Flow control device and method

A flow control device and flow control technology, which is applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of inability to achieve long-life service requirements, poor part consistency, thruster failure, etc., and achieve inhibition of solubility The effect of impurity deposition, inhibition of heat evaporation, and improvement of the life of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

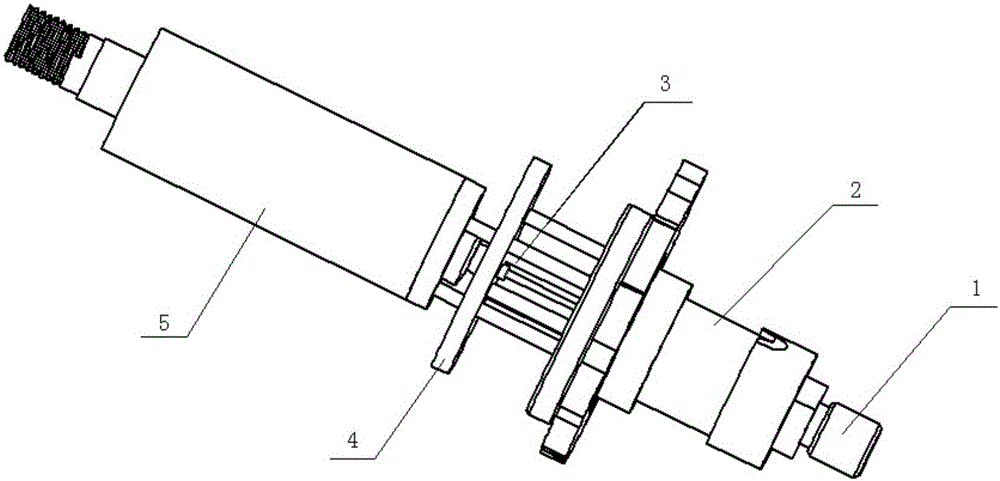

Image

Examples

Embodiment

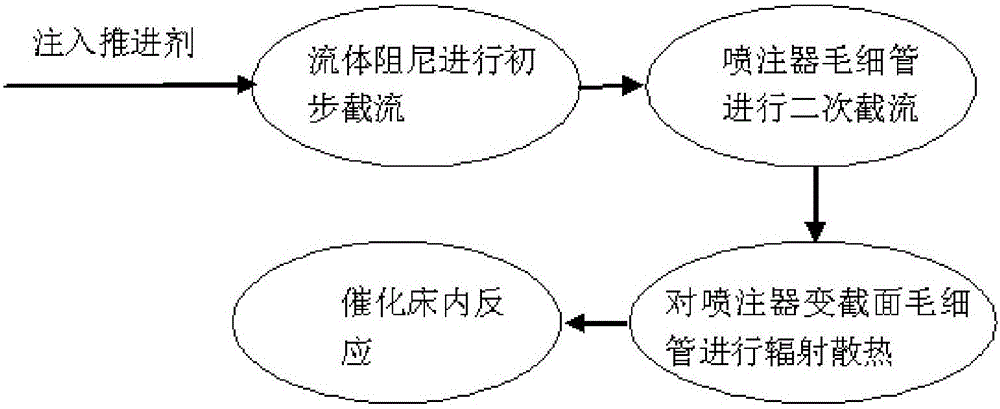

[0045] Implementation steps of the present invention are as follows:

[0046] Thruster Quantitative Parameters: Propellant Quota Injection Pressure: 1.7MPa

[0047] Rated flow of propellant: 50mg / s

[0048] Catalytic bed design fuel pressure: 0.5MPa

[0049] Thruster rated thrust: 100mN

[0050] Thruster steady state ignition life: 500 hours

[0051] The implementation steps are as follows:

[0052] 1. The upstream propellant injection pressure of the flow control damping component is 1.7MPa. Select a combined fluid control damping component with a large effective flow area, and try to avoid using a single-hole fluid damping component to improve the overall anti-pollution ability of the thruster.

[0053] 2. Select a solenoid valve with strong flow capacity. The solenoid valve only controls the on-off of the propellant flow process during the flow control process, and does not participate in the flow pressure adjustment process.

[0054] 3. The propellant flows through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com