Patents

Literature

61 results about "Monopropellant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monopropellants are propellants consisting of chemicals that release energy through exothermic chemical decomposition. The molecular bond energy of the monopropellant is released usually through use of a catalyst. This can be contrasted with bipropellants that release energy through the chemical reaction between an oxidizer and a fuel. While stable under defined storage conditions, monopropellants decompose very rapidly under certain other conditions to produce a large volume of energetic (hot) gases for the performance of mechanical work. Although solid deflagrants such as nitrocellulose, the most commonly used propellant in firearms, could be thought of as monopropellants, the term is usually reserved for liquids in engineering literature.

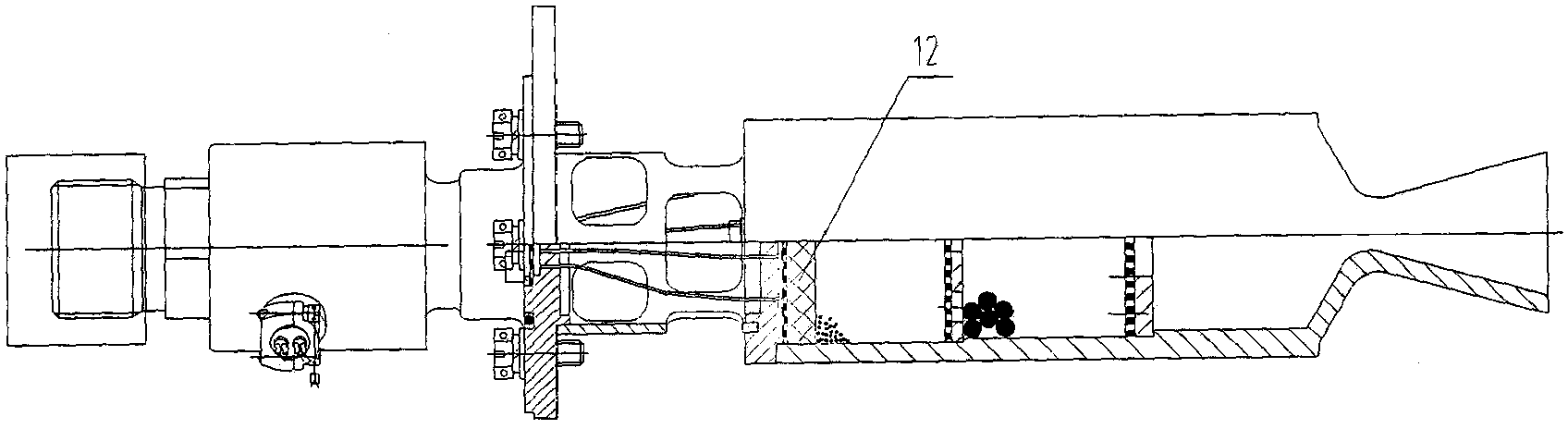

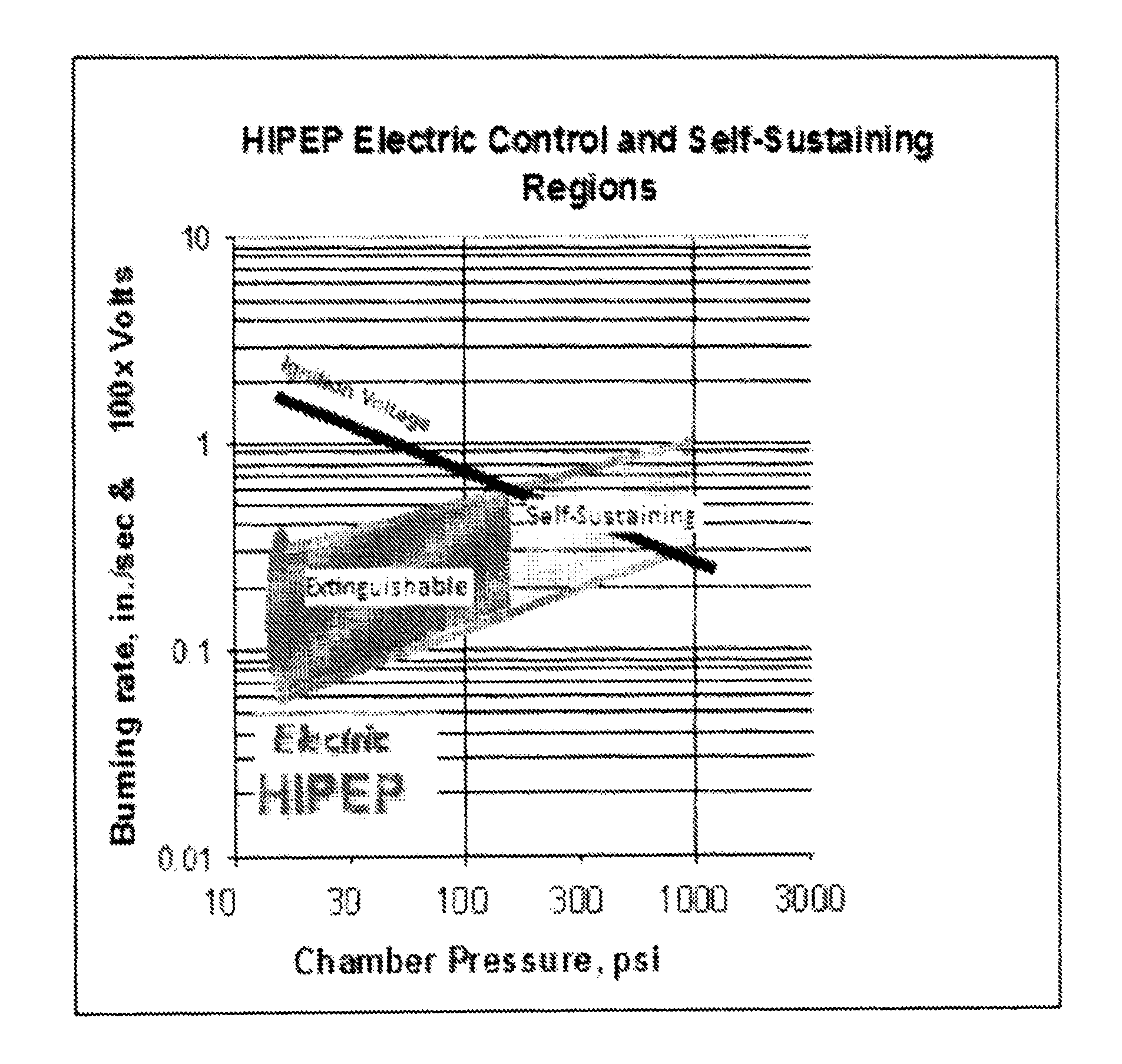

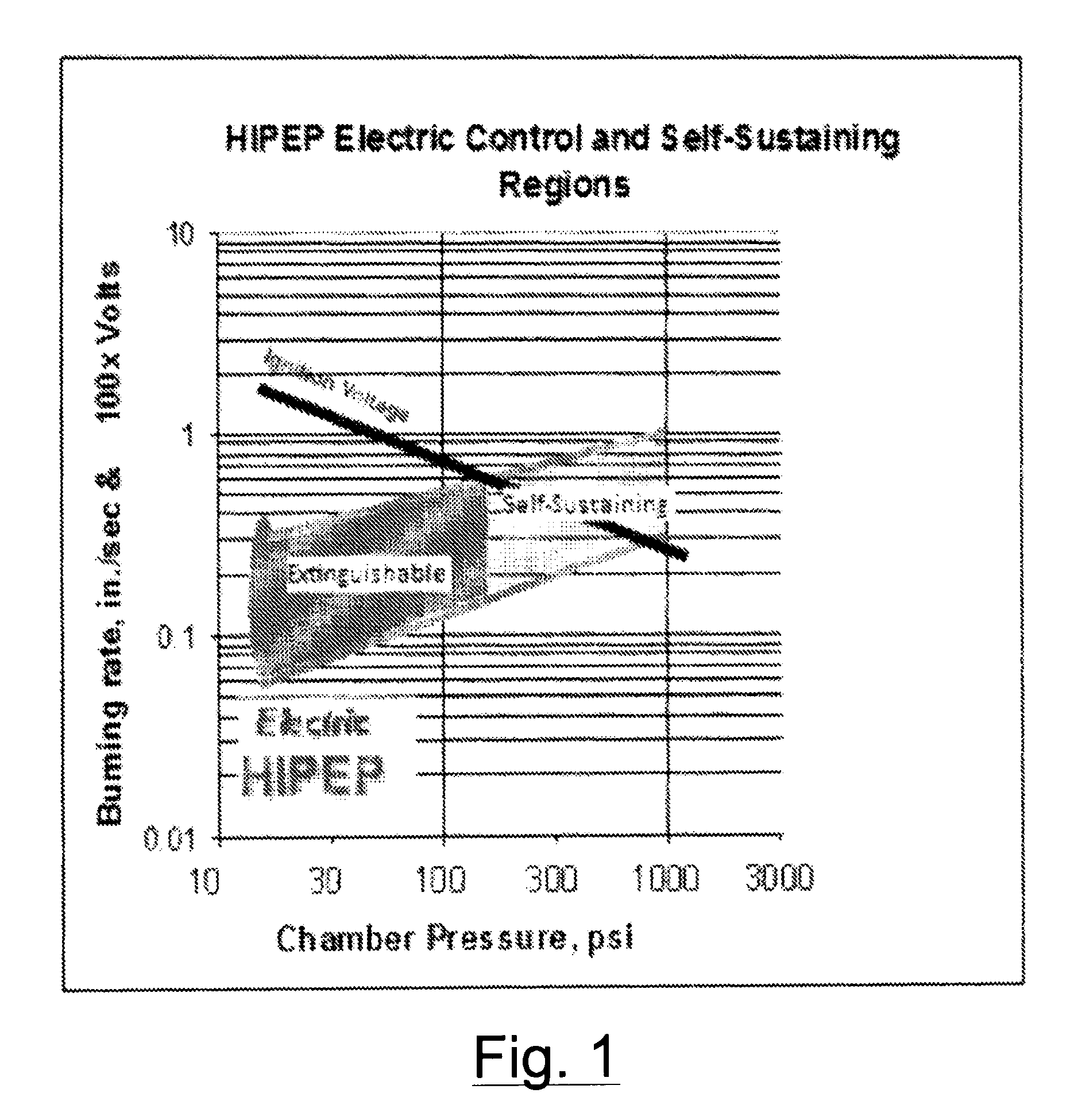

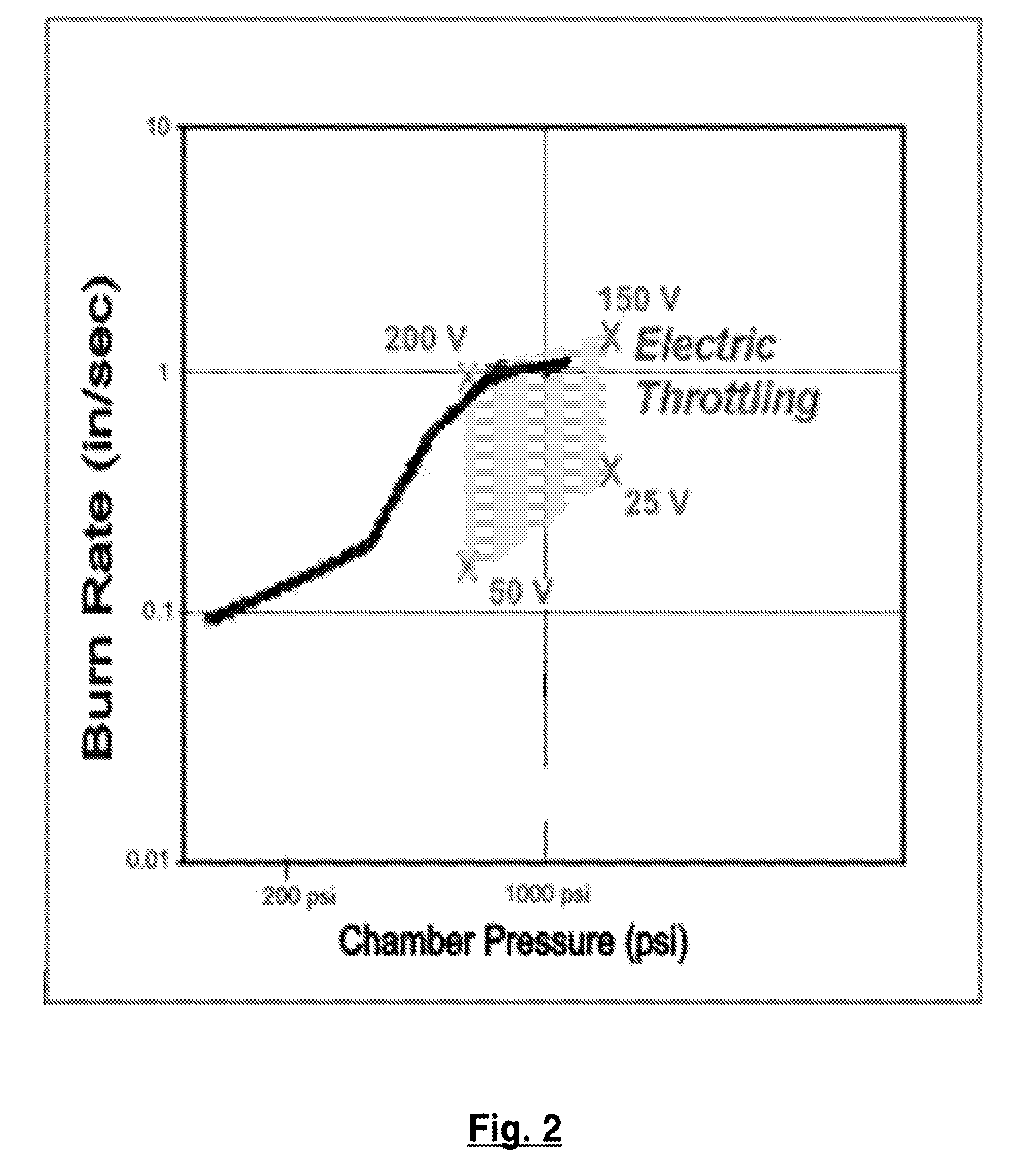

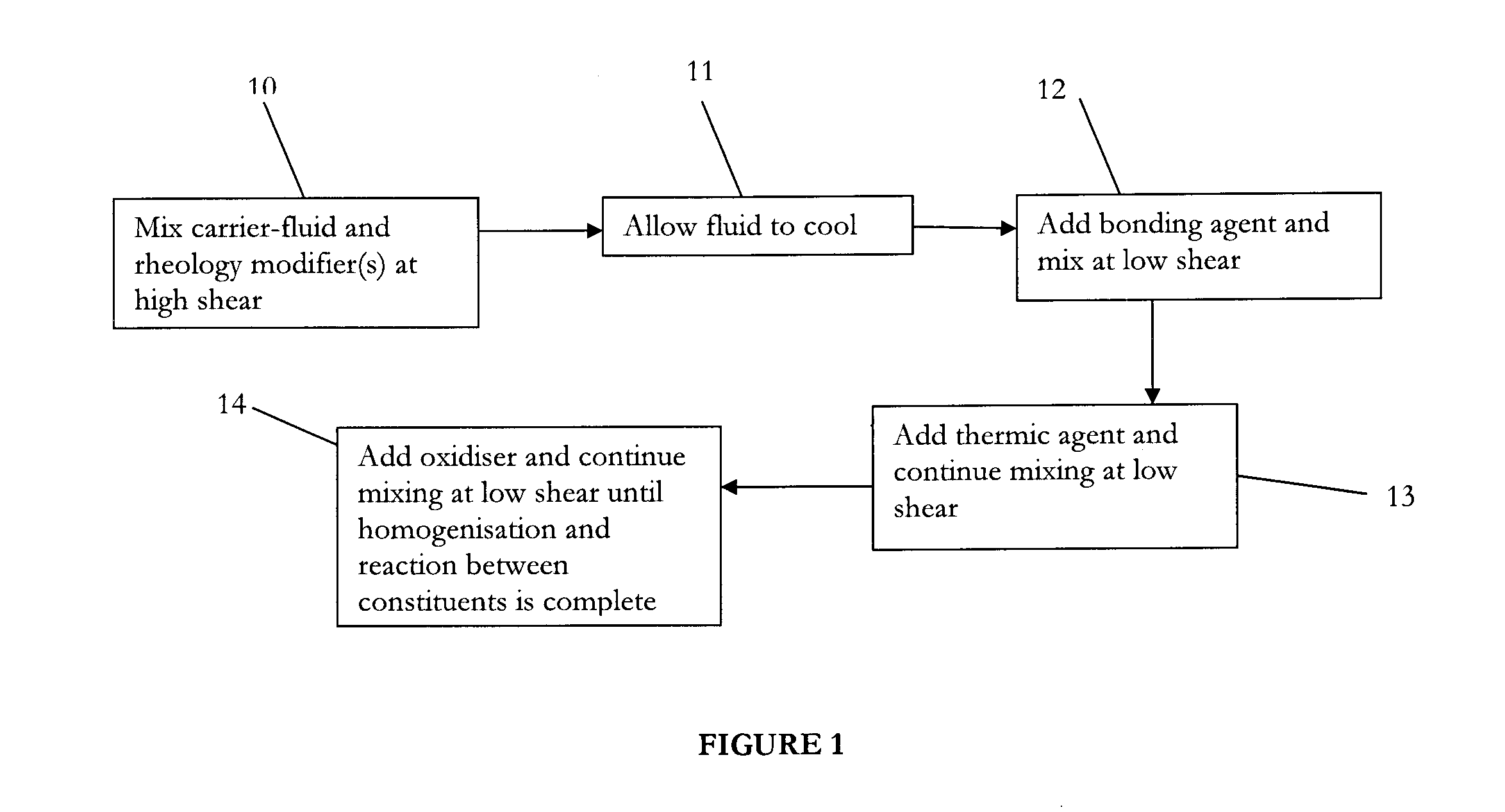

Family of Modifiable High Performance Electrically Controlled Propellants and Explosives

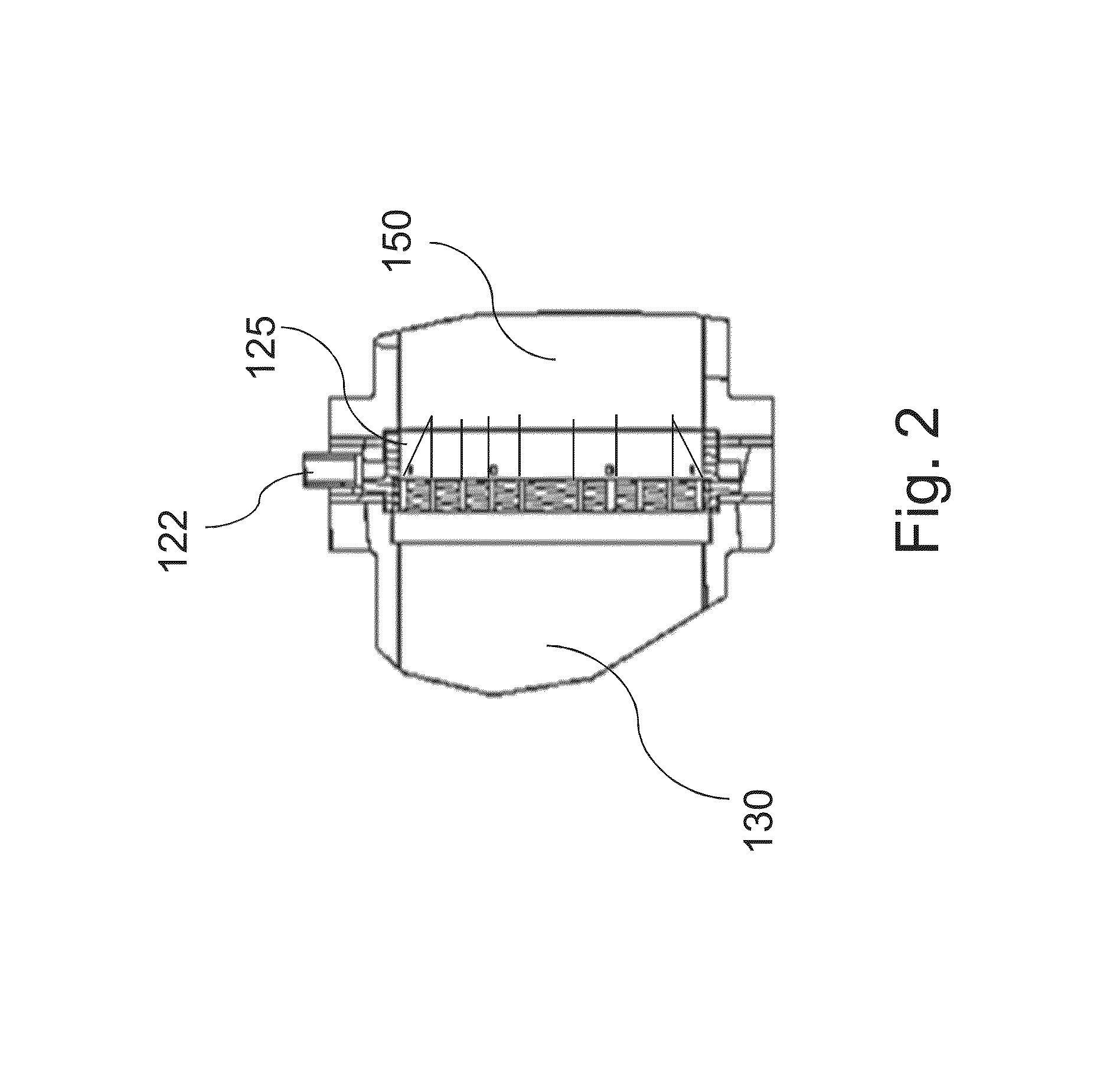

ActiveUS20110067789A1Improve simplicityLow costNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsElectricityAmbient pressure

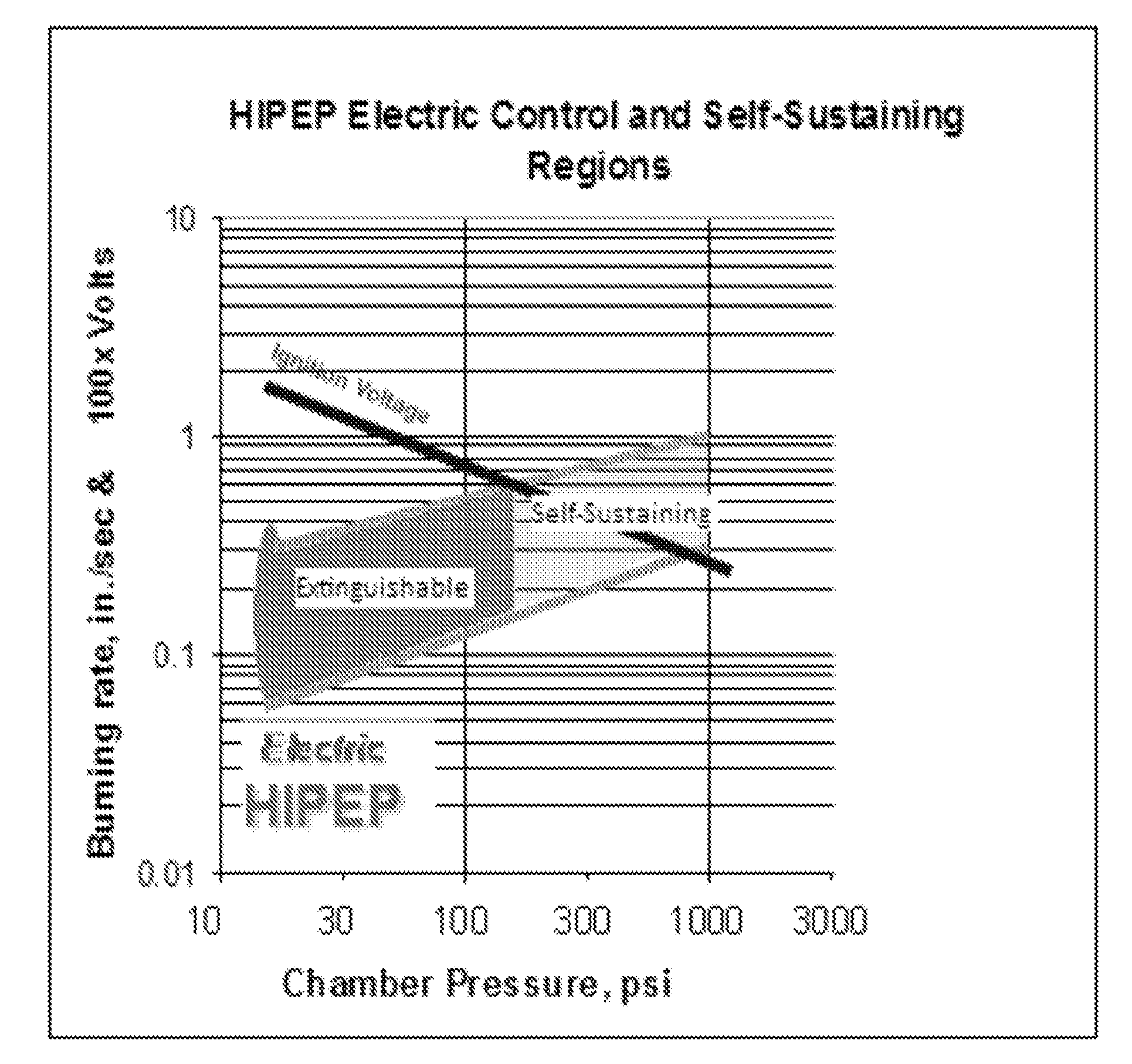

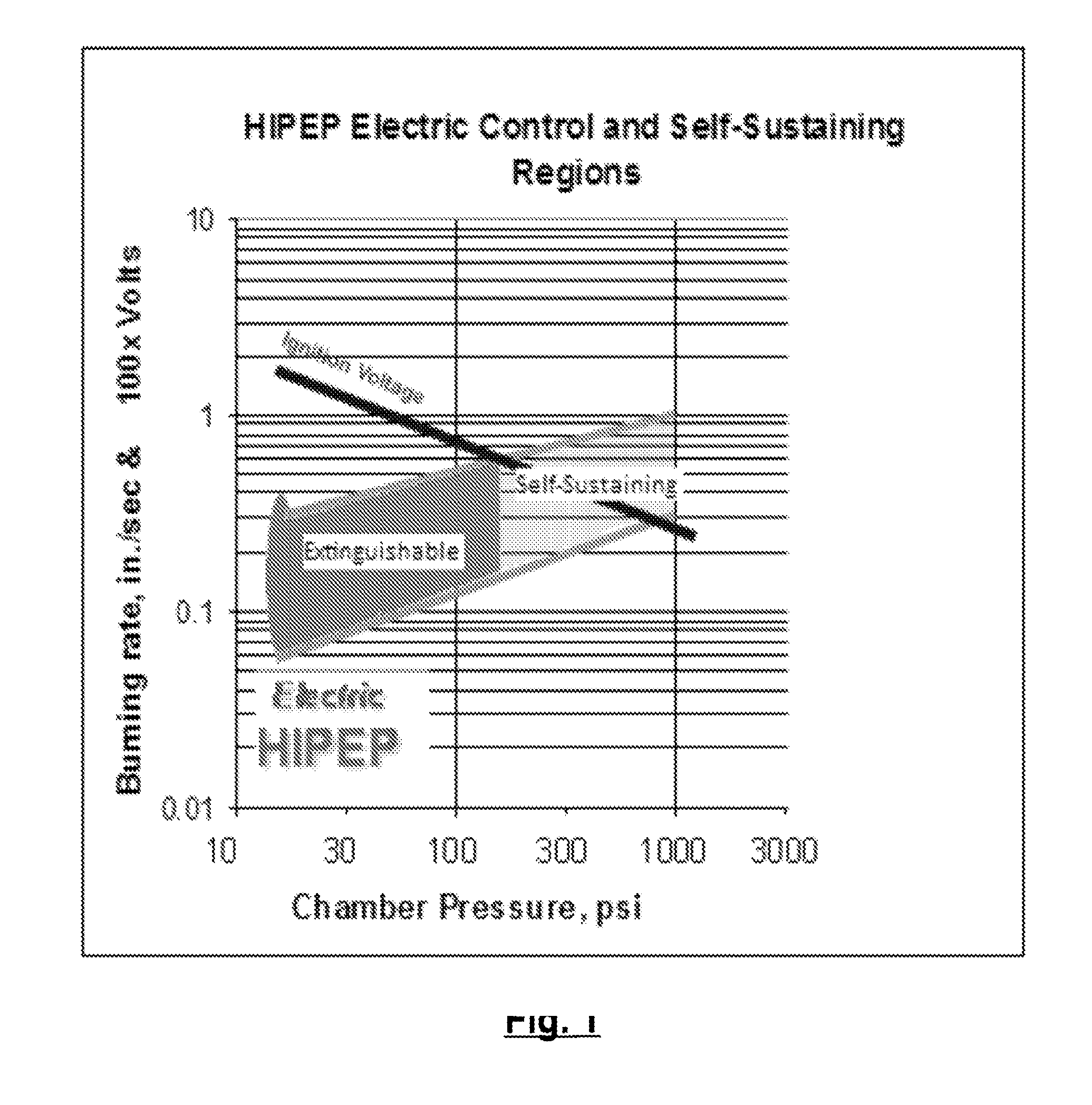

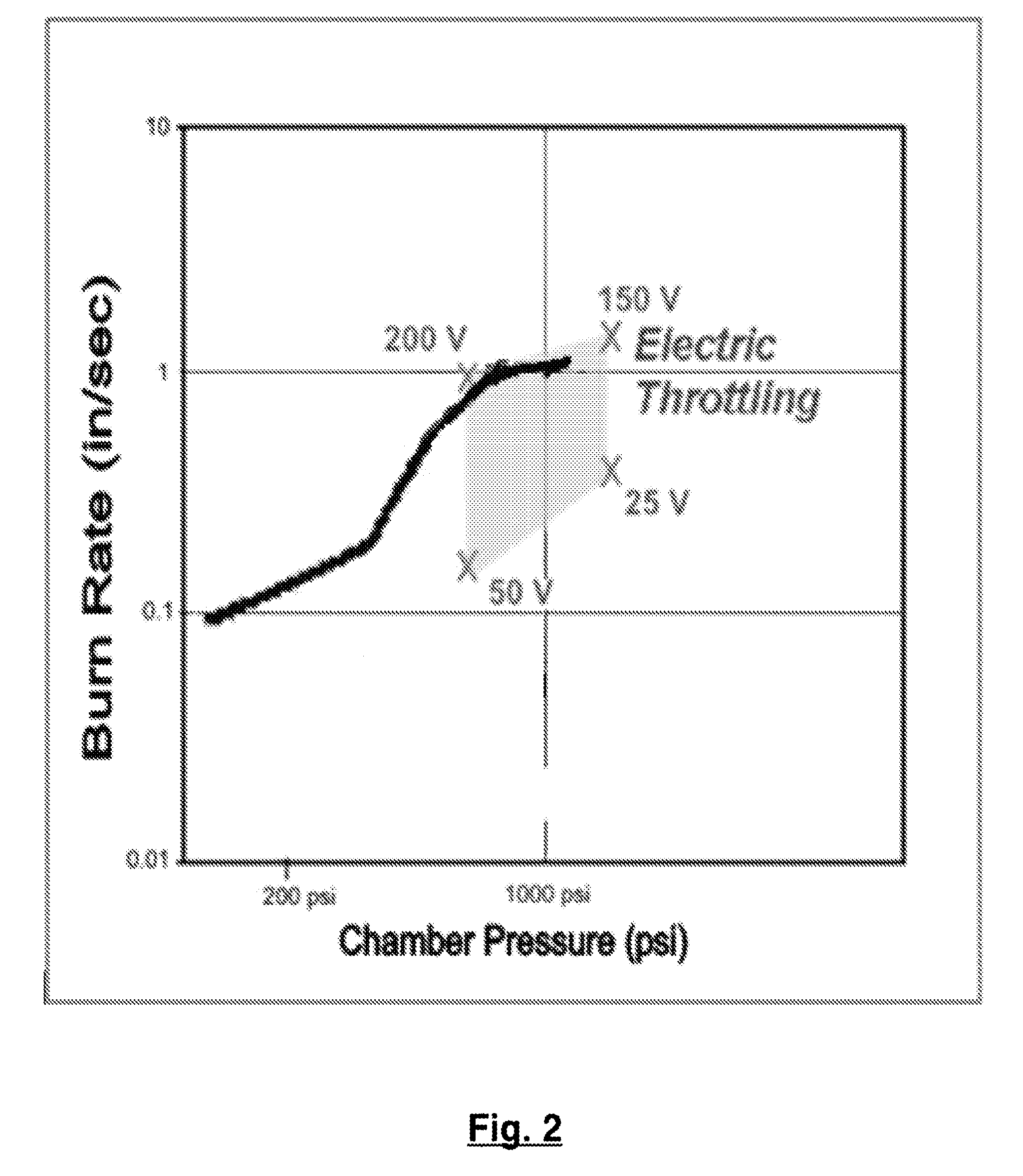

A composition capable of producing either solid propellant grains, liquid or gel monopropellants, all of which are electrically ignitable and capable of sustained controllable combustion at ambient pressure. Additional compositions capable of sustained controllable combustion at elevated pressures are described. Applications for the compositions disclosed herein are provided, and include among other applications use in small micro thrusters, large core-burning solid propellant gains, shaped explosives charges for military application, and pumpable liquids and gel monopropellants or explosives for military, commercial mining or gas and oil recovery. In alternative embodiments the above compositions may also incorporate an energetic nitrate polymer, bum rate modifiers, and / or metal fuel(s). The HIPEP formulation makes it possible to ignite and sustain combustion at ambient and vacuum conditions (a) without continuous electrical power and (b) while providing faster bum rates.

Owner:DIGITAL SOLID STATE PROPULSION

Premixed liquid monopropellant solutions and mixtures

Nondetonable, or low detonation sensitivity, substantially nontoxic liquid monopropellants are provided. The liquid propellants are formed from aqueous solutions of solid oxidizers in liquid oxidizers and water soluble liquid fuels and formulated to have a freezing point less than −10° C. Liquid oxidizers may be inorganic or organic aqueous solutions, with hydrogen peroxide being preferred. Preferred solid oxidizers are water soluble nitrates including ammonium dinitramide, aminoguanidine dinitrate, ammonium nitrate, hydroxylamine nitrate, hydrazine nitrate, guanidine nitrate and aminoguanidine nitrate. Preferred liquid fuels are water soluble alcohols, amines and amine nitrates, hydroxyethyl hydrazine, hydroxyethylhydrazine nitrate, cyanoguanidine, guanidines, aminoguanidines, triaminoguanidines, and their nitrate salts, ethanolamine dinitrate, ethylenediamine dinitrate, polyvinyl nitrate, and aziridine.

