Direct injection pendulum type monopropellant engine

A pendulum engine and single component technology, which is applied in the direction of oscillating piston engines, rotating or oscillating piston engines, engine components, etc., can solve the problems that are difficult to meet the requirements of rapid power increase, the reduction of system energy density and power density, Reduce system energy and power density, etc., to achieve the effect of compact structure, reduced friction loss, and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

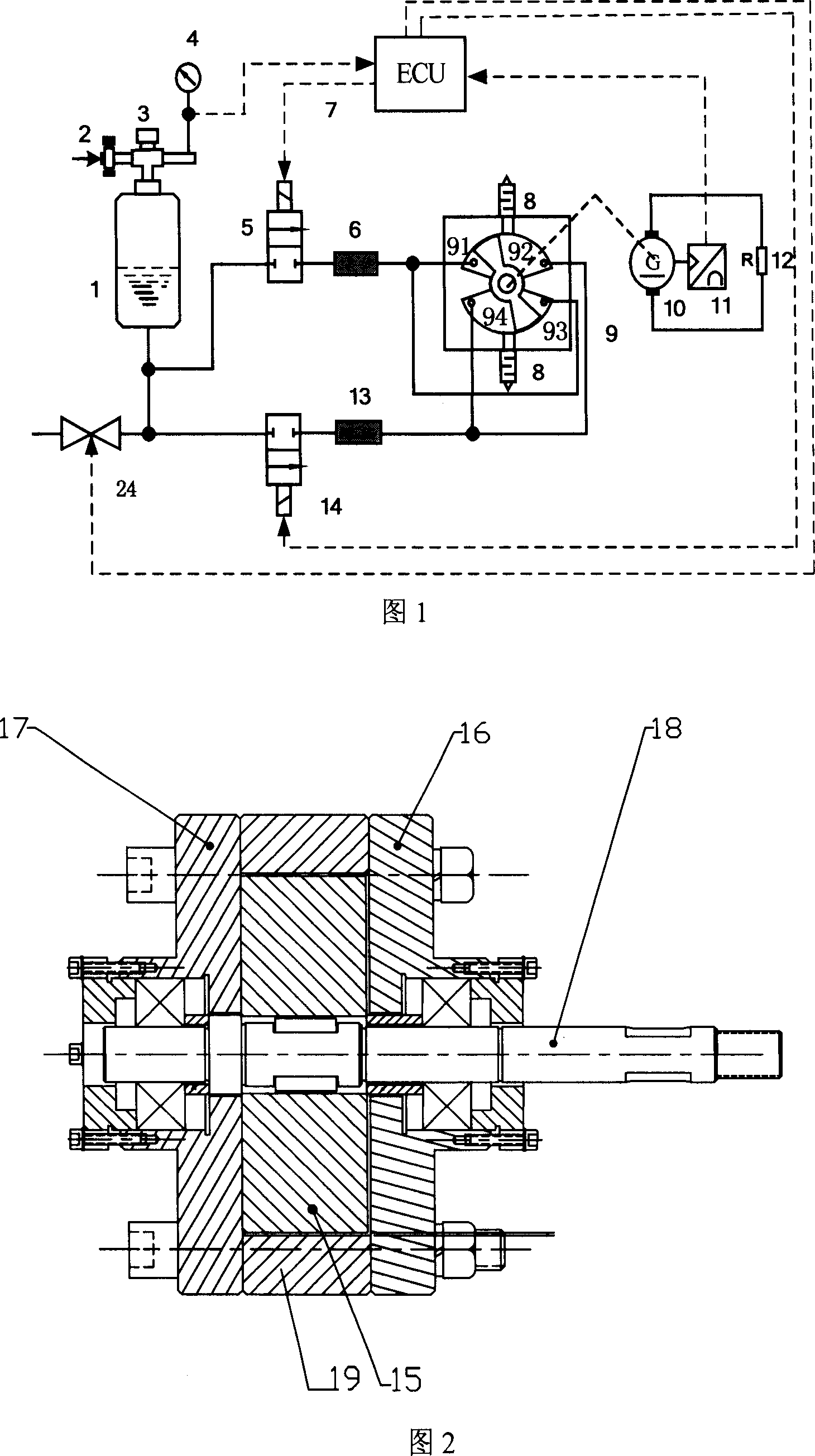

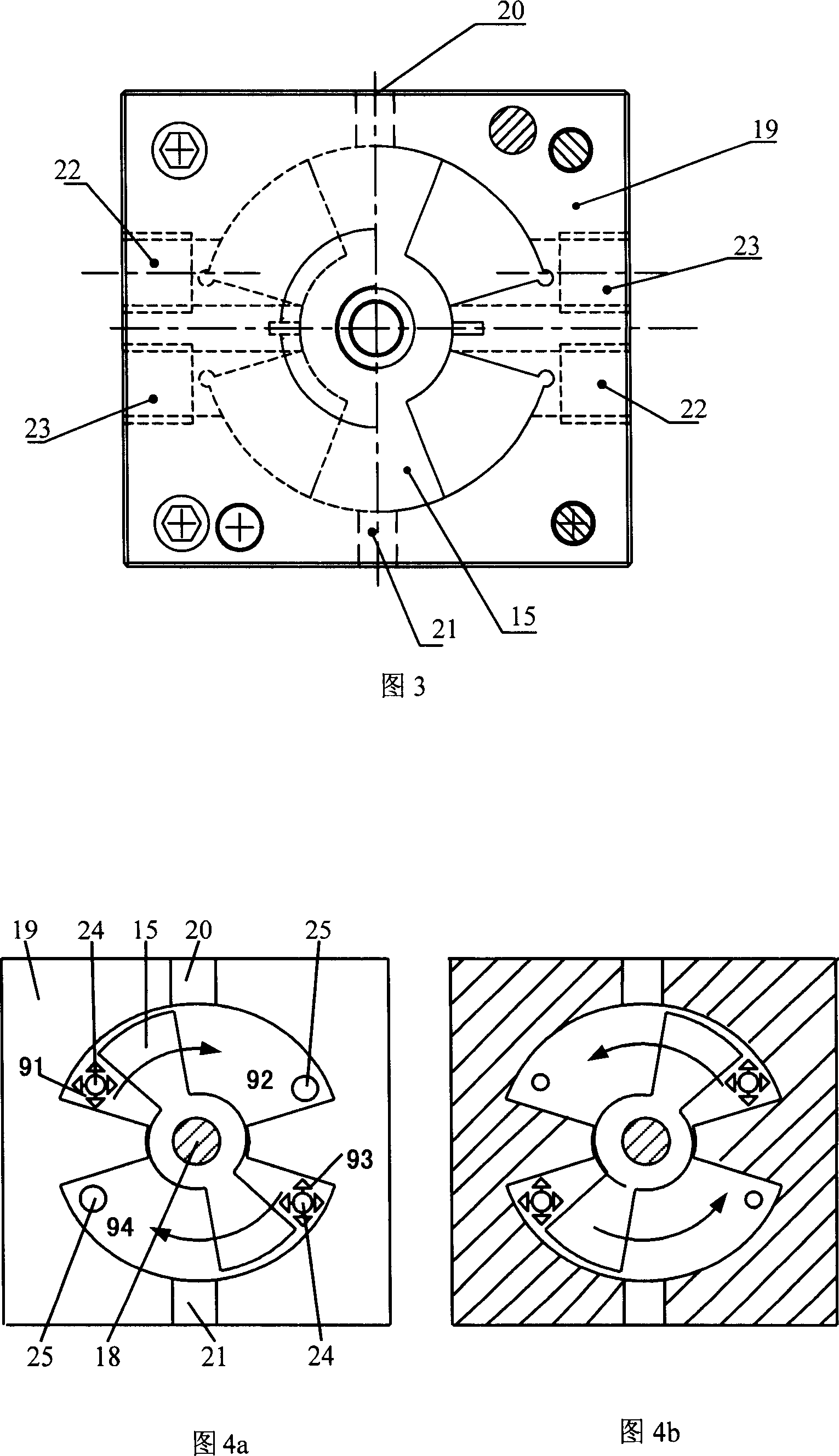

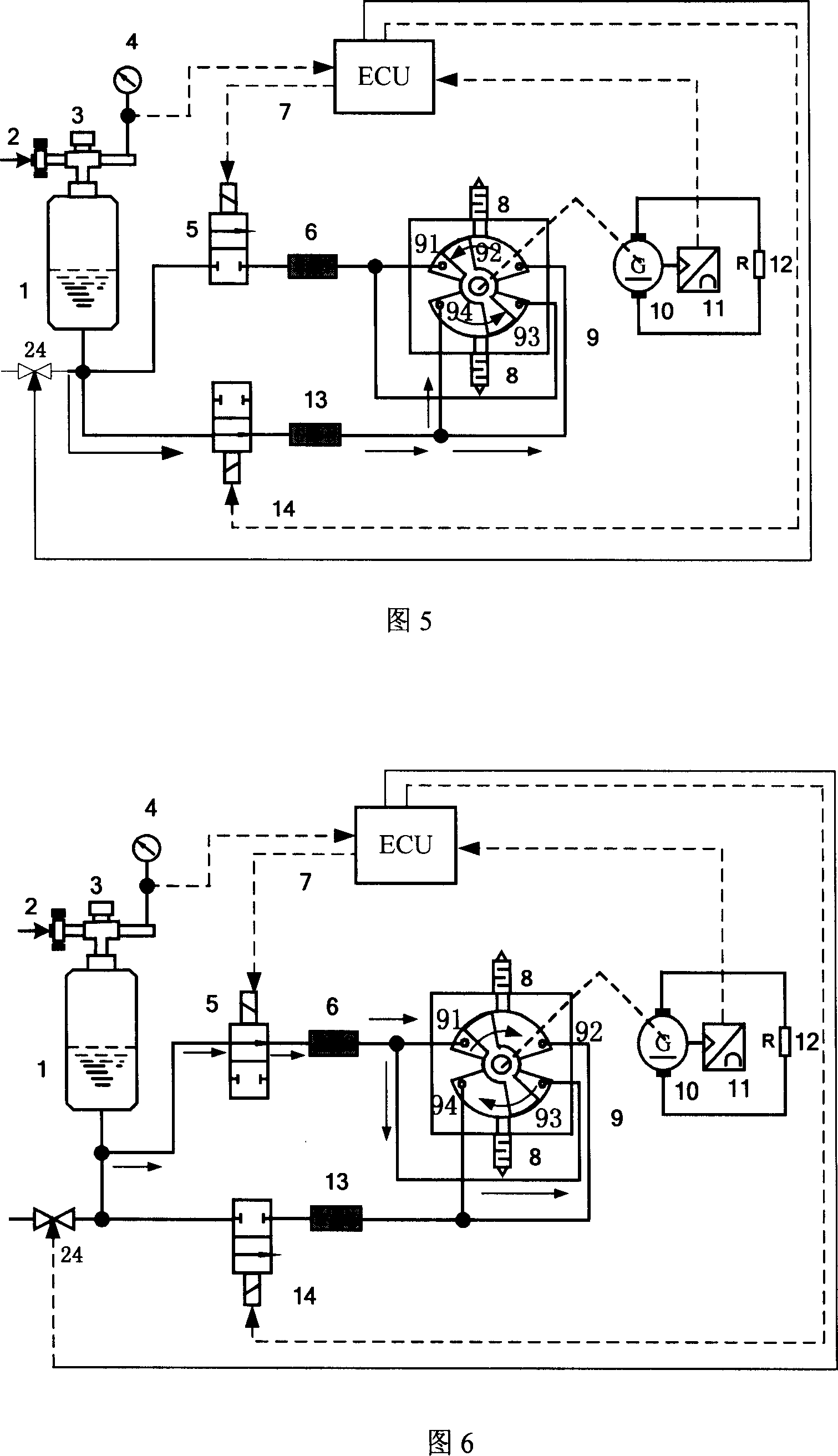

[0019] The direct-injection pendulum type mono-component engine of the present invention uses a mixture of high-concentration hydrogen peroxide and diesel oil as the mono-component fuel, and decomposes the above-mentioned mixed mono-component fuel into high-temperature and high-pressure mixed gas through catalytic decomposition to serve as a direct-drive pendulum type The working power of the engine realizes the direct output of the swing power or realizes the electric energy output through the generator. By controlling the on-off frequency of the two fuel control valves through the electronic control unit, the operating frequency of the engine swing or the frequency of the output alternating current can be controlled. This direct-injection pendulum single-component engine has the characteristics of small size, light weight, high energy density, few moving parts, reliable operation and wide application range. It is suitable for various anoxic or anoxic Energy supply devices wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com