Polyvinylidene-fluoride hollow fibre membrane and preparation method thereof

A polyvinylidene fluoride, fiber membrane technology, which is applied in hollow filament manufacturing, fiber processing, fiber chemical characteristics, etc., can solve the problems of low pure water flux, unsatisfactory, and poor anti-pollution performance of hollow fiber membrane products. Achieve the effect of being beneficial to water flux, preventing membrane pores from becoming smaller, and enhancing anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

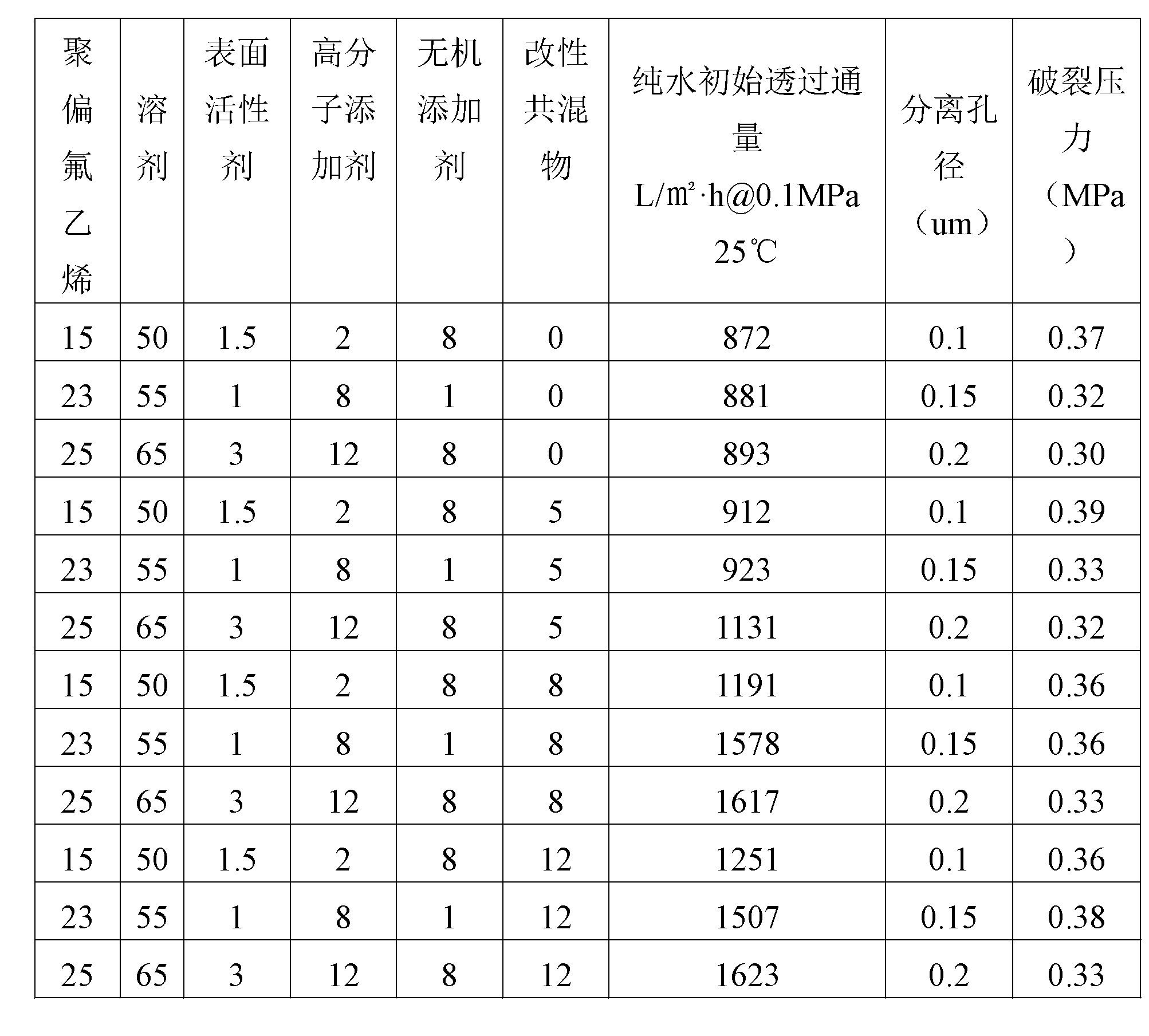

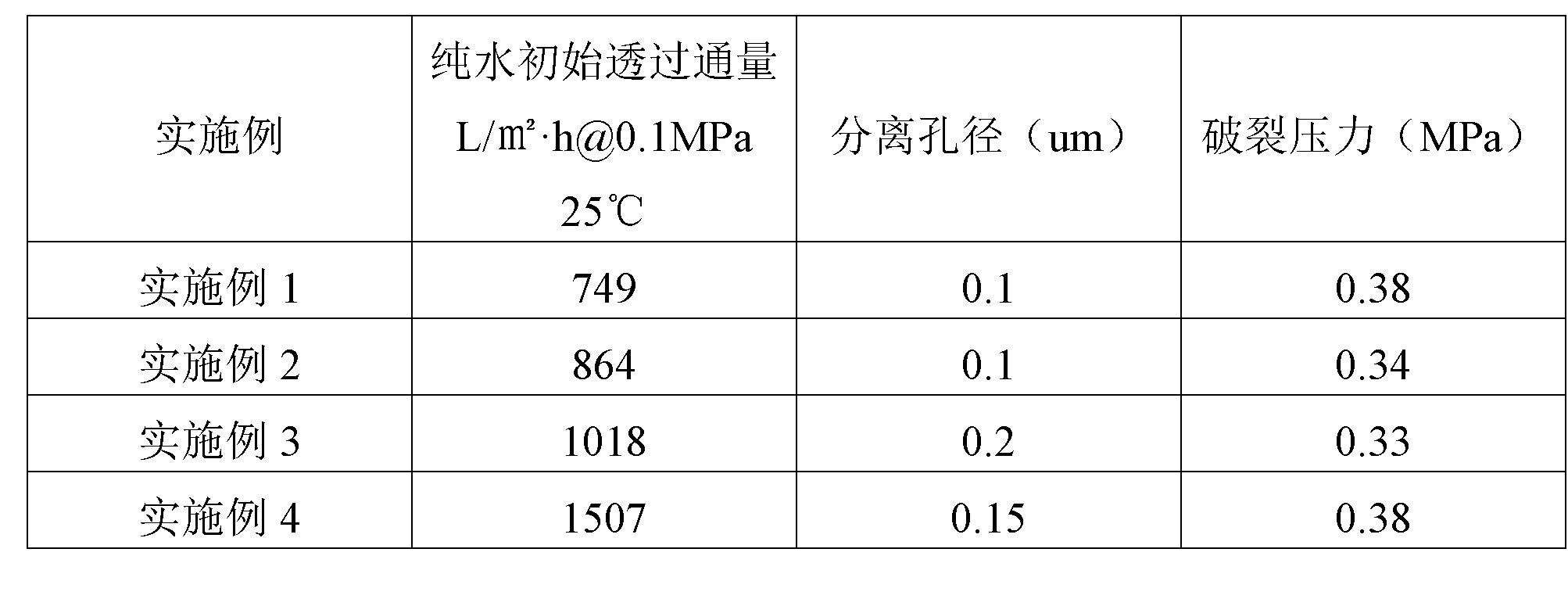

[0028] 25 parts of polyvinylidene fluoride 60 parts of dimethylformamide 1 part of sodium lauryl sulfate

[0029] 8 parts of polyethylene glycol, 1 part of lithium nitrate, 5 parts of cellulose acetate

[0030] Add the above-mentioned polyvinylidene fluoride, dimethylformamide, sodium lauryl sulfate, polyethylene glycol, lithium nitrate, and cellulose acetate into the stirring tank, stir, heat and blend at 80°C, and the stirring speed is 100r / min, and the stirring time is 3 hours; the blend solution is left to stand for 4 hours for defoaming treatment, and the temperature is lowered to 60°C to obtain the casting solution; the casting solution and the aqueous solution are extruded through the spinning nozzle under the pressure of nitrogen, and passed through a 100mm air After a distance, immerse in a 35°C aqueous solution coagulation bath at a uniform speed; stretch at a speed of 60m / min in an external coagulation bath to obtain a formed polyvinylidene fluoride hollow fiber me...

Embodiment 2

[0032] 17 parts of polyvinylidene fluoride 50 parts of dimethylformamide 3 parts of sodium lauryl sulfate

[0033] 12 parts of polyethylene glycol, 8 parts of lithium nitrate, 10 parts of cellulose acetate