Owner:AEROJET GENERAL CORP

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

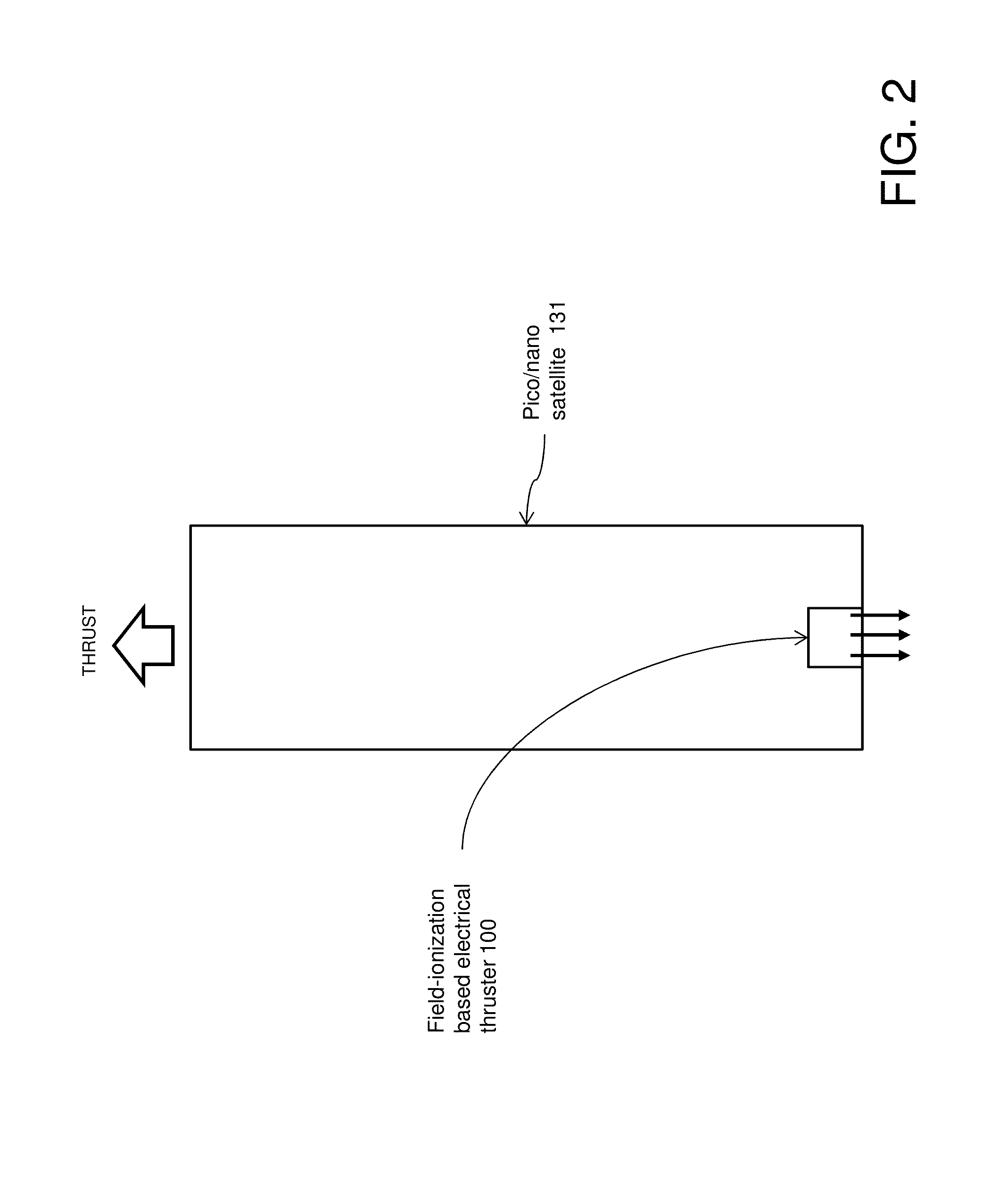

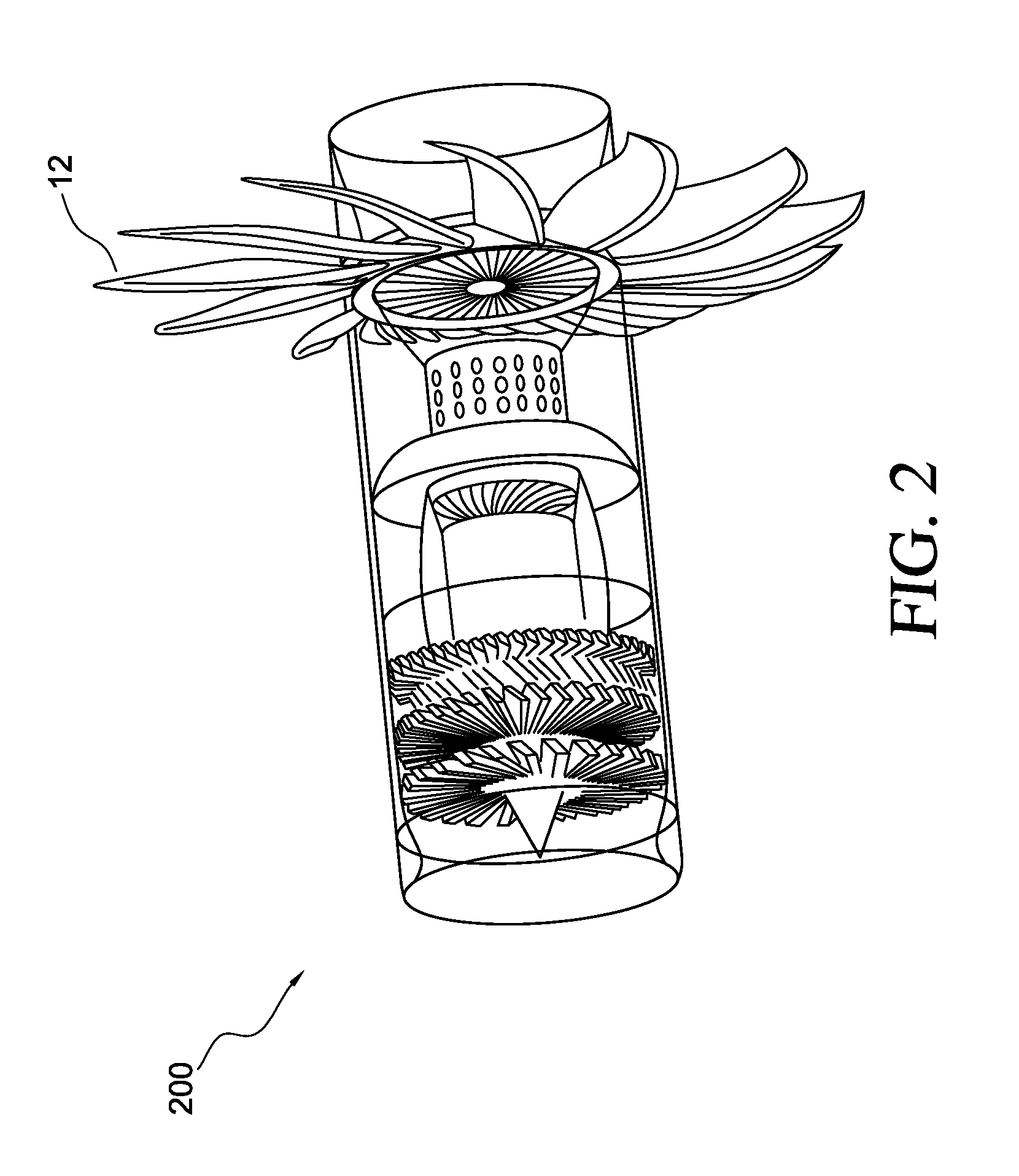

Field-ionization based electrical space ion thruster using a permeable substrate

ActiveUS9194379B1Cosmonautic vehiclesCosmonautic propulsion system apparatusField electron emissionCarbon nanotube

A field-ionization based electrical ion thruster utilizes a single propellant that can be used in either a high specific-impulse mode, i.e., ion-thruster mode, or a low-specific-impulse mode, i.e., a cold-gas thruster mode. In one embodiment, the high specific impulse mode (ion thruster mode) utilizes a miniaturized positive-ion field-ionization chamber including a permeable substrate infused with properly oriented carbon nanotubes (CNTs), which is fed propellant from a porous injection plug made from permeable carbon or equivalent material. In one embodiment, field-electron emission from a neutralizer, such as a carbon nanotube array neutralizer, positioned after one or more accelerator grids is used for ion neutralization. In one embodiment, the low specific-impulse (cold-gas mode) uses a conventional supersonic nozzle-expansion to generate thrust. In one embodiment, both the high specific-impulse mode and the low specific-impulse mode thruster embodiments share the same gas propellant, storage propellant tank, and delivery equipment.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

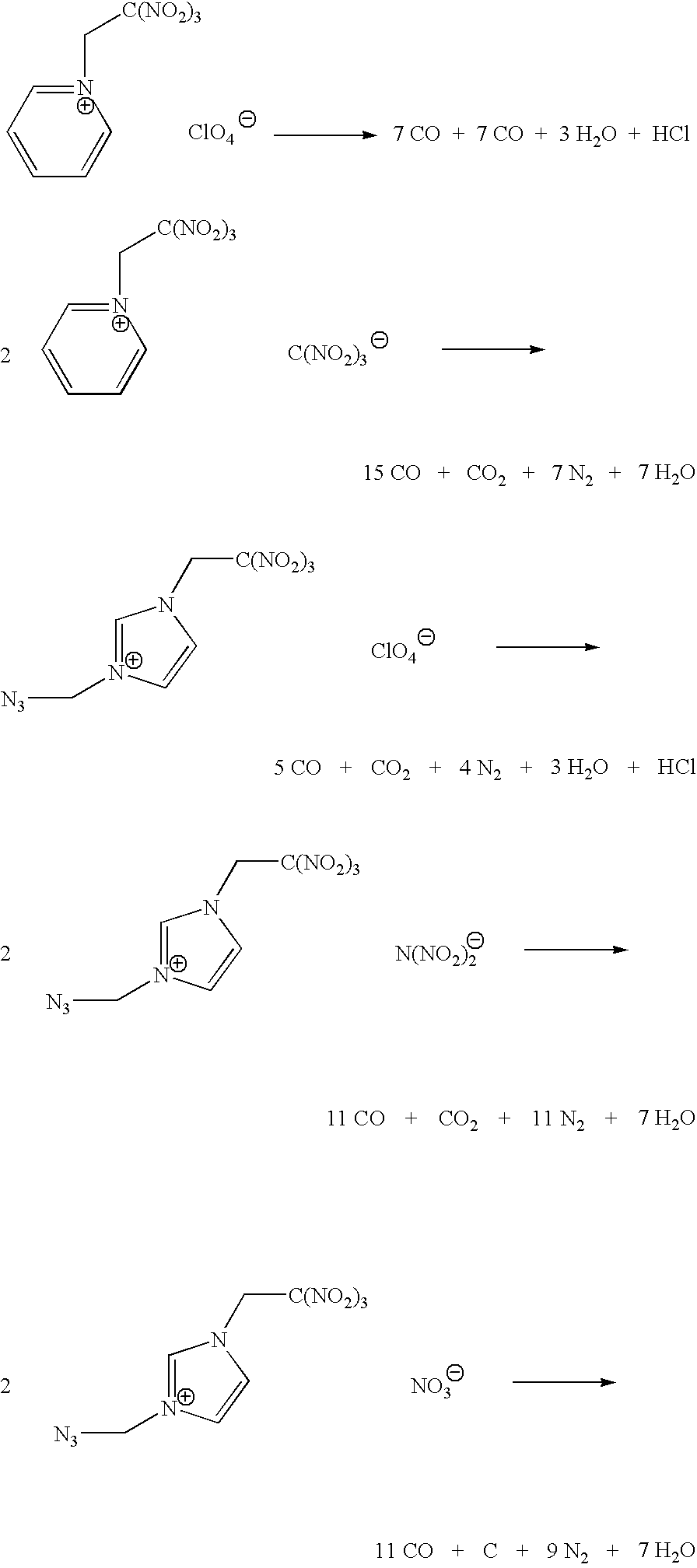

Energetic ionic liquids

Provided are energetic materials of low vapor pressure in the form of ionic liquids having fuel and oxidizer ions including, substituted pyridinium or imidazolium cations paired with nitrato-, perchlorato-, or nitramido-based anions, to form such ionic liquids or salts. The salts of the present invention are low melting and have essentially little or no vapor pressure over a wide temperature range. The salts of this invention are thus an important breakthrough since they can serve as high-performing monopropellants which are not complex mixtures and have no vapor toxicity. Such salts also find use as munitions, liquid explosives, reaction media for the synthesis of other high-energy materials, and as plasticizers.

Owner:GOVERNMENT OF THE UNITED STATES OF AMERCIA AS REPRESENTED BY THE SEC OF THE AIR FORCE

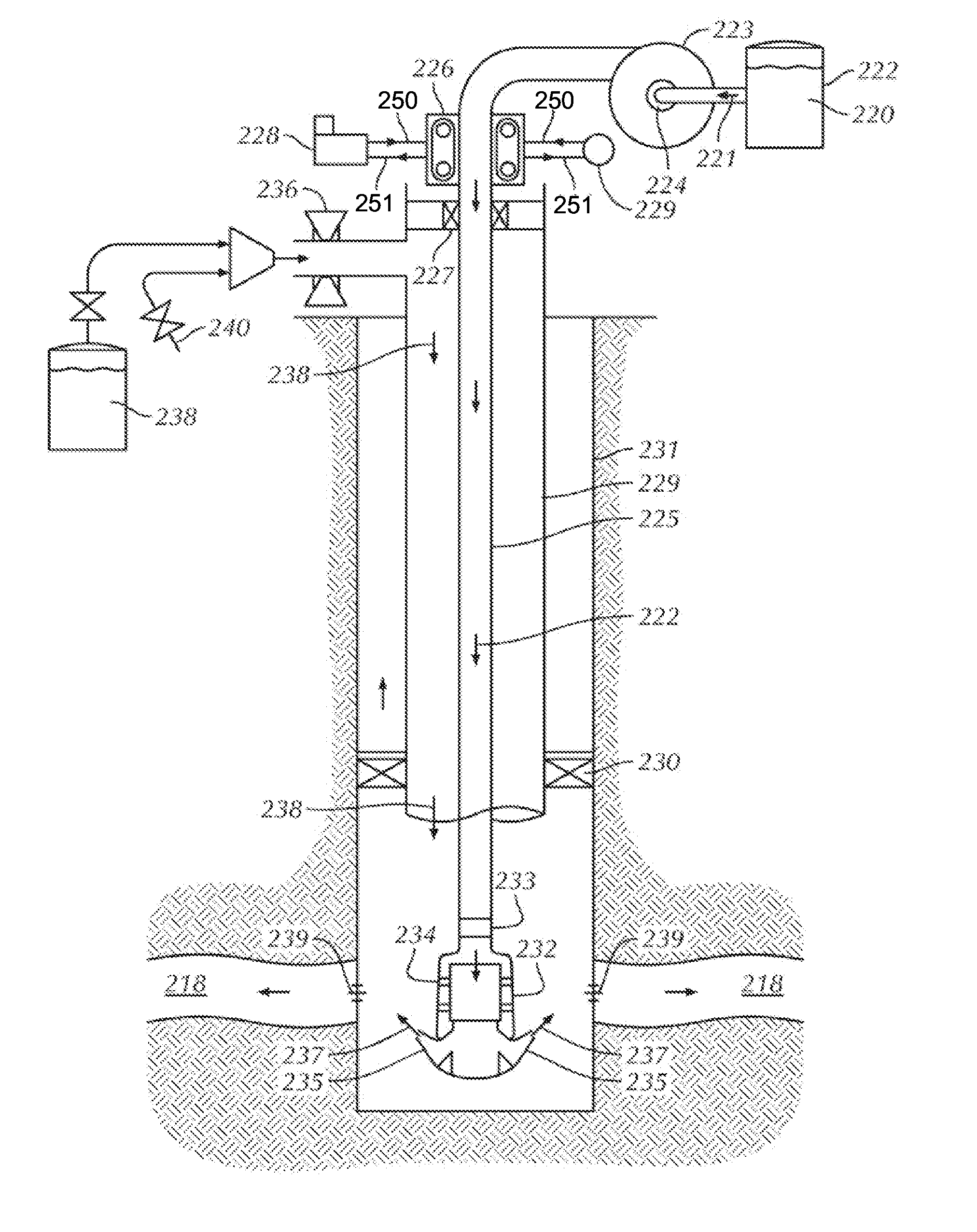

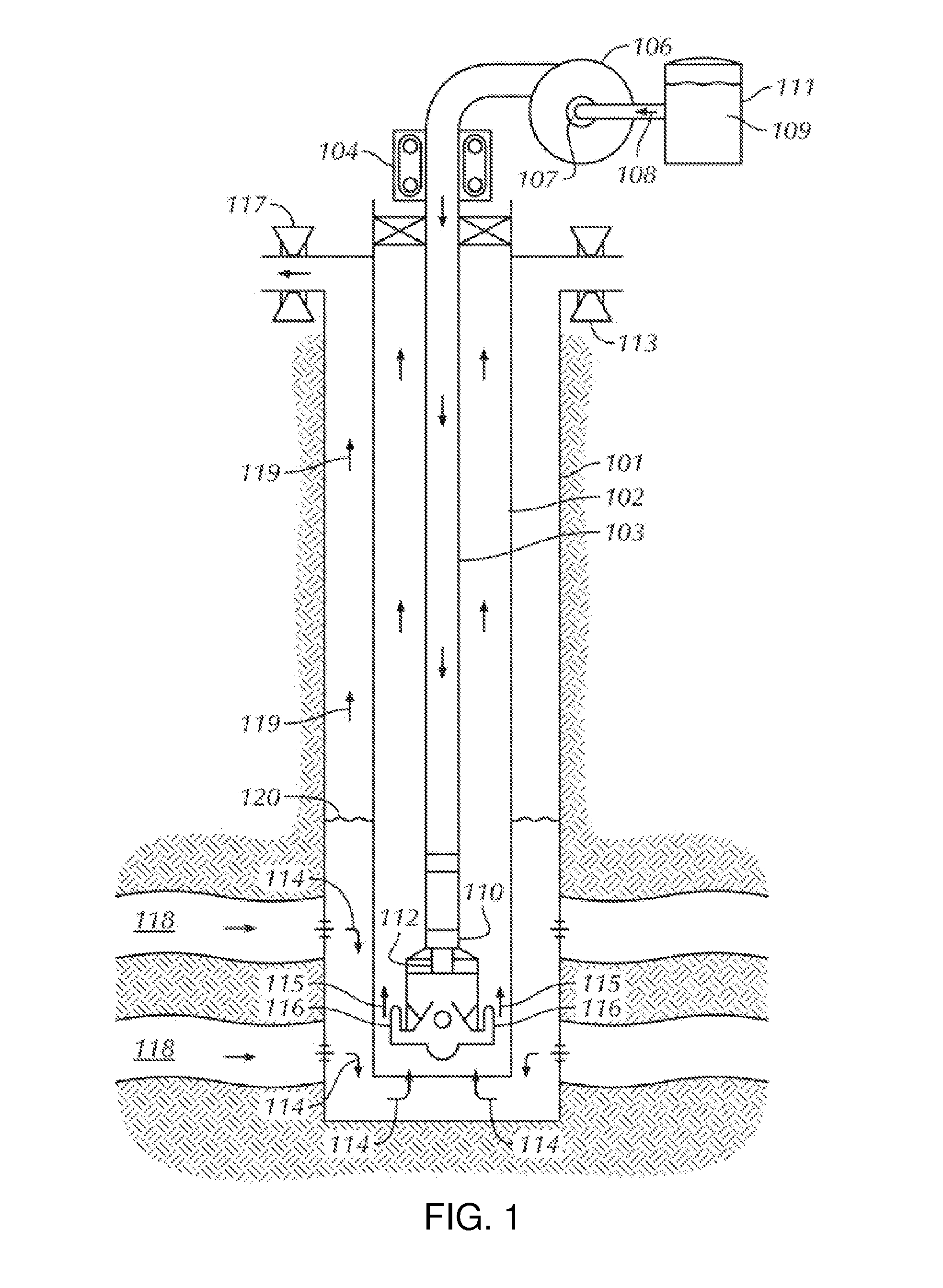

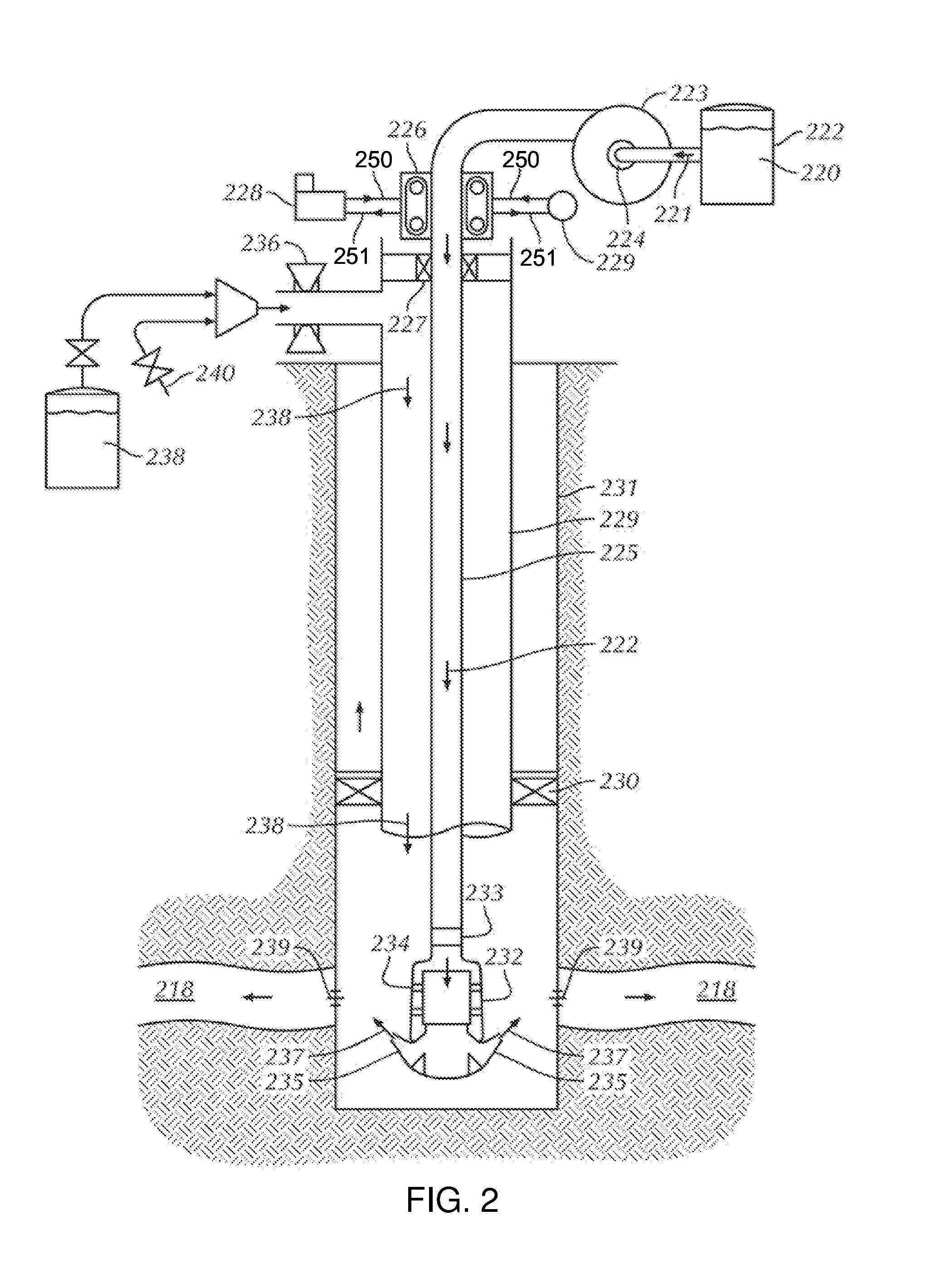

Method and apparatus to release energy in a well

InactiveUS8789591B2Increasing surface recovery and commercializationIncrease productionThermal drillingInsulationEngineeringCatalytic combustion

The present invention is directed towards methods and apparatus to release energy into wells using combustion of monopropellants. More specifically, this invention is directed to industrial methods to enhance the extraction of well fluids from wells by using the in-situ energy released from this inventions apparatus, methods, catalyst, and fluids blends for subterranean catalytic combustion of monopropellants.

Owner:SMITH DAVID R

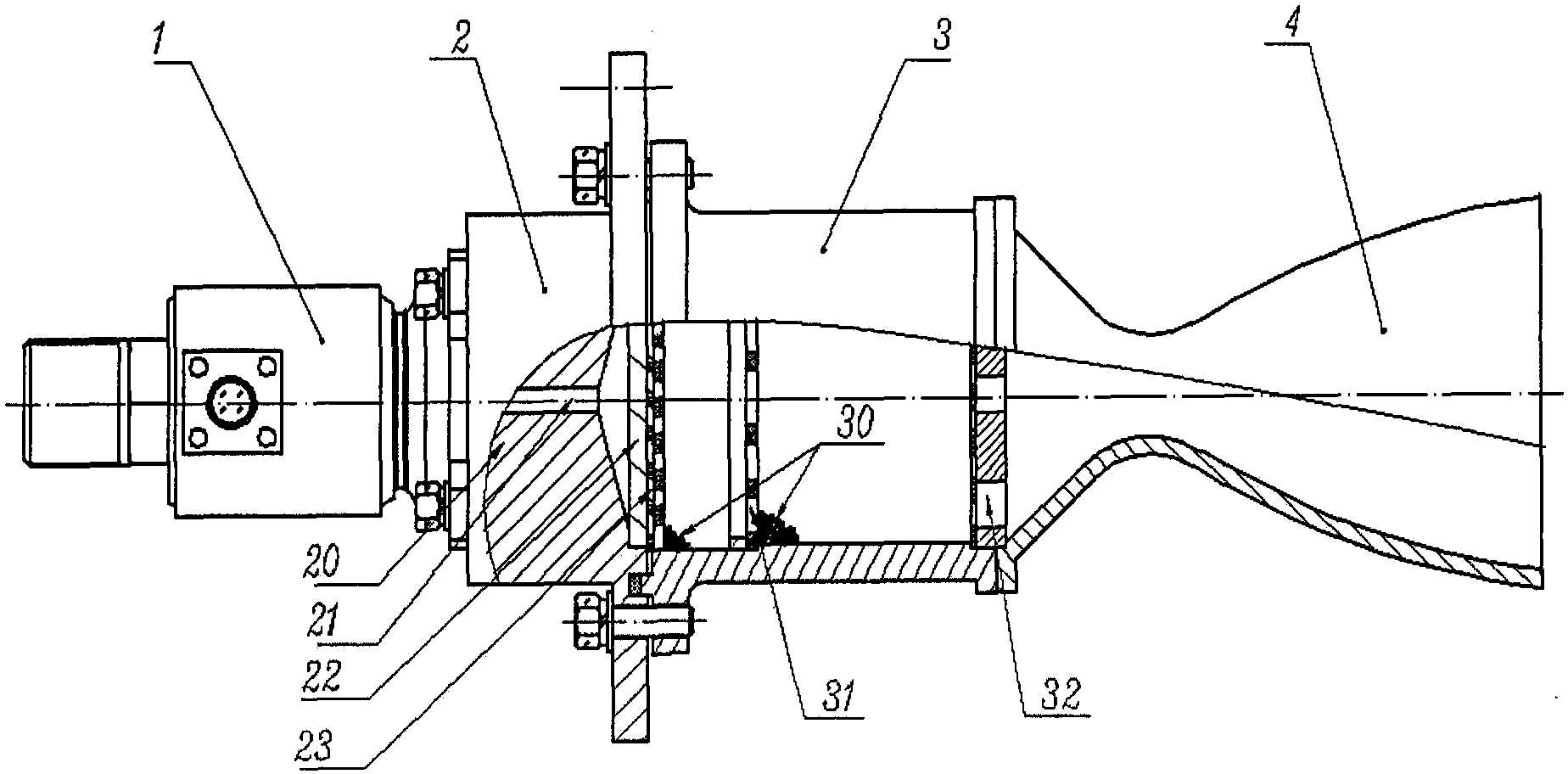

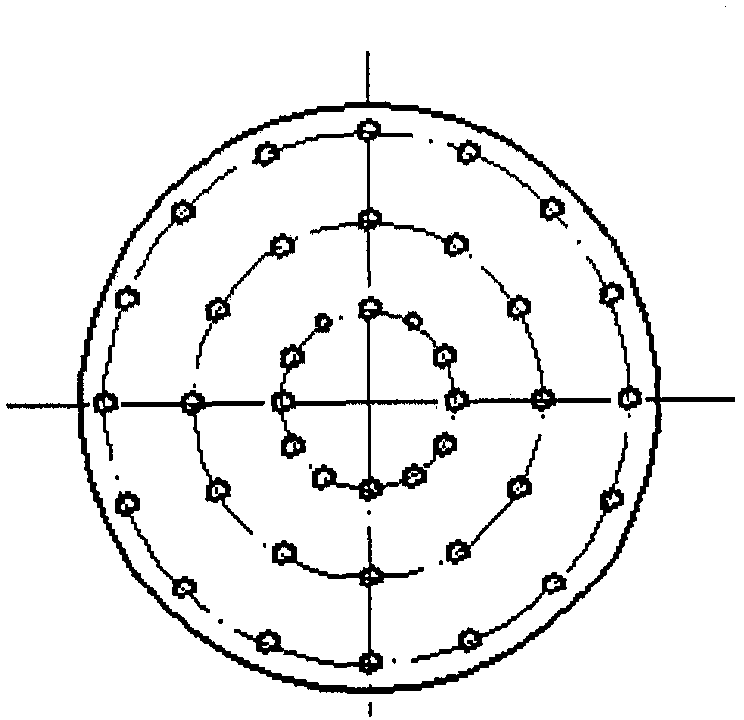

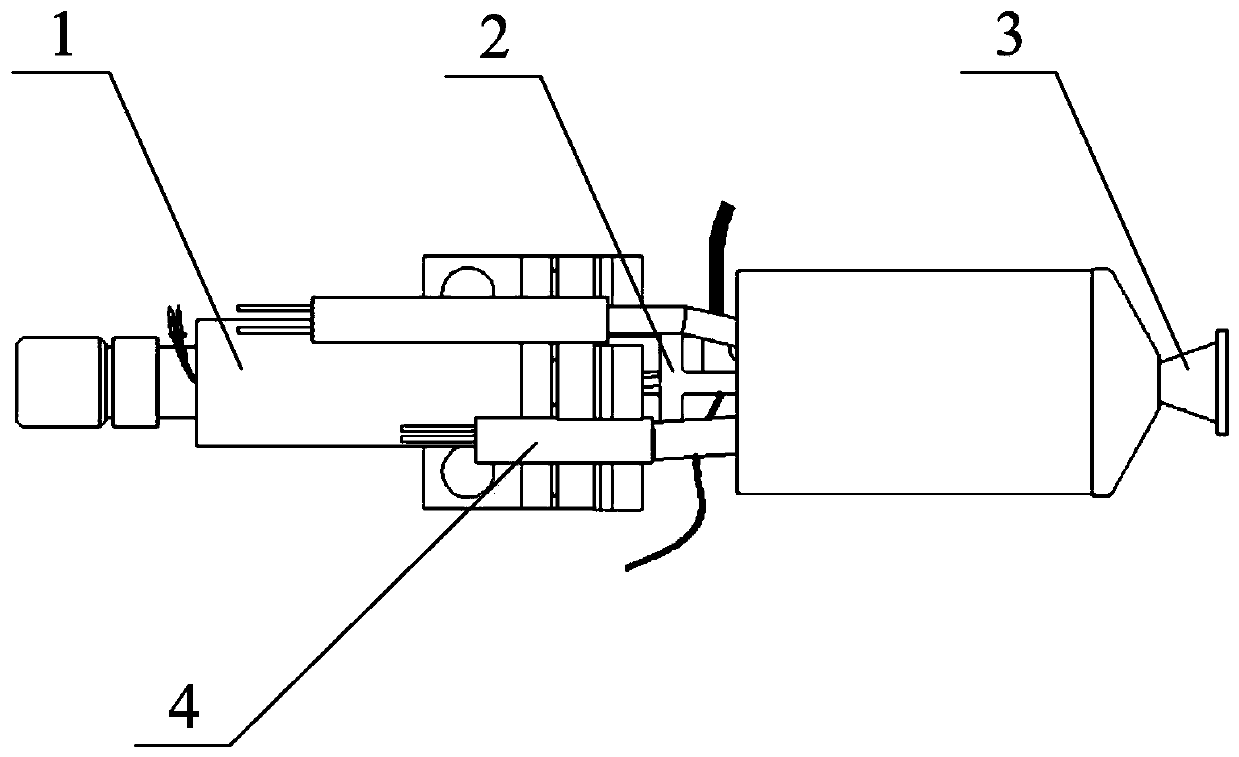

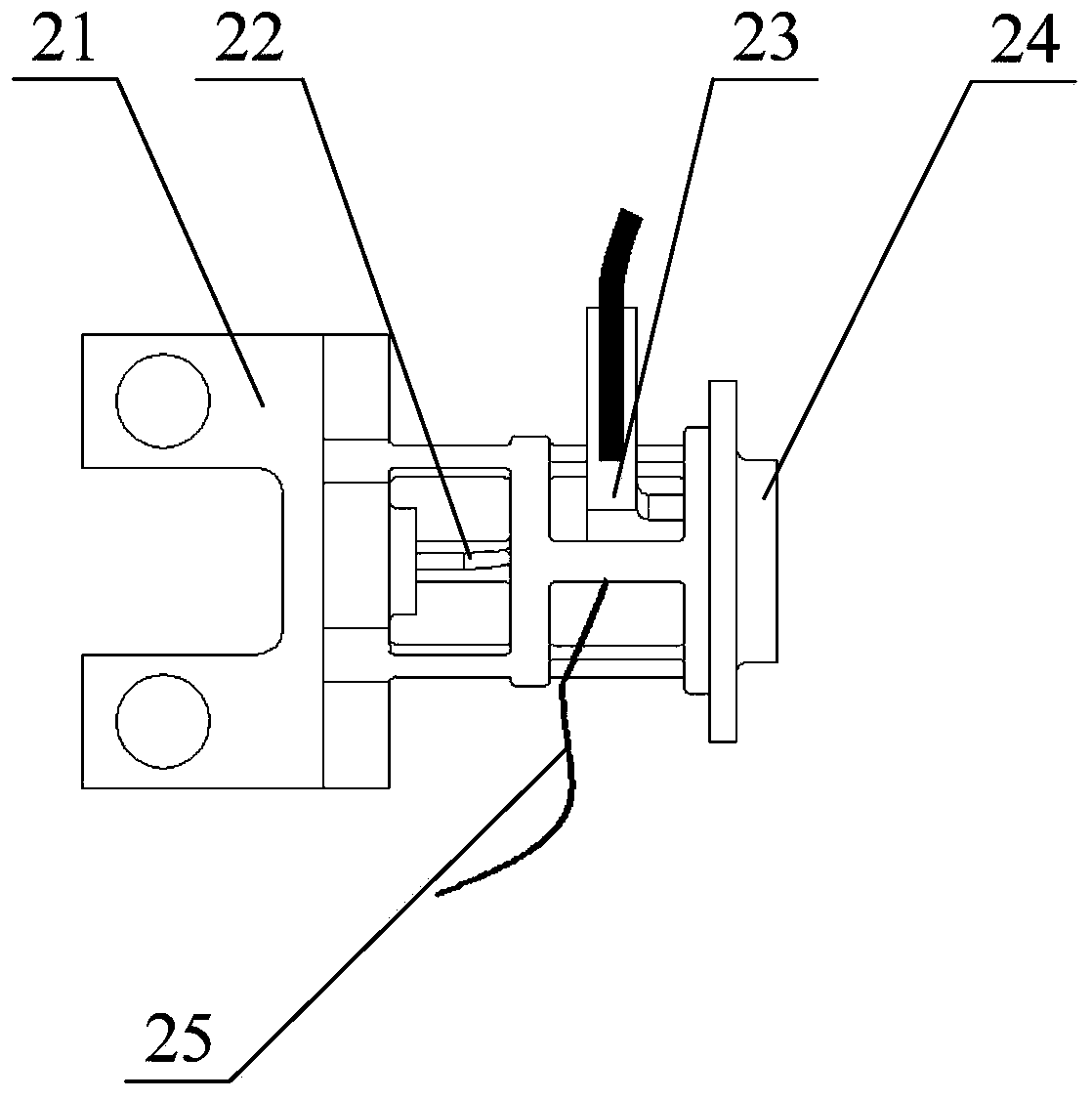

Low-thrust single-component hydrogen peroxide rocket engine

InactiveCN106134393BStable decompositionEfficient decompositionRocket engine plantsHigh concentrationHydrazine compound

The invention discloses a small-thrust single-component hydrogen peroxide rocket engine applied to space vehicles and aircrafts, which comprises a solenoid valve, an injector, a catalytic decomposition chamber and a nozzle connected in sequence. The solenoid valve delivers hydrogen peroxide to the injector. The hydrogen peroxide is transported through the injector and injected into the catalytic decomposition chamber. Under the action of the catalyst, it is decomposed into high-temperature and high-pressure gas, and then discharged from the nozzle to generate thrust. The invention uses high-concentration hydrogen peroxide as the propellant of the single-component attitude control rocket engine, which can replace the existing conventional toxic hydrazine single-component propellant, and achieves the beneficial effect of making the single-component attitude control engine non-toxic.

