Device and method for controlling atmosphere content and pressure balance in negative pressure container

A technology of balance control and container, which is applied in the field of heat treatment, can solve the problem that the gas cannot be discharged directly, and achieve the effect of simple structure, good effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

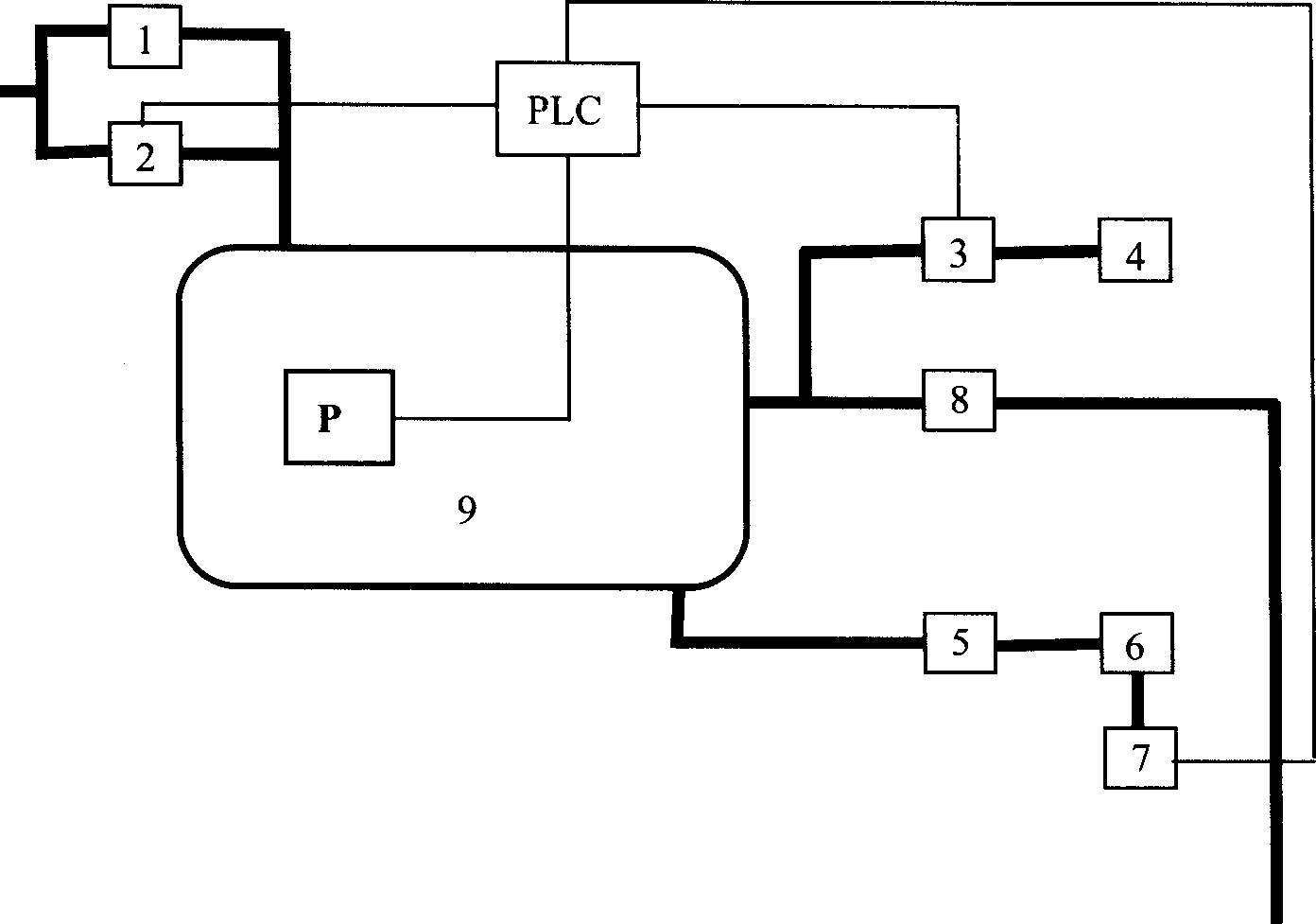

[0022] figure 1 Among them, a control device for atmosphere composition and pressure balance in a negative pressure container, the control device includes a furnace chamber 9, an inflation valve 1, a pressure stabilizing valve 2, an automatic control proportional valve 3, a stabilizing vacuum pump 4, a valve 5, and a small vacuum pump 6. Vacuum valve 8, gas analyzer 7 and PLC controller. A pressure sensor P is arranged in the furnace chamber 9; 5. The voltage-stabilizing vacuum pump 4 and the gas analyzer 7 are connected in sequence, and the small vacuum pump 6 is connected to the gas analyzer 7; the automatic control proportional valve 3 is connected to the furnace chamber 9 and the voltage-stabilizing vacuum pump 4, and the PLC controller is respectively connected to the voltage-stabilizing valve 2, The automatic control proportional valve 3, the gas analyzer 7 and the pressure sensor P are connected. Pressure stabilizing valve 2 is a manual stabilizing valve.

[0023] In ...

Embodiment 2

[0025] A control device for atmosphere composition and pressure balance in a negative pressure container. The basic structure and control method of the device are the same as in Embodiment 1, the difference is that the pressure stabilizing valve is set as an automatic proportional valve, and the gas analyzer in the gas analyzer The data is connected to the PLC to control the intake and automatically adjust the gas composition in the furnace. The data of the gas analyzer is transmitted to the PLC, and the PLC judges the difference with the required atmosphere, and then the PLC adjusts the switch size of the automatic proportional valve to automatically adjust the atmosphere in the furnace cavity; through the data of the pressure sensor P, it is automatically controlled by the PLC Automatically control the switch size of the proportional valve to keep the pressure in the furnace chamber consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com