Adjustable coaxial double-slotting bolt type inspirator

An injector and plug-type technology, which is applied in the field of liquid rocket engines, can solve problems such as atomization, poor mixing, poor propellant mixing, and reduced combustion efficiency, and achieve good mixing, consistent mixing state, and improved combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

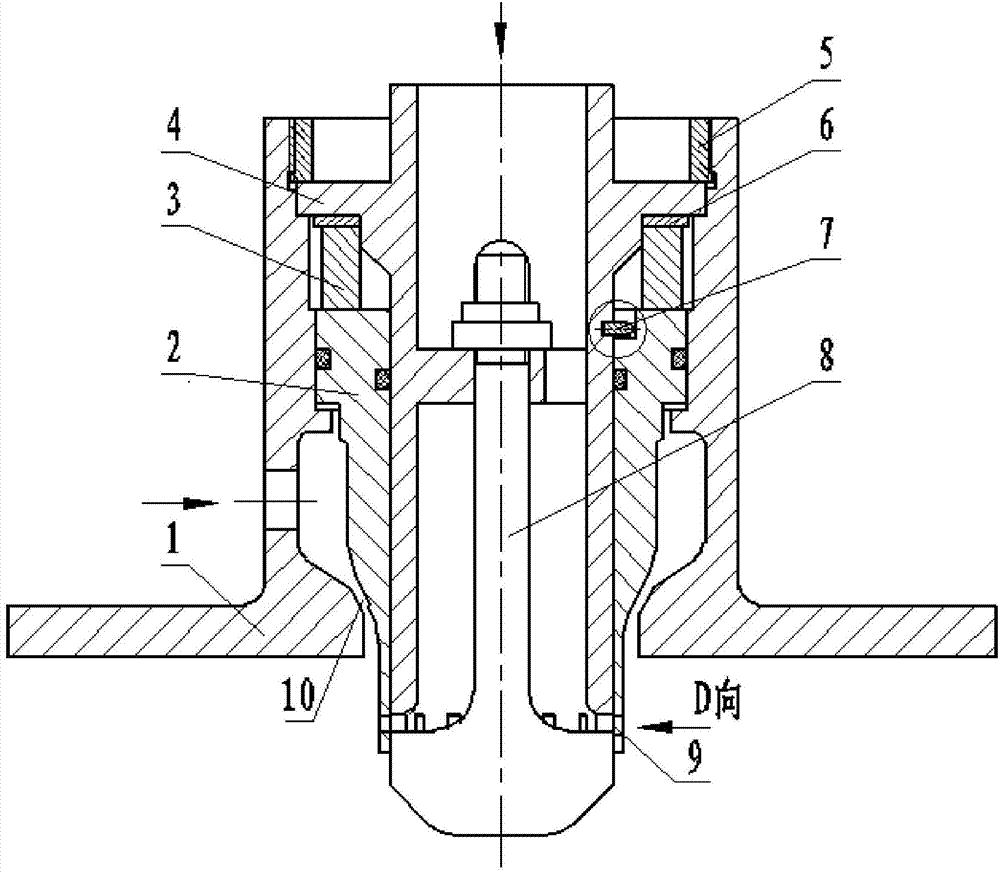

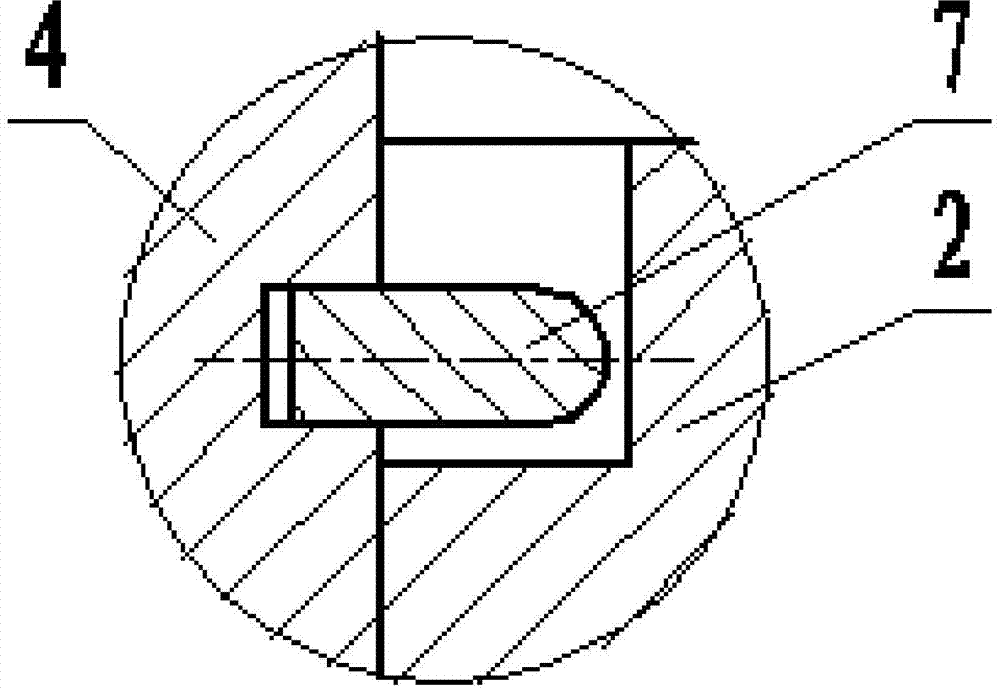

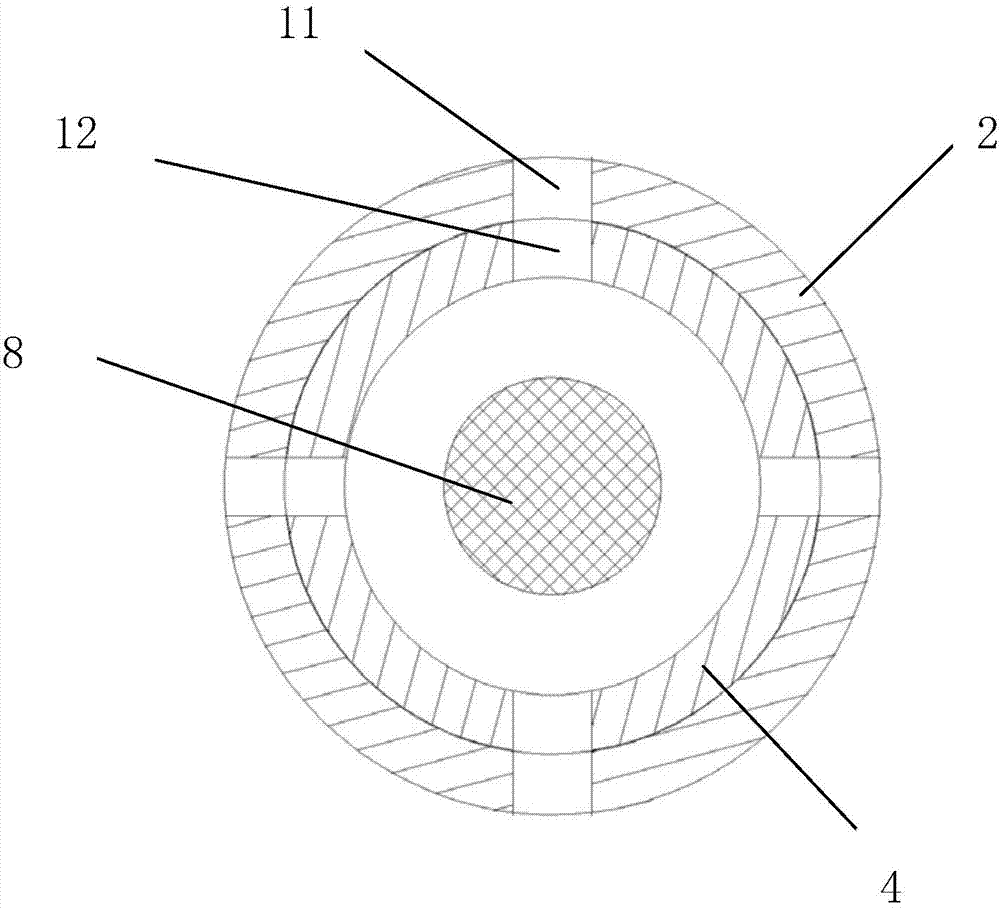

[0019] see Figure 1-2 , an adjustable coaxial double-slotted pin injector, including a central cylinder 4, a central rod 8 arranged inside the central cylinder 4 and connected by a nut, and a housing 1 surrounding the outer ring of the central cylinder 4; the central cylinder 4 There is a flange on the upper end, and the flange is fixedly connected to the housing 1 through the pressure ring 5; a needle valve 2 is also arranged between the housing 1 and the central cylinder 4; the upper end of the needle valve 2 is connected to the central cylinder by the spring 3, the gasket ring 6 4 are connected, the lower conical surface and the inner wall of the housing 1 constitute the outer ring nozzle 10; the lower end of the central cylinder 4 and the needle valve 2 are provided with corresponding slots 9, and the slots 9 are in common with the channel formed by the central rod 8 and the inner wall of the central cylinder. It forms a central channel; the central tube 4 and the slots 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com