[0034]Add the above-mentioned polyvinylidene fluoride, dimethylformamide, sodium lauryl sulfate, polyethylene glycol, lithium nitrate, and cellulose acetate into the stirring tank, stir, heat and blend at 100°C, and the stirring speed is 120r / min, and the stirring time is 6 hours; the blend solution is left to stand for 6 hours for defoaming treatment, and the temperature is lowered to 80°C to obtain the casting solution; the casting solution and the aqueous solution are extruded through the spinning nozzle under the pressure of nitrogen, and passed through a 200mm air After a distance, immerse in a 60°C dimethylacetamide aqueous solution coagulation bath at a constant speed; stretch at a speed of 100m / min in the external coagulation bath to obtain a formed polyvinylidene...

Embodiment 3

[0036] 15 parts of polyvinylidene fluoride 80 parts of dimethylformamide 1 part of sodium lauryl sulfate

[0037] Polyethylene glycol 2 parts Lithium nitrate 2 parts Cellulose acetate 1 part

[0038] Add the above-mentioned polyvinylidene fluoride, dimethylformamide, sodium lauryl sulfate, polyethylene glycol, lithium nitrate, and cellulose acetate into the stirring tank, stir, heat and blend at 70°C, and the stirring speed is 90r / min, the stirring time is 1h; the blend solution is left to stand for 1h for defoaming treatment, and the temperature is lowered to 40°C to obtain the casting solution; the casting solution is extruded through the spinning nozzle with the dimethylacetamide aqueous solution under the pressure of nitrogen , immersed in a 30°C aqueous solution coagulation bath at a uniform speed; stretched at a speed of 10m / min in the external coagulation bath to obtain a formed polyvinylidene fluoride hollow fiber membrane; the formed polyvinylidene fluoride hollow fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com