Owner:SHANGHAI INST OF SPACE PROPULSION

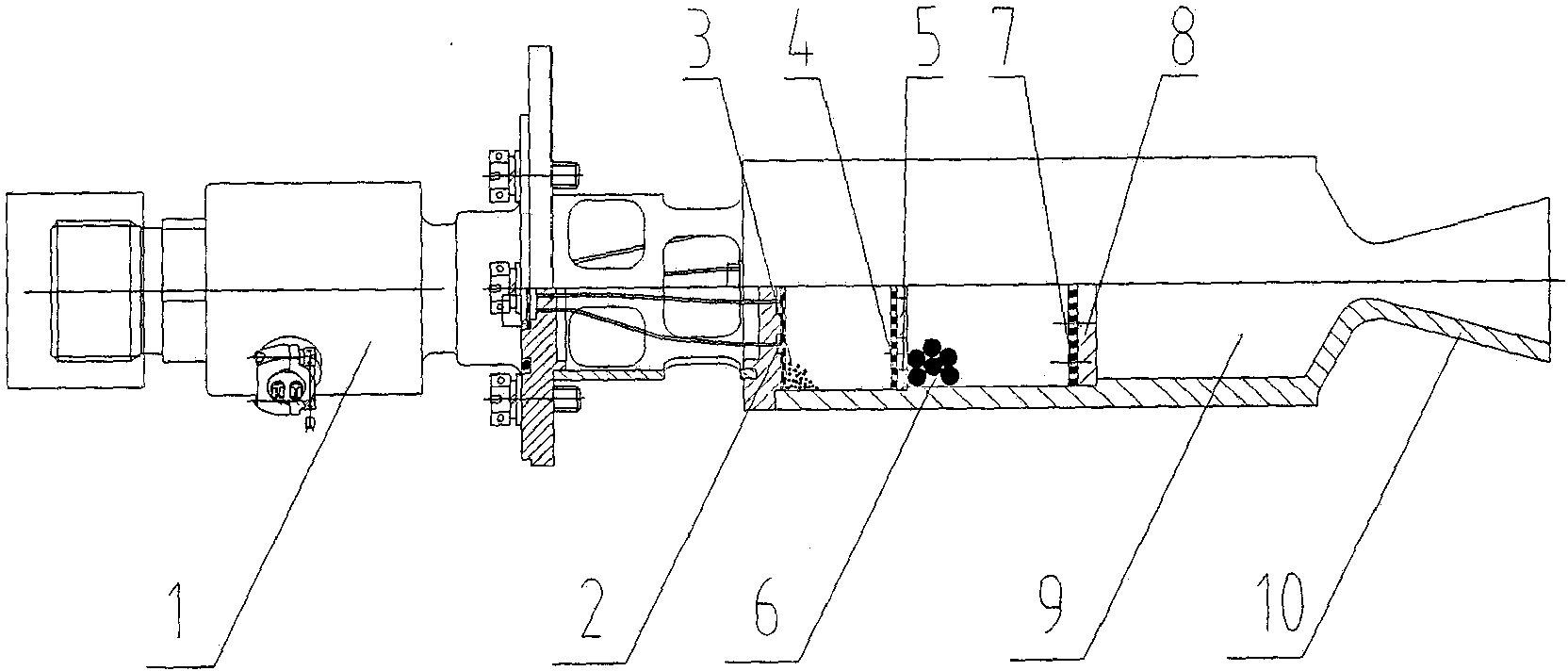

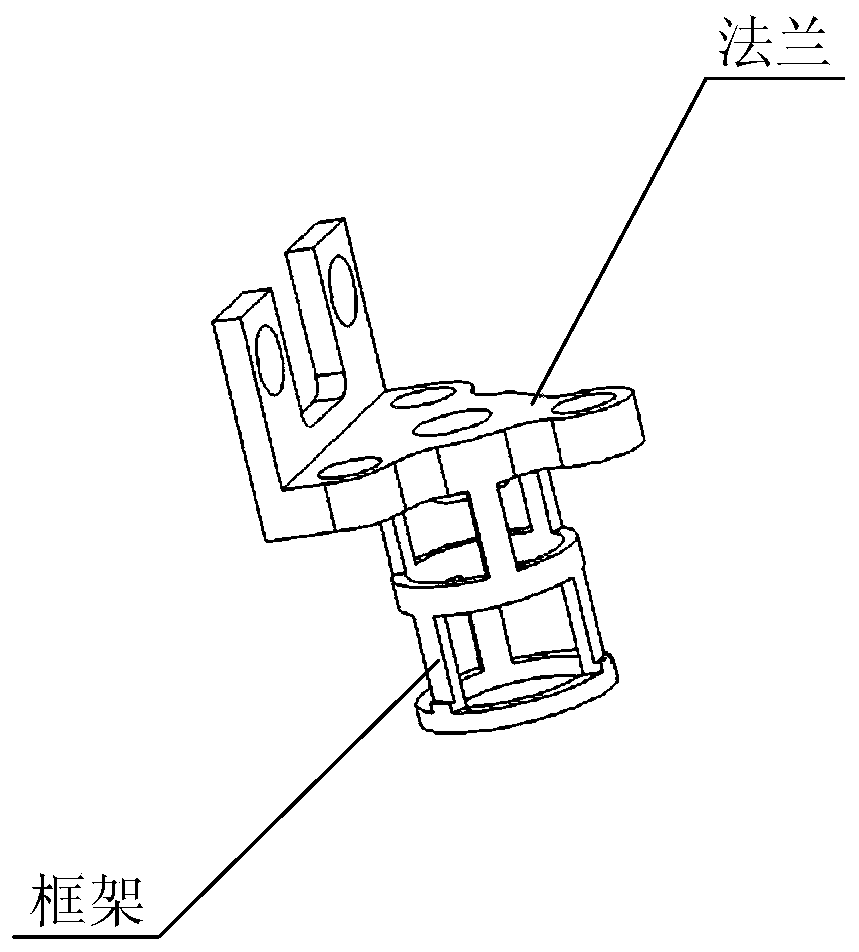

A monocomponent engine with non-toxic unit propellant

The invention proposes a non-toxic unit propellant single component engine, the engine is composed of a thrust chamber and a solenoid valve, and the thrust chamber is composed of an injector and a body. The body consists of two layers of catalytic beds and combustion chambers. The catalytic bed uses fine-grained catalysts for the front bed and coarse-grained catalysts for the rear bed. The active component of the catalyst used is metal iridium, and the iridium content is between 5% and 35%. There is a combustion chamber behind the catalytic bed. A coated refractory metal mesh and a coated refractory metal porous plate exist between the front and rear catalytic beds and between the catalytic bed and the combustion chamber. The solenoid valve is opened, and the non-toxic unit propellant is ejected from the injector, and is catalytically decomposed by the catalytic bed, and the decomposition product and the fuel of the propellant are burned in the combustion chamber, and then enter the nozzle to generate thrust. The problem of the combustion temperature and engine structure layout of the non-toxic unit propellant in the single-unit engine propellant is solved, and the expected effect of stable and reliable decomposition and combustion of the non-toxic unit structure propellant is achieved.

Owner:SHANGHAI INST OF SPACE PROPULSION

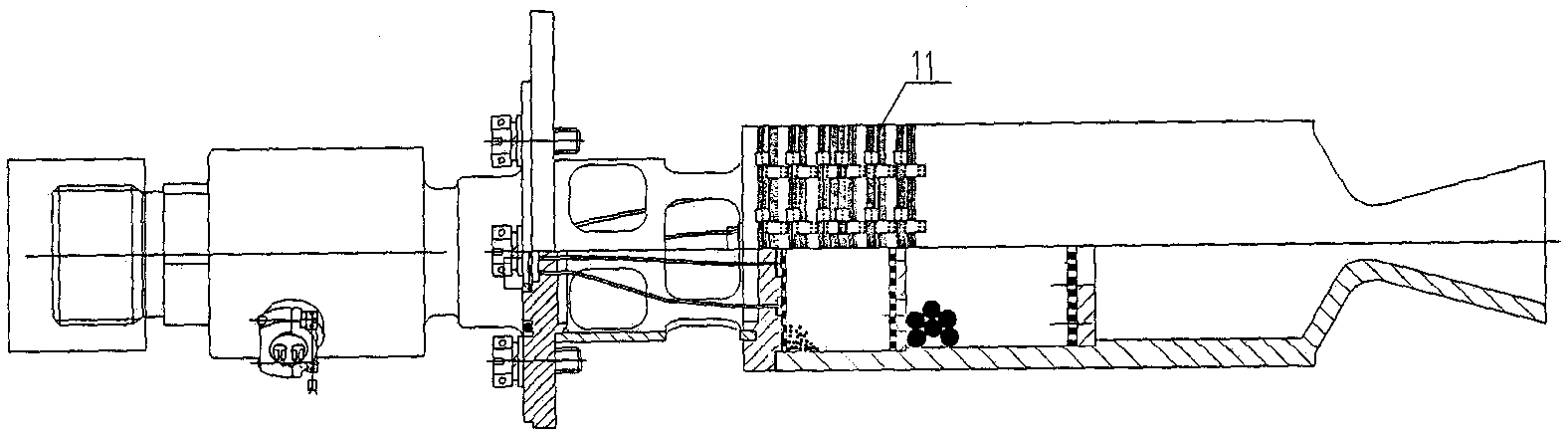

Family of modifiable high performance electrically controlled propellants and explosives

ActiveUS8888935B2Improve simplicityLow costNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsElectricityAmbient pressure

A composition capable of producing either solid propellant grains, liquid or gel monopropellants, all of which are electrically ignitable and capable of sustained controllable combustion at ambient pressure. Additional compositions capable of sustained controllable combustion at elevated pressures are described. Applications for the compositions disclosed herein are provided, and include among other applications use in small micro thrusters, large core-burning solid propellant gains, shaped explosives charges for military application, and pumpable liquids and gel monopropellants or explosives for military, commercial mining or gas and oil recovery. In alternative embodiments the above compositions may also incorporate an energetic nitrate polymer, bum rate modifiers, and / or metal fuel(s). The HIPEP formulation makes it possible to ignite and sustain combustion at ambient and vacuum conditions (a) without continuous electrical power and (b) while providing faster bum rates.

Owner:DIGITAL SOLID STATE PROPULSION

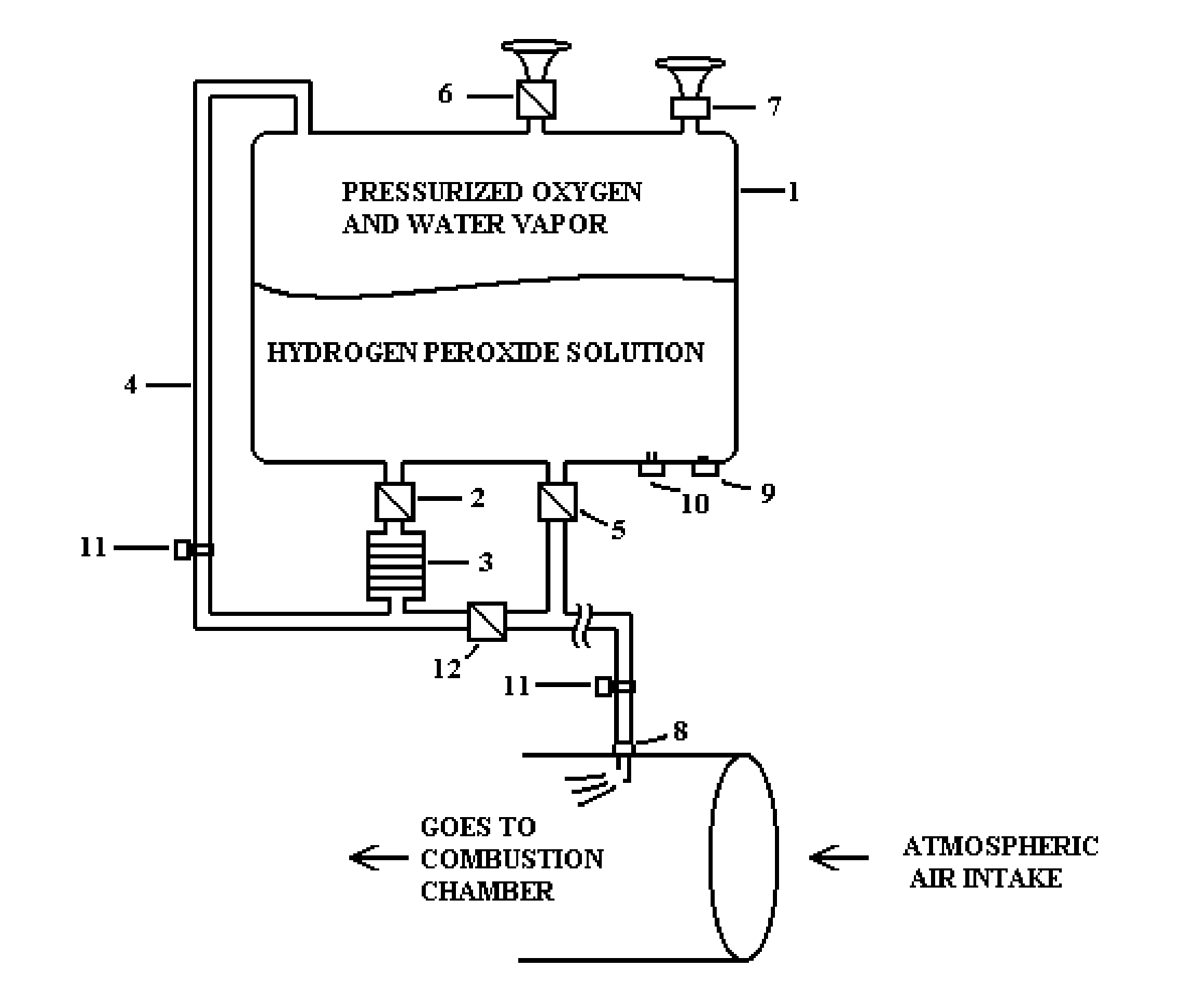

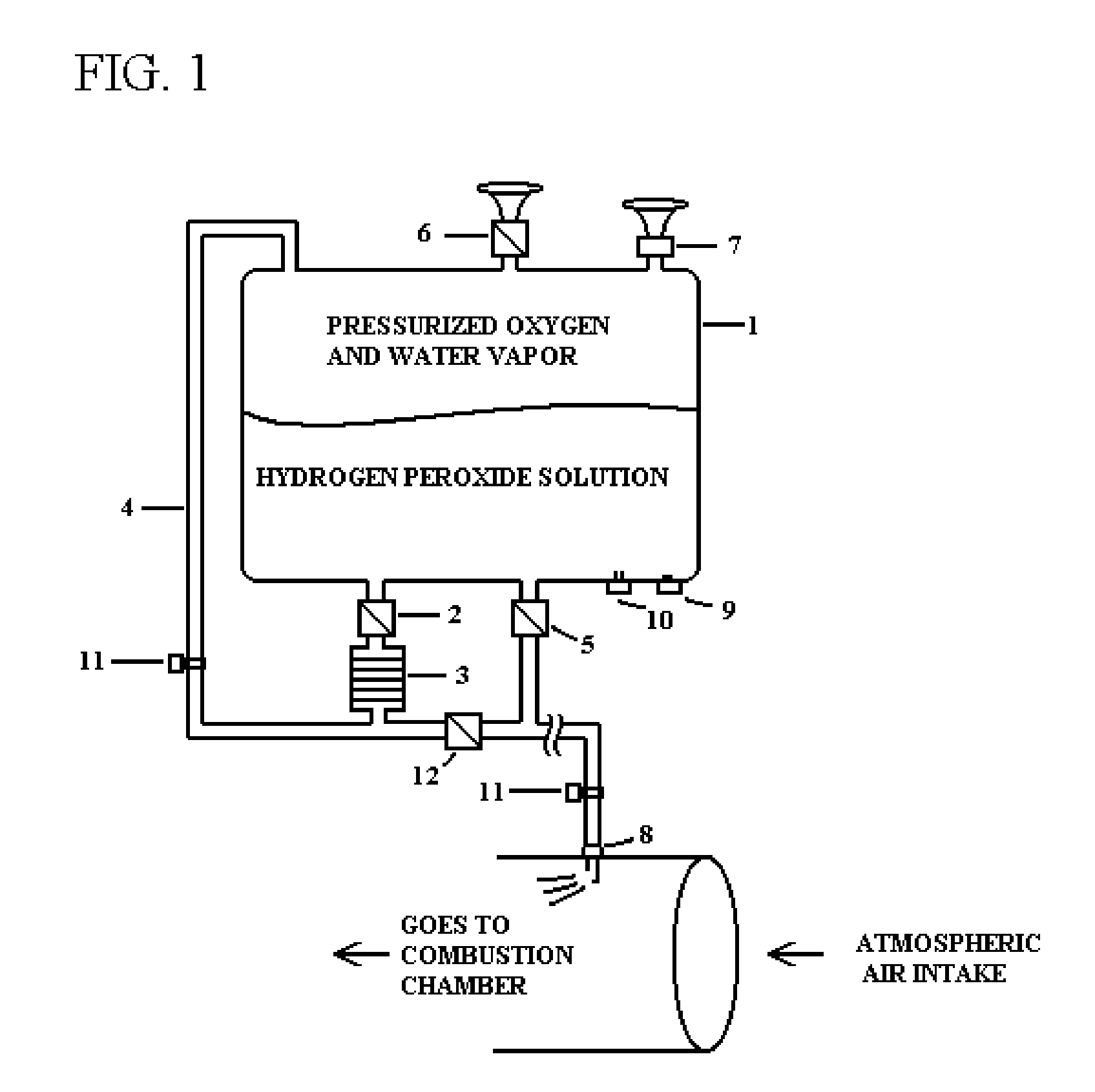

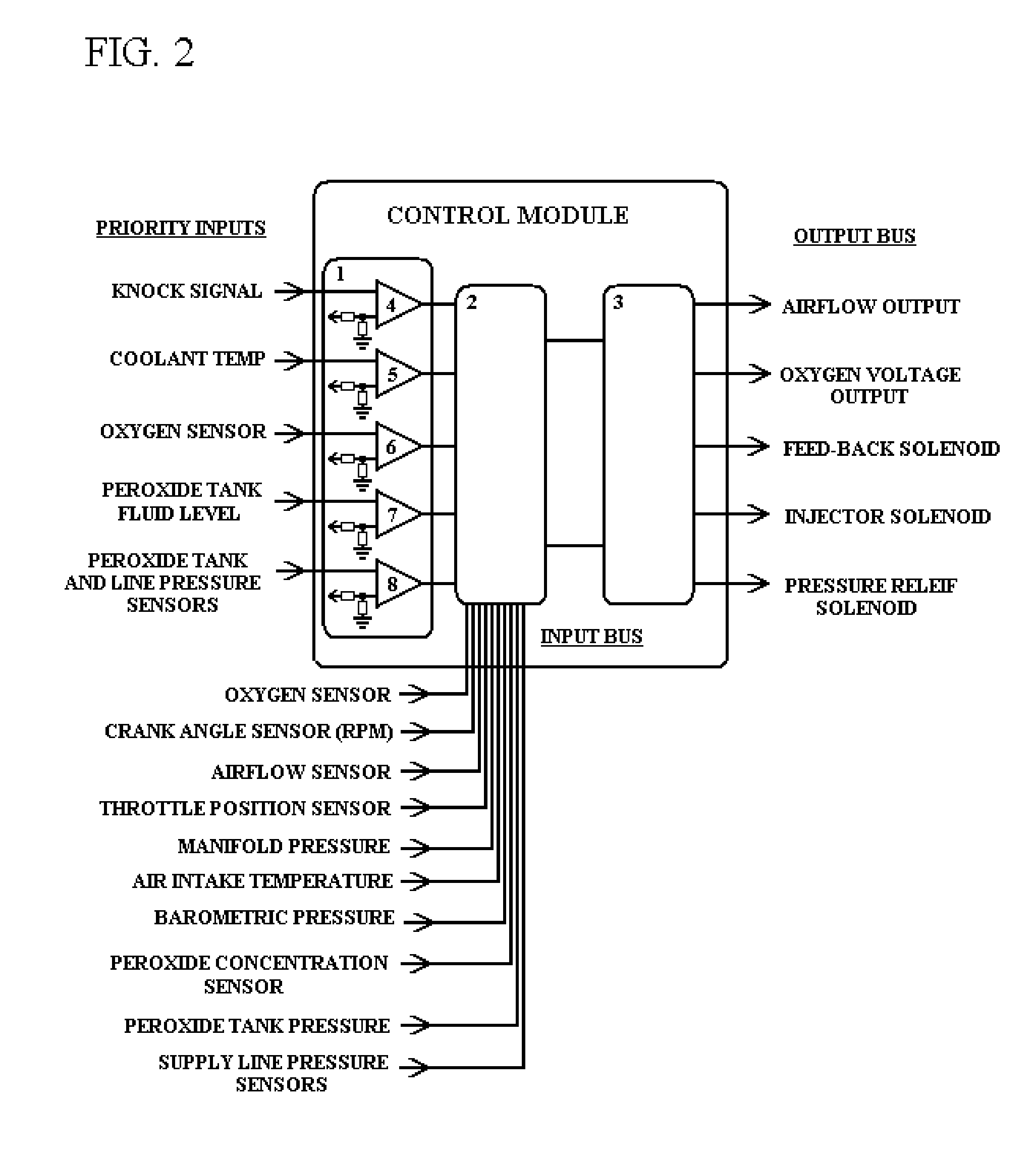

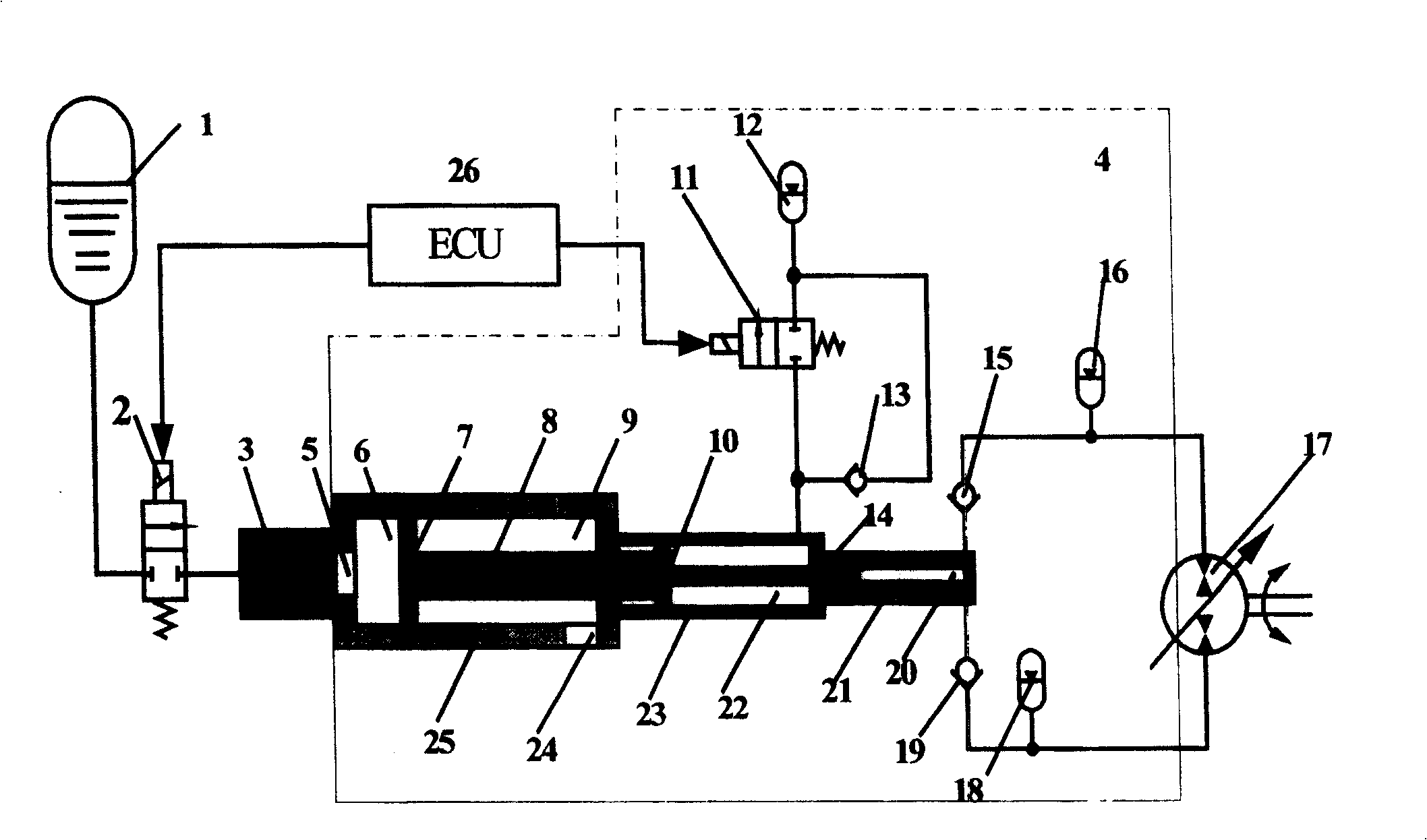

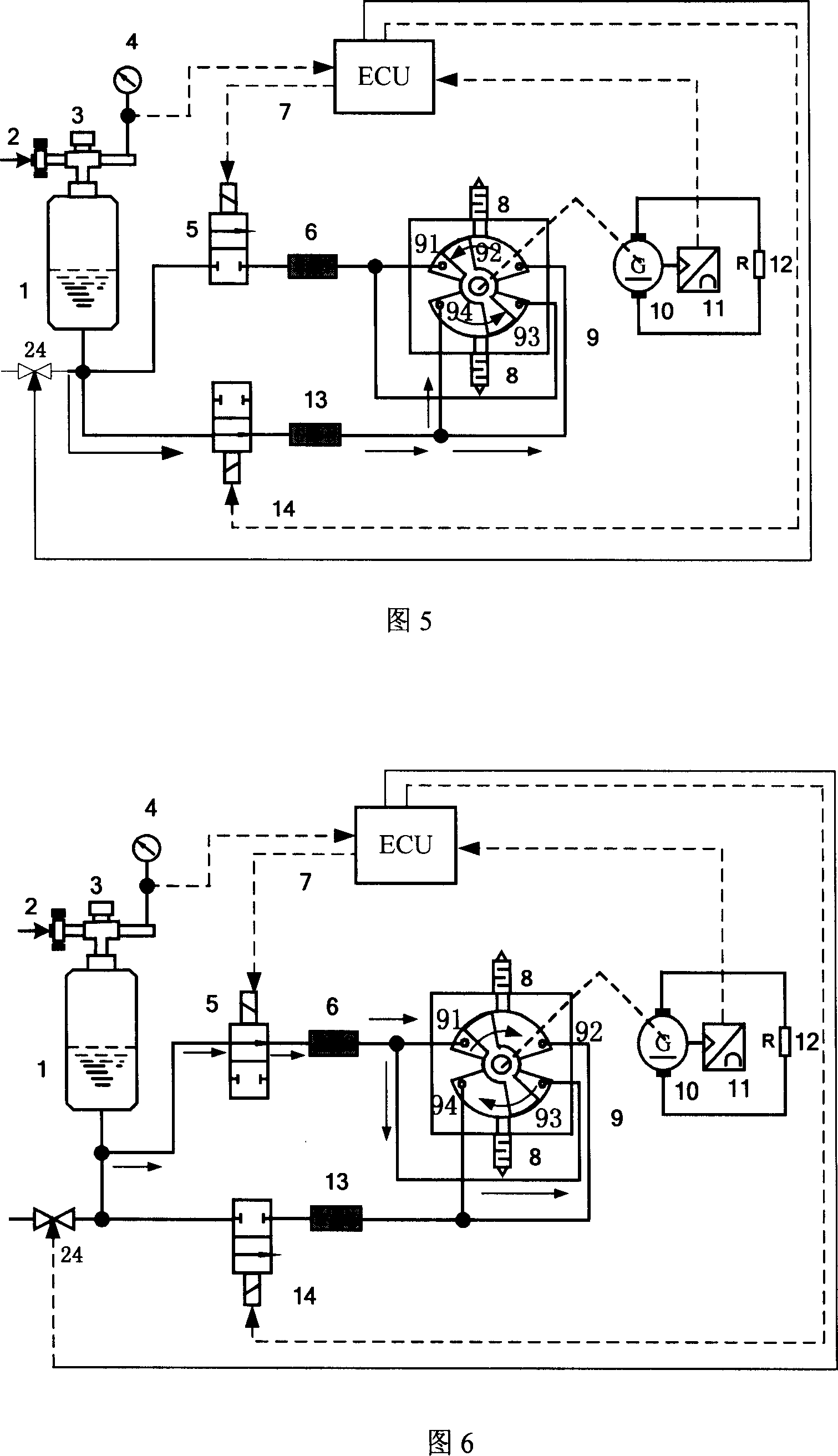

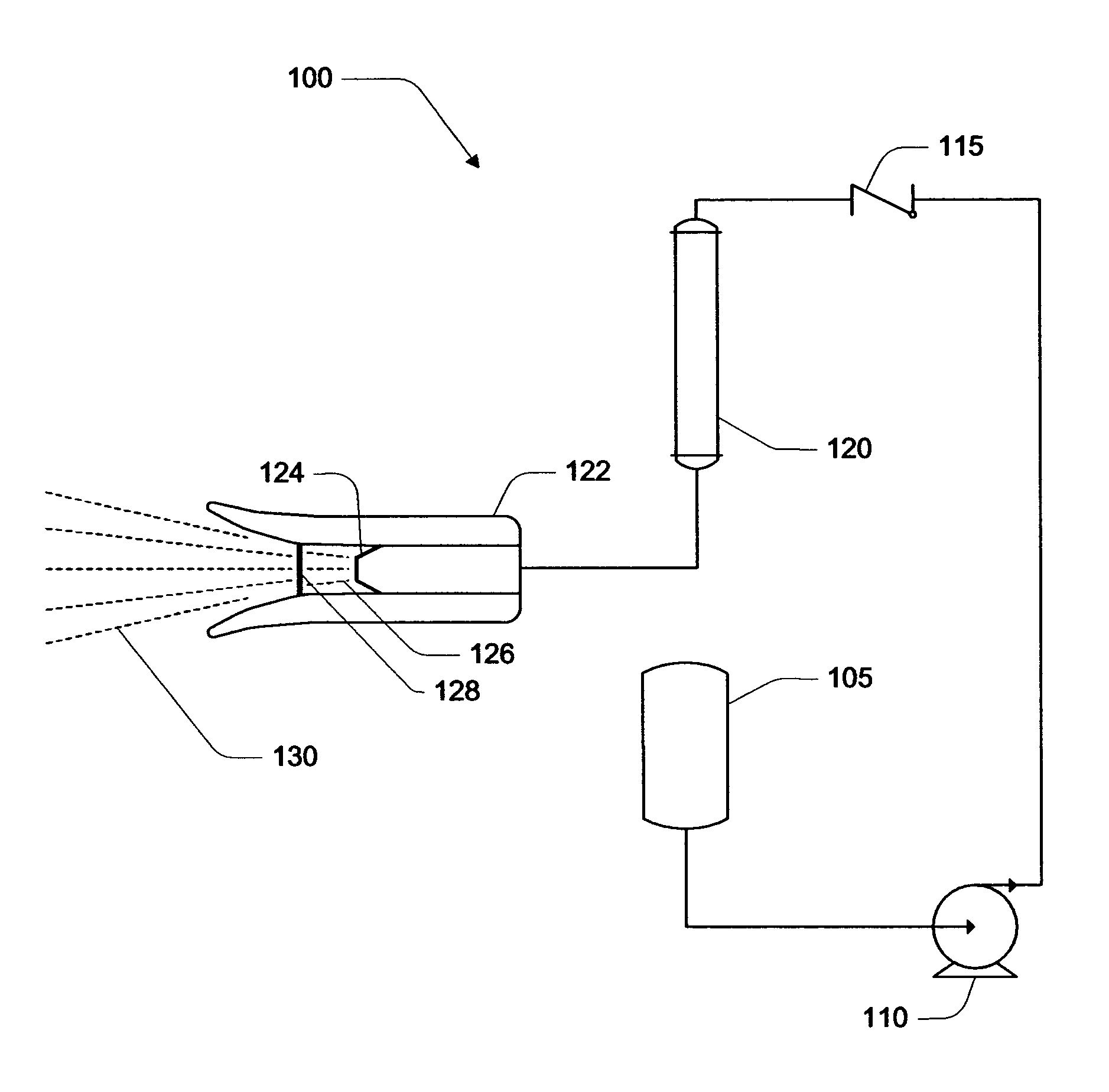

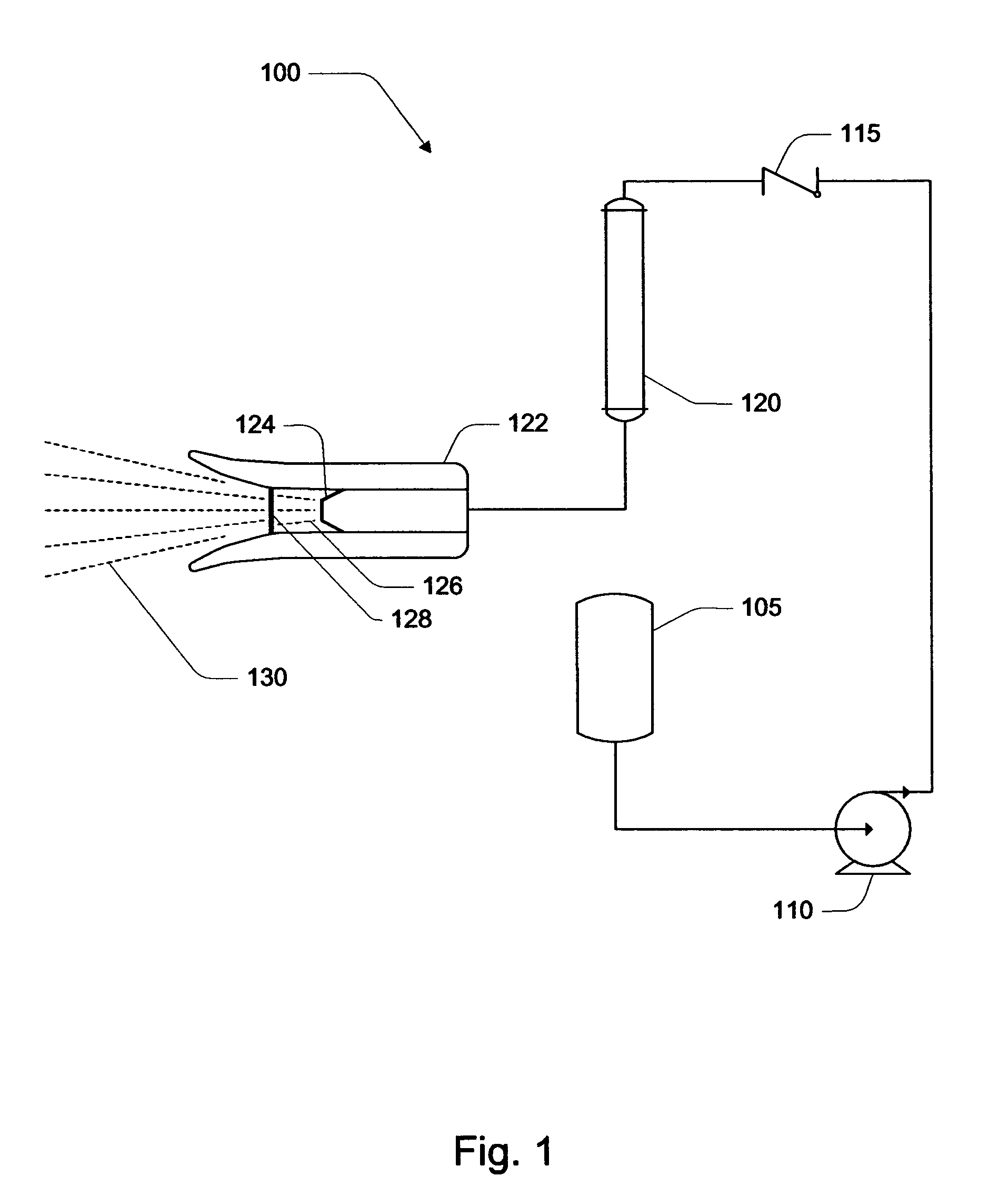

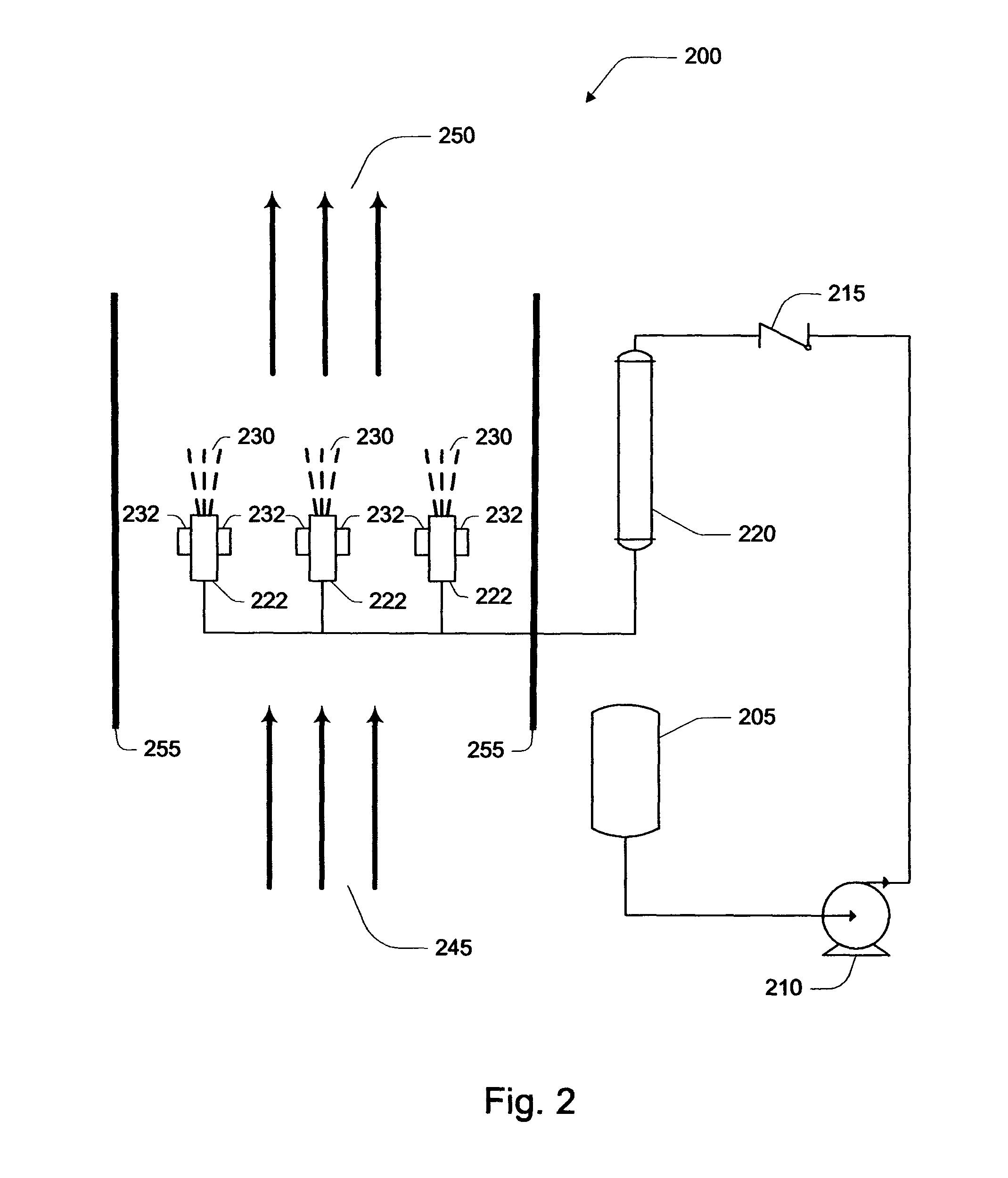

Hydrogen peroxide injection engine and combustion fuel supplamentation

InactiveUS20070084423A1Easy maintenancePromote repairNon-fuel substance addition to fuelInternal combustion piston enginesSystems designCatalytic decomposition

This invention is a electronic and mechanical system that comprises of several sub-systems which carries out a new method of using different concentrations of self-propelled hydrogen peroxide-based solutions for direct propulsion in engines designed to use only gas pressure as energy or the system may act as a fuel supplement in existing combustion engines, by manipulating existing oil-based fuel engine's sensor signals to give the system the ability to make the engine run much leaner conditions, or inject less fuel while simultaneously injecting varying concentrations of hydrogen peroxide / water / alcohol solution, consequently saving gas by lowering intake temperatures to reduce the occurrence of knock and exploiting this reduction in temperature by reducing the amount of fuel needed by the engine at all engine running ranges. Standard mechanical pump fluid injection is not new and neither is pressurized propellant system designs, but this system becomes vary abstract when analyzing its method of using an essential, non-cryogenic, safe, self-propelled liquid monopropellant, in hydrogen peroxide; one of the best natural heat absorbers, in water, and releasing the potential of the hydrogen peroxide catalytic decomposition affect in a method of controlled decomposition pressurization within a feed-back loop while adding oxygen to combustion, and the water as a supplement to reduce excess heat in an engine. The system uses a self-pressurizing, concentration-monitoring, high purity stainless steel or aluminum peroxide storage tank which when used in conjunction with a metallic screen catalytic feed-back loop provides pressurized hydrogen peroxide-based solution to the injection solenoid, and when the solenoid is open allows pressurized water and oxygen to the injectors and into an engine. This system allows for a non-cryogenic, safe, non-polluting fuel source for many applications which will only produce water and oxygen, when used as hydrogen peroxide / water for a purely pressure engine, or significantly reduces fuel consumption in piggy-backed hybrid configurations using varying concentrations of hydrogen peroxide, water, alcohol and other fuels for use in the supplementation of combustion in existing fossil fuels engines. Retrofitting this system into existing gasoline, diesel and other fossil fuel engines will be very low cost, since it can intercept most of the factory sensor signals and send manipulated signals to the existing factory ECM inputs to allow the system to change the amount of injected standard fuel and adjust for the much lower intake air temperatures and extra oxygen provided by the decomposed hydrogen peroxide solution injection, while significantly reducing factory fuel system consumption the entire time that the system is actually injecting solution. No system developed has brought the benefits of all of these elements together in this manner. The level of sophistication and methods at which this system regulates itself, manipulates external fuel systems, decomposes hydrogen peroxide solutions into water and oxygen for self-pressurizing the system, and brings these elements together in a synergistic alliance with each other, all while injecting a precise amount of pressurized water and oxygen supplement to combustion events in an engine, are the truly abstract concepts behind this system. Combined with the system's easy adaptability and upgradeability should give a complete insight into the truly abstract design and methodology of this system.

