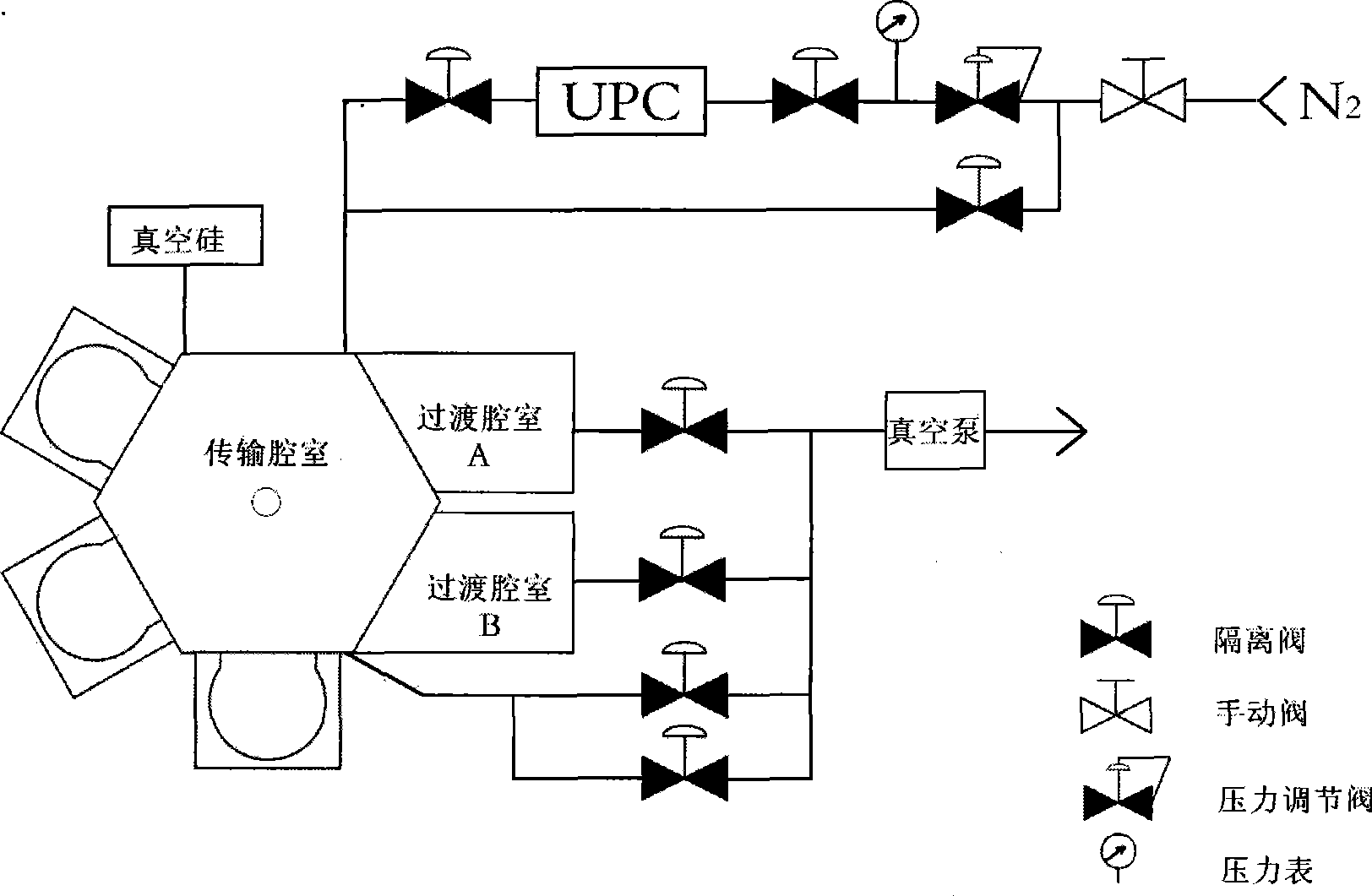

Transmission cavity pressure control system and method

A technology of control system and transmission cavity, which is applied in the field of semiconductor processing technology, can solve the problems of increasing nitrogen consumption and increasing the cost of use, and achieves the effect of low nitrogen consumption and stable pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

