Valve, especially proportional pressure control valve

A proportional relief valve and fluid technology, applied to the valve, can solve the problems of large structure space, easy failure and high manufacturing cost, so as to reduce the possibility of failure, reduce the cost of manufacturing and maintenance, and improve the reliability of operation functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

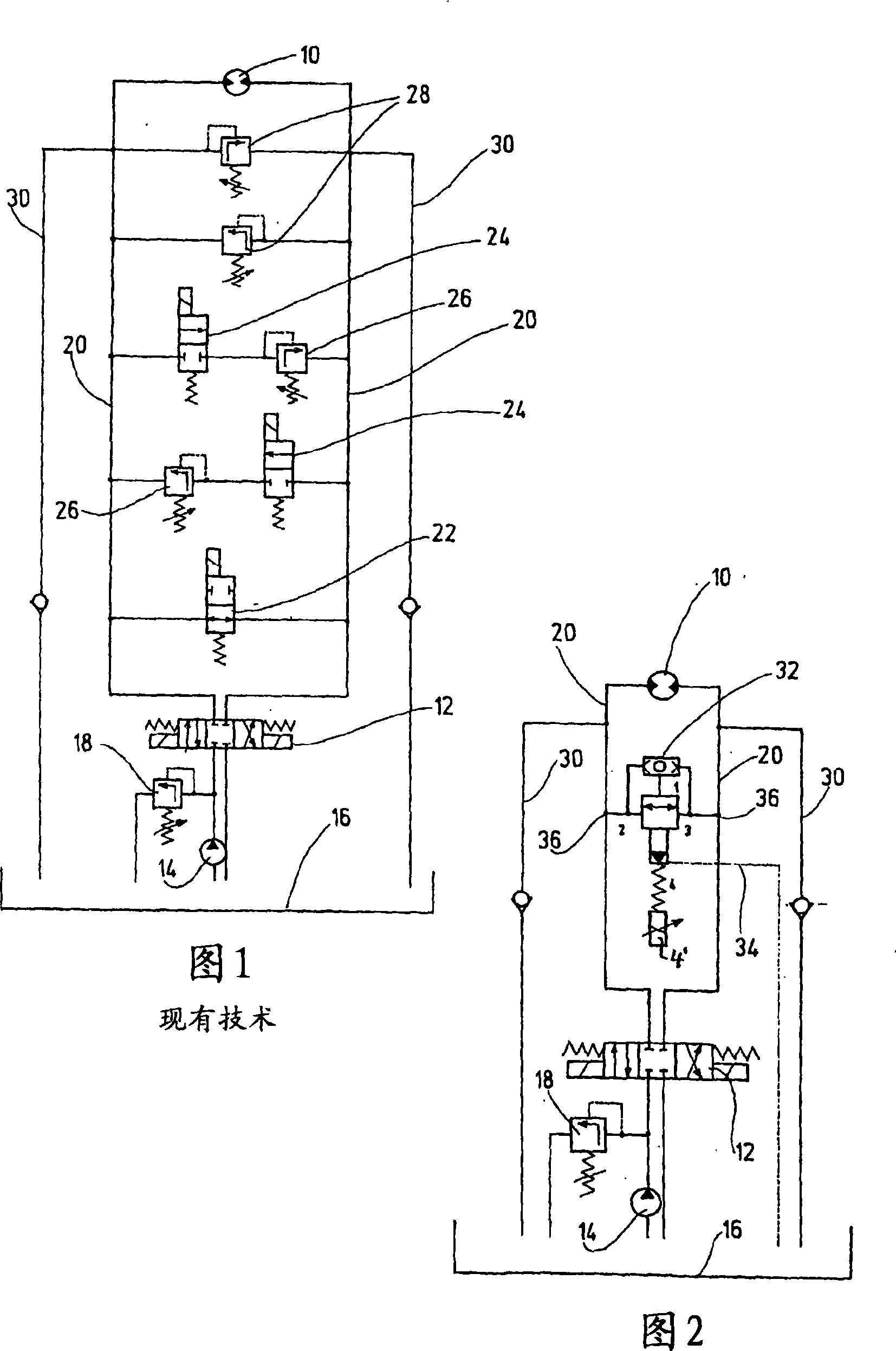

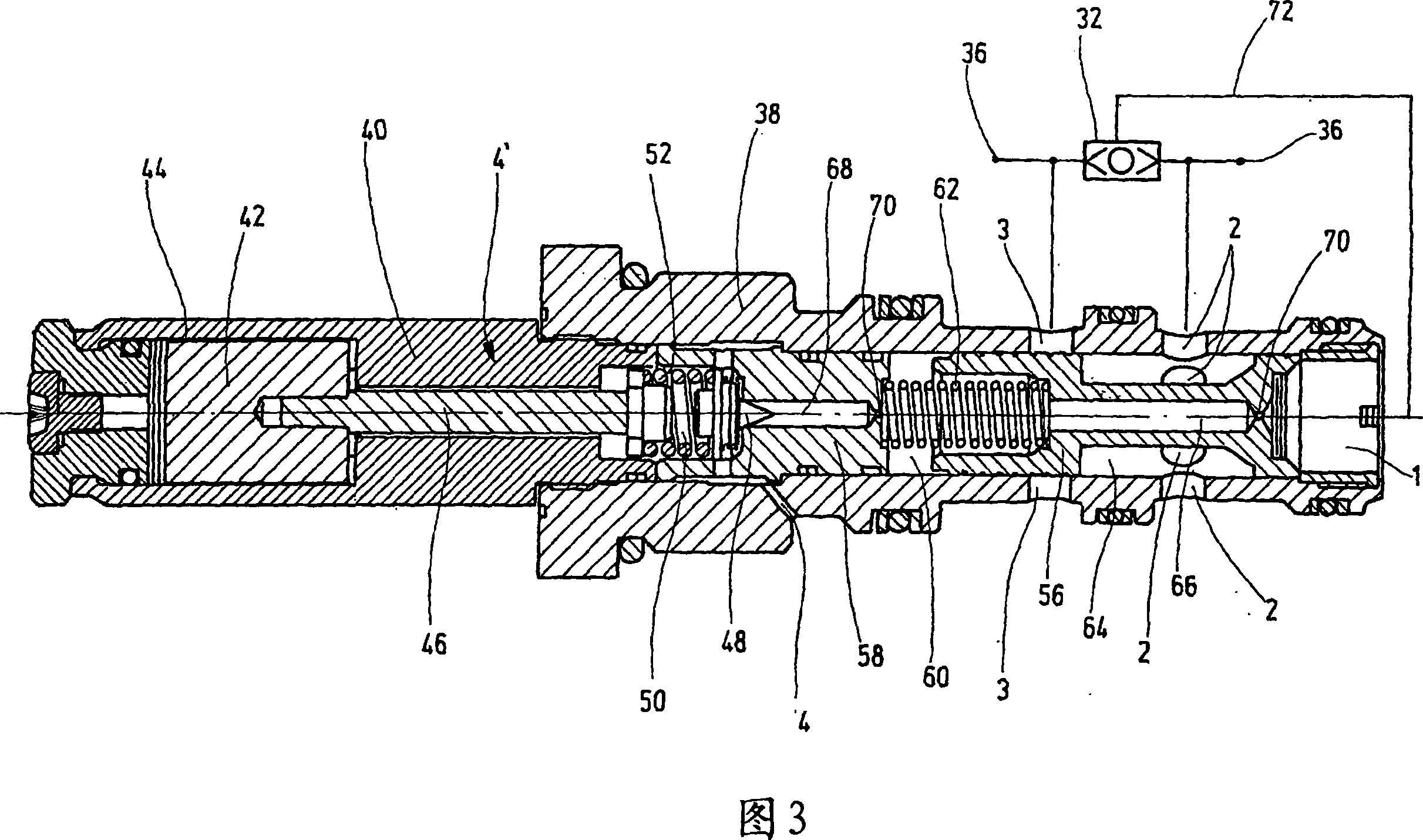

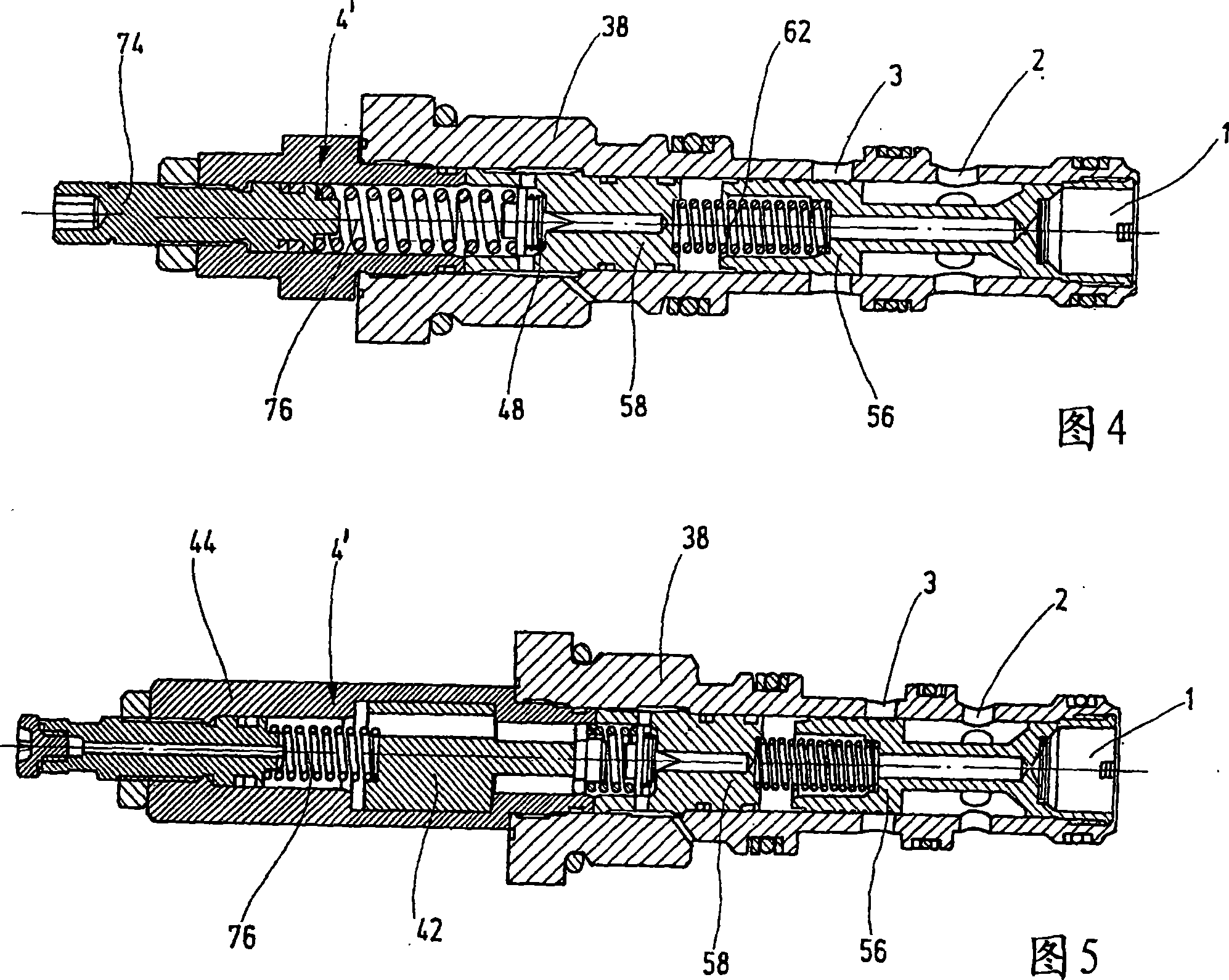

[0013] FIG. 1 shows a part of a hydrodynamic drive for a scissor lift work platform, not shown in detail, in the form of a circuit diagram. The above-mentioned means of transport usually have two axles, wherein the rear-wheel drive is generally implemented, and the front axles can be controlled separately to enable a switchable all-wheel drive, wherein the drives for the two axles are designed essentially identically. In Fig. 1 about the prior art, represent a hydraulic motor 10 as the driving device of the wheel shaft not drawn in detail for the above-mentioned means of transport, which can be turned to according to the difference of a three-position four-way reversing valve 12 switching positions Driven in both directions of rotation for forward or reverse travel and for braking functions. According to the illustration according to FIG. 1 , the 4 / 3-way directional control valve 12 is in an intermediate position and is also connected to a hydraulic pump 14 and an oil tank 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com