Owner:LEBEAUX KELVIN

High energy thermoplastic elastomer propellant

InactiveUS6997996B1Eliminate needHigh energyLoomsExplosive working-up apparatusHigh energyPlasticizer

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

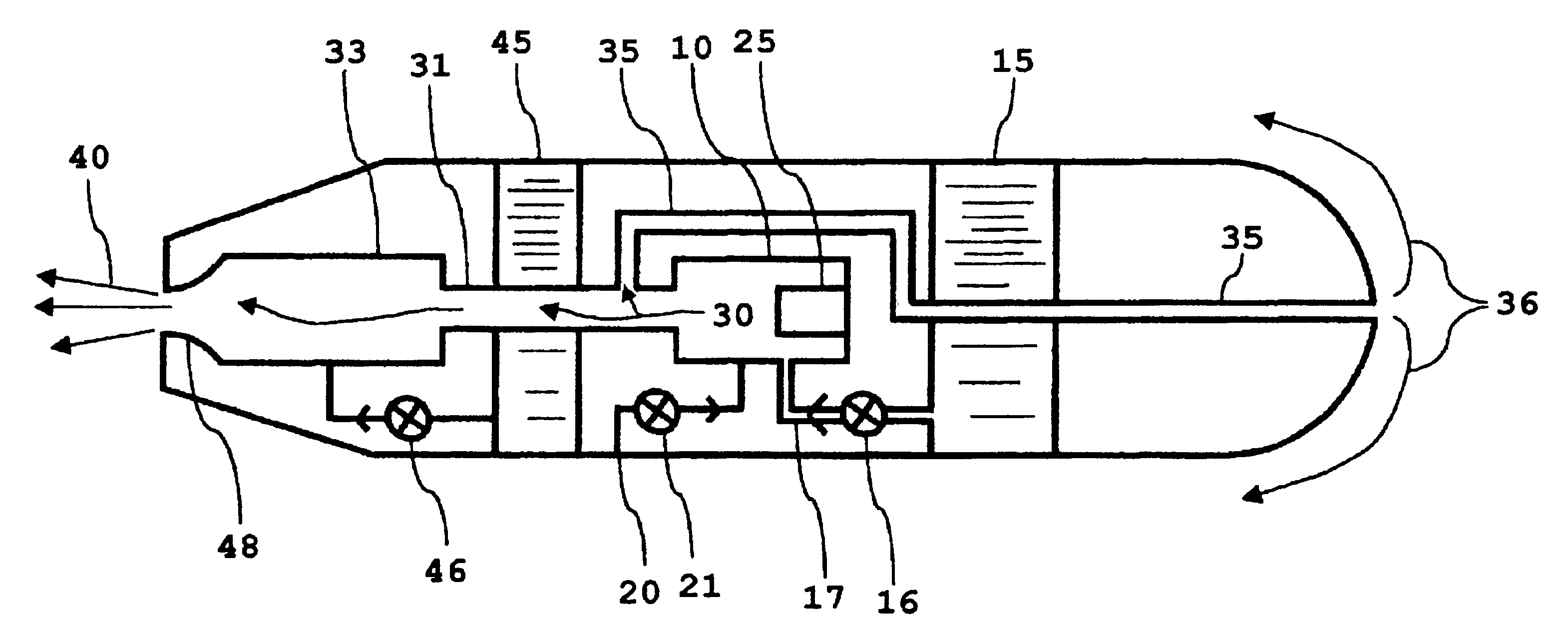

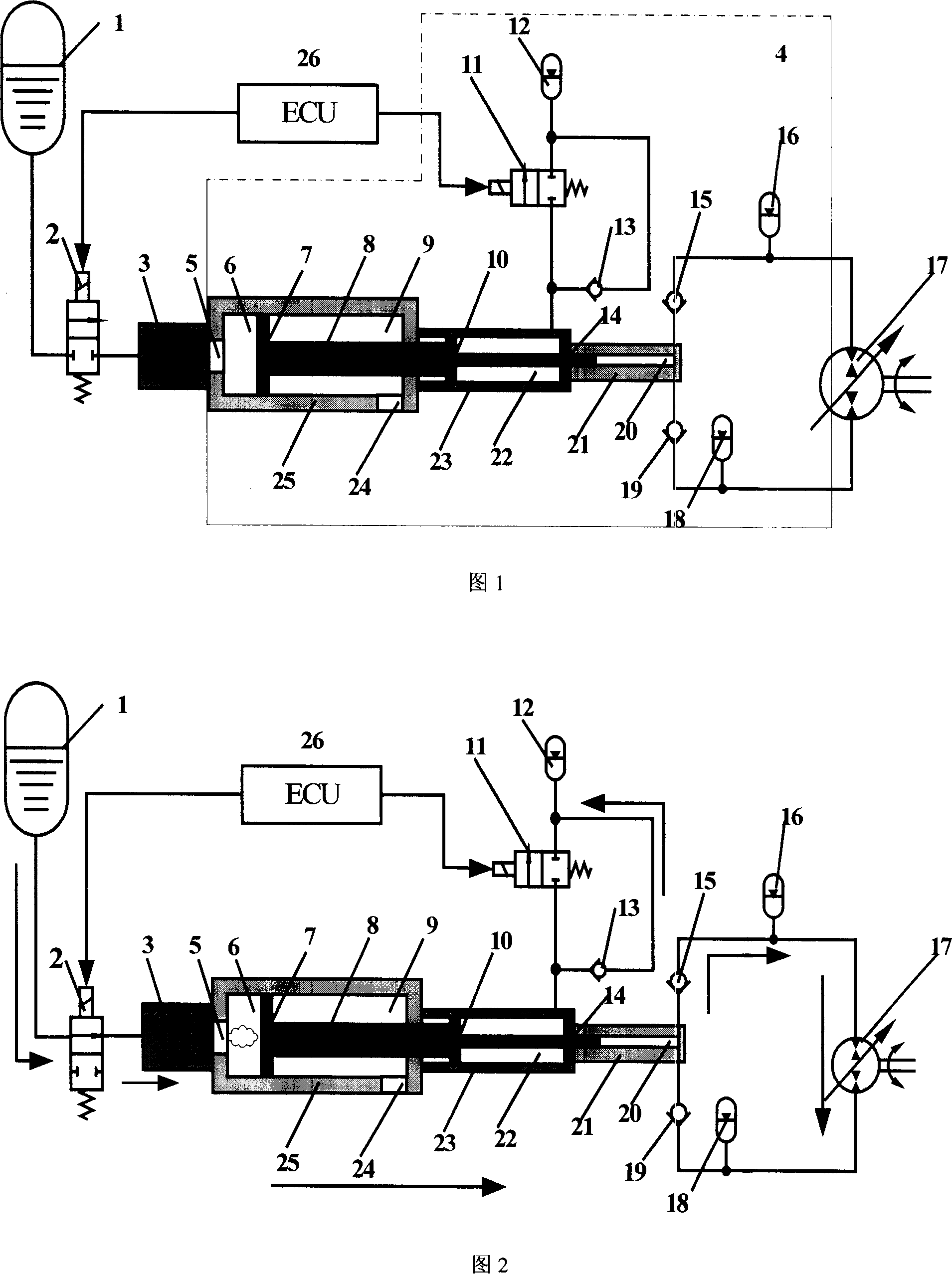

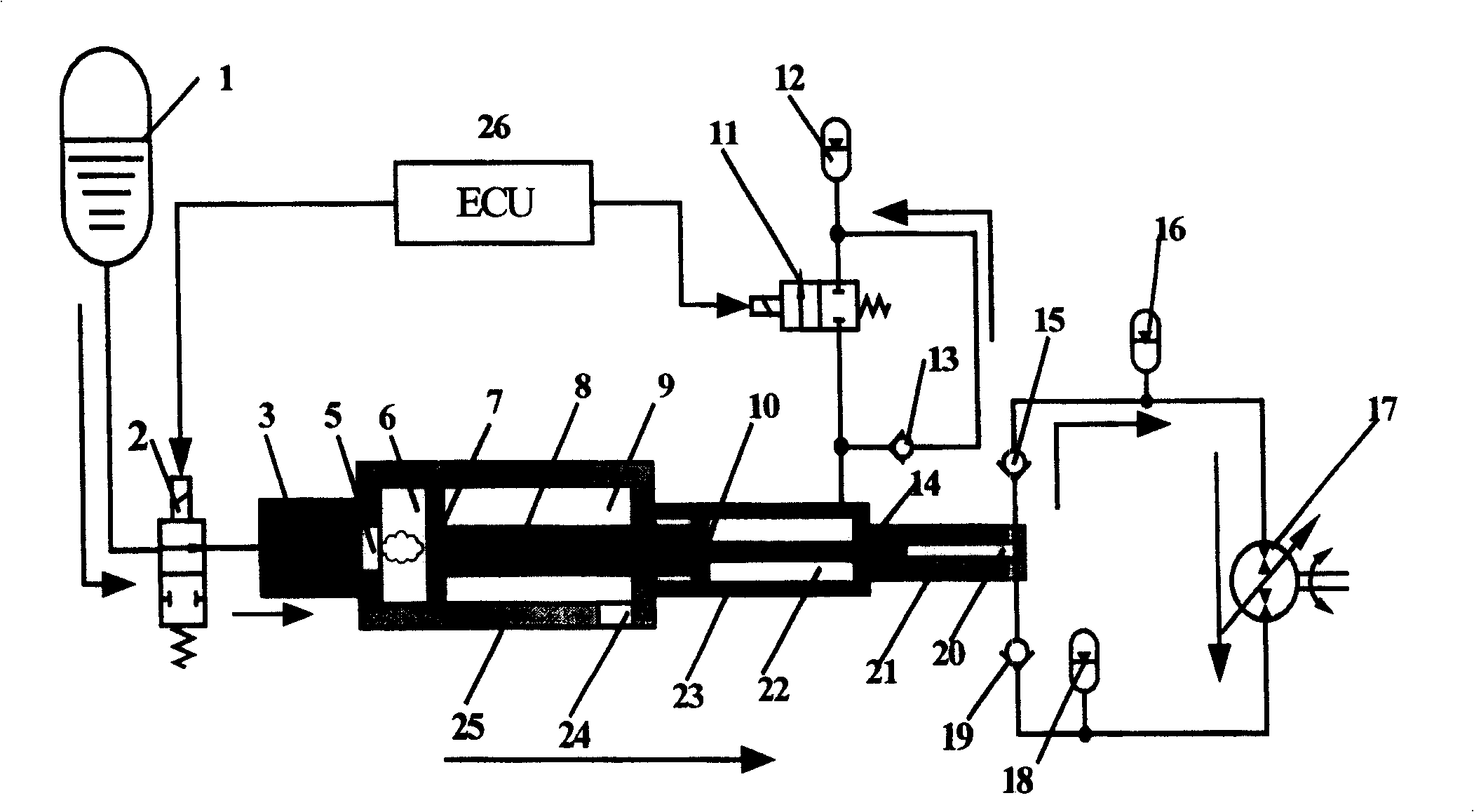

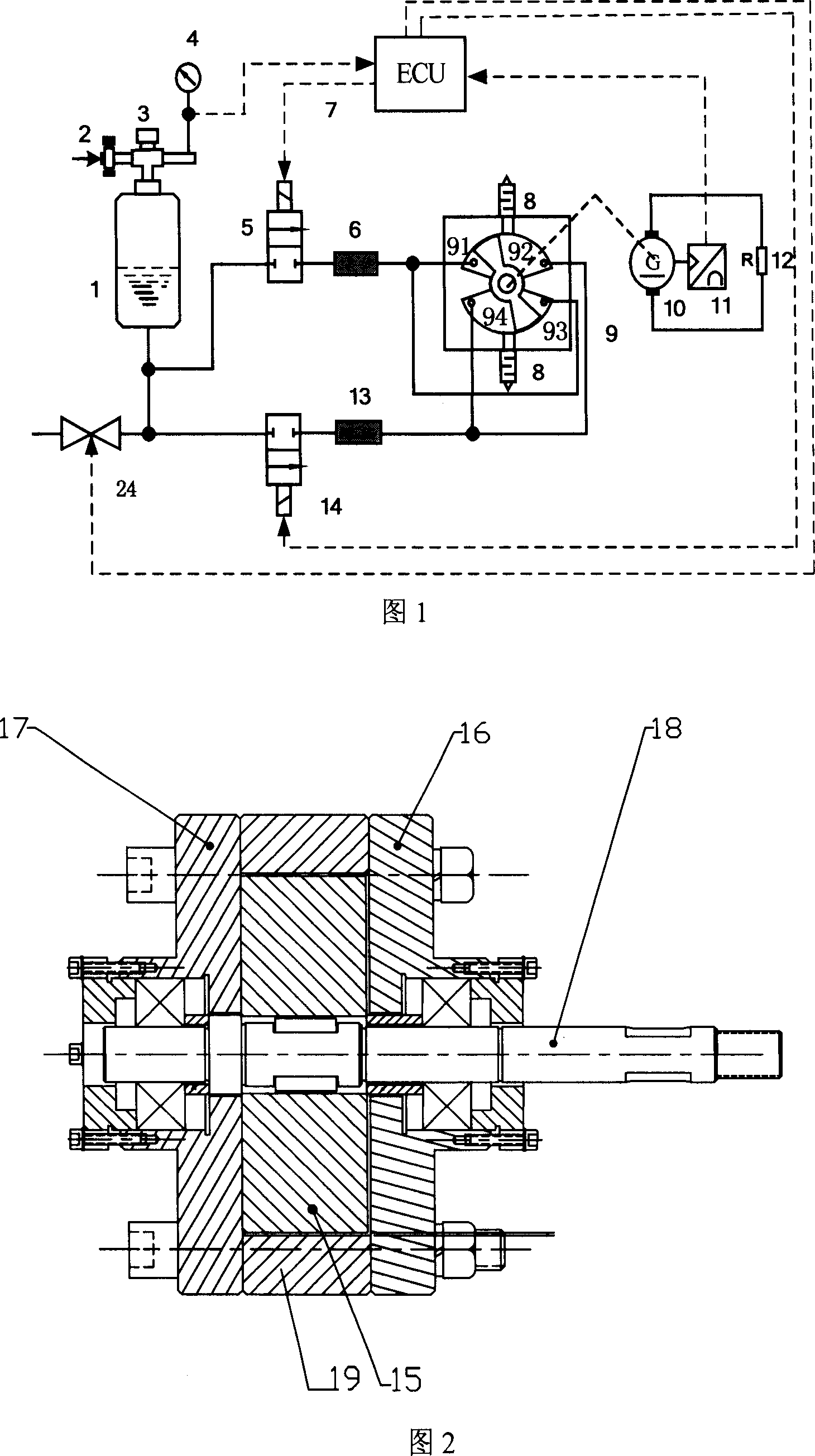

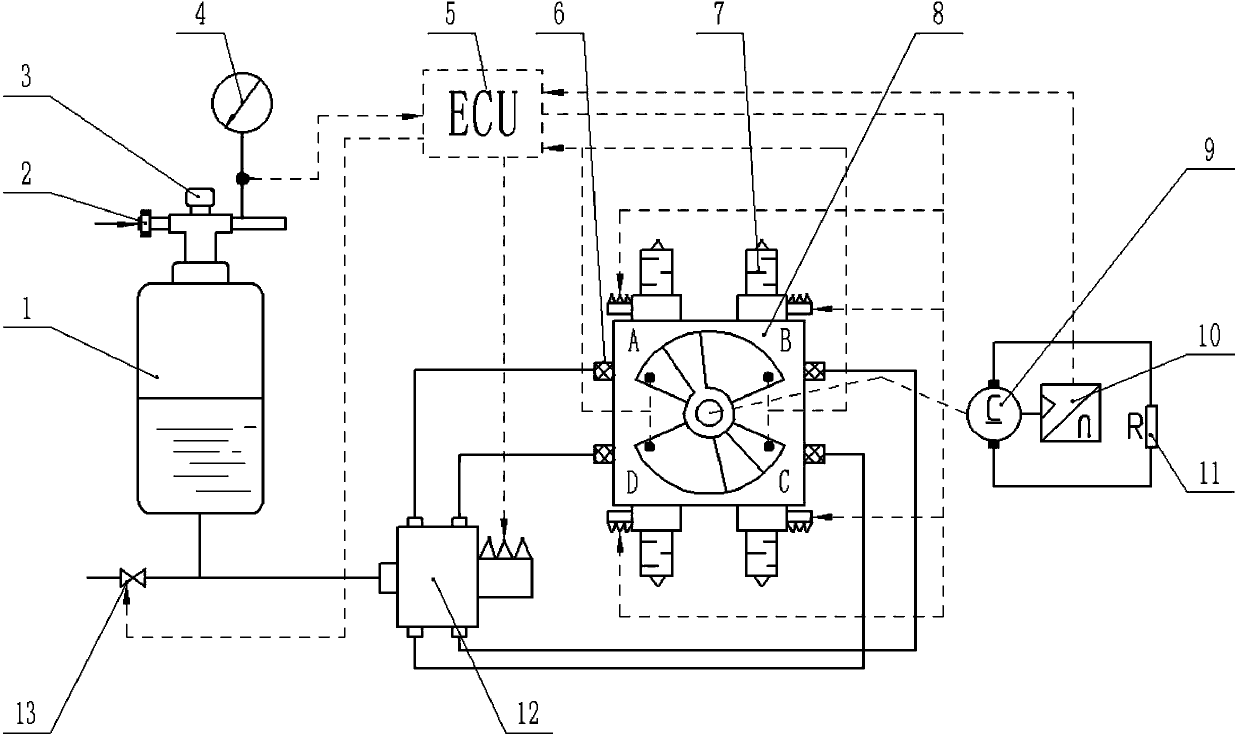

Single piston monopropellant hydraulic free piston engine

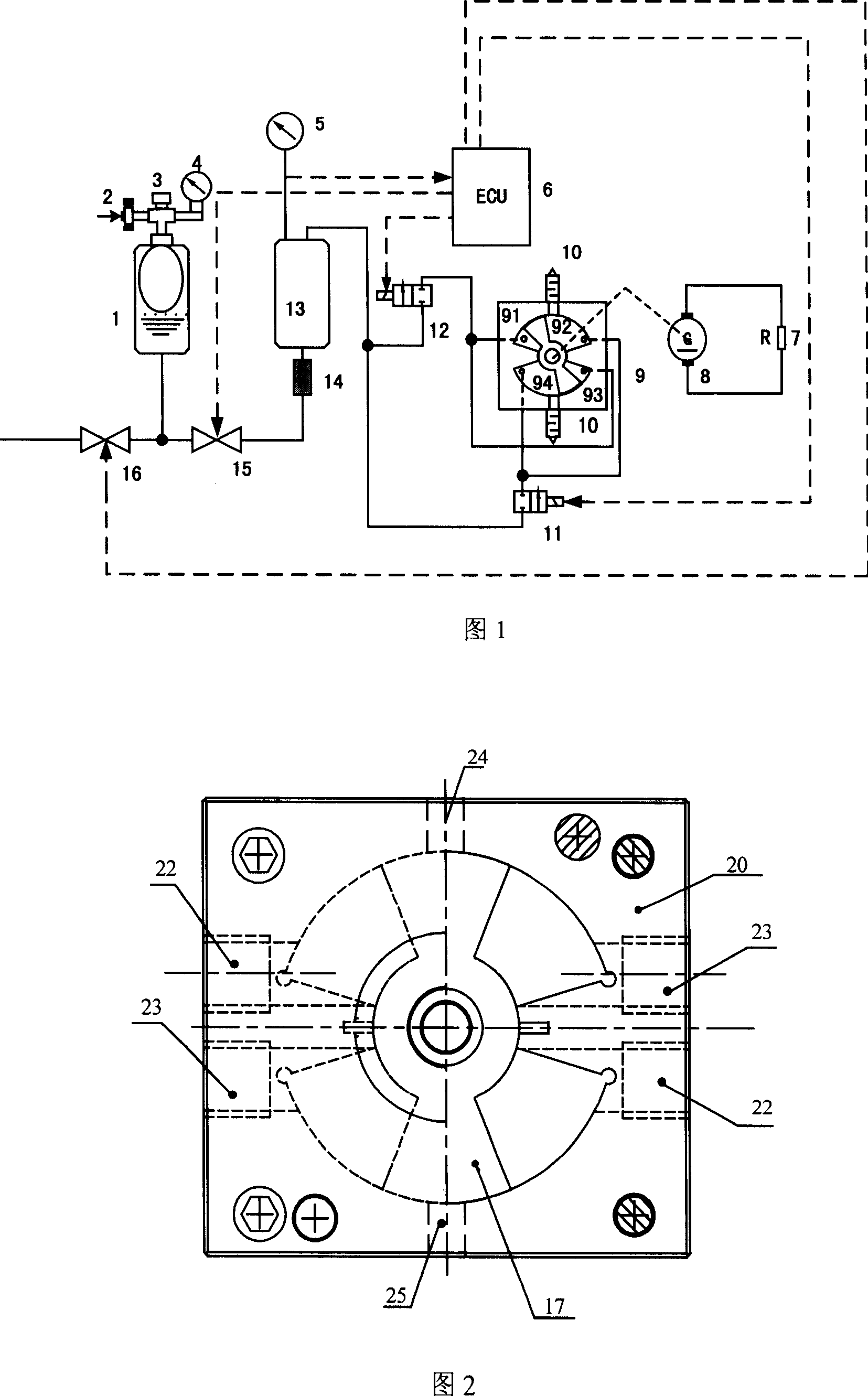

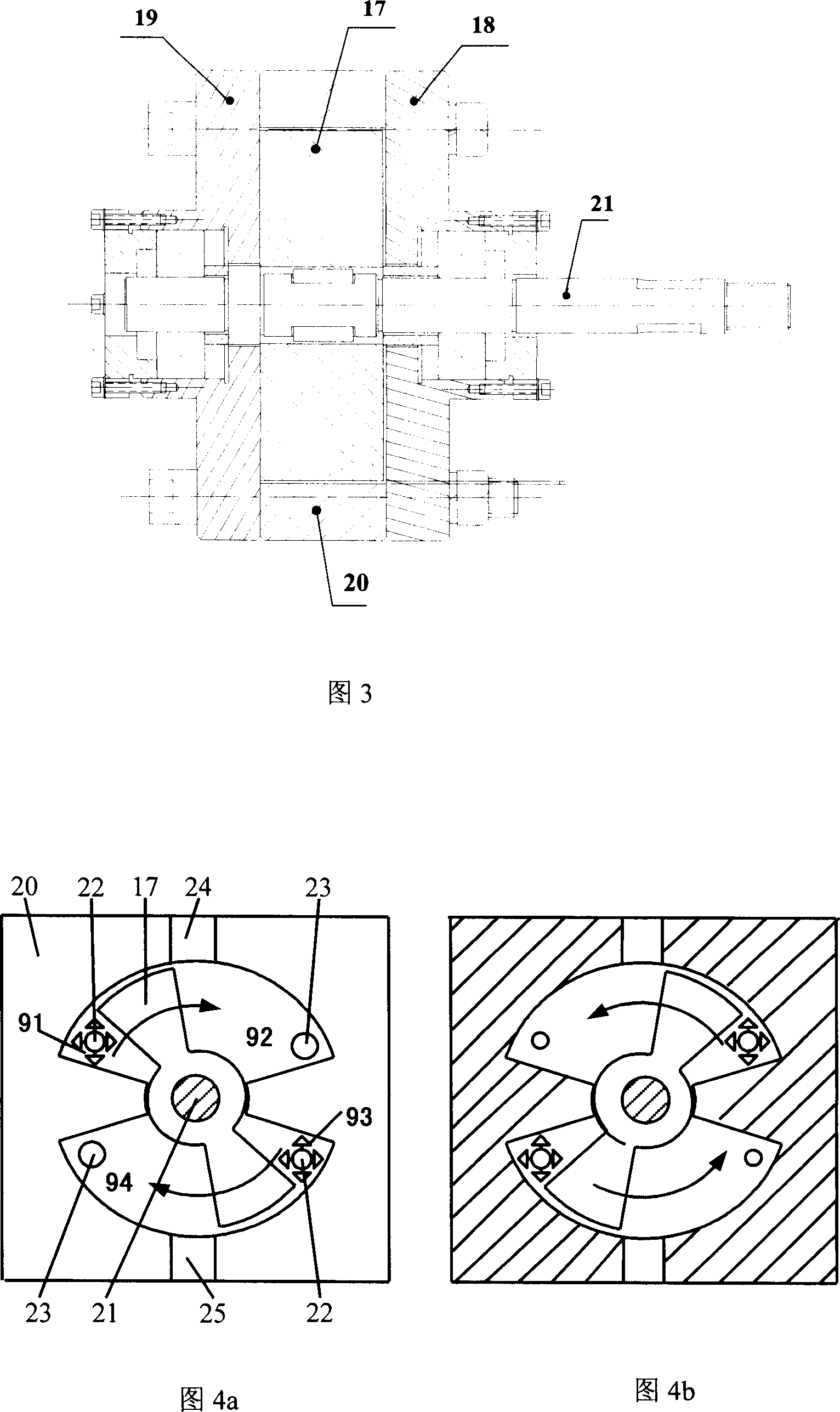

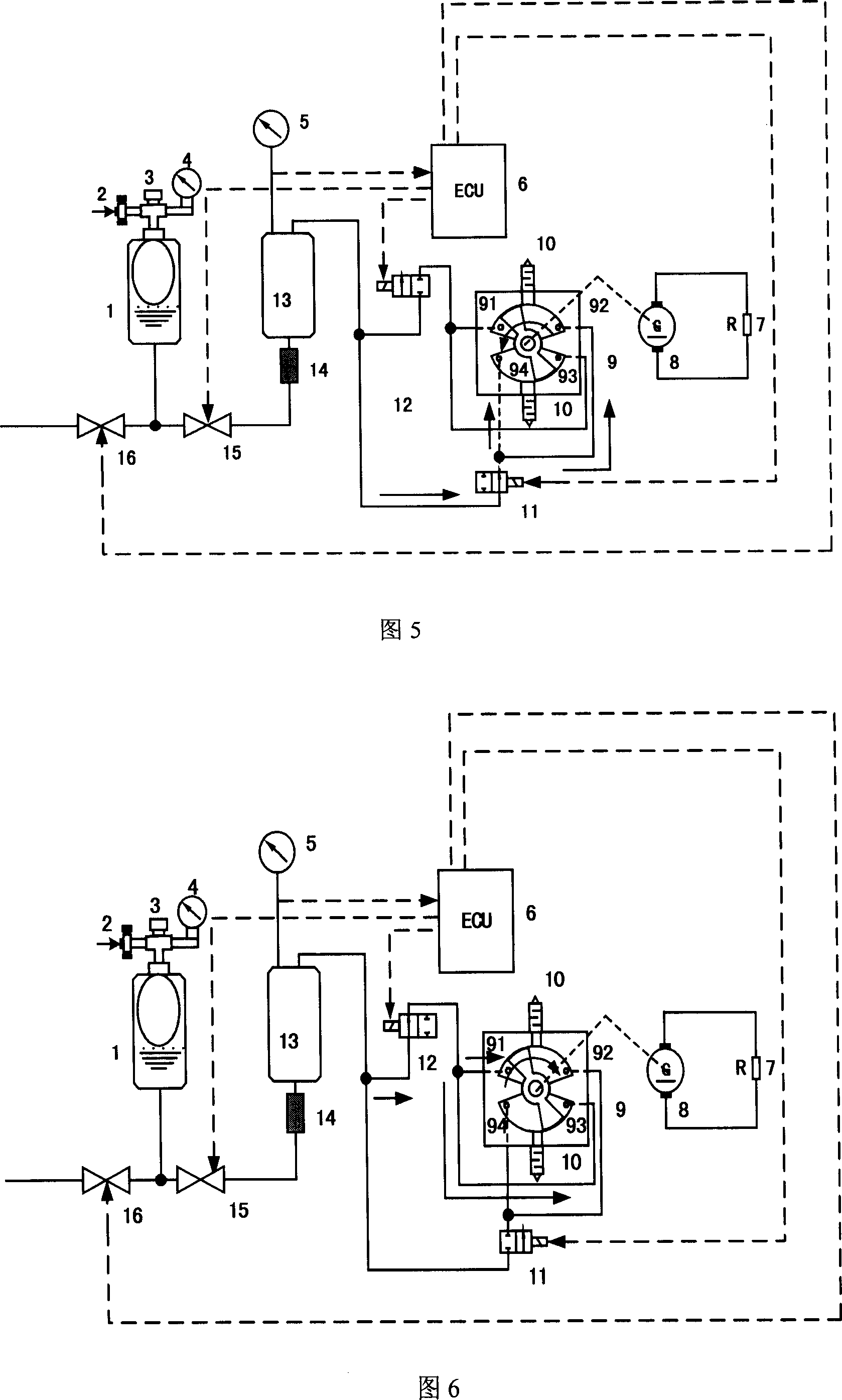

InactiveCN101008318ASimple structureWork reliablyEngines without rotary main shaftFree-piston engineHigh energy

A single-piston single-unit hydraulic free-piston engine comprises a single-unit fuel pot, a fuel controlling electromagnetic valve, a catalyze bed, a single-piston hydraulic free-piston engine and an electric-control unit. The invention uses high-density hydrogen dioxide or the mixture of hydrogen dioxide and diesel as fuel, and decomposes the fuel via catalysis and decomposition into high-temperature high-pressure mixture gas to drive the single-piston single-unit hydraulic free-piston engine, to exchange the chemical energy of fuel with the hydraulic energy. The invention has high reliability, small volume, low weight and high energy density, or the like, while it can output power in large range by changing the size of engine or the work-frequency of engine. The invention can be used to supply hydraulic energy in non-oxygen condition or oxygen-lack condition.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

