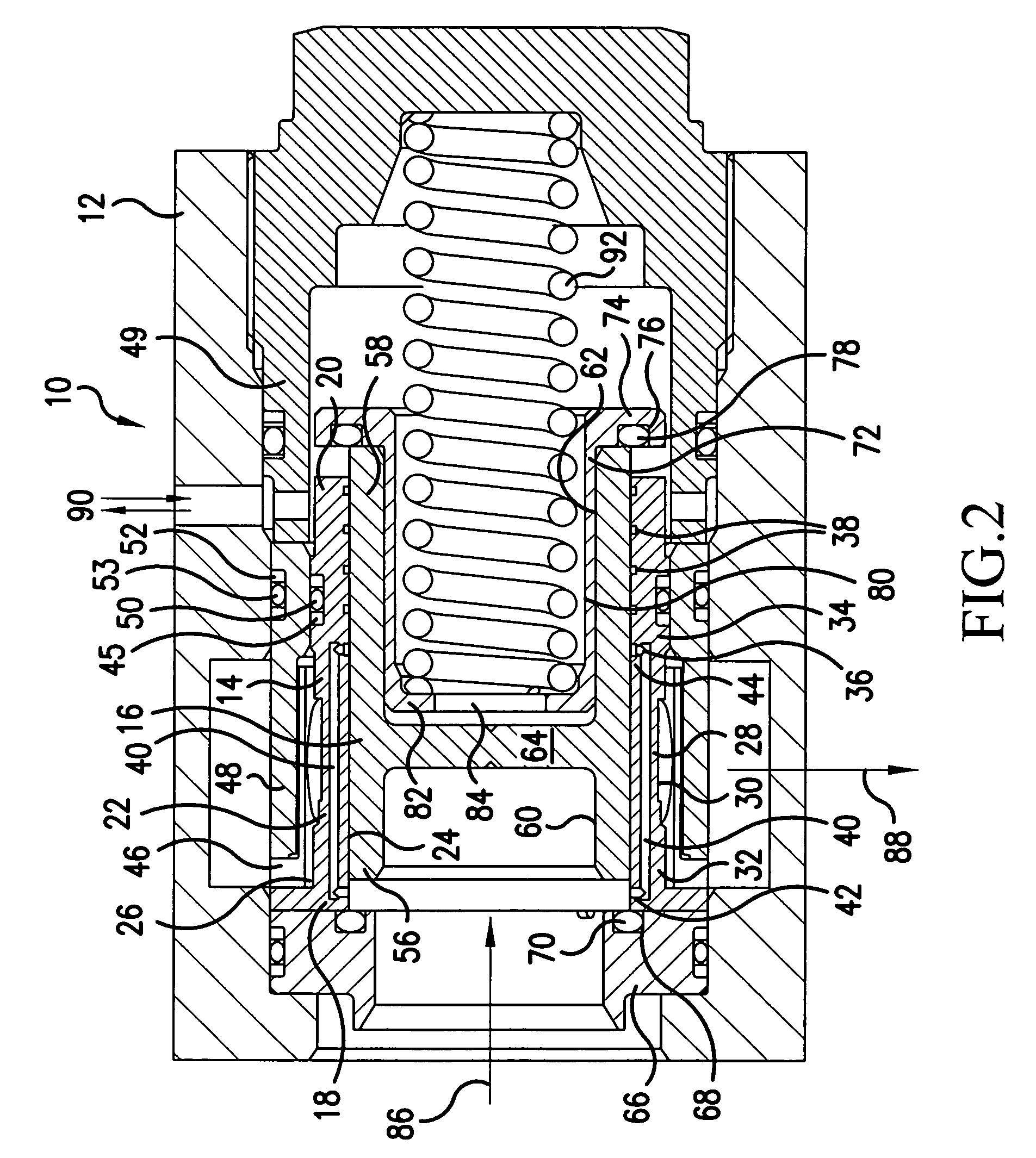

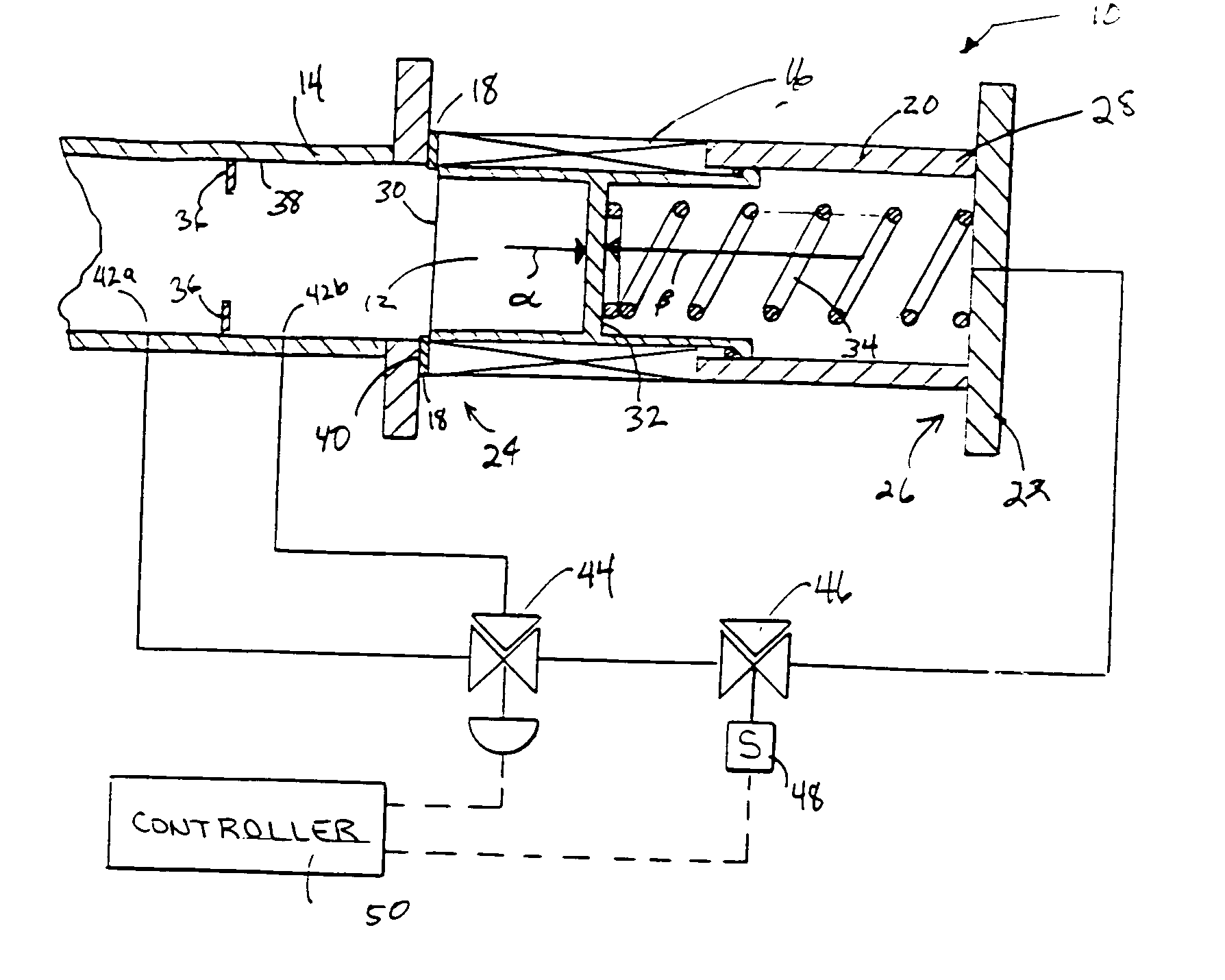

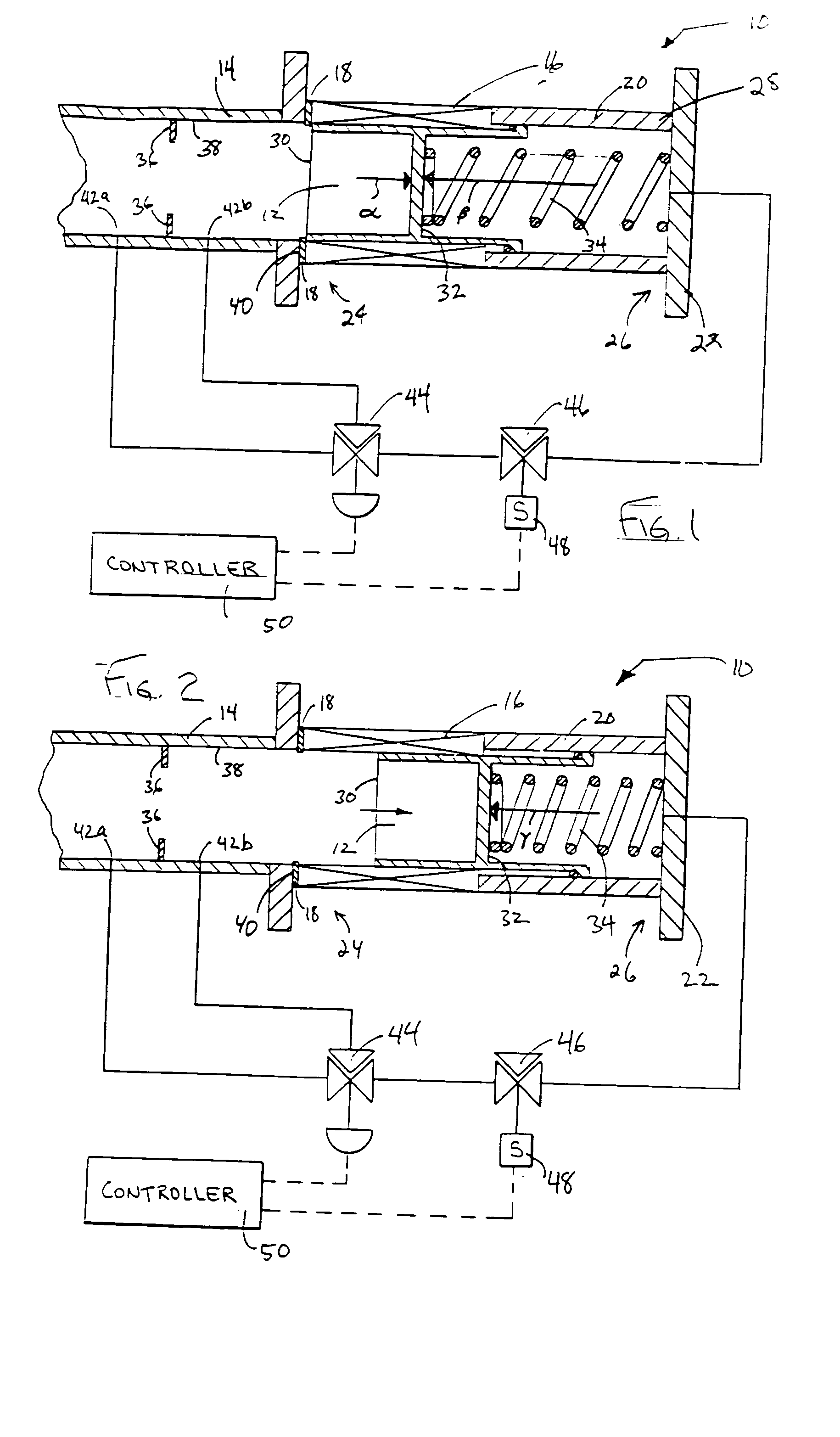

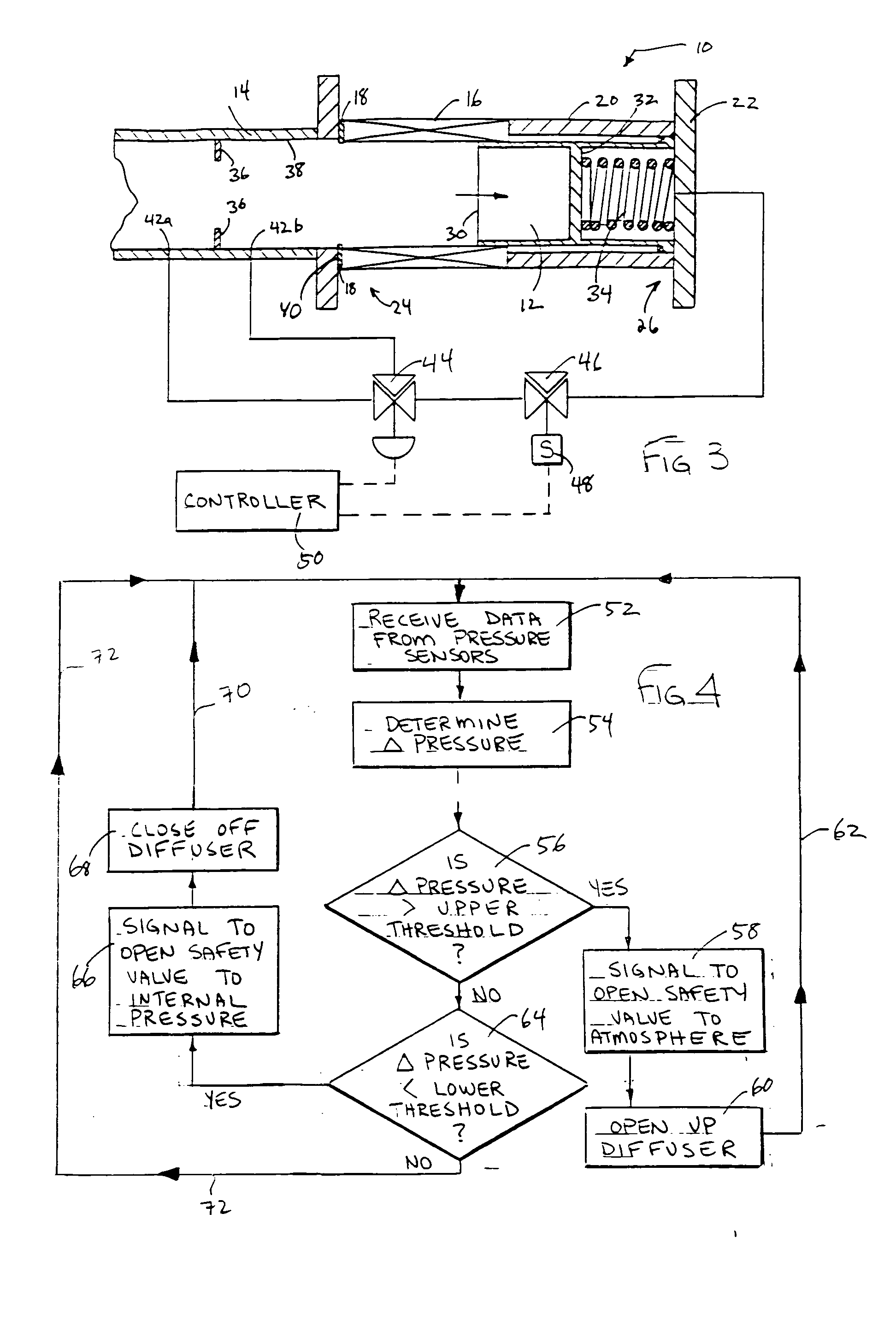

Variable vent diffuser

ActiveUS20050056316A1Operating means/releasing devices for valvesFlow control using electric meansInternal pressureEngineering

A diffuser apparatus for variably controlling fluid pressure release is provided. The diffuser apparatus includes an aperture for pressure release and an adjustable plug that can variably expose the aperture by adjusting positions in response to internal pressure levels. The diffuser apparatus may also include a safety mechanism that utilizes valves to add or release pressure acting on the plug in order to open and close the aperture.