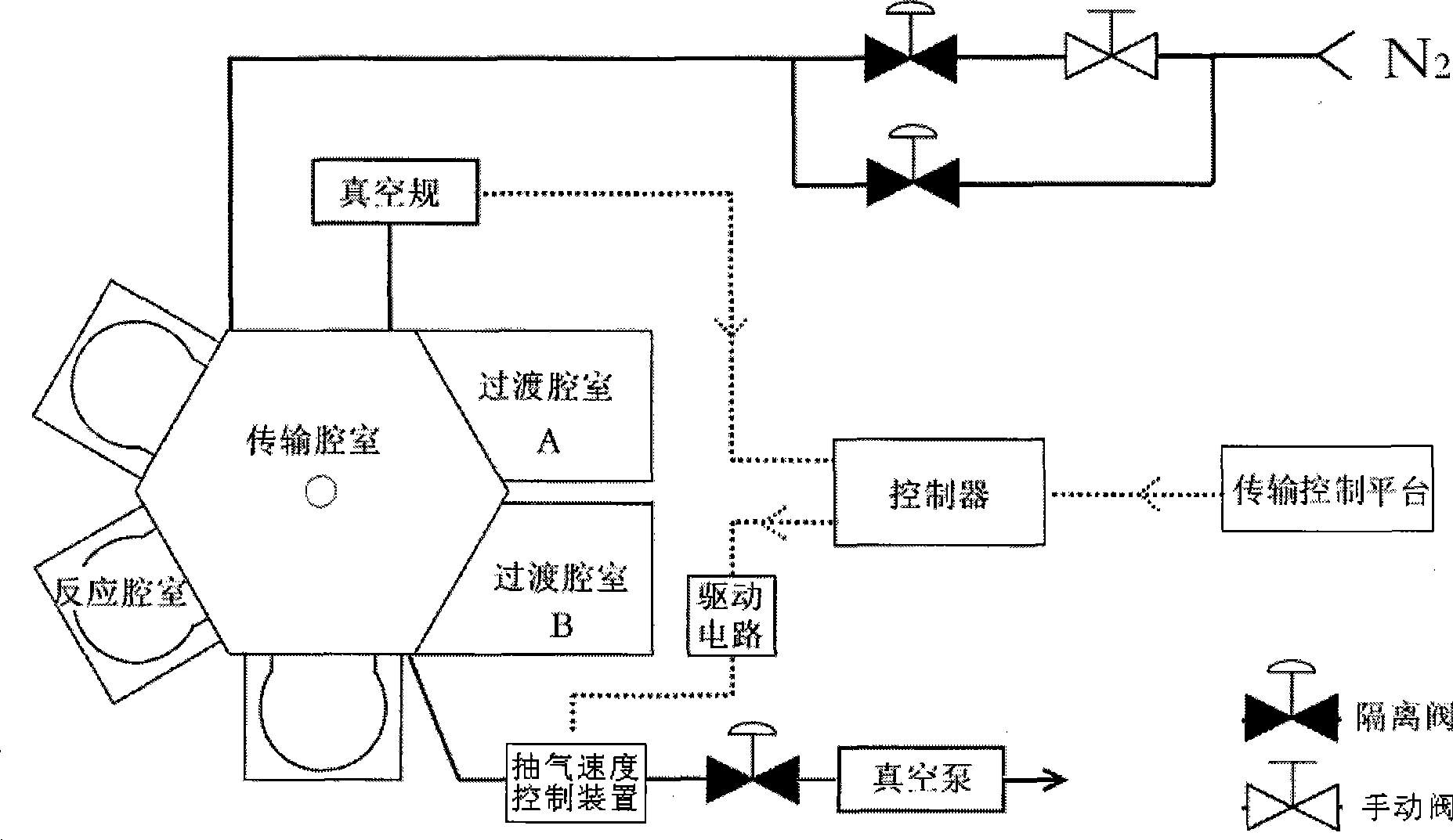

[0015] The preferred embodiment of the transmission chamber pressure control system of the present invention is as follows: figure 2 As shown in the figure, the transmission chamber is provided with an air-filling air circuit and a vacuuming air circuit. Nitrogen is charged into the transmission chamber through the air-inflating air circuit. maintain the required vacuum.

[0016] A pumping speed control device is provided on the vacuuming air circuit, which is used to control the pumping speed of the vacuuming air circuit, and then control the pressure in the transmission chamber.

[0017] The pumping speed control device may be connected with a controller, and the transfer chamber is provided with a pressure sensor, and the pressure sensor is connected with the controller. The pressure sensor may be a vacuum gauge, and the pumping speed control device may be a pendulum valve or a butterfly valve. The pressure signal in the transmission chamber can be detected by the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com