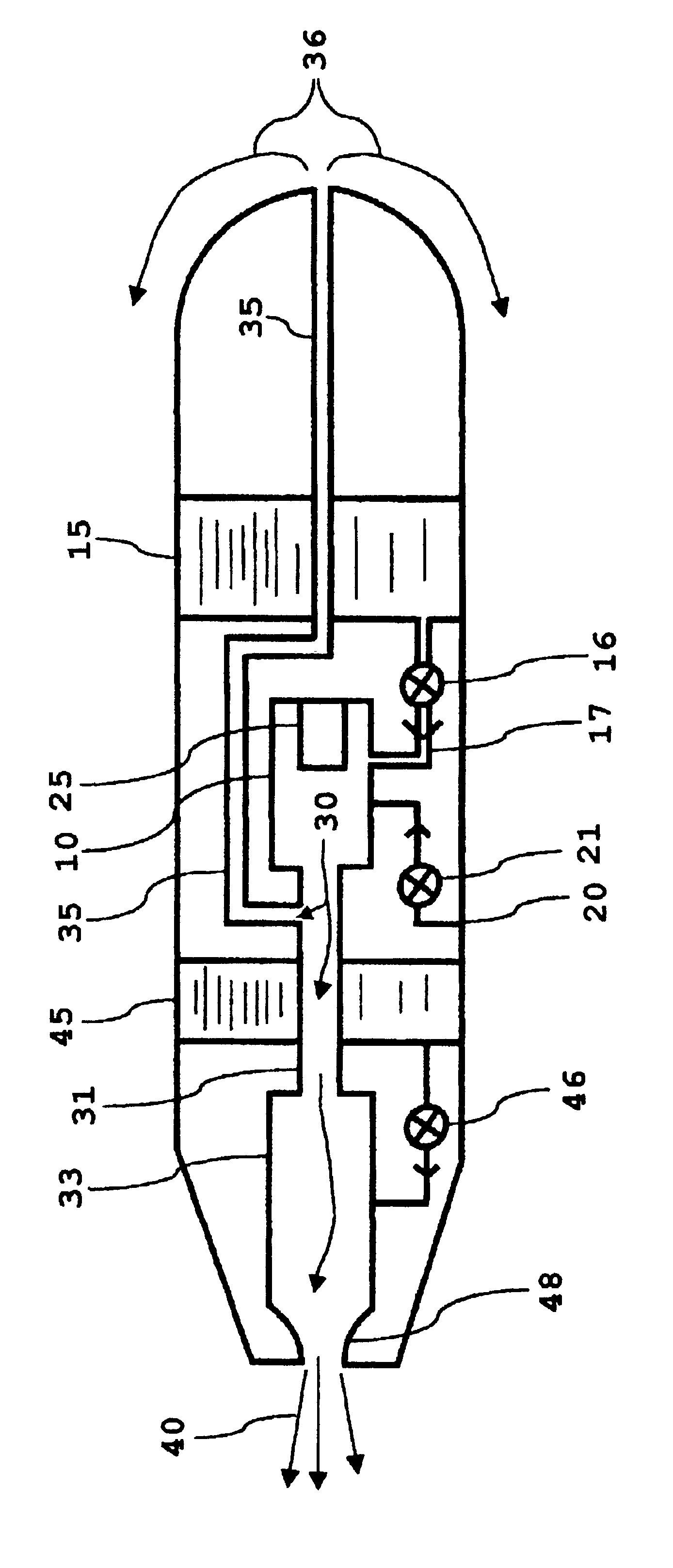

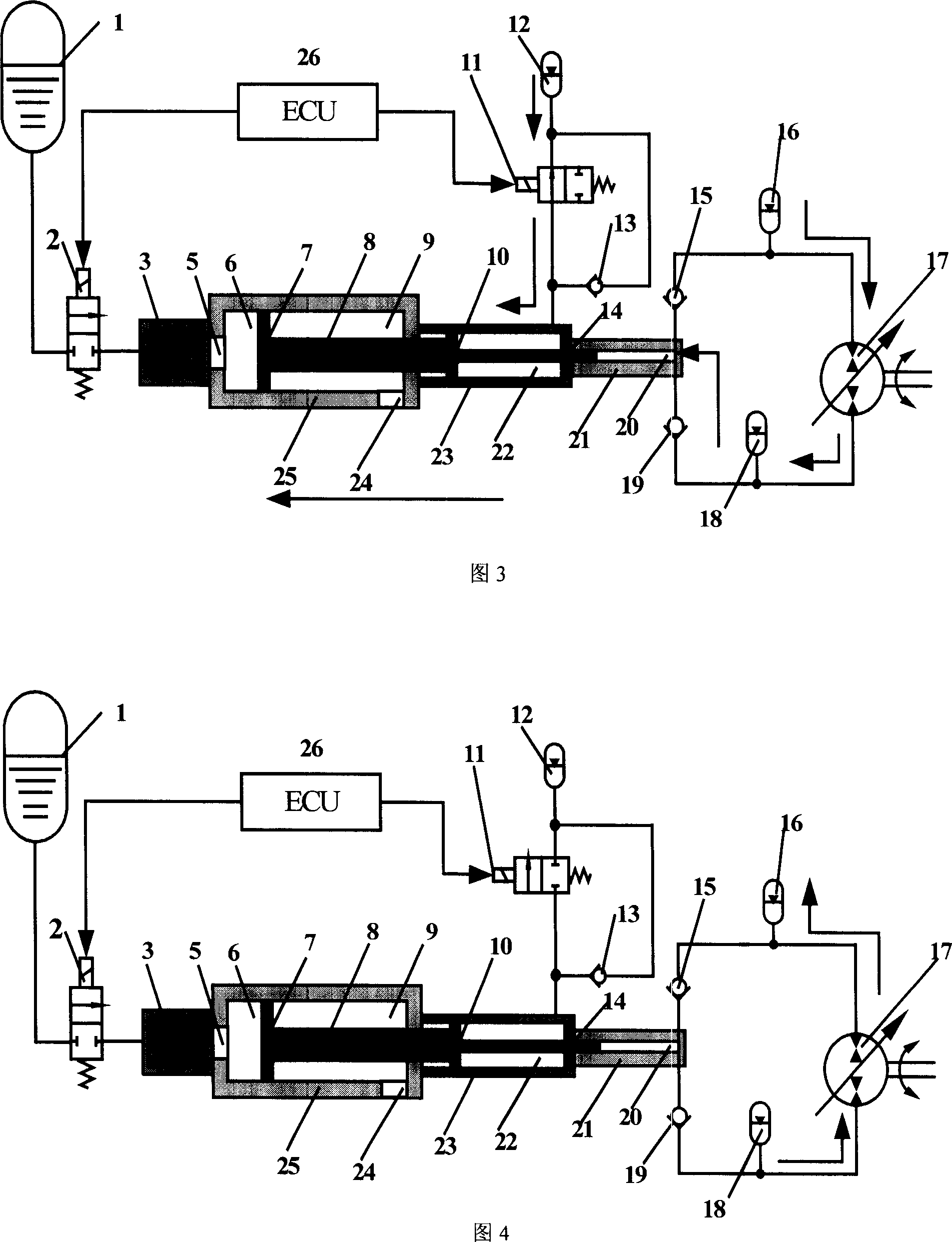

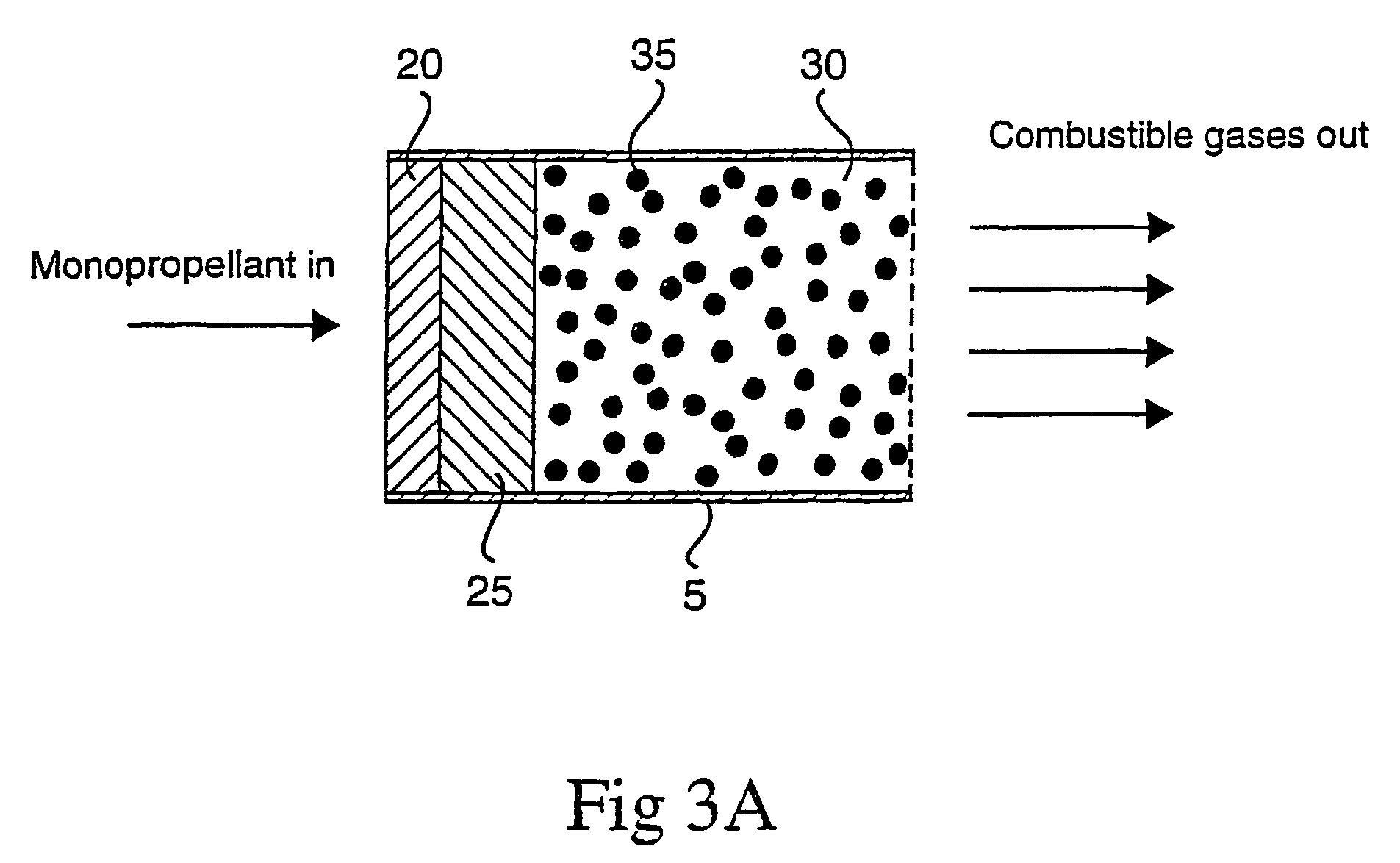

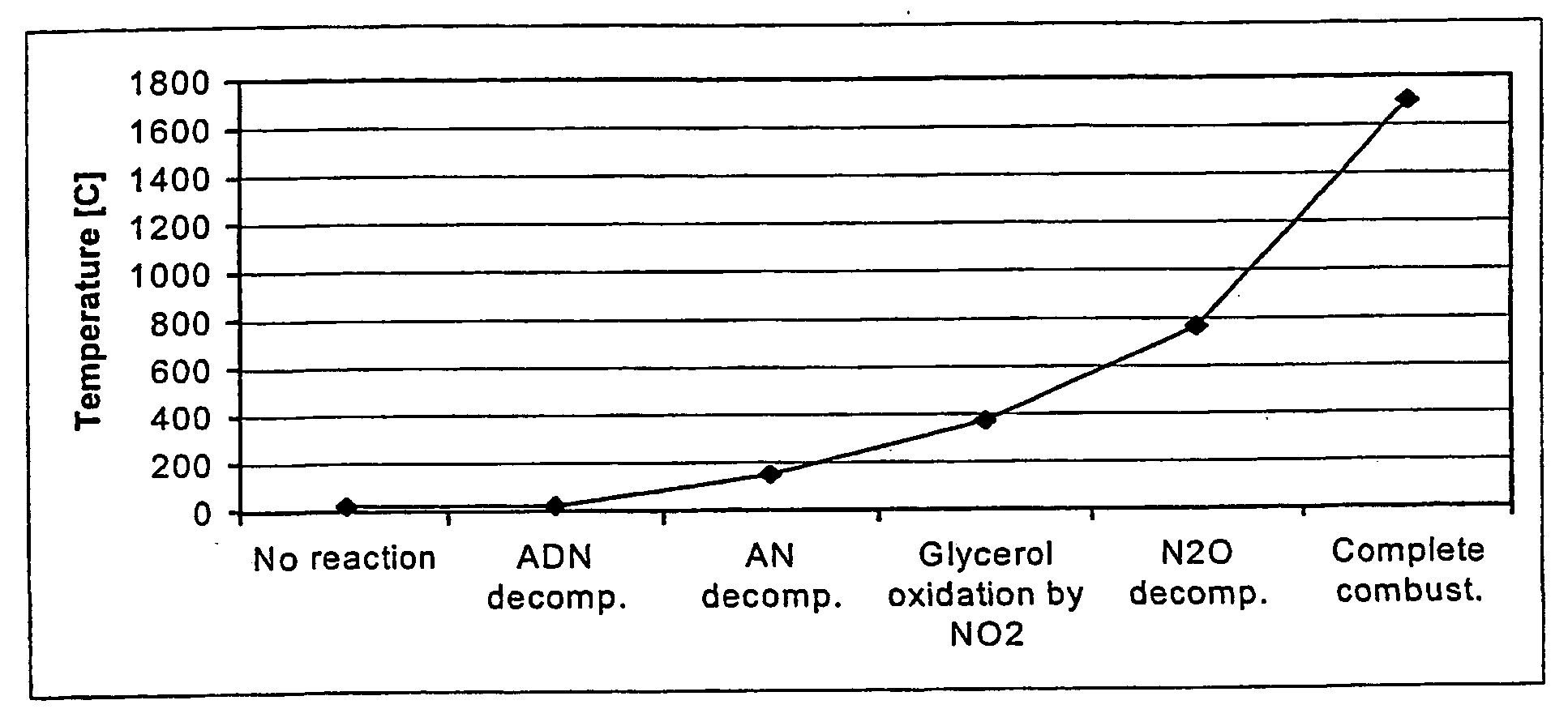

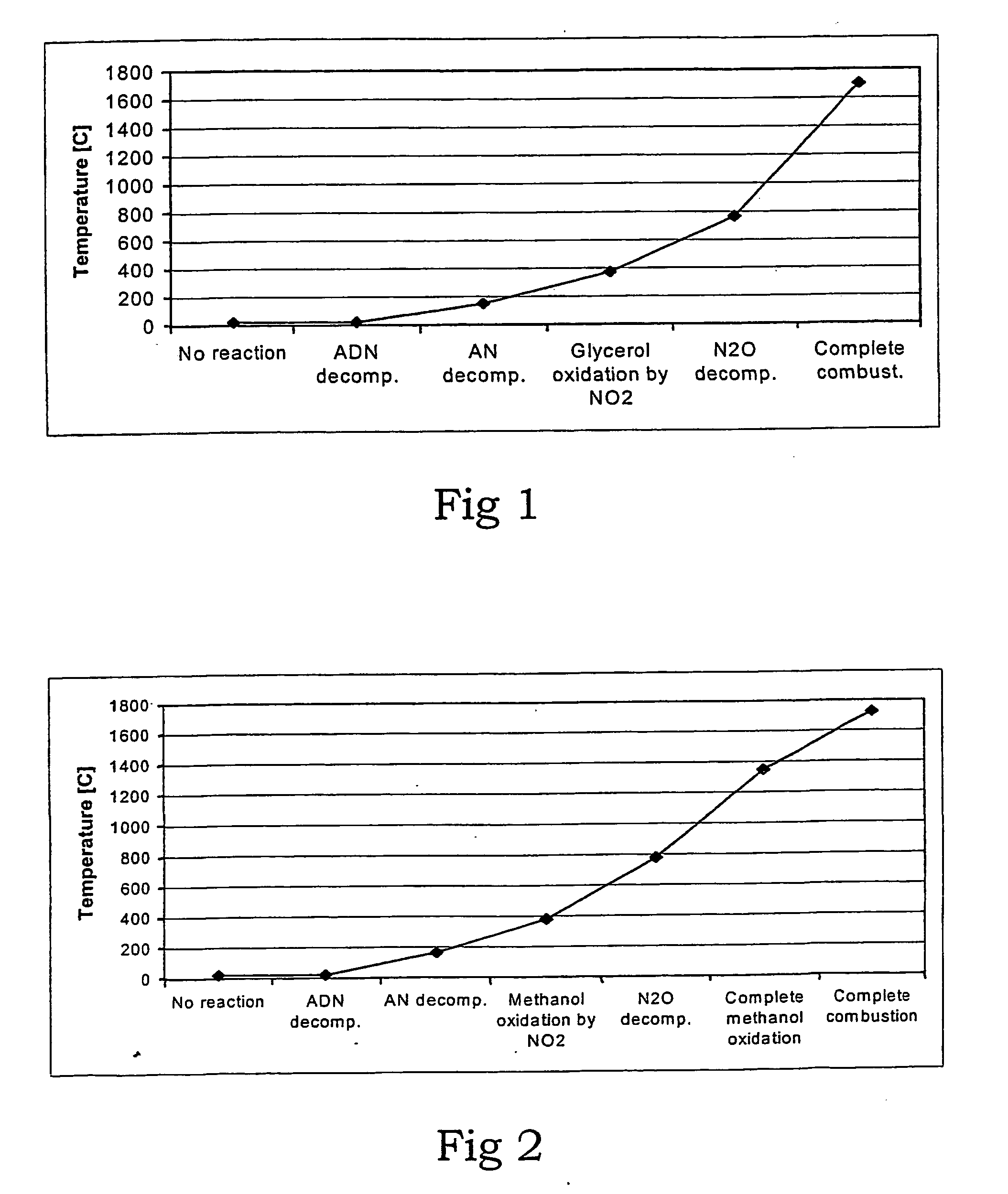

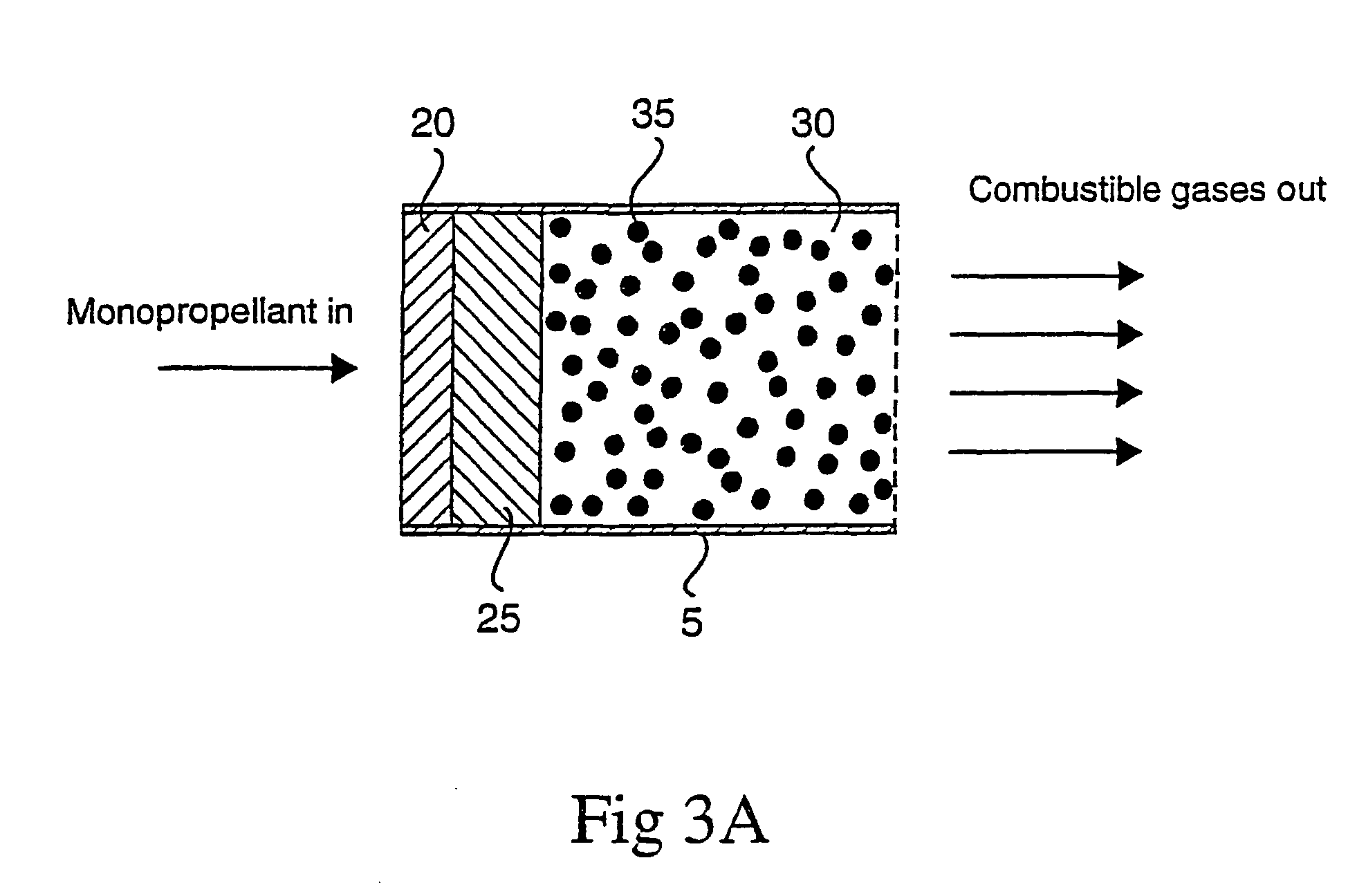

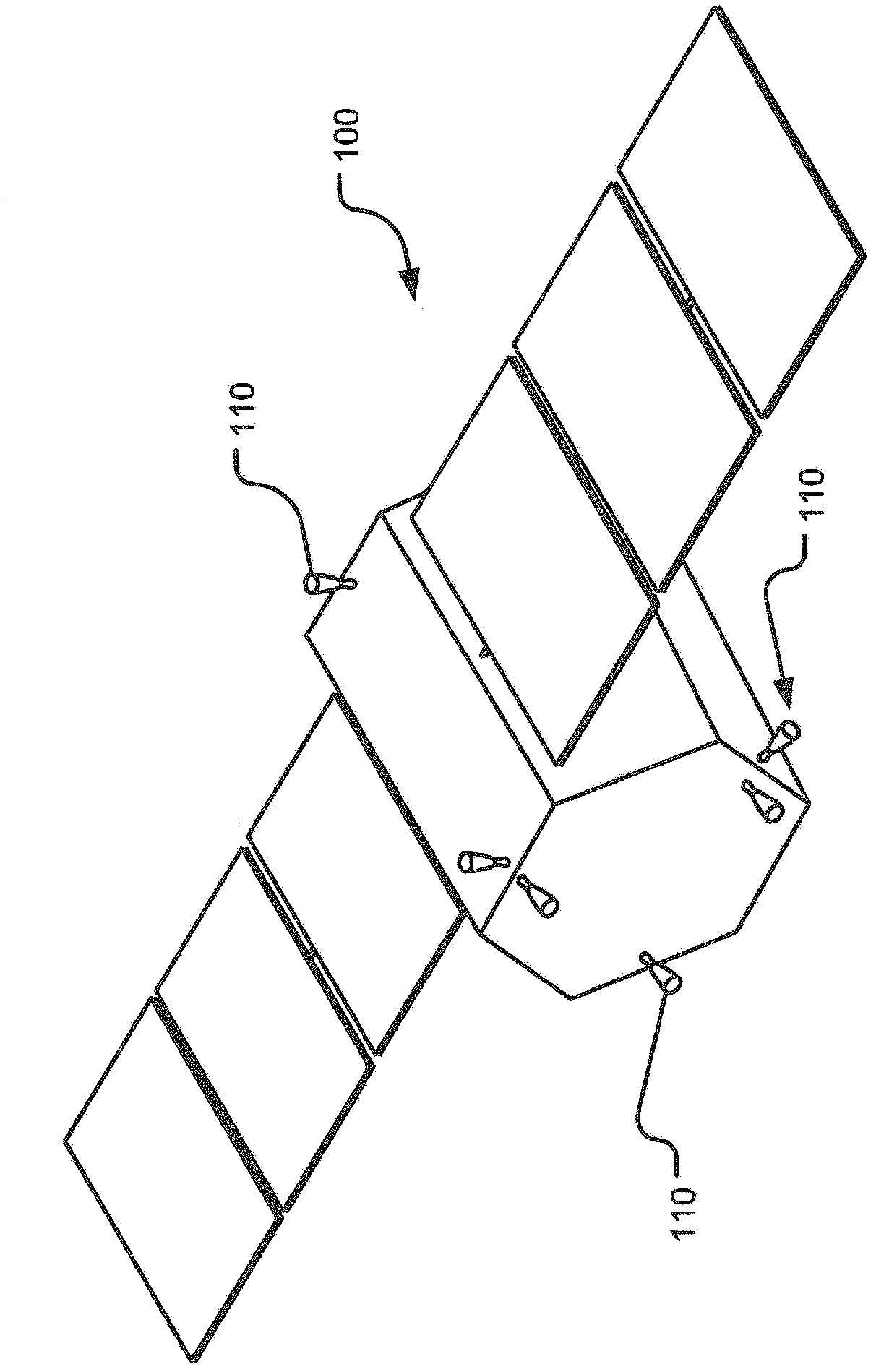

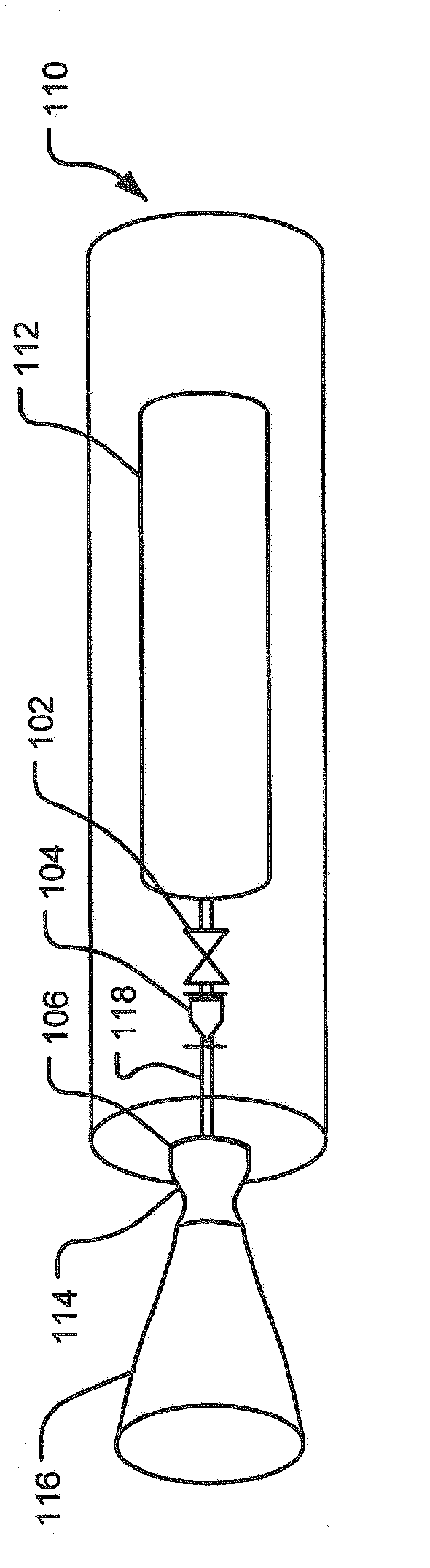

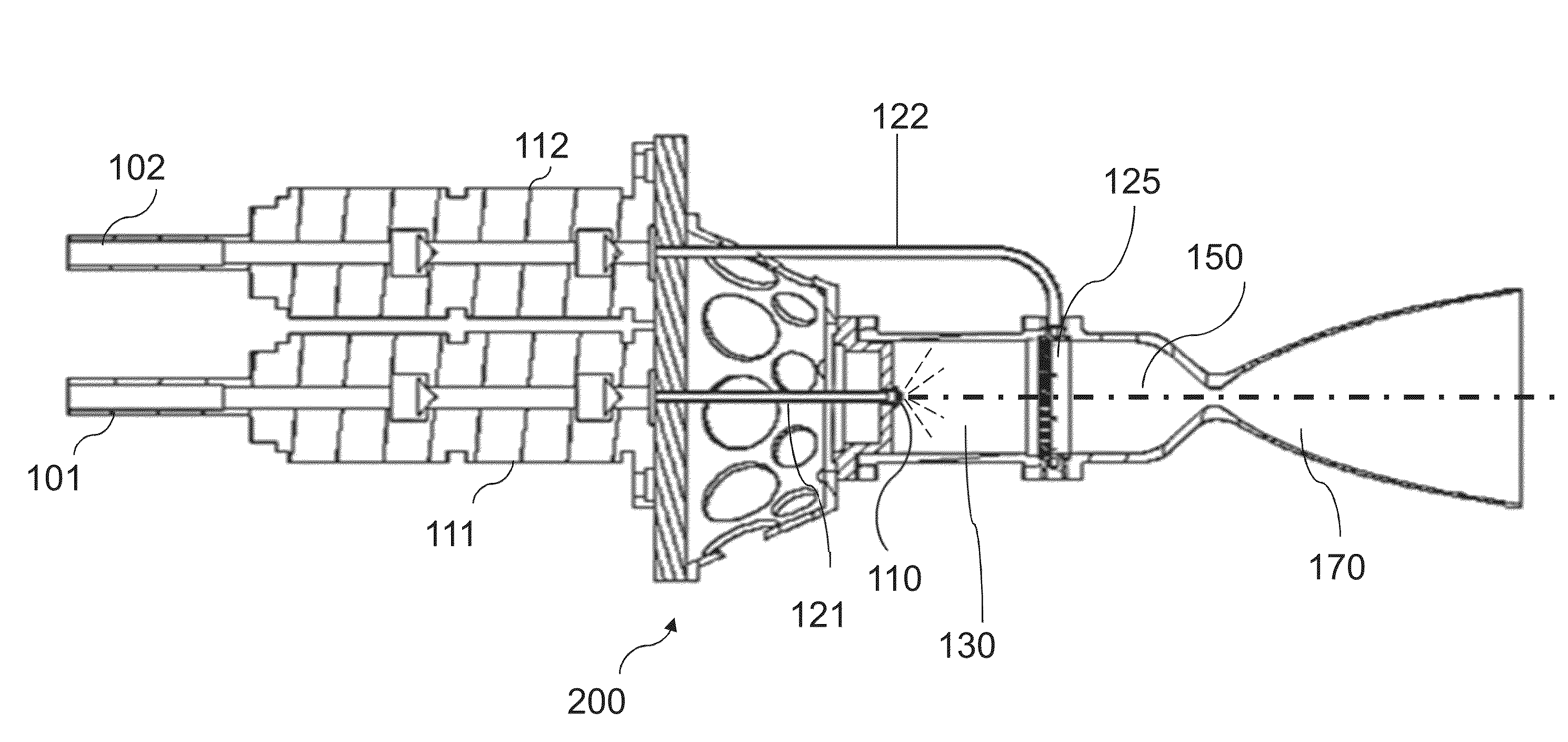

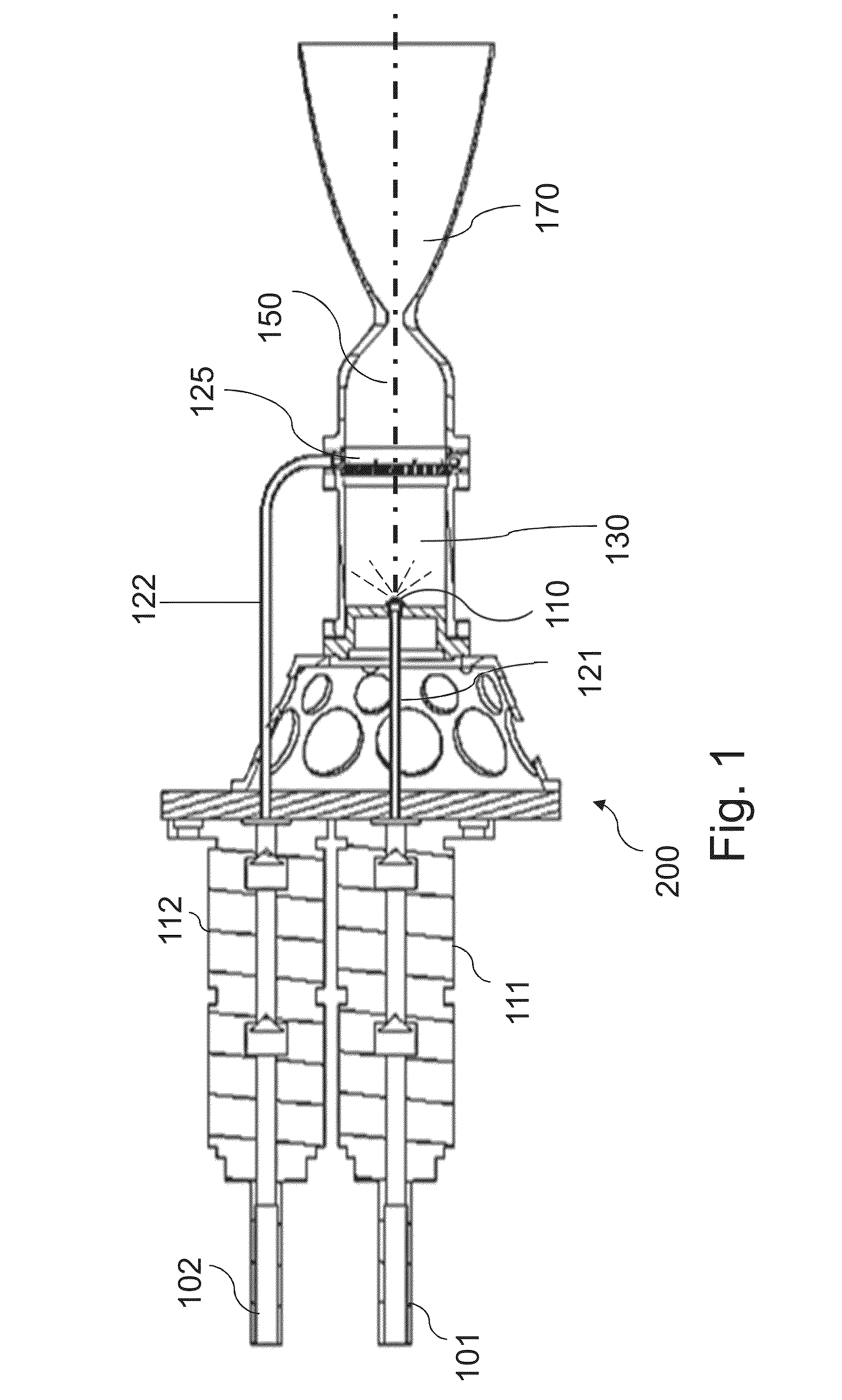

Reactor for decomposition of ammonium dinitramide-based liquid monopropellants and process for the decomposition

InactiveUS7137244B2Material nanotechnologyCatalyst activation/preparationCombustion chamberCombustible gas

The present invention relates to a reactor for the decomposition of ammonium dinitramide-based liquid monopropellants into hot, combustible gases for combustion in a combustion chamber, and more particularly a rocket engine or thruster comprising such reactor and a combustion chamber. The invention also relates to a process for the decompostion of ammonium dinitramide-based liquid monopropellants.

Owner:ECAPS

Reactor for decomposition of ammonium dinitramide-baed liquid monopropellants and process for the decomposition

InactiveUS20050014641A1Material nanotechnologyCatalyst activation/preparationCombustion chamberCombustible gas

The present invention relates to a reactor for the decomposition of ammonium dinitramide-based liquid monopropellants into hot, combustible gases for combustion in a combustion chamber, and more particularly a rocket engine or thruster comprising such reactor and a combustion chamber. The invention also relates to a process for the decompostion of ammonium dinitramide-based liquid monopropellants.