Owner:FISHER CONTROLS INT LLC

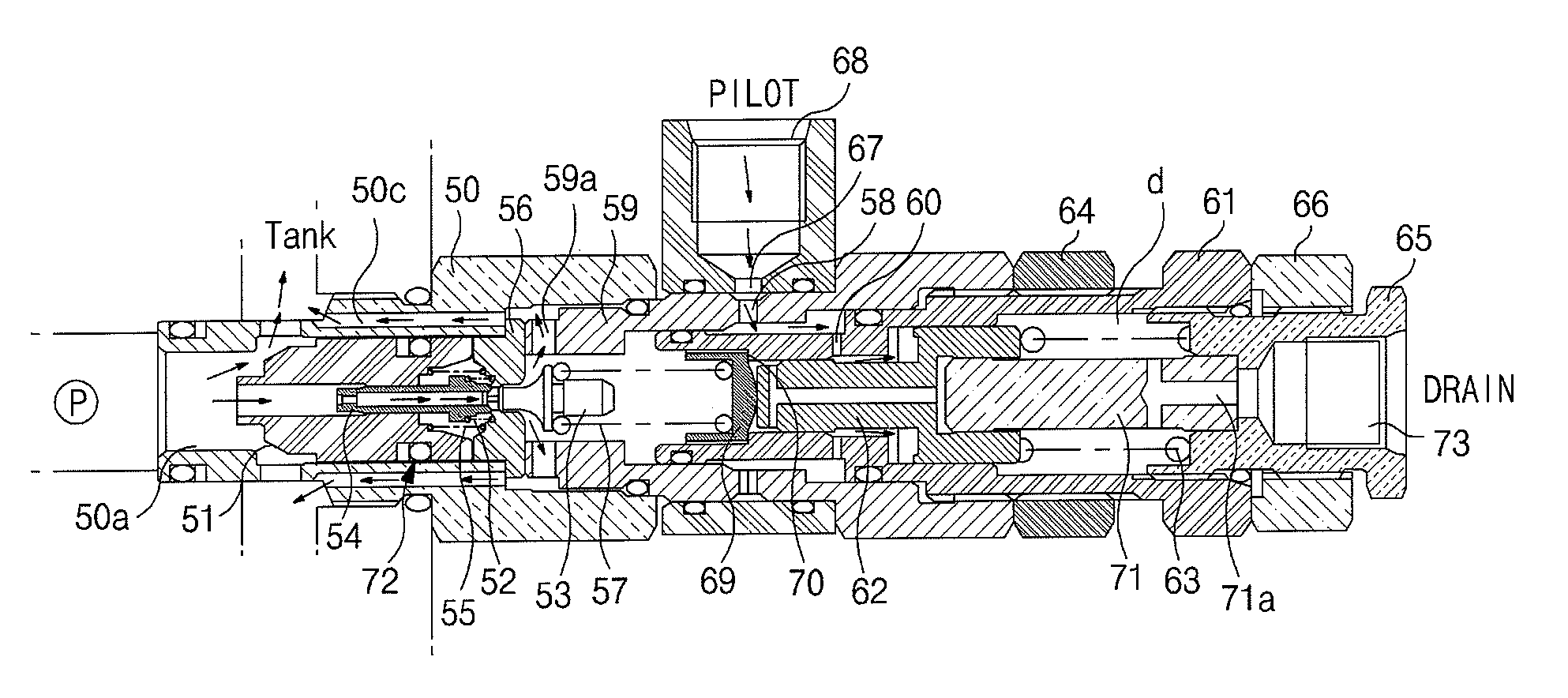

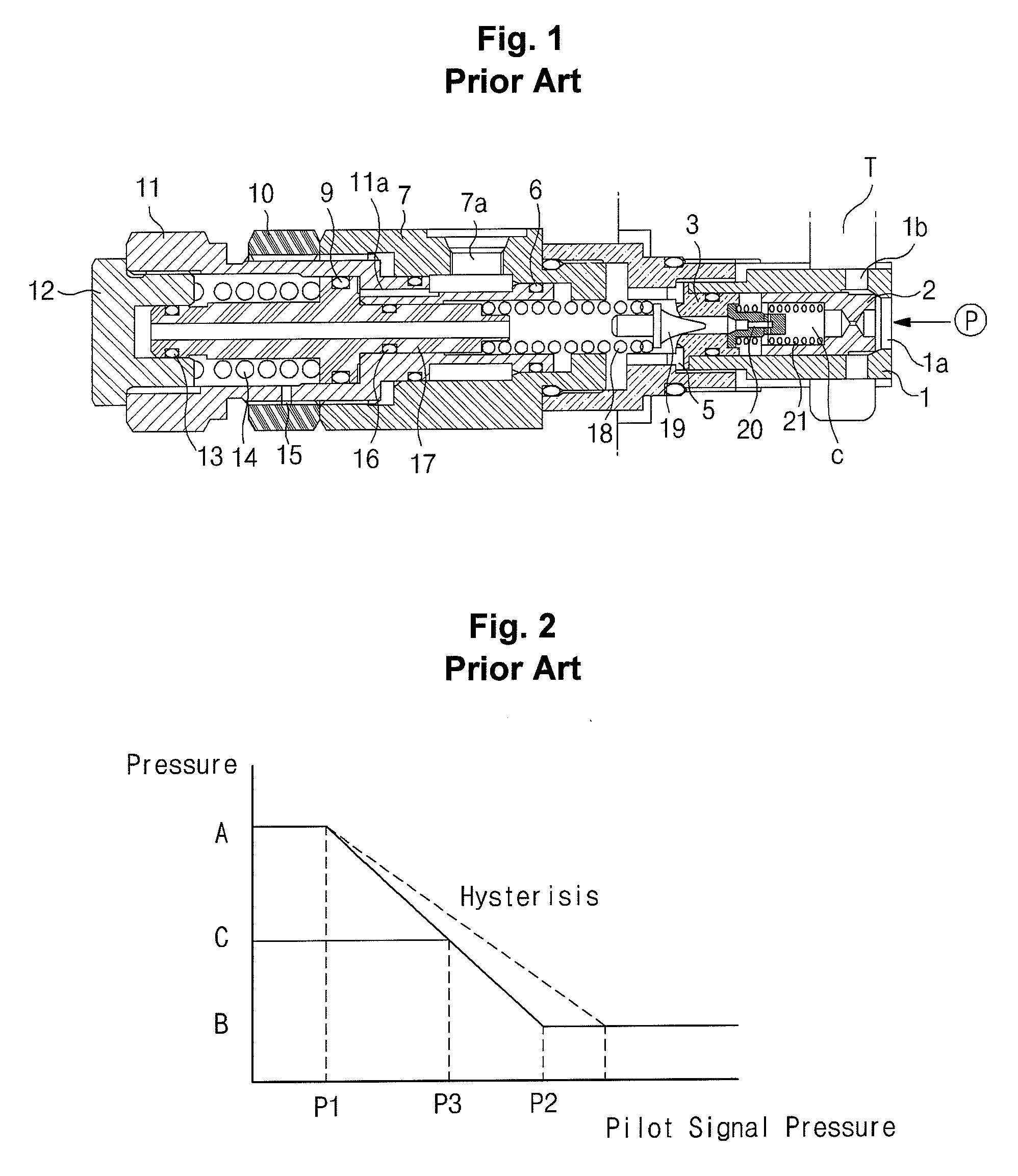

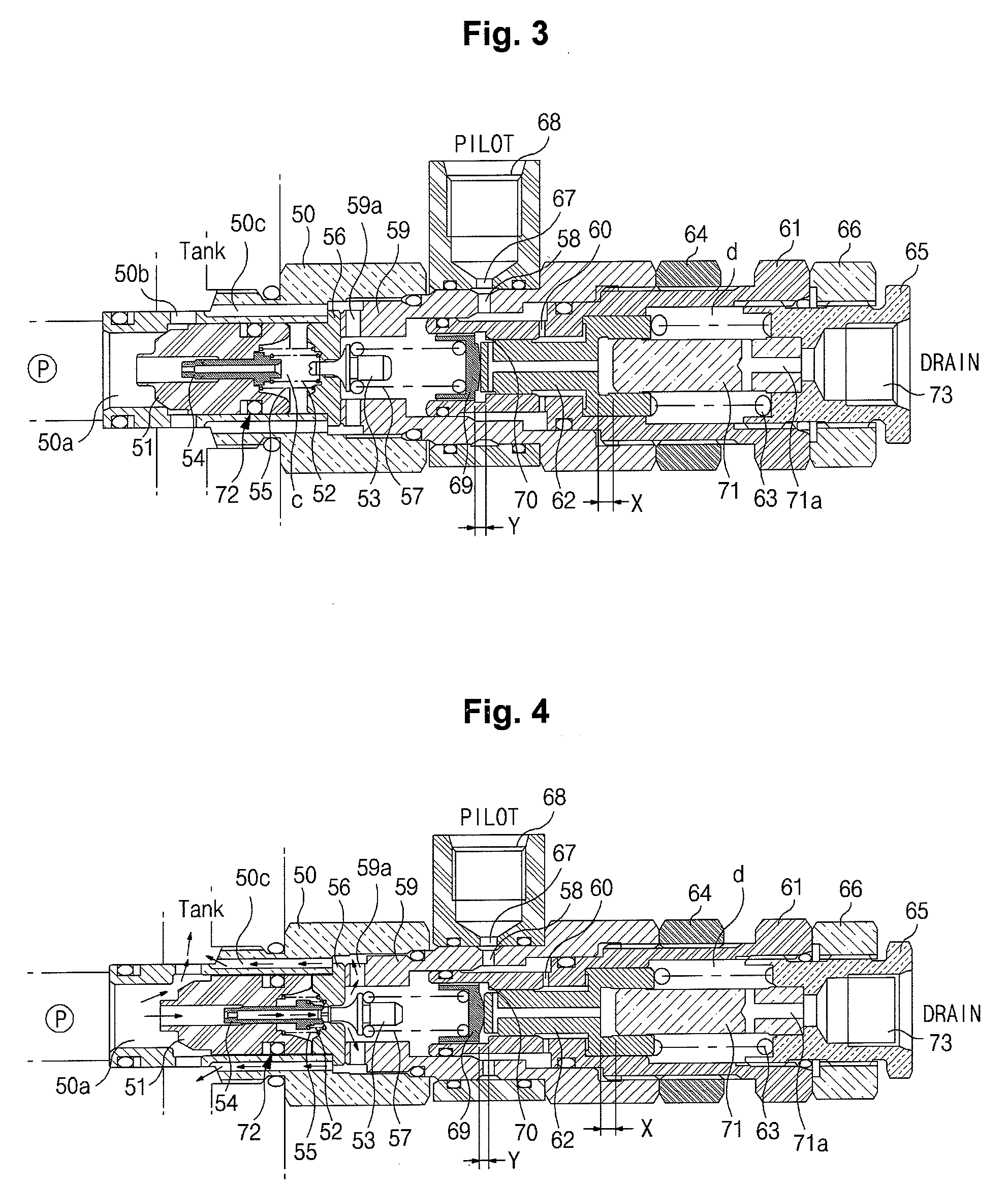

Pressure control valve

ActiveUS20090211650A1Reduce manufacturing costEasy to controlOperating means/releasing devices for valvesPressure relieving devices on sealing facesEngineeringHigh pressure

A pressure control valve is provided, which can variably control the set pressure of a relief valve in accordance with pilot signal pressure that is controlled in an operator's seat and so on when the set pressure of the relief valve required in a replaced working device is changed. The pressure control valve includes a sleeve having an inlet port and a tank path, a poppet opening / closing a flow path between the inlet port and the tank path, a poppet spring elastically supporting the path between the inlet port and the tank path in a closed state, a valve sheet installed to face the poppet so that a set pressure is formed in a pressure chamber of the sleeve, a pilot poppet draining the hydraulic fluid in the pressure chamber to the hydraulic tank when high pressure that exceeds the set pressure is generated in the pressure chamber, a pilot poppet spring elastically supporting the path of the valve sheet in a closed state, a plug coupled to the sleeve and having a pilot port to receive the pilot signal pressure from an outside, a main piston slidably coupled within a guide coupled to the plug to variably control the set pressure in the pressure chamber in accordance with the pilot signal pressure, and a control plug movably coupled to the guide to control a set pressure of a spring supporting the main piston.

Owner:VOLVO CONSTR EQUIP

Adjustable deadband control system

ActiveUS20160356389A1Operating means/releasing devices for valvesEqualizing valvesEngineeringDeadband

Owner:EMERSON PROCESS MANAGEMENT REGULATOR TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com