Owner:ECAPS

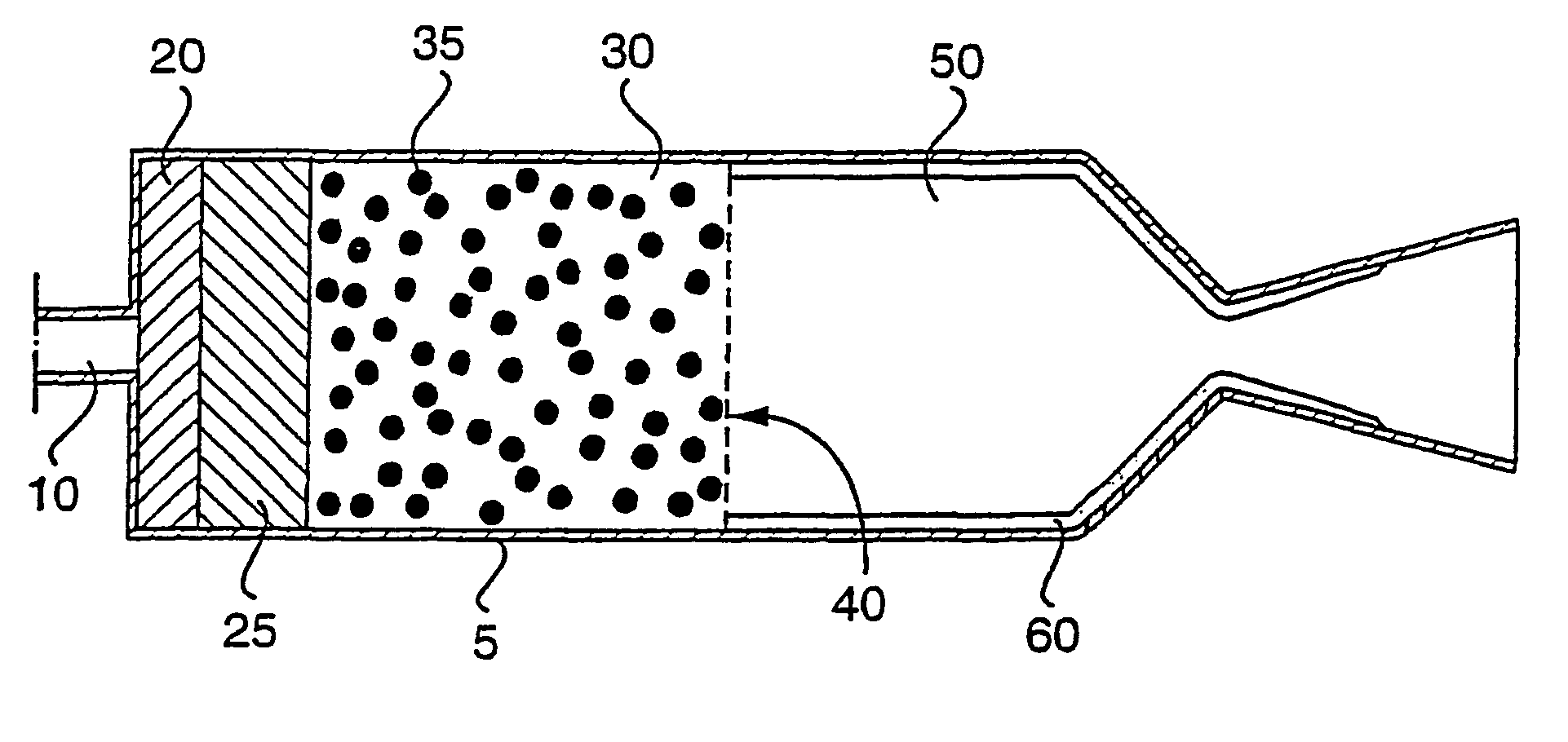

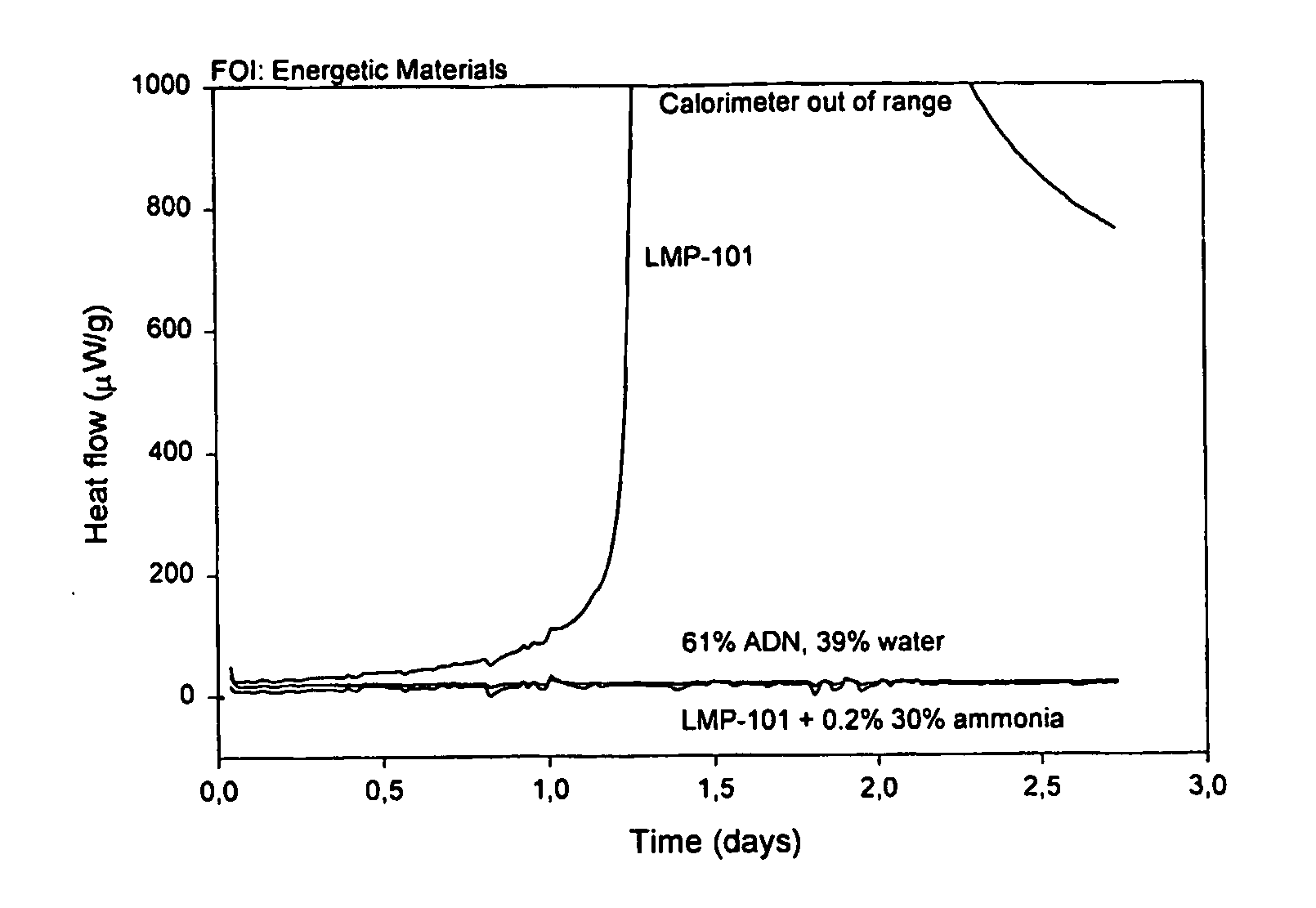

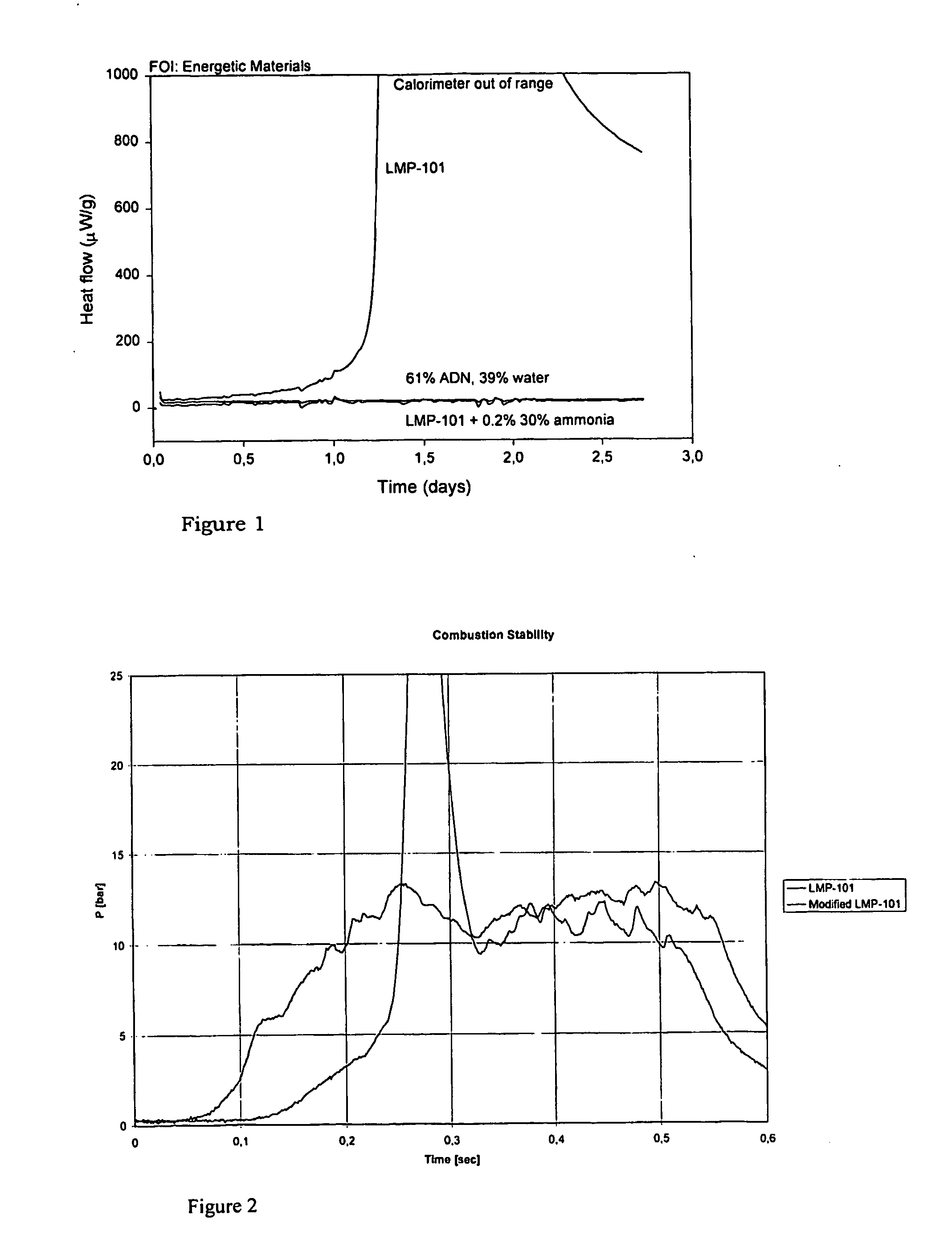

Ammonium dinitrimide based liquid monopropelants exhibiting improved combustion stability and storage life

InactiveUS20040231765A1Stabilised combustion characteristicStabilised combustion characteristicsCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAmmonium dinitramideAmmonia

Ammonium dinitramide based liquid monopropellants exhibiting stabilised combustion characteristics and improved storage life, containing ammonia, a base weaker than ammonia, or a base which is sterically hindered, added in an amount of 0.1 to 5% of the total weight of the other components of the propellant.

Owner:ECAPS

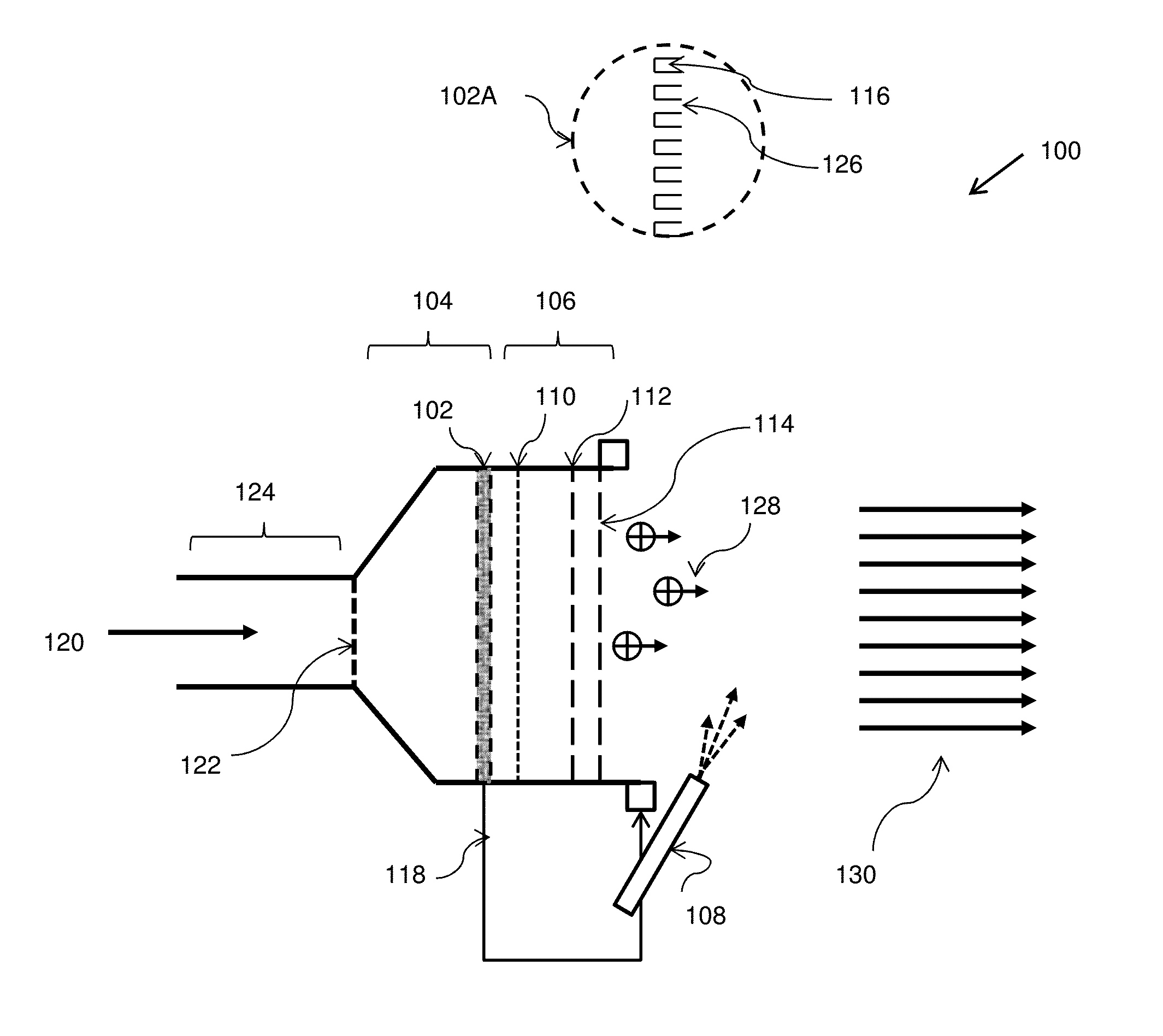

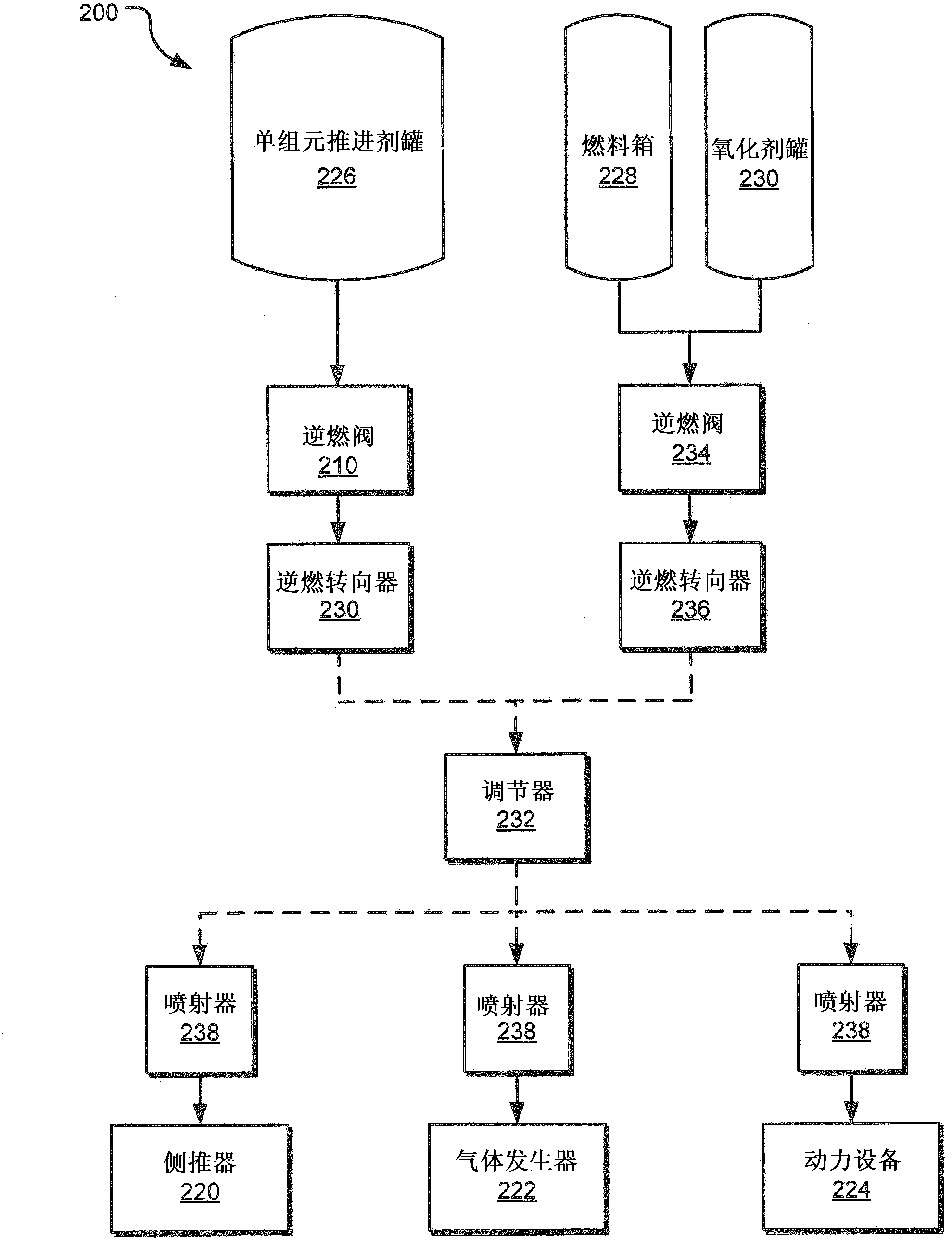

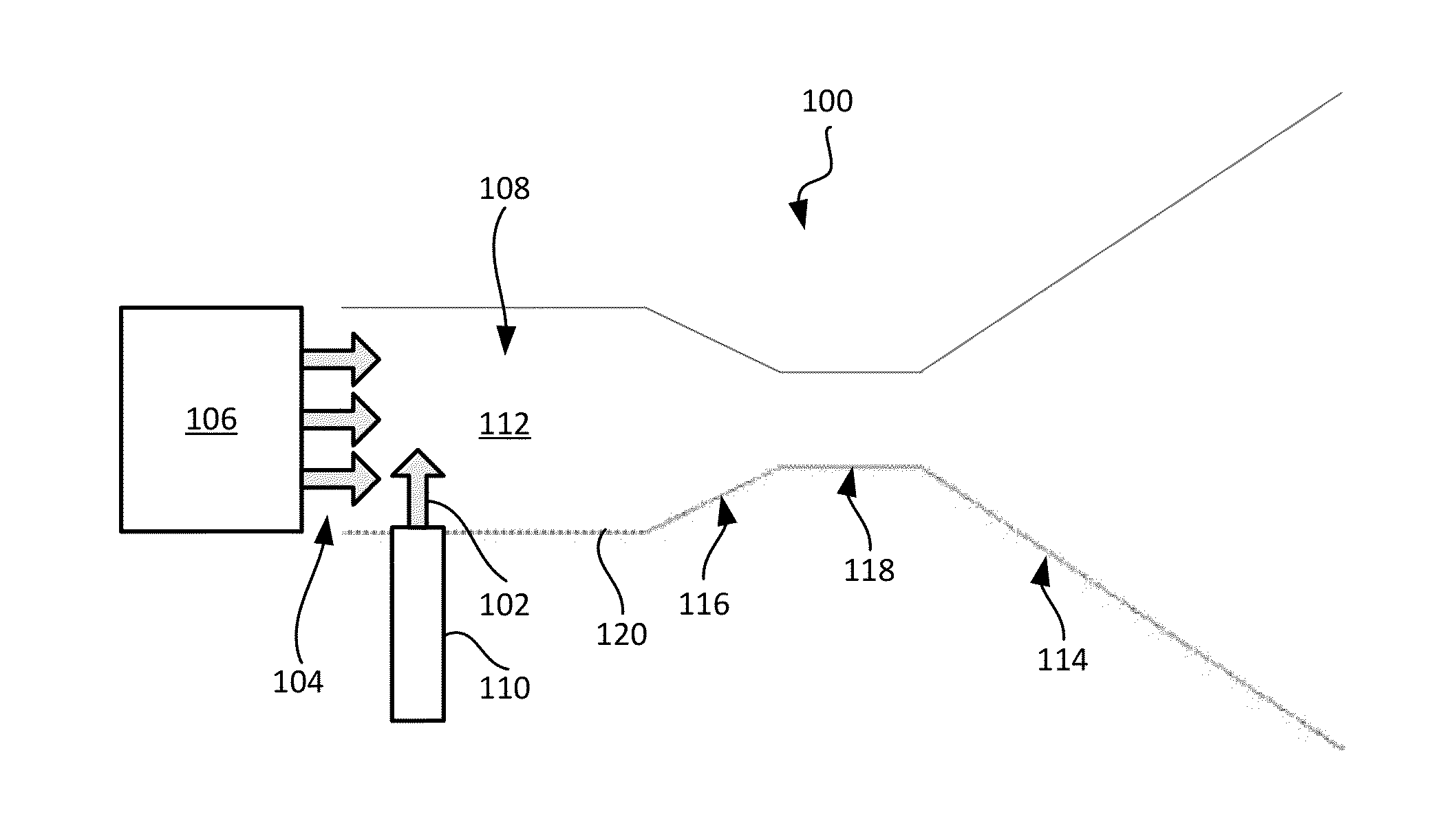

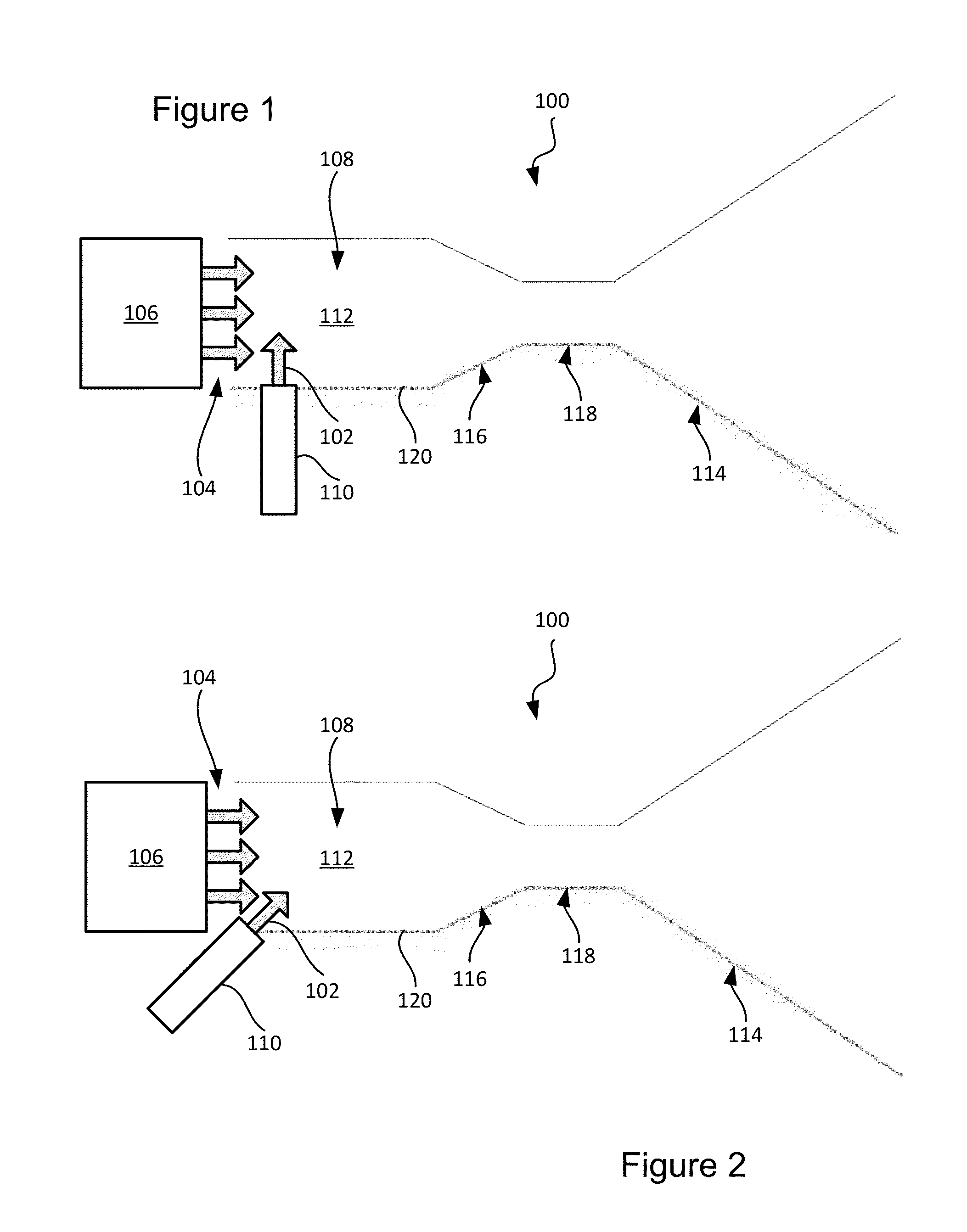

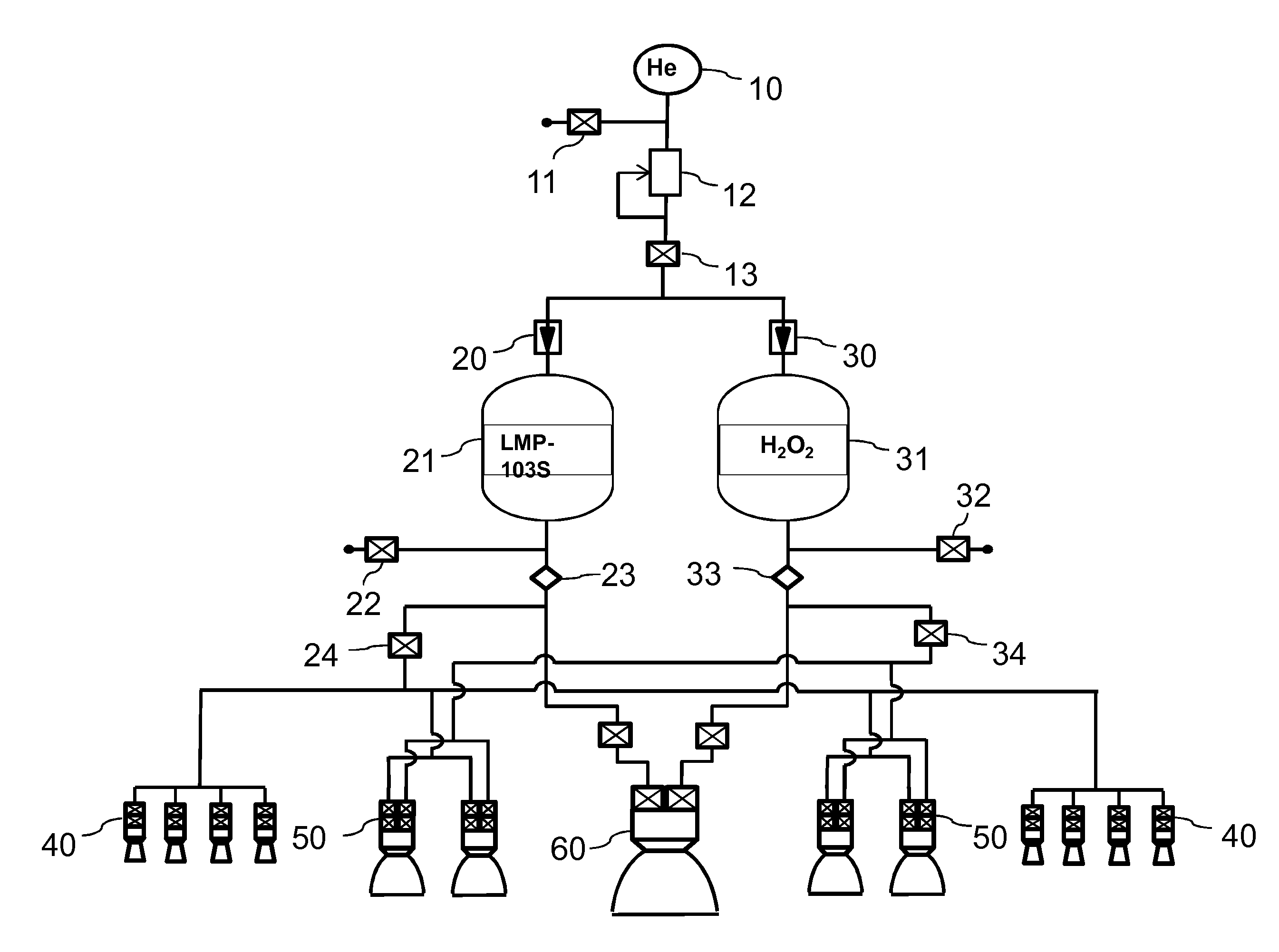

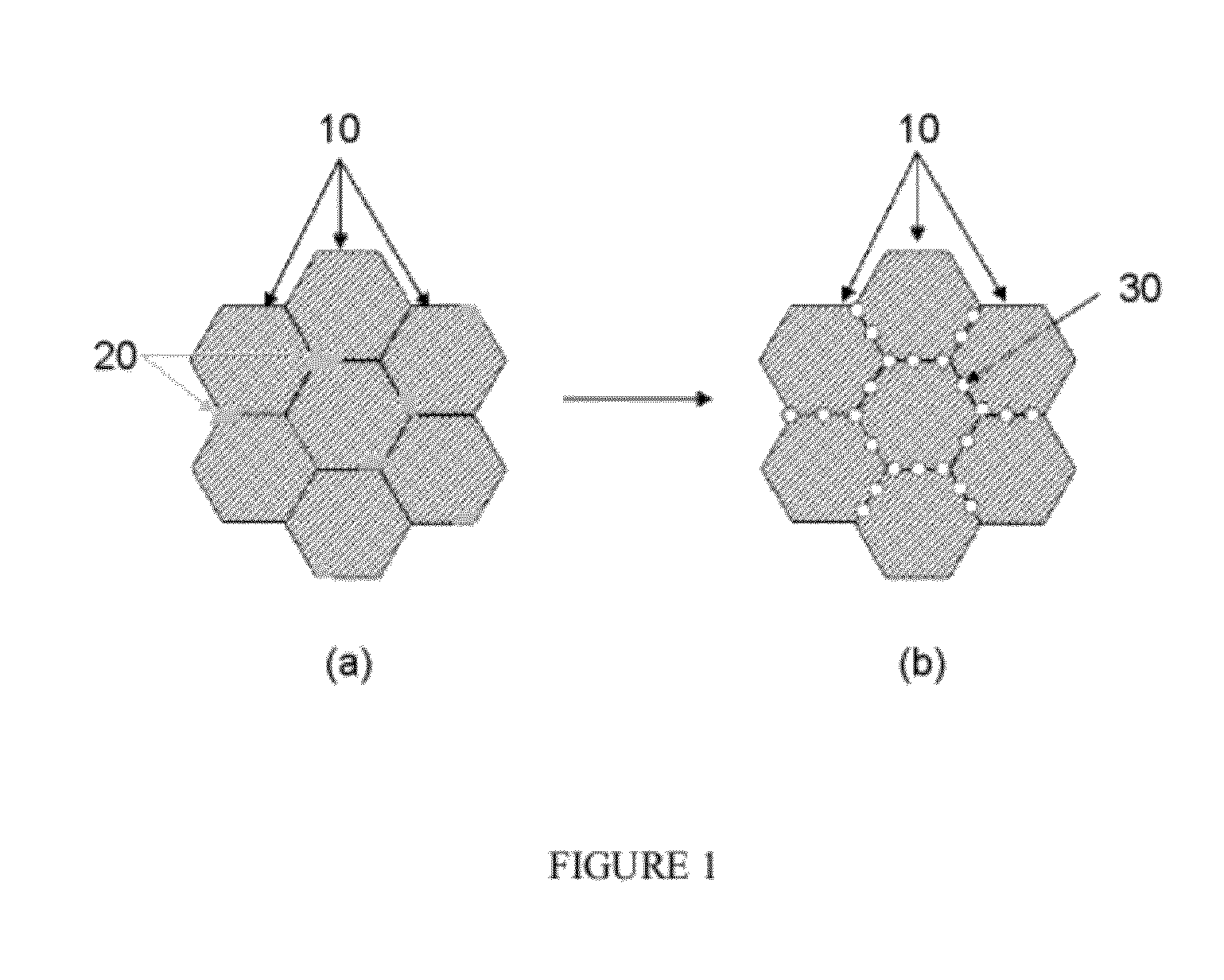

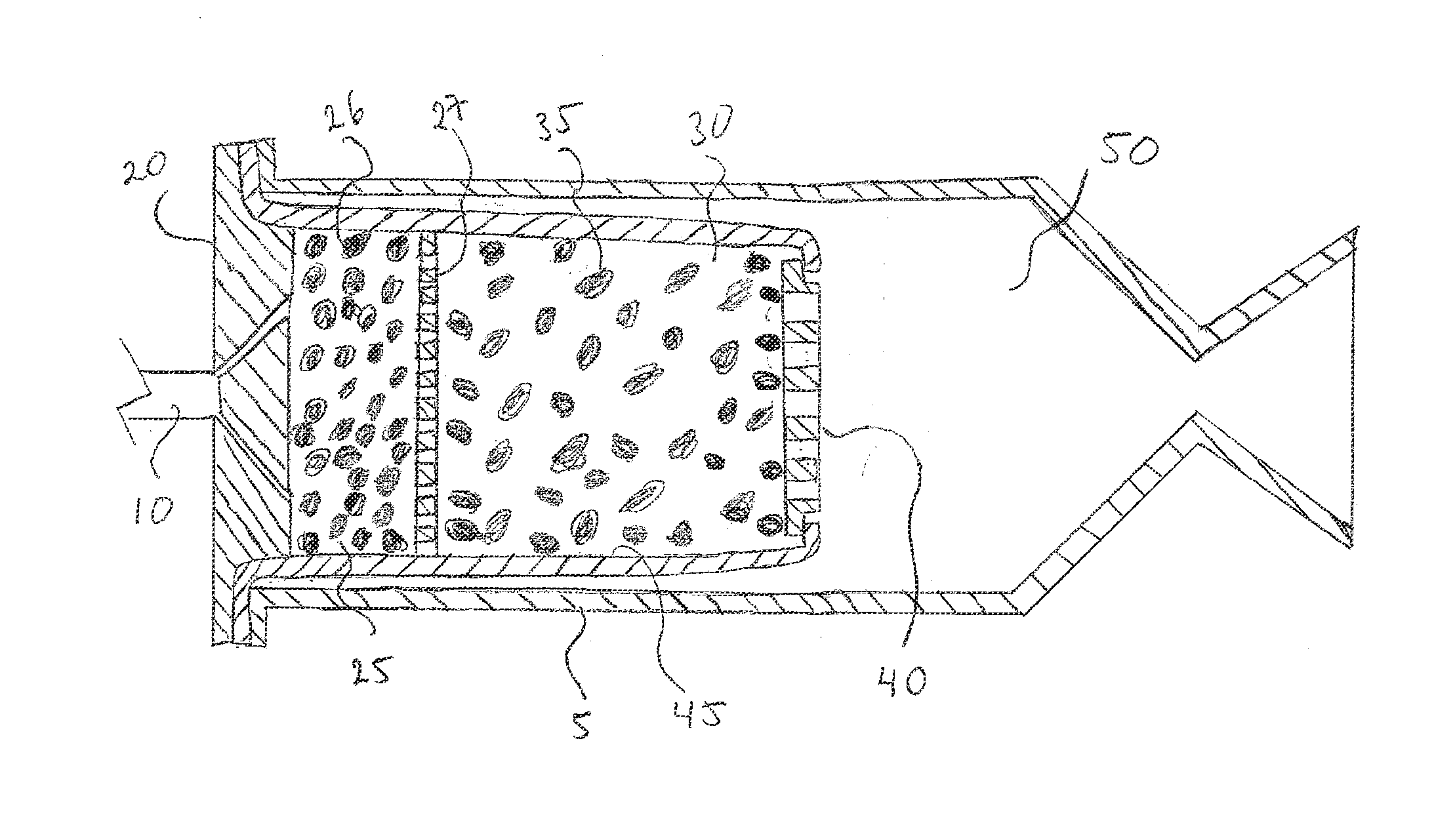

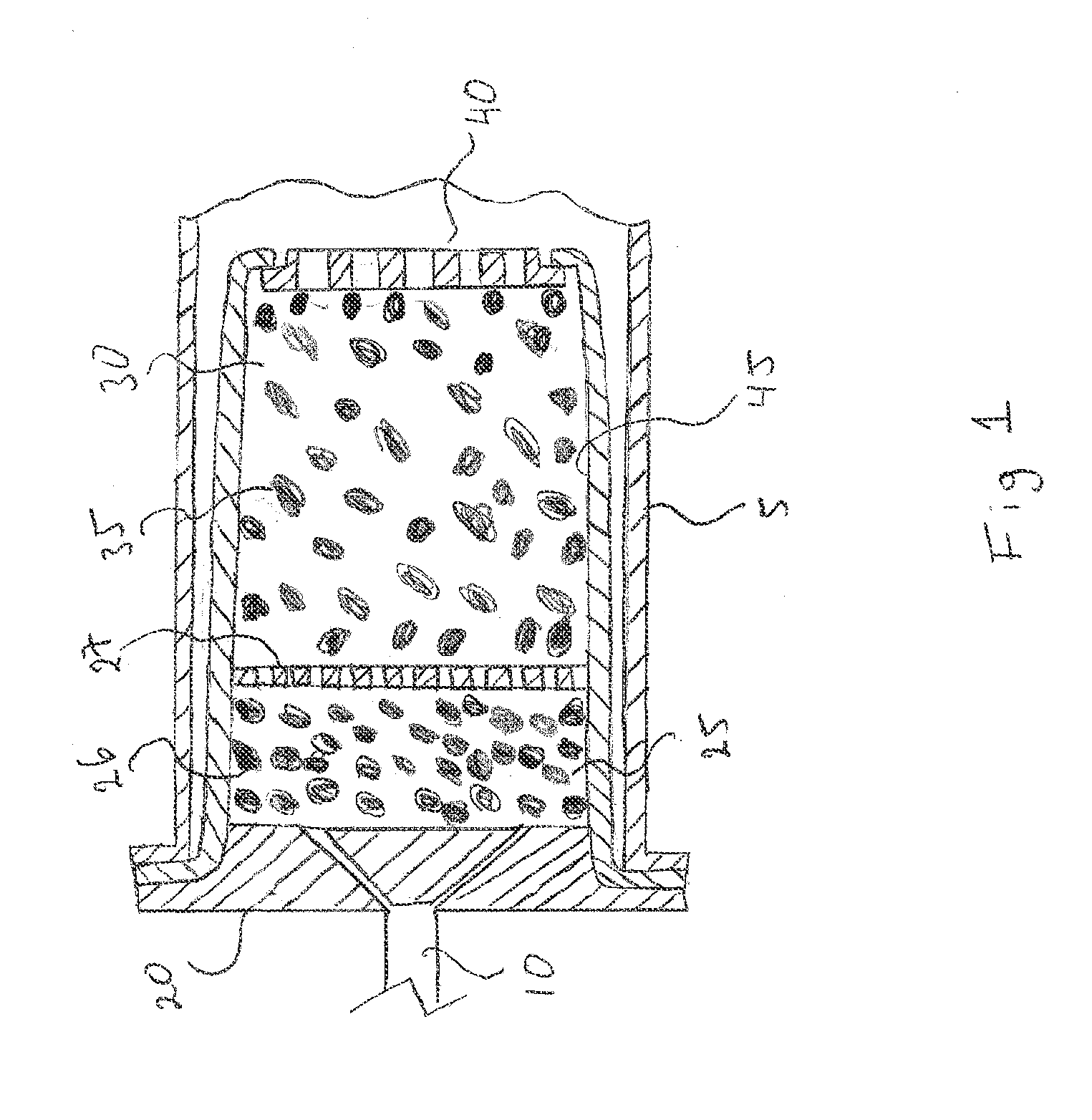

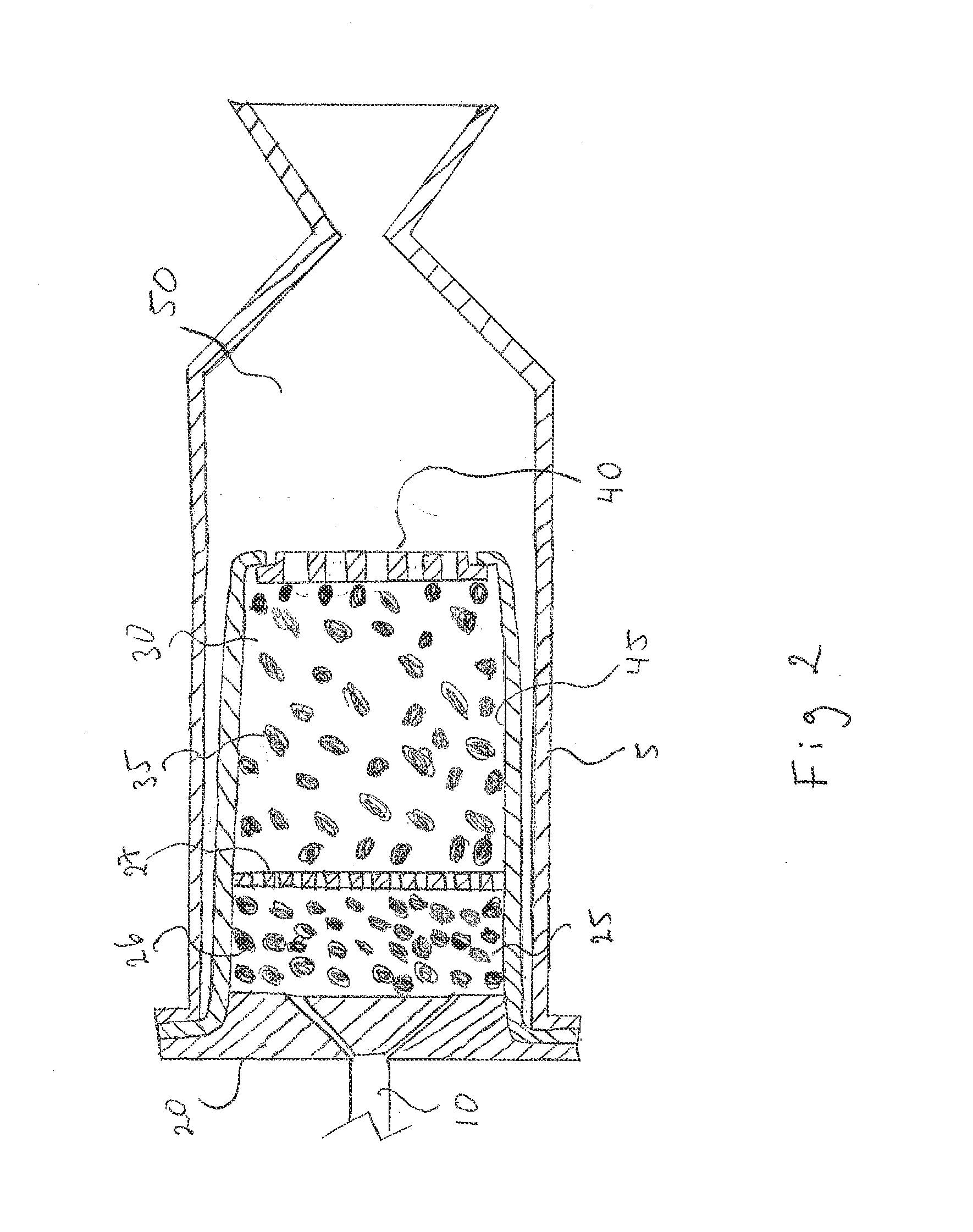

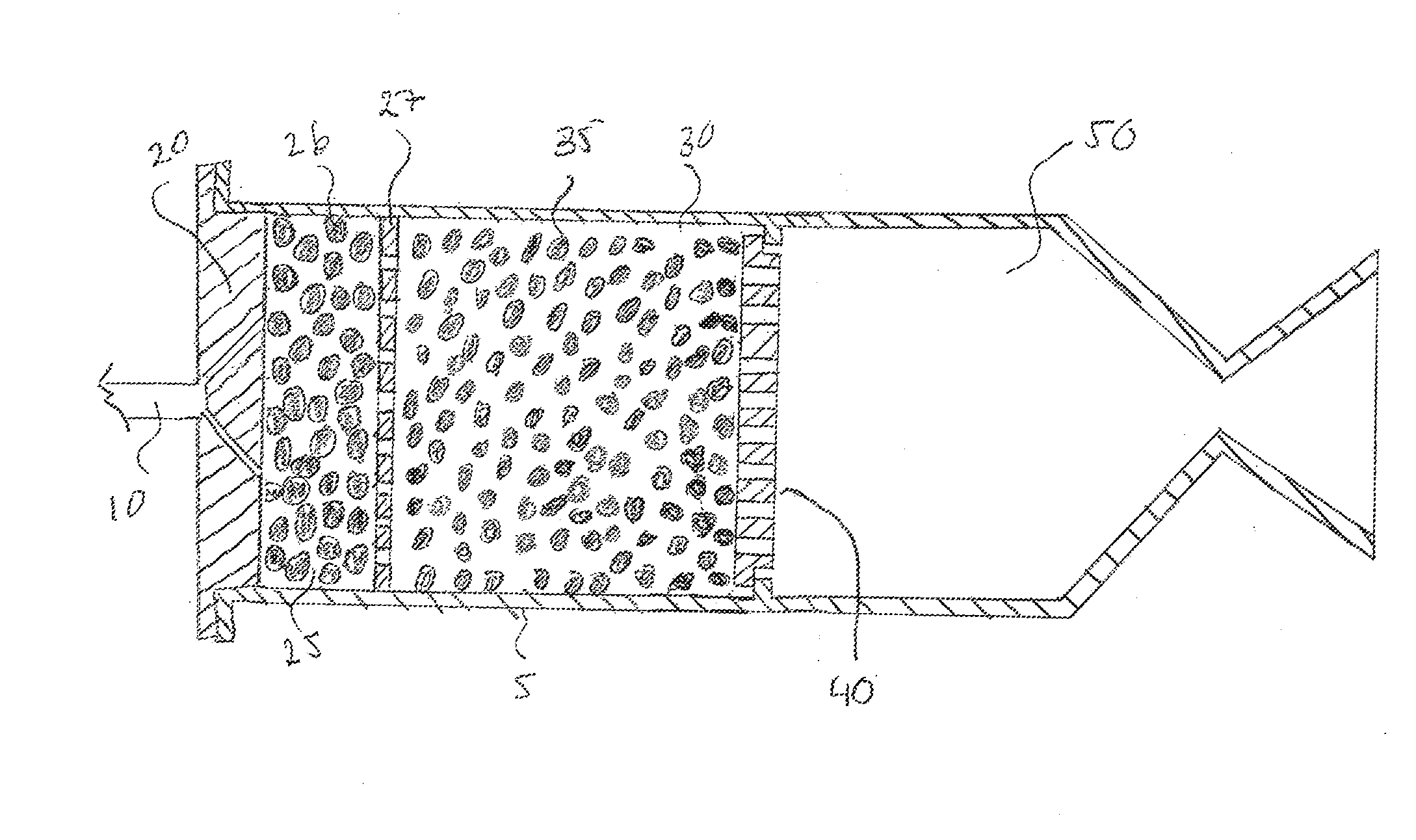

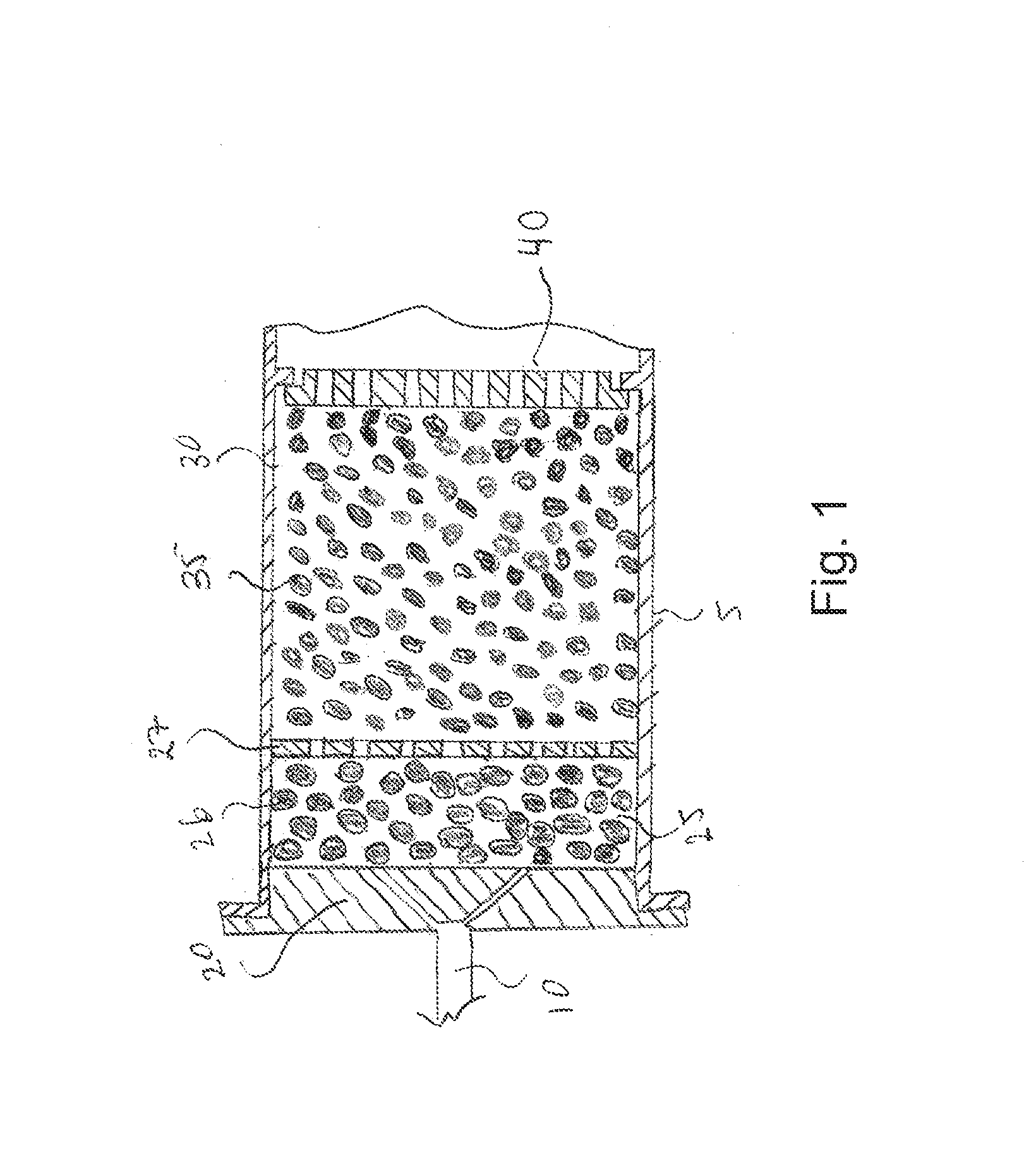

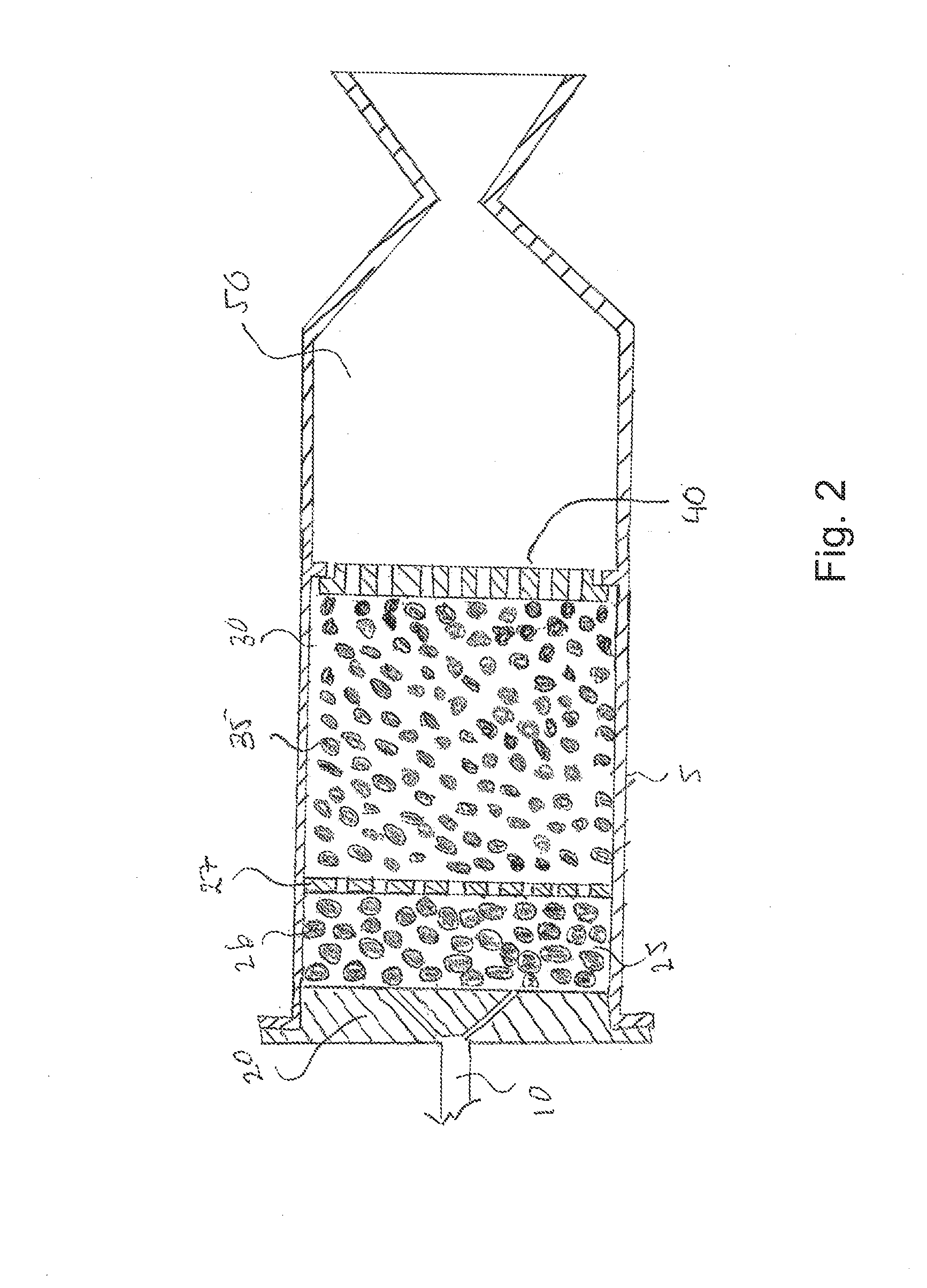

Tiered porosity flashback suppressing elements for monopropellant or pre-mixed bipropellant systems

Monopropellant and pre-mixed bipropellant storage and supply systems for rocket engines and other work producing systems are subject to damage when detonation progresses upstream from a combustion chamber to and through supply lines. Interposing one or more micro porous or micro fluidic elements into the supply conduit can limit the flame front that accompanies such unintended detonation, but inevitably restrict the flow of the propellant to the combustion chamber. A tiered micro fluidic element where a bulk of the element has relatively large pores but forms a structurally robust supports a second, relatively thin region having appropriately small mean pore diameter provides an effective flashback barrier that can resist catastrophic failure during such detonations. Such elements can be used in isolation, or they can be incorporated into detonation wave arrestors or pressure wave-triggered cut-off valves or the like to decrease the incidence of unintended detonations.

Owner:FIRESTAR ENG

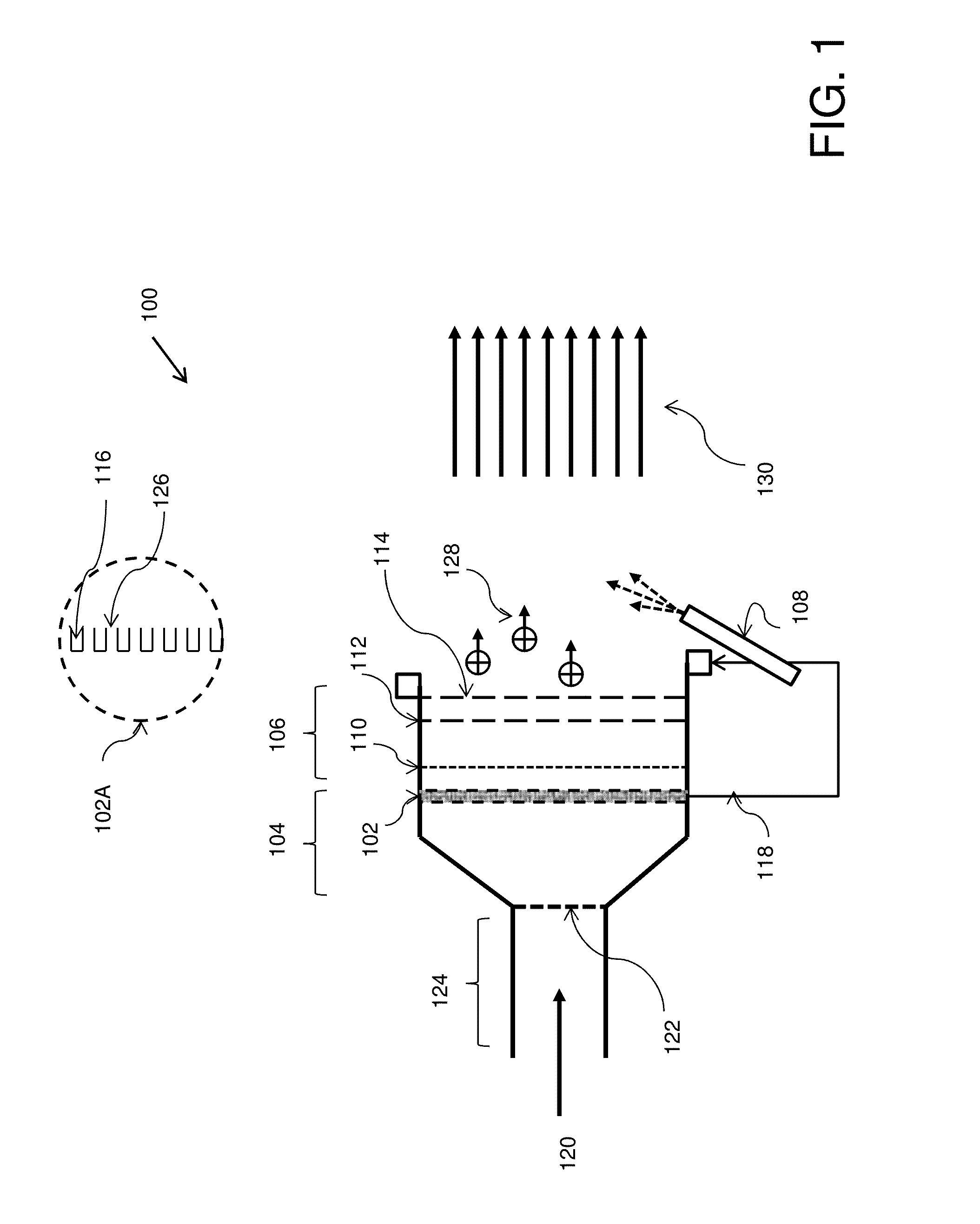

Reactants sprayed into plasma flow for rocket propulsion

ActiveUS20140290212A1Increase thrustEasy to useCosmonautic vehiclesCosmonautic partsPtru catalystPlasma flow

Specific impulse and rocket engine efficiency can be improved by injecting reactants, e.g., a propellant combination or a monopropellant and a catalyst, into a plasma flow of a rocket engine. In some aspects, a catalyst or a propellant is carried by plasma formed by passing a flow of a feed gas through an electrical arc. In some aspects, reactants are combusted in supersonic plasma flow to generate combustion ionization in the plasma flow.

Owner:LOCKHEED MARTIN CORP

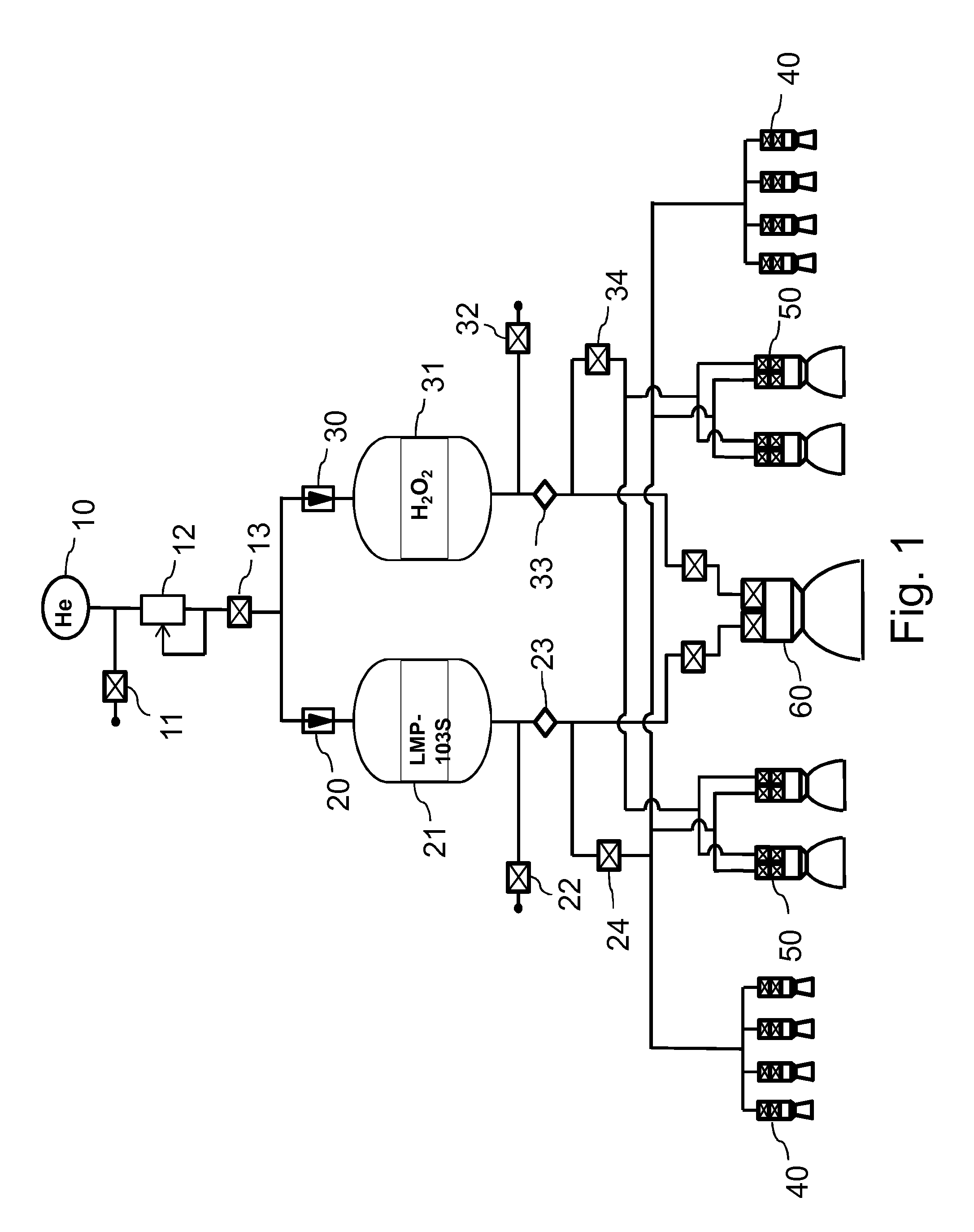

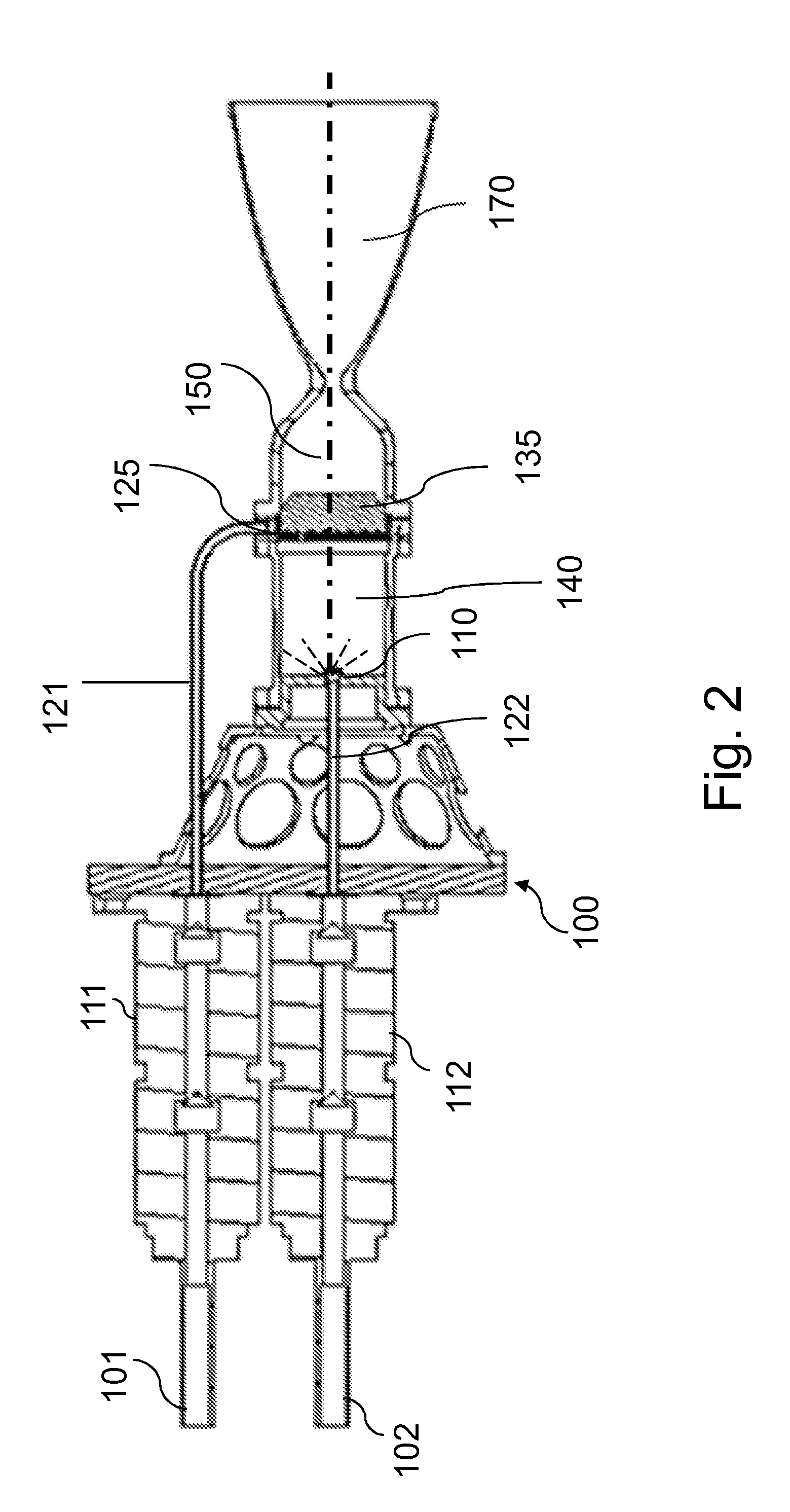

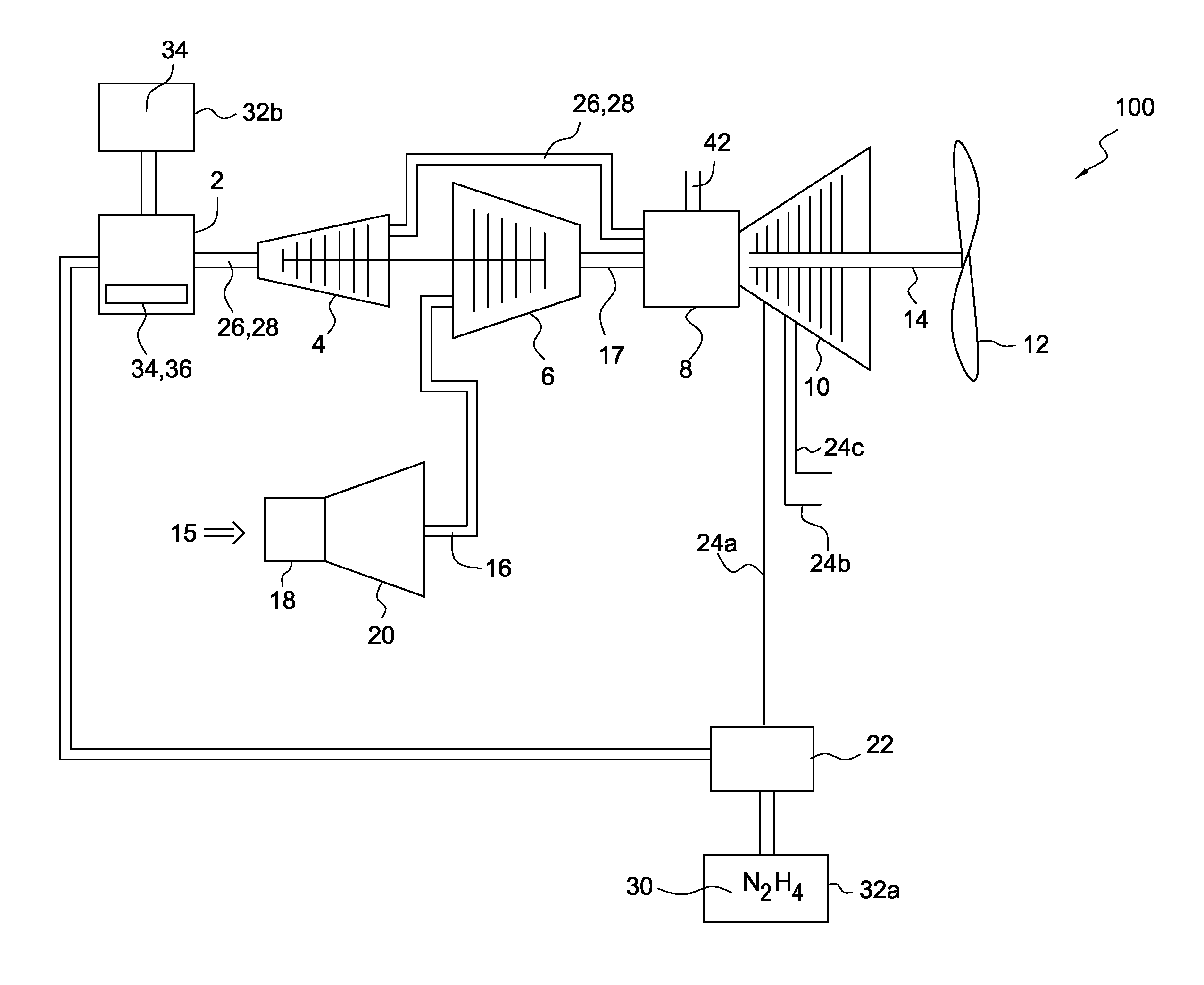

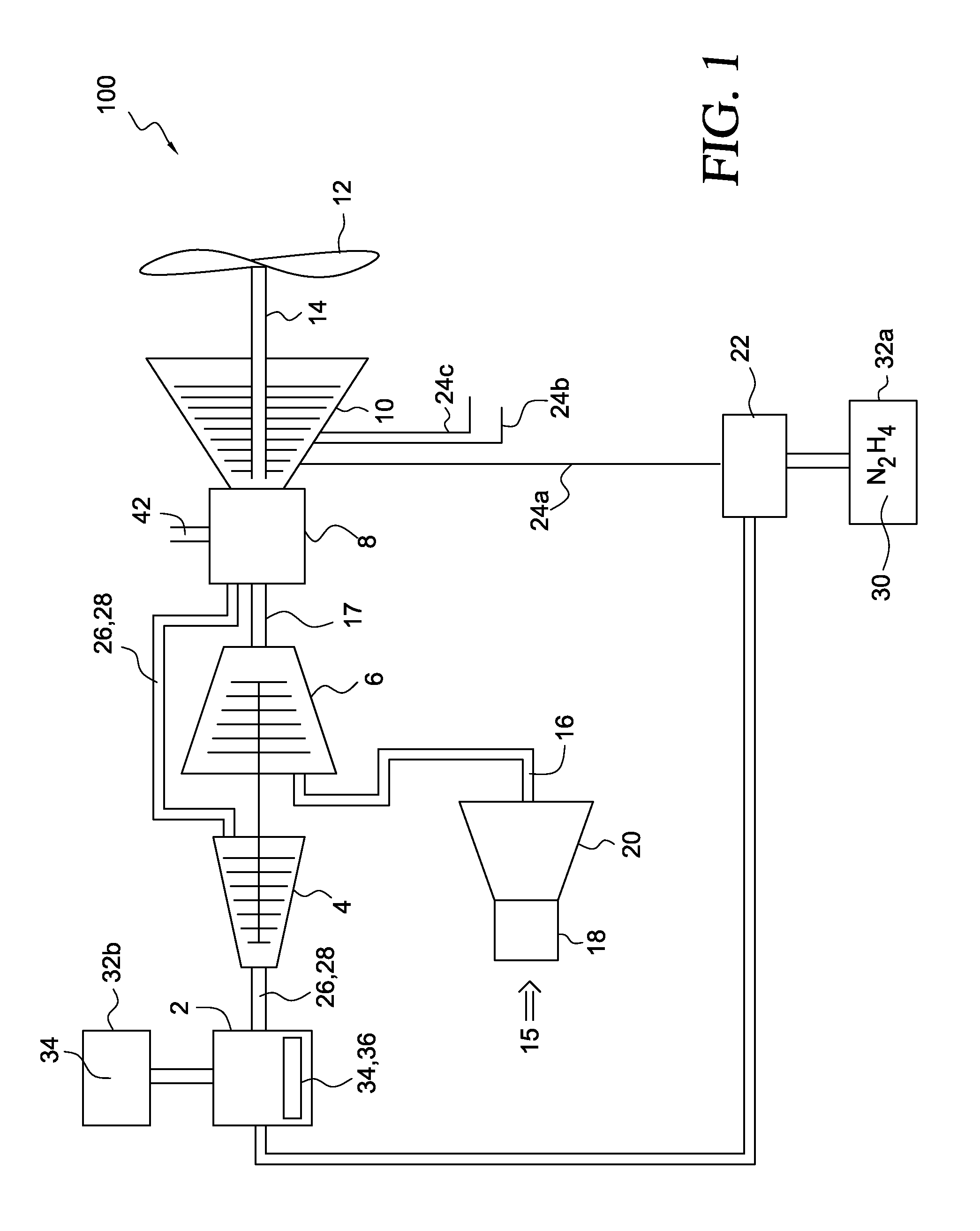

Dual mode chemical rocket engine, and dual mode propulsion system comprising the rocket engine

InactiveUS20160108855A1Improved density impulseReduce and facilitate propellant handlingCosmonautic vehiclesCosmonautic propulsion system apparatusAviationDual mode

The invention relates generally to dual mode bipropellant chemical rocket propulsion systems to be used in aerospace applications for 1) orbit raising, orbit manoeuvres and maintenance, attitude control and deorbiting of spacecraft, and / or 2) propellant settling, attitude and roll control of missiles, launchers and space planes. The present invention also relates to a dual mode chemical rocket engine for use in such systems. The engine uses low-hazardous storable liquid propellants and can be operated either in monopropellant mode or in bipropellant mode. The monopropellants used are a low-hazard liquid fuel-rich monopropellant, and hydrogen peroxide, respectively.

Owner:ECAPS

Single piston monopropellant hydraulic free piston engine

InactiveCN100419214CSimple structureWork reliablyEngines without rotary main shaftFree-piston engineHigh energy

A single-piston single-unit hydraulic free-piston engine comprises a single-unit fuel pot, a fuel controlling electromagnetic valve, a catalyze bed, a single-piston hydraulic free-piston engine and an electric-control unit. The invention uses high-density hydrogen dioxide or the mixture of hydrogen dioxide and diesel as fuel, and decomposes the fuel via catalysis and decomposition into high-temperature high-pressure mixture gas to drive the single-piston single-unit hydraulic free-piston engine, to exchange the chemical energy of fuel with the hydraulic energy. The invention has high reliability, small volume, low weight and high energy density, or the like, while it can output power in large range by changing the size of engine or the work-frequency of engine. The invention can be used to supply hydraulic energy in non-oxygen condition or oxygen-lack condition.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Hydrazine monopropellant decomposition air turboprop engine

Owner:AURORA FLIGHT SCI CORP

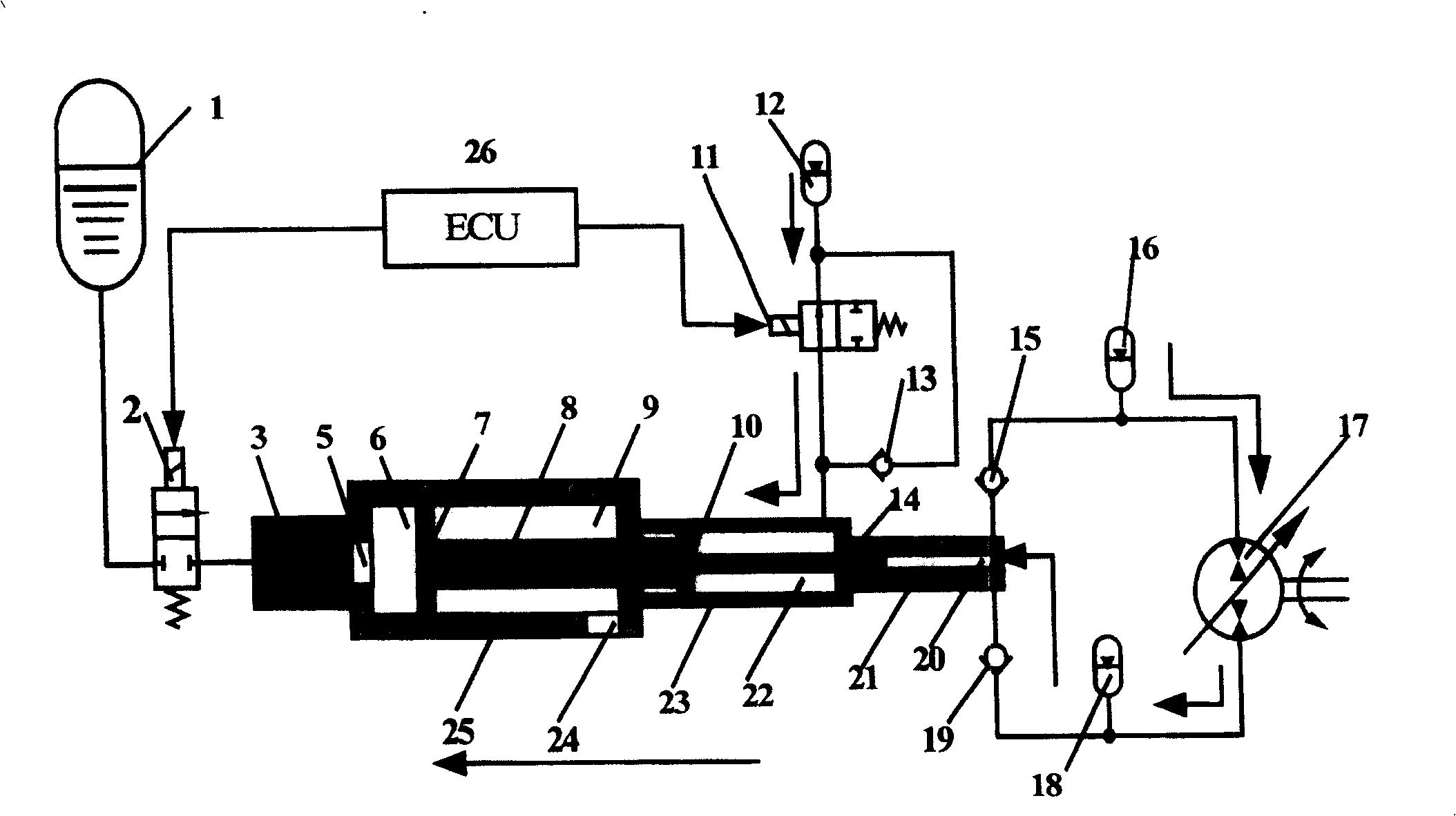

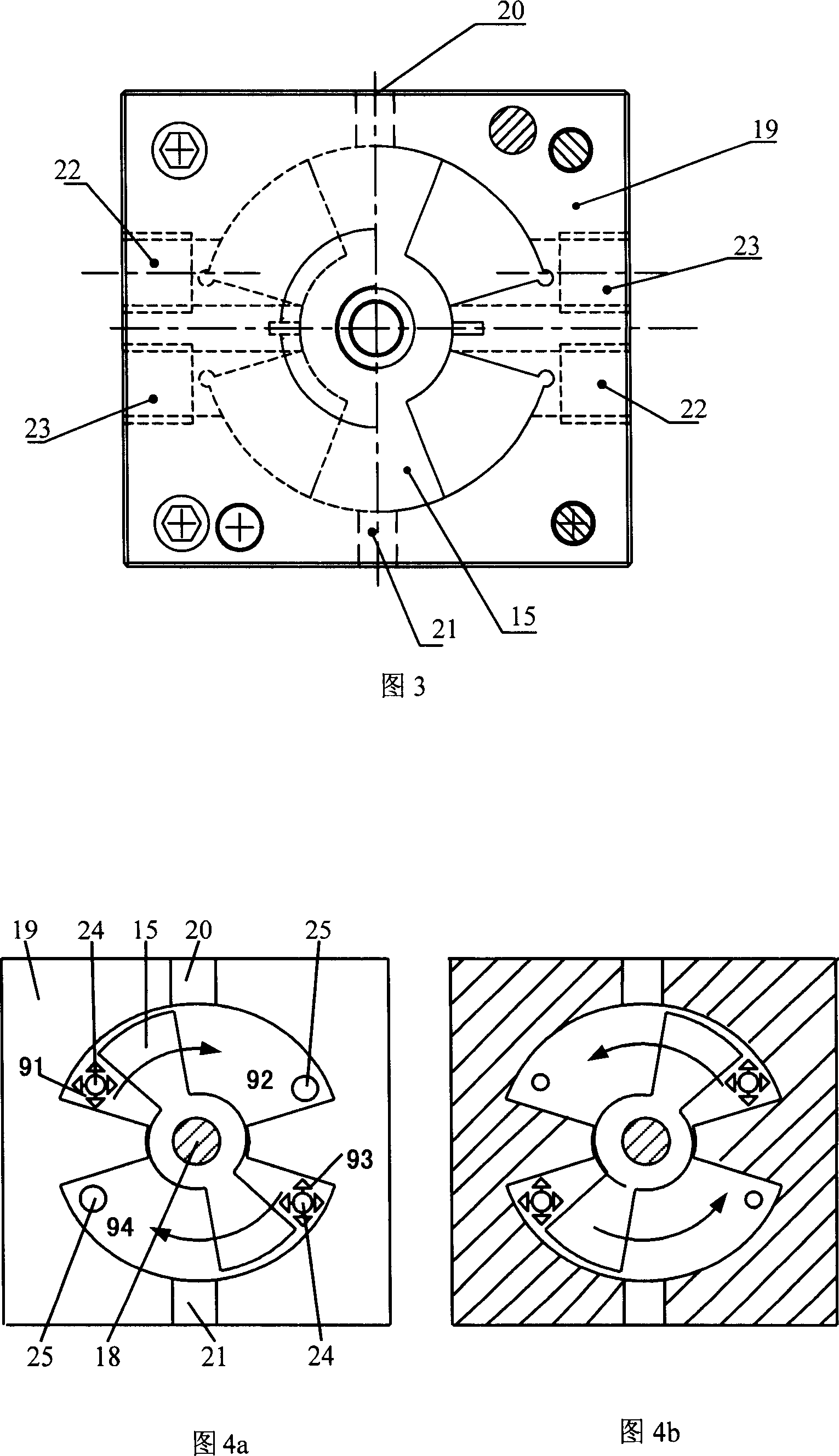

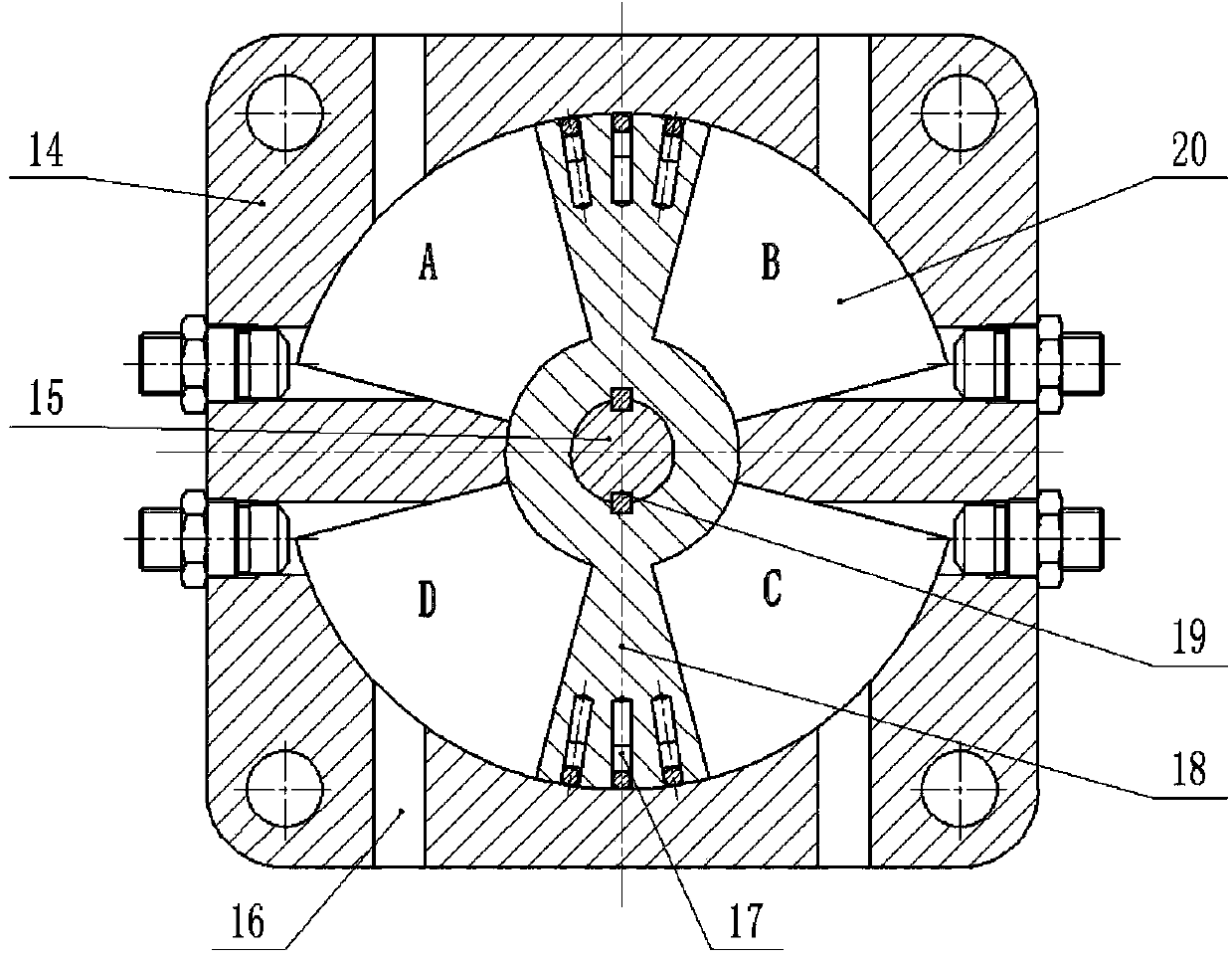

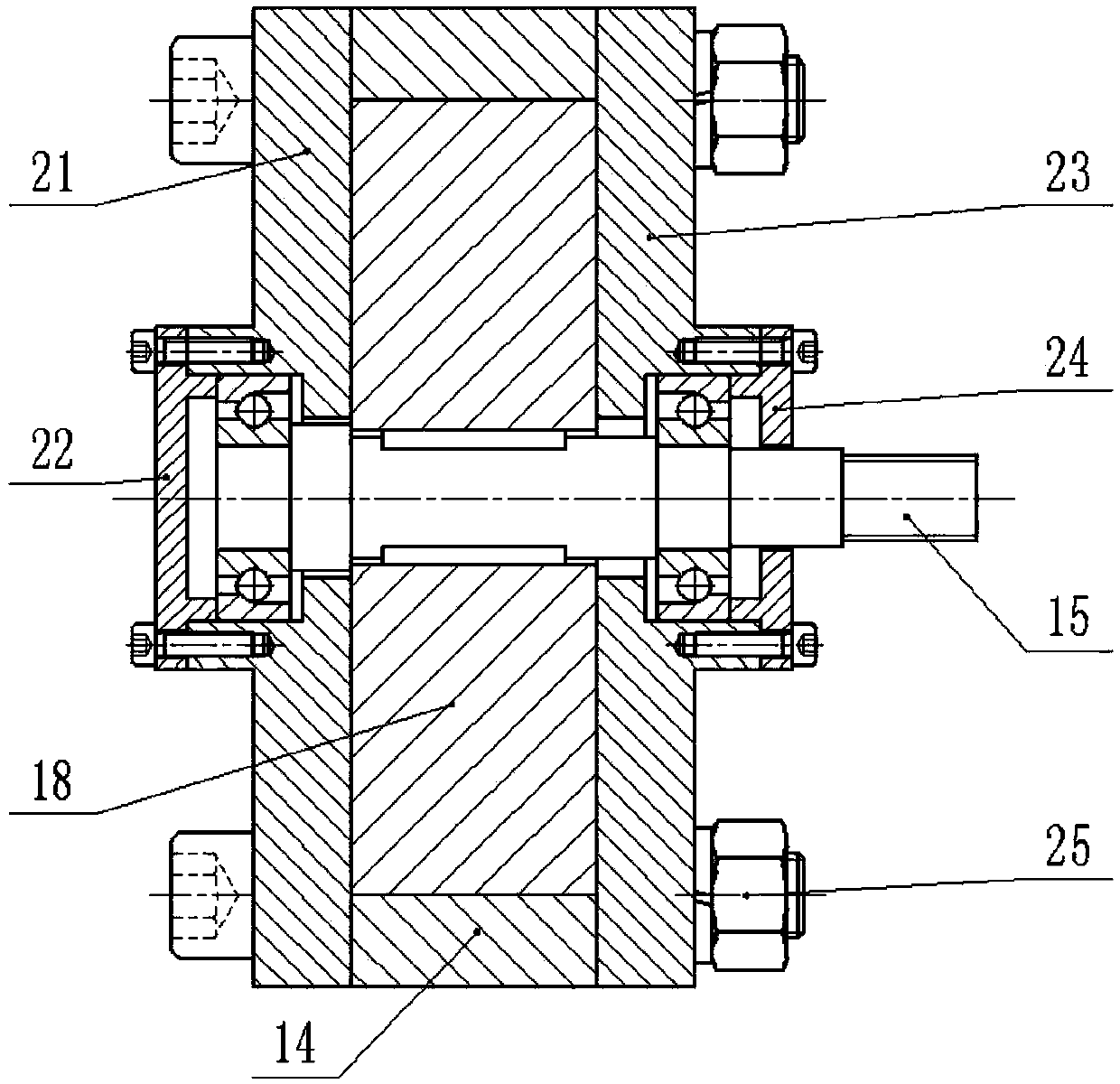

Direct injection pendulum type monopropellant engine

InactiveCN101008319ASimple structureWork reliablyOscillating piston enginesSafety/regulatory devicesHigh energyDecomposition

A direct-injection swing single-unit engine comprises a single-unit fuel pot, a swing engine, two fuel control electromagnetic valves, two catalysis beds and an electric controller. The invention uses the mixture of high-density hydrogen dioxide and diesel as the single-unit fuel, to be decomposed into high-temperature high-pressure mixture gas via catalysis decomposition, to drive the swing engine, to output swing power directly or output electricity via the generator. The electric controller can control two fuel control valves to switch the frequency to control the swing frequency of the engine or the frequency of output alternative-current. The invention has small volume, low weight, high energy density, and wide application, to be used to supply energy in non-oxygen condition or oxygen-lack condition.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

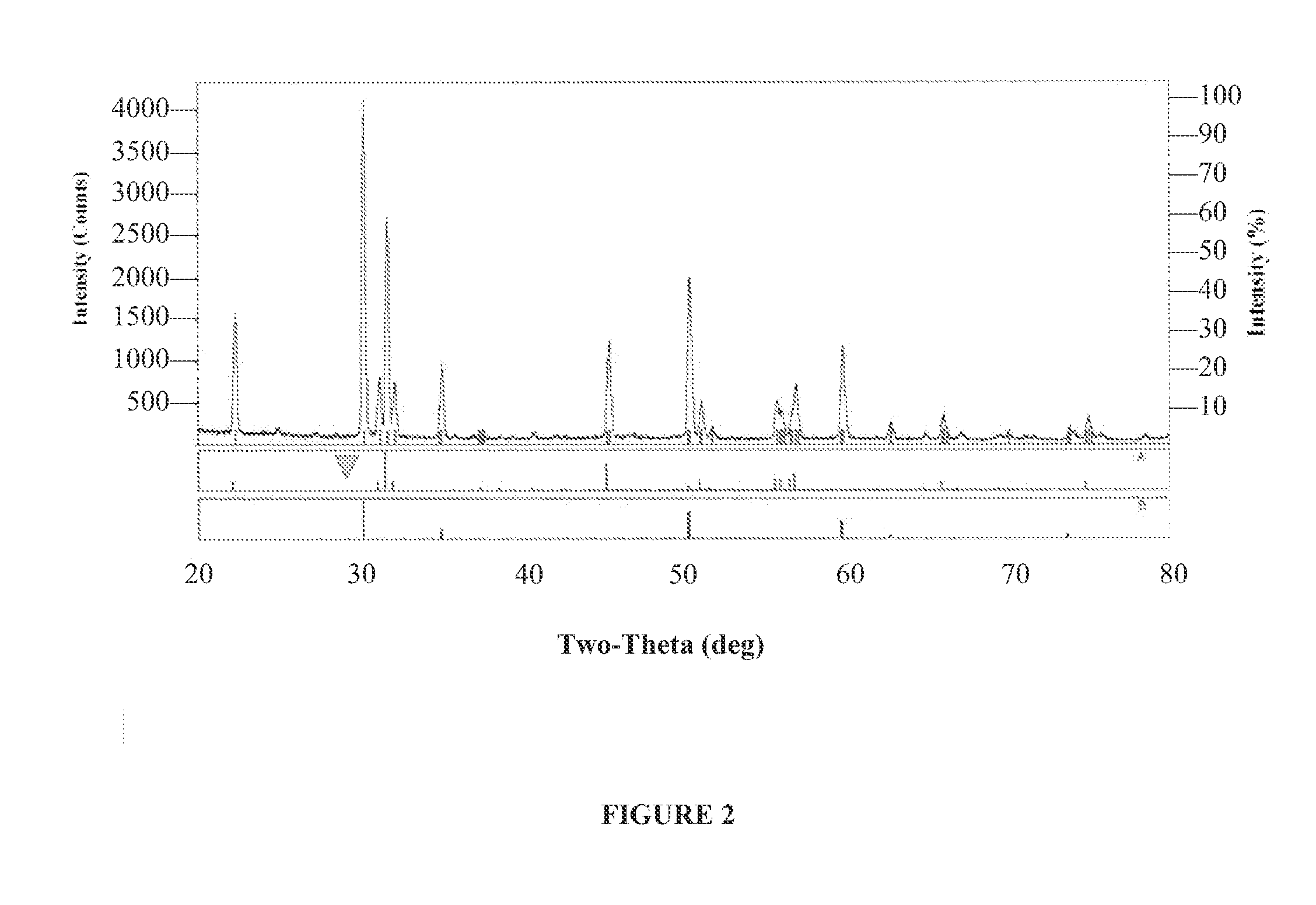

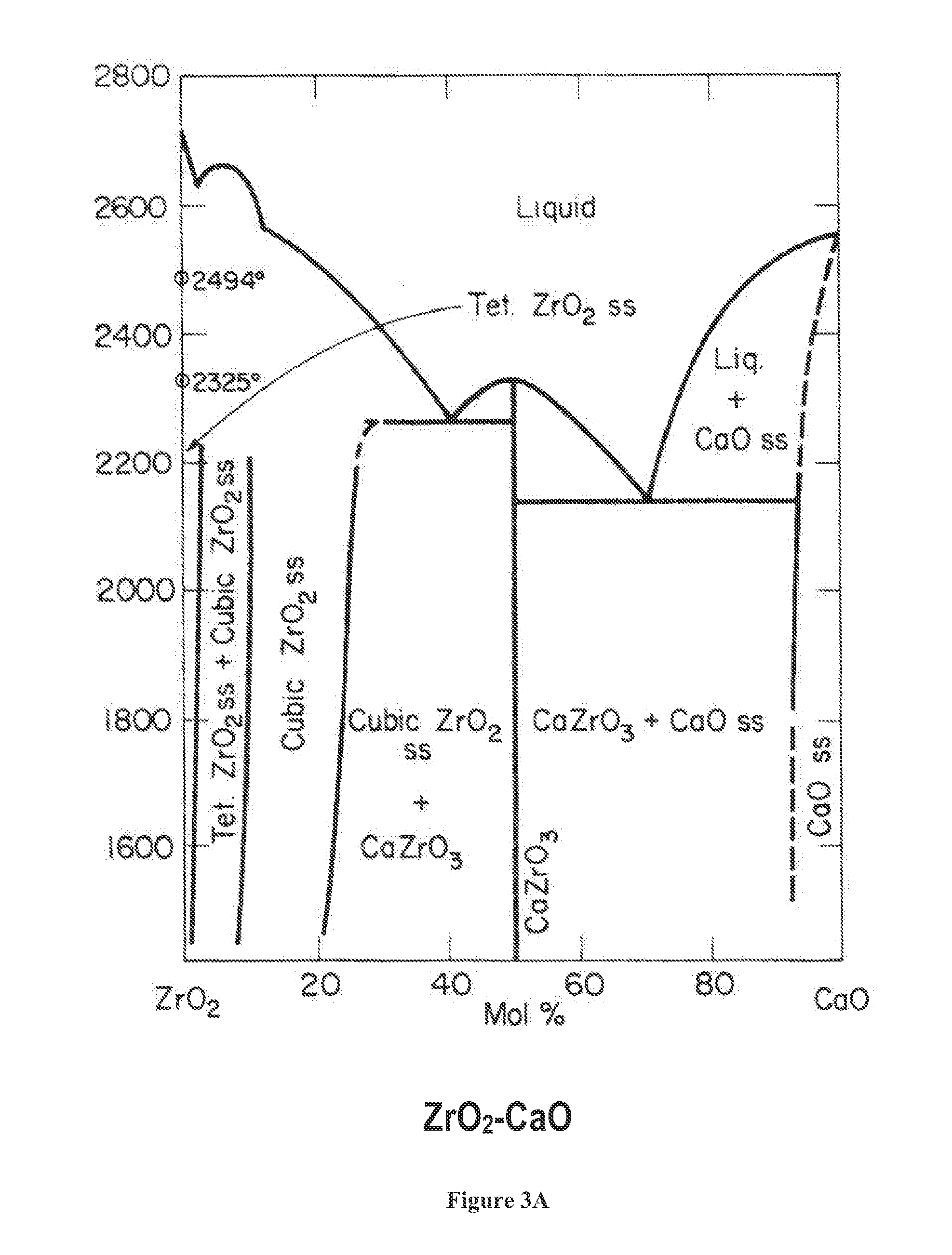

High Temperature Catalysts for Decomposition of Liquid Monopropellants and Methods for Producing the Same

InactiveUS20120115709A1Improve thermal shock resistanceImprove compatibilityCatalyst carriersMovable spraying apparatusPorosityHigh energy

Ceramic catalyst carriers that are mechanically, thermally and chemically stable in a ionic salt monopropellant decomposition environment, high temperature catalysts for decomposition of liquid high-energy-density monopropellants and ceramic processing techniques for producing spherical catalyst carrier granules are disclosed. The ceramic processing technique is used to produce spherical catalyst carrier granules with controlled porosities and desired composition and allows for reproducible packing densities of catalyst granules in thruster chambers. The ceramic catalyst carrier has excellent thermal shock resistance, good compatibility with the active metal coating and metal coating deposition processes, melting point above >2300° C., chemical resistance to steam, nitrogen oxides and nitric acid, resistance to sintering to prevent void formation, and the absence of phase transition associated with volumetric changes at temperatures up to and beyond 1800° C.

Owner:SIENNA TECH

Micro swing type monopropellant engine

InactiveCN103742198ASimple structureThe overall structure is simple and reliableOscillating piston enginesEngine componentsHigh concentrationHigh energy

The invention provides a micro swing type monopropellant engine, which comprises a fuel tank, an electronic control unit, a catalytic device, a swing type engine, a fuel distributing valve, a gas exhausting check valve and a muffler, wherein a hydrogen peroxide solution of high concentration is used as a fuel, the electronic control unit controls the fuel flow valve to provide the fuel to the specified catalytic device, high temperature and high pressure gas is generated by decomposing the fuel through catalytic reaction and acts upon a central swing of the swing type engine, so that direct output or electric energy output of swing power is realized. The micro swing type monopropellant engine provided by the invention has the advantages of high integration of work modes, simple structure, convenience in control, high energy density and the like and is applicable to energy supply devices in various anoxic or oxygen-free environments such as outer space, polar regions, plateaus, drilling platforms or underwater.

Owner:INNER MONGOLIA UNIV OF TECH

Micro-flow green high-energy monopropellant thruster structure

ActiveCN110500200AReduce the temperatureIncrease heat transfer resistanceCosmonautic propulsion system apparatusRocket engine plantsMicro nanoTemperature control

The invention relates to a micro-flow green high-energy monopropellant thruster structure. The catalytic decomposition of a propellant is realized under the action of a catalyst in a catalysis bed, and the propellant is further combusted in a combustion chamber and then is sprayed out by a spray pipe to generate thrust; and a heat control assembly is installed on the catalysis bed in a thrust chamber, and temperature control and monitoring are carried out on the catalysis bed. The micro-flow green high-energy mono propellant thruster structure has the advantages that the temperature of a capillary pipe is regulated and controlled through a heat conduction sheet, a capillary pipe heat conduction wire and the like, the two-phase flow, generated in the capillary pipe, of the propellant is inhibited under the micro-flow, and the stable operation of a micro-flow green high-energy monopropellant thruster is realized. The micro-flow green high-energy monopropellant thrust has the characteristics of being high in specific impulse, green, non-toxic, light in mass, capable of being pre-packaged and the like, the required force or torque is provided for maneuvering, fast response and the likeof a micro-nano satellite, and the application space of the micro-nano satellite is greatly expanded.

Owner:BEIJING INST OF CONTROL ENG

Hydrogen peroxide catalytic decomposition

Nitric oxide in a gaseous stream is converted to nitrogen dioxide using oxidizing species generated through the use of concentrated hydrogen peroxide fed as a monopropellant into a catalyzed thruster assembly. The hydrogen peroxide is preferably stored at stable concentration levels, i.e., approximately 50%-70% by volume, and may be increased in concentration in a continuous process preceding decomposition in the thruster assembly. The exhaust of the thruster assembly, rich in hydroxyl and / or hydroperoxy radicals, may be fed into a stream containing oxidizable components, such as nitric oxide, to facilitate their oxidation.

Owner:U S GOVERNMENT AS REPRESENTED BY THE ADMINSTRATOR OF NAT AERONAUTICS & SPACE ADMINISTATION

Pulse pendulum type monopropellant engine

InactiveCN101008320ASimple structureWork reliablyOscillating piston enginesSafety/regulatory devicesHigh energySwitching frequency

The invention relates to a pulse swing single-unit engine, which comprises a single-unit fuel pot, a gas pot, a catalysis bed, an electric controller, a swing engine, a fuel control electromagnetic valve, and an emergence discharge valve. The invention uses the mixture of high-density hydrogen dioxide and diesel as the single-unit fuel, to be decomposed into high-temperature high-pressure mixture gas via catalysis decomposition to be stored in the gas pot. When the pressure of gas pot reaches preset value, the electric controller can use two aerated switches to start the engine to output swing power directly or output electricity via the generator, while the swing frequency is equal to the switch frequency of aerated valves. The invention has small volume, low weight, high energy density, and wide application, to be used to supply energy in non-oxygen condition or oxygen-lack condition.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

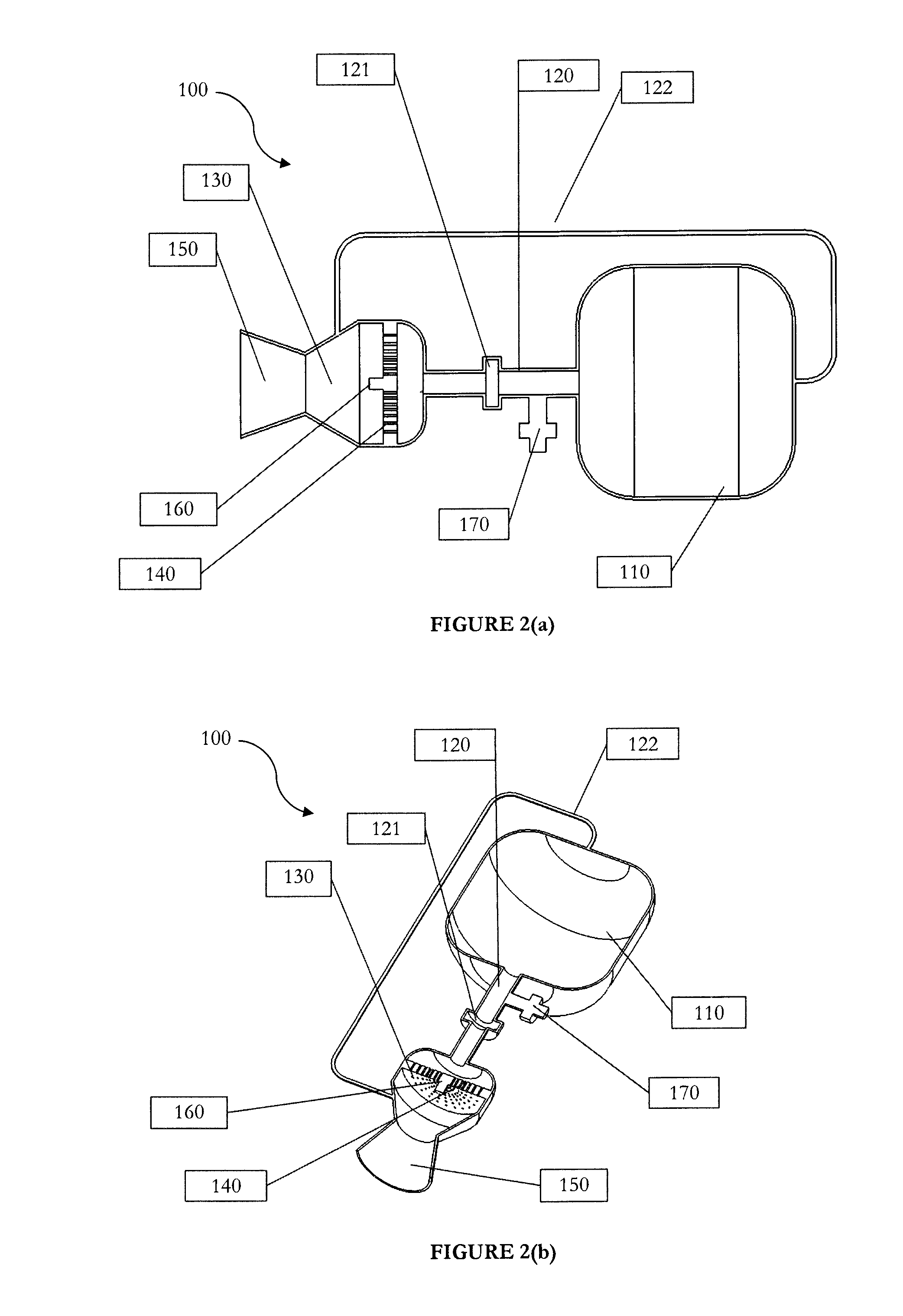

Viscous Liquid Monopropellant

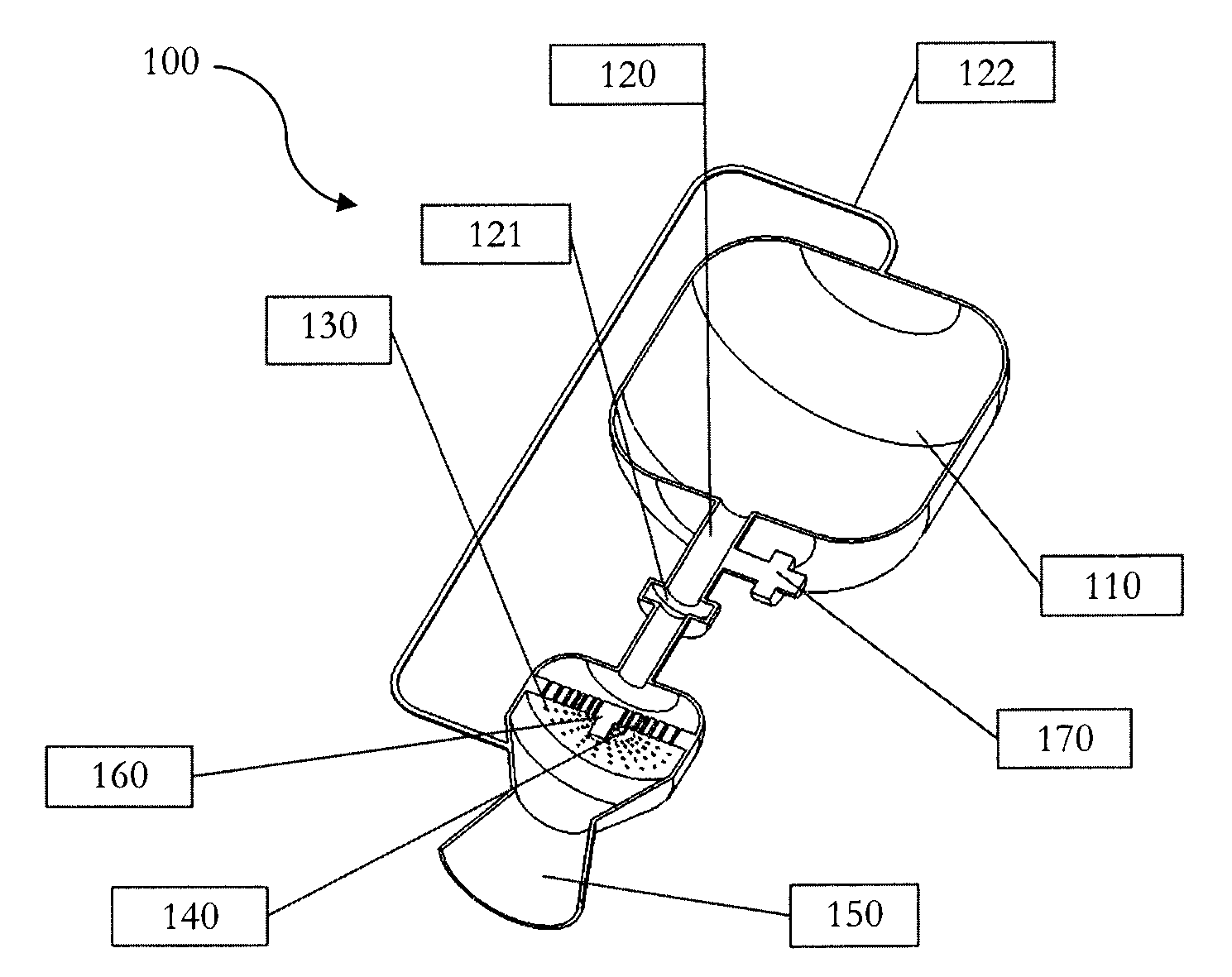

ActiveUS20120234196A1Overcome limitationsDirection controllersCosmonautic vehiclesSolid componentViscous liquid

This invention relates to the construction of a rocket motor and fuel system thereof and, in particular to a new and useful Viscous Liquid Monopropellant (VLM) rocket motor containing a liquid propellant that is pumped into the combustion chamber, atomised and then ignited. The atomisation step significantly increases the surface area of the propellant, delivering faster burn rates and smoother combustion. VLM is a non-Newtonian fluid containing both oxidisers and fuels. These monopropellants are comprised of a variety of liquid and solid components, mixed together to form a homogenous fluid, although heterogeneous in composition. The solid constituents are retained within the liquid phase by dispersion, suspension, bonding or chemical emulsification techniques, so as when a motive force is applied to the propellant, all the constituents are also transported, and held in correct proportion whilst doing so.

Owner:ROCKET LAB USA INC

Oxidizer-rich liquid monopropellants for a dual mode chemical rocket engine

InactiveUS20160090330A1Comparable performanceReduce usageCosmonautic vehiclesCosmonautic partsJet aeroplaneAviation

The subject invention relates to oxidizer-rich liquid monopropellants based on ADN or HAN for a dual mode bipropellant chemical rocket engine. Such engines may be part of propulsion systems to be used in aerospace applications for 1) orbit raising, orbit manoeuvres and maintenance, attitude control and deorbiting of spacecraft, and / or 2) propellant settling, attitude and roll control of missiles, launchers and space planes.

Owner:ECAPS

Reactor for ammonium dinitramide-based liquid mono-propellants, and thruster including the reactor

InactiveUS20150128563A1Reduce energy consumptionReduce heat lossContinuous combustion chamberCatalyst activation/preparationCombustion chamberCombustible gas

The present invention relates to a reactor for the decomposition of ammonium dinitramide-based liquid monopropellants into hot, combustible gases for combustion in a combustion chamber, and a rocket engine or thruster comprising such reactor, which reactor further comprises an inner reactor housing accommodating a heat bed and a catalyst bed, and separating the heat bed and catalyst bed from contact with the inner surface of the reactor housing.

Owner:ECAPS

Reactor for ammonium dinitramide-based liquid mono-propellants, and thruster including the reactor

ActiveUS20150121843A1Enhanced reheatShorten recovery timeContinuous combustion chamberCatalyst activation/preparationCombustion chamberCombustible gas

The present invention relates to a reactor for the decomposition of ammonium dinitramide-based liquid monopropellants into hot, combustible gases for combustion in a combustion chamber, and a rocket engine or thruster comprising such reactor, wherein the reactor comprises a heat bed exhibiting catalytic activity.

Owner:ECAPS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com